Page 1

Installation

Instructions

Combined fridge-freezer, fully

integrated

Instructions

de montage

Combiné réfrigérateur-

congélateur, entièrement

intégrable

Instrucciones

de montaje

Combinado frigorífico-congelador,

integrable en mueble alto

HC1011/1060 HC1001/1050

111113 7084000 - 03

Page 2

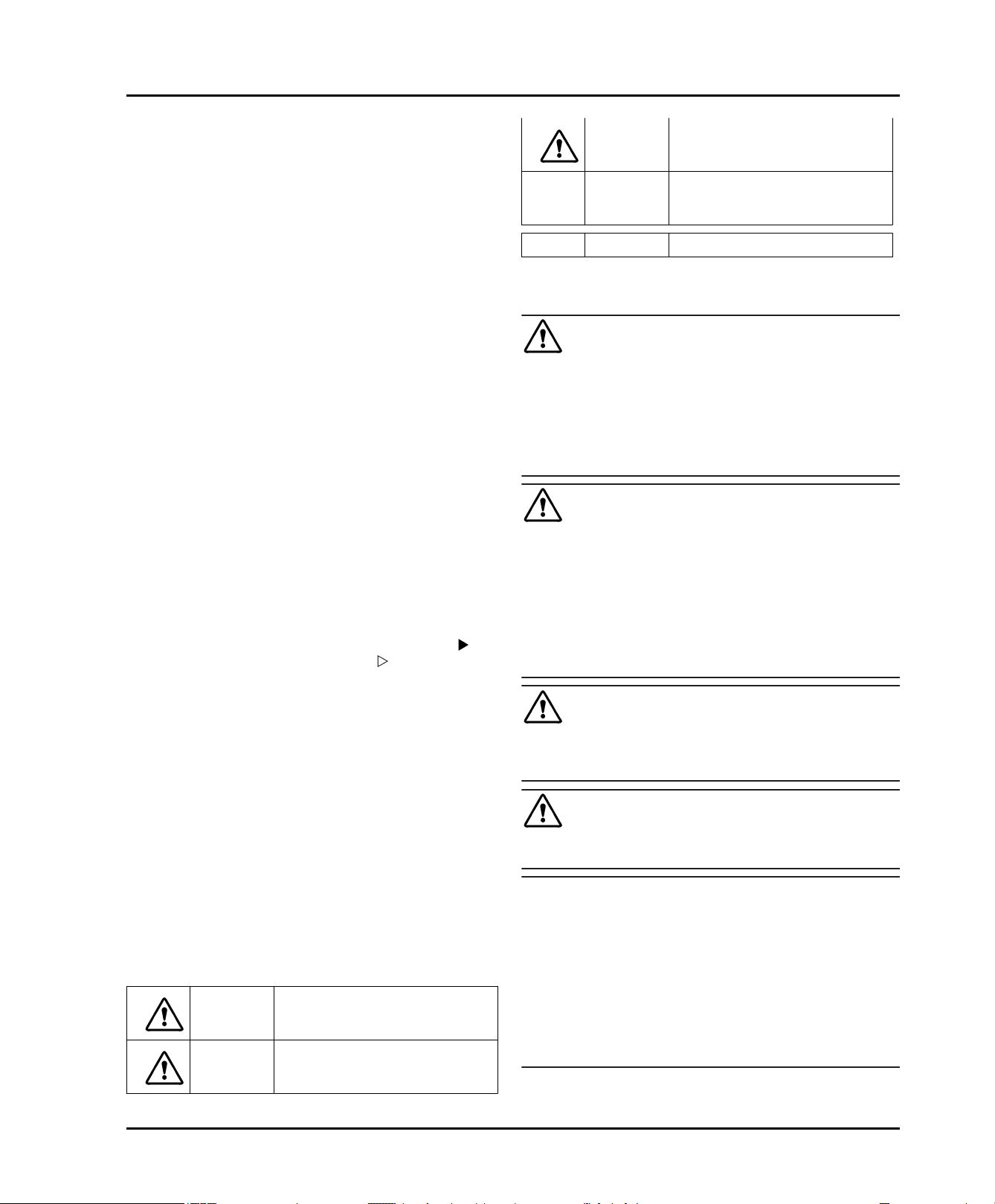

General safety information

Contents

1 General safety information........................... 2

2 Setting up the appliance............................... 2

3 Kitchen Cabinet Construction...................... 3

3.1 Kitchen Cabinet Airflow.................................... 3

3.2 Designing the Kitchen Cabinet......................... 5

3.3 Designing the Kitchen Cabinet Doors............... 6

4 Changing the door hinges............................ 8

4.1 To detach the soft stop mechanism.................. 8

4.2 Reversing the door........................................... 8

4.3 Re-attaching the soft stop mechanism............. 8

5 Water connection........................................... 9

6 Installation...................................................... 10

6.1 Assembling the appliance................................ 10

6.2 Fitting the unit doors......................................... 12

7 Connecting the appliance............................. 14

The manufacturer is constantly working to improve all

models. Therefore please understand that we reserve the

right to make design, equipment and technical modifications.

To get to know all the benefits of your new appliance,

please read the information contained in these instructions carefully.

The instructions apply to several models, so there may be

differences. Sections which only apply to certain appliances are indicated with an asterisk (*).

Instructions for action are marked with a

results of action are marked with a .

, the

CAUTION indicates a hazardous situation,

which if not avoided, will result in

minor or moderate injury.

NOTICE indicates a hazardous situation,

which if not avoided, could result in

damage to property.

Note indicates useful advice and tips.

2 Setting up the appliance

WARNING

Risk of fire due to moisture!

If live parts or the power cord get wet, this can cause a

short circuit.

u

The appliance is designed for use in enclosed spaces.

Do not operate the appliance in open space or in damp

areas or where there is spray.

u

Only operate the appliance after it has been installed.

WARNING

Risk of fire due to short circuit.

If the power cable or plug of the appliance or another

appliance and the back of the appliance touch each other

the power cable or plug will be damaged by the vibrations

of the appliance which could lead to a short circuit.

u

Install the appliance so that it does not touch any plugs

or power cables.

u

Do not connect the appliance or other appliances to the

sockets on the back of the appliance.

1 General safety information

-

Read and follow these instructions. They

contain safety advice which is important for

safe and problem-free installation and operation. Always read and follow the safety advice.

-

It is important that the guidelines and instructions in this manual are followed so that the

appliance is correctly installed and operates

properly Read and understand all information

in this manual before the appliance is installed

-

The socket must be easily accessible so that

the appliance can be disconnected from the

mains quickly in an emergency. It must not be

behind the back of the appliance.

DANGER indicates a hazardous situation,

which if not avoided, will result in

death or serious injury.

WARNING indicates a hazardous situation,

which if not avoided, could result in

death or serious injury.

WARNING

Danger of fire and damage!

u

Do not place devices that give off heat, e.g. microwaves, toasters, etc. on the appliance.

CAUTION

Risk of personal injury!

u

Have two people move this appliance into place.

NOTICE

Risk of damage caused by condensation

Installing the appliance next to any other refrigerator or

freezer can cause condensation or damage to the

Liebherr appliance.

u

Do not install this appliance next to any other refrigerator or freezer except another Liebherr model. Liebherr

models are designed to allow side-by-side installation.

They are equipped with a heating system to eliminate

condensation when refrigerators or freezers are

installed side-by-side.

2 * Depending on model and options

Page 3

Kitchen Cabinet Construction

NOTICE

Risk of damage for the finished floor surface!

u

Protect the finished floor surface before you uncrate the

unit.

Verify that:

q

The floor under the appliance is flat and level.

q

The floor can support the appliance's weight plus

approximately 1200 pounds (544 kg) of food weight.

q

The appliance is not placed in direct sunlight or near

the stove, range top, radiators and similar heat

sources.

q

The kitchen cabinet that the appliance is installed in is

shimmed to the floor level if the floor heights are not

equal.

q

Cutout dimensions are accurate.

q

Electrical outlet is in correct location.

q

The air flow is not restricted. Air flow must be provided

for the appliance to operate properly. The factory air

vents provide 31 square inches (200 cm2) of air flow

per appliance. If you are replacing the air vents with an

overlay, the air flow must be the same or greater than

the factory air vents.

u

Examine the unit and packaging for shipping damage.

Contact the carrier immediately if you suspect there is

any damage.

u

Note the type (model, number), index, appliance/serial

number, date of purchase and where purchased .

u

Remove anything attached to the rear or side walls of

appliance that would prevent proper installation or

impede proper ventilation.

u

Unscrew the red transport

lock. Close the vacated

retaining hole using the

stopper (70).

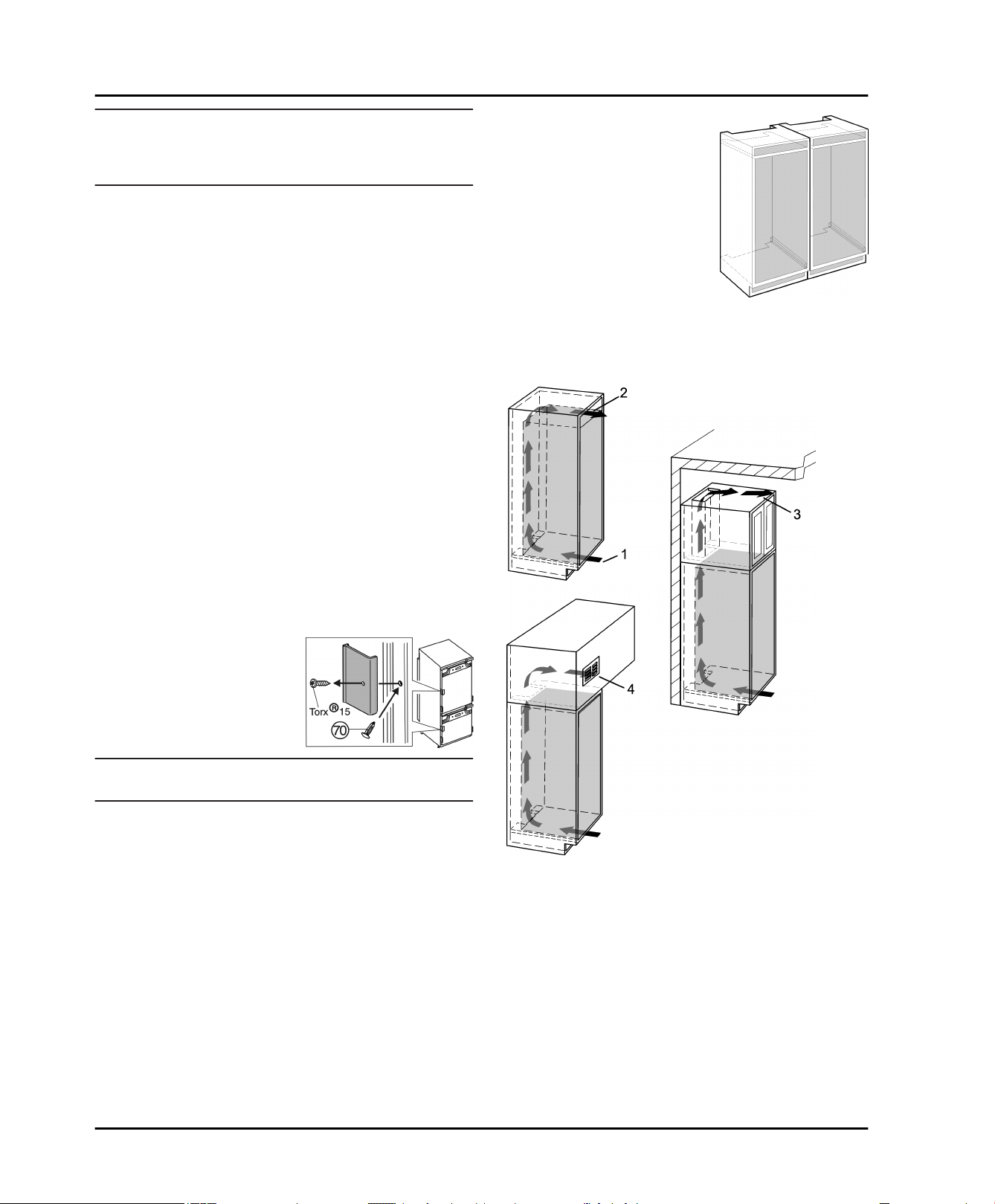

Make a separate kitchen cabinet

for each appliance for Side-bySide installations.

Consider having a professional install the appliance in

your kitchen cabinet.

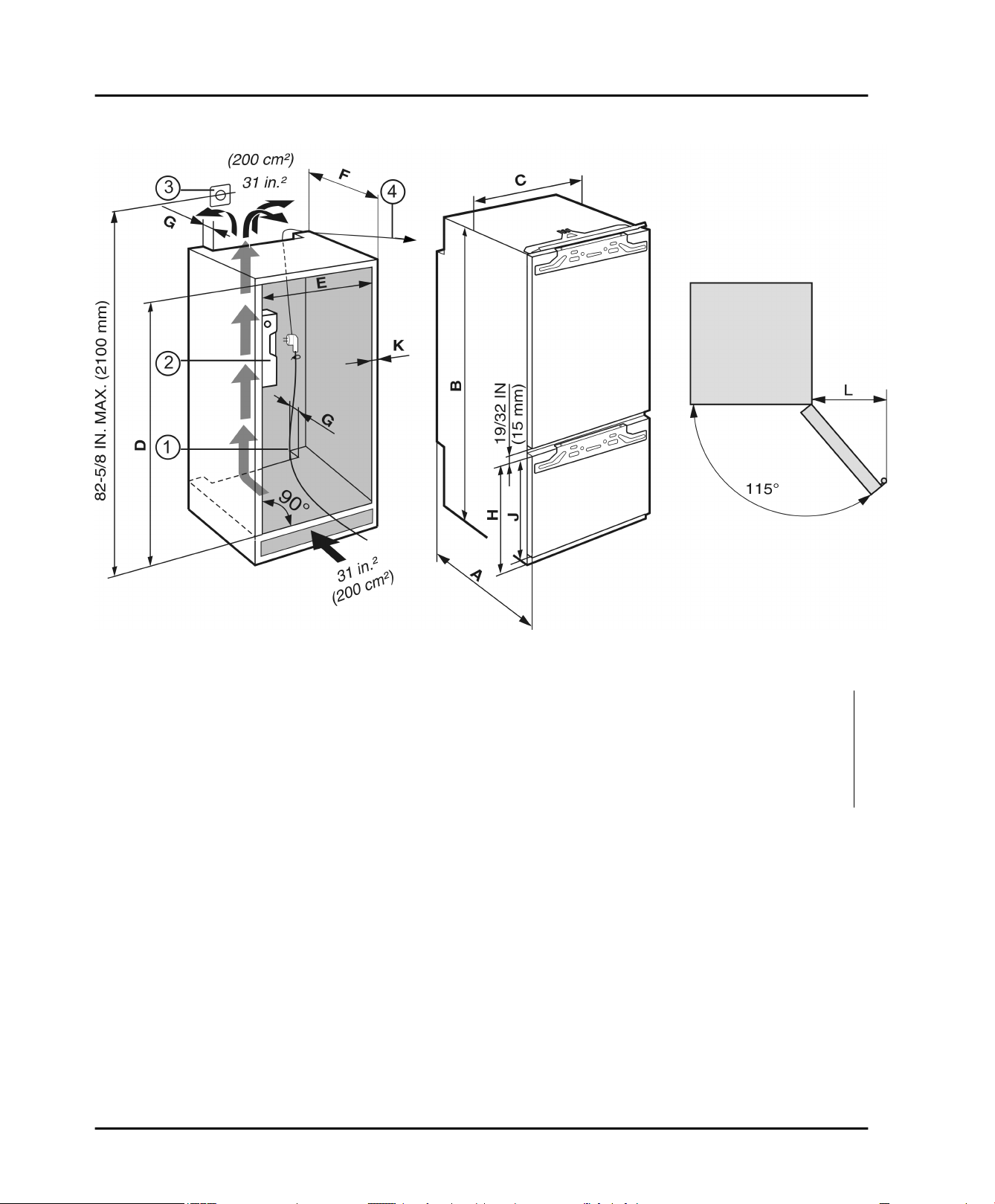

3.1 Kitchen Cabinet Airflow

Note

u

Clean the appliance .

