Lift-Master GH User Manual

OWNER'S MANUAL

MODEL GH

LOGIC CONTROL (VER. 2.0)

INDUSTRIAL DUTY DOOR OPERATOR

LOGIC CONTROL

Serial #

(located on electrical box cover)

Installation Date

Wiring Type

2 YEAR WARRANTY

The Maintenance Alert System

allows the installer to set an internal

Maintenance Cycle Counter. An LED

on the 3-button station will signal when

the set number of cycles is reached or

when the opener requires immediate

service.

TM

NOT FOR RESIDENTIAL USE

L

FACTORY SET

C2 Wiring

See pages 14 and 15

for other wiring

configurations

PATENT PENDING

41B6

LISTED DOOR OPERATOR

TABLE OF CONTENTS

SPECIFICATIONS

Packing List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Motor Specification . . . . . . . . . . . . . . . . . . . . . . . . . .3

Electrical Specifications . . . . . . . . . . . . . . . . . . . . . .3

Mechanical Specifications . . . . . . . . . . . . . . . . . . . . .3

Safety Specifications . . . . . . . . . . . . . . . . . . . . . . . . .3

Weights & Dimensions . . . . . . . . . . . . . . . . . . . . . . .3

PREP

ARATION

Site . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Operator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

INST

ALLATION INSTRUCTIONS

Wall Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Bracket or Shelf Mounting . . . . . . . . . . . . . . . . . . . . . . .5

Hand Chain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Chain Keeper/Keyhold Bracket . . . . . . . . . . . . . . . . . . .6

ENTRAPMENT PROTECTION

ACCESSORIES

Emergency Manual Operation . . . . . . . . . . . . . . . . . . . .6

Contact Reversing Edge Device . . . . . . . . . . . . . . . . . .6

Sensing Edges & Photo Eyes . . . . . . . . . . . . . . . . . . . .7

LIMIT SWITCH

ADJUSTMENT

Limit Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

POWER & CONTROL

WIRING

Safety Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Power Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Ground Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Control Station Wiring . . . . . . . . . . . . . . . . . . . . . . . .9

Radio Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Mounting Instructions . . . . . . . . . . . . . . . . . . . . . . . .9

Optional Control Mounting . . . . . . . . . . . . . . . . . . . .9

Optional Control Wiring . . . . . . . . . . . . . . . . . . . . . . .28

CLUTCH

ADJUSTMENT

Clutch Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Clutch Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . .10

BRAKE

ADJUSTMENT

Brake Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

WIRING DIAGRAMS

1 PH Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

3 PH Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

1 PH Wiring w/Contactor . . . . . . . . . . . . . . . . . . . . .13

ST

ANDARD PROGRAMMING

Wiring Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14 & 15

RPM Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Maximum Run Timer . . . . . . . . . . . . . . . . . . . . . . . . .16

Maintenance Alert System . . . . . . . . . . . . . . . . . . . .17

OPTIONAL

PROGRAMMING

Mid Stop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Timer to Close . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Red Green Warning Lights . . . . . . . . . . . . . . . . . . . .18

Board Illustration . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

REPLACEMENT P

ARTS & MAINTENANCE

Trouble Shooting Guide . . . . . . . . . . . . . . . . . . . . . .20 & 21

Maintenance Schedule . . . . . . . . . . . . . . . . . . . . . . .22

Customer Service Contact Information . . . . . . . . . . .22

Electrical Box parts . . . . . . . . . . . . . . . . . . . . . . . . . .23 & 24

Chassis Parts (J) . . . . . . . . . . . . . . . . . . . . . . . . . . .25 & 26

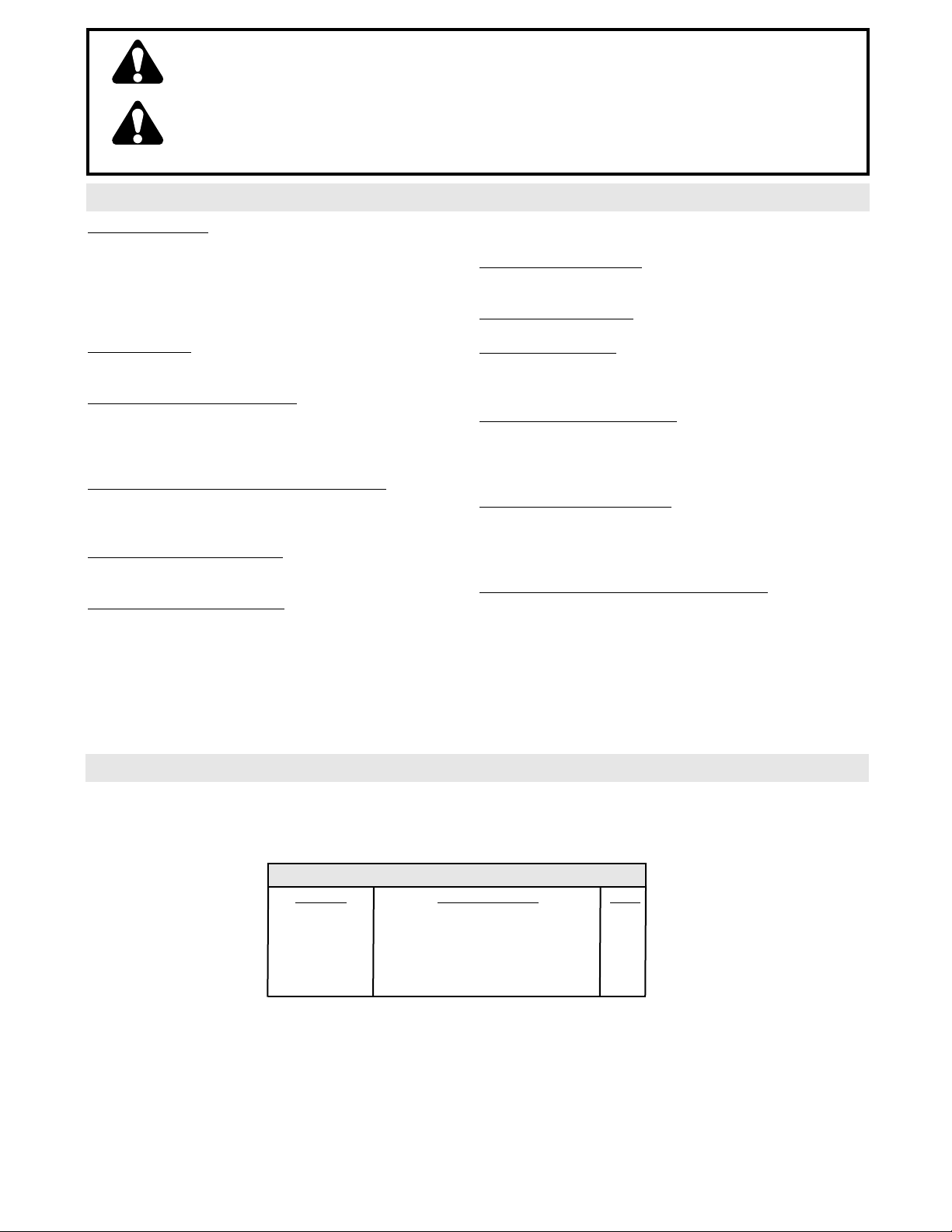

PACKING LIST

Before beginning your installation check that all components were supplied and received undamaged.

