Lift-Master SW470 User Manual

Installation and Maintenance

Instructions

Medium & Heavy Duty

Swing Gate Operators

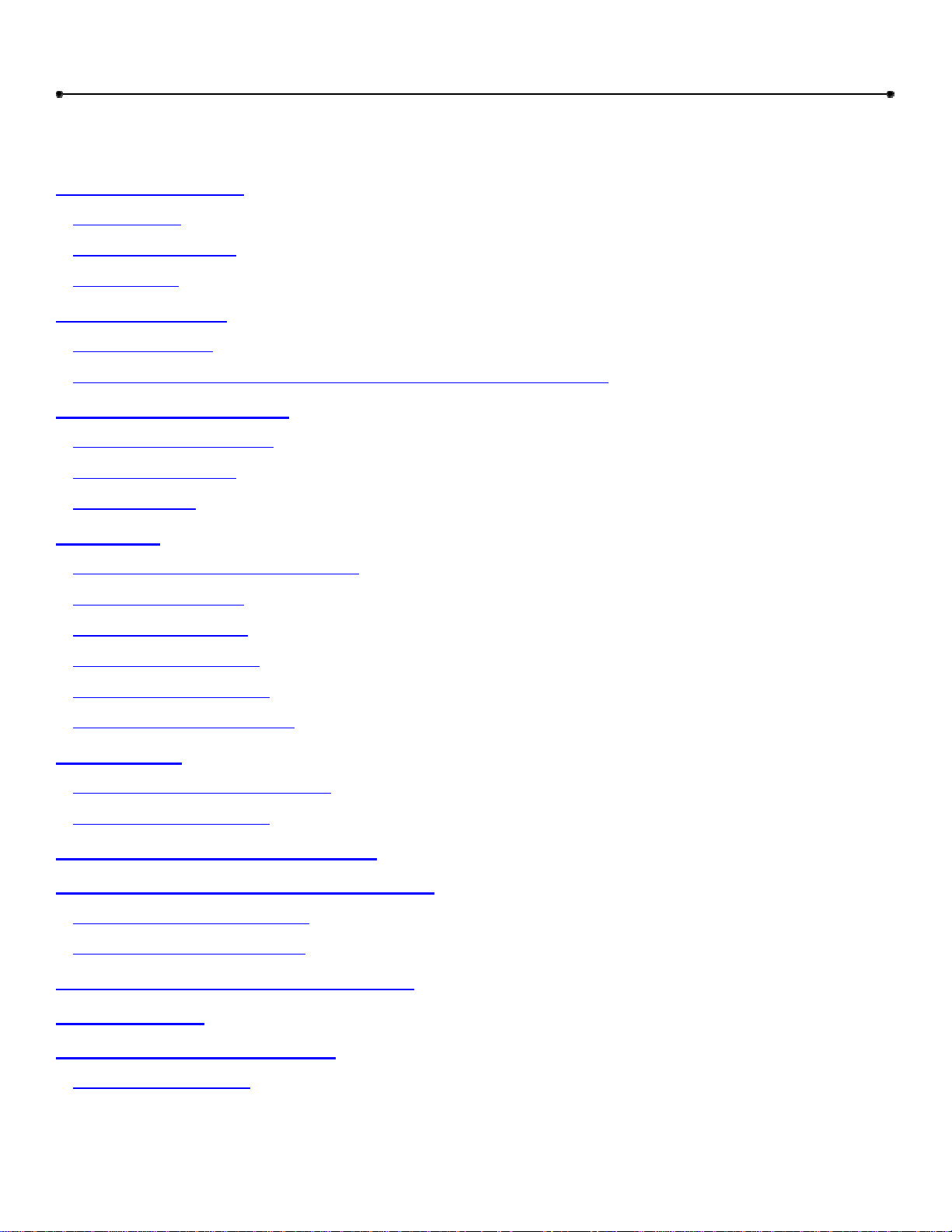

Models: SW470

SW490

Doc 01-G0665

Rev C

2

Contents

Contents

General Information ______________________________________________________ 4

Parts Supplied _______________________________________________________________________ 4

Model Classifications _________________________________________________________________ 4

Specifications _______________________________________________________________________ 5

Safety Information ________________________________________________________ 6

Safety Instructions____________________________________________________________________ 6

Safety Precautions for Swing Gates and Ornamental “Grill Type” Gates _________________________ 8

Preparing the Installation __________________________________________________ 9

Pre-Installation Check List _____________________________________________________________ 9

Wiring Specifications _________________________________________________________________ 9

System Features_____________________________________________________________________ 10

Installation_____________________________________________________________ 12

Post Mount for SW470 Operator Only ___________________________________________________ 12

Pad Mount Installation _______________________________________________________________ 13

Control Arm Assembly_______________________________________________________________ 14

Gate Bracket Installation______________________________________________________________ 16

Limit Switch Adjustments_____________________________________________________________ 17

Electrical Power Connections __________________________________________________________ 18

Programming ___________________________________________________________ 19

Switch #1: Operator Programming ______________________________________________________ 19

Switch #2: Timer to Close_____________________________________________________________ 20

Controls and Accessory Installation _________________________________________ 21

Manual Operation and System Check-Out ____________________________________ 22

SW470 Manual Gate Operation ________________________________________________________ 22

Preliminary System Check Out_________________________________________________________ 22

Required Maintenance – Normal Usage______________________________________ 23

Troubleshooting_________________________________________________________ 24

SW470 Parts Lis t and Drawing _____________________________________________ 25

SW470 Exploded View_______________________________________________________________ 25

Doc 01-G0665

Rev C

Contents

SW470 Parts List____________________________________________________________________ 26

SW490 Parts Lis t and Drawing _____________________________________________27

SW490 Exploded View_______________________________________________________________ 27

SW490 Parts List____________________________________________________________________ 28

Warranty Policy__________________________________________________________30

IMPORTANT!

