Page 1

Programming Instructions

Sentex

Sentex

SentexSentex

systems

01-16169F1

Gate Operator Models

SLMAX & SW2200

Doc 01-16169

Rev B

Page 2

2

SLMAX/SW2200 Programming Instructions

Contents

SLMAX/SW2200 Programming Controls __________________________ 3

Viewing the Gate’s Current Status ________________________________ 3

Programming the Single Button Functions__________________________ 4

Setting the Gate Open/Close Limits _______________________________ 6

Setting the Gate Operator Speed__________________________________ 7

Setting the Deceleration Limits ___________________________________ 9

Setting the Entrapment Level ____________________________________ 9

Setting the Loop Detector_______________________________________ 10

Enabling/Disabling the Operator Warning ________________________ 11

Setting the Gate’s Timer to Close ________________________________ 11

Setting the Electric Lock Delay __________________________________ 12

Factory Default Settings________________________________________ 13

NOTE: For information about the Troubleshooting screen, see the SW2200

Installation Manual and SLMAX Installation Manual.

IMPORTANT!

READ ME FIRST

The SLMAX and SW2200 Gate Operators come pre-programmed with default

settings. When first installed, you will not need to program each feature. In

fact, you may want to review the system’s default settings (see Factory Default

Settings, p. 13) before you start programming. You may or may not want different

settings than those already defined.

