Page 1

The Chamberlain Group, Inc.

©

A DUCHOSSOIS ENTERPRISE

845 Larch Avenue

Elmhurst, Illinois 60126

OWNER'S MANUAL

MODEL GJWR/HJCR

WALL MOUNTED STARTER

NEMA 4

Refer to Model GJ & GJW or HJ & HJC

Serial #

(located on electrical box cover)

Installation Date

Wiring Type

ADDENDUM

Installation Instructions

COMMERCIAL DOOR OPERATOR

LISTED

®

NOT FOR RESIDENTIAL USE

Page 2

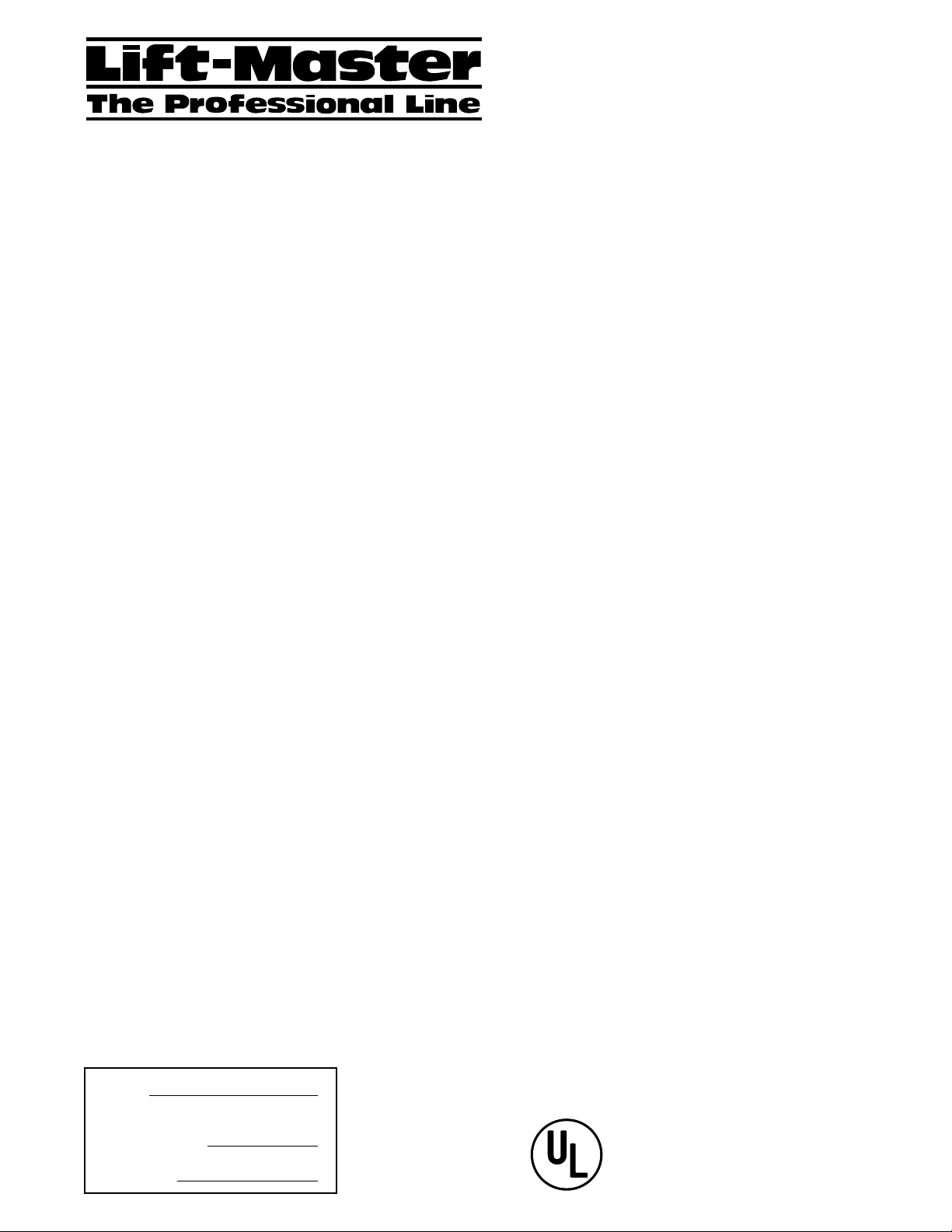

PHYSICAL MOUNTING DIMENSIONS - MODEL GJWR

11

"

27

/16

(Without Clutch)

Max.

