Page 1

CLUB SERIES ADJUSTABLE AB BENCH

Part # 7320301

Rev C.

ASSEMBLY INSTRUCTIONS

Revision: 11/18/021

Page 2

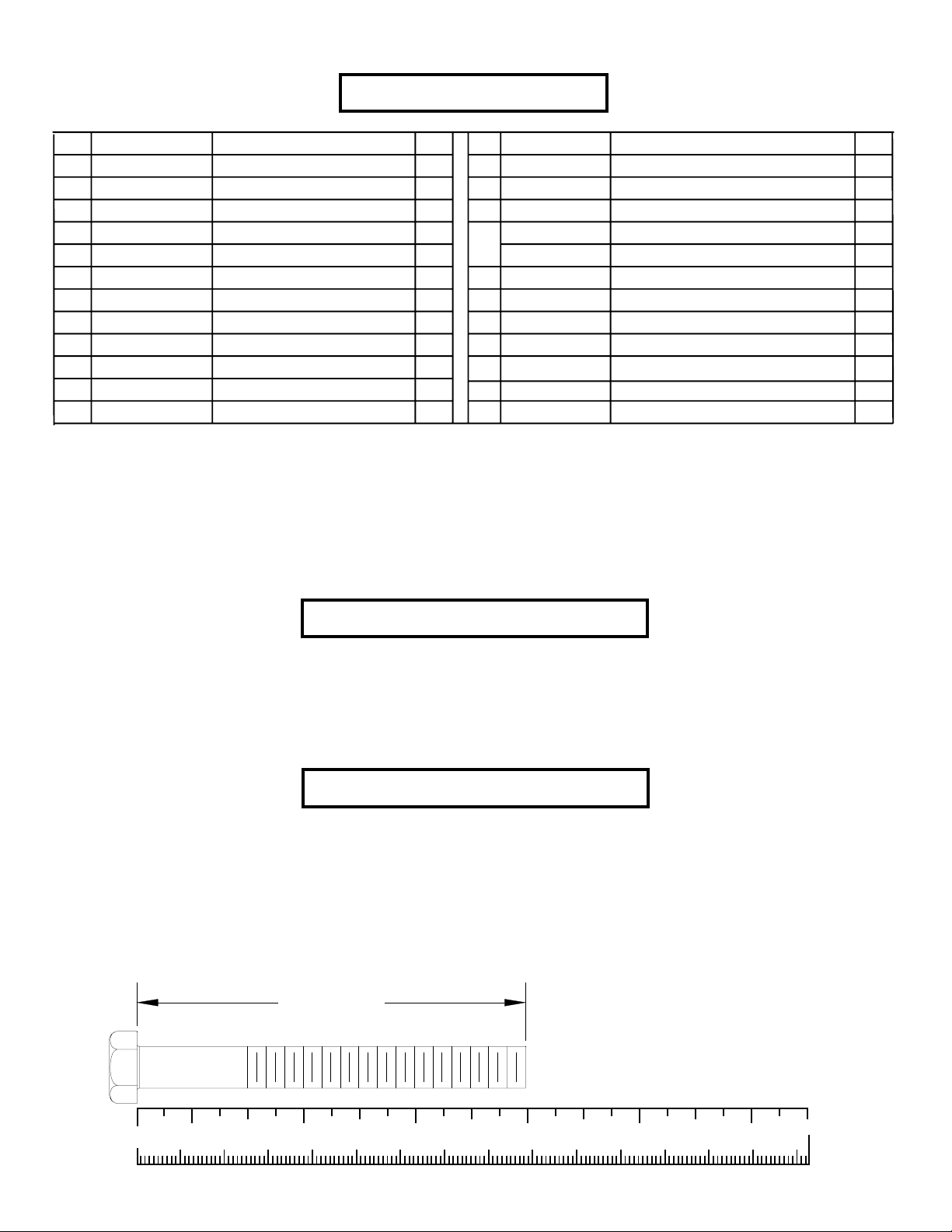

PARTS LIST

NOTICE: ALL PART NUMBERS NEED ACU ADDED TO THE NUMBER.

