Page 1

Precision Cooling

For Business-Critical Continuity™

Liebert® XDK-W™ Rack Enclosure With Integrated Liquid Cooling

User Manual–25kW, 50 and 60Hz

Page 2

Page 3

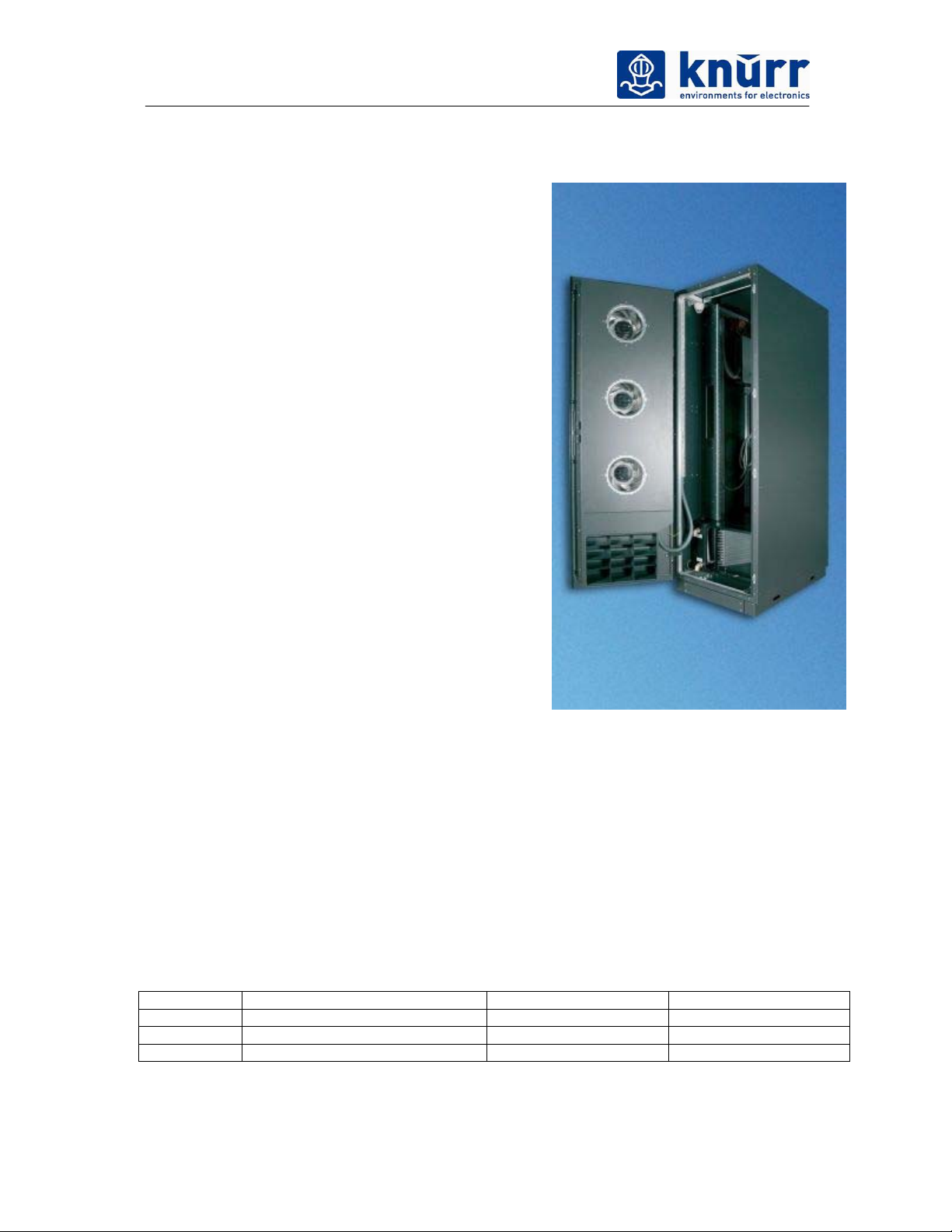

CoolTherm

Manual / Bedienungsanleitung

Manual

CoolTherm

Server Cabinet with

integrated liquid cooling

Effective cooling capacity

12 - 25 / 35 KW

Bedienungsanleitung

CoolTherm

Schaltschrank mit

integrierter Flüssigkeitskühlung

Nutzkühlleistung 12 -25 / 35 KW

(ab Seite 42)

date / Datum issue / Ausgabe author / erstellt reviewed / geprüft

2007-06-01 01_998_330_0_k Carsten Dietze Heiko Ebermann

CoolTherm 01_998_330_0_k page / Seite 1/83

Page 4

CoolTherm

Manual / Bedienungsanleitung

Contents

0.

Abstract ......................................................................................................................................... 3

1.

Safety............................................................................................................................................. 3

1.1 Work safety symbols.................................................................................................................... 3

1.2 Safety instructions........................................................................................................................ 4

2.

Operating conditions.................................................................................................................... 5

3.

Description .................................................................................................................................... 6

3.1 General function ........................................................................................................................... 6

3.2 Principle of operation of cooling ................................................................................................. 7

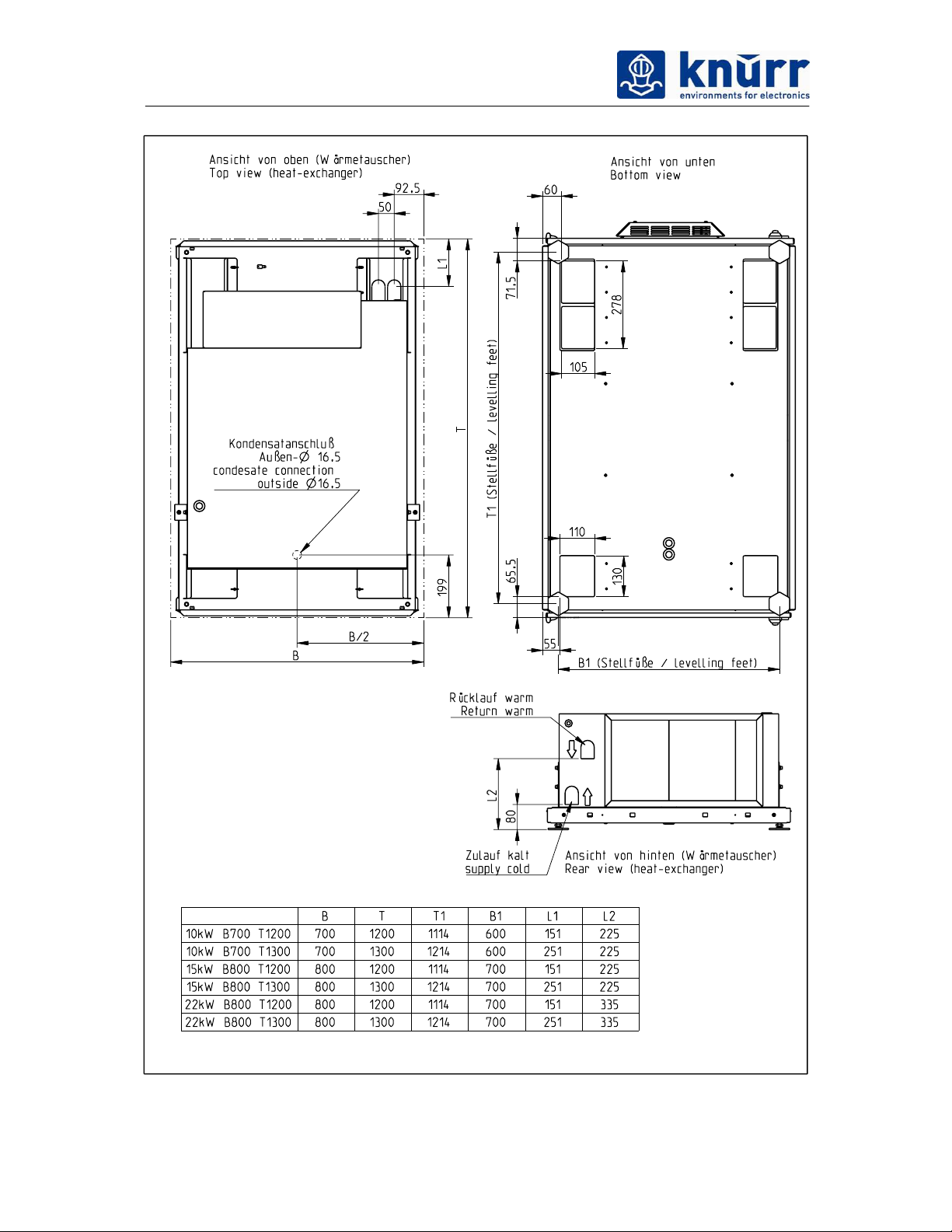

3.3 Dimensions ................................................................................................................................... 8

3.4 Technical data............................................................................................................................. 12

3.5 Control......................................................................................................................................... 15

Storage and transportation ........................................................................................................ 17

4.

Installation and commissioning................................................................................................. 19

5.

5.1 Preparation for installation ........................................................................................................ 19

5.2 Positioning the units................................................................................................................... 20

5.3 Chilled water connection............................................................................................................ 21

5.4 Condensed water connection .................................................................................................... 23

5.5 Electrical connection.................................................................................................................. 24

5.6 Sealing of cabinet ....................................................................................................................... 25

5.7 Automatic door opening............................................................................................................. 25

6.

Servicing and maintenance........................................................................................................ 29

7.

Dismantling and disposal........................................................................................................... 32

8.

Customer service, manufacturer's address.............................................................................. 32

9.

Appendix ..................................................................................................................................... 33

9.1 Quality requirements on the water used in CoolTherm........................................................... 33

9.2 Checklist for unit installation ..................................................................................................... 34

9.3 Commissioning certificate ......................................................................................................... 35

9.4 CoolTherm Diagrams.................................................................................................................. 40

9.5 Control Standard Factory Settings............................................................................................ 41

page

CoolTherm 01_998_330_0_k page / Seite 2/83

Page 5

CoolTherm

Manual / Bedienungsanleitung

0. Abstract

The CoolTherm platform provides the dissipation of heat loads from 10 up to 22 / 35 kW.

The server rack is closed to the installation area, that means no heat load will dissipate to the

environment. (see also chapter 2.) The cooling is provided by a closed cooling system via an airto-water heat exchanger. The cooling capacity is adapted to the accruing heat load.

19” hole raster profiles are designed for components as well as rails and shelves.

The cable entry is possible via bottom and top cover

1. Safety

1.1 Work safety symbols

The following symbols identify specific hazards or provide information on safe operation.

Attention! Danger! Safety instruction!

Risk of electric shock or danger due to high voltage

Caution! Hot surface

Safety-related instruction

Attention! Identifies possible damage to the unit

Risk of electric shock

Note! Identifies possible hazards for the environment

Caution! Rotating parts / automatic start

CoolTherm 01_998_330_0_k page / Seite 3/83

Page 6

CoolTherm

Manual / Bedienungsanleitung

Important note, information

1.2 Safety instructions

Our engineers will provide comprehensive support on how to install

the CoolTherm.

Extensive material, function and quality checks ensure that you

fully benefit from product functions and a long service

life. Nevertheless, this product can produce hazards if it is used

incorrectly by untrained personnel or is not used for the correct purpose.

Prior to commissioning the CoolTherm, read these

operating instructions carefully.

The electrical equipment complies with the applicable VDE and accident prevention regulations.

Hazardous voltages (higher than 50 V AC or higher than 100 V DC) are present:

→ behind the server cabinet doors

→ on the power supply in the unit's housing

→ behind the fan cover

Use only original fuses with the stipulated rating.

Immediately shut down the unit if there are problems with the supply of electrical power or supply

of cold water.

Risk of electric shock

Repair and cleaning work should only

be performed by qualified personnel.

The personnel must ensure that the unit is electrically

isolated whilst it is serviced and cleaned. For this reason

shut down the unit before starting work.

Risk due to incorrect work on the unit.

Cleaning and servicing is only allowed to be performed by

qualified personnel. To ensure that the unit remains

safe to use and has a long service life, it is imperative

that you observe the maintenance and cleaning intervals.

Only operate the CoolTherm correctly within the stipulated

ratings and with approved equipment.

CoolTherm 01_998_330_0_k page / Seite 4/83

Page 7

CoolTherm

Manual / Bedienungsanleitung

During all work on and with the unit, observe:

• The related applicable regulations (e. g. VDE regulations or

other applicable national regulations)

• The applicable accident prevention instructions (BGV)

• The applicable rules

• The applicable laws on the protection of the environment

Only operate the unit if it is in correct working condition. On the

occurrence of malfunctions or faults, you must shut down the unit

immediately and inform the responsible member of staff

in the operating organisation.

You are only allowed to use the unit again after its correct function has been reestablished.

Caution hot surface

Faulty fans, power supplies, control circuit boards can run hot.

Prior to starting work, let these cool down.

2. Operating conditions

The unit is a server cabinet cooling device and is only used for the

removal of heat from server cabinets to protect temperature

sensitive components. The cooling system in the cabinet is thermally

Ambient temperature: 10°C / 50°F to 35°C / 95°F

Absolute humidity in the installation location: 8 g H

Water temperature, feed: 12°C / 53°F

(other temperatures upon request)

Water temperature, return: 18°C / 64.4°F

(other temperatures upon request)

Correct use

independent of the room air. Total heat load of the installed equipment is

taken out of the room using the chilled water circuit. Note: Under special conditions a very

small amount can dissipate to the room (approx. 05, kW)

For reliable function of the CoolTherm, chilled water

must be available in the correct amount, and at the correct

temperature and pressure. Observe water quality as per

VGB-R 455 P. (see Appendix)

(other temperatures upon request)

Temperatures on use of RMS with

temperature-dependent alarm:

20°C / 68°F to 25°C / 77°F

O/ kg air maximum

2

CoolTherm 01_998_330_0_k page / Seite 5/83

Page 8

CoolTherm

Manual / Bedienungsanleitung

Temperature spread, water: 6K

Use of anti-freeze in the chilled water: upon request

Water connection: from below

Condensed water connection: from below

Nominal voltage at cooling capacity:

12 KW, 17 KW, 25 KW 200V to 264V /

50Hz / 60 Hz

Max. operating pressure: 10 bar / 145 PSI

3. Description

3.1 General function

CoolTherm complies with the conditions of EN 60950

The modular design facilitates the installation of all 19“ equipment of varying depth.

Heat produced by installed equipment (e. g. servers) is reliably removed using the cold water

system integrated into the server cabinet. The cooling system is inherently safe because water

cannot reach the server area.

The cooling system comprises a high-performance air/water heat exchanger, fans with fan control

unit (fan-speed according to heat load) for the ducted supply of air and cold water connection.

The air circuit is closed such that no heat (thermal load) is emitted to the environment.

