Page 1

OVERVIEW

The fail safe plug-in loop detector allows the gate to stay open when

vehicles are obstructing the gate path. The loop can be set to function as

a Shadow Loop, an Interrupt Loop, or an Exit Loop.

For use with the following gate operator models: LA400PKGU,

LA412PKGU, LA500PKGU, CSL24V, CSL24U, CSW24V, CSW24U,

RSL12U, RSW12U, SL585101U, SL585103U, SL585105U, SL585151U,

SL585501U, SL585503U, SL585505U, SL595101U, SL595103U,

SL595105U, SL595151U, SL595203U, SL595205U, SL3000101U,

SL3000501U, CSW200101U, CSW200501U, HCTDCU.

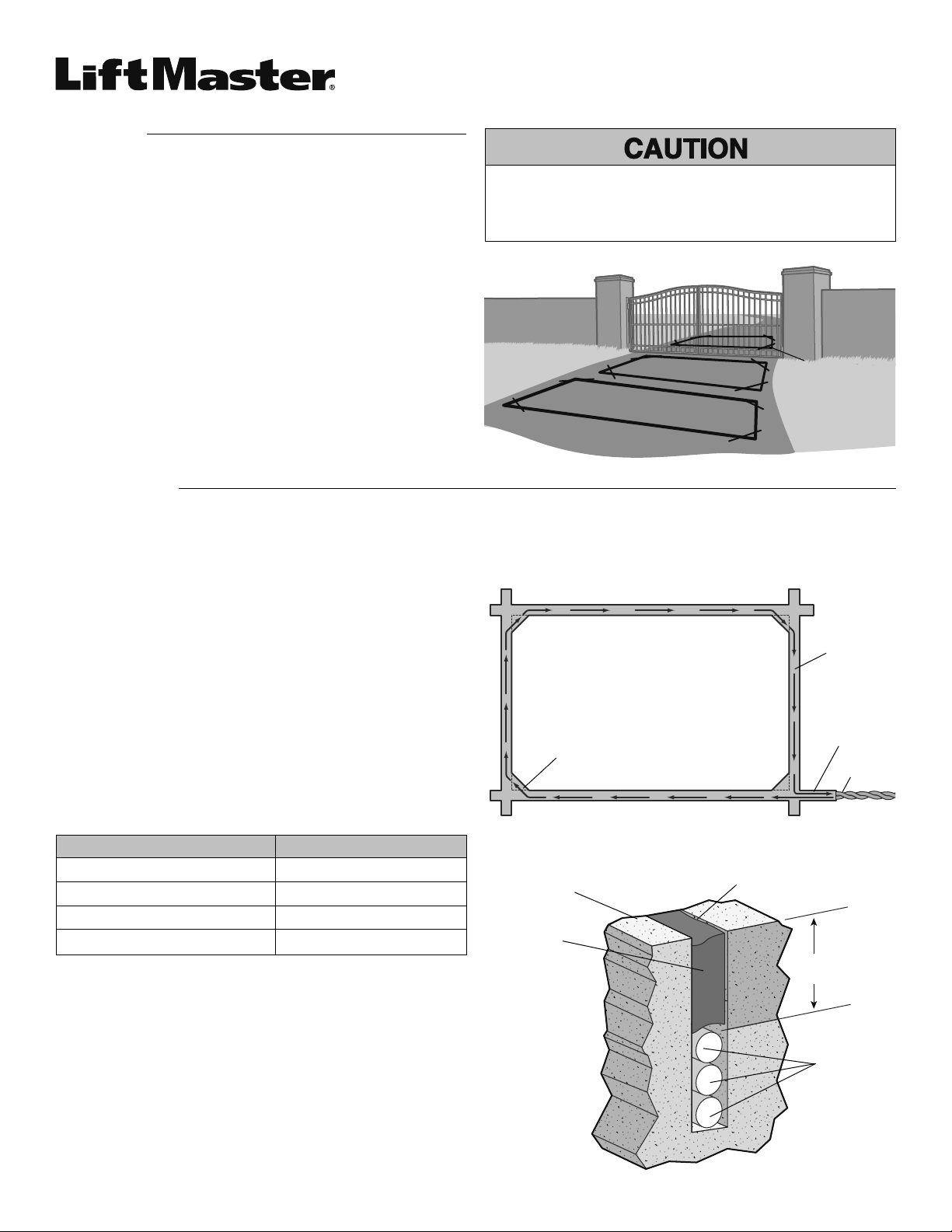

SHADOW LOOP: Positioned in the path of a swing gate and is active

ONLY when the gate is in the open position. Only used in swing gate

applications.

