Page 1

OWNER'S MANUAL

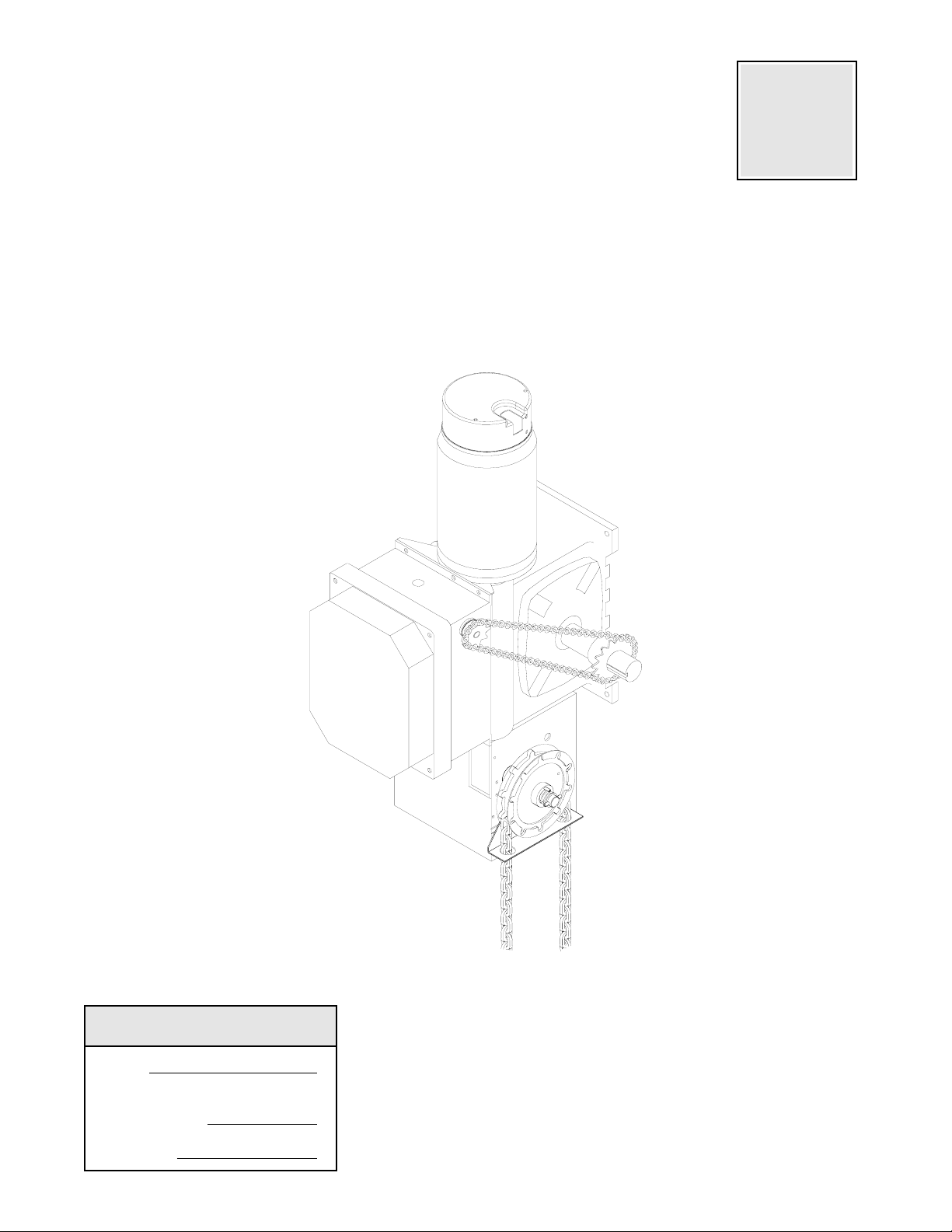

MODEL GH 5HP

HEAVY DUTY DOOR OPERATOR

Serial #

(located on electrical box cover)

Installation Date

Wiring Type

2 YEAR WARRANTY

FACTORY SET

C2 Wiring

See page 8 for

other wiring

configurations

Page 2

SPECIFICATIONS

MOTOR

TYPE:....................................AC Synchronous

continuous duty

brake motor

ENCLOSURE:.......................ODP NEMA 184TC face

mount.

HORSEPOWER:...................5 HP

Three phase

SPEED:.................................1725 RPM

VOLTAGE:.............................208/230 & 460 Three phase

OR 575V Three Phase

BRAKE HOLDING

FORCE:.................................15 Ft-Lbs

DRIVE SYSTEM

CONTINUOUS

POWER RATING: .................1000 Ft-Lbs/Sec

GEAR BOX:..........................Worm gear

LUBRICATION:.....................Oil Bath

RATIO: ..................................45:1

OUTPUT SPEED: .................38 rpm

DOOR SPEED: .....................5” per sec.

depending on door

OUTPUT SHAFT:..................1.5” Dia. with 3/8” keyway

OVERHUNG LOAD:..............1752 Lbs.

(1.5” from output bearing face)

HOIST WHEEL: ....................Standard mounting on

left or right side.

DISCONNECT:......................Floor level chain hoist with

electrical interlock for

emergency manual door

operation.

ELECTRICAL

TRANSFORMER:...............3PH: 208/230/480 VAC 24VAC

OR 3PH: 575VAC-24VAC

CONTROL STATION: ........NEMA 1 three button station.

OPEN/CLOSE/STOP

WIRING TYPE: ...................Standard C2 Wiring- Standard

operators are shipped from the factory set for C2 wiring,

which requires momentary contact to open, constant

pressure to close, stop on release.

Optional B2 Wiring- Which requires momentary contact to

open, close and stop. See schematic diagram on page 12

for instructions on how to configure the operator for B2

wiring

Wiring for sensing device to reverse and auxiliary devices to

open and close with open override.

LIMIT ADJUST: ..................Rotary driven, fully

adjustable screw type cams. Adjustable to 50 feet.

(Provides 2 minutes of operator running time).

DUTY CYCLE:....................25 Reversing cycles per hour

DELAY ON REVERSE:.......Standard

SAFETY

REVERSING EDGE:.......(Optional) Electric or pneumatic

sensing device attached to the bottom edge of door.

A REVERSING EDGE IS STRONGLY RECOMMENDED

ALL

FOR

REQUIRED

IS OUT OF SIGHT OF DOOR OR ANY OTHER

CONTROL (AUTOMATIC OR MANUAL) IS USED.

SHOULD THE CHAIN OR OPERATOR FAIL AS AN

ADDED SAFETY FEATURE, IT IS RECOMMENDED TO

USE STOP LOCK BEARINGS ON THE DOOR SHAFT

TO PREVENT THE DOOR FROM CRASHING DOWN.

