Page 1

O

W N E R ’ S M A N U A L

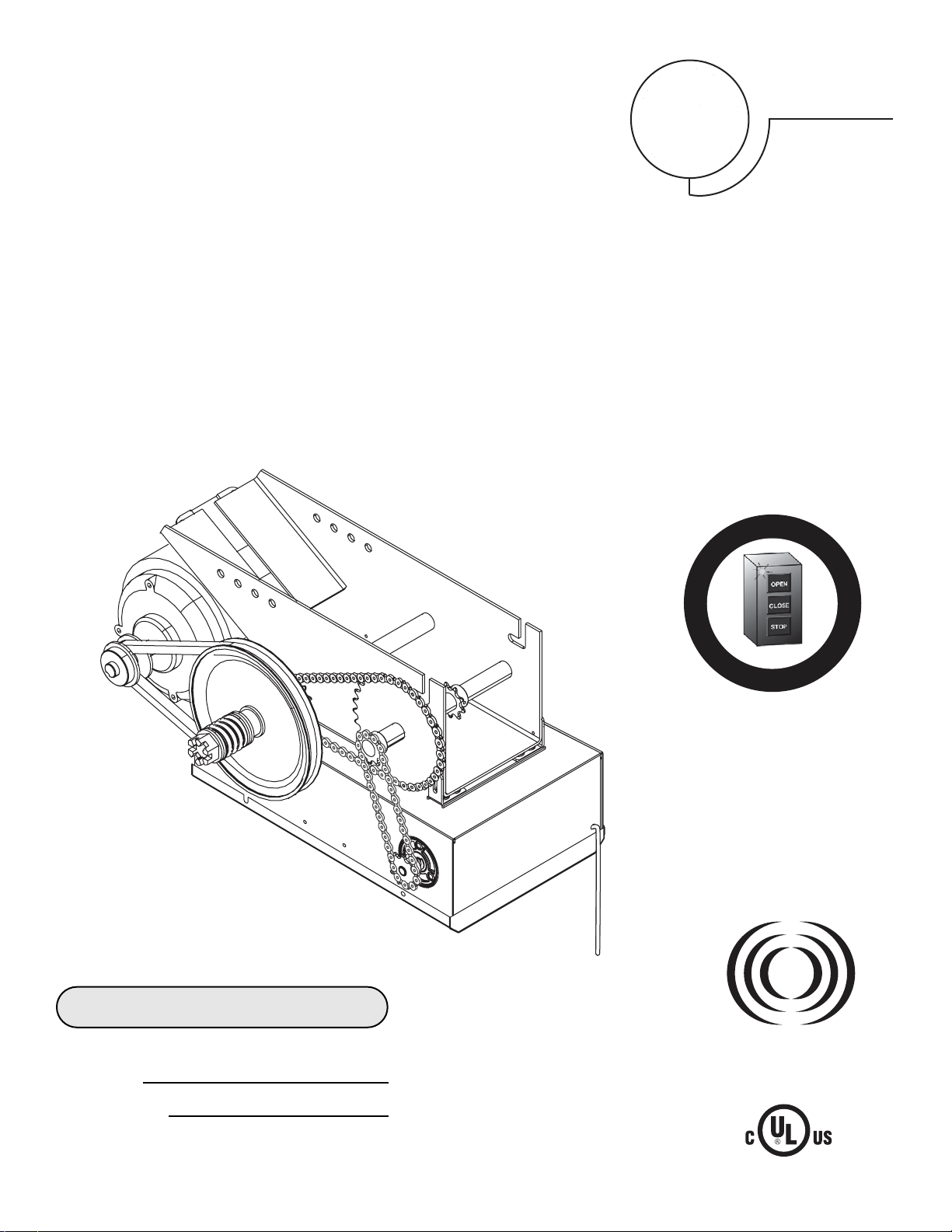

APT

INDUSTRIAL DUTY COMMERCIAL DOOR OPERATOR

ogic

L

3

NOT FOR RESIDENTIAL USE

A

L

E

R

T

S

Y

S

T

E

M

M

A

I

N

T

E

N

A

N

C

E

PATENT PENDING

The Maintenance Alert System™ allows the

installer to set an internal Maintenance

Cycle Counter. The Logic 3 operator

incorporates a self-diagnostic feature built

into the (MAS) Maintenance Alert System

LED. An LED on the 3-button station will

signal when the set number of

cycles/months is reached or when the

operator requires immediate service.

This Operator Features

the Enhanced

Radio Receiver

Built on Board

Serial # Box

Installation Date

2 YEAR WARRANTY

315MHz

Page 2

2

TABLE OF CONTENTS

SPECIFICATIONS

Carton Inventory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Operator Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Operator Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

PREPARATION

Track Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Powerhead Attachment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Trolley Carriage/Chain Attachment . . . . . . . . . . . . . . . . . . . . . . . .5

INSTALLATION

Mount the Header Bracket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Mount the Operator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Hang the Operator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Straight Arm Attachment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Entrapment Protection Accessories . . . . . . . . . . . . . . . . . . . . . . .8

ADJUSTMENT

Limit Switch Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Emergency Disconnect System . . . . . . . . . . . . . . . . . . . . . . . . . .9

Brake Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Clutch Adjustment and Auxiliary Reversal System . . . . . . . . . .10

POWER & GROUND WIRING

Safety Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Power Wiring Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Ground Wiring Connections . . . . . . . . . . . . . . . . . . . . . . . . . . .11

CONTROL STATION WIRING & INSTALLATION

Control Wiring Connections . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Mounting Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

External Radio Wiring Connections . . . . . . . . . . . . . . . . . . . . . .12

DIAGRAMS

Standard Power & Control Connection Diagrams . . . . . . . . . . .13

1 Phase Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Control Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

PROGRAMMING

Control Board Pushbuttons . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Determine and Set Wiring Type . . . . . . . . . . . . . . . . . . . . . . . . .16

Failsafe Wiring Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Self-Monitoring Safety Device Options . . . . . . . . . . . . . . . . . . .17

Programming Remotes . . . . . . . . . . . . . . . . . . . . . . . . . . . .18-19

Maintenance Alert System (MAS) . . . . . . . . . . . . . . . . . . . . . . .20

Mid Stop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Timer To Close . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21-22

AUTOMATICALLY LEARNED PROGRAMMING

Auxiliary Reversal System/RPM Sensor . . . . . . . . . . . . . . . . . .22

Maximum Run Timer (MRT) . . . . . . . . . . . . . . . . . . . . . . . . . . .23

OPTIONAL PROGRAMMING

Red/Green Warning Light Card . . . . . . . . . . . . . . . . . . . . . . . . .23

Resetting Factory Defaults - Clearing Memory . . . . . . . . . . . . .24

MAINTENANCE SCHEDULE

. . . . . . . . . . . . . . . . . . . . . . . .24

TROUBLESHOOTING

Diagnostic Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Troubleshooting Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Troubleshooting Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Troubleshooting Radio Functionality . . . . . . . . . . . . . . . . . . . . .28

REPAIR PARTS

Electrical Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30-31

Repair Parts Kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32-33

Operator Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34-35

Control Connection Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . .36

When you see these Safety Symbols and Signal Words on the

following pages, they will alert you to the possibility of serious

injury or death if you do not comply with the warnings that

accompany them. The hazard may come from something

mechanical or from electric shock. Read the warnings carefully.

When you see this Signal Word on the following pages, it will

alert you to the possibility of damage to your door and/or the

door operator if you do not comply with the cautionary

statements that accompany it. Read them carefully.

Mechanical

Electrical

WARNING

WARNING

WARNING

WARNING

CAUTION

WARNING

WARNING

IMPORTANT NOTES:

• BEFORE attempting to install, operate or maintain the operator,

you must read and fully understand this manual and follow all

safety instructions.

• DO NOT attempt repair or service of your commercial door and

gate operator unless you are an Authorized Service Technician.

Page 3

Before beginning your installation check that all components were provided.

CARTON INVENTORY

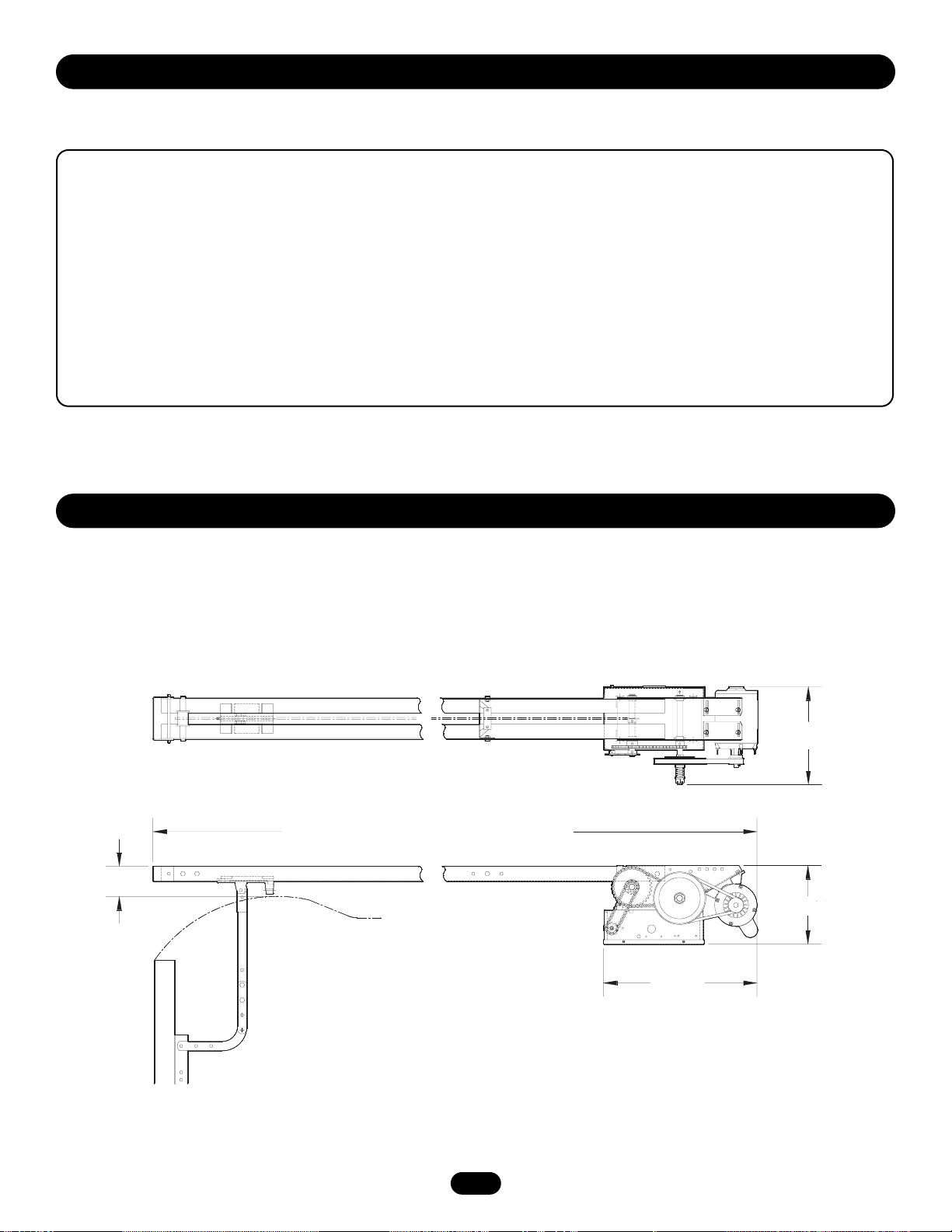

OPERATOR DIMENSIONS

3

DESCRIPTION

POWER HEAD ASSEMBLY

OWNER'S MANUAL AND CAUTION LABELS

HARDWARE BOX (INCLUDES FASTENERS, TRACK SPACERS, DOOR ARM ASSEMBLY, FRONT IDLER AND HEADER MOUNTING

BRACKET)

AUTO RECONNECT TROLLEY

3-BUTTON CONTROL STATION WITH LED

TROLLEY DRIVE CHAIN #48

NOTE: The tracks are shipped separately.

