Page 1

®

®

™

™

Installation Manual for

Installation Manual for

EL MODELS

EL MODELS

Telephone entry/access control system

© 2006 The Chamberlain Group, Inc.

All Rights Rese

rved

Page 2

Table of Contents

Page 1

Mounting the Unit Page

Dimensions 2

EL25 Installation 3

Rotating the Keypad for Vertical Mounting 3

Unlocking/Locking EL2000 4

EL2000 Installation 5

Wire Type

Wire Connections to Unit (Factory Settings for Relays) 6

Wire Specs and Run Distances 7

Power Wire Specs and Run Distances 7

Grounding the Unit

Grounding the Unit 8

Phone Lines

Wiring 1 Unit to Telco Line 9

Wiring Multiple Units to Telco Line 10

Wiring with No Telco Line 11

Wiring to Dedicated Telco Line 12

Wiring to an Internal Phone System 13

Connection to an NPBI System 14

External Devices

Wiring a Door Strike Lock 15

Wiring a Maglock 15

Wiring a Gate Operator 16

Wiring a Key Switch/PIR/REX 16

Wiring a Door Sensing Device 17

Wiring the AutoCall Feature 17

Wiring a Radio Frequency Module 18

Wiegand Card Reader / Keypad 18

Wiring a Postal Lock Switch 19

Wiring an Internal Camera (CCTV) 19

Power

Wiring Power to the Unit 20

Powering up and Checking the LEDs 20-21

Troubleshooting 22

Repair Parts

Repair Parts 23-24

“Your” Set-Up

“Your” System Diagram and Wiring Configuration 25-26

Accessories 27

FCC and DOC

FCC and DOC Requirements 28

Page 3

Page 2

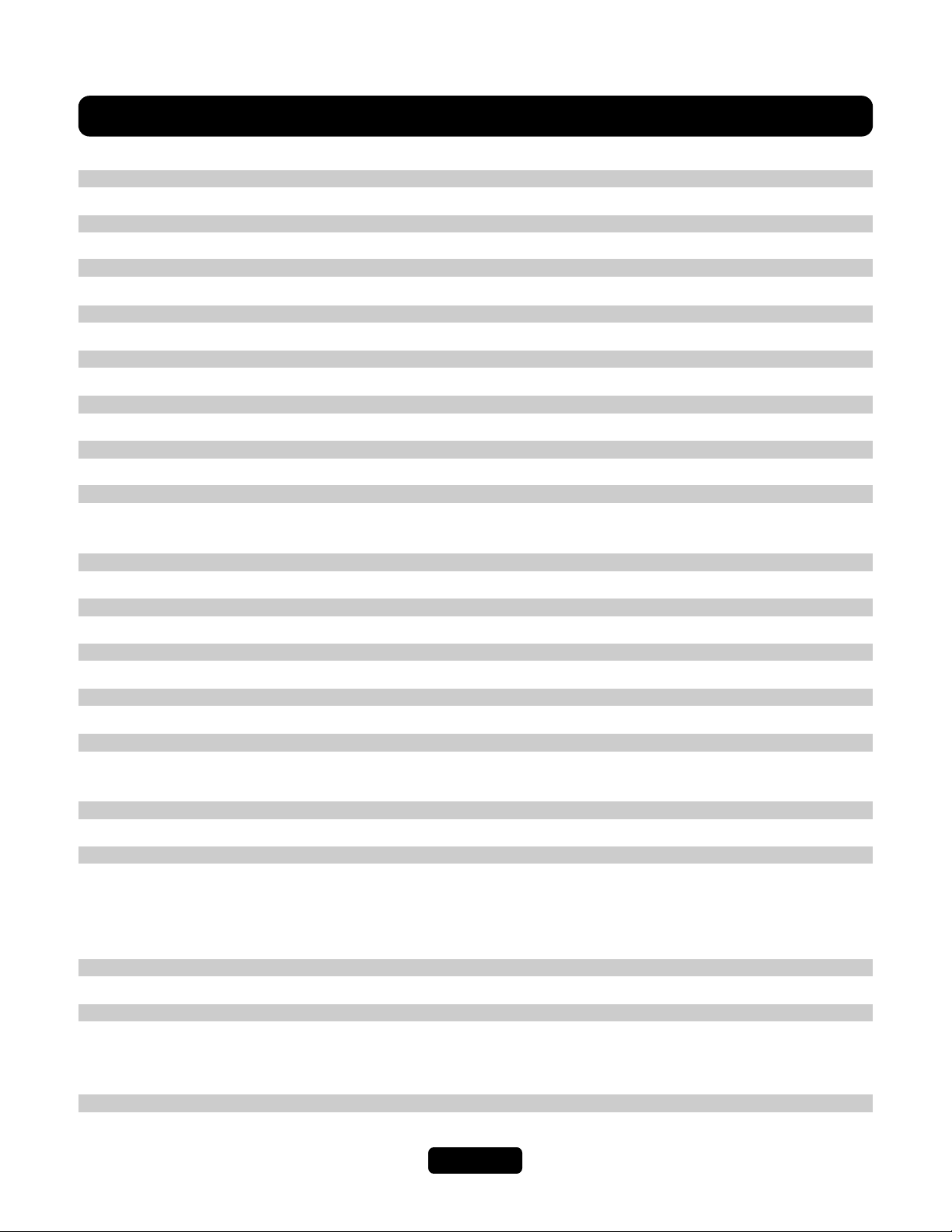

Dimensions

Dimensions

Caution! A Static Discharge can Damage Circuit Boards

6 in.

EL2000 Units

EL25 Units

AUG 10, 2005

WELCOME

3-1/16 in.

3-1/16 in.

5-1/8 in.

10-1/4 in.

3 in.

3/4 in. Conduit Hole

Mounting Holes (4)

for 5/16 in.

Knockouts for 3/8 in.

Knockouts for 5/16 in.

3-15/16 in.

9 in.

7 in.

3-1/16 in.

15 in.

1-1/2 in.

1/2 in.

12 in.

1-5/8 in. 2 in.

9-1/2 in.

3-1/16 in.

1-1/4 in. Conduit Hole

6 in.

