Page 1

CLUB SERIES ADJUST ABLE BENCH

Part # 7147801

Rev C.

ASSEMBLY INSTRUCTIONS

Revision:9/18/011

Page 2

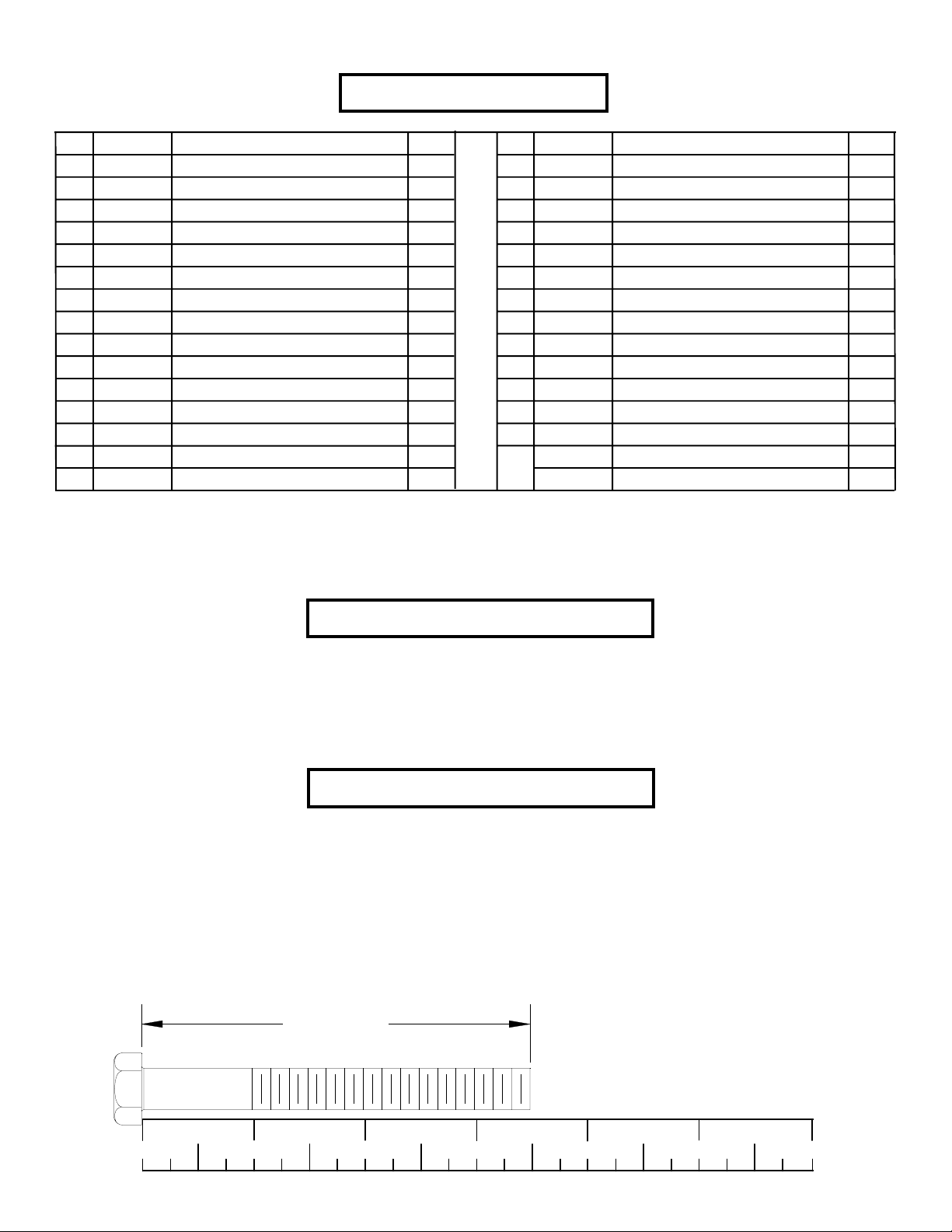

PARTS LIST

KEY

1

2

3

4

5

6

7

8

9

10

11

12

13

14

PART #

71447

71446

71443

71444

71445

71315

69131xx

69132xx

69307xx

3102941

3102922

3102904

3102905

3102906

DESCRIPTION

BENCH FRAME

BACK P AD SUPPOR T

BACK P AD ADJUST

3 X 2 X 18” TUBE

REAR UPRIGHT

BACK P AD ADJUST PLA TE

SEA T P AD

LUMBAR P AD

BACK P AD

3/8 X 1-1/2” BOLT

3/8 X 2-3/4” BOLT

3/8 X 3” BOLT

3/8 X 3-3/4” BOLT

3/8 X 4” BOLT

QTY

1

1

2

1

1

2

1

1

1

2

4

4

3

1

KEY

15

16

17

18

19

20

21

22

23

24

25

26

27

28

OR

PART #

3223320

3202406

3102807

3102514

3228501

3104901

7131002

7131001

7145501

6866701

3116001

6866601

6535501

6866602

6866603

DESCRIPTION

3/8 X 6-1/2” BOLT

3/8 X 1-1/4” BUTTON HEAD BOLT

3/8” LOW HEIGHT LOCK NUT

3/8” SAE WASHER

3/8” BLACK SAE WASHER

3/4” FLANGE BEARING

3/4 X 3” PIVOT SHAFT

3/4 X 5-5/16” PIVOT SHAFT

3/4 X 5-5/16” CHROME PIVOT SHAFT

3/8” RH WASHER

1-1/4” SQ. RUBBER BUMPER

BLACK RH CAP

3” WHEEL

WHITE RH CAP

PLA TINUM RH CAP

QTY

2

2

12

10

2

4

1

1

1

28

2

6

2

22

22

T ools Required for Assembly

* Rubber mallet or hammer

* 9/16” wrench

* Ratchet with 9/16” socket

* 7/32” Allen wrench

Bolt Length Ruler

NOTE: BOL T LENGTH IS MEASURED FROM THE UNDERSIDE OF THE HEAD OF THE BOLT.

