Page 1

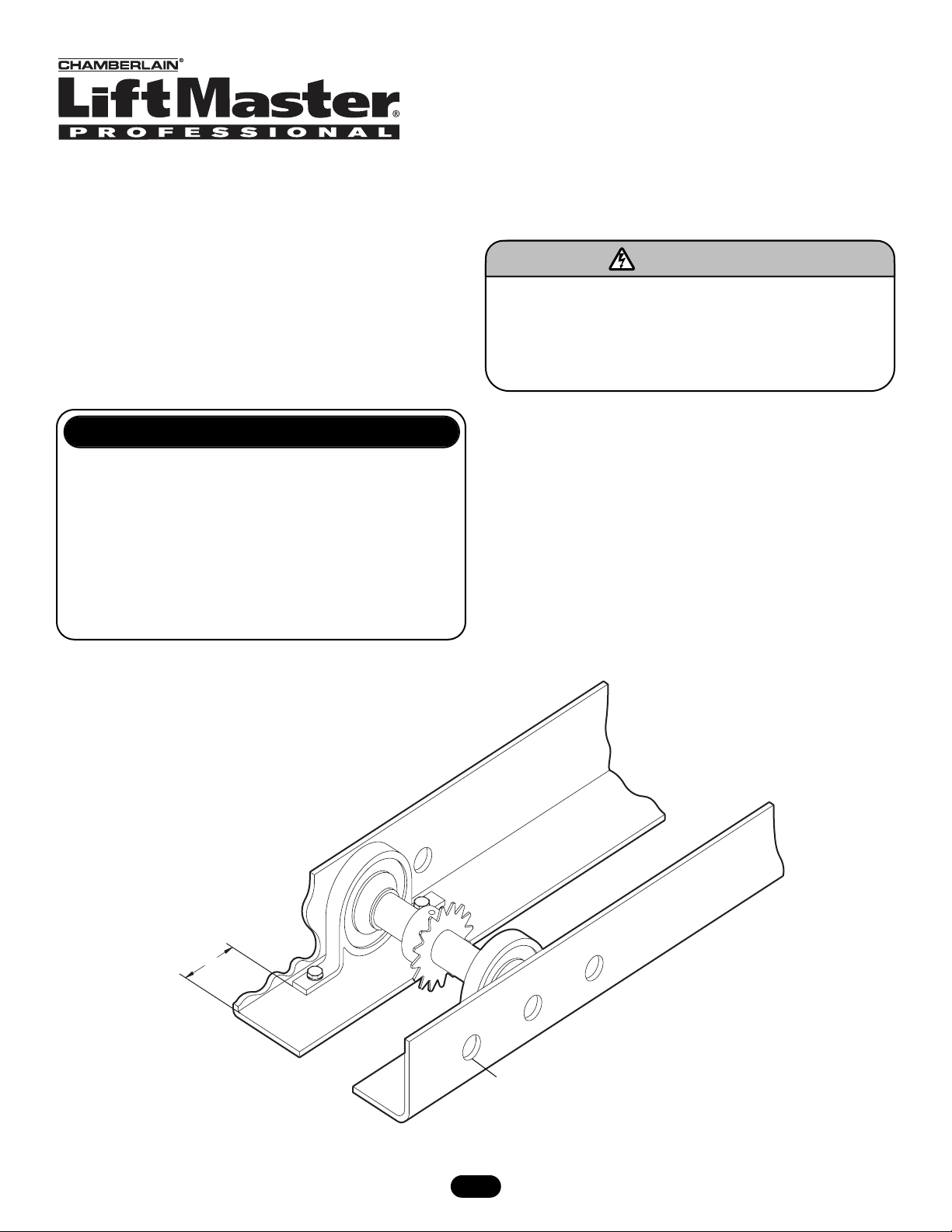

HIGH CYCLE MODIFICATION

For 1/3 and 1/2 HP Operator

Models T and SD

655211-XX

NOTE:

XX is door height

APPLICATION REQUIREMENTS

This modification is available for model T and SD 1/3 and 1/2 HP

operators. Not available on gear reduced or side mount belt drive

operators. Must be factory installed.

FUNCTIONS

Helps to extend the life of belt drive operators that are used on

doors where frequency of use is expected to be more than 100

cycles per day.

Consists of heavy-duty roller bearings on all shafts, a delay-onreverse circuit in the control system, and #41 drive chain.

PACKING LIST

1

FIGURE 1

To prevent possible SERIOUS INJURY or DEATH from

electrocution, disconnect electric power to operator BEFORE

installing.

ALL electrical connections MUST be made by a qualified

individual.

WARNING

DESCRIPTION QTY

Shaft, High Cycle Modification 1

Pillow Block Bearing 2

Sprocket, 41B10 3/4" Bore 1

Hex Bolt, #3/8-16 x 1-1/4" Long 4

Serrated Flange Nut 3/8" 4

Flatwasher 3/8" 8

Roll Pin, 1/4" X 1-3/4" 1

2''

HIGH CYCLE MODIFICATION

Front Bracket Removed For Clarity

Page 2

1. Disconnect power to operator.

2. Assemble the track per the instructions except for the front

idler.