Page 4

Page 3

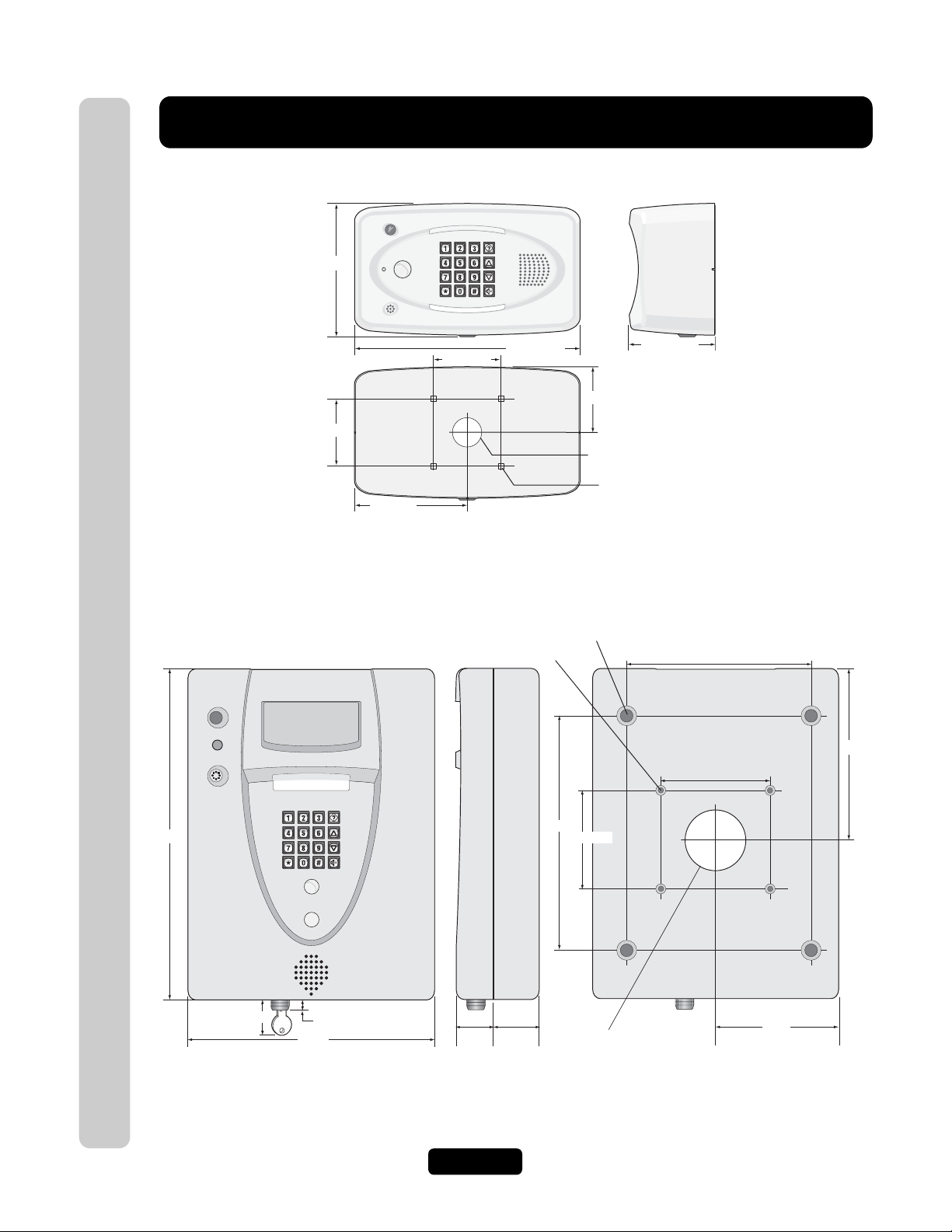

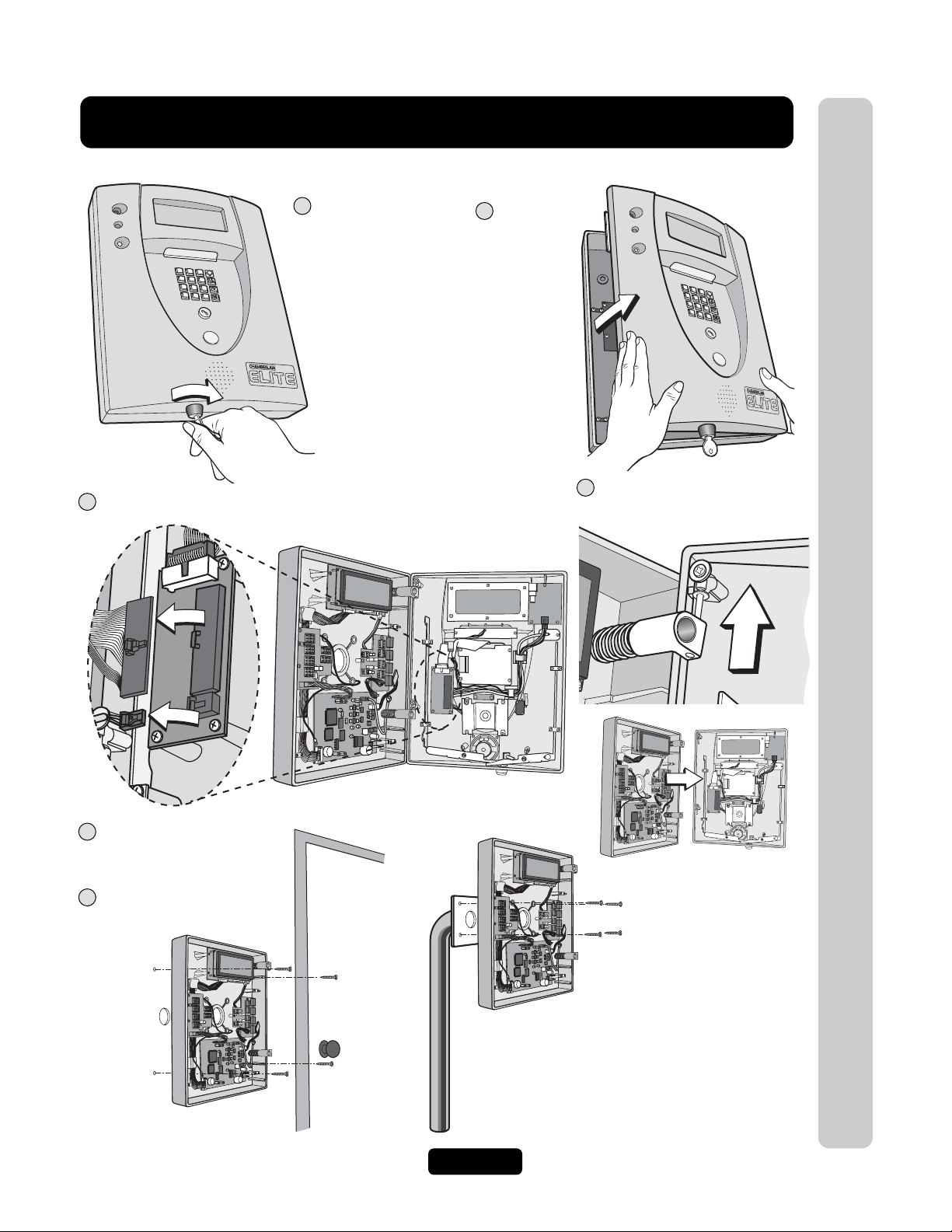

EL25 Installation

EL25 Installation

DO NOT overload the removable

terminal block connectors.

One wire per hole.

DO NOT pinch wires when

closing and locking the unit.

Rotating the Keypad for Vertical Mounting

Caution! A Static Discharge can

Damage Circuit Boards

For EL25 ONLY

Caution! A Static Discharge can Damage Circuit Boards

1

Unlock Unit

2

Carefully Lift Cover Up

then Slide Out on Hinges

3

Unplug the 2 Main Harnesses

4

Line up Notch with

Screw and Push

Hinge Out

5

Remove Back Mounting Plate from Cover

1

Disconnect all Plugs from Main Circuit Board and

Remove Board. (4 Screws)

2

Remove Bracket. (4 Screws)

3

Rotate Keypad 90 Degrees Clockwise.

4

Reverse the Sequence to Reassemble Unit.

NOTE: This unit is for surface mount applications only.

Screw

Notch

ONLY Vertical

Mounting Position

Main Circuit

1

Board

Bracket

2

Keypad

3

NOTE: Bracket notch lines up

with ribbon cable on keypad.

Main Circuit Board Connections

J200 - Speaker

J402 - Light

J404 - Call Button Board

J401 - Keypad

J406 - Light

J201 - Microphone

Page 5

Page 4

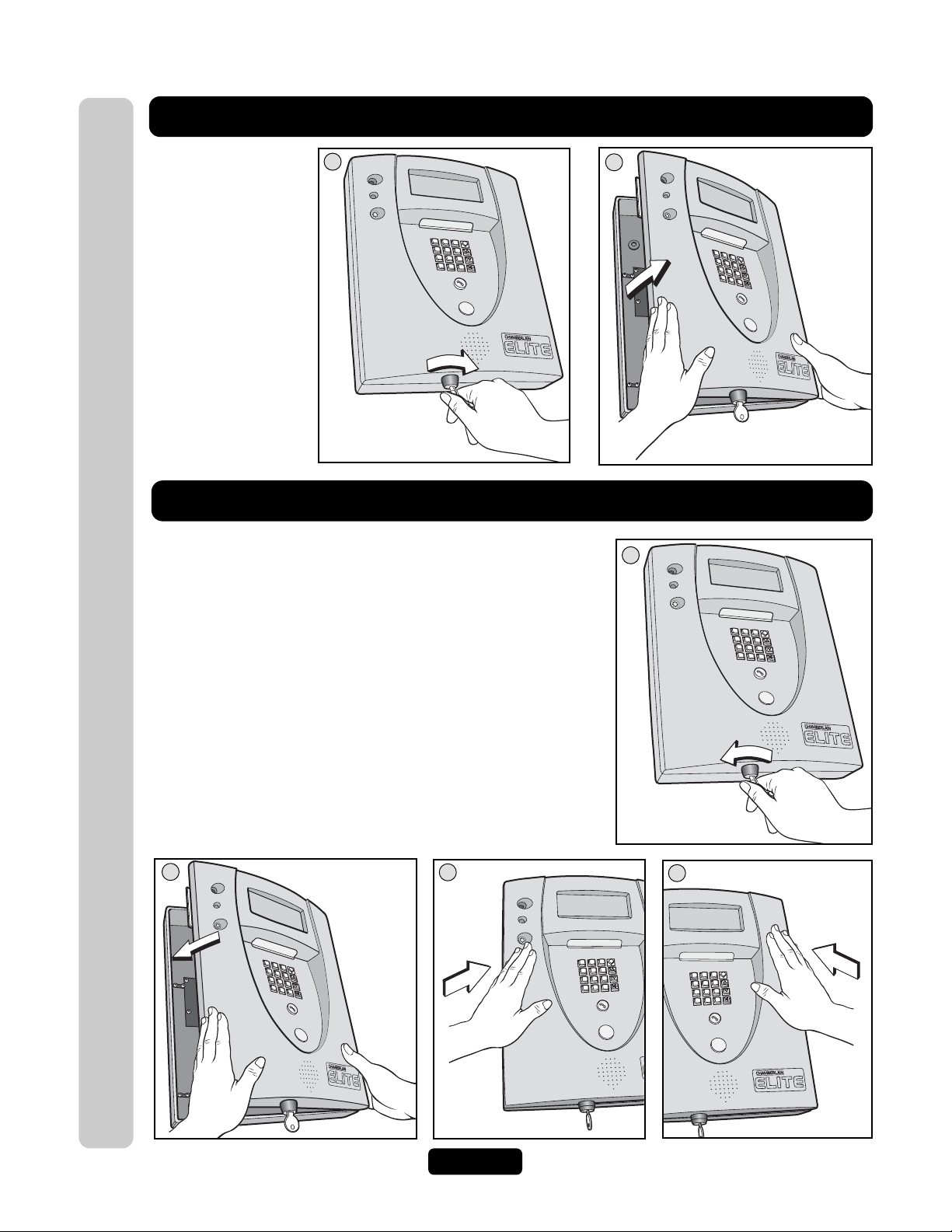

Unlocking/Locking EL2000

Unlocking EL2000

1. Turn key clockwise

2. Open cover

Locking EL2000

1. Turn key counter clockwise to lock position

2. Close cover

3. Apply pressure to left-side until you hear a

“click” sound

4. Apply pressure to right-side of unit until you

hear a "click" sound

#

#

#

#

#

#

#

#

#

#

#

#

#

#

#

#

#

1

2

2

1

3

#

4

1

2

3

?