Before attempting to install, operate or maintain the operator, you must read and fully understand this manual and follow all safety instructions.

These instructions are intended to highlight certain safety related issues. These instructions are not intended to be comprehensive. Because each application is unique, it is the

responsibility of the purchaser, designer, installer and end user to ensure that the total

door system is safe for its intended use.

2

DESCRIPTION

GH PARTS BOX

29 FT HAND CHAIN

GH PARTS BAG

# 50 CHAIN, 106 PITCH

3 BUTTON CONTROL STATION

PART #

14-10896

19-10929-29

77-11090

19-50106M

02-103L

QTY

1

1

1

1

1

PACKING LIST K77-14334

3

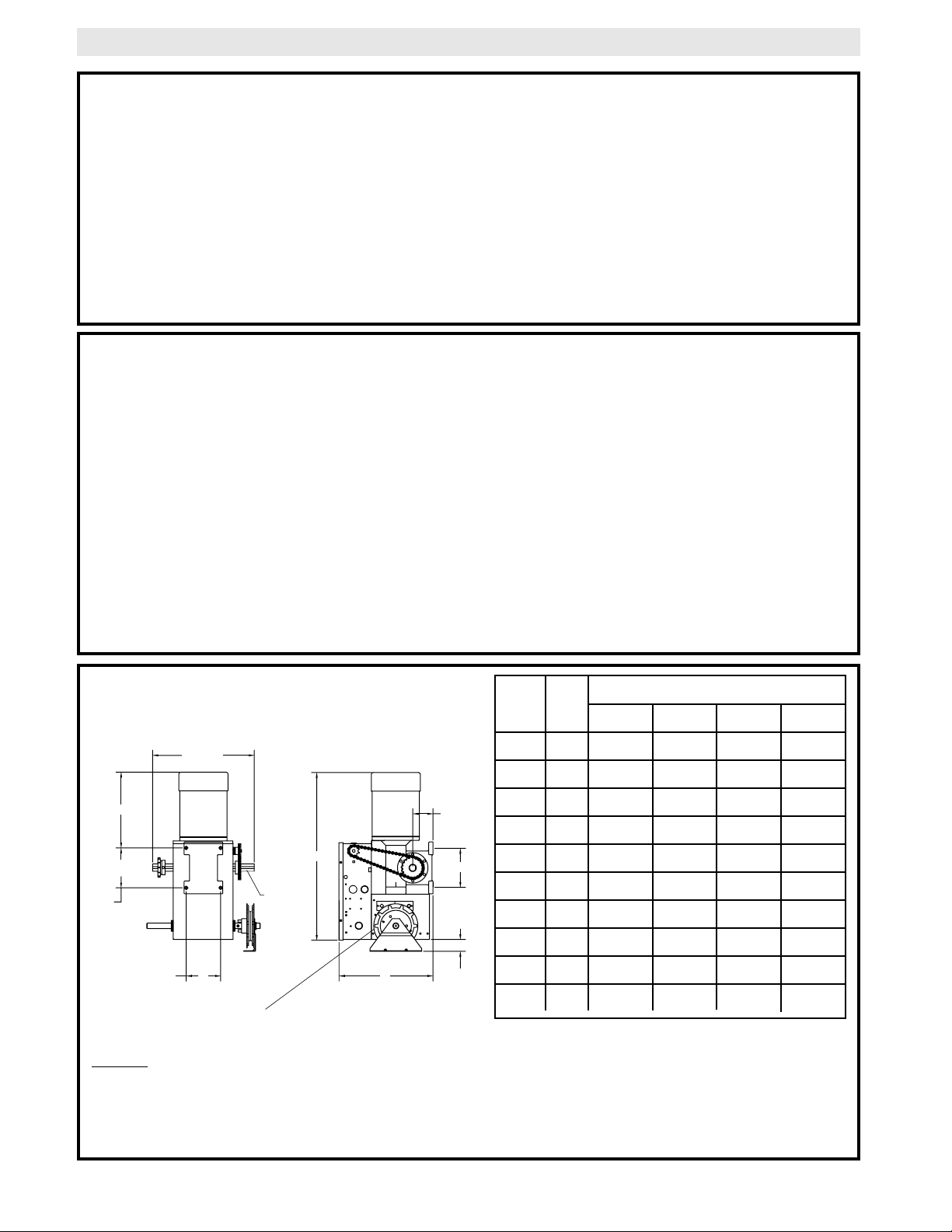

SPECIFICATIONS

MECHANICAL

DRIVE REDUCTION:.............40:1 Reduction

Heavy duty bronze

worm gear reducer

OUTPUT SHAFT SPEED:.....43 R.P.M.

DOOR SPEED: ......................4 - 10" per sec.

depending on door

BRAKE: .................................Solenoid actuated disc

brake

HOIST WHEEL: .....................Standard mounting on

left or right side

SAFETY

DISCONNECT:..............Floor level chain hoist with elect-

rical interlock for emergency manual door operation

CLUTCH: (Optional) ....Adjustable torque limiter type

SAFETY PHOTO EYES: (Optional) Thru beam or retro

reflective devices used to provide non-contact safety

protection. Directly interface to Lift Master CPS-L or

CPS-LN4 Commercial Protector Systems.

SAFETY EDGE:............(Optional) Electric or pneumatic

sensing device attached to the bottom edge of door.

A REVERSING DEVICE IS STRONGLY RECOMMENDED FOR ALL COMMERCIAL OPERATOR

INSTALLATIONS. REQUIRED WHEN THE 3 BUTTON

CONTROL STATION IS OUT OF SIGHT OF DOOR

OR ANY OTHER CONTROL (AUTOMATIC OR MANUAL) IS USED.

MOTOR

TYPE: .................................Continuous duty

HORSEPOWER: ................1/2, 3/4, 1, 1-1/2 Hp

2, 3 HP

SPEED:...............................1725 RPM

VOLTAGE:..........................115, 220, 230 Single phase

230, 380, 460, 575 Three phase

CURRENT:..........................See motor nameplate

ELECTRICAL

TRANSFORMER:.............24VAC Secondary

CONTROL STATION: ......NEMA 1 three button station

OPEN/CLOSE/STOP W/ LED

WIRING TYPE:.................C2 (Standard)

Momentary contact to OPEN & STOP, constant pressure to close, plus wiring for sensing device to reverse

and auxiliary devices to open and close with open

override. See pages 14 and 15 for optional wiring

types and operating modes.

