Page 1

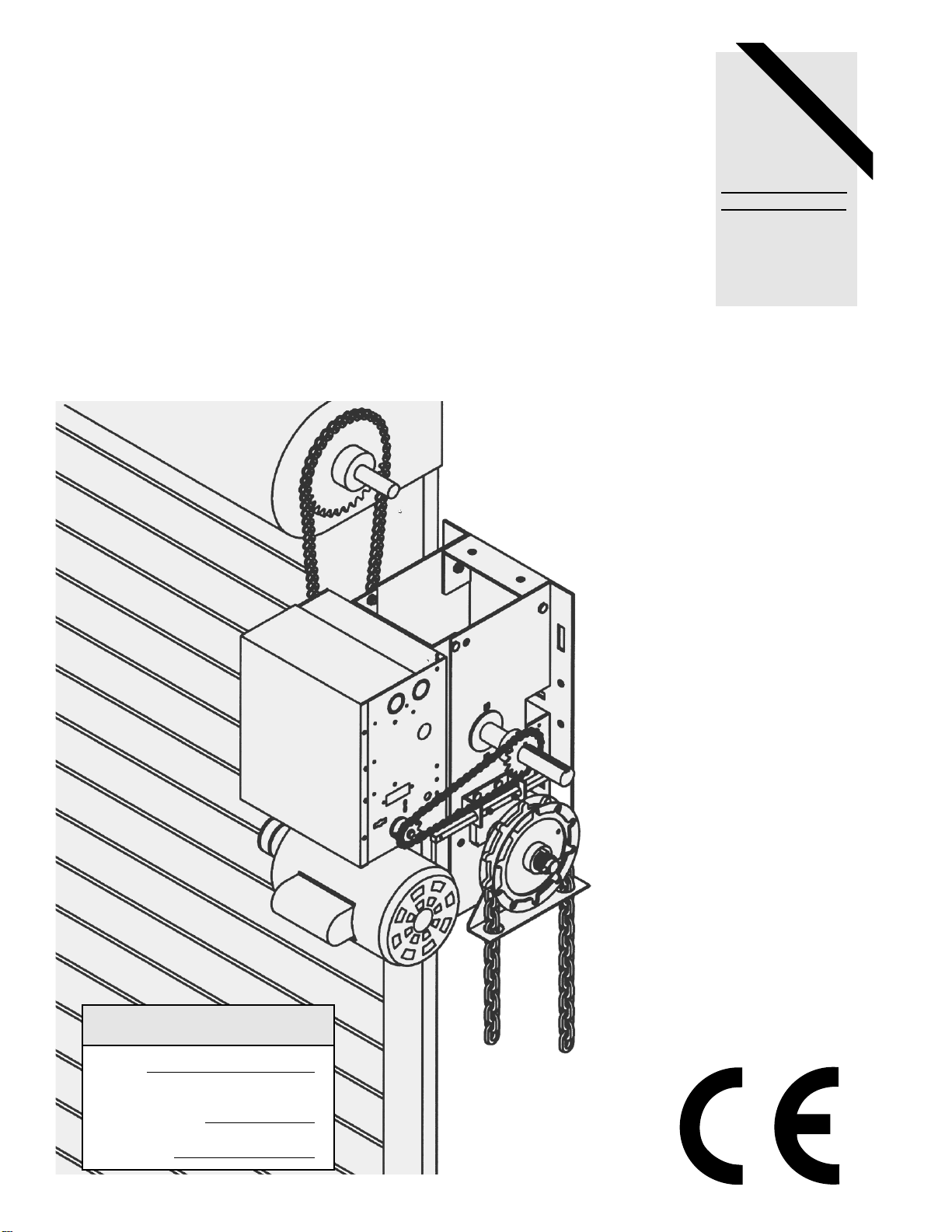

OWNER'S MANUAL

MODELS:

EJ & EH

LOGIC CONTROL (VER. 2.0)

INDUSTRIAL DUTY DOOR OPERATOR

Serial #

(located on electrical box cover)

Installation Date

Wiring Type

2 YEAR WARRANTY

LOGIC CONTROL

L

FACTORY SET

C2 Wiring

See pages 16 & 17

for other wiring

configurations

Page 2

2

IMPORTANT SAFETY NOTES

The force, as measured on the closing edge of

the door, should not exceed 150 N (15kg). If the

closing force is adjusted to more than 150 N,

additional entrapment protection devices must

be installed, see page #9 for matrix. Do not use

the force adjustments to compensate for a binding or sticking door. Excessive force will interfere

with the proper operation of the Safety Reverse

System or damage the door.

Fasten the caution label adjacent to the door con-

trol station as a reminder of safe operating procedures.

Disengage all existing door locks to avoid damage

to door. If the door lock needs to remain functional,

install an interlock switch.

Install the three button station, master disconnect switch and any additional controls in a

location where the door is visible, but out of the

reach of children. Do not allow children to operate push button(s) or remote control(s). Serious

personal injury from a closing door may result from

misuse of the opener.

CAUTION: Activate opener only when the door

is in full view, free of obstructions and opener is

properly adjusted. No one should enter or exit

through the door opening while the door is in

motion. Do not allow children to play near the

door.

Proper electrical lock-out/tag-out procedures

must be followed before making repairs or

removing covers on the door operator.

Keep door balanced. Sticking or binding doors

must be repaired. Doors, door springs, cables, pulleys, brackets and hardware are under extreme tension and can cause serious personal injury. Do not

attempt to loosen, move or adjust them. Call for

door service.

Proper protective gear should be worn when servicing or installing the door operator. Do not wear

rings, watches or loose clothing while installing or

servicing a door opener. Do wear safety glasses,

back support belt, and protective gloves. When

working on ladders and or elevated platforms, proper safety procedures must be followed.

To avoid serious personal injury from entanglement,

remove all ropes & chains connected to the

door before installing the door opener.

Installation and wiring must be in compliance with

your local building and electrical codes. Connect

the line power only to properly earthed mains.

This unit should not be installed in a damp or

wet space.

Only one (1) person is to perform work on the door

operator at a time.

All local safety regulations are to be applied when

working on the door operator.

Installation of this unit must be in accordance

with Per EN12453.

Before attempting to install, operate or maintain the operator, you must read

and fully understand this manual and follow all safety instructions.

These safety alert symbols mean Caution – a personal safety or property damage instruction. Read these

instructions carefully. This door opener is designed and tested to offer reasonable safe service provided it is

installed and operated in strict accordance with the following safety rules.

Failure to comply with the following instructions may result in serious personal injury or property damage.

Page 3

3

TABLE OF CONTENTS

WARNINGS

Safety Notes . . . . . . . . . . . . . . . . . . . . . . . . . . .2

OPERATOR SPECIFICATIONS

Packing List . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Motor Specifications . . . . . . . . . . . . . . . . . . . . .4

Electrical Specifications . . . . . . . . . . . . . . . . . .4

Mechanical Specifications . . . . . . . . . . . . . . . . .4

Safety Specifications . . . . . . . . . . . . . . . . . . . . .4

Operator Weights and Dimensions . . . . . . . . . .4

DOOR OPERATING SYSTEM

Door Operator System Illustration . . . . . . . . . . .5

Factory Supplied Components List . . . . . . . . . .5

User Supplied Components List . . . . . . . . . . . .5

INSTALLATION PREPARATION

Lifting Specifications . . . . . . . . . . . . . . . . . . . . .6

Lifting Illustration . . . . . . . . . . . . . . . . . . . . . . . .6

Site Preparation . . . . . . . . . . . . . . . . . . . . . . . .6

Operator Preparation . . . . . . . . . . . . . . . . . . . .6

OPERATOR MOUNTING

Wall Mounting . . . . . . . . . . . . . . . . . . . . . . . . . .7

Bracket Mounting . . . . . . . . . . . . . . . . . . . . . . .7

Shelf Mounting . . . . . . . . . . . . . . . . . . . . . . . . .7

EMERGENCY MANUAL OPERATION

Model EH Manual Disconnect . . . . . . . . . . . . .8

Model EJ Manual Disconnect . . . . . . . . . . . . . .8

ENTRAPMENT PROTECTION (Optional)

Sensing Edges . . . . . . . . . . . . . . . . . . . . . . . . .9

Entrapment Protection Matrix . . . . . . . . . . . . . .9

POWER & CONTROL WIRING

Safety Notes . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . .10

Power Wiring . . . . . . . . . . . . . . . . . . . . . . . . . .11

Control Wiring . . . . . . . . . . . . . . . . . . . . . . . . . .11

Ground Wiring . . . . . . . . . . . . . . . . . . . . . . . . .11

Push Button Illustration . . . . . . . . . . . . . . . . . . .11

Main/ Emergency Disconnect Illustration . . . . .11

Wiring Schematic . . . . . . . . . . . . . . . . . . . . . . .12

Electrical Box Illustration . . . . . . . . . . . . . . . . . .13

Limit Switch Adjustment . . . . . . . . . . . . . . . . . .14

PRINTED CIRCUIT BOARD SETTINGS

Program Settings . . . . . . . . . . . . . . . . . . . . . . .15

Wiring Types . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Failsafe Wiring Types . . . . . . . . . . . . . . . . . . . .17

LED Indicator Readouts . . . . . . . . . . . . . . . . . .26

MECHANICAL ADJUSTMENT

Brake Adjustment . . . . . . . . . . . . . . . . . . . . . . .18

Clutch Adjustment . . . . . . . . . . . . . . . . . . . . . . .19

REPLACEMENT PARTS

Electrical Box Illustration . . . . . . . . . . . . . . . . . .20

Electrical Box Replacement Parts List . . . . . . .21

Model EJ Illustration . . . . . . . . . . . . . . . . . . . . .22

Model EJ Replacement Parts List . . . . . . . . . . .23

Model EH Illustration . . . . . . . . . . . . . . . . . . . . .24

Model EH Replacement Parts List . . . . . . . . . .25

MAINTENANCE OF OPERATOR

Maintenance Schedule . . . . . . . . . . . . . . . . . . .26

Technical Support . . . . . . . . . . . . . . . . . . . . . . .28

Parts Ordering Information . . . . . . . . . . . . . . . .28

PACKING LIST

DESCRIPTION QTY REFERENCE

Push Button Station 1 Figure 1 & 10

Chain Keeper 1 Figure 8

Hand Chain 1 Figure 1

Chain, #50 x 106 Pitches 1 Figure 1

Label, Maintenance Alert 1 Figure 10

Label, Door Edge Caution 1 Figure 1

Label, Entrapment Warning 1 Figure 1 & 10

Label, Master Disconnect 1 Figure 1& 10

Key 1 Figure 1

Door Sprocket 1 Figure 1

DESCRIPTION QTY REFERENCE

Push Button Station 1 Figure 1 & 10

Key Hole Bracket 1 Figure 9

Chain, #50 x 106 Pitches 1 Figure 1

Label, Maintenance Alert 1 Figure 10

Label, Door Edge Caution 1 Figure 1

Label, Entrapment Warning 1 Figure 1 & 10

Label, Master Disconnect 1 Figure 1 & 10

Key 1 Figure 1

Door Sprocket 1 Figure 1

MODEL EH5025L2 (Left or Right) MODEL EJ5025L2

Before beginning your installation check that all components were supplied and received undamaged. Refer to list

below for Factory Supplied parts.

