Page 1

OWNER’S MANUAL

MODEL FDC C

ADVANCED LOGIC

INDUSTRIAL DUTY FIRE DOOR OPERATOR

US PATENT NO. 6,014,307

NOT FOR RESIDENTIAL USE

Serial # Box

(located on electrical box cover)

Installation Date

Wiring Type

2 YEAR WARRANTY

APP

LMPLC CONTROL

LMPLC

CONTROL WIRED

FM

APP

ROVOVED

Page 2

2

When you see these Safety Symbols and Signal Words on the

following pages, they will alert you to the possibility of serious

injury or death if you do not comply with the warnings that

accompany them. The hazard may come from something

mechanical or from electric shock. Read the warnings carefully.

When you see this Signal Word on the following pages, it will

alert you to the possibility of damage to your door and/or the

door operator if you do not comply with the cautionary

statements that accompany it. Read them carefully.

Mechanical

Electrical

TABLE OF CONTENTS

WARNING

WARNING

WARNING

WARNING

CAUTION

WARNING

WARNING

SPECIFICATIONS

Operator Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Operator Weights and Dimensions . . . . . . . . . . . . . . . . . . . . . . .3

THEORY OF OPERATION

General Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Fire Door Mode Type 1 Functional Operation . . . . . . . . . . . . .4-5

Door System Testing Procedures . . . . . . . . . . . . . . . . . . . . . . . .6

INSTALLATION

Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Entrapment Protection Accessories . . . . . . . . . . . . . . . . . . . . . .7

FCC Warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Operator Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

ADJUSTMENT

Limit Switch Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Installation Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Alarm Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

POWER WIRING & GROUND WIRING

Important Safety Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Power Wiring Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Ground Wiring Connections . . . . . . . . . . . . . . . . . . . . . . . . . . .11

CONTROL STATION WIRING & INSTALLATION

Control Wiring Connections . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Mounting Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

CONTROL SETTINGS

Optional Control Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Installer Control Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Electronic Fuse Link Arrangement . . . . . . . . . . . . . . . . . . . . . . .14

Optional Mechanical (Retrofit) Fuse Link Arrangement . . . . . . .15

DIAGRAMS

Standard Power and Control Connection Diagrams . . . . . . .16-17

1 Phase Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

3 Phase Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

MAINTENANCE SCHEDULE

Battery Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Battery Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Battery Maintenance / Testing . . . . . . . . . . . . . . . . . . . . . . . . . .20

Battery Handling / Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Motor Operator Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . .20

TROUBLESHOOTING

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

REPAIR PARTS

Repair Parts Kits - Electrical Box . . . . . . . . . . . . . . . . . . . . . . . .22

Illustrated Parts - Electrical Box . . . . . . . . . . . . . . . . . . . . . . . .23

Repair Parts Kits - Model FDC C . . . . . . . . . . . . . . . . . . . . . . . .24

Illustrated Parts - Model FDC C . . . . . . . . . . . . . . . . . . . . . . . . .25

OPERATOR NOTES

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .26-27

CONTROL CONNECTION DIAGRAM

. . . . . . . . . . . . . . . .28

HOW TO ORDER REPAIR PARTS

. . . . . . . . . . . . . . . . . .28

IMPORTANT NOTES:

• BEFORE attempting to install, operate or maintain the operator,

you must read and fully understand this manual and follow all

safety instructions.

• DO NOT attempt repair or service of your commercial door and

operator unless you are an Authorized Service Technician.

SAVE THESE INSTRUCTIONS

Page 3

3

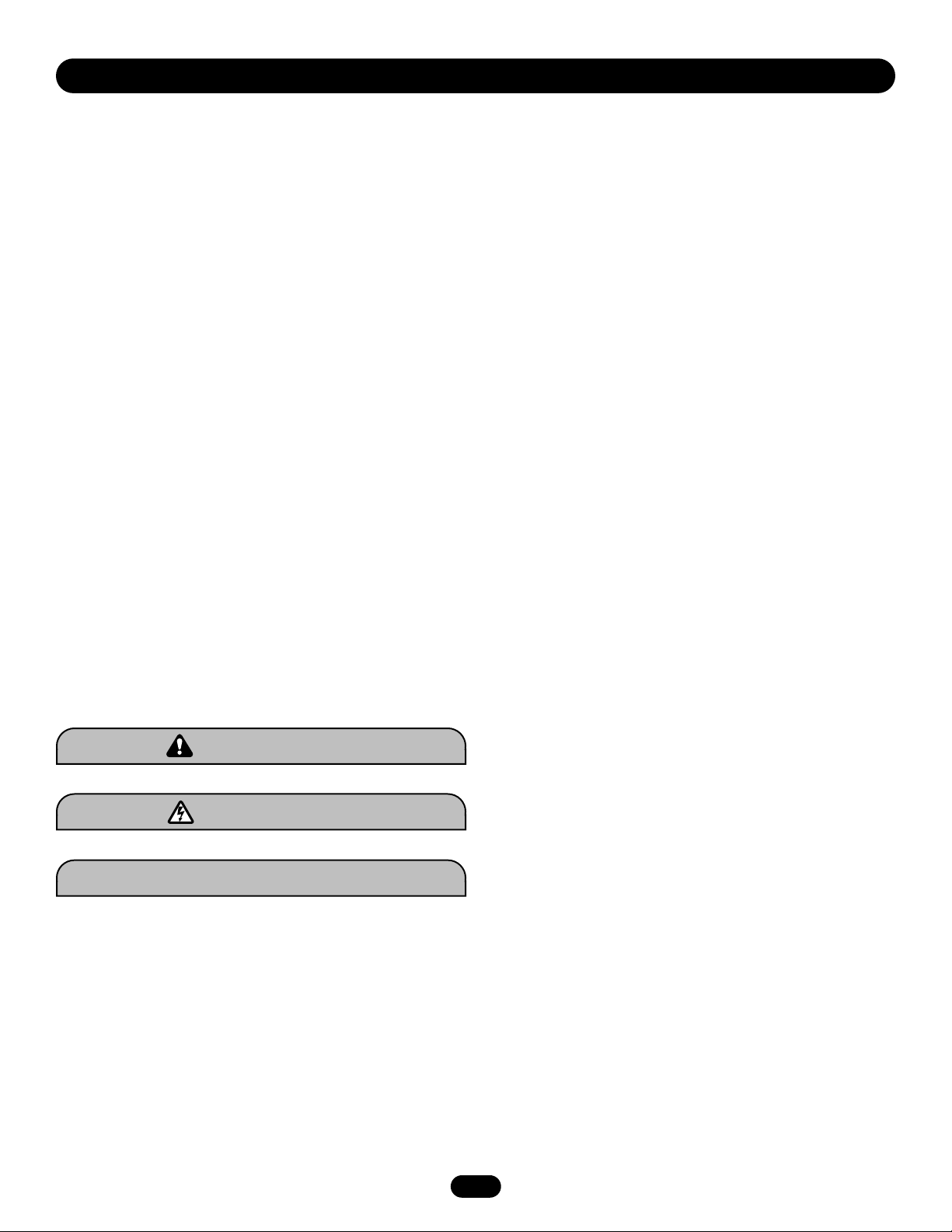

SPECIFICATIONS

17.27"

9.00"

A

9.57"

8.50"

MOUNTING DIMENSIONS

1/2HP = 5/16" Mounting Hardware (Typical)

1HP = 3/8" Mounting Hardware (Typical)

DRIVE SYSTEM

GEAR REDUCERS: . . . . . . . . . . . . . . . . . . . . . . . . .Helical inline,

oil bath permanently lubricated, non-vented

CONTINUOUS POWER RATING:

1/2 HP: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .175 ft-lbs/sec

1 HP: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .275 ft-lbs/sec

RATIO:

1/2 HP: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48.8:1

1 HP: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49.8:1

OUTPUT SPEED:

1/2 HP: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36 RPM

1 HP: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35 RPM

OUTPUT TORQUE:

1/2 HP: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .658 in-lbs.

1 HP: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1345 in-lbs.

OUTPUT SHAFT DIAMETER:

1/2 HP: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1"

1 HP: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1/4"

OUTPUT SPROCKET:

1/2 HP: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .#50-14T

1 HP: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .#60-14T

MAX. OVERHUNG LOAD: (1" from output bearing face)

1/2 HP: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .698 lbs.

1 HP: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1036 lbs.

MAX. BACK DRIVING FORCE: (torque)

1/2 HP: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .100 in-lbs.