11.63" (29.54 cm)

*Door Height Plus 4 feet (1.22 m) (minimum)

*23.43"

(59.51 cm)

13.05" (33.15 cm)

Highest Point of Door Travel

4" (10.2 cm)

WEIGHTS AND DIMENSIONS

HANGING WEIGHT: 80-110 LBS. (36.3-50 kg)

Door Height Plus 4 feet (minimum)

*

4”

Highest Point of Door Travel

*20-1/2”

13-1/8”

10-1/2”

For Units with Brake add 3-1/2”

*

(Standard on 3/4 & 1Hp models Optional on 1/3 & 1/2Hp)

Page 4

4

MECHANICAL

DRIVE REDUCTION: . . . . . . . .Primary: Heavy duty (5L) V-Belt.

Secondary: #41 chain/sprocket.

Output: #48 chain

OUTPUT SHAFT SPEED: . . . . . . . . . . . . . . . . . . . . . . .96 R.P.M.

DOOR SPEED: . . . . . . . . . .7-8" per second depending on door

BRAKE: . . . . . . . . . . . . . . . . . . . . .Solenoid actuated disc brake

BEARINGS: . . . . . . . . . . . .Output Shaft: Shielded Ball Bearing.

Clutch Shaft: Iron Copper sintered and oil impregnated.

MOTOR

TYPE: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Continuous Duty

HORSEPOWER: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1/2 HP

SPEED: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1725 RPM

VOLTAGE: . . . . . . . . . . . . . . . . . . . . . . .115 Volts - Single phase

CURRENT: . . . . . . . . . . . . . . . . . . . . . . . . .See Motor Nameplate

SAFETY

DISCONNECT: . . . . . . . . . . . . . . .Quick disconnect door arm for

emergency manual door operation.

SAFETY PHOTO EYES (Optional CPS-L): Through beam or retro

reflective devices used to provide non-contact

safety protection.

SAFETY EDGE (Optional): Electric or pneumatic sensing device

attached to the bottom edge of door.

ELECTRICAL

TRANSFORMER: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24VAC

CONTROL STATION: . . . . . . . . . . . . . .NEMA 1 3-Button Station.

Open/Close/Stop w/ LED

WIRING TYPE: . . . . . . . . . . . . . . . . . . . . . .C2 (Factory Shipped)

Momentary contact to OPEN & STOP, constant pressure to

CLOSE, plus wiring for sensing device to reverse and auxiliary

devices to open and close with open override. See pages 16 and

17 for optional wiring types and operating modes.

LIMIT ADJUST: . . . . . .Linear driven, fully adjustable screw type

cams. Adjustable to 24'.

OPERATOR SPECIFICATIONS

Page 5

5

PREPARATION

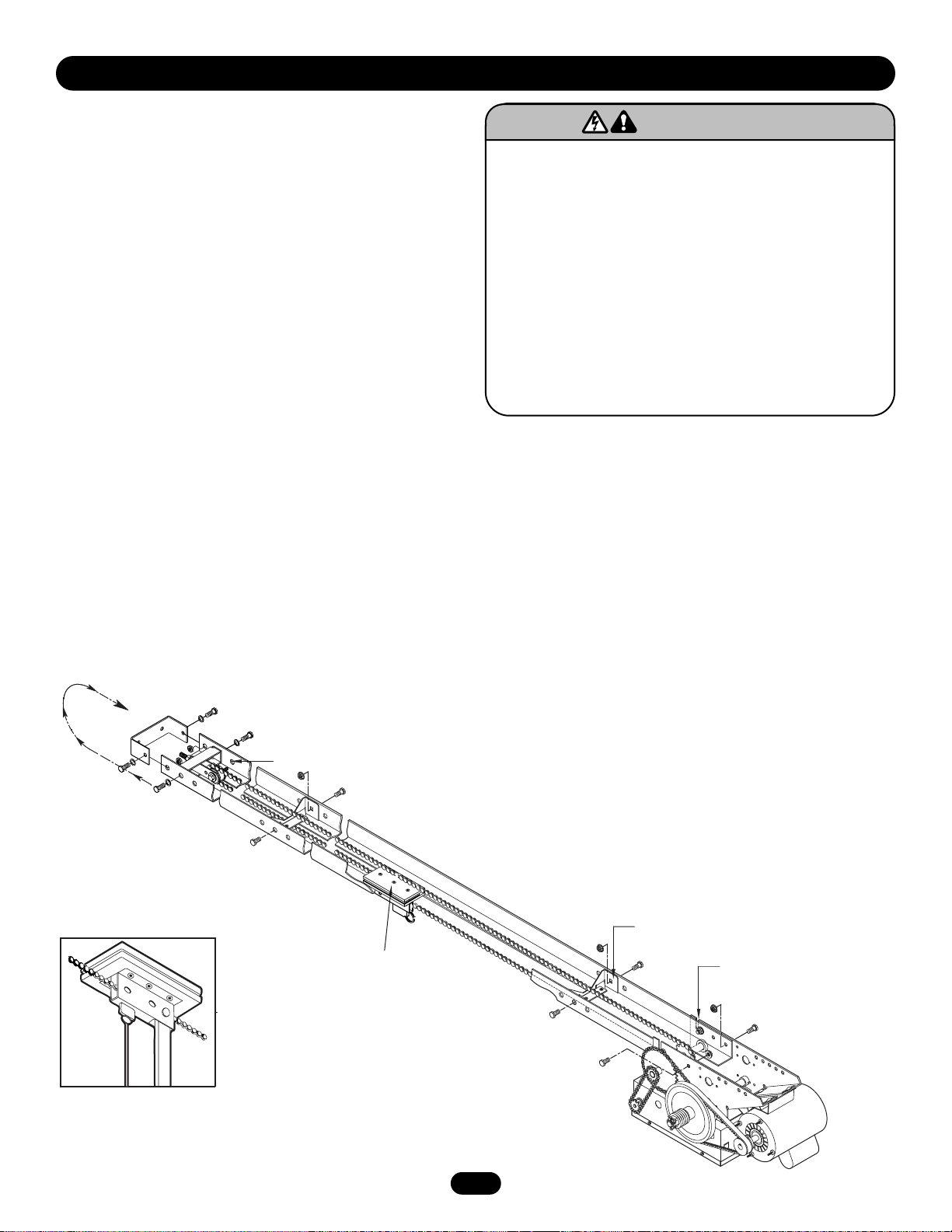

TRACK ASSEMBLY

1. Using the 3/8"-16 x 3/4" bolts and flange hex nuts provided,

assemble the operator track by installing and tightening the

track spacer brackets. Position the spacers evenly over the

length of the track. NOTE: The nylon pad on the spacer

bracket should face up.

2. Using (2) 3/8"-16 x 1" bolts and lock washers, install the front

idler assembly to the second set of holes of one end of the

track. Refer to the illustration below.

3. Slide the trolley carriage onto the track so that the hole of the

door arm faces the front (towards door).

POWERHEAD ATTACHMENT

1. Position the track assembly on the frame of the powerhead so

that the motor side of operator is in back (away from door ).

2. Using (2) 3/8"-16 x 3/4" bolts and flange hex nuts, install the

front idler assembly to the second set of holes of one end of

the track. Be sure the take-up bolt faces toward end of track.

Refer to the illustration below.

3. Connect the track to the operator by fastening (2)

3/8"-16 x 3/4" bolts and nuts through the frame and the end

holes in track. Tighten all four bolts to secure the track to the

powerhead.

TROLLEY CARRIAGE / CHAIN ATTACHMENT

1. Uncoil the chain and run it up through the idler on the chain

take-up assembly. Pull it towards the operator running it over

the nylon spacer brackets and over the top of the trolley

carriage. Pull the chain around the final drive sprocket on the

operator and back toward the trolley carriage. Pull the release

clip on the carriage and push one end of the chain through the

chain slot (see illustration). Using one of the masterlinks,

connect the drive link to one end of the chain. Pull the drive

link toward the free end of the chain and determine where to

cut chain for proper adjustment. Be sure the chain tensioning

bolt is loose before removing links. Using the other masterlink

fasten the adjusted chain to the free end of the drive link.

2. Slide the trolley carriage back and forth past the drive link to

assure that there will be no binding. Turn the chain tensioner

adjustment bolt to take out most of the chain lack.

• With trolley positioned at either end of the track, a properly

adjusted chain will sag about 3" (7.62 cm) at the midpoint. If

necessary, remove links from the chain to achieve proper

adjustment.

3. Tie the release cord to the trolley carriage.

To prevent possible SERIOUS INJURY or DEATH:

• DO NOT connect electric power until instructed to do so.

• If the door lock needs to remain functional, install an

interlock switch.

• ALWAYS call a trained professional door serviceman if door

binds, sticks or is out of balance. An unbalanced door may

not reverse when required.

• NEVER try to loosen, move or adjust doors, door springs,

cables, pulleys, brackets or their hardware, ALL of which are

under extreme tension and can cause SERIOUS PERSONAL

INJURY.

• Disable ALL locks and remove ALL ropes connected to door

BEFORE installing and operating door operator to avoid

entanglement.

WARNING

WARNING

Front Idler Assembly

Reel Chain

Around Idler and

over Spacer Brackets

Trolley Assembly

Trolley Carriage

Spacer Bracket

(mounted nylon pad side up)

L - Slot

Page 6

6

INSTALLATION

IMPORTANT NOTE: Before your operator is installed, be sure the door has been properly aligned and is working smoothly. The

operator may be wall mounted or mounted on a bracket or shelf. If necessary, refer to the preparation on page 5. Refer to the

illustrations and instructions below that suit your application.

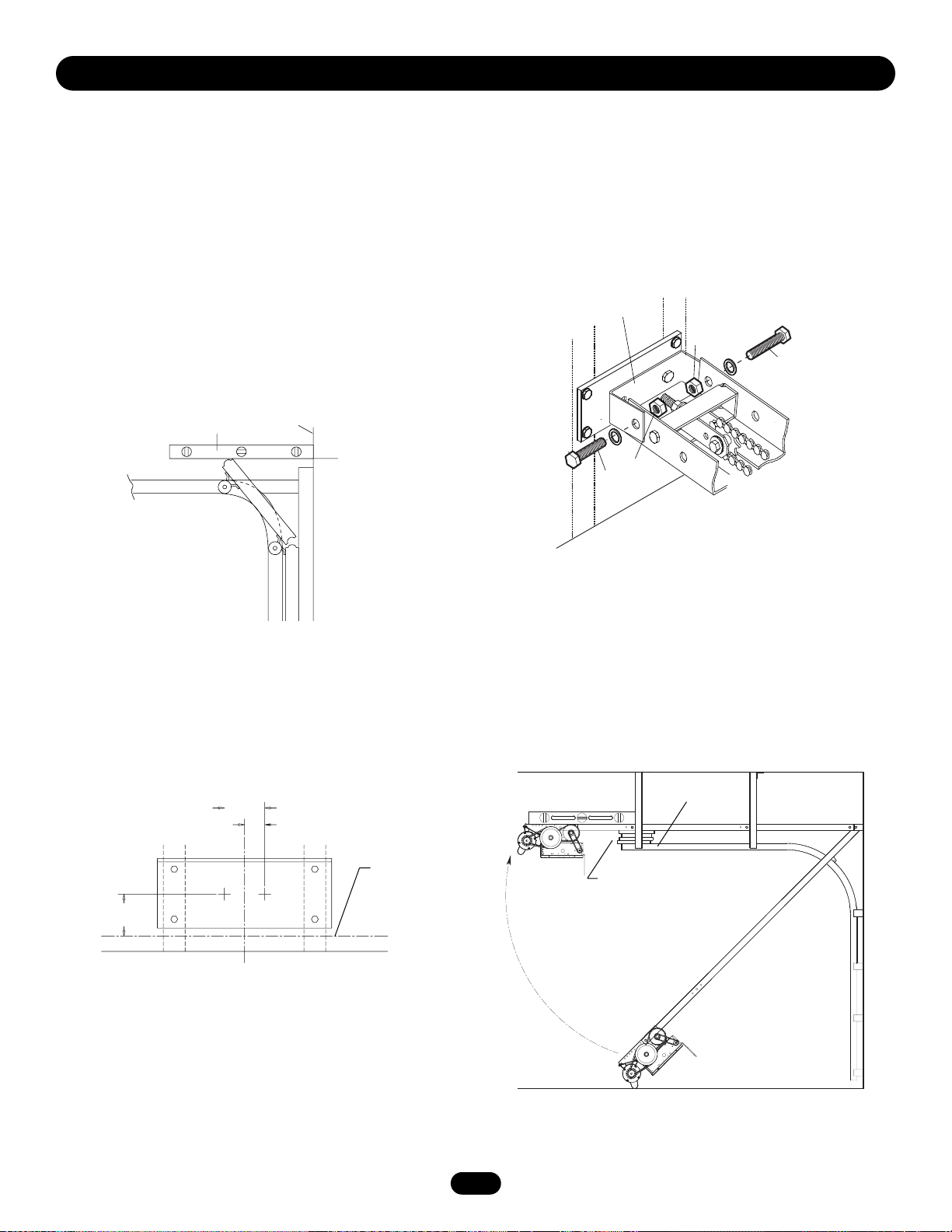

MOUNT THE HEADER BRACKET

1. Close the door and mark the inside vertical centerline of the

door.