If the appliance is set up in humid areas, condensation

may build on the outside of the appliance.

u

Always ensure proper ventilation.

- There must be a ventilation space at least 31 in

3 Kitchen Cabinet Construction

This is a fully integrated appliance which means that it is

fully enclosed by a kitchen cabinet. This type of cabinet

must be carefully constructed using the proper dimensions and it must provide proper ventilation to ensure

proper appliance operation.

* Depending on model and options 3

(200 cm2) at the airflow inlet

outlet

Fig. 1 (2)

- The top ventilation space can be either directly over the

appliance

Fig. 1 (3)

.

Fig. 1 (2)

, or through a vent installed in a soffit

or next to the ceiling over a cabinet

Fig. 1 (1)

and at the airflow

Fig. 1

Fig. 1 (4)

.

2

Page 4

Kitchen Cabinet Construction

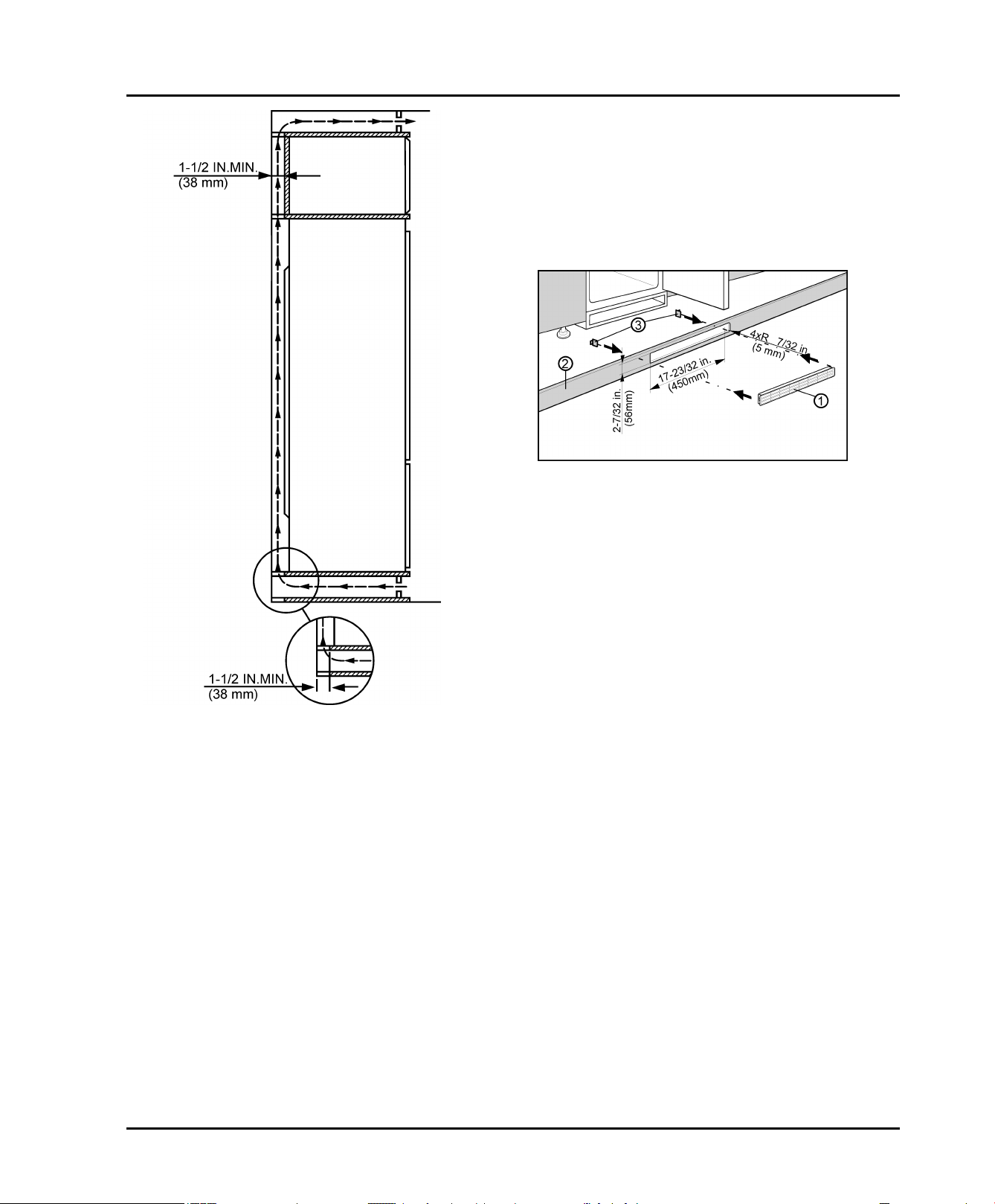

- There must be a clear ventilation space (without any

obstructions) of at least 1-1/2 in. (38 mm) at the back of

the kitchen cabinet.

u

Observe the above ventilation dimensions.

Ventilation through the cabinet base at the bottom can be

achieved by installing the provided ventilation grille

Fig. 3 (3)

or via a ventilation opening of at least 31 in

(200 cm2). When using the provided ventilation grille

Fig. 3 (3)

u

, please proceed as follows:

Fig. 3

In the cabinet base, cut out a ventilation opening that is

17-23/32 in. (450 mm) in width and 2-7/32 in. (56 mm)

in height.

u

Insert ventilation grille

cut-out

u

From the back side, slide the snap-fits

Fig. 3 (1)

.

Fig. 3 (3)

into the cabinet base

Fig. 3 (2)

into the

grille until the hooks make contact with the cabinet

base.

u

Completely mount cabinet base (with ventilation grille

and snap-fits) to kitchen cabinet.

2

Fig. 2

4 * Depending on model and options

Page 5

3.2 Designing the Kitchen Cabinet

Kitchen Cabinet Construction

Fig. 4

1 Power cord 3 Electrical outlet

2 Level 4 Fish line for power cord

A 21-7/32 in. (539 mm) B 69-21/32 in. (1769.5 mm)

C 21-15/16 in. (557 mm) D 69-3/4 in. - 70-3/8 in. (1772 mm) - (1788 mm)

E min. 22 in. (560 mm) F 21-21/32 in. (550 mm)

max. 22-3/4 in. (578 mm) G 1-1/2 in. (38 mm)

H 27-3/8 in. (695 mm) J 24-3/4 in. (629 mm)

K max. 3/4 in. (19 mm) L 9-21/32 in. (245 mm)

u

Install the appliance in stable kitchen cabinets only.

u

Construct the kitchen cabinet using the dimensions

shown in

u

Align the kitchen cabinet with a level

square. If necessary, shim underneath the cabinet to

make it level.

w

The floor and side walls must be at right angles to each

other.

The joint between the upper and the lower kitchen cabinet

door must align with the joint between the upper and

lower appliance door.

Follow distance L to the wall to allow the drawers to be

pulled out properly.

u

Follow the dimensions provided in

Fig. 4

.

Fig. 4

Fig. 4 (2)

.

and a

* Depending on model and options 5

Page 6

Kitchen Cabinet Construction

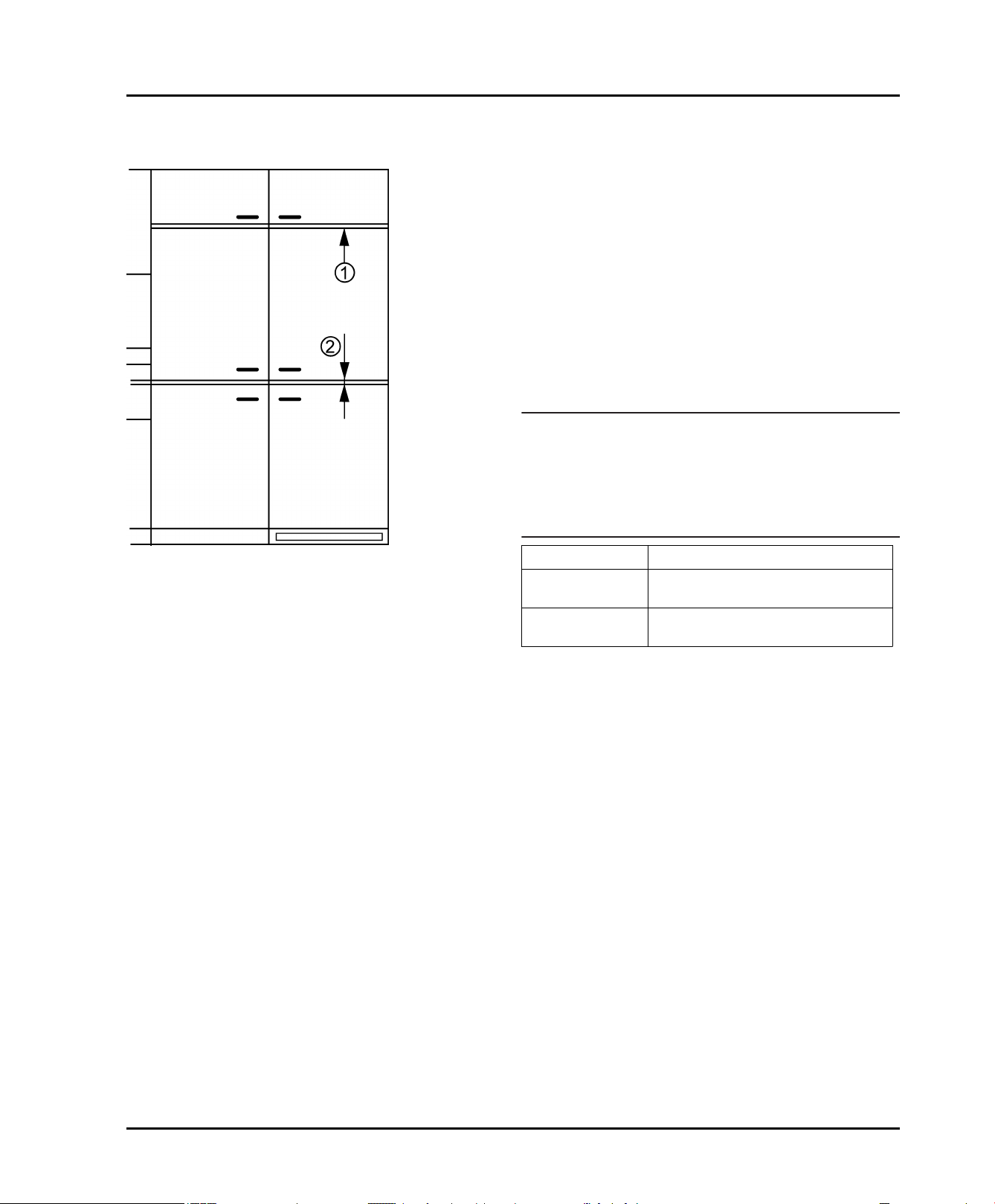

3.3 Designing the Kitchen Cabinet Doors

Fig. 5

You need two doors for the kitchen cabinet, one on top for

the refrigerator compartment, and one on the bottom for

the freezer compartment.

In general, the doors have these characteristics:

The doors should be at least 5/8 in. (16 mm) and max.

3/4 in. (19 mm) thick to allow the connecting rails to be

fastened to them.

With both doors closed, there should be a minimum of

1/8 in. (3 mm) between the upper and lower doors.

Also, there should be an 1/8 in. (3 mm) clearance

between the upper door and the cabinet door above it

(if any).

The width of the cabinet doors depends on the kitchen

style and size of the gaps between the door panels of

the cabinetry. Generally, a 1/8 in. (3 mm) vertical gap

between the cabinet doors is recommended.

The top edge of the upper door

-

Fig. 5 (2)

cabinet(s), if any.

The position of the joint between the kitchen cabinet

doors must be level with the position of the joint

Fig. 5 (2)

The unit doors must be assembled flat and free from

tension.

Adjust the door alignment before installing the appli-

ance. It is impossible to adjust the door with the appliance installed.

NOTICE

Excessively heavy unit doors can cause potential

damage!

If the unit doors are too heavy, we cannot rule out damage

to the hinges, which may compromise the use of the unit.

u

Before installing the unit doors, ensure the doors do not

exceed the permissible weight.

Fridge compartment door

Freezer compartment door

u

Check the installation dimensions according to

should be even with the doors of adjoining

between the appliance doors.

Maximum weight of unit door

30.5 lbs (14 kg)

26.5 lbs (12 kg)

Fig. 5 (1)

and lower door

Fig. 4

.

