HC 2092

Installation

Instructions

For Fully Integrated NoFrost

Combined Refrigerator-Freezers

HCB 2092

HC / HCB 2092

7082 993-00

I

mportant

Contents Page

Please Read and Follow these Instructions ................... 2

Note to the Installer ......................................................... 2

Important Safety Information ..........................................3

R600a Refrigerant........................................................... 4

Disposal of Old Appliance ..............................................4

Disposal of Packaging Material ......................................4

Electrical Safety .............................................................. 5

Blocking for Safety .......................................................... 5

Unit Dimensions .............................................................. 6

Door swing clearence .....................................................6

Unit Venting ..................................................................... 6

Cabinet Opening Dimensions .........................................7

Panel Dimensions - Inset Installation Style ....................8

Panel Dimensions - Frameless Installation Style ........... 9

Mounting the anti tipping device on concrete floors ..... 10

Mounting the anti tipping device on wooden floors ...... 10

Mounting the anti tipping device in cabinets deeper than

24” ................................................................................ 11

Cover strips ................................................................... 11

Water Connection Requirements .................................12

Water Connection Adapter ........................................... 12

Connection to the Water Supply ................................... 13

Leveling the Appliance ..................................................14

Adjusting the front of the drawer ................................... 14

Fasten the appliance in the recess ............................... 14

Before mounting the door panels ................................. 14

Mounting the attachment brackets onto the door panels ... 15

Mounting the freezer drawer panels ............................. 16

Mounting the refrigerator door panels .......................... 16

Mounting the ventilation grille .......................................19

Please Read and Follow these

Instructions

These instructions contain Danger, Warning, and

Caution notes.

This information is important for safe and efficient installation and operation.

Always read and comply with all Danger, Warning, and

Caution notes!

DANGER!

Danger indicates a hazard which will cause

serious injury or death if precautions are

not followed.

WARNING!

Warning indicates a potentially hazardous

situation which, if not avoided, could result

in death or serious injury.

CAUTION!

Caution indicates a potentially hazardous

situation which, if not avoided, may result

in minor or moderate injury.

IMPORTANT

All types and models are subject to continuous

improvement. The manufacturer reserves the right

to make modifications to the shape, equipment, and

technology.

IMPORTANT

This indicates information that is especially relevant

to a problem-free installation and operation.

Note to the Installer

It is very important to follow the instructions in the manual to ensure proper installation and operation of the unit.

Before installing the unit, be sure to thoroughly read and

understand all of the information in this manual.

WARNING!

Electrocution hazard.

Do not connect to the electrical outlet

before the installation is completed.

2

S

afety

Important Safety Information

• WARNING: Keep ventilation openings, in the

appliance enclosure or in the built-in structure,

clear of obstruction.

• WARNING: Do not use mechanical devices

or other means to accelerate the defrosting

process, other than those recommended by

the manufacturer.

• WARNING: Do not damage the refrigerant

circuit.

• WARNING: The power cord must not be

damaged while installing the appliance.

• WARNING: Multi-sockets or distributor strips

and other electronic devices (such as halogen transformers) must not be positioned and

operated at the rear of appliances.

• WARNING: Danger of injury through electric

shock! There are live parts under the cover.

Only have the interior LED light replaced or

repaired by customer service staff or trained

personnel.

• WARNING: Risk of injury from the LED lamp.

The light intensity of the LED light complies

with risk group RG 2. If the cover is defective,

do not look directly at the light through optical

lenses from close distance. This may damage

your eyes.

• WARNING: This appliance must be secured

as described in the Use and Care Manual

(Installation Instructions) to rule out any

potential risks due to its instability.

• WARNING: Do not use electrical appliances

inside the food storage compartments of the

appliance, unless they are of the type recommended by the manufacturer.

• Any repairs and work on the appliance should

only be performed by the customer service

department. Unauthorized work may be dangerous to the user. The power source cable

should only be changed or replaced by the

customer service department. Component

parts and power cords shall be replaced with

like components performed by factory authorized service personnel only.

• Do not stand on the toe kick, drawers or doors

or use them to support anything else.

• This appliance is not intended for use by persons (including children) with reduced physical, sensory or mental capabilities or lack of

experience and knowledge unless they have

been given initial supervision or instruction

concerning use of the appliance by a person

responsible for their safety. Children should

be supervised to ensure that they do not play

with the appliance.