BOLT LENGTH

1/2 1/2 1/2 1/2 1/2 1/2

0

1

2

345

2

6

Page 3

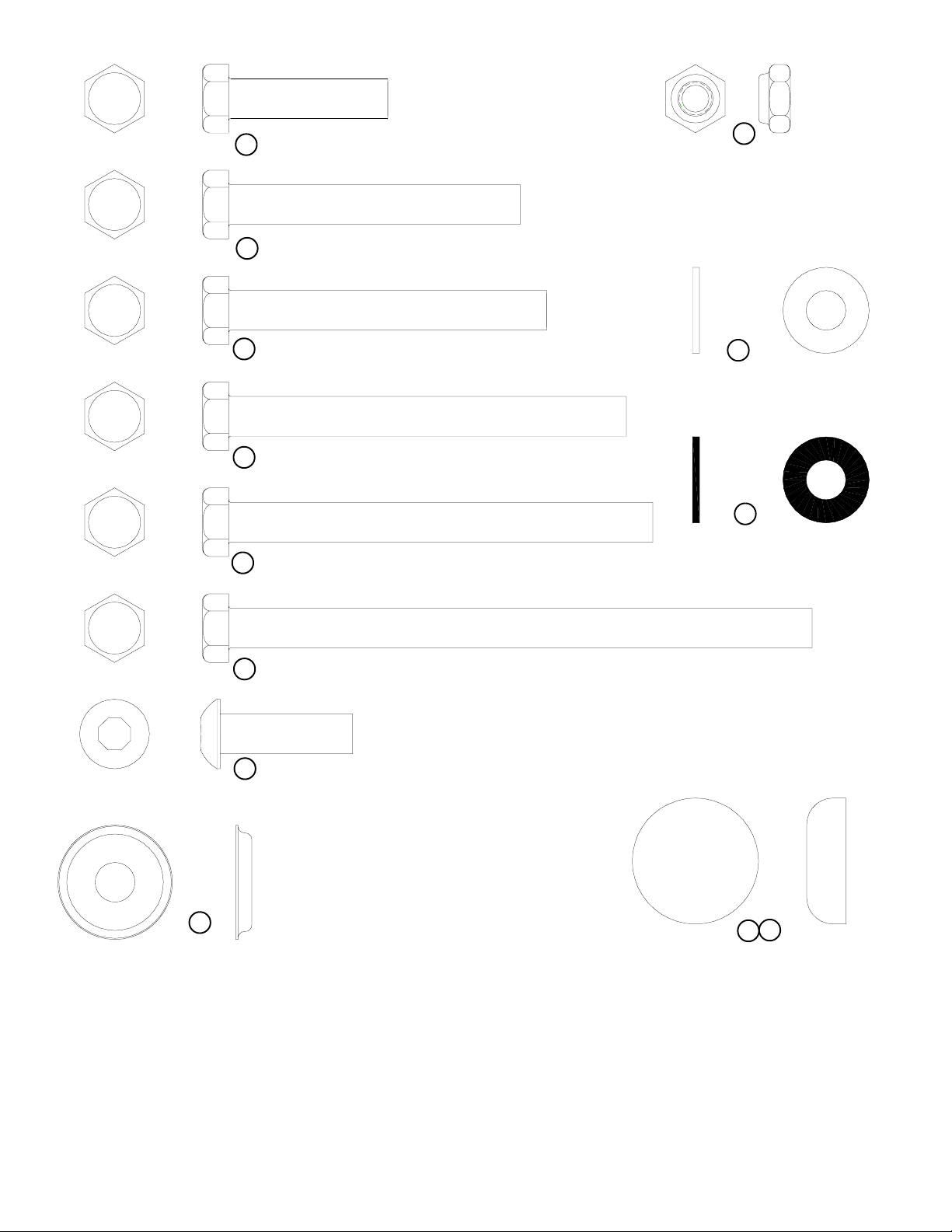

10 3/8 X 1-1/2” BOLT

11 3/8 X 2-3/4” BOLT

17

3/8” LOW

HEIGHT LOCK

NUT

12 3/8 X 3” BOLT

13 3/8 X 3-3/4” BOLT

14 3/8 X 4” BOLT

15 3/8 X 6-1/2” BOLT

16 3/8 X 1-1/4” BUTTON HEAD BOLT

18

3/8” SAE

WASHER

19

3/8” BLACK SAE

WASHER

24

RH

WASHER

28

26

RH CAP

(BLACK/WHITE/PLATINUM)

3

Page 4

FIGURE 1

1

5

24

17

18

4

28

11 3/8 X 2-3/4”

STEP 1:

• SECURELY assemble the 3 X 2 X 18” TUBE (4) and the REAR UPRIGHT (5) to the BENCH FRAME (1) using eight RH CAPS

(28), four 3/8 X 2-3/4” BOLTS (11), eight 3/8” SAE WASHERS (18), eight 3/8” RH WASHERS (24) and four 3/8” LOW

HEIGHT LOCK NUTS (17) as shown in FIGURE 1.

2

17

25

1

24

18

21

20

FIGURE 2

14 3/8 X 4”

28

STEP2:

• SECURELY assemble the BACK PAD SUPPORT (2) to the BENCH FRAME (1) using two RH CAPS (28), one 3/8 X 4” BOLT