FOR INSTANCE; ACUP07-0005

KEY

1

2

3

4

5

6

7

8

9

10

11

12

AP04-0013

AP04-0014

AP04-0012

AP01-0032

AP04-0023

DA1C03817016NU

DA1C03806816NU

DA1C03808316NU

DA1C03816416NU

PART #

P04-0011

P07-0005

P07-0002

DESCRIPTION

SEAT

FRAME

P AD ADJUST

BASE

19-1/4” ROLLER PAD TUBE

SEA T PAD

BENCH P AD

REAR BASE

3/8 X 170mm BOL T

3/8 X 68mm BOL T

3/8 X 83mm BOL T

3/8 X 164mm BOL T

QTY

1

1

2

1

2

1

1

1

2

4

4

1

KEY

13

14

15

16

OR

17

18

19

20

21

22

PART #

DB2E03807200NU

DC120010510U

P05-0009

P06-0021

P06-0021

P06-0012

P06-0005

P06-0013

P06-0007

P06-0006

P03-0004

DESCRIPTION

3/8” LOW HEIGHT LOCK NUT

3/8” SAE WASHER

3/8” RH WASHER

WHITE RH CAP

PLA TINUM RH CAP

1-1/4” SHAFT COLLAR

5 X 8” ROLLER P AD

2-3/8” OD PLASTIC W ASHER

2” SQ. END CAP

3 X 2” END CAP

3/4 X 5-5/16” CHROME PIVOT SHAFT

QTY

7

18

18

18

18

4

4

8

1

1

1

T ools Required for Assembly

* 9/16” wrench

* Ratchet with 9/16” socket

* 3mm Allen wrench (Supplied)

* 4mm Allen wrench (Supplied)

Bolt Length Ruler

NOTE: BOL T LENGTH IS MEASURED FROM THE UNDERSIDE OF THE HEAD OF THE BOL T .

