Page 1

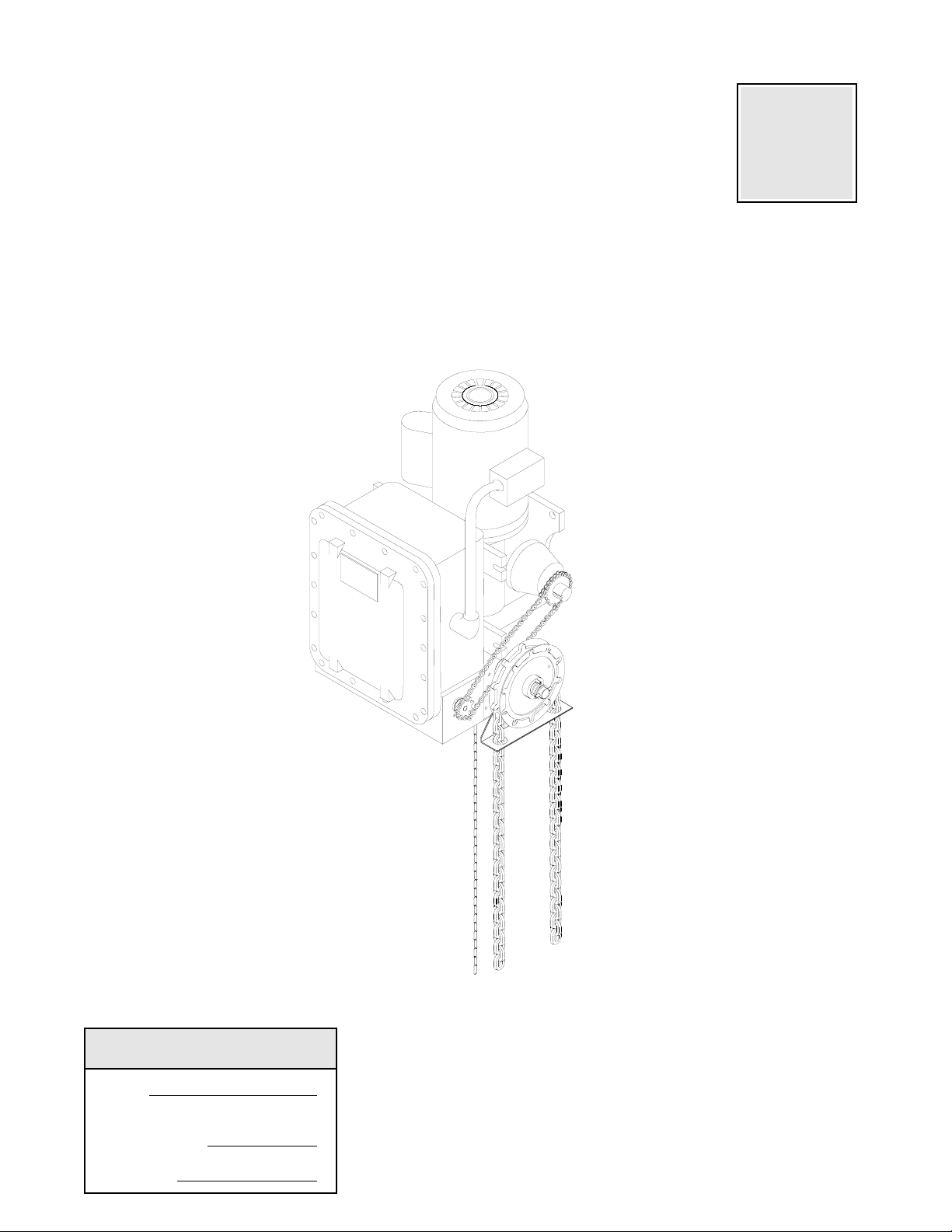

OWNER'S MANUAL

HAZARDOUS (NEMA 7/9)

INDUSTRIAL DUTY DOOR OPERATOR

Serial #

(located on electrical box cover)

Installation Date

Wiring Type

2 YEAR WARRANTY

NOT FOR RESIDENTIAL USE

FACTORY SET

C2 Wiring

See page 8 for

other wiring

configurations

Page 2

2

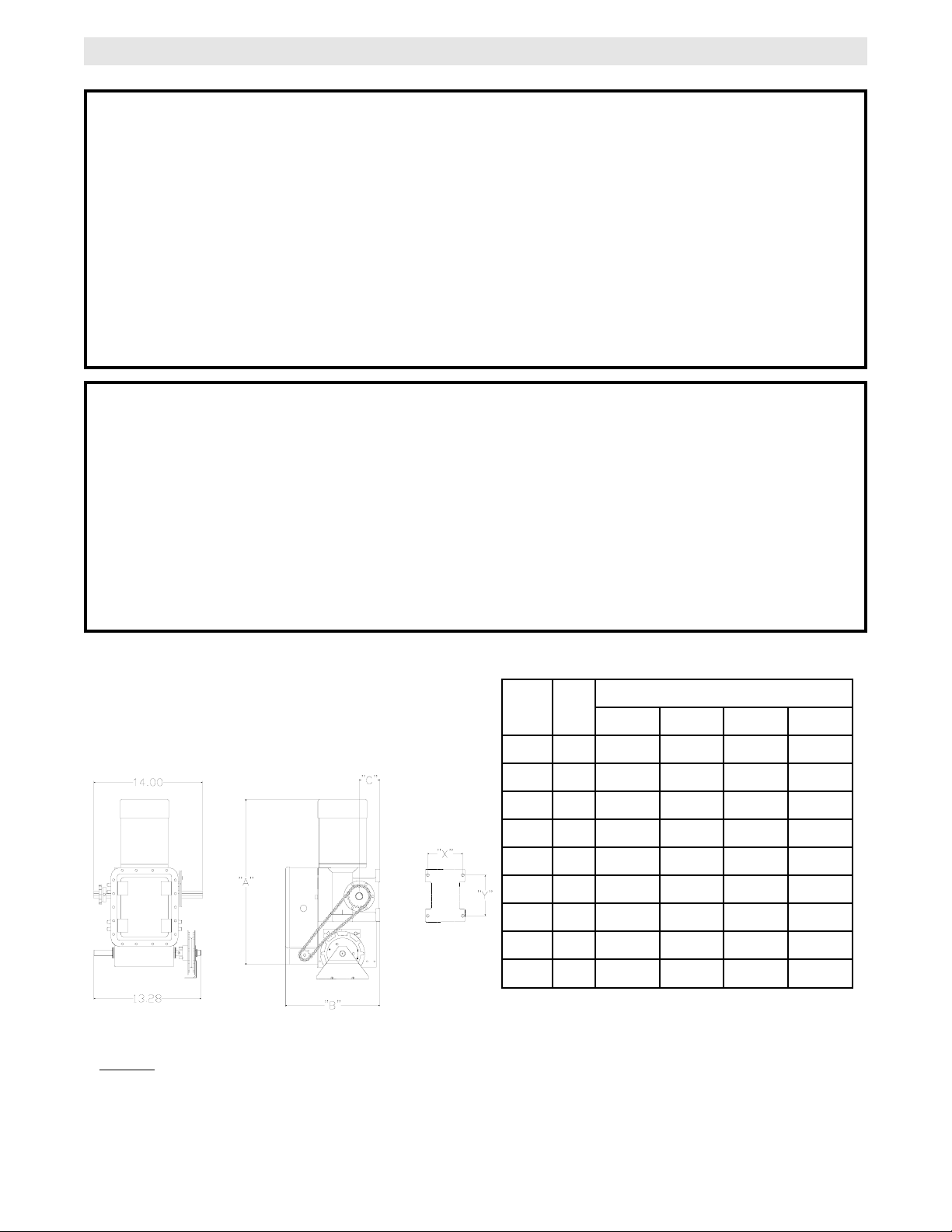

SPECIFICATIONS

WEIGHTS AND DIMENSIONS

HANGING WEIGHT:.........207 LBS.

A

11-1/2

12-1/2

12-3/4

12-3/4

11

11

12

12-1/2

12-3/4

B

25-3/4

26-3/4

27

27

25-1/4

25-1/4

26-1/4

26-3/4

27

C

12-63/64

12-63/64

12-63/64

13-63/64

12-63/64

12-63/64

12-63/64

13-63/64

13-63/64

D

3

3

3

3-1/2

3

3

3

3-1/2

3-1/2

1/2

3/4

1

1-1/2

1/2

3/4

1

1-1/2

2

1

1

1

1

3

3

3

3

3

HP

DIMENSIONS

NOTES:

1) Output Shaft with 1” x 1/4” Key.

2) MT’G CENTERS: X = 4-3/4”; Y = 5-1/2”

3) Hand Chain Wheel extends 1-5/8” beyond operator in vertical mounting position as shown.

MECHANICAL

DRIVE REDUCTION:.............45:1 Reduction

Heavy duty bronze worm

gear reducer

OUTPUT SHAFT SPEED:.....43 R.P.M.