6 * Depending on model and options

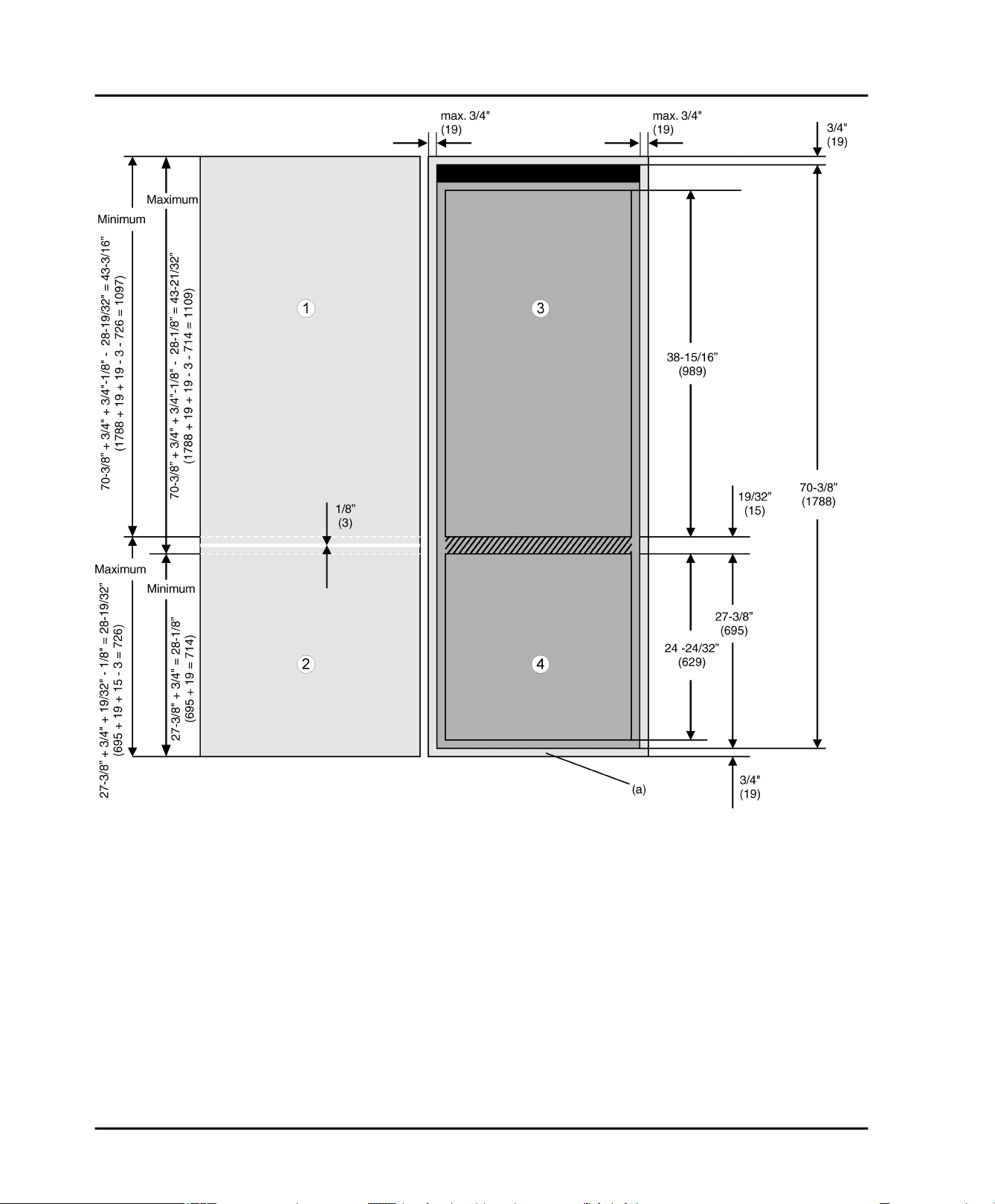

Page 7

Kitchen Cabinet Construction

Fig. 6

1 Unit door fridge compartement 3 Fridge compartement door

2 Unit door freezer comparte-

ment

The freezer door height is 24-24/32 in. (629 mm).

u

To cover the lower part of the appliance: increase the

height of the panel to 27-3/32 in. (695 mm).

The thickness of the floor board is usually 3/4 in. (19 mm).

u

To cover the face side of the floor board

increase the height of the panel to 27-3/8 in. + 3/4 in. =

28-1/8 in. ( 695 mm + 19 mm = 714 mm ).

Without door panels on the unit, there is a gap of freezer

Fig. 6 (4)

(15 mm). After the installation of the cabinet doors, the

gap between the two doors

1/8 in. (3 mm) and must be in the hatched area.

* Depending on model and options 7

betwenn the refrigerator door

Fig. 6 (1,2)

4 Freezer compartement door

Of course, the final door height depends on the gap position of the cabinets that stand to the left and right of the

appliance cabinet.

If there is other furniture standing close to the appliance

Fig. 6 (a)

Fig. 6 (3)

will only be around

19/32 in.

:

cabinet this furniture typically has a gap between two

drawers or two doors. Depending on your kitchen, these

gaps are approximately 1/8 in. (3 mm) wide.

u

In this case, increase the height of the panel to

27-3/8 in. + 3/4 in. + 19/32 in. - 1/8 in. = 28-19/32 in.

( 695 mm + 19 mm + 15 mm - 3 mm = 726 mm ).

The height of the refrigerator door panel is:

Page 8

Changing the door hinges

u

The total opening of the cabinet (i.e. 70-3/8 in.

(1788 mm)) plus the thickness of the top as well as the

floor board (usually 3/4 in. (19 mm)) minus the height of

the freezer door panel (xxx in. (xxx mm)) as calculated

above and subtract the width of the gap (approximately

1/8 in. (3 mm)): 70-3/8 in. + 3/4 in. + 3/4 in. - xxx in. 1/8 in. = 71-25/32 in. - xxx in. ( 1788 mm + 19 mm +

19 mm - xxx mm - 3 mm = 1823 mm – xxx mm )

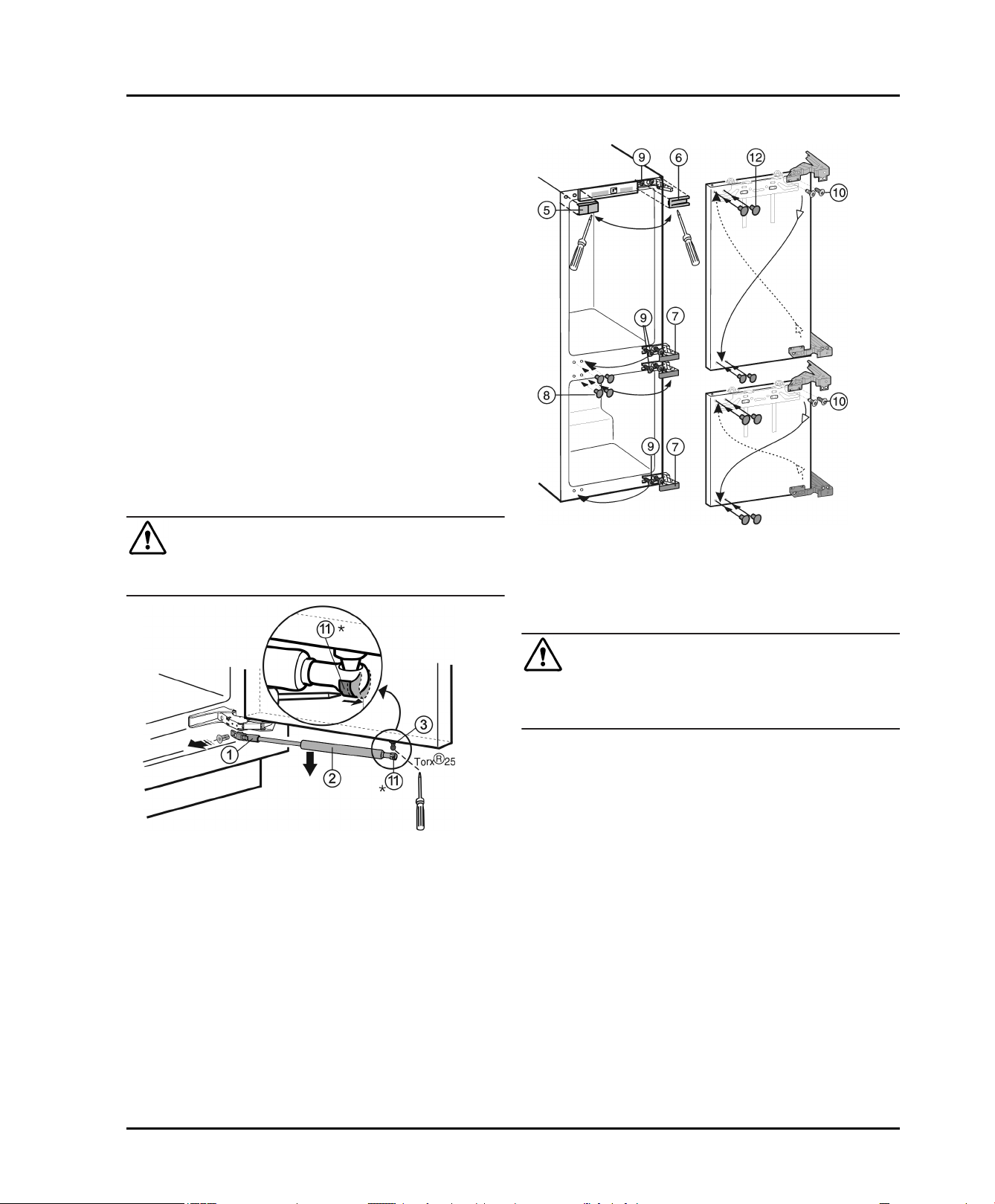

4 Changing the door hinges

Make sure you have the following tools on hand:

q

Hex wrench 13

q

Torx® 15, 20, 25, 30 cordless screwdrivers

Push the appliance 2/3 of the way into the recess.

Disconnect the power plug.

Open the doors.

4.1 To detach the soft stop mechanism*

HC1011, HC1060

CAUTION

Risk of injury if soft stop contracts!

u

Carefully remove soft stop damper.

Reversing the door

4.2

u

Lift off covers

u

Just loosen top and bottom screws

body of the appliance.

u

Push doors outwards and unhook.

u

Swap screws

them in a little.

Fig. 8 (5,6,7,8)

Fig. 8 (9)

to the opposite side and screw

using a slot screwdriver.

Fig. 8 (9)

Fig. 8

on the

u

Push tension spring

driver.*

u

Lower soft stop mechanism

u

Unscrew holder

u

Unscrew the ball stud

Fig. 7 (11)

Fig. 7 (1)

Fig. 7 (2)

.

Fig. 7 (3)

Fig. 7

outwards, using a screw-

for removal.

(Torx® 25).

CAUTION

Hinges are spring-loaded and can cause pinching injuries!

u

Leave hinges open.

u

Undo screws

diagonally.

The screws

screwdriver.

u

Securely tighten the hinges by applying a torque of

3lb-ft (4 Nm) .

u

Close off the now unused fastening holes with the

plugs

Fig. 8 (12)

u

Hang the doors on the premounted screws

and tighten the screws securely by applying a

torque of 3 lb-ft (4 Nm) .

Fig. 8 (10)

Fig. 8 (10)

supplied.

and change over the hinges

are self-tapping: use a cordless

Fig. 8 (9)

4.3 Re-attaching the soft stop mecha-

nism*

HC1011, HC1060

8 * Depending on model and options

Page 9

Fig. 9

u

Screw the ball stud

hole applying a pressure of 3 lb/ft (4 Nm) einschrauben (Torx® 25).

u

Push tension spring

u

Securely tighten theretainer

torque of 2.5 lb-ft (3 Nm) .

u

Attach soft stop mechanism

WARNING

Risk of bodily injury due to the door falling off.

If the fasteners are not installed with the proper torque,

the door may fall off. In addition, the door may not close,

thus impairing the cooling performance of the appliance.

u

Tightly secure the hinges along ball stud of the soft

stop mechanism by applying a torque of 3 lb-ft (4 Nm).

u

Tighten the soft stop mechanism retainer firmly with

2.5 lb-ft (3 Nm).

u

Check all screws and retighten if necessary.

Fig. 9 (3)

Fig. 9 (11)

securely into the new fixing

inwards again.*

Fig. 9 (1)

Fig. 9 (2)

by applying a

to ball stud.

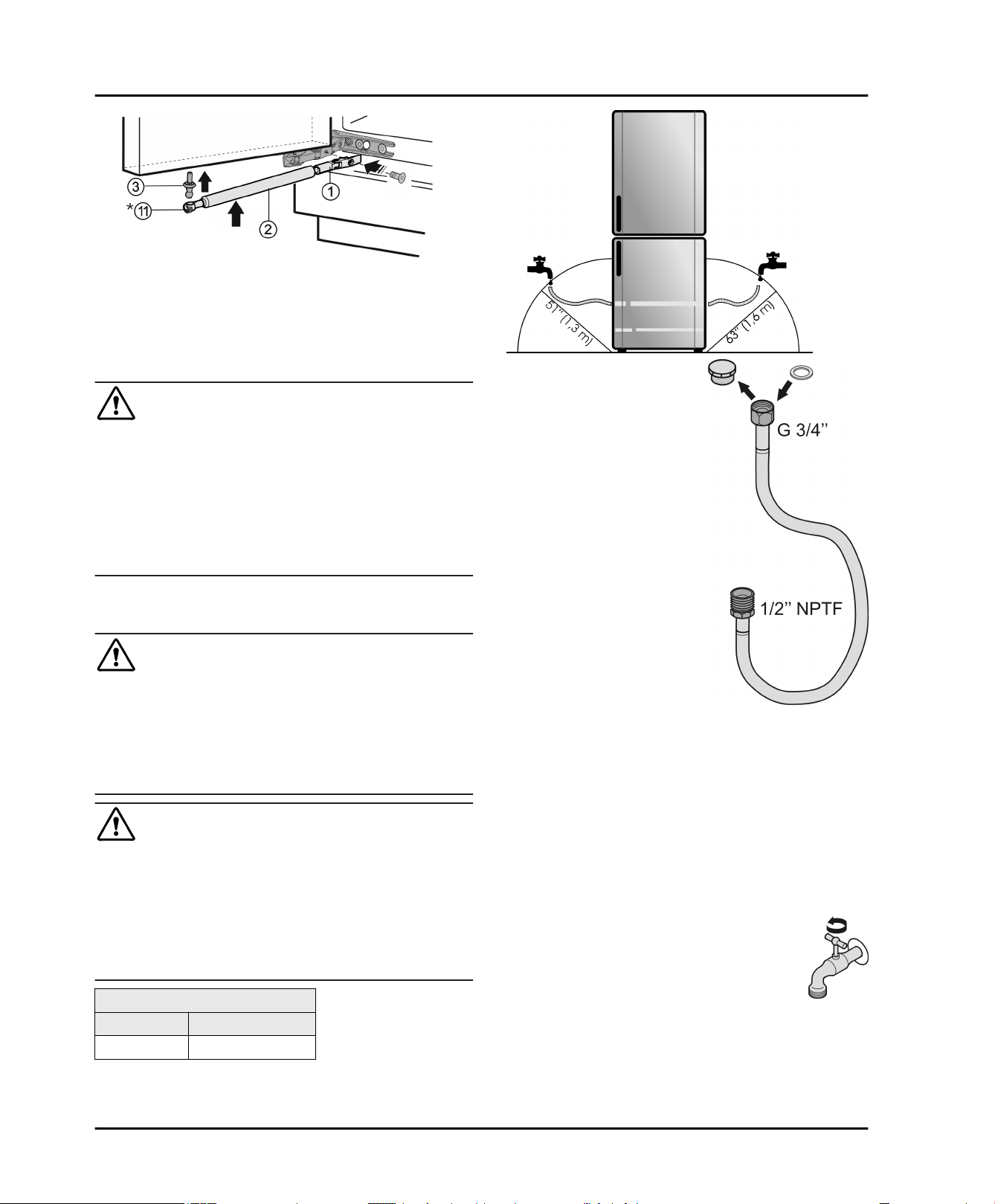

5 Water connection*

WARNING

Electrical Shock Hazard!

u

Do not make the water connection while the appliance

is connected to an electrical outlet.

u

Disconnect the water supply before connecting the

water lines for the IceMaker.

u

The connection to the water supply may only be made

by a trained and licensed plumber.

