Lift-master LM21XP User Manual

OO WW NN EE RR ’’ SS MM AA NN UU AA LL

MM OO DD EE LL

LL MM 22 11 XX PP

EEXXTTEENNDDEEDD PPEERRFFOORRMMAANNCCEE RREELLEEAASSEE DDEEVVIICCEE

The Chamberlain Group, Inc.

845 Larch Avenue

Elmhurst, Illinois 60126-1196

www.liftmaster.com

When you see these Safety Symbols and Signal Words on the

following pages, they will alert you to the possibility of serious

injury or death if you do not comply with the warnings that

accompany them. The hazard may come from something

mechanical or from electric shock. Read the warnings carefully.

When you see this Signal Word on the following pages, it will

alert you to the possibility of damage to your door and/or the

door operator if you do not comply with the cautionary

statements that accompany it. Read them carefully.

Mechanical

Electrical

TABLE OF CONTENTS

WARNING

WARNING

WARNING

WARNING

CAUTION

WARNING

WARNING

2

INTRODUCTION

General Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Agency Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

INSTALLATION

Important Installation Warnings . . . . . . . . . . . . . . . . . . . . . . . . . .4

Mount the Release Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

WIRING

Wiring Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Connections of Initiating Devices and Accessories . . . . . . . . . .7-8

Optional Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-9

TESTING

Test Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

TROUBLESHOOTING

Operational Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

MAINTENANCE

Maintenance Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Enclosure Mounted LEDs Status Indicators . . . . . . . . . . . . . . . .12

ACCESSORIES AND REPLACEMENT PARTS

. . . . . . . .13

APPENDIX

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

OPERATOR NOTES

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

IMPORTANT NOTES:

• BEFORE attempting to install, operate or maintain the release

device, you must read and fully understand this manual and

follow all safety instructions.

• DO NOT attempt repair or service of your release device unless

you are an Authorized Service Technician.

GENERAL DESCRIPTION

The LiftMaster®LM21XP Release Device is UL/ULC listed

normally energized fail-safe device designed for use on rolling

doors, single-slide and center-parting level and inclined track

doors. All models are normally energized fail-safe releasing

devices incorporating state-of-the-art electronic control circuitry.

The release devices respond to emergency conditions generated

from an automatic initiating device and are used in conjunction

with a temperature fuse link system.

This device is designated to be used with manual doors, but can

be used on motorized doors incorporating a fusible link assembly

and drop-out mechanism.

The release device must be powered from 24Vdc received from

an approved UL 1481 regulated power supply with battery

backup. The devices can be activated via a smoke detector or an

alarm relay from the panel’s Form C dry contact relay. The release

device features include a 10-, 20-, 30- or 60-second delay on

alarm, closed door detection capabilities, Form C relay outputs for

the transmission of alarm and trouble signals transmitted to the

fire alarm control panel, an audible trouble sounder, and

diagnostic feedback LEDs.

INTRODUCTION

INTRODUCTION

3

AGENCY REQUIREMENTS

Installation and testing to factory specifications shall be

performed by factory authorized personnel for proper operation in

accordance with the latest National Fire Protection Association

(NFPA), Underwriters Laboratories (UL), National Electrical Code

(NEC), local, state, county, district and/or other applicable

building and fire standards, guidelines, regulations and codes

including, but not limited to, all appendices and amendments and

the requirements of the local authority having jurisdiction (AHJ).

SPECIFICATIONS

To prevent possible SERIOUS INJURY or DEATH:

• DO NOT use this device without fuse links installed.

• Test every 90 days to assure proper operation of release

device.

WARNING

WARNING

LOAD RATING: Support and Release 40 lbs. Max.

PHYSICAL DIMENSIONS: 9.7" x 7.5" x 5" (h x w x d)

PREPARATION

It is imperative that the wall or mounting surface provide

adequate support for the release device.

Refer to the door manufacturer’s recommendations for use of this

product with specific door being utilized. Use only hardware

approved or recognized by the appropriate testing and listing

agencies in conjunction with the installation of this product.