DOOR SPEED:......................4 - 10" per sec.

depending on door

BRAKE: .................................Dynamic brake

HOIST WHEEL:.....................Standard mounting on

left or right side

SAFETY

DISCONNECT:.............Floor level chain hoist with elect-

rical interlock for emergency manual door operation

REVERSING EDGE:.....(Optional) Electric or pneumatic

sensing device attached to the bottom edge of door.

A REVERSING EDGE IS STRONGLY

RECOMMENDED FOR

ALL

COMMERCIAL

OPERATOR INSTALLATIONS.

REQUIRED

WHEN

THE 3 BUTTON CONTROL STATION IS OUT OF

SIGHT OF DOOR OR ANY OTHER CONTROL

(AUTOMATIC OR MANUAL) IS USED.

MOTOR

TYPE: .................................Continuous duty

HORSEPOWER:.................1/2, 3/4, 1 & 1-1/2 Hp

Single or Three phase

2 HP Three phase

SPEED:...............................1725 RPM

VOLTAGE: ..........................115, 220, 230 Single phase

230, 460, 575 Three phase

CURRENT: .........................See motor nameplate

ELECTRICAL

TRANSFORMER:.............24VAC

CONTROL STATION: ......NEMA 1 three button station.

OPEN/CLOSE/STOP

WIRING TYPE:.................C2 (Standard)

Momentary contact to OPEN/CLOSE/STOP plus wiring

for sensing device to reverse and auxiliary devices to

open and close with open override.

(Other types available. See chart, Pg. 8)

LIMIT ADJUST:................Linear driven, fully

adjustable screw type cams. Adjustable to 30 feet.

PHASE

Page 3

3

TO AVOID DAMAGE TO DOOR AND OPERATOR,

MAKE ALL DOOR LOCKS INOPERATIVE. SECURE

LOCK(S) IN "OPEN" POSITION.

IF THE DOOR LOCK NEEDS TO REMAIN

FUNCTIONAL, INSTALL AN INTERLOCK SWITCH.

DO NOT CONNECT ELECTRIC POWER UNTIL

INSTRUCTED TO DO SO.

KEEP DOOR BALANCED. STICKING OR BINDING

DOORS MUST BE REPAIRED. DOORS, DOOR

SPRINGS, CABLES, PULLEYS, BRACKETS AND

THEIR HARDWARE MAY BE UNDER EXTREME

TENSION AND CAN CAUSE SERIOUS PERSONAL

INJURY. CALL A PROFESSIONAL DOOR

SERVICEMAN TO MOVE OR ADJUST DOOR

SPRINGS OR HARDWARE.

WARNING

CAUTION

WARNING

WARNING

WARNING

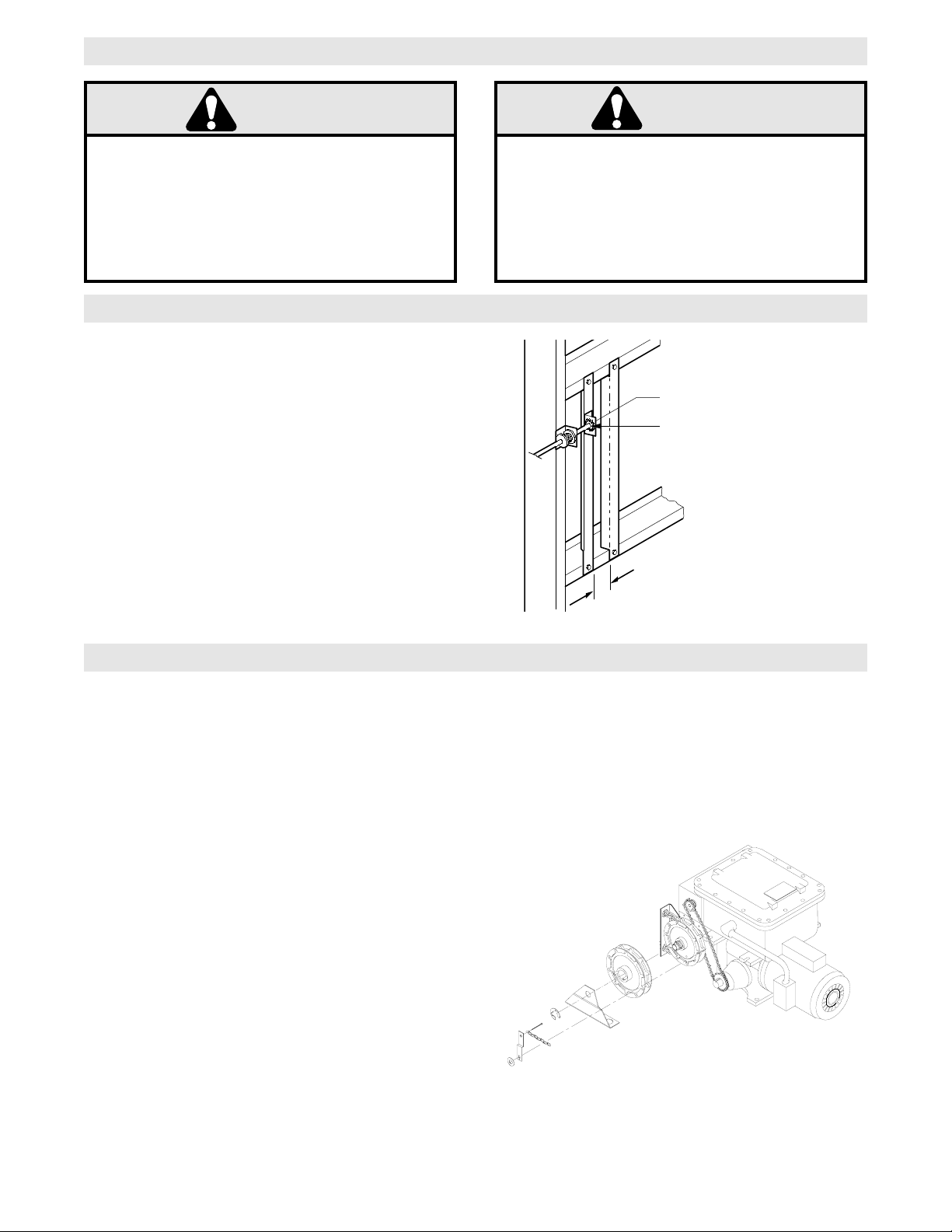

SITE PREPARATIONS

It is imperative that the wall or mounting surface

provide adequate support for the operator.

This surface must:

a) Be rigid to prevent play between operator and

door shaft.

b) Provide a level base.

c) Permit the operator to be fastened securely and

with the drive shaft parallel to the door shaft.

The safety and wear of the operator will be adversely

affected if any of the above requirements are not met.

For metal buildings, fasten 2” x 2” x 3/16” (or larger)

angle iron frames to the building purlins. Retain 51/2” between frames. See Figure 1.

OPERATOR PREPARATION

IMPORTANT SAFETY NOTES

5-1/2”

The N9GH operator may be mounted on either the right (standard) or left side of door, and in either a vertical

(standard) or horizontal mounting position. Refer to the steps below if you require the hand chain and/or

disconnect chain to be on the opposite side of the operator; Or if the operator is being mounted in a horizontal

position.

Hand Chain Right/Left Conversion

Remove the two snap rings (1 pc. outer, 1 pc inner)

on hand chain shaft assembly. Position roll-pin to fit

through cutout in frame and slide complete shaft

assembly through housing and bevel gear. Insert

shaft assembly on opposite side of housing, and

replace bevel gear, bearing, hardware, and snap rings

on the opposite side of shaft in the same manner.

Disconnect Lever Right/Left Conversion

Remove cotter pins on the ends of the disconnect

shaft (square shaft), move the disconnect lever arm to

the opposite side, and replace the cotter pins. Be

sure to keep two(2) 12ga. washers on the side without

the lever arm.

Horizontal Mounting Conversion

Remove cotter pins on the ends of the disconnect

shaft (square shaft), and remove lever. Replace lever

using square hole on opposite end of lever.

Reposition sash chain to opposite end of lever also.

Replace cotterpins.

