Page 1

Fast-erecting crane 81 K

Max. lifting capacity: 13,230 lbs

Max. radius: 147’-6”

Lifting capacity with max. radius: 3,090 lbs

Works efficiently

and looks good

Page 2

The 81 K fast-erecting crane.

Comfortable cab

with best possible view of the site

Torsionally resistant

Fully automatic play-free tower

connection

Integrated intermediate

hook heights

CC-Ballast

Saves time thanks to

boltable ballast slabs

New switch cabinet

Programmable logic control system, graphic display,

remote diagnosis, and much more besides.

Quick-Connection

for play-free connection of the

tower to the slewing platform

Variable slewing radius

9,02 - 11,48 ft

11 hook heights

Thanks to climbing capability

of tower sections

2

Page 3

SPEED 2 LIFT

Pure two-line operation for

maximum handling capacity

MICROMOVE

Millimetric precision with

fine positioning

25% more

jib end lifting capacity

4 different

jib lenghts

Contents

Working fast and safe – for sure! Page 4

Our drive is your success. Page 10

Arrive efficiently. Page 16

Simply well set-up. Page 20

Assured long life – maintenance and more. Page 24

Technical Data. Page 28

Uses in summary. Page 31

3

Page 4

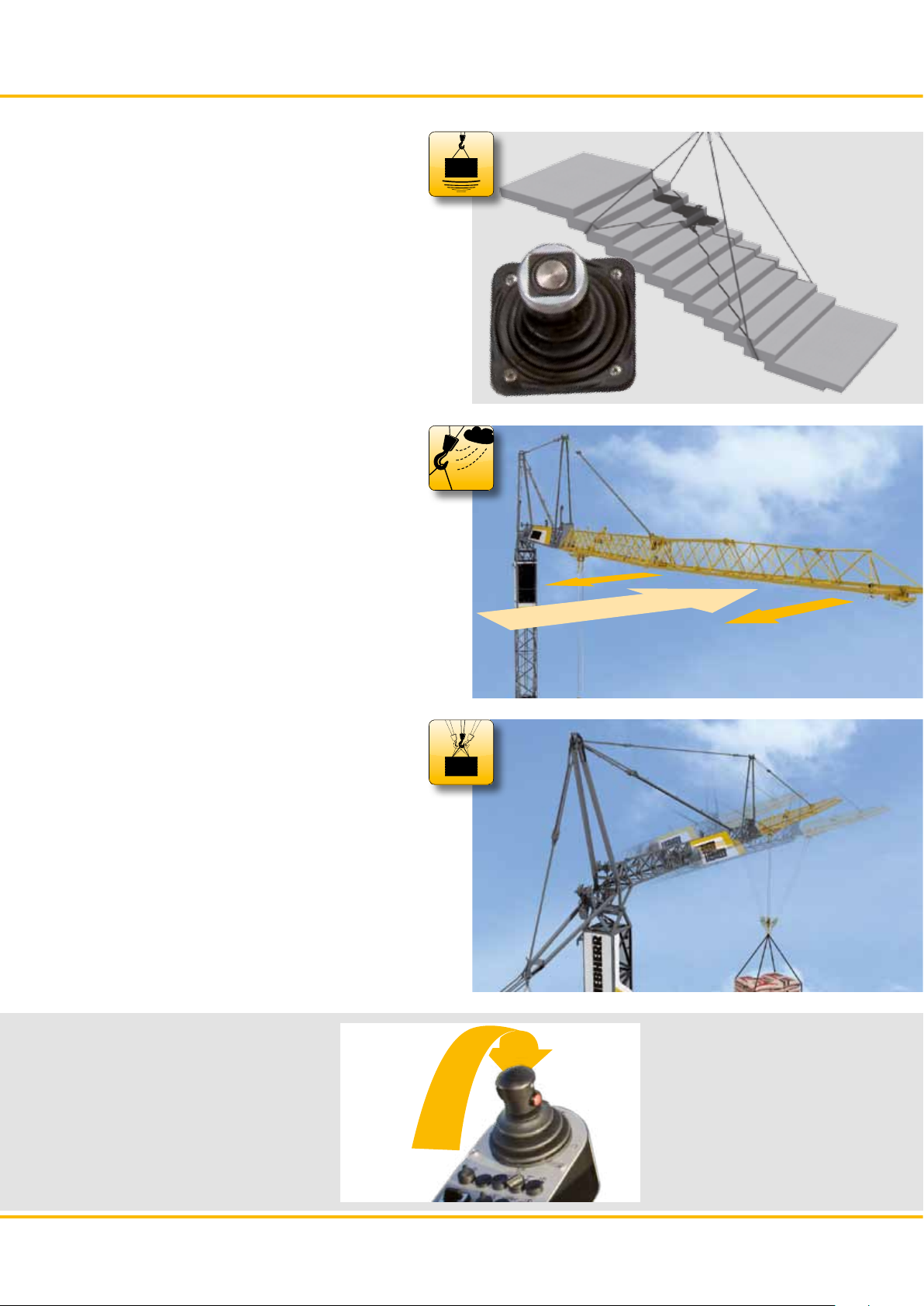

SPEED 2 LIFT

Always max. load and

full speed with two-line

operation

4

Page 5

147.6 ft / 3,090 lbs

Working fast and safe – for sure!

SPEED 2 LIFT: two-line operation for maximum performance at full speed

Unrivalled maximum lifting capacity

MICROMOVE: precision mode for millimetre precision positioning at the push of a button

Secure working movements with load swing damping and wind load control

5

Page 6

m/min

kg

Working fast and safe – for sure!

To date – Either fast or strong!

lb

New – Fast and strong.

ft/min

Rereeving – no longer required

The 81 K operates exclusively with two-line operation. Maximum performance at full speed – always! With hoists at

maximum lifting capacity and empty hook runs. Hoist speed

always matches the hanging load. By the way – half of all load

cycles are empty runs. We have increased the speed by 15%.

Strong matter

Currently up to 25% more

lifting capacity.

