Lift-master LM90 MODEL C User Manual

RELEASE DEVICES

MADE IN THE U.S.A.

RELEASE DEVICE MODEL C INSTALLATION MANUAL

UL LISTED CANADIAN LISTED CSFM: 7300-1418:100

GENERAL DESCRIPTION: S/N________________________

The LM90-C Release Device/Control Panel is a U.L. Listed, Canadian Listed (C-UL) and California State Fire Marshal Listed (CSFM)

normally energized Fail-Safe device with state of the art electronic control circuitry. This device is designed for use with motorized doors

incorporating a reversing feature safety edge to create an automated door closing system. “DO NOT” install this unit without a safety edge.

The LM90-C high performance control panel responds to emergency conditions generated by manual or automatic initiating devices. Upon

activation from such a device, the unit can provide a voice warning (option) indicating that a closure is about to occur and will then close the

door through the motor. If the alarm is still present and power is available to the operator, the door can be opened by depressing the open

switch of the operator, after which the door will close again. If the door meets an obstruction while in alarm, the door will reverse and make

three attempts to close, after which the motor will be shut off and the release mechanism will release the door onto the obstruction. The unit

can be factory ordered with cycle count from 1 through 10 (3 count standard), as well as continuous cycling capability. A safety timer

within the unit will turn the motor off and perform a mechanical release if the lower limit is not detected within a predetermined time

period. Verify factory installed options to desired features.

The Release Device features include time delay on alarm, remote test, motor voltage sensing, form-C output, lower limit detection, safety

timer, battery support for release device logic, smoke detectors, multilingual voice (option), standard annunciators and trouble diagnostic

capabilities (does not support motor). Check model label on unit to be installed to verify operating voltage.

CAUTION: Review all installation instructions, procedures, referenced publications, cautions and warnings contained within this manual

prior to installing and/or servicing this product. As with all releasing device systems, maximum fire protection is provided when installed in

accordance with factory specifications and used with fuse link systems. “DO NOT” install this unit without a fuse link system.

TEST WEEKLY TO ASSURE PROPER OPERATION OF RELEASE DEVICE/CONTROL PANEL

Installation and testing to factory specifications shall be performed by factory authorized personnel for proper operation in

accordance with all of the latest National Fire Protection Association (NFPA), Underwriters Laboratories (UL), National

Electrical Code (NEC), local, state, county, district and/or other applicable building and fire standards, guidelines, regulations

and codes including, but not limited to, all appendices and amendments and the requirements of the local authority having

jurisdiction (AHJ).

INSTALLATION INSTRUCTIONS -To be performed by factory authorized personnel only.

The following installation procedures must be followed to assure performance of the LM90 MODEL C Release Device/Control

Panel to factory standards.