Doc 01-16169

Rev B

Page 3

LiftMaster

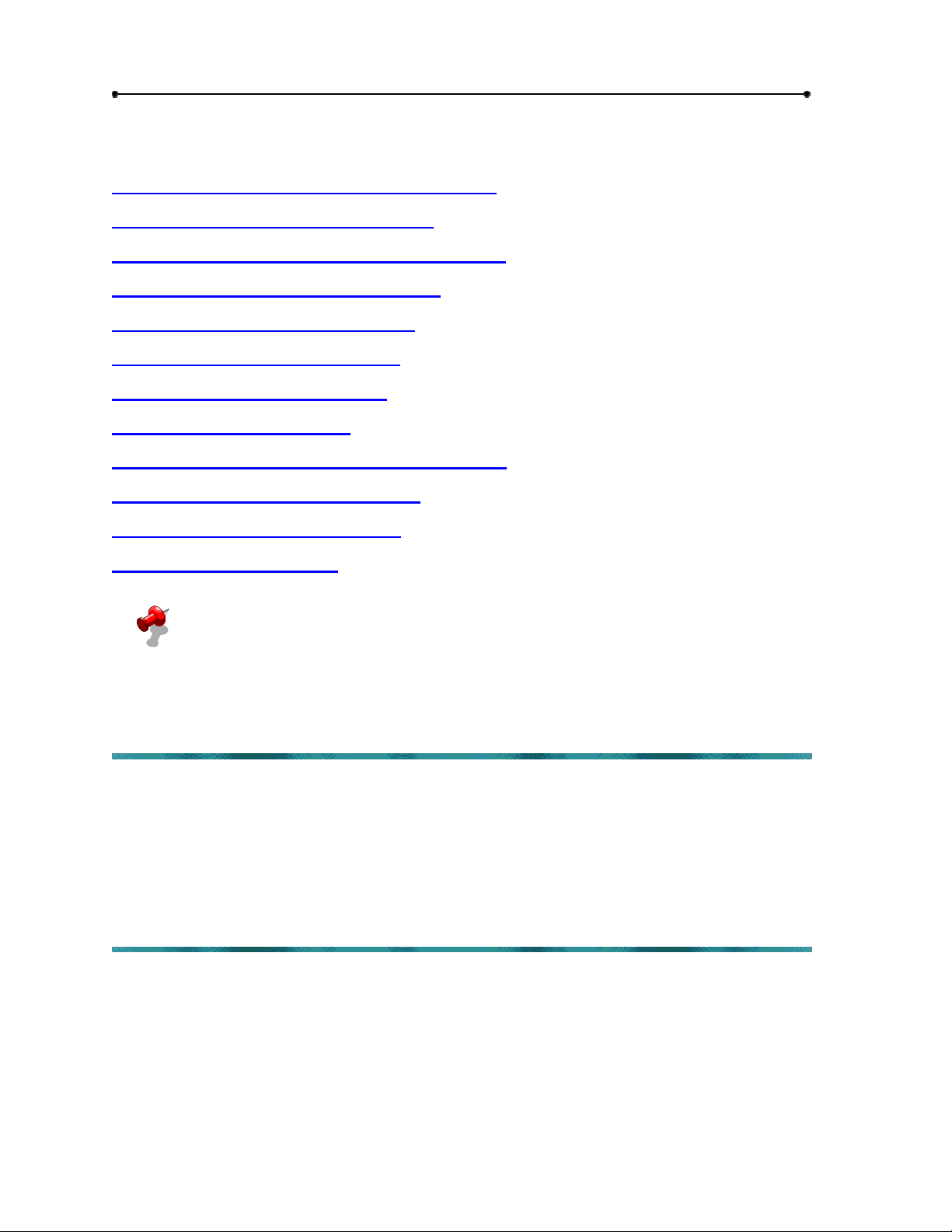

SLMAX/SW2200 Programming Controls

Programming occurs on a 5-button, 2-LED membrane switch located on top of the

control box (see Figure 1). Programming instructions appear on a 2-row, 16-character

LCD screen.

The OPEN LIMIT LED

flashes during Open Limit

programming.

LCD SCREEN

3

systems

01-16169F2

Press the ENTER button

to select a program or

save program settings.

The CLOSE LIMIT LED

flashes during Close Limit

programming.

Sentex

Sentex

SentexSentex

Use the SETTINGS

buttons to set the program

settings.