1 HP: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .100 in-lbs.

MOTOR

TYPE: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Continuous duty

HORSEPOWER: . . . . . . . . . . . . . . . . . . . . . . . .1/2 HP and 1 HP

SPEED: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1725 RPM

VOLTAGE: . . . . . . . . . . . . . . . . . . . . . . . . . . . . .115/230 1 phase

230/460 3 Phase

ENCLOSURE: . . . . . . . . . . . . . . . . . .ODP NEMA 56c face mount

ELECTRICAL

TRANSFORMER: . . . . . . . . . . . . . . . .1PH: 120/240 VAC 24VAC

3PH: 240/480 VAC 24VAC

BATTERY BACKUP: . .(2) 12VDC 7AH sealed lead acid batteries

CONTROL STATION: . . . . . . . . . . . . . . .NEMA1 3-Button Station

OPEN/CLOSE/STOP

WIRING TYPE: . . . . . . . . . . . . . . . . . . . . . . . . . . .B2 (Standard)

LIMIT ADJUST: . . . . . . . . . . . . . . .Linear driven, fully adjustable

screw type cams. (70 rev. max @ limit shaft)

DUTY CYCLE: . . . . . . . . . . . . . . . .25 Reversing cycles per hour

BRAKE: . . . . . . . . . . . . . . . . . . . . . .24VDC electromagnetic disc

THERMAL SENSORS: . . . . . . . . . . . . . . . . . . . . . . . . . . . .160° F

(Open on rise manual reset, see page 12)

ELECTRICAL ENCLOSURE RATINGS: . . . . . . .motors, electrical

enclosure and control station are rated NEMA1

FUSE: . . . . . . . . . . . . . . . . . . . . . .250V, 3AG, 2 AMP Slow-Blow

1/2HP

1HP

A

B

C

D

E

F

G

H

J

K

13.00"

21.00"

16.93"

2.44"

3.35"

4.53"

2.26"

6.67"

8.25"

2.12"

14.38"

25.73"

16.31"

2.93"

3.94"

5.61"

2.80"

7.22"

7.50"

2.51"

ITEM

DIMENSIONS

B

D

C

4.50"

J

K

H

F

G

E

WEIGHTS AND DIMENSIONS

HANGING WEIGHT

1/2HP = 80 lbs.

1HP = 100 lbs.

Operator Center Line

Output Sprocket

Center Line

Page 4

4

FIRE DOOR MODE TYPE I FUNCTIONAL OPERATION

1. UNIT HAS AC POWER AND NO ALARM CONDITION:

• The 3-Button Control Station is used to operate the door

electrically.

• Activation of the safety edge while the door is closing will

cause the door to reverse to the full open limit.

• Activation of the safety edge while the door is opening will

NOT effect operation, the door will continue to the open limit.

• Activating the key-test switch for at least 6 seconds will put

the operator in alarm active mode. See ACTIVE ALARM

section for detail operation of alarm active mode.

2. UNIT HAS AC POWER AND ACTIVE ALARM CONDITION

(ALARM INPUT #1 - Smoke Detector, etc.):

• The unit will activate the OPTIONAL warning signal, the door

will automatically close after the preset time delay (powered

down by motor). The time delay is set by means of DIP

switch 1.

• If the door is in the open position and an alarm condition

occurs, the door will automatically close under motor

operation. In the event the door should meet an obstruction

while closing, it will reverse and return to the full open

position, and then start the closing cycle (with delay and

warning) again. If the obstruction is not removed, the door

will close stopping at the lowest possible position holding

the brake for 2 seconds, then releasing the door via

controlled descent. If after the door has finished the cycling

mode and obstruction has been removed, the door will

proceed to the floor.

• In the event of a failure in motor operation, the operator will

close via controlled descent.

GENERAL DESCRIPTION

The Fire Door Controller, FDC, is configurable as a standard CDO

or a Fire Door Controller (selectable via DIP Switch 2). The Fire

Door Mode Type I functions as an integrated fire door control

system. It is designed to interface with a normally close (NC) or

normally open (NO) dry contact alarm system to control the

operation of a fire door. The control station is the standard B2

wiring, momentary contact to open, close and stop, plus wiring

for sensing device to reverse and auxiliary devices to open and

close with open override.

NOTE: This operator is not a fire alarm system. It can not detect

a fire condition.

BATTERY TEST DESCRIPTION

The FDC provides internal battery testing to ensure the battery

has not been disconnected and the system can perform it’s

intended functionality in the event of a loss of AC power. The

battery is checked for presence once an hour for 10 seconds. If

this test fails, the battery has failed or is significantly depleted. A

major fault (see below) is declared and must be immediately

rectified. The battery is also load tested for five minutes. The five

minute load test is performed once per week to ensure that the

power remaining in the batteries is sufficient to handle an

emergency condition. The test will not occur within 12 hours of a

power outage or an aborted test due to user input.

The severity of the battery test failure are defined as a minor fault

and a major fault are described as follows:

a. Minor Fault. This fault mode occurs when the system

determines that the batteries fail to maintain the minimum

voltage between 10 seconds and 5 minutes of load testing.

The alarm within operator will begin notification immediately

at 3 seconds of every minute. The batteries will be retested

every week. The controller will attempt to close the door

after 45 days of notification and test failures.

b. Major Fault. This fault mode occurs when the system

determines that the batteries fail to maintain the minimum

voltage for 10 seconds of load testing. The batteries are

either not connected or are significantly depleted. The

system will attempt to close the door after the DIP switch

selected alarm delay (see DIP Switch section of this

manual). Notification will occur as a 1 second on 1 second

off pulse train until Battery Test passes.

Whenever a battery failure occurs, the batteries must be

connected or replaced immediately in order to ensure normal

system operation. If for any reason the battery voltage drops

below the minimum voltage the unit will activate the optional

warning system and automatically close the door via a controlled

descent.

If the system passes the Battery Test, then all alarms are cleared.

THEORY OF OPERATION

Page 5

5

FIRE DOOR MODE TYPE I FUNCTIONAL OPERATION

3. UNIT HAS AC POWER AND ACTIVE ALARM CONDITION

(ALARM INPUT #2 - Thermal Sensor, Fuse Link):

• The unit will activate the OPTIONAL warning signal

(horn/strobe), the door will automatically power down after

the preset time delay (powered down by motor). The time

delay is set by means of DIP switch 1.

• If the door is in the open position and the alarm condition

occurs, the door will automatically close under motor

operation. In the event the door should meet an obstruction

while closing, the door will stop for 2 seconds, then release

the door via controlled descent. After the obstruction has

been removed, the door will proceed to the floor.

• In the event of a failure in motor operation, the operator will

close via controlled descent.

• All control station functions will be rendered inactive in this

condition.

• The safety edge will remain active.

4. UNIT HAS NO AC POWER AND NO ACTIVE ALARM

CONDITION:

• The Close and Stop buttons of the 3-Button Control Station

are functional.

• The door’s descending speed is controlled by the integrated

braking system.

• The door will stop if an obstruction is encountered while

closing.

• The Open button is not functional.

5. UNIT HAS NO AC POWER AND ACTIVE ALARM CONDITION

(Alarm #1 or Alarm #2):

• The unit will activate the OPTIONAL warning signal

(horn/strobe), the door will automatically close after the

preset time delay (controlled by integrated braking system).

The time delay is set by means of DIP switch 1.

• If the door encounters an obstruction while closing , the door

will stop on the obstruction, and release the brake after 2

seconds. If the obstruction is then removed the unit will

perform a controlled descent of the door (not powered down

by the motor).

6. ACTIVATION OF THE INTERNAL THERMAL SENSOR:

• Will activate an alarm #2 switch.

• With AC power present the unit will react as stated in #4.

• With No AC power present the unit will react as stated in #6.

7. ACTIVATION OF THE KEY TEST STATION:

• Key must be activated for 6 seconds.

• The unit will activate the OPTIONAL warning signal

(horn/strobe), the door will automatically close after the

preset time delay (controlled by integrated braking system).

The time delay is set by means of DIP switch 1 (to test the

signal devices and the delay time).

• The door will close via controlled descent in order to test the

door balance, descent speed, and the movement of the door.

• All sensing devices and control devices will be active. In

order to test these devices, see page 6 for procedures.

THEORY OF OPERATION

Page 6

6

DOOR SYSTEM TESTING PROCEDURES

Before beginning any testing, secure the door area, keep

unauthorized personnel from entering the area during testing. Be

sure AC power is present at the operator, (the green “AC” led will

be lit on the operator’s control board) and that the batteries are

connected.

NOTE: The red “DC” led will NOT be lit on the operator’s control

board when AC power is present.

1. Begin the test with the door at the full “OPEN” position.

2. Make certain dip switch #2 is in the “ON” position “FIREDOOR

TYPE I” mode.

3. If the door is equipped with safety photo eyes, make certain

dip switch #4 is in the “ON” position.

NOTE: If 2 minutes total time elapses from the beginning of step

#11 and the conclusion of step #15, the unit will automatically

exit the “TEST” mode. To re-enter the “TEST” mode repeat step

#4, and continue testing.

4. Turn the wall mounted key test switch to the “TEST” position

and hold for a minimum of 6 seconds. This action simulates

an “ALARM” signal.

5. If dip switch #1 is in the “ON” position, the door should begin

to close immediately. If dip switch #1 is in the “OFF” position,

the door should begin to close after 10 seconds time has

elapsed (the door will not motor down, it will gravity

descend).

6. Using a “stop-watch” verify that your door is closing between

6" and 24" per second (i.e., A 10' high door should close in a

time between 5 and 20 seconds). Your door should now be

fully closed.

7. Open the door by depressing the “OPEN” button on the

3-Button Control Station.

8. Repeat step #4.

9. When the door is approximately 3 to 4 feet from the floor,

activate the doors safety edge, (if so equipped) using a crate,

skid or alike. Do not introduce any part of your body to the

door system during testing. The door should reverse to the

full open position. Remove the obstruction.