(14), one 3/4” X 3” PIVOT SHAFT (21), two 3/4” FLANGE BEARINGS (20), two 3/8” SAE WASHERS (18), two 3/8” RH

WASHERS (24) and one 3/8” LOW HEIGHT LOCK NUT (17) as shown in FIGURE 2.

• Assemble two 1-1/4” RUBBER BUMPERS (25) to where the BACK PAD SUPPORT (2) contacts the BENCH FRAME (1).

4

Page 5

FIGURE 3

17

1

6

24

13 3/8 X 3-3/4”

26

STEP 3:

• SECURELY assemble the BACK PAD ADJUST PLATES (6) to the BENCH FRAME (1) using six BLACK RH CAPS (26), three 3/

8 X 3-3/4” BOLTS (13), six 3/8” RH WASHERS (24) and three 3/8” LOW HEIGHT LOCK NUTS (17) as shown in FIGURE 3.

17

3

23 CHROME

22

2

20

3

FIGURE 4

24

3/8 X 6-1/2” 15

28

STEP 4:

• SECURELY assemble two BACK PAD ADJUSTS (3) to the BACK PAD SUPPORT (2) using two RH CAPS (28), one 3/8 X 6-

1/2” BOLT (15), one 3/4” X 5-5/16” PIVOT SHAFT (22), two 3/4” FLANGE BEARINGS (20), two 3/8” RH WASHERS (24)

and one 3/8” LOW HEIGHT LOCK NUT (17) as shown in FIGURE 4.