WARNING

Poisoning Hazard!

u

The water quality must comply with the drinking water

regulations for the geographical area where the appliance is located.

u

The IceMaker is designed exclusively to make ice

cubes in quantities needed by a household and must

only be operated with water appropriate for this

purpose.

Water pressure:

psi MPa (bar)

21.76 to 87.02 0,15 to 0,6 (1.5 to 6)

Water connection

Fig. 10

- Water must be supplied to

the appliance through a cold

water pipe that complies with

hygiene standards and can

withstand the operating pressure.

- Use the supplied stainlesssteel hose (78-3/4 '' (2 m)).

Do not reuse old hoses.

- A stopcock must be placed

between the hose line and

the domestic water connection to cut off the water

supply, if necessary. The

stopcock should be located

away from the back of the

appliance and within easy

reach.

- All devices and equipment

used to supply water must

comply with the regulations in

force in the respective

country.

- Do not damage or kink the

water supply line during

installation.

- The solenoid valve is located

at the bottom of the back of

the appliance. It has a metric

R3/4 connecting thread.

u

Unscrew the cap from the hose and insert the seal.

u

To install the stainless-steel hose: connect the G 3/4”

coupling to the solenoid valve and the 1/2” NPTF

coupling to the stopcock.

u

Open the stopcock for the water supply and

check the entire water system for leaks.

Before using for the first time:

u

Have the water line bled by a competent

professional.

* Depending on model and options 9

Page 10

Installation

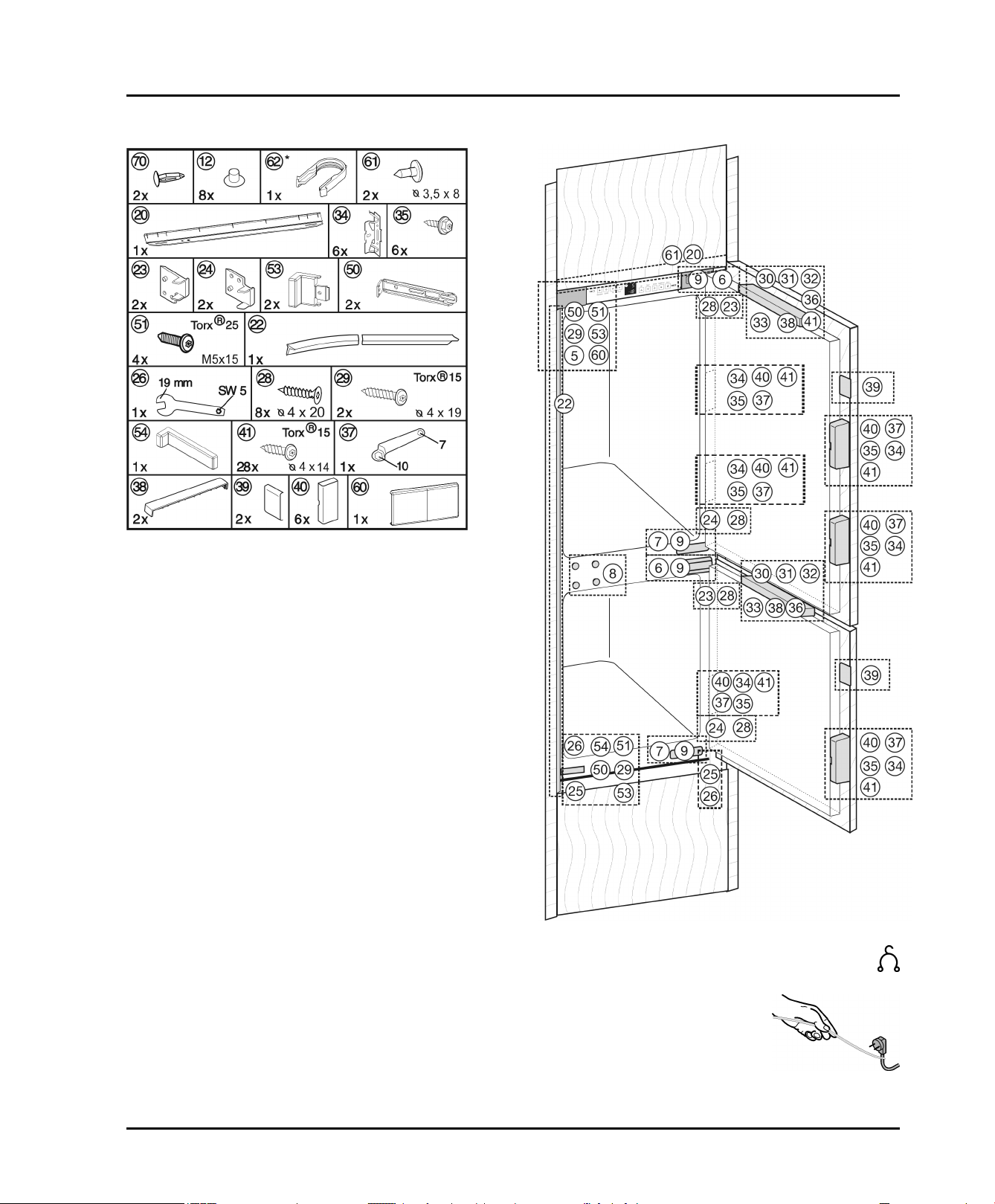

6 Installation

Fig. 11

All installation components are supplied with the appliance.

Make sure you have the following tools on hand:

q

Cordless Torx 15. 20. 25 screwdrivers

q

Screwdriver

q

Hexagonal wrench 13

6.1 Assembling the appliance

Fig. 12

u

Remove the power supply cable from the back of

the appliance. Also remove the cable holder,

otherwise there will be vibration noise!

u

Position the power supply

cable using a piece of string

so that the appliance can

easily be connected to the

electricity supply after it has

been installed.

10 * Depending on model and options

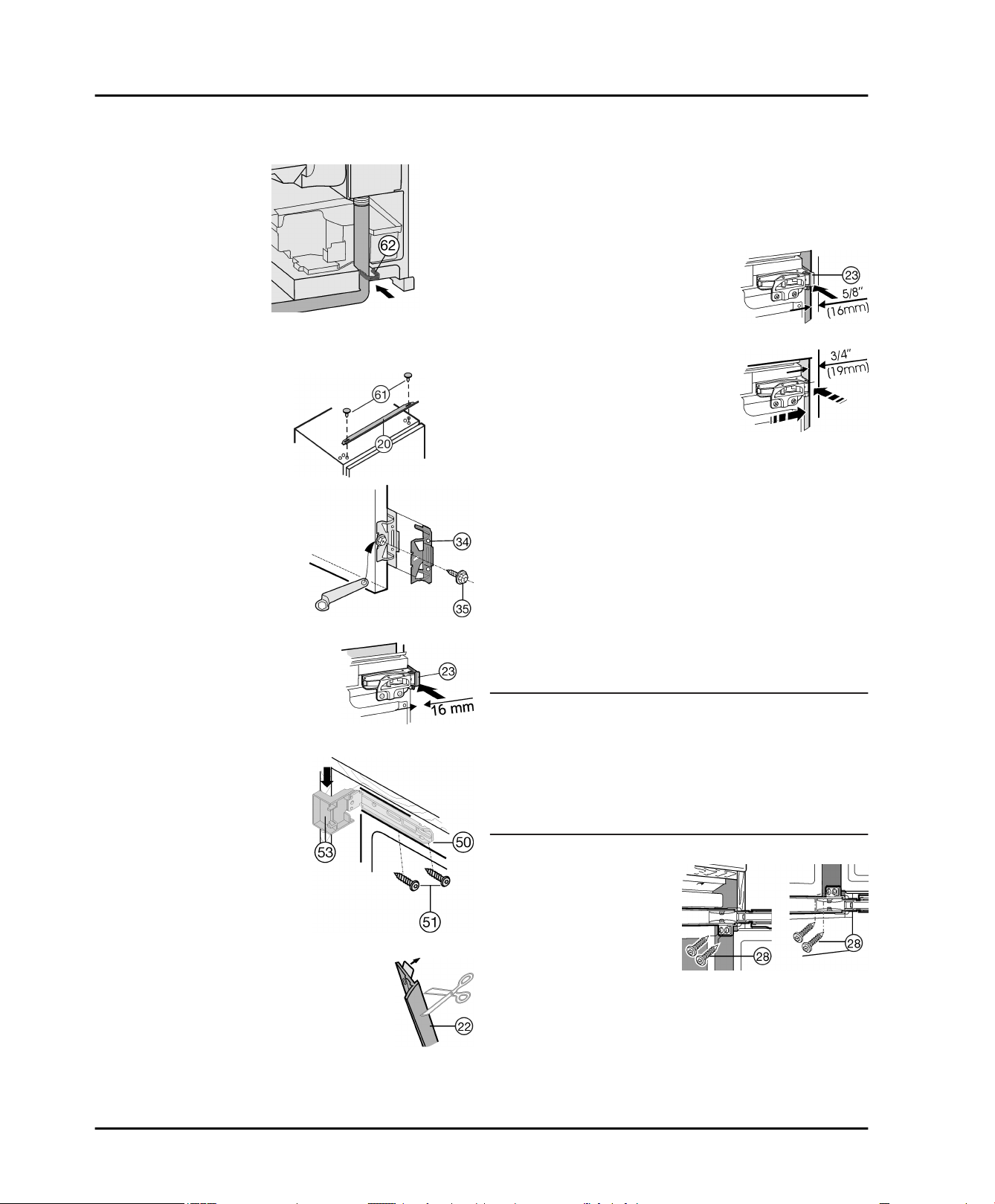

Fig. 13

Page 11

Installation

For appliances with a fixed water supply for the

IceMaker:*

u

Connect the IceMaker section entitled .*

u

Fit the locking clip

Fig. 14 (62)

.*

Fig. 14

All appliances:

u

Push the appliance 3/4 of the way into the recess.

u

Remove the covers

u

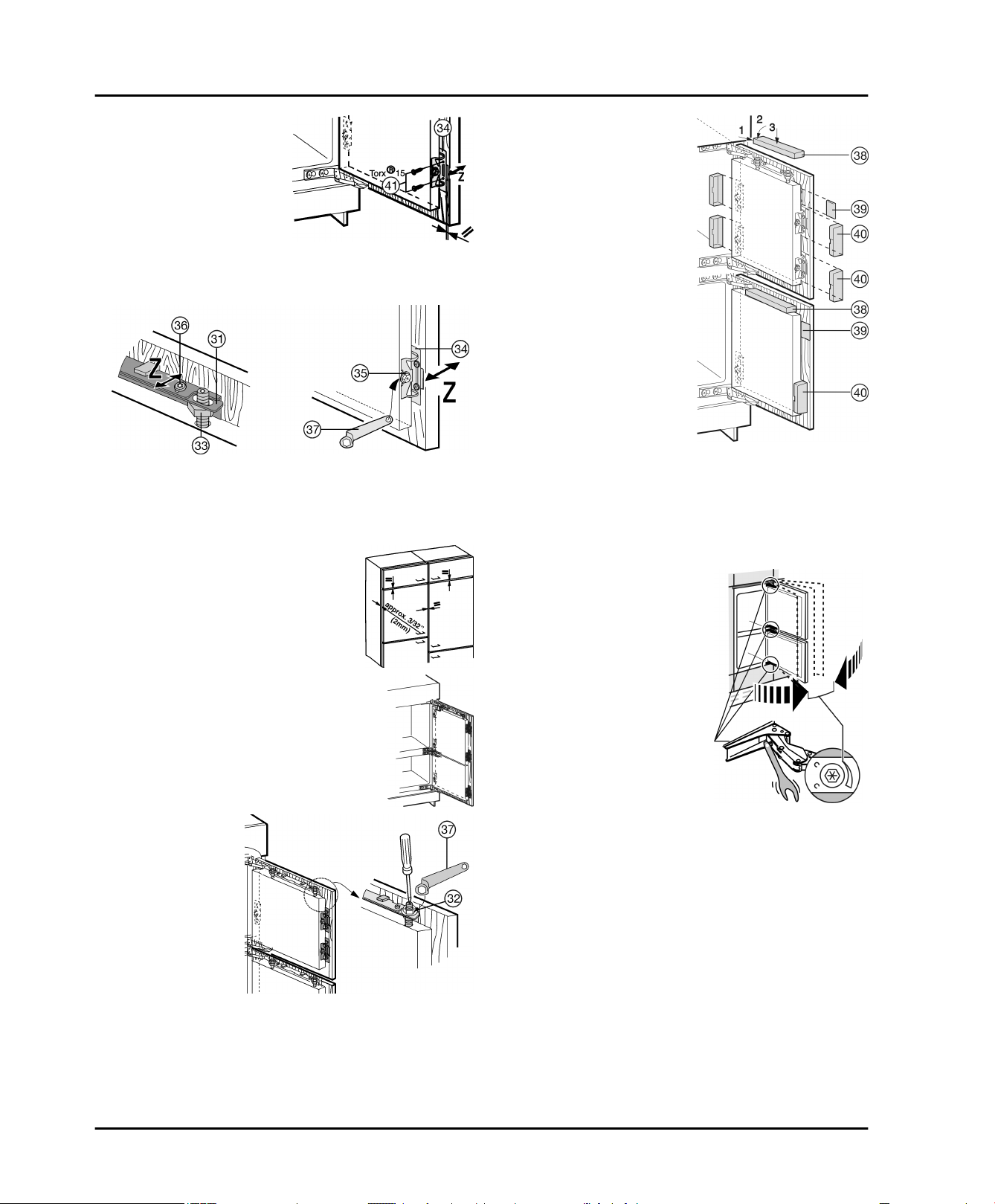

Screw

Fig. 15 (20)

equalizer trim

Fig. 12 (5,6,7)

the

Fig. 15 (61)

.

to the appliance through

the oblong holes on top.