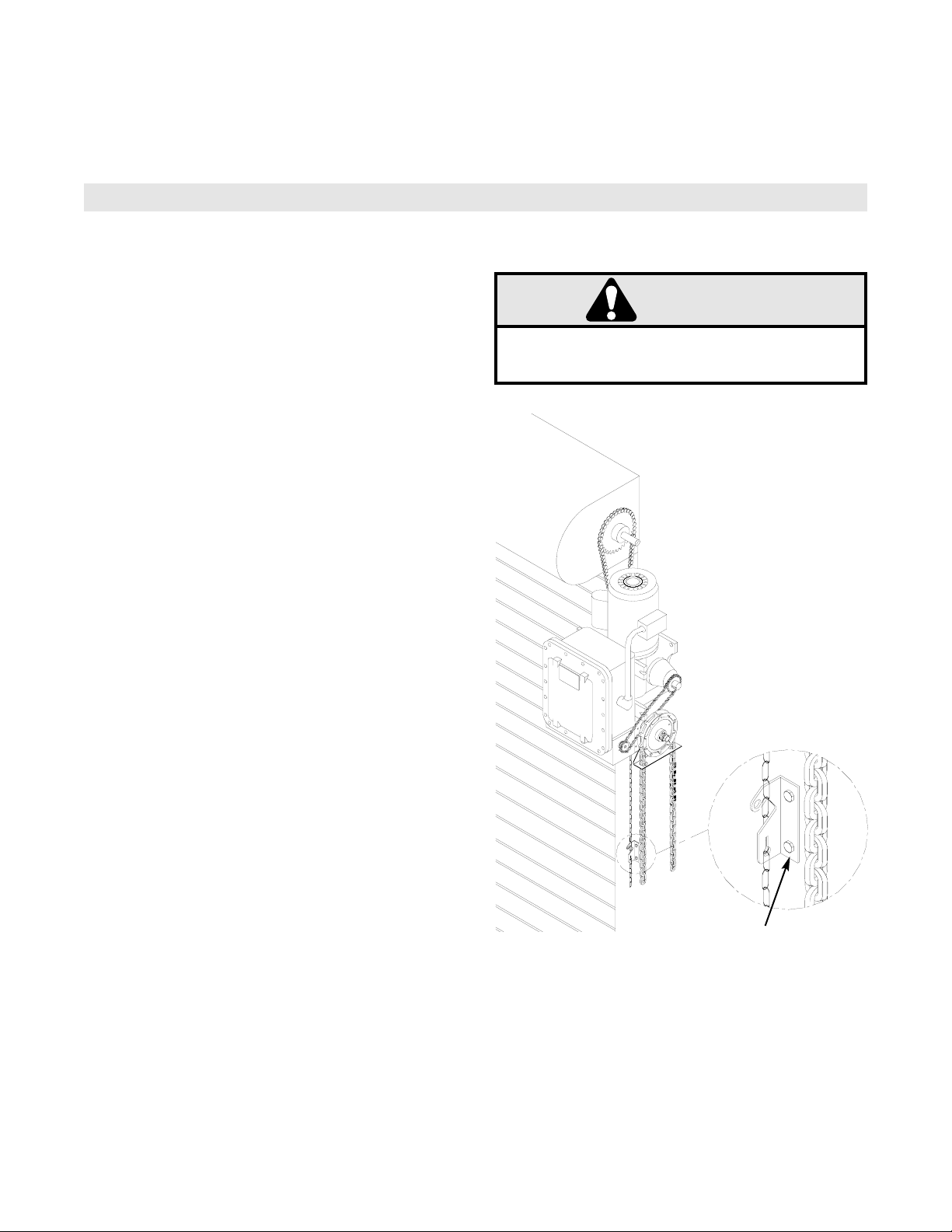

FIGURE 2

CAUTION

WARNING

Shaft Support Bracket

with Bearing (Not Supplied)

Door Sprocket

2-1/4"

FIGURE 1

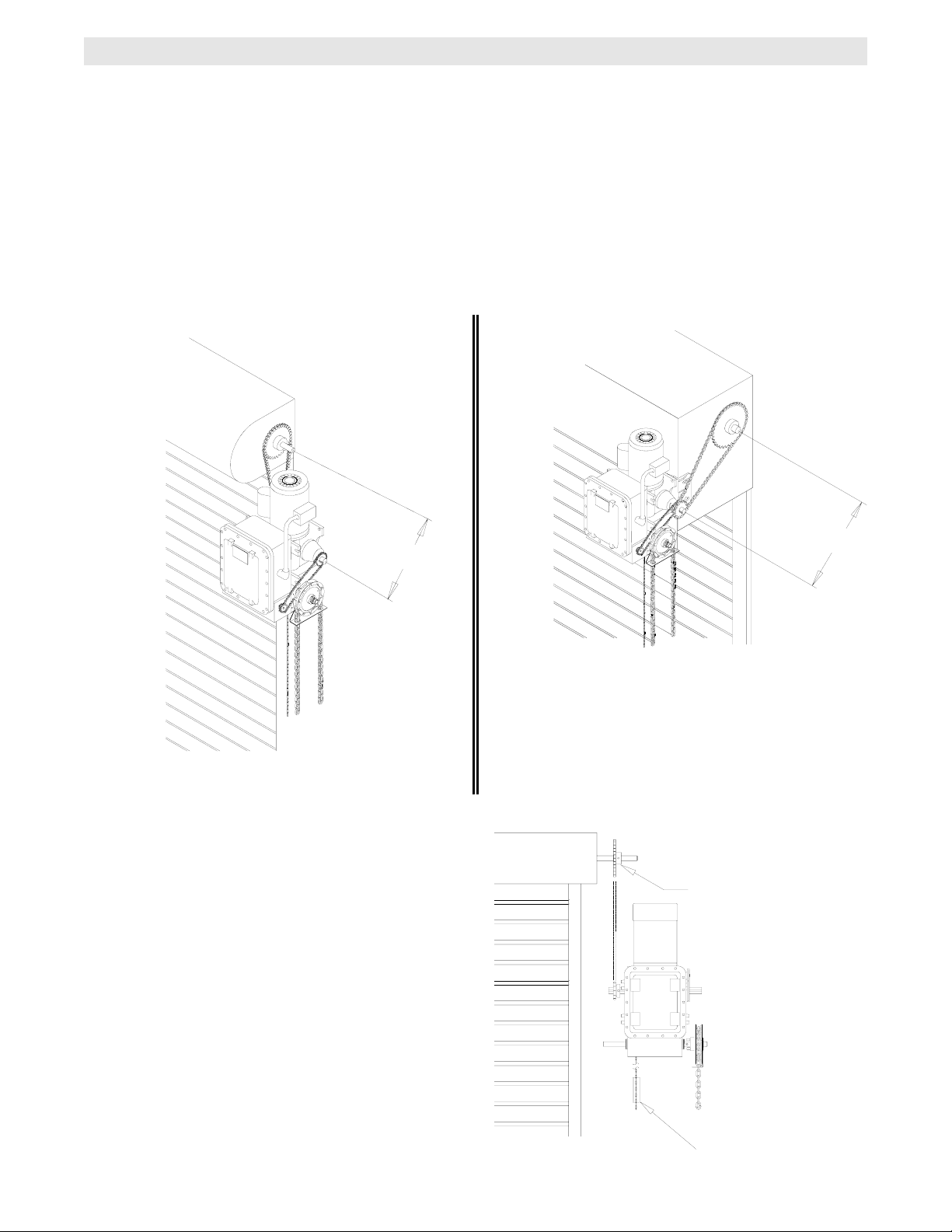

Page 4

4

1a. Wall Mounting

The operator should generally be installed below

the door shaft, and as close to the door as

possible. The optimum distance between the door

shaft and operator drive shaft is between 12” - 15”.

Refer to Figure 3.

OPERATOR MOUNTING

IMPORTANT:

The shelf or bracket must

provide adequate support, prevent play

between operator and door shaft, and permit

operator to be fastened securely and with the

drive shaft parallel to the door shaft.

1b. Bracket or Shelf Mounting

The operator may be mounted either above or

below the door shaft. The optimum distance

between the door shaft and operator drive shaft

is between 12” - 15”. Refer to Figure 4.

1c. Place door sprocket on the door shaft. Do not

insert the key at this time.

2. Place drive sprocket on the appropriate side of

the operator. Do not insert the key at this time.

3. Wrap drive chain around door sprocket and join

roller chain ends together with master link.

4. Raise operator to approximate mounting position

and position chain over operator sprocket.

5. Raise or lower operator until the chain is taut (not

tight). Make sure the operator output shaft is

parallel to door shaft and sprockets are aligned.

When in position, secure the operator to wall or

mounting bracket.

6. Align sprockets and secure, (see Figure 5).

FIGURE 4

FIGURE 3

Before your operator is installed, be sure the door has been properly aligned and is working smoothly. The

operator may be wall mounted or mounted on a bracket or shelf. If necessary, refer to the operator preparations

on page 3. Refer to the illustration and instructions below that suits your application.

Be sure door

sprocket is properly

aligned with drive

before securing to

the shaft.

Chain Keeper

FIGURE 5

Optimum Distance

12 - 15”

Optimum Distance

12 - 15”

Page 5

These operators are equipped with a manual hoist. An

electrical interlock will disable the electrical controls

when the hoist is used.

To operate the hoist:

1. Pull the disconnect chain (small chain) to engage

the hoist mechanism. The disconnect chain may be

locked in position by slipping the end through the

keyhole of the chain keeper mounted on the wall.