Plug-in Loop Detector

MODEL LOOPDETLM

To prevent DAMAGE to circuit board, loop detectors and/or the gate

operator, installation MUST be performed by a trained gate systems

technician.

Shadow Loop

Interrupt Loop

INTERRUPT LOOP: Positioned outside the property and when activated

will open a closing gate.

Exit Loop

(Inside Property)

EXIT LOOP: Positioned inside the property and when activated will open a

closed gate.

INSTALLATION

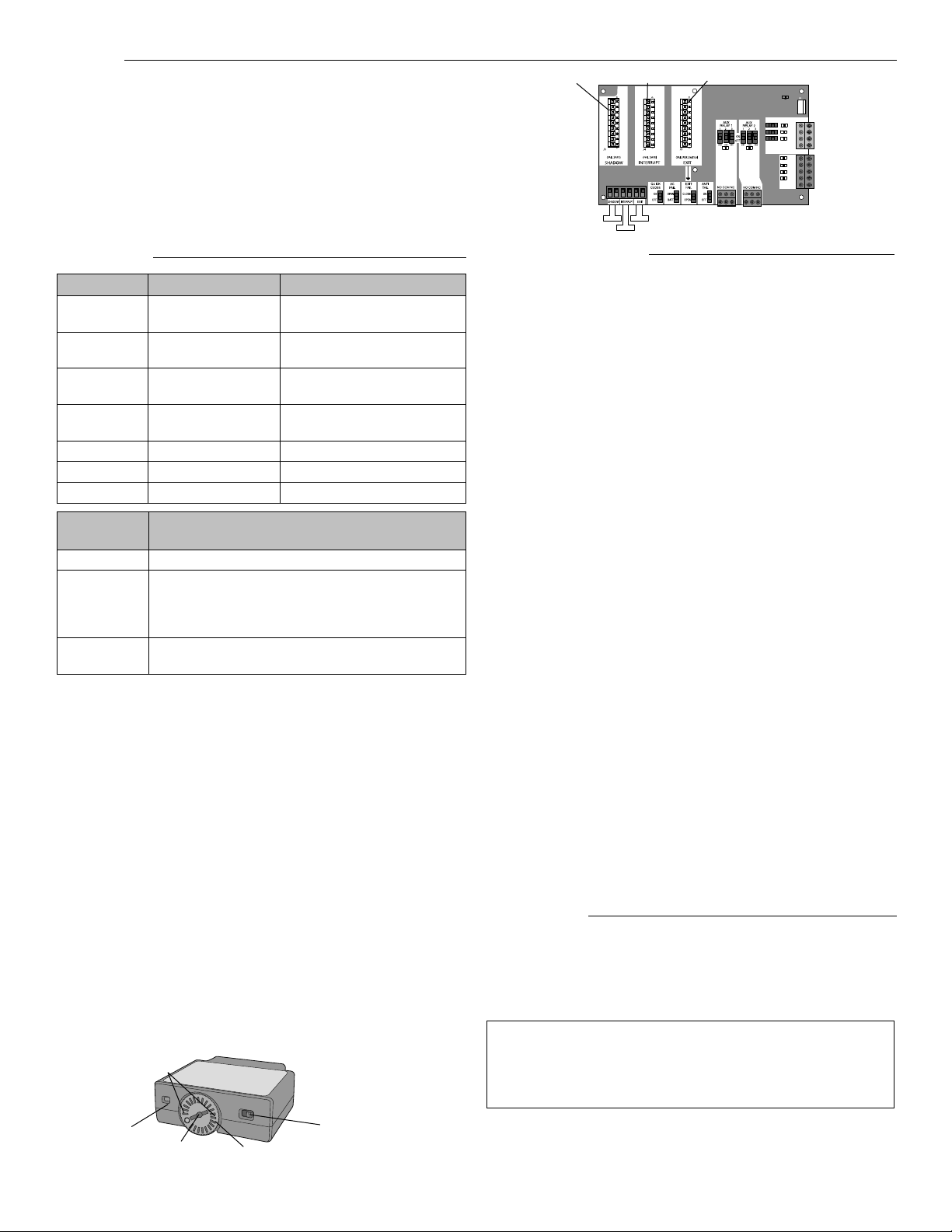

The loop itself must be a continuous length of wire without any breaks or splices. The loop wire can be 14, 16, or 18 gauge stranded wire with either a

cross-linked polyethylene (XLPE) or polyester insulation.

1. Mark the loop layout on the pavement. Remove sharp inside corners

that can damage the loop wire insulation.

2. Determine the thickness of the pavement to ensure that the depth of

the cut will not exceed the thickness of the pavement before

attempting to cut the loop slots. Set the saw to cut a depth (typically

2-2.5 inches [5.1-6.4 cm]) that will ensure a minimum of 1 inch

(2.5 cm) from the top of the loop wires to the pavement surface. The

saw width must be larger than the diameter of the loop wire to avoid

damage to the wire insulation when placed in the saw cut. Cut the

loop, corner angles, and feeder slots. Remove all debris from the

saw slot with compressed air. Check that the bottom of the cut is

smooth and did not break though the thickness of the pavement.

3. Wrap the loop wire in the loop slot using a wooden stick or roller to

insert the wire to the bottom of the saw slot until the desired

number of turns are reached (Caution: do not use a sharp object).

Each turn of wire must lay flat on top of the previous turn.

LOOP PERIMETER NUMBER OF TURNS

10-13 feet (3-4 m) 4

14-26 feet (4.3-7.9 m) 3

27-80 feet (8.2-24.4 m) 2

81 feet (24.7 m) and up 1

4. The wire must be twisted a minimum of 6 turns per foot from the