25 %

6

Page 7

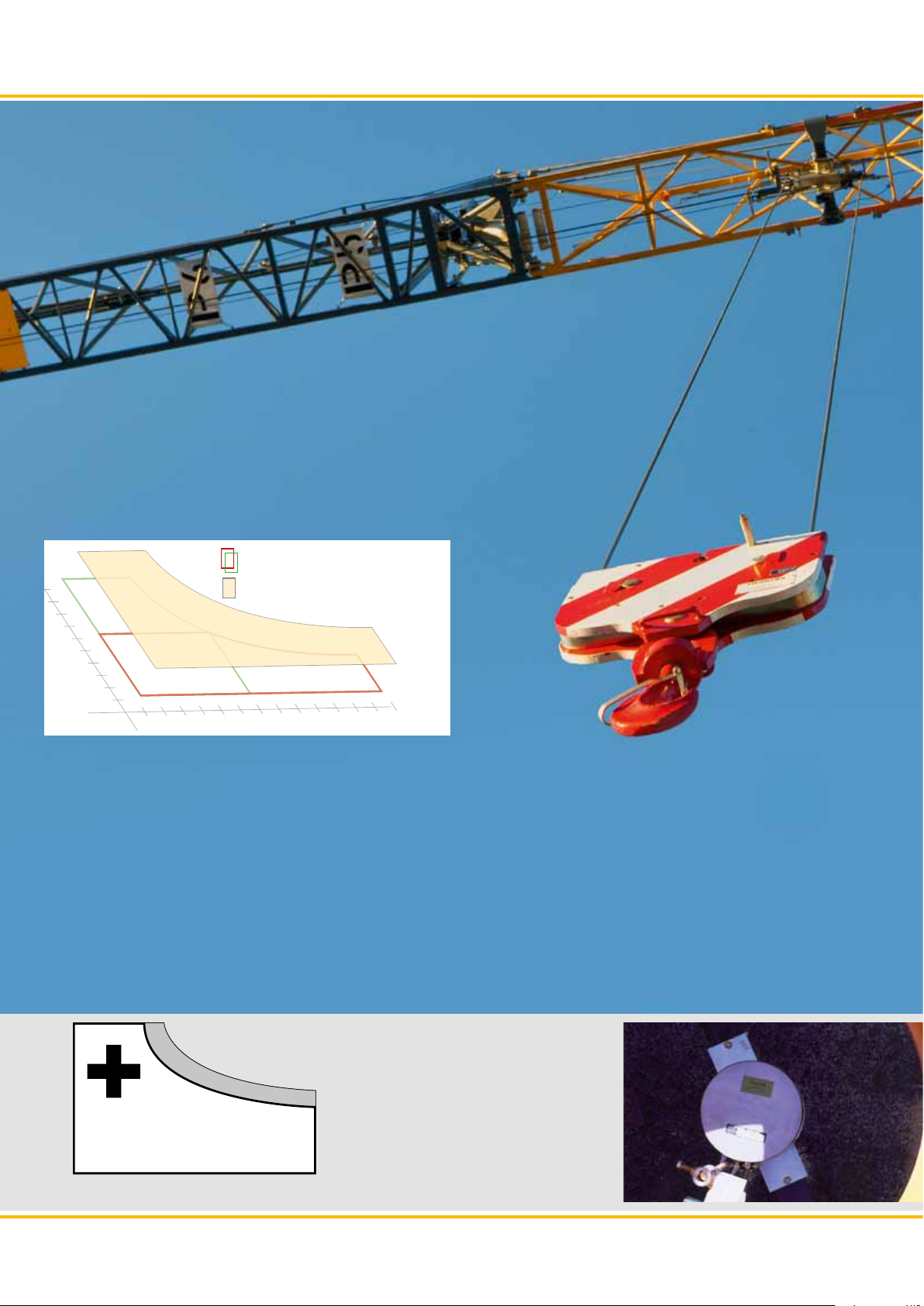

Loads precisely positioned

With MICROMOVE, at the push of a button on the

control lever, lowering speed is reduced to micro levels. Even the heaviest loads can be precisely suspended and positioned without using the hoist gear

brakes.

Accurate against the wind

Wind influences the movement of the jib! With the wind

load control, the jib position is regulated automatically.

Counter measures are not necessary. Large-scale loads

(i.e. form panels) can be moved and suspended precise-

ly even in wind.

Steady handling

Fast turning movements can lead to swinging loads. The

integrated load swing damping automatically compensates for this. A significant step for safety on the building

site!

Standard current collector

No restrictions with slewing and no

wound cables.

Always full

lever control

The bigger the load, the more

precisethe control.