COMMERCIAL OPERATOR INSTALLATIONS.

WHEN THE 3 BUTTON CONTROL STATION

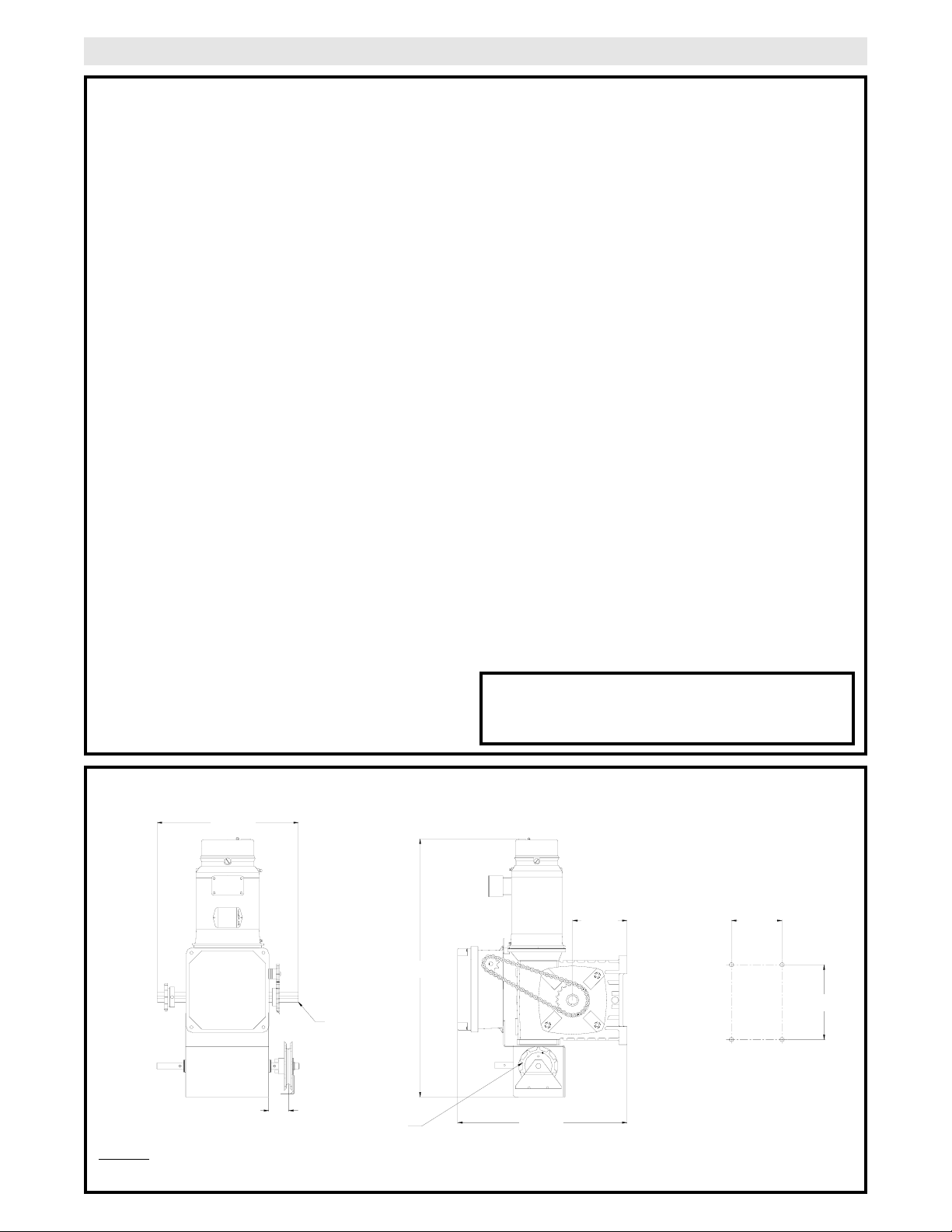

WEIGHTS AND DIMENSIONS

HANGING WEIGHT:.......300 LBS.

18.00”

See

Note #1

2.38”

Hand Chain Wheel

NOTES:

1) Output Shaft 1.5” Dia. with 3/8” Keyw a y.

40.25”

8.50”

26.38”

7.87”

11.61”

2

Page 3

TO AVOID DAMAGE TO DOOR AND OPERATOR,

MAKE ALL DOOR LOCKS INOPERATIVE. SECURE

LOCK(S) IN "OPEN" POSITION.

IF THE DOOR LOCK NEEDS TO REMAIN

FUNCTIONAL, INSTALL AN INTERLOCK SWITCH.

DO NOT CONNECT ELECTRIC POWER UNTIL

INSTRUCTED TO DO SO.

KEEP DOOR BALANCED. STICKING OR BINDING

DOORS MUST BE REPAIRED. DOORS, DOOR

SPRINGS, CABLES, PULLEYS, BRACKETS AND

THEIR HARDWARE MAY BE UNDER EXTREME

TENSION AND CAN CAUSE SERIOUS PERSONAL

INJURY. CALL A PROFESSIONAL DOOR

SERVICEMAN TO MOVE OR ADJUST DOOR

SPRINGS OR HARDWARE.

