Page 1

OO WW NN EE RR ’’ SS MM AA NN UU AA LL

MM OO DD EE LL SS

LL MM 22 11 AA FF CC BB

LL MM 22 11 AA FF CC BB VV BB

AADDVVAANNCCEE FFIIRREE CCOONNTTRROOLL RREELLEEAASSEE DDEEVVIICCEE

The Chamberlain Group, Inc.

845 Larch Avenue

Elmhurst, Illinois 60126-1196

www.liftmaster.com

FM

APPAPPROVOVED D

Page 2

When you see these Safety Symbols and Signal Words on the

following pages, they will alert you to the possibility of serious

injury or death if you do not comply with the warnings that

accompany them. The hazard may come from something

mechanical or from electric shock. Read the warnings carefully.

When you see this Signal Word on the following pages, it will

alert you to the possibility of damage to your door and/or the

door operator if you do not comply with the cautionary

statements that accompany it. Read them carefully.

Mechanical

Electrical

TABLE OF CONTENTS

WARNINGWARNING

WARNING

WARNINGWARNING

WARNING

CAUTIONCAUTION

WARNING

WARNING

2

INTRODUCTION

General Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Agency Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

INSTALLATION

Important Installation Warnings . . . . . . . . . . . . . . . . . . . . . . . . . .4

Mount the Release Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

WIRING

Power Wiring Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Connections from Device to the Operator . . . . . . . . . . . . . . . . . .6

Connections of Initiating Devices and Accessories . . . . . . . . . . .7

Optional Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

ADJUSTMENTS

DIP Switch Configuration Setting . . . . . . . . . . . . . . . . . . . . . . . . .9

Selectable Delay Settings (Switches 3 & 4) . . . . . . . . . . . . . . . . .9

TESTING

Test Release Device and Door Operator . . . . . . . . . . . . . . . .10-11

Test Release Device With Battery Backup Without AC Power . .12

TROUBLESHOOTING

Diagnostic LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

MAINTENANCE

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Enclosure Mounted LEDs Status Indicators . . . . . . . . . . . . . . . .14

ACCESSORIES AND REPAIR PARTS

. . . . . . . . . . . . . . .15

APPENDIX

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

IMPORTANT NOTES:

• BEFORE attempting to install, operate or maintain the release

device, you must read and fully understand this manual and

follow all safety instructions.

• DO NOT attempt repair or service of your release device unless

you are an Authorized Service Technician.

GENERAL DESCRIPTION

The LiftMaster®Fire Control LM21AFCB and LM21AFCBVB

Release Device is UL/ULC listed normally energized fail-safe

device incorporating state-of-the-art electronic control circuitry.

This release device is designed to be used with manual doors or

motorized doors incorporating a reversing electric safety edge to

create an automated door closing system.

The high performance control panel responds to emergency

conditions generated from an automatic initiating device. Upon

activation, the device will then automatically close a motorized

door or mechanically release a door in the absence of motorized

operation. If the alarm is still present and power is available to

the operator, a motorized door can be opened by depressing the

open switch of the operator, after which the door will close again.

If the door meets an obstruction while in alarm, the door will

reverse and make three attempts to close, after which the motor

will be shut off and the door will rest on the obstruction. The

release device may also be optionally set to fully open the door

and subsequently mechanically release the fire door onto the

obstruction.

The device provides 3 count obstruction cycling. A safety timer

within the device will turn the motor off and perform a

mechanical release if the lower limit is not detected within a

predetermined time period. Verify factory-installed options to

desired features during initial testing.

Features include a selectable 10, 20, 30 or 60-second time delay

on alarm, remote test, motor voltage sensing, Form C relay

output, lower limit detection, safety timer, battery support for

release device logic, smoke detectors, standard annunciators and

trouble diagnostic capabilities (does not support operator).

Operating voltage is 120Vac.

As with all releasing device systems, maximum fire protection is

provided when installed in accordance with factory specifications

and used with fuse link systems.

INTRODUCTION

Page 3

INTRODUCTION

3

AGENCY REQUIREMENTS

Installation and testing to factory specifications shall be

performed by factory authorized personnel for proper operation in

accordance with the latest National Fire Protection Association

(NFPA), Underwriters Laboratories (UL), National Electrical Code

(NEC), local, state, county, district and/or other applicable

building and fire standards, guidelines, regulations and codes

including, but not limited to, all appendices and amendments and

the requirements of the local authority having jurisdiction (AHJ).

SPECIFICATIONS

To prevent possible SERIOUS INJURY or DEATH:

• DO NOT install this device on a motorized door without an

electric safety edge.

• DO NOT use this device without fuse links installed.

• Test every 90 days to assure proper operation of release

device.

WARNINGWARNING

WARNING

VOLTAGE RATING: 120Vac, 60Hz

STANDBY CURRENT: .20A

ALARM CURRENT: .25A

BATTERY RATING: 12V 4.5AH Sealed Lead Acid

Batteries (2), Maximum charge

current .150Amps

BATTERY STANDBY TIME: LM21AFCB, 48 hours

LM21AFCBVB, 36 hours

INITIATING DEVICE: Maximum line impedance 20 ohm;

Maximum current not to exceed

.010A.; Maximum voltage 24Vdc

LOAD RATING: Support and Release 40 lbs. Max.

PHYSICAL DIMENSIONS: 10" x 10" x 5" (h x w x d)

PREPARATION

It is imperative that the wall or mounting surface provide

adequate support for the release device.

Refer to the door manufacturer’s recommendations for use of this

product with specific door being utilized. Use only hardware

approved or recognized by the appropriate testing and listing

agencies in conjunction with the installation of this product.

Additional items may be required to complete the installation:

• Concrete anchors or fasteners

• Sash chain or 1/16 cable

• Eyebolts-hook

• Fuse links

• Turnbuckles

• Smoke detectors (up to 4 may be installed with this device)

Refer to NFPA 72 and NFPA 80 for instructions concerning proper

placement and detection coverage. End-of-line devices shall be

installed for supervision of electrical power to 4-wire smoke

detector. When using 4-wire smoke detectors with this device,

electrical supervision must be provided by means of a UL/ULC

listed end-of-line relay.

ELECTRICAL SPECIFICATIONS

MECHANICAL SPECIFICATIONS

FUSES: 2A @ 250V, 2AG Slo-Blo Type

MOTOR CONTROL SENSE: Input Voltage 24Vac/dc

Typical +15% / –10%;

Input Current not to exceed .004A

AUXILIARY POWER: 24Vdc @ .75A Maximum

COMMON ALARM RELAY:

.5A 125Vac 60Hz

(MAX. CONTACT RATING) 1A 24Vdc Resistive

WEIGHT: Approximately 18 lbs.