Page 4

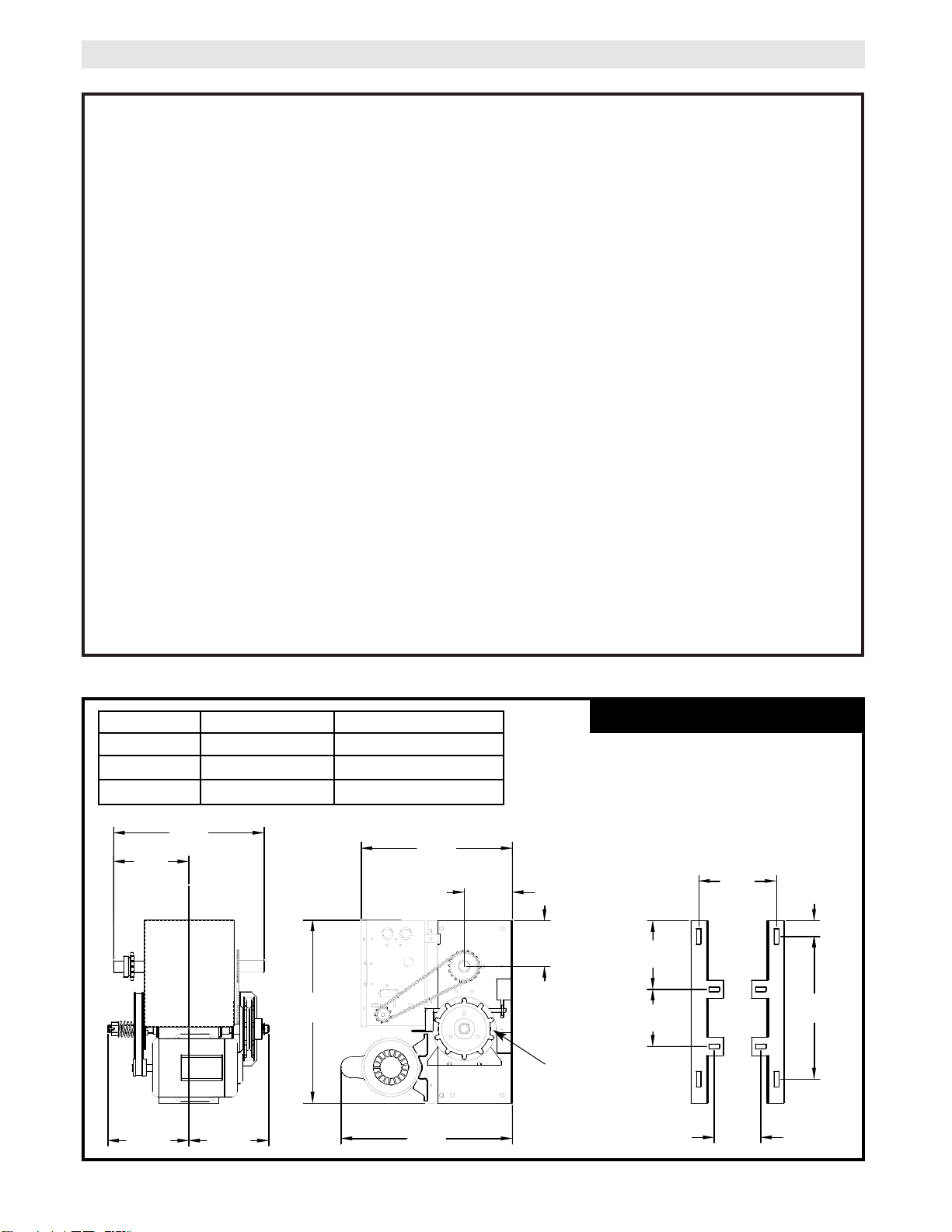

4

368mm

(14.50")

185mm

(7.25")

203mm

(8.00")

A

371mm

(14.60")

112mm

(4.41")

118mm

(4.63")

419mm

(16.50")

448mm

(17.63")

191mm

(7.50")

168mm

(6.63")

140mm

(5.50")

349mm

(13.75")

38mm

(1.50")

121mm

(4.75")

A

A

B

B

A

B

B

A

MOTOR

TYPE: .................................Continuous duty

HORSEPOWER: .....................375 W (1/2 Hp) Single phase

SPEED:...............................1425 RPM

VOLTAGE: ..........................230V/50Hz Single phase

CURRENT:..........................4.0 A

MECHANICAL

RATED POWER: ................190 W

DRIVE REDUCTION: .........Primary: Heavy duty (5L)

V-Belt. Secondary: #48 chain/sprocket. Output: #50

chain

OUTPUT SHAFT SPEED:.....34 R.P.M.

DOOR SPEED: ...........................150-180mm (6 - 7”) per

sec.

depending on door

BRAKE: .................................Solenoid actuated disc

brake

BEARINGS: ...........................Output Shaft: Shielded

Ball Bearing. Clutch Shaft: Iron Copper sintered and

oil impregnated.

HAND CHAIN WHEEL: .........Left or right handing

Model EH only.

WORKING ENVIRONMENT

: Indoor and Dry

Environment use only.

OPERATOR SPECIFICATIONS

ELECTRICAL

TRANSFORMER:.............24VAC Secondary

CONTROL STATION: ......NEMA 1 three button station.

OPEN/CLOSE/STOP W/ LED

WIRING TYPE:.................C2 (Factory Shipped)

Momentary contact to OPEN & STOP, constant pressure to CLOSE, open override plus wiring for sensing

device to reverse. See pages 16 and 17 for optional

wiring types and operating modes.

LIMIT ADJUST: ................Linear driven, fully

adjustable screw type cams. Adjustable to 7.3M (24 ft.)

SAFETY

DISCONNECT :

Model EJ: Floor level disconnect for emergency manual

door operation.

Model EH: Floor level chain hoist with electrical interlock

for emergency manual door operation.

REVERSING EDGE:......(Optional) Electric or pneumatic

sensing device attached to the bottom edge of door.

A REVERSING DEVICE IS STRONGLY RECOMMENDED FOR ALL COMMERCIAL OPERATOR

INSTALLATIONS. REQUIRED WHEN THE 3 BUTTON

CONTROL STATION IS OUT OF SIGHT OF DOOR

OR ANY OTHER CONTROL (AUTOMATIC OR MANUAL) IS USED. SEE MATRIX ON PAGE 9.

PHOTO EYES:...............Interface directly to LiftMaster

CPSII.

MOUNTING DIMENSIONS

A - Wall Mounting

B - Bracket Mounting (rolling door)

WEIGHTS AND DIMENSIONS

Hand Chain Wheel

present with Model

EH.

MODEL DIMENSION “A” WEIGHT

EH5025L2R 191mm (7.50”) 43.1 Kg. (95 Lbs.)

EH5025L2L 191mm (7.50”) 43.1 Kg. (95 Lbs.)

EJ5025L2 101mm (4.00”) 39.5 Kg. (87 Lbs.)