4

5

6

7

8

9

0

#

*

1

2

3

?

4

5

6

7

8

9

0

*

#

1

2

3

?

4

5

6

7

8

9

0

#

*

1

2

3

?

4

5

6

7

8

9

0

*

#

?

3

2

1

6

5

4

9

8

7

#

0

*

?

3

2

1

6

5

4

9

8

7

#

0

*

Page 6

Page 5

#

#

#

#

EL2000 Model Installation

EL2000 Installation

1

Unlock Unit

2

Open Cover

3

Unplug the 2 Main Harnesses (Optional)

4

Slide Front Cover Out of

Hinges (Optional)

6

Mount Back Housing

to Wall or Pedestal

5

Knock-out Desired

Mounting Plugs

Using Punch

NOTE: This unit is for surface and recessed mount ONLY.

1

2

3

?

4

5

6

7

8

9

0

#

*

1

2

4

5

7

*

3

?

6

8

9

0

#

Page 7

Page 6

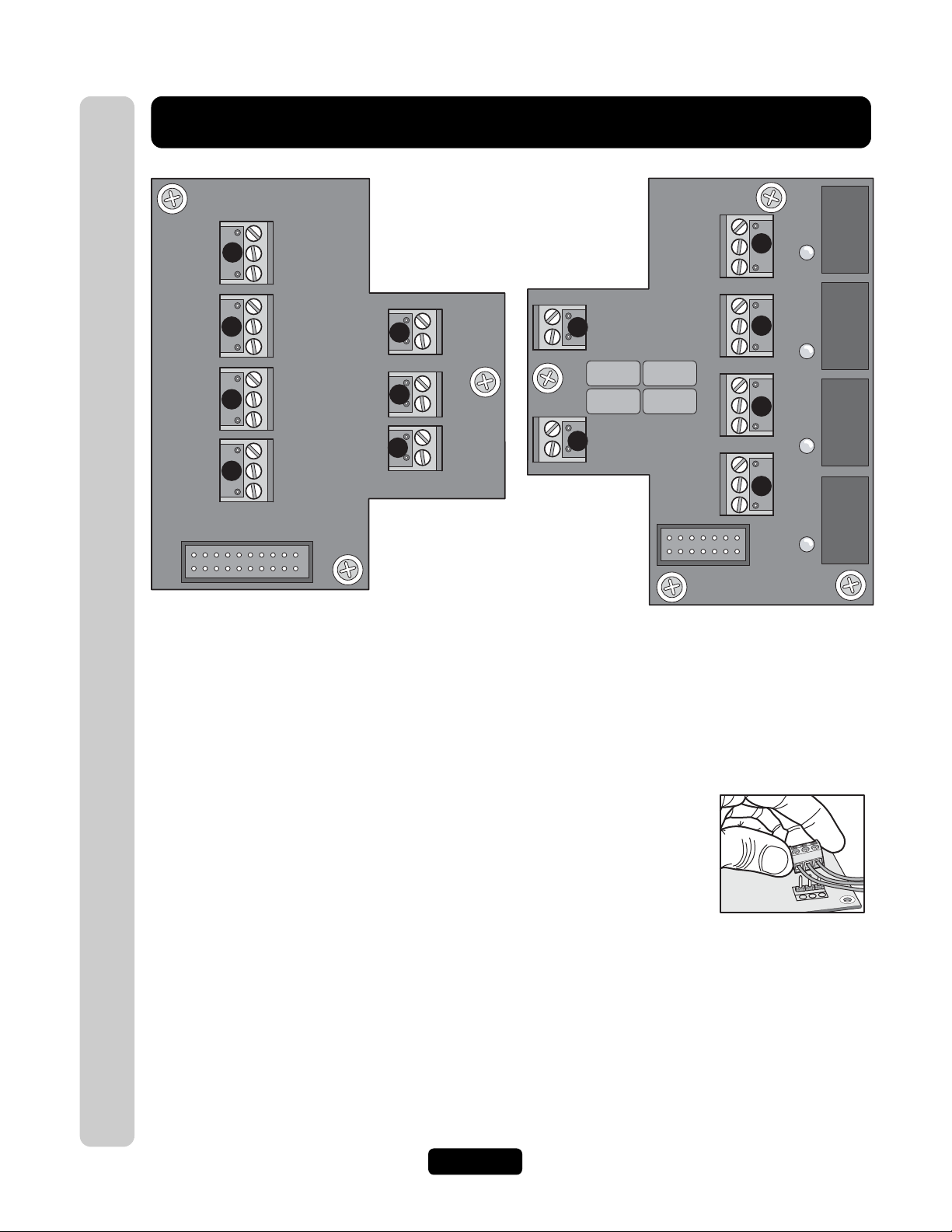

Wire Connections to the Unit

Input Board Connections

1. Door 1 Exit Request and Door Status

2. Door 2 Exit Request and Door Status

3. Door 3 Exit Request and Door Status

4. Door 4 Exit Request and Door Status

5. Postal Lock Input

6. AutoCall Input

7. Power 12 VAC Input

Output Board Connections

8. Resident Tip/Ring

9. Telco Tip/Ring

10. Relay 4, NO, NC, COM

11. Relay 3, NO, NC, COM

12. Relay 2, NO, NC, COM

13. Relay 1, NO, NC, COM

NOTE: All relays are factory set to “Strike”

and “10 sec.”

DO NOT overload the removable

terminal block connectors. One wire

per hole.

Wire Connections to the Unit

IO Output Board

EXIT

REQ 4

COM

DOOR

STAT 4

EXIT

REQ 3

COM

DOOR

STAT 3

EXIT

REQ 2

COM

DOOR

STAT 4

EXIT

REQ 1

COM

DOOR

STAT 1

to Main Board

4

3

2

1

20-Pin

NO

J7

RES

J6

J5

POSTAL

AUTO

5

6

7

J4

IO Input Board

J3

J2

J1

POWER

12VAC/DC

8

J6

TELCO

9

J8

J5

J4

J3

J1

10

11

12

13

NC

C

NO

NC

C

RELAY 3

NO

NC

C

LED 2

NO

NC

C

LED 1

RELAY 1

LED 4

RELAY 4

LED 3

RELAY 2

14-Pin

to Main Board

Page 8

Page 7

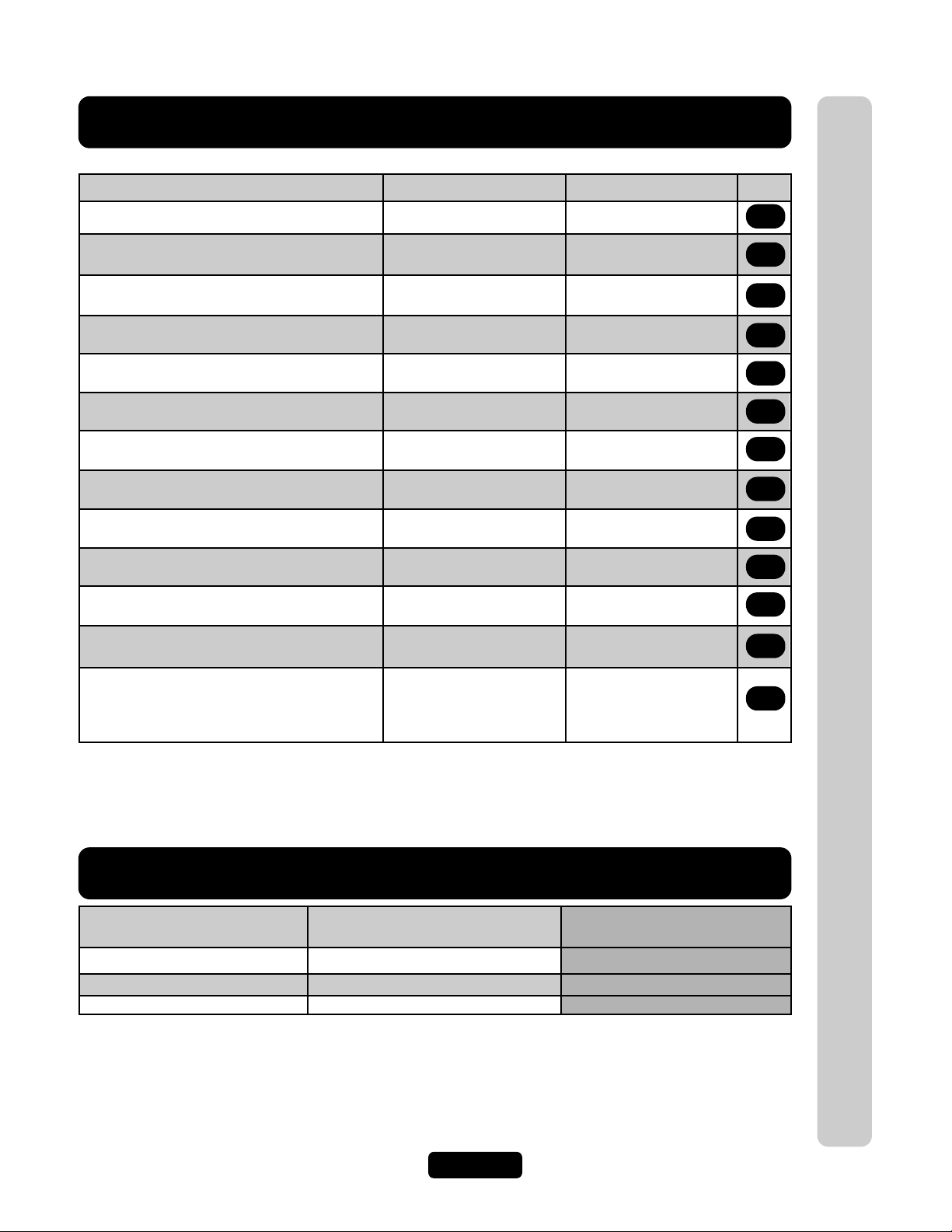

Wire Specs and Run Distances

Wire Specs and Run Distances

Use this chart to pull wires in preparation of your installation:

Power Wire Specs and Run Distances

Description of Wire Run

Grounding the Chassis

Residence and Telco Phone Lines

Door Strike

Magnetic Lock

Dry Contact Closure (Most Gate Operators)

Exit Request (REX) / Auxiliary Open Devices

AutoCall

Door Status Sensor

Barium Ferrite and Wiegand Readers

Proximity Readers

Radio Frequency Module (RF)

Postal Lock

CCTV Camera (Optional)

Wire Specification

12 AWG Copper

2 Twisted Pairs

18-24 AWG Shielded

2-Conductor

18-22 AWG Shielded

2-Conductor

18-22 AWG Shielded

2-Conductor

18-24 AWG Shielded

2-Conductor

18-24 AWG Shielded

2-Conductor

18-24 AWG Shielded

2-Conductor

18-24 AWG Shielded

5-Conductor

18-24 AWG Shielded

5-Conductor

22 AWG Shielded

RG-6 Coaxial

75 ohm

2-Conductor

18-24 AWG Shielded

Single Conductor

RG-59u Coaxial

Maximum Distance

12 feet

5000 feet*

500 feet

500 feet

100 feet

1000 feet

(Monitor with a .25 volt

p-p composite signal

sensitivity)

Page

8

9-14

15

15

16

16

17

17

18

18

18

19

19

NOTE: Use metal conduit - run wires in metal conduit instead of PVC pipe. Wires run in PVC conduit may

experience interference. Metal conduits also add extra protection against lightning strikes.

Never run Telco Wires and High Voltage wires in the same conduit. The high voltage may interfere with the Telco

Wires, possibly causing the system to malfunction.

* Total distance from Telco to residence regardless of number of units in chain.

Distance

Under 30 Feet

30 - 75 Feet

75 - 250 Feet

12 VAC Power (Included)

2-Conductor Shielded

14 AWG

14 AWG

14 AWG

12 VDC Power (Not Provided)

2-Conductor Shielded

14 AWG

14 AWG

N/A

Always provide power from a dedicated source. Plug provided transformer into an outlet wired to its own 10 AMP

minimum circuit breaker. This will prevent two problems:

• Other equipment cannot introduce spikes, noise, surges or dips into the power circuit that will affect the system.

• The system’s operation will not be affected if any other equipment develops a short circuit across the power line.

CAUTION: Not responsible for conflicts between the information listed in the above table and the requirements of

your local building codes. The information is for suggested use only. Check your local codes before installation.

Page 9

Page 8

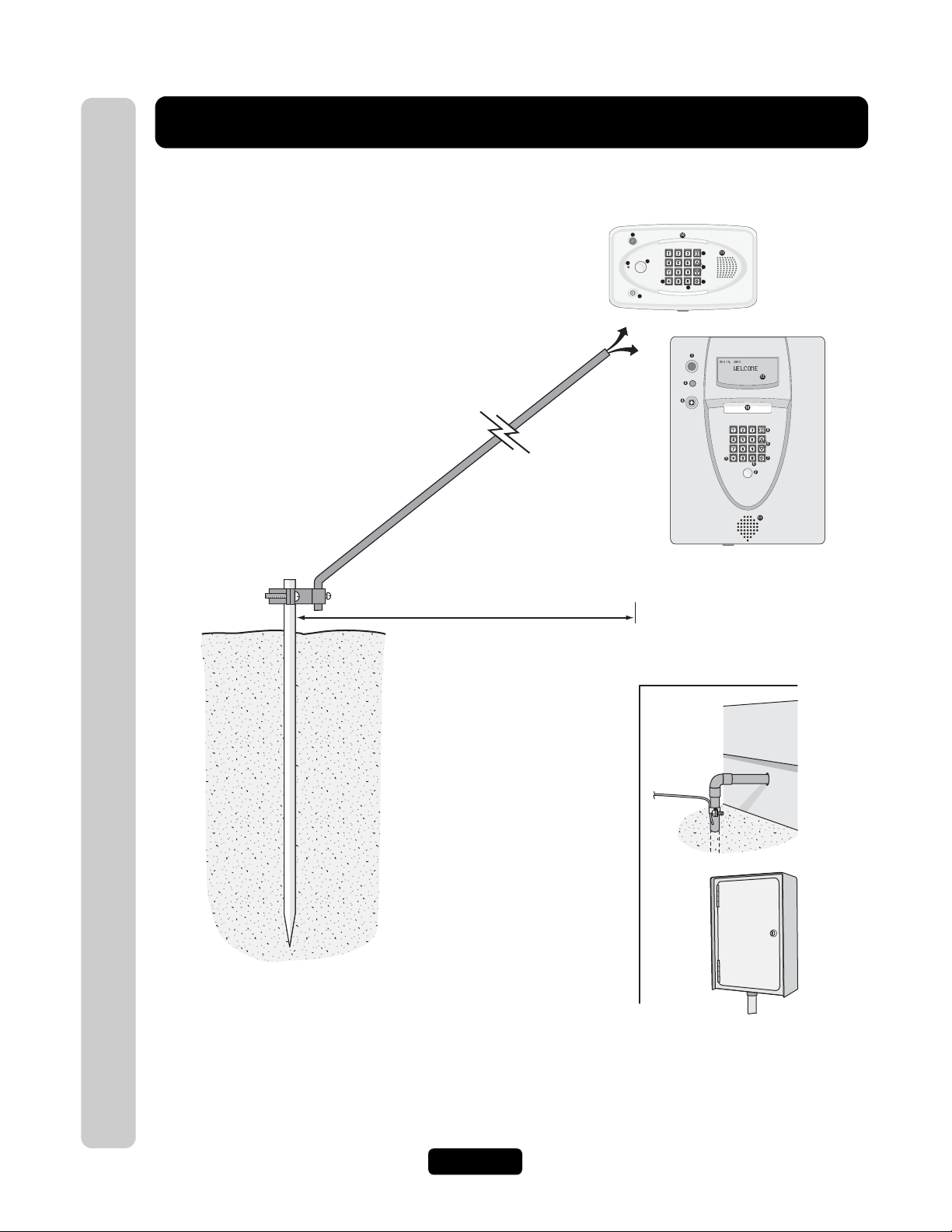

Grounding the Units

Grounding the Units

Ensure that the system is grounded properly. The units contain a number of static sensitive components that can

be damaged by static discharge.

IMPORTANT: An Earth Ground Rod is Strongly

Recommended and should be no further than 12

feet from the unit and use a minimum of 12

gauge wire in most cases. The type and length of

earth ground rods vary by region. Contact the

building inspector’s office in the municipality

where you plan to install the unit for correct

grounding materials and installation

procedures.

Other Ground Sources

within 12 ft of Unit

Green Ground

Wire

Earth Ground Rod

Ground to

Existing

Electrical

System

Elec

trical

Panel

Ground to

Metallic Cold

Water Pipe

12 ft Maximum

12 AGW Minimum

1

2

3

4

5

6

7

8

9

AUG 10, 2005

WELCOME

1

2

3

4

10

11

5

6

7

8

9

10

12

11

OR

NOTE: Keep ground wire as

straight as possible.

Before digging, contact your local

utility companies, to avoid

damaging gas, power, or other

underground utility lines.

DO NOT ground the units to a

pedestal post (gooseneck) if

one is used.

Page 10

Page 9

Wiring 1 Unit to Telco Line

Wiring 1 Unit to Telco Line

The bypass board allows the unit to be disconnected without interrupting normal telephone operation.

• When the unit is in use, the bypass switch must be set to the operate position.

• When the unit is disconnected, the bypass switch must be set to the bypass position.

Home Phone

IMPORTANT: The Bypass

Board (located inside the

Bypass Board

(Mount in the House)

OPERATE BYPASS

Ring

Tip Ring

4 3 2 1

HOME

SYSTEM

Ring

Tip Ring

Use 18-24 AWG

2 twisted pair

TELCO

Tip

property) allows access to

the phone in case the unit

fails.

NOTE: If the unit will be used in

conjunction with an alarm system, you

MUST connect the telephone line to the

alarm system first. If the units are not

connected in this order, they will not

operate properly.

