PARTS & SERVICE MANUAL

Fusion Conveyor Toaster

Series 2030 & 2040 – Domestic & International

P/N: L371077

REV: 2.24.09

Lincoln Foodservice Products, LLC

1111 North Hadley Road

Fort Wayne, Indiana 46804

Telephone: 260.459.8200

Fax: 888.790.8193

Technical Support: 800.678.9511

lincolnfp.com

TABLE OF CONTENTS

SEQUENCE OF OPERATION (DOMESTIC UNITS)…................................................... .............................. 3

SEQUENCE OF OPERATION (EXPORT UNITS)………………………………………………………………… 4

SCHEMATICS………………………………………………………………………………………..………………. 5

TROUBLESHOOTING……………………………………………………………………………………………….. 10

OPERATING INSTRUCTIONS…………………………………………………………………………………..…. 14

SPARE PARTS LISTS & DRAWINGS………………………………………………………………..……………. 24

Fusion Toaster Service Manual

2

SEQUENCE OF OPERATION

FUSION DOMESTIC MODELS

MODEL VOLTAGE HERTZ PHASE

2030-000-U 208/240 50/60 1

2040-000-U 208/240 50/60 1

2040-001-U 208/240 50/60 1

2041-000-U 208/240 50/60 3

2041-001-U 208/240 50/60 3

POWER SUPPLY

Electrical power is supplied to the oven by either a single phase, 3 conductor

service, or three phase, 4 conductor service.

Single:

Black conductor is hot.

White conductor is hot.

The green conductor is ground.

Three Phase:

Black conductor is hot.

Red conductor is hot.

Orange conductor is hot.

The green conductor is ground.

FAN CIRCUIT

Electrical power is permanently supplied to the normally open contacts of the

main power relay, the main switch 1 A fuse, terminal 1 of the time delay unit, also

through the normally closed hi limit thermostat, to the main power switch.

Closing the main switch enables the 30 minute timer delay relay. The time delay

relay supplies line voltage to the cooling fan motor.

INFRARED HEAT

Closing the main switch supplies line voltage to the coil of the main power relay,

closing the contacts to feed the normally open solid state relays for the top and

bottom heaters.

Power also feeds the primary of the transformer, secondary 16V feeds through a

circuit breaker to the control unit. The control energizes the solid state relays for

the top and bottom heaters feeding voltage to the heating elements.

TEMPERATRE CONTROL Closing the main switch supplies line voltage to the primary of the control

transformer, secondary 16vac is supplied to the control unit which is set to a

desired temperature. The thermocouple will provide varying millivolts to the

control unit. The control unit supplies voltage to the coil of the heater relays at

intermittent intervals, to maintain a desired temperature. The display on the

control unit will signal when the main heater relay is energized.

NOTE: The control unit will also display oven temperature.

CONVEYOR DRIVE

Closing the main switch supplies line voltage to the primary of the control

transformer, secondary 16vac is supplied to the control unit. Setting the control

unit to the desired time, outputs voltages to the conveyor motor.

AUTOMATIC COOL

DOWN

When the machine is started, the time delay unit is energized, permitting the main

fan to operate for approximately 30 minutes after the machine is shut off, to cool

the machine. When the machine is turned off the time delay unit keeps the main

fan energized, maintaining operation of the fan for 30 minutes.

Fusion Toaster Service Manual

3

SEQUENCE OF OPERATION (CONT’D)

FUSION EXPORT MODELS

MODEL VOLTAGE HERTZ PHASE

2032-000-E 220/380, 230/400, 240/415 50/60 3

2042-000-E 220/380, 230/400, 240/415 50/60 3

2042-001-E 220/380, 230/400, 240/415 50/60 3

POWER SUPPLY

FAN CIRCUIT

INFRARED HEAT

TEMPERATRE CONTROL Closing the main switch supplies line voltage to the primary of the control

CONVEYOR DRIVE

AUTOMATIC COOL

DOWN

Electrical power is supplied to the oven by a three phase, 5 conductor service.

Black conductor is hot.

Red conductor is hot.

Orange conductor is hot.

White conductor is neutral.

The green conductor is ground.

Electrical power is permanently supplied to the normally open contacts of the

main power relay, through a set of noise suppressers, through an EMI filter,

through a 1 A fuse, through the normally closed hi limit thermostat, to the main

power switch. Power is also supplied to the time delay relay. Closing the main

switch enables the 30 minute time delay relay. The time delay relay supplies line

voltage to the cooling fan motor.

