Page 1

High Low

OFF

ON

Plug-In Loop Detector

for the OmniControl™ Board

Part # AELD

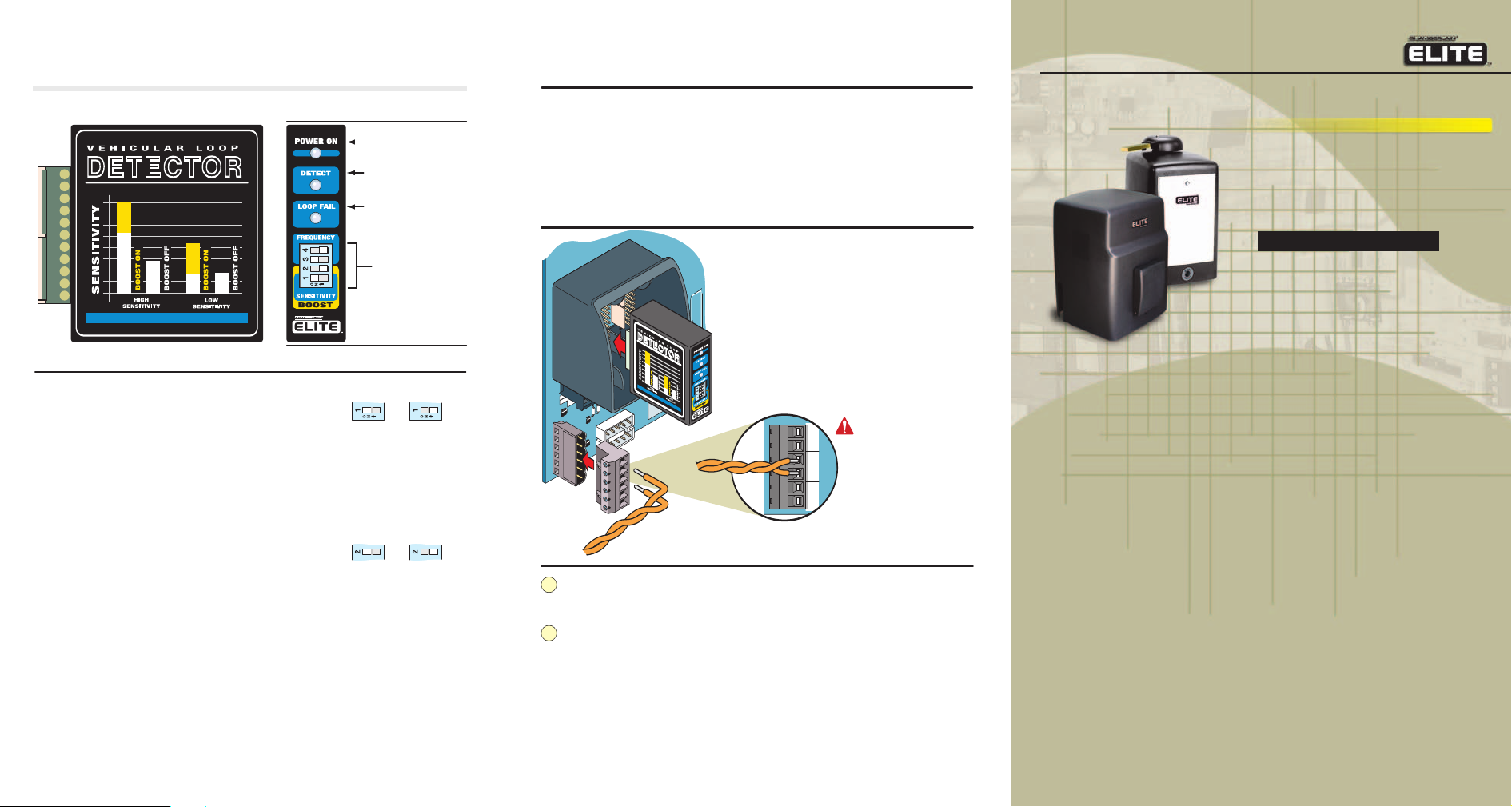

Dip Switch 1 - Sensitivity Level: The sensitivity is controlled by the setting of

switch1 on the front edge of the detector.

