Page 1

©

OWNER'S MANUAL

MODEL GJ

SOLID STATE

INDUSTRIAL DUTY

GEARHEAD JACKSHAFT OPERATOR

The Chamberlain Group, Inc.

A DUCHOSSOIS ENTERPRISE

845 Larch Avenue

Elmhurst, Illinois 60126

Lift-Master

The Professional Line

U

169l LISTED

L

COMERCIAL DOOR OPENER

ASSEMBLED IN MEXICO

INSTALL MORE THAN 8' ABOVE THE FLOOR

FOR INDOOR USE ONLY

LOCATE CONTROL STATION SO THAT IS WITHIN

SIGHT OF PERSON OPERATING THE CONTROL. DOOR

MUST BE CONTROLLED BY 3 BUTTON STATION ONLY.

CAUTION

CONNECT REVERSING EDGE

SWITCH - SEE INSTALLATION

Model No.

Seial No.

Amperage

Rated Load

Horsepower.

Voltage/Phase

INSTRUCTIONS

WIRING

1

2

NEC CLASS 2 CIRCUIT

3

CONTROL

Serial #

(located on electrical box cover)

Installation Date

Wiring Type

COMMERCIAL DOOR OPERATOR

LISTED

®

NOT FOR RESIDENTIAL USE

Page 2

SPECIFICATIONS

MOTOR

TYPE:.....................................Continuous duty

HORSEPOWER:....................1/2, 3/4 & 1 Hp

Single or Three phase

1-1/2 & 2 HP Three phase

SPEED:..................................1725 RPM

VOLTAGE:.............................115/208-230 Single phase

208-230 Three phase

CURRENT: ............................See motor nameplate

MECHANICAL

DRIVE REDUCTION:.............40:1 Reduction

Heavy duty bronze worm

gear reducer

OUTPUT SHAFT SPEED:.....43 R.P.M.

DOOR SPEED:......................4 - 10" per sec.

depending on door

BRAKE: .................................Solenoid drum brake

HOIST WHEEL:.....................Standard mounting on

left or right side

ELECTRICAL

CONTROL VOLTAGE:.5V dc

AUXILIARY VOLTAGE: 24V dc

CONTROL STATION: ..3 Button

OPEN/CLOSE/STOP, NEMA 1

WIRING TYPE:.............B2 (Standard)

Momentary contact to OPEN/CLOSE/STOP plus wiring

for sensing device to reverse and auxiliary devices to

open and close with open override.

(Other types available. See chart, Pg. 14)

LIMIT ADJUST:............Linear driven, fully

adjustable screw type cams. Adjustable to 30 feet.

SAFETY

DISCONNECT:.............Spring loaded floor level

disconnect arm

CLUTCH: (optional)....Adjustable torque limiter type

REVERSING EDGE:.....(Optional) Electric or pneumatic

sensing device attached to the bottom edge of door.

A REVERSING EDGE IS STRONGLY

ALL

RECOMMENDED FOR

OPERATOR INSTALLATIONS.

THE 3 BUTTON CONTROL STATION IS OUT OF

SIGHT OF DOOR OR ANY OTHER CONTROL

(AUTOMATIC OR MANUAL) IS USED.

COMMERCIAL

REQUIRED

WHEN

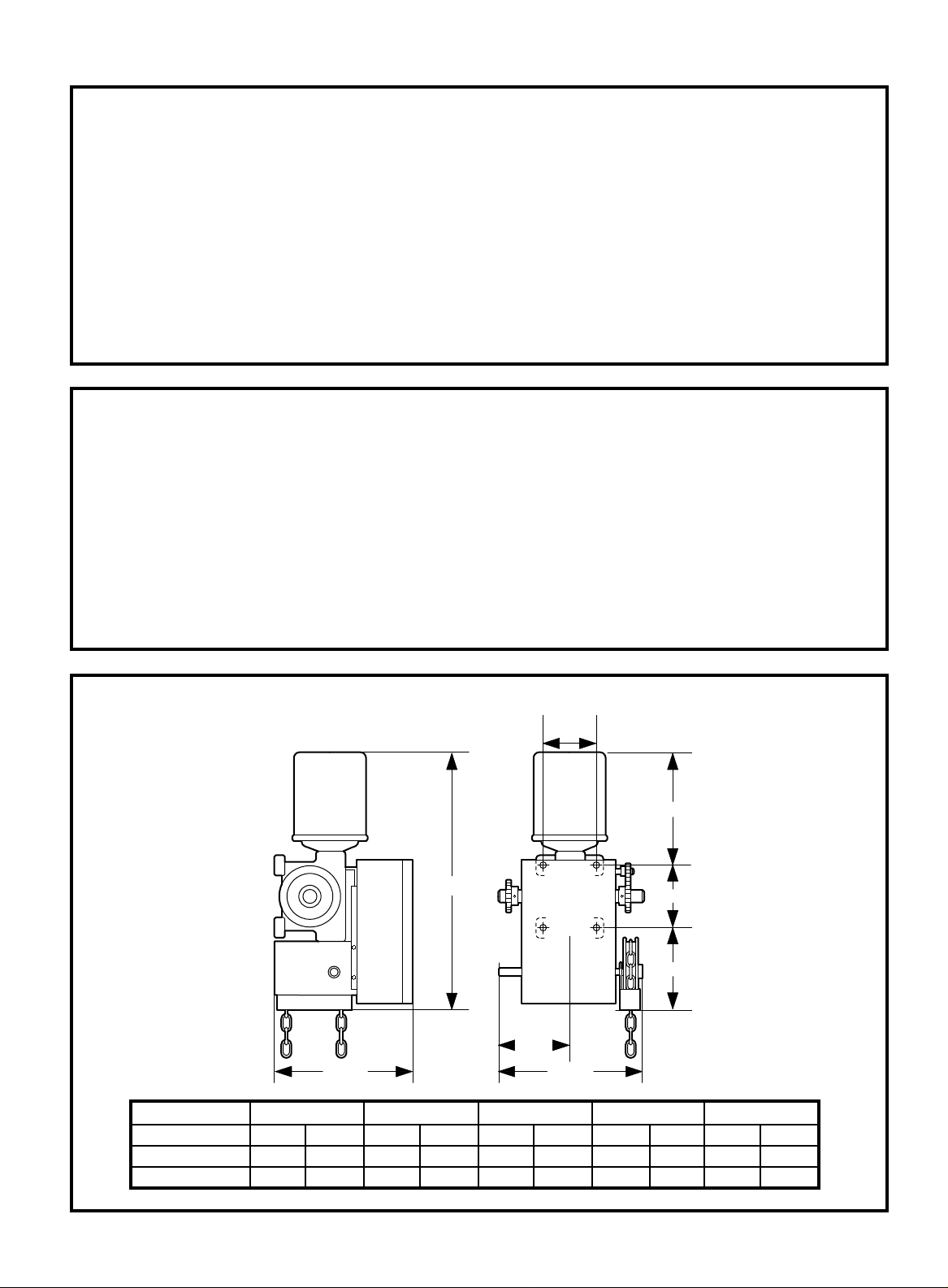

WEIGHTS AND DIMENSIONS

HANGING WEIGHT:.........80-110 LBS.