BOLT LENGTH

0

1/2 1/2 1/2 1/2 1/2 1/2

10 20 30 40 50 60 70 80 90 100 110 120 130 140 150

1

23456

2

Page 3

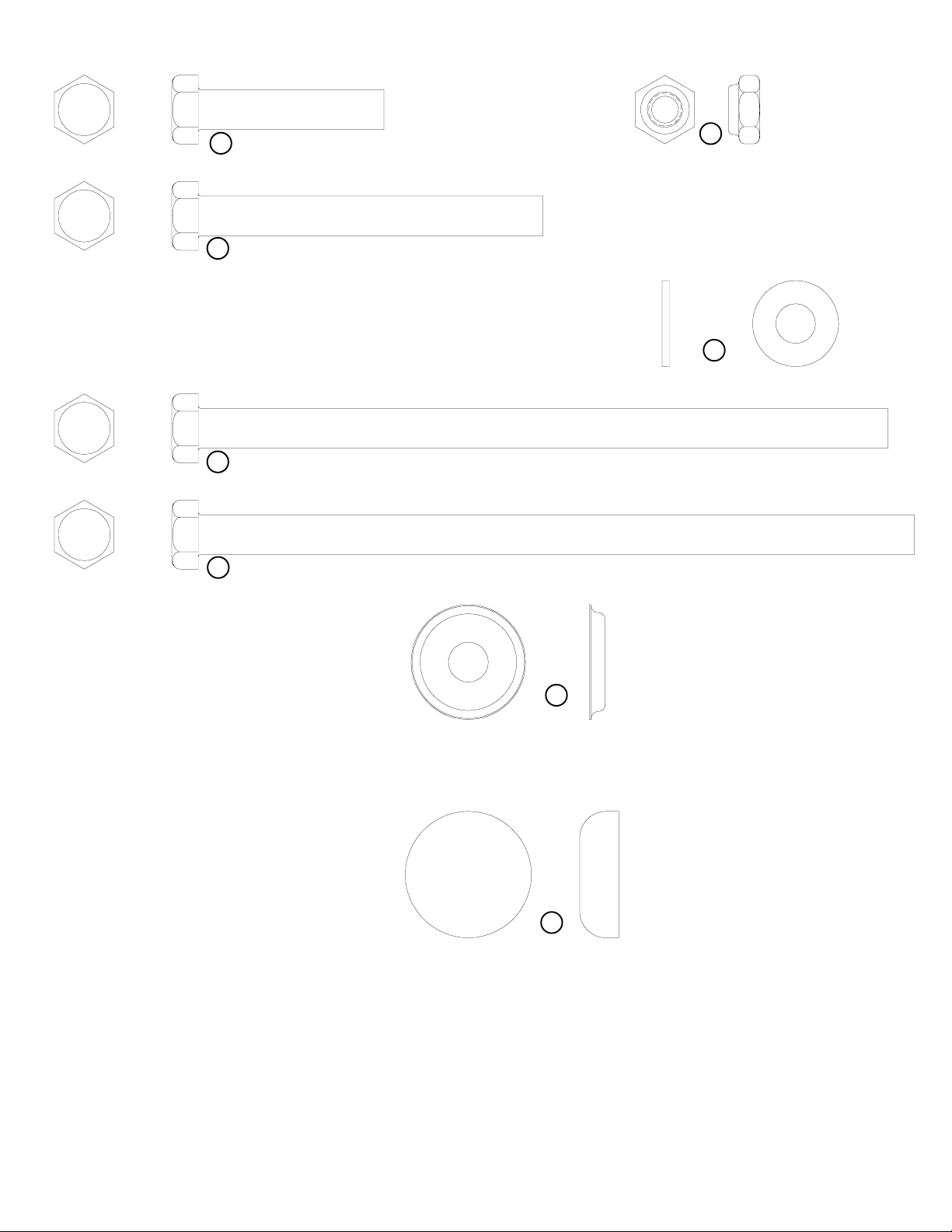

10 3/8 X 68mm BOL T

11 3/8 X 83mm BOL T

12 3/8 X 164mm BOL T

9 3/8 X 170mm BOL T

13

3/8” LOW

HEIGHT LOCK

NUT

14

3/8” SAE

WASHER

15

RH

WASHER

16

RH CAP

(WHITE/PLATINUM)

3

Page 4

FIGURE 1

8

13

14

15

2

4

16

10 3/8 X 68mm

10 3/8 X 68mm

STEP 1:

• SECUREL Y assemble the BASE (4) to the FRAME (2) using four RH CAPS (16), two 3/8 X 68mm BOLTS (10), four 3/8” SAE

W ASHERS (14), four 3/8” RH W ASHERS (15) and two 3/8” LOW HEIGHT LOCK NUTS (13) as shown in FIGURE 1.

• SECURELY assemble the REAR BASE (8) to the FRAME (2) using four RH CAPS (16), two 3/8 X 68mm BOL TS (10), four 3/8” SAE

W ASHERS (14), four 3/8” RH W ASHERS (15) and two 3/8” LOW HEIGHT LOCK NUTS (13) as shown in FIGURE 1.

4

Page 5

13

1

2

15

14

12 3/8 X 164mm

16

FIGURE 2

STEP 2:

• SECURELY assemble the SEA T (1) to the FRAME (2) using two RH CAPS (16), one 3/8 X 164mm BOLT (12), two 3/8” SAE W ASH-

ERS (14), two 3/8” RH WASHERS (15) and one 3/8” LOW HEIGHT LOCK NUT (13) as shown in FIGURE 2.

5

Page 6

FIGURE 3

13

1

3

22 CHROME

14

15

3/8 X 170mm 9

16

STEP 3:

• SECURELY assemble two P AD ADJUSTS (3) to the SEAT (1) using two RH CAPS (16), one 3/8 X 170mm BOL T (9), two 3/8” SAE

W ASHERS (14), two 3/8” RH WASHERS (15) and one 3/8” LOW HEIGHT LOCK NUT (13) as shown in FIGURE 3.