Note: Changing the sensitivity setting will automatically reset the detector.

Changing the frequency setting will not reset the detector. It is always necessary

to reset the detector after changing the frequency setting by turning the gate

operator power off.

Dip Switch 2 - Boost on/off: When the switch 2 is off, the sensitivity boost is

disabled. When the switch 2 is on, the sensitivity boost is enabled. Boost enabled

will increase the sensitivity to detect high profile vehicles.

Dip Switch 3 & 4 - Frequency: The opera ting frequency of the detector is

controlled by the setting of switches 3 and 4 on the front edge of the

detector. Sometimes when buried loops are in close proximity to each other, it

may be necessary to select different frequencies for each buried loop to

avoid loop interference (commonly called crosstalk). The actual loop operating

frequency is a function of the size of the loop, the number of turns in the

loop, the length of the lead-in cable, and the setting of the frequency

switches (SW 3 & 4). Therefore, setting one detector to Low and the other

to High may not provide any separation of operating frequency. The most

accurate method of setting the operating frequency of multiple detectors is to

use a frequency meter connected to the loop to actually read the operating

frequency. The detectors frequency should be adjusted so that there is a

minimum of 5 kilohertz of separation between all adjacent loops.

LED Functions

The “FAIL” LED indicates whether or not the loop is within tolerances. If the

loop is out of tolerance, the LED indicates whether the loop circuit was

shorted (3Hz Flash) or open (.5 Hz Flash). When the detector is detecting a

loop failure it will force a call output and the CALL LED will be on. If the loop

problem corrects itself, the detector will begin operating normally again and

the Fail LED will revert back to the Off state.

OFF

–

No Power

ON

–

Power Applied

OFF

– No Presence

ON

– Presence Detected

OFF

– Loop OK

.5 Hz Flash

– Open Loop

3 Hz Flash

– Shorted Loop

Dip Switches

Dip Switch Functions

Failed Loop Diagnostics

Mark the loop layout on the pavement. Remove sharp inside corners that

can damage the loop wire insulation.

Determine the thickness of the pavement to insure that the depth of the

cut will not exceed the thickness of the pavement before attempting to

cut the loop slots. Set the saw to cut a depth (typically 2" to 2.5") that

will insure a minimum of 1" from the top of the loop wires to the pavement

surface. The saw width must be larger than the diameter of the loop wire

to avoid damage to the wire insulation when placed in the saw cut. Cut

the loop, corner angles, and feeder slots. Remove all debris from the

saw slot with compressed air. Check that the bottom of the cut is smooth

and did not break though the thickness of the pavement.

Loop Installation

1

2

www.chamberlain.com

F

IR

E

D

EPT.