12 3/4"

GJ OPERATOR

CLUTCH

DIMENSION A 28 9/16" 24 13/16" 28 11/16" 24 15/16" 28 15/16" 25 3/16" 29 1/16" 25 5/16" 29 11/16" 25 15/16"

DIMENSION B 14 5/16" 10 9/16" 14 7/16" 10 11/16" 14 11/16" 10 15/16" 14 13/16" 11 1/16" 15 7/16" 11 11/16"

1/2 HP

YES NO YES NO YES NO YES NO YES NO

A

7 3/8"

3/4 HP 1 HP

4 3/4"

B

5 1/2"

8 3/4"

14 3/4"

1-1/2 HP 2 HP

2

Page 3

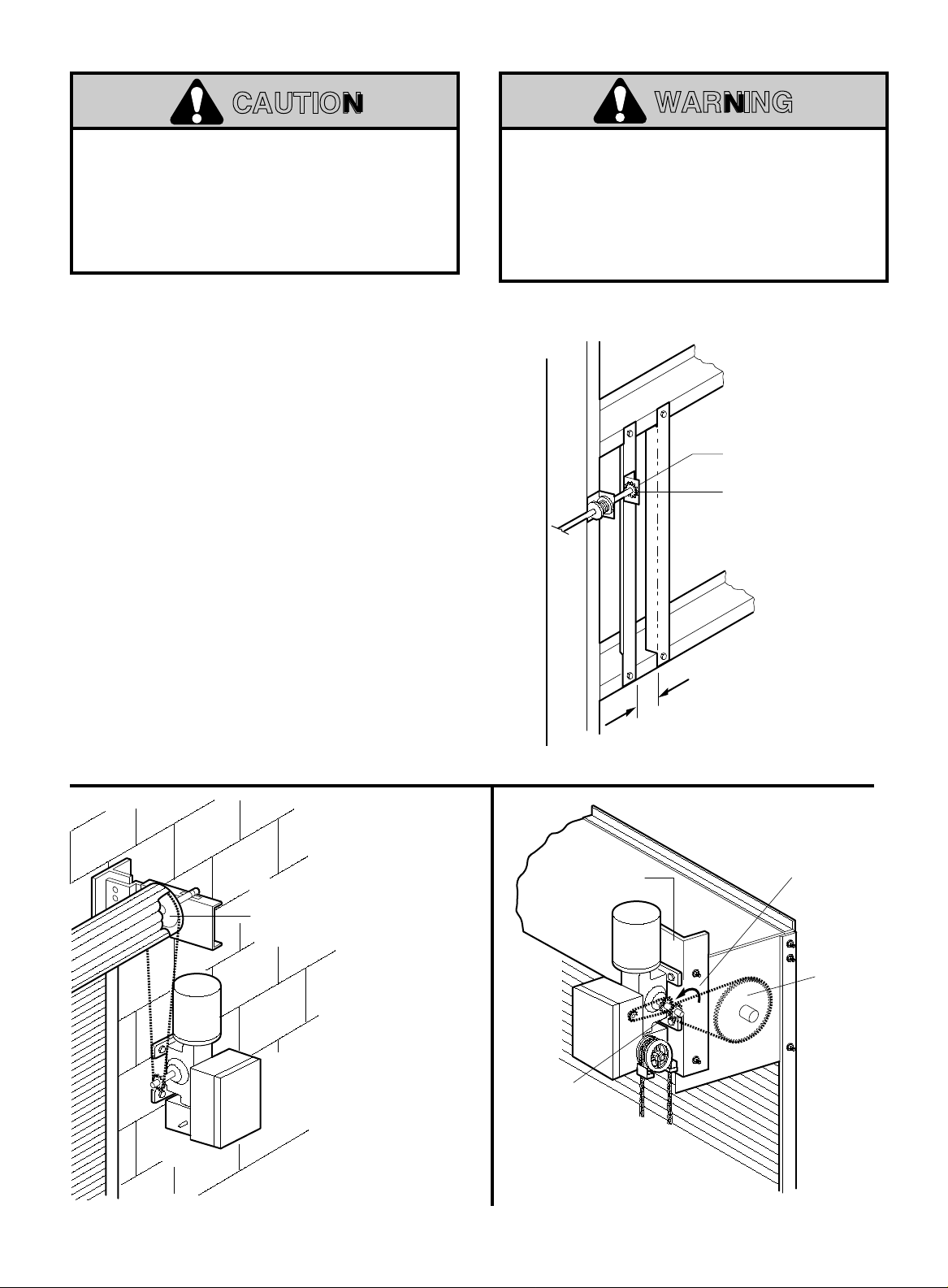

INSTALL OPERATOR

CAUTION

TO AVOID DAMAGE TO DOOR AND OPERATOR,

MAKE ALL DOOR LOCKS INOPERATIVE. SECURE

LOCK(S) IN "OPEN" POSITION.

IF THE DOOR LOCK NEEDS TO REMAIN

FUNCTIONAL, INSTALL AN INTERLOCK SWITCH.

DO NOT CONNECT ELECTRIC POWER UNTIL

INSTRUCTED TO DO SO.

FOR SECTIONAL AND ROLLING TYPE DOORS

CAUTION: AT LEAST 2 PERSONS AND A SAFE

WORKING PLATFORM ARE REQUIRED FOR

INSTALLATION.

Check the operator name plate mounted on the

electrical box to be sure the voltage, phase and h.p.

are correct for your needs.