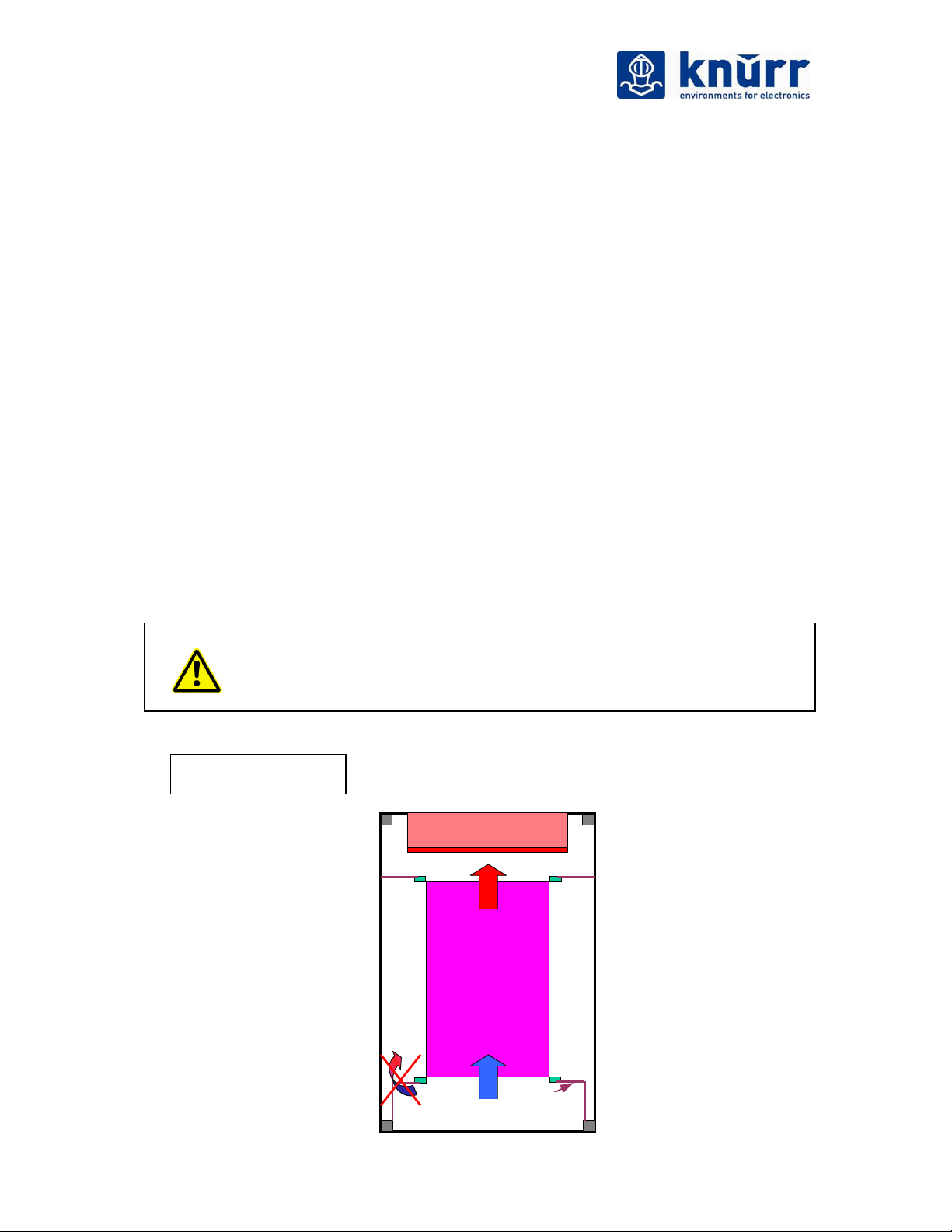

Attention! CoolTherm only works if cold server feed air

and heated server outlet air are fully separated.

Height units not in use have to be sealed using blanking panels.

Top view

WARM

WARM

WARM

WARM

Air duct

Luftkanal

Server

KALT

KALT

Air separation

COLD

WARM

WARM

WARM

WARM

Lufttrennung

CoolTherm 01_998_330_0_k page / Seite 6/83

Page 9

CoolTherm

Manual / Bedienungsanleitung

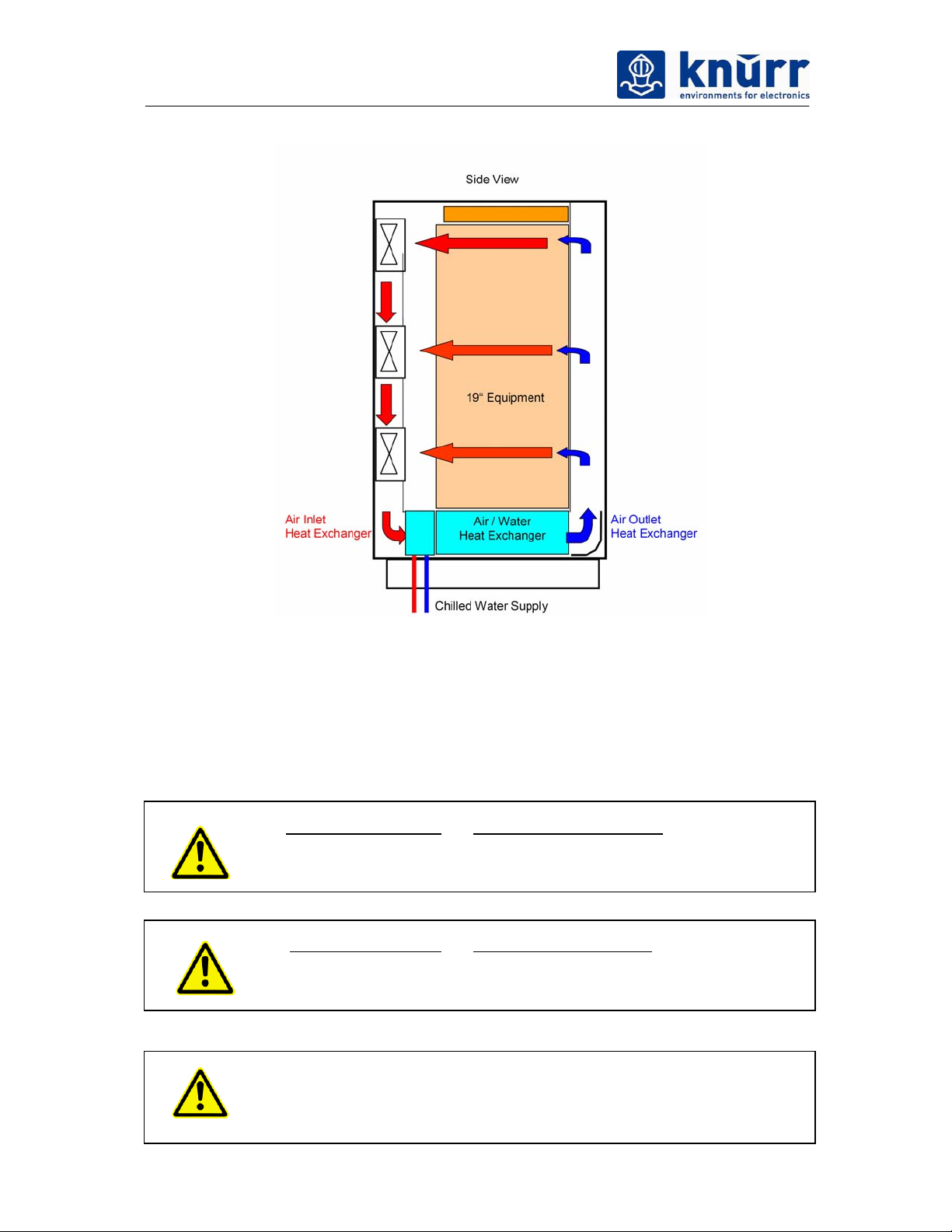

3.2 Principle of operation of cooling

Air that has been heated by the servers (to 35°C/95°F, e.g.) is fed to a specially designed air/water

heat exchanger using high-performance fans.

There the air is cooled to approx. 20-25°C / 68-77°F, and fed to the front of the server.

The server fans can draw in the air and feed it over internal equipment.

Chilled water is provided by a chiller made available on site.

Below the heat exchanger there is a condensed water tray with a 5/8“ outlet.

When the cooling system fails

to prevent a build up of heat in the cabinet. In this case the heat load is

dissipated into the room where the unit is located.

When the CoolTherm fans fail

to prevent a build up of heat in the housing. In this case the heat is

emitted into the room where the unit is installed as a thermal load.

If the rear door (with fans) is opened, the front door

must be opened.

, the unit doors have to be opened

, the unit doors are to be opened

CoolTherm 01_998_330_0_k page / Seite 7/83

Page 10

CoolTherm

Manual / Bedienungsanleitung

If the front door is opened, it is not necessary to open the rear door.