2. Operate the door in the desired direction by pulling

on one side or the other of the continuous loop hoist

chain (large chain).

3. The disconnect chain must be released from the

chain keeper before the door will operate again

electrically.

5

7. Install Hand Chain

Place hand chain around hand chain wheel. Be

sure to pass it through both openings in the chain

guide. Remove enough links so chain hangs

approximately two feet above the floor

EMERGENCY MANUAL OPERATION

This operator has provisions for manually operating the door in case of emergency or power failure. Refer to the

appropriate instructions below for your model operator.

Model N9GH

Chain Keeper

(with pad locking provisions)

8. Mount Chain Keeper / Keyhole Bracket

Using suitable hardware mount the chain keeper

approximately 4 feet above the floor, near the free

hanging chain. Remove disconnect sash chain

from bag and place the end through the keyhole

in the the chain keeper. Remove excess links if

necessary.

TURN OFF POWER TO THE OPERATOR BEFORE

MANUALLY OPERATING YOUR DOOR.

WARNING

CAUTION

WARNING

WARNING

Chain Keeper

CAUTION

Page 6

6

TO AVOID SERIOUS PERSONAL INJURY OR DEATH

FROM ELECTROCUTION, DISCONNECT ELECTRIC

POWER BEFORE MANUALLY MOVING LIMIT NUTS.

WARNING

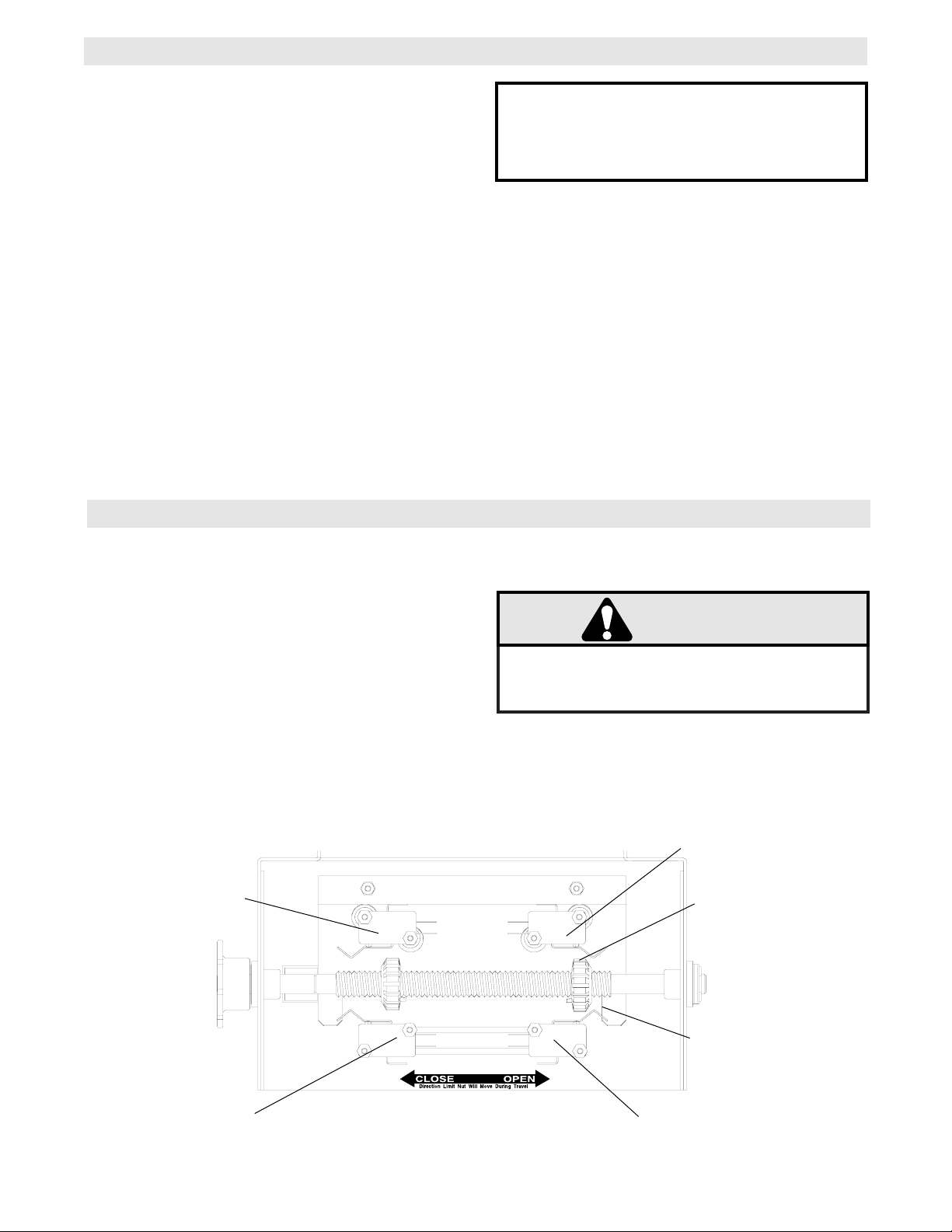

LIMIT SWITCH ADJUSTMENT

MAKE SURE THE LIMIT NUTS ARE POSITIONED BETWEEN THE LIMIT SWITCH ACTUATORS BEFORE

PROCEEDING WITH ADJUSTMENTS.

If other problems persist, call our toll-free number for

assistance - 1-800-528-2806.

1. To adjust limit nuts depress retaining plate to allow

nut to spin freely. After adjustment, release plate

and ensure it seats fully in slots of both nuts.

2. To increase door travel, spin nut away from

actuator. To decrease door travel, spin limit nut

toward actuator.

3. Adjust open limit nut so that door will stop in open

position with the bottom of the door even with top

of door opening.

4. Repeat Steps 1 and 2 for close cycle. Adjust close

limit nut so that actuator is engaged as door fully

seats at the floor.

Retaining Plate

CLOSE Limit Switch

SAFETY

(Aux. Close) Limit Switch

OPEN Limit Switch

Actuator

Aux. OPEN Limit Switch

SENSING EDGES

All types of sensing edges with an isolated normally

open (N.O.) output are compatible with your operator.

This includes pneumatic and electric edges. If your

door does not have a bottom sensing edge and you

wish to purchase one, contact the supplier of your

operator.

If not pre-installed by the door manufacturer, mount

the sensing edge on the door according to the

instructions provided with the edge. The sensing

edge may be electrically connected by either coiled

cord or take-up reel. Refer to the steps below.

Important Notes:

a) Proceed with Limit Switch Adjustments before

making any sensing edge wiring connections to

operator as described below.

b) Electrician must hardwire the junction box to the

operator electrical box in accordance with local

codes.

ENTRAPMENT PROTECTION ACCESSORIES (OPTIONAL)

IT IS STRONGLY RECOMMENDED THAT A

SENSING EDGE OR OTHER ENTRAPMENT

PROTECTION DEVICE BE USED IN

CONJUNCTION WITH THIS OPERATOR.

WIRING:

For wiring of your sensing device to the operator,

refer to the wiring diagram supplied with your

operator. See field connection terminals identified

as Sensing Device or Safety Edge.

TAKE-UP REEL: Take-up reel should be installed

12" above the top of the door.

COIL CORD: Connect operator end of coil cord to

junction box (not supplied) fastened to the wall

approximately halfway up the door opening.