1. Close door.

2. For metal buildings, fasten 2"x2"x3/16" (or larger)

angle iron frames to the building purlins. Retain

2-1/4" between frames. See Figure 1.

3. Place door sprocket and shaft support bracket

(sectional door only) on door shaft as shown.

Attach shaft support bracket to angle brace.

On concrete buildings, attach shaft support bracket

to wall of building.

NOTE 1: On concrete or block walls, install the

operator as shown in Figure 2.

NOTE 2: For standard rolling steel doors, install

operator as shown in Figure 3. (If mounting to a

steel building, make an angle iron mounting

frame as shown in Figure 1.)

WARNING

KEEP DOOR BALANCED. STICKING OR BINDING

DOORS MUST BE REPAIRED. DOORS, DOOR

SPRINGS, CABLES, PULLEYS, BRACKETS AND

THEIR HARDWARE MAY BE UNDER EXTREME

TENSION AND CAN CAUSE SERIOUS PERSONAL

INJURY. CALL A PROFESSIONAL DOOR

SERVICEMAN TO MOVE OR ADJUST DOOR

SPRINGS OR HARDWARE.

Shaft Support Bracket

with Bearing

(Not Supplied)

Door Sprocket

6"

FIGURE 1

Mount Door Sprocket to Door.

Sprocket Supplied with Door,

(Not with Operator).

Refer to Door Owner's Manual

for Installing Door Sprocket

Installation of Operator to

Sheet Type Rolling Doors

or Rolling Doors without

Live Drive Shaft

FIGURE 2

Mounting

Bracket

(Optional)

Drive

Sprocket

Direction of Output Shaft

Rotation for OPEN

Door

Sprocket

FIGURE 3

3

Page 4

4. Place drive sprocket on the appropriate side of

the operator. Do not insert the key at this time.

5. Join roller chain ends together with master link.

6. Raise operator to approximate mounting position

and position chain over door and operator

sprockets.

7. Raise or lower operator until the chain is taut (not

tight). Make sure the operator output shaft is

parallel to door shaft and sprockets are aligned.

When in position, secure the operator to wall or

mounting bracket.

8. Hand chain wheel is factory installed. To change

position to opposite side of operator, remove Ering, chain guide, hand chain wheel and re-install

on operator in reverse order of disassembly.

Place hand chain around hand chain wheel. Be

sure to pass it through both openings in the chain

guide. Remove enough links so chain hangs

approximately two feet above the floor.

FIGURE 5

FIGURE 4

Position of cable

sheave bracket for

VERTICAL (standard)

mounting of operator.

Position of cable sheave bracket for

HORIZONTAL mounting of operator.

Relocate bracket using existing hardware.

9. Uncoil emergency operating cable assembly and

mount the chain keeper bracket to the wall of the

building four feet above the floor, using two 1/4"

dia. bolts.

10. Insert cable assembly into bracket (Figure 6) and

remove slack from the cable by sliding spacer,

handle and set collar up the cable until spacer

touches underside of bracket. Temporarily tighten

set screw in set collar.

11. Remove cable assembly from bracket and slide

spacer, handle and set collar up the cable for a

distance of 3" +1/4". Permanently tighten set

screw in set collar and cut off excess cable about

1/4" from collar.

12. To engage the gears for manual hand chain

operation, pull down on handle and insert chain

keeper into bracket (Figure 6).

NOTE: To maintain proper cable tension during

manual operation, the cable assembly must be

pre-tensioned. Refer to steps 11 and 12 above.

Installation of Operator to

Standard Rolling Steel Doors.

NOTE: Vertical installations are standard, as

shown in Figures 2, 3 and 4.

For horizontal mounting applications, relocate the

cable sheave bracket (Figure 5) before proceeding

with the cable assembly installation.

Cable

4 Ft.

Above Floor

Chain Keeper

Handle

Spacer

Set Collar

FIGURE 6

4

Page 5

OPTIONAL FEATURES AVAILABLE

REEL (OPTIONAL)

Take-up reel should be installed 12" above the top of

the door.

COIL CORD (OPTIONAL)

Connect operator end of coil cord to junction box (not

supplied) fastened to the wall approximately halfway

up the door opening.

Electrician must hardwire the junction box to the

operator electrical box in accordance with local

codes.