Alarm System Position

Tip

(NOT Provided)

Never run Telco wires and High

Voltage wires in the same

conduit. The high voltage wires

may interfere with the Telco

wires, possibly causing the

system to malfunction.

Telco Entrance Box

Demarcation Point

DO NOT overload the removable

terminal block connectors. One

wire per hole.

RES

3

4

TELCO

1

2

Output Board

(See page 6)

Ring

Tip

Ring

Tip

Page 11

Page 10

Wiring Multiple Units to Telco Line

Wiring Multiple Units to Telco Line

Up to 7 units can share the same phone line. The bypass boards allow the units to be disconnected without

interrupting normal telephone operation.

• When the units are in use, the bypass switches must be set to the operate position.

• When the units are disconnected, the bypass switches must be set to the bypass position.

Bypass Board for Unit 1 Bypass Board for Unit 2

Home Phone

OPERATE BYPASS

Ring

Tip Tip

Never run Telco wires and High

Voltage wires in the same

conduit. The high voltage wires

may interfere with the Telco

wires, possibly causing the

system to malfunction.

DO NOT overload the removable

terminal block connectors. One wire

per hole.

Ring

Tip Ring

4 3 2 1

HOME

SYSTEM

OPERATE BYPASS

TELCO

Tip

Ring

HOME

Ring

IMPORTANT: The Bypass

Boards (located inside the

property) allow access to

the phone in case any of

the units fail.

Use 18-24 AWG

2 twisted pair

RES

3

4

Ring

Tip

Tip Ring

4 3 2 1

SYSTEM

Last Bypass Board

BYPASS

TELCO

Tip

Ring

TELCO

Tip

Tip

Ring

Telco Entrance Box

Demarcation Point

Tip

Ring

IMPORTANT: You must program the unit ID's

for each unit wired in the series. See Keypad

Programming Manual.

RES

1

2

Ring

Tip

TELCO

1

2

Unit ID 1

Output Board

(See page 6)

Ring

Tip

TELCO

3

4

Unit ID 2

Output Board

(See page 6)

Ring

Tip

Page 12

Page 11

Wiring with No Telco Line

Wiring with No Telco Line

The unit can be a stand alone system that allows communication between the unit and a resident’s phones.

Single Unit

Multiple Units (Up to 7)

NOTE: Ringer Equivalence Number (REN) of “5” maximum.

Output Board

Use 18-24 AWG

2 twisted pair

(See page 6)

RES

Ring

Tip

Never run Telco wires and High

Voltage wires in the same

conduit. The high voltage wires

may interfere with the Telco

wires, possibly causing the

system to malfunction.

NOTE: Ringer Equivalence Number (REN) of “5” maximum.

IMPORTANT: You must program the unit ID's for each

unit wired in the series. See Keypad Programming Manual.

IMPORTANT: Only disable the Telco mode of the unit farthest

away from the house. See “Disable Telco Mode” in the

Keypad Programming Guide.

Home Phone

RES

TELCO

TELCO

Ring

Tip

Ring

Tip

Ring

Tip

Unit ID 1

Output Board

(See page 6)

Use 18-24 AWG

2 twisted pair

To next unit (Unit ID 3 then 4 etc.)

RES

TELCO

Ring

Tip

Ring

Tip

Unit ID 2

Output Board

(See page 6)

Page 13

Page 12

Wiring to Dedicated Telco Line

Wiring to Dedicated Telco Line

Single Unit

Multiple Units (Up to 7)

Never run Telco wires and High

Voltage wires in the same

conduit. The high voltage wires

may interfere with the Telco

wires, possibly causing the

system to malfunction.

IMPORTANT: You must program the Unit

ID's for each unit wired in the series. See

Keypad Programming Manual.

Ring

Tip

Ring

Tip

Telco Entrance Box

Demarcation Point

Telco Entrance Box

Demarcation Point

Use 18-24 AWG

2 twisted pair

To next unit (Unit ID 5 then

4 etc.) Unit ID 1 is farthest away

from Telco Box)

Use 18-24 AWG

2 twisted pair

Ring

Tip

Ring

Tip

Output Board

(See page 6)

Ring

Tip

Ring

Tip

Output Board

(See page 6)

Ring

Tip

RES

J6

TELCO

J8

Unit ID 6

RES

J6

TELCO

J8

Unit ID 7

RES

J6

TELCO

J8

IO Output Board

IO Output Board

J5

J4

J3

J1

IO Output Board

J5

J4

J3

J1

NO

LED 4

J5

NC

C

RELAY 4

NO

NC

J4

LED 3

C

RELAY 3

NO

J3

NC

C

LED 2

NO

RELAY 2

NC

J1

C

LED 1

RELAY 1

NO

LED 4

NC

C

RELAY 4

NO

NC

LED 3

C

RELAY 3

NO

NC

C

LED 2

NO

RELAY 2

NC

C

LED 1

RELAY 1

NO

LED 4

NC

C

RELAY 4

NO

NC

LED 3

C

RELAY 3

NO

NC

C

LED 2

NO

RELAY 2

NC

C

LED 1

RELAY 1

Page 14

Page 13

Wiring to an Internal Phone System

Wiring to an Internal Phone System

The units can be wired to any Analog Trunk in an internal home phone system.

IO Output Board

LED 2

LED 1

RELAY 1

RELAY 2

RELAY 3

RELAY 4

J3

J5

J4

J1

NO

NC

C

NO

NC

C

NO

NC

C

NO

NC

C

LED 4

LED 3

RES

TELCO

J6

J8

Tip

Ring

Use 18-24 AWG

2 twisted pair

Analog

Trunk

Telco Entrance Box

Demarcation Point

Internal

Phone System

Ring

Tip

EX 1 EX 3Analog EX 4 2

T

R

Tip

Ring

Never run Telco wires and High

Voltage wires in the same

conduit. The high voltage wires

may interfere with the Telco

wires, possibly causing the

system to malfunction.

Single Unit

Multiple Units (Up to 7)

IO Output Board

LED 2

LED 1

RELAY 1

RELAY 2

RELAY 3

RELAY 4

J3

J5

J4

J1

NO

NC

C

NO

NC

C

NO

NC

C

NO

NC

C

LED 4

LED 3

RES

TELCO

J6

J8

Tip

Ring

Tip

Ring

IO Output Board

LED 2

LED 1

RELAY 1

RELAY 2

RELAY 3

RELAY 4

J3

J5

J4

J1

NO

NC

C

NO

NC

C

NO

NC

C

NO

NC

C

LED 4

LED 3

RES

TELCO

J6

J8

Tip

Ring

Tip

Ring

Use 18-24 AWG

2 twisted pair

IMPORTANT: You must program the unit

ID's for each unit wired in the series. See

Keypad Programming Manual.

Unit ID 6

Output Board

(See page 6)

Unit ID 7

Output Board

(See page 6)

To next unit (Unit ID 5 then

4 etc.) (Unit ID 1 is farthest away

from Telco Box)

Analog

Trunk

Telco Entrance Box

Demarcation Point

Internal

Phone System

Ring

Tip

EX 1 EX 3Analog EX 4 2

T

R

Tip

Ring

Page 15

Page 14

Connection To A NPBI System

Connection To An NPBI System

Single Unit

Multiple Units (Up to 7)

Never run Telco wires and High

Voltage wires in the same

conduit. The high voltage wires

may interfere with the Telco

wires, possibly causing the

system to malfunction.

Sentex

Ovation

Unit

Use 18-24 AWG

2 twisted pair

Ring

Tip

RES

J6

TELCO

J8

IO Output Board

J5

J4

J3

J1

LED 2

NO

NC

C

NO

NC

C

NO

NC

C

NO

NC

C

LED 1

RELAY 1

LED 4

RELAY 4

LED 3

RELAY 3

RELAY 2

IMPORTANT: You must program the Unit

ID's for each unit wired in the series. See

Keypad Programming Manual.

Sentex

Ovation

Unit

To next unit (Unit ID 5 then

4 etc.) Unit ID 1 is farthest away

from Telco Box)

Use 18-24 AWG

2 twisted pair

RES

Ring

J6

Tip

TELCO

Ring

J8

Tip

Unit ID 6

Output Board

(See page 6)

RES

Ring

J6

Tip

TELCO

Ring

Tip

J8

Unit ID 7

Output Board

(See page 6)

IO Output Board

J5

J4

J3

J1

IO Output Board

J5

J4

J3

J1

LED 2

LED 2

NO

NC

C

RELAY 4

NO

NC

C

RELAY 3

NO

NC

C

NO

RELAY 2

NC

C

LED 1

RELAY 1

NO

NC

C

NO

NC

C

NO

NC

C

NO

NC

C

LED 1

RELAY 1

LED 4

LED 3

LED 4

RELAY 4

LED 3

RELAY 3

RELAY 2

Page 16

Page 15

Wiring a Door Strike Lock/Maglock

Wiring a Door Strike Lock

Wiring a Maglock

IO Output Board

LED 2

LED 1

RELAY 1

RELAY 2

RELAY 3

RELAY 4

J3

J5

J4

J1

NO

NC

C

NO

NC

C

NO

NC

C

NO

NC

C

LED 4

LED 3

RES

TELCO

J6

J8

Use 18-22 AWG

For DC Power: Install a 1N4005

diode or equivalent.