• SECURELY assemble one 3/4” X 5-5/16” CHROME PIVOT SHAFT (23) between the two BACK PAD ADJUSTS (3) using

two RH CAPS (28), one 3/8 X 6-1/2” BOLT (15), two 3/8” RH WASHERS (24) and one 3/8” LOW HEIGHT LOCK NUT (17)

as shown in FIGURE 4.

1/2 1/2 1/2 1/2 1/2 1/2

0

1

2

345

6

5

Page 6

FIGURE 5

7

1

24

3/8 X 3” 12

28

STEP 5:

• SECURELY assemble the SEAT PAD (7) to the BENCH FRAME (1) using two RH CAPS (28), two 3/8 X 3” BOLTS (12) and

two 3/8” RH WASHERS (24) as shown in FIGURE 5.

3”

8

2

19 BLACK

16 3/8 X 1-1/4” BUTTON

HEAD BOL T

FIGURE 6

STEP 6:

• SECURELY assemble the LUMBAR PAD (8) to the BACK PAD SUPPORT (2) using two 3/8 X 1-1/4” BUTTON HEAD BOLTS

(16) and two 3/8” BLACK SAE WASHERS (19) as shown in FIGURE 6. (Note direction of PAD.)

6

Page 7

FIGURE 7

9

2

24

12 3/8 X 3”

28

STEP 7:

• SECURELY assemble the BACK PAD (9) to the BACK PAD SUPPORT (2) using two RH CAPS (28), two 3/8 X 3” BOLTS (12)

and two 3/8” RH WASHERS (24) as shown in FIGURE 7.

FIGURE 8

5

17

STEP 8:

• SECUREL Y assemble two 3” WHEELS (27) to the REAR UPRIGHT (5) using four RH CAPS (28), two 3/8 X 1-1/2” BOLTS (10),

four 3/8” RH WASHERS (24) and two 3/8” LOW HEIGHT LOCK NUTS (17) as shown in FIGURE 8. (NOTE: T ighten connec-

tion enough to allow wheels to rotate freely, do not over tighten.)

1/2 1/2 1/2 1/2 1/2 1/2

0

1

2

345

27

24

10 3/8 X 1-1/2”

28

6

7

Page 8

CAUTION-PLEASE READ

There is a risk assumed by individuals who use this type of equipment. To minimize risk, please

follow these rules:

1. Inspect equipment daily . Tighten all loose connections and replace worn parts immediately .

Failure to do so may result in serious injury.

2. Do not allow minors or children to play on or around this equipment.

3. Exercise with care to avoid injury .

4. Consult your physician before beginning any exercise program.

WARRANTY INFORMATION

10 YEARS STRUCTURUAL FRAME

3 YEARS PILLOW BLOCKS, PULLEYS, WEIGHT PLA TES AND GUIDE RODS

1 YEAR CABLES

90 DA YS UPHOLSTERY

PREVENTATIVE MAINTENANCE TIPS

Action DAILY WEEKLY QUARTERLY BI-ANNUALLY AS NEEDED

CLEAN

Uphol s tery

Guide Rods

Hand Grips

INSPECT

Visual Overall

Cabl e s

Hardware

Frame

Hand Grips

LUBRICATE

Guide Rods

X

X

X

X

X

X

X

X

X

Clean:

• Upholstery with mild soap and water.

• Guide rods with a cotton cloth.

• Hand grips with mild soap and water.

• Frame damage can be repaired with touch-up paint can be purchased from your LifeFitness customer service representative at

(800)351-3737.

Inspect:

• Cables for wear or damage and proper tension (should not exceed 3/4” deflection.) Pay close attention at bends and attachment

points.

• Hardware should be checked for looseness. Tighten as required.

• Frames should be inspected for wear or damage.

• Hand Grips should be checked for wear or damage

Lubricate:

• Lube the Guide Rods. Apply the lubricant to a cotton cloth, then run the cotton cloth up and down the guide rods as needed. Do not

spray lubricant directly on the Guide Rods.

Thank you for purchasing the LifeFitness CLUB SERIES ADJUST ABLE BENCH. If unsure of pr oper use

of equipment, call your local LifeFitness distributor or call the LifeFitness customer service department at

(800) 351-3737.

8

Loading...

Loading...