Page 1

APPLICATION

Manual Hoist Modification for use with model T or GT operators.

• 655209 for 1/3 & 1/2 HP trolley operators with #48 drive chain

• 6552091 for 3/4 & 1 HP trolley operators with #48 drive chain

• 6552092 for GT operators with #41 drive chain

Modification provides hand chain operation for manually

opening/closing the door as follows:

1. A chain wheel is coupled to a cross header shaft which in turn

is coupled to the front idler of the trolley.

2. The front idler pulley is replaced by a #48 sprocket thus

allowing the chain wheel to drive the door arm.

QTY

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

DESCRIPTION

Instructions

Chain Retaining Bracket

Bearing Assembly

Sprocket, 48B14 1" Bore

Sprocket, 50B35 1" Bore and 5/16" Set Screws

Hand Chain

Chain (47 Pitches) #41

Master Link #41

Chain (49 Pitches) #48

Master Link #48

Chain Package #50

Front Idler Assembly for #41 Chain

Manual Hoist Housing

Brake Cable Release Kit

Roll Pin 3/16" x 3"

Roll Pin 1/4" x 1-3/4"

Roll Pin 5/16" x 3"

Front Idler Assembly For #48 Chain

PART #

10-10893

12-11438

15-48B14LXX

15-50B35LGH

19-10929-25

*19-41047

*19-41ML

**19-48049

**19-48ML

19-50106M

75-11503

75-11973

75-11459

86-RP06-300

86-RP08-112

86-RP10-300

75-11502

Manual Hoist Modification

Used For Trolley Operators

655209 (1/3 & 1/2 HP trolley operators)

6552091 (3/4 & 1 HP trolley operators)

6552092 (GT operators)

PREPARATION

1. Door size to be indicated at time of order. If the door size

specified is 16 feet or taller a sash chain and key ring package

will also be included with packing list.

2. A cross header shaft is required for installation of this manual

hoist (not provided).

This shaft is available and will be provided if specified at time

of order.

1" cold rolled steel shaft 12 ft. long, for doors up to 20 ft. wide.

1" cold rolled steel shaft 20 ft. long, for doors over 20 ft. wide.

* Used on #41 Drive Chain only.

** Used on #48 Drive Chain only.

PACKING LIST

3. Hand chain length is twice the door height less 3 feet. Ensure

the proper length of chain has been provided.

4. If the manual hoist is being added to pre-installed operator, it

will be necessary to move the operator and track assembly

back (into the garage) approximately 6" to allow for installation

of the new front drive assembly.