end of the feeder slot to the expansion board to minimize noise or

interference. If a splice is required in the feeder cable, solder each

splice and protect with a moisture proof seal.

5. Apply the sealant. The sealant selected should have good adhering

properties with similar contraction and expansion characteristics as

the pavement material.

Loops MUST BE 4 feet (1.2 m) away from each other.

Remove sharp inside corners.

1/8" to 1/4" (3.2 to 6.4 mm)

Saw Slot

NOTE: Ensure the saw cut is

wide enough to allow the

Road Surface

Sealant

sealant to flow around the loop

wires.

Minimum of 1 inch

(2.5 cm)

Loop Wire

(3 wires shown)

1/8" to 1/4"

(3.2 to 6.4

mm) Saw

Slot

Feeder Slot

End of Saw Cut

1

Page 2

WIRING

1. Plug the loop detector into the desired slot (Shadow, Interrupt, or Exit)

on the expansion board of the operator. NOTE: If only LOOPDETLM

loop detectors are used, manual frequency adjustments are not

required and crosstalk is eliminated. If a LOOPDETLM is used in

combination with other alternate loop detectors, then manual

frequency adjustments may be required.

2. Insert the twisted wires from the loop into the corresponding terminal

(Shadow, Interrupt, or Exit) on the expansion board of the operator.

Polarity does not matter.

OPERATION

BLUE LED WHITE LED EXPLANATION

1 Blink (every

10 seconds)

2 Blinks Rapid Blinks (active

3 Blinks Rapid Blinks (active

4 Blinks Rapid Blinks (active

OFF 2 Blinks Successful Reset

OFF Slow Blinks Loop detector is in TEST mode

Solid Solid Active Loop

DIAL

SETTINGS

TEST Mode Used to test the loop detector

1-8 Determines the sensitivity setting for the loop detector:

PROG Mode Used to change the frequency and track out options of

FREQUENCY

To change the frequency of the loop detector:

1. Turn the dial to PROG.

2. The blue LED will show the current frequency setting.

3. Press and release the frequency button to cycle through the 4

frequency settings.