7

Page 8

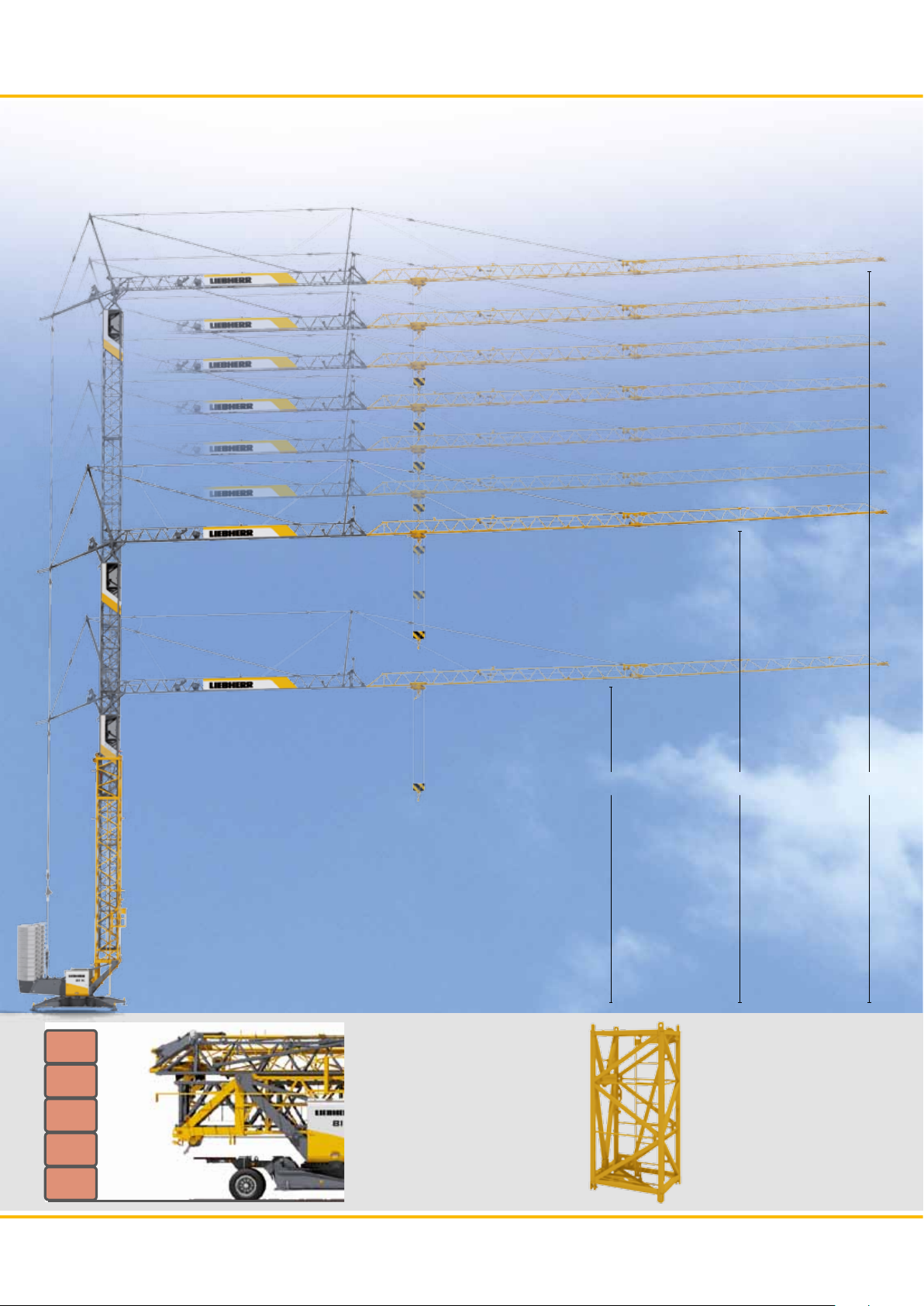

Flexible is efficient.

The success

on your site

The operational area of the 81 K encompasses apartment

block construction to industrial projects. Great flexibility with

11 different crane heights, the 30° raised jib angle and the

45°-obstruction avoidance angle equips the 81 K for every building site. Operations under power lines or in halls are

possible through the telescopic tower. Define the success of

your construction site yourself!

Short projection

You can use the full radius

also with limited building

site space.

57‘-1“ 85‘-3“ standard hook hight up to 132‘-5“

Fast climbing

Up to 6 inserted tower

sections enable 11 hook

heights.

8

Page 9

30

Range with lifting capacity

Adjustable jib in 4 lengths to meet individual requirements

– between 101 ft and 147 ft. You profit from customised

lifting curves.