(INCLUDING BATTERIES)

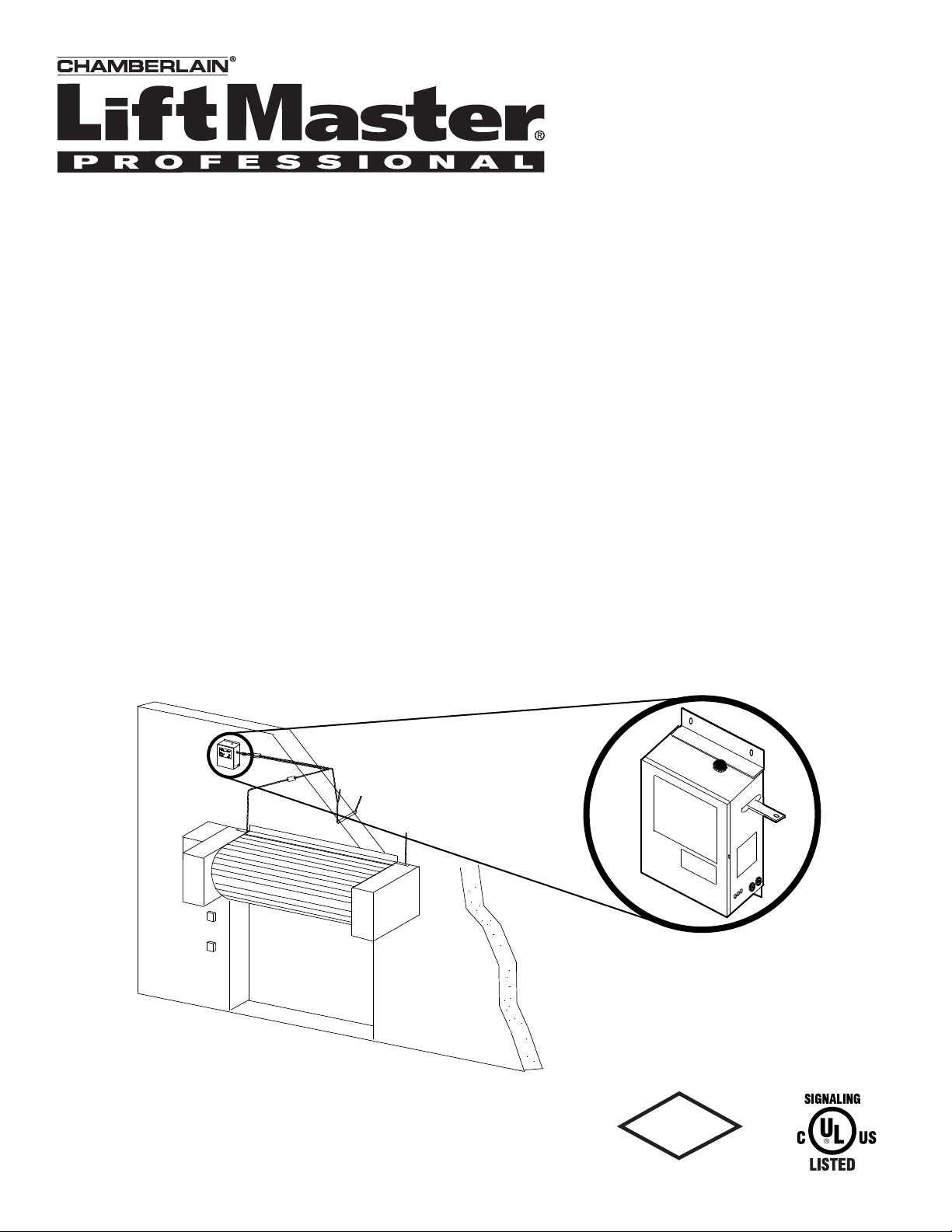

Smoke

Detector

Release

Device

Turnbuckle

Annunciator

Test/Reset

Switch

Fire Door

Chain

End Link

Fuse Links

Eyebolt

Electric Safety Edge

(Motorized Doors Only)

Page 4

4

INSTALLATION

Classification:

Releasing device as defined by Underwriters Laboratories.

Installation Requirements:

Intended for “Indoor Dry” locations; all wiring must be performed

in accordance with the most current version of NFPA 72 - National

Fire Alarm Code and the National Electric Code.

MOUNT THE RELEASE DEVICE

Installation procedures vary according to door types. Refer to

door manufacturer’s recommendation that applies to your door.

1. Mount the release device on a vertical surface with chain end

link exiting side of enclosure.

2. Secure the release device enclosure with fasteners (#10 is the

minimum size recommended). If installing in masonry, use

concrete anchors (not provided).

3. Install hardware (sash chain or 1/16 cable, eyebolts-hook, fuse

links, turnbuckles—not provided) according to door

manufacturer’s recommendations. NOTE: The end link

direction of pull must be perpendicular to the side of the

release device enclosure. Install an eyebolt a minimum

distance of 12" from the release device to adequately redirect

sash chain pull.

4. Install end link by pressing mechanical reset to allow insertion

of end link. Push end link completely in and release mechanical

reset to latch end link.

5. Remove sash chain or cable slack by adjusting turnbuckle.

IMPORTANT INSTALLATION INSTRUCTIONS

To reduce the risk of SEVERE INJURY or DEATH:

WARNING

WARNINGWARNING

1. READ AND FOLLOW ALL INSTALLATION WARNINGS

AND INSTRUCTIONS.

2. NEVER connect release device to power source until

instructed to do so.

3. DO NOT install this device on a motorized door without

an electric safety edge.

4. DO NOT use this device without fuse links installed.

5. Concrete anchors MUST be used if mounting release

device into masonry.

6. DO NOT exceed maximum pull rating of 40 lbs. on

releasing device.