Please leave this manual at the job site, preferably with the end user or facility manager. Read

and follow all instructions.

3

This gate operator is intended for use on a gate that swings in an arc in a horizontal plane.

Doc 01-G0665

Rev C

4

General Information

General Information

Parts Supplied

Inspect the operator for any possible shipping damage and any shortage of parts. Please note that if

accessories were ordered with this unit, some may be packed separately.

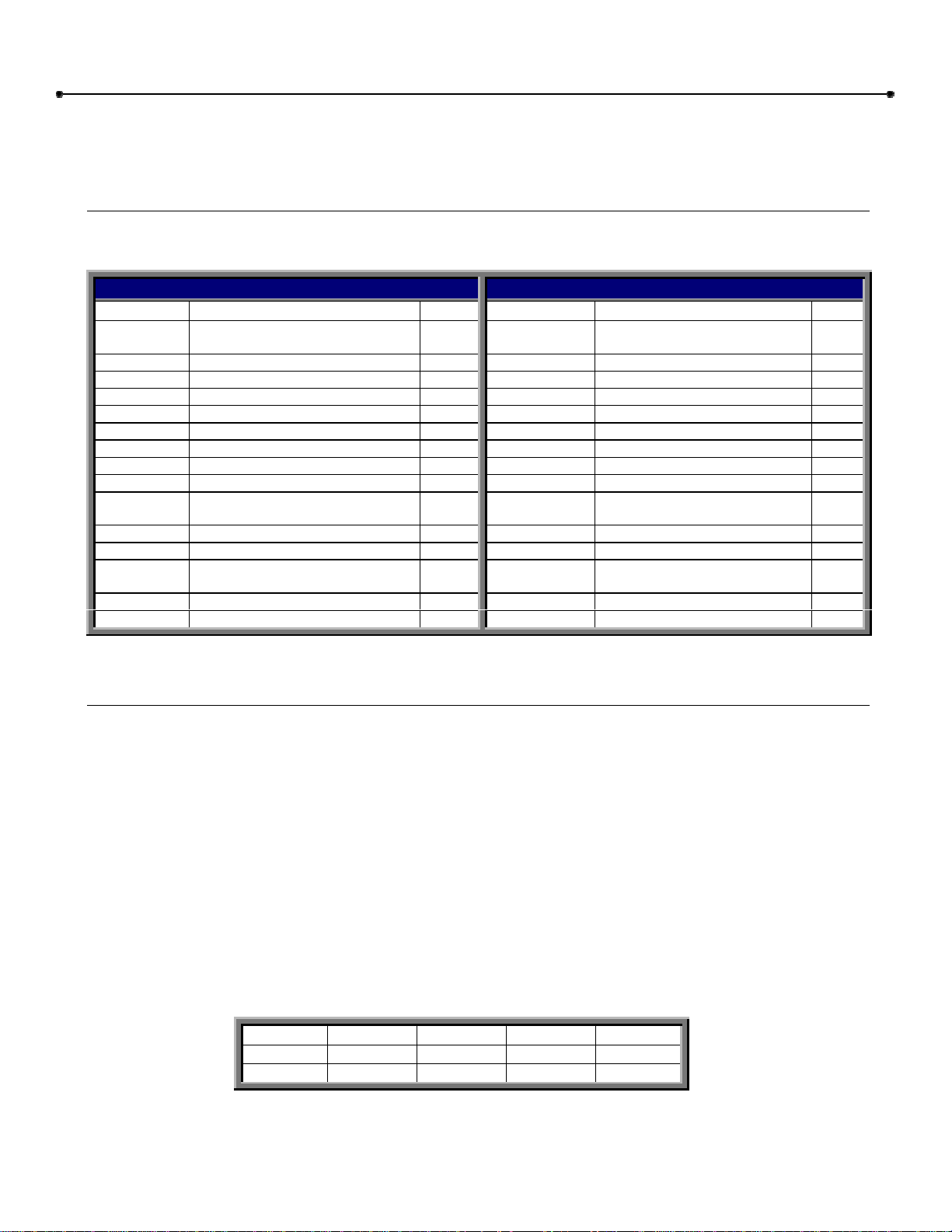

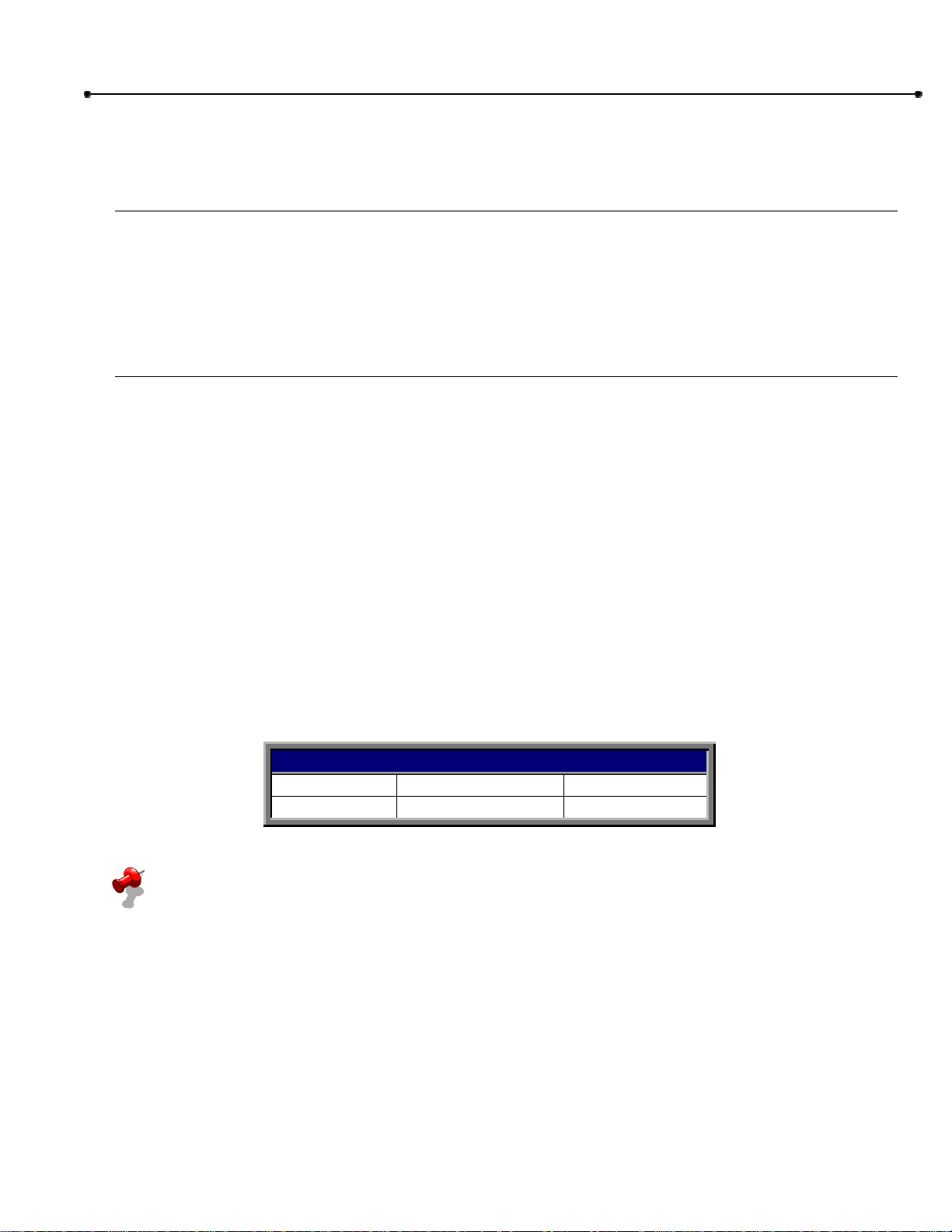

SW470 SW490

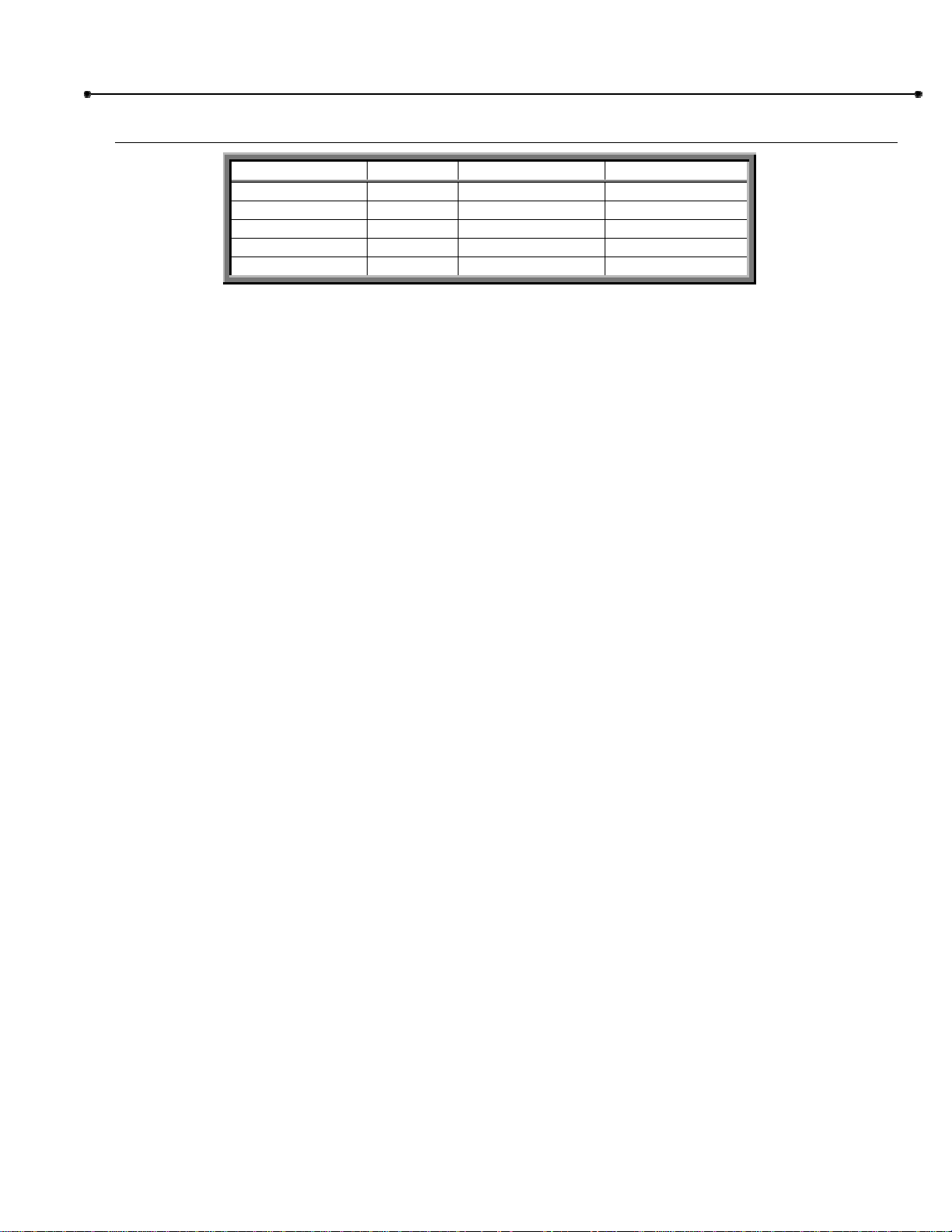

PART # DESCRIPTION QTY. PART # DESCRIPTION QTY.