Fig. 15

u

Fasten all mounting

brackets

Fig. 16 (34)

with hex head screws

Fig. 16 (35)

to the prebored holes in the

appliance door.

Fig. 16

With 5/8 '' (16 mm) thick

unit walls = 22-3/8 ''

(568 mm) wide recess:

u

Clip a spacer

Fig. 17 (23)

onto

the upper hinges and a

spacer

lower hinges.

u

Attach the top and

bottom covers

Fig. 12 (24)

Fig. 18 (53)

onto the

Fig. 17

to the mounting brackets

Fig. 18 (50)

u

Fasten the mounting

brackets

.

Fig. 18 (50)

at

the top and at the bottom

with screws

Fig. 12 (51)

such that the bracket can

still be moved slightly to

the left and to the right.

Fig. 18

u

Remove the protective film from the

trim

Fig. 19 (22)

Fig. 19 (22)

on the handle side and flush

. Attach the trim

with the front to the projecting edge of

the cover

Fig. 18 (53)

and glue to the

sidewall of the appliance.

Fig. 19

u

If necessary, shorten the trim

Fig. 19 (22)

Fig. 19 (22)

at the bottom: The trim

has to end 1/8 '' (3 mm)

above the upper edge of the bottom

mounting bracket

Fig. 12 (50)

.

To slide the appliance in and align it:

u

Slide in the appliance until the covers

Fig. 18

against the side wall of the kitchen unit.

Fig. 18 (53)

With 5/8 '' (16 mm) thick

unit walls = 22-3/8 ''

(568 mm) wide recess:

u

Allow the spacers on the side

*

wall of the unit to butt up

against the appliance.

With 3/4 '' (19 mm) thick

unit walls = 22-1/8 ''

(562 mm) wide recess:

u

Align the front edges of the

hinges flush with the side

wall of the unit.

With 5/8 '' (16 mm) and 3/4 '' (19 mm)) with door

stop components (knobs, sealing lips, etc.):

u

Allow for the additional distance (depth of door stop

components). Allow the hinges and the covers

Fig. 18 (53)

to protrude by the additional distance.

All appliances:

u

Adjust the adjustable feet

open-ended wrench

Fig. 12 (25)

Fig. 12 (26)

with the supplied

to align the appliance

vertically.

w

The appliance is now correctly positioned in depth. The

gap between the front edge of the side wall of the unit

and the body of the appliance is 1-21/32 '' (42 mm) all

the way around. (Allow for door stop components, such

as knobs and sealing lips.)

Note

Malfunction due to incorrect assembly!

If the spacing is not correct, the door may not close. This

can cause icing up, the formation of condensate, and

malfunctions.

u

A continuous space of 1-21/32 '' (42 mm) must be

maintained. (Allow for door stop components, such as

knobs and sealing lips.)

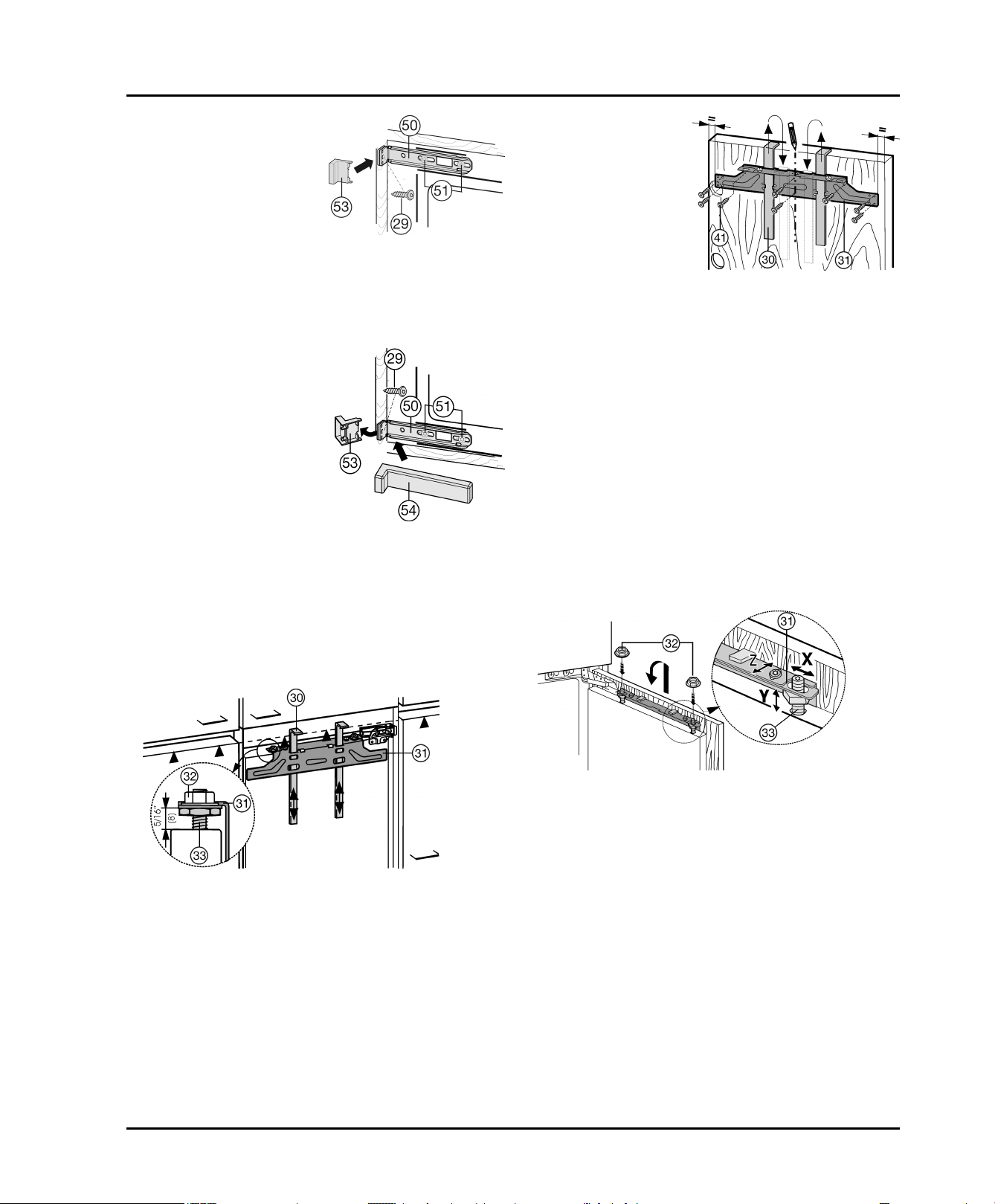

To secure the appliance in the recess:

u

Screw chipboard

screws

Fig. 22 (28)

on

both doors at the top

and at the bottom

through the hinge

plates.

On the handle side at the top:

abut

Fig. 20

Fig. 21

Fig. 22

* Depending on model and options 11

Page 12

Installation

u

Slightly loosen the

screws

u

Secure the top

Fig. 23 (51)

.

mounting bracket

Fig. 23 (50)

to the unit

wall with a ø4x19 chipboard screw

Fig. 23 (29)

u

Break off the

.

protruding end of the

cover

Fig. 23 (53)

u

Tighten the screws

u

Place the cover

.

Fig. 23 (51)

Fig. 23 (53)

in position.

On the handle side at the bottom:

u

Slightly loosen the

screws

u

Secure the bottom

Fig. 24 (51)

.

mounting bracket

Fig. 24 (50)

to the unit

wall with a ø4x19 chipboard screw

u

Break off the protruding

Fig. 24 (29)

.

end of the cover

Fig. 24 (53)

u

Tighten the screws

Fig. 24 (51)

u

Place the cover

Fig. 24 (54)

.

.

into position

on the bottom mounting

bracket

Fig. 24 (50)

.

u

u

Slide the

u

Unscrew the

crosspiece

Fig. 26 (31)

by

undoing the locknuts

Fig. 26 (32)

u

Hang the crosspiece

Fig. 26 (31)

.

on the inside of the

Fig. 23

unit door using the

fitting aids

Fig. 26 (30)

.

For a 23-5/8 '' (600 mm) wide recess:

u

To center the crosspiece

.

Fig. 26 (31)

: Mark a short

Fig. 26

center line on the unit door and place the tip of the

arrow on the crosspiece over it.

w

Distances to the outer edges are the same to the right

and to the left.

For a 24 '' (609.6 mm) wide recess:

u

To align the crosspiece

Fig. 26 (31)

: Mark a short center

line on the unit door and place the tip of the arrow on

the crosspiece over it. Now shift the crosspiece

Fig. 26 (31)

3/16 in. (5.5 mm) towards the hinge side.

For chipboard doors:

u

Fig. 24

Fasten the crosspiece

Fig. 26 (41)

.

For frame and panel doors:

u

Fasten the crosspiece

Fig. 26 (41)

u

Lift up the fitting aids

at the edge.

Fig. 26 (31)

Fig. 26 (31)

Fig. 26 (30)

with at least 6 screws

with 4 screws

, turn them around, and

insert them into the adjacent openings.

6.2 Fitting the unit doors

Fig. 25

The fitting aids

You must therefore fit the unit doors one after the

other.

u

Verify the 5/16 '' (8 mm) presetting. (Distance between

appliance door and lower edge of crosspiece)

u

Raise the fitting aids

Bottom stop edge ▲ of fitting aid = top edge of unit door

to be fitted.

Fig. 25 (30)

Fig. 25 (30)

are required for both doors.

to the unit door height.

Fig. 27

u

Attach the unit door on the adjusting bolts

and loosely screw the locknuts

Fig. 27 (32)

Fig. 27 (33)

onto the

adjusting bolts.

u

Close the door.

u

Check the gap between the door and the surrounding

unit doors.

u

To laterally align the unit door: Move the unit door in the

X direction.

u

To align the unit door in height and in lateral inclination:

Adjust the adjusting bolts

w

The unit door is flush and in alignment with the

Fig. 27 (33)

with a screwdriver.

surrounding unit fronts.

u

Tighten the locknuts

Fig. 27 (32)

.

12 * Depending on model and options

Page 13

Installation

Ensure that both metal

edges are flush,

symbol //:

u

Drill pilot holes in the

door of the unit (you

could make a preliminary hole with a

bradawl).

u

Fasten the appliance door to the unit door with screws

Fig. 28 (41)

Fig. 29

u

To align the unit door in depth Z: Undo the screws

Fig. 29 (36)

Fig. 29 (35)

Fig. 29 (37)

u

Do not allow the knobs and sealing

through the mounting brackets

Fig. 28 (34)

at the top and the hex head screws

at the bottom using the ring wrench

supplied, then move the door.

lips to come into contact with the

door - important for function!

u

Set an air gap of 3/32 '' (2 mm)

between the door of the unit and the

body of the unit.

For large unit doors:

u

Fit a 3rd pair of mounting brackets

Fig. 29 (34)

u

Use the holes pre-drilled in the handle

.

area of the appliance door for this

purpose.

Fig. 28

.

u

Position the upper

covers

Fig. 31 (38)

and

snap into place.

u

Place the side covers

Fig. 31 (39)

in position,

slide to the limit and

then press until they

snap audibly into

place.

u

Attach the covers

Fig. 31 (40)

to the side

and then draw them

forward with a screwdriver, so that they

snap properly into

place.

Fig. 31

For a 24 '' (609.6 mm) wide recess:

u

Position the covers

Fig. 12 (6,7,60)

and snap into place.

For a 23-5/8 '' (600 mm) wide recess:

u

Position the covers

Fig. 12 (5,6,7)

and snap into place.

For appliances without a stop mechanism, adjust the

opening resilience:

The opening resilience of the

door can be adjusted if necessary using the Allen wrench

supplied:*

u

For more spring force: Turn

clockwise.*

u

For less spring force (factory

setting): Turn counterclockwise.*

u

Attach the remaining covers to

the hinges.*

u

Check the fit

of the door

and re-adjust,

if necessary.

u

Tighten all

screws.

Check the following points to ensure that the appliance

has been installed correctly. Incorrect installation can

cause icing up, the formation of condensate, and malfunctions:

w

The door must close properly.

w

The door of the unit must not touch the body of the unit.

w

The seal at the top edge on the handle side must fit

tightly. To verify this, darken the room, place a flashlight inside the appliance near the top, and close the

door. If you see light shining through, check the

assembly.

Fig. 30

u

Tighten the locknuts

Fig. 30 (37)

while bracing the adjusting bolts

Fig. 30 (32)

with the ring wrench

Fig. 30 (33)

with a screwdriver.

* Depending on model and options 13

*

Page 14

Connecting the appliance

7 Connecting the appliance

WARNING

Electrical shock hazard!

u

Start-up should only take place once the appliance has

been installed according to these instructions.

u

Electrically ground appliance.

u

Do not ground to a gas pipe.

u

Check with a qualified electrician if you are not sure the

appliance is properly grounded.

u

Do not have a fuse in the neutral or grounding circuit.

u

Do not use an extension cord, power bar or a multiple

socket adapter.

u

Do not use a power cord that is frayed or damaged.

WARNING

Electrical shock hazard!