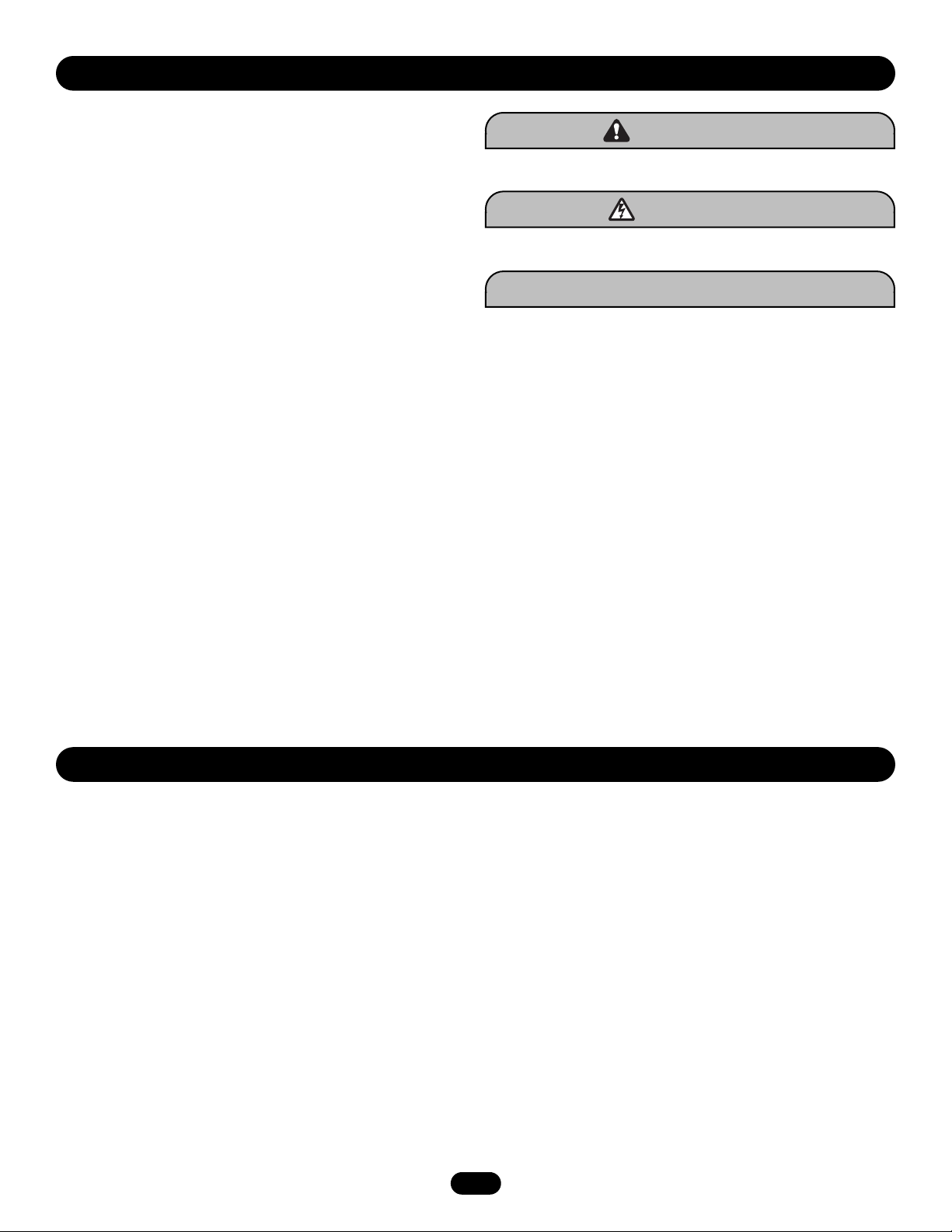

Smoke

Detector

Release

Device

Turnbuckle

Annunciator

Test/Reset

Switch

Fire Door

Chain

End Link

Fuse Links

Eyebolt

Mechanical

Reset Plunger

End Link

Electric Safety Edge

(Motorized Doors Only)

Page 5

5

WIRING

POWER WIRING CONNECTIONS

This device is designed to be used on motorized doors

incorporating a reversing feature safety edge. Verify wiring

configuration with that recommended by door manufacturer for

use of this product with specific door and accessories being

utilized.

1. Confirm power source for adequate voltage of 108 to 132Vac.

2. Disconnect power at fuse box to the release device and door

operator before continuing.

3. Connect 120Vac (single phase) power source inputs to

terminals L1 (line) and L2 (neutral) of the power strip. The

third position is used for earth ground. NOTE: Do not apply

incoming power or connect battery at this point.

WIRE ROUTING

To reduce the risk of SEVERE INJURY or DEATH:

• ALL electrical connections MUST be made by a qualified

individual.

• Disconnect power at the fuse box BEFORE proceeding. Release

device MUST be properly grounded and connected in

accordance with local electrical codes.

• Installation of ALL wiring and connections, including Class 1

and Class 2 circuits, shall be performed in accordance with,

but not limited to, the latest NFPA, UL and N.E.C. standards

and codes. In addition, ALL installations subject to Canadian

standards shall be performed in accordance with the Canadian

Electrical Code, Part I, with respect to wiring material type,

wiring gauge related to power capacity requirements and

circuit length and wiring methods.

• ALL power wiring should be on a dedicated circuit and well

protected. The location of the power disconnect should be

visible and clearly labeled.

• ALL power and control wiring MUST be run in separate

conduit.

• A reversing edge MUST be installed on ALL motorized doors

BEFORE proceeding with the installation.