01-G0582

02-401-SP STOP BUTTON 1 06-2025-T ARM CHANNEL 1

10-2108-T ARM CHANNEL 1 08-2001 EXTENSION ARM HOLDER 2

10-2109 EXTENSION ARM 1 10-2001 GATE BRACKET 1

10-2111 GATE BRACKET 1 10-2026-T EXTENSION ARM 1

40-3505 DORCMA WARNING SIGN 2 10-3900 39" GALVANIZED STEEL PIPE 1

80-2103 BLACK PLASTIC KNOB 2 12-10172 3/4 BUSHING 2

82-HN38-20 3/8-16 x 1-1/2 HEX HEAD BOLT 2 40-3505 DORCMA WARNING SIGN 2

82-SB50-08 1/2-13 x 1/2 SHOULDER BOLT 2 80-207-20 3/8 x 3/8 x 1-1/2 KEY 1

84-WH-38

85-FW-38 3/8" FLAT WASHER 2 82-HN38-16 3/8-16 x 1 HEX HEAD BOLT 2

GATE OPERATIONAL SAFETY

INSTRUCTION MANUAL

3/8-16 SERRATED FLANGED

NUT

1 02-401-SP STOP BUTTON 1

4 80-575 3/4 FLAT WASHER 6

82-HN75-28 3/4-10 x 3 HEX HEAD BOLT 2

82-NH38-06

84-RH-75 3/4-10 HEX NUT 2

85-LS-38 3/8 SPLIT LOCKWASHER 2

3/8-16 X 3/8 CONE POINT SET

SCREW

4

Table 1: Parts Supplied

Model Classifications

RESIDENTAL VEHICULAR GATE

OPERATOR – CLASS 1

A vehicular gate operator or system that is

intended for use in one to four single family

homes or its garage or parking area.

COMMERCIAL/GENERAL ACCESS

VEHICULAR GATE OPERATOR –

CLASS 2

A vehicular gate operator or system intended for

use in commercial locations such as gated

communities, apartment complexes, hotels,

garages, retail stores, or other buildings

servicing the general public.