This appliance is equipped with a three-prong (grounding)

polarized plug for your protection against possible shock

hazards. Electrical Grounding Required.

u

Do not remove the round grounding prong from the

plug.

u

Use only an grounded adapter.

Wait 1 hour after installation before you plug in the

appliance. This allows the refrigerant and system lubrication to reach equilibrium.

Make sure incoming voltage is the same as the appli-

ance rating. A 110-120 Volt, 60 Hz, 15 Amp electrical

supply (20 Amp for side-by-side installations) circuit

that is controlled by a circuit breaker or fuse is required.

We recommend using a dedicated circuit for this appli-

ance to prevent electrical overload.

Follow all Federal, State and local electrical, fire and

building codes and ordinances when installing the

receptacle and / or the appliance.

In some communities, a wall switch is required to turn

power to the appliance ON and OFF.

To reduce the risk of fire, electric shock, or personal

injury, installation work and electrical wiring must be

done by a qualified electrician in accordance with all

applicable codes and standards, including fire-rated

construction.

The Power Plug must be easily accessible so that the

appliance can be disconnected from the mains quickly

in an emergency. It must not be behind the back of the

appliance.

The top of the electric outlet must be located within

82-5/8 in. (2100 mm) from the top of the base in the

cabinet.

14 * Depending on model and options

Page 15

Instructions

de montage

Combiné réfrigérateur-

congélateur, entièrement

intégrable

HC1011/1060 HC1001/1050

111113 7084000 - 03

Page 16

Consignes de sécurité générales

Sommaire

1 Consignes de sécurité générales................ 16

2 Mise en place de l'appareil........................... 16

3 Réalisation du meuble de cuisine................ 17

3.1 Ventilation et aération dans le meuble de

cuisine.............................................................. 18

3.2 Réalisation du meuble de cuisin....................... 19

3.3 Réalisation des portes du meuble.................... 20

4 Changement de la butée de la porte............ 22

4.1 Démonter l'amortisseur de fermeture............... 22

4.2 Changer la butée de la porte............................ 22

4.3 Remonter les amortisseurs de fermeture......... 22

5 Prise d'eau...................................................... 23

6 Montage.......................................................... 24

6.1 Monter l'appareil............................................... 24

6.2 Monter les portes du meuble............................ 26

7 Brancher l'appareil........................................ 28

Le fabricant travaille constamment au développement de

tous les types et modèles d'appareils.C'est pourquoi nous

nous réservons le droit de modifier la forme, l'équipement

et la technique de nos appareils. Nous vous remercions

de votre compréhension.

Afin de découvrir tous les avantages de votre nouvel

appareil, nous vous prions de lire attentivement ces

instructions de montage.

Ces instructions de montage sont valables pour plusieurs

modèles, des différences sont donc possibles.Les paragraphes ne concernant que certains appareils sont indiqués par un astérisque (*).

Les instructions de manipulation sont indiqués par

, les résultats de manipulation par un .

un

1 Consignes de sécurité générales

-

Lire et respecter les instructions suivantes.

Elles contiennent des consignes de sécurité

importantes pour une installation et un fonctionnement sûrs et parfaits de votre appareil.

Lisez et respectez toujours ces consignes de

sécurité !

-

Il est important de respecter les directives et

consignes de ces instructions afin d'assurer

l'installation et le fonctionnement corrects de

l'appareil. Lisez et comprenez toutes les informations de ces instructions avant d'installer

l'appareil.

-

La prise de courant doit être bien accessible

afin de pouvoir débrancher rapidement l'appareil en cas d'urgence. Elle doit se situer en

dehors de la partie arrière de l´appareil.

DANGER indique une situation dangereuse

imminente entraînant la mort ou des

blessures corporelles graves si elle

n'est pas évitée.

AVERTISSEMENT

PRUDENCE indique une situation dangereuse

ATTENTION indique une situation dangereuse

Remarque indique les remarques et conseils

indique une situation dangereuse

susceptible d'entraîner la mort ou

des blessures corporelles graves si

elle n'est pas évitée.

susceptible d'entraîner des blessures corporelles moyennes ou

légères si elle n'est pas évitée.

susceptible d'entraîner des

dommages matériels si elle n'est

pas évitée.

utiles.

2 Mise en place de l'appareil

AVERTISSEMENT

Risque d'incendie dû à l'humidité !

Lorsque des pièces sous tension ou le câble de raccordement au secteur deviennent humides, un court-circuit

peut se produire.

u

L'appareil a été conçu pour être placé dans des locaux

fermés. Ne pas exploiter l'appareil dehors ou dans des

endroits humides non à l'abri de projections d'eau.

u

Uniquement exploiter l'appareil à l'état monté.

AVERTISSEMENT

Danger de brûlures par court-circuit!

Lorsque les câbles de raccord / fiches de l´appareil se

trouvent en contact avec la partie arrière d´un autre appareil, ils peuvent être endommagés à cause des vibrations

de l´appareil et par la suite causer un court-circuit.

u

Placer l'appareil de façon à ce qu'il n'y ait pas de

contact avec la fiche ou le câble d´alimentation.

u

Ne pas brancher d´appareils ni autres dispositifs sur

les prises de courant situées sur la partie arrière de l

´appareil.

AVERTISSEMENT

Risque d'endommagement et d'incendie !

u

Ne pas placer un appareil diffusant de la chaleur (p.ex.

four à micro-ondes, grille-pain, etc.) sur l'appareil !

PRUDENCE

Danger de blessure!

u

L’appareil doit être porté par deux personnes à son lieu

d’emplacement.

16 * selon le modèle et l‘équipement

Page 17

Réalisation du meuble de cuisine

ATTENTION

Risque de dommage par eau de condensation

Si votre appareil Liebherr est placé à côté d’un autre réfrigérateur ou congélateur, il risque d’être endommagé par

la formation d’eau de condensation.

u

Eviter d’installer votre appareil à côté d’autres réfrigérateurs ou congélateurs à moins qu’il ne s’agisse également d’appareils de la marque Liebherr. Les appareils

Liebherr sont conçus pour une mise en place côte à

côte. Ils sont équipés d’un dispositif chauffant éliminant

l’eau de condensation au cas où des réfrigérateurs ou

congélateurs seraient disposés côte à côte.

ATTENTION

Risque de dommage pour le sol!

u

Protéger le sol en le couvrant avant de retirer les matériaux d'emballage de l’appareil.

S’assurer que:

q

le sol du lieu de mise en place de l’appareil est plat et

horizontal.

q

la capacité porteuse du sol est conçue pour le poids de

l’appareil ainsi que1200 livres (544 kg) de denrées.

q

l’appareil n’est pas exposé aux rayons de soleil directs

sur le lieu de sa mise en place et qu’il n’est pas installé

pas à proximité d’un four, d’un plan de cuisson, d’un

radiateur de chauffage ou autres sources de chaleur.

q

le meuble de cuisine dans lequel est monté l’appareil

est mis à niveau si le sol n’est pas plat.

q

le fusible est bien adapté.

q

la prise de courant est disposée selon les normes.

q

l’aération et la ventilation ne sont pas obstruées. Pour

un bon fonctionnement de l’appareil une aération et

ventilation suffisantes sont nécessaires. Les grilles

d’aération mises en place par l’usine assurent une

section d’aération efficace sur un appareil

de31 pouces2 (200 cm2). Si la grille d’aération est

remplacée par un panneau, sa section d’aération doit

au moins égale ou même plus élevée que la grille

d’aération du fabricant.

u

Vérifiez l’appareil et les matériaux d’emballage pour

dommages de transport. Consultez sans délai le fournisseur si des dommages quelconques sont constatés.

u

Notez le type (modèle, numéro), la désignation de

l’appareil, le numéro de l’appareil / de série, la date

d’achat et l’adresse du commerçant dans les champs

prévus à cet effet .

u

Retirez tous les matériaux de la face arrière ou des

parois latérales de l’appareil qui risqueraient d'empêcher une mise en place, une aération ou ventilation

correcte.

u

Dévisser la fixation de transport rouge. Boucher le trou

de fixation vide avec un

bouchon (70).

Remarque

u

Nettoyer l'appareil .

Si l’appareil est mis en place dans un environnement très

humide, de l’eau de condensation risque de se former sur

l’extérieur de l’appareil.

u

Toujours assurer une bonne aération et ventilation sur

le lieu de la mise en place.

3 Réalisation du meuble de cuisine

L’appareil est un réfrigérateur à encastrer et sera donc

inséré dans un meuble de cuisine. Le meuble de cuisine

concerné doit être exécuté dans les dimensions indiquées et doit disposer d’une aération et d’une ventilation

suffisante pour assurer le bon fonctionnement de votre

appareil.

En cas de mise en place côte à

côte, prévoyez un meuble de

cuisine individuel pour chaque

appareil.

Faîtes installer l’appareil dans votre meuble de cuisine

par un spécialiste.

* selon le modèle et l‘équipement 17

Page 18

Réalisation du meuble de cuisine

3.1 Ventilation et aération dans le

meuble de cuisine

Fig. 1

- Prévoir une section d’aération efficace d’au moins

31 pouces2 (200 cm2) sur l’entrée

d'air

Fig. 1 (2)

- La section supérieure d’aération peut soit parvenir

directement au dessus de l’appareil

dessus d'un élément de l’armoire

forme d’une ouvà proximité du plafond erture d’évacuation d’air intégrée à un faux plafond

.

Fig. 1 (1)

Fig. 1 (2)

Fig. 1 (3)

Fig. 1 (4)

et la sortie

, au

soit sous

.

Fig. 2

- Prévoir une cheminée d’aération (sans obstacles)

située au dos du meuble de cuisine avec une profondeur d’au moins 1-1/2 pouces (38 mm).

u

Respecter les distances indiquées ci-dessus entre la

ventilation et l’aération.

La ventilation par le bas à partir du sol du meuble de

cuisine peut être effectuée par la grille d’aération

livrée ou par une ouverture de ventilation de surface de

section d’au moins 31 pouces2 (200 cm2). Si vous avez

recours à la grille d’aération

étapes suivantes :

Fig. 3 (3)

ci-jointe, suivez les

Fig. 3 (3)

Fig. 3

18 * selon le modèle et l‘équipement

Page 19

Réalisation du meuble de cuisine

u

Prévoir une ouverture d’entrée d’air dans le plancher

du meuble de cuisine de 17-23/32 pouces (450 mm) de

large et 2-7/32 pouces (56 mm) de hauteur.

u

Introduire la grille d’aération

du plancher du meuble de cuisine

Fig. 3 (3)

Fig. 3 (1)

dans l’ouverture

.

3.2 Réalisation du meuble de cuisin

u

Introduire les contacts à ressort

Fig. 3 (2)

par l’arrière de

la grille jusqu’à ce que le crochet touche le plancher du

meuble de cuisine.

u

Monter le plancher du meuble de cuisine (avec la grille

emboîtée) dans le meuble de cuisine.

Fig. 4

1 Câble de raccordement au

3 Prise de courant électrique

réseau

2 Niveau à eau 4 Câble d’arrivée pour le câble

de raccordement au réseau

A 21-7/32 pouces (539 mm) B 69-21/32 pouces (1769.5 mm)

C 21-15/16 pouces (557 mm) D 69-3/4 pouces - 70-3/8 pouces (1772 mm) - (1788 mm)

E min. 22 pouces (560 mm) F 21-21/32 pouces (550 mm)

max. 22-3/4 pouces (578 mm) G 1-1/2 pouces (38 mm)

H 27-3/8 pouces (695 mm) J 24-3/4 pouces (629 mm)

K max. 3/4 pouces (19 mm) L 9-21/32 pouces (245 mm)

u

Ne monter l’appareil que dans un meuble de cuisine

stable.

u

Monter le meuble de cuisine en vous référant

Fig. 4

dimensions mentionnées.

u

Ajuster le meuble de cuisine avec un niveau à eau

Fig. 4 (2)

et une équerre à chapeau. Mettre à niveau le

aux

Le jeu entre la porte du meuble du haut et celle du bas

doit correspondre au jeu entre la porte du haut et celle du

bas de l’appareil.

Respecter la cote de distance L par rapport au mur afin

de pouvoir tirer facilement les tiroirs.

u

Respecter les cotes de montage indiquées

Fig. 4

.

meuble de cuisine, au besoin le caler.

w

Le sol et les parois latérales doivent être d’équerre.

* selon le modèle et l‘équipement 19

Page 20

Réalisation du meuble de cuisine

3.3 Réalisation des portes du meuble

Fig. 5

Vous avez besoin de deux portes pour le meuble de

cuisine: une porte supérieure pour le réfrigérateur et une

inférieure pour le congélateur.

Les portes sont réalisées, en général de la façon

suivante:

Les portes doivent avoir une épaisseur minimum de

5/8 pouces (16 mm) et maximum de 3/4 pouces

(19 mm) pour pouvoir y fixer les rails de jonctions.

Garder un jeu d’au moins 1/8 pouces (3 mm) entre la

porte supérieure et la porte inférieure, lorsque les deux

portes sont fermées.

Garder également un jeu d’au moins 1/8 pouces

(3 mm) entre la porte supérieure et la porte de l’armoire

située au dessus, si presente.

La largeur des portes des meubles dépend du style de

la cuisine et de la grandeur de la fente entre les portes

des meubles. En général, une fente verticale de

1/8 pouces (3 mm) entre les portes des meubles est

recommandée.

Garder à la même hauteur que les portes de l’armoire

voisine (ou des armoires si présentes) les arêtes supérieurs des portes du haut

Garder à la même hauteur que le jeu entre les portes

de l’appareil lejeu

Les portes des placards doivent être planes et sont à

-

Fig. 5 (2)

Fig. 5 (1)

et du bas

Fig. 5 (2)

entre les portes du meuble.

.

monter sans tensions.

Aligner les portes avant l’installation de l’appareil.

Après l’installation de l’appareil, la position des portes

ne peut plus être corrigée.

ATTENTION

Risque de détérioration par des portes de placard trop

lourdes !

Des portes de placards trop lourdes peuvent endommager les charnières et le bon fonctionnement peut éventuellement être entravé.

u

Avant le montage des portes des placards, veiller à ne

pas dépasser le poids admissible des portes des

placards.

Poids maximal de la porte du placard

Porte du compartiment réfrigérateur

Porte du compartiment congélateur

u

Vérifier que les cotes de montage correspondent bien

aux instructions

30.5 lbs (14 kg)

26.5 lbs (12 kg)

Fig. 4

.