WARNING

WARNINGWARNING

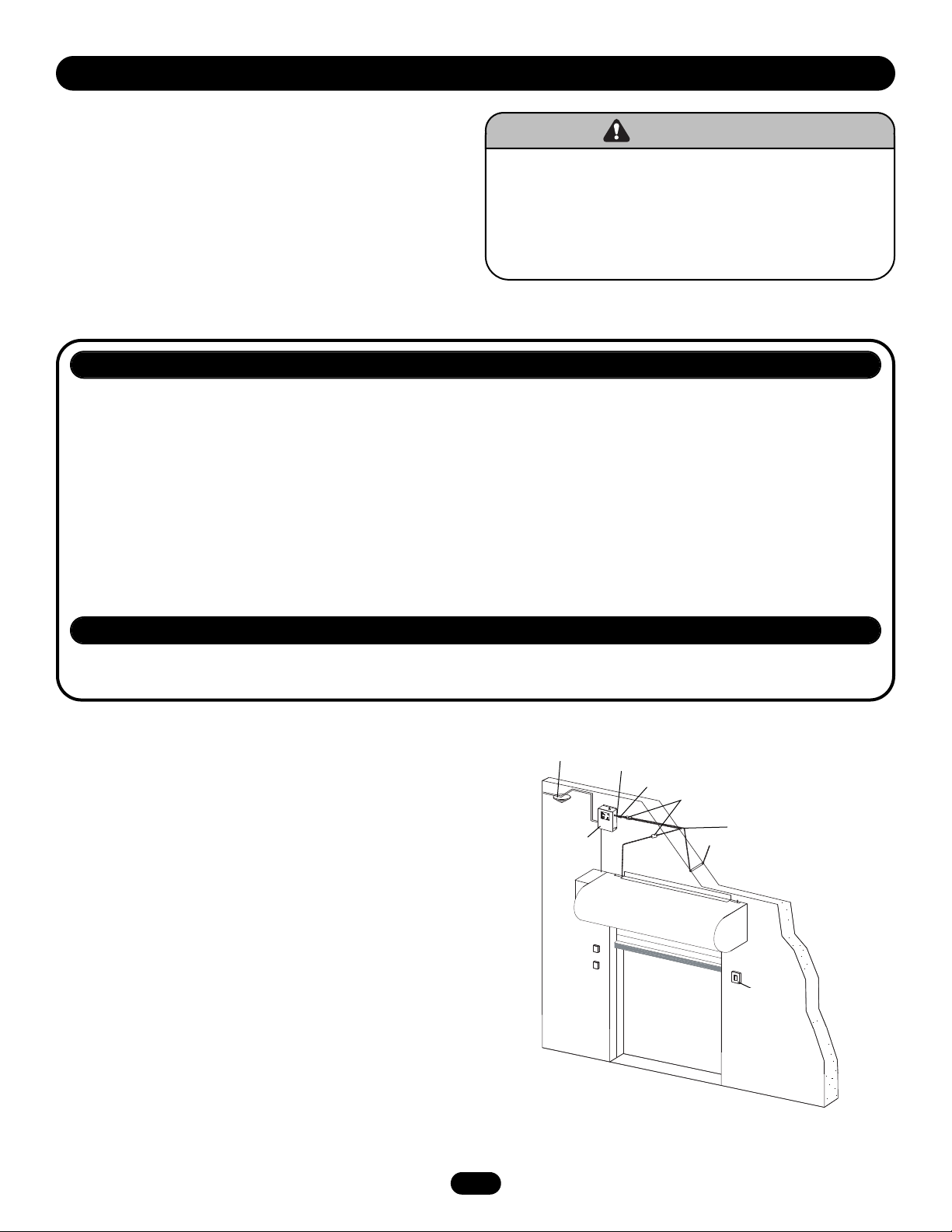

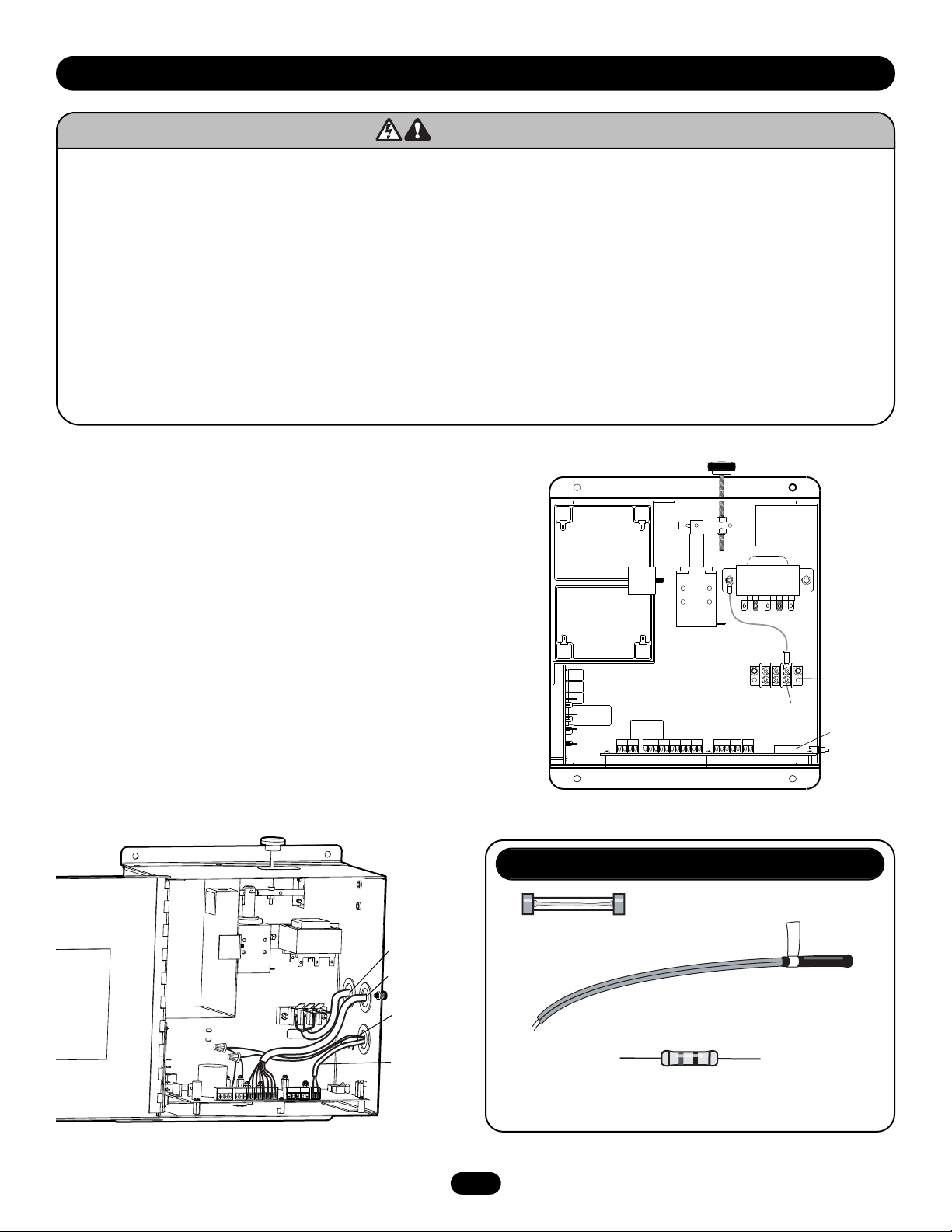

Mechanical Reset

Plunger

Ground

Option

DIP Switch

Power

Strip

High Voltage

Wiring

Low Voltage

Wiring

Voice Board

Wiring

Annunciator

Wiring with

Sleeving

PARTS KIT

Refer to Wiring section for proper application of these parts.

LM2AG2AMP

2.2k Ohm Resistor

LMEOLRES-2-2

L1L2

Page 6

CONNECTIONS FROM DEVICE TO THE OPERATOR

NOTE: For low voltage wiring #18 AWG is recommended.

OPERATOR CONNECTIONS

1. Connect terminals 11 and 12 from the release device to the

transformer secondary in the door operator. The required

voltage should be 24-30Vac.

NOTE: This connection must be made in order to avoid a

mechanical release in alarm conditions when the door is not

closed (Figure 2).

2. Connect release device to auxiliary limit switches on the

operator. These are required and must be provided by the

door operator manufacturer.

Auxiliary Closed Limit Switch (Figure 1):

Connect a wire from the common and N/O of the auxiliary limit

switch to terminals 13 and 14 on the release device. This input

will not allow a mechanical release if the auxiliary close limit is

activated. This circuit also turns off annunciators when the

auxiliary close limit is activated.

6

WIRING

To prevent DAMAGE to the circuit board, auxiliary limit switches

MUST be provided as dry contacts and may not be used in

conjunction with the simultaneous switching of a motor control

or ANY other voltage through the same contacts. Connections of

this type will result in immediate damage to the release device.

WARNING

CAUTIONCAUTION

WARNING

WARNING

Auxiliary Open Limit Switch (Figure 1):

Connect a wire from the common and N/O of the auxiliary limit

switch to terminals 14 and 15 on the release device. A

connection to an auxiliary up limit switch is required for

3-cycle obstruction count feature. Adjust the auxiliary open

limit to activate just before the operators open limit is activated.

3. Connect wires from terminals 7, 8, 9, and 10 to the door

operator terminals that are used for 3-button station (for use

with N/O ‘Close’ switch, N/O ‘Open’ switch and N/C ‘Stop’

switch). The close relay output latches to initiate a door closure

through the operator after the factory set delay.

Figure 1

Figure 2

Auxiliary Limit Switches

Auxiliary Close Limit (N.O.)

Auxiliary Open Limit (N.O.)

Common

LMEOLRES-2-2

4-Wire Smoke

Detector Wiring

End of Line Relay

24 Vdc

4-Wire Smoke

Detector Wiring

(4 Detector

Maximum)

2.2

kOhm

Smoke

Detector

Smoke

Detector

Additional Dry Contact

2.2

kOhm

Safety Edge

Safety Edge Common

Open Button Input

Close Button Input

Stop Button Input

Open Button

Close Button

Stop Button

Auxiliary Close Limit (N.O.) (4)

Auxiliary Open Limit (N.O.) (4)

.75 A Maximum Curren t

During Alarm

DC

DC

3-Button Common

Control V oltag e

Control Ground

Safety

Edge

Operator Annunciator

3-Button

Station

Auxiliary Limit

Switches

2-Wire Smoke

Detector Wiring

2-Wire Smoke

Detector Wiring

(4 Detector

Maximum)

Smoke

Detector

2.2

kOhm

Smoke

Detector

(PU) (YE)

Voice Board

Speaker - V oic e

Board Model Only

+ Speaker

- Speaker

OR

BATTERY CONNECTION / MAINTENANCE

Use two (2) 12V 4.5AH sealed

lead acid batteries in series.

Maximum charge current 1A.

Replace batteries every 2 years.

Black Wire to Black T ermina l

Battery Interconnect Wire

Battery 1 Red to Battery 2 Black

Battery 1

Battery 2

Red Wire to Red T ermina l

Power Con.

TB2

POWER CONNECTION

Hot

120Vac

1-Phase

Neutral

120Vac

1-Phase

TB2

L1 L2 L3

Replace batteries every 2 years.

Field Wiring shall consist of 22-18 AWG wiring.

Use only 250 VAC, 2 Amp, 3 AG Slo-Blo fuses.

1. Supervised, power limited circuit, 20 Ohm

maximum line impedance.

2. Unsupervised circuit, 20 Ohm maximum line

impedance.

3. Unsupervised, power limited circuit, 20 Ohm

maximum line impedance.

4. Maximum of 4 Class B Style A detectors.

LMEOLRES-2-2 required for supervision.

5. Maximum of 2 Class B Style W notification

appliances. 0.75 Amp at 24 VDC maximum.

