LiftMaster GH User Manual

QuickStart for the model GH door operator

HOT

IMPORTANT: This QuickStart is intended to highlight a typical installation. These instructions are not intended to be comprehensive. Since each application is unique, it is the responsibility of

the purchaser, designer, installer and end user to ensure that the total door system is safe for its intended use. Please consult the manual and/or a qualified technician for further information.

LOGIC 4

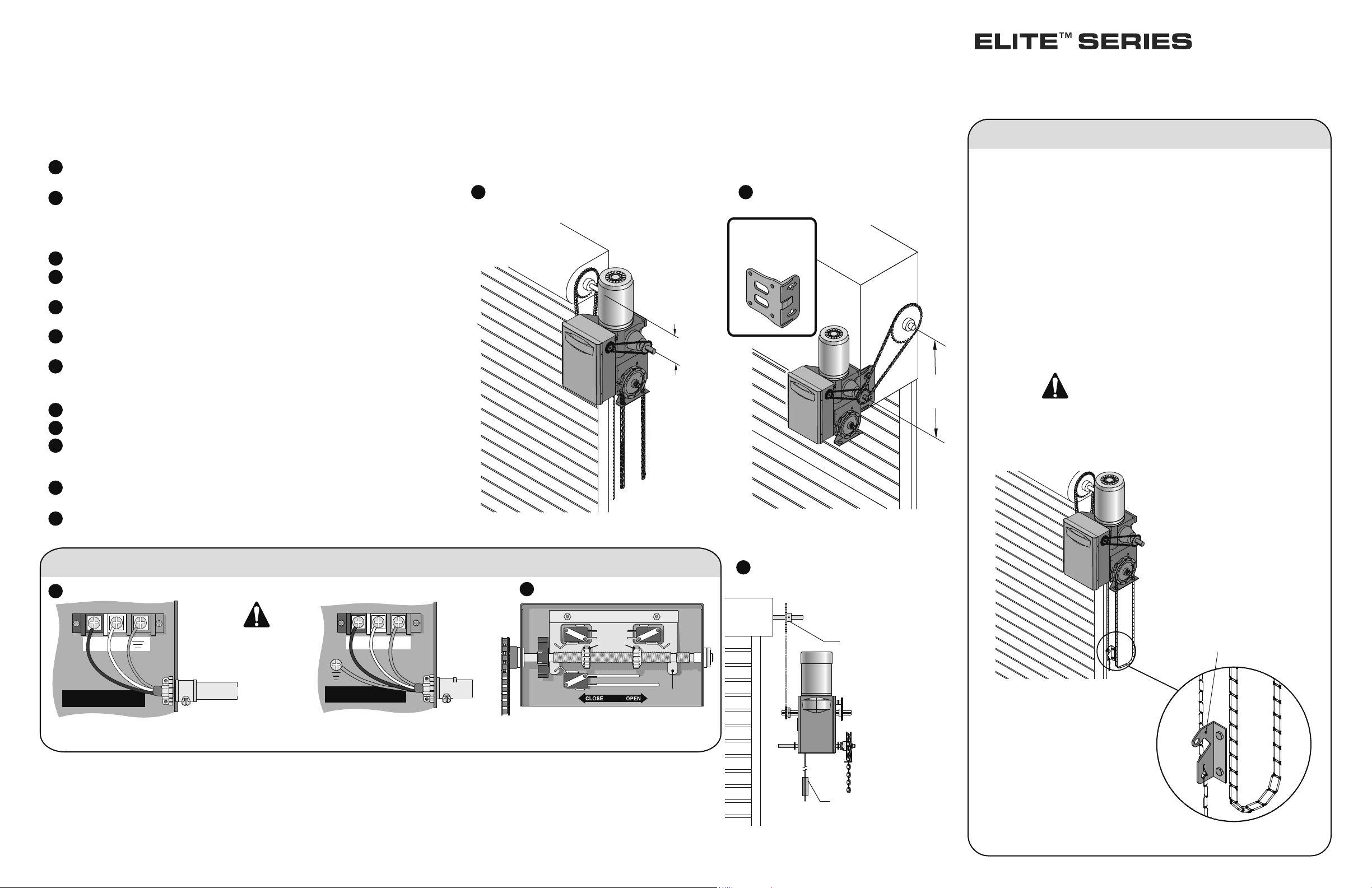

Operator Mounting

1a

Wall Mount: The operator should generally be installed below the door shaft, and

as close to the door as possible.