Page 5

5

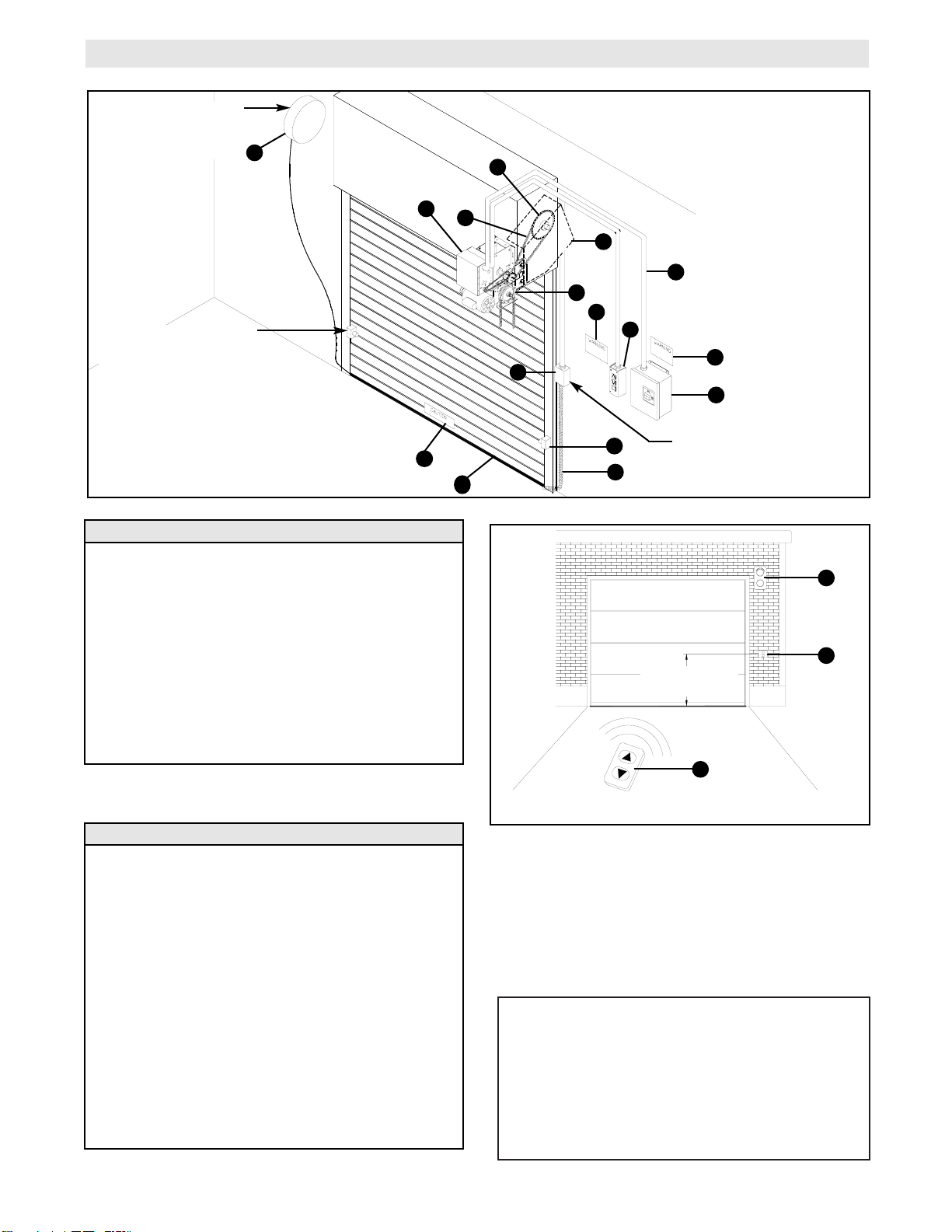

DOOR OPERATING SYSTEM

Qty

1

1

1 Ea.

1

1

1

1

1

1

1

Item

1

2

3

4

5

6

7

8

9

10

Description

Operator Power Head

Drive Chain

Door Sprocket & Key

Hoist Chain

Chain Keeper (See Page 8, Figure 8)

Keyhole Bracket (See Page 8, Figure 9)

3 Button Station

Entrapment Waring Label

Main/ Emergency Disconnect Warning Label

Door Edge Caution Label

FACTORY SUPPLIED COMPONENTS

USER SUPPLIED COMPONENTS

1

3

7

2

4

8

9

C

F

E

P

H

J

L

K

FIGURE 2 (VIEW FROM OUTSIDE)

FIGURE 1 (VIEW FROM INSIDE)

Qty

1

1

1

AR

1

1

1

1 Set

1

1

1

1

1

1

Item

A

B

C

D

* E

F

G

H

J

K

L

M

N

P

Description

Shaft Support Bracket (See Page 6, Figure 3)

Mounting Bracket (See Page 7, Figure 6)

Main/ Emergency Disconnect

Mounting Hardware

Guards (Chain & Belt)

Electrical Conduit & Wiring

Electric Safety Edge

Photo Eyes

Remote Control

Key Switch

Traffic Light

Coil Cord

Take-up Reel

Junction Box

1219 mm (4 Ft.)

MINIMUM

Mount Approximately

305mm (12”) above top

of door.

Mount 102-152mm (4-6”)

above bottom of door. Do

not exceed 152mm (6”)

Mount approximately

halfway up door opening.

G

N

M

10

It is the installers responsibility to guard all moving

chains, sprockets and pinch points at installation. It

is recommended that fixed guards be used to protect

against components which may become dislodged

in the event of a failure. If a complete enclosure is

used the cover should provide a minimum of 1016

mm (40 In ) of ventilation.

*

WHEN ORDERING REPAIR PARTS AND ACCESSORIES

ADDRESS ORDER TO:

CHAMBERLAIN GmbH

Alfred-Nobel-Str. 4

66793 Saarwellingen

PHONE ORDER: FAX ORDER:

(49) 6838-907105 (49) 6838-907239

TECHNICAL HOTLINE:

(49) 6838-907171

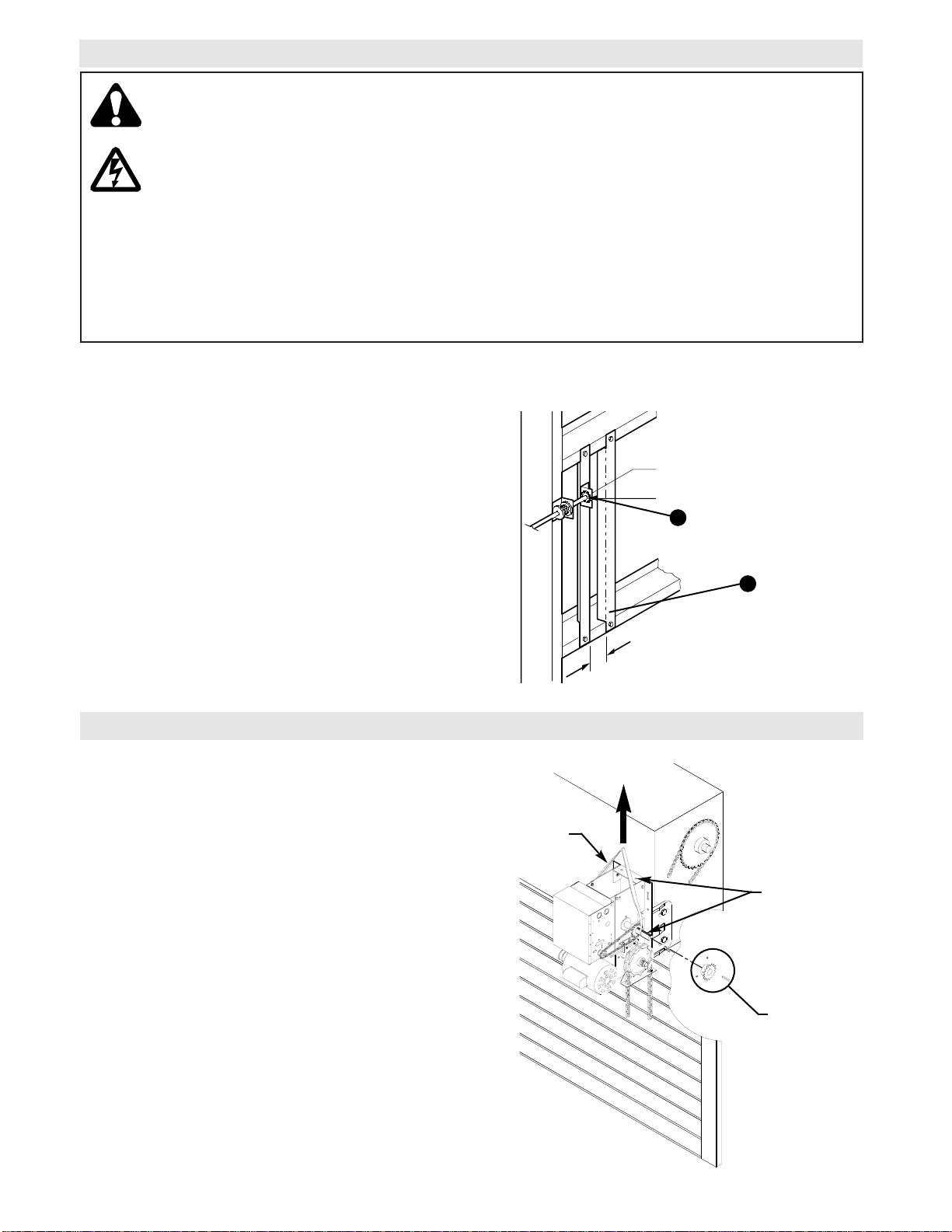

Page 6

6

SITE PREPARATIONS

It is imperative that the wall or mounting surface provide adequate support for the operator.

This surface must:

a) Be rigid to prevent play between operator and

door shaft.

b) Provide a level base.

c) Permit the operator to be fastened securely,

with the drive shaft parallel to the door shaft.

The safety and life of the operator will be adversely

affected if any of the above requirements are not met.

For metal buildings, fasten 50mm x 50mm x 5mm (2”

x 2” x 3/16”) (or larger) angle iron frames to the building purlins. Retain 140mm (5-1/2”) between frames.

See Figure 3.

Both EJ and EH series operators have dual output

shafts and may be mounted on either the right (standard) or left side of door, and in either a vertical (standard) or horizontal mounting position. If you need to

move the drive sprocket, loosen BOTH set screws,

remove the sprocket and key, and place on the opposite side of the drive shaft. Be sure to tighten BOTH

set screws securely

Hand Chain Handing

For model EH with manual hoist hand chain systems,

the handing of the operator must be determined at the

time of order. The handing is indicated by last letter of

the model name (R or L). The hand chain wheel can

not be switched on site. If your installation causes

the hand chain to hang in the door opening, hook the

chain off to the side near the top of the door jamb.

OPERATOR PREPARATION

140mm

(5-1/2”)

Door Requirements: Door must be balanced within 150N and must have mechanical fixed stops at the end

points of travel

FIGURE 3

A

D

The weight of this operator powerhead is excessive, and can cause severe injury upon lifting, installing

or dislodging from its mounted position.

The operator powerhead should be raised into its mounting position by use of a hoist or elevated platform. Acceptable lifting points are output shaft or chassis frame. Do not lift by electrical enclosure. The

unit should be secured to the lifting apparatus to prevent it from swaying or dislodging during installation. The unit should be fastened to its mounting surface with the correct size and grade hardware. All

mounting hardware should be securely fastened before releasing supporting devices. (See figure 4 on

page 6 for proper lifting).

The above stated procedures must be followed in the event that the unit is to be removed from

its mounted position when servicing is required.