WARNING

CAUTION

WARNING

WARNING

WARNING

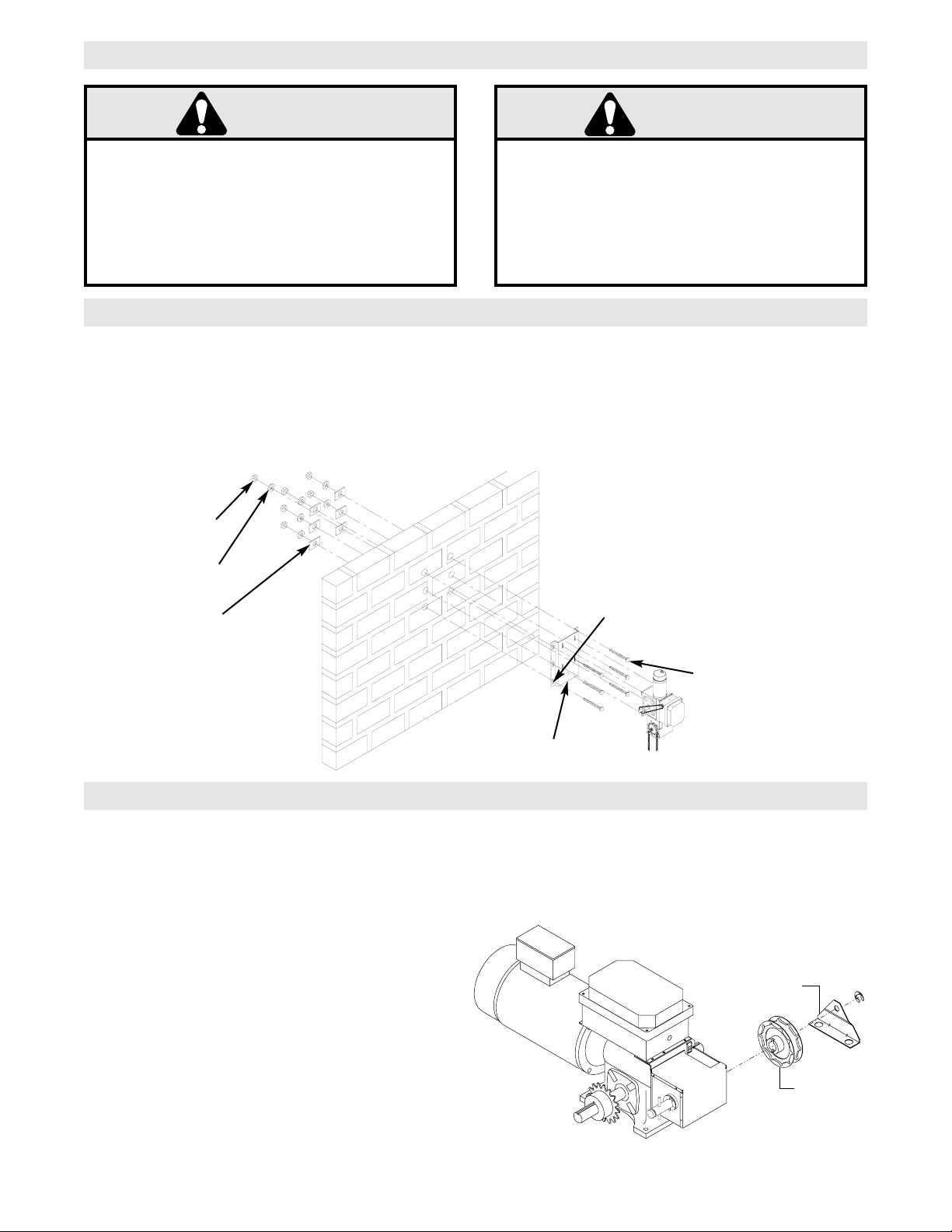

SITE PREPARATIONS

It is imperative that the wall or mounting surface

provide adequate support for the operator.

This surface must:

a) Be rigid to prevent play between operator and

door shaft.

b) Provide a level base.

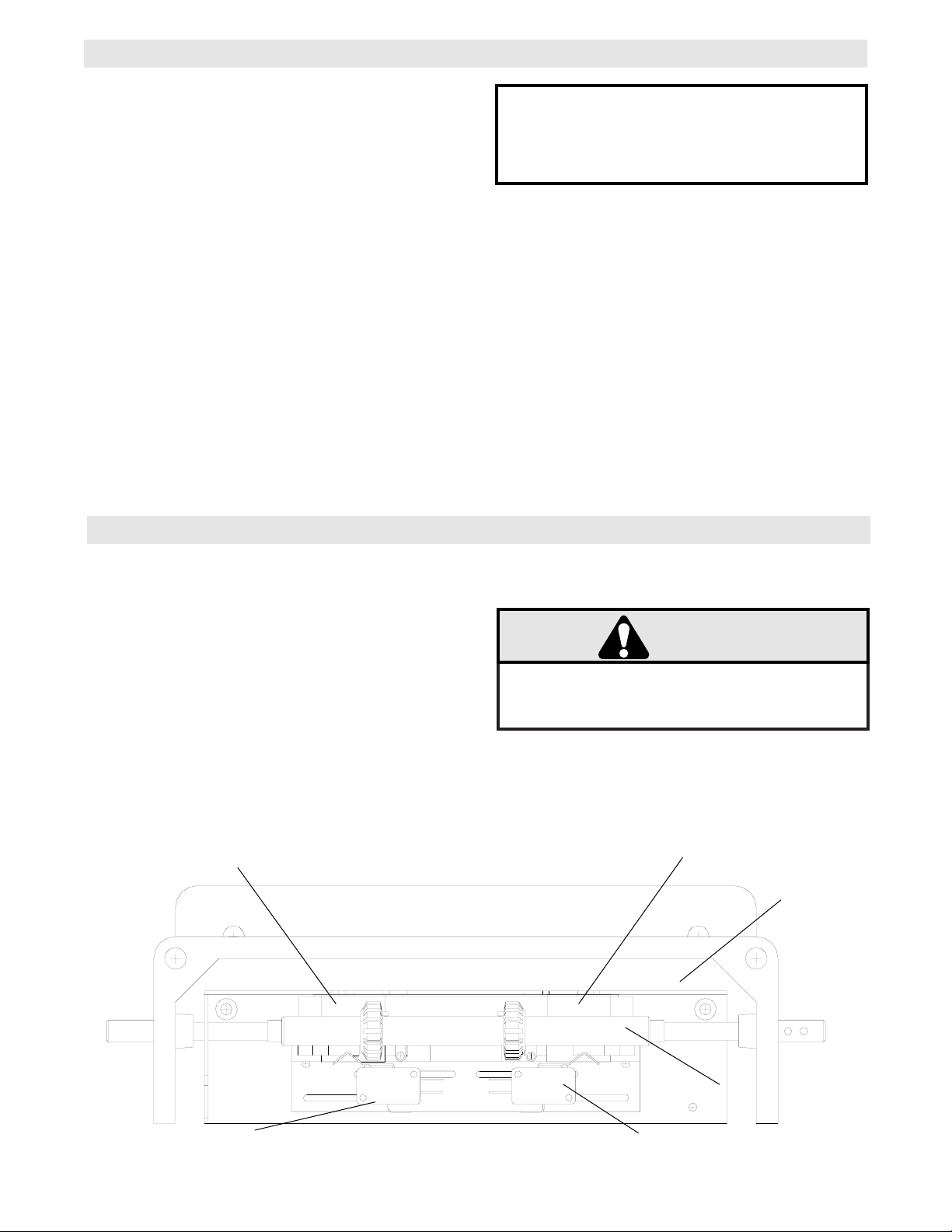

OPERATOR PREPARATION

IMPORTANT SAFETY NOTES

The GH operator may be mounted on either the right (standard) or left side of door, and in either a vertical

(standard) or horizontal mounting position. Refer to the steps below if you require the hand chain and/or

disconnect chain to be on the opposite side of the operator; Or if the operator is being mounted in a horizontal

position.