WARNING

Page 7

7

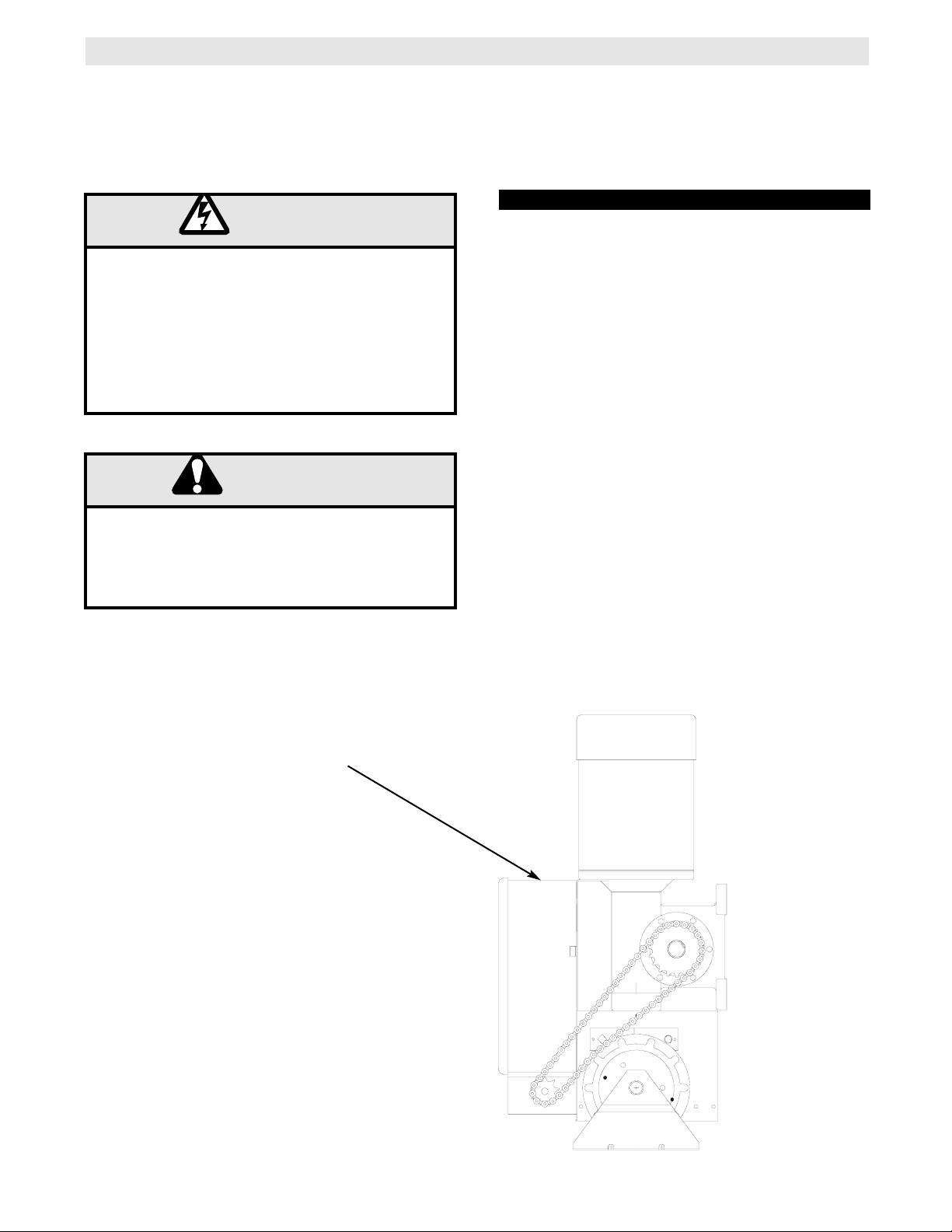

POWER WIRING CONNECTIONS

3/4-14 NPT FOR

POWER WIRING

CONDUIT ACCESS

POWER WIRING

1. Be sure that the power supply is of the correct

voltage, phase, frequency, and amperage to supply

the operator. Refer to the operator nameplate on the

cover.

2. Using the 3/4-14 NPT conduit access as shown

below, bring supply lines to the operator and connect

wires to the terminals indicated on the WIRING

CONNECTIONS DIAGRAM.

DO NOT TURN POWER ON UNTIL YOU HAVE

FINISHED MAKING ALL POWER AND CONTROL

WIRING CONNECTIONS AND HAVE COMPLETED

THE LIMIT SWITCH ADJUSTMENT PROCEDURE.

IMPORTANT: THIS UNIT MUST BE PROPERLY

GROUNDED. A GROUND SCREW IS SUPPLIED IN

THE ELECTRICAL BOX FOR CONNECTION OF

THE POWER SUPPLY GROUND WIRE. FAILURE

TO PROPERLY GROUND THIS UNIT COULD

RESULT IN ELECTRIC SHOCK AND SERIOUS

INJURY.

Remove the cover from the electrical enclosure. Inside this enclosure you will find the wiring diagram(s)

for your unit. Refer to the diagram (glued on the inside of the cover) for all connections described below.

If this diagram is missing, call the number on the back of this manual. DO NOT INSTALL ANY WIRING OR

ATTEMPT TO RUN THIS OPERATOR WITHOUT CONSULTING THE WIRING DIAGRAM.

DISCONNECT POWER AT THE FUSE BOX BEFORE

PROCEEDING.

OPERATOR MUST BE PROPERLY GROUNDED AND

PERMANENTLY WIRED IN ACCORDANCE WITH

LOCAL ELECTRICAL CODES. NOTE: THE

OPERATOR SHOULD BE ON A SEPARATE FUSED

LINE OF ADEQUATE CAPACITY.

ALL ELECTRICAL CONNECTIONS MUST BE MADE

BY A QUALIFIED INDIVIDUAL.

WARNING

TO AVOID DAMAGE TO DOOR AND OPERATOR,

MAKE ALL DOOR LOCKS INOPERATIVE. SECURE

LOCK(S) IN "OPEN" POSITION.

IF THE DOOR LOCK NEEDS TO REMAIN

FUNCTIONAL, INSTALL AN INTERLOCK SWITCH.

WARNING

WARNING

Page 8

8

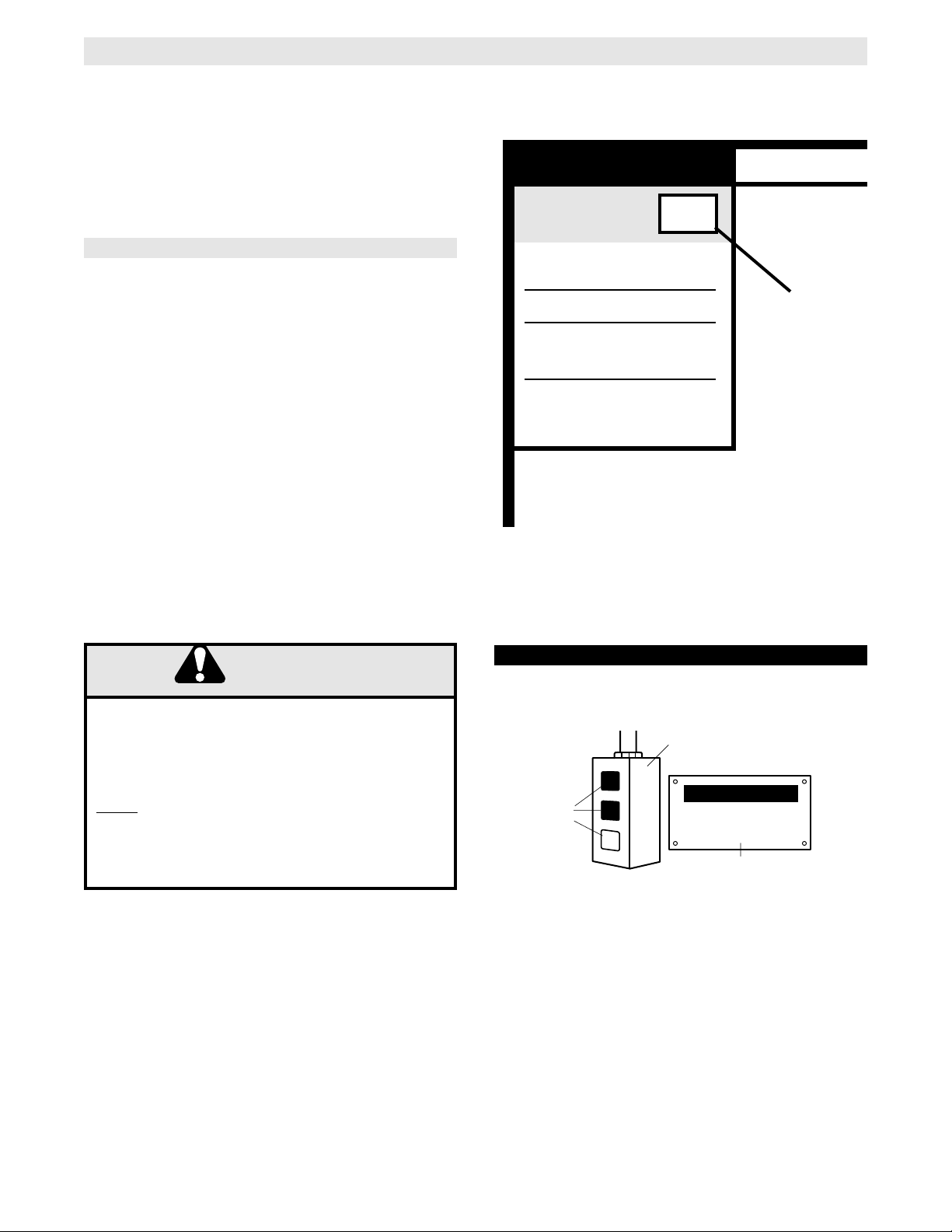

CONTROL WIRING

LOCATING THE CONTROL STATION

All operators are supplied with some type of control station. Generally a three button station

(OPEN/CLOSE/STOP) is provided. A two-position key switch or control station (OPEN/CLOSE) may be added or

substituted when requested at the time of order. Mount the control station near the door.

WARNING

INSTALL THE CONTROL STATION WHERE THE

DOOR IS VISIBLE, BUT AWAY FROM THE DOOR AND

ITS HARDWARE. IF CONTROL STATION CANNOT BE

INSTALLED WHERE DOOR IS VISIBLE, OR IF ANY

DEVICE OTHER THAN THE CONTROL STATION IS

USED TO A CTIVATE THE DOOR,

A REVERSING EDGE

MUST

BE INSTALLED ON THE BOTTOM OF THE

DOOR.