SYSTEM ON

EXIT

L

OOP

ALARM

SENSOR

SA

F

ET

Y

L

OOP

OPEN

L

EF

T

SEN

SOR

S

COMMAND

PROCESSED

CENTER SAFETY EXIT

1

3

G

B

M

SL

IN

K

A

CENTER

S

A

F

ETY

EXIT

CENTER SAFETY EXIT

6 twists per ft from Loop

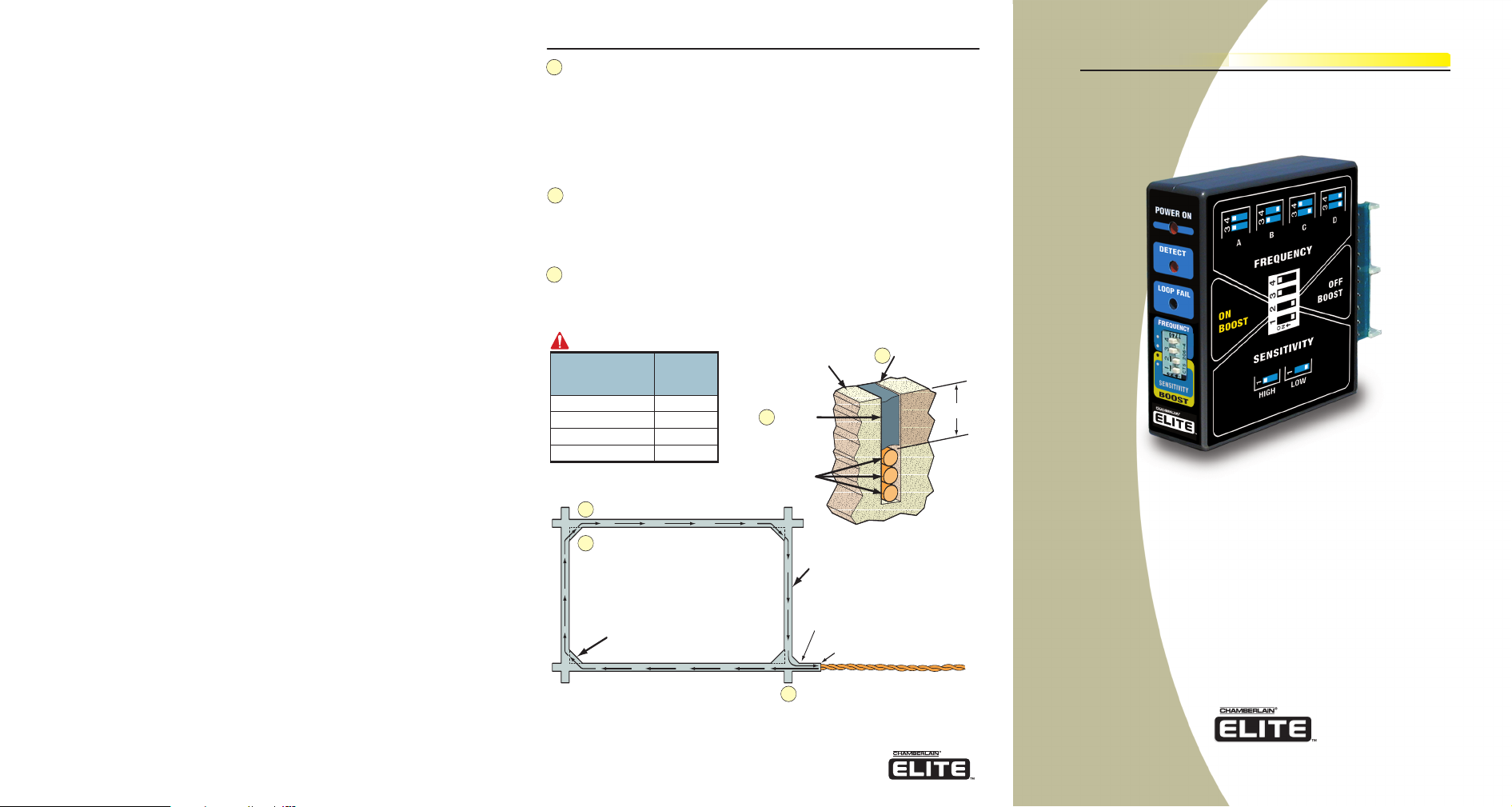

Turn the power

OFF

to the gate operator.

Plug in the loop detector in the desired slot

(i.e. center, safety, exit)

Plug in the terminal plug (provided) into terminal

J8 receptacle on the bottom left of the Omni board.

Bring twisted wires from the loop into the proper

terminal on the terminal plug (i.e. center, safety,

exit).

Turn the power back on.

Caution:

If using more than 1 loop

detector, set them to

different frequencies.

(Refer to Dip Switch 3& 4)

1.

2.

3.

4.

5.

Plug-In Loop Detector Installation

•

•

•

•

ST

R

IK

E

OPEN

REVERSE

SENSOR

1

3

www

.c

ham

b

er

lain

.com

The “FAIL” LED indicates whether or not the loop is within tolerances. If the

loop is out of tolerance, the LED indicates whether the loop circuit was

shorted (3Hz Flash) or open (.5 Hz Flash). When the detector is detecting a

loop failure it will force a call output and the CALL LED will be on. If the loop

problem corrects itself, the detector will begin operating normally again and

the Fail LED will revert back to the Off state.

Failed Loop Diagnostics

Mark the loop layout on the pavement. Remove sharp inside corners that

can damage the loop wire insulation.