1b

Bracket Shelf Mounting: The operator may be mounted either above or below the

door shaft.

NOTE: The optimum distance between the door shaft and operator drive shaft is

between 12 - 15 inches.

2

Place door sprocket on the door shaft. Do not insert the key at this time.

Place drive sprocket on the appropriate side of the operator.

3

Do not insert the key at this time.

Wrap chain drive around door sprocket and join roller chain ends together with

4

master link.

5

Raise operator to approximate mounting position and position chain over operator

sprocket.

6

Raise or lower operator until the chain is taut (not tight). Make sure the operator

output shaft is parallel to door shaft and sprockets are aligned. When in position,

secure the operator to wall or mounting bracket.

Align sprockets, insert key into keyway, and secure.

7

Place hand chain around hand chain wheel.

8

9

Run the power wires through the power wiring conduit hole in the electrical box

enclosure. Connect the power to the operator. Connect the earth ground to the

ground screw in the electrical box enclosure. Follow ALL local electrical codes.

10

Adjust the limit switches to open and close door properly. Make sure the limit nuts

are positioned between the limit switches before proceeding with adjustments.

Radio programming and troubleshooting instructions inside cover of operator.

11

1a

Right Hand Wall Mounted Operator

Optimum Distance

12" - 15"

1b

Bracket Shelf Mounted Operator

OPTIONAL

Mounting Bracket

P/N 08-9098

Optimum

Distance

12" - 15"

Manual Operation

This operator has provisions for manually operating the door in case

of emergency or power failure. These operators are equipped with a

manual hoist. An electrical interlock will disable the electrical controls

when the hoist is used. Turn off power to the operator BEFORE

manually operating your door.

Electrical Interlock with Hoist

To operate the hoist, pull the disconnect chain (small chain) to

engage the hoist mechanism. The disconnect chain may be locked

in position by slipping the end through the keyhole of the chain

keeper mounted on the wall. Operate the door in the desired

direction by pulling on one side or the other of the continuous loop

hoist chain (large chain). The disconnect chain must be released

from the chain keeper before the door will operate again electrically.

Turn off power

to the operator

BEFORE manually

operating your door.

Electrical Interlock with Hoist

Inside the Electrical Box

9

Single Phase Connections

NEUTRAL EARTH

HOT

L1 L2

POWER WIRING

USE COPPER WIRE ONLY

14 AWG Minimum

Follow ALL national

and local electrical codes.

Power wiring ONLY!

DEDICATED CIRCUIT

Three Phase Connections

L1 L2

POWER WIRING

USE COPPER WIRE ONLY

L3

DEDICATED

CIRCUIT

10

Limit Switches

Retaining

CLOSE

SAFETY

Direction Limit Nut Will Move During Travel

Plate

Limit Nuts

OPEN

Push

Align Sprockets

7

Be sure door

sprocket is properly

aligned with drive

before securing to

the shaft.