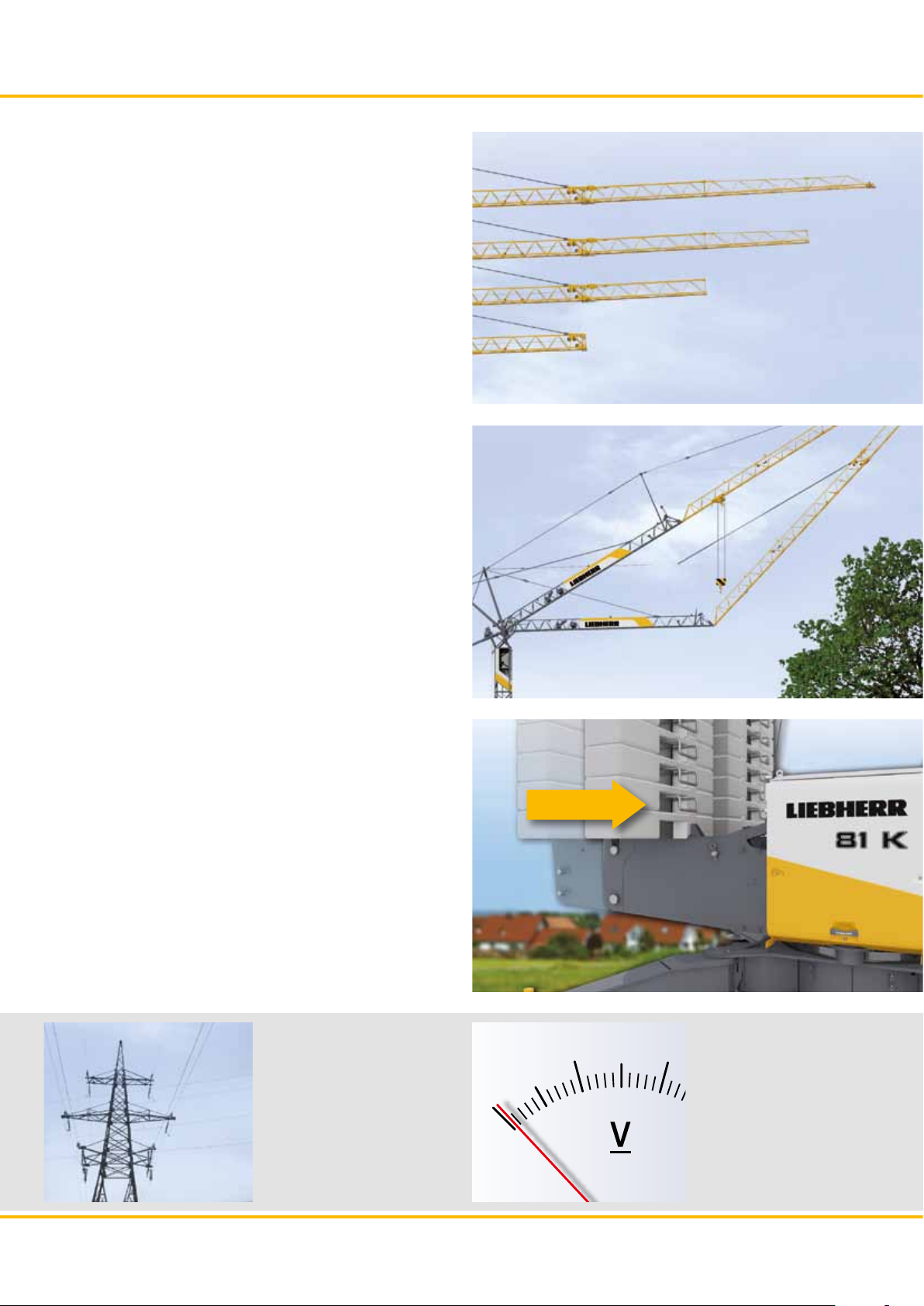

Obstructions or high reaches

With the 30° raised jib position and the 45° jib obstruction

avoidance position you can match the crane to every operation – and reach hook heights of up to 180 ft.

147‘-1“ / 3,090 lbs

137‘-8“ / 3,640 lbs

121‘-4“ / 4,740 lbs

101‘-7“ / 6,390 lbs

30°

Variable slewing radius

Save more than 35% space requirements through reduced

slewing radius. The crane can be set up nearer buildings or

during operations with limited building site space. Choose

between reduced space requirements or less ballast.

Extreme situations

Also work with obstructions i.e. under power li-

nes with retracted tower.

45°

11‘-48“ - 9‘-0“

Multi-volt

100

200

Adjustment of operating

voltage to local condi-

0

tions (380 - 500 v / 5060 Hz).

9

Page 10

Our drive to your success.

Powerful drives manufactured in-house ensuring the highest quality – for decades

PLC-control for increased safety and user comfort

Steel construction resistant to torsion for durability and precise working

Comfortable cabin with optimum view for maximum working comfort

10

Page 11

11

Page 12

Unrivalled drives.

Strong and sensitive

The strong and precise hoist gear is central requirement

for increased handling capacity and safe working. It is

specially manufactured and assembled in-house for this

construction crane. For the first time ever in a fast-erecting crane in its class, the hoist gear can lift and lower

all loads absolutely steplessly. The wide rpm enables 2

rope operation at full speed. The intelligent ventilation

system cools the drive to optimum operation temperatures – independent from hoist rpm.

12

Power connection

Energy supply through easy access

connection at the undercarriage.

Page 13

Like the big ones

Due the stepless speeds of all to FC drives the driving performance corresponds to the top slewer and guarantees maximum handling capacity.

Slewing just as you want

Choose between absolutely sensitive slewing with low rpm

and high torque and high handling capacity with high rpm and

low torque. The ratio is freely adjustable.

Safe Control