• Do not store explosive substances such as

aerosol cans with a flammable propellant in

this appliance.

• To prevent injury and damage to property,

the appliance should only be installed by 4

people.

• Check the appliance for signs of damage after

unpacking. Contact the supplier if it is damaged. Do not connect the appliance to the

mains power supply.

• Avoid prolonged skin contact with cold surfaces (e.g., chilled/frozen products). If necessary,

take safety action (e.g., gloves).

• Do not consume food which has been stored

for too long; it could cause food poisoning.

• Any repairs and work on the appliance should

only be performed by the customer service

department or other trained personnel. The

same applies to changing the power cord.

3

• Only perform repair and other work on the

appliance when the plug has visibly been disconnected.

• Only install, connect, and dispose of the

appliance as described in this Use and Care

Manual.

• In the event of a fault, pull out the plug or

switch off the fuse.

R600a Refrigerant

WARNING!

The refrigerant R600a contained within the

appliance is environmentally friendly, but

flammable. Leaking refrigerant can ignite.

• When disconnecting the appliance from the

power source, pull it out by the plug, never

pull on the cable.

• If you have a lockable appliance, do not keep

the key near the appliance or within reach of

children.

• The appliance is designed for use in enclosed

rooms. Do not operate the appliance outdoors

or in areas where there is moisture or splashing water.

• Do not use the interior LED light to light the

room. The interior LED light is only designed

to illuminate the interior of the appliance.

• Do not allow naked flames or ignition sources

to enter the appliance.

• Alcoholic drinks or other vessels containing

alcohol should be sealed tightly for storage.

Disposal of Old Appliance

WARNING!

Risk of child entrapment.

Child entrapment and suffocation are not problems of

the past.

Junked or abandoned refrigerators are still dangerous –

even if they will sit for “just a few days.”

If you are getting rid of your old refrigerator, please follow

these instructions to help prevent accidents.

Before you discard old appliances:

• Take off the doors.

• Leave the shelves in place so that children

may not easily climb inside.

• Cut off the power cord from the discarded

appliance. Discard separately from the appliance.

• Be sure to follow your local requirements for

disposal of appliances.

Contact the trash collection agency in your

area for additional information.

Disposal of Packaging Material

WARNING!

Keep packaging materials away from

children. Polythene sheets and bags can

cause suffocation!

If possible, please recycle packaging material at a recycling facility.