Drive Sprocket (1)

Key (1)

Set Screw (2)

FIGURE 4

LIFT

Approved Lifting

Points (Output

Shaft and Frame)

Suitable Strap

or Chain

Shaft Support Bracket

with Bearing (Not Supplied)

Door Sprocket

2-1/4"

FIGURE 1

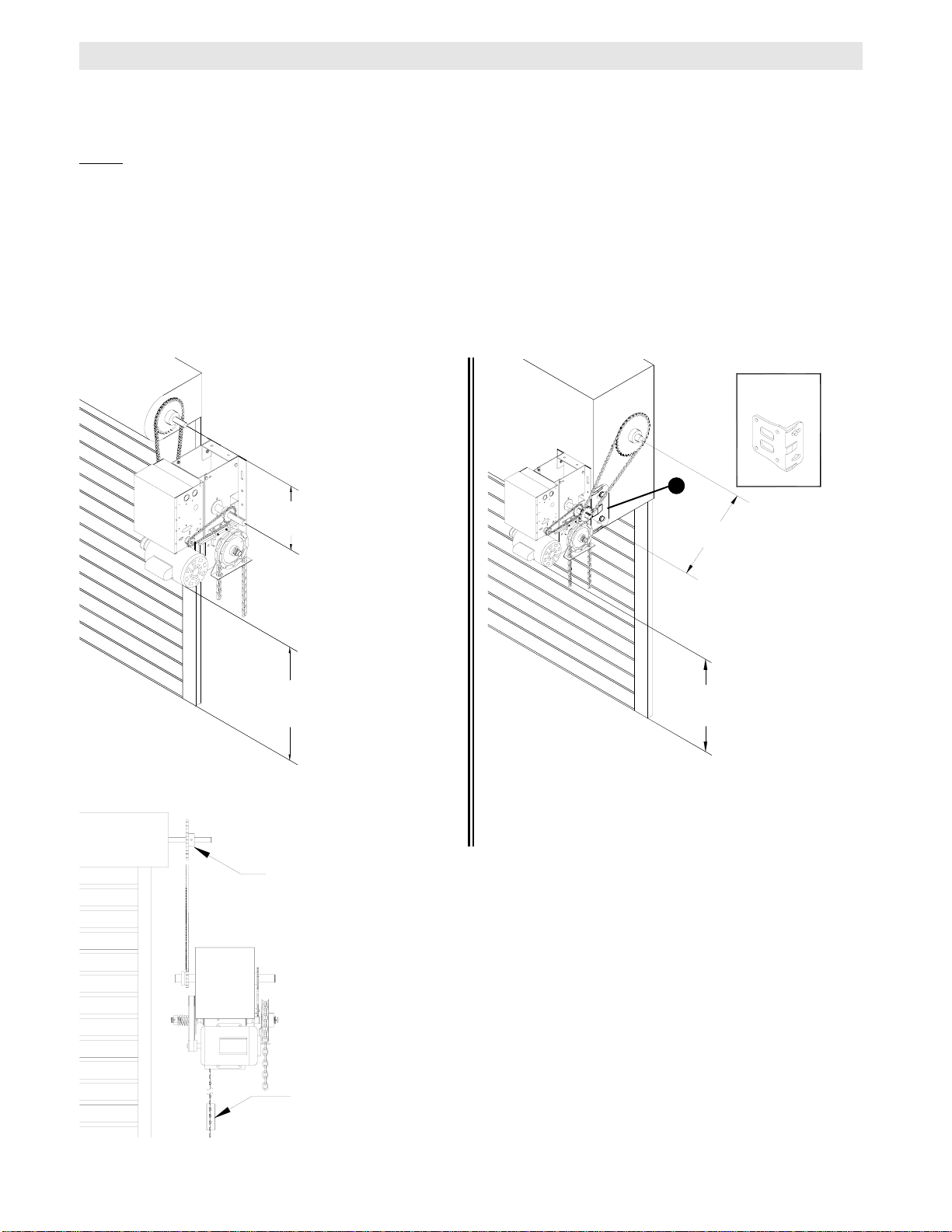

Page 7

7

1a. Wall Mounting

The operator should generally be installed below

the door shaft, and as close to the door as possible. The optimum distance between the door shaft

and operator drive shaft is between 305-380mm

(12 - 15”). Refer to Figure 5.

OPERATOR MOUNTING

IMPORTANT:

The shelf or bracket must provide adequate support, prevent play between operator and door

shaft, and permit operator to be fastened securely, with

the drive shaft parallel to the door shaft.

1b. Bracket or Shelf Mounting

The operator may be mounted either above or

below the door shaft. The optimum distance

between the door shaft and operator drive shaft is

between 305-380mm (12 - 15”).

Refer to Figure 6.

1c. Place door sprocket on the door shaft. Do not

insert the key at this time.

2. Place drive sprocket on the appropriate side of the

operator. Do not insert the key at this time.

3. Wrap drive chain around door sprocket and join

roller chain ends together with master link.

4. Raise operator to approximate mounting position

and position chain over operator sprocket.

5. Raise or lower operator until the chain is taut (not

tight). Make sure the operator output shaft is parallel to door shaft and sprockets are aligned. When

in position, secure the operator to wall or mounting

bracket.

6. Align sprockets and tighten all set screws and

mounting hardware. (see Figure 7).

FIGURE 6

FIGURE 5

Before your operator is installed, be sure the door has been properly aligned and is working smoothly. The operator may be wall mounted or mounted on a bracket or shelf. Refer to the operator preparations on page 6. Refer

to the illustration and instructions below that suits your application.

NOTE

Mounting Hardware: Minimum (4) M8, Grade 5 Bolts.

Electrical Connections: All fittings and conduit connections must meet local electrical code requirements.

FIGURE 7

Typical Right Hand

Wall Mounted Operator

Optimum Distance

305-380mm (12 - 15”)

OPTIONAL

Mounting Bracket

P/N 08-9098

Be sure door

sprocket is properly aligned with

drive sprocket

before securing to

the shaft.

Chain Keeper

2.5M Minimum

(8.2’ Minimum)

FLOOR

FLOOR

Optimum Distance

305-380mm (12 - 15”)

B

2.5M Minimum

(8.2’ Minimum)

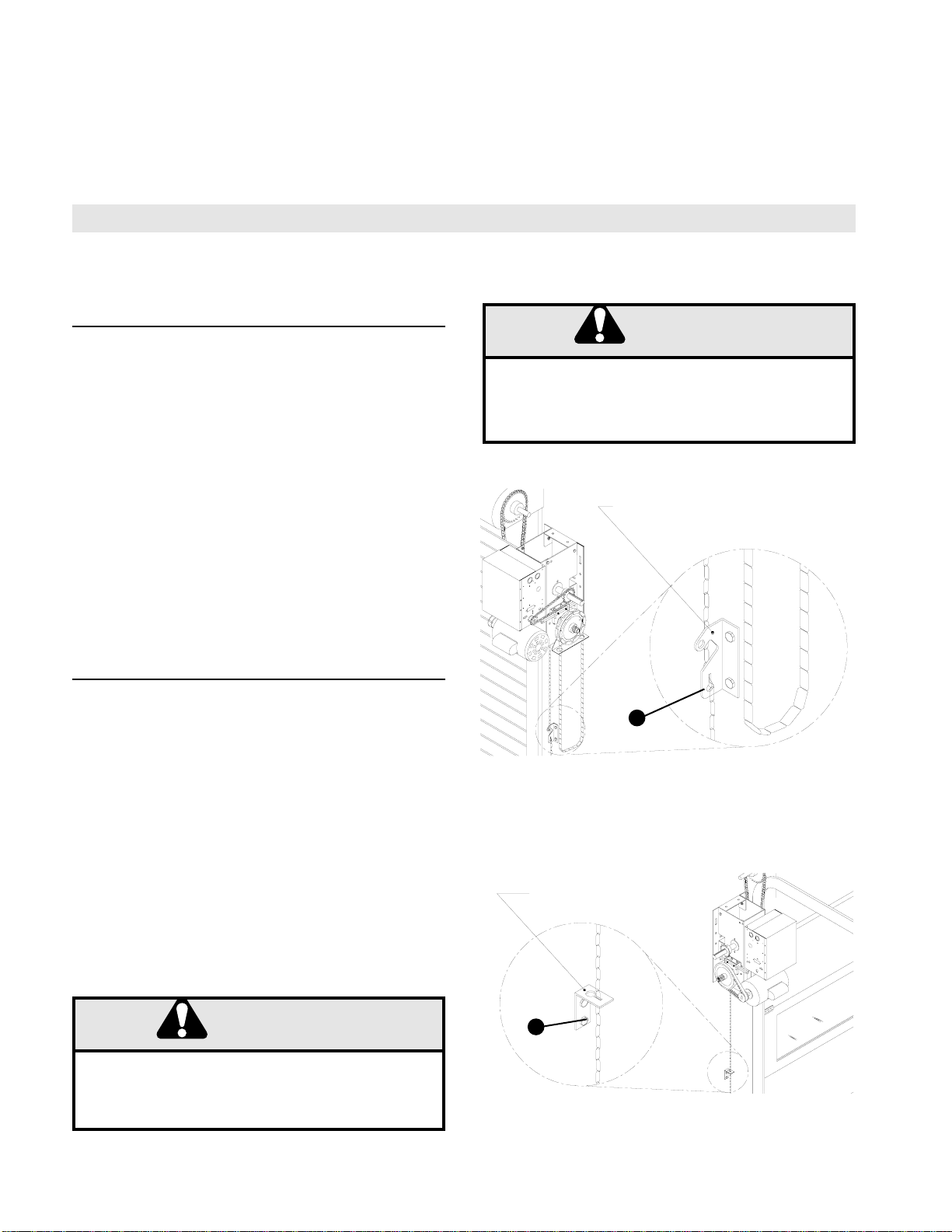

Page 8

8

These operators are equipped with a manual hoist. An

electrical interlock will disable the electrical controls

when the hoist is used. To operate the hoist:

1. Pull the disconnect chain (small chain) to engage the

hoist mechanism. The disconnect chain may be locked

in position by slipping the end through the keyhole of

the chain keeper mounted on the wall.

2. Operate the door in the desired direction by pulling

on one side or the other of the continuous loop hoist

chain (large chain).

3. The disconnect chain must be released from the

chain keeper before the door will operate again electrically.

7. Install Hand Chain (Model EH) Place hand

chain around hand chain wheel. Be sure to pass

it through both openings in the chain guide.