3. With the front bracket in place, slide the pillow block idler

assembly into the track. Locate approximately 2" from the end

of the track.

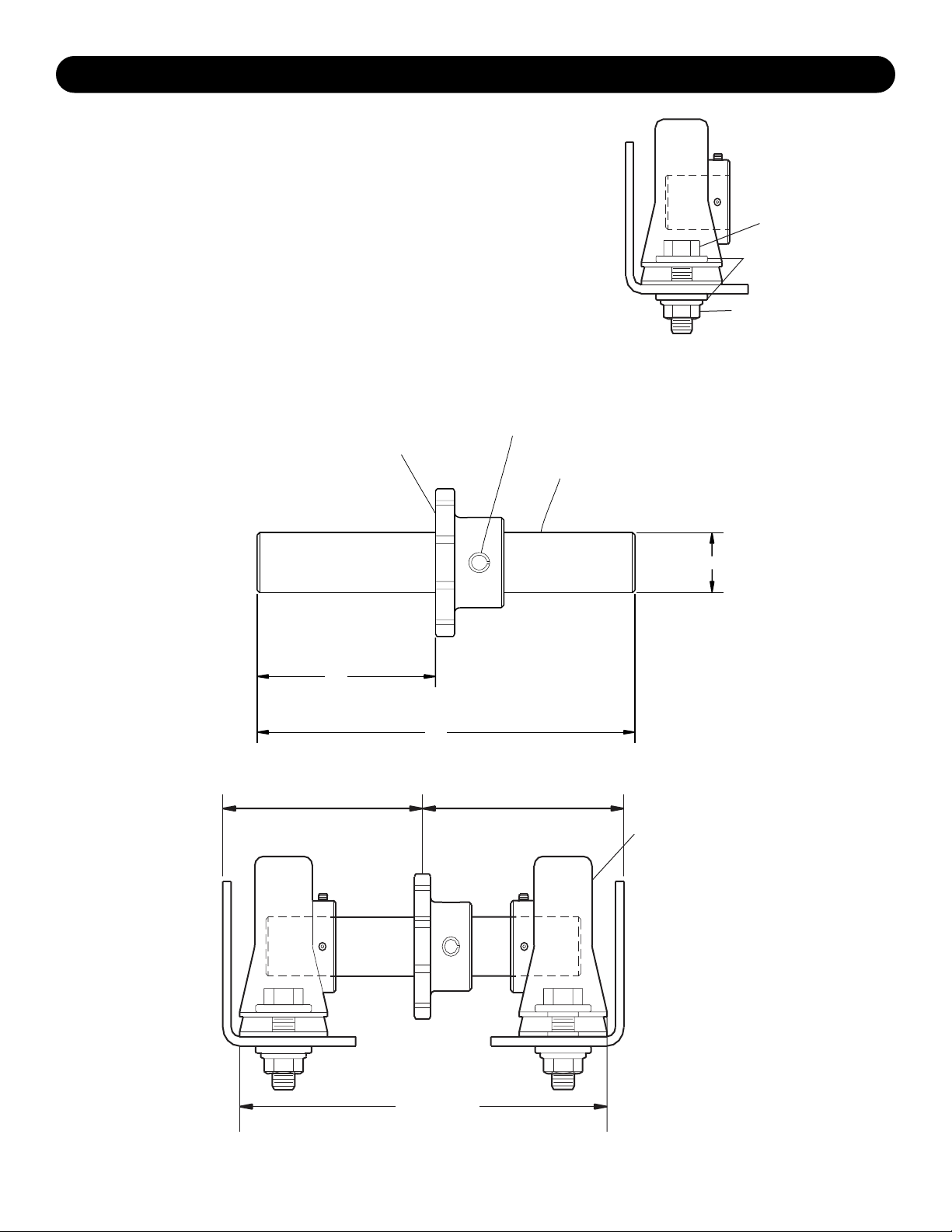

4. Drill four (4) holes (3/8" diameter) in the track, using the holes

in the bearings for guides (Figure 1).

5. Fasten in place, be sure to use flatwashers over the slots in the

bearing (Figure 2).

6. Be sure that the sprocket is centered, if not, adjust shaft by

loosening set screws on the bearings. Adjust as needed and

retighten set screws.

7. Reconnect power to operator.

FIGURE 2

FIGURE 3

FIGURE 4

INSTALLATION INSTRUCTIONS

© 2005, The Chamberlain Group, Inc.

01-12012B All Rights Reserved Printed in Mexico

Sprocket

#3/8-16x1-3/4" Lg.

Hex Bolt

3/8" Flatwasher

3/8" Serrated

Flange Nut

Roll Pin

Shaft

.750 Dia.

1.13"

4.50"

Centerline

Bearing

5.125" to 5.250"

Loading...

Loading...