4

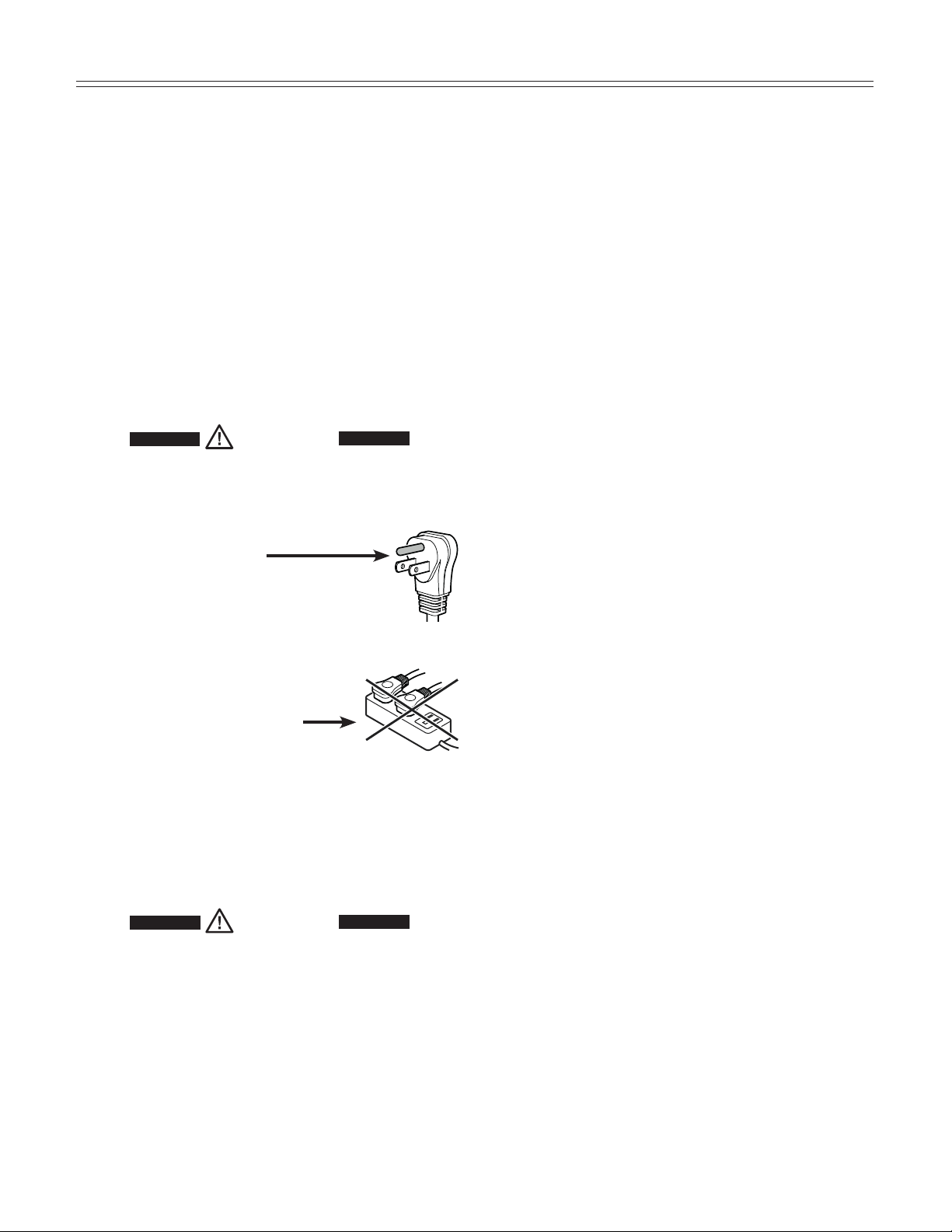

Electrical Safety

Connect this appliance to a 15 amp or 20 amp, 110120 VAC circuit which is grounded and protected by a

circuit breaker or fuse.

We recommend using a dedicated circuit for this appliance to prevent circuit overload and the chance of interruption to the appliance.

This appliance is equipped with a three-prong (grounding) polarized plug for your protection against possible

shock hazards.

Where a two-prong wall receptacle is encountered, contact a qualified electrician and have it replaced with a

properly grounded three-prong receptacle in accordance

with all local codes and ordinances.

WARNING!

Electrocution hazard.

Electrical grounding required.

Do not remove the round grounding

•

prong from the plug.

Do not use extension cords or

•

ungrounded (two prong) adapters.

• Do not use a power cord that is frayed or

damaged.

• Do not use a power strip.

Failure to follow these instructions may

result in fire, electric shock or death.

Blocking for Safety

WARNING!

To avoid a hazard due to instability of the

appliance, it must be fixed in accordance

with the instructions.

5

p

lannIng

I

nformatIon

Unit Dimensions - Figure 1

A = 3" (76 mm)

B = 79-13/16" (2027 mm)

Figure 1

C = 35-13/16" (910 mm)

D = 4" (102 mm)

E = 24" (610 mm)

G = 42-7/16" (1078 mm)

H = 37-1/8" (943 mm)

Unit Venting - Figure 3

HC/HCB 20 appliances do not require any ventilation

openings in the cabinet. The required airflow is directed

through the toe kick area.

Door swing clearence - Figure 2

Please allow for door swing clearance at locations next

to a wall.

The illustrated measurement is without mounted front

panels. Be sure to add your panel thickness and handle

depth to this measurement in order to avoid interferences.

Figure 3

It is important to use the provided cover grille for the ventilation opening. This opening must not be covered with a

cabinet base.