FAILURE TO INSTALL A REVERSING EDGE

UNDER THESE CIRCUMSTANCES MAY RESULT IN

SERIOUS INJURY OR DEATH TO PERSONS

TRAPPED BENEATH THE DOOR.

CLOSE

IMPORTANT: Mount WARNING NOTICE beside or

below the push button station.

MOUNT WARNING NOTICE

DETERMINE WIRING TYPE

Refer to the wiring diagram located on the inside cover the electrical box to determine the type of control wiring.

Wiring Diagram label on inside cover

of electrical box

Wiring

Type

SPECIAL CONTROL WIRING

If your operator was shipped from the factory with

non-standard control wiring or with optional

accessories that require addition instructions, refer to

the wiring diagram(s) indicated in the special control

wiring data box. When a replacement wiring diagram

is present, wiring diagrams in this manual will not

apply. Refer only to the replacement wiring diagram

for all connections.

IMPORTANT NOTE: If your wiring diagram is

missing, or you are unsure of the wiring type for

your operator, contact the customer service

department @ 1-800-528-2806.

Standard C2 Wiring

Standard operators are shipped from the factory with

jumper set for C2 wiring, which requires constant

pressure on button to close the door.

Additional Access Control Equipment

Locate any additional access control equipment as desired (but so that the door will be in clear sight of the person

operating the equipment), and connect to the terminal block in the electrical enclosure as shown on the FIELD

WIRING CONNECTIONS diagram. Any control with a normally (N.O.) isolated output contact may be connected

in parallel with the OPEN button. More than one device may be connected in this manner. Use 16 gauge wire or

larger for all controls. DO NOT USE THE CONTROL CIRCUIT TRANSFORMER (24VAC) IN THE OPERATOR

TO POWER ANY ACCESS CONTROL EQUIPMENT.

External Interlock Switch

The operator has a terminal connection for an external interlock switch. This switch must be a normally closed

(N.C.) two-wire device with a contact rating of at least 3 amps @ 24VAC. When such a switch is connected as

shown on the FIELD WIRING CONNECTIONS diagram, the control circuit will be disabled when the switch is

actuated, thereby preventing electrical operation of the door from the control devices.

SPECIAL CONTROL

WIRING DATA

This Operator has

WIRI

Control Wiring.

SUPPLEMENTAL WIRING DIAGRAM(S)

REPLACEMENT WIRING DIAGRAM

Note: Supplemental Wiring Diagrams are

to be used in addition to 1742-1.

Replacement Wiring Diagram is to be used

in place of 1742-1.

WARNING

Control Station

OPEN

Push

Buttons

C

STOP

LO

SE

WARNING

TO PREVENT ENTRAPMENT

DO NOT START DOOR DOWNWARD

UNLESS DOORWAY IS CLEAR

WARNING Notice

Page 9

9

TEST THE SYSTEM

Turn on power. Test all controls and safety devices to

make sure they are working properly. It will be

necessary to refer back to page 6 for fine adjustment

of the limit switches.

IMPORTANT NOTES:

Do not leave operator power on unless all safety

and entrapment protection devices have been

tested and are working properly.

Be sure you have read and understand all Safety

Instructions included in this manual.

Be sure the owner or person(s) responsible for

operation of the door have read and understand

the Safety Instructions, know how to electrically

operate the door in a safe manner, and know how

to use the manual disconnect operation of the

door operating system.

WARNING

DO NOT PLACE HANDS OR TOOLS IN OR NEAR

THE OPERATOR WHEN THE POWER IS ON OR

WHEN TESTING CONTROL OR SAFETY

DEVICES. ALWAYS DISCONNECT POWER

BEFORE SERVICING OR ADJUSTING THE

OPERATOR.

The operator has been pre-wired to accept

connection of a reversing edge device. Connect the

normally open contacts to terminals T10 and T11 on

the low voltage terminal block. A cut-off switch will deactivate the safety device during the last few inches of

the door's downward travel.

IF CONTROL STATION CANNOT BE INSTALLED WHERE

DOOR IS VISIBLE, OR IF ANY DEVICE OTHER THAN

THE CONTROL STATION IS USED TO ACTIVATE THE

DOOR,

A REVERSING EDGE MUST BE INSTALLED ON

THE BOTTOM OF THE DOOR.

FAILURE TO INSTALL A

REVERSING EDGE UNDER THESE CIRCUMSTANCES

MAY RESULT IN SERIOUS PERSONAL INJURY OR

DEA TH T O PERSONS TRAPPED BENEATH THE DOOR.

CONNECT REVERSING EDGE DEVICE (OPTIONAL)

NOTICE:

This equipment has been tested and found to comply with the limits for a Class A digital

device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference when the equipment is operated in a

commercial environment. This equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in accordance with the instruction

manual, may cause harmful interference to radio communications. Operation of this

equipment in a residential area is likely to cause harmful interference, in which case the

user will be required to correct the interference at his own expense.

WARNING

WARNING

WARNING

Page 10

10

HOW TO ORDER REPAIR PARTS

OUR LARGE SERVICE ORGANIZATION

SPANS AMERICA

INSTALLATION AND SERVICE INFORMATION

ARE AVAILABLE 6 DAYS A WEEK

CALL OUR TOLL FREE NUMBER - 1-800-528-2806

HOURS 7:00 TO 3:30 p.m. (Mountain Std. Time)

MONDAY Through SATURDAY

WHEN ORDERING REPAIR PARTS

PLEASE SUPPLY THE FOLLOWING INFORMATION:

PART NUMBER DESCRIPTION MODEL NUMBER

ADDRESS ORDER TO:

THE CHAMBERLAIN GROUP, INC.

Electronic Parts & Service Dept.

2301 N. Forbes Blvd., Suite 104

Tucson, AZ 85745

MAINTENANCE SCHEDULE

Use SAE 30 Oil (Never use grease or silicone spray).

T Repeat ALL procedures.

Do not lubricate motor. Motor bearings are rated for continuous operation.

Inspect and service whenever a malfunction is observed or suspected.

CA UTION: BEFORE SERVICING, AL WAYS DISCONNECT OPERA T OR FR OM POWER SUPPLY.

Check at the intervals listed in the following chart.

EVERY EVERY EVERY

ITEM PROCEDURE 3 MONTHS 6 MONTHS 12 MONTHS

Drive Chain Check for excessive slack.

Check & adjust as required.

Lubricate.*

z T

Sprockets Check set screw tightness z T

Fasteners Check & tighten as required z T

Manual Disconnect Check & Operate z T

Bearings & Shafts Check for wear & lubricate z T

Page 11

11

AVAILABLE ACCESSORIES

Available Accessories for N9GH Operators

Part Number

PUSH BUTTON CONTROL STATION

Style

Description

02 101

Indoor Surface Mount (NEMA 1) Single Button, Steel Enclosure

02 102

Indoor Surface Mount (NEMA 1) Two Button, Steel Enclosure

02 103

Indoor Surface Mount (NEMA 1) Three Button, Steel Enclosure

02 103 L

Indoor Surface Mount (NEMA 1) Three Button, With Maintenance Alert System

02 106

Indoor Flush Mount (NEMA 1) Single Button, Stainless Faceplate

02 107

Indoor Flush Mount (NEMA 1) Two Button, Stainless Faceplate

02 108

Indoor Flush Mount (NEMA 1) Three Button, Stainless Faceplate

02 401

Outdoor Surface Mount (NEMA 4/12) Single Button, Die Cast Enclosure

02 402

Outdoor Surface Mount (NEMA 4/12) Two Button, Die Cast Enclosure

02 403

Outdoor Surface Mount (NEMA 4/12) Three Button, Die Cast Enclosure

02 403 P

Outdoor Surface Mount (NEMA 4/12) Three Button, Polycarbonate Enclosure

02 406

Outdoor Surface Mount (NEMA 4/12) Three Button With Key, Die Cast Enclosure

02 703

Hazdardous Area (NEMA 7/9) Three Button, Die Cast Enclosure

PULL-SWITCH CONTROLS

02 111

Indoor Overhead Mount (NEMA 1) Single Pull-Switch, Steel Enclosure

02 411

Outdoor Overhead Mount (NEMA 4/12) Single Pull-Switch, Steel Enclosure

02 711

Hazdardous Area Overhead Mount (NEMA 7/9) Single Pull-Switch, Die Cast Enclosure

KEY CONTROL STATIONS

02 109

Indoor Flush Mount (NEMA 1), Tamperproof Two Position, Steel/Aluminum Enclosure

02 109 B

Indoor Flush Mount (NEMA 1), Tamperproof Two Position, Steel/Aluminum Enclosure

02 109 U

Indoor Flush Mount (NEMA 1), Tamperproof Two Position, Steel/Aluminum Enclosure

02 109 C

Indoor Flush Mount (NEMA 1), Tamperproof Two Position, Steel/Aluminum Enclosure

02 110

Indoor Flush Mount (NEMA 1), Tamperproof Two Position With Stop Button, Steel/Aluminum Enclosure