Chain Keeper

(4' above floor)

Chain Keeper

(with pad locking provisions)

Mount Chain

Keeper 4'

above floor

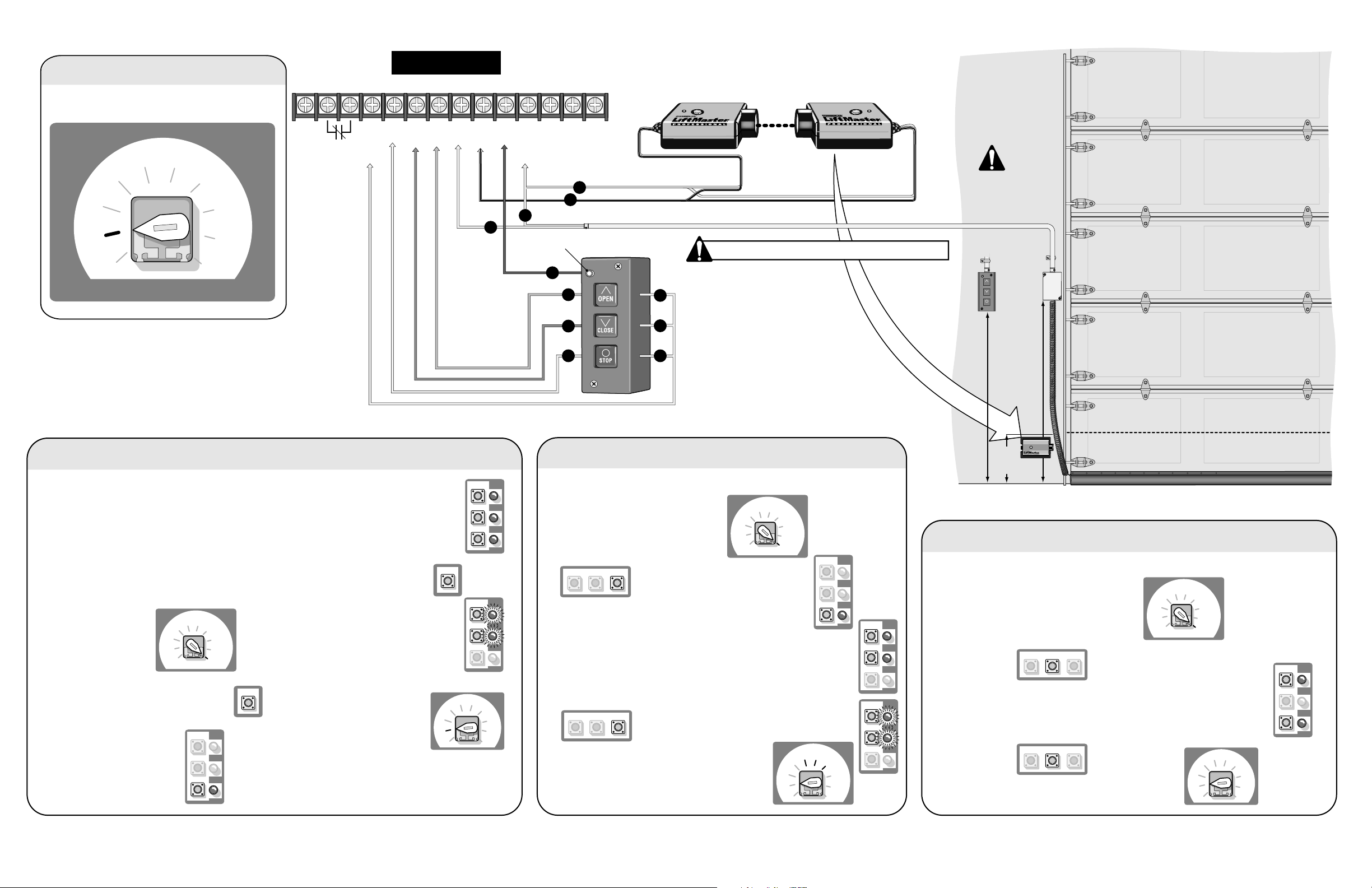

Board Selector Dial

Factory Setting is C2

T

TS

E2

D1

C2

B2

FSTS

DIAG

OPTN

PROG

SBC

CONTROL WIRING

USE COPPER WIRE ONLY

Close

Stop

Common

Open

Edge

20 AWG or Greater

Common

MAS

LMEP

11

8

Maintenance Alert LED

141 2 3 4 5 6 7 8 9 10 11 12 13

24VAC

24VAC

Timer Defeat

11

White/Black

9

10

7

White

LiftMaster Monitored Entrapment Protection (LMEP)

is required for most programmable settings.