2. Extend the line onto the header wall above the door.

You can fasten the header bracket within 2' (.61 m) of the

left or right of the door center only if a torsion spring or

center bearing plate is in the way.

3. Open your door to the highest point of travel as shown. Draw

an intersecting horizontal line on the header wall 4" (10.2 cm)

above the high point. This height will provide travel clearance

for the top edge of the door.

MOUNT THE OPERATOR

1. Position the operator on the floor below the header bracket.

2. Position the front idler assembly against the header bracket.

3. Align the bracket holes and join with hardware as shown.

4. Raise the operator to a horizontal position above the guide rails

and temporarily secure with a suitable rope, chain, or support

from the floor. Open door slowly, being careful not to dislodge

the temporary support. Using the door as a support, place a

level against the rail and shim the operator until it is horizontal.

Make sure that the operator is aligned with the center line of

the door.

4. Using the projected lines for location, mount a suitable wood

block or length of angle iron to the wall above the door

opening. Refer to the illustration below. This will provide a

mounting pad for the front header bracket of the operator. If

necessary reinforce the wall with suitable mounting brackets to

ensure adequate support of mounting pad. Using suitable

hardware, mount the (U-shaped) front header bracket to the

pad.

Carpenterʼs

Level

Door Travel

Projection

Header Wall

High Point

of Travel

Header Bracket

Nut

Bolt

Nut

Bolt

3.5"

4" Min.

(10.2 cm)

(8.9 cm)

Vertical Center Line of Door

Header Bracket Drill Pattern

1.75" (4.5 cm)

High Rise Point

Projection Line

Guide

Rails

Using the door as support, shim

operator to a horizontal position.

Operator Alignment

Page 7

7

To avoid possible SERIOUS INJURY from a falling operator,

fasten it SECURELY to structural supports of the garage.

Concrete anchors MUST be used if installing ANY brackets

into masonry.

WARNING

WARNING

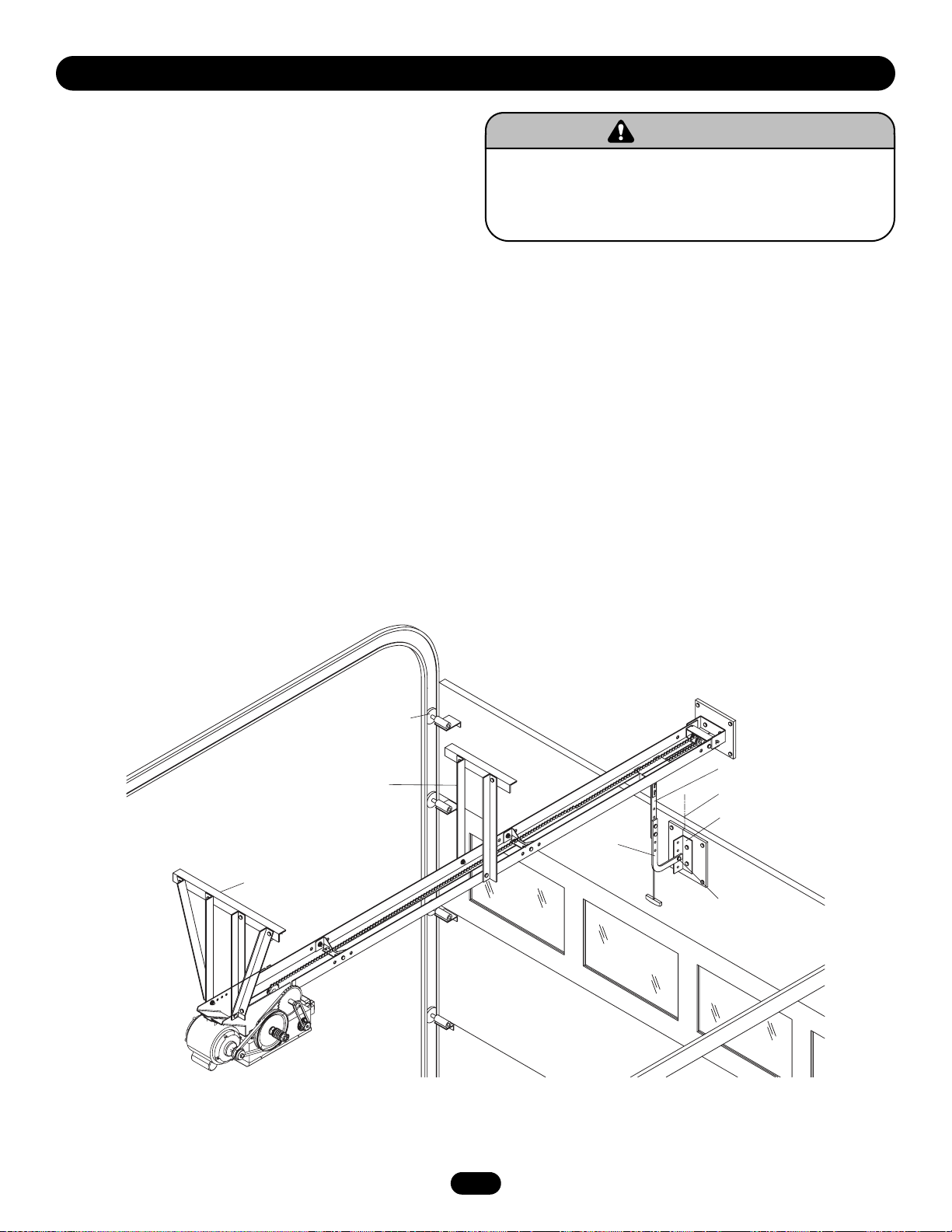

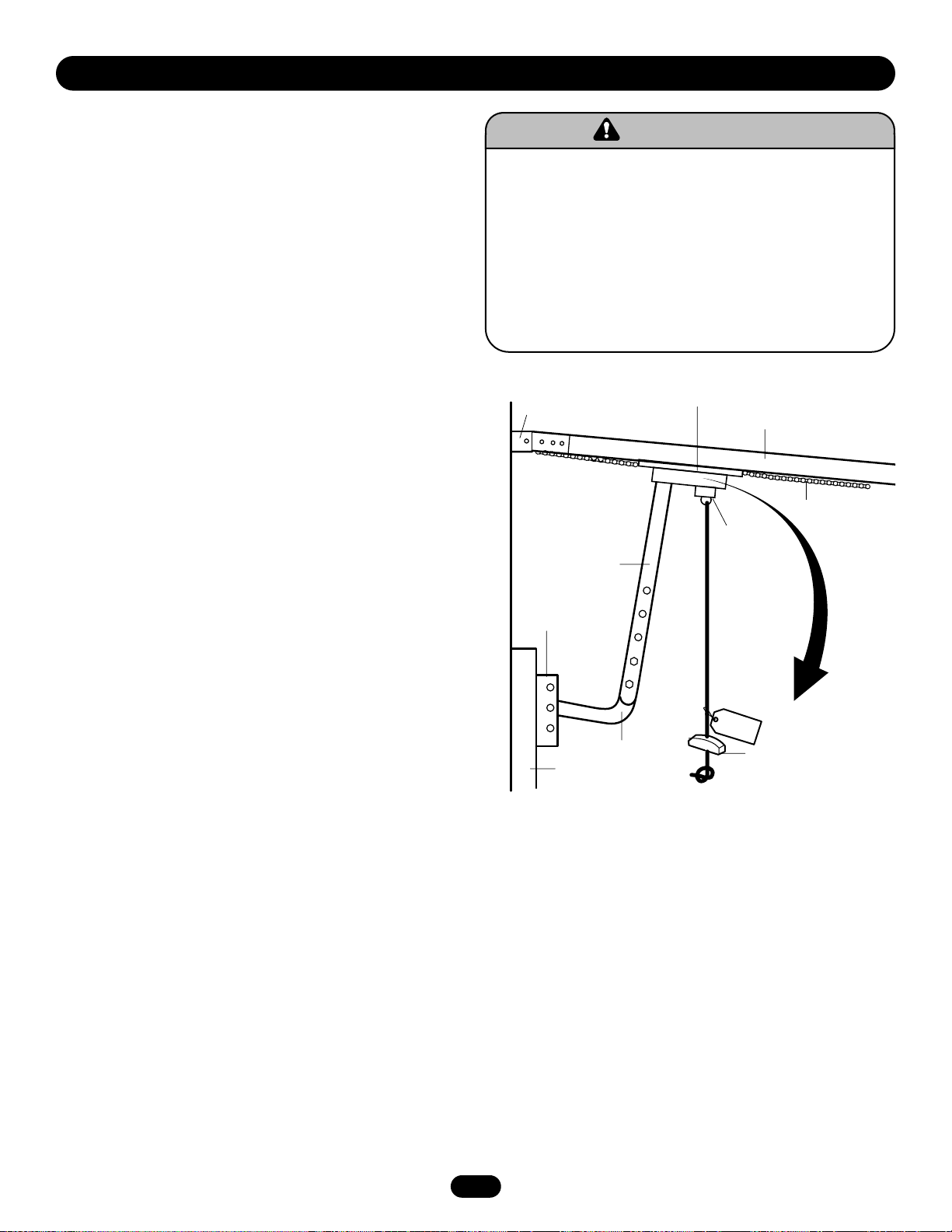

HANG THE OPERATOR

1. The illustration below shows a typical method of hanging the

operator from the ceiling. Each installation may vary, but in all

cases side braces should be used for additional strength.

2. For mounting of the support brace(s) to the powerhead. Four

holes (clearance up to 3/8" bolts) are located on each side of

frame.

3. Check to make sure the track is centered over the door (or in

line with the header bracket if the bracket is not centered above

the door).

NOTE: If the operator is longer than 15' (4.57 m) use of a

mid-span support is recommended.

STRAIGHT ARM ATTACHMENT

1. Fully close the door and move the trolley slider to within 2"

(5.08 cm) of the front idler.

2. Attach straight door arm to the fixed roll pin in the trolley

carriage.

3. Attach the door bracket to the door arm using the 3/8"-16 x 1"

bolt and nylon locking nut provided. Leave the nut and bolt

loose enough to allow the two pieces to pivot freely.

4. Using 3/8" hardware provided, bolt the curved door arm to the

straight arm, aligning the mounting holes in such a way that

the door bracket pivot bolt will be in line with the top rollers on

the door.

5. Position the door bracket to the center line on the door. Using

suitable hardware, attach the door bracket to the door. Many

installations, except solid wood doors, will require additional

support for the door. Refer to the illustration below.

NOTE: At this time, ensure all bolts and lag screws are properly

secured.

INSTALLATION

Mid-Span Support Brace

Powerhead Support Brace

Top Roller

Straight Arm

Vertical Centerline

of Door

Door Bracket

Curved

Door Arm

Pivot Bolt

Page 8

8

ENTRAPMENT PROTECTION ACCESSORIES

(OPTIONAL)

PHOTO EYES & SENSING EDGES

Sensing devices provided for door industry type operators with an

isolated normally open (N.O.) dry contact output are compatible

with your operator. This includes pneumatic and electric edges,

and through beam and retro reflective photo eyes. If you would

like to order or receive more information on safety devices, please

contact your local Authorized Dealer.

If not pre-installed by the door manufacturer, mount the sensing

edge on the door according to the instructions provided with the

edge. The sensing edge may be electrically connected by either

coiled cord or take-up reel.

Important Notes:

a. Proceed with Limit Switch Adjustments described below before

making any sensing edge wiring connections to operator.

b. Electrician must hardwire the junction box to the operator

electrical box in accordance with local codes.

