Page 1

Design Guide 2008

Fully Integrated Models - 36"

Page 2

Page 3

Welcome

Liebherr's engineering excellence in Germany provides the largest

selection of freezers, refrigerators and wine refrigerators worldwide.

Liebherr-appliances consistently specializes in the manufacturing of high

quality freezers and refrigerators. With more than 300 basic models, we have

the widest selection in the world. Liebherr appliances feature premium quality,

numerous innovative product ideas and advanced design. Liebherr freezers and

refrigerators are manufactured at three modern production plants:

Liebherr Marica in Bulgaria, Liebherr-Hausgeräte Ochsenhausen GmbH in

Germany and the Liebherr-Hausgeräte Lienz GmbH in Austria.

We produce more than 2.3 million quality freezers, refrigerators and wine

refrigerators each year, and these are sold all over the world. LiebherrHausgeräte Ochsenhausen GmbH in Germany makes over 1,100,000 appliances

a year and employs 1,900 people. The Liebherr-Hausgeräte Lienz GmbH

manufactures more than 700,000 freezers and refrigerators and employs 1,500

people.

The appliances for the North American market are produced in Austria and in

Germany.

Liebherr is commited to the protection of the environment and recognizes it

as a critical priority. To guarantee an optimum and consistent implementation,

all ecological aspects were observed and integrated into the quality control of

Liebherr in compliance with DIN EN ISO 9001.

Liebherr's Commitment to the Environment

The components of Liebherr products can be recycled when the necessary

resources are applied. A concern for the environment and a desire to protect

resources has lead to increased levels of recycling year after year. When

Liebherr manufactures products, it is essential that the recyclable recovery rate

of the materials we use constantly increases.

Recycling is a common goal among all manufacturers, municipalities and

recycling companies to protect our environment. Protecting the environment

and producing products which have a low impact on the environment, is one

of Liebherr's core values. Whether you are replacing a unit or starting fresh,

remember to dispose of your old appliance in an environmentally safe and

friendly manner.

Page 4

Introduction

LIEBHERR WARRANTY PLAN

FULL TWO YEAR WARRANTY - For two years from the date of original purchase, your Liebherr Warranty

covers all parts and labor to repair or replace any part of the product which proves to be defective in materials or workmanship.

FULL FIVE YEAR WARRANTY - For five years from the date of original purchase, your Liebherr Warranty

covers all parts and labor to repair or replace any components that prove to be defective in materials or

workmanship in the sealed system. The "Sealed System" means only the compressor, condenser, evaporator, drier and all connecting tubing.

LIMITED 6TH THROUGH 12TH YEAR WARRANTY - From the 6th through 12th year from the date of

original purchase, your Liebherr Warranty covers all parts that prove to be defective in materials or workmanship in the sealed system (parts only).

Customer Service

If your appliance is not working properly, or if the temperature display reads "F0" to "F5”, please call the

numbers listed below.

Give the fault number displayed, together with the

Type Designation,

Service Number and

Appliance Number (Serial Number)

from the model plate, to ensure prompt, accurate servicing. The model plate is located inside the appliance.

Leave the appliance door closed until the customer service technician arrives to minimize any further cold loss.

For Service and Parts in the U.S.:

Liebherr Service Center

15545 N. 77th Street

Scottsdale, AZ 85260

Phone: (480) 998-0141

Fax: (480) 998-7877

Toll Free: 1-866-LIEBHERR or

1-866-543-2437

www.liebherr-appliances.com

For Service and Parts in Canada:

Euro-Line Appliances

2278 Speers Rd.

Oakville, Ontario, L6L 2X8

Phone: (905) 829-3980

Fax: (905) 829-3985

Toll Free: 1-888-Liebherr,

1-888-543-2437

www.euro-parts.ca

Page 5

Contents

General Remarks

Safety Warnings I

Electrical Requirements & Safety II

IceMaker (if equipped) III

Area Requirements IV

Safety Regulations V

Fully Integrated Models

36" Models: HC 2062 / HCS 2062 1

Unit Dimensions 3

Cabinet Opening Dimensions 4

Ventilation Requirements 5

Framed Cabinet, Frameless Cabinet 6

Door and Drawer Panel Dimensions - Framed Cabinet 7

Door and Drawer Panel Dimensions - Frameless Cabinet 8

Page 6

Page 7

General Remarks

I. Safety Warnings

PLEASE READ AND FOLLOW THESE INSTRUCTIONS

This design guide contains Warning and Caution statements. This information is important for safe and

efficient installation.