10. The door will begin to close within 1 second, if dip switch #1

is in the “ON” position. If dip switch # 1 is in the “OFF”

position, the door will wait 10 seconds before beginning to

close, the door should fully close to the floor (the door will

not motor down, it will gravity descend).

11. Repeat steps #6 and #7.

12. When the door is approximately halfway to the floor, interrupt

the safety photo eye beam, (if so equipped) by blocking with

a piece of cardboard or alike. Do not introduce any part of

your body to the door system during testing. The door

should reverse to the full open position. Remove the

obstruction.

13. Step #10 repeats.

14. When the door is approximately half way to the floor, depress

and hold the “STOP” button on the 3-Button Control Station.

The door should stop.

15. Release the “STOP” button on the control station. Step #10

repeats.

16. Depress the “OPEN” button on the 3-Button Control Station.

The door should open to the full open position. The unit is

now ready to be returned to service.

THEORY OF OPERATION

To avoid SERIOUS PERSONAL INJURY or DEATH, do NOT

introduce ANY part of your body to the door system during

testing.

WARNING

WARNING

Page 7

7

INSTALLATION

PREPARATION

Before your operator is installed, be sure the door has been

properly aligned and is working smoothly. The operator may be

wall mounted or mounted on a bracket or shelf. Refer to the

illustration and instructions on the following page that suits your

application. This motor operator is an integral part of the door

system. The motor operator, controls door descent speed under

power outage conditions, therefore the motor operator mounting

surface is of major importance. The mounting must provide the

following:

• All surfaces should be flat, square, and parallel to the door shaft.

• The mounting surface must be rigid, and braced off as required.

• When wall mounting the motor operator, it should be through

bolted to the wall.

• All (4) motor operator mounting points MUST be used.

• All mounting hardware should be a minimum of grade 5.

ENTRAPMENT PROTECTION ACCESSORIES

PHOTO EYES

NOTE: LiftMaster recommends the use of safety photo eyes as a

non-contact method of entrapment protection.

The operator has been manufactured to accept direct connection

of LiftMaster Infrared Eyes. See pages 12 and 13 for proper dip

switch settings, and pages 16 and 17 for wiring connections.

Follow the wiring instructions provided with your LiftMaster

Infrared Eyes.

ELECTRIC OR PNEUMATIC EDGE

This operator will also accept various safety edges offered by

LiftMaster. Refer to pages 16 and 17 for proper wiring

connections to the operator.

To prevent possible SERIOUS INJURY or DEATH:

• DO NOT connect electric power until instructed to do so.

• If the door lock needs to remain functional, install an

interlock switch.

• ALWAYS call a trained professional door serviceman if door

binds, sticks or is out of balance. An unbalanced door may

not reverse when required.

• NEVER try to loosen, move or adjust doors, door springs,

cables, pulleys, brackets or their hardware, all of which are

under EXTREME tension and can cause SERIOUS personal

injury.

• Disable ALL locks and remove ALL ropes connected to door

BEFORE installing and operating door operator to avoid

entanglement.

• To prevent possible SERIOUS INJURY or DEATH from a

falling door, ALL doors intended to be motor operated should

be manufactured with solid door shafts.

• This firedoor controller will NOT close a balanced door in the

absence of AC power. The door system MUST be able to

generate a minimum backdriving torque of 100 in/lbs. at the

operator output shaft.

WARNING

WARNING

NOTICE:

This equipment has been tested and found to comply with

the limits for a Class A digital device, pursuant to Part 15 of

the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference when the

equipment is operated in a commercial environment. This

equipment generates, uses, and can radiate radio frequency

energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio

communications. Operation of this equipment in a

residential area is likely to cause harmful interference, in

which case the user will be required to correct the

interference at his own expense.

