Life Fitness GK53-00002-0012, AK53-00053-0000 User Manual

How To...Install U-Bracket

Tools Required: Two 9/16 inch wrenches or sockets KIT # GK53-00002-0012

REPLACING BRACKET ASSEMBLY # AK53-00053-0000

WARNING: Turn the power OFF at the ON/OFF switch and disconnect the plug from the electrical

outlet prior to servicing any machine operating on AC current.

1. Turn the unit off and unplug the power cord from the wall.

2. Loosen (do not remove) the two bracket mounting bolts.

3. Back out the tensioning bolt from the tension bracket.

4. Remove the bracket mounting bolts and remove the two-piece bracket assembly.

5. Discard the two-piece bracket.

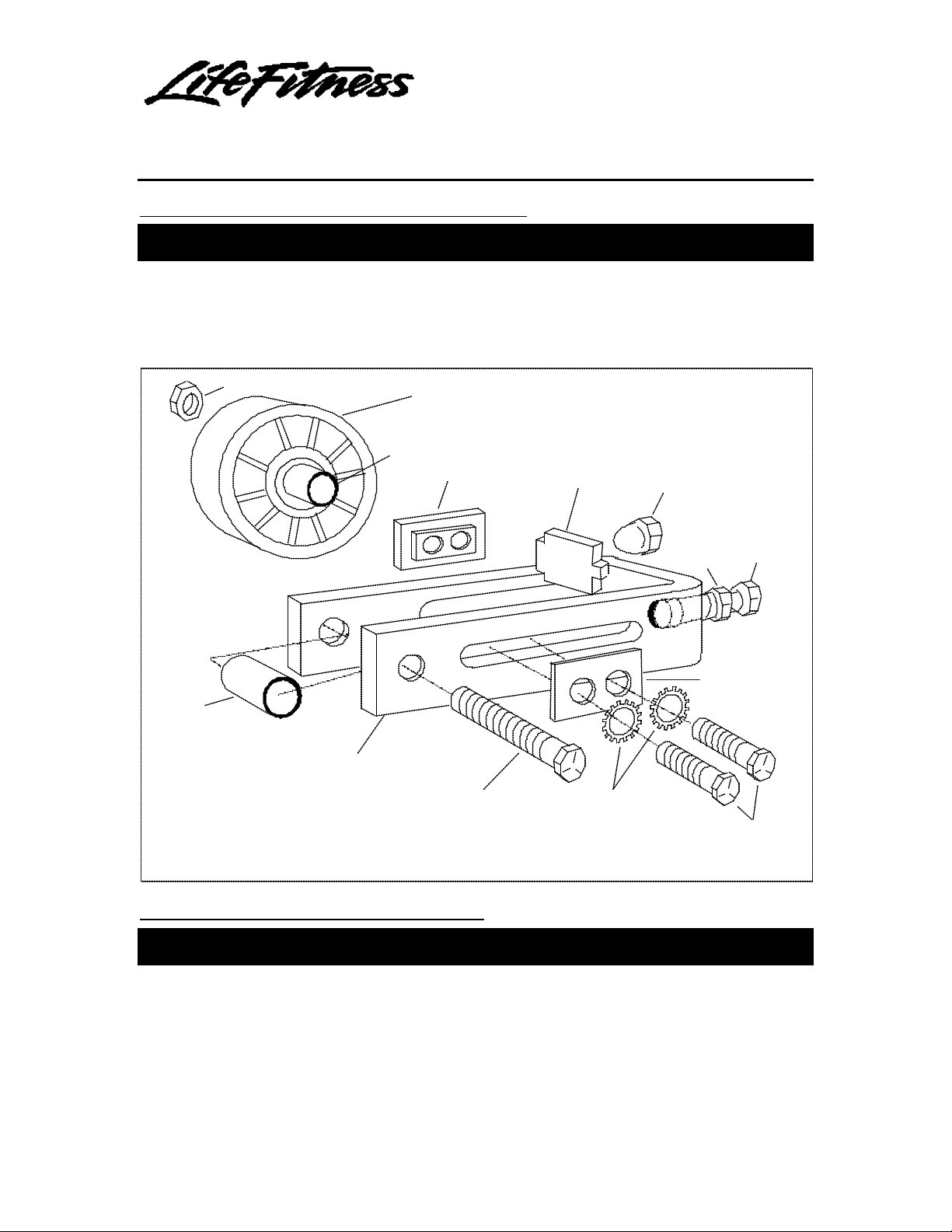

Spacer

sleeve

Nyloc nut

Tension bracket

Idler

pulley

Hub

Slide plate

Pulley bolt

U-Bracket Assembly

Wear plate

Acorn nut

Tooth

washers (2)

Tensioning

Jam

bolt

bolt

Plate washer

square

Mounting

bolts (2)

INSTALLING U-BRACKET KIT# GK53-00002-0012

WARNING: Make sure the power is OFF at the ON/OFF switch and disconnect the plug from the

electrical outlet prior to servicing any machine operating on AC current.

1. Position the U-bracket with wide slot to the inside of the frame and the narrow slot over the

mounting holes in the frame.

2. Place external tooth washer on each mounting bolt and install square plate washer over the

mounting bolts.

3. Install the bolts through the U-bracket narrow slot and mounting holes in the frame.

4. Position the slide plate on the back side of the U-bracket and hand tighten the mounting bolts

into the threaded plate.