Figure 1: Programming Controls

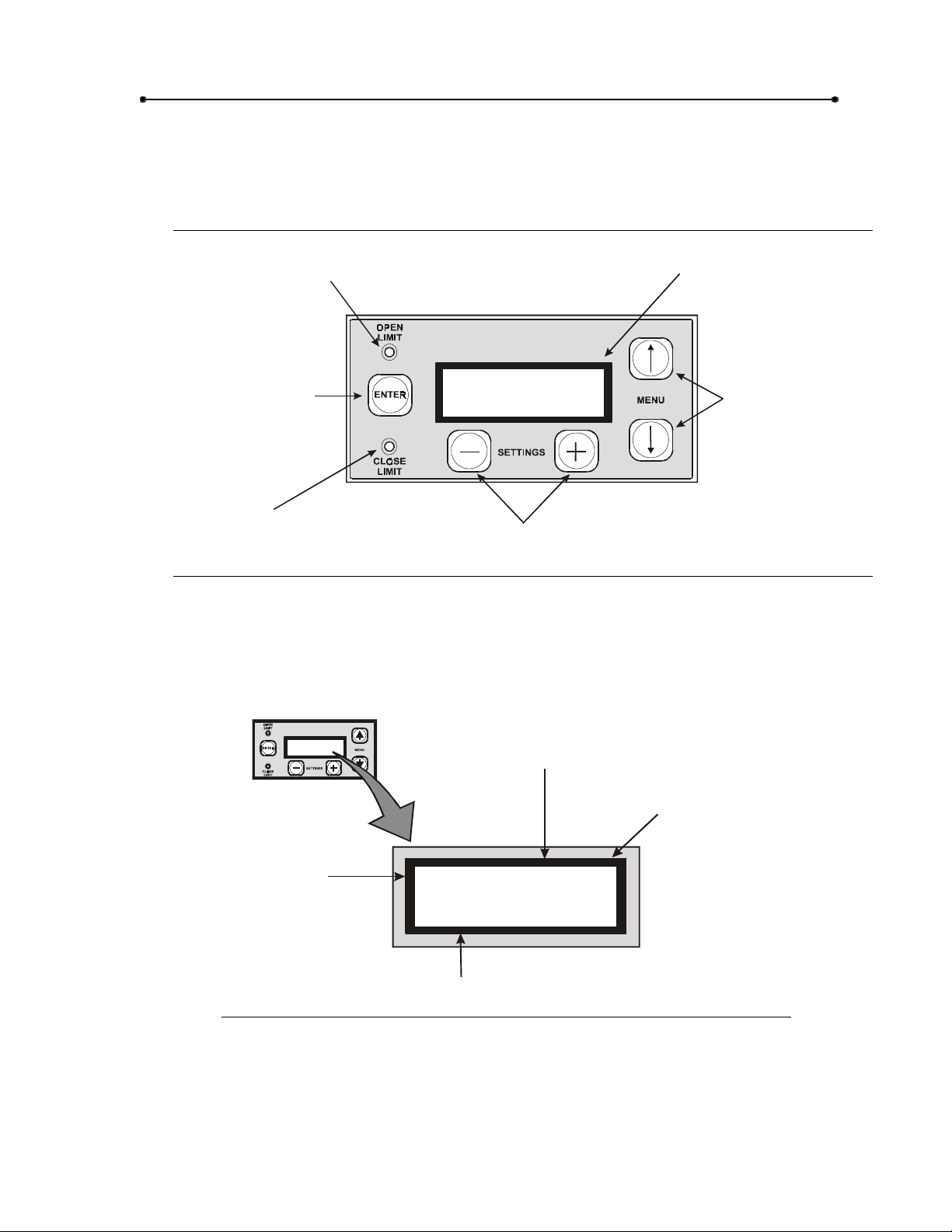

Viewing the Gate’s Current Status

The system’s default screen displays the gate’s current status. Refer to Figure 2.

systems

Sentex

Sentex

SentexSentex

Gate Type: SINGLE

or MASTER/SLAVE

Microprocessor

Revision

Use the MENU Buttons

to scroll up/down the

programming menu.

Gate Power:

AC or UPS

AC SINGL 3.0

CLOSED

01-161 69F3

Gate Status:

OPEN or CLOSED

Figure 2: Status Screen

Doc 01-16169

Rev B

Page 4

4

SLMAX/SW2200 Programming Instructions

Programming the Single Button Functions

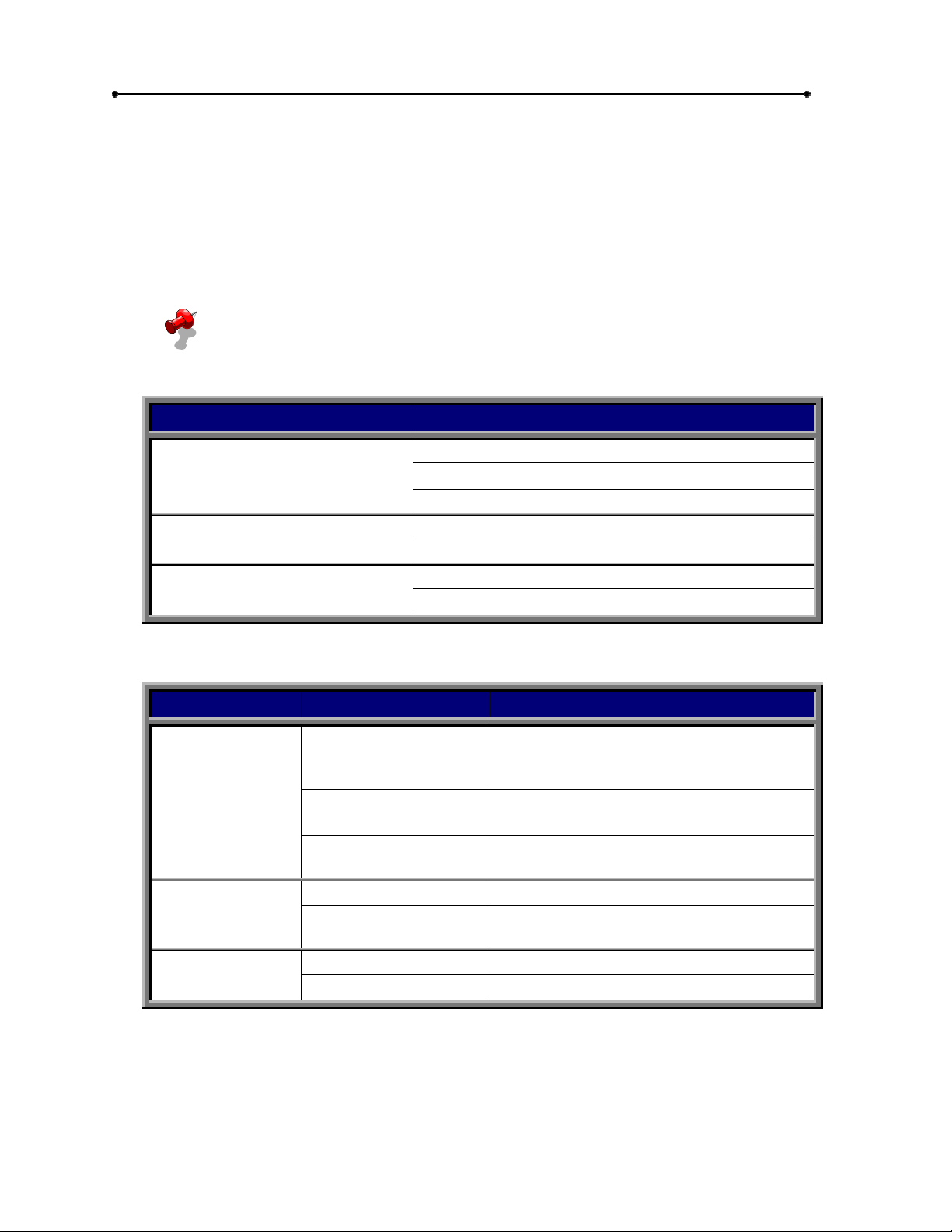

FACTORY DEFAULT: OPENING = STOP, NO TIMER RESET

CLOSING = (None—button has no effect)

MID-STOP = MID -STOP OPEN

The Single Button (connected at the J8 input connector) programming feature allows

you to configure the single button function (i.e., how the gate reacts after you press the

single button). You may program the single button function to perform the actions

outlined in Table 2.

NOTE: There is no factory default setting when the gate is “CLOSING”. When

the gate closes, the single button will have no effect. However, you may

program the “STOP” or “REVERSE” options (see below).

Selectable options include the following:

GATE CONDITIONS PROGRAMMABLE FUNCTIONS POSSIBLE

STOP

OPENING

CLOSING

AT MID-STOP

OPEN ONLY

STOP, NO TMR RST

STOP

REVERSE

MID-STOP OPE N

MID-STOP REVERSE

Table 1: Programmable Options

If the gate is . . . and you select . . . the gate will . . .

Stop. If “TIMER TO CLOSE” is activated

OPENING

CLOSING

AT MID-STOP

STOP

OPEN ONLY

STOP, NO TMR RST

STOP Stop.

REVERSE

MID-STOP OPEN Travel to the open position.

MID-STOP REVERSE Close if the gate was previously opening.

Table 2: Single Button Functions

(see p. 11), the gate closes after timer

elapses.

Continue to open—does not allow you to

stop gate using single button.

Stop. If activated, “TIMER TO CLOSE”

function will not occur.

Stop and then reverse to the open

position.

Doc 01-16169

Rev B

Page 5

Set the Single Button Function

To set the single button function, follow the steps below:

PROCEDURES DISPLAY PROMPT

LiftMaster

5

1 Pressing the MENU buttons (!"), locate the

SINGLE BUTTON option and press ENTER.

2 For the first setting, press (–) or (+) to select the

desired option and press ENTER to save.

Options: Stop—Stop, No Tmr Rst—Open Only

3 For the second setting, press (–) or (+) to select

the desired option and press ENTER to save.

Options: Stop—Reverse

4 For the third setting, press (–) or (+) to select the

desired option and press ENTER to save.

Options: Open—Reverse

SINGLE BUTTON

OPENING

(OPTION)

CLOSING

(OPTION)

MIDSTOP

(OPTION)

Doc 01-16169

Rev B

Page 6

6

SLMAX/SW2200 Programming Instructions

Setting the Gate Open/Close Limits

NO FACTORY DEFAULT SETTING

This feature allows you to set the gate’s open or close limits without utilizing limit

switches. You are essentially setting the operator so it knows how far to open and

close its gate.