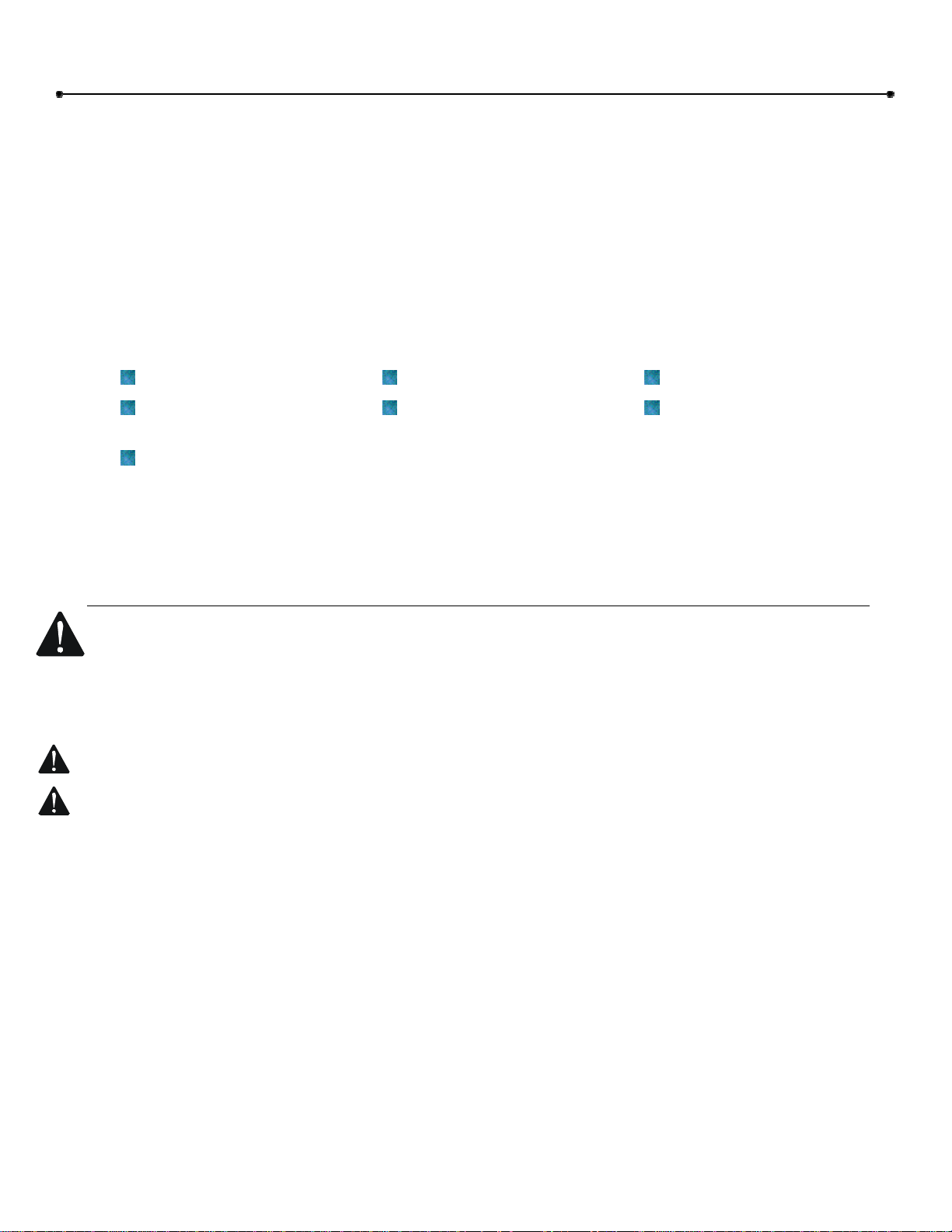

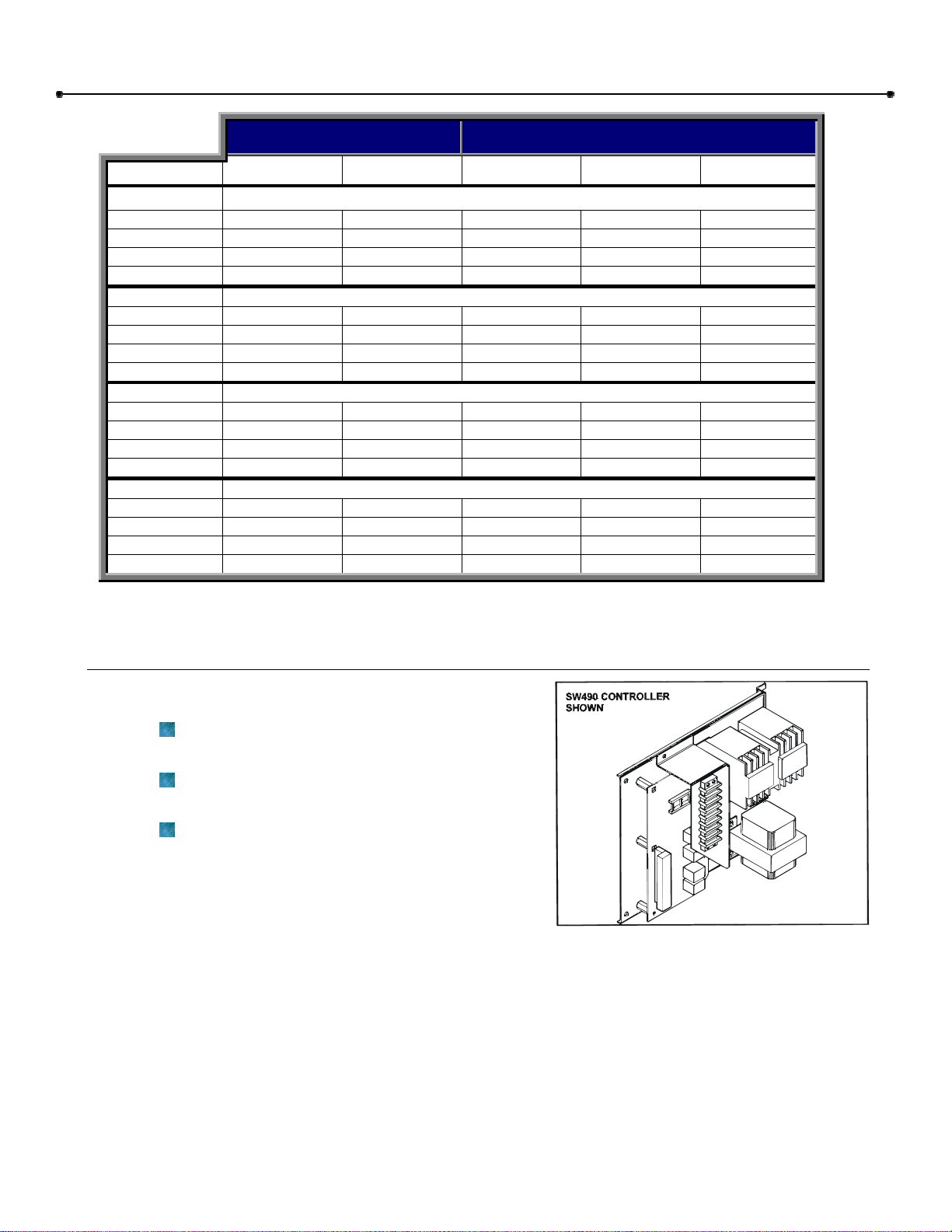

MODEL

SW470

SW490

CLASS 1 CLASS 2 CLASS 3 CLASS 4

!!!!