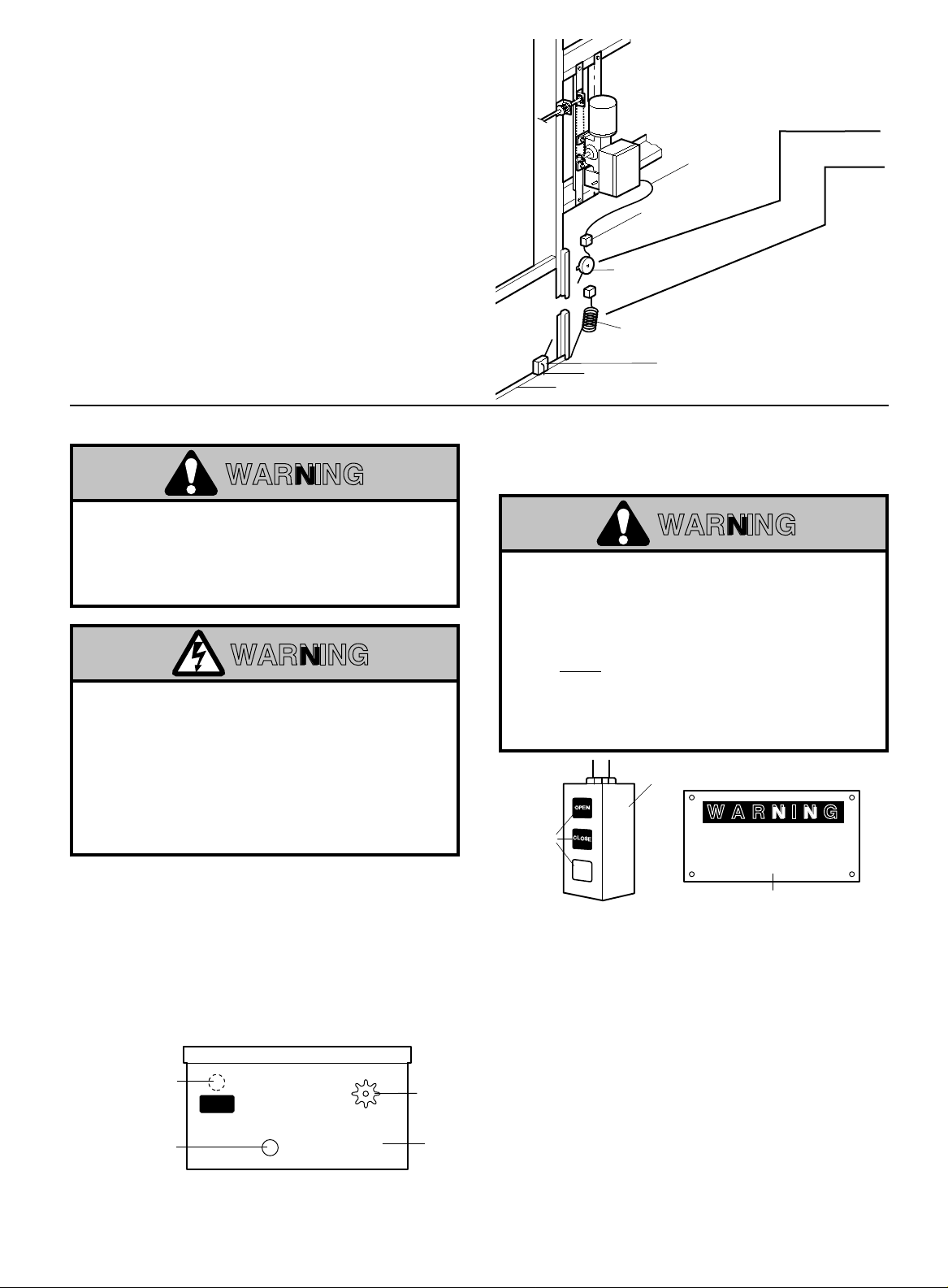

INSTALL CONTROL STATION

WARNING

FIGURE 7

Installation of Operator

to Sectional Door

(Metal Building)

Wire (24V)

Make-up Box

(Not Provided)

Take-up Reel

(Optional)

Coil Cord

(Optional)

Pneumatic Air Switch:

Not required or supplied

Air Hose

Reversing Edge

Install the optional Reversing Edge before

proceeding with the Control Station installation.

when electric sensing

edge is used

TO AVOID DAMAGE TO DOOR AND OPERATOR,

MAKE ALL DOOR LOCKS INOPERATIVE. SECURE

LOCK(S) IN "OPEN" POSITION.

IF THE DOOR LOCK NEEDS TO REMAIN

FUNCTIONAL, INSTALL AN INTERLOCK SWITCH.

WARNING

DISCONNECT POWER AT THE FUSE BOX BEFORE

PROCEEDING.

OPERATOR MUST BE PROPERLY GROUNDED AND

CONNECTED IN ACCORDANCE WITH LOCAL

ELECTRICAL CODES. NOTE: THE OPERATOR

SHOULD BE ON A SEPARATE FUSED LINE OF

ADEQUATE CAPACITY.

ALL ELECTRICAL CONNECTIONS MUST BE MADE

BY A QUALIFIED INDIVIDUAL.

Refer to Master Wiring Diagram. Make connection

through holes labeled for power and control. Do

not run control wires in the same conduit as

power wires.

CABLE CONNECTION NOTE:

Be sure to use the control box opening with the

1-1/16" hole for the POWER cable. All control wires

use the 7/8" hole.

7/8" Hole for

CONTROL

(LOW Voltage) Wires

Hole for POWER

(HIGH Voltage) Wires

WIRING

CONTROL

Sprocket

Electrical

Box

WARNING

INSTALL THE CONTROL STATION WHERE THE

DOOR IS VISIBLE, BUT AWAY FROM THE DOOR AND

ITS HARDWARE. IF CONTROL STATION CANNOT BE

INSTALLED WHERE DOOR IS VISIBLE, OR IF ANY

DEVICE OTHER THAN THE CONTROL STATION IS

USED TO ACTIVATE THE DOOR,

EDGE MUST

THE DOOR.

BE INSTALLED ON THE BOTTOM OF

FAILURE TO INSTALL A REVERSING

EDGE UNDER THESE CIRCUMSTANCES MAY

RESULT IN SERIOUS INJURY OR DEATH TO

PERSONS TRAPPED BENEATH THE DOOR.

Control Station

Push

Buttons

OPEN

CLOSE

STOP

WARNING

TO PREVENT ENTRAPMENT

DO NOT START DOOR DOWNWARD

UNLESS DOORWAY IS CLEAR

13. Complete electrical connections to the operator

and the control station. Fasten the control station

to the wall and MOUNT THE WARNING NOTICE

BESIDE OR BELOW THE PUSH BUTTONS.

14. Apply power to the operator. Press OPEN push

button and observe direction of output shaft

rotation. See Figure 3, page 3. Press the

STOP button.

If shaft does not rotate in the correct direction,

check for improper wiring at the control station or

between operator and control station.

If the operator is three phase and control station

wiring is correct, exchange any two of the three

incoming power leads.

If electrical problems persist, call our Toll Free

number for assistance (1-800-528-6563).