Determine the thickness of the pavement to insure that the depth of the

cut will not exceed the thickness of the pavement before attempting to

cut the loop slots. Set the saw to cut a depth (typically 2" to 2.5") that

will insure a minimum of 1" from the top of the loop wires to the pavement

surface. The saw width must be larger than the diameter of the loop wire

to avoid damage to the wire insulation when placed in the saw cut. Cut

the loop, corner angles, and feeder slots. Remove all debris from the

saw slot with compressed air. Check that the bottom of the cut is smooth

and did not break though the thickness of the pavement.

Loop Installation

1

2

F

IR

E

D

EPT.

SYSTEM ON

EXIT

L

OOP

ALARM

SENSOR

SA

F

ET

Y

L

OOP

OPEN

L

EF

T

SEN

SOR

S

COMMAND

PROCESSED

CENTER SAFETY EXIT

1

3

G

B

M

SL

IN

K

A

CENTER

S

A

F

ETY

EXIT

CENTER SAFETY EXIT

6 twists per ft from Loop

Turn the power

OFF

to the gate operator.

Plug in the loop detector in the desired slot

(i.e. center, safety, exit)

Plug in the terminal plug (provided) into terminal

J8 receptacle on the bottom left of the Omni board.

Bring twisted wires from the loop into the proper

terminal on the terminal plug (i.e. center, safety,

exit).

Turn the power back on.

Caution:

If using more than 1 loop

detector, set them to

different frequencies.

(Refer to Dip Switch 3& 4)

1.

2.

3.

4.

5.

Plug-In Loop Detector Installation

ST

R

IK

E

OPEN

REVERSE

SENSOR

1

3

www

.c

ham

b

er

lain

.com

vehicular loop

detector

now with BOOST CONTROL

Plug-In Loop Detector

for Chamberlain Elite

Enabled Controllers

MODEL # AELD

Page 2

The loop itself must be a continuous length of wire without any breaks or

splices. The loop wire can be 14, 16 or 18 gauge stranded wire with

either a cross-linked polyethylene (XLPE) or polyester insulation.

Wrap the loop wire in the loop slot using a wooden stick or roller to

insert the wire to the bottom of the saw slot until the desired number of

turns are reached. (Caution: do not use a sharp object) Each turn of wire

must lay flat on top of the previous turn.

The wire must be twisted a minimum of 6 turns per foot from the end of

the feeder slot to the detector to minimize noise or interference. If a splice

is required in the feeder cable, solder each splice and protect with a

moisture proof seal.

Apply the sealant. The sealant selected should have good adhering properties

with similar contraction and expansion characteristics as the pavement

material.

Loop Installation

10 feet - 13 feet

Loop

Perimeter

Important

Number

of Turns

4

314 feet - 26 feet

27 feet - 80 feet 2

181 feet and up

1/8" to 1/4"

Saw Slot

Feeder Slot

End of Saw Cut

1

The wire is continuously wound in

the loop saw slot for the required

number of turns. One turn shown.

(Refer to table above)

The wire must be twisted together

6 twists per foot from the end of

the saw cut to the detector

4

1/8" to 1/4"

Saw Slot

Road Surface

Sealant

Loop Wire

(3 Wires Shown)

Min 1"

2

5

3

Remove Sharp

Inside Corners

For Technical Support: 1-800-528-2806

5

4

3

#AELD Plug-In Loop Detection

now with BOOST CONTROL

f

or the OmniControl™ and other Chamberlain Elite

#AELD enabled controllers.

01-50969B

These high quality loop detectors are for use with the

OmniControl™ Board available on Chamberlain Elite’s

commercial line and other enabled controllers. With

Chamberlain Elite's proven design and integration technology, these component detectors will make installation

of loop detection systems simple.

© 2005 the chamberlain group, inc. – all rights reserved

845 Larch Avenue Elmhurst, Illinois 60126-1196

www.chamberlain.com

Warning: Chamberlain Elite does not warrant nor assumes liability for #AELD Loop Detectors installed in non Chamberlain Elite enabled controllers.

Loading...

Loading...