NOTE: After a power outage or operator gate disengagement, the operator will

retain its limit settings.

Also, to stop the gate while setting the limits, release the (+) or (-) buttons.

Press these buttons to correct any over-travel.

To set the Gate Open/Close Limits, follow these steps:

PROCEDURES DISPLAY PROMPT

1 Pressing the MENU buttons (!"), locate the LIMITS

MENU option and press ENTER.

2 At the RESET LIMITS (+) prompt, press (+) to start

programming.

3 Press (+) to continue programming. (+) TO CONTINUE

4 Press and hold (+) or (–) to close the gate. SET CLOSE LIMIT

5 When the gate reaches the desired closed limit position,

release (+) or (-) and press ENTER.

The Close Limit LED will blink to indicate that the close

limit position is accepted but not yet stored in the

memory.

6 Press and hold (+) or (–) to open the gate. SET OPEN LIMIT

7 When the gate reaches the desired open limit position,

release (+) and (-) and press ENTER.

The Open Limit LED will blink to indicate that the open

limit position is accepted but not yet stored in the

memory.

LIMI TS MEN U

ENTER TO CHANGE

RESET LIMITS (+)

(–) TO EXIT

(+/–) TO POSI TION

SET CLOSE LIMIT

ENTER TO SET

(+/–) TO POSI TION

SET OPEN LIMIT

ENTER TO SET

8 Press ENTER to test the gate’s limits .

The gate will automatically close, open, and finally close

to the programmed close/open limit positions.

Press any key to stop the gate during the limit test.

9 When the operator finishes the test, the Close Limit and

Open Limit LEDs will stay lit to indicate that the limit

positions are now stored in the system’s memory.

Doc 01-16169

Rev B

PRESS ENTER TO

TEST LIMITS

Page 7

LiftMaster

Setting the Gate Operator Speed

This feature allows you to change the speed of the gate. Please note that max speed

(normal gate speed) and min speed (decelerated gate speed) have their own minimum

and maximum range.

For the SW2200, Table 4 provides speed settings based on the total amount of time it

takes the gate to fully open or close.

Refer to Table 3 and Table 4 to select proper gate speeds for the SLMAX and SW2200:

7

MAX GATE

SPEED

(INCHES/SEC)

12” 170 8.8” 120 (Max.)

11” 157 8” 110

10” 144 7” 97

9” 130 6” 83

8” 117 5” 70

7” 104 4.2 60 (Min.)

6.8” 100 (Min.) --- ---

GATE OPEN OR CLOSE

PROGRAMMED

SETTING

Table 3: Max and Min Gate Speeds for the SLMAX

TIME ( S EC)

14 220 (Max.)

15 200

16 190

17 170

MIN GATE

SPEED

(INCHES/SEC)

PROGRAMMED SETTING

PROGRAMMED

SETTING

18 155

19 145

20 130

21 120

22 115

23 110

24 105

25 100 (Min.)

Table 4: Max Gate Speed for the SW2200

Doc 01-16169

Rev B

Page 8

8

SLMAX/SW2200 Programming Instructions

NOTE: The open/close time settings in Table 4 are valid if:

(1) You install the gate with the gate dimensions recommended in the

installation manual.

(2) T he Open and Close Deceleration Limits are programmed at the

minimum (100) setting.

(3) T he Min Gate Speed is programmed to 120.

Factory Defaults

SLMAX = MAX SPEED: 220

MIN SPEED: 60

SW2200 = MAX SPEED: 220

MIN SPEED: 60

Setting the Gate Speed

To set the operator speed, follow the steps below:

-and-

-and-

PROCEDURES DISPLAY PROMPT

1 Pressing the MENU buttons (!"), locate the

OPERATOR SPEED option and press ENTER.

2 Press (–) or (+) to set the maximum gate speed.

NOTE: Maximum speed refers to the speed of

the gate during opening or closing.

3 Press ENTER to save.

4 Press (–) or (+) to set the minimum gate speed.

NOTE: Minimum speed refers to the speed of

the gate when it slows down prior to reaching the

open or close limit.