Page 8

8

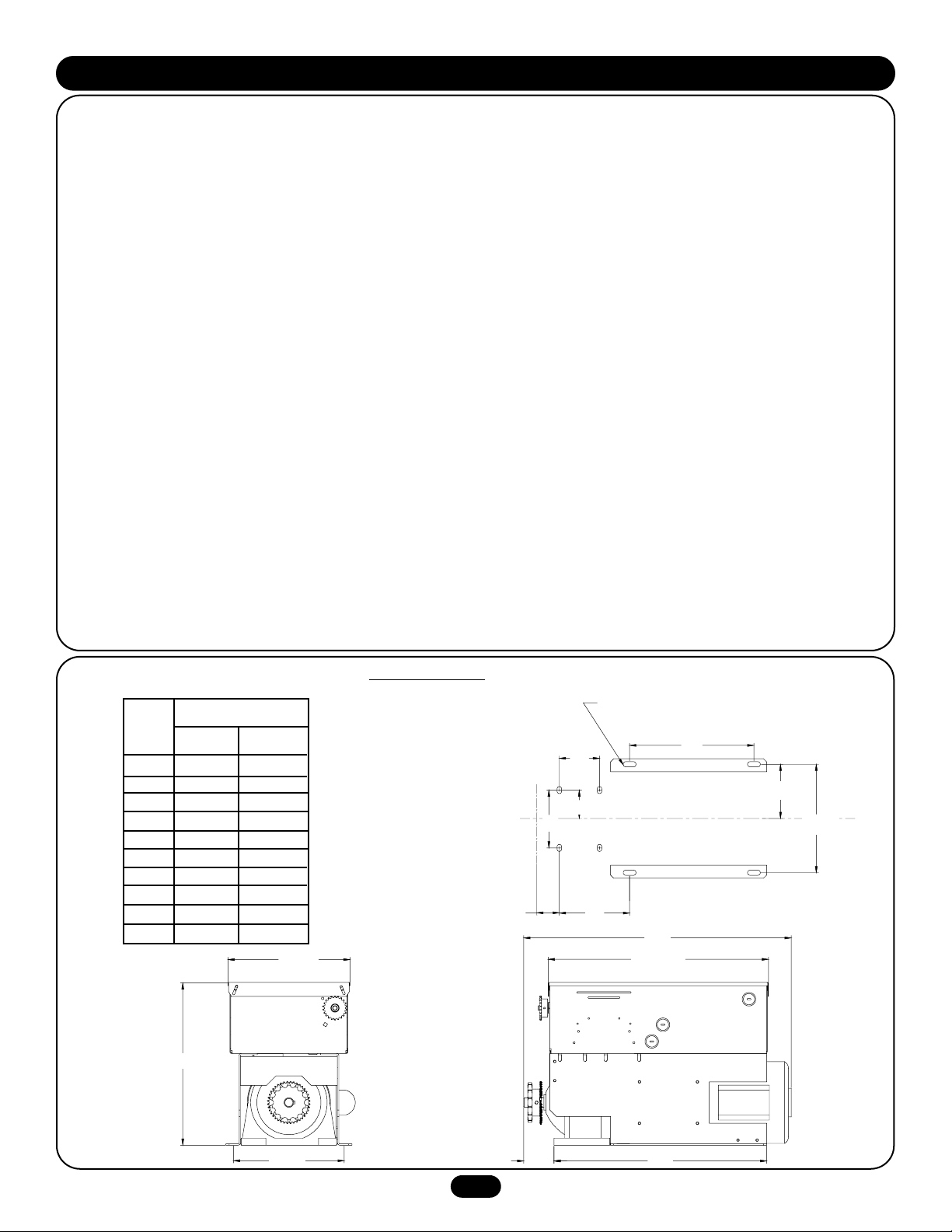

OPERATOR MOUNTING

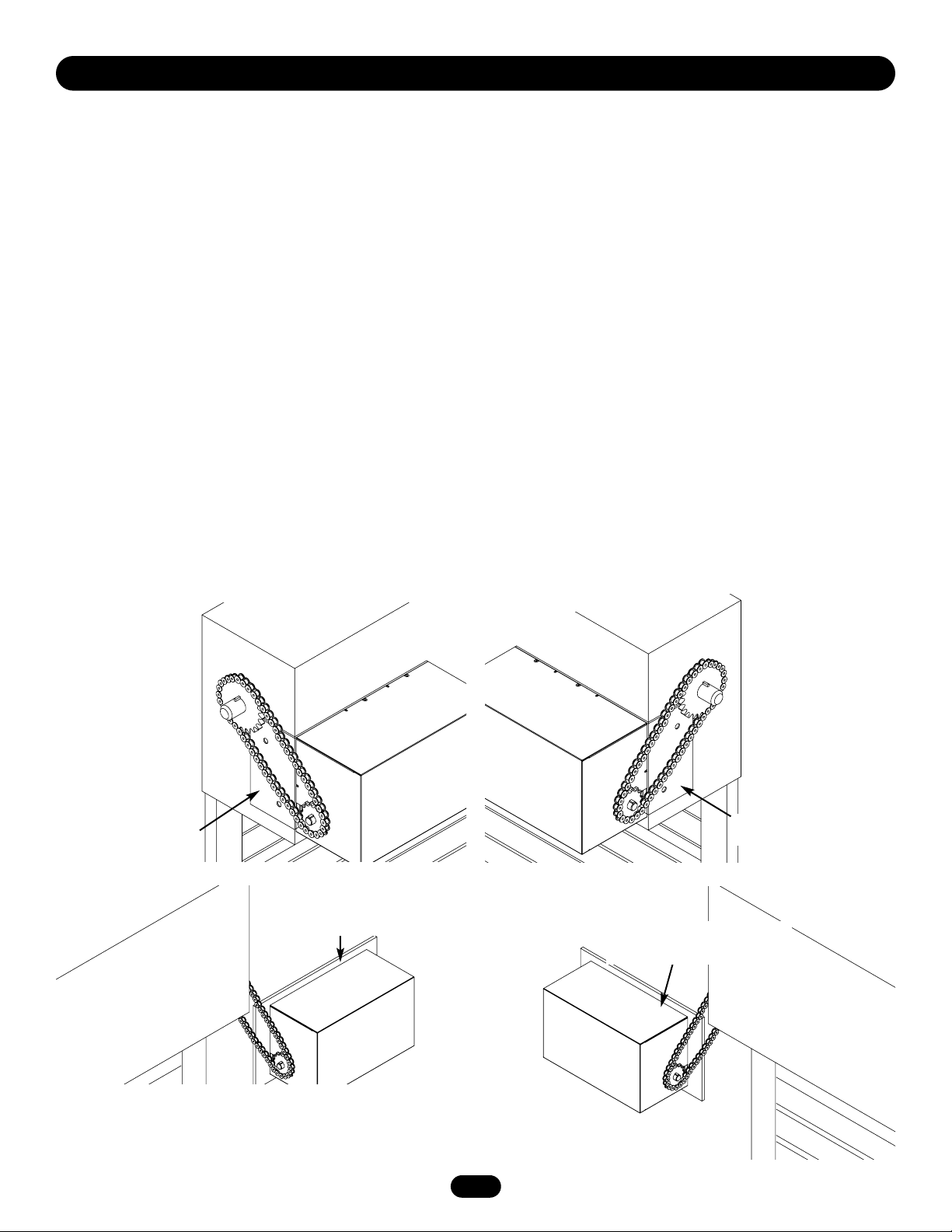

1. Wall Mount: The operator should generally be installed below

the door shaft, and as close to the door as possible (Figure 1).

Bracket Shelf Mounting: The operator may be mounted either

above or below the door shaft (Figure 2).

IMPORTANT: The shelf or bracket must provide adequate support,

prevent play between operator and door shaft, and permit

operator to be fastened securely and with the drive shaft parallel

to the door shaft.

NOTE: The optimum distance between the door shaft and

operator drive shaft is between 12" - 15".

Liftmaster products are shipped for inside wall mount

applications. If the operator is mounted to the front of the hood

the “Handing” is reversed. The last letter of the model number

indicates the mounting with a “R” for right and “L” for left.

Left Hand Models: FDC1011LC, FDC1021LC, FDC1023LC,

FDC1043LC, FDC5011LC, FDC5021LC, FDC5023LC, FDC5043LC

(Figures 1 & 2).

Right Hand Models: FDC1011RC, FDC1021RC, FDC1023RC,

FDC1043RC, FDC5011RC, FDC5021RC, FDC5023RC, FDC5043RC

(Figures 3 & 4).

INSTALLATION

FIGURE 2

FIGURE 1

Load Spreading Plate Mounted to

Wall Both Sides

(Not Provided)

Hood Mount Bracket

(Not Provided)

FIGURE 4

FIGURE 3

Load Spreading Plate Mounted to

Wall Both Sides

(Not Provided)

Hood Mount Bracket

(Not Provided)

NOTE: The door hood, end plates, and mounting bracket must be

rigid, and provide adequate structural support.

2. Place door sprocket on the door shaft. Do not insert the key at

this time.

3. Wrap drive chain around door sprocket and join roller chain

ends together with master link. (Link clip should face away

from operator.)

4. Raise operator to approximate mounting position and position

chain over operator sprocket.

5. Raise or lower operator until the chain is taut (not tight). Make

sure the operator output shaft is parallel to door shaft and

sprockets are aligned. When in position, secure the operator to

wall or mounting bracket.

6. Install all remaining drive keys and set screws. Apply locking

compound to set screws. Check that all mounting hardware is

tight, and the drive chains are taut.

LEFT HAND MOUNTS - FIGURES 1 & 2 RIGHT HAND MOUNTS - FIGURES 3 & 4

Page 9

9

To avoid SERIOUS PERSONAL INJURY or DEATH from

electrocution, disconnect electric power BEFORE manually

moving limit nuts.

WARNING

WARNING

If other problems persist, call our toll-free number for assistance:

1-800-528-2806.

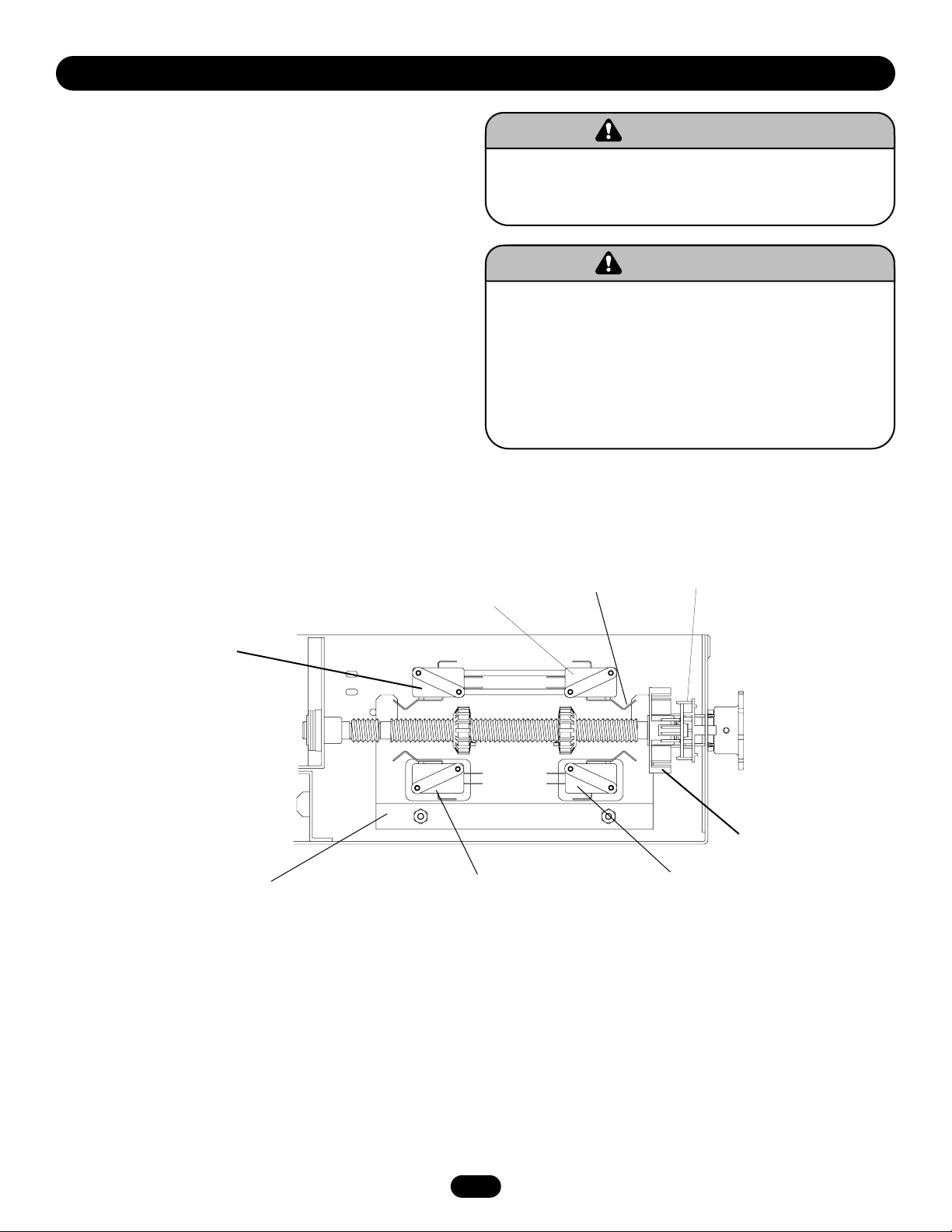

LIMIT SWITCH ADJUSTMENT

NOTE: Make sure the limit nuts are positioned between the limit

switch actuators before proceeding with adjustments. Be certain

that DIP switch #2 is in the “OFF” position (CDO mode) before

making adjustments.

NOTE: The DIP switch #2 must be in the “ON” position before

using the operator as a fire door operator.

1. Depress retaining plate to allow nut to spin freely. After

adjustment, release plate and move nut back and forth to

ensure it is fully seated in slot.

2. To increase door travel, spin nut away from actuator. To

decrease door travel, spin limit nut toward actuator.

3. Adjust open limit nut so that door will stop in open position

with the bottom of the door even with top of door opening.

4. Repeat Steps 1 and 2 for close cycle. Adjust close limit nut so

that actuator is engaged as door fully seats at the floor.

Depress Plate

CLOSE Limit Switch

SAFETY

(Aux. Close) Limit Switch

OPEN Limit Switch

Actuator

RPM Board

Rotator Cup

(Shown as LEFT

Hand Unit)

SPARE

Limit Switch

ADJUSTMENT

To avoid SERIOUS PERSONAL INJURY or DEATH:

• It is the end users sole responsibility to check that ALL

systems are installed and functional.