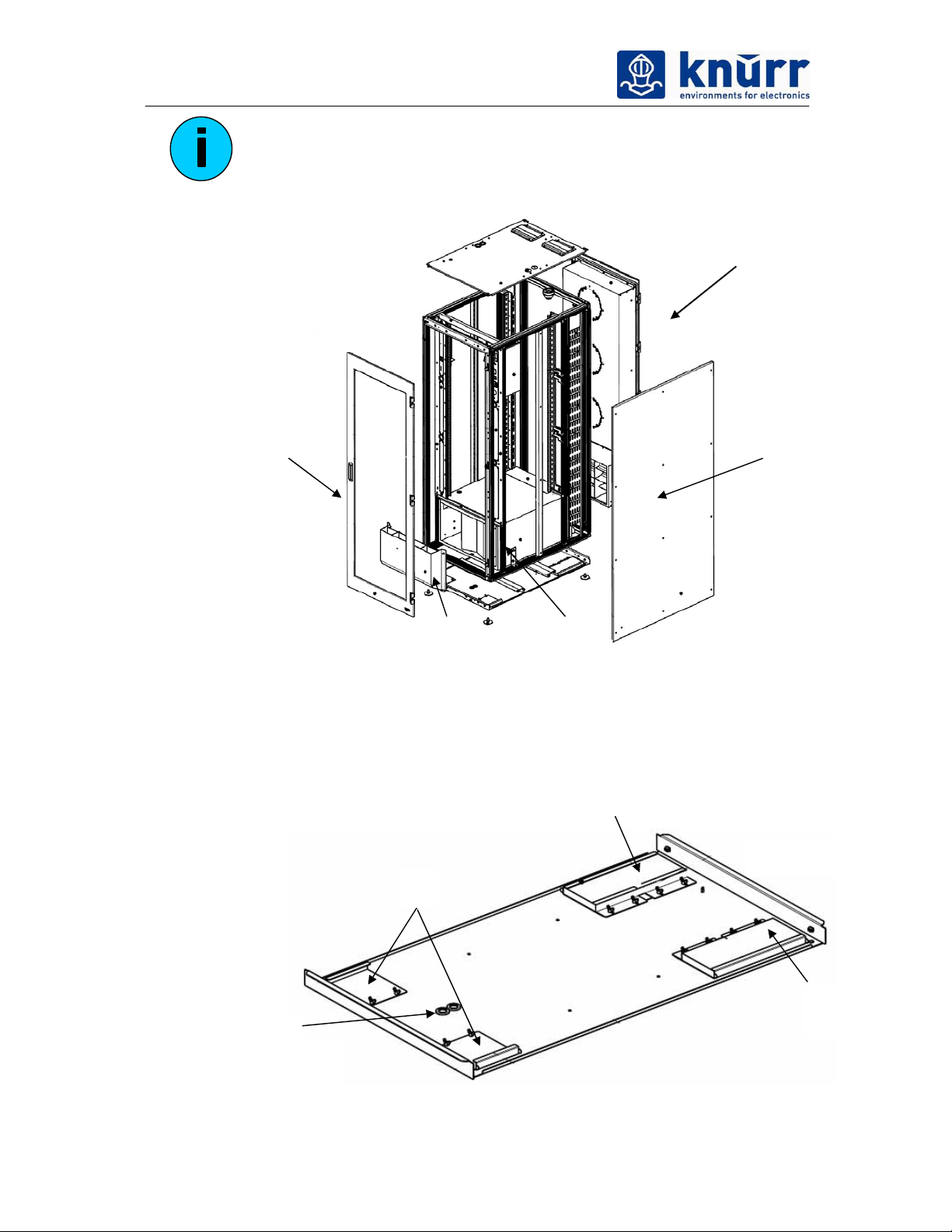

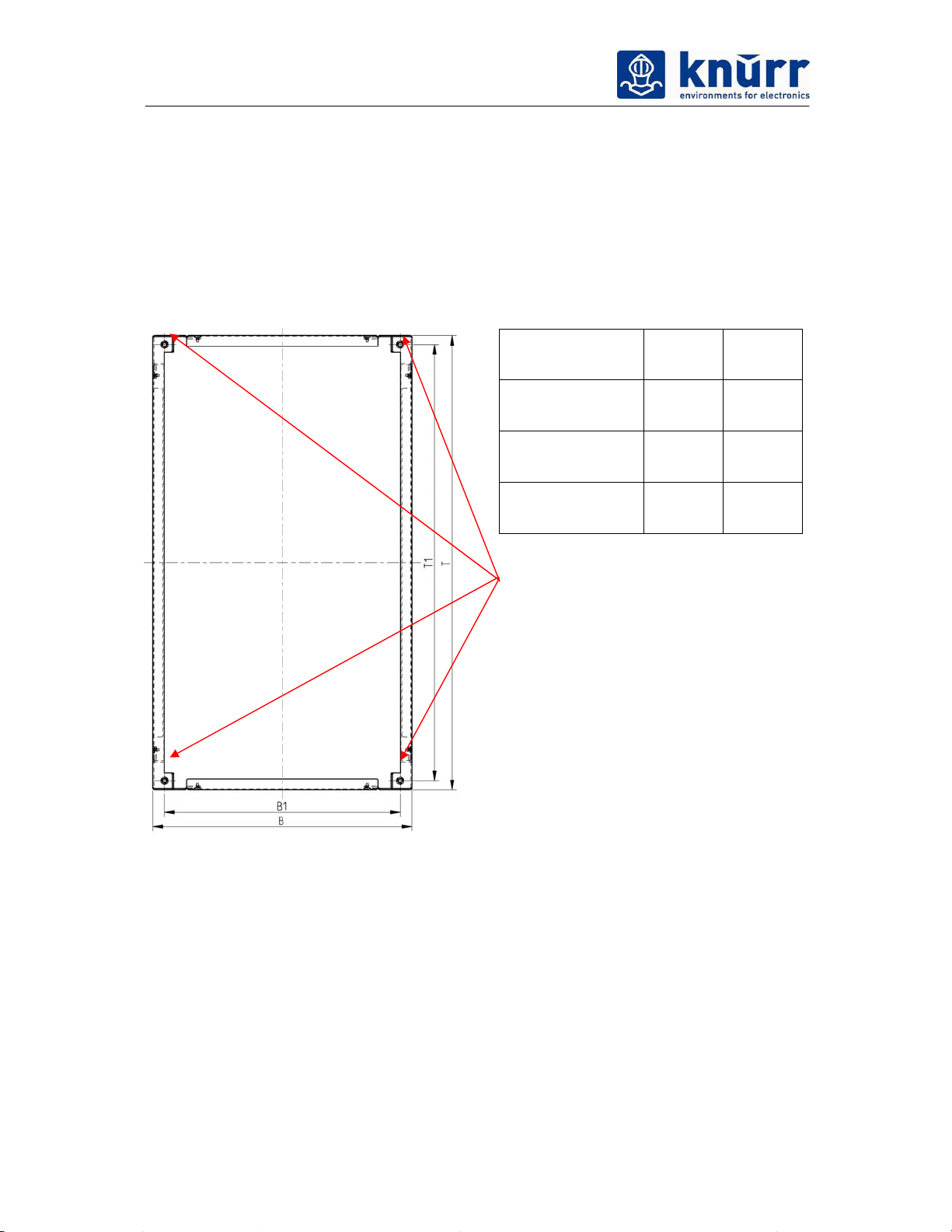

3.3 Dimensions

1 Multifunction door (rear) with embedded redundant fans, air duct and sealing

2 Heat exchanger with condensate tray, condensate connection

3 recirculation deflector

4 Side panel

5 Glass door (front)

Bottom plate with cutouts

4

front

23

1

3

1

45

rear

2

CoolTherm 01_998_330_0_k page / Seite 8/83

Page 11

CoolTherm

Manual / Bedienungsanleitung

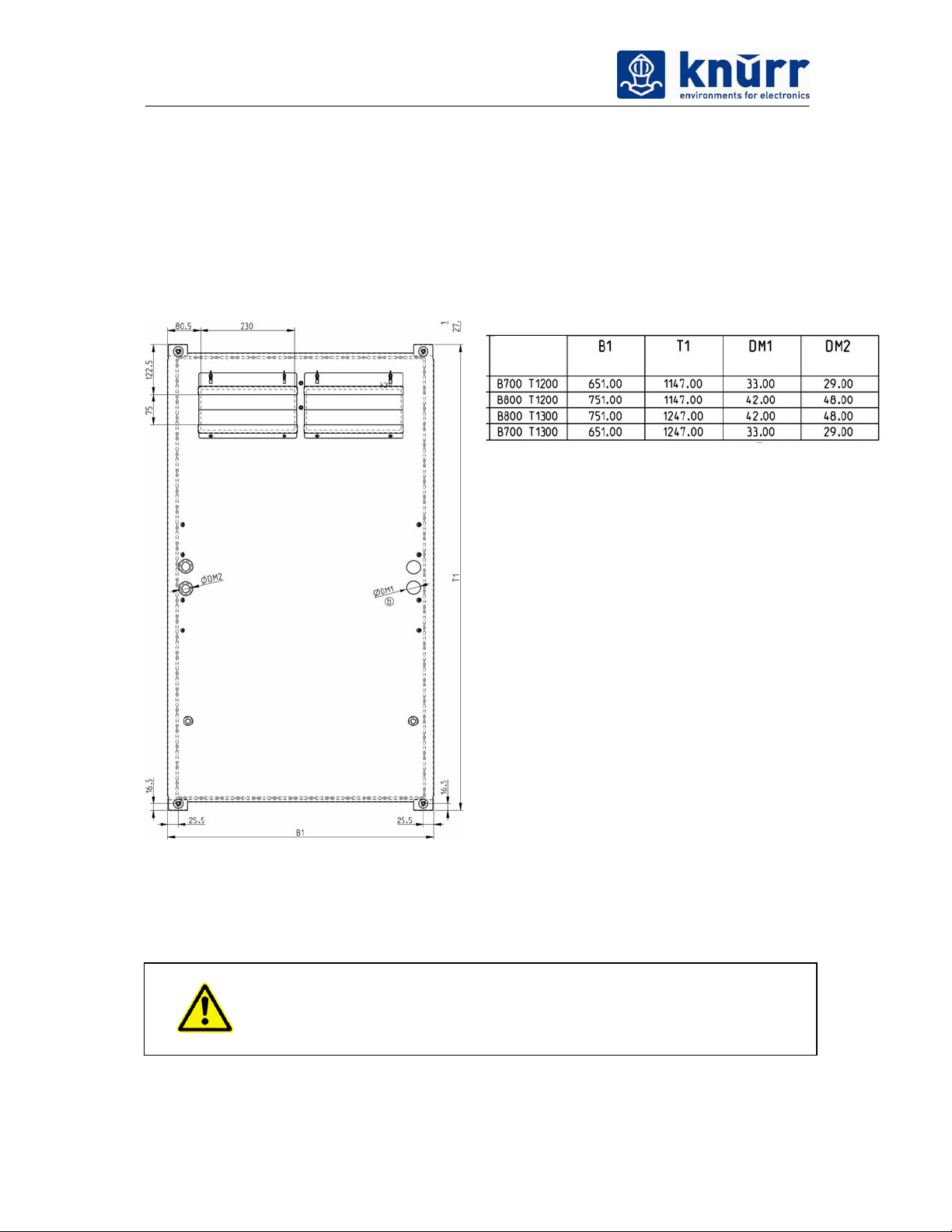

legend:

1 sealed cable cutout

2 cutout for chilled water pipes

3 cable entry (network cable)

4 cutouts for condensed water

rear side

standard

dimension

front side

cover dimensions with cable entries 12- 17 - 25 / 35 kW plan view)

Cable and pipe openings are to be sealed air-tight

on completion of work.

CoolTherm 01_998_330_0_k page / Seite 9/83

Page 12

CoolTherm

Manual / Bedienungsanleitung

Dimensions bottom plate / cut outs / connections 12- 17 - 25 / 35 kW

CoolTherm 01_998_330_0_k page / Seite 10/83

Page 13

CoolTherm

Manual / Bedienungsanleitung

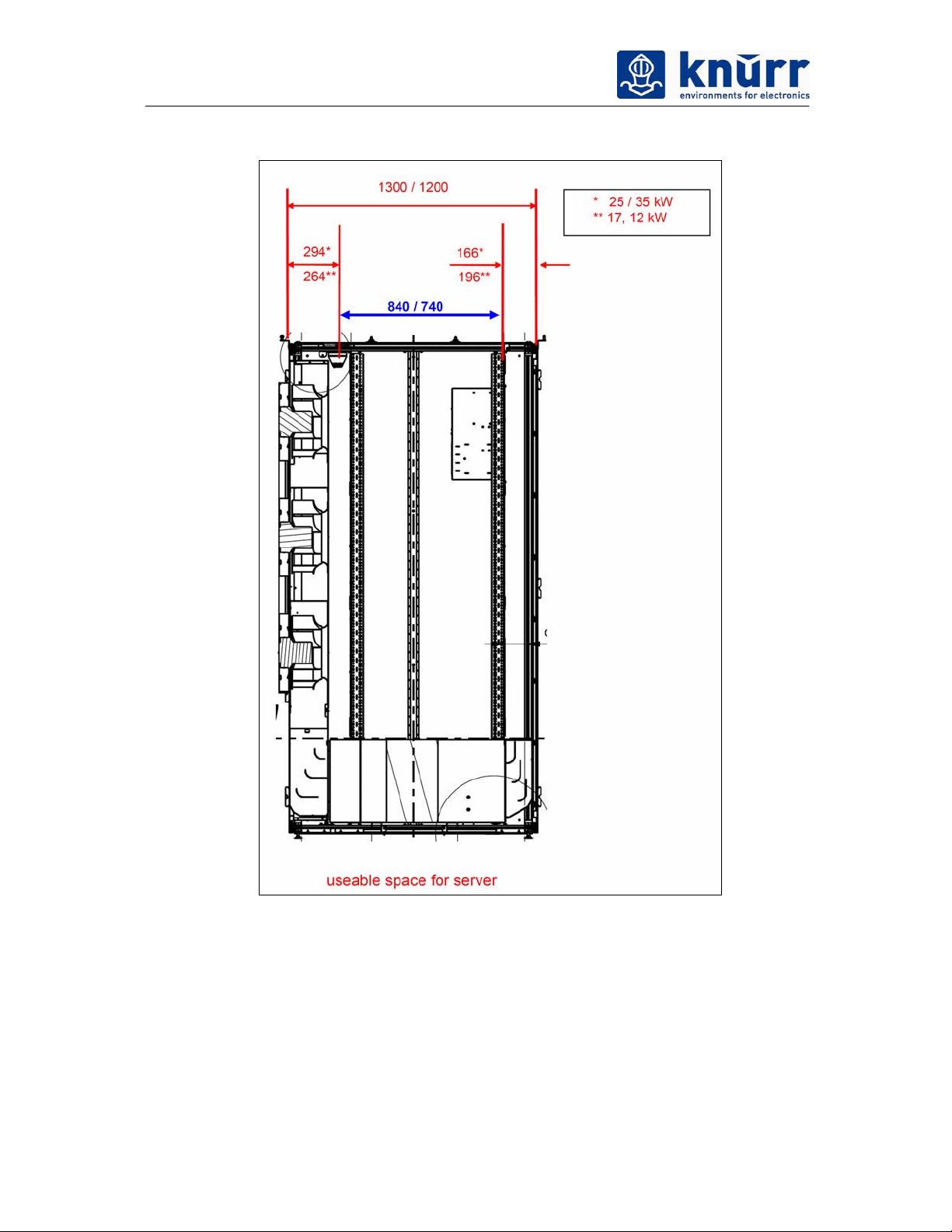

Useable space for server

CoolTherm 01_998_330_0_k page / Seite 11/83

Page 14

CoolTherm

Manual / Bedienungsanleitung

3.4 Technical data

Housing material: Aluminium sheet, sheet steel, galvanized

and coated

Operating Temperature range: 10 °C to 35 °C / 50°F to 95°F

abs. atmospheric humidity: 8g / kg maximum

Air outlet to heat exchanger: 20 to 25°C / 68 to 77°F according to ASHRAE

Temperature difference across server: approx. 15K

Noise level: 55 dB(A) sound pressure at a distance

of 1 m

Useful load 1.000 kg / 2204 pounds

Chilled water

Effective cooling capacity

depending on type: 12 KW to 25 / 35)* KW

Feed temperature: 12°C / 54°F (other temp. upon consultation)

Return temperature: 18°C / 64°F

)*21°C/ 69,8°F at 35 kW (Blade application)

(other temp. upon consultation)

Max. operating pressure: 10 bar / 145 PSI

Feed/return supply connection: 1“

CoolTherm 01_998_330_0_k page / Seite 12/83

Page 15

CoolTherm

Manual / Bedienungsanleitung

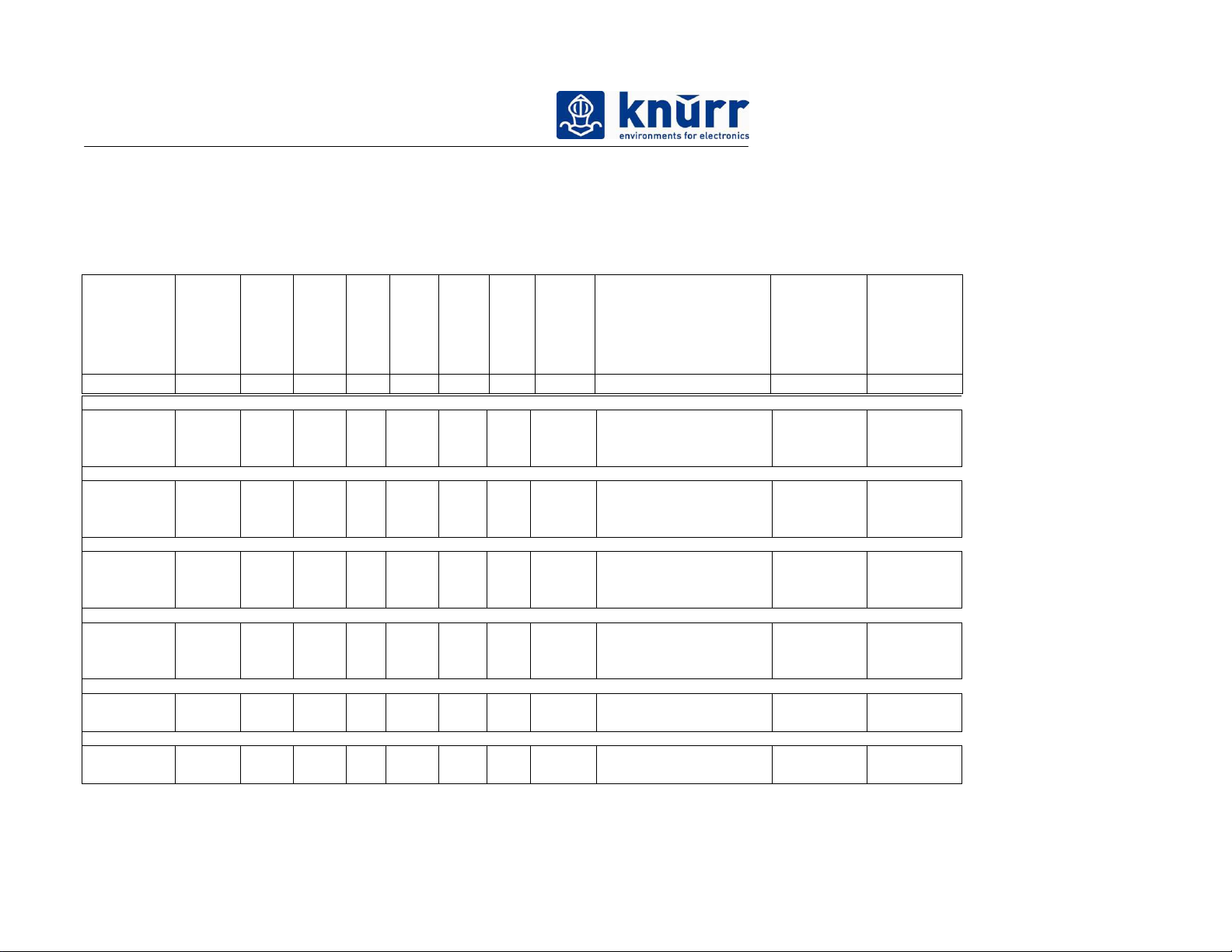

Data overview CoolTherm Table A

General data

Spread chilled water: 12 / 18°C (nominal conditions) Maximum operation pressure heat exchanger: 10 bar

Air temperature to server: 22°C Maximum absolute humidity on site : 8g/kg

Connection heat exchanger: 1“ female threat Colour code for standard colours: x = 8 = RAL 7021 (black grey)

Connection condensate tray: 5/8“ condensed water hose connection x = 1 = RAL 7035 (light grey)

Electrical connection data

Item

no.

08.006.001.x

08.006.002.x

08.006.003.x

08.006.006.x

08.006.007.x

08.006.008.x 12 38 2200 700 1300

08.006.012.x

08.006.013.x

08.006.014.x

08.006.022.x

08.006.023.x

08.006.024.x

08.006.033.x

08.006.034.x

08.006.043.x

Effective

cooling

capacity U (useable)

Height

Width

Depth [D]

Useable depth

[d]

Weight

Recirculated

kW mm mm mm mm kg m³/h

12 29

12 33

12 38

12 29

12 33

17 35

17 40

17 44

17 35

17 40

17 44

25(35) 37

25 (35) 42

25 (35) 37

1800 700 1200

2000 700 1200 740 290 2.000 200 to 264 / 7 / 1000

2200 700 1200

1800 700 1300

2000 700 1300 840 295 2.000 200 to 264 / 7 / 1000

2000 800 1200

2200 800 1200 740 310 3.100 200 to 264 / 8 / 1400

2400 800 1200

2000 800 1300

2200 800 1300 840 320 3.100 200 to 264 / 8 / 1400

2400 800 1300

2200 800 1200 740 340 4.500 200 to 264 / 8 / 1800

2400 800 1200

2200 800 1300 840 350 4.500 200 to 264 / 8 / 1800

voltage / currency / power

air flow rate in

cabinet

08.006.044.x 25 (35) 42 2400 800 1300

V / A / Watt

frequency

Hz

50 / 60

50 / 60

50 / 60

50 / 60

50 / 60

50 / 60

Fuse / supply

A / mm²

16 / 3 x 2,5

16 / 3 x 2,5

16 / 3 x 2,5

16 / 3 x 2,5

16 / 3 x 2,5

16 / 3 x 2,5

CoolTherm 01_998_330_0_k page / Seite 13/83

Page 16

CoolTherm

Manual / Bedienungsanleitung

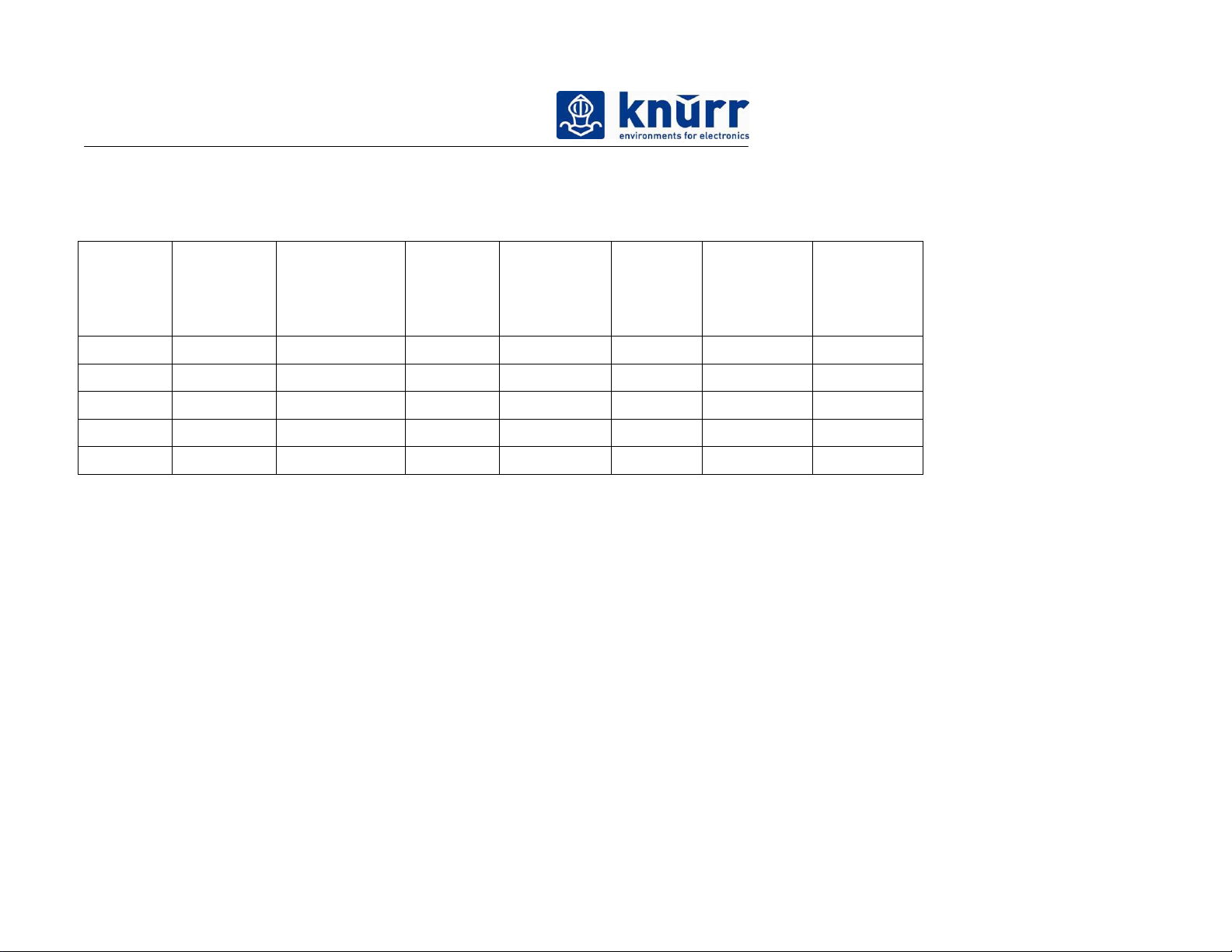

Data overview CoolTherm Table B (Hydraulic Data)

