Lincoln 2500 Owner’s Manual

operator manual

Digital Countertop Impinger Conveyor Oven

This document includes:

• Safety Notices

• Specifi cations

• Installation Instructions

• Operating Instructions

• Cleaning Instructions

• Warranty Statement

P/N: 20000260

Revision: C

Series 2500

Lincoln Foodservice Products, LLC

Technical Support Hotline: (800) 678-9511

1111 North Hadley Road

Fort Wayne, Indiana 46804

United States of America

Telephone: (260) 459-8200

www.lincolnfp.com

IMPORTANT WARNING AND SAFETY INFORMATION

This manual contains important safety and installation-operation instructions.

NOTE:

Require all operators to read this manual thoroughly before installing, operating or servicing this equipment. Improper installation, adjustment, alteration,

service or maintenance can cause property damage, injury or death.

DANGER:

DANGER:

DANGER:

DANGER:

DANGER:

Minimum clearances must be maintained from all walls and combustible materials.•

Keep the oven area free and clear of combustible material.•

Adequate clearance for air openings to the control chamber on both sides of the oven is required.•

Do not obstruct the ventilation holes in the control boxes and covers as these provide cooling air •

for the controls.

The oven is to be operated only on the type of electricity as shown on the specifi cation plate.•

This manual should be retained for future reference.•

The electrical wiring diagram is located under the control box covers.•

Do not work around conveyor belt with long hair, loose clothing, or dangling

jewelry. Getting caught in the belt could result in serious injury.

For your safety, do not store or use gasoline or other fl ammable vapors or

liquids in the vicinity of this or any other appliance.

Do not spray aerosols in the vicinity of this appliance while it is in operation.

If the power supply cord appears to be damaged, do not attempt to operate

the unit. Contact a service agent or qualifi ed electrician to repair!

Do not use parchment paper when placing food product through the appliance!

Use of such materials may cause a fi re and should never be placed in the

appliance.

2

PURCHASER’S RESPONSIBILITY

It is the responsibility of the purchaser to:

Confi rm the electric services for the oven are installed on site in accordance with the manufactur-1.

ers specifi cations.

Unload, uncrate, and install the oven in its proper location in accordance with this operator manual.2.

Confi rm the electric services are connected properly by a qualifi ed installer of your choice. All 3. such

connections must be in accordance with applicable code requirements. See “Code References”

section for more information.