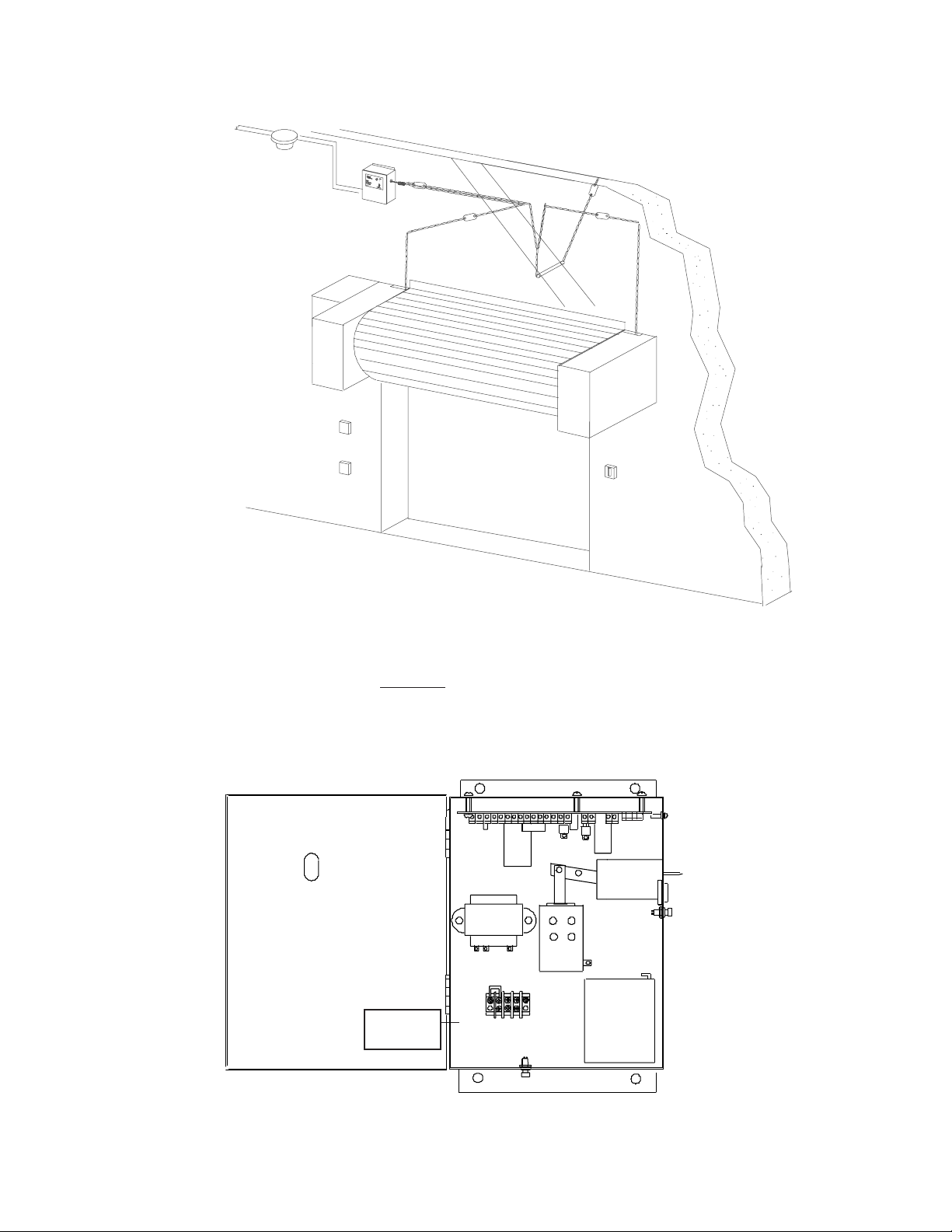

A. MOUNTING PROCEDURE (Figure 1)

Typical installation configuration may not accurately depict door manufacturer’s recommendations. See door manufacturer’s

recommendations for use of this product with specific door being utilized. All hardware required shall be supplied by the door

installer or manufacturer. Use only hardware approved or recognized by the appropriate testing and listing agencies in conjunc-

tion with the installation of this product.

1. Release device shall be mounted on a vertical surface with chain end link exiting side of enclosure as illustrated in figure 1.

2. Release device enclosure shall be mounted with minimum #10 size fastening screws or bolts for securing to structures

other than masonry. Masonry applications shall utilize 1/4" or greater anchors or studs as required to ensure proper

mounting strength.

3. Release device and associated hardware (sash chain or 1/16 cable, eyebolts, *fuse links, turnbuckles) shall be installed as

per figure 1 or door manufacturers recommendations. Take note that the end link direction of pull is perpendicular to the

enclosure side. An eyebolt installed at a minimum distance of 12 inches from the release device should adequately redirect

sash chain pull as illustrated in Figure 1. *DO NOT use this device without fuse links.

4. Complete hardware installation by connecting fuse links, sash chain, S-hooks and turnbuckles where required. Push reset

lever in direction of arrow on label to allow insertion of end link through release device side opening. Push end link

completely in and release reset lever to latch end link. Remove sash chain or cable slack by adjusting turnbuckle. * DO

NOT exceed maximum pull rating of 40 lbs. on releasing device.