!!!!

INDUSTRIAL/LIMITED ACCESS VEHICULAR

GATE OPERATOR – CLASS 3

A vehicular gate operator or system intended for

use in an industrial location such as a factory,

loading dock area, or other locations not intended

to service the general public.

RESTRICTED ACCESS VEHICULAR GATE

OPERATOR – CLASS 4

A vehicular gate operator or system intended for

use in a guarded industrial location such as an

airport security area or other restricted access

location not servicing the general public, in which

unauthorized access is prevented via supervision

by security personnel.

Doc 01-G0665

Rev C

Table 2

Specifications

SW470-50

SW490-33

SW490-50

SW490-75

SW490-100

General Information

Model HP Max. Wt. (Lbs.) Max. Gate Width

½ 500 12 FT.

1/3 600 12 FT.

½ 750 16 FT.

¾ 900 19 FT.

1 1000 22 FT.

Table 3

5

Doc 01-G0665

Rev C

6

Safety Information

Safety Information

Vehicular gate systems provide convenience and security. Gate systems are comprised of many

component parts. The gate operator is only one component. Each gate system is specifically designed

for an individual application. Gate operating system designers, installers and users must take into

account the possible hazards associated with each individual application.

Improperly designed, installed or maintained systems can create risks for the user as well as the

bystander. The design and installation of gate systems must reduce public exposure to potential

hazards.

A gate operator can create high levels of force, in its function as a component part of a gate system.

Therefore, safety features must be incorporated into every design. Specific safety features include:

Gate Edges Enclosed Track Vertical Posts

Guards for exposed

rollers

Screen Mesh

Important instructions follow. These instructions are intended to highlight certain safety related issues.

These instructions are not intended to be comprehensive. Because each application is unique, it is the

responsibility of the purchaser, designer, installer and end user to ensure that the total gate system is

safe for its intended use.

Photo-electric Sensors Instructional and

Precautionary Signage

Safety Instructions

Selected Instructions are highlighted with a precautionary symbol (see left margin). Failure to follow

these selected instructions can result in serious injury or death.

STEP 1: BEFORE INSTALLATION

1

Confirm gate operator model is specified by Installation and Maintenance Manual for

application type, gate size and frequency of use.

2

Confirm ALL appropriate safety features, such as gate edges, photo-electric sensors,

vertical posts and enclosed tracks, are specified.

3

Confirm the gate system design reduces pinch points and protects against entrapment.

4

Confirm gate system design has pedestrian access separate from vehicular entrance.

5

Confirm gate system design reduces traffic backup.

6

Confirm warning signage is included in design.

7

Confirm gate moves freely before installation of operator.

8

Repair or service worn or damaged gate hardware before installation of operator.

9

To avoid installation hazards, review the gate system operation and installation

procedures, such as manual disconnect mechanism procedure.

10

Confirm control design prohibits unauthorized use.

Doc 01-G0665

Rev C

STEP 2: DURING INSTALLATION

1

Disconnect power at service panel before making any electrical connection.

2

Avoid pinch points; be aware of all moving parts.

3

Adjust clutch or load sensing device to minimum force setting.

4

Do not overtighten clutch or adjust force setting above minimum.

5

Install controls where user cannot touch gate while operating controls.

6

Install two or more warning signs on the gate to alert persons in the area of automatic

gate operation. Warning signs must be conspicuous.

7

Install operator inside fence line. DO NOT install operator on public side of fence line.

8

Secure gate operator cover.

STEP 3: AFTER INSTALLATION

1

Test all safety features.

Safety Information

7

2

Train end user about basic functions and safety features of gate system.

3

Leave Installation and Maintenance Manual and Safety Information with end user.