Figure 2

6

p

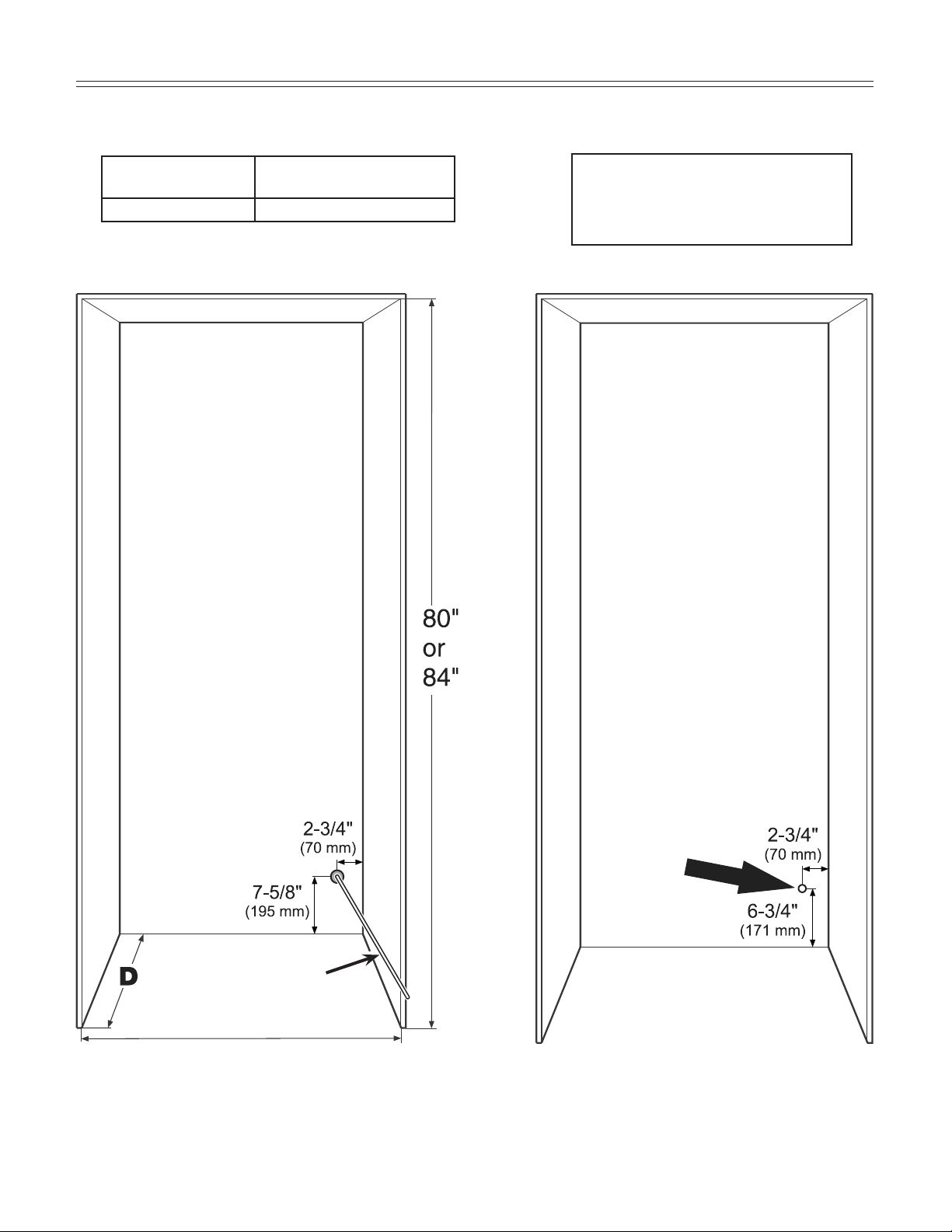

Cabinet Opening Dimensions - Figure 4

lannIng

I

nformatIon

Inset cabinet

Depth D

24" + panel thickness 24"

Frameless/faceframe cabinet

Depth D

IMPORTANT

For 24" cabinets, the water line

opening must be in the location

as shown.

With cabinets deeper than

24", there is room to t the

pipe behind the appliance

and the wall so there are no

requirements for the water line

lead out position.

The free length of the water sup-

ply line must be at least 31-1/2"

(800 mm) when the tube comes

out of the prescribed opening.

Do not install the shut-o valve

behind the appliance.

For appliance with panel to be flush,

adjacent cabinetry depth must equal

appliance depth (24") plus panel

thickness (5/8" - 3/4").

This is where the power cord

extends from the back of the

appliance.

Free length of the power cord =

90 inch (2280 mm)

Be sure to take these specifications into consideration

when choosing the location of

the electrical outlet.

IMPORTANT

The electrical outlet must

not be situated behind the

appliance and must be

easily accessible.