effective

cooling

capacity

kw

12

17

25

35

total cooling

capacity

(at normal

operation)

kw kw l m³/h bar K K

12,5 13,0 5,9 1,79 0,41 6 6,2

17,8 18,4 7,9 2,55 0,62 6 6,2

26 26,8 9,9 3,72 0,58 6 6,2

36 36,8 9,9 3,72 0,58 8,1 8,51

total cooling

capacity

(at full speed

operation /

emergency)

water

content

water flow

rate

pressure

loss

cabinet

water

temperature

rise

(at normal

operation)

water

temperature

rise

(at full speed

operation /

emergency)

CoolTherm 01_998_330_0_k page / Seite 14/83

Page 17

CoolTherm

Manual / Bedienungsanleitung

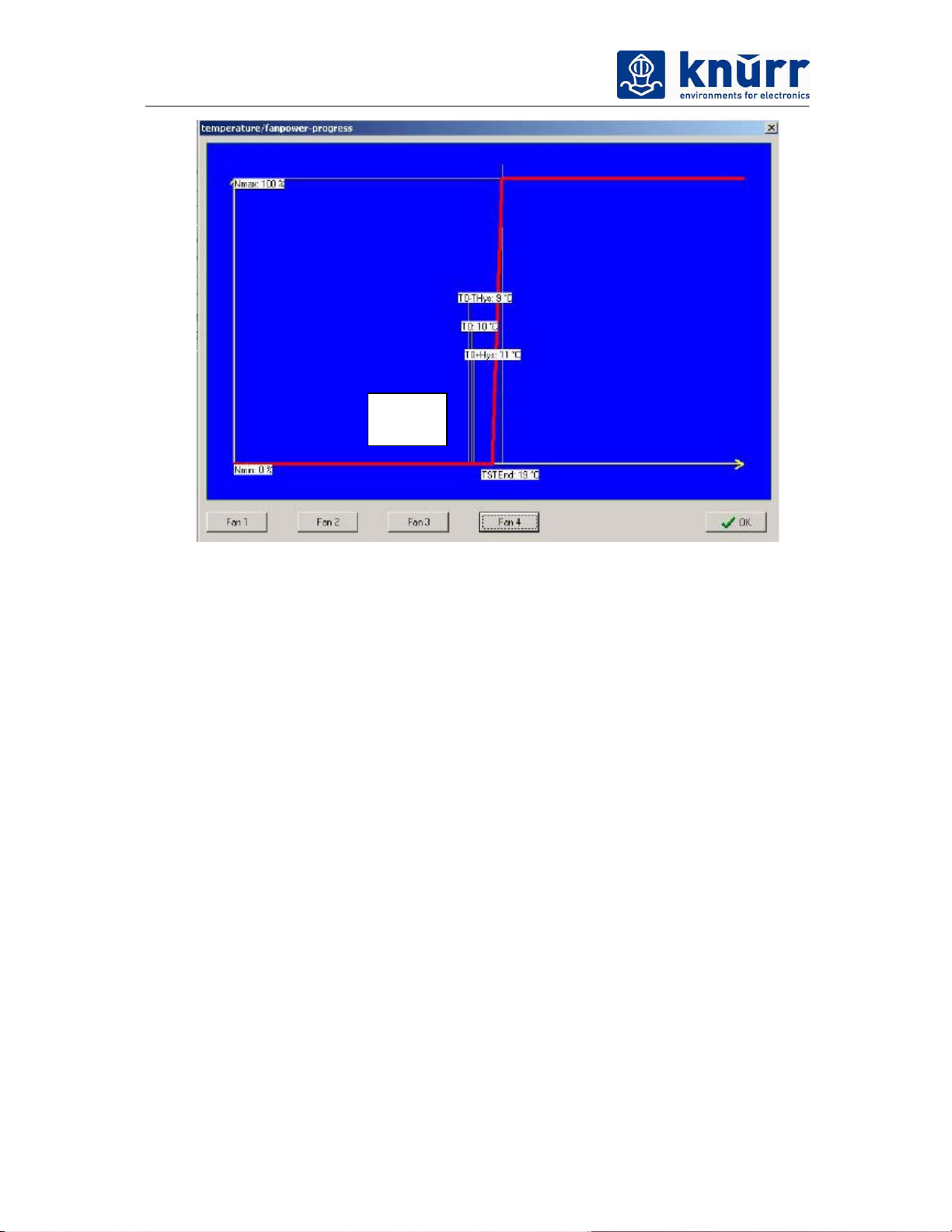

3.5 Control

The server cabinet temperature is controlled by the fan control board VR 2.2. A air temperature

sensor continuously measures the temperature of the server cabinet (server feed air). The air

circulation flow rate is controlled by the fan speed according to the current thermal load.

At temperatures lower than 20°C / 68°F fans rotate at 75% of maximum speed.

Between 20°C / 68°F and 23°C / 73,4°F speed increases proportional to the temperature up to

96% of maximum speed.

The failure of the temperature sensor set the fans to maximum speed.

PDU – Box*)

*) by 12 kW rack

under the roof

CoolTherm front view

The water flow rate is controlled by a three-way valve depending on thermal load. (distribution flow

control) Before all a undertemperature at part load operation can be avoided.

By using a blind sieve in the bypass a hydraulic volume control could be achieved

(two way valve function).

In case of failure the valve opens and the all the chilled water flows through the heat exchanger.

From 16°C / 60,8°F to 19°C / 66,2°F the three-way valve controls the water flow rate from 0% to

100% of the nominal flow rate.

Air temperature

sensor

Status LED:

Green

System OK

Yellow

fault controller

cooling/fans or

rear door open

Red

fault controller

cooling/fans and

rear door open

Fuses for each

fan and

switching power

supply

Space for

optional

equipment

Service socket

and fuse

CoolTherm 01_998_330_0_k page / Seite 15/83

Page 18

CoolTherm

Manual / Bedienungsanleitung

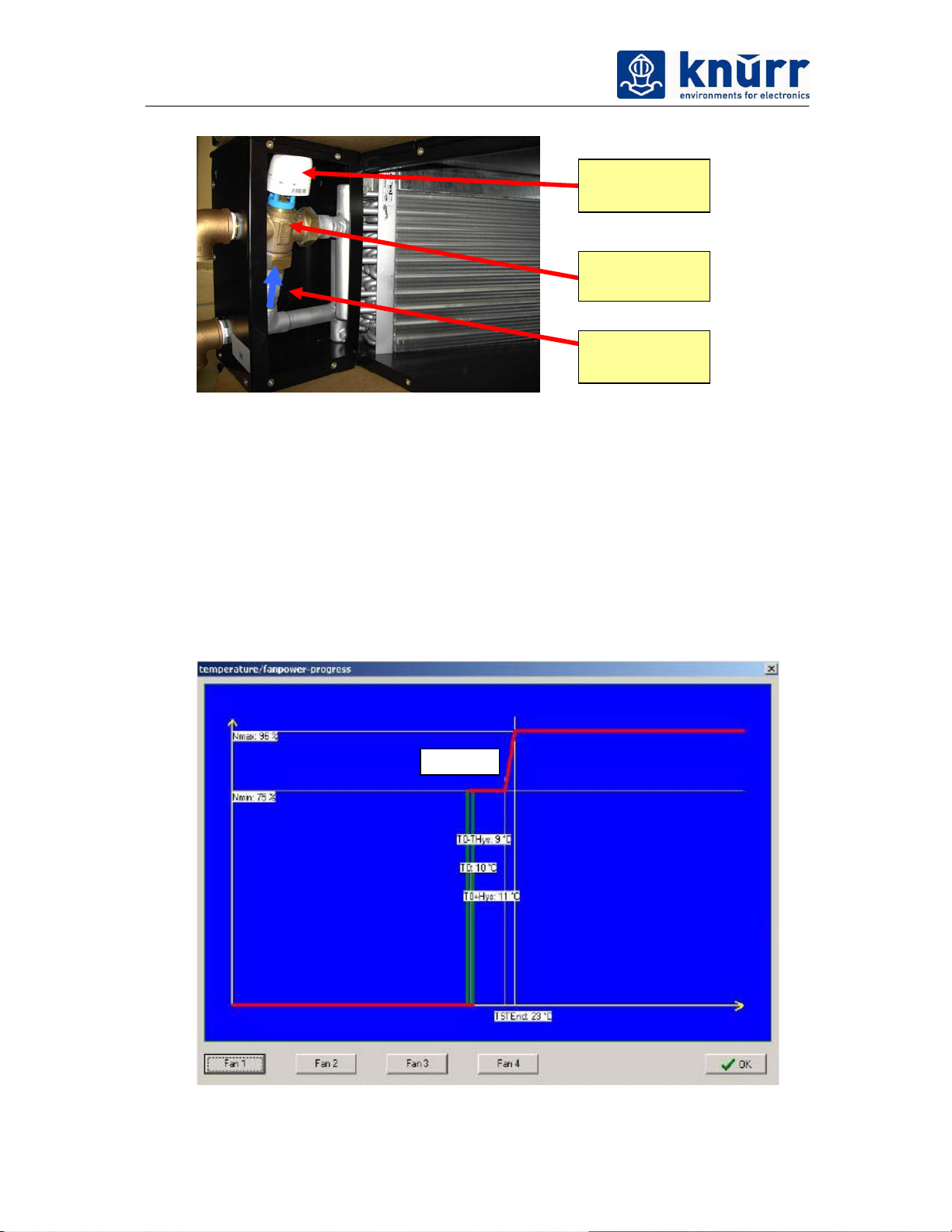

valve actuator

Three way valve

Bypass

(flow direction)

CoolTherm Heat Exchanger (rear view)

The programming of the control is factory preset and password protected.

The failure of the temperature sensor or one of the fans set an alarm using a potential free contact.

Following alarms can be also provided to potential free contacts:

- sensor error

- fan malfunction

- high temperature (two levels)

The fans are automatically shut down if the server cabinet rear door is opened.

Start at 20°C

fan control characteristic (factory setting)

CoolTherm 01_998_330_0_k page / Seite 16/83

Page 19

CoolTherm

Manual / Bedienungsanleitung

Start at 16°C

air inlet

temperature

three- way valve control characteristic (factory setting)

4. Storage and transportation

• Cover open pallets with tarpaulins and protect the components

from soiling (e. g. sand, rain, dust, etc.).

• Keep storage temperatures between –30 °C and +50 °C / -22°F and 104°F.

• The heat exchanger must be completely drained (to prevent the risk of

frost damage)

• When stored for more than 1 year, check the the fan bearings prior to

installation. (⇒ Turn fans by hand.)

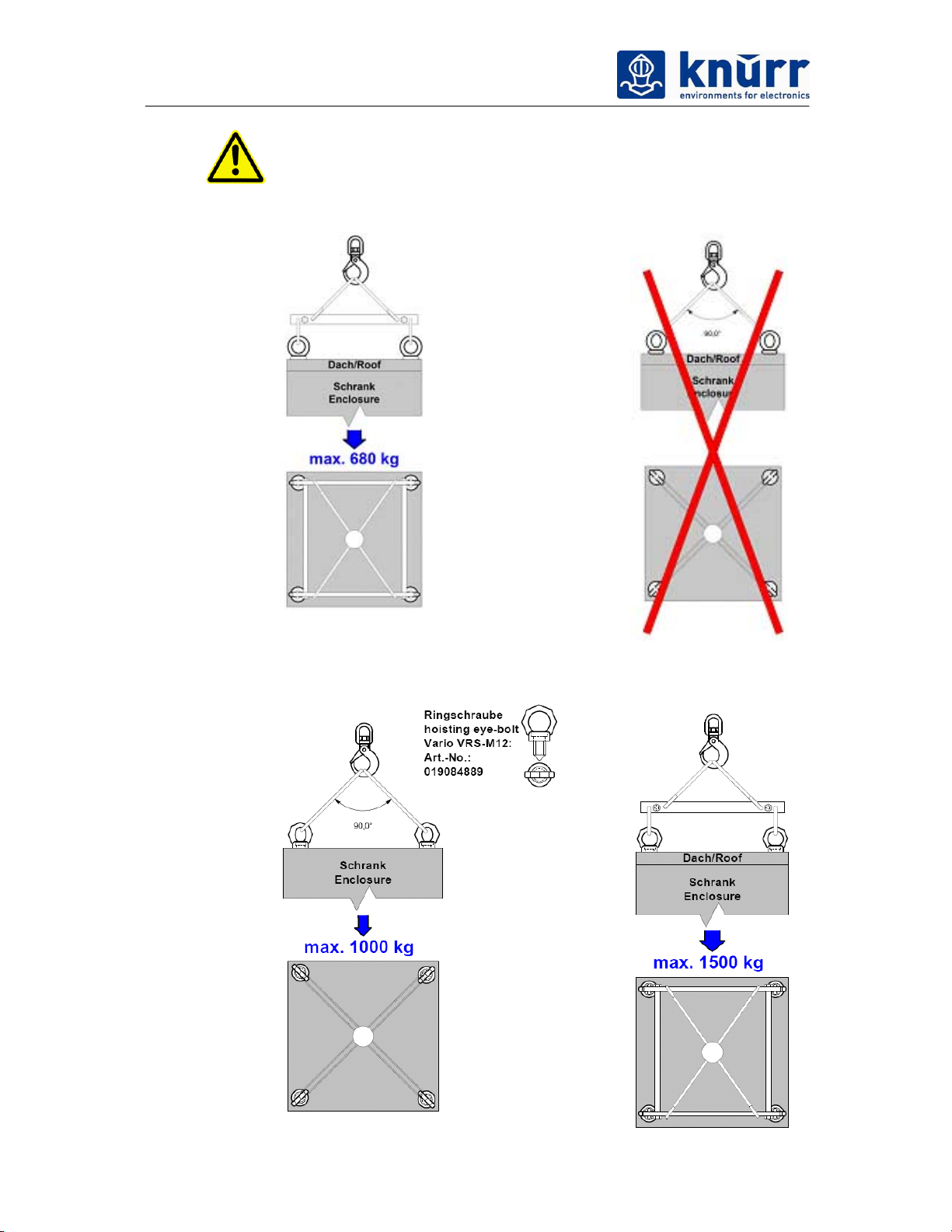

• CoolTherm can be transported using a forklift truck or crane. For transport

using a crane, straps must be used. The CoolTherm weighs, depending on

the version, up to 340 kg / 749 lbs. (net weight)

• Avoid twisting the housing or other damage.