Remove enough links so chain hangs approximately 609mm (24”) above the floor.

EMERGENCY MANUAL OPERATION

This operator has provisions for manually operating the door in case of an emergency or power failure. Refer to

the appropriate instructions below for your model operator.

Model EH

Model EJ

This operator has a floor level disconnect chain to disconnect the door from the door operator. An electrical

interlock will disable the electrical controls when the

operator is disengaged.

1. To disengage, pull the chain and secure in the dis-

engaged position by slipping the end through the keyhole bracket mounted on the wall. Or if emergency

egress device is used, pull handle to disengage operator from door.

2. The door may now be pushed up or pulled down

manually. Release the disconnect chain to operate the

door again electrically.

8. Mount Chain Keeper / Keyhole Bracket

Using suitable hardware mount the chain keeper

approximately 1219mm (48”) above the floor, near

the free hanging chain. Remove disconnect sash

chain from bag and place the end through the keyhole in the the chain keeper. Remove excess links

if necessary.

Manual Disconnect for Model EJ

Electrical Interlock with Hoist for Model EH

LOCK-OUT ELECTRICAL POWER TO THE OPERATOR VIA, THE MAIN/ EMERGENCY DISCONNECT

BEFORE MANUALLY OPERATING YOUR DOOR.

WARNING

CAUTION

WARNING

WARNING

Chain Keeper

(with pad locking provisions)

Keyhole Bracket

FIGURE 8

5

FIGURE 9

7

WHEN USING THIS OPTION THE OPERATOR IS NOT

AUTOMATICALLY ELECTRICALLY INTERLOCKED.

WARNING

CAUTION

WARNING

Page 9

9

ENTRAPMENT PROTECTION ACCESSORIES (OPTIONAL)

SENSING EDGES

If not pre-installed by the door manufacturer, contact

you local LIFTMASTER Dealer for available sensing

edges.

Mount the sensing edge on the door according to the

instructions provided with the edge. The sensing

edge may be electrically connected by either coiled

cord or take-up reel. Refer to the steps below.

Important Notes:

a) Proceed with Limit Switch Adjustments before

making any sensing edge wiring connections to

operator as described below.

b) Electrician must hardwire the junction box to the

operator electrical box in accordance with local

codes.

TAKE-UP REEL: Take-up reel should be installed

approximately 305mm (12”) above the top of the

door.

COIL CORD: Connect operator end of coil cord to

junction box (not supplied) fastened to the wall

approximately halfway up the door opening.

IT IS STRONGLY RECOMMENDED THAT A

SENSING EDGE OR OTHER ENTRAPMENT

PROTECTION DEVICE BE USED IN CONJUNCTION WITH THIS OPERATOR. SEE INSTALLATION MATRIX FOR INSTALLATIONS WHICH

REQUIRE THE USE OF SENSING EDGES.

ENTRAPMENT PROTECTION MATRIX

z A: Hold to run control push button.

z B: Hold to run control with key switch or similar.

z C: Limitation of operating forces with force limiting devices (clutch) & safeguarding (safety edge)

z D: Device for the detection of the presence of a person or an obstacle standing on the floor at one side

(inside) of the door. (Infrared Eyes).

z E: Device for the detection of the presence of a person or an obstacle standing on the floor at both sides

(inside & outside) of the door leaf. (Infrared Eyes).

NOTE: For detailed access information refer to Per EN12453.

Hold to Run Control

Impulse Activation in Sight of the

Door

Automatic Control

Trained Users

(No Public)

Group 1

A

C

C and D

Trained Users

(Public Area)

Group 2

B

C and D

C and E

Trained Users

(General Public Area)

Group 3

N/A

C and E

C and E

WHEN ORDERING REPAIR PARTS AND ACCESSORIES

ADDRESS ORDER TO:

CHAMBERLAIN GmbH

Alfred-Nobel-Str. 4

66793 Saarwellingen

PHONE ORDER: FAX ORDER:

(49) 6838-907105 (49) 6838-907239

TECHNICAL HOTLINE:

(49) 6838-907171

TYPE OF CONTROLS DOOR USE

Page 10

10

DISCONNECT POWER AT THE FUSE BOX BEFORE

PROCEEDING.

OPERATOR MUST BE PROPERLY GROUNDED AND

CONNECTED IN ACCORDANCE WITH LOCAL ELECTRICAL CODES. NOTE: THE OPERATOR SHOULD

BE ON A SEPARATE FUSED LINE OF ADEQUATE

CAPACITY.

ALL ELECTRICAL CONNECTIONS MUST BE MADE

BY A QUALIFIED INDIVIDUAL.

WARNING

TO AVOID DAMAGE TO DOOR AND OPERATOR,

MAKE ALL DOOR LOCKS INOPERATIVE. SECURE

LOCK(S) IN "OPEN" POSITION.

IF THE DOOR LOCK NEEDS TO REMAIN FUNCTIONAL, INSTALL AN INTERLOCK SWITCH.

WARNING

INSTALL ALL CONTROL STATIONS NO FURTHER

THAN 305mm (12”) FROM THE DOOR ENCLOSURE.

IF THE CONTROL STATION CANNOT BE INSTALLED

AT THIS DISTANCE, A REVERSING EDGE MUST

BE

INSTALLED ON THE BOTTOM OF THE DOOR. FAIL-

URE TO INSTALL A REVERSING EDGE UNDER

THESE CIRCUMSTANCES MAY RESULT IN SERIOUS

INJURY OR DEATH TO PERSONS TRAPPED

BENEATH THE DOOR.

Before installing power wiring or control stations be sure to follow all specifications and warnings described below. Failure to do so may result in severe injury to persons and/or damage to

operator.

The operator electrical box is only to be accessed by trained “LIFTMASTER” technicians. If service is required contact your local LIFTMASTER dealer.

Do not install any wiring or attempt to run the operator without consulting the wiring diagram.

Install the optional Reversing Edge before proceeding with the Control Station installation.

IMPORTANT SAFETY NOTES

INSTALL POWER WIRING & CONTROL STATION

ANY MAINTENANCE TO THE OPERATOR OR IN THE

AREA NEAR THE OPERATOR MUST NOT BE PERFORMED UNTIL DISCONNECTING THE ELECTRICAL POWER AND LOCKING-OUT THE POWER VIA,

THE MAIN DISCONNECT SWITCH. UPON COMPLETION OF MAINTENANCE THE AREA MUST BE

CLEARED AND SECURED, AT THAT TIME THE UNIT

MAY BE RETURNED TO SERVICE.

MAIN/ EMERGENCY DISCONNECT

Minimum rating for a Main/ Emergency Disconnect

Switch: 600 VAC , 16.0 A, 1 phase, 1 normally closed

auxiliary contact switch must comply with EN (IEC)

60947.

POWER & CONTROL

WIRES

Must be run in ducting meeting (IP 33 minimum) or be

suitably protected (double insulation, sufficient HAR rating). The minimum cross sectional area 2.5 mm .

For all other control and safety accessories contact

you local LIFTMASTER dealer.

SUGGESTED MAIN/ EMERGENCY DISCONNECT & WIRING SPECIFICATIONS

NOTE: All electrical wiring must pertain to local electrical codes.

2

WHEN ORDERING REPAIR PARTS AND ACCESSORIES

ADDRESS ORDER TO:

CHAMBERLAIN GmbH

Alfred-Nobel-Str. 4

66793 Saarwellingen

PHONE ORDER: FAX ORDER:

(49) 6838-907105 (49) 6838-907239

TECHNICAL HOTLINE:

(49) 6838-907171

WARNING

WARNING

WARNING

WARNING

Page 11

11

POWER WIRING CONNECTIONS

1. Connect power wires coming from the main/ emergency disconnect to the captive terminal block in the

electrical box enclosure marked with the label shown

below.

2. Be sure to run all power wires through the conduit

hole in the electrical box enclosure marked with the label

shown below.

POWER WIRING

CONTROL STATION WIRING

CONTROL WIRING CONNECTIONS

1. Connect control wires to the TB1 terminal block

located on the Printed Circuit Board (shown below).

2. Be sure to run all control wires through the conduit

hole in the electrical box enclosure marked with the label

shown below.

3. Apply power to the operator. Press OPEN push button and observe direction of door travel and then Press

the STOP button.

If door did not move in the correct direction, check for

improper wiring at the control station or between operator and control station.

For Control Station and Main/ Emergency Disconnect

mounting refer to figure 10 below.

GROUND WIRING

1. Connect earth ground to chassis ground screw in the

electrical box enclosure marked with the label shown

below.

2. Use same conduit entry into the electrical box as the

power wiring.

4 ft. (1219mm)

(Approximate)

1. Mount Control Station and Main/ Emergency

Disconnect no further than 305mm (12”) from

each other.

2. Mount Control Station and Main/ Emergency

Disconnect no further than 305mm (12”) from

the door enclosure.

3. Mount WARNING NOTICE beside or below

the Control Station and Main/ Disconnect.

4. Mount MAINTENANCE ALERT label to

either side of control station.

MOUNTING INSTRUCTIONS

FIGURE 10

Control

Station

Main

Disconnect

L1 L2 L3

40-16308A

40-10033B

PROGRAMMING OPTIONS IN THE OPERATOR

OR IN THE AREA NEAR THE OPERATOR MUST

MAINTENANCE THE AREA MUST BE CLEARED

AND SECURED, AT THAT TIME THE UNIT MAY

ANY MAINTENANCE OTHER THAN

NOT BE PERFORMED UNTIL DISCONNECTING

THE ELECTRICAL POWER AND LOCKING-OUT

THE POWER VIA, THE MAIN DISCONNECT

SWITCH. UPON COMPLETION OF

BE RETURNED TO SERVICE.

Maintenance Alert

TM

System

If light is Flashing,

it is time for routine

Door and Opener

Maintenance.

If light is Steady

On, call for

immediate service.