Hand Chain Right/Left Conversion

Remove the outer snap ring securing the chain wheel

assembly. In reverse of disassembly, install the chain

wheel assembly on the opposite side of the gear hoist

housing.

FIGURE 2

c) Permit the operator to be fastened securely and

with the drive shaft parallel to the door shaft.

The safety and wear of the operator will be adversely

affected if any of the above requirements are not met.

FIGURE 1

BEARING PLATES

RECOMMENDED MIN. SIZE

1/4” THK. 2” X 2” SQ. MIN.

STEEL

OPTIONAL

MOUNTING PLATE

(SEE PAGE 16)

USE 5/8” DIA. BOLTS THAT

PROTRUDE THROUGH THE

WALL, WITH BEARING PLATES

ON THE OUTSIDE OF THE

BUILDING TO DISPLACE THE

LOAD.

5/8” DIA. BOLT

HEX NUT

LOCK WASHER

CAUTION

WARNING

Chain Guide

Hand

Chain Wheel

Page 4

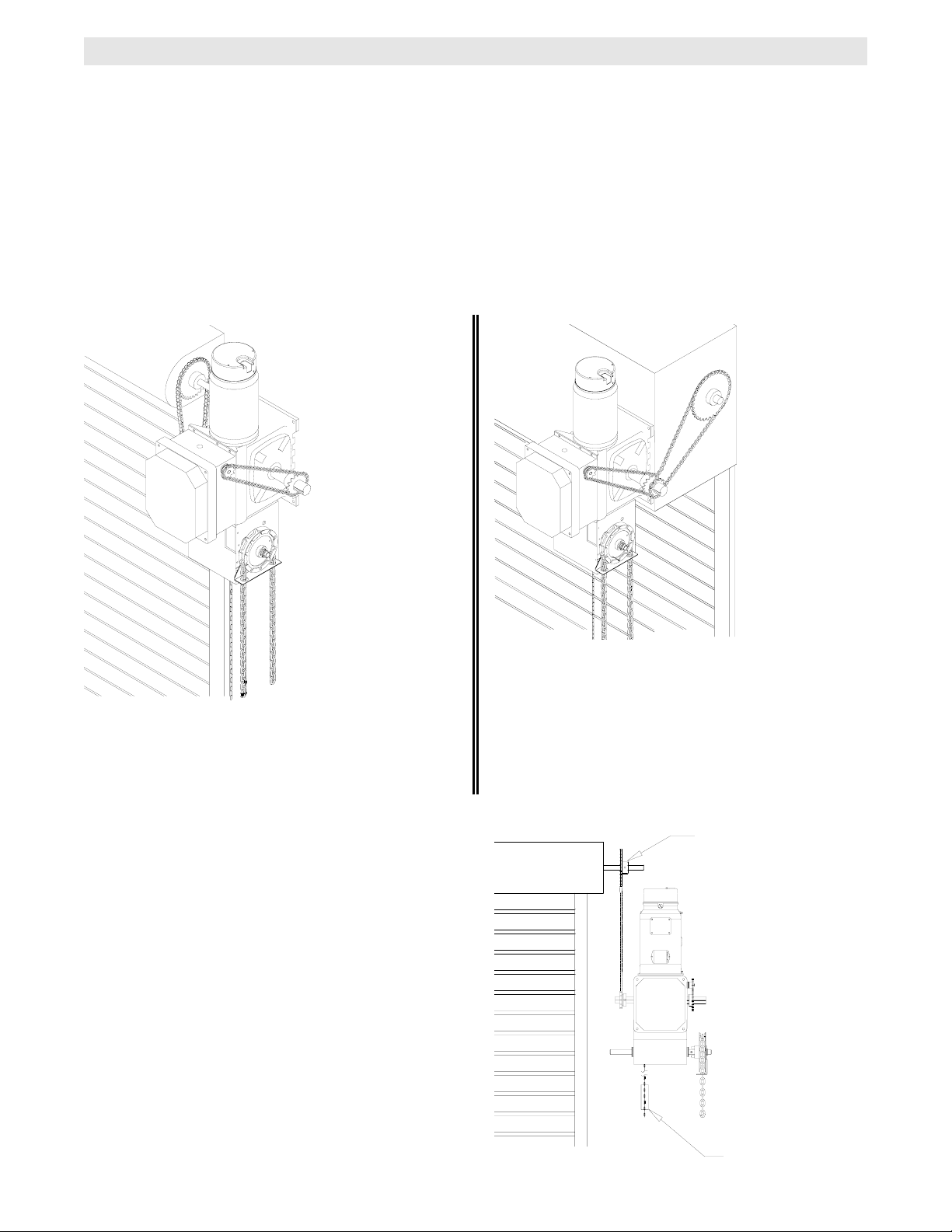

OPERATOR MOUNTING

Before your operator is installed, be sure the door has been properly aligned and is working smoothly. The

operator may be wall mounted or mounted on a bracket or shelf. If necessary, refer to the operator preparations

on page 3. Refer to the illustration and instructions below that suits your application. NOTE: The operator has a

weight of 300 lbs.

1a. Wall Mounting

The operator should generally be installed below

the door shaft, and as close to the door as

possible. Refer to Figure 3.

1b. Bracket or Shelf Mounting

The operator may be mounted either above or

below the door shaft. Refer to Figure 4.

Typical Right Hand

Wall Mounted Operator

FIGURE 3

1c. Place door sprocket on the door shaft. Do not

insert the key at this time.

2. Place drive sprocket on the appropriate side of

the operator. Do not insert the key at this time.

3. Wrap drive chain around door sprocket and join

roller chain ends together with master link.

4. Raise operator to approximate mounting position

using suitable lifting apparatus and position chain

over operator sprocket.

5. Raise or lower operator until the chain is taut (not

tight). Make sure the operator output shaft is

parallel to door shaft and sprockets are aligned.

When in position, secure the operator to wall or

mounting bracket.

6. Align sprockets and secure, (see Figure 5).

IMPORTANT:

provide adequate support, prevent play

between operator and door shaft, and permit

operator to be fastened securely and with the

drive shaft parallel to the door shaft.

The shelf or bracket must

FIGURE 4

Be sure door

sprocket is properly

aligned with drive

before securing to

the shaft.

Chain Keeper

FIGURE 5

4

Page 5

This operator is equipped with a manual hoist. An

electrical interlock will disable the electrical controls

when the hoist is used.