Additional items may be required to complete the installation:

• Concrete anchors or fasteners

• Sash chain or 1/16 cable

• Eyebolts-hook

• Fuse links

• Turnbuckles

• Smoke detectors (up to 4 may be installed with this device)

Refer to NFPA 72 and NFPA 80 for instructions concerning proper

placement and detection coverage. End-of-line devices shall be

installed for supervision of electrical power to 4-wire smoke

detector. When using 4-wire smoke detectors with this device,

electrical supervision must be provided by means of a UL/ULC

listed end-of-line relay.

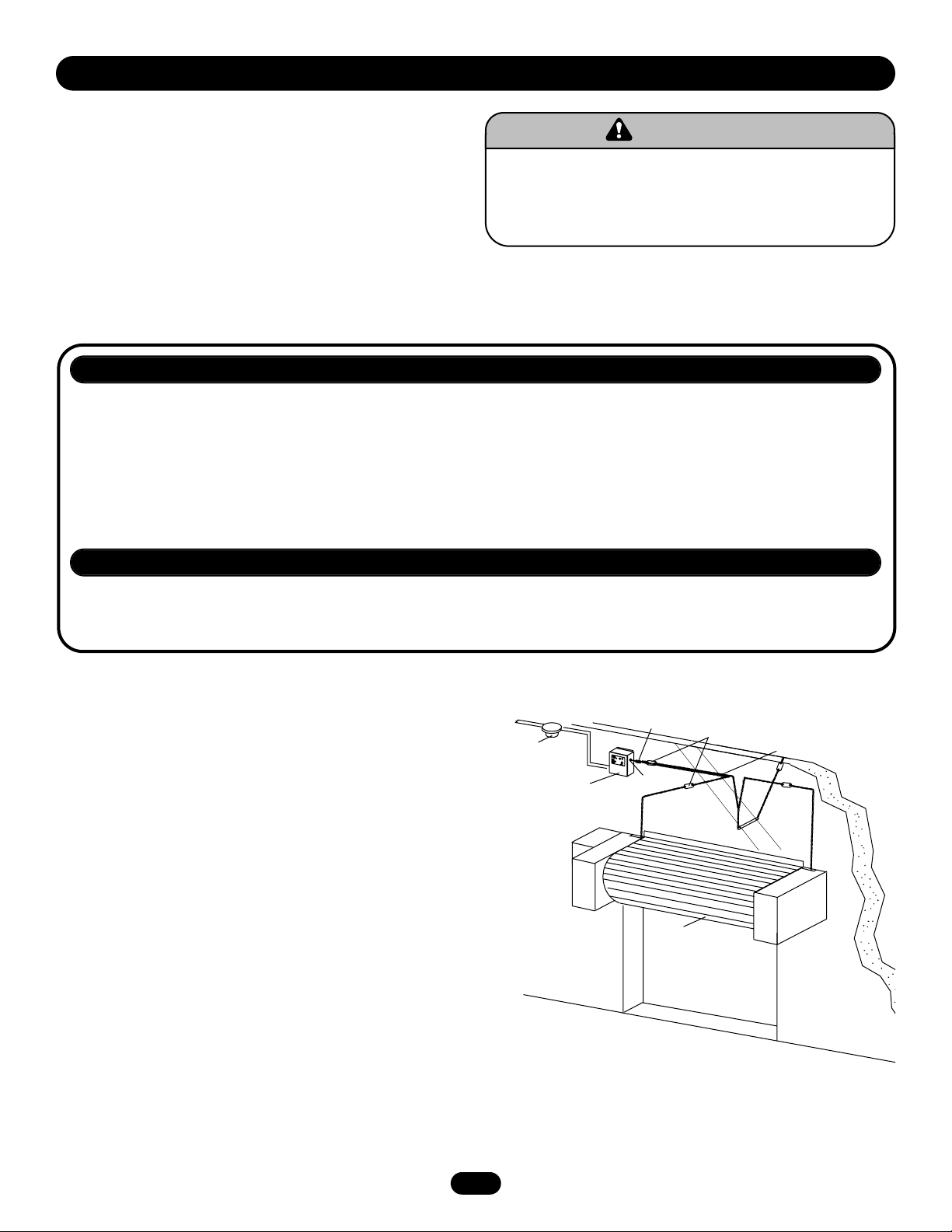

Smoke Detector

Releasing

Unit

Fuse Links

Eyebolt

Turnbuckle

Chain

Chain End

Link

Fire Door

ELECTRICAL SPECIFICATIONS

MECHANICAL SPECIFICATIONS

COMMON ALARM AND

TROUBLE RELAY:

.5A 125Vac, 60Hz

(MAX. CONTACT RATING) 1A 24Vdc Resistive

WEIGHT: Approximately 8 lbs.

VOLTAGE RATING: 24Vdc

STANDBY CURRENT: .100A

ALARM CURRENT: .15A

INITIATING DEVICE: Maximum line impedance 20 ohm;

Maximum current not to exceed

.010A.; Maximum voltage 28Vdc

4

INSTALLATION

Classification:

Releasing device as defined by Underwriters Laboratories.

Installation Requirements:

Intended for “Indoor Dry” locations; all wiring must be performed

in accordance with the most current version of NFPA 72 - National

Fire Alarm Code and the National Electric Code.

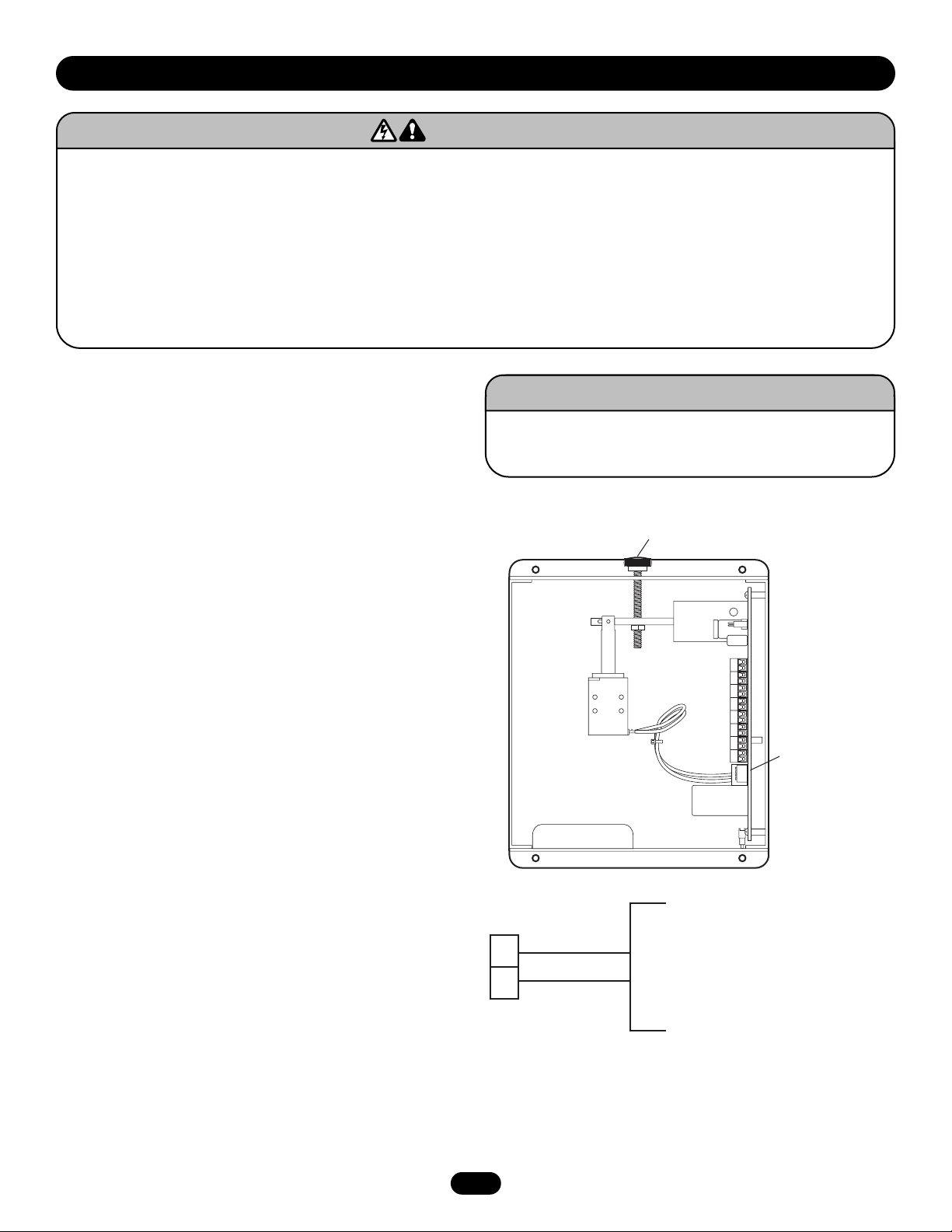

MOUNT THE RELEASE DEVICE

Installation procedures vary according to door types. Refer to

door manufacturer’s recommendation that applies to your door.