Service every

________ cycles.

Page 12

12

RADIO (24V)

LOGIC CONTROL (VER. 2.0) 1 PH WIRING SCHEMATIC

1874-1

R1 R3

(BR)

AUXILIARY CLOSE

LIMIT SWITCH

125/24VAC 10 A

(WH)

(WH)

(WH)

R2

(GY/WH)

(YE)

(GY)5V(YE)N(RD)N(WH)

28VNN

TO RPM

SENSOR

(YE)

OPEN LIMIT

SWITCH

125/24VAC 10 A

(BL)

CLOSE LIMIT

SWITCH

125/24VAC 10 A

(RD)

N

(WH) 5V

3241 1234 4321

P4 P5 P6

POWER PHASE JUMPER IN 1PH POSITION

SINGLE PHASE

CONTACTOR/ 3 PHASE

1 BUTTON

STATION (OPTIONAL)

TB1

1

2345678910111213

SENSING DEVICE

(YE)

INTER.

SWITCH

(YE)

24VAC

STOP

3 BUTTON

STATION (5V)

CLOSE

OPEN

E14 E9

(YE)

(OR)

N

TRANSFORMER

(240VAC PRIMARY

24VAC SECONDARY

N

SECONDARY

50/60HZ 40VA)

PRIMARY

(OR)

(BK)

230V

E19

(GN/YE)

E12

(RD)

E2

L3 L2 L1

(GN/YE)

LINE FILTER

(250VAC 10A)

L3 L2 L1

(YE)

(BK)

N

N1 P1

NPE

(BK)

N

(BK)

N

E13

E4

E17

E15

E10

E5

E1

E11

(RD)

230V

(RD)

230V

TERMINAL BLOCK

(RD)

230V

(BK) 230V

(YE) N

(BL) 230V

(BL/BK) 230V

(BL/BK) N

(BK) 230V

(BK) N

(600V)

TO MOTOR

(1/2HP 230V/50HZ 1PH)

BRAKE SOLENOID

(240V)

OVERLOAD

(250VAC 32VDC 6A)

KEY SWITCH

(OPTIONAL)

MAINTENACE ALERT LED

EMERGENCY

STOP

PE

L1N

FUSED POWER IN

(230V 50HZ 1PH)

MAIN/ EMERGENCY

DISCONNECT

(600VAC 16A)

Page 13

13

ELECTRICAL BOX COMPONENT LOCATION

The operator electrical box is only to be accessed by trained “LIFTMASTER” technicians. If service is required contact your local LIFTMASTER dealer.

SWITCH BEFORE REMOVING COVER.

POWER VIA, MAIN DISCONNECT

ELECTRICAL POWER AND LOCK-OUT

ELECTROCUTION, DISCONNECT

INJURY OR DEATH FROM

TO AVOID SERIOUS PERSONAL

HIGH VOLTAGE

COVER LABEL

HIGH VOLTAGE

COVER

TB1 TERMINAL

BLOCK

GROUND

SCREW

PRINTED CIR-

CUIT BOARD

CAPTIVE TERMINAL

BLOCK

230V/50Hz 1PH

WARNING

40-16307A

Page 14

14

LIMIT SWITCH ADJUSTMENT

FIGURE 11

The operator electrical box is only to be accessed by trained “LIFTMASTER” technicians. If service is required contact your local LIFTMASTER dealer.

TO AVOID SERIOUS PERSONAL INJURY OR DEATH

FROM ELECTROCUTION, DISCONNECT ELECTRIC

POWER BEFORE MANUALLY MOVING LIMIT NUTS.

WARNING

MAKE SURE THE LIMIT NUTS ARE POSITIONED BETWEEN THE LIMIT SWITCH ACTUATORS BEFORE

PROCEEDING WITH ADJUSTMENTS. (Limit switch adjustments are located on the front wall of the electrical enclosure, see figure below)

1. To adjust limit nuts depress retaining plate to allow

nut to spin freely. After adjustment, release plate

and ensure it seats fully in slots of both nuts.

2. To increase door travel, spin nut away from actu-

ator. To decrease door travel, spin limit nut toward

actuator.

3. Adjust open limit nut so that door will stop in open

position with the bottom of the door even with top

of door opening.

4. Repeat Steps 1 and 2 for close cycle. Adjust close

limit nut so that actuator is engaged as door fully

seats at the floor.

WHEN ORDERING REPAIR PARTS AND ACCESSORIES

ADDRESS ORDER TO:

CHAMBERLAIN GmbH

Alfred-Nobel-Str. 4

66793 Saarwellingen

PHONE ORDER: FAX ORDER:

(49) 6838-907105 (49) 6838-907239

TECHNICAL HOTLINE:

(49) 6838-907171

CUT-AWAY VIEW OF ELECTRICAL BOX

WARNING

OPEN

LIMIT SW.

LIMIT

NUT

DEPRESS

PLATE

CLOSE

LIMIT SW.

ROTATOR

CUP

RPM

BOARD

SAFETY

LIMIT SW.

Page 15

15

Open

Close

Stop

Single Button

Control Station

Adds 5 seconds to countdown timer.

Resets the timer to close to 0 seconds.

Turns off electronic search for photo eyes after photo eyes

have been intentionally removed.

Adds 5 seconds to “Red warning light before closing”

time.

Adds 60 seconds to countdown timer.

Press This Button To Get This Result

PROGRAM SETTINGS

Logic Control Pushbuttons Open, Close, Stop

Open, Close and Stop buttons are mounted directly on the Logic Control board. This will provide easy programming ability and door control at the electrical box.

M

Figure 1

Maintenance

Alert LED

Programmable Mid-stop:

The system will learn a programmable Mid-Stop point and will stop at that point whenever the door is opened from a fully closed position.

Setting Mid-Stop:

Start with the door in the fully closed position. Set DIP switches to “set mid-stop”

mode. Press the open button. When the door reaches the desired Mid point, press

the stop button. Set DIP switches to the desired operating mode (B2, C2, T, TS,

FSTS). Press the open button and allow the door to run to the open limit.

Clearing Mid-Stop:

Start with the door in the fully closed position. Set DIP switches to “set mid-stop”

mode. Press the open button. Allow the door to run to the open limit. Set DIP switches to the desired operating mode (B2, C2, T, TS, FSTS).

Programmable Maximum Run Timer:

Any time a “closing” or “opening” door takes 10 seconds longer than its programmed

normal cycle time, the door will stop. The factory default for maximum run time is 90

seconds.

Setting Maximum Run Timer:

Start with the door in the fully closed position. Set DIP switches to “set max run timer”

mode. Press the open button. Allow the door to run to the open limit. Once the door

has stopped, set DIP switches to the desired operating mode (B2,C2, D1, E2, T, TS,

FSTS). The maximum run time is now set to the door’s travel time + 10 seconds.

Maintenance Alert System

Set dip switch to set cycle counter mode. When the operator is in this mode the LED

will flash the number of times in 5k increments the operator has cycled followed by a

five second delay.

(Refer to figure 1 for LED location on the pushbutton).

Open

Close

Stop

Adds 5,000 cycles to Maintenance Alert System Activation

Counter

Clears memory, sets Maintenance Alert System Activation

Counter to 0 cycles.

Adds 10,000 cycles to Maintenance Alert System Activation

Timer

Press This Button To Get This Result

Set Timer to Close (CPSII Required)

Begin with the door in the closed position. Set dip switch to “Set Timer to Close”.

l The Maintenance Alert System LED will light when you press button.

l The Timer to Close only works in T, TS, and FSTS wiring modes with a CPSII.

When the door has cycled the number of times you set, the Maintenance Alert System

LED will flash once every second until the unit is serviced and the cycle counter is

cleared.

ON

ON

SET

MAX RUN

TIMER

1 2 3 4

OFF

ON

ON

AINTENANCE

ALERT

SYTSTEM

1 2 3 4

OFF

MIDSTOP

SET

TIMER

TO CLOSE

ON

ON

SET

1 2 3 4

OFF

ON

ON

1 2 3 4

OFF

Page 16

16

WIRING TYPES

WIRING

TYPE STATION

C2 3 Button, 3 Button Radio Control

Function

: Momentary contact to open and stop with constant pressure to close, open

override plus wiring for sensing device to reverse.

B2 3 Button, 1 Button, 1 & 3 Button Radio Control

Function: Momentary contact to open, close and stop, plus wiring for sensing device to

reverse and auxiliary devices to open and close with open override.

D1 2 Button, 3 Button Radio Control

Function

: Constant pressure to open and close with wiring for sensing device to stop.

E2 2 Button, 3 Button Radio Control

Function

: Momentary contact to open with override and constant pressure to close.

Release of close button will cause door to reverse (roll-back feature) plus wiring for

sensing device to reverse.

T* 3 Button, 1 Button, 1 & 3 Button Radio Control

Function

: Momentary contact to open, close, and stop, with open override and timer to

close. Every device that causes door to open, except a reversing device, activates timer

to close. Auxiliary controls can be connected to open input to activate the timer to close.

If the timer has been activated, the open button and radio control can recycle the timer.

The stop button will deactivate the timer until the close button is used to close the door.

(NOTE: Requires Optional failsafe photo eyes to operate.)

TS* 3 Button, 1 Button, 1 & 3 Button Radio Control

Function

: Momentary contact to open, close, and stop with open override and timer to

close. Every device that causes door to open, including a reversing device, activates

timer to close. Auxiliary controls can be connected to open input to activate the timer to

close. If the timer has been activated, the open button and radio control can recycle the

timer. The stop button will deactivate the timer until the close button is used to close the

door. (NOTE: Requires Optional failsafe photo eyes to operate.)

FSTS Momentary button contact for open, close and stop. Radio controls

allowing open, close and stop. User set midstop. User set timer to close, functional at

open limit. The single button station opens the door and activates the timer to close,

putting the operator in TS mode until the door reaches the down limit, or is stopped in

travel. At which time the operator enters the B2 mode. A failsafe is required to operate

in this mode. (NOTE: Requires Optional failsafe photo eyes to operate.)

NOTE:

1. External interlocks may be used with all functional modes.

2. Auxiliary devices are any devices that have only one set of contacts. Examples are:

photocell, loop detector, pneumatic or electrical treadles, residential radio controls,

one button stations, pull cords, etc.

3. Open override means that the door may be reversed while closing by activating an

opening device without the need to use the stop button first

.