LIMIT ADJUST: ................Linear driven, fully

adjustable screw type cams. Adjustable to 30 feet.

14.00”

WEIGHTS AND DIMENSIONS

HANGING WEIGHT: .........80-110 LBS.

Hand Chain Wheel

See

Note #1

See

Note #2

A

X

B

Y

C

D

Y

See

Note #3

A

11-1/2

12-1/2

12-3/4

12-3/4

11

11

12

12-1/2

12-3/4

13-1/4

B

25-3/4

26-3/4

27

27

25-1/4

25-1/4

26-1/4

26-3/4

27

28-5/8

C

12-63/64

12-63/64

12-63/64

13-63/64

12-63/64

12-63/64

12-63/64

13-63/64

13-63/64

15-15/64

D

3

3

3

3-1/2

3

3

3

3-1/2

3-1/2

3

1/2

3/4

1

1-1/2

1/2

3/4

1

1-1/2

2

3

1

1

1

1

3

3

3

3

3

3

HP

DIMENSIONS

NOTES:

1) Output Shaft with 1” x 1/4” Key for 1/2 thru 2Hp operators, 1-1/4” x 1/4” Key for 3Hp operators.

2) MT’G CENTERS: X = 4-3/4”; Y = 5-1/2” for 1/2 thru 2Hp operators

X = 7-17/32”; Y = 9-1/16” for 3Hp operators

3) Hand Chain Wheel extends 1-5/8” beyond operator in vertical mounting position as shown.

PHASE

4

TO AVOID DAMAGE TO DOOR AND OPERATOR,

MAKE ALL DOOR LOCKS INOPERATIVE. SECURE

LOCK(S) IN "OPEN" POSITION.

IF THE DOOR LOCK NEEDS TO REMAIN FUNCTIONAL, INSTALL AN INTERLOCK SWITCH.

DO NOT CONNECT ELECTRIC POWER UNTIL

INSTRUCTED TO DO SO.

KEEP DOOR BALANCED. STICKING OR BINDING

DOORS MUST BE REPAIRED. DOORS, DOOR

SPRINGS, CABLES, PULLEYS, BRACKETS AND

THEIR HARDWARE MAY BE UNDER EXTREME TENSION AND CAN CAUSE SERIOUS PERSONAL

INJURY. CALL A PROFESSIONAL DOOR SERVICEMAN TO MOVE OR ADJUST DOOR SPRINGS OR

HARDWARE.

WARNING

CAUTION

WARNING

WARNING

WARNING

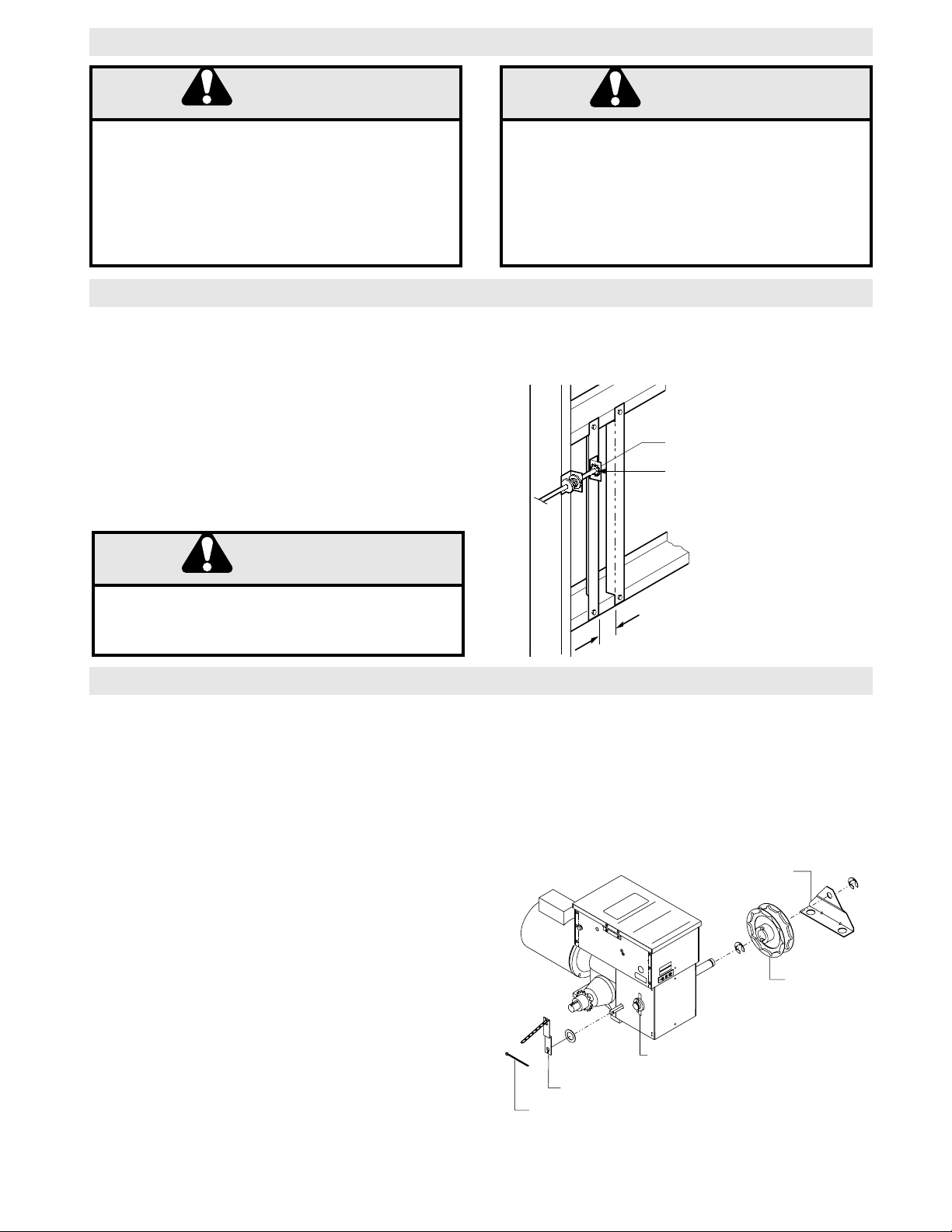

SITE PREPARATIONS

It is imperative that the wall or mounting surface provide adequate support for the operator.

This surface must:

a) Be rigid to prevent play between operator and

door shaft.

b) Provide a level base.

c) Permit the operator to be fastened securely and

with the drive shaft parallel to the door shaft.

The safety and wear of the operator will be adversely

affected if any of the above requirements are not met.

OPERATOR PREPARATION

IMPORTANT SAFETY NOTES

5-1/2”

The GH operator may be mounted on either the right (standard) or left side of door, and in either a vertical (standard) or horizontal mounting position. Refer to the steps below if you require the hand chain and/or disconnect

chain to be on the opposite side of the operator; Or if the operator is being mounted in a horizontal position.