WIRING

For wiring of your sensing device to the operator, refer to the

wiring diagram provided on page 14. See field connection

terminals identified as Reversing Device.

TAKE-UP REEL

Take-up reel should be installed 12" (30.48 cm) above the top of

the door.

COIL CORD

Connect operator end of coil cord to junction box (not provided)

fastened to the wall approximately halfway up the door opening.

ADJUSTMENT

To avoid SERIOUS PERSONAL INJURY or DEATH from

electrocution, disconnect electric power BEFORE manually

moving limit nuts.

WARNING

WARNING

LIMIT SWITCH ADJUSTMENT

NOTE: Make sure the limit nuts are positioned between the limit

switches before proceeding with adjustments.

1. Depress retaining plate to allow nut to spin freely. After

adjustment, release plate and move nut back and forth to

ensure it is fully seated in slot.

2. To increase door travel, spin nut away from limit switch. To

decrease door travel, spin limit nut toward limit switch.

3. Adjust open limit nut so that door will stop in open position

with the bottom of the door even with top of door opening.

4. Repeat steps 1 and 2 for close cycle. Adjust close limit nut so

that the limit switch is engaged as door fully seats at the floor.

INSTALLATION

To reduce the risk of SEVERE INJURY or DEATH, ALWAYS

install reversing sensors when the 3-button control station is

out of sight of door or ANY other control (automatic or manual)

is used. Reversing devices are recommended for ALL

installations.

WARNING

WARNING

CLOSE OPEN

SAFETY

(Aux. Close) Limit Switch

CLOSE Limit Switch

OPEN Limit Switch

Page 9

9

To prevent possible SERIOUS INJURY or DEATH from a falling

door or arm:

• DO NOT stand under the door arm when pulling the

emergency release.

• If possible, use emergency release handle to disengage

trolley ONLY when door is CLOSED. Weak or broken springs

or unbalanced door could result in an open door falling

rapidly and/or unexpectedly.

• NEVER use emergency release handle unless doorway is

clear of persons and obstructions.

WARNING

WARNING

EMERGENCY DISCONNECT SYSTEM

ADJUSTMENT

TO DISCONNECT DOOR FROM OPERATOR

The door should be in the fully closed position, if possible. Pull

down on the emergency release handle and raise or lower the

door manually.

TO RECONNECT DOOR ARM TO TROLLEY

The trolley will reconnect on the next UP or DOWN operation,

either manually or by using the door control or remote.

Header

Bracket

Straight

Door Arm

Assembly

Door

Bracket

Trolley

Track

Chain

Emergency

Disconnect

NO EC

T

I

Emergency

Release

Handle

Door

Curved

Door Arm

Page 10

10

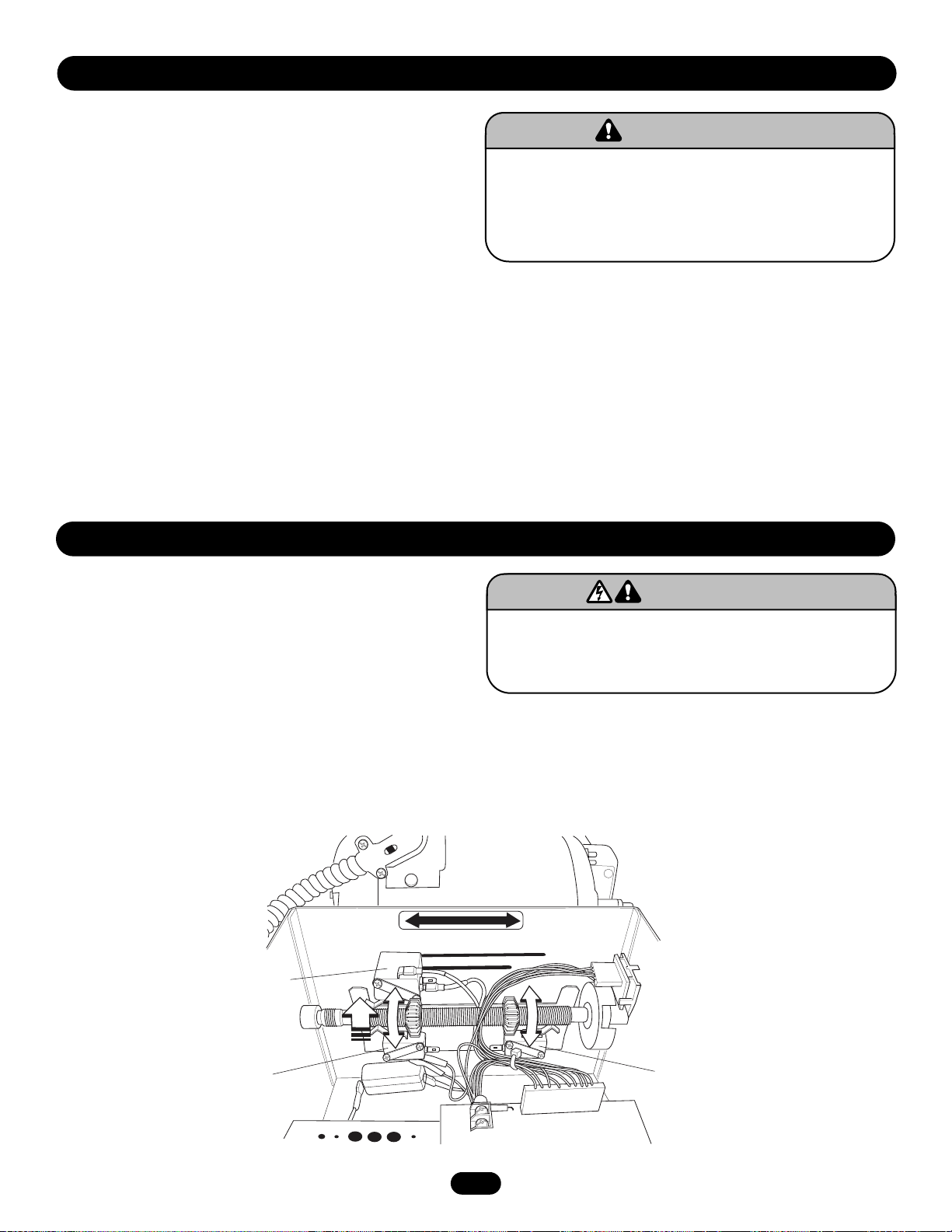

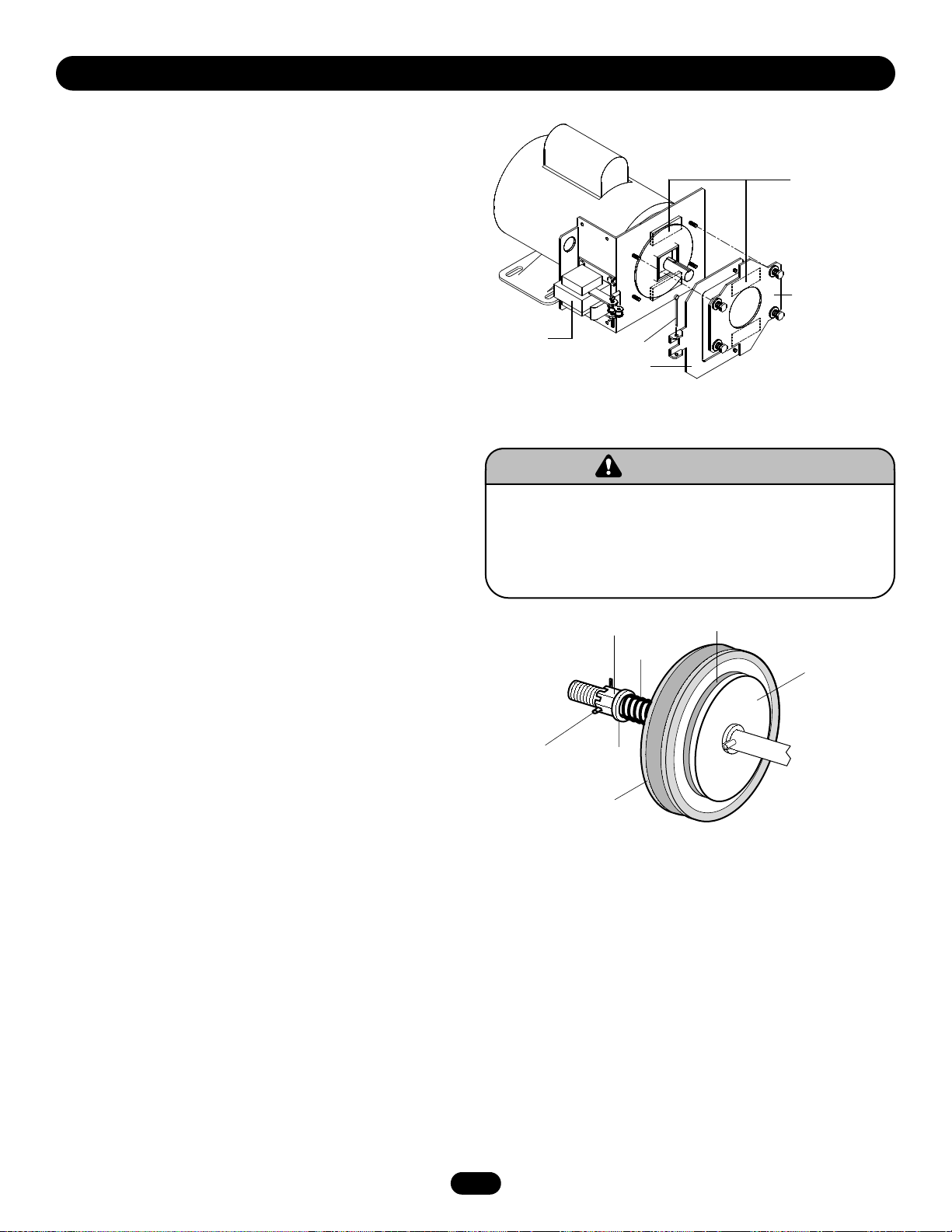

BRAKE ADJUSTMENT

The solenoid brake is adjusted at the factory and should not need

additional adjustment for the life of the brake assembly.

Replace brake assembly when necessary. Refer to the illustration

for identification of components for the solenoid type brake

system.

CLUTCH ADJUSTMENT AND

AUXILIARY REVERSAL SYSTEM

The Auxiliary Reversal System is designed to protect the door

and motorized operator. It is NOT a substitute for a safety sensing

device. The Auxiliary Reversal System works in tandem with the

adjustable clutch to detect if a closing door runs into or comes

across an obstruction. If an obstruction is met and causes the

clutch to slip, the Auxiliary Reversal System will return the door

to the full open position when closing or stops the door when

opening.

1. Remove cotterpin from nut on the clutch shaft.

2. Back off clutch nut until there is very little tension on the

clutch spring.

3. Tighten clutch nut gradually until there is just enough tension

to permit the operator to move the door smoothly but to allow

the clutch to slip if the door is obstructed. When the clutch is

properly adjusted, it should generally be possible to stop the

door by hand during travel.

4. Reinstall cotterpin.

ADJUSTMENT

To prevent possible SERIOUS INJURY or DEATH, install

reversing sensors when the 3-button control station is out of

sight of the door or ANY other control (automatic or manual) is

used. Reversing devices are recommended for ALL

installations.