Water supply line

36" Single

72" Side by Side

Figure 4

7

p

lannIng

I

nformatIon

Panel Dimensions - Inset Installation Style - Figure 5

The panels should be at least 5/8 inch (16 mm) thick to

Appliance and panels sit fully within the opening and

are flush with what could be its own box, between two

pantry cabinets or decorative columns, etc. This is the

most common installation scenario.

You can order stainless steel panels for inset installation style.

Refrigerator door panels 80”- article-number 9900 337-00

Refrigerator door panels 84”- article-number 9900 335-00

Freezer drawer panels - article-number 9900 323-00

allow the connecting rails to be fastened to them.

The maximum panel thickness is 3/4" (19 mm).

Cabinet Opening A Refrigerator door panel B

80" (2032 mm) 45 - 1/4" (1150 mm)

84" (2134 mm) 49 - 1/4" (1251 mm)

IMPORTANT

Figure 5

8

p

lannIng

I

Panel Dimensions - Frameless Installation Style - Figure 6

The gap between panels with frameless installation style

With this installation style, these wider appliance

panels partially overlay the shared side gables of

adjacent cabinetry so as to mimic the look of a frameless style cabinet.

is 1/4" (6 mm). The panels should be at least 5/8 inch (16

mm) thick to allow the connecting rails to be fastened to

them.

IMPORTANT

The maximum panel thickness is 3/4" (19 mm).

Cabinet Opening C Refrigerator door panel D

80" (2032 mm) 45 - 3/4" (1162 mm)

84" (2134 mm) 49 - 3/4" (1264 mm)

nformatIon

Figure 6

9

B

lockIng for

S

afety

Mounting the anti tipping device on

concrete floors - Figure 7 - 8

Secure the appliance in place so it does not tip forward

when the fully stocked door is opened.

bracket is provided with the appliance.

1. Mark the center line of the appliance on the back wall.

Align the anti tipping bracket center to this line.

WARNING!

Be sure that there is no plumbing or

electrical wiring located in this area which

screws or drills could damage.

2. Drill a 3/8" diameter hole in any position as shown in

Figure 7 using a carbide drill bit.

The depth of the holes must exceed the overall length

of the anchors provided.

Clean the holes after drilling.

3. Attach washer and screw on hex nut to the end of each

anchor.

The anti tipping

Wall Plate

Wall

Figure 7

Wall

Drive in all 3 anchors.

Align the bracket center to the center line on the back

wall again.

Fasten the anchors by turning the hex nut.

4. Fasten bracket with 3 screws (1/4" x 2-1/8") into the

wall plate (Figure 8).

Mounting the anti tipping device on

wooden floors

1. Mark the center line of the appliance on the back wall.

Align the anti tipping bracket center to this line.

Be sure that there is no plumbing or

electrical wiring located in this area which

screws or drills could damage.

2. Fasten bracket to the wooden floor using 5 screws

(1/4" x 2-1/8"). Drill pilot holes if necessary.

3. Fasten bracket with 3 screws (1/4" x 2-1/8") into the

wall plate.

- Figure 9

WARNING!

Figure 8

Wall Plate

Wall

10

Figure 9

Wall Plate

B

lockIng for

S

afety

Mounting the anti tipping device in

cabinets deeper than 24" - Figure 10 - 11

To ensure the compressor mounting plate reaches the

anti tipping bracket in cabinets deeper than 24", a wooden spacer must be mounted between the appliance back

and the wall. The anti tipping bracket will be fastened to

the floor downwards and to the spacer backwards.

WARNING!

Be sure the wooden spacer is fastened

securely to the floor.

Measuring for mounting the wooden spacer on

inset kitchen cabinets - Figure 10

Depth of spacer depending on clearance between appliance and wall

Cover strips - Figure 12

Before connection to the water supply, the cover strips

provided must be fitted to the appliance. It is necessary

because the appliance will be moved into its recess.

• Remove the cover band from the strips and stick

them to the left and right front edge of the appliance housing (Figure 12).

Panel thickness

Figure 10

Measuring for mounting the wooden spacer on

frameless kitchen cabinets - Figure 11

Depth of spacer depending on clearance between appliance and wall

Figure 11

IMPORTANT

If the floor slopes down sideways, the anti-tipping

bracket must be fitted horizontally. Lay down spacers

in the appropriate positions.

