Lift-master APT BRAKE User Manual

APT BRAKE INSTALLATION

INSTRUCTIONS

71AB120

APPLICATION

This service kit is available for Model APT.

FUNCTIONS

Provides up to 5ft.-lb. of braking torque at 1725 RPM motor shaft.

INSTALLATION

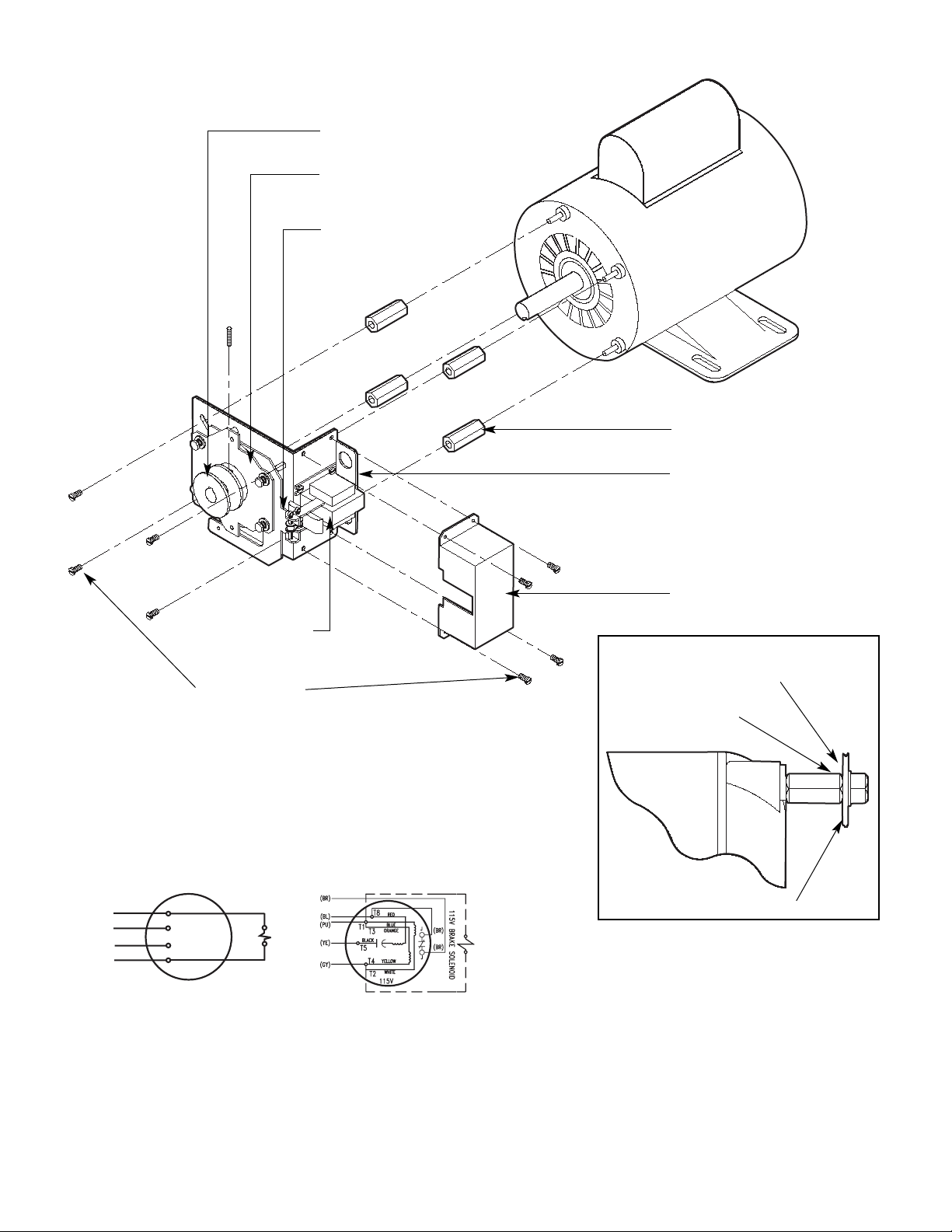

NOTE: Refer To Brake Assembly Diagram On Next Page For

Additional Help.

1. Disconnect power to operator.

2. Remove the existing motor pulleys and belt from the operator.

3. Install a coupling nut to the bolts on the face of the motor

(Figure 1).

4. Remove the brake pressure plate, brake release lever and pulley

assembly from the brake mounting plate and set them aside.

5. Slide the brake mounting plate over the motor shaft, align the

holes in the mounting bracket with the coupling nuts and

secure in place with (4) #10-32 x 1/2" self tapping screws

(Figure 1).

6. Slide the pulley assemblies onto the shaft. Using a ruler or a

straight edge align the large and small pulley. Secure the new

pulley assembly in place with the key and set screw provided.

7. Reinstall the brake release lever and brake pressure plate to the

brake mounting plate.

8. Reinstall the belt.

WIRE CONNECTIONS

1. Remove conduit connector on motor and replace with the

double connector. Remove screws from capacitor cover. This

will enable you to screw the connector on the motor freely.

Replace cover when completed. Use the original single

connector from motor on the brake.

2. Using conduit and anti-short bushing provided, wire the brake

solenoid as shown (Figure 2). Secure conduit connectors.

3. Install solenoid cover and secure with #10 screws provided.

4. Reconnect power to operator.

1

DESCRIPTION QTY

Instructions 1

Conduit 3/8" 1

Hardware Bag 1'

Brake Kit APT, 115V 1PH 1

PACKING LIST

To prevent possible SERIOUS INJURY or DEATH, disconnect

electric power to operator BEFORE installing.

ALL electrical connections MUST be made by a qualified

individual.

WARNING

WARNING

P

BL

GY

Y

115V. Connection

Logic 2

115V. Connection

Logic 3

4

1

5

BL-BK

BL-BK

115V. BRAKE SOLENOID

8

Solenoid Cover

Coupling Nut

Screw #10-32 X 1/2"

Brake Solenoid

Brake Mounting Plate

Release Lever

Pressure Plate

Pulley Assembly

MOTOR CONNECTION DIAGRAM

BRAKE PLATE SPACING

Coupling Nut

Brake Mounting Plate

Self Tap Screw #10-32 X 1/2"

FIGURE 1

FIGURE 2

© 2005, The Chamberlain Group, Inc.

01-12792B All Rights Reserved Printed in Mexico

Loading...

Loading...