5 Press ENTER to save.

OPERATOR SPEED

MAX SPEED: (See Table)

(+/–) TO ADJUST

MIN SPEED: (See Table)

(+/–) TO ADJUST

Doc 01-16169

Rev B

Page 9

LiftMaster

Setting the Deceleration Limits

This feature allows you to set the distance during which the gate starts to slow down

prior to stopping at the open or close limit.

Set the Open Deceleration Limit

FACTORY DEFAULT = MEDIUM

To set the Open Deceleration Limit, follow these steps:

PROCEDURES DISPLAY PROMPT

9

1 Pressing the MENU buttons (!"), locate the

OPEN DECEL LIMIT option and press ENTER.

2 Press (–) or (+) to set the distance.

3 Press ENTER to save.

OPEN DECEL LIMIT

__ __ __ I __ __ __

[LESS MOREΨ

Set the Close Deceleration Limit

FACTORY DEFAULT = MEDIUM

To set the Close Deceleration Limit, follow these steps:

PROCEDURES DISPLAY PROMPT

1 Pressing the MENU buttons (!"), locate the

CLOSE DECEL LIMIT option and press ENTER.

2 Press (–) or (+) to set the distance.

3 Press ENTER to save.

CLOSE DECEL LIMIT

__ __ __ I __ __ __

[LESS MOREΨ

Setting the Entrapment Level

FACTORY DEFAULT = 25

This feature allows you to set the gate’s sensitivity to an obstruction.

0 = Most Sensitive

99 = Least Sensitive

To set the entrapment level, follow these steps:

PROCEDURES DISPLAY PROMPT

1 Pressing the MENU buttons (!"), locate the

ENTRAPMENT option and press ENTER.

2 Press (–) or (+) to set the entrapment level. ENTRAPMENT LEVEL

3 Press ENTER to save.

ENTRAPMENT

SET LEVEL: (0-99)

Doc 01-16169

Rev B

Page 10

10

SLMAX/SW2200 Programming Instructions

Setting the Loop Detector

FACTORY DEFAULT = LOOP INPUT A: OPEN LOOP

LOOP INPUT B: SAFETY LOOP

LOOP INPUT C: SHADOW LOOP

This feature allows you to program the desired loop function using the J4 inputs (A, B,

and C). Before setting the loop detector, check which loop types are connected to the

J4 inputs.

EXAMPLE: Input A may be connected to an Open Loop Detector. If so, set

Input A on J4 to Open Loop.

Loop types include:

Open Loops

Safety Loops

Shadow Loops (may be used in swing gate systems—not slide gates).

To set the Loop Detectors, follow these steps:

PROCEDURES DISPLAY PROMPT

1 Pressing the MENU buttons (!"), locate the

LOOP DETECTORS option and press ENTER.

2 Assign a loop type to Input A. Press (–) or (+) to

select the desired option.

3 Press ENTER to save.

4 Assign a loop type to Input B. Press (–) or (+) to

select the desired option.

5 Press ENTER to save.

6 Assign a loop type to Input C. Press (–) or (+) to

select the desired option.

7 Press ENTER to save.

NOTE: Setting multiple Loop Inputs to the same

option (e.g., Open, Safety, or Shadow) will not

adversely affect the operator’s loop function.

LOOP DETECTORS

LOOP INPUT A

(OPTION)

LOOP INPUT B

(OPTION)

LOOP INPUT C

(OPTION)

Doc 01-16169

Rev B

Page 11

LiftMaster

Enabling/Disabling the Operator Warning

FACTORY DEFAULT = OFF

This feature allows you to enable or disable the operator alarm that warns people with

beeps when the gate is moving.

NOTE: If you enable the operator warning, and when the gate is prompted to

open, the alarm will sound immediately, but the gate will start opening after a

programmed number of seconds (1-9).

To enable or disable the operator warning, follow the steps below:

PROCEDURES DISPLAY PROMPT

11

1 Pressing the MENU buttons (!"), locate the

OPERATOR WARNING option and press ENTER.

2 Press (–) or (+) to enable or disable the warning

alarm.

OFF = Alarm does not sound off during gate

movement.

Gate has no delay.