5

A REVERSING

WARNING Notice

Page 6

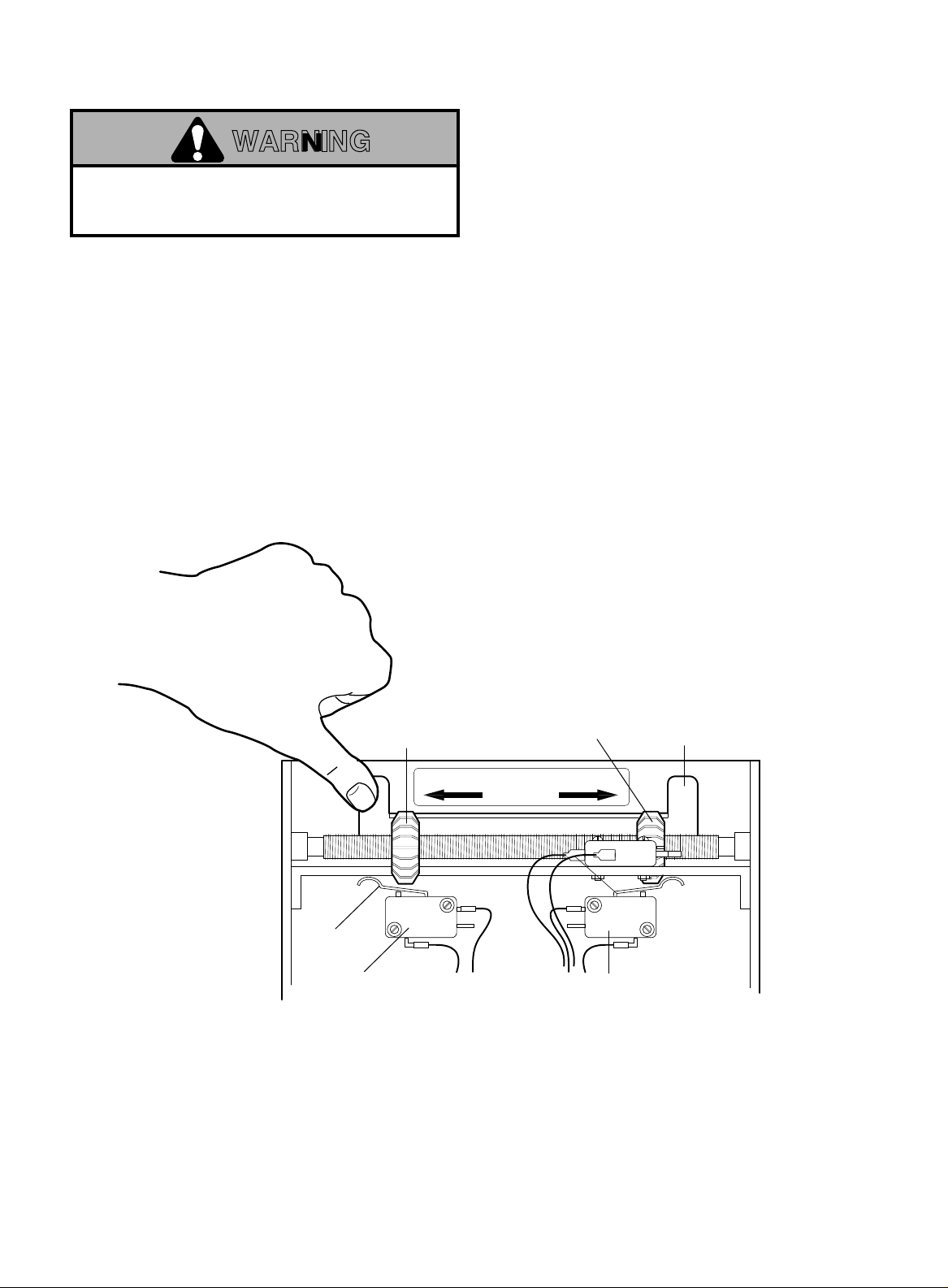

ADJUST LIMITS

WARNING

TO AVOID SERIOUS PERSONAL INJURY OR DEATH

FROM ELECTROCUTION, DISCONNECT ELECTRIC

POWER BEFORE MANUALLY MOVING LIMIT NUTS.

MAKE SURE THE LIMIT NUTS ARE POSITIONED BETWEEN THE LIMIT SWITCH ACTUATORS BEFORE

PROCEEDING WITH ADJUSTMENTS.

1. Depress open limit switch. The operator should stop.

2. To increase door travel, spin nut away from actuator. To decrease door travel, spin limit nut toward actuator.

3. Adjust open limit nut so that door will stop in open position with the bottom of the door even with top of door

opening.

4. Repeat Steps 1 and 2 for close cycle. Be sure close limit actuator is engaged as door fully seats at the floor.

If other problems persist, call our toll-free number for assistance - 1-800-528-6563.

Actuator

Open Limit

Switch

Press Travel Nut Retainer Down

Toward Frame TO DISENGAGE.

Open Limit

Nut

Close Limit

Nut

CLOSEOPEN

OLS

CLS

Close Limit

Switch

Travel Nut

Retainer

SLS

6

Page 7

ADJUST CLUTCH (OPTIONAL)

WARNING

TO AVOID SERIOUS PERSONAL INJURY OR DEATH

FROM ELECTROCUTION, DISCONNECT ELECTRIC

POWER TO OPERATOR BEFORE ADJUSTING SLIP

CLUTCH.

Remove clutch cover and adjust clutch so that it is

tight enough to open and close the door but will slip

when the door meets an obstruction. Either loosen or

tighten the clutch nut with 1/4 turn increments. After

adjustment is completed, tighten locking set screw

and re-install clutch cover. Reconnect power to

operator and test for proper operation. The clutch will

require periodic inspection and adjustment.

CONNECT REVERSING EDGE DEVICE (OPTIONAL)

WARNING

IF CONTROL STATION CANNOT BE INSTALLED

WHERE DOOR IS VISIBLE, OR IF ANY DEVICE OTHER

THAN THE CONTROL STATION IS USED TO ACTIVATE

THE DOOR,

ON THE BOTTOM OF THE DOOR.

A REVERSING EDGE UNDER THESE CIRCUMSTANCES

MAY RESULT IN SERIOUS PERSONAL INJURY OR

DEATH TO PERSONS TRAPPED BENEATH THE DOOR.

A REVERSING EDGE MUST BE INSTALLED

FAILURE TO INSTALL

Motor

Clutch

Adjusting

Nut

CAUTION: The torque limiter clutch is NOT an

automatic reversing device. An electric or

pneumatic reversing edge can be added to bottom

edge of door if desired.

The operator has been pre-wired to accept

connection of a reversing edge device. Connect the

normally open contacts to terminals T4 and T8 on the

low voltage terminal block. A cut-off switch will deactivate the safety device during the last few inches

of the door's downward travel.

MAINTENANCE SCHEDULE

Check at the intervals listed in the following chart.

EVERY EVERY EVERY

ITEM PROCEDURE 3 MONTHS 6 MONTHS 12 MONTHS

Drive Chain Check for excessive slack.

Check & adjust as required.

Lubricate.*

Sprockets Check set screw tightness ●✔

Clutch (Optional) Check & adjust as required ●✔

Gear Reducer** Check for leaks and replace

seals as needed

Fasteners Check & tighten as required ●✔

Manual Disconnect Check & Operate ●✔

Bearings & Shafts Check for wear & lubricate ●✔

✳ Use SAE 30 Oil (Never use grease or silicone spray).

✳✳ Use Mobil SHC75W90 all climate synthetic oil.

✔ Repeat ALL procedures.