• The motor operator MUST be switched to the “firedoor mode

type 1” to enable ALL alarm and warning systems.

• DIP switch #2 MUST be switched to the “ON” position to

enable the “firedoor” mode. Failure to do so, could result in

loss of life and property.

WARNING

WARNING

Page 10

10

INSTALLATION MODE

The motor operator is manufactured as a standard commercial

operator with standard B2 wiring functionality. Once installation is

completed and all alarm devices are connected, and tested, the

installer must then switch the dip switch setting (see page 13).

Upon completion of installation, the unit’s functionality should be

checked by activating the key test station.

ACTIVATION OF THE KEY TEST STATION:

• Key must be activated for 6 seconds.

• The unit will activate the OPTIONAL warning signal

(horn/strobe), the door will automatically close after the

preset time delay (controlled by integrated braking system).

The time delay is set by means of DIP switch 1 (to test the

signal devices and the delay time).

• The door will close via controlled descent in order to test the

door balance, descent speed, and the movement of the door.

• All sensing devices and control devices will be active. In

order to test these devices, see page 6 for procedures.

If for any reason your unit does not respond as described in this

manual, check that you have read and followed all installation and

operating instructions. If difficulties persist, contact the LiftMaster

technical hotline: 1-800-528-2806.

ALARM INPUTS

Alarm Input #1:

Used for electronic alarm devices such as smoke detection

devices or similar alarm systems. Devices may be N/O or N/C.

Switchable using DIP Switch #3. This alarm will activate a

motored closure of the door, and all sensing and control devices

will remain active.

It is imperative that the alarm signal contact is maintained for a

time period greater than the alarm delay to close setting (i.e., if

dip switch #1 is in the “OFF” position 10 seconds, the alarm

system must supply a “DRY” contact signal to terminals J2-11

and J2-12 for a minimum of 12 seconds).

Alarm Input #2:

Used for the thermal sensors (electronic fusible links) or similar

systems (N.C. state only) the sensor or similar system must

supply a “DRY N.C.” contact signal. This alarm condition will

activate a motored closure of the door, and all sensing devices

and control stations will be rendered inactive. EXCEPT THE

SAFETY EDGE. This alarm will override any other alarm condition

or input.

To avoid SERIOUS PERSONAL INJURY or DEATH:

• It is the end users sole responsibility to check that ALL

systems are installed and functional.

• The motor operator MUST be switched to the “firedoor mode

type 1” to enable ALL alarm and warning systems.

• DIP switch #2 MUST be switched to the “ON” position to

enable the “firedoor” mode. Failure to do so, could result in

loss of life and property.

WARNING

WARNING

ADJUSTMENT

Page 11

11

To reduce the risk of SEVERE INJURY or DEATH:

• DISCONNECT and LOCK-OUT power BEFORE installation or

performing ANY maintenance to the operator or in the area

near the operator. Upon completion of maintenance the area

MUST be cleared and secured BEFORE returning the operator

to service.

• Operator MUST be properly grounded and connected in

accordance with local electrical codes. The operator should be

on a separate fused line of adequate capacity.

• Operator MUST be permanently wired as per NFPA 70

(National Electrical Code) ground MUST be pulled with each

service. Service voltage MUST be run separately from class 2

circuits.

• To avoid damage to door and operator, make ALL door locks

inoperative. Secure lock(s) in “open” position. If the door lock

needs to remain functional, install an interlock switch.

• ALL electrical connections MUST be made by a qualified

individual.

• DO NOT install ANY wiring or attempt to run the operator

without consulting the wiring diagram. It is required you install

a reversing edge before proceeding with the control station

installation (although suggested, optional in C2 mode).

• ALL power wiring should be on a dedicated circuit and well

protected. The location of the power disconnect should be

visible and clearly labeled.

• ALL power and control wiring MUST be run in separate

conduit.

WARNING

WARNING

Remove the cover from the electrical enclosure. Inside this

enclosure you will find the wiring diagram(s) for your unit. Refer

to the diagram (glued on the inside of the cover) for all

connections described below. If this diagram is missing, see

contact information on page 28.

POWER WIRING CONNECTIONS

1. Connect power wires to the J1 terminal block located on the

circuit board.

2. Be sure to run all power wires through the conduit hole in the

electrical box enclosure marked with the label shown below.

Service voltage must be run separately from class 2 circuits

(controls). See pages 16 and 17 for standard power

connections.

GROUND WIRING CONNECTIONS

1. Connect earth ground to the chassis ground screw in the

electrical box enclosure.

2. Use same conduit entry into the electrical box as the power

wiring.

IMPORTANT NOTE: This unit must be properly grounded. Failure

to properly ground this unit could result in electric shock and

serious injury.

POWER WIRING & GROUND WIRING

Page 12

CONTROL WIRING CONNECTIONS

1. Connect control wires to the J2 terminal block located on the

Logic Board (shown below).

2. Be sure to run all control wires through the conduit hole in the

electrical box enclosure marked with the label shown below.

Class 2 circuits (controls) must be run in separate conduit

from service voltage.

3. Apply power to the operator. Press OPEN push button and

observe direction of door travel and then Press the STOP

button.

If door did not move in the correct direction, check for

improper wiring at the control station or between operator and

control station (see pages 16 and 17).

MOUNTING INSTRUCTIONS

1. Mount Control Station and Key Test Switch no further than 12"

from each other.

2. Mount Control Station and Key Test Switch within clear line of

sight of door.

3. Mount WARNING NOTICE beside or below the Control Station.

12

4'

Approximate

Control

Station

Key Test

Station

(Left Hand Unit Shown)

“UL” WARNING

(See Note)

NOTE: The “UL” Warning label must be read “right side up” from

the floor level. Should your operator mounting cause this label to

be read “upside down,” your accessory kit is supplied with an

additional label. Install the new label so that it will be read “right

side up” from the floor level.

CONTROL STATION WIRING & INSTALLATION

To reduce the risk of SEVERE INJURY or DEATH:

• Install the control station where the door is visible, but away from

the door and its hardware. If control station CANNOT be installed

where door is visible, or if ANY device other than the control

station is used to activate the door, a reversing edge MUST be

installed on the bottom of the door. Failure to install a reversing

edge under these circumstances may result in SERIOUS INJURY

or DEATH to persons trapped beneath the door.

• To avoid damage to door and operator, make ALL door locks

inoperative. Secure lock(s) in “open” position. If the door lock

needs to remain functional, install an interlock switch.

• Disconnect power at fuse box BEFORE proceeding.

• Service voltage MUST be run separately from class 2 circuits

(controls).

• ALL electrical connections MUST be made by a qualified

individual.

• DO NOT install ANY wiring or attempt to run the operator

without consulting the wiring diagram. It is required you install

a reversing edge before proceeding with the control station

installation (although suggested, optional in C2 mode).

WARNING

WARNING

Page 13

13

Terminal

Block (J2)

Terminal

Block (J1)

Heat Sink

DIP Switch (S1)

NOTICE:

This equipment has been tested and found to comply with

the limits for a Class A digital device, pursuant to Part 15 of

the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference when the

equipment is operated in a commercial environment. This

equipment generates, uses, and can radiate radio frequency

energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio

communications. Operation of this equipment in a

residential area is likely to cause harmful interference, in

which case the user will be required to correct the

interference at his own expense.

OPTIONAL CONTROL SETTINGS

NOTE: All functions are independent of each other and do not

require other control settings to be set at any certain

configuration. For dip switch location refer to illustration on next

page. All switches are factory preset to the “OFF” position.

SI-1 ALARM DELAY TO CLOSE

Alarm Delay to Close is the time between when the

operator first receives an active alarm signal and the door

starts to close (in seconds).

SI-4 INFRARED EYES STATE

The operator will support LiftMaster Infrared Safety Photo

Eyes when enabled, and ignore IR inputs when disabled.

INSTALLER CONTROL SETTINGS

SI-2 FIRE DOOR MODE TYPE I/CDO MODE

The operator only monitors alarm inputs when in the Fire

Door Mode Type I. The operator functions as a standard

Commercial Door Operator with B2 wiring when in the

CDO mode.

SI-3 ALARM STATE

The operator can accept either a normally open or

normally closed dry contact alarm input. DO NOT INDUCE

VOLTAGE!

CONTROL SETTINGS

ON (0 SECOND DELAY)

1 2 3 4

OFF (10 SECOND DELAY)

ON (IR'S ENABLED)

1 2 3 4

OFF (IR'S DISABLED)

ON (FIRE DOOR MODE TYPE I)

1 2 3 4

OFF (CDO MODE)

ON (N.C. ALARM)

1 2 3 4

OFF (N.O. ALARM)

Page 14

Single Gang Junction Box

(*2 Required, Not Provided)

14

A permanent fuse link arrangement shall be set-up for all

installations. Use the illustration to the right as a guide.

1. Mount (2) single gang junction boxes (not provided) on the center

line of the door (one on each side of the door opening), see

example below. Install (2) thermal sensors (supplied with cover

plates and screws) to the junction boxes installed in step #1.