Figure 12

11

I

ce

m

aker

Safety Instructions and Warnings

• Do not install the water connection while the combined refrigerator-freezer is connected to an electrical

outlet.

• The connection to the water supply may only be

made by a trained and licensed plumber.

• All equipment and devices used to supply the water

to the appliance must comply with the current regulations for your geographical area.

WARNING!

Connect to potable water supply only.

Water Connection Requirements

• The water supply pressure requirements are different

based on whether or not the supplied Liebherr water

filter is installed.

With the filter installed, the pressure must be in the

range of 40-90 psi (2.8-6.2 bar).

Water Connection Adapter - Figure 13

IMPORTANT

Only use the supplied adapter for connection to the

solenoid valve. The solenoid valve has a metric R3/4

male connector. Any attempt to use other adapters

for connection could damage the thread on the

solenoid valve.

The supplied adapter enables different connection

options for different kinds of water lines. A water line is

not supplied with the appliance.

IMPORTANT

Do not use any old or already premounted water

supply lines.

Seal

Connects to 1/4" compression end

Valve connector (union nut

for connection to the solenoid valve)

Without the filter installed, the acceptable pressure

range is 22-87 psi (1.5-6 bar).

Failure to meet these requirements will likely result

in ice maker malfunction and possibly cause a water

leakage that can damage flooring and surrounding

furniture.

• A shut-off valve, must be installed between the hose

line and the main water supply so the water supply

can be stopped if necessary.

IMPORTANT

Do not install the shut-off valve behind the appliance.

Angle connector

Connects to 1/4" compression end

Union nut with compression ring for

use with 1/4" OD copper lines

Figure 13

The connection to the valve connector can be done with

or without the angle connector, as required.

Braided style ice maker hoses can be connected directly

to the threaded ends.

For connection with 1/4" OD copper lines, use the union

nut with compression ring.

IMPORTANT

Make sure that the connection is fitted with a seal

and is tight.

• Insert the water strainer supplied into the

valve connector (Fi g ure 14).

12

Figure 14

Connection to the Water Supply

1. Move the appliance

towards the final position and leave enough

space to work behind.

2. Insert the water supply line into its intended opening at the

back of the appliance

(Figure 15).

3. Move the power supply

line to the area of the

electrical outlet.

WARNING!

Figure 15

I

ce

m

aker

WARNING!

To prevent the appliance from tipping

forward the compressor mounting plate

must have contact with the anti tipping

bracket (Figure 16).

5. Remove the cover from the solenoid valve

(Figure 17).

6. Connect the water line to the adapter in the respective configuration, depending on the type of water line

used. Figure 18 shows the configuration with a copper line as an example.

Do not connect to the electrical outlet

before the installation is completed and

the water line is connected to the solenoid

valve.

4. Push the appliance slowly to the back wall until the

compressor mounting plate makes contact with the

anti-tipping bracket (Figure 16).

Wall

Appliance

Anti tipping bracket

Compressor mounting

plate

7. Bleed the air from the water line by opening the water

supply temporarily.

Figure 17

8. Screw the adapter

onto the solenoid

valve (Figure 18).

Figure 16

9. Open the shut-off valve

for the water supply and

check the entire water system

for leaks.

Figure 18

13

I

nStallatIon

Leveling the Appliance - Figure 18

1. Adjust the height of the

appliance at the front

by twisting the leveling

feet (1) (A/F 27).

Use the open-ended

spanner provided.

2. Adjust the height of the

appliance at the rear

by turning the adjusting

bolts (2).

3. Rotate leveling feet

(1)until firmly in place

against the floor.

WARNING!

To prevent the appliance from tipping

forward the leveling feet (1) (Figure 19)

must have contact with the floor.