11

"

31

/16

Max.

(With Clutch)

13 1/32

10 29/32

"

"

"

2 3/4

3

"

4

/4

"

13 7/16

1

"

/2

5

Room Required to

Open Hinged

Electrical Box

"

10 1/8

14 3/4

"

2

Page 3

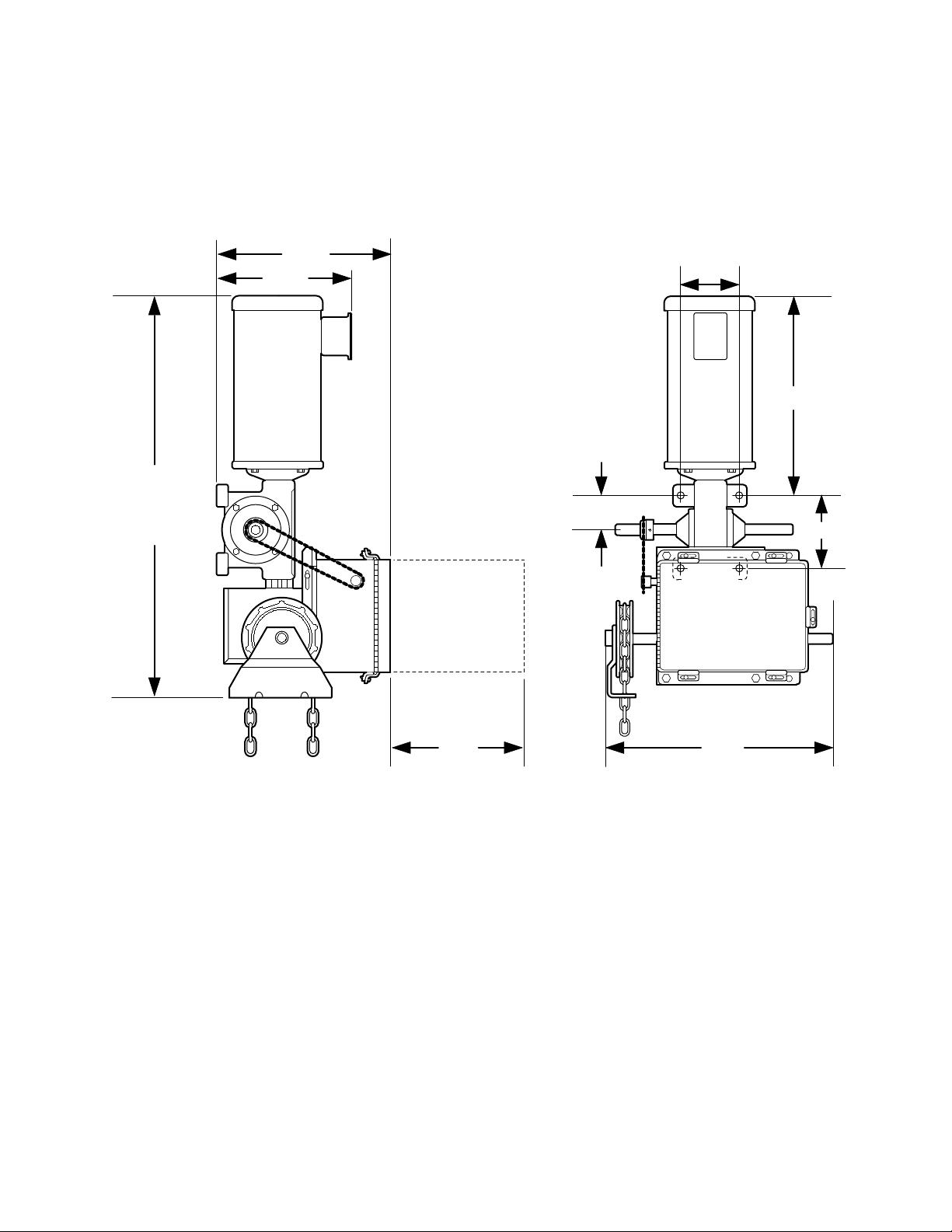

PHYSICAL MOUNTING DIMENSIONS - MODEL HJCR

"

11 3/32

"

17 7/8

Max.