• Use suitable tools during installation, e. g. approved scaffolding.

• Prior to lifting the CoolTherm using a crane or forklift truck, close all doors.

• Do not stand under suspended loads.

• Hooks attached to the load must be be of appropriate tensile strength.

• CoolTherm must not be lifted at an angle using a crane.

• All packaging is to be removed prior to commissioning CoolTherm.

CoolTherm 01_998_330_0_k page / Seite 17/83

Page 20

CoolTherm

Manual / Bedienungsanleitung

Safety instruction for crane transport:

> 680 kg > 1000 kg

< 680 kg

Eyebolts M 12

according to standard

DIN 580!

CoolTherm 01_998_330_0_k page / Seite 18/83

Page 21

CoolTherm

Manual / Bedienungsanleitung

5. Installation and commissioning

5.1 Preparation for installation

Before you install the unit, you have to check a number of points.

These checks are for safety and to ensure the correct function of the

server cabinet. Take care when performing these checks

to ensure that the unit functions correctly.

Check unit for transport damage:

The packaging for the CoolTherm must not show signs of transport damage on delivery. Any

damage on the packaging indicates possible transport damage.

In the worst case this damage may result in the loss of function.

Returning the unit in case of transport damage:

If the unit is not returned in the original packaging, the packaging used for return must comply with

following criteria:

There must be at least 30 mm space between the unit and the packaging.

As an installation aid, there is a checklist in the appendix, that you should complete prior to

commissioning.

The commissioning also can be carried out by approved staff. Use the commissioning certificate

included in the appendix for this purpose.

CoolTherm must be installed on a level surface.

For this reason, check the horizontal alignment with a spirit level

prior to starting installation.

Note that the floor must be able to support a rack load of

1.500 kg/m² (with installed equipment per CoolTherm).

there is no packaging material or other equipment that could hinder

To achieve good air circulation, ensure that

• in the area of the equipment

• in the area of the heat exchanger

• in the air inlet

• in the air outlet

or prevent air circulation

CoolTherm 01_998_330_0_k page / Seite 19/83

Page 22

CoolTherm

Manual / Bedienungsanleitung

5.2 Positioning the units

After positioning, the feet on the CoolTherm are to be set such that the cabinet is vertical. When

positioned the doors must close easily.

The feet are adjusted using a spanner (spanner width 65mm). Watch the length of the thread.

As an option it is possible to connect the cabinets together. There for remove the plugs from the

side panels and connect with hex screw, item no. 4000 1411.

Distance

W700 D1200

W800 D1200

W800 D1300

Adjustable Feet

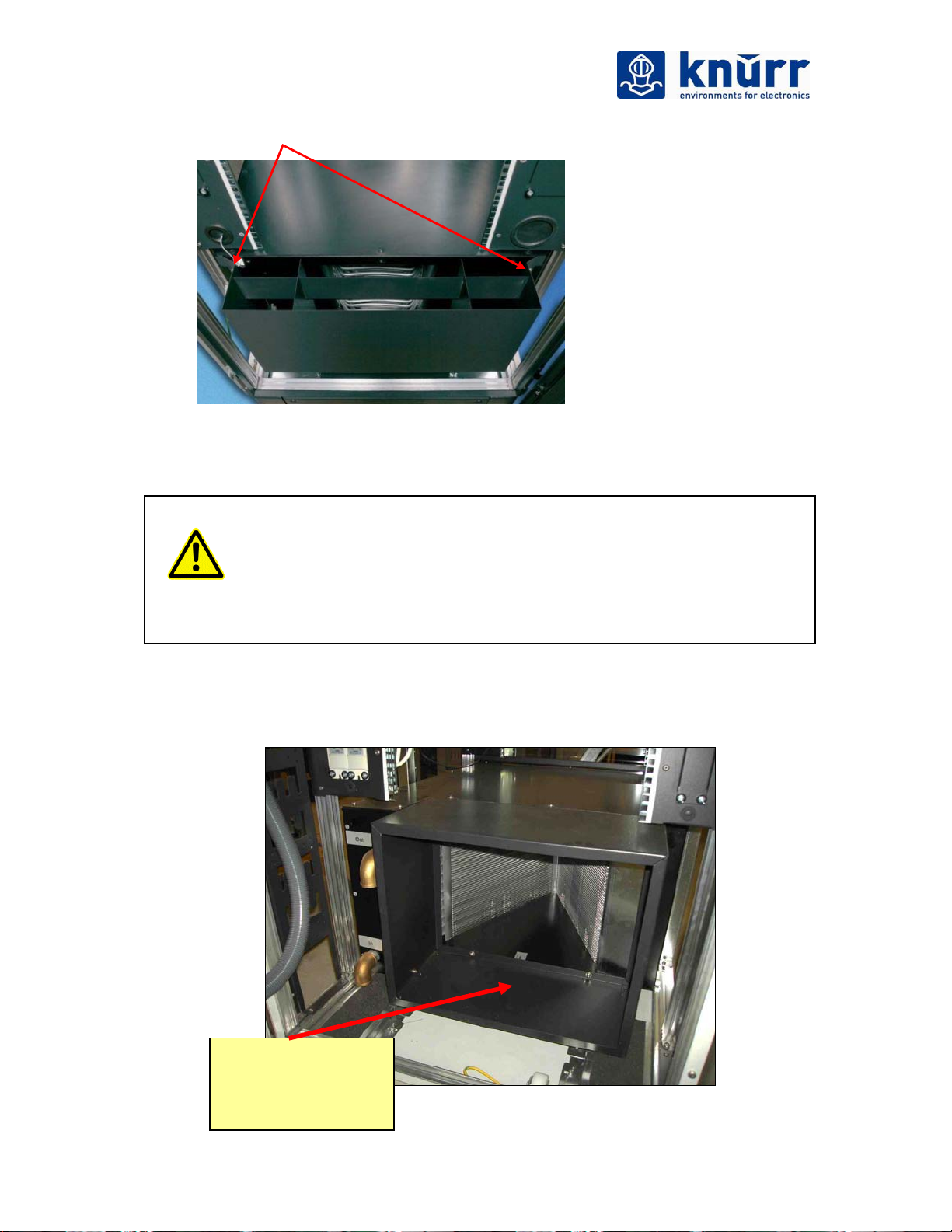

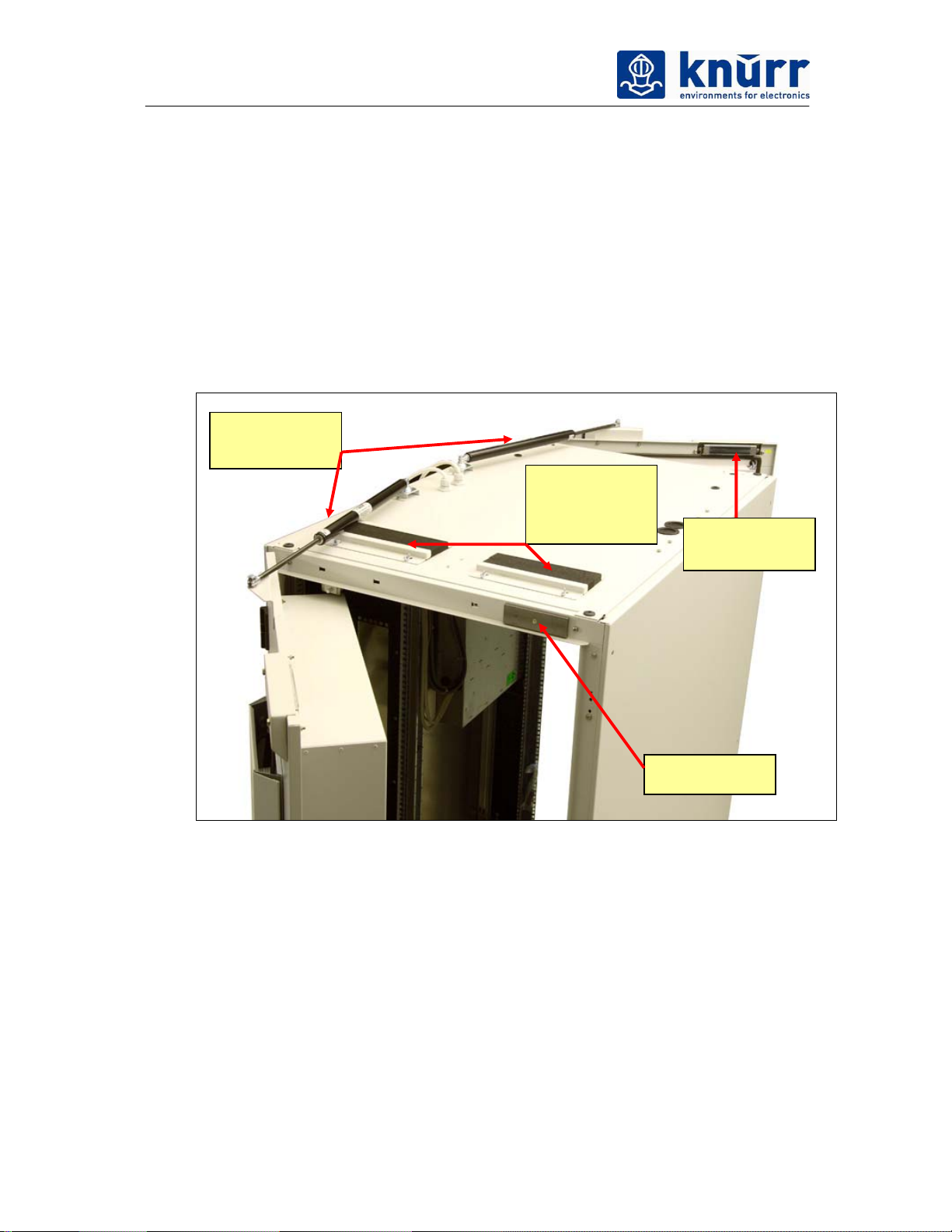

Remove recirculation air duct transport lock

After positioning remove the transport lock screws at the sides of the recirculation air duct.

The recirculation air duct can be pulled out to remove items which possibly had felt into the head

exchanger tray.

feets

B1

(mm)

600 1114

700 1114

700 1214

T1

(mm)

CoolTherm 01_998_330_0_k page / Seite 20/83

Page 23

CoolTherm

Manual / Bedienungsanleitung

Remove both screws

5.3 Chilled water connection

The heat exchanger can be pulled out for servicing

Chilled water pipes should be connected so that the heat exchanger

can be pulled out when the connection is undone.

If the heat exchanger is connected to the chilled water network using threaded fittings,

the pipe fitting must be supported on tightening.

Prior to commissioning the server cabinet, the pipe connections

should be checked for leaks.

Preparing heat exchanger for initial commissioning:

- Check the mechanical installation and the supply pipe connection.

Remove this air duct for

bleeding, draining the

CoolTherm 01_998_330_0_k page / Seite 21/83

heat exchanger and

checking the valve

Page 24

CoolTherm

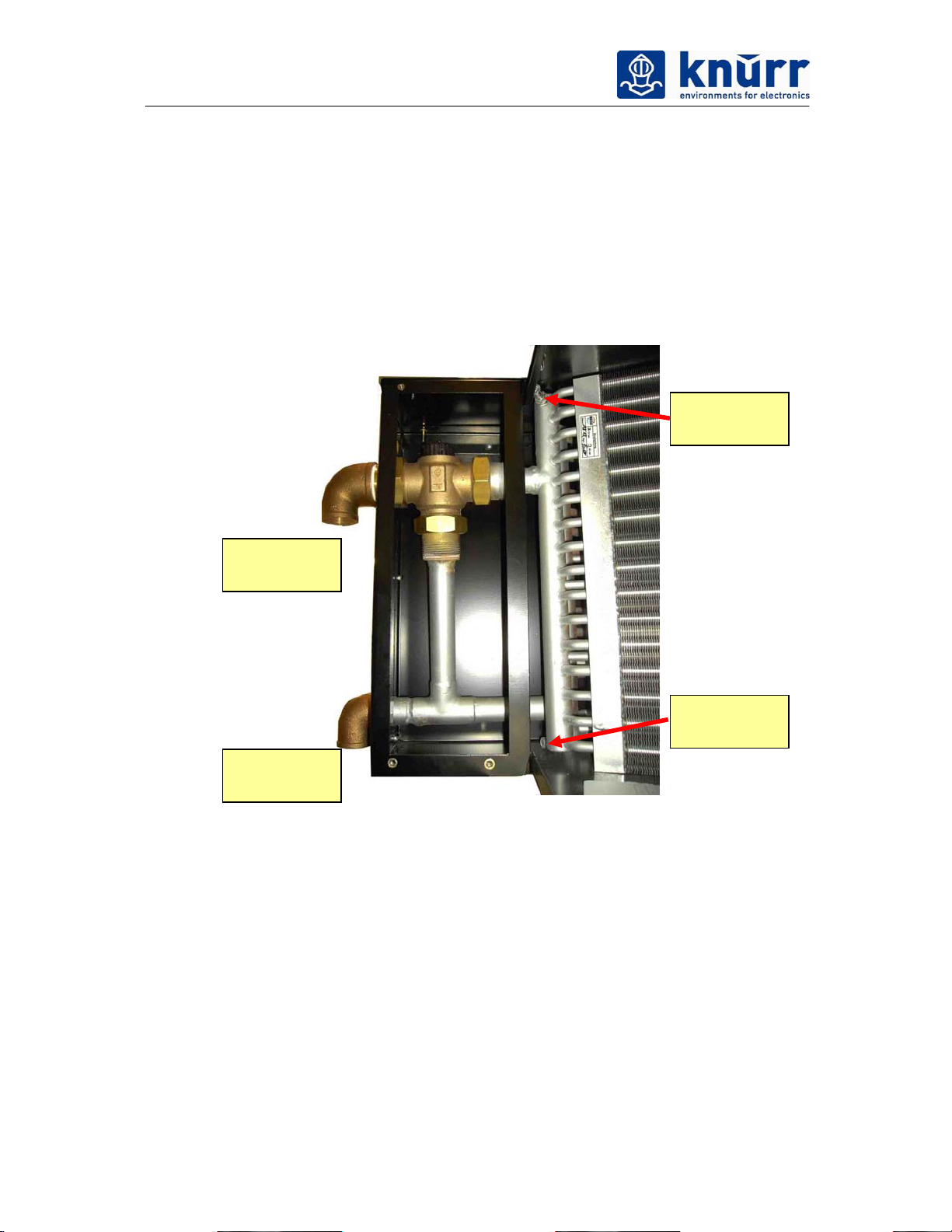

Manual / Bedienungsanleitung

- Carefully bleed heat exchanger when filling the system.

- Open the air bleed valve until the coming out water is bubble free.

- Close this valve after bleeding carefully.

Air bleed valve

Chilled water

return

Drain valve

Chilled water

feed

- If necessary, re-tighten threaded fittings.

- After an extended period without use, and particularly in case of risk of

frost, the heat exchanger and the supply pipe are to be completely drained.

- Drain completely by blowing out with compressed air and remove all bleed

and drain plugs.