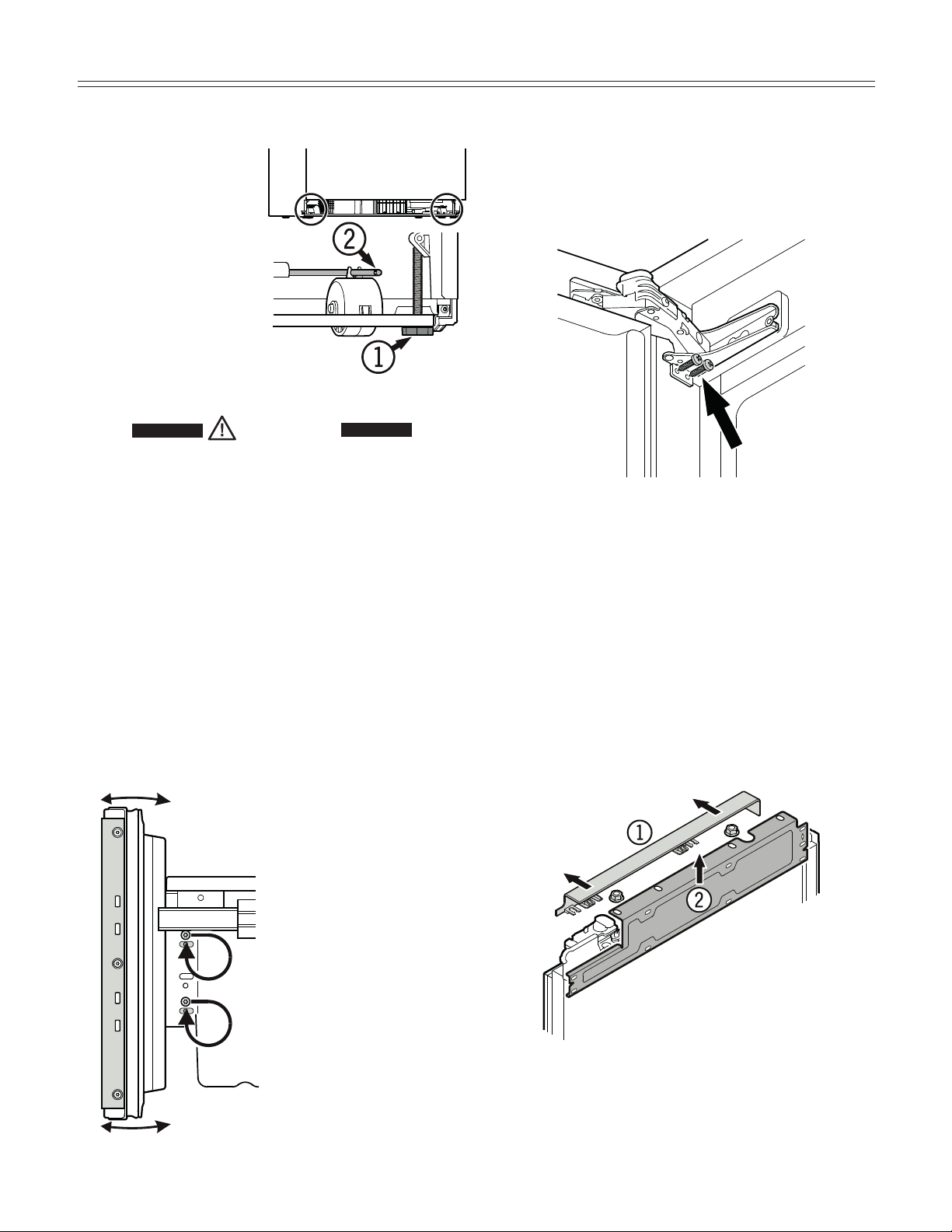

Adjusting the front of the drawer

Figure 19

If required, the front of the freezer drawers can be adjusted.

Transfer the screws shown in the illustration (on the left

and right sides of the freezer drawer) individually to the

long slots below.

Tighten the screws in the front of the drawer once it is in

the right position.

Figure 18

-

Fasten the appliance in the recess -

Figure 20

Fasten the appliance in the recess through the upper

and lower hinges of the refrigerator doors.

Use 2 screws for each hinge.

screws

(4 x 16 mm)

Figure 20

Before mounting the door panels -

Figure 21

Remove cover (1) and unscrew the upper attachment

bracket (2) of both refrigerator doors. These brackets will

be mounted onto the refrigerator door panels.

IMPORTANT

The nuts are needed to fit the premounted

panels onto the refrigerator doors.

Side view of the freezer drawer pulled out

Figure 19

Figure 21

14

I

nStallatIon

Mounting the attachment brackets onto the door panels - Figure 22

Mark lines on the refrigerator door panels as shown in

Align the dismounted brackets of the refrigerator doors to the lines on the refrigerator door panels as shown in

22 a.

Fasten each bracket with any hole wherever possible using a minimum of 6 screws 4 x 16 mm.