3"

"

13

"

3

/16

5 9/32

13

1

/32

3/4"

"

1

"

2

/32

15

"

/16

3

8"

19 13/16

17 1/2

"

13

1

"

5

/2

7

"

/16

"

3

"

/4

16

3

Page 4

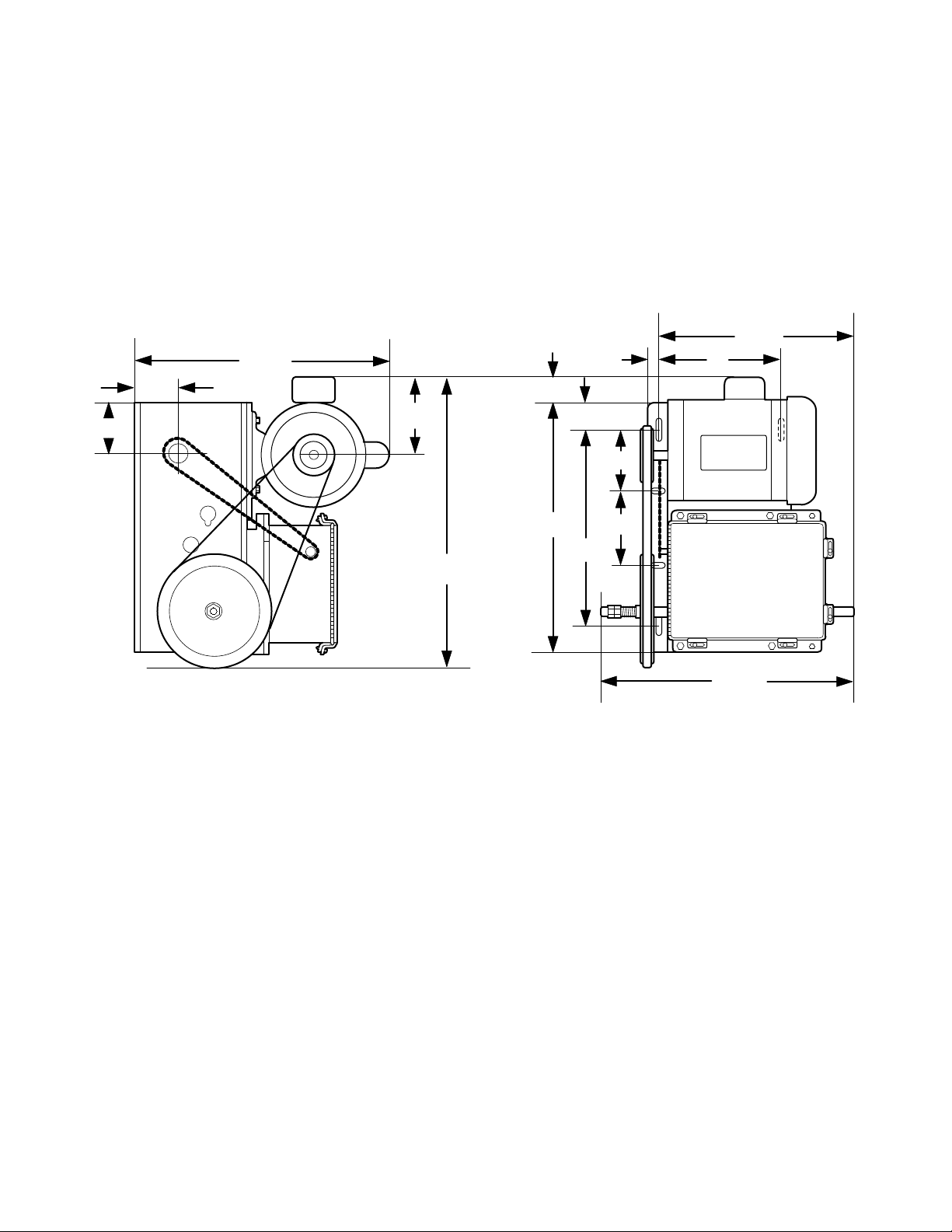

ELECTRICAL ENCLOSURE WALL MOUNTED

STARTER MODELS HJCR/GJWR

"

13 1/2

12

3

"

/4

6 7/32

"

10"

12 15/16

"

Important Notes

Please Read Before Proceeding

1. Make sure that the serial number on the operator limit switch cover matches the serial

number on the electrical enclosure cover.