How To...Install U-Bracket (Continued)

Tools Required: Two 9/16 inch wrenches or sockets KIT # GK53-00002-0012

5. Next position the spacer sleeve between the fork end of the U-bracket.

6. Position the pulley bolt through the bracket and spacer.

7. Now install the idler pulley on the bolt with its hub facing against the back side U-bracket.

8. Secure the nyloc nut and tighten.

9. Place the main drive belt onto the idler pulley.

10. Position the wear plate between the slots of the U-bracket up against the frame.

11. Turn in the tensioning bolt as required to adjust the belt tension.

12. Using a belt tensioning gauge, adjust new belt tension from 165 to 170 lbs, and existing belt

from 160 to 165 lbs. If a belt tensioning gauge is unavailable, place a straight edge between the

intermediate pulley and the crank pulley then at the center of the belt press down on the belt

and measure for deflection which should be a 1/4 inch.

13. With the main drive belt properly tensioned, tighten the bracket mounting bolts 5 to 10 ft. lbs.

NOTE: Over tightening the mounting bolts will cause damage to the slide plate.

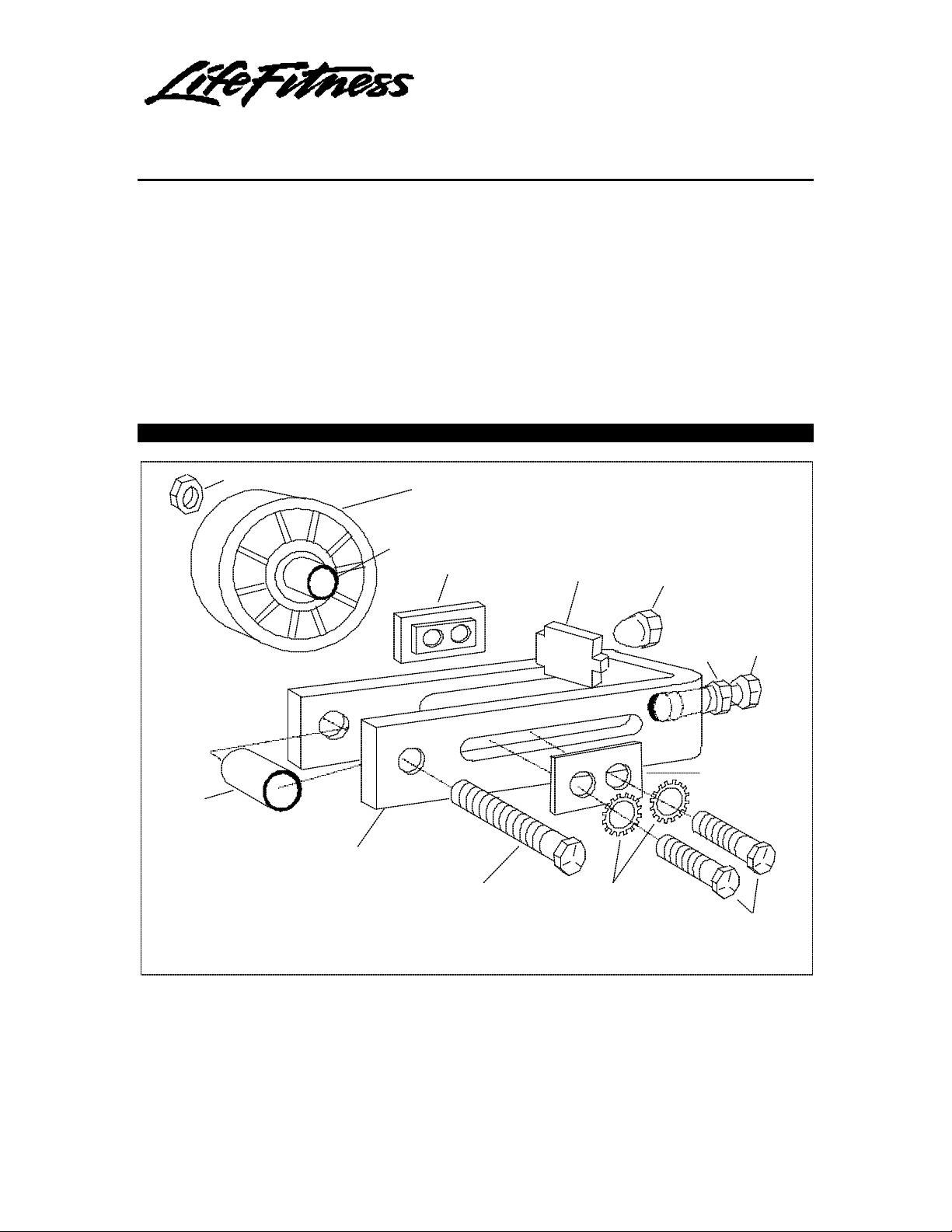

Spacer

sleeve

Nyloc nut

Tension bracket

Idler

pulley

Hub

Slide plate

Pulley bolt

U-Bracket Assembly

Wear plate

Acorn nut

Tooth

washers (2)

Tensioning

Jam

bolt

bolt

Plate washer

square

Mounting

bolts (2)

MO51-00K53-A032

Loading...

Loading...