WARNING

WARNING

Brake Assembly

Brake

Plate Assembly

Solenoid

Cotterpin

Release Lever

Clutch Pad

Clutch Plate

Cotterpin

Adjusting Nut

Spring

Washer

Clutch Pulley

Page 11

11

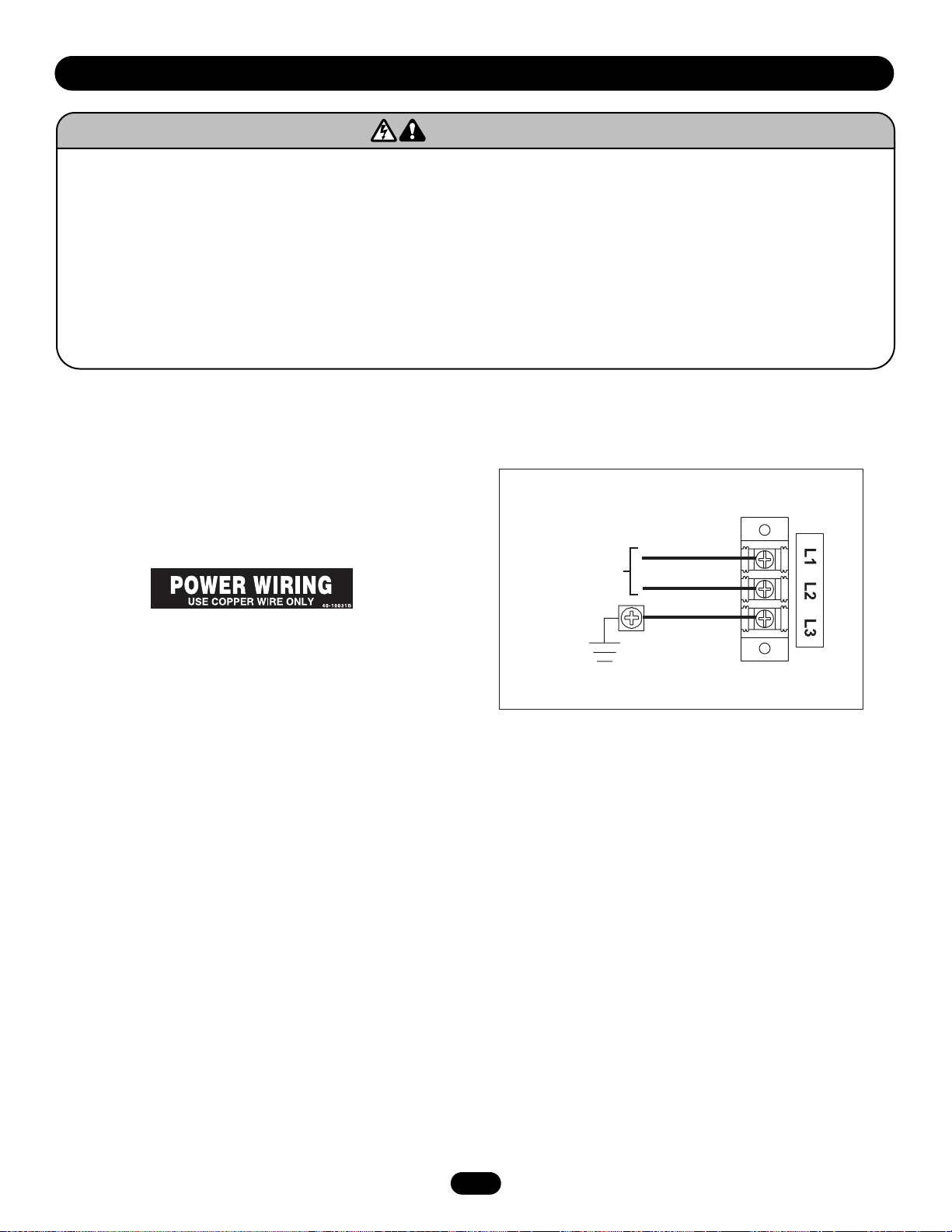

POWER WIRING & GROUND WIRING

GROUND WIRING CONNECTIONS

1. Connect earth ground to the chassis ground screw in the

electrical box enclosure.

2. Use same conduit entry into the electrical box as the power

wiring.

IMPORTANT NOTE: This unit must be properly grounded. Failure

to properly ground this unit could result in electric shock and

serious injury.

POWER WIRING CONNECTIONS

1. Connect power wires coming from the main to the captive

terminal block in the electrical box enclosure marked with the

label. All power and control wiring must be run in separate

conduit in accordance with local electrical codes.

2. Be sure to run all power wires through the conduit hole in the

electrical box enclosure marked with the label shown below.

NOTE: Must use #14 AWG or thicker wire for power wiring.

To reduce the risk of SEVERE INJURY or DEATH:

• ANY maintenance to the operator or in the area near the

operator MUST NOT be performed until disconnecting the

electrical power and locking-out the power via the operator

power switch. Upon completion of maintenance the area MUST

be cleared and secured, at that time the unit may be returned

to service.

• Disconnect power at the fuse box BEFORE proceeding.

Operator MUST be properly grounded and connected in

accordance with local electrical codes. The operator should be

on a separate fused line of adequate capacity.

• ALL electrical connections MUST be made by a qualified

individual.

• DO NOT install ANY wiring or attempt to run the operator

without consulting the wiring diagram. We recommend that

you install an optional reversing edge BEFORE proceeding with

the control station installation.

• ALL power wiring should be on a dedicated circuit and well

protected. The location of the power disconnect should be

visible and clearly labeled.

• ALL power and control wiring MUST be run in separate

conduit.

WARNING

WARNING

Single Phase Power Wiring

Line Power

115/230 Vac

Single Phase

Hot

Neutral

Gnd

Page 12

12

CONTROL WIRING CONNECTIONS

1. Connect control wires to the P1 terminal block located on the

logic board as shown.

2. Connect conduit with all control wires through the conduit

hole in the electrical box enclosure marked with the label

shown below.

3. Apply power to the operator. Press OPEN push button and

observe direction of door travel and then Press the STOP

button.

If door did not move in the correct direction, check for improper

wiring at the control station or between operator and control

station. NOTE: In “Diag” mode the 3-button control station can be

tested to verify correct wiring of Open, Close and Stop buttons

without moving the door.

If the door moves in the wrong direction and or the limits move

in the wrong direction, simply move the motor direction jumper

located on the logic board from the factory default setting (STD)

to the (REV) pins. This will change the motor rotation as well as

the functional position of the OPEN and CLOSE limit switch’s.

Then relocate the safety limit switch (SLS) only to the opposite

side with the new functional close limit location. Orient the arm

(lever) of the limit switch away from the center.

EXTERNAL RADIO WIRING CONNECTIONS

On all models a radio terminal bracket marked R1 R2 R3 is

located on the outside of the electrical enclosure. In B2 mode the

operator will then open a fully closed door, close a fully open

door, stop an opening door, and reverse a closing door from the

radio remote. In TS control wiring the operator will only open the

door or reset the timer to close. However, for additional door

control from a 3-button remote, a commercial three-channel radio

receiver (with connections for OPEN/CLOSE/STOP) is

recommended.

NOTE: If an external radio receiver is being used in place of the

built-in receiver, remove or disconnect the coaxial cable from the

logic board.

MOUNTING INSTRUCTIONS

1. Mount WARNING NOTICE beside or below the control station.

2. Mount MAINTENANCE ALERT label to either side of control

station.

3. Mount control station(s) within line of sight of door(s).

CONTROL STATION WIRING AND INSTALLATION

CONTROL WIRING

USE COPPER WIRE ONLY

40-10032B

To prevent possible SERIOUS INJURY or DEATH, install

reversing sensors when the 3-button control station is out of

sight of the door or ANY other control (automatic or manual) is

used. Reversing devices are recommended for ALL installations.

WARNING

WARNING

4'

Approximate

Control

Station

Optional

Controls

T

D

S

O

24 VOLT AC

24 VOLT AC

TIMER DEFEAT

COMMON

MAINTENANCE ALERT SYSTEM

PHOTO EYES (LiftMaster Only)

REVERSE

OPEN

CLOSE

STOP

COMMON

INTERLOCK

INTERLOCK

SINGLE BUTTON CONTROL

24V

AC

14

24V

AC

TIMER

DEFEAT

CMN

MAS

EYES

EDGE

OPEN

CLOSE

STOP

CMN

SBC

13

12

11

10

9

8

7

6

5

4

3

2

1

C18

DEFEAT

MAS

PEN

LOSE

TOP

OG

D1 E2

ILSAFE

R31

C3

D8

Ø

P1

POWER

TIMER

R8

4

EYES

EDGE

S

IAG

Ø

U7

D31

D7

D6

D5

D4C25

C17

24V

AC

14

24V

AC

D19

D17

D28

D23

D15

D2

Ø

D21

D13

SBC

)

D14

13

TIMER

12

DEFEAT

11

CMN

10

MAS

9

EYES

8

EDGE

7

OPEN

6

CLOSE

5

STOP

4

CMN

3

2

1

SBC

P1

F1

D34

OR IN THE AREA NEAR THE OPERATOR MUST

NOT BE PERFORMED UNTIL DISCONNECTING

THE ELECTRICAL POWER AND LOCKING-OUT

THE POWER VIA, THE MAIN DISCONNECT

SWITCH. UPON COMPLETION OF

MAINTENANCE THE AREA MUST BE CLEARED

AND SECURED, AT THAT TIME THE UNIT MAY

BE RETURNED TO SERVICE.

Maintenance

Alert System

If light is Flashing

Rapidly, it is time

for routine door

maintenance.

If light is Flashing

Slowly, followed

by a pause, call for

immediate service.

Service every

cycles/months

TM

Page 13

13

STANDARD POWER & CONTROL CONNECTION DIAGRAMS

Open

Close

Stop

Maintenance

Alert LED

Open/Close

Single Button

(WH)(RD)

Sensing Edge

CPS-L &

CPS-LN4

Timer Defeat

Switch

R1

R2

R3

Radio Control

(24V DC only)

Remove Jumper

To Install External

Interlock

3-Button

Station

OPEN

CLOSE

STOP

Line Power

115 Vac

Single Phase

Single Phase Power Wiring

Hot

Neutral

Gnd

Page 14

14

LOGIC (VER. 3.0) 1 PHASE WIRING DIAGRAM

OPEN

115V MOTOR CONNECTION 230V MOTOR CONNECTION

NOTE: Gray (GY) and purple (PU) motor wires are reversed

for H and HJ right hand models and all GH and J models.

CPS-L & CPS-LN4

Hoist Interlock

When Present

Ø

C3

R31

D8

657–A

Ø

14GP

Ø

657–A

Ø

14LG

Ø

P4

D31

D7D6D5

U7

C18

R29

E1

(YE) (BL)

2

Ø

D3

C11

D4C25

C17

Ø

P1

X1

TMR DEF

SWITCH

14

24VAC24V

POWER

U1

K3

Maintenance

CLOSE

Alert LED

(RD) (WH)

STOP

Open

3-Button

Sensing

Close

Station

Edge

Stop

Open/Close

Single Button

Remove Jumper

To Install External

9

8

7

6

5

4

3

11

13

12

TIMER

AC

DEFEAT

D19

TIMER

DEFEAT

ØØ

J3

J1

10

MAS

CMN

D17

R8

D25

OLS

EYES

EDGE

OPEN

CLOSE

D23

D15

4

D16

EYES

DIRECTION

MOTOR

D27

CLS

D1

TIMER

MID

MRT

P7

EDGE

OPEN

D22

D2ØD21

TIMER

ENABLE

3

2

D36

1RADIO

CLOSE

RELAY A

D28

MAS

D24

D26

MID

SLS

CMN

STOP

D13

STOP

TTS

RELAY B

D35

C77

C73

2

SBC

FSTSE2

D1 DIAG

C2

C54

L1

C71

C78

®

1

SBC

D14

)

B2 C2 D1 E2

NON FAILSAFE

(

S8

B2 PROG

FAILSAFE

L5

Door Interlock

F1

P1

D34

(YE)

(OR)

(WH)

(YE)

(PU)

(WH)

(RD)

(GY)

(YE)

(RD)

(WH)

(PU)

(YE)

(OR)

(GY)

P6

hot

neutral

ground

115 / 230

VOLT 1PH.

POWER IN

(YE)

NOTE: Lock Sensor is provided on Models

DJ and DH only, red wire from main harness

connects to NC on Bypass L/S and to NO on

Lock Sensor switch. White wires connect the

COM on Bypass L/S and Lock Sensor switch to

NC on Open L/S.