2. All field installed wiring must be run using U.L. listed liquid tight conduit and connectors.

3. Install high voltage wiring and 24VAC (control and limit) wiring in separate conduits.

Installation

1. Install the operator motor and frame assembly according to the Owner's Manual for your

model operator, (either GJ or HJ).

2. Securely attach the electrical enclosure to the wall, adjacent to and within sight of the door.

See Figure 1.

3. Refer to Figure 1 and wiring diagrams for locations of conduit and wiring connections.

4

Page 5

NOTE: Model GJWR installation shown, for Model HJCR mount operator per

HJ Installation Manual and install Electrical Enclosure as shown below.

Wires from Motor

P1 & P2 on 1/2 HP

3 Phase GJ

Motor Wiring also

Wires from P1 & P2

on 1/3 & 1/2 HP

3 Phase HJ

Junction Box

As Required

24 VAC Limit Wiring

Also Interlock Wiring for GJ

Safety Switch (Optional)

Wall Mounted

Electrical

Enclosure

Control

Station

High Voltage

To Power Source

Coil Cord or Take-Up Reel (Optional)

FIGURE 1

5

Page 6

NEMA 4 WITH DYNAMIC BRAKE - 1 PHASE WIRING DIAGRAM

(For PC Board #14D0379)

Red

LIMIT SWITCH WIRING

123456789

Gray

Yellow

P1

41

2

1.5 Sec.

TIMER

Blue

Gray

Yellow

Red

Brown

Gry./Wht.

Yellow

123

RADIO CONTROL

Blue

Gray

Orange

P3

1

2

4

Brown

Brown

Brown

P2 P1

Remove Jumper to Install

Timer Defeat Switch.

T12 T11 T10 T9 T8 T7 T6 T5 T4 T3 T2 T1

Blue

Brown

Blue

Yellow

Blue

Brown

Org.

Brown

Red

A2

T2 T1

14 T3

NO NO NO NO NO NO NO NO

Yellow

82 72 54

81 71 53

OPEN

13 L3

L2 L1 13 L3

A2 A1

Org.

Orange

Orange

Blue

Blue

Blue

Red Red

Org.

Red

Red

1234567891011121314 1234567891011121314

SW5

Open/Close

Sensing Device

Open/Timer Close

Yellow

Orange

Orange

Brown

Yellow

Blue

A2

14 T3 T2 T1

828172

71

Gray

CLOSE

Yellow

NO NO NONONO NO NONO

L2 L1

A2 A1

115V Only

Blue

Blue

TI TL

SW4 SW3 SW2 SW1

Red

54

53

Orange

Blue

S

Brown

Brown

Open

Close

Stop

Orange

White

White

Red

Gray

Gray

Blue

Red

IR

Red

Red Red

230V

Only

Yellow

Red

14D0379

Black

Red

Red

Gray

Yellow

Red

Orange

Red

Neutral 115V 1Ø

Hot 230V 1Ø

Black

White

Orange

L2L1L3

Hot 115V 1Ø

Hot 230V 1Ø

14D383A

P2

178914

Blue

Blue

LOAD

LINE

LINE

LOAD

Orange

Black

Red

Yellow

Red

Interlock

(When Used)

Black

Orange

Orange

Black

GND

Orange

BRAKE

XMFR

Orange

LOAD

LINE

TRANSFORMER

LINE

LOAD

OVERLOAD

PROTECTOR

STANDARD

Orange

Yellow

Red

Black

MOTOR

WIRING

12345

6

Page 7

NEMA 4 WITH DYNAMIC BRAKE - 3 PHASE WIRING DIAGRAM

(For PC Board # 14D0379)

LIMIT SWITCH WIRING

123456789

Red

Gray

Yellow

P1

2

41

Brown

Blue

Gray

Yellow

Red

Gry./Wht.