Hand Chain Right/Left Conversion

Remove the two snap rings (1 pc. outer, 1 pc inner) on

hand chain shaft assembly. Position roll-pin to fit

through cutout in frame and slide complete shaft

assembly through housing and bevel gear. Insert shaft

assembly on opposite side of housing, and replace

bevel gear, bearing, hardware, and snap rings on the

opposite side of shaft in the same manner.

Disconnect Lever Right/Left Conversion

Remove cotter pins on the ends of the disconnect

shaft (square shaft), move the disconnect lever arm to

the opposite side, and replace the cotter pins. Be sure

to keep two(2) 12ga. washers on the side without the

lever arm.

Horizontal Mounting Conversion

Remove cotter pins on the ends of the disconnect

shaft (square shaft), and remove lever. Replace lever

using square hole on opposite end of lever. Reposition

sash chain to opposite end of lever also. Replace cotter pins.

FIGURE 2

ALL DOORS INTENDED TO BE MOTOR OPERATED

SHOULD BE MANUFACTURED WITH SOLID DOOR

SHAFTS.

WARNING

For metal buildings, fasten 2” x 2” x 3/16” (or larger)

angle iron frames to the building purlins. Retain 51/2” between frames. See Figure 1.

CAUTION

WARNING

Shaft Support Bracket

with Bearing (Not Supplied)

Door Sprocket

WARNING

Cotterpin

Disconnect Lever

2-1/4"

FIGURE 1

Chain Guide

N

I

H

R

T

R

I

O

O

W

O

O

Y

D

S

D

N

I

L

.

E

O

N

L

R

I

V

T

O

O

O

O

A

R

O

E

B

T

T

D

S

A

S

N

U

.

T

N

O

T

A

R

F

C

O

H

O

T

8

T

E

O

T

H

N

O

D

U

T

A

S

B

N

I

H

G

3

N

T

R

N

I

O

Y

I

E

O

T

B

T

F

R

A

A

D

O

R

T

E

E

M

S

L

P

L

L

L

L

O

O

O

A

R

N

R

T

T

T

O

S

N

N

S

N

I

O

R

O

C

E

C

P

E

E

B

F

T

A

O

T

C

S

E

O

U

T

I

L

M

CAUTION

S

INSTRUCTIONS

CONNECT REVERSING EDGE

SWITCH - SEE INSTALLATION

Cutout for Rollpin

(typical both sides)

Hand

Chain Wheel

5

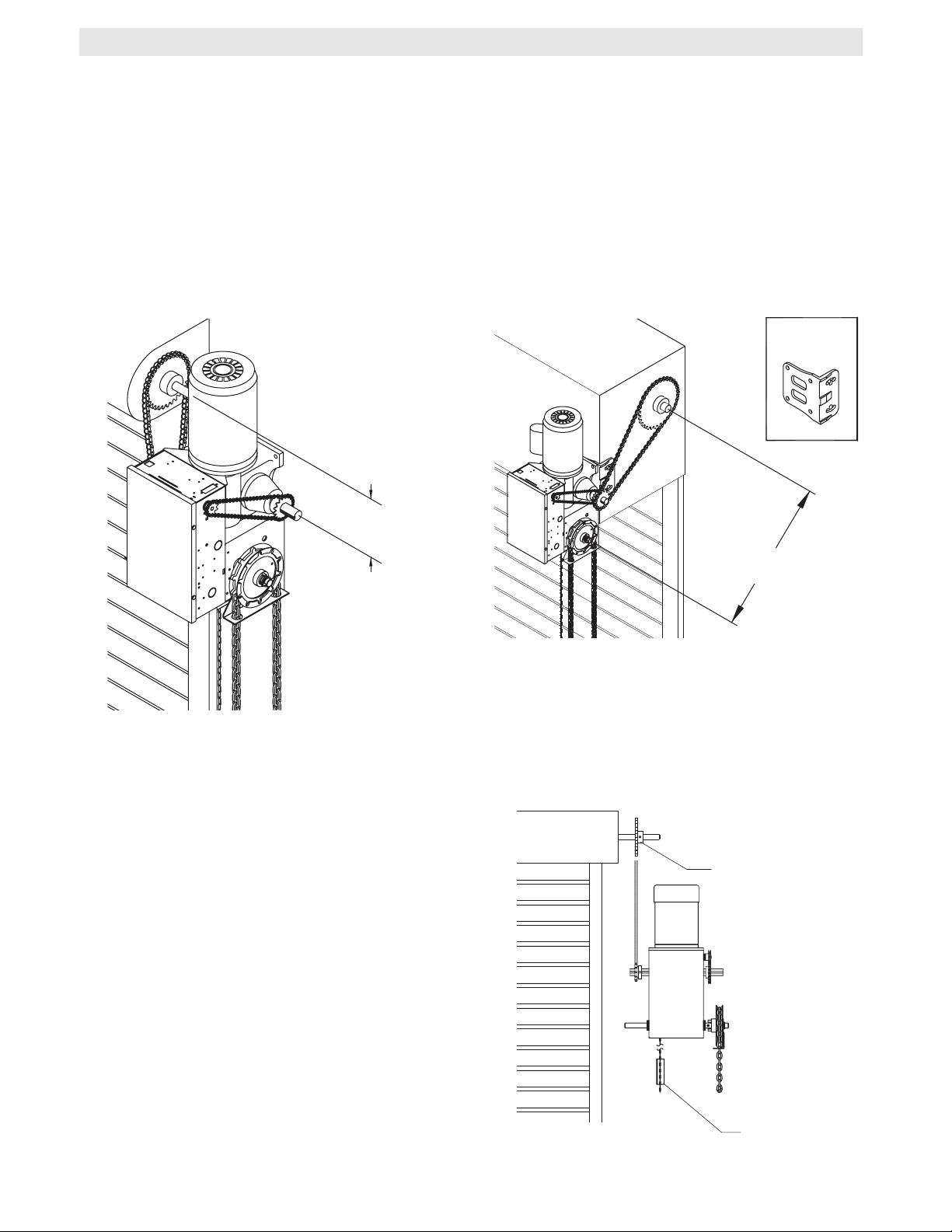

1a. Wall Mounting

The operator should generally be installed below

the door shaft, and as close to the door as possible. The optimum distance between the door shaft

and operator drive shaft is between 12” - 15”. Refer

to Figure 3.

OPERATOR MOUNTING

IMPORTANT: The shelf or bracket must provide adequate support, prevent play between

operator and door shaft, and permit operator

to be fastened securely and with the drive

shaft parallel to the door shaft.

1b. Bracket or Shelf Mounting

The operator may be mounted either above or

below the door shaft. The optimum distance

between the door shaft and operator drive shaft is

between 12” - 15”. Refer to Figure 4.