To operate the hoist:

1. Pull the disconnect chain (small chain) to engage

the hoist mechanism. The disconnect chain may be

locked in position by slipping the end through the

keyhole of the chain keeper mounted on the wall.

2. Operate the door in the desired direction by pulling

on one side or the other of the continuous loop hoist

chain (large chain).

3. The disconnect chain must be released from the

chain keeper before the door will operate again

electrically.

5

7. Install Hand Chain Place hand chain around hand chain wheel. Be

sure to pass it through both openings in the chain

guide. Remove enough links so chain hangs

approximately two feet above the floor

8. Mount Chain Keeper / Keyhole Bracket Using suitable hardware mount the chain keeper approximately 4 feet above the floor, near the free hanging chain. Remove disconnect sash chain from bag. Install locking collar onto the disconnect chain. Place end through the keyhole in the chain keeper. With the disconnect chain having no slack slide collar up 3” from keyhole in the chain keeper and lock into place by tightening the set screw. Confirm that when the sash chain is pulled, the locking collar is against the chain keeper and at the same time, the bevel gears located in the operator hoist mechanism are in full engagment. If not then readjust the collar to assure full engagment. Remove excesss links if necessary.

EMERGENCY MANUAL OPERATION

This operator has provisions for manually operating the door in case of emergency or power failure.

Model GH 5HP

Chain Keeper

(with pad locking provisions)

Manual Hoist

TURN OFF POWER TO THE OPERATOR BEFORE

MANUALLY OPERATING YOUR DOOR.

WARNING

Released Position

Engaged Position

3”

COLLAR

12-14737

WARNING

Page 6

WARNING

ENTRAPMENT PROTECTION ACCESSORIES (OPTIONAL)

SENSING EDGES

All types of sensing edges with an isolated normally

open (N.O.) output are compatible with your operator.

This includes pneumatic and electric edges. If your

door does not have a bottom sensing edge and you

wish to purchase one, contact the supplier of your

operator.

If not pre-installed by the door manufacturer, mount

the sensing edge on the door according to the

instructions provided with the edge. The sensing

edge may be electrically connected by either coiled

cord or take-up reel. Refer to the steps below.

Important Notes:

a) Proceed with Limit Switch Adjustments before

making any sensing edge wiring connections to

operator as described below.

b) Electrician must hardwire the junction box to the

operator electrical box in accordance with local

codes.

IT IS STRONGLY RECOMMENDED THAT A

SENSING EDGE OR OTHER ENTRAPMENT

PROTECTION DEVICE BE USED IN

CONJUNCTION WITH THIS OPERATOR.

WIRING:

For wiring of your sensing device to the operator,

refer to the schematic diagram supplied with your

operator. See field connection terminals identified

as Sensing Device or Safety Edge.

TAKE-UP REEL: Take-up reel should be installed

12" above the top of the door.

COIL CORD: Connect operator end of coil cord to

junction box (not supplied) fastened to the wall

approximately halfway up the door opening.

LIMIT SWITCH ADJUSTMENT

MAKE SURE THE LIMIT NUTS ARE POSITIONED BETWEEN THE LIMIT SWITCH ACTUATORS BEFORE

PROCEEDING WITH ADJUSTMENTS.

1. To adjust limit nuts depress retaining plate to allow

nut to spin freely. After adjustment, release plate

and ensure it seats fully in slots of both nuts.

2. To increase door travel, spin nut away from

actuator. To decrease door travel, spin limit nut

toward actuator.

3. Adjust open limit nut so that door will stop in open

position with the bottom of the door even with top

of door opening.

4. Repeat Steps 1 and 2 for close cycle. Adjust close

limit nut so that actuator is engaged as door fully

seats at the floor.

CLOSE Limit Switch

WARNING

TO AVOID SERIOUS PERSONAL INJURY OR DEATH

FROM ELECTROCUTION, DISCONNECT ELECTRIC

POWER BEFORE MANUALLY MOVING LIMIT NUTS.

If other problems persist, call our toll-free number for

assistance - 1-800-528-2806.

OPEN Limit Switch

Actuator

SAFETY

(Aux. Close) Limit Switch

Retaining Plate

Aux. OPEN Limit Switch

6

Page 7

Remove the cover from the electrical enclosure. Inside this enclosure you will find the wiring diagram(s)

for your unit. Refer to the diagram (glued on the inside of the cover) for all connections described below.

If this diagram is missing, call the number on the back of this manual. DO NOT INSTALL ANY WIRING OR

ATTEMPT TO RUN THIS OPERATOR WITHOUT CONSULTING THE WIRING DIAGRAM.

POWER WIRING CONNECTIONS

DISCONNECT POWER AT THE FUSE BOX BEFORE

PROCEEDING.

OPERATOR MUST BE PROPERLY GROUNDED AND

PERMANENTLY WIRED IN ACCORDANCE WITH

LOCAL ELECTRICAL CODES. NOTE: THE

OPERATOR SHOULD BE ON A SEPARATE FUSED

LINE OF ADEQUATE CAPACITY.

ALL ELECTRICAL CONNECTIONS MUST BE MADE

BY A QUALIFIED INDIVIDUAL.

WARNING

TO AVOID DAMAGE TO DOOR AND OPERATOR,

MAKE ALL DOOR LOCKS INOPERATIVE. SECURE

LOCK(S) IN "OPEN" POSITION.

IF THE DOOR LOCK NEEDS TO REMAIN

FUNCTIONAL, INSTALL AN INTERLOCK SWITCH.

1. Be sure that the power supply is of the correct

voltage, phase, frequency, and amperage to supply

the operator. Refer to the operator nameplate on the

cover, and motor nameplate.

2. Recommended conduit entrance to be 7/8”

Dia. to be drilled by installer. Take care not to

damage the internal components, see below. Bring

supply lines to the operator and connect wires to the

terminals indicated on the WIRING CONNECTIONS

DIAGRAM.

DO NOT TURN POWER ON UNTIL YOU HAVE

FINISHED MAKING ALL POWER AND CONTROL

WIRING CONNECTIONS AND HAVE COMPLETED

THE LIMIT SWITCH ADJUSTMENT PROCEDURE.

IMPORTANT: THIS UNIT MUST BE PROPERLY

GROUNDED. A GROUND SCREW IS SUPPLIED IN

THE ELECTRICAL BOX FOR CONNECTION OF

THE POWER SUPPLY GROUND WIRE. FAILURE

TO PROPERLY GROUND THIS UNIT COULD

RESULT IN ELECTRIC SHOCK AND SERIOUS

INJURY.