Supervised, non-power limited circuit. 20 Ohm

maximum line impedance. Place 2.2 kOhm

resistor between 16 & 20 if unused.

LMEOLRES-2-2

(1)

(4)

(4)

(2)

(5)

(3)

Wall Mounted

Test/Reset Switch

Red

Yellow

Page 7

7

CONNECTIONS OF INITIATING DEVICES AND ACCESSORIES

A maximum of 4 smoke detectors may be installed with this

device. Refer to NFPA 72 and NFPA 80 for instructions

concerning proper placement and detection coverage. End-of-line

devices must be installed for supervision of electrical power to

4-wire smoke detector. When using 4-wire smoke detectors with

this device, electrical supervision must be provided by means of a

UL/ULC listed end-of-line relay.

NOTE: For low voltage wiring #18 AWG is recommended.

Normally Open “2-Wire,” Class B Style A 12Vdc Initiating

Devices

1. Connect wiring from N/O initiating device loop to terminals 2

and 3.

2. Place the supervisory resistor (LMEOLRES-2-2) across the

terminals of the last initiating device. Observe proper polarity,

2 (+), 3 (-) (Figure 3).

OR

Normally open “4-Wire,” Class B Style A Initiating Devices

1. Connect wiring from N/O 4-Wire initiating device loop to

terminals 2 and 3. (Do not share alarm loop with other alarm

circuits.)

2. Place the supervisory resistor (LMEOLRES-2-2) as illustrated

in figure 4 or 5. (Do not share alarm loop with other alarm

circuits.)

3. Auxiliary power (+24Vdc) for smoke detectors may be

obtained from terminals 1 (+) and 4 (-) for +24Vdc. There is a

4 detector maximum, and an end-of-line relay device must be

used (Figures 4 & 5).

NOTE: End-of-line devices must be installed adjacent and after

the last initiating device. Initiating device loops are supervised

and cannot be direct series or paralleled between multiple release

devices or shared with other alarm equipment. For proper wiring

configurations from multiple smoke detectors or signaling for

simultaneous closure on multiple doors, call technical support,

1-888-528-7870. Incorrect wiring between devices may cause

damage to the release control circuit and void warranty.

4. In lieu of smoke detectors, the release device may be put into

alarm by the fire alarm control panel. Most commonly, a relay

module is used as an interface between the fire alarm control

panel and the release device. The relay module must provide

Form C dry contacts for connection to the appropriate

terminals on the release device (Figure 6).

NOTE: When choosing a relay module to activate the release

device in an alarm condition, always select one that provides

Form C dry contact relays. Do not use any relay module

providing or passing any (control) voltage through the contacts

into the release device. The passage of voltage through such a

relay module into the release device will cause problems with the

operation of the device and may damage the device's terminals

and/or circuit board.

WIRING

To prevent possible SERIOUS INJURY or DEATH:

• End-of-line devices MUST be installed for supervision of

electrical power to 4-wire smoke detector.

• DO NOT install this device on a motorized door without an

electric safety edge.

WARNINGWARNING

Figure 3

–

+

Figure 5

Figure 6

2.2k Ohm @ 1/2 watt

Supervisory Resistor

(LMEOLRES-2-2)

NOTE: Follow this method of

attachment when using LM2W-B,

LM2WT-B, other 2-wire smoke

detector. See last page for

approved devices.

On Circuit

Board

NOTE: Follow this method

of attachment when using

LM4W-B or LM4WT-B.

2.2k Ohm @ 1/2 watt

Supervisory Resistor

(LMEOLRES-2-2)

LMEOLR1224

12/24 Vdc

EOL Relay

NOTE: Follow this

method of attachment

when using LM1424.

2.2k Ohm @ 1/2 watt

Supervisory Resistor

(LMEOLRES-2-2)

LMEOLR1224

12/24 Vdc

EOL Relay

Alarm

Contacts

Style A

(N/O)

Relay Module

Normally Open

Common

2.2k Ohm @ 1/2 watt

Supervisory Resistor

(LMEOLRES-2-2)

Red

Black

Fire Alarm

Control

Panel

Figure 4

2

3

+ IN

– IN/OUT

+ OUT

+ IN

– IN/OUT

+ OUT

1

4

COM

NO

– IN/OUT

+ OUT

COM

NO

– IN/OUT

+ OUT

2

3

+ IN

+ IN

1

4

2

3

2

3

(+)

(–)

(+)

(–)

Page 8

8

WIRING

To prevent DAMAGE to the circuit board, auxiliary limit switches

MUST be provided as dry contacts and may not be used in

conjunction with the simultaneous switching of a motor control

or ANY other voltage through the same contacts. Connections

of this type will result in immediate damage to the release

device.

WARNING

CAUTIONCAUTION

WARNING

WARNING

OPTIONAL CONNECTIONS

WALL MOUNTED REMOTE TEST / RESET SWITCH

The provided LMRT switch should be wall mounted using a single

gang junction box at approx. 4’ above floor level. Connections

should be made between N/O contacts (red and yellow wires) on

the LMRT to terminals 21 and 22 in the releasing device

(Figure 9). The LMRT test / reset switch provides two functions to

the releasing device:

1) Test Function. The releasing device can be tested by turning

and holding the LMRT switch. See Testing section for

details.

2) Alarm Resetting. The LMRT can be used to reset a latched

alarm condition if the door is closed and the alarm input

has returned to the standby state (alarm is no longer

active). Reset can be accomplished by turning and releasing

the switch. Door may re-open automatically if auto-open

feature is enabled, see DIP Switch Configuration Setting

section.

NOTE: This connection is necessary if floor level resetting of the

device or Auto Opening is required.

ANNUNCIATOR

Connect annunciator (#LMHS2475ADA) to 16 (+) and 20 (–).

End-of-line resistor (LMEOLRES-2-2) must be installed as

illustrated (Figure 7). A maximum of two annunciators may be

connected. Maximum output current of the devices must not

exceed .75A dc. Route wires through the non-conductive

sleeving (provided) covering any exposed bare wires. Maximum

distance of wire run within conduit not to exceed 20' total. NOTE:

If installing two visual annunciators they must be installed on

opposite walls. If these inputs are not used, place the 2.2k

Ohm resistor from the parts kit between terminals 16 and 20.

ADDITIONAL DRY CONTACT RELAY

An additional dry contact relay is provided between 17

(Common) and 18 (N/C ) and 19 (N/O). Maximum switched

current is .15A 125Vac, 1A 24Vdc. Switching of this relay

occurs immediately upon sensing an alarm.

VOICE BOARD OPTION

The voice board provides one of two verbal warnings that the

fire door is closing. Typically, depending on the length of the

delay chosen on the release device, a warning tone will occur

prior to the message, which is approximately 10 seconds in

length (for example, a 20 second delay setting on the release

device will result in a 10 second warning tone followed by the

verbal warning message). There are two messages that may

be selected:

Message 1: Warning tone followed by the message, “Warning!

An emergency condition exists and this fire door is about to

close; please remove any obstructions from its path and stand

clear.”

Message 2: Warning tone followed by the message, “Warning!

This fire door will close in 10 seconds... 5 seconds... the fire

door is now closing; please remove any obstructions from its

path and stand clear.”

NOTE: LMRT key switch must be installed within a single gang

junction box with a minimum 2" depth using appropriate 6-32

mounting screws and mounted on the same wall and within the

same room as is the release device. All wire connections must be

secured with appropriate wire nuts.