NOTE: Reference NFPA80, or applicable state and local codes for

proper installation.

2. Wire sensors in series making required connections to motor

operator (TB1-5, TB1-6). Remove and discard factory provided

“jumper” and wire as shown on pages 16 and 17 (Alarm input #2).

3. All wiring and conduit should be run in accordance with all state

and local electrical codes.

EXAMPLE OF PROPER MOUNTING FOR DETECTORS

Run Conduit

Through Wall

Junction Box

Center Line

of Door

Thermal Sensor

(*2 Provided)

4"

(0.1 m)

4".

(0.1 m)

Minimum

12"

(0.3 m)

Maximum

Sidewall

Ceiling

NOTE: Measurements shown are to

the closest edge of the detector.

Acceptable Here

ELECTRONIC FUSE LINK ARRANGEMENT

Never Here

Top of Detector

Acceptable Here

Door Hood

CONTROL SETTINGS

Page 15

15

CONTROL SETTINGS

OPTIONAL MECHANICAL (RETROFIT) FUSE LINK

ARRANGEMENT 71-17148

1. Mount (optional) fuse link retrofit switch in any convenient

location to interface with existing fuse link arrangement.

2. Connect existing fuse link chain to “key-ring” on fuse link

switch.

3. Adjust existing fuse link arrangement to be sure that proper

tension is supplied to the fuse link switch actuator (key-ring).

The actuator should be fully extended. There should be

continuity between the switch leads (Normally Closed).

4. Release the fuse link and be sure the fuse link switch actuator

(key-ring) retracts completely with no binding. There should

be NO continuity between the switch leads (Open Electrically).

5. Wire fuse link switch leads through conduit (not provided).

a) Remove factory provided “Jumper” between TB1-5, TB1-6

and discard.

b) Make required connections to motor operator TB1-5, TB1-6

(Alarm Input #2).

NOTE: For additional wiring help refer to wiring diagrams on

pages 16 and 17.

6. All wiring and conduit should be run in accordance with all

state and local electrical codes.

Existing Fuse Link

Existing Fuse Link Chain

Fuse Link Retrofit

Switch (Optional)

Center Line

of Door

Page 16

16

STANDARD POWER & CONTROL CONNECTION DIAGRAMS

NOTE: The operator should be on a separate fused line of

adequate capacity.

LMPLC BOARD - 115/230V 1PH

Operator must be permanently wired as per NFPA 70 (National

Electrical Code). Ground must be pulled with each service.

Service voltage must be run separately from class 2 circuits

(controls).

(RD)(WH)

LOW BATTERY

INDICATOR

13 141516 17 18 19 20 21 22 23

(BR)

(FACTORY JUMPER)

123456789101112

J2

24

J1

L1 L2 L3

TB1

IRs

INTERNAL

THERMAL

SENSOR

1 2 3 4 5 6 7 8 9 10

24

V

AC

GRD

+24 VDC

(1 AMP MAX)

(1 AMP MAX)

ALARM INPUT#2

(FACTORY JUMPER SUPPLIED)

ELECTRONIC

FUSE LINK

NO

C

KEY-TEST

OPEN

CLOSE

STOP

REVERSE

EDGE

115 /230V

HOT

ALARM INPUT #1

(DRY CONTACT)

N.O. or N.C.

115 /230V

NEUTRAL

POWER IN 115/230V 1PH

GND

Page 17

17

STANDARD POWER & CONTROL CONNECTION DIAGRAMS

NOTE: The operator should be on a separate fused line of

adequate capacity.

LMPLC BOARD - 230/460V 3PH

Operator must be permanently wired as per NFPA 70 (National

Electrical Code). Ground must be pulled with each service.

Service voltage must be run separately from class 2 circuits

(controls).

(RD)(WH)

LOW BATTERY

INDICATOR

13 141516 17 18 19 20 21 22 23

(BR)

(FACTORY JUMPER)

123456789101112

J2

24

J1

L1 L2 L3

TB1

IRs

INTERNAL

THERMAL

SENSOR

1 2 3 4 5 6 7 8 9 10

24 VAC

GRD

+24 VDC

ELECTRONIC

FUSE LINK

(1 AMP MAX)

(1 AMP MAX)

ALARM INPUT#2

(FACTORY JUMPER SUPPLIED)

C

KEY-TEST

OPEN

CLOSE

STOP

REVERSE

EDGE

NO

ALARM INPUT #1

(DRY CONTACT)

N.O. or N.C.

L1 L2 L3 GND

POWER IN 230/460V 3PH

Page 18

18

FDC SINGLE PHASE WIRING 1892

NOTES:

1. See owner’s manual for dip switch functions and programming

procedures.

2. To reverse motor direction, reverse purple and gray motor

wires running to J6 and J7 on the board.

3. To reverse limit switch direction, move yellow and white wires

from safety limit switch to spare auxiliary switch (see page 9).

4. Connections shown in dotted boundaries are optional user

interface.

** (K7, K8) are normally open dry contacts which are

programmed to close on any alarm signal.

5. (K6) are normally open dry contacts which are programmed to

close when the door is in motion or inhibited during a gravity

close.

(BK)

(YE)

(RD)

J4

J3J7

J6

J1

J5

J2

(WH)

(WH)

(RD)

OUTPUTS **

(K6) OPTIONAL

MOTION STROBE

(K7) OPTIONAL

FIRE SIREN

(K8) OPTIONAL

FIRE STROBE

GND

TB1

ALARM INPUT#2

(FACTORY JUMPER SUPPLIED)

ELECTRONIC

FUSE LINK

10

9

8

7

6

5

1 AMP MAX

1 AMP MAX

+24 VAC

+24 VAC

+24 VDC

GRD

4

3

2

1

115 VOLT 230 VOLT

INTERNAL MOTOR CONNECTIONS

12VDC

BATTERY

INTERNAL

THERMAL

SENSOR

(BK)

(BK)

(BR)

(BR)

(RD)

(BK)

POWER

DISCONNECT

-

+

(RD)

+

FUSE

2AMP

(BL)

(WH)

J3 J4

(BK)

(RD)

J14

J13

J15

J12

J9

J8

J2

(BK)

(WH/BK)

IR'S

(BL)

-

(BK)

NO

(RD)

RESISTOR

BRAKE

COIL

-

(WH)

J17J30

J18

(BL)

(BR)

(RD)(WH)

DC

J16

J19

+

(RD)

+

(WH/BK)

J22

J27 J26

(BK)

OVERLOAD

TRANSFORMER

1

SECONDARY

J5

(YE)

(BK)

PRIMARY

(BK)

(YE)

(OR)

(BL)

J1

L1 L2 L3

N

115V

115V 1PH

POWER IN ONLY

ALARM INPUT#1

(DRY CONTACT ONLY, DO NOT

INDUCE VOLTAGE!)

GND

(SPARE)

LIMIT SWITCH

SAFETY

LIMIT SWITCH

CLOSE

LIMIT SWITCH

OPEN

LIMIT SWITCH

RPM

BOARD

(YE)

(RD)

(WH)

(GW)

S1

ZILOG PROCESSOR

13 14 15 16 17 18 19 20 21 22 23 24

(FACTORY JUMPER)

123456789101112

C

(WH)

(BR)

(BR)

REVERSE

EDGE

POWER

DISCONNECT

KEY-TEST

OPEN

CLOSE

STOP

LOW BATTERY

INDICATOR

J21

J24

J23

J25

J28

J20

J29

MOTOR

(GY)

J6

(PU)

J7

(BL)

(WH)

(BK)

Page 19

19

FDC THREE PHASE WIRING 1893

NOTES:

1. See owner’s manual for dip switch functions and programming

procedures.

2. To reverse motor direction, reverse purple and gray motor

wires running to J6 and J7.

3. To reverse limit switch direction, move yellow and white wires

from safety limit switch to spare auxiliary switch (see page 9).

4. Connections shown in dotted boundaries are optional user

interface.

*5. Internal motor overload on models up to and including 3/4

HP. External overload located in electrical enclosure for 1 HP

models.

** (K7, K8) are normally open dry contacts which are

programmed to close on any alarm signal.

6. (K6) are normally open dry contacts which are programmed to

close when the door is in motion or inhibited during a gravity

close.