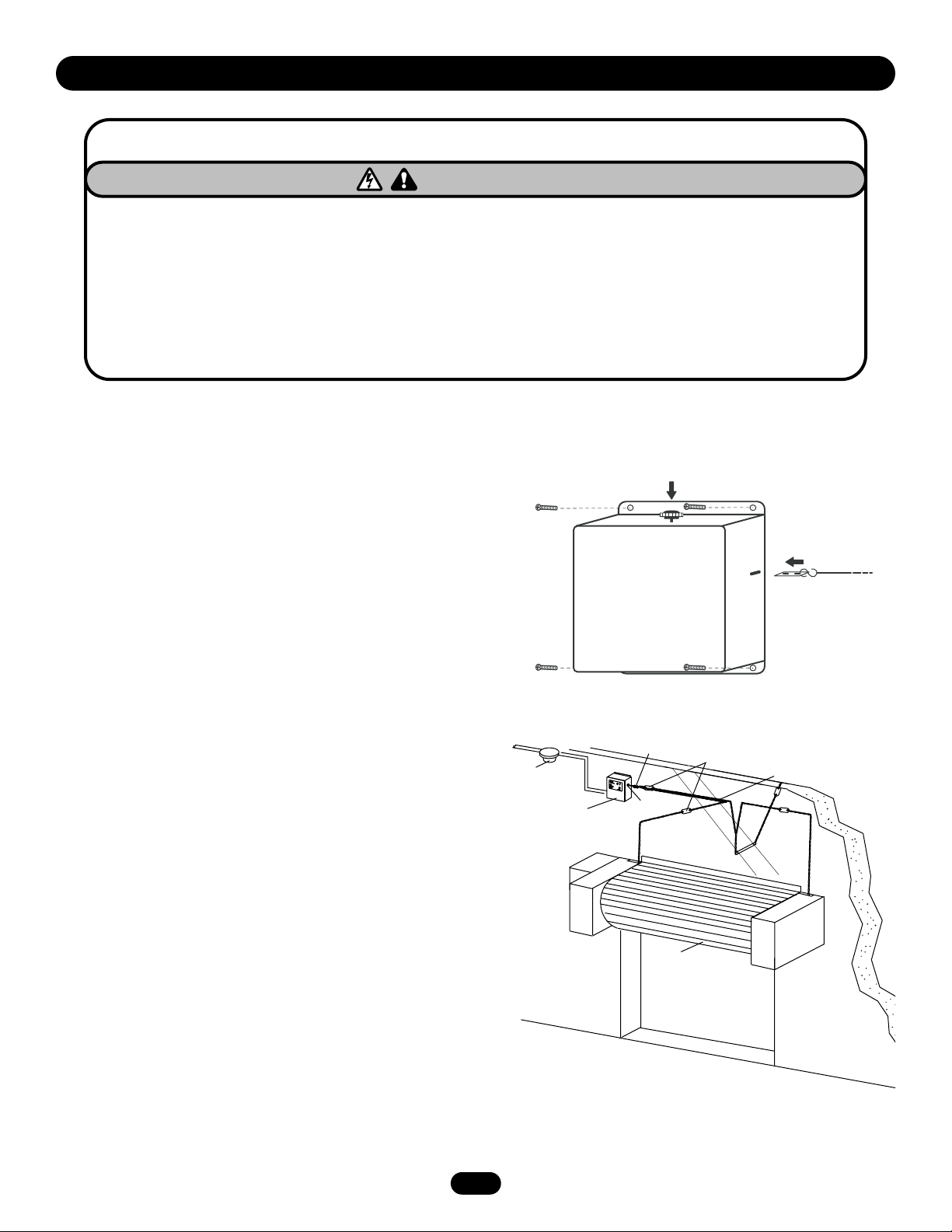

1. Mount the release device on a vertical surface with chain end

link exiting side of enclosure.

2. Secure the release device enclosure with fasteners (#10 is the

minimum size recommended). If installing in masonry, use

concrete anchors (not provided).

3. Install hardware (sash chain or 1/16 cable, eyebolts-hook, fuse

links, turnbuckles—not provided) according to door

manufacturer’s recommendations. NOTE: The end link direction

of pull must be perpendicular to the side of the release device

enclosure. Install an eyebolt a minimum distance of 12" from

the release device to adequately redirect sash chain pull.

4. Install end link by pressing mechanical reset to allow insertion

of end link. Push end link completely in and release mechanical

reset to latch end link.

5. Remove sash chain or cable slack by adjusting turnbuckle.

IMPORTANT INSTALLATION INSTRUCTIONS

To reduce the risk of SEVERE INJURY or DEATH:

WARNING

WARNING

WARNING

1. READ AND FOLLOW ALL INSTALLATION WARNINGS

AND INSTRUCTIONS.

2. NEVER connect release device to power source until

instructed to do so.

3. DO NOT install this device on a motorized door without

an electric safety edge.

4. DO NOT use this device without fuse links installed.

5. Concrete anchors MUST be used if mounting release

device into masonry.

6. DO NOT exceed maximum pull rating of 40 lbs. on

releasing device.

Mechanical

Reset Plunger

End Link

Smoke Detector

Releasing

Unit

Eyebolt

Chain End

Link

Fuse Links

Turnbuckle

Chain

Fire Door

5

WIRING

WIRING INSTRUCTIONS

Verify wiring configuration with that recommended by door

manufacturer for use of this product with specific door and

accessories being utilized. 18-gauge wire is recommended.