Closing the main switch supplies line voltage to the coil of the main power relay,

closing the contacts to feed the normally open solid state relays for the top and

bottom heaters.

Power also feeds the primary of the transformer, secondary 16V feeds through a

circuit breaker to the control unit. The control energizes the solid state relays for

the top and bottom heaters feeding voltage to the heating elements.

transformer, secondary 16vac is supplied to the control unit which is set to a

desired temperature. The thermocouple will provide varying millivolts to the

control unit. The control unit supplies voltage to the coil of the heater relays at

intermittent intervals, to maintain a desired temperature. The display on the

control unit will signal when the main heater relay is energized.

NOTE: The control unit will also display oven temperature.

Closing the main switch supplies line voltage to the primary of the control

transformer, secondary 16vac is supplied to the control unit. Setting the control

unit to the desired time, outputs voltages to the conveyor motor.

When the machine is started, the time delay unit is energized, permitting the main

fan to operate for approximately 30 minutes after the machine is shut off, to cool

the machine. When the machine is turned off the time delay unit keeps the main

fan energized, maintaining operation of the fan for 30 minutes.

Fusion Toaster Service Manual

4

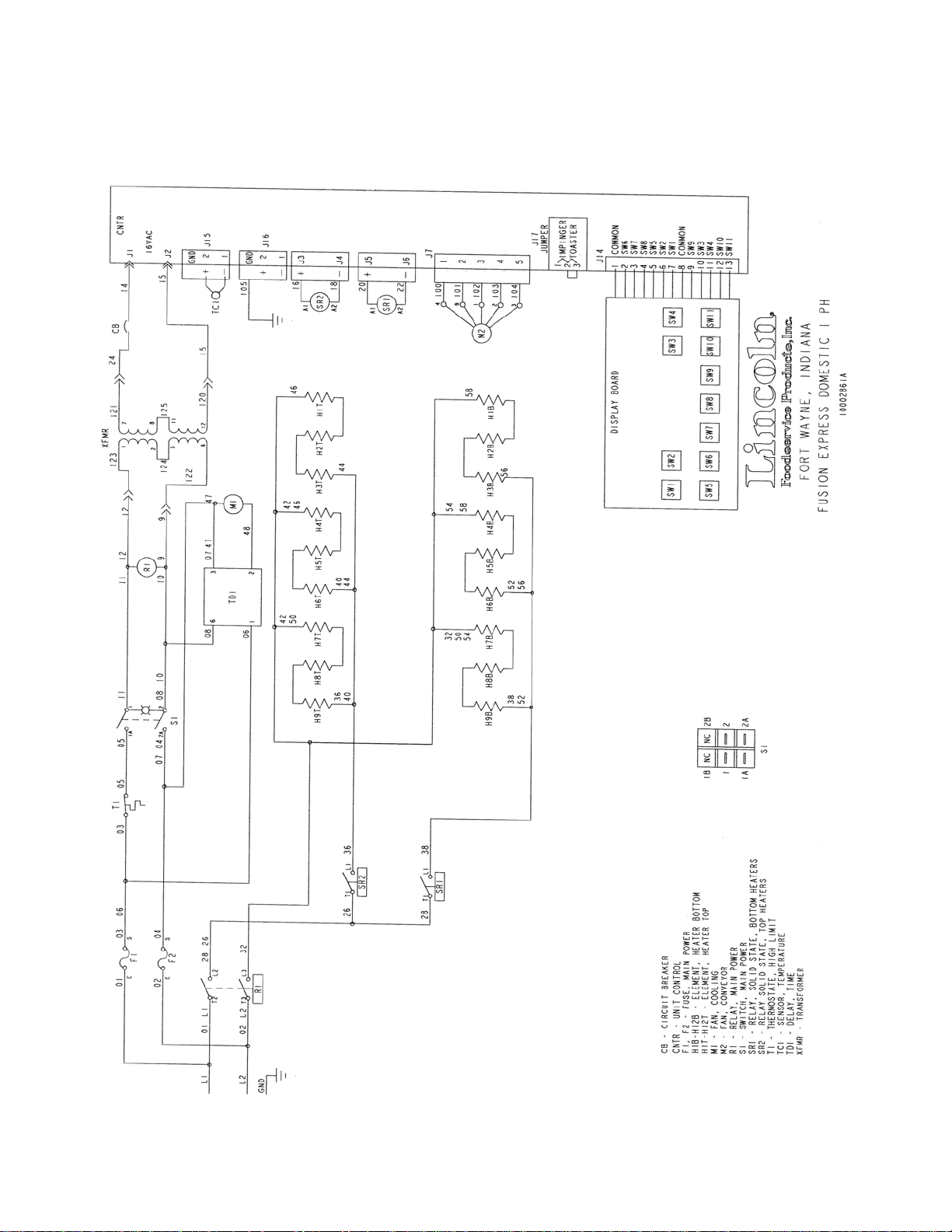

SCHEMATIC – FUSION MODEL: 2030-000-U

208/240V Single Phase Unit - Domestic

Fusion Toaster Service Manual

5

SCHEMATIC – FUSION MODEL: 2032-000-E

208/240V Three Phase Unit - Export

Fusion Toaster Service Manual

6

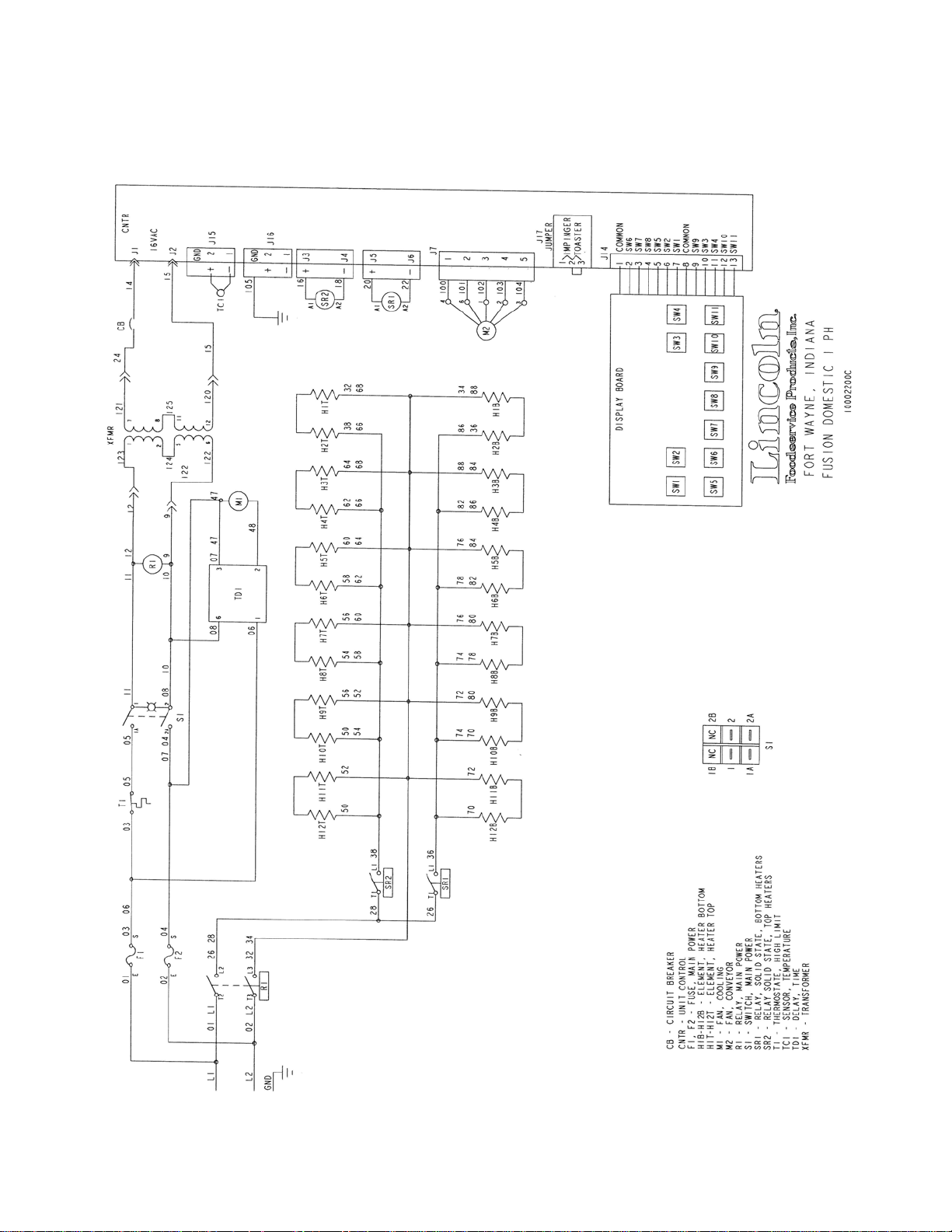

SCHEMATIC – FUSION MODELS: 2040-000-U & 2040-001-U

208/240V Single Phase Unit - Domestic

Fusion Toaster Service Manual

7

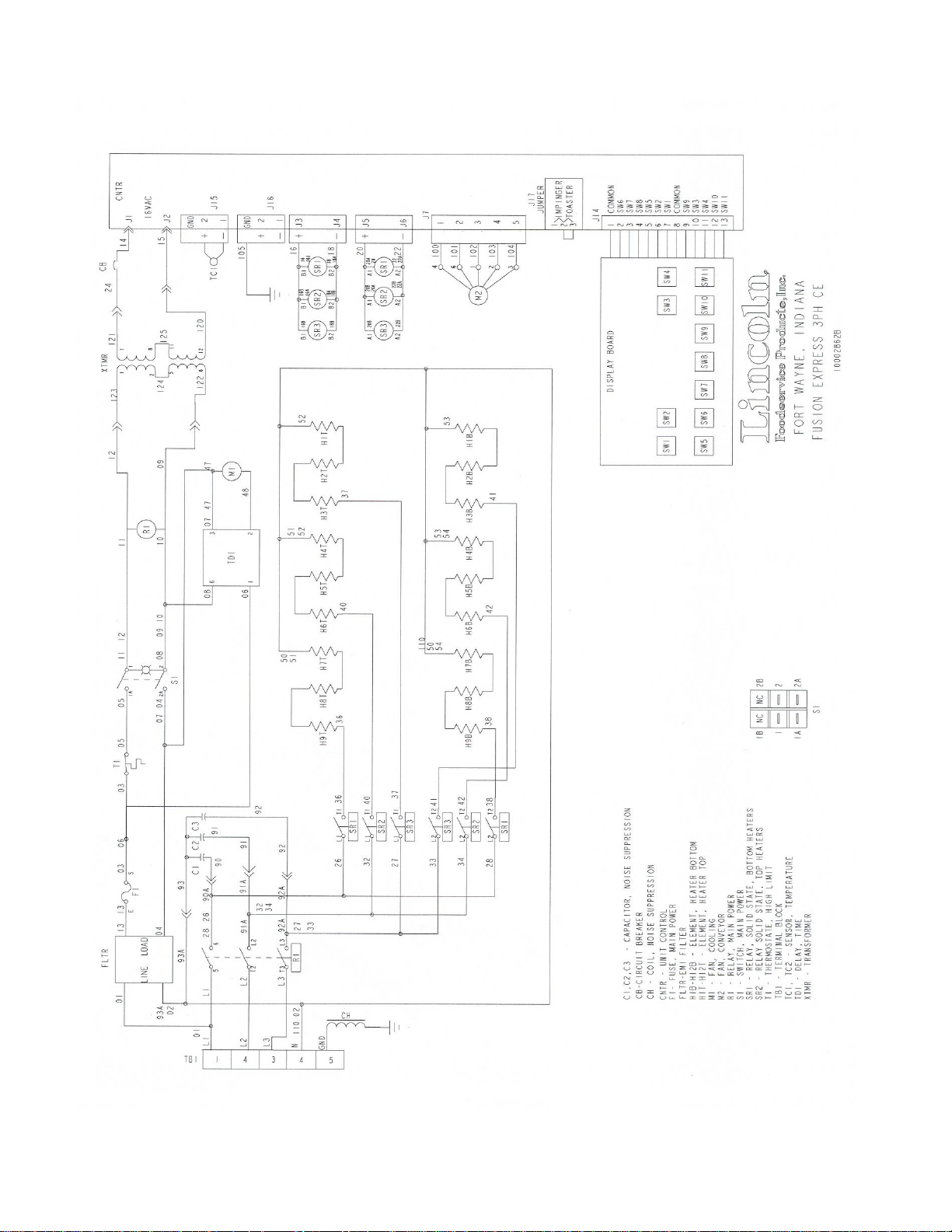

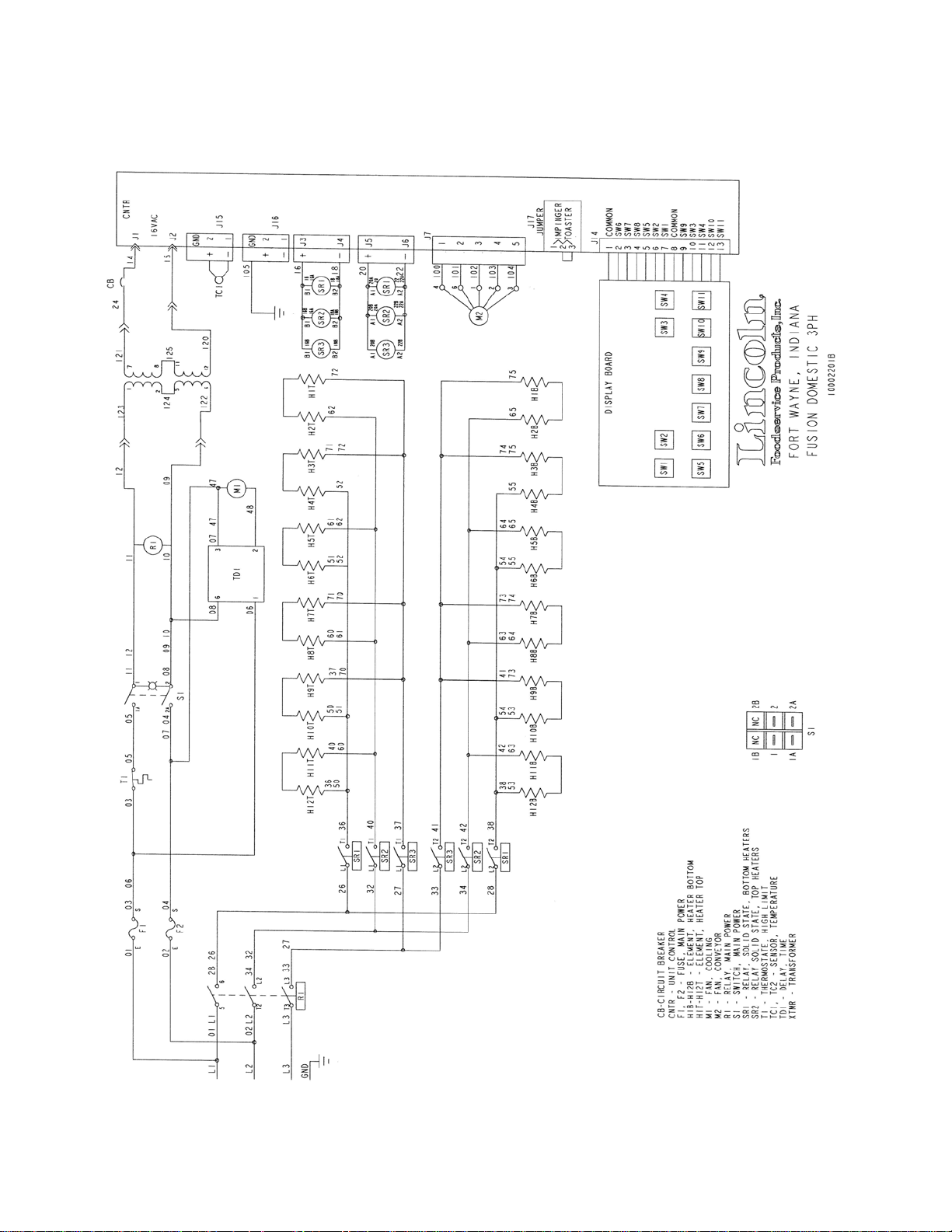

SCHEMATIC – FUSION MODELS: 2041-000-U & 2041-001-U

208/240V Three Phase Unit – Domestic

Fusion Toaster Service Manual

8

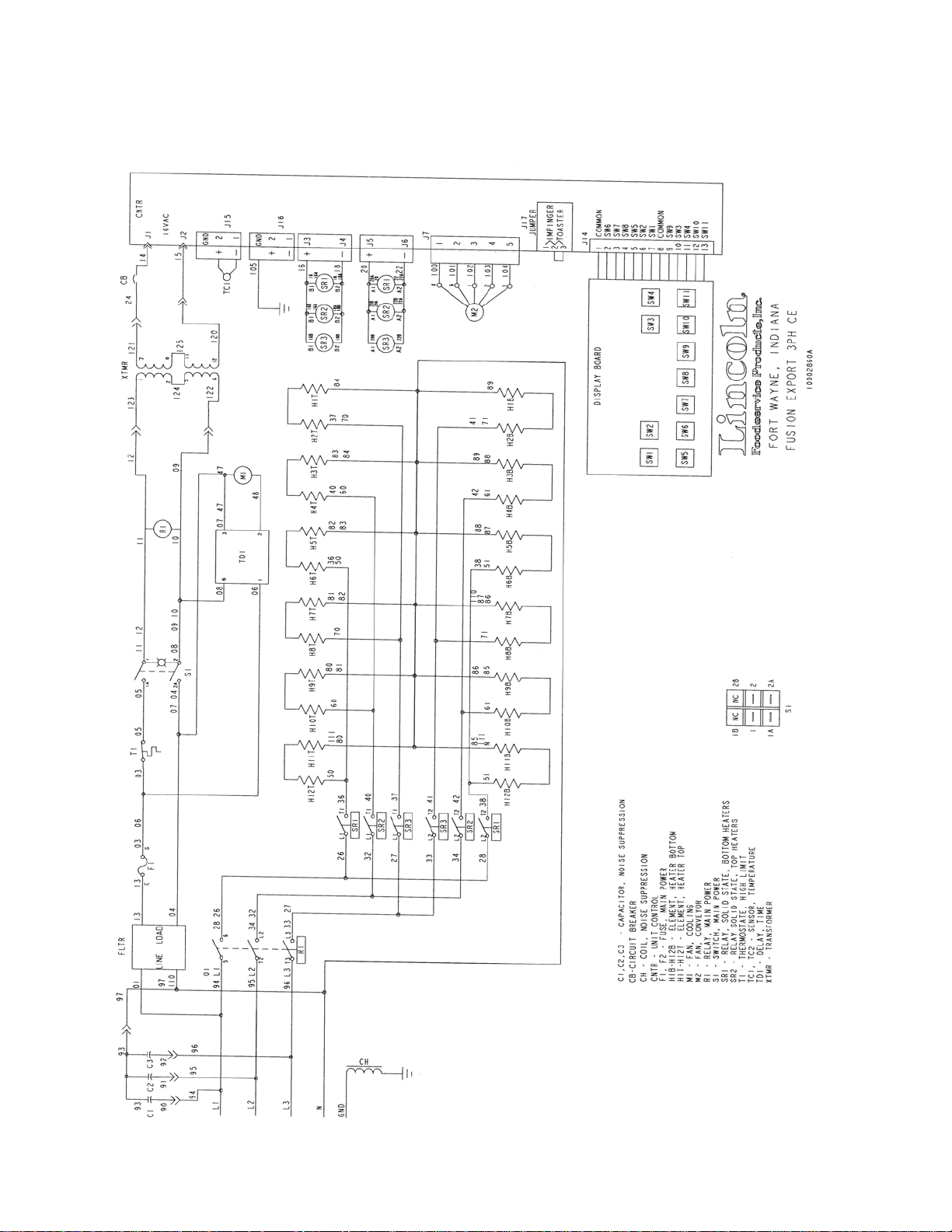