1

Page 2

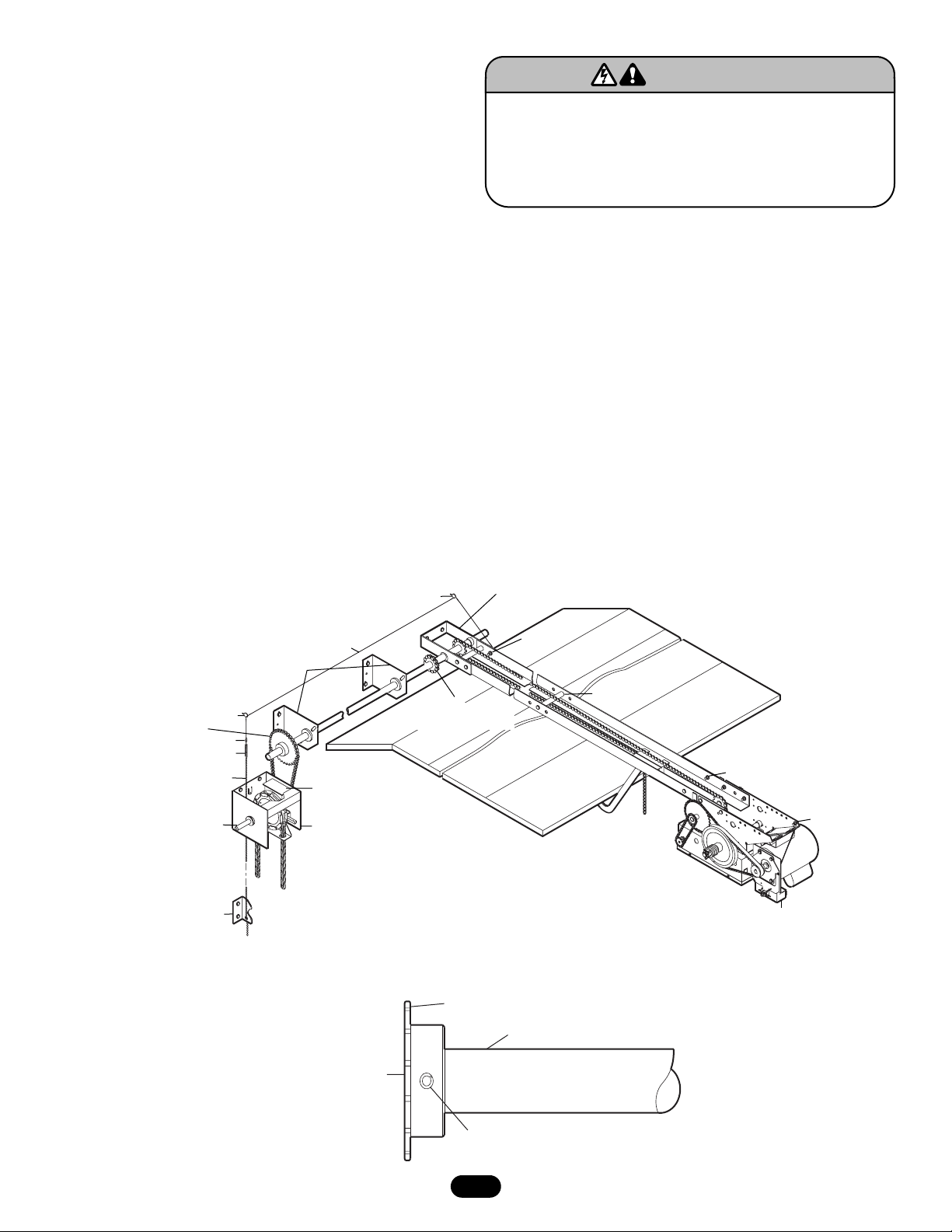

FIGURE 1

FIGURE 2

2

1. Disconnect power to operator.

2. Existing Installation: Using proper temporary support for the

operator and track assembly, disassemble the existing front

bracket and idler assembly from the track end (Refer to

owner’s manual if necessary).

New Installation: Assemble the trolley operator according to

the owner’s manual. Use the new front bracket and idler

provided.

3. The chain hoist can be installed on the left or right side of the

door. Determine which side the chain hoist will be mounted on

and install the front idler assembly with the sprocket coupling

facing in the desired direction. Be sure to install a track spacer

at the end of the track.

4. Using the chain and master link provided, lengthen the existing

chain provided with the operator. Add/Remove links as required

for proper tension of the drive chain. Refer to the owner’s

manual for the proper tension value.

5. Position and mount the operator/track assembly as indicated in

the owner's manual.

NOTE: The front bracket will not pivot as shown in the manual so

temporary support of the operator will be required.

6. If you supply your own shaft you will need a length of 1" solid

shaft (ideally cold rolled steel). The approximate length of this

shaft should be one-half the door width plus 2 feet. Determine

the chain hoist location and cut the shaft to the desired length.

To prevent possible SERIOUS INJURY or DEATH, disconnect

electric power to operator BEFORE installing.

ALL installations and electrical connections MUST be made by

a qualified individual.

WARNING

WARNING

7. Install the 48B14 sprocket on one end of the shaft, (Figure 2).

Align sprocket flush with end of shaft, drill a 1/4" diameter hole

through sprocket hub and shaft. Secure using 1/4" x 1-3/4"

rollpin. Slide the two shaft support bearings onto the shaft.

Drill and pin the 40 tooth drive sprocket in desired location on

the opposite end of the shaft.