This design guide is not replacing the use and care manual which contains important information on how to use Liebherr appliances.

Always read and follow all Warning and Caution statements!

States a hazard that may cause serious injury or death if precautions are not followed.

Signals a situation where minor injury or product damage may occur if you do not follow instructions.

States a hazard will cause serious injury or death if precautions are not followed.

IMPORTANT

This highlights information that is especially relevant to a problem-free installation.

Make sure incoming voltage is the same as the unit rating.

To reduce the risk of fire, electric shock, or personal injury, the installation work and electrical wiring must be done by

a qualified electrician in accordance with all applicable codes and standards, including fire rated construction.

To the Installer

It is very important that the guidelines and instructions are followed in this design guide to ensure proper installation and operation of the unit. The Installation Guidelines section contains important information for making sure the

installation is correct. Read and understand all the information and installation guidelines in this manual before the

unit is installed.

It is also very important to know the Safety Information.

Page 8

General Remarks

II. Electrical Requirements & Safety

A 115 Volt, 60 Hz, 15 Amp (20 Amp for side-by-side

installation) fused electrical supply is required. Connect

undercounter wine cabinet to a 115 VAC, 10 amp (15

Amp for side-by-side installations) circuit that is controlled by a circuit breaker or fuse.

We recommend using a dedicated circuit for these appliances to prevent electrical overload. Comply with

the National Electrical Code as well as local codes and

ordinances when installing the receptacle.

The power cord is equipped with a three-prong (grounding) plug for your protection against possible shock

hazards. To maintain this protection:

• Do not modify the plug by removing the round grounding prong.

• Do not use a power cord that is frayed or damaged.

Do not ground to a gas pipe. Check with a

qualified electrician if you are not sure the

appliance is properly grounded. Do not have

a fuse in the neutral or grounding circuit.

III. IceMaker (if equipped)

The icemaker is located in the freezer compartment.

It must be connected to the water supply to function

properly. The appliance must be level for the icemaker to

function properly.

The water pressure must be between 21.8-87.0 psi (1.5-6 bar).

Use a 1/4" OD copper line to connect the water supply to

the solenoid valve. This is not supplied with the refrigerator.

If you have hard water, we recommend you install a

water softener. Also, a filter must be installed if the water

contains solids such as sand. All equipment and devices

used to supply the water to the appliance must comply

with the current regulations for your geographical area.

Safety Instructions and Warnings

• Do not attach the water source while the appliance is

connected to an electrical outlet.

• A shut-off valve, must be installed between the hose

line and the main water supply so that the water supply can be stopped if necessary. Do not install the

shut-off valve behind the refrigeration unit.

• The connection to the water supply may only be made

by a trained and licensed plumber.

ELECTROCUTION HAZARD

Electrical Grounding Required. This

appliance is equipped with a threeprong(grounding) polarized plug for your

protection against possible shock hazards.

• DO NOT remove the round grounding

prong from the plug.

• DO NOT use a two-prong grounding

adapter.

• DO NOT use an extension cord to connect

power to the unit.

• The water quality must comply with the drinking water

regulations for the geographical area where the appliance is located.

• The icemaker is designed exclusively to make ice

cubes in quantities needed by a household and may

only be operated with water appropriate for this purpose.

• All repairs and work on the icemaker may only be done

by customer service personnel or other trained personnel.