OFF

All modes contain: Wiring for sensing devices to reverse. Wiring for failsafe reversing devices. Connection for

electrical detection of clutch slippage. External interlocks and auxiliary devices. Open button override while

door is traveling down.

NOTE: Open, Close, and Stop buttons are located on the Logic Control board. This will provide programming

ability and door control at the electrical box.

OFF

ON

OFF

ON

ON

C2

1 2 3 4

OFF

ON

ON

B2

1 2 3 4

OFF

ON

ON

D1

1 2 3 4

OFF

ON

ON

E2

1 2 3 4

ON

ON

T

1 2 3 4

ON

ON

TS

1 2 3 4

OFF

ON

FSTS

1 2 3 4

Page 17

17

WHEN ORDERING REPAIR PARTS AND ACCESSORIES

ADDRESS ORDER TO:

CHAMBERLAIN GmbH

Alfred-Nobel-Str. 4

66793 Saarwellingen

PHONE ORDER: FAX ORDER:

(49) 6838-907105 (49) 6838-907239

TECHNICAL HOTLINE:

(49) 6838-907171

TYPE STATION

C2 Failsafe 3 Button, 3 Button Radio Control

Same functions as C2. Failsafe safety device must be installed to operate door. See

Failsafe Safety Device Options below.

B2 Failsafe 3 Button, 1 Button, 1 & 3 Button Radio Control

Same functions as B2. Failsafe safety device must be installed to operate door. See

Failsafe Safety Device Options below.

D1 Failsafe 2 Button, 3 Button Radio Control

Same functions as D1. Failsafe safety device must be installed to operate door. See

Failsafe Safety Device Options below.

E2 Failsafe 2 Button, 3 Button Radio Control

Same functions as E2. Failsafe safety device must be installed to operate door. See

Failsafe Safety Device Options below.

Failsafe Safety Device Options

To use the operator in any of the Failsafe wiring modes, or Timer to Close wiring modes, a

LiftMaster failsafe safety device must be installed.

Timer to Close with Failsafe Safety Device

NOTE: The board will check attached Failsafe devices after setting the Timer to Close and

activate them for the timer. If a failsafe device is added later the Timer to Close must be

reentered to activate the new failsafe device.

Lif

tMaster Failsafe Safety Devices:

CPSII CPSII Option Board - NEMA 1 eyes included

(Also can interface to 4 wire edge)

CPS-L NEMA 1 Direct Connect Eyes

CPS-LN4 NEMA 4 Direct Connect Eyes

OFF

FAILSAFE WIRING TYPES

“Failsafe” self mounting wiring types: These wiring types require the use of self monitoring sensing devices. (The

optional Lift Master CPSII photoeye package)

FIGURE 13

DIP SWITCH

ON

ON

C2

FAIL

SAFE

1 2 3 4

OFF

ON

ON

B2

FAIL

SAFE

1 2 3 4

OFF

ON

ON

D1

FAIL

SAFE

1 2 3 4

ON

ON

E2

FAIL

SAFE

1 2 3 4

OFF

Page 18

18

BRAKE ADJUSTMENT

A solenoid brake is standard on all models. The brake

is adjusted at the factory and should not need additional adjustment for the the life of the friction pad.

If replacement should be necessary. Refer to the illustration for identification of components for the solenoid

type brake system.

Friction

Pads

Release Lever

Plate

Assembly

Solenoid

FIGURE 14

Any accidents resulting from incorrect settings or maintenance operations are not the responsibility of Chamberlain. Safety of this operator can only be assured if these operations are performed by trained “LIFTMASTER” technicians.

All maintenance to the operator must not be performed until disconnecting the electrical power

and locking-out the power via. the main/ emergency disconnect. All maintenance must be performed by trained “LIFTMASTER” technicians. If service is required contact your local LIFTMASTER dealer.

WHEN ORDERING REPAIR PARTS AND ACCESSORIES

ADDRESS ORDER TO:

CHAMBERLAIN GmbH

Alfred-Nobel-Str. 4

66793 Saarwellingen

PHONE ORDER: FAX ORDER:

(49) 6838-907105 (49) 6838-907239

TECHNICAL HOTLINE:

(49) 6838-907171

Page 19

19

CLUTCH ADJUSTMENT

1. The clutch has been factory set to limit the

dynamic force of the operator to 400N (spring

length to 34mm.)

2. Replace clutch pad when necessary (please refer

to “Maintenance Schedule” on page 26).

3. Procedures to replace clutch pad:

3.1. Remove cotterpin from nut on the clutch

shaft.

3.2. Back off clutch nut and remove.

3.3. Remove washer, spring, clutch pulley and

clutch pad.

3.4. Install new clutch pad and replace

components in reverse order.

3.5. Set the spring length to 34mm (1.34”). (Refer

to figure 16)

3.6. Reinstall Cotterpin.

CAUTION: The adjustable friction clutch is NOT

an automatic reversing device. An electric

reversing edge can be added to the bottom

edge the of door if desired.

WARNING

FIGURE 15

34mm

(1.34”)

Clutch Spring

FIGURE 16

Any accidents resulting from incorrect settings or maintenance operations are not the responsibility of Chamberlain. Safety of this operator can only be assured if these operations are performed by trained “LIFTMASTER” technicians.

All maintenance to the operator must not be performed until disconnecting the electrical power

and locking-out the power via. the main/ emergency disconnect. All maintenance must be performed by trained “LIFTMASTER” technicians. If service is required contact your local LIFTMASTER dealer.

WHEN ORDERING REPAIR PARTS AND ACCESSORIES

ADDRESS ORDER TO:

CHAMBERLAIN GmbH

Alfred-Nobel-Str. 4

66793 Saarwellingen

PHONE ORDER: FAX ORDER:

(49) 6838-907105 (49) 6838-907239

TECHNICAL HOTLINE:

(49) 6838-907171

Adjusting Nut

Clutch Pad

WARNING

Cotterpin

Spring

Clutch Plate

Washer

Clutch Pulley

Page 20

20

ILLUSTRATED PARTS - ELECTRICAL BOX

S2

S1

S6

S5

S3

S7

S8

S4

L3

11

12

13

5

S9

6

7

8

L5

2

L8

L6

L2

L3

L1

L7

L8

L9

L2

L6

L4

1

9

3

10

Page 21

21

Qty

1

3

3

2

3

3

6

2

2

Item

S1

S2

S3

S4

S5

S6

S7

S8

S9

P/N

10-10013

10-12553

10-12806

18-10036

23-10041

31-12542

82-PX04-20

82-PX06-16

84-LH-06

Description

Depress Plate

Nut Plate, Switch

Backup Plate

Spring, Depress Plate

Limit Switch

Standoff, Limit Switch

Screw, Pan Head Phillips

Screw, Pan Head Phillips

Locknut, Nylon Hex

Below are replacement kits available for your operator. For replacement of electrical box, motor or brake components be sure to

match model number of your unit to kit number below to ensure proper voltage requirements. Optional modifications and/or

accessories included with your operator may add or remove certain components from these lists. Please consult a parts and service

representative regarding availability of individual components of kits specified below. Refer to page 28 for all repair part ordering

information.

Electrical Box Replacement Kits

K-EJ5025L2 EJ Electrical box replacement kit

K-EH5025L2 EJ Electrical box replacement kit

Motor Kits

K20-51050B-6T 1/2 HP 230 Volt/50 Hz

Model EJ and RIght Hand Model EH to use right hand

assembly,

Left hand Model EH to use left hand assembly.

Brake Kits

71-B240H 230V Model EH

Note: Single phase units are equipped with an external line break

device, and may be equipped with an additional internal pilot duty

thermal O/L device.

K72-14130 LIMIT SHAFT ASSEMBLY KIT

Item

L1

L2

L3

L4

L5

L6

L7

L8

L9

Description

Limit Shaft

Flange Bearing

Limit Nut

Sprocket 48B9

Washer, Shim

Washer, Shim

Roll Pin

E Ring

Rotating Cup

Qty

1

2

2

1

1

4

1

3

1

K72-12515 LIMIT SWITCH ASSEMBLY KIT

P/N

11-13361

12-10028

13-10024

15-48B9A1

80-10025

80-10026

86-RP04-100

87-E-038

29-10344

COMPLETE ELECTRICAL BOX KITS

Item

1

2

3

5

6

7

8

9

10

11

12

13

Description

Electrical Box

Electrical Box Cover

Transformer

Overload

PCB Assembly

Terminal Block, Radio

Standoff, Assembly

RPM Sensor Board

Housing, RPM Board

Cover, PCB High Voltage

Line Filter

Terminal Block, 3 Pole

Qty

1

1

1

1

1

1

9

1

1

1

1

1

P/N

10-13792

10-13899

21-16473

25-16470

79-13433

42-10040

75-13705

79-15016

093D0148

10-16068

29-16136

42-9203

REPAIR PARTS KITS – ELECTRICAL BOX

LOGIC CONTROL (VER. 2.0)

Page 22

22

ILLUSTRATED PARTS – Model EJ

10

9

3

11

2

8

C13

C12

C11

C10

1

C2

C13

C5

C14

C9

C6

C8

C4

C5

C13

C3

C1

O1

O3

O6

O7

O12

C2

O2

O10

C13

C5

O4

O8

011

O12

7

1

O9

C7

O12

O11

O5

O8

O9

6

Page 23

23

REPLACEMENT PARTS KITS – MODEL EJ

Refer to the parts lists below for replacement kits available for your operator. If optional modifications and/or

accessories are included with your operator, certain components may be added or remove from these lists. Individual

components of each kit may not be available. Please consult a parts and service representative regarding availability of

individual components. Refer to page 28 for all repair part ordering information.