L3 L2 L1

(WH)

MOV

MOV

(WH)

COM

+24 VAC -24 VAC

(WH)

COM

OPEN L/S

COM

BYPASS

L/S

LOCK

SENSOR

(see note at left)

(GY)

(YE)

(WH)

(WH)

(WH)

8

(WH)

(WH)

6

(WH)

(YE)

(OR)

(PU)

(PU)

01

A

8

4

6

2

(BL) (GY)

See Motor

Connections

(YE)

(WH)

(OR)

R1 R2 R3

Radio

(BK)

(BR)

See Motor

Connections

(WH)

(WH)

01

B

4

(PU)

(WH)

(WH)

(YE)

NO

NC

NO

NC

120

VAC

(WH)

(RD)

(RD)

120 / 240

VAC

(WH)

(RD)

NO

NC

COM

NO

CLOSE L/S

NC

NC

SAFETY L/S

NO

COM

NO

COM

COIL

2

C

(GY)

(RD)

(YE)

(WH)

1 2 3 4

RPM Board

Page 15

15

CONTROL BOARD

Auxilliary Board

Connectors

Programmed Chip

Maximum Run

Timer Button

Radio Learn

Button

Mid Stop Learn

Button

Timer to Close

Learn Button

C11

Ø

14LGØ657–A Ø14GPØ657–A

P4

E1

R29

D3

Ø

2

U1

K3

OLS

MID

SLS

D16

P7

C73

CLS

MRT

1RADIO

C77

MID2TIMER

D36

D35

C54

X1

D25

D24

D26

D27

RELAY A

RELAY B

J1

REV

STD

MOTOR

DIRECTION

TIMER

3

ENABLE

TTS

J3

ØØ

CONTACTOR/3 PH

D22

D8

C18

P1

Ø

C17

POWER

D19

TIMER

DEFEAT

D17

R8

D28

MAS

D23

4

SINGLE PHASE

EYES

EDGE

OPEN

CLOSE

STOP

D15

D2

D21

D13

Ø

D1

FSTSE2

D1 DIAG

C71

L1

C2

L5

P6

B2 PROG

FAILSAFE

S8

(

B2 C2 D1 E2

NON FAILSAFE

SBC

)

D14

D34

C78

®

R31

Ø

C3

U7

D31

D7

D6

D5

D4C25

24V

AC

14

Motor Direction

Jumper

Single Phase &

Three Phase Jumper

24V

AC

13

TIMER

DEFEAT

12

Maintenance Alert

System Button for

Programming

CMN

11

MAS

10

EYES

EDGE

OPEN

CLOSE

STOP

CMN

9

8

7

6

5

4

3

Open Button

Close Button

Stop Button

Control Wiring

Terminal Block

2

SBC

P1

1

F1

Wiring Type

Selector Dial

Failsafe Switch

Page 16

16

PROGRAMMING

DETERMINE AND SET WIRING TYPE

Read the descriptions of the different wiring types to determine

which setting will be correct for each application.

SET THE SELECTOR DIAL TO THE DESIRED WIRING MODE:

NOTE: For failsafe wiring you must also set failsafe switch to

FAILSAFE.

TYPE

C2 Momentary contact to open and stop with constant

pressure to close, open override plus wiring for sensing

device to reverse. Programmable mid stop available with

this wiring type. Compatible with 3-Button Station and

1-Button Station.

B2 Momentary contact to open, close and stop, plus wiring

for sensing device to reverse and auxiliary devices to

open and close with open override. Programmable mid

stop available with this wiring type. Compatible with

3-Button Station, 1-Button Station and 1 & 3 Button

Remote Control.

D1 Constant pressure to open and close with wiring for

sensing device to stop. Compatible with 2-Button

Station.

E2 Momentary contact to open with override and constant

pressure to close. Release of close button will cause

door to reverse (roll-back feature) plus wiring for

sensing device to reverse. Compatible with 3-Button

Station.

SELECTOR DIAL

FAILSAFE SWITCH

LOGIC CONTROL PUSHBUTTONS OPEN, CLOSE, STOP

Open, Close and Stop buttons are mounted directly on the logic

board. Thus, making it easy to program as well as have door

control at the electrical box. Either the stop control or a jumper

must be wired between terminals 4 and 5 for the on board push

buttons to function.

NOTE: Refer to logic board illustration on page 15 for all

component locations. Before programming the logic board, set

the operators open and close limits. LEDs on the logic board are

provided to assist setting the limits. As each limit is activated the

corresponding LED will light up. The abbreviations are Open

Limit Switch (OLS), Close Limit Switch (CLS) and Sensing Limit

Switch (SLS). Refer to page 8 for limit switch adjustment

instructions.

Page 17

17

FAILSAFE WIRING TYPES

TYPE

TS Momentary contact to open, close, and stop with

open override and Timer To Close. Every device that

causes door to open, including a reversing device,

activates the Timer To Close. Auxiliary controls can

be connected to open input to activate the Timer To

Close. If the timer has been activated, the open

button and radio control can recycle the timer. The

stop button will deactivate the Timer To Close until

the next command input. The Timer To Close will

function from the programmable mid stop with this

wiring type. Compatible with 3-Button Station,

1-Button Station and 1 & 3 Button Remote Control.

(NOTE: Requires Optional self monitoring photo

eyes to operate.)

T Momentary contact to open, close, and stop, with

open override and Timer To Close. Every device that

causes the door to open, except a reversing device,

activates the Timer To Close. Auxiliary controls can

be connected to open input to activate the Timer To

Close. If the Timer To Close has been activated, the

open button and radio control can recycle the timer.

The stop button will deactivate the timer until the

next command input. The Timer to Close will

function from the programmable mid stop with this

wiring type. Compatible with 3-Button Station,

1-Button Station and 1 & 3 Button Remote Control.

(NOTE: Requires Optional self monitoring photo

eyes to operate.)

FSTS Momentary button contact for open, close and stop

programming. Radio controls allowing open, close

and stop. User set mid stop. User set Timer To

Close. The single button station opens the door to

the full open limit bypassing the mid stop and

activates the Timer To Close, putting the operator in

TS mode until the door reaches the down limit, or

is stopped in travel. At which time the operator

enters the B2 mode. Compatible with 3-Button

Station, 1-Button Station, 1 & 3 Button Remote

Control. (NOTE: Requires Optional self monitoring

photo eyes to operate this feature/wire type.)

C2 Failsafe Same functions as C2. Self Monitoring safety device

must be installed to operate door for each of the

following failsafe wiring types. See Self Monitoring

Safety Device Options. Compatible with 3-Button

Station, 1-Button Station, 1 & 3 Button Remote

Control.

PROGRAMMING

SELF-MONITORING SAFETY DEVICE OPTIONS

To use the operator in any of the Failsafe wiring modes, or Timer

To Close wiring modes (TS, T, FSTS), a self monitoring safety

device or CPS3 card with photo eyes or safety edges must be

installed.

RECOMMENDED SELF-MONITORING SAFETY DEVICES:

CPS-L NEMA 1 Direct Connect Eyes

CPS-LN4 NEMA 4 Direct Connect Eyes

IMPORTANT NOTES:

1. External interlocks may be used with all functional modes.

2. Auxiliary devices are any devices that have only dry contacts.

Examples: photocell, loop detector, pneumatic or electrical

treadles, radio controls, one button stations, pull cords, etc.

3. Open override means that the door may be reversed while

closing by activating an opening device without the need to use

the stop button first.

B2 Failsafe Same functions as B2. Self Monitoring safety

device must be installed to operate door for each of

the following failsafe wiring types. See Self

Monitoring Safety Device Options. Compatible with

3-Button Station, 1-Button Station and 1 & 3

Button Remote Control.

D1 Failsafe Same functions as D1. Self Monitoring safety

device must be installed to operate door for each

of the following failsafe wiring types. See Self

Monitoring Safety Device Options. Compatible with

2-Button Station and 2-Button Remote.

E2 Failsafe Same functions as E2. Self Monitoring safety device

must be installed to operate door for each of the

following failsafe wiring types. See Self Monitoring

Safety Device Options. Compatible with 3-Button

Station and 3-Button Remote.

Page 18

18

SINGLE BUTTON CONTROL (SBC) REMOTE

This function programs a remote as a wireless single button

control. In B2 mode, operation is OPEN / STOP / CLOSE /

REVERSE / STOP. In C2 mode, operation is OPEN / STOP/

Constant pressure to CLOSE / STOP on release. There is no

operation in D1 mode. In T and TS modes, operation is OPEN /

STOP / CLOSE / REVERSE / STOP and Timer to Close

start/refresh. In FSTS mode, operation is OPEN with Timer to

Close start/refresh only bypassing all up mid stops. Momentary

and constant pressure commands are processed in this function.

1. Press and release the RADIO button on the logic board (LED

will light).

2. Press and release the SBC externally wired button or TIMER on

the logic board (LED flashes rapidly and then remains on

solid).

3. Press and hold the remote button until the LED flashes rapidly.

The LED will then remain on solid after releasing.

4. Press and release the RADIO button on the logic board (LED

flashes rapidly and then turns off). The programming mode is

exited if no activity is performed within 30 seconds.

ERASING REMOTES

Press and hold the RADIO button on the logic board until the

RADIO LED flashes rapidly (approximately 5 seconds).

All remotes will be erased.

Built in 3-channel, 315MHz radio receiver allows you to add as

many as 23 Security✚®remotes or dip switch remote controls.

PROGRAMMING REMOTES

STANDARD SINGLE BUTTON REMOTE

1. To enter programming press and release the RADIO button on

the logic board (LED will light).

2. Press and hold the remote button until the LED flashes rapidly,

then release remote button. The LED will then remain on solid

after releasing the button. Repeat to add additional remote(s).

3. Press and release the RADIO button to complete the

programming. The programming mode is exited if no activity is

performed within 30 seconds.

NOTE: Single button remote is not supported with D1 and E2

failsafe wiring modes.

NOTE: Requires self-monitoring photo eyes when using constant

pressure to close (wiring C2, D1 and E2 ).

OPERATION

MODE

B2

C2

D1

E2

T, TS

FSTS

OPEN STOP CLOSE Reverse

Constant

Pressure

Timer To

Close

PROGRAMMING

L

i

f

t

M

a

s

t

e

r

U1

MRT

1RADIO

MID2TIM

E2

RELAY

RELAY

D1

C2

B2

OLS

MID

SLS

MOTOR

REV

CLS

D25

D24

D26

D27

D36

C77

C73

C54

C78

L1

L5

P6

D35

D16

P7

K3

FAILSAFE

X1

E1

R29

C11

D3

Ø

2

P4

Ø

14LGØ65

C71

®

RADIO

NOTICE: To comply with FCC and or Industry Canada (IC) rules, adjustment or modifications of this

receiver and/or transmitter are prohibited, except for changing the code setting or replacing the

battery. THERE ARE NO OTHER USER SERVICEABLE PARTS.

Tested to Comply with FCC Standards FOR HOME OR OFFICE USE. Operation is subject to the

following two conditions: (1) this device may not cause harmful interference, and (2) this device

must accept any interference received, including interference that may cause undesired operation.

To prevent possible SERIOUS INJURY or DEATH, install

reversing sensors when the 3-button control station is out of

sight of the door or ANY other control (automatic or manual) is

used. Reversing devices are recommended for ALL installations.

WARNING

WARNING

Page 19

19

OPEN

CLOSE

STOP

Open

Close

Stop

U1

POWER

TIMER

DEFEAT

MAS

4

MRT

1RADIO

MID2TIMER

TIMER

ENABLE

TTS

FSTSE2

RELAY A

RELAY B

D1 DIAG

C2

B2 PROG

3

24V

AC

24V

AC

TIMER

DEFEAT

CMN

MAS

EYES

EDGE

OPEN

CLOSE

STOP

CMN

SBC

11

10

9

14

13

12

8

7

6

5

4

3

2

1

CLOSE

STOP

OPEN

EDGE

OLS

MID

SLS

MOTOR

DIRECTION

REV

STD

CLS

D25

D24

D26

D27

D36

C77

C73

C54

C78

L1

L5

P6

D35

S8

D16

P7

EYES

K3

P1

D34

F1

FAILSAFE

(

B2 C2 D1 E2

)

NON FAILSAFE

D23

D15

D1

D22

R8

J1

X1

E1

R29

C18

D8

U7

R31

D31

C3

Ø

D7

D6

D5

D4C25

C17

C11

D3

Ø

2

P1

Ø

P4

Ø

14LGØ657–A Ø14GPØ657–A

J3

ØØ

D2

Ø

D21

D13

D14

D28

D17

D19

CONTACTOR/3 PH

SINGLE PHASE

SBC

C71

®

CLOSE

STOP

OPEN

EDGE

D1

D22

D2

Ø

D21

D13

Your 315MHz Security✚

®

or dip switch remote control can be

programmed to operate as a 3-button wireless control station:

the large button will open the door, the middle button will close

the door, and the third button will stop the door’s movement.

You may set up this feature as follows:

1. To enter programming press the RADIO button on the logic

board (the RADIO LED will light).

