Page 1

Installation Manual Addendum

MODELS

FF SS XX PP -- FF LL RR

FF SS XX PP BB BB -- FF LL RR

FF SS XX PP BB BB VV BB -- FF LL RR

FIRE SENTINEL FLOOR RESET

Reset Mechanism

Overhead Door Corporation

Pennsylvania Division

23 Industrial Park Road

Lewistown, Pennsylvania 17044

Phone: (800) 929-2553

(717) 248-0131

Fax: (717) 248-6447

Installation and testing to factory specifications shall be performed by factory authorized personnel for proper operation in

accordance with all of the latest National Fire Protection Association (NFPA), Underwriters Laboratories (UL), National Electrical Code

(NEC), local, state, county, district and/or other applicable building and fire standards, guidelines, regulations and codes including,

but not limited to, all appendices and amendments and the requirements of the local authority having jurisdiction (AHJ).

Page 2

GENERAL DESCRIPTION

The Fire Sentinel Floor Reset is a factory installed option on the

FSXP-FLR, FSXPBB-FLR and FSXPBBVB-FLR Release Devices.

The reset Mechanism enhances the standard releasing device by

providing a captured end link, which is easily reset from ground

level after a door release by means of a push-pull cable assembly.

The reset mechanism has been designed for use with the Grifco

fire door hoist, and is ideally suited for use on all doors and

shutters requiring frequent testing.

NOTE: This addendum serves as a supplement to the Fire Sentinel

release device manual. Review all installation instructions,

procedures, cautions and warnings contained within this

addendum as well as the unit installation manual prior to

installing and/or servicing this product. As with all release device

systems, maximum fire protection is provided when installed in

accordance with factory specifications and used with fuse link

systems.

Test system regularly to assure proper operation.

INSTALLATION INSTRUCTIONS ADDENDUM

Installation procedures, and door manufacturer instructions, must

be followed to assure performance of the release device/reset

mechanism to factory standards. To be performed by factory

authorized personnel only.