1-9 = Alarm sounds off during gate movement.

Gate will start after set number of seconds

(1-9).

3 Press ENTER to save.

OPERATOR WARN ING

OPERATOR WARN ING

DELAY START: (0-9)

Setting the Gate’s Timer to Close

FACTORY DEFAULT = OFF

This feature allows you to set the time (in seconds) the gate stays open prior to closing

automatically.

To set the gate’s Timer to Close, follow these steps:

PROCEDURES DISPLAY PROMPT

1 Pressing the MENU buttons (!"), locate the

TIMER TO CLOSE option and press ENTER.

2 Press (–) or (+) to enable or disable the timer to

close function.

OFF = Gate does not close automatically.

1-120 = Gate will close automatically after a

programmed number of seconds (1-120).

3 Press ENTER to save.

TIMER TO CLOSE

OPERATOR WARN ING

DELAY START: (1-120)

Doc 01-16169

Rev B

Page 12

12

SLMAX/SW2200 Programming Instructions

Setting the Electric Lock Delay

FACTORY SETTING = OFF

All gates installed with a maglock (connected to the JP6 connector/input) may have the

electric lock delay function programmed into the system. This delays the gate from

opening for a programmed number of seconds (1-10) when the operator is prompted to

open. After the delay, the operator will de-energize the maglock (allowing the gate to

unlock) and open the gate.

To set the Electric Lock Delay, follow these steps:

PROCEDURES DISPLAY PROMPT

1 Pressing the MENU buttons (!"), locate the

ELECTRIC LOCK option and press ENTER.

2 Press (–) or (+) to select the delay time.

OFF = No delay.

1-10 = Gate will open after set number of

seconds (1-10).

3 Press ENTER to save.

ELECTRIC LOCK

ELECTRIC LOCK

DELAY START: (1-10)

Doc 01-16169

Rev B

Page 13

LiftMaster

Factory Default Settings

The SLMAX and SW2200 come programmed with factory default settings so that you

won’t have to program each step when an operator is first installed. If the operator has

been installed recently, review the factory default settings (Table 5) and decide which

settings you’d like to change.

You may also reset the existing settings to their default parameters. To do this, follow

the steps below:

PROCEDURES DISPLAY PROMPT

13

1 Pressing the MENU buttons (!"), locate

FACTORY DEFAULTS and press ENTER.

2 Press (+) to restore th e factory default se ttings. RESTORE DEFAU LTS

PROGRA MMIN G OPTION DEFAULT SETTING

OPENING = STOP, NO TIMER RESET

SINGLE BUTTON

SLMAX/SW2200

OPERATOR SPEED

OPEN DECELERATION LIMIT MEDIUM

CLOSE DECELERATION LIMIT MEDIUM

ENTRAPMENT LEVEL 25

LOOP DETECTORS

CLOSING = (None—button has no effect)

MID-STOP = MID-STOP OPEN

MAXIMUM SPEED: 220

MINIMUM SPEED: 60

LOOP INPUT A: OPEN LOOP

LOOP INPUT B: SAFETY LOOP

LOOP INPUT C: SHADOW LOOP

FACTORY DEFAULTS

–NO +YES

OPERATOR WARN ING OFF

TIMER TO CLOSE OFF

ELECTRIC LOCK OFF

Table 5: Default Settings

Doc 01-16169

Rev B

Page 14

COPYRIGHT 2001

ALL RIGHTS RESERVED

This document is protected by copyright and may not be copied or adapted without the prior written

consent of LiftMaster. This documentation contains information proprietary to LiftMaster and such

information may not be distributed without the prior written consent of LiftMaster. The software and

firmware included in the LiftMaster product as they relate to this documentation are also protected by

copyright and contain information proprietary to LiftMaster.

FOR TECHNICAL SUPPORT

Call our toll free numbers:

(800) 323-2276

(800) 998-9197

Installation and service information is

available six days a week.

TO ORDER REPAIR PARTS

Call our toll free numbers:

(800) 528-2806

(800) 998-9197

Prepare to provide the following

information when ordering repair parts:

! Part Number

! Part Name

! Model Number

Loading...

Loading...