CoolTherm 01_998_330_0_k page / Seite 22/83

Page 25

CoolTherm

Manual / Bedienungsanleitung

Heat exchanger connection

Chilled water

feed

The chilled water pipes should be insulated against condensation and losses using a waterproof

insulation.

Insulation thickness : „F“ (9 - 12mm) λ = 0,037 W/mK (10°C)

Chilled water

return

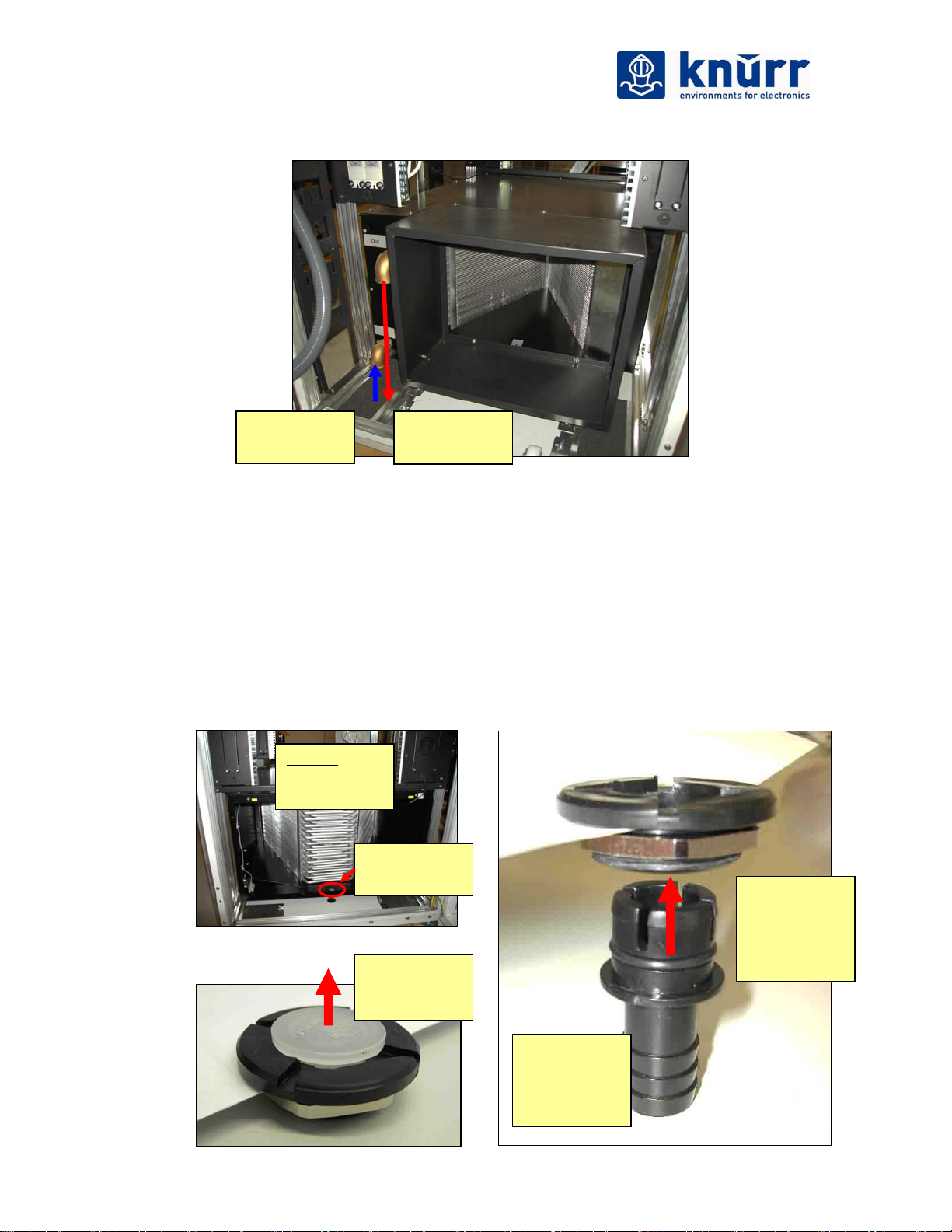

5.4 Condensed water connection

If the CoolTherm is operated below dew point, condensed water may occur. As standard there is a

water connection, 5/8“ diameter, in the condensed water tray for drainage.

Preparations for connecting:

Step 1):

Remove air

duct

Condensat

connection

Step 2.)

Remove cap

Step 3.)

Connect the

nipple with a

drain hose

”

Step 4.)

Move and

click the nipple

with hose into

the hole

CoolTherm 01_998_330_0_k page / Seite 23/83

Page 26

CoolTherm

Manual / Bedienungsanleitung

When connecting to the condensed water tray, ensure that the condensed water pipe is connected

to a self-filling siphon with return protection and that the condensed water pipe has a drop.

The height of the siphon must be designed for an under or overpressure of 800 Pa so that air is

not drawn in or blown out of the waste pipe.

5.5 Electrical connection

The wiring diagram is enclosed in the unit.

Make sure the server cabinet is electrically disconnected during

installation. Prior to beginning installation work shut down the

server cabinet, disconnect it and secure it against unauthorised

switch on.

As soon as all preparations for installation have been made, you can start electrical installation.

The unit should only be connected by appropriately

qualified personnel (electrician). The personnel must ensure

that the server cabinet is electrically isolated for the

duration of the connection work and is secured against

unauthorised switch on.

Check whether voltage and frequency at installation site as well as

fuse ratings match the specifications on the rating plate.

Power supply connection is done by a terminal block.

To connect the unit to the power supply:

• Correctly shut down the server cabinet.

• See the wiring diagram for information on the connections to be made.

• Connect the supply cable in the computer room.

• Check the secure connection of the earth wire.

To put the server cabinet correctly back in operation:

Switch on the fuse protected power supply.

The unit's fans will rotate clockwise.

The status indicator on the RMS viewer will go green if running.

CoolTherm 01_998_330_0_k page / Seite 24/83

Page 27

CoolTherm

Manual / Bedienungsanleitung

5.6 Sealing of cabinet

The air tightness of the housing corresponds to RAL 652

To ensure the optimal cooling function the cabinet must be sealed:

- Pipe entries should be cut into the foam and properly closed with a extra foam if required.

- Cable entries should be closed with the pivoting plate and foamed material

- Air flows on the warm and cold sides of the cabinet must be separated from each other

5.7 Automatic door opening

gas pressure

springs

Upper cable

entry

(standard)

upper magnet

retaining plate

Cover CoolTherm with automatic door opening

Function

Front and rear door are kept closed with two electromagnets.

The door will be pushed off smoothly by a gas pressure spring, if the power supply of the

electromagnets breaks.

The electric door opening can prevent damages through overtemperature in the rack as well as

occurring humidity.

If the doors are opened the thermal load can disappear to the room. There is no overheating of the

servers.

The suck in of air with water droplets can also be prevented (Door opening due to humidity alarm).

When the rear door is opened, the fans will be shut down.

CoolTherm 01_998_330_0_k page / Seite 25/83

Page 28

CoolTherm

Manual / Bedienungsanleitung

In case of fire and smoke development in the rack the doors are kept closed and the fans will be

shut down. The door opening due to overtemperature will be suppressed.

Alternative the consciously opening of the doors is possible to extinguish the fire by a room

extinguishing device.

It is possible that every time the doors could open themselves.

Mind this during staying in door area.

Release of Automatic Door Opening

- via temperature sensor front side (standard)

CoolTherm 01_998_330_0_k page / Seite 26/83

Page 29

CoolTherm

Manual / Bedienungsanleitung

adjusting screw

for upper

magnet plate

upper and lower

transport-lock

screw

Initial Commissioning:

- unfix upper and lower transport lock screw

- connection with general power supply

Automatic door opening operates approx. one minute after initialisation of fan

control unit

- see: Manual closing

- Attention:

If in the time of commissioning the power supply is broken, the doors open itself. If you

use the transport lock screws again,

use always both

damaged.

- Adjusting Magnet Plate:

After rack transport and setup check the position of the magnet plates, it could be

necessary to adjust the magnets to the retain plate. Therfore turn both adjusting screws

(A) until the magnets are in a absolute parallel position to the retain plate and the door

remains closed.

The screw position is to be fixed by locking the nut (B) to threaded bushing,

transport lock screws, otherwise the door could be

Door opening

switch with LED

(green)

adjusting screw

for bottom

magnet plate

CoolTherm 01_998_330_0_k page / Seite 27/83

Page 30

CoolTherm

Manual / Bedienungsanleitung

A

B

figure: detail magnet

Manual closing:

Note: Rear door must be closed before front door! (safety function)

- Press LED switch for electromagnet activation

- LED lights

- Push door evenly shut, both

magnetic areas must bond

Manual opening:

Note: Rear door opens only when front door is opened! (safety function)

- Press LED switch - green LED doesn’t light

- Rack door opens itself

Technichal Data:

Power supply for electromagnets

Output: 24 V DC

max. 100 W

CoolTherm 01_998_330_0_k page / Seite 28/83

Page 31

CoolTherm

Manual / Bedienungsanleitung

6. Servicing and maintenance

Servicing and maintenance work is to be performed by

correctly trained personnel only and in accordance with

applicable regulations as well as manufacturers’ specifications!

Only use original spare parts that have been tested and approved

by the manufacturer.

(If necessary, request a comprehensive spare parts list from the

manufacturer)

For cleaning use commercially available cleaning agents only.

Follow the stipulated safety measures and do not use any tools that

may cause scratching or tools for scraping (surface treatment will be

irreversibly damaged!)

Prior to all servicing work:

- Correctly shut down fans and any other electrical

components and disconnect from the electricity supply!

General inspection on fans (annually)

- Check for unusual bearing noises. (Check for excessive bearing play)

Replacement of fans (expected service life is approx. 40.000 operating hours

at a temperature of 40°C / 104°F).

1. Remove the housing cover from the unit (with earth cable)

2. Check out which fan is failed, check the surface temperature of the fan e.g. and switch of the

regarding fuse on the front side

3. Disconnect supply cable at the fan terminal block

4. Undo the four fastening bolts for the fan to be replaced.

5. Remove the failed fan.

- Wait until the fan blades have stopped!

- Secure against switch on!

- Shut down water cooling circuit and secure against

switch on.

CoolTherm 01_998_330_0_k page / Seite 29/83

Page 32

CoolTherm

Manual / Bedienungsanleitung

Step 3:

Disconnect

supply cable

at the fan

terminal block

(unscrewing 2

screws and

remove

connector)

Step 4:

Undo the four

fastening bolts

The fan is installed in the reverse order of removal.

- Tighten the fan fixing bolts.

- Connect the power supply cable to the fan

- Attention: Reconnect earth cable at the sheet steel cover !

- Switch on the the fuse

Dispose of the old fans correctly!

Regularly inspect the heat exchanger (annually)

- Check heat exchanger on air side for soiling and damage.

- Check feed and return for correct function.

- If necessary clean the air side.

- Regularly check odour trap (external) for correct function.

- Heat exchanger can be pulled out for improved cleaning.

- Regularly visually inspect the water circuit for leaks.

CoolTherm 01_998_330_0_k page / Seite 30/83

Page 33

CoolTherm

Manual / Bedienungsanleitung

The efficiency of heavily soiled heat exchangers is very limited these

have to be cleaned regularly. Use a vacuum cleaner, compressed air or

a soft brush to clean the fins.

Do not bend the fins during cleaning, because this will interfere with the

correct ait flow through the unit.

Replacement of Heat Exchanger

Step 1:

Unfix cable

strap of

temperature

sensor

Step 2:

Remove air

duct into

upper

direction

Step 3:

Unfix cable strap

of humidity sensor

and unscrew it

including fixing

screw.

Put the sensor

outside of the heat

exchanger

Step 6:

Unfix fixing

four screws

Step 7:

Pull out heat

exchanger

Step 4:

Unfix earth

cable

Step 5:

Unfix

condensate

connection

CoolTherm 01_998_330_0_k page / Seite 31/83

Page 34

CoolTherm

Manual / Bedienungsanleitung

The heat exchanger is installed in the reverse order of removal.

Regularly check the condensed water drain and clean if necessary

7. Dismantling and disposal

The CoolTherm may be dismantled by suitably qualified personnel only.

Prior to dismantling:

- Correctly shut down fans and any other electrical

Disconnect the unit from the external water circuit by closing the shut-off valves and drain the

water circuit in the unit.

Transport the unit as described in "Transportation" section using a lifting device with sufficient load

bearing capacity.

Dispose of the air-conditioner as per the locally applicable disposal and

safety instructions. We recommend using a specialist recycling organisation.

All parts can be stripped down and consist of:

- labelled plastic parts

- electronic parts

8. Customer service, manufacturer's address

All Knürr products are subject to continuous quality control and comply with applicable regulations.

For all questions that you may have in relation to our products, please contact the provider of your

server cabinet system or contact directly:

- aluminium, steel, brass, copper

components and disconnect from power supply!

- Secure against switch on!

- Shut down water cooling circuit and secure against

switch on.

Raubaer Strasse 1

01623 Lommatzsch

Tel.: +49 (0) 800 000 6295

Email: service@knuerr.com

Knürr AG

CoolTherm 01_998_330_0_k page / Seite 32/83

Page 35

CoolTherm

Manual / Bedienungsanleitung

9. Appendix

9.1 Quality requirements on the water used in CoolTherm

To ensure the maximum service life of air-water heat exchangers, chilled water must comply with

the VGB chilled water regulations (VGB-R 455 P). Chilled water used must be soft enough to

prevent deposits, but must not be so soft that heat exchanger corrosion occurs.

The following table contains the most important impurities and methods for removing them:

Water impurity Method of removal

Mechanical pre-treatment (dp < 1 mm) Filtering the water

Excessive hardness Soften the water using ion exchange

Moderate content of mechanical impurities and hardness formers Addition of dispersing agents or stabilising

Moderate content of chemical impurities Addition of passivation agents and

Biological impurities (bacteria and algae) Addition of biocides

It is recommended to achieve the following hydrological data as far as possible:

Hydrological data

pH values

Carbonate hardness

Free carbon dioxide

Bound carbon dioxide

Aggressive carbon dioxide

Sulphides

Oxygen

Chloride ions

Sulphate ions

Nitrates and nitrides

CSB

Ammonia

Iron

Manganese

Conductivity

Solid evaporation residue

Potassium permanganate consumption

Suspended matter

(Partial flow cleaning is recommended)

(Continuous cleaning)

>7

>3 <8 °dH

8 - 15 mg/dm3

8 - 15 mg/dm3

0 mg/dm3

< 10 mg/dm3

< 50 mg/dm3

< 250 mg/dm3

< 10 mg/dm3

< 7 mg/dm3

< 5 mg/dm3

< 5 mg/dm3

< 0.2 mg/dm3

< 0.2 mg/dm3

< 30 µS/cm

< 500 mg/dm3

< 25 mg/dm3

< 3 mg/dm3

> 3 < 15 mg/dm3

> 15 mg/dm3

agents

inhibitors

CoolTherm 01_998_330_0_k page / Seite 33/83

Page 36

CoolTherm

Manual / Bedienungsanleitung

9.2 Checklist for unit installation

Checked performed Completed

Check unit for damage on delivery

Check for level floor

Check max. floor load

CoolTherm feet adjusted

CoolTherm is level

Automatic door opening adjusted

No remains of packaging in the

CoolTherm

All installation tools removed

Cable entries into the

unit correct and air-tight

Cable connections checked

Chilled water connection does not leak

Pressure test performed

Chilled water network bled

Chilled water flow rate adjusted

Condensed water pipe clear

Chilled water system odour trap in order

(After completion confirm

with signature

)

Comments

Heat exchanger tray connected to

condensed water pipe

Fan function checked

All front panels closed

(separation of air flows)

............................................. ........................................ ....................