2. To program the OPEN button to a remote control press the

OPEN button on the logic board. The RADIO LED will flash and

then stay on solid. Then press the corresponding button on the

remote control. The RADIO LED on the logic board will flash,

this confirms that the remote control has been programmed.

(By programming the remote you use 1 channel of the 23

channels on the radio receiver.)

3. To program the CLOSE button to a remote control press the

CLOSE button on the logic board. The RADIO LED will flash

and then stay on solid. Then press the corresponding button

on the remote control. The RADIO LED on the logic board will

flash, this confirms that the remote control has been

programmed. (By programming the remote you use 1 channel

of the 23 channels on the radio receiver.)

PROGRAMMING

4. To program the STOP button to a remote control press the

STOP button on the logic board. The RADIO LED will flash and

then stay on solid. Then press the corresponding button on the

remote control. The RADIO LED on the logic board will flash,

this confirms that the remote control has been programmed.

(By programming the remote you use 1 channel of the 23

channels on the radio receiver.)

5. After learning remote controls press the RADIO button on the

logic board (LED will turn off). NOTE: If no activity within 30

seconds the radio will automatically exit programming mode.

Page 20

20

PROGRAMMING

MAINTENANCE ALERT SYSTEM (MAS)

Feature: An internal cycle counter will activate a flashing LED on

the 3-button control station when the preset number of cycles or

months has elapsed (whichever occurs first). Setting this feature

is optional. By default this feature will never activate. Logic 3.0

operators incorporate a self diagnostic feature built into the MAS

LED. In addition to indicating when routine maintenance is due,

the MAS LED can be used to troubleshoot some problems with

the operator.

Benefit: The Maintenance Alert System (MAS) assists the

installing dealer in setting up a routine maintenance program.

Once programmed, the MAS notifies the end user (with a flashing

LED on the 3-button station) when a preset number of

cycles/months has elapsed and scheduled maintenance is due.

To Program:

1. The Maintenance Alert System (MAS) assists the installing

dealer in setting up a routine maintenance program. Once

programmed, the MAS notifies the end user (with a flashing

LED on the 3-button station) when a preset number of

cycles/months has elapsed and scheduled maintenance is due.

2. Close the door.

3. Turn the selector dial to PROGRAM.

4. Press and release the MAS SET button.

5. Press the STOP button once to clear the MAS counter.

6. Press the OPEN button once for every 5,000 cycles

increments. Press the CLOSE button once for every 3 month

increments. Press the STOP button once to clear the MAS

memory.

7. Press the MAS SET button to complete the programming. The

on board LED will flash back the programmed settings. The

OPEN LED will flash once for every 5,000 cycles. The CLOSE

LED will flash once for every 3 months.

8. Turn the selector dial back to the desired wiring type.

NOTE: If MAS LED flashes 2 or more flashes in a row followed by

a pause, an operator error occurred. Turn to page 27 to diagnose

problem.

Example: A door is installed with 30,000 cycle springs and has

an annual service contract. To set the MAS, turn selector dial to

PROGRAM, press MAS button, press the STOP button to clear

the memory and then press the OPEN button 6 times (30,000

cycles) and close 4 times (12 months). Press the MAS again to

complete the programming. Set the selector dial to desired wiring

type.

Special Notes about MAS: A 5th wire must be run to the control

station to activate the MAS LED. The MAS LED on the logic board

is always enabled. When the operator is serviced after the MAS

LED has started to flash, repeat the setup procedure to program

in the number or cycles desired until the next service visit OR

press and hold the MAS button for 5 seconds in the PROGRAM

mode to reset the MAS with its current programmed value. To

disable the MAS, follow the programming procedure above and

press the STOP button to reset the counter to zero. Every time

the operator leaves the close limit is counted as one cycle.

To view how many cycles are programmed into the MAS, set the

Operation will vary

depending on

wiring type

SELECTOR DIAL

OPEN

CLOSE

STOP

Adds 5,000 cycles to Maintenance Alert System

Activation Counter.

Adds 3 Months to Maintenance Alert System

Activation Timer.

Clears memory, sets Maintenance Alert System

Activation Counter to 0 cycles and

0 months.

Press This To Get This

3-BUTTON STATION

Maintenance

Alert LED

selector dial to DIAGNOSTIC and press the MAS button. The

OPEN button LED will flash once for every 5,000 cycle increment

programmed and the CLOSE button LED will flash once for every

3 month increment programmed.

To view how many cycles have elapsed since the last time the

MAS was programmed, set the selector dial to “Diagnostic” and

press the “MAS” button. Press the OPEN button; the OPEN LED

will flash once for every 5,000 cycles that has elapsed. Press the

CLOSE button; the CLOSE LED will flash once for every (3)

months that has elapsed. Press the MAS button to exit.

OPEN

CLOSE

STOP

Page 21

21

Operation will vary

depending on

wiring type

SELECTOR DIAL

Operation will vary

depending on

wiring type

SELECTOR DIAL

PROGRAMMING

OPEN MID STOP

Feature: The mid stop feature is to open the door to a preset point

prior to the fully open position.

Benefit: The door opens to a midpoint between open and close

reducing heating and cooling costs. The door will not cycle fully,

providing longer door and operator life.

To Program:

1. Close the door.

2. Turn selector dial to “PROGRAM.”

3. Press the “MID SET” button on logic board.

4. Press the OPEN button, wait until the door reaches the desired

mid stop height, then press the STOP button.

5. Press the “MID SET” button to complete programming.

6. Turn selector dial back to desired wiring type.

NOTE: A momentary open command will open the door fully from the

“Mid Stop” position. Once at the “Mid Stop,” photo eyes and other

safety devices will not open the door beyond the mid stop position,

except in E2 mode. The Timer to Close will work from the Mid Stop.

To clear the Mid Stop set the selector dial to Program and press and

hold the MID SET button for 5 seconds. The MID SET LED will flash

rapidly and turn off once the Mid Stop has been cleared.

DOWN MID STOP

A new feature is the down mid stop which can be enabled with the

purchase of the red/green light kit (RDGRNCARD). See kit

instructions of how to enable this new feature.

TIMER TO CLOSE

Feature: Timer automatically closes door after preset time. All safety

devices must be unobstructed.

Benefit: The door will automatically close after pre set amount of

time. Great for apartment buildings, fire stations and other

applications where the end user wants the door to close

automatically after a specified amount of time.

Requirements: Must have at least one of the following safety

devices attached: CPS-L, CPS-LN4 or CPS3 card with valid safety

device. Wiring type must be set to TS, T or FSTS.

To Program Manually (Method 1):

1. Close the door.

2. Turn the selector dial to PROGRAM.

3. Press the TIMER button on the logic logic board.

4. Press the STOP button to clear the timer.

5. Press the OPEN button for every 5 seconds the operator should wait

before attempting to close the door. Press the CLOSE button for

every 60 seconds the operator should wait before closing the door.

6. Press the TIMER button to complete programming. The

OPEN/CLOSE button LEDs will flash to confirm the timer setting.

The OPEN LED will flash once for every 5 seconds programmed and

the CLOSE LED will flash once for every 60 seconds programmed.

7. Turn the selector dial to desired timer wiring type (TS ,T or FSTS).

Example: To close the door after 70 seconds. Turn selector dial to

Program, press the TIMER button, press the STOP button to clear the

timer, press the CLOSE button once for 60 seconds and press the

OPEN button twice for 10 seconds. Press the TIMER button to finish

programming the timer. Turn selector dial to desired timer wiring type.

(TS, T, FSTS).

To reduce the risk of SEVERE INJURY or DEATH, ALWAYS

install reversing sensors when the 3-button control station is

out of sight of door or ANY other control (automatic or manual)

is used. Reversing devices are recommended for ALL

installations.

WARNING

WARNING

Page 22

22

TIMER TO CLOSE

PROGRAM TIMER TO CLOSE BY EXAMPLE (Method 2):

To Program:

1. Close the door

2. Turn the selector dial to PROGRAM.

3. Press and hold TIMER button for 5 seconds until TIMER LED

flashes.

4. Press the OPEN button and wait for the door to reach full open or

mid stop position.

5. Wait for desired amount of time to pass. (An internal stop watch

starts counting when the door stops moving.)

6. Press the TIMER button or CLOSE button to stop the timer.

(TIMER SET LED will turn on.)

7. Turn the selector dial to the desired wiring type.

Example: The door should close 15 seconds after a truck enters a

garage. To program the Timer to Close, turn the selector dial to

PROGRAM, press the TIMER button until the TIMER LED blinks,

press the OPEN button and wait until the door reaches the open

position, wait for the truck to pass through, count 15 seconds and

then press the CLOSE button.

NOTES: To read back the Timer to Close setting, turn the selector

dial to Diagnostic and press the TIMER button. The OPEN LED will

flash once for every 5 seconds programmed and the CLOSE LED

will flash once for every 60 seconds programmed.

To deactivate the timer from the open position press the STOP

button. The timer will be reactivated on the next operation

command. To deactivate the timer for more than one cycle, attach a

switch to 11 & 12 (Common and Timer Defeat).

All timer modes require a supervised safety device to be installed.

Reminders: FSTS wiring mode allows the Timer to Close to be

activated by the Single Button Control (terminal 1) only. T wiring

mode allows the door to attempt to close only one time for safety

purposes.

Operation will vary

depending on

wiring type

SELECTOR DIAL

AUTOMATICALLY LEARNED PROGRAMMING

AUXILIARY REVERSAL SYSTEM / RPM SENSOR

Feature: This feature utilizes the RPM sensor connected to the

logic board to detect when the clutch slips and reverses the door

(clutch must be properly adjusted). In addition, the RPM

eliminates the need for a centrifugal switch on 1/3 and 1/2

horsepower single phase motors.

Benefit: The Auxiliary Reversal System reverses the operator

upon hitting an obstruction, preventing excessive door and

operator damage. We require the use of safety devices for

primary safety protection. By removing the centrifugal for 1/3 and

1/2 horsepower single phase motors, the leading cause of motor

failures is eliminated. (Auxiliary Reversal System not applicable

on models GH and GT.)

NOTE: This feature is automatically learned and does not require

programming.

PROGRAMMING

OSE OPEN

RPM Sensor

Logic Board

Page 23

23

MAXIMUM RUN TIMER (MRT)

Feature: The operator can learn the time it takes to open or close

the door plus and an additional 10 seconds.

Benefit: If the operator does not meet its open or close limit

within the set time it will stop, limiting damage to the door and

operator.

To Program:

NOTE: The default setting for the MRT is 90 seconds. In the event

the application requires the MRT be manually learned for a longer

duration follow steps below.

1. Start with the door in the closed position.

2. Set the selector dial to “PROGRAM.”

3. Press MRT button on logic board.

4. Press the OPEN button and wait for the door to reach the full

open limit.

5. Once the door has reached the open position, programming is

complete.

6. Turn dial to desired wiring type.

NOTE: To reset MRT only, turn selector dial to program and press

and hold the MRT button until the MAS led flashes rapidly.

Operation will vary

depending on

wiring type

SELECTOR DIAL

OPTIONAL PROGRAMMING

RED/GREEN WARNING LIGHT CARD

Feature: The Red/Green warning light card flashes a warning light

for 10 seconds prior to the Timer to Close activating the door to

close.

Benefit: Advanced warning of the door closing helps prevent

traffic collisions with the door.

Light Control Module Operation: The green lights on the OPTION

BOARD will turn on if the board is seated properly and the power

is on. When the door reaches the full open limit or mid stop the

timer circuit and the green lamp holder will be activated. (Green

lamp will not be activated if timer setting is less than 10

seconds.) The red lamp holder will receive power as indicated at

right.

Requirements: Must have the Red/Green warning light kit

RDGRNCARD and must have at least one of the following safety

devices attached: CPS-L, CPS-LN4 or CPS3. See Red/Green

warning light instructions for further details.

TIMER SETTING RED LAMP HOLDER RECEIVES POWER

Timer setting equals

zero

Activates when the door closes and until

close limit is activated

Greater than 10

seconds

10 seconds before door starts to close

and until close limit is activated

Less than or equal to

10 seconds

Activates when the door reaches the

open limit or mid stop

The red lamp holder receives power

when the door opens and remains

activated if the door is stopped manually

before reaching the mid stop or the open

limit

AUTOMATICALLY LEARNED PROGRAMMING

Page 24

24

RESETTING FACTORY DEFAULTS CLEARING MEMORY

To reset most of the user installed settings back to factory

defaults:

1. Turn the selector dial to DIAGNOSTIC.

2. Press and hold the STOP button for 5 seconds. The MAS LED

will flash momentarily when the factory defaults have been

restored.