Figure 7

Figure 8

21 22

Figure 9

2.2k Ohm @ 1/2 watt

Supervisory Resistor

(LMEOLRES-2-2)

Annunciator

+ DC

- DC

.75A Maximum Current

During Alarm

NonConductive

Sleeve

Additional

Form-C

Dry Contact

Red

Yellow

N.O.

Common

LMRT

Wire to Speaker

Volume Control

CCW for Max.

The release device has an 8-position DIP Switch mounted on the

circuit board, and the switch at position #8 permits selection of

either message. In the “ON” position, Message 1 is activated; in

the “OFF” position, Message 2 is activated.

The voice board can drive up to two 70.7V speakers (Model

LM8SP) or speaker inputs to speaker strobes (Model

LMPSTR2475ADA). Maximum delivered power is 5 watts.

A potentiometer (VR1) is mounted on the board and rotation

counterclockwise increases the volume (clockwise to decrease

volume) (Figure 8).

Page 9

1 Motorized door. The device will attempt to close the door with

the motor before releasing.

Manual door. The device will drop the door without attempting

to close it with a motor.

2 Stop on obstruction. If a motorized door is used, the device

will attempt to close the door but will reverse if the safety

edge is triggered. The device will stop the door on the

obstruction when it is sensed the third time.

Drop after sensing an obstruction three times. The device will

attempt to close the door but will reverse if the safety edge is

triggered. The device will fully open the door after a third

obstruction is sensed and then drop the door.

3 DIP switches 3 and 4 control the length of the delay, either 10,

20, 30 or 60 seconds depending on the switch settings.

DIP switches 3 and 4 control the length of the delay, either 10,

20, 30 or 60 seconds depending on the switch settings.

4 DIP switches 3 and 4 control the length of the delay, either 10,

20, 30 or 60 seconds depending on the switch settings.

DIP switches 3 and 4 control the length of the delay, either 10,

20, 30 or 60 seconds depending on the switch settings.

5 6-Minute safety timer. Will drop the door after 6 minutes if the

close limit is not achieved by a motorized closure.

3-Minute safety timer. Will drop the door after 3 minutes if the

close limit is not achieved by a motorized closure

6 Line Power Loss Alarm. Treat a loss of line power as an alarm,

which leads to door closure or drop.

Operate normally from battery power when line power is lost.

(Standard)

7 Auto-Open. Open a motorized door automatically after alarm

condition is cleared by Remote Test / Reset Switch.

Auto-Open Disabled. Keep door closed after alarm condition is

cleared. (Standard)

8 For voice board option only, this selects Message 1. For voice board option only, this selects Message 2.

9

ADJUSTMENTS

DIP SWITCH CONFIGURATION SETTING

The release device has DIP switch selectable options. The options

DIP switch is located next to terminal block 5. Set all DIP switch

options before applying power to the system. The selection of

positions is listed below.

SELECTABLE DELAY SETTINGS (SWITCHES 3 & 4)

The release device will provide a factory default delay of 10

seconds before releasing the fusible link chain upon alarm. The

length of the delay is controlled by the positions (Off or On) of

the number 3 and 4 switches on the 8-position DIP switch

mounted on the logic board. Four preset delays are available and

are shown.

Delay Setting Switch Position

34

10 Seconds Off Off

20 Seconds Off On

30 Seconds On Off

60 Seconds On On

DIP Switch Switch “ON” Switch “OFF”

Factory default setting of 10 seconds shown.

ON

1 2 3 4 5 6 7 8

Page 10

10

TESTING

TESTING

Testing does not affect normal operation of alarm system when

connected to release device/control panel. Testing of the release

device is independent of, and shall in no way be interpreted as an

alternative method of, testing of a central fire alarm system,

motorized operator and/or any other system component

employed on the fire door or counter fire door installation.

Complete testing and normal operation can only be accomplished

with power applied to device. Verify options ordered and installed

with device.

TEST RELEASE DEVICE AND DOOR OPERATOR

AUTOMATIC DOOR CLOSURE TESTS

(MOTORIZED DOORS ONLY)

Release Device Test Button – with AC Power

1. Clear fire door opening and prohibit traffic through door

opening while testing.

2. Turn on power to release device. The Red power LED will light

on the release device and the battery trouble sounder will

begin to beep.

3. Connect battery leads using the included battery interconnect

wire and the release device battery wires (Figure 10). Green

LED will light indicating battery is connected and charging.

4. Turn on power to motor. Motor sense disable Yellow LED will

light indicating power is present at motor control secondary.

5. Fully open door.

6. Depress and continue to hold the test button on the release

device. The optional annunciator (or voice board) will turn on

and after the preset delay the door will begin to close.

Annunciator will turn off when door reaches the auxiliary

close limit.

7. Release test button. The test is complete.

8. Depress “Open” button on door control to raise door to fully

open position.

To prevent possible SERIOUS INJURY or DEATH:

• Clear fire door opening and prohibit traffic through door

opening while testing.

• DO NOT install this device on a motorized door without an

electric safety edge.

• Test every 90 days to assure proper operation of release

device.

WARNINGWARNING

WARNING

Figure 10

Red Wire to Red Terminal

Test Button

Battery Interconnect Wire

Battery 1 Red to Battery 2 Black

Use two 12V 4.5H sealed

lead acid batteries in series.

Maximum charge current 1A.

Replace batteries every 2 years.

Black Wire to Black Terminal

Page 11

11

TESTING

TEST RELEASE DEVICE AND DOOR OPERATOR

AUTOMATIC DOOR CLOSURE TESTS (CONTINUED)

(MOTORIZED DOORS ONLY)

Three-Cycle Obstruction Test

1. With the door fully open, place an obstruction no less than

12" in height in the normal path of the door.

2. Depress and continue to hold the test button of release device

through step 4. Optional annunciator will turn on indicating a

door closure is about to occur. After the preset delay the door

will begin to close.

3. Upon contact with the suitable obstruction being utilized, the

safety edge will reverse the operator raising the door to the

open position. The release device will make three attempts to

close through the operator. The release device will turn off the

operator when the door reaches the open position and

releases the door mechanically through the drop release

mechanism. NOTE: The release device can optionally be set to

stop the door on the obstruction after the third triggering of

the safety edge (see DIP switch options). The door will stop

on the obstruction and will close fully after the obstruction is

removed. The annunciator will continue to sound until the

alarm condition has been cleared.

4. Release test button. The test is complete.

5. Reset the fire door per manufacturer’s instructions.

6. Reset release device by pushing in and holding the

mechanical reset plunger. Insert end link through enclosure

opening and release reset plunger latching the end link.

7. Depress Open button on operator control raising door to open

position.

Wall Mounted Test / Reset Switch (provided)

This test disables the internal counter circuit and allows the door

to continuously cycle if a suitable obstruction is utilized (refer to

Three –Cycle Obstruction Test.)

1. Clear fire door opening and prohibit traffic through door

opening while testing.

2. Insert key into wall mounted Test / Reset switch, turn key and

hold in direction of test indicator until test is complete.

Annunciator will turn on and the door will begin to close after

preset delay. If no obstruction is placed in the path of the

closing door, the door will fully close and the motor will turn

off. If an obstruction is encountered, the door will close until

it strikes the obstruction and reverse to a fully open position.

The door will immediately begin to close again and continue

this cycle until the key is returned to the off position.

3. Return Test / Reset switch to off position to silence the

annunciator. The door will re-open if Auto-Open feature is

enabled, see DIP Switch Configuration Setting.

Auxiliary Closed/Open Limit Detection Test

1. Clear fire door opening and prohibit traffic through door

opening while testing.