B. SMOKE DETECTORS.

When installing smoke detectors with this unit refer to NFPA 72 and NFPA 80, for instructions concerning proper placement

and detection coverage. See Electrical Connections page 5 for wiring information. End of Line Devices shall be installed for

supervision of electrical power to smoke detector. “DO NOT” interface this unit to smoke detectors if electrical supervision is

not provided by means of an End-of-Line Device used in conjunction with the Model C!

C. ELECTRICAL CONNECTIONS

Installation of all wiring and connections, including Class 1 and Class 2 circuits, shall be performed in accordance with, but not

limited to, the latest NFPA, UL and NEC standards and codes. In addition, all installations subject to Canadian standards shall

be performed in accordance with the Canadian Electrical Code, Part I, with respect to wiring material type, wiring gauge related

to power capacity requirements and circuit length and wiring methods. This unit is designed to be used on motorized doors

incorporating a reversing feature safety edge. DO NOT use this unit on a motorized door if a safety edge has not been installed.

SEE Figure 2 - Verify wiring configuration with that recommended by door manufacturer for use of this product with specific

door and accessories being utilized. All wiring beginning at step 4 is low voltage. 18 gauge wire is recommended.

1. Turn off power supply sources for Model C as well as motor before beginning.

2. Verify voltage rating of release device/control panel to power source. Model voltage is indicated on side of unit.

3. Connect power source inputs to TB5, screws 1 & 2. On 24VDC units observe proper polarity by placing positive (+) wire

to screw 1. TB5 screw 3 shall be utilized for earth ground where applicable. (DO NOT connect battery)

4. (a) Normally closed initiating devices - remove jumper from TB1 screw 2 & 3. Connect wiring from N/C initiating device

loop to TB1 screws 2 & 3. Auxiliary power (+12VDC) for smoke detectors may be obtained from TB2. Observe proper

polarity, TB2-2 (+), TB2-1 (-). 4 detector maximum. (b) Normally open initiating devices - (The N/C & N/O loops may be

used simultaneously, but if the N/C loop is "NOT” used, make sure jumper is installed across TB1 screws 2 & 3). Connect

wiring from N/O initiating device loop to TB1 screws 4 & 5 (do not share loop with other alarm circuits), making sure end

of line supervisory resistor (51 Kohm @ 1/4 Watt) is installed at end of line as indicated. Auxiliary power (+12VDC) for

smoke detectors may be obtained from TB2. Observe proper polarity, TB2-2 (+),TB2-1 (-). 4 detector maximum.

Note: TB1 initiating device loops are supervised and cannot be directly series or paralleled between multiple release devices or

shared with other alarm equipment. For proper wiring configurations for multiple smoke detectors or signalling for simultaneous

closure on multiple doors call tech support. Incorrect wiring between units may cause damage to the release control circuit and

void warranty.

5. Connect motor control sensing voltage (24-30V AC or DC) from motor controller transformer secondary to TB3 screws

1 (+) & 2 (-). This connection must be made or the unit will perform a mechanical release in all alarm conditions.

Continued on page 4

2

* TYPICAL INSTALLATION FIGURE 1

END LINK

LM90-C

RELEASE DEVICE/

CONTROL PANEL

MOTOR

REMOTE TEST PLATE

TURNBUCKLE

FUSE LINK

FUSE LINKS

ANNUNCIATOR

* Actual configuration may differ. See door manufacturers recommendations and NFPA 80 for use of this

device and fusible links with specific door. DO NOT install this unit without fusible links.

DO NOT exceed 40lb. maximum pull rating on release mechanism.

LM90 - C INSIDE VIEW FIGURE 1A

TB2

TB3

TB4

BATTERY

DIAGNOSTIC LEDs

END LINK

TROUBLE SOUNDER

AUX. POWER RESET

* TRANSFORMER FOUND IN 120VAC

MODELS ONLY

CLASS 2 WIRING

UPPER ENTRY

CLASS 1 WIRING

LOWER ENTRY

TB1

*TRANSFORMER

TB5

CLASS 1

CLASS 1

WIRING

WIRING

TEST SWITCH

3

* 6. (a) Aux. Lower limit switch. Connect wiring from N/C electrical loop (switch closed when door is up) to TB1 screws 1 &

18 "or" N/O electrical loop (switch open with door up) to TB1-1 & 16. This input precludes the door mechanism from

releasing if a lower limit is detected (door is already closed). This circuit also turns off sounders in down limit. (b) Aux.