NOTE: The door strike can

be connected to any of the

4 relays.

Normally Open

Common

DO NOT use the unit’s power

supply for the Door Strike.

–

+

AC or DC

Power for

Door Strike

(Not Provided)

DO NOT overload

the removable

terminal block

connectors. One

wire per hole.

Output Board (See page 6)

For AC Power: Install a

Siemens S10K30 MOV

(Metal Oxide Varistor) or

equivalent.

IO Output Board

LED 2

LED 1

RELAY 1

RELAY 2

RELAY 3

RELAY 4

J3

J5

J4

J1

NO

NC

C

NO

NC

C

NO

NC

C

NO

NC

C

LED 4

LED 3

RES

TELCO

J6

J8

Output Board (See page 6)

Install a 1N4005 diode or

equivalent.

NOTE: The maglock can be

connected to any of the

4 Relays.

DO NOT use the unit’s power

supply for the Maglock.

Use 18-22 AWG

–

+

Normally Closed

Common

AC or DC

Power for

Door Strike

(Not Provided)

For AC Power: Install a

Siemens S10K30 MOV

(Metal Oxide Varistor) or

equivalent.

Page 17

Page 16

Wiring a Gate Operator / Key Switch / PIR / REX

Wiring a Gate Operator

Wiring a Key Switch/PIR/REX

Any auxiliary opening device such as a key switch or PIR (Passive Infrared Device), or an exit request button

(REX) that provides normally open contact closure can be hooked up to the Door Input terminals.

NOTE: Refer to your gate operators owner’s manual for proper relay strike time.

Output Board

(See page 6)

DO NOT overload

the removable

terminal block

RES

connectors. One

wire per hole.

J6

TELCO

Normally Open

J8

Common

Use 18-24 AWG

NOTE: The gate operator can be

connected to any of the 4 relays.

IO Output Board

J5

J4

J3

J1

NO

NC

C

NO

NC

C

NO

NC

C

LED 2

NO

NC

C

LED 1

RELAY 1

LED 4

RELAY 4

LED 3

RELAY 3

RELAY 2

Input Board

(See page 6)

EXIT

REQ 4

COM

DOOR

STAT 4

EXIT

REQ 3

COM

DOOR

STAT 3

EXIT

REQ 2

COM

DOOR

STAT 4

EXIT

REQ 1

COM

DOOR

STAT 1

J7

J6

J5

J4

POSTAL

AUTO

IO Input Board

NOTE: Additional opening or exit devices can be

connected to any of the 4 Exit Request inputs.

J3

J2

J1

POWER

12VAC/DC

Exit Request

Common

Use 18-24 AWG

Page 18

Page 17

Wiring a Door Sensing Device / AutoCall

Wiring a Door Sensing Device

The units can monitor the position of up to four doors/gates and may react to a change in their status with one of

the relays (not set as a control relay). For example, if a door is pried open or is held open after its relay deactivates,

the unit will record the breach in its transactions and can perform the following actions:

• Energize a relay to activate an alarm device such as a siren, light or CCTV camera.

• Main use is to terminate strike time early.

Wiring the AutoCall Feature

Using the AutoCall feature, the unit will automatically call the main residence phone when a driveway sensor is

activated (any device that provides a contact closure). For example, when a visitor drives over a loop sensor that is

connected to the AutoCall feature, the unit will call the main residence phone automatically so the visitor can speak

to the resident without pressing the call button on the unit.

IO Input Board

J2

J3

DOOR

STAT 4

EXIT

REQ 4

COM

DOOR

STAT 3

EXIT

REQ 3

COM

DOOR

STAT 4

EXIT

REQ 2

COM

DOOR

STAT 1

EXIT

REQ 1

COM

J5

J7

J6

J4

POSTAL

AUTO

J1

POWER

12VAC/DC

Use 18-24 AWG

Door Status

Common

Input Board

(See page 6)

NOTE: Additional sensing devices can be

connected to any of the 4 Door Stat inputs.

IO Input Board

J2

J3

J5

J6

J4

POSTAL

AUTO

J1

POWER

12VAC/DC

Loop

Detector

Use

18-24 AWG

Common

In

Loop

Sensor

Input Board

(See page 6)

NOTE: Door sensing device should provide contact closure when door is closed.

Page 19

Page 18

Wiring a RF Module / Card Reader / Keypad

Wiring a Radio Frequency Module

An optional radio frequency module and a remote antenna can be installed if the residents will access a

controlled area with a transmitter. Refer to instructions supplied with the optional RF Module for more

information.

Wiegand Card Reader/Keypad

Wiegand card readers and keypads can be connected to either of 2 optional Wiegand modules that can be placed

in the unit. Each Wiegand module supports two card readers/keypads. Some Wiegand card reader/keypads have

a sixth blue wire. DO NOT connect this blue wire to the unit. Insulate this wire from the unit to prevent a short

(Refer to instructions supplied with your Wiegand device for more information).

RG-6

Coaxial

Connector

RG-6 Coaxial Cable

100 Feet Maximum

Remote Antenna

Avoid any metallic

surface around the

antenna.

RF Module(s) will fit in positions

J400 (Device 1) and/or J407 (Device 3)

(4 Mounting Screws per Board are Required)

1 RF Module Kit

Part # RFMODKT

(390 MHz)

or

Part # RFMODKT3

(315 MHz)

J407 Position J400 Position

Card Reader is Wired to Device 1

P12V

P5V

DATA 0

DATA 1

LED

COM P12V

P5V

DATA 0

DATA 1

LED

COM

J1J2 J1J2

Device 1Device 3 Device 2Device 4

Red Power

Green

White

Brown

Black

Shield

(Attach to the

unit ground only).

Blue (Insulate this wire).

Use 18-24

AWG

1 Wiegand Module Kit

Part # WOMODKT

P12V

P5V

DATA 0

DATA 1

LED

COM P12V

P5V

DATA 0

DATA 1

LED

COM

Wiegand Modules will fit in

J400 as Device 1 (J1) and 2 (J2)

and/or

J407 as Device 3 (J1) and 4 (J2)

(4 Mounting Screws per Board are Required)

NOTE: The remote can control 1-4 doors.

Page 20

Page 19

Wiring a Postal Lock Switch / Internal Camera (CCTV)

Wiring a Postal Lock Switch - EL25 Models Only

The Post Office requires installation of a postal lock if postal carriers do not have access to a controlled area.

Contact the local post office and arrange for them to install the postal lock while you are on site. The postal lock

requires a switch to activate one of the four relays (Configurable with programming number 69 , in the Keypad

Programming Manual).

Wiring an Internal Camera [CCTV]

An Optional CCTV (Close Circuit Television) camera can be installed inside the unit. Refer to instructions supplied

with the camera kit for more information.

IO Input Board

J2

J3

J5

J7

J6

J4

POSTAL

AUTO

J1

POWER

12VAC/DC

Use

18-24 AWG

Common

In

N.C.

Switch

Input Board

(See page 6)

DO NOT overload the removable terminal

block connectors. One wire per hole.

RG-59u Coaxial Cable 1000 Feet Maximum

(Monitor with a .25 volt p-p composite signal sensitivity)

A Closed Circuit Monitor

Home Entertainment

System

Contact your dealer/ installer

for more information

EL2000EL25

OR

NOTE: In the EL2000 models, the postal lock switch is pre-wired.

Page 21

Page 20

Wiring Power to the Unit

Wiring Power to the Unit

The 110 VAC outlet must be dedicated to the unit ONLY. This outlet should be wired back to its own 10 Amp

minimum circuit breaker. This will prevent two problems:

• Other equipment cannot introduce spikes, noise, surges or dips into the power circuit.

• The system’s operation will not be affected if any other equipment develops a short circuit across the

power line.

Connect the transformer into a 110 VAC outlet after all connections have been made. Any other type of outlet will

cause damage to the system.

IO Input Board

J2

J3

J5

J7

J6

J4

POSTAL

AUTO

J1

POWER

12VAC/DC

OffO

ff

OffOff

OnOn

OnOn

OnOn

OffOff

OffOf

f

OffO

f

f

OnOn

OffOff

OffOff

EL Mo

d

e

l

Main

Room

Eug. Rm

O

per. Rm

E

u

g

.

D

e

p

t

.

M

a

n

u

.

1

R

m

Mai

n

Dept

.

Man

u.

2 Rm

A

ir

(1

)

C

o

n

d

it

i

o

n

e

r

A

ir (2)

Conditioner

C

o

n

f

e

r

e

n

c

e

R

o

o

m

1

Conference

Rm 2, 3

R

ef

er

.

B

u

s

1

,

2

,

3

C

o

n

f

e

r

e

n

c

e

R

o

o

m

2

Co

m

p

.

S

e

r

ve

2

Co

m

p

.

S

er

ve

1

Polarity Does Not Matter

(See table on page 7 for AWG)

Dedicated 10 Amp

Minimum Circuit

AC Power

12 VAC or 16 VDC

110 VAC

Dedicated Outlet

EL Series Unit

MUST be

Properly

Grounded!

See Page 8.

Input Board

(See page 6)

Page 22

Page 21

Powering Up and Checking the LEDs

Wiring Power and Powering Up Unit

4

3

J500

J406 LCD

H2

100A

UD

D102

J201

5

MIC

D2

J401

D300

2

H2

100A

UD

J405

3D2

100

16B

1

7

6

J403

11

J400

DEVICE 1,2

D153

H2

100A

UD

14

22

DescriptionType

12

15

No.