• SECURELY assemble one 3/4” X 5-5/16” CHROME PIVOT SHAFT (22) between the two PAD ADJUSTS (3) using two RH

CAPS (16), one 3/8 X 170mm BOL T (9), two 3/8” SAE WASHERS (14), two 3/8” RH WASHERS (15) and one 3/8” LOW HEIGHT

LOCK NUT (13) as shown in FIGURE 3.

6

Page 7

FIGURE 4

6

1

7

15

14

3/8 X 83mm 11

16

STEP 4:

• SECURELY assemble the SEA T P AD (6) to the SEA T (1) using two RH CAPS (16), two 3/8 X 83mm BOL TS (11), two 3/8” SAE

W ASHERS (14) and two 3/8” RH W ASHERS (15) as shown in FIGURE 4.

• SECURELY assemble the BACK P AD (7) to the SEA T (1) using two RH CAPS (16), two 3/8 X 83mm BOLTS (11), two 3/8” SAE

W ASHERS (14) and two 3/8” RH W ASHERS (15) as shown in FIGURE 4.

7

Page 8

FIGURE 5

21

SET SCREWS

20

1

SET SCREWS

SERIAL #

LOCA TION

5

19

18

17

STEP 5:

• Assemble four 5 X 8” ROLLER PADS (18) to the SEAT (1) using four 1-1/4” SHAFT COLLARS (17), eight 2-3/8” OD PLASTIC

WASHERS (19) and two 19-1/4” ROLLER PAD TUBES (5) as shown in FIGURE 5. Once the ROLLER PADS (18) are assembled

to the SEAT (1), SECURE the 19-1/4” ROLLER PAD TUBES (5) in place using the four SET SCREWS in the tubes on the SEAT

(1) as shown in FIGURE 5..

• Insert one 3 X 2” END CAPS (21) and one 2” SQ. END CAP (20) into the BASE (1) as shown in FIGURE 5.

8

Page 9

CAUTION-PLEASE READ

There is a risk assumed by individuals who use this type of equipment. To minimize risk, please

follow these rules:

1. Inspect equipment daily . T ighten all loose connections and replace worn parts immediately.

Failure to do so may result in serious injury.

2. Do not allow minors or children to play on or around this equipment.

3. Exercise with care to avoid injury .

4. Consult your physician before beginning any exercise program.

WARRANTY INFORMA TION

10 YEARS STRUCTURUAL FRAME

3 YEARS PILLOW BLOCKS, PULLEYS, WEIGHT PLATES AND GUIDE RODS

1 YEAR CABLES

90 DA YS UPHOLSTERY

PREVENT ATIVE MAINTENANCE TIPS

Action DAILY WEEKLY QUARTERLY BI-ANNUALLY AS NEEDED

CLEAN

Uphol s tery

Guide Rods

Hand Grips

INSPECT

Visual Overall

Cabl e s

Hardware

Frame

Hand Grips

LUBRICATE

Guide Rods

X

X

X

X

X

X

X

X

X

Clean:

• Upholstery with mild soap and water.

• Guide rods with a cotton cloth.

• Hand grips with mild soap and water.

• Frame damage can be repaired with touch-up paint can be purchased from your LifeFitness customer service representative at

(800)351-3737.

Inspect:

• Cables for wear or damage and proper tension (should not exceed 3/4” deflection.) Pay close attention at bends and attachment

points.

• Hardware should be checked for looseness. Tighten as required.

• Frames should be inspected for wear or damage.

• Hand Grips should be checked for wear or damage

Lubricate:

• Lube the Guide Rods. Apply the lubricant to a cotton cloth, then run the cotton cloth up and down the guide rods as needed. Do not

spray lubricant directly on the Guide Rods.

Thank you for purchasing the LifeFitness CLUB SERIES ADJUSTABLE AB BENCH. If unsure of

proper use of equipment, call your local LifeFitness distributor or call the LifeFitness customer service

department at (800) 351-3737.

9

Loading...

Loading...