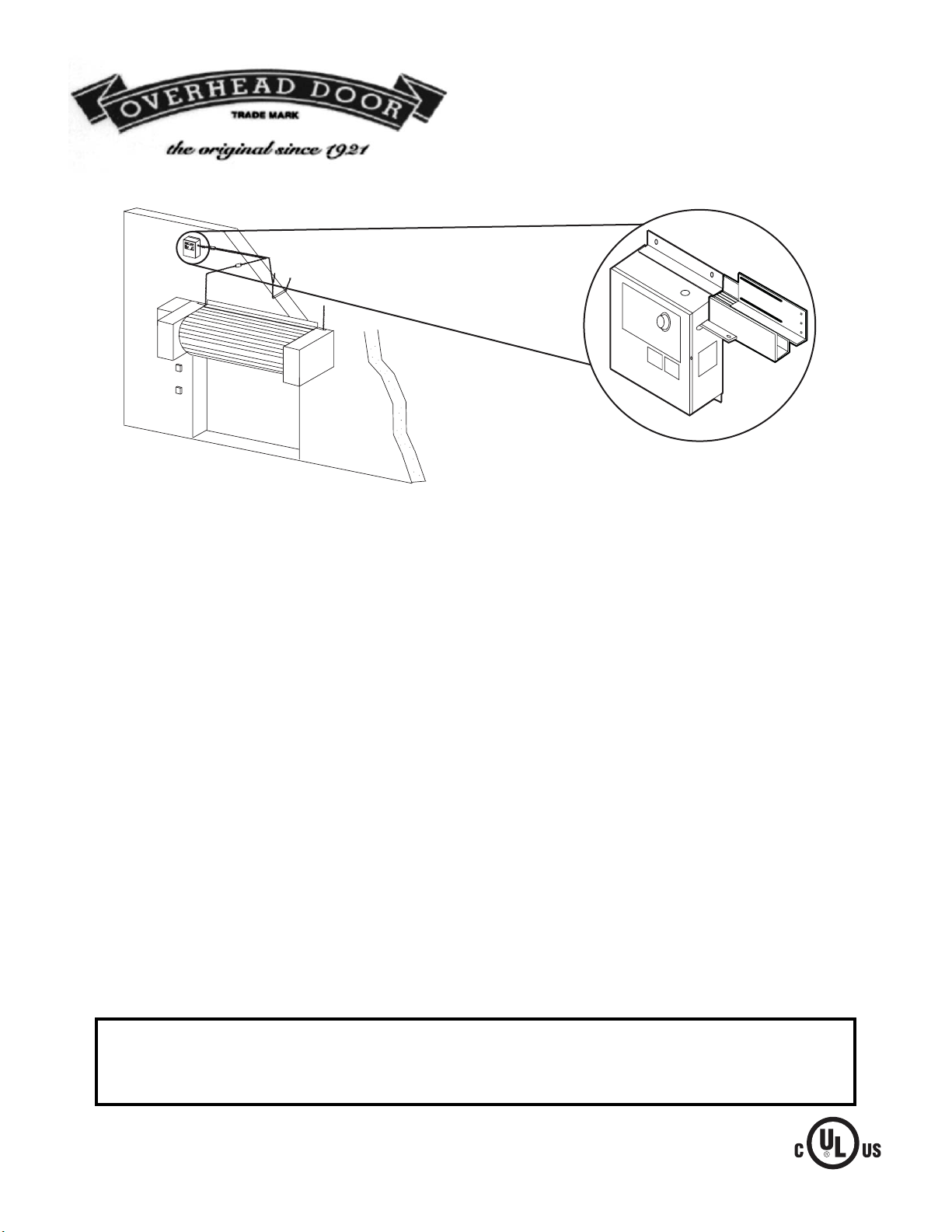

MOUNTING PROCEDURE (Figure 1)

1. The release device shall be mounted on a vertical surface with

chain end link exiting side of enclosure. The unit may be

rotated 90 degrees CW for a direct vertical pull.

2. Secure the release device enclosure with fastener (#10 is the

minimum size recommended). If installing in masonry, use

concrete anchors (not provided).

3. Release device and associated hardware [sash chain or 1/16

cable, eyebolts, fuse links (Do not install this unit without fuse

links), turnbuckles] shall be installed as per door

manufacturers recommendations (Figure 1). End link direction

of pull should be perpendicular to the enclosure side. An

eyebolt installed at a distance of 18" to 24" from the release

device should adequately redirect sash chain.

4. Connect fuse links, sash chain, S-hooks and turnbuckles as

required. Remove sash chain slack by adjusting turnbuckle.

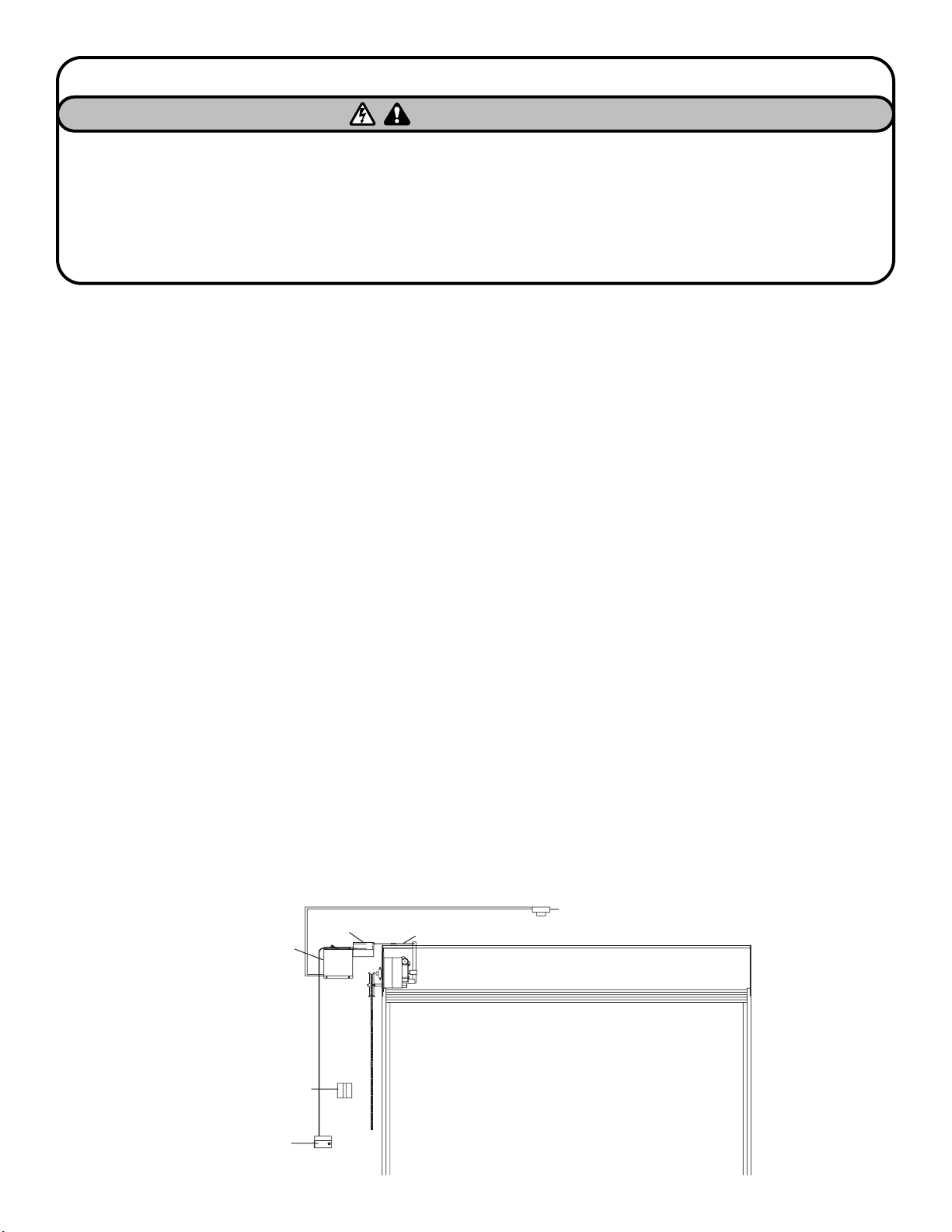

RESET CABLE MOUNTING PROCEDURE (Figure 2)

1. Reset cable mounting box should be mounted with minimum

#6 size fastening screws/bolts for surfaces other than masonry.