1

LED D300 X X PWR LED Indicates Unit is receiving power

2

Connector J405 X X 20-Pin Connector Connector to IO Input Board. The IO Input Board contains all REX inputs,

J301

J404

J300

Board

Label

+

BT300

16

13

Used on Model

EL25 EL2000

J407

DEVICE 3,4

SW300

17

18

Name

D513

UV

OV

3D2

100

16B

16B

100

3D2

J402 LEDJ200 SPKR

D514

20

19

3D2

100

16B

3D2

100

16B

21

to IO Input Board DSC inputs and Postal input, Auto Sensor input and Power. Provides power

3

Connector J500 X LCD PWR to LCD Display.

4

Connector J406 X X EL25=LED BOTTOM For the EL25 provides power to bottom lighted LEDs for the main keypad.

KEYPAD On the EL2000 this is the top lighted LEDs for main keypad.

EL2000=LED keypad

5

Connector J201 X X MIC Microphone connector

6

Connector J403 X X 14-Pin Connector to Connector to the Output Board. The Output Board contains the Resident,

Output Board Telco and dry contact Relays.

7

Connector J401 X X KEYPAD Connector for the main keypad

8

LED D2 X X Local Mode Unit supplying Central Office Power to Resident

9

LED D102 X X RES DAA OFF HOOK Resident side of circuit is off hook

10

LED D153 X X TELCO DAA OFF HOOK Telco side of circuit is off hook

11

Connector J301 X X Direct Connect Used for direct connect and handheld programming and Real

(Serial Port) Time Monitoring.

12

Connector J404 X X LED Power Supply

13

Connector J407 X X Module Device (3,4) Connect a module (Wiegand or RF) device here. The device address

becomes 3 (RF or Wiegand-J1) or 4 (Wiegand-J2)

14

Connector J400 X X Module Device (1,2) Connect a module (Wiegand or RF) device here. The device address

becomes 1 (RF or Wiegand-J1) or 2 (Wiegand-J2)

15

Connector J300 X LCD Data Data wires for LCD Display

16

Connector BT300 X X Battery Battery used to back-up the Unit’s real time clock.

17

Switch SW300 X X OV/UV Reset Switch to turn off OV/UV LEDs. This button will turn off the OV/UV

LEDs momentarily. If a poor power condition still exists then the

OV or UV LEDs may turn on again.

LED D513 X X Over-Voltage (OV) Over-Voltage LED. Turns on when the Unit detects an over voltage

18

of 16.5 VAC or 22.3 VDC at power block J1. Measure the voltage at

power block J1 to confirm.

19

LED D514 X X Under-Voltage (UV) Under-Voltage LED. Turns on when the Unit detects an under

voltage of 9.5 VAC or 10.2 VDC at power block J1. Measure the

voltage at power block J1 to confirm.

20

Connector J402 X LED TOP KEYPAD For the EL25, provides power to the top lighted LEDs for main keypad.

21

Connector J200 X X Main Speaker Main Speaker

Switch SW500 X X Soft Reboot Reboots firmware without removing power.

22

8

9

10

Page 23

Page 22

Troubleshooting

Troubleshooting

Wiring

• Check for correct length and AWG of wires. See page 7.

• Check that wires are correctly inserted into the terminal blocks (not loose, no two sharing the same position).

• Check board markings for correct terminal block placements.

• Make sure high voltage and Telco Wires do not share the same conduit.

• Use metal conduit, not PVC.

No Power To Unit

• Check power at source. Power must come from a dedicated 110VAC outlet.

• The transformer’s outlet should be wired to its own circuit breaker.

• Check “SYS PWR” LED indicators. If “UV” or “OV” are lit, press “PWR MON RST” button. If either of those two

LEDs are still lit, check transformer and outlet.

Door Strikes/Maglocks/Gate Operator not working

• Check power source. Strikes, Maglocks and Gate Operator must be powered independent from unit.

• Connect and test different Strike or Maglock. Make sure Strike or Maglock is not defective.

• Door Strike: Pin connections “NO” and “COM” at Relay terminal.

• Maglock: Pin connections “NC” and “COM” at Relay terminal.

• Gate Operator: Pin connections “NO” and “COM” at Relay terminal.

Postal Lock or AutoCall device not working

• Short “IN” and “COM” pin connections to verify functionality. If wiring is correct and device still does not work,

contact technical support.

Card Reader not communicating with Unit

• Make sure Wiegand is configured to a door (program step 60).

• Check Wiegand reader module connections.

• Connect and test a functioning reader. Make sure reader is not defective.

• Did you add the card(s) to the database while in programming mode?

• Check card format compatibility. The unit is only compatible with 26 and 30-Bit.

• Review the transactions using Versa XS, if applicable, and check whether card failed.

Phone not functioning with the Unit

• Did you wire the Bypass Board correctly? See page 10.

• Is Bypass Board switch set to “OPERATE”?

• Using an alarm system? If so, see page 9.

• Using an alarm system on multiple unit configuration? If so, see pages 9 and 10.

Aux Open/Exit Request device not working

• Did you assign a relay to the REX? See the unit’s programming manual.

• Check connections at Door # terminal(s). Wires to “COM” and “EXT REQ #” connection.

Transmitter not working

• Did you use the correct coaxial cable? See page 7.

• Is the remote antenna installed correctly? Is it outside of the unit’s enclosure?

• Did you add the transmitter(s) to the database while in programming mode?

• Only Passport or Homelink transmitters can be used.

Page 24

Page 23

Repair Parts

Repair Parts

Installation and Service Information is Available 6 Days a Week

Call our Toll Free Number 1-800-528-2806

Monday through Friday 5:00 am to 6:00 pm

(Mountain Standard Time)

Saturday 7:00 am to 3:30 pm (MST)

www.chamberlain.com

When ordering repair parts, please supply the following information:

Description and Model Number

EL25 Parts

4

6

5

1

21

2

8

9

7

3

13

10

12

11

22

15

14

19

11

20

16

17

18

Part Description Model Number

1

Silver Cover

Nickel Cover

Mist Gray Cover

2

Lens Black, Camera

3

Lens Clear, Camera

4

Actuator, Call Button, Silver

Actuator, Call Button, Nickel

Actuator, Call Button, Mist Gray

5

E-Ring, Call Button

6

Spring, Call Button

7

Gasket, Back

8

Assembly Lock EL25 Focus

9

Key

10

Assembly, Speaker EL25

Part Description Model Number

11

93D341

93D341-1

93D341-2

108B81

108B81-1

101A159

101A159-1

101A159-2

158A94

177A166

84B81-1

2B809

41B12

2B639

Assembly, LED, Focus

12

Assembly, Mic Cable, EL25

13

Gasket, Key Pad

14

Assembly Keypad 16 Button

15

Assembly EL25 Main Board

16

Assembly PCB Output Board Focus

17

Assembly PCB Input Board Focus

18

Assembly, Mounting Back, Silver EL25

Assembly, Mounting Back, Nickel EL25

Assembly, Mounting Back, Mist Gray EL25

19

Assembly, 20-Pin Cable, EL25 Focus

20

Assembly, 14-Pin Cable, EL25 Focus

21

Assembly, Call Button Board

22

Direct Connect Cable

2B721

2B692

84C87

180D236

2B735

2B737

2B736

2C607

2C607-1

2C607-2

2B705

2B704

2B731

2B747

Page 25

Page 24

EL2000 Parts

Repair Parts

Repair Parts

Installation and Service Information is Available 6 Days a Week

8

1

2

3

4

6

7

5

16

17

20

9

19

13

12

21

18

22

14

10

15

23

When ordering repair parts, please supply the following information:

Description and Model Number

Part Description Model Number

1

Assembly Display and Display Board

2

3

4

5

6

7

8

9

10

11

12

Display Cables Kit

Assembly, PCB Output Board

Assembly, PCB Input Board

Assembly EL Main Board

Assembly, 20-Pin Input Board Cable

Assembly, 14-Pin Output Board Cable

EL2000 Housing Assembly (Black)

EL2000 Housing Assembly (Gray)

EL2000 Housing Assembly (Nickel)

Door Interconnect Cables Kit

Assembly, Speaker EL Series

Assembly, Call Button Board EL2000

Postal Lock Switch EL2000

Part Description Model Number

13

41B989

41B990

2B737

2B736

2B735

2B705

2B704

41B991

41B992

41B993

41B994

2B639

41B995

41B996

Interconnect Board

14

Assembly, Lock and Key EL2000

15

Replacement Key

16

Assembly, Keypad 16 Button

17

Gasket, Keypad

18

Assembly, Mike Cable EL Series

19

Assembly, Entry LED Board

20

Assembly, Keypad Light Board

21

Lens Black, Camera

Lens Clear, Camera

22

Gasket and Display Window (Clear)

Gasket and Display Window (Black)

Faceplate Assembly Black (No Window)

23

Faceplate Assembly Gray (No Window)

Faceplate Assembly Nickel (No Window)