1c. Place door sprocket on the door shaft. Do not

insert the key at this time.

2. Place drive sprocket on the appropriate side of the

operator. Do not insert the key at this time.

3. Wrap drive chain around door sprocket and join

roller chain ends together with master link.

4. Raise operator to approximate mounting position

and position chain over operator sprocket.

5. Raise or lower operator until the chain is taut (not

tight). Make sure the operator output shaft is parallel to door shaft and sprockets are aligned. When

in position, secure the operator to wall or mounting

bracket.

6. Align sprockets and secure, (see Figure 5).

Optimum Distance

12 - 15”

Typical Right Hand

Wall Mounted Operator

Optimum Distance

12 - 15”

FIGURE 4

FIGURE 3

Before your operator is installed, be sure the door has been properly aligned and is working smoothly. The operator may be wall mounted or mounted on a bracket or shelf. If necessary, refer to the operator preparations on

page 3. Refer to the illustration and instructions below that suits your application.

Be sure door

sprocket is properly

aligned with

drive before securing

to the shaft.

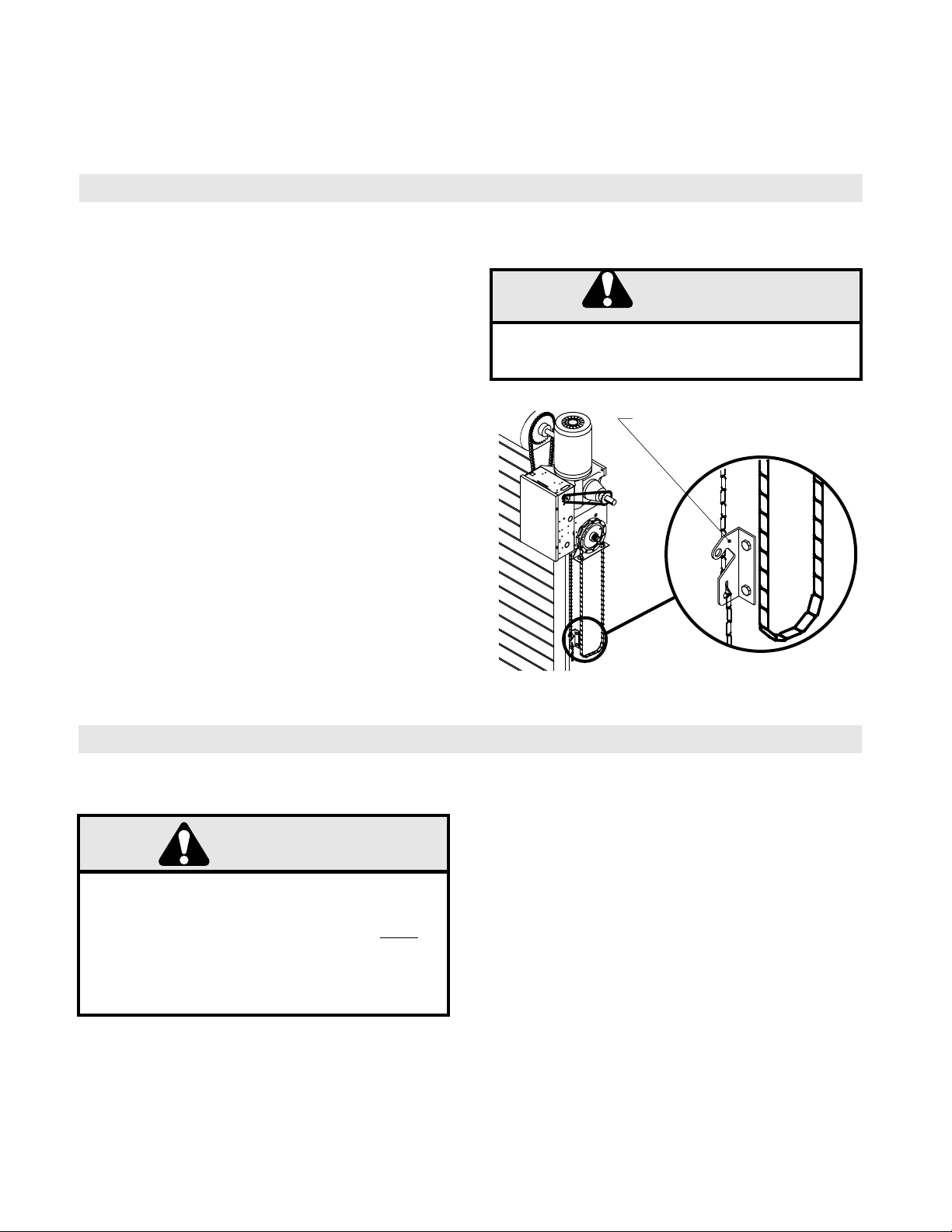

Chain Keeper

FIGURE 5

OPTIONAL

Mounting Bracket

P/N 08-9098

6

These operators are equipped with a manual hoist. An

electrical interlock will disable the electrical controls

when the hoist is used.

To operate the hoist:

1. Pull the disconnect chain (small chain) to engage

the hoist mechanism. The disconnect chain may be

locked in position by slipping the end through the keyhole of the chain keeper mounted on the wall.

2. Operate the door in the desired direction by pulling

on one side or the other of the continuous loop hoist

chain (large chain).

3. The disconnect chain must be released from the

chain keeper before the door will operate again electrically.

7. Install Hand Chain

Place hand chain around hand chain wheel. Be

sure to pass it through both openings in the chain

guide. Remove enough links so chain hangs approximately two feet above the floor

EMERGENCY MANUAL OPERATION

This operator has provisions for manually operating the door in case of emergency or power failure. Refer to the

appropriate instructions below for your model operator.

Model GH

Chain Keeper

(with pad locking provisions)

Electrical Interlock with Hoist for Models H and HJ

8. Mount Chain Keeper / Keyhole Bracket

Using suitable hardware mount the chain keeper

approximately 4 feet above the floor, near the free

hanging chain. Remove disconnect sash chain

from bag and place the end through the keyhole in

the the chain keeper. Remove excess links if necessary.

TURN OFF POWER TO THE OPERATOR BEFORE

MANUALLY OPERATING YOUR DOOR.

WARNING

CAUTION

WARNING

WARNING

IF CONTROL STATION CANNOT BE INSTALLED IN THE

LINE OF SIGHT WITH THE DOOR, OR IF ANY DEVICE

OTHER THAN THE CONTROL STATION IS USED TO

ACTIVATE THE DOOR, A REVERSING DEVICE MUST

BE

INSTALLED ON THE BOTTOM OF THE DOOR. FAILURE

TO INSTALL A REVERSING DEVICE UNDER THESE CIRCUMSTANCES MAY RESULT IN SERIOUS PERSONAL

INJURY OR DEATH.