The modern and safety orientated PLC control includes operating-range limiting system ABB, the interface to the anticollision system AKS or machine data recording MDE. The

graphic display offers a simple menu guide and shows all important operational data in one view. LiDAT offers additional

possibilities for remote diagnosis and data evaluation.

Simple scaling

With one weight the crane is scaled in

mi nutes. This saves time and money!

13

Page 14

Exceptionally equipped.

New design for efficient operation

In addition to the technical innovations the 81K was completely

redesigned. Optimum arrangement of controls in the new cabin

enables efficient and exhaustion free work. The optimised field of

vision maximises the view of building site. Tinted glass reduces

heat and protects against glare.

14

Large tool

compartment

and extra space for

radio control with

220 v socket for recharger.

New radio remote

control

with feedback. All the

important information

is shown on the display.

Page 15

Clear information

With the electronic monitoring system (EMS) the crane driver

has all the important parameters in one view. The display gives extensive information on loads, driving modes and many

other operational functions.

Safe guying

The jib is mounted with rods. Above all, increased safety and

low maintenance are aimed for in assembly.

Play-free tower connection

After the tower is extended, it is tensed at 3 defined points

with the automatic tower locking device. Through the clearance free tower connection the whole steel structure is torsion

resistant and stable. Equipped as standard, the intermediate

hook heights can now be used quickly and easily.

Centrally

positioned jib

distributes the forces equally and carefully through the

tower.

Increased control stand height

for a better view.

15

Page 16

16

Page 17

Arrive efficiently.

Compact and flexible when transporting

Modular axle system – use your existing fleet

Maximum speed – up to 80 km/h to destination

Foldable A frame enables increased slope angle

17

Page 18

Arrive efficiently.

Sleak dimensions

Despite the unique standard hook height of the 81 K is compact

and flexible to transport. Moved as complete, ready assembly

unit. Fast into operation.