02 110 B

Indoor Flush Mount (NEMA 1), Tamperproof Two Position With Stop Button, Steel/Aluminum Enclosure

02 110 U

Indoor Flush Mount (NEMA 1), Tamperproof Two Position With Stop Button, Steel/Aluminum Enclosure

02 110 C

Indoor Flush Mount (NEMA 1), Tamperproof Two Position With Stop Button, Steel/Aluminum Enclosure

02 409

Outdoor Surface Mount (NEMA 4/12), Tamperproof Two Position, Die Cast Enclosure

02 409 B

Outdoor Surface Mount (NEMA 4/12), Tamperproof Two Position, Die Cast Enclosure

02 409 U

Outdoor Surface Mount (NEMA 4/12), Tamperproof Two Position, Die Cast Enclosure

02 409 C

Outdoor Surface Mount (NEMA 4/12), Tamperproof Two Position, Die Cast Enclosure

02 410

Outdoor Surface Mount (NEMA 4/12), Tamperproof Two Position, With Stop Button, Die Cast Enclosure

02 410 B

Outdoor Surface Mount (NEMA 4/12), Tamperproof Two Position, With Stop Button, Die Cast Enclosure

02 410 U

Outdoor Surface Mount (NEMA 4/12), Tamperproof Two Position, With Stop Button, Die Cast Enclosure

02 410 C

Outdoor Surface Mount (NEMA 4/12), Tamperproof Two Position, With Stop Button, Die Cast Enclosure

02 404

Outdoor Surface Mount (NEMA 4/12), Non-Tamperproof

Two Position, Die Cast Enclosure

180C0152

Outdoor Surface Mount (NEMA 4/12), Non-Tamperproof Two Position, Die Cast Enclosure

02 405

Outdoor Surface Mount (NEMA 4/12), Non-Tamperproof Two Position, With Stop Button, Die Cast Enclosure

02 407

Outdoor Surface Mount (NEMA 4/12), Non-Tamperproof Two Position, Die Cast Enclosure

SENSING EDGES

65 8202

Pneumatic Sensing Edge 2 Wire

65 8302

Pneumatic Sensing Edge 2 Wire

65 5202

Pneumatic Sensing Edge

2 Wire

65 5302

Pneumatic Sensing Edge 2 Wire

65 8203

Electric Sensing Edge 2 Wire, Sectional, Sliding, Bi-fold Doors

65 8204

Electric Sensing Edge 2 Wire, Rolling Doors

VEHICLE DETECTION SYSTEM

65 8206

Pneumatic Sensing Treadle

2 Wire

Page 12

120V 1 PHASE SCHEMATIC/ FIELD WIRING DIAGRAM

12

Page 13

13

240V 1 PHASE SCHEMATIC/ FIELD WIRING DIAGRAM

Page 14

14

208/230V 3 PHASE SCHEMATIC/ FIELD WIRING DIAGRAM

Page 15

TEST THE SYSTEM

Turn on power. Test all controls and safety devices to

make sure they are working properly. It will be

necessary to refer back to page 6 for fine adjustment

of the limit switches.

IMPORTANT NOTES:

Do not leave operator power on unless all safety

and entrapment protection devices have been

tested and are working properly.

Be sure you have read and understand all Safety

Instructions included in this manual.

Be sure the owner or person(s) responsible for

operation of the door have read and understand

the Safety Instructions, know how to electrically

operate the door in a safe manner, and know how

to use the manual disconnect operation of the

door operating system.

WARNING

DO NOT PLACE HANDS OR TOOLS IN OR NEAR

THE OPERATOR WHEN THE POWER IS ON OR

WHEN TESTING CONTROL OR SAFETY

DEVICES. ALWAYS DISCONNECT POWER

BEFORE SERVICING OR ADJUSTING THE

OPERATOR.

The operator has been pre-wired to accept

connection of a reversing edge device. Connect the

normally open contacts to terminals T10 and T11 on

the low voltage terminal block. A cut-off switch will de-

activate the safety device during the last few inches of

the door's downward travel.

IF CONTROL STATION CANNOT BE INSTALLED WHERE

DOOR IS VISIBLE, OR IF ANY DEVICE OTHER THAN

THE CONTROL STATION IS USED TO ACTIVATE THE

DOOR,

A REVERSING EDGE MUST BE INSTALLED ON

THE BOTTOM OF THE DOOR.

FAILURE TO INSTALL A

REVERSING EDGE UNDER THESE CIRCUMSTANCES

MAY RESULT IN SERIOUS PERSONAL INJURY OR

DEA TH T O PERSONS TRAPPED BENEATH THE DOOR.

NOTICE:

This equipment has been tested and found to comply with the limits for a Class A digital

device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference when the equipment is operated in a

commercial environment. This equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in accordance with the instruction

manual, may cause harmful interference to radio communications. Operation of this

equipment in a residential area is likely to cause harmful interference, in which case the

user will be required to correct the interference at his own expense.

WARNING

460V 3 PHASE SCHEMATIC/ FIELD WIRING DIAGRAM

15

WARNING

WARNING

Page 16

16

REPAIR PARTS KITS – LIMIT BOX FOR MODEL N9GH

K72-14130 LIMIT SHAFT ASSEMBLY KIT

Item

L1

L2

L3

L4

L5

L6

L7

L8

Description

Limit Shaft

Flange Bearing, 3/8” I.D.

Limit Nut

Sprocket 48B9 x 3/8” Bore

Washer, Shim 3/8” I.D. x .050 THK.

Washer, Shim 3/8” I.D. x .010 THK.

Roll Pin, 1/8 DIA. x 1” Long

E Ring, 3/8”

Qty

1

2

2

1

1

4

1

1

P/N

11-13361

12-10028

13-10024

15-48B9A1

80-10025

80-10026

86-RP04-100

87-E-038

* COMPLETE LIMIT BOX KITS

Item

1

2

3

Description

Limit Box

Limit Box Cover

Terminal Block, 6 Position

Qty

1

1

2

P/N

10-17531

10-17532

42-106

Below are replacement kits available for your operator. For replacement of electrical box, motor or brake components be sure to match

model number of your unit to kit number below to ensure proper voltage requirements. Optional modifications and/or accessories

included with your operator may add or remove certain components from these lists. Please consult a parts and service representative

regarding availability of individual components of kits specified below. Refer to page 10 for all repair part ordering information.

Complete Electrical Box Replacement Kits

To order a complete electrical box replacement kit, add a Kprefix to the model number of your operator. For example:

N9GH5011M (Operator) = K-N9GH5011M (Elec. Box Kit)

Limit Box Sub-Assembly Kits

K72-14130 Limit Shaft Assembly

K75-12511 Limit Switch Assembly

Complete Gear Reducer Housing Kits

See Page 18 for more information

Shaft Assembly Kits

K72-12789 Hand Chain Shaft Assembly

K72-13379 Hand Chain Shaft Assembly

K75-12783 Disconnect Assembly

Individual Components

21-5115 Transformer, 115V Operators

21-5230 Transformer, 230V Operators

21-5460 Transformer, 380-460V Operators

Motor Kits for Model N9GH

(Gear Reduced Style Operators)

Item

S1

S2

S3

S4

S5

S6

S7

S8

S9

P/N

10-10013

10-12553

10-12806

18-10036

23-10041

31-12542

82-PX04-20

82-PX06-16

84-LH-06

Description

Depress Plate

Nut Plate, Switch

Backup Plate

Spring, Depress Plate

Limit Switch

Standoff, Limit Switch

Screw, #4-40 Pan Head Phillips

Screw, #6-32 x 1” Pan Hd Phillips

Locknut, #6-32 Nylon Hex

K75-12511 LIMIT SWITCH ASSEMBLY KIT

1 HORSE POWER

CIRCUIT TYPE

MODEL

1011 M 115 1 60 K20-1100C2X

1021 M 230 1 60 K20-1100C2X

1023 M 208/230 3 60 K20-3100C4X

1043 M 460 3 60 K20-3100C4X

VOLTS PHASE HZ

MOTOR KIT REQ

3/4 HORSE POWER

CIRCUIT TYPE

MODEL

7511 M 115 1 60 K20-1075C2X

7521 M 230 1 60 K20-1075C2X

7523 M 208/230 3 60 K20-3075C4X

7543 M 460 3 60 K20-3075C4X

VOLTS

PHASE HZ MOTOR KIT REQ

1/2 HORSE POWER

CIRCUIT TYPE

MODEL

5011 M 115 1 60 K20-1050C2X

5021 M 230 1 60 K20-1050C2X

5023 M 208/230 3 60 K20-3050C4X

5043 M 460 3 60 K20-3050C4X

VOLTS PHASE HZ MOTOR KIT REQ

1-1/2 HORSE POWER

CIRCUIT TYPE

MODEL

1511 M 115 1 60 K20-1150C2X

1521 M 230 1 60 K20-1150C2X

1523 M 208/230 3 60 K20-3150C4X

1543 M 460 3 60 K20-3150C4X

VOLTS PHASE

HZ

MOTOR KIT REQ

2 HORSE POWER

CIRCUIT TYPE

MODEL

2023 M 208/230 3 60 K20-3200C4X

2043 M 460 3 60 K20-3200C4X

VOLTS

PHASE

HZ MOTOR KIT REQ

*Limit Box Kits include parts from K72-14130 and K72-12511

Qty

1

4

4

2

4

4

8

2

2

Page 17

17

ILLUSTRATED PARTS – ELECTRICAL BOX

Page 18

18

REPAIR PARTS KITS – MODEL N9GH

Refer to the parts lists below for replacement kits available for your operator. If optional modifications and/or

accessories are included with your operator, certain components may be added or remove from these lists.