8. Supporting the far end of the shaft, butt together the two

48B14 sprockets and connect using the #41 chain provided.

9. Position the bearings on shaft so that one bearing is at the mid

point and the other as close to the 40 tooth sprocket as

possible. With the shaft level and using suitable hardware,

secure the bearings.

10.Vertically align the hand chain sprocket with the 40 tooth drive

sprocket. With the chain in place, and using suitable hardware,

secure the hoist housing. Align and secure the hand chain

retaining bracket.

Driven Sprocket #50B35

Cable Clamps (2) *

Brake Release Chain*

Drive Sprocket

(Can Be on Either Side)

Chain Retaining Bracket

Eyelet*

Spring*

Brake Release Cable*

Bearings

Interlock Switch

(Wired to Operator)

See Instructions

Manual Hoist Housing

* Items are Provided Only if Operator is Equipped with Solenoid Brake.

Eyelet*

Chain and Sprocket

Coupling

48B14 Sprocket 1" Bore

Front Bracket and Idler Assembly

(Can be Installed for Right or Left

Hand Drive, Left Hand Shown)

Eye Bolt*

Track Spacer*

Eye Bolt*

Eye Bolt*

Solenoid Brake

(When Required)

1" Diameter Shaft

Be Sure Shaft is Flush With

Sprocket. Do Not Let Shaft

Protrude Beyond Sprocket.

Drill 1/4" Hole - Pin With 1/4"x1-3/4" Roll Pin

Page 3

Manual Hoist Model GT operators are equipped with a power train

disconnect mechanism and an interlock switch to disable the

electrical operation of the operator. A disconnect cable, used to

activate the disconnect, must be installed. Follow the directions

below referring to the illustrations as necessary.

1. Install (2) eye bolts in the track at the locations (Figure 1). It is

not necessary to install the third eye bolt.

3. Install the two (2) eyelets on the jamb.

4. Attach one end of the disconnect cable to the end of the

disconnect lever (Figure 4).

5. Install the spring and key ring assembly to the length of

disconnect chain.

6. Run the cable through the eye bolts and the eyelets and loosely

fasten to the spring with the two (2) cable clamps.

7. Adjust the cable to insure that the disconnect lever actuates

when the disconnect chain is pulled.

MODEL T OPERATORS WITH A SOLENOID BRAKE

MODEL GT OPERATORS

If the operator is equipped with a solenoid brake it will be

necessary to install a release cable.

1. Install the (3) eye bolts in the approximate locations (Figure 3).

Drill a hole in the operator frame.

2. Install the two (2) eyelets on the jamb.

3. Thread the brake release cable through the holes in the brake

plate and the release plate (Figure 3). Slide the #8 flat washer

on and fasten the cable stop sleeve on the end.

4. Install the spring and key ring assembly to the length of

disconnect chain.

5. Run the cable through the eye bolts and the eyelets and loosely

fasten to the chain with the two (2) cable clamps.

6. Adjust the cable so that the brake releases when the brake

release chain is engaged. Ensure that the brake functions

normally at all other times.

FIGURE 3

FIGURE 4

3

Washer

Cable

Sleeve

Brake

Release

Cable

Brake Release

Lever

Solenoid Brake

(When Required)

Eye Bolt

Disconnect Cable

Disconnect Lever

Page 4

© 2005, The Chamberlain Group, Inc.

01-11241E All Rights Reserved Printed in Mexico

Wiring must be in compliance with local building and electrical

codes. Using 16 gauge wire, wire the interlock switch located on

the hand chain mechanism to the operator terminal block.

Refer to the wiring diagram provided on the inside cover of the

operator for proper wire connections.

Remove the factory provided jumper between terminals in the

electrical box. Terminals 4 and 5 in mechanical operators, and

terminals 2 and 3 in logic operators. If other external interlock

devices are present connect interlocks in series.

INTERLOCK SWITCH WIRING

To prevent possible SERIOUS INJURY from moving parts

when hand chain is in use, interlock MUST be installed.

WARNING

WARNING

Loading...

Loading...