41B997

41B999

41B12

180D236

84C87

2B692

41B998

41B773-1

108B881

108B81-1

41B1000

41B1001

41B1002

41B1003

41B1004

Page 26

Page 25

Your System Diagram

Your System Diagram

Page 27

Page 26

Your Wiring Configuration

Your Wiring Configuration

External Access Control Device(s) connected to optional board(s)

Device 0 ________________________________________________________________________________

J400 Position on Main Board

Device 1 ________________________________________________________________________________

Device 2 ________________________________________________________________________________

J407 Position on Main Board

Device 3 ________________________________________________________________________________

Device 4 ________________________________________________________________________________

(Default Internal Keypad)

Relay Connections (Output Board)

Relay 1 ________________________________________________________________________________

Relay 2 ________________________________________________________________________________

Relay 3 ________________________________________________________________________________

Relay 4 ________________________________________________________________________________

Door Connections (Input Board)

Door 1

Connection

Door Sensor

and/or

Exit Device

Door 2

Connection

Door Sensor

and/or

Exit Device

Door 3

Connection

Door Sensor

and/or

Exit Device

Door 4

Connection

Door Sensor

and/or

Exit Device

Dealer / Installer

Postal

Lock

Yes

No

AutoCall

Device

Yes

No

CCTV

Camera

Yes

No

RF Module

Wiegand

Wiegand

RF Module

Wiegand

Wiegand

Page 28

Page 27

Accessories

Accessories

00

4

J

0

0

2

J

2

0

4

J

6

0

4

J

1

0

2

J

7

0

4

J

4

0

4

J

1

0

4

J

6

0

4

J

4

0

4

J

1

0

4

0

0

4

J

e

s

eh

T

.

e

n

i

l

e

n

o

h

p

e

n

o

h

t

i

w

e

mo

h

y

l

i

m

a

f

eh

t

si

t

i

,

e

uq

i

n

u

s

i

n

oi

t

a

ci

l

p

p

a

h

l

o

r

t

n

o

c

l

a

t

o

t

e

h

t

t

a

h

t

e

r

u

s

n

e

o

t

r

e

s

u

d

n

e

n

ai

c

i

n

h

cet

d

e

if

i

l

a

u

q

r

o

/

d

n

a

s

l

a

u

n

a

m

e

h

t

o

S

EI

R

ES

L

E

Q

u

i

c

k

S

t

a

r

t

G

u

i

d

e

V

e

r

s

a

t

i

l

e

A

c

c

e

s

s

C

on

t

r

o

l

P

r

og

r

a

m

m

i

n

g

S

o

f

t

w

a

r

e

f

or

E

L

S

e

r

i

e

s

U

n

i

t

s

Ve

r

s

a

X

S

2

.0

T

M

Wiegand Module Kit

WOMODKT

RF Module Kit

RFMODKT (390 MHz)

RFMODKT3 (315 MHz)

Wiegand Remote Keypad

123

456

789

0

*

ESSWOKSG

Directory Insert

#

ELDI

EL25BWCAMKT (Black & White Camera)

EL25 Camera Kits

EL25DVRCAMKT (Low Lux DVR Color Camera)

EL25CAMKT (Color Camera)

EL2000

?

1

.

C

l

i

c

k

t

h

e

N

E

W

U

N

I

T

I

C

O

N

Q

u

i

c

k

F

o

1

r

S

E

i

n

n

g

tS

t

e

l

e

r

F

U

n

i

t

r

t

N

G

ma

e

a

n

d

u

i

d

U

n

i

t

e

T

t

o

y

r

p

y

e

C

o

d

e

s

)

I

n

s

t

a

l

l

a

t

i

o

n

u

s

i

n

g

V

e

r

s

a

X

S

2

.

0

3

2

C

h

o

o

s

e

“

N

o

n

e

”

f

o

r

J

4

3

0

7

C

h

o

o

s

e

“

f

o

r

J

4

0

0

4

C

l

i

c

O k

K

5

.

C

l

i

c

k

t

h

e

D

O

O

R

S

T

a

b

1

R

e

an

m

e

“

D

o

o

r

1

”

t

o

“

G

a

t

e

O

p

e

r

a

t

o

r

2

S

e

l

e

c

t

“

V

e

h

i

c

el

G

a

t

e

G

r

f

r

o

o

u

m

p

”

t

eh

d

r

o

p

d

o

w

n

m

e

n

u

Versa

EL2000BWCAMKT (Black & White Camera)

EL2000 Camera Kits

EL2000DVRCAMKT (Low Lux DVR Color Camera)

EL2000CAMKT (Color Camera)

EL25

1

4

5

7

2

.

C

l

i

c

k

t

eh

U

n

i

t

C

o

n

f

i

g

u

r

a

t

i

o

n

I

C

O

N

a

dn

S

e

l

ce

t

t

h

e

C

O

N

T

2

R

O

nE

L

1

t

S

e

C

E

r

T

l

C

i

T

c

o

k

I

u

N

n

o

n

t

r

SG

y

t

h

T

,

e

a

b

S

t

a

t

“

/e

E

P

r

id

o

”t

v

.

b

a

u

n

t

t

d

o

n

C

i

t

y

2

U

n

c

h

e

c

k

t

h

e

“

U

s

e

T

e

l

e

p

h

o

n

e

eS

r

v

i

c

c

e

h

”

e

c

k

b

o

x

C

il

c

k

O

K

W

i

5

e

g

R

na

e

d

n

a

D

m

e

v

e

i

c

“

e

D

”

ve

i

c

1 e

”

t

o

“

P

e

d

e

s

t

r

i

na

R

e

a

d

re

”

”

3

R

e

n

a

m

e

“

D

o

o

r

”2

t

o

“

P

s

e

e

d

l

e

e

c

s

t

t

r

“

i

P

a

e

n

d

G

e

a

s

t

t

e

r

i

”

a

a

n

n

R

d

e

a

d

re

”

f

o

r

t

h

D e

ve

i

c

e

P

de

se

t

r

i

a

n

G

a

t

e

4

S

e

l

e

c

t

“

P

e

d

e

s

t

r

i

a

n

G

r

o

f

u

r

p

o

”

m

t

h

e

d

r

o

p

d

o

w

5

n

m

e

C

n

l

u

kci

S

A

V

E

Wiegand Remote Keypad/Prox Combo

8

*

HIDWOKPRO

Heater Kit

ELHTRKT

EL2000 ONLY

32

6

9

#0

XS

Versa XS Software

VERSWR20

Page 29

Page 28

FCC and DOC Requirements

FCC and DOC Requirements

FCC Requirements

The units comply with Part 68 of the FCC Rules. The label affixed to this equipment contains, among other

information, the FCC Registration Number and Ringer Equivalence Number (REN) for this equipment. You must,

upon request, provide this information to your telephone company.

The REN is useful to determine the quantity of devices you may connect to your telephone line and still have all of

those devices ring when your telephone number is called. In most, but not all areas, the sum of the RENs of all

devices connected to one line should not exceed five (5.0). To be certain of the number of devices you may

connect to your line, as determined by the REN, you should contact your local telephone company. They will tell

you what the maximum REN is for your calling area.

The following jacks must be ordered from the telephone company in order to interconnect this equipment with the

public communication network: None.

If your unit causes harm to the telephone network, the Telephone Company may discontinue your service

temporarily. If possible, they will notify you in advance. If advance notice is not practical, you will be notified as

soon as possible. You will be informed of your right to file a complaint with the FCC.

Your Telephone Company may make changes in its facilities, equipment, operations or procedures that could affect

the proper functioning of your equipment. If they do you will be notified, in advance, to give you an opportunity to

maintain uninterrupted telephone service.

Connections to party lines are subject to state tariffs. Contact your local telephone company if you plan to use this

equipment on party lines.

This equipment cannot be used on public coin service lines provided by the telephone company.

DOC Requirements

Notice: The Canadian Department of Communications label identifies certified equipment. This certification means

that the equipment meets certain telecommunications network protective, operational, and safety requirements. The

Department does not guarantee the equipment will operate to the user’s satisfaction.

Before installing this equipment, users should ensure that it is permissible to be connected to the facilities of the

local Telecommunications Company. The equipment must also be installed using an acceptable method of

connection. In some cases, the company’s inside wiring associated with single line individual service may be

extended by means of a certified connector assemble (telephone extension cord). The customer should be aware

that compliance with the above conditions may not prevent degradation of service in some situations.

Repairs to certified equipment should be made by an authorized Canadian maintenance facility designated by the

supplier. Any repairs or alterations made by the user to this equipment, or equipment malfunctions, may give the

telecommunications company cause to request the user to disconnect the equipment.

Users should ensure for their own protection that the electrical ground connections of the power utility, telephone

lines, and internal metallic water pipe unit, if present, are connected together. This precaution may be particularly

important in rural areas.

Caution: Users should not attempt to make such connections themselves, but should contact the appropriate

electric inspection authority, or electrician, as appropriate.

The Load Number (LN) assigned to each terminal device denotes the percentage of the total load to be connected

to a telephone loop, which is used by the device, to prevent overloading. The termination on a loop may consist of

any combination of devices subject only to the requirement that the total of the Load Numbers of all the devices

does not exceed 100. The Load Number for EL Series Units is 3.

Page 30

Elmhur

®

™

845 Larch Avenue

st, Illinois 60125-1196

114A2980C

© 2006 The Chamberlain Group, Inc.

All Rights Rese

rved

Loading...

Loading...