(BK)

CCB

J6

J1

J2

(WH)

(WH)

OUTPUTS * *

MOTION STROBE

ALARM INPUT#2

(FACTORY JUMPER SUPPLIED)

ELECTRONIC

FUSE LINK

1 AMP MAX

1 AMP MAX

BN

GY

PU

YE

BN

17 4

28 5

39 6

230V - 3PH

MOTOR CONNECTION

J4

J3J7

J5

(RD)

(K6) OPTIONAL

(K7) OPTIONAL

FIRE SIREN

(K8) OPTIONAL

FIRE STROBE

GND

+24 VAC

+24 VAC

+24 VDC

GRD

(RD)

POWER

DISCONNECT

-

+

12VDC

BATTERY

TB1

10

(RD)

+

FUSE

2AMP

9

8

7

6

5

4

3

2

1

INTERNAL

THERMAL

SENSOR

(BK)

(BK)

(BR)

(BR)

(RD)

(BK)

POWER

DISCONNECT

BN

* *

GY

PU

OL

YE

17 4

28 5

39 6

BN

460V - 3PH

MOTOR CONNECTION

(YE)

(RD)

(BL)

J14

(BK)

(RD)

J13

J12

J9

J8

(BK)

OL

(SPARE)

LIMIT SWITCH

SAFETY

LIMIT SWITCH

CLOSE

LIMIT SWITCH

OPEN

LIMIT SWITCH

(WH)

RPM

BOARD

(YE)

(GW)

J3 J4

J15

ZILOG PROCESSOR

13 14 15 16 17 18 19 20 21 22 23 24

123456789101112

J2

(WH/BK)

(WH)

REVERSE

EDGE

IR'S

(BR)

(BR)

(BL)

(RD)

DC

BRAKE

COIL

(BR)

(BR)

(RD)

+

(WH/BK)

J16

J19

(BK)

TRANSFORMER

SECONDARY

+

J22

J27 J26

(BL)

(BK)

1

J5

(WH)

PRIMARY

(BK)

(BK)

J1

L1 L2 L3

GND

L3

L1

L2

230/460 3PH

POWER IN

ALARM INPUT#1

(DRY CONTACT ONLY, DO NOT

INDUCE VOLTAGE!)

MOTOR

(YE)

(PU) (GY)

(BK)

J21

(BK)

J24

J23

J6

J7

(BK)

J25

(BK)

J28

(1HP & ABOVE)

J20

J29

(BK)

(BK)

(BK)

(BK)

(WH)

(BK)

(BR)

(BR)

-

(BK)

(RD)

(WH)

J18

S1

(BL)

(FACTORY JUMPER)

NO

C

KEY-TEST

OPEN

CLOSE

STOP

LOW BATTERY

INDICATOR

RESISTOR

-

(WH)

J17J30

(RD)(WH)

MOTOR O/L

OVERLOAD

L3

L2

L1

SEE NOTE 4

*

95

96

T3

(BK)

T2

(BK)

T1

INTERNAL MOTOR CONNECTIONS

Page 20

EVERY EVERY EVERY EVERY

ITEM PROCEDURE 3 MONTHS 6 MONTHS 12 MONTHS 24 MONTHS

Drive Chain Check for excessive slack.

Check and adjust as required.

Lubricate.

◆

Sprockets Check set screw tightness. ◆

Fasteners Check and tighten as required. ◆

Bearings & Shafts Check for wear and lubricate. ◆

Battery Maintenance Replace batteries. ◆

Functionality Activate Key Test switch (see pg. 5). Monthly or as required by regulatory agency

20

Check at the intervals listed in the following chart:

Gearbox: The gearbox on the motor operator is factory sealed, and non vented, and should not require service for the life of the operator.

Brake Friction Material: The electromagnetic brake on the motor operator is factory adjusted, and should not require service for the

life of the operator. Should service be required, the entire unit should be replaced.

MOTOR OPERATOR MAINTENANCE

Operators require practically no special maintenance other than

periodic checking to see that mechanical parts where necessary

are lubricated and the electrical compartments are clear of dirt.

Service technicians should familiarize themselves with the proper

sequence of operation and all related controls. Power to operator

must be disconnected when removing or replacing covers on

electrical components, making adjustments, or performing

maintenance.

1. Check wire connections for tightness and wire insulation for

defects of abrasions.

2. Check to see that all conduit connections are secure.

3. Check wires to safety edge, or infrared safety eyes, if unit is

equipped with a safety to reverse feature.

4. Inspect operation of brake.

5. Inspect gearbox for leaks.

6. Inspect roller chain and drive sprockets. Align, lubricate the

sprockets, and tighten the set screws.

7. Generally inspect the motor mounting, and tighten the

fasteners and bracing.

8. Verify that all conduit connections are tight and have no

exposed wires.

9. Inspect the electrical enclosure for debris, arching and

moisture. Check for and tighten loose wiring connections.

10. Test motor operation through all control stations.

11. Check limit switch settings.

12. Examine safety edge, coil cord and take-up reel for damage.

13. Test the operation of the safety edge.

14. Check motor amperage draw for a full open and close cycle.

Compare readings to those listed on the motor nameplate.

MAINTENANCE SCHEDULE

BATTERY DISPOSAL

Replaced batteries must be treated as a hazardous waste and

disposed of in accordance with State, Local and Federal

Regulations. See the battery manufacture’s Material Safety Data

Sheets (01-30839 “MSDS Sheets, Battery, Standard”).

BATTERY REPLACEMENT

Service Kits are available for battery replacement. Please contact

Technical Support (see back of this document for contact

information).

BATTERY MAINTENANCE / TESTING

The batteries are maintenance free. However, to insure proper and

safe operation, it is recommended that the batteries be replaced

every two years. Battery testing is conducted automatically. For

information, see the Battery Test Description section on page 4.

BATTERY HANDLING / STORAGE

Refer to the battery manufacturer’s Material Safety Data Sheets

(01-30839 “MSDS Sheets, Battery, Standard”). LiftMaster does

not recommend storage of batteries in the field. Batteries are

intended for immediate use.

Use SAE 30 Oil (Never use grease or silicone spray).

Repeat ALL procedures.

• Do not lubricate motor. Motor bearings are lubricated and

sealed at the factory.

• Inspect and service whenever a malfunction is observed or

suspected.

To avoid SERIOUS PERSONAL INJURY or DEATH from

electrocution, disconnect ALL electric power BEFORE

performing ANY maintenance.

WARNING

WARNING

Page 21

21

Motor does not run when OPEN or

CLOSE button is pushed.

Motor runs but door does not move.

Motor hums but does not run.

Operator runs in wrong direction and

limits do not function.

Limit switches do not hold their

settings.

Door ‘drifts’ when motor shuts off.

Operator does not shut off at full OPEN

or at full CLOSE position.

Operator functions erratically.

Alarm within operator sounds for 3

seconds for every minute.

Alarm within operator sounds

continuously at 1 second on and 1

second off.

Check circuit breaker, power fuses, safety switch;

check cause.

Reset; check cause.

Check fuse, check cause.

Close interlocks.

Check drive train for operation.

Close and lock off door, remove motor and inspect;

check cause.

Check door. Try to operate manually.

Check power supply.

Check power to brake coil.

Check all motor connections.

Interchange any 2 wires in 30.

Adjust chain to proper tension.

Be sure retainer is in slots of BOTH nuts.

Lubricate screw thread. Limit nuts should turn

freely.

Check brake operation.

Adjust (see above).

Inspect limit chain and sprocket. Adjust chain

tension, replace sprocket and chain if required.

Operate limit switch manually to determine.

Check line voltage at operator. Low voltage, check

cause.

Check circuit for high current draws. Eliminate all

other units from the circuit.

Check ground connections. Check alarm circuits.

Simultaneously depress the “OPEN” and “CLOSE”

limit switches, this will reset the operator’s

microprocessor.

Batteries must be replaced. Call Technical Support

to order.

Check the battery connections including the battery

disconnect plug and battery terminal connections.

Circuit breaker tripped or power fuse blown.

Thermal overload tripped.

Secondary transformer fuse blown.

External interlock open (if provided).

Sprocket key missing or drive chain broken.

Intermediate shaft or key damaged.

Door jammed. Drive train jammed.

Dead phase in 3 phase system.

Brake does not release.

Open motor winding.

On 3 phase operators power supply is out of

phase.

Drive chain loose, allows chain to jump sprocket

teeth.

Limit nut retainer not engaging slots in limit nuts.

Limit nuts binding on screw threads which allows

them to jump position on retainer.

Brake inoperative or worn.

Limit nuts not adjusted properly.

Sprocket on limit shaft loose or limit drive chain

broken.

Defective limit switch.

Low line voltage.

Bad ground.

“Noise” on electrical line.

Faulty alarm wiring.

Batteries have failed the weekly load test.

Batteries are not connected to the circuit or have

experienced a major fault condition.

SYMPTOM

POSSIBLE CAUSE REPAIR

TROUBLESHOOTING

NOTE: All units are checked for proper rotation at factory. Limit switch adjustment instructions in

electrical enclosure indicates proper direction of travel for OPEN and CLOSE limit nuts.

Page 22

22

Refer to the parts lists below for replacement kits available for

your operator. If optional modifications and/or accessories are

included with your operator, certain components may be added or

removed from these lists. Individual components of each kit may

not be available. Please consult a parts and service representative

regarding availability of individual components. Refer to page 28

for all repair part ordering information.