To reset frequency to factory default, hold the frequency button for 5

seconds.

CALL TRACK OUT

To change the amount of time the loop will stay active:

1. Turn dial to PROG.

2. The white LEDs will show the current track out setting:

• Top and Bottom LEDs ON- infinite (DEFAULT)

• Top LED ON- fast (5 minutes)

• Bottom LED ON- slow (15 minutes)

3. Toggle the boost switch to cycle through the track out settings.

BOOST SWITCH

The boost switch will increase the sensitivity of the loop detector to

detect high profile vehicles (such as semi trucks).

White LEDs

(located under dial)

OFF Normal Operation

Open Loop (see

fault) or OFF

TROUBLESHOOTING)

Shorted Loop (see

fault) or OFF

TROUBLESHOOTING)

Failed Authentication (see

fault)

TROUBLESHOOTING)

EXPLANATION

1 is the lowest sensitivity (large vehicle) setting and 8

is the highest sensitivity (small vehicle). Default

setting is 4.

the loop detector

Exit Loop

Exit Slot

POWER

BOARD

TO MAIN

EYE

1

ONLY

EYE/

2

EDGE

EYE/

3

EDGE

COM

OPEN

CLOSE

SBC

OPN

CLS

STP

COM

Shadow Slot

Shadow Loop EXPANSION BOARD

Interrupt Slot

Interrupt Loop

TROUBLESHOOTING

Open or Shorted Loop (2 and 3 Blink errors):

Test the loop detector (refer to TEST THE LOOP DETECTOR section). If

the loop detector passes the test, this indicates the loop detector is

working properly and there is an issue with the loop wiring.

Failed Authentication (4 Blink error):

• Check the wire connecting the expansion board to the main board or

• Unplug the loop detector then plug it back into the same slot (clears

all faults and keeps the current frequency settings, authenticates) or

• Unplug the loop detector. Then unplug the J15 plug on the operator’s

control board and plug it back in after 2-3 seconds. This allows the

loop detector to be plugged into a different slot (clears all faults and

keeps the current frequency settings, authenticates).

To clear a fault:

• Press the reset button on the operator (clears all faults) or

• Unplug the loop detector then plug it back into the same slot.

The loop is making false detections:

• There is crosstalk between the LOOPDETLM and the alternate loop

detector or

• Change the frequency or lower the sensitivity setting of the loop

detector.

The loop will not activate when a vehicle passes over it:

• Turn the boost switch ON or increase the sensitivity of the loop

detector or

• If the blue and white LEDs are solid, indicating an Active Loop, and the

operator does not activate, there could be a fault. Once the loop is

inactive, check the LED codes for a fault (refer to LED table).

TEST THE LOOP DETECTOR

1. Turn the dial to TEST. The loop detector will send a signal to the main

board simulating a vehicle over the loop.

Exit: If the gate is closed, it will open or if the gate is already open it

will remain open.

Shadow: Active ONLY when the gate is in the open position. If the gate

is open, it will remain open.

Interrupt: If the gate is closing, it will open.

2. Turn the dial back to the desired sensitivity setting.

WARRANTY

ONE YEAR LIMITED WARRANTY

LiftMaster warrants to the first consumer purchaser of this product that

is free from defect in materials and/or workmanship for a period of 1 year

from the date of purchase.

THIS DEVICE COMPLIES WITH PART 15 OF THE FCC RULES. OPERATION IS SUBJECT TO

THE FOLLOWING TWO CONDITIONS: (1) THIS DEVICE MAY NOT CAUSE HARMFUL

INTERFERENCE, AND (2) THIS DEVICE MUST ACCEPT ANY INTERFERENCE RECEIVED,

INCLUDING INTERFERENCE THAT MAY CAUSE UNDESIRED OPERATION.

This Class B digital apparatus complies with Canadian ICES-003.

Cet appareil numérique de la classe B est conforme à la norme NMB-003 du Canada.