REVERSING DEVICE (OPTIONAL)

WARNING

ENTRAPMENT PROTECTION ACCESSORIES (OPTIONAL)

CAUTION

WARNING

7

TO AVOID SERIOUS PERSONAL INJURY OR DEATH

FROM ELECTROCUTION, DISCONNECT ELECTRIC

POWER BEFORE MANUALLY MOVING LIMIT NUTS.

WARNING

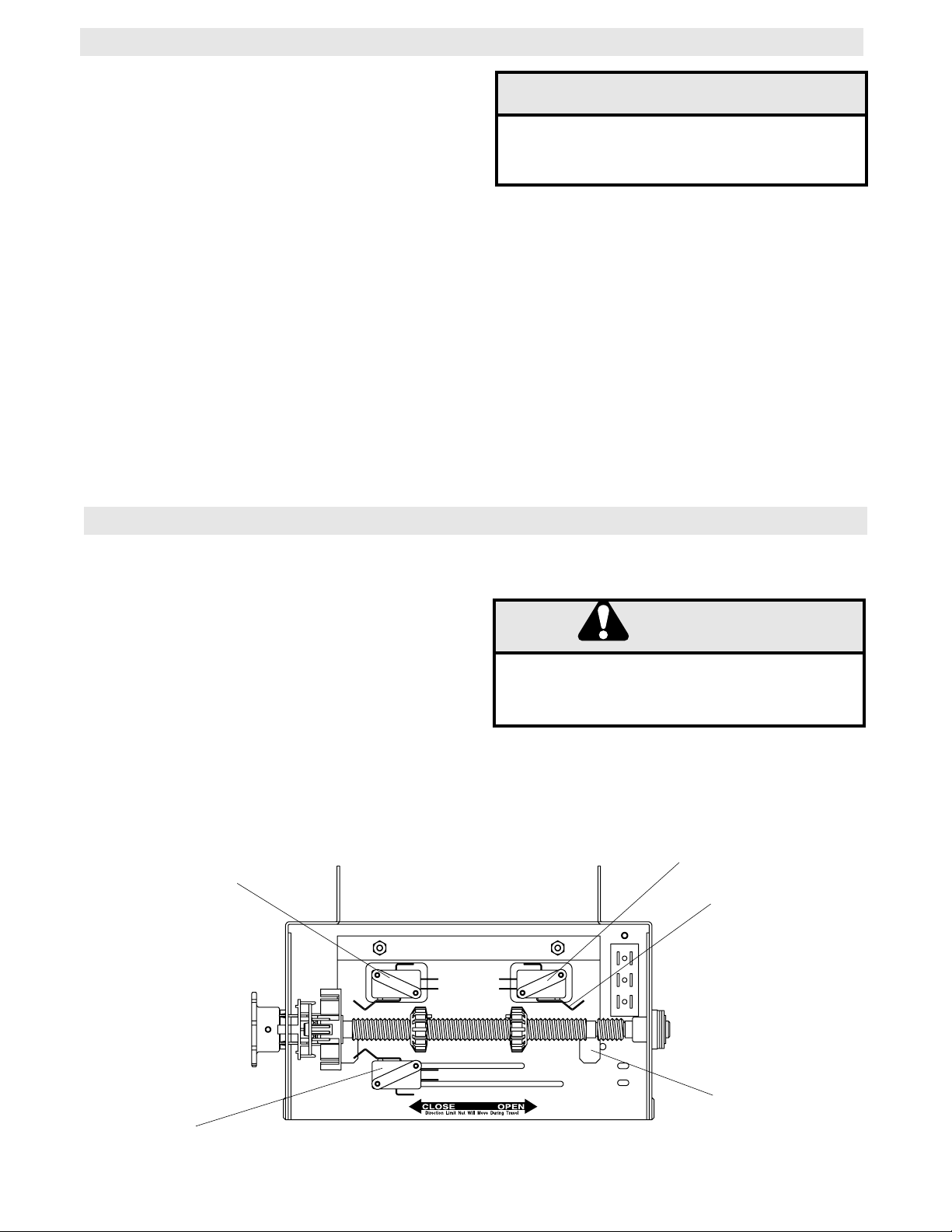

LIMIT SWITCH ADJUSTMENT

MAKE SURE THE LIMIT NUTS ARE POSITIONED BETWEEN THE LIMIT SWITCH ACTUATORS BEFORE

PROCEEDING WITH ADJUSTMENTS.

If other problems persist, call our toll-free number for

assistance - 1-800-528-2806.

1. To adjust limit nuts depress retaining plate to allow

nut to spin freely. After adjustment, release plate

and ensure it seats fully in slots of both nuts.

2. To increase door travel, spin nut away from actu-

ator. To decrease door travel, spin limit nut toward

actuator.

3. Adjust open limit nut so that door will stop in open

position with the bottom of the door even with top

of door opening.

4. Repeat Steps 1 and 2 for close cycle. Adjust close

limit nut so that actuator is engaged as door fully

seats at the floor.

PHOTO EYES & SENSING EDGES

Sensing devices supplied for door industry type operators

with an isolated normally open (N.O.) dry contact output

are compatible with your operator. This includes through

beam and retro reflective photo eyes, and pneumatic and

electric edges. If your door does not have bottom safety

photo eyes or a sensing edge and you wish to add a safety device to your application, please contact your local

LiftMaster Authorized Dealer.

If not pre-installed by the door manufacturer, mount the

sensing edge on the door according to the instructions provided with the edge. The sensing edge may be electrically connected by either coiled cord or take-up reel.

Important Notes:

a) Proceed with Limit Switch Adjustments before making

any sensing edge wiring connections to operator as

described below.

b) Electrician must hardwire the junction box to the oper-

ator electrical box in accordance with local codes.

ENTRAPMENT PROTECTION ACCESSORIES (OPTIONAL) CONT’D

WIRING: For wiring of your sensing device to the

operator, refer to the wiring diagram on pages 11-13.

See field connection terminals identified as

Reversing Device.

TAKE-UP REEL: Take-up reel should be installed 12"

above the top of the door.

COIL CORD: Connect operator end of coil cord to

junction box (not supplied) fastened to the wall

approximately halfway up the door opening.

IT IS STRONGLY RECOMMENDED THAT A

SAFETY PHOTO EYE OR SENSING EDGE BE

USED IN CONJUNCTION WITH THE OPERATOR.