• The manufacturer cannot accept liability for damage

caused by equipment or water lines between the solenoid valve and the water supply.

Page 9

General Remarks

IV. Area Requirements

Verify the following:

• Floors can support refrigerator’s weight plus approximately 1200 pounds (544 kg) of food weight. Not

all Liebherr products are designed for 1200 pounds

(544 kg) of food. Some units are smaller and total

weights may vary.

• Finished kitchen floor height is level. Refrigerator must

be shimmed to the floor level, or levelled, to make

sure, air vents are not obstructed.

• Remove anything attached to the rear or side walls

that can obstruct refrigerator opening.

• Cutout dimensions are accurate.

• Electrical outlet is in correct location.

Do not install this unit next to any other refrigerator or

freezer except another Liebherr model. Liebherr models

are designed to allow side by side installation. They are

equipped with a heating system to eliminate condensation when units are installed side by side. Installing this

unit next to any other refrigerator or freezer can cause

condensation or cause damage to the Liebherr unit.

V. Safety Regulations

The appliance complies with UL250 and CAN/CSA-C

22,2 No. 63 and is designed to cool, freeze, store food

as well as make ice (if equipped). It is designed as a

household appliance. If used commercially, the relevant

regulations on commercial use must be observed.

The appliance is set to operate within specific ambient

temperature limits according to its climate rating. These

temperature limits should not be exceeded. The correct climate rating for your appliance is indicated on the

model plate.

This is explained as follows:

Climate

Rating

SN 50°F to 90°F (10°C to 32°C)

N 61°F to 90°F (16°C to 32°C)

ST 61°F to 100°F (16°C to 38°C)

T 61°F to 109°F (16°C to 43°C)

SN-ST

SN-T

Set for Ambient Temperatures of

50°F to 100°F (10°C to 38°C)

50°F to 109°F (10°C to 43°C)

To protect the refrigerator from possible

damage, allow the appliance to stand 1/2 to

1 hour in place before turning the electricity

on. This allows the refrigerant and system

lubrication to reach equilibrium.

Blocking For Safety

The anti-tip bracket must be installed to prevent the unit

from tipping after it is installed. Refer to chapter "Blocking For Safety" in the installation instructions.

- The refrigerant circuit has been tested for leaks.

Page 10

Fully Integrated

HC 2062, HCS 2062

36" Models: HC 2062, HCS 2062

Integrated units are the most stylish option available - they create a totally flush appearance with the surrounding cabinets in the

kitchen.

Please choose the HC 2062 to use custom finished door panels that match your kitchen’s cabinetry.

HC 2062

Energy Star: qualified

Energy consumption p. a.: 452 kWh

Energy Supply: 115V / 60Hz / 2.5A

Total capacity: 19.5 cu ft (552 L)

Refrigerator: 13.5 cu ft (382 L)

Freezer: 6 cu ft (170 L)

Ice cube capacity: 3 pd./24h

Ice cube stock: 6 pd.

Climate Rating: SN-T

• Automatic refrigerator defrosting

• Automatic freezer compartment defrosting

• Automatic IceMaker can be switched off

• Maximum door opening angle is 105°

1

Page 11

Fully Integrated

Please choose the HCS 2062 for a stainless steel finish of your unit – no additional door panels or handles are required.

HCS 2062

Energy Star: qualified

Energy consumption p. a.: 452 kWh

Energy Supply: 115V / 60Hz / 2.5A

Total capacity: 19.5 cu ft (552 L)

Refrigerator: 13.5 cu ft (382 L)

Freezer: 6 cu ft (170 L)

Ice cube capacity: 3 pd./24h

Ice cube stock: 6 pd.

Climate Rating: SN-T

• Automatic refrigerator defrosting

• Automatic freezer compartment defrosting

• Automatic IceMaker can be switched offf

• Maximum door opening angle is 105°

2

Page 12

Fully Integrated

Unit Dimensions

HC 2062, HCS 2062

Overall height can be increased on HC 20

and HCS 20 units by 1-1/2" (40 mm) by adjusting the roller base.