POWER WIRING

WARNING

Do Not Run Power &

Control Wiring in the

Same Conduit

Recommended location for

7/8” Dia Holes for

power wiring conduit access

WARNING

WARNING

Page 8

CONTROL WIRING THREE PHASE FIELD WIRING

WARNING

CLOSE

DETERMINE WIRING TYPE

Refer to the wiring diagram located on the inside cover the electrical box to determine the type of control wiring.

Standard C2 or B2 Wiring

Standard operators are shipped from the factory with

jumper set for C2 wiring, which requires constant

pressure on button to close the door. If momentar y

contact on close direction is desired (B2 wiring) you

must include an entrapment protection device. See

close control jumper setting below.

Constant pressure on close (C2 wiring)

Red jumper wire was placed on terminal #2 in

electrical enclosure. The operator will require

constant pressure on close control in order to keep

door moving in the close direction.

Momentary contact on close (B2 wiring)

Move red jumper wire from terminal #2 to terminal

#3. The operator will require only momentary

contact to close the door.

SPECIAL CONTROL WIRING

If your operator was shipped from the factory with

non-standard control wiring or with optional

accessories that require addition instructions, refer to

the wiring diagram(s) indicated in the special control

wiring data box. When a replacement wiring diagram

is present, wiring diagrams in this manual will not

apply. Refer only to the replacement wiring diagram

for all connections.

IMPORTANT NOTE: If your wiring diagram is

missing, or you are unsure of the wiring type for

your operator, contact the customer service

department @ 1-800-528-2806.

LOCATING THE CONTROL STATION

All operators are supplied with some type of control station. Generally a three button station

(OPEN/CLOSE/STOP) is provided. A two-position key switch or control station (OPEN/CLOSE) may be added or

substituted when requested at the time of order. Mount the control station near the door.

MOUNT WARNING NOTICE

WARNING

INSTALL THE CONTROL STATION WHERE THE

DOOR IS VISIBLE, BUT AWAY FROM THE DOOR AND

ITS HARDWARE. IF CONTROL STATION CANNOT BE

INSTALLED WHERE DOOR IS VISIBLE, OR IF ANY

DEVICE OTHER THAN THE CONTROL STATION IS

USED TO A CTIVATE THE DOOR,

MUST

DOOR.

UNDER THESE CIRCUMSTANCES MAY RESULT IN

SERIOUS INJURY OR DEATH TO PERSONS

TRAPPED BENEATH THE DOOR.

BE INSTALLED ON THE BOTTOM OF THE

FAILURE TO INSTALL A REVERSING ED GE

A REVERSING EDGE

IMPORTANT: Mount WARNING NOTICE beside or

below the push button station.

Control Station

OPEN

Push

Buttons

C

STOP

LO

S

E

WARNING

TO PREVENT ENTRAPMENT

DO NOT START DOOR DOWNWARD

UNLESS DOORWAY IS CLEAR

WARNING Notice

8

Page 9

9

CONTROL WIRING (con’t)THREE PHASE SCHEMATIC DIAGRAM

Radio Controls

On all models with type B2 control wiring, a terminal

block marked R1 R2 R3 is located in the inside of the

electrical enclosure. All standard radio control

receivers may be used. The operator will then open a

fully closed door, close a fully open door, and reverse

a closing door from the radio transmitter. However, for

complete door control from a transmitter, a

commercial three-channel radio set (with connections

for OPEN/CLOSE/STOP) is recommended.

Additional Access Control Equipment

Locate any additional access control equipment as desired (but so that the door will be in clear sight of the person

operating the equipment), and connect to the terminal block in the electrical enclosure as shown on the FIELD

WIRING CONNECTIONS diagram. Any control with a normally (N.O.) isolated output contact may be connected

in parallel with the OPEN button. More than one device may be connected in this manner. Use 16 gauge wire or

larger for all controls. DO NOT USE THE CONTROL CIRCUIT TRANSFORMER (24VAC) IN THE OPERATOR

TO POWER ANY ACCESS CONTROL EQUIPMENT OTHER THAN A STANDARD TYPE RADIO RECEIVER.

External Interlock Switch

The operator has a terminal connection for an external interlock switch. This switch must be a normally closed

(N.C.) two-wire device with a contact rating of at least 3 amps @ 24VAC. When such a switch is connected as

shown on the FIELD WIRING CONNECTIONS diagram, the control circuit will be disabled when the switch is

actuated, thereby preventing electrical operation of the door from the control devices.

WARNING

DO NOT USE RADIO CONTROLS WITH YOUR

OPERATOR UNLESS YOU HAVE INSTALLED

SOME TYPE OF ENTRAPMENT PROTECTION

DEVICE. THE USE OF RADIO CONTROLS

PRESENTS POTENTIAL HAZARDS DUE TO THE

USER’S ABILITY TO OPEN OR CLOSE THE

DOOR WHEN OUT OF SIGHT OF THE DOOR. IN

ADDITION, IF A SINGLE CHANNEL CONTROL IS

USED, THE USER WILL NOT BE ABLE TO STOP

THE DOOR FROM THE TRANSMITTER.

WARNING

Page 10

WARNING

CONNECT REVERSING EDGE DEVICE (OPTIONAL)

WARNING

WARNING

IF CONTROL STATION CANNOT BE INSTALLED WHERE

DOOR IS VISIBLE, OR IF ANY DEVICE OTHER THAN

THE CONTROL STATION IS USED TO ACTIVATE THE

DOOR,

THE BOTTOM OF THE DOOR.

REVERSING EDGE UNDER THESE CIRCUMSTANCES

MAY RESULT IN SERIOUS PERSONAL INJURY OR

DEA TH T O PERSONS TRAPPED BENEATH THE DOOR.

A REVERSING EDGE MUST BE INSTALLED ON

FAILURE TO INSTALL A

NOTICE:

This equipment has been tested and found to comply with the limits for a Class A digital

device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference when the equipment is operated in a

commercial environment. This equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in accordance with the instruction

manual, may cause harmful interference to radio communications. Operation of this

equipment in a residential area is likely to cause harmful interference, in which case the

user will be required to correct the interference at his own expense.

The operator has been pre-wired to accept

connection of a reversing edge device. Connect the

normally open contacts to terminals T4 and T8 on the

low voltage terminal block. A cut-off switch will deactivate the safety device during the last few inches of

the door's downward travel.

TEST THE SYSTEM

Turn on power. Test all controls and safety devices to

make sure they are working properly. It will be

necessary to refer back to page 6 for fine adjustment

of the limit switches.

IMPORTANT NOTES:

Do not leave operator power on unless all safety

and entrapment protection devices have been

tested and are working properly.

Be sure you have read and understand all Safety

Instructions included in this manual.