■ Do not lubricate motor. Motor bearings are rated for continuous operation

■ Do not lubricate clutch.

■ Inspect and service whenever a malfunction is observed or suspected.

■ CAUTION: BEFORE SERVICING, ALWAYS DISCONNECT OPERATOR FROM POWER SUPPLY.

●✔

●✔

7

Page 8

ADJUST THE BRAKE

Refer to illustration below. Tighten the screw until the spring compresses to the 1-1/4" dimension. Adjust screw

"A" until cone shaped stud just touches the two brake shoes as shown.

CAUTION: Do NOT over-adjust screw "A". If the cone shaped stud spreads the shoes, the brake will not

function correctly.

Brake

Shoe

Cone

Shaped Stud

1-1/4"

(+ or - 1/32")

Set

Screw "A"

HOW TO ORDER REPAIR PARTS

OUR LARGE SERVICE ORGANIZATION

SPANS AMERICA

INSTALLATION AND SERVICE INFORMATION

ARE AVAILABLE 6 DAYS A WEEK

CALL OUR TOLL FREE NUMBER – 1-800-528-6563

HOURS 7:00 TO 3:30 p.m. (Mountain Std. Time)

MONDAY Through SATURDAY

IN CANADA

CALL OUR TOLL FREE NUMBER – 1-800-654-4736

Spring

Tighten Screw

to Adjust

Spring Compression

WHEN ORDERING REPAIR PARTS

PLEASE SUPPLY THE FOLLOWING INFORMATION:

PART NUMBER DESCRIPTION MODEL NUMBER

ADDRESS ORDER TO:

THE CHAMBERLAIN GROUP, INC.

Electronic Parts & Service Dept.

2301 N. Forbes Blvd., Suite 104

Tucson, AZ 85745

8

Page 9

NOTE:

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to

Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful

interference when the equipment is operated in a commercial environment. This equipment generates, uses, and

can radiate radio frequency energy and, if not installed and used in accordance with the instruction manual, may

cause harmful interference to radio communications. Operation of this equipment in a residential area is likely to

cause harmful interference, in which case the user will be required to correct the interference at his own expense.

MEMO:

9

Page 10

SOLID STATE SINGLE PHASE

WIRING DIAGRAM

OPEN

NC

INDUCTOR

White

Gry./Wht.

2

Yellow

Red

Yellow

3

Blue

Brown

1

RADIO CONTROL

LIMIT

SWITCH

C

POWER

Yellow

Red

White

Blue

NO

P7-

Remove Jumper

to Install Interlock

Blue

White

Blue

White

Yellow

Red

Orange

Black

E10

P1-

15

P6-

E12

Q7

E8

E9

P3-

P2-

U1

4

12345678910

TB1-

1

Open / Close

Yellow

White

Red

Q9

Q8

E14

E11

E13

P4-

234

1

ON

OFF

Open

Close

Stop

Sensing Device

White

E17

E16

NC

NO

Red

White

White

Q10

E15

E1

E2

E3

SENSING

SWITCH

E20

E19

LIMIT

C

NC

NO

Orange

White

Q11

E18

L1

L3 L2

E4

E21

XMFR SECONDARY

CLOSE

LIMIT

SWITCH

C

Yellow

*

Black

Black

Red

White

Black

White White

Neutral 115V

N

208-230V, 1Ø

Hot 115V

H

208-230V, 1Ø

Black

Black

Blue

Yellow

E6 E7

Yellow

Black

Black

Black

Black

Black 115V

Orange 208-230V

Blue

Blue

Yellow

Internal Interlock

(when used)

OVERLOAD

PROTECTOR

Blue

MOTOR

*THIS WIRE NOT USED

WITH POWER INDUCTOR

RedRedRed

OrangeOrange

TO

MECHANICAL

BRAKE

GND

White

Orange 115V

Black 208-230V

LINE

TRANSFORMER

LOAD

10

Page 11

STANDARD POWER AND

CONTROL CONNECTION DIAGRAM

(Solid State Board CDO - 115V, 208-230V, 1Ø)

123

RADIO CONTROL

(24V dc only)

TB1-

Remove Jumper

to Install Interlock

12 345678910

Open

Close

Open / Close

Stop

Sensing Device

L1 N

L2 H

L3

GND

Neutral 115V, 208-230V, 1Ø

Hot 115V, 208-230V, 1Ø

The Chamberlain Group, Inc.

1Ø Standard Power & Control Connection Diagram

Solid State CDO

2/22/94 - 2/25/94

11

Page 12

SOLID STATE THREE PHASE

WIRING DIAGRAM

OPEN

NC

LIMIT

SWITCH

C

NO

Blue

White

Yellow

White

White

NC

NO

Red

White

White

SENSING

LIMIT

SWITCH

C

NC

NO

CLOSE

LIMIT

SWITCH

C

*THIS WIRE NOT USED ON 3/4 HP

AND ABOVE WITH POWER INDUCTOR

Blue

Yellow

Orange

Blue

White

Yellow

POWER

INDUCTOR

Red

Yellow

Red

White

Blue

Blue

White

Yellow

E10

P1-

P7-

P6-

Red

Yellow

Yellow Yellow

Orange

Q7

Q8

E12

E14

E11

E9 E8

Red

1/3 &1/2 HP ONLY

P2-

51

41

12345678910

TB1-

P4-

P3-

U1

234

1

ON OFF

Q9

E13

E16

E17

Red

Q10

E15

E3

Black

MOTOR

Red

Yellow

1/3 & 1/2 HP ONLY

Orange

Yellow

Yellow

White

*

Black

E19

E20

Q11

E18

Red

Orange

Black

& Above

3/4 HP & Above

Orange

White

E1

L1

E2

White

N

208-230V, 3Ø

H

208-230V, 3Ø

**THIS WIRE NOT USED ON 1/3 & 1/2 HP

WITH POWER INDUCTOR

Black

White

Black

Blue

3/4 HP

RedRed

T1

T2

T3

96

95

OVERLOAD

TO

MECHANICAL

BRAKE

Black

**

White

GND

L1

Black

L2

Wht.

L3

208-230V, 3Ø

L3 L2

E4

E21

Black

White

E5

Black

Orange

Black

E7

Blue

Black

Black

Blue

White

Orange

208-230V

YellowYellow

Black

LINE

Yellow

E6

XMFR SECONDARY

TRANSFORMER

Brown

1

Yellow

Gry./Wht.