Individual components of each kit may not be available. Please consult a parts and service representative

regarding availability of individual components. Refer to page 10 for all repair part ordering information.

K75-12783 DISCONNECT ASSEMBLY KIT

ITEM PART # DESCRIPTION QTY

D1

D2

D3

D4

D5

D6

D7

D8

D9

D10

D11

D12

D13

D14

D15

D16

D17

D18

D19

D20

GH Disconnect Lever

Bevel Gear Yoke

Brake Release

Actuator Bracket

Switch Actuator

Disconnect Shaft

GH Tension Spring

12ft. Of Sash Chain

Screw, #8-32 x 1/4” Self Tap

Screw, #10-32 x 7/8” Long

Screw, #10-32 x 1/2” Serrated Fl.

Nut, #10-32 Serrated Flange

USS Flatwasher, 3/4”

#10 Lockwasher ZP

Cotter Pin, 1/8” x 1-3/4” Long

Roll Pin, 3/16” x 3” Black Oxide

Interlock Switch

Spacer

Screw, #6-32 x 1-3/8” Long

#6-32 Lock Nut

1

1

1

1

1

1

1

1

1

2

2

2

3

2

3

1

1

2

2

2

10-11021

10-11023

10-11024

10-17591

10-17590

11-11106

18-11007

19-17160

82-PX08-04T

82-SH10-14

82-WX10-08T

84-FN-10

85-FW-50

85-LS-10

86-CP04-112

86-RP06-300

23-10916

31-11119

82-PX06-19

84-LH-06

K72-12789 OR K72-13379

HAND CHAIN SHAFT KIT

ITEM PART # DESCRIPTION QTY

H1

H2

H3

H4

H5

H6

H7

H8

H9

H10

H11

H12

H13

H14

H15

Bevel Gear, 5/8” ID

Bevel Gear, 3/4” ID

Hand Chain Guide

Hand Chain Shaft, GH

Bearing, 3/4” I.D.

Nyliner Bearing

Compression Spring, GH

Chain Wheel Assembly

Shim Washer, Thick

Washer, .656 I.D. x 1.25 O.D.

Roll Pin, 1/4” x 1-1/2” Long

Roll Pin, 5/16” x 1-5/8” Long

Roll Pin, 5/16” x 2-1/2” Long

E Ring, 5/8”

E Ring, 3/4”

1

1

1

1

2

1

1

1

4

1

1

1

1

1

4

08-11012

08-11013

10-10882

11-11105

12-10029

12-10883

18-11008

75-10884

80-10022

80-11014

86-RP08-108

86-RP10-110

86-RP10-208

87-E-062

87-E-075

INDIVIDUAL PARTS

ITEM PART # DESCRIPTION QTY

1

2

3

4

5

6

7

Elec. Box Mounting Bracket

Sprocket, 48B18 LGE

Sprocket, 50B12 LGH

Electrical Box

Motor

Gear Reducer

Limit Box

1

1

1

1

1

1

1

10-11045

15-48B18LGE

15-50B12LGH

See Page 16

See Page 16

See Var. Comp.

See Page 16

COMPLETE GEAR REDUCER HOUSING KITS

ITEM PART # DESCRIPTION QTY

G1

G2

G3

G4

Housing Support Bracket

Gear Brake Housing

Housing Cover

Bottom Cover

2

1

1

1

10-11006

10-11026M1

10-11046M1

10-11031

* Gear Housing Kits also include:

K75-12788 Disconnect Assembly Kit

K72-12789 Hand Chain Shaft Kit

For All Operators

K75-17991

KIT REQUIRED FOR OPERATOR(S)

VARIABLE COMPONENTS

ITEM PART # DESCRIPTION QTY

6

Gear Reducer (1 HP Opers, 45:1)

Gear Reducer (1.5-2 HP Opers, 45:1)11

32-11009

32-11010

Page 19

ILLUSTRATED PARTS – MODEL N9GH

19

Page 20

REPAIR PARTS KITS – MODEL N9GH

Refer to the parts lists below for replacement kits available for your operator. If optional modifications and/or

accessories are included with your operator, certain components may be added or remove from these lists.

Individual components of each kit may not be available. Please consult a parts and service representative

regarding availability of individual components. Refer to page 10 for all repair part ordering information.

INDIVIDUAL PARTS

ITEM PART # DESCRIPTION QTY

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

Din Rail

Contactor

Mounting Plate

Transformer (Not Used on 115VAC)

Relay, 24V

Auxiliary Contact Block

Flex Conduit

Elbow

Ground Lug

Timer

Spacer

Terminal Block, 3 Pole

Enclosure

3 Phase, Dynamic Brake

1 Phase, Dynamic Brake

Intrinsically Safe Assembly

Bulk Head Assembly

Overload (3 PH Only)

Transformer

1

1

1

1

1

2

1

1

1

1

4

1

1

1

1

1

1

1

1

03-AB-DIN4

03-8024-D

10-17530

21-17524

24-24-1

27-8002-D

28-17535

28-17536

28-17579

29-438

31-17539

42-103

44-17529

74-17554

74-17555

74-17561

74-17585

See Overloads

See Page 16

20

OVERLOADS

OPERATOR

N9GH1023M

N9GH1043M

N9GH1053M

N9GH1523M

N9GH1543M

N9GH2023M

N9GH2043M

N9GH5023M

N9GH5043M

N9GH7523M

N9GH7543M

ITEM 17

25-4002-5D

1.5-2.0 Amp

25-4004-D

2.5-4.0 Amp

25-4006-D

4.0-6.0 Amp

25-4008-D

5.5-8.0 Amp

25-4001-5D

1.0-1.6 Amp

Page 21

ILLUSTRATED PARTS – MODEL N9GH

21

6

2

9

7

8

16

10

4

15

3

17

11

9

14

5

12

13

18

19

Page 22

OPERATOR NOTES

22

Page 23

OPERATOR NOTES

23

Page 24

CONTROL CONNECTION DIAGRAM

IMPORTANT NOTES:

1) The 3-Button Control Station provided must be connected for operation.

2) If a STOP button is not used, a jumper must be placed between termianls 3 and 4.

3) Auxiliary control equipment may be any normally open two wire device such as

pullswitch, single button, loop detector, card key or such device.

3 BUTTON STATION or 3 POSITION KEYSWITCH w/ SPRING RETURN TO CENTER AND STOP BUTTON

STANDARD

1 2 3 4

1 2 3 4

Open

Close

Stop

ALL CONTROL WIRING TYPES

2 BUTTON STATION or 3 POSITION KEYSWITCH w/ SPRING RETURN TO CENTER

STANDARD

1 2 4

1 2 4

2 OR MORE KEY LOCKOUT

Open

Close

Stop

2 OR MORE

Open

Close

Stop

SEE NOTE #2SEE NOTE #2 SEE NOTES

ATTENTION ELECTRICIAN:

USE 16 GAUGE OR HEAVIER WIRE

FOR ALL CONTROL CIRCUIT WIRING.

1 2 3 4

Open

Close

Stop

Keyswitch

ALL CONTROL WIRING TYPESALL CONTROL WIRING TYPES

1 BUTTON STATION or

ANY AUXILIARY DEVICE

3

7

#2 AND #3

Open

Close

ALL CONTROL WIRING TYPES

SENSING DEVICE TO REVERSE OR STOP

3

10

Sensing Device

ALL CONTROL WIRING TYPES

Open

Close

ALL CONTROL WIRING TYPES

Open

Close

4

ONE 2 OR MORE

OPEN / CLOSE

B2 or T1

WIRING TYPES ONLY

EXTERNAL INTERLOCK

Remove Jumper

When Interlock is Used

5

ALL CONTROL WIRING TYPES

4

5

01-17505B

©

2003, The Chamberlain Group, Inc.

All rights Reserved

Loading...

Loading...