Frequency Button

Blue LED

(located under dial)

Boost Switch

Dial

LiftMaster.com

2

Page 3

Capteur de bouche enfichable

MODÈLE LOOPDETLM

VUE D’ENSEMBLE

Le détecteur à boucle enfichable à dispositif de sécurité intégré permet à

la barrière de rester ouverte lorsque des véhicules obstruent la trajectoire

de la barrière. La boucle peut être réglée pour fonctionner comme boucle

de passage, boucle d’interruption ou boucle de sortie.

Pour usage avec les modèles d’actionneur de barrière suivants :

LA400PKGU, LA412PKGU, LA500PKGU, CSL24V, CSL24U, CSW24V,

CSW24U, RSL12U, RSW12U, SL585101U, SL585103U, SL585105U,

SL585151U, SL585501U, SL585503U, SL585505U, SL595101U,

SL595103U, SL595105U, SL595151U, SL595203U, SL595205U,

SL3000101U, SL3000501U, CSW200101U, CSW200501U, HCTDCU.

BOUCLE DE PASSAGE : Positionnée dans la trajectoire d’une barrière

pivotante et est active UNIQUEMENT lorsque la barrière est en position

d’ouverture. Utilisée uniquement dans les applications de barrière

pivotante.

BOUCLE D’INTERRUPTION : Positionnée à l’extérieur de la propriété et a

pour effet d’ouvrir une barrière en course de fermeture lorsqu’elle est

activée.

BOUCLE DE SORTIE : Positionnée à l’intérieur de la propriété et a pour

effet d’ouvrir une barrière fermée lorsqu’elle est activée.

INSTALLATION

La boucle elle-même doit être une longueur de fil continue sans épissure. Le fil à boucle peut être torsadé et de calibre 14, 16 ou 18 à gaine d’isolation

en polyéthylène réticulé (XLPE) ou en polyester.

1. Marquer la disposition de la boucle sur la surface pavée. Enlever les

coins intérieurs coupants qui peuvent endommager l’isolant du fil à

boucle.

2. Déterminer l’épaisseur du pavé pour s’assurer que la profondeur de la

coupe ne dépassera pas l’épaisseur de la surface pavée avant de

tenter de couper les fentes pour la boucle. Régler la scie à une

profondeur de coupe (en général 5,1 à 6,4 cm [2 à 2,5 po]) assurant

un dégagement d’environ 2,5 cm (1 po) entre la partie supérieure des

fils de la boucle et la surface de la chaussée. La largeur de la scie doit

être plus large que le diamètre du fil à boucle pour éviter

d’endommager l’isolant du fil lorsque ce dernier est placé dans la

fente coupée. Couper la boucle, les angles de coin et les fentes

d’alimentation. Enlever tous les débris des fentes coupées avec de

l’air comprimé. Vérifier que le fond de la coupe est lisse et n’a pas

brisé l’épaisseur de la chaussée.

3. Enrouler le fil à boucle dans la fente de boucle. Se servir d’un bâton

ou d’un rouleau pour insérer le fil au fond de la fente au nombre de

tours désiré. (Attention : Ne pas se servir d’un objet pointu). Chaque

tour de fil doit reposer à plat par-dessus le tour précédent.

PÉRIMÈTRE DE LA BOUCLE NOMBRE DE TOURS

3-4 m (10-13 pi) 4

4,3-7,9 m (14-26 pi) 3

8,2-24,4 m (27-80 pi) 2

24,7 m (81 pi) et plus 1

Pour prévenir les DOMMAGES au circuit imprimé, l’installation des

détecteurs à boucle et/ou de l’actionneur de barrière DOIT être

effectuée par un technicien formé en systèmes de barrière.

Boucle de passage

Boucle de sortie

Boucle

d’interruption

(Intérieur de la

propriété)

Les boucles DOIVENT ÊTRE à une distance de 1,2 m (4 pi)

l’une de l’autre.

Fente de scie de

3,2 à 6,4 mm

(1/8 à 1/4 de po)

Fente d’alimentation

Éliminer les coins intérieurs coupants.

Surface de la chaussée

Enduit d’étanchéité

Fente de scie de 3,2 à 6,4 mm (1/8

à 1/4 de po)

REMARQUE : S’assurer que la

coupe de scie est suffisamment

large pour permettre à l’enduit

d’étanchéité de circuler autour des

fils de la boucle.