Yellow

1.5 Sec.

TIMER

Org.

Gray

Blue

Bwown

Bwown

Blue

Bwown

Orange

Orange

Yellow

Red

Orange

Blue

Yellow

Blue

3/4 to 2HP

3 Phase

Overload

T2 T1T3

Orange

Red Red

White

Blue

Red

Org.

Brown

Brown

A2

9695

14 T3

T2 T1

NO NO NO NO NO NO NO NO

72

NC

Yellow

OPEN

71

NC

L2 L1 13 L3

13 L3

A2 A1

Org.

Blue

Blue

Org.

Orange

Orange

Orange

Org.

Red

Red

Org.

Yel.

Blue

547282

537181

Blue

Blue

Blue

Red

A2

14 T3 T2 T1

828172

71

Gray

Yel.

CLOSE

NO NO NONONO NO NONO

A2 A1

Blue

Blue

54

53

L2 L1

Orange

1234567891011121314 1234567891011121314

P3

1

2

4

P2 P1

Remove Jumper to Install

Timer Defeat Switch.

TI TL

SW4 SW3 SW2 SW1

SW5

S

T12 T11 T10 T9 T8 T7 T6 T5* T4* T3 T2 T1

71

NC

72

NC

Blue

Gray

Gray

JU2 JU1

Blue

Red

Red Red

Brown

Brown

Red

Gray

Orange

Red

Blue

Black

Red

Yellow

> 1 HP

Only

Red

Red

14D0379

Yellow

Orange

White

Red

Red

14D383A

P2

178914

Blue

Blue

LOAD

LINE

LINE

LOAD

BRAKE

XMFR

White

Orange

Orange

Interlock

(When

Used)

*1/3 &

1/2 HP

Three

Phase

Black

Red

Yellow

Red

Red

Orange

LOAD

LINE

LINE

LOAD

MOTOR

WIRING

Orange

Blue

Yellow

Red

Black

TRANSFORMER

12345

123

RADIO CONTROL

Open/Close

Sensing Device

Open/Timer Close

Open

Close

Stop

7

L2L1L3

L2L1L3

GND

External Interlock If Required

On 1/3 & 1/2 HP 3Ø

• For ≥ 3/4 HP

Install Interlock

Between T4 and T5

Page 8

LIMIT SWITCH WIRING

OPEN

LIMIT

SWITCH

AUXILIARY

DEVICE LIMIT

SWITCH

CLOSE

LIMIT

SWITCH

SENSING

LIMIT

SWITCH

NC

NO

NC

NO

NC

NO

NC

NO

C

C

C

C

123456789

BROWN

BROWN

BLUE

GRAY

BLUE

BROWN

ORANGE

YELLOW

RED

RED RED

BROWN

Wires from

GJ Interlock

Switch

Limit Switch Enclosure

Wires from

GJ Interlock

Switch

Figure 2

YELLOW

BROWN

BROWN

ORANGE

BLUE

NC

NO

C

RED RED

RED

OPEN

LIMIT

SWITCH

C

AUXILIARY

DEVICE LIMIT

SWITCH

NC

NO

BROWN

BROWN

NC

NO

BLUE

SENSING

LIMIT

SWITCH

GRAY

123456789

C

CLOSE

NC

LIMIT

NO

SWITCH

C

8

Page 9

FIELD WIRING SHOWN IN DASHED LINES

MOTOR

MAKE-UP BOX

LIMIT SWITCH ENCLOSURE

SEE NEMA MOTOR WIRING DIAGRAMS

(PAGE 10) FOR TERMINAL NUMBERS IN

ELECTRICAL ENCLOSURE TO CONNECT

MOTOR LEADS TO. ASLO WIRES FROM

(P1 & P2) FOR 1/3 & 1/2 HP 3Ø HJ.

123456789

WIRES FROM (P1 & P2)

FOR 1/2 HP 3Ø GJ.