1. Turn off power supply sources for the release device as well as

the door operator, if applicable, before beginning.

2. Verify voltage rating of release device to power source being

utilized. Voltage is indicated on the side of the unit. Verify that

power is disconnected before proceeding.

3. Connect 24Vdc power to terminal board positions 1 and 2

(Figure 2). Observe proper polarity. 24Vdc power input from an

approved UL 1481 regulated power supply with battery backup.

To reduce the risk of SEVERE INJURY or DEATH:

• ALL electrical connections MUST be made by a qualified

individual.

• Disconnect power at the fuse box BEFORE proceeding. Release

device MUST be properly grounded and connected in

accordance with local electrical codes.

• ALL power wiring should be on a dedicated circuit and well

protected. The location of the power disconnect should be

visible and clearly labeled.

• ALL power and control wiring MUST be run in separate

conduit.

• Installation of ALL wiring and connections, including Class 1

and Class 2 circuits, shall be performed in accordance with,

but not limited to, the latest NFPA, UL and N.E.C. standards

and codes. In addition, ALL installations subject to Canadian

standards shall be performed in accordance with the Canadian

Electrical Code, Part I, with respect to wiring material type,

wiring gauge related to power capacity requirements and

circuit length and wiring methods.

WARNING

WARNING

FIGURE 2

FIGURE 1

To prevent DAMAGE to the circuit board, ALL connections from

terminals 3 through 16 MUST be dry contact type.

WARNING

CAUTION

WARNING

WARNING

Mechanical Reset

Plunger

Option

DIP Switch

+

1

2

–

24Vdc from an Approved UL 1481

Regulated Power Supply

with Battery Backup

Loading...

Loading...