Place: Date: Signature

Checker

CoolTherm 01_998_330_0_k page / Seite 34/83

Page 37

CoolTherm

Manual / Bedienungsanleitung

9.3 Commissioning certificate

CoolTherm – Commissioning certificate

1. General data

1.1 Client/Setup site

client name ………………………..

client address ………………………..

………………………..

………………………..

contact persons ………………………..

phone number ………………………..

setup site / room number: ..................................

air humidity at setup site: ................................... % relative humidity

ambient temperature ................................... ° C

nominal values at setup site:

temperature

°C

max. rel.

humidity

%

10 15 18 19 20 21 22 23 24 25 26 27 28 30 35

100 76 62 58 55 52 48 46 43 40 38 36 34 30 23

nominal values kept: yes □ no □

1.2 Configuration

type of cabinet:

CoolTherm 12kW

cabinet number: ...................................

commission number ...................................

serial number: ...................................

fan: no. 1 no. 2 no. 3

manufacturer: ......................... ...................... ………………

CoolTherm 01_998_330_0_k page / Seite 35/83

□ CoolTherm 17kW □ CoolTherm 25 (35) kW □

Page 38

CoolTherm

Manual / Bedienungsanleitung

2. Control of status

2.1 General condition

load carrying capacity checked (by client)

level alignment checked

transportation damages of cabinet: yes

comments: .........................................................................................................................

.........................................................................................................................................

.........................................................................................................................................

packaging removed: yes

installation tools removed: yes

air separation: yes

(front panels closed)

2.2 Chilled water facility on site

□

□

□ no □

□ no □

□ no □

□ no □

chilled water: with antifreeze

CoolTherm

connected to: CTU

Site loop directly

chilled water temperature: feed: ......... °C/°F return: ........°C/°F

chilled water pressure: feed: ......... bar return: .........bar

quick connection: yes

hydraulic installation o.k.

(visual check) yes

comments: ……………………………………………………..

□ without antifreeze □

□ Chiller directly □

□

□ no □

□ no □

CoolTherm 01_998_330_0_k page / Seite 36/83

Page 39

CoolTherm

Manual / Bedienungsanleitung

2.3 Electrical data / Documents

wiring scheme attached: yes □ no □

comments:

.........................................................................................................................................

cable connections checked:

electrical acceptance certificate by approved staff:

comments:

.........................................................................................................................................

3. Function check

3.1 Mechanical functions

damages on heat exchanger/

connections/ radiator gills/ surface: yes

comments:

.........................................................................................................................................

front door closing easily: yes

comments:

.........................................................................................................................................

rear door closing easily: yes

Comments:

.........................................................................................................................................

Hose / cable entries closed: yes

comments:

.........................................................................................................................................

yes

□ no □

□ no □

□ no □

□ no □

□ no □

cable entries air tight: yes

comments:

.........................................................................................................................................

condensate drain open / connected: yes

comments:

.........................................................................................................................................

fans run correct (bearings o.k.):

visual check yes

comments:

.........................................................................................................................................

CoolTherm 01_998_330_0_k page / Seite 37/83

□ no □

□ no □

□ no □

Page 40

CoolTherm

Manual / Bedienungsanleitung

3.2 Electrical functions

function check valve / fan control. yes □ no □

comments:

.........................................................................................................................................

fans shut down when rear door is opened yes

comments:

.........................................................................................................................................

function check smoke detector yes

comments:

.........................................................................................................................................

function check temperature control yes

comments:

.........................................................................................................................................

function check automatic door opening yes

adjustment magnet plates see manual “initial commissioning automatic door”

comments:

.........................................................................................................................................

function check water sensor yes

comments:

.........................................................................................................................................

malfunction indicator function yes

comments:

.........................................................................................................................................

3.3 Thermal checks

□ no □

□ no □

□ no □

□ no □

□ no □

□ no □

condensate occurrence at heat exchanger yes

comments:

.........................................................................................................................................

chilled water feed at heat exchanger ............... °C

chilled water return at heat exchanger ............... °C

air temperature in the cabinet

at the heat exchanger inlet: ............... °C

air temperature in the cabinet

at the heat exchanger outlet: ............... °C

chilled water cycle bled: yes

CoolTherm 01_998_330_0_k page / Seite 38/83

□ no □

□ no □

Page 41

CoolTherm

Manual / Bedienungsanleitung

pressure test chilled water cycle: yes □ no □

(protocol by client present)

water flow rate adjusted: yes

flow rate: …………. l / min external

comments:

.........................................................................................................................................

Commissioning performed by day to day operating.

Correctness of function check protocol certified by:

......................................... ................................ .............................................

approved staff date signature

......................................... ................................ ..............................................

client date signature

□ no □ external □

□

CoolTherm 01_998_330_0_k page / Seite 39/83

Page 42

CoolTherm

Manual / Bedienungsanleitung

9.4 CoolTherm Diagrams

12 kW CoolTherm at 1.72m³/h chilled water flow rate

16 kW

14 kW

12 kW

10 kW

8 kW

cooling capacity

6 kW

4 kW

2 kW

0 kW

10,0 12,0 14,0 16,0 18,0 20,0 22,0 24,0

chilled water supply temperature [°C]

20°C supply air temperature

22°C supply air temperature

25°C supply air temperature

17kW CoolTherm at 2.44 m³/h chilled water flow rate

25 kW

20°C supply air temperature

20 kW

15 kW

10 kW

cooling capacity

5 kW

0 kW

10,0 12,0 14,0 16,0 18,0 20,0 22,0 24,0

chilled water supply temperature [°C]

22°C supply air temperature

25°C supply air temperature

CoolTherm 01_998_330_0_k page / Seite 40/83

Page 43

CoolTherm

Manual / Bedienungsanleitung

25kW-CoolTherm at 3.58m³/h chilled water flow rate

40 kW

35 kW

30 kW

25 kW

20 kW

cooling capacity

15 kW

10 kW

5 kW

0 kW

10,0 °C 12,0 °C 14,0 °C 16,0 °C 18,0 °C 20,0 °C 22,0 °C 24,0 °C

chilled water supply temperature [°C]

9.5 Control Standard Factory Settings

start of fan rotation 10°C (start with 75% rotation)

fan speed control 20 – 23°C (75% - 100% rotation)

start of 3-way valve 10°C (start with closed position)

control of 3way valve 16 – 19°C (0 – 100% control water flow rate)

front LED yellow temperature alarm >26°C or rear door open

front LED red temperature alarm >26°C and rear door open

automatic door opening door release at 35°C

Note: All settings could vary by project.

20°C supply air temperature 1)

22°C supply air temperature 1)

25°C supply air temperature 1)

CoolTherm 01_998_330_0_k page / Seite 41/83

Page 44

CoolTherm

Manual / Bedienungsanleitung

Inhalt

0. Allgemein..................................................................................................................................... 43

Sicherheit .................................................................................................................................... 43

1.

1.1 Arbeitssicherheits - Symbole..................................................................................................... 43

1.2 Sicherheitshinweis ..................................................................................................................... 44

2.

Einsatzbedingungen................................................................................................................... 46

3.

Beschreibung.............................................................................................................................. 47

3.1 Allgemeine Funktion................................................................................................................... 47

3.2 Funktionsprinzip Kühlung.......................................................................................................... 48

3.3 Abmessungen ............................................................................................................................. 49

3.4 Technische Daten ....................................................................................................................... 53

3.5 Regelung ..................................................................................................................................... 56

Lagerung und Transport ............................................................................................................ 58

4.

5.

Montage und Inbetriebnahme .................................................................................................... 60

5.1 Vorbereitung zur Montage.......................................................................................................... 60

5.2 Aufstellung der Geräte ............................................................................................................... 61

5.3 Anschluss Kühlwasser............................................................................................................... 62

5.4 Anschluss Kondensat ................................................................................................................ 65

5.5 Anschluss Elektro....................................................................................................................... 66

5.6 Abdichtung Gehäuse.................................................................................................................. 66

5.7 Automatische Türöffnung .......................................................................................................... 67

6.

Wartung und Instandhaltung ..................................................................................................... 70

7.

Demontage und Entsorgung...................................................................................................... 73

8.

Kundendienst, Herstelleradressen............................................................................................ 74

9.

Anlagen........................................................................................................................................ 75

9.1 Anforderungen an die Wasserqualität für den Einsatz im CoolTherm ................................... 75

9.2 Checkliste zur Geräteaufstellung .............................................................................................. 76

9.3 Inbetriebnahmeprotokoll............................................................................................................ 77

9.4 CoolTherm Kennlinien................................................................................................................ 82

9.5 Werkseinstellungen der Regelung ............................................................................................ 83

Seite

CoolTherm 01_998_330_0_k page / Seite 42/83

Page 45

CoolTherm

Manual / Bedienungsanleitung

0. Allgemein

Die CoolTherm Plattform bietet eine Abführung von Wärmelasten von 10 bis über 22 / 35 kW.

Dabei ist der Serverschrank gegenüber dem Aufstellungsraum abgeschlossen, d.h. keine Wärme

wird in die Umgebung abgegeben.

(s. auch Punkt 2)

Die Kühlung erfolgt mittels einen geschlossenen Kreislauf über einem Luft-Wasserwärmetauscher.

Die Kühlleistung wird der anfallenden Wärmelast angepasst.

Für die Einbauten sowie Einschubschienen und Zwischenböden sind 19” Lochraster Profile

vorgesehen.

Die Kabeleinführung kann über den Boden sowohl auch über den Deckel erfolgen.

1. Sicherheit

1.1 Arbeitssicherheits - Symbole

Folgende Symbole weisen auf bestimmte Gefährdungen hin oder geben Ihnen Hinweise zum

sicheren Betrieb.

Achtung! Gefahrenstelle! Sicherheitshinweis!

Gefahr durch elektrischen Strom oder hohe Spannung

Vorsicht! Heiße Oberfläche

Vorsicht! Drehende Teile / automatischer Anlauf

Vor Arbeiten freischalten!

Achtung! Kennzeichnet mögliche Beschädigungen des Gerätes

Gefahr durch elektrische Spannung

CoolTherm 01_998_330_0_k page / Seite 43/83

Page 46

CoolTherm

Manual / Bedienungsanleitung

Hinweis! Kennzeichnet mögliche Gefahren für die Umwelt

1.2 Sicherheitshinweis

Wichtiger Hinweis, Informationen

Zur Montage des CoolTherm können Sie unsere Ingenieure

umfangreich beraten.

Umfangreiche Material-, Funktions- und Qualitätsprüfungen sichern

Ihnen einen hohen Nutzen und eine lange Lebensdauer.

Trotzdem können von diesen Maschinen Gefahren ausgehen, wenn

sie von unausgebildetem Personal unsachgemäß und nicht zum

bestimmungsgemäßen Gebrauch eingesetzt werden.

Lesen Sie vor Montage und Inbetriebnahme des CoolTherm

diese Montage und Betriebsanleitung aufmerksam durch.

Die elektrische Ausrüstung entspricht den geltenden VDE- und Unfallverhütungs-vorschriften.

Lebensgefährliche Spannungen (größer 50V AC oder größer

100V DC) sind vorhanden:

→ Hinter den Schaltschranktüren

→ An den Ventilatoren und deren Anbindungen

→ Hinter der Lüfterabdeckung

Verwenden Sie nur Originalsicherungen mit der vorgeschrieben Stromstärke.

Schalten Sie das Gerät sofort ab, wenn die elektrische Energieversorgung oder

Kaltwasserversorgung gestört ist.

Gefahr durch elektrische Spannung

Instandsetzungs-, und Reinigungsarbeiten darf nur

Fachpersonal durchführen. Dabei muss das Personal

sicherstellen, dass für den Zeitpunkt der Instandhaltung

und Reinigung das Gerät spannungsfrei ist. Nehmen Sie

deshalb vor Beginn der Arbeiten das Gerät vorschriftsmäßig

außer Betrieb.

CoolTherm 01_998_330_0_k page / Seite 44/83

Page 47

CoolTherm

Manual / Bedienungsanleitung

Gefahr durch unsachgemäße Arbeiten am Gerät

Die Reinigungen und Instandhaltungen darf nur Fachpersonal

durchführen. Damit das Gerät betriebssicher

bleibt und eine lange Lebensdauer hat, müssen Sie

Instandhaltung und Reinigungsintervalle unbedingt

einhalten.

Betreiben Sie CoolTherm nur bestimmungsgemäß in angegeben.

Leistungsgrenzen und mit genehmigten Betriebsmitteln.

Beachten Sie bei allen Arbeiten an und mit dem Gerät:

• Die jeweils geltenden Vorschriften (z. B.VDE- Vorschriften oder andere gültige

nationale Richtlinien)

• Die zutreffenden Unfallverhütungsvorschriften (BGV)

• Die einschlägigen Bestimmungen

• Die geltenden Umweltschutzgesetze

Betreiben Sie das Gerät nur in einwandfreiem Zustand. Bei Funktionsstörungen oder

Fehlern müssen Sie das Gerät sofort außer Betrieb setzen und den zuständigen

Verantwortlichen des Betreibers über diesen Zustand informieren.

Sie dürfen das Gerät erst wieder in Betrieb nehmen, nachdem die einwandfreie

Funktion des Gerätes wiederhergestellt wurde.

Vorsicht heiße Oberfläche

Defekte Lüfter, Netzteile, Regelplatinen können heißgelaufen sein.

Vor Beginn der Montage diese abkühlen lassen.

CoolTherm 01_998_330_0_k page / Seite 45/83

Page 48

CoolTherm

Manual / Bedienungsanleitung

2. Einsatzbedingungen

Bestimmungsgemäße Verwendung

Das Gerät ist ein 19” Schrank mit integrierter Umluftkühlung und dient ausschließlich zur

Abfuhr von Wärme aus Serverschränken zum Schutz temperaturempfindlicher Bauteile.

Das Kühlsystem im Schrank arbeitet thermisch unabhängig von der Raumluft.

Die gesamte Abwärme der Einbauten wird über den Kühlwasserkreislauf nach außen

geführt und an ein bauseitiges Kaltwassersystem abgegeben

Hinweis: Ein im Verhältnis zur abgeführten Wärmelast des Equipments äußerst geringer

Anteil (ca. 0,5 kW) kann jedoch unter Umständen in den Raum abgegeben werden.

Zur sicheren Funktion von CoolTherm muss Kühlwasser in einer abgestimmten

Wassermenge, Temperatur und Druck vorliegen. Wasserqualität gemäß

VGB-R 455 P einhalten. (siehe Anhang)

Temperatur im Aufstellungsort: 10°C bis 35°C

(andere Temperaturen nach Absprache)

Temperaturen bei Einsatz von

RMS mit temperaturabhängigem Alarm:

20°C bis 25°C

Absolute Feuchte im Aufstellungsort: 8 g H

Wassertemperaturen Vorlauf: 12°C

(andere Temperaturen nach Absprache)

Wassertemperaturen Rücklauf: 18°C bei Nennverlustleistung

(andere Temperaturen nach Absprache)

Temperaturspreizung Wasser: 6K

Verwendung von Frostschutzmittel

im Kühlwasser: nicht empfohlen (auf Anfrage)

Wasseranschluss: von unten

Kondensatanschluss: von unten

Nennspannung bei Kühlleistung:

12 KW, 17 KW, 25 KW 200V bis 264V/

50 / 60 Hz

max. Betriebsdruck: 10 bar

O/ kg Luft

2

CoolTherm 01_998_330_0_k page / Seite 46/83

Page 49

CoolTherm

Manual / Bedienungsanleitung

3. Beschreibung

3.1 Allgemeine Funktion

CoolTherm erfüllt die Bedingungen der EN 60950.

Die modulare Bauweise erlaubt den Einbau aller 19“- Einbauten mit unterschiedlicher Tiefe.

Wärme, welche durch Einbauten (z. B. Server) entsteht, wird zuverlässig mit dem im

Schaltschrank integriertem Kaltwassersystem abgeführt. Das Kühlsystem ist vollständig

eigensicher, so dass kein Wasser in den Serverbereich gelangen kann.