TABLE OF CONTENTS

WARRANTY AND SAFETY INFORMATION......................................... 2

PURCHASER’S RESPONSIBILITY....................................................... 3

UTILITY SPECIFICATION - ELECTRIC................................................ 4

EXTERIOR DIMENSIONS.................................................................... 4

GENERAL INFORMATION.................................................................... 5

SPACING.............................................................................................. 5

ELECTRICAL GROUNDING INSTRUCTIONS..................................... 5

ELECTRICAL CODE REFERENCES................................................... 5

VENTILATION GUIDELINES................................................................ 5

ASSEMBLY INSTRUCTIONS............................................................... 6

STACKING INSTRUCTIONS................................................................ 7

MOUNTING INSTRUCTIONS............................................................... 7

DIGITAL DISPLAY ILLUSTRATION...................................................... 8

OPERATING INSTRUCTIONS............................................................. 8

CLEANING INSTRUCTIONS................................................................ 10

PREVENTIVE MAINTENANCE............................................................. 11

HOW TO OBTAIN SERVICE................................................................. 11

CONVEYOR REMOVAL........................................................................ 11

FINGER REMOVAL AND DISASSEMBLY............................................. 12

FUNCTIONS.......................................................................................... 12

WARRANTY........................................................................................... 13

3

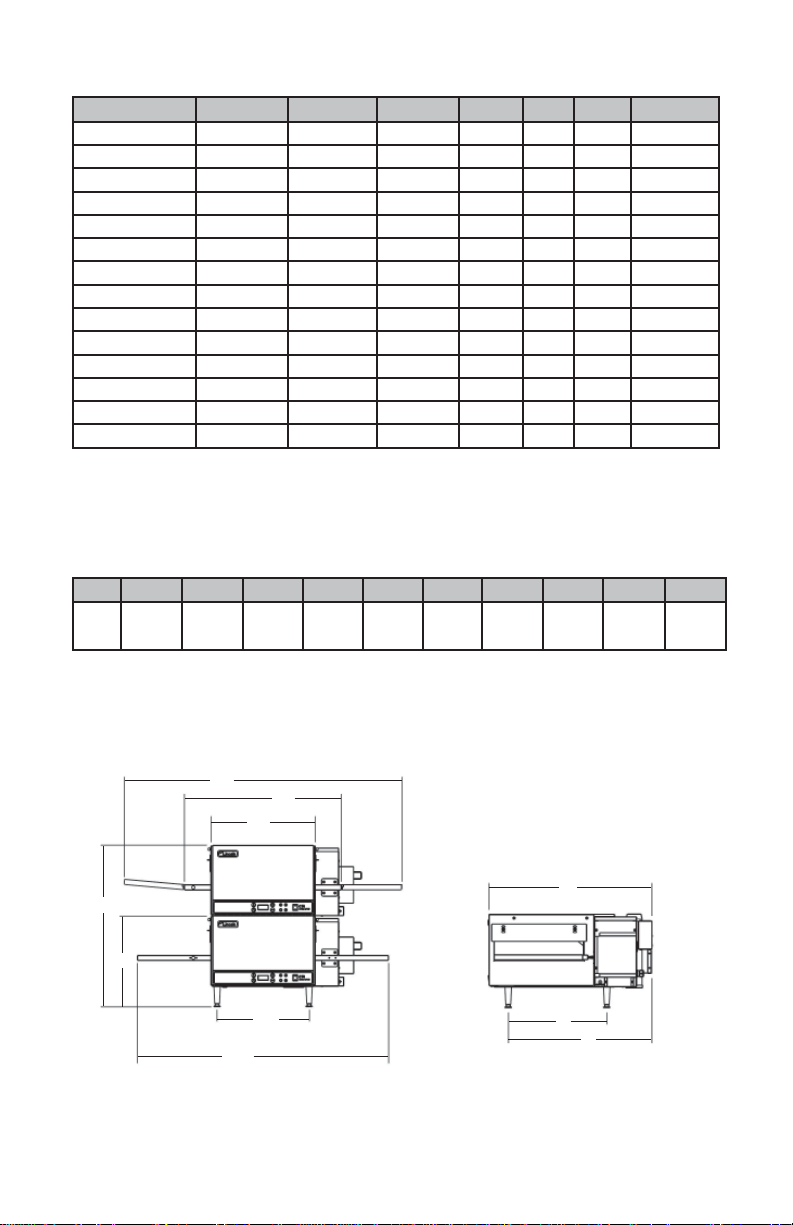

UTILITY SPECIFICATION

MODEL # Motor RPM Input Rate Voltage Amps Hz Phase # of wires

2501-000 3100 6 kW 208 27 60 1 3

2501-001 (Quiet) 1750 6 kW 208 27 60 1 3

2502-000 3100 6 kW 240 24 60 1 3

2502-001 (Quiet) 1750 6 kW 240 24 60 1 3

2504-000 3100 6 kW 240 24 50 1 3

2504-001 (Quiet) 1750 6 kW 240 24 50 1 3

2505-000 3100 6 kW 380/220 15 50 1 4

2507-000 3100 6 kW 200 16 50/60 3 5

2508-000 3100 6 kW 380/220 9 50 3 5

2509-000 3100 6 kW 415/240 8 50 3 5

2510-000 3100 6 kW 220 27 60 1 3

2512-000 3100 6 kW 400/230 9 50 3 5

2512-004 3100 6 kW 400/230 9 50 3 5

2514-000 3100 6 kW 240 24 50 1 3

*Specifi cations subject to change without notice.

NOTE: Do not install this (these) oven(s) in any area with an ambient temperature in excess of 95

o

F, 35o C. Doing so will cause damage to unit.

EXTERIOR DIMENSIONS

A* B** C D E F G*** H I J

Inches

51.125

----

mm

1298.6

Note: Specifi cations subject to change without notice.

* “A” dimension pertains to a unit with standard conveyor and 12” (304mm) take-off shelves included on each end.

** “B” dimension pertains to a unit with standard length conveyor.

*** “G” dimension shown below pertains to a unit with an extended conveyor only.

31.10

----

789.9

20.50

----

----

520.7

17.9375

----

455.6

31.875

----

809.6

18.25

----

463.6

49.75

----

1263.7

31.25

----

793.8

18.9375

----

481.0

27.50

----

698.5

A

B

C

H

E

D

F

G

I

J

4

GENERAL INFORMATION

The instructions that follow are intended as a guide for preparing for the installation of the Impinger

Conveyor oven.

First and foremost, each crate should be examined before signing the Bill of Lading to report any visible

damage caused during shipment and account for the number of crates.

IF THERE IS APPARENT DAMAGE: United States and Canada - arrangements should be made to fi le

a claim against the carrier. As Interstate Commerce Regulations require that the claim must be initiated

by the consignee. All shipments to other countries - freight terms will be developed and extended on an

individual basis.

Proper and secure storage facilities should be arranged for the oven(s) if necessary to protect it from

outdoor or damp conditions at all times before installation.

SPACING

The oven must have 6 inches (152mm) of clearance from combustible surfaces. In case other equipment is located on the right side of oven, a minimum clearance of 24 inches (609mm) is required from

that equipment.

FOR ALL OVENS: A 24-inch (609mm) clearance at the rear of the oven must be obtainable for service

access.

ELECTRICAL GROUNDING INSTRUCTIONS

As it pertains to domestic model units, this appliance is equipped with a three-

WARNING

DOMESTIC:

prong (grounding) plug for your protection against shock hazard and should be

plugged directly into a properly grounded three-prong receptacle. Do not cut

or remove the grounding prong from this plug.

WARNING

INT’L (CE):

WARNING:

This appliance must be properly grounded at time of installation. Failure to

ensure that this equipment is properly grounded can result in electrocution,

dismemberment or fatal injury.

If the supply cord appears to be damaged, do not attempt to operate unit.

Contact a service agent or qualifi ed electrician to repair.

ELECTRICAL CODE REFERENCE

IN USA

When installed, this appliance must be electrically grounded and its installation must comply with the

National Electric Code, ANSI-NFPA 70, latest version, the manufacturers installation instructions, and

applicable municipal building codes.

IN CANADA

All electrical connections are to be made in accordance with CSA C22.1 - Canadian Electrical Code Part

1 and/or local codes.

ALL OTHER COUNTRIES

Local electrical codes will prevail.

Strain relief is provided with each oven. International Dealer/Distributors provide applicable power 1.

cord/plug for each customer.

All pole disconnection switch 3mm open contact distance.2.

To prevent electrical shock, an equal potential bonding ground lug is provided in the back. This 3.

allows the oven to be connected to an external bonding system.

If used as double stack and each oven has its own disconnection switch, all switches should be 4.

close together.

VENTILATION

Local codes prevail. These are the “authority having jurisdiction” as stated by the NATIONAL FIRE

PROTECTION ASSOCIATION, INC. in NFPA 96, latest edition.

5

Loading...

Loading...