13‘-0“

18

52‘-0“

8‘-5“

Maximum speed

At up to 50 mp/h

you get your crane

to its destination.

50

Page 19

You have the choice

The modular high-speed and slow-speed axle system or se-

mitrailer offers the best transport possibility for every operational area. Existing axles can also be used.

Increased slope angle

With the foldable A frame, the 81 K reaches an angle of 15° –

that means: approx. 4.5 ft ground clearance.

Good to manoeuvre

With its steering angle of 180°, the steering axle guarantees

best manoeuvrability.

Twin tyres

If the road doesn’t

go all the way to

the building site,

twin tyres prevent

sinking.

15°

180°

Tower sections

Easily transported on

a lorry with an ideal

packing size of 7‘-9“

x 3‘-6“.

19

Page 20

20

34‘-8“ - 82‘-0“

Save money

– without hydraulics!

Page 21

Simply well set-up.

Adaptable assembly kinematics – without hydraulics

Different erecting curves for every situation

Fast ballasting with the semi-automatic ballasting device

Comfortable insertion of up to 6 tower sections

21

Page 22

Simply well set-up.

Get ready for work

Proceeds through thought out installation kinematics with rope. Assembly

is also possible at extremely low temperatures. The narrow air assembly

requires little installation space and and can be carried out with obstructions

of up to 82 ft.

82‘-0“

Choose the right erecting curve depending

on your operation

22

Screw jacks

Thanks to the trapeze thread,

the erected crane can be levelled and readjusted with little

effort.

Page 23

The better ballasting

The interplay of hoist and assembly winches enables fast and

comfortable mounting of the counterweight. With the assembly

winch, the tower moves up to 5 metres when unloading the

counterweight. Ballast plates are quickly mounted with the

hoist winch.

CC-Ballast

Bolted ballast plates reduce the time for mounting of counterweights by up to 50%. Only 8 hoists are required. Save time

and money!

Fast climbing

Up to 6 tower sections can be inserted comfortably and without

ground contact.

Quick-Connection

Simple interlocking between tower

and slewing platform with only one

hammer blow.

One-Man-Assembly

Patented, semi-automatic ballasting tongs and the ballast

centring enable one-man assembly.

23

Page 24

24

Page 25

Assured long life – maintenance and more.

Remote diagnosis with LiDAT

Replacement parts available quickly and long-term

Service network of authorized Liebherr dealers

Skilled personnel

25

Page 26

Assured long life – maintenance and more.

All information at a glance: always and everywhere

LiDAT is a data transmission and positioning system for Liebherr machines

and the machines of other manufacturers. Based on stateof- the-art data

transmission technology, LiDAT provides information on the location and operation of your machines, enabling their efficient management, optimal operation

scheduling and remote supervision.

26

Worldwide

service network

Liebherr is represented worldwide.

You can profit

from this network.

Delivery

A large network of

notable forwarding

agencies guarantee

fast and secure transportation.

Page 27

Original spare parts

Our spare parts are optimally tailored to every Liebherr crane.

The quality and functionality is of the highest standard across

the range. For a long life and high operational readiness of

your machines.

Smooth operation

With the central lubricating system the slewing ring is automatically lubricated. Care is never forgotten.

Liebherr construction cranes.

The development of the first quickly transportable and simple assembly crane over sixty years ago characterises the start of

Liebherr’s company history. The Liebherr construction crane programme is multifaceted like no other. It encompasses machines of all systems and sizes and offers the right lifting technology for high rise building. The flexible fast-erecting cranes and

powerful top-slewing models prove themselves in residential construction, industrial or large projects throughout the world.

Liebherr is an owner-managed company with long-term organisation. You can profit from this continuity.

27

Page 28

K

81

Turmdrehkran / Grue à tour / Gru a torre / Grúa torre

Guindaste de torre / Башенный поворотный кран

Tower Crane

lbs

lbs

lbs

K

81

K

81

K

81

K

81

44,090 lbs

r = 11’-5”

r = 9’-0”

77,160 lbs

88,190 lbs

30°

45°

123’

203’-4”

196’-5”

116’-1”

185’-0”

104’-7”

171’-6”

91’-2”

147’-6”

6’-6”

52’-8”

9’-8”6’-2”

0

1

3

0

1

2

3

4

5

62127’-6”

119’-7”

111’-9”

104’-0”

96’-1”

88’-3”

80’-4”

75’-8”

67’-9”

60’-0”

52’-2”

ca. 49,710 lbs

8’-5”

13’-0”

52’-0”

0’-82”