Upper limit switch. Connect wiring from N/O electrical loop (switch closed when door is up) to TB1-8 & 9 “or” N/C

electrical loop (switch open with door up) to TB1-8 & 13. Connection to an auxiliary up limit switch is required for 3 cycle

obstruction count feature.

Set aux. limit to toggle before operator limit when door is traveling toward open position.

Improper adjustment will result in continuous cycling of door.

* Note: Electrical loops must be provided as dry contacts and may not be used in conjunction with the simultaneous

switching of a motor control or any other voltage through the same contacts. Connections of this type will result in

immediate damage to the release device.

Jumpers must remain installed on loops not being used.

7. Motor control relay (Delay relay) - Connect wiring from TB1-14 & 17 across motor control down switch (For use with N/O

down switch). This relay output latches to initiate a door closure through the operator after a 10 sec. delay.

8. Remote test station. - (option) This option disables the cycle counter to allow testing of the door without a mechanical

release after 3 cycles. Connect remote test switch common to TB2-2, N/C to TB4-1 and N/O to TB4-3. Factory jumper

should be removed between TB2-2 & TB4-1 when using test switch. Leave jumper in if test plate is not used.

9. Annunciator - (option) connect annunciator to TB1-6 (-) & 7 (+). If Voice Module has been factory installed see LM21-VAS

Installation manual.

Note: Battery should “not” be connected until testing of unit is being performed.

TESTING OF RELEASE DEVICE/CONTROL PANEL SHALL BE PERFORMED AND WITNESSED FOR NORMAL OPERATION AFTER INSTALLATION. REFER TO TEST PROCEDURES CONTAINED HEREIN, AS WELL AS ANY OTHER TESTING

PROGRAMS RECOMMENDED BY DOOR MANUFACTURER.

LM90 MODEL C RELEASE DEVICE/CONTROL PANEL

POWER REQUIREMENTS & MECHANICAL SPECIFICATIONS

VOLTAGE RATING

LM90-C-24DC ........ 24VDC +10% / -15%

LM90-C-24AC ........ 24VAC +10% / -15%

LM90-C-120AC ....... 120VAC +10% / -15%

(1) Current max. with standard accessories including one Voice Module. Current of additional accessories shall not exceed fuse ratings.

NOTE: Initial power up inrush current shall not exceed 3 times rated supervisory current on any model.

MOTOR CONTROL SENSE - ALL MODELS

Input Voltage: 24V AC/DC typical +15% / -10%

Input Current: Not to exceed .004A

CURRENT REQUIREMENTS (1)

SUPERVISORY (non-alarm) .100A / ALARM .500A MAX

SUPERVISORY (non-alarm) .100A / ALARM .500A MAX

SUPERVISORY (non-alarm) .100A / ALARM .500A MAX

INITIATING/DOOR INPUTS

CAUTION: All initiating devices shall be dry contact type only

Maximum loop resistance: 100 Ohms

Maximum current: Not to exceed .002A

Maximum voltage: 15VDC

FORM C OUTPUT (MAX. CONTACT RATING)

2A/30VDC 60 Watt DC Resistive Load Only

FUSES

All fuses 1A @ 250V, 2AG Fast Acting Type

Combined Auxiliary Power: 12VDC @ .450A

MECHANICAL SPECIFICATIONS

LOAD RATING (all models) PHYSICAL DIMENSIONS (all models) WEIGHT (includes battery)

Support and Release : 40 LB. MAX. 11 5/8" x 10 x 15 w/flange (H x W x D)

10 x 10 x 4 3/4 w/out LM90-C-24VAC approx. 12 lbs.

4

LM90-C-120VAC approx. 13 lbs.

LM90-C-24VDC approx. 12 lbs.

Loading...

Loading...