20 * selon le modèle et l‘équipement

Page 21

Réalisation du meuble de cuisine

Fig. 6

1 Porte de meuble de réfrigéra-

teur

2 Porte de meuble de congéla-

teur

La hauteur de la porte du congélateur est de

24-24/32 pouces (629 mm).

u

Pour couvrir la section inférieure de l’appareil :

rallonger la hauteur de la plaque à 27-3/8 pouces

(695 mm).

L’épaisseur de la plaque de sol est en règle générale de

3/4 pouces (19 mm).

u

Pour recouvrir la face frontale de la plaque de sol

Fig. 6 (a)

27-3/8 pouces + 3/4 pouces = 28-1/8 pouces ( 695 mm

+ 19 mm = 714 mm ).

* selon le modèle et l‘équipement 21

: rallonger la hauteur de la plaque à

3 Porte de réfrigérateur

4 Porte de congélateur

Si aucune portede meuble n'est encore montée, l'entrebaîllement entre la porte du congélateur

porte du réfrigérateur

(15 mm). Lorsque les portes sont montées, l'entrebaîllement entre les deux portes

1/8 pouces (3 mm) et doit être situé dans l'espace de la

surface hachurée.

Naturellement la hauteur définitive de la porte s’aligne sur

la hauteur du jeu de porte du meuble de cuisine situé à

droite et à gauche du meuble d’intégration de l’appareil.

Fig. 6 (3)

Fig. 6 (1,2)

Fig. 6 (4)

est de 19/32 pouces

est d'env.

et la

Page 22

Changement de la butée de la porte

Si d’autres éléments de meuble se situent à côté du

meuble d’intégration de l’appareil, ceci auront un jeu entre

deux tiroirs ou deux portes. Selon le modèle de votre

cuisine ces jeux sont d’environ 1/8 pouces (3 mm) de

large.

u

Dans ce cas, la hauteur de la plaque doit être

rehaussée de 27-3/8 pouces + 3/4 pouces +

19/32 pouces - 1/8 pouces = 28-19/32 pouces

( 695 mm + 19 mm + 15 mm - 3 mm = 726 mm ).

La hauteur de la porte de réfrigérateur résulte de :

u

La hauteur totale de l’armoire (c.a.d. 70-3/8 pouces

(1788 mm)) + l’épaisseur de la plaque couvrante +

plaque de sol (habituellement 3/4 pouces (19 mm))

moins la hauteur de la porte du congélateur

(xxx pouces (xxx mm)) calculée comme ci-dessus, et

moins le jeu (env. 1/8 pouces (3 mm)): 70-3/8 pouces +

3/4 pouces + 3/4 pouces - xxx pouces - 1/8 pouces =

71-3/4 pouces - xxx pouces ( 1788 mm + 19 mm +

19 mm - xxx mm - 3 mm = 1823 mm - xxx mm )

4 Changement de la butée de la porte

S'assurer que les outils suivants soient disponibles :

q

Clé mâle à six pans 13

q

Visseuse sans fil Torx® 15, 20, 25, 30

Glisser l'appareil au 2/3 dans la niche.

Retirer la fiche de la prise.

Ouvrir la porte.

4.1 Démonter l'amortisseur de fermeture*

HC1011, HC1060

u

Démonter l'amortisseur

bas.

u

Dévisser le support

u

Dévisser le pivot sphérique

Fig. 7 (2)

Fig. 7 (1)

de fermeture vers le

.

Fig. 7 (3)

(Torx® 25).

4.2 Changer la butée de la porte

u

Soulever les caches

pour vis à fentes.

u

Seulement desserrer les vis

bas au corps de l'appareil.

u

Pousser la porte vers l'extérieur et la décrocher.

u

Intervertir les vis

visser provisoirement.

Fig. 8 (5,6,7,8)

Fig. 8 (9)

avec un tournevis

Fig. 8 (9)

sur le côté opposé et les

vis en haut et en

Fig. 8

PRUDENCE

Risque de blessures lorsque l'amortisseur de fermeture

se contracte !

u

Démonter soigneusement l'amortisseur de fermeture.

Risque de blessures lorsque les charnières se replient !

u

u

Les vis

nevis à accu.

u

u

u

PRUDENCE

Laisser les charnières ouvertes.

Dévisser les vis

diagonale.

Fig. 8 (10)

Visser les charnières avec un couple de serrage de

3 lb-ft (4 Nm) .

Fermer les anciens trous de fixation avec les bouchons

Fig. 8 (12)

Mettre les portes dans les vis

les visser avec un couple de serrage de 3 lb-ft

(4 Nm) .

.

Fig. 8 (10)

sont auto-taraudantes : Utiliser le tour-

et retourner la charnière en

Fig. 8 (9)

pré-montées et

4.3 Remonter les amortisseurs de

Fig. 7

u

Pousser le ressort tendeur

l'aide du tournevis.*

22 * selon le modèle et l‘équipement

Fig. 7 (11)

vers l'extérieur à

fermeture*

HC1011, HC1060

Page 23

Fig. 9

u

Visser le pivot sphérique

nouveau trou de fixation avec3 lb-ft (4 Nm) (Torx®

25).

u

Remettre le ressort tendeur

u

Visser le support

de 2.5 lb-ft (3 Nm) .

u

Accrocher l'amortisseur

tourillon.

AVERTISSEMENT

Risque de blessures lorsque la porte culbute !

Si les éléments de fixation ne sont pas serrées avec le

bon couple de serrage, la porte de culbuter.

u

Visser chaque charnière ainsi que le tourillon sphérique

avec un couple de serrage de 3 lb-ft (4 Nm).

u

Visser l’élément de fixation de l’amortisseur de fermeture avec un couple de serrage de 2.5 lb-ft (3 Nm).

u

Vérifier la bonne fixation de chaque vis, si nécessaire

resserrer les vis.

Fig. 9 (1)

Fig. 9 (3)

Fig. 9 (11)

avec un couple de serrage

Fig. 9 (2)

à fond dans le

à l'intérieur.*

de fermeture au

5 Prise d'eau*

AVERTISSEMENT

Risque de décharge électrique !

u

Débranchez l'appareil de la prise avant de le raccorder

à la conduite d'eau.

u

Coupez l'alimentation en eau avant de raccorder les

conduites d'arrivée d'eau du distributeur de glaçons.

u

Le raccord au réseau d'eau potable doit être uniquement effectué par un plombier qualifié.

AVERTISSEMENT

Danger d'intoxication !

u

La qualité de l'eau doit être conforme à celle prescrite

par le décret relatif à l'eau potable du pays dans lequel

l'appareil est utilisé.

u

L'IceMaker sert uniquement à produire des glaçons en

quantité normale pour un usage domestique et doit

fonctionner avec de l'eau appropriée à la consommation.

Pression d'eau :

psi MPa (bar)

21,76 à 87,02 0,15 à 0,6 (1,5 à 6)

Prise d'eau

Fig. 10

- L'arrivée d'eau à l'appareil

doit se faire via une conduite

d'eau froide résistant à la

pression de service et

conforme aux normes en

matière d'hygiène.

- Utiliser le tuyau en acier inox

fourni (longueur : 78-3/4 ''

(2 m)). Ne pas réutiliser d'anciens tuyaux.

- Un robinet d'arrêt doit être

prévu entre la tuyauterie et la

prise d'eau domestique afin

de pouvoir fermer l'arrivée

d'eau en cas de besoin. Le

robinet d'arrêt doit être situé

en dehors de l'espace arrière

de l'appareil et être facilement accessible.

- Tous les appareils et dispositifs utilisés pour l'arrivée

d'eau doivent satisfaire aux

prescriptions en vigueur dans

le pays respectif.

- Ne pas endommager ou plier

le tuyau d'arrivée d'eau lors

de l'installation.

- L'électrovanne se trouve sur

la paroi arrière de l'appareil

en bas. Elle possède un filetage de raccordement

métrique R3/4.

u

Dévisser le capuchon du tuyau et insérer le joint d’étanchéité.

u

Installer le tuyau en acier inox : raccorder le raccord

3/4” G à l'électrovanne et le raccord NPTF 1/2” au

robinet d'arrêt.

u

Ouvrir le robinet d'arrêt de l'arrivée d'eau et

vérifier l'étanchéité du système d'eau

complet.

Avant la première mise en service :

u

Faire purger la canalisation d'eau par un

spécialiste compétent.

* selon le modèle et l‘équipement 23

Page 24

Montage

6 Montage

Fig. 11

Toutes les pièces de fixation sont livrées avec l'appareil.

S’assurer d’avoir les outils suivants à portée de main :

q

Tournevis à accu Torx 15. 20. 25

q

Tournevis

q

Clé mâle à six pans 13

6.1 Monter l'appareil

Fig. 12

u

Enlever le câble de raccord sur la paroi arrière de

l'appareil. Retirer le serre-câble pour empêcher les

bruits dus aux vibrations!

u

Installer le raccordement

électrique à l’aide d’un fil de

manière à ce que l’appareil

puisse être facilement

raccordé après montage.

Fig. 13

24 * selon le modèle et l‘équipement

Page 25

Montage

Aux appareils avec raccord fixe à une prise d'eau

pour l'IceMaker :*

u

raccorder l'IceMaker .*

u

Monter l' étrier d'enclenchement

Fig. 14 (62)

.*

Fig. 14

Tous les appareils :

u

Glisser l'appareil au 3/4 dans la niche.

u

Ôter le cache

u

Visser

Fig. 15 (61)

Fig. 12 (5,6,7)

le

.

panneau d'ajustement

Fig. 15 (20)

sur le dessus

de l'appareil en opérant

parles trous oblongs.

Fig. 15

u

Visser l’ensemble des

cornières de fixation

Fig. 16 (34)

avec un tour-

nevis à six pans

Fig. 16 (35)

dans les

trous préperforés de la

porte de l’appareil.

Fig. 16

Pour des parois de meuble

d'une épaisseur de 5/8 ''

(16 mm) dicken Möbelwänden = prévoir une niche

d'une largeur de 22-3/8 ''

(568 mm):

u

Cliper l'écarteur

Fig. 17 (23)

sur

Fig. 17

les charnières supérieures et

l'écarteur

Fig. 12 (24)

sur les

charnières inférieures.

u

Placer lescaches

Fig. 18 (53)

en haut et en

bas sur les cornières de

fixation

u

Visser

Fig. 18 (50)

Fig. 12 (51)

.

les

cornières de fixation

Fig. 18 (50)

en haut et en

bas de telle manière

qu’une cornière puisse

être bougée légèrement

sur la droite et sur la

gauche.

Fig. 18

u

Retirer le film de protection de la

baguette de finition

Fig. 19 (22)

. Posi-

tionner la baguette de finition

Fig. 19 (22)

par l’avant au nez du cache

côté poignée en l’alignant

Fig. 18 (53)

et la coller à la paroi latérale de l’appareil.

u

Si nécessaire, raccourcir la baguette de

recouvrement

Fig. 19 (22)

en bas : l'ex-

trémité de la baguette de recouvrement

Fig. 19 (22)

(3 mm) sur le bord supérieur de l'étrier

*

du bas

doit dépasser de 1/8 ''

Fig. 12 (50)

.

Insérer l’appareil et l’aligner:

u

Glisser l’appareil à l’intérieur jusqu’à ce que les caches

Fig. 18 (53)

heurtent la paroi latérale du meuble

Pour des parois de meuble

d'une épaisseur de 5/8 ''

(16 mm) dicken Möbelwänden = prévoir une niche

d'une largeur de 22-3/8 ''

(568 mm):

u

Positionner et fixer les écarteurs contre la paroi latérale du

meuble.

Pour des parois de meuble

d'une épaisseur de 3/4 ''

(19 mm) dicken Möbelwänden = niche d'une largeur

de 22-1/8 '' (562 mm):

u

Aligner les arêtes avant de la

charnière de façon à ce

qu’elles affleurent la paroi latérale du meuble.

Pour les meubles (5/8 '' (16 mm) et 3/4 '' (19 mm))

avec éléments du butée de porte (pastilles de

protection, lèvres d’étanchéité etc....):

u

Respecter les dimensions d'encombrement (épaisseur

des éléments de butée de porte) : faire dépasser les

charnières et les caches

Fig. 18 (53)

en tenant compte

des dimensions d'encombrement.

tous les appareils :

u

Aligner l’appareil avec les pieds réglables

l’aide d’une clé ouverte

Fig. 12 (26)

jusqu’à ce qu’il soit

droit.

w

Maintenant l’appareil est positionné correctement dans

sa profondeur. Le jeu de l’arête avant de la paroi latérale du meuble par rapport au corps de l’appareil fait

1-21/32 '' (42 mm) sur le pourtour. (tenir compte des

éléments de butée de porte tels que pastilles de

protection ou lèvres d’étanchéité.)

Fig. 19

Fig. 18

Fig. 20

Fig. 21

Fig. 12 (25)

.

à

* selon le modèle et l‘équipement 25

Page 26

Montage

Remarque

Dysfonctionnements à cause d’un mauvais montage!

Si les cotes de distance ne sont pas respectées, la porte

risque de mal fermer. Ceci risque d’entraîner givrages,

formation d’eau de condensation ou dysfonctionnements.

u

Il est fortement conseillé de respecter une cote de

distance de 1-21/32 '' (42 mm) tout autour. (tenir

compte des éléments de butée de porte tels que

pastilles de protection ou lèvres d’étanchéité.)

Visser l'appareil dans la niche :

u

sur les deux portes,

visser les vis pour

panneaux d'agglomérés

Fig. 22 (28)

respectivement en

haut et en bas au

travers des pattes de

charnière.

Fig. 22

Côté poignée en haut:

u

Desserrer un peu les vis

Fig. 23 (51)

u

Visser à fond la cornière

.

supérieure de fixation

Fig. 23 (50)

à la paroi du

meuble avec une vis à

panneaux d'agglomérés

Fig. 23 (29)

u

Enlever les parties du

cache

ø4x19.

Fig. 23

Fig. 23 (53)

dépassant en les

cassant.

u

Resserrer les vis

u

Poser le cache

Fig. 23 (51)

Fig. 23 (53)

.

.

Côté poignée en bas:

u

Desserrer un peu les vis

Fig. 24 (51)

u

Visser à fond la cornière

.

inférieure de fixation

Fig. 24 (50)

à la paroi du

meuble avec une vis à

panneaux d’agglomérés

Fig. 24 (29)

u

Enlever les parties du

cache

ø4x19.