Thru-Beam Photoelectric Sensors (Shown)

Follow ALL national and local electrical codes

Push and Release to Open

4

(without Mid Stop programming)

NEVER run Control wiring

in same conduit as the

Power wiring!

OPEN

CLOSE

STOP

MAS Programming (Maintenance Alert System)

D1

MAS

E2

B2

T

OPEN

CLOSE

STOP

OPEN

CLOSE

STOP

TS

1. The MAS assists the installing dealer in setting

up a routine maintenance program. Once

programmed, the MAS notifies the end user

(with a flashing LED on the 3 button station)

when a preset number of cycles/months has

elapsed and scheduled maintenance is due.

2. Close the Door.

T

TS

3. Turn the selector dial

to PROG.

E2

D1

C2

B2

FSTS

DIAG

OPTN

PROG

MAS

4. Press and release the MAS button.

OPEN

D20

5. Press the STOP button once

CLOSE

D21

to clear the MAS counter.

STOP

D13

6. Press the OPEN button once for

every 5,000 Cycles increments.

Press the CLOSE button once for

every 3 Month increments.

Press the STOP button once to

Clear the MAS Setting.

7. Press the MAS button to

complete the programming.

The on board LED will flash back

the programmed settings. The

OPEN LED will flash once for every

5,000 cycles. The CLOSE LED will

flash once for every 3 months.

8. Turn the selector dial back

to the desired wiring type.

C2

FSTS

PROG

D20

D21

D13

DIAG

OPTN

6

5 4

Timer-to-Close Programming

D20

D21

D13

Timer automatically closes door after a preset time.

1. Close the Door.

2. Turn selector to PROG.

3. Press and release the TIMER button.

TIMERMIDMRT

4. Press and release the STOP button to clear the timer.

5. Press and release the OPEN button once for every 1 second.

Press and release the CLOSE button once for every 15 seconds.

Example:

Push CLOSE + Push OPEN + Push OPEN = 17 seconds total

(15 seconds) (1 second) (1 second)

6. Press and release the TIMER button to complete programming.

TIMERMIDMRT

7. Turn selector to T, TS or FSTS wiring types.

NOTE: Must have at least one LiftMaster

Monitored Entrapment Protection (LMEP)

device installed.

4

Push and

Hold to Close

Push and Release to Stop

T

TS

E2

D1

C2

B2

The OPEN LED will flash once for every 1 sec.

The CLOSE LED will flash once for every 15 sec.

FSTS

DIAG

OPTN

PROG

E2

D1

C2

B2

OPEN

CLOSE

STOP

T

TS

FSTS

DIAG

OPTN

PROG

Approximately 5 Feet

Half the Height of the Door

6" max

above the

floor

Edge Sensor

OPEN Mid Stop Programming

D20

D21

D13

OPEN

D20

CLOSE

D21

STOP

D13

OPEN

D20

CLOSE

D21

STOP

D13

The mid stop feature is to open the door to a preset point prior to the fully open position.

1. Close the Door.

2. Turn selector to PROG.

T

TS

E2

D1

C2

B2

FSTS

DIAG

OPTN

PROG

3. Press and release the MID button.

TIMERMIDMRT

OPEN

D20

CLOSE

STOP

D21

D13

4. Press the OPEN button, wait until the door reaches the desired

mid stop height, then press and release the STOP button.

5. Press and release the MID button to complete programming.

TIMERMIDMRT

6. Turn selector back to selected wiring type.

T

TS

E2

D1

C2

B2

FSTS

DIAG

OPTN

PROG

01-35245

© 2010, The Chamberlain Group Inc.

All Rights Reserved

Loading...

Loading...