Fin de la coupe

de scie

Minimum de

2,5 cm (1 po).

4. Le fil doit être torsadé sur au moins six tours par 30 cm, de

l’extrémité de la fente d’alimentation au tableau d’extension afin de

minimiser le bruit ou l’interférence. S’il est nécessaire de faire une

épissure dans le câble d’alimentation, souder chaque épissure et

protéger chacune avec un enduit d’étanchéité approprié.

5. Appliquer l’enduit d’étanchéité. L’enduit d’étanchéité doit avoir de

bonnes propriétés adhérentes de même que des caractéristiques de

contraction et d’expansion similaires à celle du matériau de la

chaussée.

Fil à boucle

(3 fils montrés)

3

Page 4

OVERVIEW

The fail safe plug-in loop detector allows the gate to stay open when vehicles are

obstructing the gate path. The loop can be set to function as a Shadow Loop, an

Interrupt Loop, or an Exit Loop.

Plug-in Loop Detector

MODEL LOOPDETLM

To prevent DAMAGE to circuit board, loop detectors and/or the gate operator,

installation MUST be performed by a trained gate systems technician.

For use with the following gate operator models: LA400PKGU, LA412PKGU,

LA500PKGU, CSL24V, CSL24U, CSW24V, CSW24U, RSL12U, RSW12U,

SL585101U, SL585103U, SL585105U, SL585151U, SL585501U, SL585503U,

SL585505U, SL595101U, SL595103U, SL595105U, SL595151U, SL595203U,

SL595205U, SL3000101U, SL3000501U, CSW200101U, CSW200501U, HCTDCU.