Retaining Plate

CLOSE Limit Switch

SAFETY

(Aux. Close) Limit Switch

OPEN Limit Switch

Actuator

NOTICE

WARNING

8

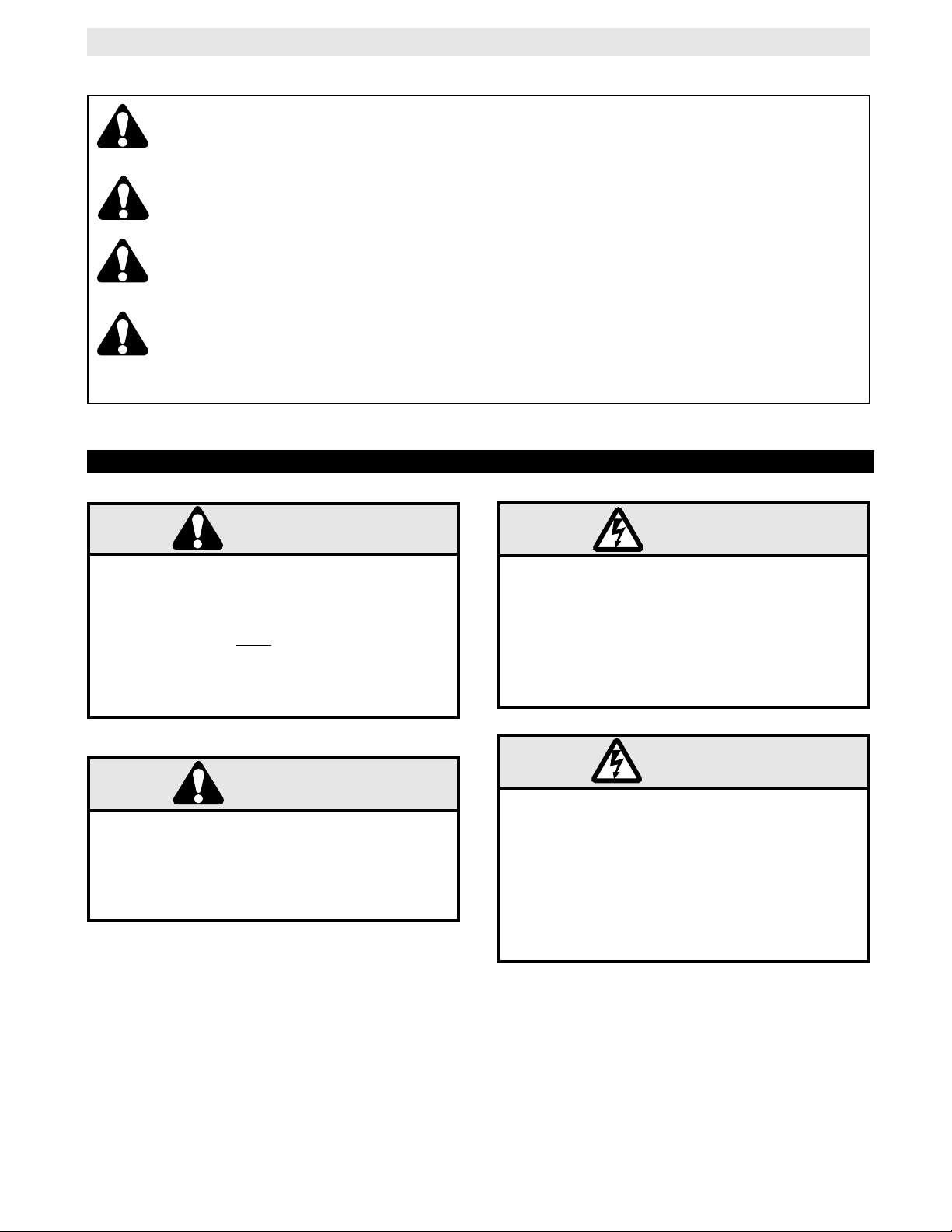

DISCONNECT POWER AT THE FUSE BOX BEFORE

PROCEEDING.

OPERATOR MUST BE PROPERLY GROUNDED AND

CONNECTED IN ACCORDANCE WITH LOCAL ELECTRICAL CODES. NOTE: THE OPERATOR SHOULD

BE ON A SEPARATE FUSED LINE OF ADEQUATE

CAPACITY.

ALL ELECTRICAL CONNECTIONS MUST BE MADE

BY A QUALIFIED ELECTRICIAN.

WARNING

TO AVOID DAMAGE TO DOOR AND OPERATOR,

MAKE ALL DOOR LOCKS INOPERATIVE. SECURE

LOCK(S) IN "OPEN" POSITION.

IF THE DOOR LOCK NEEDS TO REMAIN FUNCTIONAL, INSTALL AN INTERLOCK SWITCH.

Before installing power wiring or control stations be sure to follow all specifications and warnings described below. Failure to do so may result in severe injury to persons and/or damage

to operator.

The operator electrical box is only to be accessed by trained “LIFTMASTER” technicians. If

service is required contact your local LIFTMASTER dealer.

Do not install any wiring or attempt to run the operator without consulting the wiring diagram.

Install the optional Reversing Edge before proceeding with the Control Station installation.

Remove the cover from the electrical enclosure. Inside this enclosure you will find the wiring

diagram(s) for your unit. Refer to the diagram (glued on the inside of the cover) for all connections described below. If this diagram is missing, call the number on the back of this manual.

DO NOT INSTALL ANY WIRING OR ATTEMPT TO RUN THIS OPERATOR WITHOUT CONSULTING THE WIRING DIAGRAM.

IMPORTANT SAFETY NOTES

INSTALL POWER WIRING & CONTROL STATION

ANY MAINTENANCE TO THE OPERATOR OR IN THE

AREA NEAR THE OPERATOR MUST NOT BE PERFORMED UNTIL DISCONNECTING THE ELECTRICAL POWER AND LOCKING-OUT THE POWER VIA,

THE MAIN DISCONNECT SWITCH. UPON COMPLETION OF MAINTENANCE THE AREA MUST BE

CLEARED AND SECURED, AT THAT TIME THE UNIT

MAY BE RETURNED TO SERVICE.

WARNING

INSTALL THE CONTROL STATION IN LINE OF SIGHT WITH

THE DOOR, BUT AWAY FROM THE DOOR AND ITS HARDWARE. IF CONTROL STATION CANNOT BE INSTALLED

WHERE DOOR IS VISIBLE, OR IF ANY DEVICE OTHER THAN

THE CONTROL STATION IS USED TO ACTIVATE THE DOOR,

A REVERSING DEVICE MUST

BE INSTALLED ON THE BOT-

TOM OF THE DOOR. FAILURE TO INSTALL A REVERSING

DEVICE UNDER THESE CIRCUMSTANCES MAY RESULT IN

SERIOUS INJURY OR DEATH.