HC 2062

A. 3" (76 mm)

B. 79-13/16" (2027 mm)

C. 35-13/16" (910 mm)

D. 3" (76 mm)

E. 24" (610 mm)

G. 42-7/16" (1078 mm)

H. 37-1/8" (943 mm)

Please allow for door swing clearance at

locations next to a wall.

The illustrated measurement for HC 2062 is

without mounted front panels. Be sure to add

your panel thickness and handle depth to this

measurement in order to avoid interferences.

HCS 2062

A. 3-17/32" (90 mm)

B. 79-13/16" (2027 mm)

C. 35-13/16" (910 mm)

D. 3-1/2" (89 mm)

E. 24-7/32" (615 mm)

G. 42-7/16" (1078 mm)

H. 39-7/16" (1002 mm)

Please allow for door swing clearance at

locations next to a wall.

The illustrated measurement for HCS 2062 is

with mounted front panels.

3

Page 13

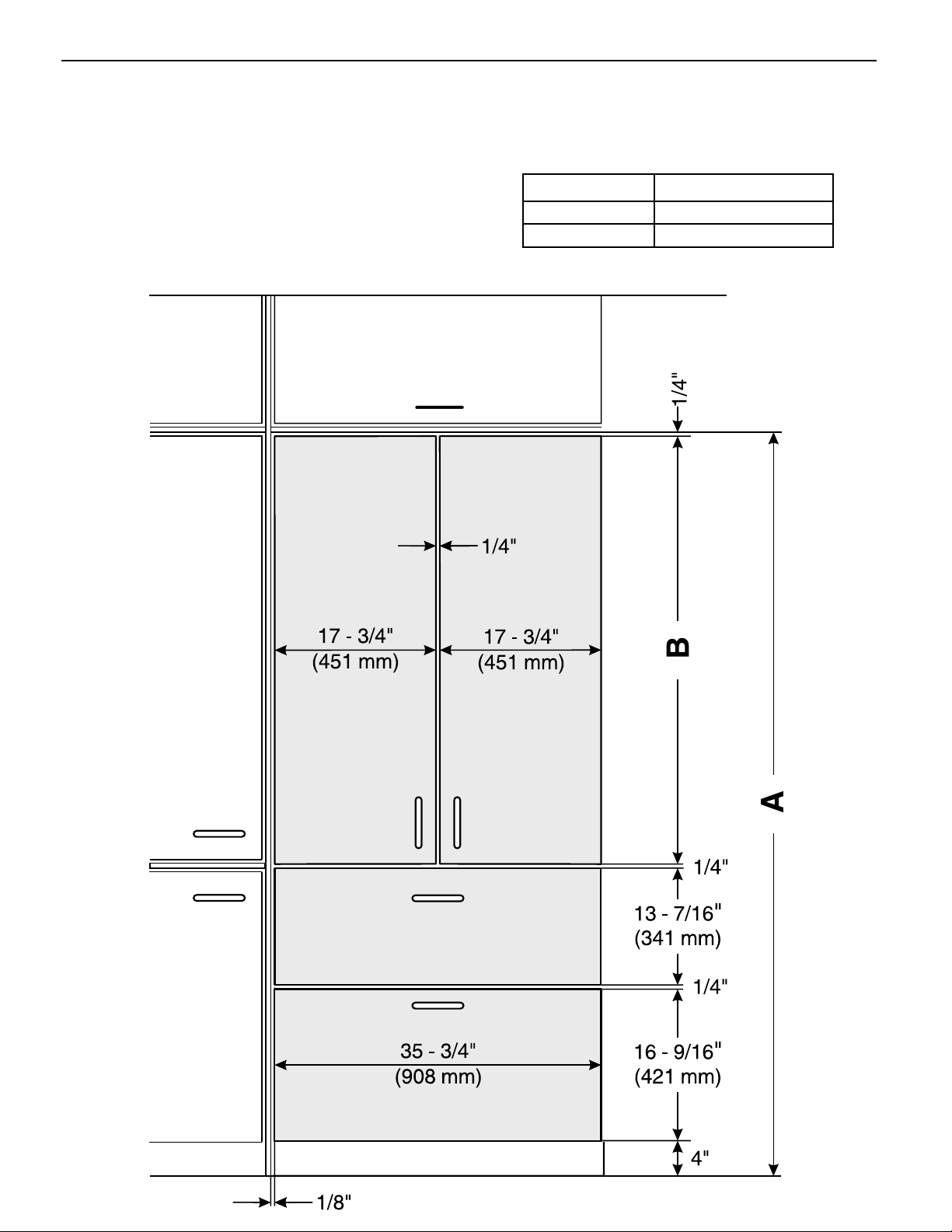

Fully Integrated

Cabinet Opening Dimensions

HC 2062, HCS 2062

Cabinet

Height C

HC 2062

HCS 2062

80" 24 3/4" 24"

84" 24 3/4" 24"

80" 24 3/4" not available

84" 24 3/4" not available

A = 36" (914 mm)

Framed cabinet

Depth B

Frameless cabinet

Depth B

For the model HCS 2062 there are standard accessories

available for 80“ or 84“ high cabinets.

Concerning the refrigerator compartment there is the option to choose between stainless steel panels for a 80” or

a 84” installation situation.

The freezer drawers are always preinstalled with a stainless steel finish.

Electrical outlet

IMPORTANT

At 24" cabinets, the water line opening must be in the

location as shown.

At cabinets deeper than 24" there is room to fit the

pipe behind the appliance and the wall so there are no

requirements for the water line lead out position.

IMPORTANT

Do not install the shut-off valve

behind the appliance.

Water line opening

Water supply line

IMPORTANT

The free length of the water supply line must be at least

31 - 1/2" (800 mm) when the tube comes out of the pre-