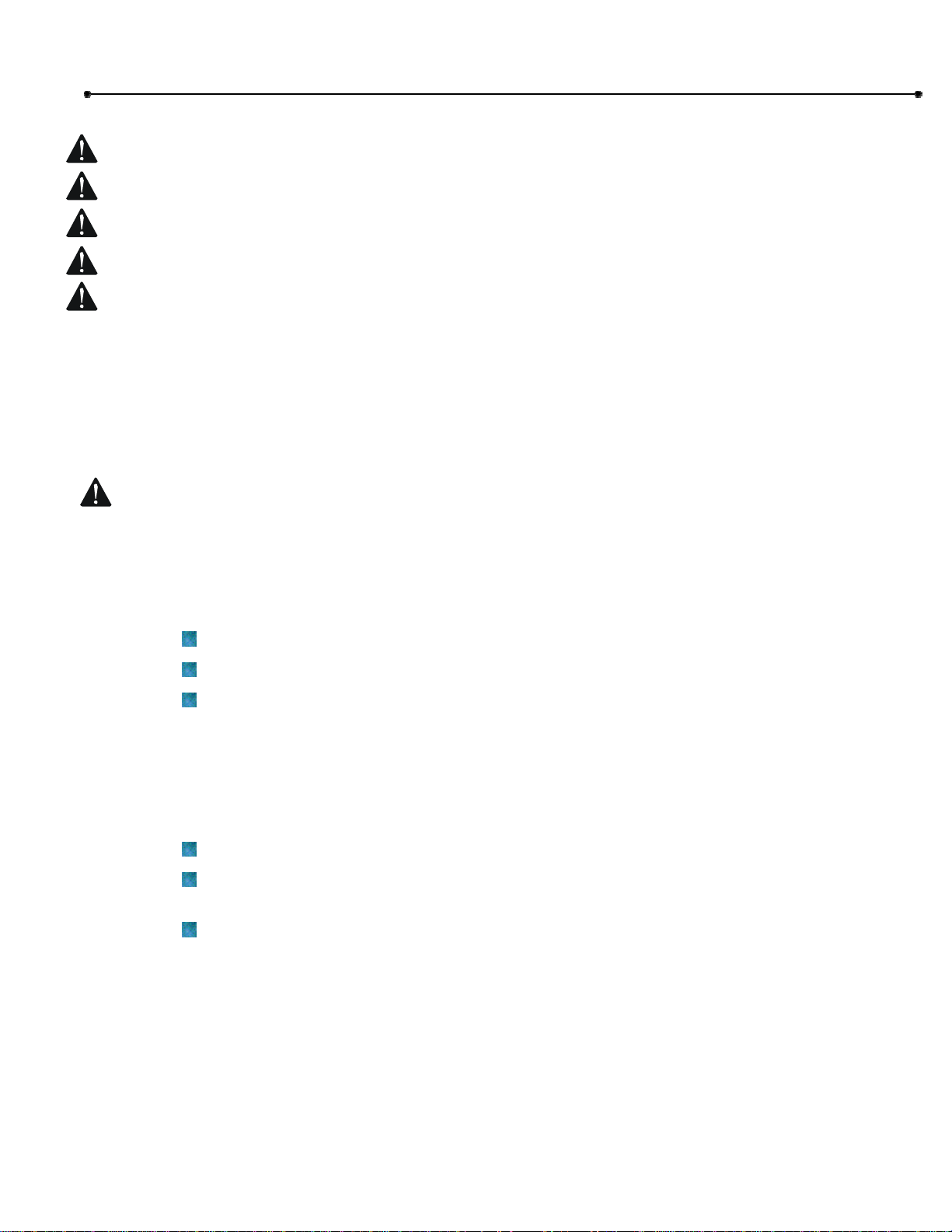

FOR GATE OPERATORS USING NON-CONTACT SENSOR(S)

See instruction supplied with sensor for proper placement.

Precautions must be taken to reduce the risk of nuisance tripping of the sensor.

If there are multiple areas of risk of entrapment or obstruction, then more than one sensor

should be incorporated into the system.

FOR GATE OPERATORS USING CONTACT SENSOR(S)

One or more sensors shall be located as shown on page 8.

Care must be taken during the wiring of the sensor(s) to the operator. Make sure that the

wiring cannot be damaged or interrupted.

When using a sensor with a gate edge transmitter, care must be taken to insure that the

RF signal is not interfered with or obstructed.

SECONDARY ENTRAPMENT PROTECTION

It is recommended that secondary safeties always be used for both the open and close directions.

Use photo eyes, safety edges or both. In any case, the device must sense people. Loops cannot

be used.