WARNING

WARNING

WARNING

WARNING

9

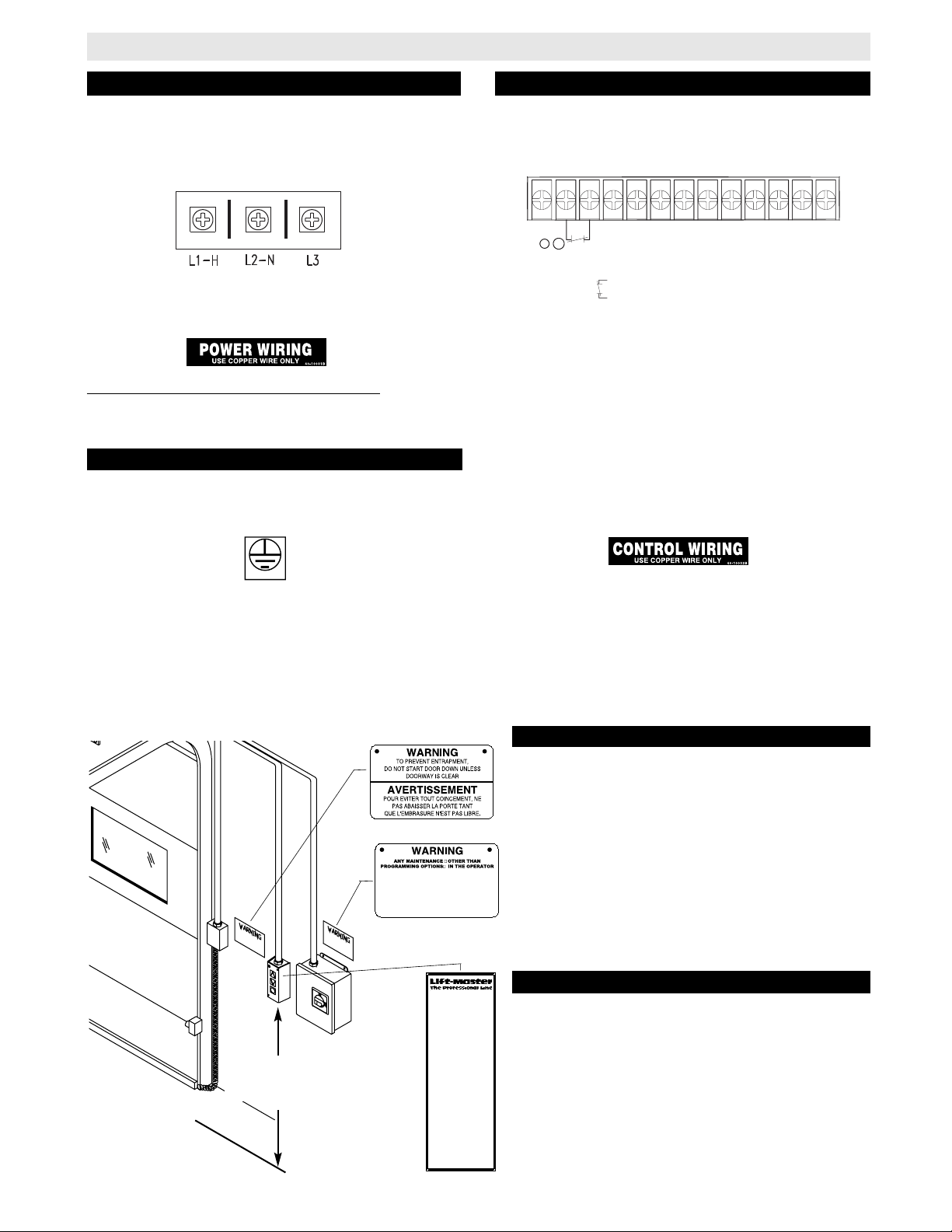

POWER WIRING CONNECTIONS

1. Connect power wires coming from the main to the

captive terminal block in the electrical box enclosure

marked with the label shown below.

2. Be sure to run all power wires through the conduit

hole in the electrical box enclosure marked with the label

shown below.

POWER WIRING

CONTROL STATION WIRING

CONTROL WIRING CONNECTIONS

1. Connect control wires to the TB1 terminal block

located on the Printed Circuit Board (shown below).

GROUND WIRING

ON THREE PHASE MACHINES ONLY: Incorrect

phasing of the power supply will cause the motor to

rotate in the wrong direction.

4 Feet

Approximate

Control

Station

Optional

Controls

MOUNTING INSTRUCTIONS

1. Mount Control Stations no further than (12”) from

each other.

2. Mount Control Stations (12”) from the door enclosure.

3. Mount WARNING NOTICE beside or below the

Control Station.

4. Mount MAINTENANCE ALERT label to either side

of control station.

1. Connect earth ground to the chassis ground screw in

the electrical box enclosure marked with the label shown

below.

2. Use same conduit entry into the electrical box as the

power wiring.

IMPORTANT: THIS UNIT MUST BE PROPERLY

GROUNDED. FAILURE TO PROPERLY GROUND

THIS UNIT COULD RESULT IN ELECTRIC SHOCK

AND SERIOUS INJURY.

RADIO CONTROLS

INSTALL POWER WIRING & CONTROL STATION (CONT’D)

1

2

3

4

5

6

7

8

9

10

11

12

13

SBC

CMN

STOP

CLOSE

OPEN

REV

IR

MAS

CMN

24AC+

24AC-

SINGLE BUTTON CONTROL

INTERLOCK

INTERLOCK

COMMON

STOP

CLOSE

OPEN

REVERSE

INFRARED PHOTO EYES

MAINTENANCE ALERT SYSTEM

COMMON

24 VOLT AC

24 VOLT AC

On all models with B2 control wiring, a terminal bracket

marked R1 R2 R3 is located on the outside of the electrical enclosure. Any commercial type LiftMaster brand

receiver may be mounted to this bracket. The operator

will then open a fully closed door, close a fully open

door, stop an opening door, and reverse a closing door

from the radio transmitter. In TS control wiring the operator will only open the door or reset the timer to close.

However, for additional door control from a 3 button

transmitter, a commercial three-channel radio receiver

(with connections for OPEN/CLOSE/STOP) is recommended.

2. Be sure to run all control wires through the conduit

hole in the electrical box enclosure marked with the label

shown below.

3. Apply power to the operator. Press OPEN push button

and observe direction of door travel and then Press the

STOP button.

If door did not move in the correct direction, check for

improper wiring at the control station or between operator

and control station.

13 24AC-

12 24AC+

11 CMN

10 MAS

9 IR

8 REV

7 OPEN

6 CLOSE

5 STOP

4 CMN

3

2

1 SBC

2

3

40-10033B

OR IN THE AREA NEAR THE OPERATOR MUST

NOT BE PERFORMED UNTIL DISCONNECTING

THE ELECTRICAL POWER AND LOCKING-OUT

THE POWER VIA, THE MAIN DISCONNECT

SWITCH. UPON COMPLETION OF

MAINTENANCE THE AREA MUST BE CLEARED

AND SECURED, AT THAT TIME THE UNIT MAY

BE RETURNED TO SERVICE.

Maintenance Alert

System

If light is Flashing,

it is time for routine

Door and Opener

Maintenance.

If light is Steady

On, call for

immediate service.

Service every

________ cycles.

TM

Loading...

Loading...