18’-2” (19’-9”)

24’-9” (26’-6”)

7’-5”

10’-5”

55’-0”

8’-5”

13’-0”

52’-0”

0’-8”

53’-0” – 55’-0”

6’-2”

7’-1” – 9’-1”

24’-4”

16’-2”

ca. 55,560 lbs

8’-5”

13’-1”

0’-8”

52’-0”

28’-2”

16’-2”

ca. 51,590 lbs

4’-1”

lbs

lbs

lbs

lbs

44,090 lbs

123’

203’-4”

196’-5”

116’-1”

185’-0”

147’-6”

6’-6”

ca. 49,710 lbs

8’-5”

13’-0”

10’-5”

8’-5”

13’-0”

6’-2”

7’-1” – 9’-1”

ca. 55,560 lbs

8’-5”

13’-1”

ca. 51,590 lbs

4’-1”

Technical data.

167’-3”

104’-0”

30°

45°

157’-4”

86’-9”

6,390 lbs

4,740 lbs

118’-1”

3,640 lbs

175’-5”

126’-6”

3,090 lbs

4 180’-4”

180’-4”

3 172’-6”

2 164’-7”

1 156’-8”

0 148’-9”

6

5

4

3

2

1

0

3

101’-7”

121’-4”

6,390 lbs

137’-8”

4,740 lbs

147’-6”

3,640 lbs

3,090 lbs

6 132’-5”

5 124’-7”

4 116’-8”

3 108’-9”

2 101’-0”

1 93’-2”

0 85’-3”

3 80’-7”

2 72’-8”

1 65’-0”

0

*

57’-1”

14’-8”x 14’-8”

Weight

* see instruction manual

28

81

K

2

1

0

r=3.50 m

r=2.75 m

14’-8”x 14’-8”

35000 kg

40000 kg

EN 14439:2009 –C25

20000 kg

Page 29

203’-4”

Ausladung und Tragfähigkeit / Portée et charge / Sbraccio e portata

Alcances y cargas / Alcance e capacidade de carga / Вылет и грузоподъемность

Radius and capacity

123’

196’-5”

116’-1”

185’-0”

104’-7”

171’-6”

30°

45°

9’-8”6’-2”

91’-2”

6’-6”

147’-6”

max. 149’-3”

min. 68’-9”

11’-5”

9’-0”

81

K

14’-8”x 14’-8”

52’-8”

62127’-6”

5

119’-7”

4

111’-9”

104’-0”

3

96’-1”

2

1

88’-3”

0

80’-4”

75’-8”

3

67’-9”

1

60’-0”

52’-2”

0

52’-0”

0’-82”

18’-2” (19’-9”)

24’-9” (26’-6”)

55’-0”

52’-0”

0’-8”

16’-2”

24’-4”

53’-0” – 55’-0”

0’-8”

16’-2”

28’-2”

52’-0”

81

K

7’-5”

10’-5”

81

K

6’-2”

7’-1” – 9’-1”

81

K

4’-1”

13’-0”

8’-5”

13’-0”

8’-5”

13’-1”

8’-5”

lbs

ca. 49,710 lbs

lbs

ca. 55,560 lbs

lbs

ca. 51,590 lbs

Radius and capacity

ft/lbs

ft

99’-2”

92’-6”

81’-6”

68’-3”

ft/lbs

9’-8” – 43’-6”

13,230

9’-8”

– 46’-3”

13,230

9’-8”

– 49’-5”

13,230

9’-8”

– 53’-5”

13,230

42’-7”

13,230

13,230

13,230

13,230

49’-2”

59’-1”

68’-9”

78’-7”

6,680

7,140

7,850

8,580

88’-6”

5,820

6,220

6,860

7,500

11,510

12,280

13,230

13,230

9,330

9,970

10,870

11,840

7,800

8,360

9,150

9,970

95’-1”

5,340

5,710

6,330

6,900

101’-7”

4,920

5,290

5,840

6,390

108’-3”

4,560

4,850

5,420

114’-8”

4,230

4,560

5,070

121’-4”

3,970

4,260

4,740

128 ’-0”

3,700

3,990

134’-5”

3,480

3,750

137 ’-8”

3,370

3,640

144’-4”

3,180

147 ’-6”

3,090

29

Page 30

m

Technical data.