For masonry applications use 1/4" or greater anchors or studs

as required for proper mounting strength.

2. Insert cable through knockout and secure with 9/16" jam nut.

3. Make sure release device/reset is in released position

(Figure 3) and cable is fully pushed in with reset handle seated

the against jam nut. Cut cable to length 1-1/4" of cable through

end link slot. Do not exceed a 9" bend radius on 1 x 19 strand

cable. When using solid cable, refer to manufacturer specified

bend radius restrictions. Install wire stop a maximum of 1"

from end of cable. Secure cable at 36" maximum spacing using

suitable 3/16" cable clip or clamp (Figure 3).

NOTE: Actual configuration may differ. This unit may be rotated

90° CW for vertical pull. See door manufacturer recommendations

and NFPA 80 for use of this product with specific door.

TYPICAL INSTALLATION

Releasing Device

with Reset Mechanism

End Link

Smoke Detector

Fuse Link, Sash Chain or Cable

Grifco Fire Door Hoist

Optional Signal Appliance

Tamper Resistant

Reset Handle

FIGURE 1

IMPORTANT INSTALLATION INSTRUCTIONS

To reduce the risk of SEVERE INJURY or DEATH:

WARNING

WARNING

WARNING

1. READ AND FOLLOW ALL INSTALLATION WARNINGS AND

INSTRUCTIONS.

2. NEVER connect release device to power source until

instructed to do so.

3. DO NOT install this device on a motorized door without an

electric safety edge.

4. DO NOT use this device without fuse links installed.

5. Concrete anchors MUST be used if mounting release device

into masonry.

6. DO NOT exceed maximum pull rating of 40 lbs. on

releasing device.

Page 3

RELEASING DEVICE TEST / RESET PROCEDURES

NOTE: To be performed by factory authorized personnel only.

Regular testing of all release device equipment is recommended.

Testing shall be witnessed for proper operation.

The following test/reset procedure applies to all release devices

using the reset mechanism. These procedures are supplemental to

test procedures provided in the release device manual. Testing

affects normal operation of central alarm system when connected

to release device. Testing and normal operation can only be

accomplished with power applied to unit. When power is applied

to unit under test, the “Power” LED (red) will be lit on the release

device.

NOTE: Clear fire door opening and prohibit all traffic through

opening while testing the system.

Door must be in open position with power applied to unit to

begin testing.

1. Depress and continue to hold test button on side of release

device (Figure 1). After factory adjusted 10 second alarm

verification (10 sec. delay) device will release door (Figure 3a).

Release test button.

2. Reset and release device by pulling reset cable in a downward

until end link fully engages release device (Figure 3b). Push

reset cable inward until handle rests against jam nut or set

position (Figure 3c).

3. Using a chain hoist, raise door to fully open position.

4. Follow steps 2 and 3 for resetting of release device. See the

release device manual for complete release device test

procedures.

After completing tests, make sure door is in normally open

position and all power required for normal operation is restored.

NOTE: Testing of release devices is independent of, and shall in

no way be interpreted as an alternative method of, testing fire

alarm systems, motorized operator and/or any other system

component employed on the fire door or counter fire door

installation.

FIGURE 3a

FIGURE 2

FIGURE 3b

FIGURE 3c

9" minimum

bend radius

SS90 A/B

7.5x8 x4

(H x w x D)

Wire Stop:

1" maximum

from cable end

See door manufacturer

instructions and NFPA 80

for proper cable and

fusible link configuration.

3/16" conduit clip

or conduit clamp

Page 4

01-30632 © 2006, The Chamberlain Group, Inc.

Issue Date 8/18/2006 All Rights Reserved

WARRANTY SERVICE PROCEDURE

Contact technical support at the number provided below for assistance in determining possible product failure. Installer shall provide

the following information when contacting technical support:

• Serial Number, found in the following locations

• Individual unit shipping box

• Cover of installation manual

• On unit

• Name of Distributor who supplied product

• Name of End User and/or installation company if different from Distributor

• Detailed description of product non conformity

To receive a Return Goods Authorization (RGA) and shipping address for a product believed to be defective, all of the above information

shall be required. Products returned without a valid RGA shall be refused receipt. If provided, reference troubleshooting guide that

accompanies product prior to requesting an RGA.

Contact Information

Technical Support: 1-800-929-2553

Loading...

Loading...