Fig. 24 (53)

dépas-

sant en les cassant.

u

Resserrer les vis

Fig. 24 (51)

u

Poser le cache

Fig. 24 (54)

de fixation

.

sur la ornière

Fig. 24 (50)

du

Fig. 24

bas.

u

Glisser le panneau d’ajustement

Fig. 15 (20)

jusqu’à la

butée en direction du côté poignée.

u

Fermer la porte de l'appareil.

Monter les portes du meuble

6.2

Fig. 25

Les dispositifs de montage

Fig. 25 (30)

sont requis pour

les deux portes. C'est pourquoi il faut monter les

portes du placard l'une après l'autre.

u

Vérifier le pré-réglage de 5/16 '' (8 mm). (distance entre

la porte de l'appareil et le bord inférieur de la traverse)

u

Pousser les dispositifs de montage

Fig. 25 (30)

à la

hauteur de la porte du meuble. Arête inférieure de la

butée ▲ du dispositif de montage = arête supérieure de

la porte du meuble à monter.

u

Dévisser la

traverse de fixation

Fig. 26 (31)

au

moyen des contreécrous

u

Suspendre la

Fig. 26 (32)

.

traverse de fixation

Fig. 26 (31)

avec les

dispositifs de

montage

sur la face intér-

Fig. 26 (30)

Fig. 26

ieure de la porte du

meuble.

Pour une niche d'une largeur de 23-5/8 ''

(600 mm):

u

Aligner la traverse de fixation

Fig. 26 (31)

au centre :

tracer la ligne courte médiane sur la porte de meuble et

venir y placer la pointe de flèche de la traverse.

w

Les écarts par rapport à l’arête extérieure doivent être

les mêmes à gauche comme à droite.

Pour une niche d'une largeur de 24 '' (609.6 mm):

u

Aligner la traverse

Fig. 26 (31)

de fixation: tracer la ligne

courte médiane sur la porte de meuble et venir y placer

la pointe de flèche de la traverse. Décaler ensuite

Fig. 26 (31)

la traverse de fixation de 3/16 pouces

(5.5 mm) en direction de la charnière.

Pour portes en panneaux d'agglomérés :

u

Fixer la traverse de fixation

Fig. 26 (41)

sur le bord.

Fig. 26 (31)

avec 6 vis

Pour portes à caissons :

u

Fixer la traverse de fixation

Fig. 26 (41)

u

Retirer les dispositifs de montage

sur le bord.

Fig. 26 (31)

Fig. 26 (30)

avec 4 vis

en les

tirant par le haut et les pousser en les tournant dans les

orifices d’extraction à proximité.

26 * selon le modèle et l‘équipement

Page 27

Fig. 27

u

Suspendre la porte du meuble sur lestenons d’ajuste-

Fig. 27 (33)

ment

Fig. 27 (32)

u

Fermer la porte.

u

Vérifier la distance de la porte par rapport aux portes

et visser légèrement les contre-écrous

sur les tenons d’ajustement.

de meuble avoisinantes.

u

Aligner latéralement la porte du meuble : décaler la

porte du meuble en direction de X.

u

Aligner la porte de placard en hauteur et en inclinaison

latérale : Régler les boulons d'ajustage

Fig. 27 (33)

l'aide d'un tournevis.

w

La porte de meuble doit s’aligner de façon à affleurer

les façades de meuble qui l’entourent.

u

Serrer les contre-écrous

Fig. 27 (32)

.

Bien respecter le bon

alignement des deux

arêtes en métal,

symbole //:

u

Préperforer les trous

de fixation de la porte

de meuble (si nécessaire entailler avec un

burin).

u

Visser

Fig. 28 (41)

. la porte de l’appareil sur la porte du

meuble à travers les cornières de fixation

Fig. 28 (34)

à

Fig. 28

.

Pour les grandes portes de placard :

u

Monter une 3ème paire de cornières de

fixation

u

Utiliser pour ceci les trous préperforés de

Fig. 29 (34)

.

la porte de l’appareil dans la zone de la

poignée.

u

Vérifier le bon

positionnement de la

porte et

l’ajuster ultérieurement si

nécessaire.

u

Serrer toutes

les vis à fond.

u

Serrer les contre-écrous

nale

Fig. 30 (37)

Fig. 30 (33)

u

Mettre en place les

en bloquant les boulons d'ajustage

à l'aide d'un tournevis.

Fig. 30 (32)

caches supérieurs

Fig. 31 (38)

et les encli-

queter.

u

Poser les caches latéraux

Fig. 31 (39)

; les

faire glisser jusqu'à la

butée puis appuyer sur

les caches jusqu'à ce

que vous les entendiez

encliqueter.

u

Faire coulisser les

caches

Fig. 31 (40)

latéralement, ensuite les

tirer vers l'avant à l'aide

d'un tournevis jusqu'à

ce qu'ils encliquettent.

Montage

Fig. 30

avec la clé polygo-

Fig. 29

u

Aligner la porte du meuble dans la profondeur Z:

Desserrer les vis

Fig. 29 (35)

Fig. 29 (37)

u

Ne pas faire buter les plots et lèvres

Fig. 29 (36)

en bas, à l'aide de la clé polygonale

jointe. Ensuite déplacer la porte.

en haut, les vis à six pans

d'étanchéité - important pour le bon

Pour une niche d'une largeur de 24 '' (609.6 mm):

u

Poser les caches

Fig. 12 (6,7,60)

et les encliqueter.

Pour une niche d'une largeur de23-5/8 '' (600 mm):

u

Poser les caches

Fig. 12 (5,6,7)

et les encliqueter.

Aux appareils sans amortisseurs de fermeture régler

l'amortissement de la butée de fin de course :

Fig. 31

fonctionnement !

u

Prévoir un passage d’air de 3/32 ''

(2 mm) entre la porte et le corps du

meuble.

* selon le modèle et l‘équipement 27

Page 28

Brancher l'appareil

Le ressort de la butée finale de la

porte peut être réglé si nécessaire avec la clé a six pans

prévue à cet effet:*

u

Augmenter la force de

ressort : tourner dans le sens

des aiguilles d'une montre.*

u

Diminuer la force de ressort

(réglage au départ de l'usine) :

tourner dans le sens contraire

des aiguilles d'une montre.*

u

Mettre en place les caches

restants sur les charnières.*

Vérifier les points suivants afin de s’assurer du montage

correct de l’appareil. Sinon givrages, formation d’eau de

condensation ou dysfonctionnements peuvent survenir:

w

La porte doit fermer correctement

w

La porte du meuble ne doit pas être accolée au corps

du meuble.

w

Le joint côté poignée dans le coin en haut doit être bien

apposé. Pour vérifier, assombrir la pièce, placer une

lampe de poche en haut dans l'appareil et fermer la

porte. Si la lumière est visible de l'extérieur, vérifier le

montage.

7 Brancher l'appareil

AVERTISSEMENT

Risque de décharge électrique !

u

L’appareil ne doit être mis en marche qu’après avoir

été monté et encastré selon les consignes mentionnées ci-dessus.

u

Mise à la terre de l’appareil

u

Ne pas effectuer de mise à la terre de l’appareil au

dessus d’une conduite de gaz.

u

Faites venir un spécialiste si vous n’êtes pas certain de

la mise à la terre correcte de l’appareil.

u

Ne pas intégrer de fusible dans le circuit électrique du

conducteur neutre ou de la mise à la terre.

u

Ne pas utiliser de rallonges ou de multiprises.

u

Ne pas utiliser de câble d’alimentation abrasé ou

endommagé.

Attendre 1 heure après la mise en place avant de

raccorder l’appareil au réseau électrique. Ceci permet

au fluide réfrigérant et à l’huile réfrigérante de se

répartir correctement.

S’assurer que la tension du réseau électrique corres-

pond à la tension d’alimentation de l'appareil. Pour un

fonctionnement correct de l’appareil, prévoir une

alimentation de 110 - 120 V, 60 Hz (et 15 A (20 A si la

mise en place se fait côte à côte) sécurisé par un

commutateur principal ou un fusible.

Le fabricant conseille d’alimenter l’appareil par un

circuit électrique séparé pour éviter les surcharges

électriques.

Respecter l’ensemble des normes en vigueur pour ce

-

*

qui est des installations électriques, de la protection

contre les incendies et du code de construction lors de

la mise en place d’une prise et/ou de l’appareil.

Dans certains pays, le branchement de l’appareil au

réseau électrique doit être fait avec la mise en place

d’un commutateur MARCHE/ARRET installé dans le

mur.

La mise en place et le branchement de l’appareil

doivent être effectués par un spécialiste, en respectant

l’ensemble des consignes et normes en vigueur ainsi

que les règles en matière de , protection contre les

incendies afin de réduire tout risque d’incendie, de

décharges électriques, d’électrocution ou autres blessures.

La prise de courant doit être bien accessible afin de

pouvoir débrancher rapidement l'appareil en cas d'urgence.Elle doit se situer en dehors de la partie arrière

de l´appareil.

La prise doit être disposée de telle manière que son

arête supérieure se situe à une distance maximale

de82-5/8 pouces (2100 mm) par rapport à l’arête supérieure de la plaque de base du meuble de cuisine.

AVERTISSEMENT

Risque de décharge électrique !

Cet appareil est équipé d’une prise à trois pôles avec

détrompeur pour éviter tout risque décharge électrique.

La prise doit être mise à la terre correctement.

u

Il est formellement interdit de retirer la broche circulaire

de mise à la terre de la prise.

u

Utilisez exclusivement un adaptateur de prise mis à la

terre.

28 * selon le modèle et l‘équipement

Page 29

Instrucciones

de montaje

Combinado frigorífico-congelador,

integrable en mueble alto

HC1011/1060 HC1001/1050

111113 7084000 - 03

Page 30

Notas generales sobre seguridad

Contenido

1 Notas generales sobre seguridad................ 30

2 Instalación del aparato................................. 30

3 Montaje del mueble de cocina..................... 31

3.1 Ventilación y salida de aire del mueble de

cocina............................................................... 32

3.2 Montaje del mueble de cocina.......................... 33

3.3 Montaje de las puertas del mueble de cocina.. 34

4 Cambio del tope de puerta........................... 36

4.1 Desmontaje del amortiguador de cierre........... 36

4.2 Cambio del tope de puerta............................... 36

4.3 Nuevo montaje del amortiguador de cierre...... 37

5 Conexión de agua.......................................... 37

6 Montaje........................................................... 38

6.1 Montaje del aparato......................................... 38

6.2 Montaje de las puertas del mueble................... 40

7 Conexión del aparato.................................... 42

El fabricante trabaja continuamente para seguir desarrollando todos los tipos y modelos. Por lo tanto, agradeceríamos su comprensión ante posibles modificaciones de

la forma, el equipo y la técnica.

Para conocer todas las ventajas de su nuevo aparato, lea

detenidamente las indicaciones de este manual.

Las instrucciones son válidas para varios modelos;

pueden producirse variaciones. Las secciones que sólo

se refieren a determinados aparatos aparecen marcadas

con un asterisco (*).

Las instrucciones de procedimiento aparecen

marcadas con un

aparecen marcados con un .

, los resultados de procedimiento

1 Notas generales sobre seguridad

-

Lea y siga estas instrucciones. pues contienen

indicaciones sobre la seguridad que son

importantes para una instalación y un funcionamiento perfectos. Lea y siga siempre las

indicaciones sobre la seguridad

-

Es importante que se sigan las directrices e

indicaciones de estas instrucciones para que

el aparato se instale y funcione correctamente.

Lea y comprenda toda la información que

figura en estas instrucciones antes de instalar

el aparato.

-

La caja de enchufe debe ser fácilmente accesible para poder desconectar el aparato rápidamente de la toma de corriente en caso de

emergencia. Se debe encontrar fuera del área

de la parte trasera del aparato.

PELIGRO identifica una situación de peligro

inminente que, si no se evita, puede

producir lesiones graves o incluso la

muerte.

ADVERTENCIA

ATENCIÓN identifica una situación de peligro

AVISO identifica una situación de peligro

Nota identifica indicaciones y recomen-

identifica una situación de peligro

que, si no se evita, puede producir

lesiones graves o incluso la muerte.

que, si no se evita, puede producir

lesiones leves o moderadas.

que, si no se evita, puede producir

daños materiales.

daciones útiles.

2 Instalación del aparato

ADVERTENCIA

Riesgo de incendio derivado de la humedad

Si las piezas conductoras de electricidad o la línea de

alimentación eléctrica se humedecen, puede producirse

un cortocircuito.

u

El aparato está diseñado para utilizarse en espacios

cerrados. No ponga en funcionamiento el aparato en

un lugar al aire libre, expuesto a la humedad ni a las

salpicaduras de agua.

u

Utilice el aparato sólo cuando esté instalado.

ADVERTENCIA

¡Peligro de incendio a consecuencia de un cortocircuito!

Si los cables de red/conectores del aparato o de otro

aparato entran en contacto con la parte trasera del

mismo, los cables de red/conectores pueden sufrir daños

debido a las vibraciones del aparato y se puede producir

un cortocircuito.

u

Coloque el aparato de tal forma que no entre en

contacto con ningún conector o cable de red.

u

No conecte el aparato ni otros aparatos en cajas de

enchufe situadas en el área de la parte trasera del

aparato.

ADVERTENCIA

Peligro de incendio y de sobrecalentamiento

u

No coloque aparatos que emiten calor como, por ej.

microondas, tostadoras etc. sobre el aparato.

ATENCIÓN

¡Peligro de lesiones!

u

El aparato debe transportarse a su lugar de instalación

con la ayuda de dos personas.

30 * según modelo y dotación

Page 31

AVISO

Riesgo de daños derivado de agua de condensación

Si el aparato Liebherr se instala cerca de otro frigorífico o

congelador, la formación de agua de condensación

puede producir daños.

u

No instale el aparato cerca de otro frigorífico o congelador, a menos que se trate de aparatos fabricados por

Liebherr. Los aparatos Liebherr son aptos para

montarse en el modo Side-by-Side. Disponen de un

dispositivo de calentamiento que elimina el agua de

condensación cuando se instalan frigoríficos o congeladores próximos entre sí.

AVISO

¡Existe riesgo de que el suelo del mueble sufra daños!

u

Proteja el suelo cubriéndolo antes de retirar el embalaje del aparato.

Asegúrese de que:

q

El suelo del lugar de instalación del aparato está

perfectamente liso y nivelado.

q

La capacidad de carga del suelo admite el peso del