Be sure the owner or person(s) responsible for

operation of the door have read and understand

the Safety Instructions, know how to electrically

operate the door in a safe manner, and know how

to use the manual disconnect operation of the

door operating system.

WARNING

DO NOT PLACE HANDS OR TOOLS IN OR NEAR

THE OPERATOR WHEN THE POWER IS ON OR

WHEN TESTING CONTROL OR SAFETY

DEVICES. ALWAYS DISCONNECT POWER

BEFORE SERVICING OR ADJUSTING THE

OPERATOR.

10

Page 11

11

HOW TO ORDER REPAIR PARTS

OUR LARGE SERVICE ORGANIZATION

SPANS AMERICA

INSTALLATION AND SERVICE INFORMATION

ARE AVAILABLE 6 DAYS A WEEK

CALL OUR TOLL FREE NUMBER - 1-800-528-2806

HOURS 7:00 TO 3:30 p.m. (Mountain Std. Time)

MONDAY Through SATURDAY

WHEN ORDERING REPAIR PARTS

PLEASE SUPPLY THE FOLLOWING INFORMATION:

PART NUMBER DESCRIPTION MODEL NUMBER

ADDRESS ORDER TO:

THE CHAMBERLAIN GROUP, INC.

Electronic Parts & Service Dept.

6020 S. Country Club Road

Tucson, AZ 85706

MAINTENANCE SCHEDULE

Use SAE 30 Oil (Never use grease or silicone spray).

U Repeat ALL procedures.

Motor grease fitting to be greased every 12,000 Hrs. of Motor operation. Recommended grease for

standard service conditions is Polyrex EM (Exxon Mobile).

Inspect and service whenever a malfunction is observed or suspected.

CA UTION: BEFORE SERVICING, AL WAYS DISCONNECT OPERA T OR FR OM POWER SUPPLY.

Check at the intervals listed in the following chart.

EVERY EVERY EVERY

ITEM PROCEDURE 3 MONTHS 6 MONTHS 12 MONTHS

Drive Chain Check for excessive slack.

Check & adjust as required.

Lubricate.*

z U

Sprockets Check set screw tightness z U

Fasteners Check & tighten as required z U

Manual Disconnect Check & Operate z U

Bearings & Shafts Check for wear & lubricate z U

Page 12

WARNING

1942

12

Page 13

13

1942

Page 14

WARNING

REPAIR PARTS KITS – ELECTRICAL BOX

Below are replacement kits available for your operator. For replacement of electrical box, motor or brake components be sure

to match model number of your unit to kit number below to ensure proper voltage requirements. Optional modifications and/or

accessories included with your operator may add or remove cer tain components from these lists. Please consult a par ts and

service representative regarding availability of individual components of kits specified below. Refer to page 11 for all repair

part ordering information.

COMPLETE ELECTRICAL BOX KITS

Item

1

03-8224-D

2

03-ABDIN-4

3

10-10477-1

4

21-xxxx

5

24-24-1

6

24-264-4

7

25-xxxx

8

27-8002-D

9

35-204

10

42-114

11

44-18194

12

80-10054

13

82-HS10-06

14

82-PX08-04T

15

82-PX08-10T

16

82-WS08-06G

17

85-FW-10

18

85-LS-10

P/N

Description

Contactor

Din Rail

Electrical Panel (Reworked)

Transformer 230/460V 3 HP

24VAC DPDT Relay

24VDC DPDT Relay

(See Overloads)

Contact Block

Fuse 4 Amp 125V

Terminal Block, 14 Position

Enclosure 12 x 10 x 6

Washer, #8 Terminal

Screw, #10-32 x 3/8” Long

Screw, #8-32 x 1/4” Long

Screw, #8-32 x 11/16” Long

Screw, #8-32 x 3/8” Long

Flatwasher, #10

Lockwasher, #10

K74-18346 LIMIT SHAFT ASSEMBLY KIT

Item

L1

11-10480

L2

12-10481

L3

12-10483

L4

13-10024

L5

13-10516

L6

15-48B18AXX

L7

80-10026

L8

82-PX08-10T

L9

84-FN-08

L10

86-RP04-100

L11

87-E-038

P/N

Description

Limit Shaft

Flange Bearing

Bearing Seal, 3/8” I.D.

Limit Nut

Neoprene Gasket

Sprocket 48B18 x 3/8” Bore

Washer, Shim

Screw, #8-32

Nut , #8-32 Serrated Flange

Roll Pin, 1/8 DIA. x 1” Long

E Ring, 3/8”

Qty

1

1

1

1

1

1

1

2

1

1

1

1

4

8

6

2

4

4

Qty

1

2

2

2

2

1

32

4

4

1

2

Overloads

25-4018-D Overload Model GH5HP23M

25-4010-D Overload Model GH5HP43M

25-4008-D Overload Model GH5HP53M

Transformers

21-3460-1 Model GH5HP23M &

Model GH5HP43M

21-3575-1 Model GH5HP53M

Electrical Box Kits

74-17965 Model GH5HP23M

74-17966 Model GH5HP43M

74-18081 Model GH5HP53M

K72-18345 LIMIT SWITCH ASSEMBLY KIT

Item

10-10476

S1

10-10478

S2

10-12553

S3

18-10036

S4

23-10041

S5

31-12378

S6

82-PX04-12

S7

82-PX04-20

S8

82-PX06-16

S9

82-PX08-04T

S10

84-LH-06

S12

P/N

Description

Depress Plate

Aux. L/S Mtg. Bracket

Nut Plate, Switch

Spring, Depress Plate

Limit Switch

Standoff, Limit Switch

Screw, #4-40 x 3/4” Long

Screw, #4-40 x 1-1/2” Long

Screw, #6-32 x 1” Pan Hd Phillips

Screw, #8-32 x 1/4” Long

Locknut, #6-32 Nylon Hex

Qty

1

1

4

2

4

4

4

4

2

2

2

14 7

Page 15

15

ILLUSTRATED PARTS – ELECTRICAL BOX

Page 16

WARNING

REPAIR PARTS KITS – MODEL GH 5HP

Refer to the parts lists below for replacement kits available for your operator. If optional modifications and/or

accessories are included with your operator, cer tain components may be added or removed from these lists.

Individual components of each kit may not be available. Please consult a parts and service representative

regarding availability of individual components. Refer to page 11 for all repair part ordering information.