SCHEMATIC – FUSION MODELS: 2042-000-E & 2042-001-E

208/240V Three Phase Unit – Export

Fusion Toaster Service Manual

9

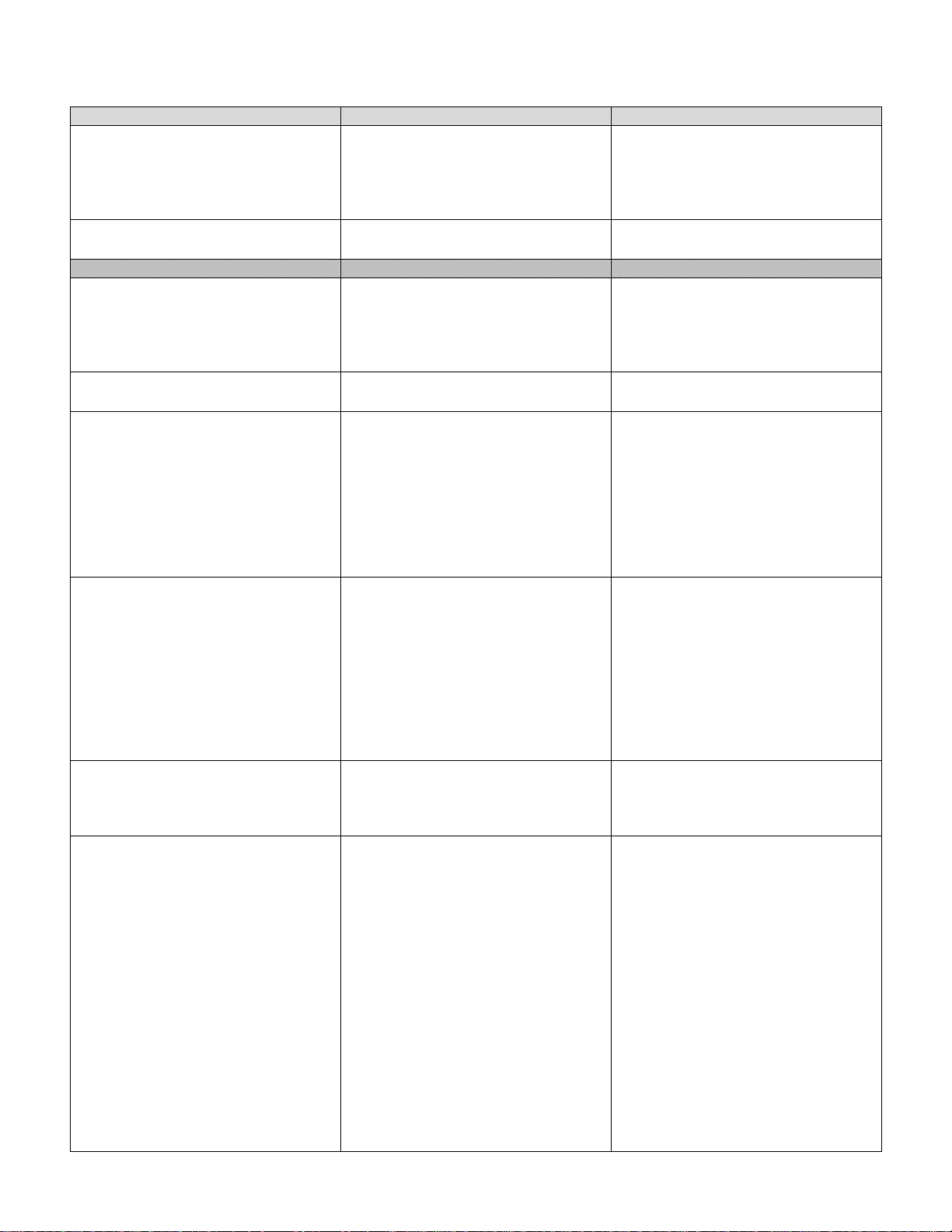

TROUBLESHOOTING GUIDE

SYMPTOM POSSIBLE CAUSE EVALUATION

Cooling Fan will not run

Oven will not heat

Fusion Toaster Service Manual

10

Incoming power supply

Fuse has opened

Incoming power supply

Fuse has opened

Hi-limit thermostat

Control Transformer

Switch Pad

Oven Control

Check power cord to ensure it is

plugged into receptacle. Check

circuit breakers. Reset if required.

Call power company if needed.

Check and replace if necessary.

Check power cord to ensure it is

plugged into receptacle. Check

circuit breakers. Reset if required.

Call power company if needed.

Check and replace if necessary.

Check for voltage on both sides of

thermostat. Terminals are normally

closed. If open, wait for oven to cool

down. Once oven has cooled,

contacts should go back to normally

closed position. If thermostat does

not return to normally closed or will

not hold, replace.

Check for main power to the primary

side of the control transformer. If no

voltage is present, trace wiring back

to main power switch. Check for

secondary voltage off of the

transformer 16~26VAC. If there is

no secondary voltage off of

transformer then replace

transformer.

Check that the switch pad is plugged

into the controller. Ensure all

electrical connections are tight.

Check for supply voltage to control

(16~26 VAC). If no voltage is

present, trace wiring back to

transformer. If control voltage is

present, check display to see that

information is displayed on the

screen. If nothing is displayed on

screen, replace controller. If there is

a read-out on the controller, set the

temperature to the maximum setting

(see operations manual). With the

control at the maximum setting,

check for output voltage (5 VDC) to

the solid state relays. If there is a 5

VDC signal to the solid state relays,

proceed to “solid state relays” for

more troubleshooting information. If

Loading...

Loading...