Fasten the brackets provided onto the freezer drawer panels using three screws (4 x 16 mm) for each bracket (

22 b)

.

Refrigerator door panels

Figure 22.

Figure 22 a

Figure

Figure

Freezer drawer panel

Freezer drawer panel

Figure 22 Figure 22 b

15

I

nStallatIon

Mounting the freezer drawer panels -

Figure 23

1. Pull out the upper freezer drawer and screw on the

panel with three screws at left and right hand side

using the screws as shown in Figure 23.

2. Close the drawer and check the position to the surrounding cabinet panels. Align the panel in vertical

direction by loosening the screws left and right. Finally

tighten the screws.

CAUTION!

Do not overtighten. Do not use a power

driver.

3. Pull out the lower freezer drawer and fasten the lower

panel in the same way.

4. Finally cover the gap between the drawer and the

panel of both freezer drawers with the strips provided.

Remove the foil from the adhesive surface of the strip

and stick on the top of the appliance drawer (Figure

23) making sure the flexible gasket is fully inserted in

the gap.

Mounting the refrigerator door panels

- Figures 24 - 33

The description is for one panel only. The procedure is

the same for both panels.

1. Open the refrigerator door and hang the panel on the

adjusting bolts (Figure 24).

2. Screw on the hex nuts to the adjusting bolts and finger

tighten temporarily (Figure 24).

Screw 3.5 x 13 mm

Figure 24

3. Close the door and check the height of the panel.

4. Align the panel in its vertical position if necessary.

Loosen the hex nuts and turn the adusting bolts using

a screwdriver for slotted screws (Figure 25).

Figure 25

Figure 23

16

I

nStallatIon

To make it possible to fasten the refrigerator panel at the

bottom the soft-stop cylinder must be dismantled.

5. Grasp the soft-stop cylinder and pull down (Figure

26).

CAUTION!

The soft-stop cylinder retracts in the

detached state.

7. Dismantle the lower attachment bracket from the

refrigerator door. Align the bracket to the lines on the

refrigerator door panel. (Figure 28).

Fasten the bracket with any hole wherever possible

using a minimum of 6 screws 4 x 16 mm.

Figure 28

Figure 26

6. Transfer the lower edge of the attachment bracket

onto the panel using a pencil. (Figure 27). Remove

the panel from the refrigerator door.

8. Open the refrigerator door and hang the panel on the

adjusting bolts (Figure 29).

9. Screw on the hex nuts to the adjusting bolts and finger tighten temporarily (Figure 29).

Figure 29

Figure 27

17

I

nStallatIon

10. Move the panel to the left until it makes contact with

the center rail (Figure 30).

11. Tighten the hex nuts finally.

Figure 30

13. Extend the soft-stop cylinder and connect with the

ball stud (Figure 32).

Figure 32

14. Click cover into place (Figure 33).

12. Fasten the refrigerator panel using the same screws

that held the lower bracket before removal (Figure

31).

Figure 31

Figure 33

18

Mounting the ventilation grille - Figure

34, 35

1. Pull out the bottom freezer drawer.

2. Remove the blue protection film from the dust

filter provided and insert the filter into its opening

in the toe kick area as shown in Figure 34.

Attach the filter at the bottom, press down the

button and click into place.

I

nStallatIon

Figure 34

3. Mount the ventilation grille as shown in Figure 35.

IMPORTANT

Only use the ventilation grille provided with the

appliance. This grille is required for proper operation

of the appliance.

The ventilation opening must not be covered with a

cabinet base.

Failure to use the supplied grille can result in product

failure and will void the warranty.

Figure 35

19

For Service in the U.S.

Liebherr Service Center

Toll Free: 1-866-LIEBHER or 1-866-543-2437

Email: Service-appliances.us@liebherr.com

PlusOne Solutions, Inc.

3501 Quadrangle Blvd, Suite 120

Orlando, FL 32817

For Service in Canada

Liebherr Service Center

Toll Free: 1-888-LIEBHER or 1-888-543-2437

www.euro-parts.ca

EURO-PARTS CANADA

39822 Belgrave Road

Belgrave, Ontario, N0G 1E0

Phone: (519) 357-3320

Fax: (519) 357-1326

*708299300*

www.liebherr-appliances.com

Loading...

Loading...