3

2

RADIO CONTROL

Open / Close

Open

Close

Stop

Sensing Device

Black

Blue

12

Blue

Yellow

Blue

Yellow

Internal Interlock

(when used)

External Interlock

(if required)

LOAD

Page 13

STANDARD POWER AND

CONTROL CONNECTION DIAGRAM

(Solid State Board CDO - 208-230V, 3Ø)

123

RADIO CONTROL

(24V dc only)

TB1-

12 345678910

Open

Close

Open / Close

Stop

Sensing Device

L1 N

L2 H

L3

GND

208-230V, 3Ø

208-230V, 3Ø

208-230V, 3Ø

OPTIONAL SETTINGS

Set Maximum Run Timer

Begin with door in closed position. Set dip switch to max. run timer

mode. Press control station open button to operate door from closed to

full open position without stopping. Set dip switch to desired operating

mode (B2, C2, D1, E2, T, TS).

Set Adjustable Mid Stop

Begin with door in closed position. Set dip switch to adj. mid stop mode.

Press control station open button to operate door from closed to mid

stop position and stop with control station stop button. Set dip switch to

desired operating mode (B2, C2, D1, E2, T, TS).

Set Timer to Close (NOTE: Requires P/N 1A4811 CPSII

Option Board with Timer to Close Function.)

Set dip switch to timer to close mode. Momentarily press control station

open button to set timer duration in 5 second increments. (Red

diagnostic L.E.D. will flash to indicate the entry of each 5 second

increment into memory). To re-set timer memory to zero, press control

station close button. Set dip switch to (T or TS) operating mode after

timer is programmed.

Diagnostic Mode

Set dip switch to diagnostic mode. Flashing red diagnostic L.E.D.

indicates proper microprocessor function. If the diagnostic L.E.D. does

not light, the control logic board requires replacement.

Set

max.

run

timer

Set

adj.

mid

stop

Set

timer

to close

Diagnostic

mode

123

OFF

123

OFF

123

OFF

123

OFF

4

4

4

4

13

Page 14

TYPE STATION

OPERATING MODE

B2 3 Button, 1 Button, 1 & 3 Button Radio Control

Function: Momentary contact to open, close and stop, plus wiring for

sensing device to reverse and auxiliary devices to open and close

with open override.

C2 3 Button, 3 Button Radio Control

Function: Momentary contact to open and stop with constant pressure

to close, open override plus wiring for sensing device to reverse.

D1 2 Button, 3 Button Radio Control

Function: Constant pressure to open and close with wiring for sensing

device to stop.

E2 2 Button, 3 Button Radio Control

Function: Momentary contact to open with override and constant

pressure to close. Release of close button will cause door to reverse

(roll-back feature) plus wiring for sensing device to reverse.

T* 3 Button, 1 Button, 1 & 3 Button Radio Control

Function: Momentary contact to open, close, and stop, with open

override and timer to close. Every device that causes door to open,

except a reversing device, activates timer to close. Auxiliary controls

can be connected to open input to activate the timer to close. If the

timer has been activated, the open button and radio control can

recycle the timer. The stop button will deactivate the timer until the

close button is used to close the door. (NOTE: Requires P/N 1A4811

CPSII Option Board with Timer to Close Function.)

B2

C2

D1

E2

T

123

OFF

123

OFF

123

OFF

123

OFF

123

4

4

4

4

4

TS* 3 Button, 1 Button, 1 & 3 Button Radio Control

Function: Momentary contact to open, close, and stop with open

override and timer to close. Every device that causes door to open,

including a reversing device, activates timer to close. Auxiliary

controls can be connected to open input to activate the timer to close.

If the timer has been activated, the open button and radio control can

recycle the timer. The stop button will deactivate the timer until the

close button is used to close the door. (NOTE: Requires P/N 1A4811

CPSII Option Board with Timer to Close Function.)

NOTE:

1. External interlocks may be used with all functional modes.

2. Auxiliary devices are any devices that have only one set of

contacts. Examples are: photocell, loop detector, pneumatic or

electrical treadles, residential radio controls, one button stations,

pull cords, etc.

3. Open override means that the door may be reversed while closing

by activating an opening device without the need to use the stop

button first.

TS

OFF

123

OFF

4

14

Page 15

NEMA MOTOR WIRING DIAGRAMS

The Chamberlain Group, Inc.

NEMA Motor Wiring Diagrams

2/19/94

Motor

Cable

Motor

T2 White

T4 YellowYellow

115V

Blue

Yellow

Orange

SINGLE VOLTAGE

1/3 & 1/2HP 115V only

115V

T1 - BlueBlack

T4 - Yellow

1KΩ 5W

T5 - Black

T8 - RedRed

1 PHASE

208-230V

Motor

T4 YellowOrange

Orange

Blue

Black

Red

Cable

Motor

Yellow

Black

Blue

Orange

Red

T5 Black

T3 Orange

T1 Blue

T8 Red

Cable

Yellow

Blue

Black

Red

T5-Black

T1 Blue

3 PHASE

1/3 & 1/2HP 3/4HP & OVER

Motor

Yellow

Black

Blue

Orange

Red

T1

T7

T2

T8

T3

T9

P2

P1

T7

T2

T8

T3

208-230V

T1

T4

T5

T6

T9

T8

RedT3Orange

T2

White

208-230V

T4

T5

T6

Cable

DENOTES WIRENUT CONNECTION

Cable

15

15

Page 16

Page 17

ITEM

NO.

10 155B16 1 Heat Sink

11 133A182 2 Limit Nut 1/2"

12 171A411 4 Screw 4/40 x 1-1/2" Pan Head

13 216A184 2 Thrust Washer

14 216A191 1 Washer, Spring Curved

15 158A49 1 Retaining Ring 3/8"

16 184A109 4 Spacer - Stand Off - Round

17 180B133 2 Limit Switch

PART NO. QTY. DESCRIPTION

1 1B3727 1 Terminal Assy. 3-Lug

2 41K4304 1 Switch Bracket Assy. (Aux. & Sensing)

3 1B3796 1 Ltd. Shaft-Sprocket Assy.

4 1B4681 1 Cover & Hinge Assy.

5 1C4691 1 Electric Box Assy.