2. Depress “Close” button on door control to close door.

3. Green Close Limit LED will be lit on Logic Board

(Figure 11).

4. Depress “Open” button on door control to open door.

5. Green Open Limit LED will be lit on Logic Board

(Figure 11).

Page 12

12

TEST RELEASE DEVICE WITH BATTERY BACKUP WITHOUT AC POWER

MECHANICAL DOOR CLOSURE TEST

This test verifies a mechanical release in absence of power to the

operator. NOTE: This test requires mechanical door resetting per

manufacturer’s instructions before returning the Fire Door to

service.

1. Clear fire door opening and prohibit traffic through door

opening while testing.

2. Fully open door. Disconnect power to operator and release

device. NOTE: Batteries must be connected and the Green

LED must be lit, if not door will release (close).

3. The mechanical release disabled LED (Yellow) is off if the

door is not closed. Turn and hold the Test / Reset Switch or

depress and hold "Test" button on release device.

Annunciator will sound indicating a door closure is about to

occur and after preset time delay (refer to the Configuration

Settings) device will release door. Release Test / Reset Switch.

4. Reset fire door per door manufacturer’s instructions, then

reset device release mechanism by pressing mechanical reset

plunger. Fully insert end link through release device side

opening and release mechanical reset plunger to latch end

link.

5. Restore power to the operator and the release device. Red

LED should light on the release device indicating power has

been restored

6. Raise door to its fully open position. Press the “Reset” button

on the device.

7. After completing all tests, verify that door is in its normal

condition (open or closed) and that all power required for

normal operation is restored to device and operator. The

device is designed to operate with its primary power source

applied.

TESTING

Page 13

Battery

Present

Green

(Fig. 13)

If lit, batteries have been installed correctly and are

charging or have been fully charged.

If the LED does not come back on after installing the

batteries, check battery connections are as illustrated.

Open Limit Green

(Fig. 11)

If lit, the device senses a triggered normally open limit

switch.

If door is on the Open limit, input is connected properly. If

door is not on the Open limit, check that auxiliary limit

connections are made as illustrated.

Close Limit Green

(Fig. 11)

If lit, the device senses a triggered normally close limit

switch.

If door is on the Close limit, input is connected properly. If

door is not on the Close limit, check that auxiliary limit

connections are made as illustrated.

Mechanical

Release

Disabled

Yellow

(Fig. 13)

If lit, the device is in a state where it will not release the

door.

This is caused by being in close limit or by sensing an

electric door operator. Check limit switch connections and

motor operator control voltage connections.

Annunciator

Open

Yellow

(Fig. 11)

If lit, 2.2k Ohm resistor is not installed on the annunciator

circuit. Note that LED lights when system is in alarm condition.

Check that the annunciator is installed as described in

Wiring Instructions.

Detector

Open

Yellow

(Fig. 11)

If lit, 2.2k Ohm resistor is not installed on the smoke

detector circuit.

Check that a 2.2k Ohm resistor is connected in the circuit

as illustrated.

Ground

Fault

Yellow

(Fig. 12)

If lit, a short to earth ground exists. Check that release device and all ancillary devices/loops

(detectors, annunciators, etc.) are grounded properly.

Annunciator

Short

Red

(Fig. 11)

If lit, the annunciator circuit is short-circuited. Check that the annunciator is installed as described in

Wiring Instructions.

Line Power

Present

Red

(Fig. 13)

If lit, the line power is connected and switched “on.” If the LED does not light when power is applied, check

that the power is connected to L1 and L2 as described in

Wiring Instructions.

Detector

Short

Red

(Fig. 11)

If lit, the smoke detector circuit is short-circuited. Check that the smoke detectors are connected in the

circuit as illustrated. Press the “Reset” button to reset the

detectors.

13

TROUBLESHOOTING

DIAGNOSTIC LEDS

LED LED Color Description Action Required

Figure 11 - Logic Board LED Descriptions

Figure 12 - Power Supply Board LED Descriptions

Close Limit (Green)

Ground Fault

(Yellow)

Power

(Red)

Detector Open

(Yellow)

Open Limit (Green)

Annunciator Short (Red)

Detector Short

(Red)

Annunciator Open (Yellow)

Page 14

MAINTENANCE

To avoid SERIOUS PERSONAL INJURY or DEATH from

electrocution, disconnect ALL electric and battery power

BEFORE performing ANY maintenance.

WARNING

WARNINGWARNING

MAINTENANCE

The release device has no scheduled maintenance requirements.

The device has been designed and tested for use in dry, indoor

locations. Testing of the device at least once every 90 days is

recommended, but test intervals shall ultimately be subject to

criteria established by the Authority Having Jurisdiction (AHJ).

FUSE REPLACEMENT PROCEDURE AND REPAIR PARTS

Two serviceable fuses, both 2 Amp, 2AG, slo-blo fuses, are

required for proper operation and protection of the power supply

circuit board. The fuse present at position F1 limits the amount of

current coming into and going from the battery. The fuse present

at position F2 limits amount of current into power supply board.

The device is shipped with the fuses installed and replacement

fuses (2) are provided in a separate parts bag.

For replacement parts, refer to Accessories and Replacement

Parts page.

BATTERY MAINTENANCE/TESTING

No maintenance or testing is required for the battery. An audible

warning tone, generated by the trouble annunciator, will sound

when the battery is approaching the minimum operating

threshold. This indicates the need to replace the battery. Replace

the batteries every 2 years.

For replacement parts, refer to Accessories and Replacement

Parts page.

BATTERY DISPOSAL

Spent batteries must be treated as hazardous waste and disposed

of in accordance with State, Local and Federal Regulations.

Battery Green

(Fig. 13)

If the Green LED is lit, then the battery is connected

properly and charged above the minimum acceptable

level.

If the LED does not light, check that the leads are

connected to the battery as shown on the wiring diagram

in this manual. Check Battery Fuse, F1 (Fig. 12).

Disable Yellow

(Fig. 13)

If the Yellow LED is lit, the releasing device will attempt to

close through the operator and not perform a mechanical

release door closure in alarm. It should light if the

operator control voltage is connected or the auxiliary close

limit is active

Connect operator control voltage connections to terminals

11, 12 and auxiliary close limit connections to terminals

13, 14.

Power Red

(Fig. 13)

If the Red LED is lit, then the line power is connected and

switched “on.”

If the LED does not light when power is applied, check

that power is connected as described in the installation

manual electrical connections.Check 24Vac Fuse,

F2, (Fig. 12).