INTERLOCK

WIRES (GJ)

LIMIT SWITCH WIRING

CONNECT TERMINAL #1 IN

LIMIT SWITCH ENCLOSURE

TO TERMINAL #1 IN ELECTRICAL

ENCLOSURE, ETC., THROUGH #9.

SEE FIGURE 2

FOR (P1 & P2)

CONNECTIONS

ELECTRICAL ENCLOSURE

987654321 54321

L1 L2 L3

SEE WIRING DIAGRAMS

LINE POWER IN

CONTROL

STATION

CONTROL WIRING

SEE OWNERS MANUAL

9

Page 10

NEMA MOTOR WIRING DIAGRAMS

1 PHASE

115V

T2 White

3

5

Black

1

Red

2

T4 YellowYellow

T5 BlackOrange

T3 Orange

T1 Blue

T8 Red

3

Orange

5

Red

2

Black

1

T4 YellowYellow

T5-Black

T1 Blue

230V

Red

T8

T3

Orange

T2

White

3 PHASE

1/3 & 1/2 H.P. 3/4 H.P. & OVER

Yellow

3

Orange

5

Blue

4

Black

1

Red

2

P1

P2

T7

T2

T8

T3

230 V

T1

T4

T5

T6

T9

Yellow

3

Black

1

Red

2

T7

T2

T8

T3

230 V

T1

T4

T5

T6

T9

1/3 & 1/2 H.P.

Yellow

3

Orange

5

Blue

4

Black

1

Red

2

P1

P2

T2

T3

NOTES: 1. Denotes wirenut connection

Number shown in circle indicates terminal number in electrical enclosure. Wire color indicates color of wire

2.

connected to the corresponding terminal in the electrical enclosure.

T1

460 V

T4

T5

T6

T8

T9

T7

10

3/4 H.P. & OVER

460 V

Yellow

3

Black

1

Red

2

T2

T3

T1

T6

T5

T4

T7

T8

T9

Page 11

REPLACEMENT PARTS FOR MODEL GJWR/HJCR

2

1

NOTE: For parts not shown refer to the

3

Parts List in your Owner's Manual

for your model operator.

10

11

4

5

4

3

2

12

1

9

5

6

8

7

7

ITEM

NO. PART NO. QTY. DESCRIPTION

1 12B0535 1 Limit Switch Assembly Support Bracket

2 28A0097 1 GJW Cable Clamp

3 1B4516 1 Terminal Strip Mounting Panel Assembly

1D4524 1 Enclosure, NEMA 4 Limit Switch GJ

4

2D0415 1 Enclosure, NEMA 4 Limit Switch HJ

5 12B0538 1 HJC Bracket, Limit Switch NEMA HJ (Left)

6 12B0539 1 HJC Bracket, Limit Switch NEMA HJ (Right)

7 12B0536 2 GJW Limit Switch Box Mounting Bracket

1D4526

8

2D4016

9

1D4525 1 Panel Assembly, NEMA Remote

10

203B0233 1 Terminal 9 Position

11 203A0234 1 Terminal 5 Position

12 132A2093 1 Marker 5 Position

1

1

Enclosure NEMA Remote 1Ø

Enclosure NEMA Remote 3Ø

1

11

Page 12

HOW TO ORDER REPAIR PARTS

OUR LARGE SERVICE ORGANIZATION

SPANS AMERICA

INSTALLATION AND SERVICE INFORMATION

ARE AVAILABLE 6 DAYS A WEEK

CALL OUR TOLL FREE NUMBER - 1-800-528-9131

HOURS 7:00 TO 3:30 p.m. (Mountain Std. Time)

MONDAY Through SATURDAY

PLEASE SUPPLY THE FOLLOWING INFORMATION:

PART NUMBER DESCRIPTION MODEL NUMBER

WHEN ORDERING REPAIR PARTS

ADDRESS ORDER TO:

THE CHAMBERLAIN GROUP, INC.

Electronic Parts & Service Dept.

2301 N. Forbes Blvd., Suite 104

Tucson, AZ 85745

© 1993, The Chamberlain Group, Inc.

114A1733A All Rights Reserved Printed in Mexico

Loading...

Loading...