3. Return the selector dial to the desired wiring type.

Factory Defaults:

a. Timer to close = 0 seconds

b. CPS-L photo eyes = unlearned

c. The Mid Stop is deactivated

d. The Maintenance Alert System is deactivated

e. The Maximum Run Timer is set to 90 seconds

Operation will vary

depending on

wiring type

SELECTOR DIAL

MAINTENANCE SCHEDULE

For use with Maintenance Alert System.

Check at the intervals listed in the following chart:

ITEM

Drive Chain

Sprockets

Clutch

Belt

Fasteners

Manual Disconnect

Bearings and Shafts

PROCEDURE

Check for excessive slack.

Check and adjust as required.

Lubricate.

Check set screw tightness.

Check and adjust as required.

Check condition and tension.

Check and tighten as required.

Check and operate.

Check for wear and lubricate.

EVERY 3 MONTHS

OR

5,000 CYCLES

"#

"

"#

EVERY 6 MONTHS

OR

10,000 CYCLES

"

"

"

"

EVERY 12 MONTHS

OR

20,000 CYCLES

$

$

$

$

$

HOW TO ORDER REPAIR PARTS

OUR LARGE SERVICE ORGANIZATION SPANS AMERICA

Installation and service information

are available 6 days a week.

Call our TOLL FREE number:

1-800-528-2806

Monday through Friday 5 a.m. to 6 p.m. (MST)

Saturday 7 a.m. to 3:30 p.m. (MST)

OPTIONAL PROGRAMMING

#

Use SAE 30 Oil (Never use grease or silicone spray).

• Do not lubricate motor. Motor bearings are rated for

continuous operation.

• Do not lubricate clutch or V-belt.

$

Repeat ALL procedures.

"

Inspect and service whenever a malfunction is observed or

suspected.

To avoid SERIOUS PERSONAL INJURY or DEATH from

electrocution, disconnect ALL electric power BEFORE

performing ANY maintenance.

WARNING

WARNING

Page 25

25

DIAGNOSTIC CHART

The logic board has several LEDs to assist in the installation and troubleshooting of the operator. The following chart should assist in

verifying the operator is functioning properly. Turn the selector dial to DIAGNOSTIC to keep the door from moving while

troubleshooting.

TROUBLESHOOTING

Power Green Indicates that power is being generated for the logic board.

Stop Green Indicates a closed circuit between common and terminal 5. Pressing stop should turn off this LED.

Open Yellow Indicates a closed circuit between common and terminal 7. Pressing the open button should turn

ON this LED.

Close Yellow Indicates a closed circuit between common and terminal 6. Pressing the close button should turn

ON this LED.

Eyes Green Solid on indicates photo eyes learned. Flashing indicates photo eyes need to be connected or obstructed.

Solid off indicates no eyes learned.

Timer Defeat Yellow Solid on indicates a closed circuit between common and terminal 12. Timer to close will not close.

OLS Yellow Pressing the Open Limit Switch should turn ON this LED.

CLS Yellow Pressing the Close Limit Switch should turn ON this LED.

SLS Yellow Pressing the Sensing Limit Switch should turn ON this LED.

Edge Yellow Indicates a closed circuit between common and terminal 8. Pressing the edge should turn ON this LED.

Mid Stop Yellow Solid on indicates door is stopped on up or down mid stop. Flashing indicates MID STOP is being set.

Timer Enabled Green Solid on indicates TIMER is programmed and will activate from open or mid stop position. Flashing

indicates Timer is counting down and door will close after preset time.

SBC Yellow Indicates a closed circuit between common and terminal 1. Pressing the single button control station

should turn ON this LED.

MAS Yellow Indicates the Maintenance Alert System has been activated or an error code has been triggered.

Relay A Yellow Indicates open or close command has been given to the motor. LED turns on when OPEN/CLOSE button is

pressed.

Relay B Yellow Indicates open or close command has been given to the motor. LED turns on when OPEN/CLOSE button is

pressed.

LED COLOR DEFINITION

Page 26

26

TROUBLESHOOTING GUIDE

THE OPERATOR WILL

NOT RESPOND TO ANY

COMMANDS

POWER LED IS NOT ON

STOP BUTTON LED IS

NOT ON

THE DOOR WILL MOVE

ABOUT A FOOT THEN

STOP. AFTER STOPPING,

ONLY CONSTANT

PRESSURE COMMANDS

WILL MOVE THE DOOR

THE DOOR WILL MOVE

MOST OF THE WAY

TOWARDS A LIMIT THEN

STOP. AN EXTRA OPEN OR

CLOSE COMMAND IS ABLE

TO GET DOOR TO

COMPLETE CYCLE

THE DOOR WILL OPEN

SOME BUT NOT

COMPLETELY. AN EXTRA

OPEN IS ABLE TO GET THE

DOOR TO OPEN

COMPLETELY

THE DOOR WILL OPEN BUT

WILL ONLY CLOSE AFTER

A FIVE SECOND DELAY

WITH CONSTANT

PRESSURE ON THE CLOSE

BUTTON

a) No power supply

➤ Verify primary line voltage from power source.

b) Operator control station is wired wrong

➤ Use the OPEN, CLOSE and STOP LEDs to help check correct wiring.

Verify that the board is accepting commands by using the onboard

station. Green light next to stop button must be on.

c) Interlock switch is activated

➤ Check Interlock(s). If more than one external interlock is present they

must be wired in series.

d) Dial still in programming or diagnostic

➤ Set dial to desired wiring type.

mode

e) Motor is malfunctioning

➤ Verify proper voltage getting to the motor (Check motor name plate).

f) Motor thermal overload tripped

➤ Check for obstructions and verify the door moves freely. Cycle operator

in constant pressure one full cycle open and close to reset fault. Check

to see if motor is hot. Allow motor to cool before attempting to move

door.

g) Failsafe switch is activated requiring

➤ Move switch to non-failsafe or connect a failsafe sensing device.

photo eyes

h) Off Board relay may need to be

➤ When the OPEN or CLOSE button is pressed, Relay A or B LED should

replaced see wiring diagram turn on and the door should move in the corresponding direction. If

Relay A or B lights and the door does not move, off board relay may

need to be replaced (see wiring diagram Off Board Relays).

i) Possible accessory malfunction

➤ Disconnect all devices, reattach them one at a time testing for a failure

after each one is replaced.

j) Possible logic board failure

➤ Replace logic board.

a) Control station not connected or wired

➤ Check wiring to control station.

correctly

b) Interlock switch

➤ Check interlock switch(es) for continuity.

a) The photo eyes, edge or other sensing

➤ If the on board EYES LED is flashing, the photo eyes are misaligned or

device is obstructed or activated not connected. Remove any obstructions, check the safety device wires

for continuity and shorts.

b) The logic board thinks that the direct

➤ Unlearn the photo eyes from the memory by resetting factory defaults.

connect photo eyes are attached and

blocked

c) Failsafe switch set

➤ Slide switch to Non-Failsafe mode.

FAULT POSSIBLE CAUSE FIX

RPM sensor is not connected properly ➤ Check the RPM assembly for loose connections. Check that RPM wheel

or may need to be replaced is turning when operator is running. Check for foreign matter blocking

optical lens.

➤ Replace RPM sensor.

The Maximum Run Timer is not set

➤ Manually reprogram the Maximum Run Timer (page 24).

correctly OR reset the factory defaults (page 25).

There may be a Mid Stop set

➤ Check to see if the Mid Stop LED is on. Clear the Mid Stop by turning

the selector dial to program. Press and hold the MID STOP button for

5 seconds. Return dial to desired wiring type.

a) Loose secondary wiring connections

➤ Repair or replace connections or control transformer.

or a faulty control transformer

b) Logic board failure

➤ Replace logic board.

c) Interlock switch

➤ Check interlock(s).

Page 27

27

TROUBLESHOOTING ERROR CODES

Logic 3.0 operators incorporate a self diagnostic feature built into

the MAS LED. In addition to indicating when routing maintenance

is due, the MAS LED can be used to troubleshoot some problems

with the operator.

If the MAS LED is flashing on and off rapidly, the Maintenance

Alert System has been triggered and the schedule operator

service is due. If the MAS LED flashes 2 or more pulses in a row

ERROR CODE DESCRIPTION EFFECT DISPLAY CORRECTION

E1 MAS triggered (cycles or months) None normal operation 1 blink Reset MAS.

E2 No RPM input during opening or closing The door only responds to 2 blinks Clutch is slipping,

constant pressure commands adjust clutch, or verify RPM

sensor connection or replace

RPM sensor.

NOTE: To relearn the RPM

sensor, move the door with a

constant pressure command.

The door will stop once

relearned and normal

operation will resume.

E3 (MRT) Maximum Run Time timed out The door stops before reaching 3 blinks First check Operator

the desired time for any faults (i.e., Bad Limit

switch), manually learn Max

Run Timer (see page 23)

OR reset factory defaults

(see page 24).

E4 Obstruction sensed on closing Operator will be in the OPEN 4 blinks Cleared by removing

position obstruction or realigning

photo eyes and giving a close

command.

E5 Stuck key button pressed for greater than Stuck key on 3-button station 5 blinks Stuck key must be

2 minutes. will not respond unstuck before it will be

recognized as an input.

E6 Rotary dial in invalid position for greater The door will not respond to 6 blinks Rotary dial must be

than 30 seconds. the 3-button station or any set to a valid position.

other input

E7 Failsafe Safety device faulted or not Normal operation (5 second 7 blinks Cleared when safety

connected for greater than 2 minutes constant pressure override device is cleared or

required to close) connected.

E8 Brownout Detected Operator will run as long as 8 blinks 1. Check AC line for

enough power is present voltage.

2. Check transformer

secondary for low voltage. To

many accessories may be

connected to the transformer.

E9 Motor movement at invalid time Operator will continue to Flash on start Check relays and the

function normally for 5 operations of movement drive circuitry to insure

and then default to a constant that they are turning off.

pressure mode. Operator must run correctly

for two starts for the error to

be cleared.

followed by a pause, an operator error has occurred. To view how

many errors currently exist, turn the selector dial to DIAGNOSTIC

and press the OPEN button. To read out each individual error

code (if more than one exists) press CLOSE. It is possible to have

more than one error at a time.

The chart below can assist with identifying the flashes on the

MAS LED.

NOTES: Error codes take priority over normal MAS LED operation. Error codes will repeat on the MAS every 1.5 seconds until cleared.

There may be more than one error present, but only the highest priority will flash. If the highest error is cleared, the next highest will

flash. All errors self-correct when the corrective action is taken and a reset is not needed.

Page 28

28

TROUBLESHOOTING RADIO FUNCTIONALITY

The error codes will display at the radio LED.

NOTE: Radio receiver is compatible with 315MHz remotes

ERROR CODE SYMPTOM DISPLAY POSSIBLE PROBLEM CORRECTION

R1 No response from the remote Quick Flash Unlearned remote - Try re-learning the

A user tries to use a remote, remote (page 18).

but the RADIO LED only flashes

briefly and there is no response

from the operator.

R2 No response from the remote No LED Cannot recognize remote - Replace battery - OR -

activity A weak signal caused by a eliminate interference - OR-

discharged battery or outside obtain a qualified remote.

interference with the

radio - OR - the radio

being learned is not compatible

with the operator.

R3 The remote cannot be learned Radio LED Cannot recognize remote - Replace battery - OR -

turns off after A weak signal caused by a eliminate interference - OR30 seconds discharged battery or outside obtain a qualified remote.

interference interfering with the

learn process - OR - the radio

being learned is not compatible

with the operator.

R4 The remote cannot be learned 2 Blinks No free records - Erase all learned remotes

A user enters RADIO function and re-learn the desired

learning mode but there is no remote.

space left to add another remote.

R5 The remote cannot be learned 3 Blinks Duplicate remote - This remote already has a

A user enters RADIO function function associated with it. To

learning and selects the function change the function, erase all

to be learned. When the remote learned remotes and

button is pressed for learning, a re-learn the desired remote.

search reveals that remote

is already learned.

R6 Cannot close via constant pressure in IR LED flashes No safety device present - Obtain direct connect eyes or