scribed opening.

4

Page 14

Fully Integrated

Ventilation Requirements

HC and HCS appliances dont need any ventilation openings in the

cabinet. The required airflow is directed through the plinth area.

Model HC 2062 with door panels Model HCS 2062 with stainless steel front

HC 2062, HCS 2062

It is important to use the provided cover grille for the ventilation opening.

This opening must not be covered with a cabinet base.

5

Page 15

Fully Integrated

HC 2062

Frameless CabinetFramed Cabinet

Cabinet frame.

At Framed Cabinets the panel front is

in line with the Cabinet frame.

At Frameless Cabinets the panels are

in front of the Cabinet frame.

6

Page 16

Fully Integrated

Door and Drawer Panel Dimensions HC 2062 - Framed Cabinet

The panels should be at least 5/8 inch (16 mm) thick to allow

the connecting rails to be fastened to them.

Cabinet Opening A Refrigerator door panel B

IMPORTANT

The maximum panel thickness is 3/4" (19 mm).

80" (2032 mm) 45 - 9/32" (1150 mm)

84" (2134 mm) 49 - 9/32" (1252 mm)

HC 2062

Cabinet Opening

7

Page 17

Fully Integrated

IMPORTANT:

Even in a frameless cabinet

kitchen design it is very common

for the installation of this unit to

dictate a framed cabinet

configuration. If the doors of

adjacent cabinets are full overlap

of the end gables rather than

partial overlap you will want to

use the framed panel

dimensions for installation.

Door and Drawer Panel Dimensions HC 2062 - Frameless Cabinet

The gap between all panels at frameless cabinet design is 1/4" (6 mm)

Cabinet Opening C Refrigerator door panel D

IMPORTANT

The maximum panel thickness is 3/4" (19 mm).

80" (2032 mm) 45 - 3/4" (1162 mm)

84" (2134 mm) 49 - 3/4" (1264 mm)

HC 2062

Cabinet Opening

8

Page 18

Design Guide 2008

Fully Integrated Models - 36"

Loading...

Loading...