13,230

13,230

13,230

13,230

99’-2”

9’-8” – 43’-6”

13,230

9’-8”

13,230

– 46’-3”

9’-8”

13,230

– 49’-5”

9’-8”

13,230

– 53’-5”

92’-6”

81’-6”

68’-3”

42’-7”

ft/lbs

ft/lbs

ft

Ausladung und Tragfähigkeit / Portée et charge / Sbraccio e portata

Alcances y cargas / Alcance e capacidade de carga / Вылет и грузоподъемность

Radius and capacity

Driving units Antriebe / Mécanismes d’entraînement / Meccanismi / Mecanismos / Mecanismos / Приводы

11,510

12,280

13,230

13,230

49’-2”

9,330

9,970

10,870

11,840

59’-1”

7,800

8,360

9,150

9,970

68’-9”

6,680

7,140

7,850

8,580

78’-7”

5,820

6,220

6,860

7,500

88’-6”

5,340

5,710

6,330

6,900

95’-1”

4,920

5,290

5,840

6,390

101’-7”

4,560

4,850

5,420

108’-3”

4,230

4,560

5,070

114’-8”

3,970

4,260

4,740

121’-4”

3,700

3,990

128 ’-0”

3,480

3,750

134’-5”

3,370

3,640

137 ’-8”

3,180

144’-4”

3,090

147 ’-6”

6,610

6,610

6,610

6,610

147’-6”

9’-8” – 55’-1”

6,660

9’-8” – 58’-1”

6,660

9’-8” – 69’-6”

6,660

9’-8” – 69’-6”

6,660

137’-8”

121’-4”

101’-7”

39’-4”

ft/lbs

ft/lbs

ft

6,610

6,610

6,610

6,610

45’-9”

6,550

6,610

6,610

6,610

52’-5”

6,020

6,530

6,610

6,610

59’-1”

5,560

6,040

6,610

6,610

65’-6”

5,160

5,600

6,420

6,610

72’-2”

4,630

5,050

5,800

6,610

82’-0”

4,410

4,810

5,530

6,390

86’-9”

4,190

4,590

5,290

91’-9”

3,950

4,320

4,980

98’-4”

3,750

4,100

4,740

104’-0”

3,620

3,950

108’-3”

3,420

3,750

114’-8”

3,310

3,640

118’-1”

3,220

141’-4”

3,090

126’-6”

Elevated jib 30° Auslegersteilstellung 30° Braccio inclinato a 30°

Pluma inclinada 30° / Lança inclinada 30° / 30°Положение стрелы под углом

/ / Flèche inclinée 30° /

Erection procedure

1

Standard erecting curves from

1 to 6 tower sections

2

Elevated erecting curve (+ 14‘-8“)

using the example of 6 tower

sections

55

50

45

40

35

30

25

2

1

20

15

10

5

0

K

81

0m

-5-10 5

6

5

4

3

2

1

0

10

15 20 25 30 35 40 45

Driving units

0 0,8

0 197 ft/min

0 82 ft/min

0 – 45°, 110 sec.

tr./min

BGL

6.7 hp FU

4 hp FU

2x2hpFU

4 hp FU

C.0.08.0080

20.1 hp FU

WIW 210 MZ 404

13,230

11,020

8,820

6,610

4,410

2,210

0

400 V Hz kVA

33

stepless

Speed

Speed

1

66 98 131 164

50 21,0 FU285’4” 4.3 x 6.5 qf

lbs ft/min

13,230

1

880

197

230 262

0 39

0 230

30

Page 31

Uses in summary.

SPEED

Pure two-line operation

Always maximum performance at full

speed.

25% more lifting capacity

In comparison to series precursors.

25 %

CC-Ballast

Save assembly time through bolted ballast

plates and heavy ballast.

MICROMOVE

Millimetre precise positioning at the touch

of a button.

Wind load control

The control reacts automatically to the

counter torque on the jib.

Load swing damping

Automatic compensation of jib movements

for static load.

Simple scaling

With only one weight the crane is scaled

in a few minutes.

Low maintenance assembly kinematics

Reliable assembly with ropes even at low

temperatures.

Variable slewing radius

35% less space requirements through

decrease of the slewing platform.

LMB

Fast climbing

Up to 6 tower sections can be inserted. Hook

heights of up to 180 ft can be reached.

Electronic load moment limitation

Secure transport of load until end stop.

Display on switch cabinet

with simple menu guide.

Operating data recording / evaluation

Recording of all operating and performance data of the crane for

evaluation and optimum servicing and maintenance.

31

Page 32

Don’t hang on…

Go for it!

Printed in Germany DWS LBC 675-06.09-1enUS. This information is supplied without liability. Subject to technical modifications.

Liebherr Construction Equipment Co.

4100 Chestnut Avenue, Newport News, VA 23607

Phone: (757) 245-5251, E-mail: info.lce@liebherr.com

www.liebherr.com

Loading...

Loading...