ENCLOSURE MOUNTED LEDS STATUS INDICATORS

14

LED Label LED Color Description Action Required

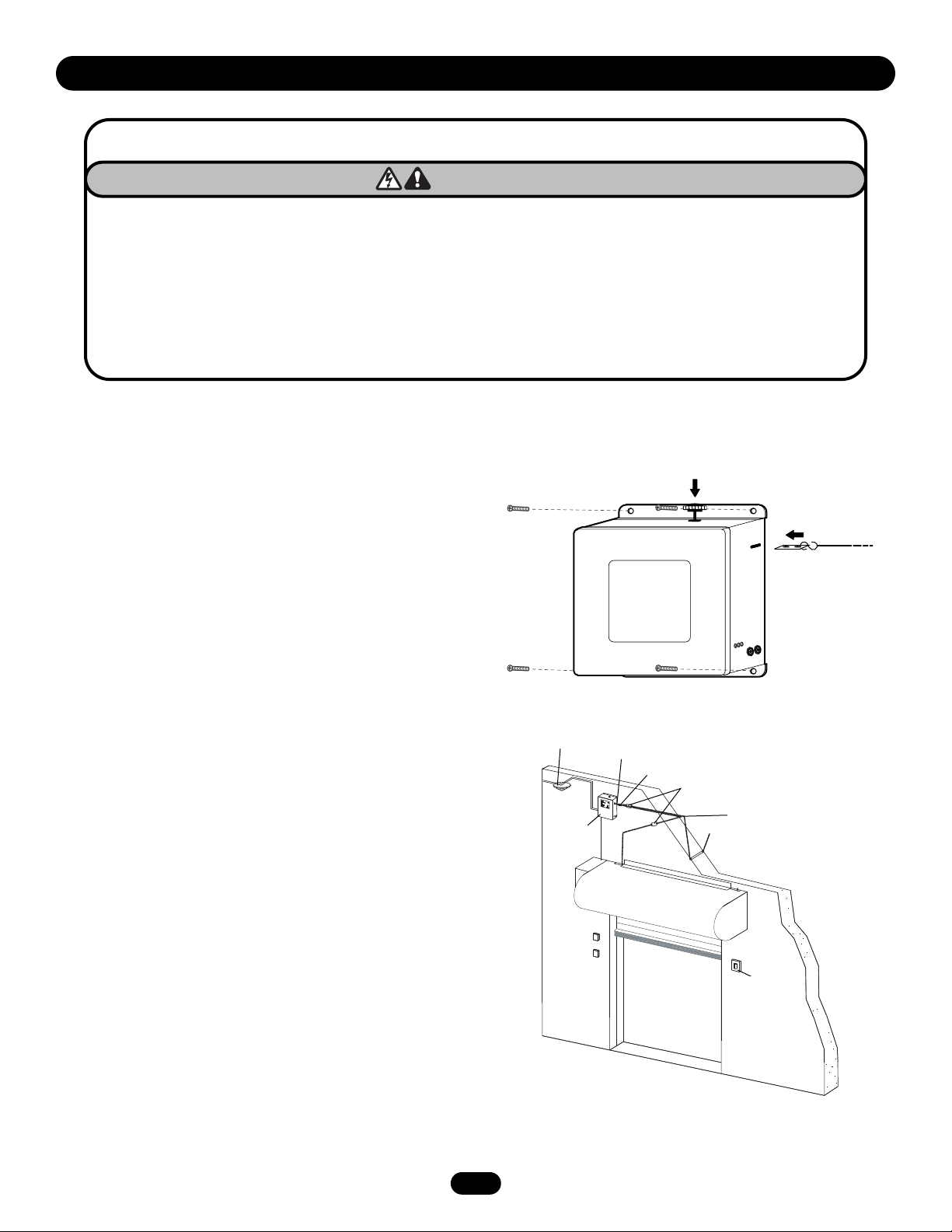

Front of Release Device

End Link

Mechanical

Reset Plunger

Test Button

Electronic

Reset Button

Side of

Release Device

Yellow LED (Close Door Detection/Release Disabled)

Red LED (Line Power Present)

Green LED (Battery Backup Power Present)

Figure 13

Page 15

15

ACCESSORIES AND REPLACEMENT PARTS

ACCESSORIES

ITEM PART # DESCRIPTION

1 LM8100 Smoke Detector - 120V Photo

2 LM8100T Smoke Detector - 120V Photo with Thermal

3 LM8100I Smoke Detector - 120V Ion

4 LM2W-B Smoke Detector - 12/24Vdc 2-Wire Photo

5 LM2WT-B Smoke Detector - 12/24Vdc 2-Wire Photo

with Thermal

6 LM4W-B Smoke Detector - 12/24Vdc 4-Wire Photo

7 LM4WT-B Smoke Detector - 12/24Vdc 4-Wire Photo

with Thermal and Form C Relay

8 LM1424 Smoke Detector - 24Vdc Ion

9 LM1412 Smoke Detector - 12Vdc Ion

10 LMTH135 Heat Detector - 135 Degree Fixed Temperature

11 LMTH194 Heat Detector - 194 Degree Fixed Temperature

ITEM PART # DESCRIPTION

12 LMEH1224ADA Horn - 12/24Vdc

13 LMPSTR2475ADA Speaker Strobe - 24Vdc

14 LML2475ADA Strobe - 24Vdc

15 LMHS2475ADA Horn/Strobe - 24Vdc

16 LMEH1224ADA Horn - 24Vdc

17 LMPSTR1V75ADA Speaker Strobe - 120Vac

18 LML1V750ADA Strobe - 120Vac

19 LMHS1V75ADA Horn/Strobe - 120Vac

20 LMEH120ADA Horn - 120Vac

21 LM8SP Speaker 8"

22 LMEOLR1224 End-of-Line Relay - 12/24Vdc

23 LMEOLR120 End-of-Line Relay - 120Vac

REPLACEMENT PARTS

ITEM PART # DESCRIPTION

1 LMRK Reset Knob

2 LMELH End Link

3 01-32675 Owner's Manual

4 LM2AG2AMP Fuse - 2Amp

5 LMRT Remote Test / Reset Switch

6 LMEOLRES-2-2 End-of-Line Resistor, 2.2 kOhm

7 LM4AH12 Battery

HOW TO ORDER REPAIR PARTS

OUR LARGE SERVICE ORGANIZATION SPANS AMERICA

Installation and service information

call our TOLL FREE number:

1-888-528-7870

NOTE: Certain accessories above will require a separate power source. Refer to product manual.

Page 16

MODEL NO. DESCRIPTION

LM2W-B 24Vdc 2-Wire Photo 2W-B

LM2WT-B 24Vdc 2-Wire Photo with Thermal 2WT-B

LM4W-B 24Vdc 4-Wire Photo 4W-B

LM4WT-B 24Vdc 4-Wire Photo with Thermal & Form C Relay 4WT-B

LM1424 24Vdc Ion #1424

MODEL NO. DESCRIPTION

LMTH135 135 Degree Fixed Temperature #603 #5603 #283B-PL

LMTH194 194 Degree Fixed Temperature #604 #5604 #284B-PL

HEAT DETECTORS

MODEL NO. DESCRIPTION

LMPSTR2475ADA 24Vdc Speaker Strobe SP2R1224MC

LML2475ADA 24Vdc Strobe S1224MC

LMHS2475ADA 24Vdc Horn/Strobe P1224MC, P2R

LMEH1224ADA 24Vdc Horn H12/24

LM8SP Speaker SP201R

MODEL NO. DESCRIPTION

LMEOLRES-2-2 2.2 kOhm End-of-Line Resistor LMEOLRES-2-2

LMEOLR1224 End-of-Line Device EOLR-1

LMEOLR120 End-of-Line Device PAM-1

01-32675D © 2008, The Chamberlain Group, Inc.

Issue Date 2/11/2008 All Rights Reserved

APPENDIX

SMOKE DETECTORS

ACCESSORY COMPATIBILITY GUIDE

SYSTEM SENSOR

MODEL NO.

CHEMTRONICS SYSTEM SENSOR EDWARDS SYSTEM TECHNOLOGY (EST)

MODEL NO. MODEL NO. MODEL NO.

SYSTEM SENSOR

MODEL NO.

SYSTEM SENSOR SPACE AGE LIFTMASTER NO.

MODEL NO. ELECTRONICS NO.

HEAT DETECTORS

NOTIFICATION DEVICES

END-OF-LINE DEVICE

NOTE: Certain accessories above will require a separate power source. Refer to product manual.

Loading...

Loading...