Doc 01-G0665

Rev C

8

g

Safety Information

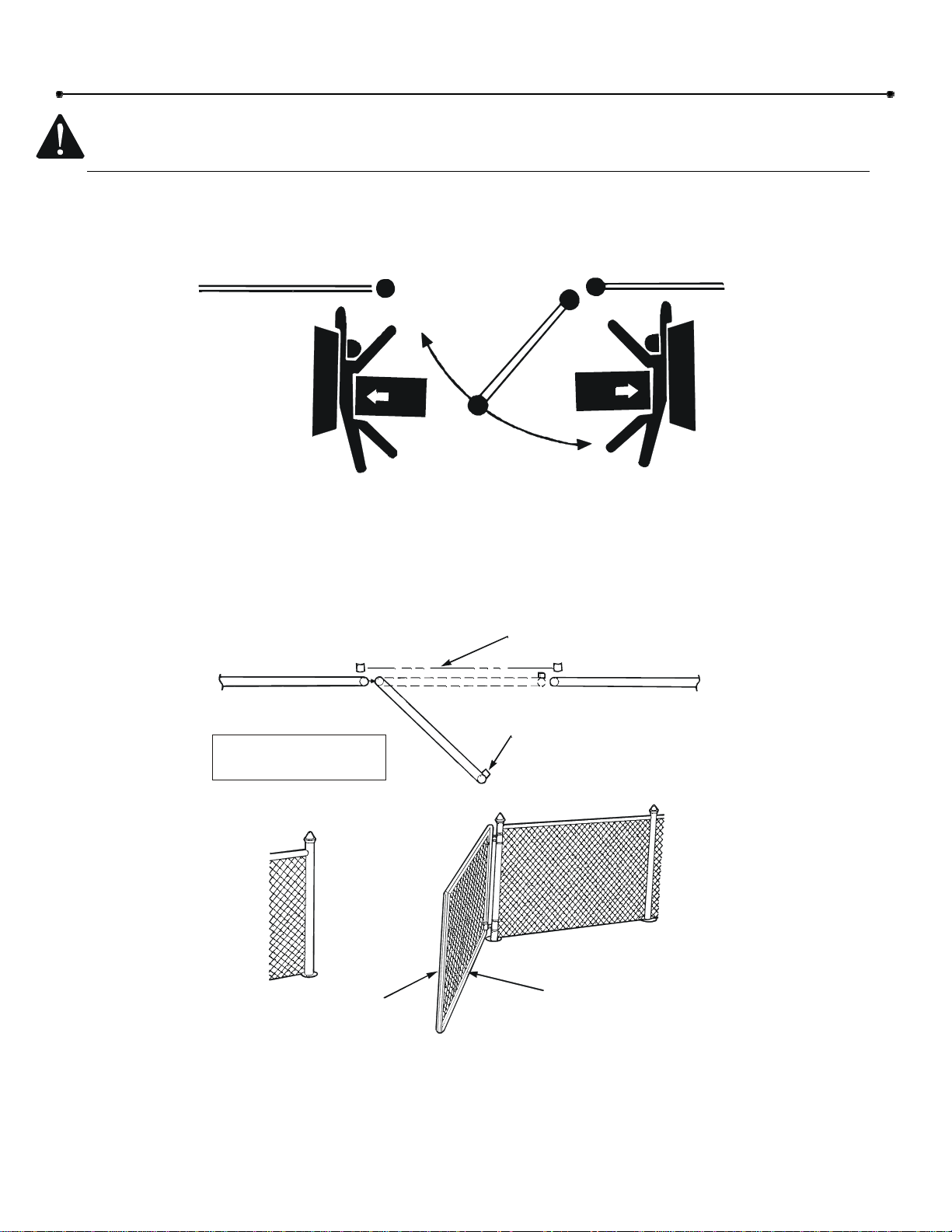

Safety Precautions for Swing Gates and Ornamental “Grill Type”

Gates

ENTRAPMENT ZONES

Pedestrians must stay clear of the gate path, particularly the area where the gate can trap them,

as shown in Figure 1.

01-G0665F18

Figure 1

Gate edges and/or photo-electric beams must be incorporated into the swing gate system to assist

in the protection of people who may come near the gate operating system.

Also, injuries can occur when people put their hands and arms through openings in a grill type

gate and it is operated. This potential hazard can be averted by placing a screen mesh on the

gate to prevent access through the openings. See Figure 2.

Photo-Electric Beam

Always test Gate Edges an d

Photo Beams anytime they are

adjusted or serviced.

Gate Ed

e on Leading Edge of Gates

01-G0610F4

Doc 01-G0665

Rev C

Gate Edge

Screen Mesh

Figure 2

9

Preparing the Installation

Preparing the Installation

Pre-Installation Check List

! Check the gate. It

or repair the gate prior to operator installation. The gate

! Double check the size and weight of the gate to make sure that it is proper for this application.

! If wiring has already been installed, check to make sure it meets the following specifications.

must

operate smoothly and freely. If necessary, lubricate the hinges, adjust

must

be level.

Wiring Specifications

Refer to Table 4 and Table 5 for wiring specifications.

A.

The distances shown are measured in

feet from the operator to the power

source.

B.

These calculations are based on the

National Electrical Code and allows for a

5% voltage drop.

C.

Supply voltage must be within 10% of the

operator’s rating under load conditions.

D.

These calculations are based on stranded

copper wire.

E.

It is highly recommended that only 90% of

the distances shown be used; this will

allow for a 10% safety factor.

F.

For dual units, the distance shown should

be cut in half.

G. All local codes must be strictly adhered

to.

It is very important that operator is

properly grounded.

H.

Do not run control wires in the same conduit

with power wires.

I.

Do not run multi conductor or parallel

conductor cable for controls.

J.

All power wiring should be dedicated and

protected.

CONTROL WIRING

VOLT MAX. DISTANCE WIRE GUAGE

24 1000 18

Table 4: Control Wiring Chart

NOTE:

suitability of wire installation. Master/Slave units must be installed on separate circuits.

Calculated using NEC guidelines. Local codes and conditions must be reviewed for

Doc 01-G0665

Rev C

10

Preparing the Installation

Single Phase 3 Phase

115 VAC 230 VAC 230 VAC 460 VAC 575 VAC

AWG Maximum wire length in feet for 1/3 HP motor

6 700 3,100 4,750 14,225 35,550

8 450 1,950 3,000 8,975 22,425

10 275 1,225 1,900 5,650 14,075

12 175 775 1,175 3,525 8,825

AWG Maximum wire length in feet for ½ HP motors

6 475 2,075 2,850 14,225 17,775

8 300 1,300 1,800 8,975 11,225

10 200 825 1,125 5,650 7,050

12 125 525 725 3,525 4,425

AWG Maximum wire length in feet for ¾ HP motors

6 325 1,250 2,050 7,125 11,850

8 225 800 1,300 4,500 7,475

10 150 500 825 2,825 4,700

12 100 325 525 1,775 2,950

AWG Maximum wire length in feet for 1 hp motors

6 250 950 1,425 5,700 8,900

8 150 600 900 3,600 5,625

10 100 375 575 2,275 3,525

12 75 250 375 1,425 2, 225

Table 5: Power Wiring Chart

System Features

ACTIVITY LED

Steady indication when gate is at either open

or close limit.

1 second flash when gate is off a limit in

normal operation.

2 second flash when an entrapment has

occurred.

AUDIBLE WARNING DEVICE

If the operator should have a second inherent

obstruction in sequence with the first; (i.e. back to

back), the sounder will activate. Also, the sounder can

be programmed to come on 3 seconds prior to gate

movement, and remain on during gate movement.

THREE BUTTON CONTROL (SEQUENCE OF OPERATION)

Open, stop, close. Stop will override all other functions. If closing, Open will cause the operator to

stop and reverse to full open. If gate is at its fully opened position, the Close function will cause

the gate to close.

Figure 3

01-G 0665F15

Doc 01-G0665

Rev C

Loading...

Loading...