LOGIC CONTROL (VER. 2.0)

1

2

1

1

4

1

1

1

1

1

1

1

5

1

K72-19975 CLUTCH SHAFT ASSEMBLY KIT

ITEM PART # DESCRIPTION QTY

C1

C2

C3

C4

C5

C6

C7

C8

C9

C10

C11

C12

C13

C14

SHAFT, J CLUTCH

1" KEYED FLANGE BEARING

DUAL SPROCKET 32/14

SPLINED CORE SPROCKET

E RING, 1" PLATED

COMPRESSION SPRING

ASSEMBLY, PULLEY

WASHER, .048 THICK

THRUST BEARING, 1.02" ID

THRUST BEARING, 1.26" ID

RETAINING RING

SPLINED HUB, J DISCONNECT

WASHER 1” ID X 1/16" TH

ROLL PIN, 5/16" X 1.75"

K72-19974 OUTPUT SHAFT ASSEMBLY KIT

ITEM PART # DESCRIPTION QTY

O1

O2

O3

O4

O5

O6

O7

O8

O9

O10

O11

O12

SHAFT, H/J OUTPUT

SPROCKET ASSEMBLY

DUAL SPROCKET 32/14

SPRKT 48B18 x 1"BORESPRKT

50B12 x 1BOREE RING ,1"

PLATED

WASHER 1" ID X 1/16" TH

KEY 1/4 X 1-1/2"LONG

SET SCREW, 5/16"-18

ROLL PIN, 5/16" X 1.75"

THIN WALLED RECEIVER

SPACER

1

1

1

1

1

1

1

2

3

1

4

3

11-19485

15-19478

15-19480

15-48B18LGE

15-50B12LGH

158A0056

80-206-11

80-207-19

82-NH31-06

86-RP10-112

87-P-100S

80-206-12

11-19470

12-19504

15-19480

15-19484

158A0056

18-19487

75-19985

80-19473

80-19474

80-19475

80-19476

80-19846

80-206-11

86-RP10-112

INDIVIDUAL PARTS

ITEM PART # DESCRIPTION QTY

1

2

3

N/S

6

7

8

9

10

11

2

1

1

4

1

1

1

1

1

1

10-10874

10-15569

16-5L304

19-48047M

K75-19978-L

K75-19978-R

K75-19977

17-6014

SEE PAGE 21

SEE PAGE 21

CONNECTING BRACKET

MOTOR PLATE H,J-PAINT

V BELT COGGED 30.4"

CHAIN,#48x47 W/MASTER

SVC. KIT, FRAME, (LH)

SVC. KIT, FRAME, (RH)

SVC. KIT, J ARM

MOTOR PULLEY

MOTOR KITS

ELECTRICAL BOX KITS

Page 24

24

ILLUSTRATED PARTS – Model EH

C8

3

O8

O9

O4

011

O12

C5

C11

C2

O2

1

7

O10

O7

O6

O3

11

9

10

2

5

C4

C12

C13

C5

C3

C11

1

8

C1

O1

C2

C11

O12

6

O12

O11

O8

O9

O5

C5

C9

C10

C7

C6

C14

Page 25

25

REPLACEMENT PARTS KITS - MODEL EH

Refer to the parts lists below for replacement kits available for your operator. If optional modifications and/or

accessories are included with your operator, certain components may be added or remove from these lists. Individual

components of each kit may not be available. Please consult a parts and service representative regarding availability of

individual components. Refer to page 28 for all repair part ordering information.

LOGIC CONTROL (VER. 2.0)

1

2

1

1

3

1

1

1

1

2

3

1

1

1

K72-19979 CLUTCH SHAFT ASSEMBLY KIT

ITEM PART # DESCRIPTION QTY

C1

C2

C3

C4

C5

C6

C7

C8

C9

C10

C11

C12

C13

C14

SHAFT, H CLUTCH

1" KEYED FLANGE BEARING

DUAL SPROCKET 32/14

SPROCKET, 14 TOOTH

E RING,1" PLATED

SPRING, COMPRESSION

ASSEMBLY,CHAIN WHEEL

ASSEMBLY, PULLEY

ASSEMBLY, CHAIN GUIDE

SHIM WASHER

WASHER 1" ID X 1/16 "TH

THRUST WASHER 1" ID 1.5" OD

ROLL PIN, 5/16" X 1.75"

ROLL PIN 5/16 X 2 1/2

K72-19974 OUTPUT SHAFT ASSEMBLY KIT

ITEM PART # DESCRIPTION QTY

O1

O2

O3

O4

O5

O6

O7

O8

O9

O10

O11

O12

SHAFT, H/J OUTPUT

SPROCKET ASSEMBLY

DUAL SPROCKET 32/14

SPRKT 48B18 x 1"BORESPRKT

50B12 x 1BOREE RING ,1"

PLATED

WASHER 1" ID X 1/16" TH

KEY 1/4 X 1-1/2"LONG

SET SCREW, 5/16"-18

ROLL PIN, 5/16" X 1.75"

THIN WALLED RECEIVER

SPACER

1

1

1

1

1

1

1

2

3

1

4

3

11-19485

15-19478

15-19480

15-48B18LGE

15-50B12LGH

158A0056

80-206-11

80-207-19

82-NH31-06

86-RP10-112

87-P-100S

80-206-12

11-19471

12-19504

15-19480

15-19481

158A0056

18-11379

75-10884

75-19985

75-19986

80-10022

80-206-11

85-19418

86-RP10-112

86-RP10-208

INDIVIDUAL PARTS

ITEM PART # DESCRIPTION QTY

1

2

3

N/S

5

6

7

8

9

10

11

2

1

1

4

1

1

1

1

1

1

1

10-10874

10-15569

16-5L304

19-48047M

K74-19987-E

K75-19978-L

K75-19978-R

K75-19981

17-6014

SEE PAGE 21

SEE PAGE 21

CONNECTING BRACKET

MOTOR PLATE H,J-PAINT

V BELT COGGED 30.4"

CHAIN,#48x47 W/MASTER

SVC. KIT, INTERLOCK SW.

SVC. KIT, FRAME, (LH)

SVC. KIT, FRAME, (RH)

SVC. KIT, H ARM

MOTOR PULLEY

MOTOR KITS

ELECTRICAL BOX KITS

Page 26

26

MAINTENANCE SCHEDULE

If for any reason your operator does not function, perform as desired, or described in the manual, check that you have read and followed all instructions completely. If you are still experiencing difficulties, contact your local Liftmaster dealer for troubleshooting assistance.

All maintenance to the operator must not be performed until disconnecting the electrical power

and locking-out the power via. the main/ emergency disconnect. All maintenance must be performed by trained “LIFTMASTER” technicians. If service is required contact your local LIFTMASTER dealer.

LED INDICA

TOR READOUTS

11 LED’s ease installation and speed troubleshooting of control functions as follows.

z (DIAG) System Diagnostic Indicator - signal identifies fault in logic board.

z (OLS) Open Limit Indicator - indicates open limit switch actuation and continuity.

z (CLS) Close Limit Indicator - Indicates close limit switch actuation and continuity.

z (SLS) Sensing Limit Indicator - Indicates auxiliary limit switch actuation and continuity.

z (DIO) Open Function Indicator - indicates function actuation from control devices.

z (D12) Close Function Indicator - indicates function actuation from control devices.

z (D11) Stop Function Indicator - indicates function actuation from control devices.

z (D14) Reversing Function Indicator - indicates function actuation from sensing devices.

z (SBC) Function Indicator - indicates function activation of a single button control.

z 24V Supply Indicator - indicates secondary voltage at circuit board.

z 5V Supply Indicator - indicates circuit board continuity.

6

Use SAE 30 Oil (Never use grease or silicone spray).

Repeat ALL procedures.

Do not lubricate motor. Motor bearings are rated for continuous operation.

Do not lubricate clutch or V-belt.

Inspect and service whenever a malfunction is observed or suspected.

CAUTION: BEFORE SERVICING, ALWAYS DISCONNECT OPERATOR FROM POWER SUPPLY.

For use with Maintenance Alert System.

Check at the intervals listed in the following chart.

ITEM

Drive Chain

Sprockets

Clutch

Belt

Fasteners

Manual Disconnect

Bearings & Shafts

PROCEDURE

Check for excessive slack.

Check & adjust as required.

Lubricate

Check set screw tightness

Check & adjust as required

Check condition & tension

Check & tighten as required

Check & Operate

Check for wear & Lubricate

EVERY 3 MONTHS

OR

5,000 CYCLES

z

z

z

EVERY 6 MONTHS

OR

10,000 CYCLES

z

z

z

z

EVERY 12 MONTHS

OR

20,000 CYCLES

Page 27

27

OPERATOR NOTES

Page 28

c

2004, The Chamberlain Gmbh

All rights Reserved

01-19970C

HOW TO ORDER REPAIR PARTS

WHEN ORDERING REPAIR PARTS AND ACCESSORIES

PLEASE SUPPLY THE FOLLOWING INFORMATION:

PART NUMBER DESCRIPTION MODEL NUMBER

EUROPEAN SER

VICES

ADDRESS ORDER TO:

Chamberlain GmbH

Alfred-Nobel-Str. 4

66793 Saarwellingen

PHONE ORDER:

(49) 6838-907105

FAX ORDER:

(49) 6839-907239

TECHNICAL HOTLINE:

(49) 6838-907171

NORTH

AMERICAN SERVICE

ADDRESS ORDER TO:

The Chamberlain Group Inc. Technical Support

Electronic Parts and Service Department

2301 N. Forbes Blvd., Suite 104

Tucson, Arizona 85745 USA

PHONE ORDER:

1-800-528-2806

FAX ORDER:

1-520-798-3960

TECHNICAL HOTLINE:

1-800-528-2806

Declaration of Conformity

Commercial Door Operator . . . . . . . . . . . . . . . . . . . . . . . . . . . .Model No. EH5025L2L, EH5025L2R &

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .EJ5025L2.

In Conformity with applicable Sections and Standards . . . . . . . .EN60204-1, IEC61010-1, EN55014-1,

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .EN55014-2 & EN61000-3.

Per the Provisions & Amendments of the EU Directives . . . . . . .93/68/EEC, 73/23/EEC & 89/336/EEC

Declaration of Incorporation

Commercial door operator Models EH5025L2R, EH5025L2L & EJ5025L2, when installed and main-

tained according to all the Manufacturer’s instructions in combination with a Commercial Door,

which has also been installed and maintained according to all the manufacturer’s instructions,

meet the provisions of EU Directive 89/239/EEC and all amendments.

Chamberlain GmbH

66793 Saarwellingen

January, 2000

Loading...

Loading...