INDIVIDUAL PARTS

ITEM PART # DESCRIPTION QTY

1

09-17985

2

09-17986

3

09-17989

4

10-17940

5

10-17984

6

10-17988

7

10-17990

8

15-48B18TKK

9

15-100B15TKK

10

23-10916

11

32-17914-1

12

44-18194

32 Degree Stop Block

0 Degree Stop Block

Wedge

Elec. Box Mounting Bracket

Interlock Bracket

Housing-Gear Hoist

Cover Gear Hoist

Sprocket, 48B18 TKK

Sprocket, 100B15 TKK

SPDT Interlock Switch

Gear Reducer

Electrical Box

1

1

2

1

1

1

1

1

1

1

1

1

K09-17987-1 ENGAGEMENT LEVER ASSEMBLY

ITEM PART # DESCRIPTION QTY

L1

L2

L3

L4

L5

L6

09-17987-1

10-17983

12-18052

31-18054

80-10022

82-SH31-10S

Engagement Lever

Interlock Actuator

Radial Ball Bearing

Spacer

Shim Washer

Shoulder Bolt 3/8” Body x 5/8” Long

1

1

2

2

6

4

K75-18323 CHAIN WHEEL ASSEMBLY KIT

ITEM PART # DESCRIPTION QTY

C1

C2

C3

C4

C5

10-10882

12-10883

75-10884

80-10022

87-E-075

Hand Chain Guide

Nyliner Bearing

Chain Wheel Assembly

Shim Washer

E Ring, 3/4”

1

1

1

1

1

K75-13344 CHAIN ASSY/ BRAKE RELEASE KIT

ITEM PART # DESCRIPTION QTY

R1

R2

R3

R4

R5

R6

R7

18-18190

80-11646

80-1012

82-18077

84-FN31

85-FW-31

96-3575

Safety Draw-Bar Extension Spring

Double Sleeve

S-Hook

Hex Bolt-Modified

Hex Nut, Serrated Flange 5/16-18

Flat Washer For 5/16 Bolt

Braided Cable

1

2

2

1

1

1

1

OPTIONAL ACCESSORIES

PART # DESCRIPTION

50-18084 Mounting Bracket Kit

Motors

20-3500C-4B Model GH5HP23M &

Model GH5HP43M

20-3500C-5B Model GH5HP53M

K75-18324 HAND CHAIN SHAFT KIT

ITEM PART # DESCRIPTION QTY

H1

H2

H3

H4

H5

H6

H7

H8

H9

H10

H11

H12

08-17694-1

08-17695-1

11-18051

12-10029

18-9301

31-18053

80-10022

80-10026

86-DP06-104

86-RP08-112

86-RP10-208

87-E-075

Bevel Gear

Bevel Gear

Shaft

Flanged Bearing

Compression, Spring

Spacer

Shim Washer, .050 Thk.

Shim Washer, 3/8” I.D. x .010 Thk.

Dowel Pin 3/16 Dia. x 1.25 Long

Roll Pin, 1/4” x 1-3/4” Long

Roll Pin, 5/16” x 2-1/2” Long

E-Ring, 3/4”

K75-18180 MOTOR BRAKE ASSEMBLY KITS

ITEM PART # DESCRIPTION QTY

B1

B2

B3

B4

B5

B6

B7

B8

B9

B10

B11

B12

B13

10-17996

10-17997

10-18057

12-18074-1

20-xxxx

80-10026

82-SH31-06S

82-PX25-10

84-FN-25-2

84-FN-31

85-FW-25

85-LS-25

39-18086

Brake Release Bracket

Brake Motor Release Arm

Motor, Brake Cover (Reworked)

Flanged Bearing (Reworked)

(See Motors)

Shim Washer

Shoulder Bolt 3/8” Body x 3/8”Long

Pan Head Screw 1/4-20 x 5/8 Long

Hex Nut, Serrated Flange 1/4-20

Hex Nut, Serrated Flange 5/16-18

Flat Washer for 1/4 Dia. Bolt

Lock Washer for 1/4 Dia. Bolt

Friction Disc Kit

K75-18075 CHAIN ASSY/ CABLE - SASH KIT

ITEM PART # DESCRIPTION QTY

S1

S2

S3

S4

S5

18-13343

19-17160

80-1012

80-11646

96-3575

Safety Draw-Bar Extension Spring

Sash Chain-12’

S-Hook

Double Sleeve

Braided Cable

1

1

1

2

1

1

2

5

1

1

2

3

1

1

1

1

1

5

1

2

2

1

2

2

1

1

1

2

2

1

16

Page 17

17

ILLUSTRATED PARTS – MODEL GH 5HP

Page 18

WARNING

CAUTION

WARNING

WARNING

WARNING

OPERATOR NOTES

18 3

Page 19

19

OPERATOR NOTES

Page 20

CONTROL CONNECTION DIAGRAM

IMPORTANT NOTES:

1) The 3-Button Control Station provided must be connected for operation.

2) If a STOP button is not used, a jumper must be placed between termianls 3 and 4.

3) Auxiliary control equipment may be any normally open two wire device such as

pullswitch, single button, loop detector, card key or such device.

3 BUTTON STATION or 3 POSITION KEYSWITCH w/ SPRING RETURN TO CENTER AND STOP BUTTON

STANDARD

1 2 3 4

Open

Close

Stop

ALL CONTROL WIRING TYPES

2 BUTTON STATION or 3 POSITION KEYSWITCH w/ SPRING RETURN TO CENTER

STANDARD

1 2 4

1 2 4

2 OR MORE KEY LOCKOUT

1 2 3 4

Open

Close

Stop

2 OR MORE

Open

Close

Stop

SEE NOTE #2SEE NOTE #2 SEE NOTES

ATTENTION ELECTRICIAN:

USE 16 GAUGE OR HEAVIER WIRE

FOR ALL CONTROL CIRCUIT WIRING.

1 2 3 4

Open

Close

Stop

Keyswitch

ALL CONTROL WIRING TYPESALL CONTROL WIRING TYPES

1 BUTTON STATION or

ANY AUXILIARY DEVICE

3

7

#2 AND #3

Open

Close

ALL CONTROL WIRING TYPES

SENSING DEVICE TO REVERSE OR STOP

3

10

Sensing Device

ALL CONTROL WIRING TYPES

Open

Close

ALL CONTROL WIRING TYPES

EXTERNAL INTERLOCK

Remove Jumper

When Interlock is Used

4

5

Open

Close

OPEN / CLOSE

B2 WIRING TYPES ONLY

RADIO CONTROLS

R2

R1

RADIO CONTROL

B2 WIRING TYPES

4

5

R3

LOCATED ON MAIN

TERMINAL BLOCK

01-18177E

ONE 2 OR MORE

ALL CONTROL WIRING TYPES

©2003, The Chamberlain Group, Inc.

All rights Reserved

Loading...

Loading...