WARNING: This product can expose you to chemicals including

lead, which are known to the State of California to cause cancer or

birth defects or other reproductive harm. For more information go to

www.P65Warnings.ca.gov

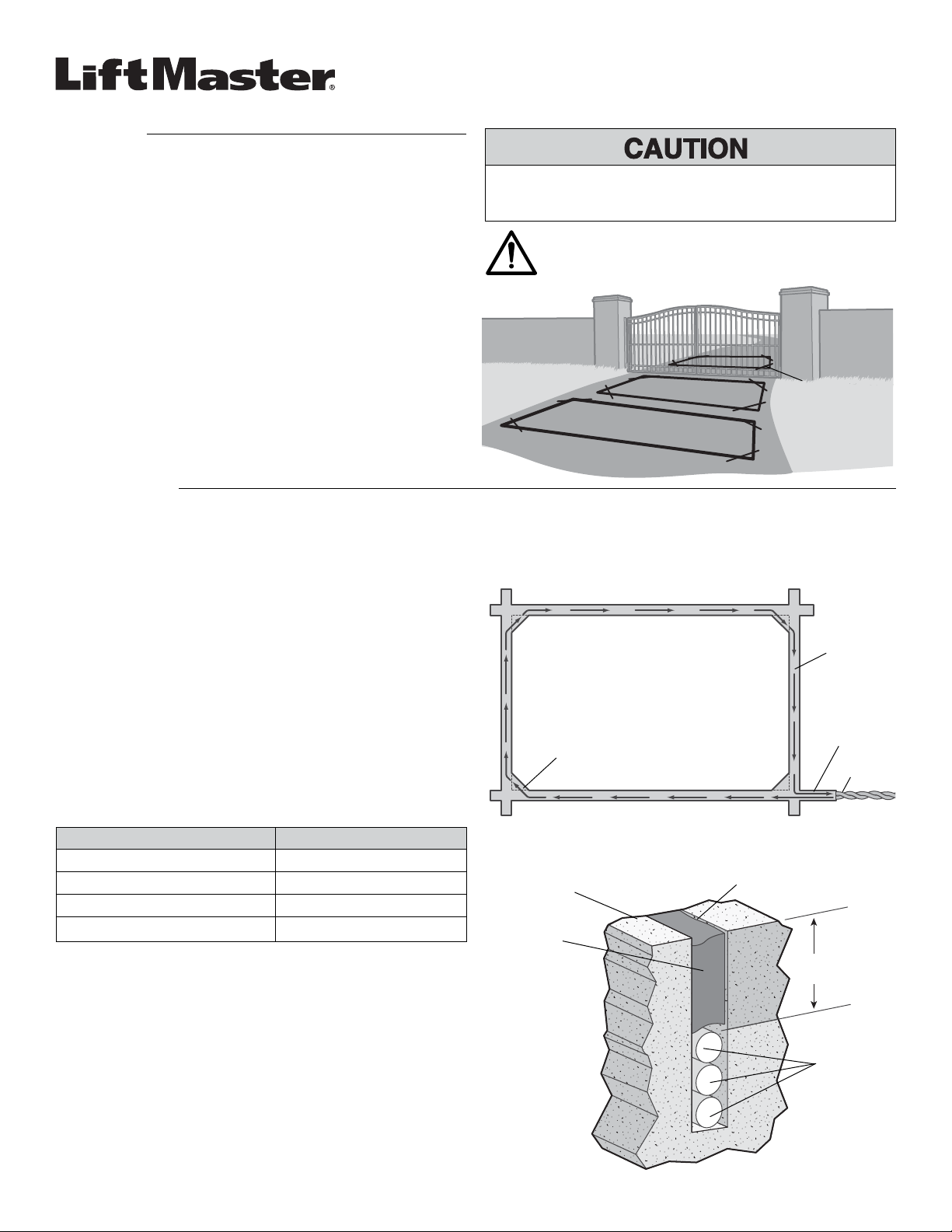

SHADOW LOOP: Positioned in the path of a swing gate and is active ONLY when

the gate is in the open position. Only used in swing gate applications.

INTERRUPT LOOP: Positioned outside the property and when activated will open a

closing gate.

EXIT LOOP: Positioned inside the property and when activated will open a closed

gate.

Shadow Loop

Exit Loop

Interrupt Loop

(Inside Property)

INSTALLATION

The loop itself must be a continuous length of wire without any breaks or splices. The loop wire can be 14, 16, or 18 gauge stranded wire with either a cross-linked

polyethylene (XLPE) or polyester insulation.

1. Mark the loop layout on the pavement. Remove sharp inside corners that can

damage the loop wire insulation.

2. Determine the thickness of the pavement to ensure that the depth of the cut

will not exceed the thickness of the pavement before attempting to cut the

loop slots. Set the saw to cut a depth (typically 2-2.5 inches [5.1-6.4 cm])

that will ensure a minimum of 1 inch

(2.5 cm) from the top of the loop wires to the pavement surface. The saw

width must be larger than the diameter of the loop wire to avoid damage to

the wire insulation when placed in the saw cut. Cut the loop, corner angles,

and feeder slots. Remove all debris from the saw slot with compressed air.

Check that the bottom of the cut is smooth and did not break though the

thickness of the pavement.

3. Wrap the loop wire in the loop slot using a wooden stick or roller to insert

the wire to the bottom of the saw slot until the desired number of turns are

reached (Caution: do not use a sharp object). Each turn of wire must lay flat

on top of the previous turn.

Loops MUST BE 4 feet (1.2 m) away from each other.

Remove sharp inside corners.

1/8" to 1/4"

(3.2 to 6.4

mm) Saw

Slot

Feeder Slot

End of Saw Cut

LOOP PERIMETER NUMBER OF TURNS

10-13 feet (3-4 m) 4

14-26 feet (4.3-7.9 m) 3

27-80 feet (8.2-24.4 m) 2

81 feet (24.7 m) and up 1

4. The wire must be twisted a minimum of 6 turns per foot from the end of the

feeder slot to the expansion board to minimize noise or interference. If a

splice is required in the feeder cable, solder each splice and protect with a

moisture proof seal.

5. Apply the sealant. The sealant selected should have good adhering properties

with similar contraction and expansion characteristics as the pavement

material.

1/8" to 1/4" (3.2 to 6.4 mm)

Saw Slot

NOTE: Ensure the saw cut is

wide enough to allow the

Road Surface

Sealant

sealant to flow around the loop

wires.

Minimum of 1 inch

(2.5 cm)

Loop Wire

(3 wires shown)

1

Loading...

Loading...