6 1B4683 1 Wire Harness Limit Switch

7 11A012 1 Flanged Sleeve Bearing

8 12B552 1 Limit Bracket

9 31A388 1 Dome Plug

REPAIR PARTS – GJ

REPAIR PARTS -

SOLID STATE

SOLID STATE

ELECTRICAL BOX

ELECTRICAL BOX

1/2 HP, 115V, 1 PHASE

123D0135

1/2 HP, 230V, 1 PHASE

123D0135

1/2 HP, 230V, 3 PHASE

123D0138

3/4 HP, 115V, 1 PHASE

DESCRIPTION

MOTOR P/N

ITEM PART NO.

M

18

19

20

21

22

23 1B4824 Inductor Power Assy.

REMARKS: *Overload to be set at 115% maximum of motors rated current.

1D4650

180C0104-3

180C0104-4

204B0134

180B0159-1

180B0159-2

180B0159-3

180B0159-4

180B0159-5

180B0159-9

1B4682

DESCRIPTION

Motor

PCB Assy.

Overload 2.8 - 4.4A

Overload 5.2 - 8A

Transformer 115V/230V

Overload 5A

Overload 7A

Overload 8A

Overload 10A

Overload 15A

Overload 12A

Radio Control Harness

111

11

11

1

11

11

11111 1111

11111 1111

1

11111 1111

11111 1111

123D0136

11 1

1

3/4 HP, 230V, 1 PHASE

123D0136

3/4 HP, 230V, 3 PHASE

123D0139

1 HP, 115V, 1 PHASE

123D0137

1 HP, 230V, 1 PHASE

123D0137

1111

1

1

1

1

1

1 HP, 230V, 3 PHASE

123D0140

1 1/2 HP, 230V, 3 PHASE

123D0143

2 HP, 230V, 3 PHASE

123D0142

1

1

1

17

Page 18

Page 19

ITEM

PT. NO. DESCRIPTION QTY.

1 See Chart Motor 1

80D8 Gear Reducer, 1-1/2 & 2 HP 1

2

80D9 Gear Reducer up to 1 HP 1

3 See Detail Electric Box 1

4 1D4098 Frame Assembly, GJ Brake/Hoist 1

5 31C373 Cover, GJ Brake Housing 1

6 1B4421 Brake Shoe/Lining Assembly 2

7 81B127 Gear, 12 D.P. 18T. Bevel Pinion 1

8 81B128 Gear, 12 D.P. 36T. Bevel 1

9 60B32 Drum, Brake 1

10 177A138 Spring, Compression 1

11 1C4205 Bracket Assembly, Pivot Bar 1

12 See Chart Brake Solenoid 1

13 142A143 Plate, Brake Pivot 1

14 41K4106 Bearing w/Key, 3/4"I.D. & Washer 2

15 181B120 Shaft, GJ Hoist 1

16 1B3885 Emergency Cable Assembly 1

17 23A89 1/4" x 1/4" x 1" Key 2

18 81B86 Sprocket 50B11 x 1 1

19 177B128 Spring, Extension 1

20 1B4688 Brake Cable 1

1A4092 Chain 45P #48 1-1/2 & 2 HP 1

21

1A3742 Chain 43P #48 up to 1 HP 1

22 1A995 Master Link #48 1

23 81A72 Sprocket 43B14 x 1 1

24 158A53 Retaining Ring, .750 "E" 3

184A124 Spacer, 1-1/2 & 2 HP 4

25

184A123 Spacer up to 1 HP - .625 4

26 146B68-2 Pin, Cotterless Clevis 1

27 25B13 Coupling, Bevel Gear 1

28 146A81 Cotter Pin 1

29 1C3758 Hoist Wheel Assembly 1

30 22A14 Hand Chain, Gold Color 1

31 12C513 Chain Guide 1

32 184A102 Tie Bar 1

33 113B50 Lever Brake Pivot 1

34 179A46 Stud - Brake Release 1

35 12B393 Chain Keeper 1

36 2B377 Pulley Assembly 1

37 12B517 Bracket, Electrical Box 1

38 12B515 Bracket Right 1

39 12B516 Bracket Left 1

REPAIR PARTS – MODEL GJ

SOLID STATE

DESCRIPTION

MOTOR P/N

1/2 HP, 115V, 1 PHASE

123D0135

1/2 HP, 230V, 1 PHASE

123D0135

1/2 HP, 230V, 3 PHASE

123D0138

3/4 HP, 115V, 1 PHASE

123D0136

3/4 HP, 230V, 1 PHASE

123D0136

3/4 HP, 230V, 3 PHASE

123D0139

1 HP, 115V, 1 PHASE

123D0137

1 HP, 230V, 1 PHASE

123D0137

1 HP, 230V, 3 PHASE

123D0140

11/2 HP, 230V, 3 PHASE

123D0143

2 HP, 230V, 3Ø

ITEM PART NO. DESCRIPTION

1 Motor 1 1111111111

12 204B0118 Brake Solenoid 115V 1 1 1

204B0118-1 Brake Solenoid 230V 1 1 1 1 1 1 1 1

19

123D0142

Page 20

CONTROL CONNECTION DIAGRAM

ATTENTION: The 3-Button Control Station provided must be connected for operation.

3 BUTTON STATION OR 3 POSITION KEYSWITCH WITH SPRING RETURN TO CENTER AND STOP BUTTON

STANDARD

7645

Open

Close

Stop

2 BUTTON STATION OR 3 POSITION KEYSWITCH WITH SPRING RETURN TO CENTER

STANDARD

764

7645

2 OR MORE KEY LOCKOUT

7645

Open

Close Close

Stop Stop

Open

2 OR MORE

764

Open

Close

Stop

Keyswitch

®

D1 & E2

MODE ONLY

Open

Close

1 BUTTON STATION OR ANY AUXILIARY DEVICE

OPEN / CLOSE

14

SENSING DEVICE TO REVERSE OR STOP EXTERNAL INTERLOCK

48

B2, T & TS

MODE ONLY

Open

Close Close

RESIDENTIAL RADIO CONTROLS

OPEN TIMER TO CLOSE

4110

RADIO CONTROL

REMOVE JUMPER

23

Open

123

(24Vdc only)

D1 & E2

MODE ONLY

23

ONE

WIRING TYPES - ALL

2 OR MORE

© 1994, The Chamberlain Group, Inc.

114A1802C All Rights Reserved Printed in Mexico

Loading...

Loading...