ELECTRICAL BOX KIT

ITEM PART # DESCRIPTION QTY

E1 K74-16513 RPM Board Kit 1

E2 10-16156 Electrical Box Cover 1

E3 75-16135 Electrical Box 1

E4 10-16133 Battery Plate 1

E5 10-16157 Electrical Box Back Plate 1

E6 21-XXXX Transformer (See Variable Chart)1

E7 25-XXXX Overload (See Variable Chart) 1

E8 25-3000K Overload Plate (3 Phase Only) 1

E9 29-NP712 Battery, 12V 2

E10 K74-32686 Power Resistor Kit 1

E11 03-8024K Contactor (Optional) AR

E12 42-110 10 Pole Terminal Block 1

E13 29-16241 Sensor, Thermostat 1

E14 75-13705 Standoff Assembly, FDO PCB 7

E15 K79-13493-1 Logic Board Kit 1

E16 28-4875-1 Grommet 1

E17 28-10219 Connector 3/8 x 90 deg. 1

28-10220 Anti-Short Bushing 1

E18 40-10031 Label, Power 2

E19 40-10032 Label, Control 2

E20 29-448 Bridge Rectifier 1

E21 35-313-002 Fuse, 2 AMP 1

E22 K-002D0776 Charging Circuit Board 1

K72-16327 LIMIT SHAFT ASSEMBLY KIT

ITEM PART # DESCRIPTION QTY

L1 09-13701 Rotator Cup 1

L2 11-13361 Limit Shaft 1

L3 12-10028 Flange Bearing 2

L4 13-10024 Limit Nut 2

L5 15-25B22AXX Sprocket 1

L6 80-10053 Washer, Spacer 4

L7 86-RP04-100 Roll Pin, 1/8" x 1" long 1

L8 87-E-038 E-Ring, 3/8" 2

K75-16515 LIMIT SWITCH ASSEMBLY KIT

ITEM PART # DESCRIPTION QTY

S1 10-10013 Depress Plate 1

S2 10-12553 Nut Plate Switch 4

S3 10-12806 Backup Plate 4

S4 18-10036 Depress Spring 2

S5 23-10041 Limit Switch 4

S6 31-12542 Switch Standoff 4

S7 82-PX04-20 Screw, #4-40 Pan Head 8

S8 82-PX06-16 Screw, #6-32 Pan Head 2

S9 84-LH-06 Lock Nut, #6-32 2

K77-32684 LABEL KIT

PART # DESCRIPTION QTY

132A2060 Label, Ground 1

40-10231 Label, 115V 1 Phase (115V 1PH Only) 1

40-10232 Label, 230V 1 Phase (230V 1PH Only) 1

40-10233 Label, 230V 3 Phase (230V 3PH Only) 1

40-10234 Label, 460V 3 Phase (460V 3PH Only) 1

40-10306 Label, Direction 1

40-12407 Label, (1A-4A) 1

40-16070 Label, (1-12) 1

40-16071 Label, (13-24) 1

40-19990 Label, Wiring Diagram (1PH Only) 1

40-19991 Label, Wiring Diagram (3PH Only) 1

40-16485 Label, FDC Electrical Box UL Caution 1

40-16509 Label, Class 2 Circuit 2

40-16601 Label, Electrical Box Cover SW. Settings 1

40-6000 Label, Door Operator Warning Sign 1

40-65 Label, Door Edge Caution 2

40-790 Label, Reset 2

40-9054 Label, Rating 1

P/N

21-16699

21-16698

25-2006

25-2008

25-2010

25-2015

25-4004-K

25-4002-5K

ITEM

E6

E7

DESCRIPTION

Transformer, 115/230V 75VA 1 Phase

Transformer, 230/460V 75VA 3 Phase

Overload, 6 Amp

Overload, 8 Amp

Overload, 10 Amp

Overload, 15 Amp

Overload, 3.3 - 5.5 Amp

Overload, 1.6 - 2.5 Amp

FDC5011

FDC5021

FDC5023

FDC5043

FDC1011

FDC1021

FDC1023

FDC1043

REPAIR PARTS KITS - ELECTRICAL BOX

CHARGING CIRCUIT BOARD UPGRADE KIT - INCLUDES

UPGRADE CHIP, PCB BATTERY BOARD AND BATTERIES

PART # DESCRIPTION

K29-FDC-500CCB Upgrade for operators with 350 and 400 firmware

Page 23

23

ILLUSTRATED PARTS - ELECTRICAL BOX

E2

E7

E11

E13

E8

E12

E15

E10

E4

E5

E14

L7

E18

E19

E3

L6

E1

E9

E17

E7

L3

L5

L8

L1

L6

L4

L2

S9

S7

S3

S6

E6

S5

S2

S8

S4

S1

E17

E20

E21

E22

Page 24

24

Refer to the parts lists below for replacement kits available for

your operator. If optional modifications and/or accessories are

included with your operator, certain components may be added or

removed from these lists. Individual components of each kit may

not be available. Please consult a parts and service representative

regarding availability of individual components. Refer to page 28

for all repair part ordering information.

INDIVIDUAL COMPONENTS

ITEM PART # DESCRIPTION QTY

1 10-16158R Frame, Right (1/2HP Operators) 1

10-16159R Frame, Right (1HP Operators) 1

2 10-16158L Frame, Left (1/2HP Operators) 1

10-16159L Frame, Left (1HP Operators) 1

3 10-16140 Bracket, Frame 4

4 10-16160 Bracket, Front & Rear 2

5 10-16483 Bracket, Lifting 2

6 15-16333 Output Sprocket (1/2HP Operators) 1

15-16244 Output Sprocket (1HP Operators) 1

7 11-16112 Extension Shaft 1

8 K20-XXXX Motor Kit (See Motor Kits) 1

9 28-10219 Connector, 90 Degree 1

28-10220 Anti-Short Bushing 1

10 28-12029 Connector, Straight 1

28-10220 Anti-Short Bushing 1

11 28-10218 Brake Conduit (1/2HP Operators) 6.5"

Brake Conduit (1HP Operators) 8"

12 28-10218 Motor Conduit (1/2HP Operators) 13"

Motor Conduit (1HP Operators) 14"

13 80-16113 Step Key 7

14 82-NH10-04 Set Screw, #10 2

15 82-WX10-10T Screw, #10-32 x 5/8" 16

K32-16214 - GEAR REDUCER 1/2HP ASSEMBLY KIT

ITEM PART # DESCRIPTION QTY

G1 32-16214 Gear Reducer 1

G2 82-HN38-20G5 Hex Bolt, 3/8" 4

G3 85-LS-38 Lockwasher, 3/8" 4

G4 85-FW-38 Flatwasher, 3/8" 4

REPAIR PARTS KITS - MODEL FDC C

K08-16114 - INTERFACE HOUSING ASSEMBLY KIT

ITEM PART # DESCRIPTION QTY

H1

08-16114 Interface Housing 1

H2

82-HN38-16 Hex Bolt, 3/8"

4

H3

85-LS-38 Lockwasher, 3/8"

4

MOTOR KITS

K20-1050C2 Models FDC5011C, FDC5021C

K20-3050C4 Models FDC5023C, FDC5043C

K20-1100C2 Models FDC1011C, FDC1021C

K20-3100C4 Models FDC1023C, FDC1043C

COMPLETE ELECTRICAL BOX REPLACEMENT KITS

To order a complete electrical box replacement kit, add a K- prefix

to the model number of your operator. For example:

FDC5011RC = K-FDC5011RC

* Electrical Box Kits include parts K72-16327 and K75-16515

K32-16234 - GEAR REDUCER 1HP ASSEMBLY KIT

ITEM PART # DESCRIPTION QTY

G1 32-16234 Gear Reducer 1

G2 82-HN38-20G5 Hex Bolt, 3/8" 4

G3 85-LS-38 Lockwasher, 3/8" 4

G4 85-FW-38 Flatwasher, 3/8" 4

G5 84-FN38 Flange nut, 3/8" 4

K75-16512 - BRAKE ASSEMBLY KIT

ITEM PART # DESCRIPTION QTY

B1

36-16221 Electromagnetic Brake 1

B2

82-SH10-06S Socket Head Screw, #10 4

ACCESSORIES

PART # DESCRIPTION QTY

02-109FDC Key Test Station 1

02-103 3-Button Control Station 1

71-17148 Fuse Link Retrofit Kit (see page 13) 1

74-16685 Thermal Sensor Assembly 2

Page 25

25

ILLUSTRATED PARTS - MODEL FDC C

2

12

1

3

4

9

10

H2

H1

H3

G4

11

8

5

G3

G2

6

B1

B2

G1

7

13

14

15

G5

Page 26

26

26

OPERATOR NOTES

Page 27

27

OPERATOR NOTES

Page 28

CONTROL CONNECTION DIAGRAM

©2005, The Chamberlain Group, Inc.

01-32788B

All Rights Reserved

HOW TO ORDER REPAIR PARTS

OUR LARGE SERVICE ORGANIZATION SPANS AMERICA

Installation and service information

are available 6 days a week

Call our TOLL FREE number:

1-800-528-2806

Monday through Friday 5 a.m. to 6 p.m. (MST)

Saturday 7 a.m. to 3:30 p.m. (MST)

www.liftmaster.com

IMPORTANT NOTE:

The 3-Button Control Station provided MUST be connected for operation.

3 BUTTON STATION AND SYSTEM TEST

ALARM SYSTEM NO OR NC CONTACTS

J2

6 7 8

Open

Close

Stop

Keyswitch

2

TB1

KEY-TEST

9 10 11 12

15

Low Battery

18

J2

Installer supplied jumper

24

Indicator

STROBE LIGHT WIRING

11

12

J2

NC Contacts

Must set DIP switch #3

(S1,3) to ON.

SENSING DEVICE TO REVERSE OR STOP

5

6

11

J2

NO Contacts

Must set DIP switch #3

(S1,3) to OFF.

J2

Sensing Device

15

17

J2

-+

24V Strobe

12

Loading...

Loading...