Das Kühlsystem besteht aus einem Hochleistungs- Luft/ Wasser Wärmetauscher, Ventilator mit

temperaturabhängiger Drehzahlregelung zur kanalisierten Luftführung und Kaltwasseranschluss.

Der Luftkreislauf ist geschlossen, so dass keine Wärme (thermische Last) in den umliegenden

Raum abgegeben wird.

Achtung! CoolTherm funktioniert nur, wenn eine

lufttechnische Trennung zwischen kalter Serverzuluft und erwärmter

Serverabluft eingebaut ist. Nicht benutzte Höheneinheiten sind durch Blindplatten zu

verschließen.

Ansicht von

oben

WARM

WARM

WARM

WARM

Luftkanal

Server

KALT

KALT

WARM

WARM

WARM

WARM

Lufttrennung

CoolTherm 01_998_330_0_k page / Seite 47/83

Page 50

CoolTherm

Manual / Bedienungsanleitung

3.2 Funktionsprinzip Kühlung

Luft, welche durch die Server erwärmt wurde (z.B. 35°C), wird mittels Hochleistungs-Ventilatoren

angesaugt und über einen speziellen Wärmetauscher Luft/ Wasser geführt.

Dort wird die Luft z. B. auf 20 - 25°C abgekühlt und zu Vorderseite der Server gefördert,

Die Serverventilatoren können die Luft ansaugen und über interne Einbauten führen.

Das Kühlwasser wird über einen bauseitigen Kaltwassersatz zur Verfügung gestellt.

Unter dem Wärmetauscher befindet sich eine Kondensatwanne mit Abfluss 5/8“.

Bei Ausfall der Kühlanlage

Wärmestau im Gehäuse zu vermeiden. Die Wärme wird in diesem Fall

als thermische Last an den Aufstellungsraum abgegeben.

Bei Ausfall der CoolTherm – Ventilatoren

Gerätetüren

wird in diesem Fall als thermische Last an den Aufstellungsraum abgegeben.

Bei Öffnung der Rücktür (mit Ventilatoren) muss die Fronttür

geöffnet sein.

zu öffnen um einen Wärmestau im Gehäuse zu vermeiden. Die Wärme

sind die Gerätetüren zu öffnen um einen

sind die

CoolTherm 01_998_330_0_k page / Seite 48/83

Page 51

CoolTherm

Manual / Bedienungsanleitung

Die Öffnung der Fronttür bedingt kein Öffnen der Rücktür.

3.3 Abmessungen

1 Multifunktions-Tür (Hinten) mit eingebauten redundaten Ventilatoren, Luftkanal und

Dichtung

2 Wärmetauscher mit Kondensatwanne, Kondensatanschluss

3 Luftumlenkblech

4 Seitenwand

5 Glas-Tür (vorn)

Bodenplatte mit Öffnungen für Durchführungen

4

vorn

23

1

3

1

45

hinten

2

CoolTherm 01_998_330_0_k page / Seite 49/83

Page 52

CoolTherm

Manual / Bedienungsanleitung

Legende:

1 Kabeleingangsplatte geschlossen

2 Kühlwassereingang

3 Kabeleingang (Netzwerkkabel)

4 Durchführungen Kondensat, wählbar

Rückseite

Standarddimension

Frontseite

Abmessungen Deckel mit Kabeleingängen 12- 17 - 25 / 35 kW (Draufsicht)

Die Durchführungen sind nach Abschluss der Arbeiten luftdicht

zu verschließen.

CoolTherm 01_998_330_0_k page / Seite 50/83

Page 53

CoolTherm

Manual / Bedienungsanleitung

Abmessungen Bodenplatte / Öffnungen / Anschlüsse 12- 17 - 25 / 35 kW

CoolTherm 01_998_330_0_k page / Seite 51/83

Page 54

CoolTherm

Manual / Bedienungsanleitung

Nutzbare Länge für Server / Einbauten

CoolTherm 01_998_330_0_k page / Seite 52/83

Page 55

CoolTherm

Manual / Bedienungsanleitung

3.4 Technische Daten

Gehäusewerkstoff: Alublech / Stahlblech verzinkt und beschichtet

Temperatureinsatzbereich: 10 °C bis 35 °C

absolute Luftfeuchte: 8 g/kg

Luftaustritt nach Wärmetauscher: 20 - 25°C gemäß ASHRAE

Temperaturdifferenz über Server: ca. 15K

Schallpegel: 55 dB(A) Schalldruck in 1m Entfernung

Zuladung: 1.000 kg

Kühlwasser

Kühlleistung je nach Typ: 12 KW bis 25 / 35)* KW

Vorlauftemperatur Kühlwasser: 12°C (andere Temp. in Abstimmung)

Rücklauftemperatur Kühlwasser: 18°C (andere Temp. in Abstimmung)

)*21°C bei 35 kW (z.B. Blade Verwendung)

max Betriebsdruck Kühlwasser: 10 bar

Anschluss Vorlauf/ Rücklauf: 1”

CoolTherm 01_998_330_0_k page / Seite 53/83

Page 56

CoolTherm

Manual / Bedienungsanleitung

Datenübersicht CoolTherm Tabelle A

Allgemeine Daten

Spreizung Kühlwasser: 12 / 18°C (Auslegungsbedingungen) max. Betriebsdruck Wärmetauscher: 10 bar

Zulufttemperatur zum Server: 22°C max. abs. Feuchte im Aufstellraum: 8g/kg

Anschluss Wärmetauscher: 1” Innengewinde Farbcode Standard Farben: x = 8 = RAL 7021 (schwarzgrau)

Anschluss Kondensatwanne: 5/8” Schlauchanschluss x = 1 = RAL 7035 (lichtgrau)

Artikel

Nummer

08.006.001.x

08.006.002.x

08.006.003.x

08.006.006.x

08.006.007.x

08.006.008.x 12 38 2200 700 1300

08.006.012.x

08.006.013.x

08.006.014.x

08.006.022.x

08.006.023.x

08.006.024.x

08.006.033.x

08.006.034.x

08.006.043.x

nutzbare

Kühlleistung-

HE

(nutzbar)

Höhe

Breite

Tiefe [D]

Nutztiefe [d]

Gewicht

Wasserinhalt

kW mm mm mm mm kg l m³/h V / A / Watt Hz A / mm²

5,9

5,9

2.000 200 bis 264 / 7 / 1000

2.000 200 bis 264 / 7 / 1000

12 29

12 33

12 38

12 29

12 33

1800 700 1200

2000 700 1200 740 290

2200 700 1200

1800 700 1300

2000 700 1300 840 295

7,9

7,9

3.100 200 bis 264 / 8 / 1400

3.100 200 bis 264 / 8 / 1400

17 35

17 40

17 44

17 35

17 40

17 44

25(35) 37

25 (35) 42

25 (35) 37

2000 800 1200

2200 800 1200 740 310

2400 800 1200

2000 800 1300

2200 800 1300 840 320

2400 800 1300

2200 800 1200 740 340 9,9 4.500 200 bis 264 / 8 / 1800 50 / 60 16 / 3 x 2,5

2400 800 1200

2200 800 1300 840 350 9,9 4.500 200 bis 264 / 8 / 1800 50 / 60 16 / 3 x 2,5

08.006.044.x 25 (35) 42 2400 800 1300

Elektrische Anshlussdaten

Umluftmenge

im

Spannung / Strom / Leistung

Serverschrank

Frequenz

50 / 60

50 / 60

50 / 60

16 / 3 x 2,5

16 / 3 x 2,5

16 / 3 x 2,5

50 / 60

16 / 3 x 2,5

Sicherung /

Einspeisung

CoolTherm 01_998_330_0_k page / Seite 54/83

Page 57

CoolTherm

Manual / Bedienungsanleitung

Datenübersicht CoolTherm Tabelle B (Hydraulische Daten)

nutzbare

Kühlleistung

kw

12

17

25

35

Gesamtkühl

-leistung

(bei Normal-

betrieb)

kw kw l m³/h bar K K

12,5 13,0 5,9 1,79 0,41 6 6,2

17,8 18,4 7,9 2,55 0,62 6 6,2

26 26,8 9,9 3,72 0,58 6 6,2

36 36,8 9,9 3,72 0,58 8,1 8,51

Gesamtkühl-

leistung

(bei max.

Lüfterdrehzahl /

Notlauf)

Wasser-

inhalt

Durchfluss-

menge

Druckverlust

Schrank

Spreizung

Kühlwasser

(bei Normal

betrieb)

Lüfterdrehzahl /

Spreizung

Kühlwasser

(bei max.

Notlauf)

CoolTherm 01_998_330_0_k page / Seite 55/83

Page 58

CoolTherm

Manual / Bedienungsanleitung

3.5 Regelung

Die Temperaturregelung erfolgt mittels der Ventilatorregelung VR2.2 in Abhängigkeit von der

Serverschrank-Innentemperatur. Ein Temperaturfühler misst ständig die Temperatur im

Serverschrank. (Zuluftseite der Server)

Die Umluftmenge wird von Ventilatoren auf den jeweiligen Kühlbedarf angepasst.

Bei einer Temperatur kleiner 20°C drehen sich die Ventilatoren mit einer Minimal-Drehzahl von

75% der Maximaldrehzahl. Zwischen 20°C und 23°C steigt die Drehzahl proportional der

Temperatur auf 96% der Maximaldrehzahl.

Bei einem Bruch oder Kurzschluss des Temperatursensors werden die Ventilatoren auf

maximale Drehzahl geregelt

PDU – Box*)

*) beim 12 kW Rack

unterm Dach

CoolTherm Vordersansicht

Durch ein Dreiwegeventil wird der Kühlwasserdurchfluss an die

Entwärmungsleistung angepasst. Vor allem kann so im Teillastbetrieb eine Untertemperatur

vermieden werden. Im Havariefall öffnet das Ventil und der gesamte Volumenstrom wird über

das Register gefahren.

Von 16°C bis 19°C regelt das Dreiwegeventil den Wasserdurchfluss zwischen 0%

und 100% des Solldurchflusses (Verteilregelung). Durch den Einsatz einer Blindscheibe

in den Bypass kann eine hydraulische Mengenregelung (Zweiwegeventil) erreicht

werden.

Lufttemperaturfühler

Status LED:

Grün

System OK

Gelb

Störung Klimaregelung / Lüfter

oder Rücktür

offen

Rot

Störung Klimaregelung / Lüfter

und Rücktür

offen

Sicherungen für

jeden Ventilator

und

Schaltnetzteil

Raum für

optionale

Ausstattungen

ServiceSteckdose mit

Sicherung

CoolTherm 01_998_330_0_k page / Seite 56/83

Page 59

CoolTherm

Manual / Bedienungsanleitung

Ventilantrieb

Dreiwegeventil

Bypass

(Fließrichtung)

CoolTherm Wärmetauscher Ansicht (von hinten)

Die Programmierung der Regelung erfolgt werkseitig und ist mittels Passwort geschützt.

Fehler des Temperatursensors oder einer der Lüfter werden über einen potentialfreien

Meldekontakt bereitgestellt.

Folgende Alarme stehen als potentialfreie Kontakte zur Verfügung:

- Sensorbruch

- Lüfterausfall

- Übertemperatur (2 Schwellwerte)

Diese Alarme können als Einzelalarme oder als Sammelalarm generiert werden.

Beim Öffnen der Schaltschranktür werden die Ventilatoren automatisch abgeschaltet.

Kennlinie Lüfterregelung (Werkseinstellung)

CoolTherm 01_998_330_0_k page / Seite 57/83

Page 60

CoolTherm

Manual / Bedienungsanleitung

Kennlinie der Regelung des Dreiwegeventils (Werkseinstellung)

4. Lagerung und Transport

• Lagern Sie das CoolTherm Gerät in seiner Originalverpackung trocken und wettergeschützt.

• Decken Sie offene Paletten mit Planen ab und schützen Sie die Funktionsteile vor

Schmutzeinwirkung (z. B. Sand, Regen, Staub usw.).

• Halten Sie Lagertemperaturen zwischen –30°C und +50°C ein.

• Der Wärmetauscher muss komplett entleert sein. (Gefahr von Frostschäden)

• Bei Lagerzeiträumen von über 1Jahr prüfen Sie vor der Montage die Leichtgängigkeit der

Lager der Ventilatoren. (⇒ Drehen mit der Hand).

• CoolTherm kann mit dem Gabelstapler oder Kran transportiert werden. Der Transport mit dem

Kran muss mit Gurten erfolgen. Das Gewicht je CoolTherm beträgt, je nach Ausführung bis zu

340 kg. (Leergewicht)

• Vermeiden Sie ein Verwinden des Gehäuses oder anderer Beschädigungen.

• Verwenden Sie geeignete Montagehilfen, wie z. B vorschriftsmäßige Gerüste.

• Vor dem Anheben von CoolTherm durch Kran oder Gabelstapler alle Wartungstüren

verschließen.

• Nicht unter schwebende Lasten treten

• Haken, welche in die Lasthaken eingehängt werden, müssen geeignet sein und die Zugkräfte

aufnehmen können.

CoolTherm 01_998_330_0_k page / Seite 58/83

Page 61

CoolTherm

Manual / Bedienungsanleitung

• CoolTherm darf nicht durch den Kran schräg gezogen werden

• Vor der Inbetriebnahme von CoolTherm sind alle Verpackungen zu entfernen.

Sicherheitshinweis für Krantransport

< 680 kg

Ringschrauben M 12

nach Norm DIN 580!

CoolTherm 01_998_330_0_k page / Seite 59/83

Page 62

CoolTherm

Manual / Bedienungsanleitung

> 680 kg > 1000 kg

5. Montage und Inbetriebnahme

5.1 Vorbereitung zur Montage

Bevor Sie das Gerät montieren können, müssen Sie einige Punkte

überprüfen.

Diese Prüfungen dienen der Sicherheit und der störungsfreien Funktion

des Schaltschrankes. Gehen Sie bei diesen Prüfungen mit größter

Sorgfalt vor, um eine reibungslose Funktion des Gerätes zu

gewährleisten.

Gerät auf Transportschäden überprüfen:

Die Verpackung von CoolTherm darf bei Lieferung von außen keine durch den Transport

bedingten Beschädigungen aufweisen. Jede Beschädigung der Verpackung ist ein Hinweis auf

einen möglichen transportbedingten Schaden. Dies kann im schlechtesten Fall einen

Funktionsausfall zur Folge haben.

Rücksendung des Gerätes bei eventuellen Transportschäden

Wird das Gerät nicht in der Originalverpackung zurückgesandt, so muss die

Rücksendeverpackung folgende Kriterien erfüllen:

Der Abstand des Gerätes zur Verpackung muss mindesten 30 mm

betragen.

Als Hilfestellung für die Montage befindet sich in der Anlage, eine Checkliste,

welche Sie vor der Inbetriebnahme ausfüllen sollten.

Die Inbetriebnahme kann auch durch eine Fachfirma erfolgen. Dazu ist das in der Anlage

enthaltene Inbetriebnahmeprotokoll anzuwenden.

CoolTherm 01_998_330_0_k page / Seite 60/83

Page 63

CoolTherm

Manual / Bedienungsanleitung

Die Aufstellung von CoolTherm muss auf einen waagerechten Untergrund

erfolgen. Überprüfen Sie deshalb vor Beginn

der Montage mit Hilfe einer Wasserwaage die horizontale Ausrichtung.

Beachten Sie, dass der Boden mindestens eine Masse von 1500 kg/m²

CoolTherm aufnehmen muss.

Um eine gute Luftzirkulation zu erreichen stellen Sie sicher, dass sich

• in den Einschüben

• im Bereich Kühler

• am Lufteintritt

• am Luftaustritt

keine Verpackungsmaterialien oder andere Einbauten befinden,

welche die Luftzirkulation behindern oder versperren.

5.2 Aufstellung der Geräte

Nach der Aufstellung sind die Füße von CoolTherm so einzustellen, dass der Schrank lotrecht

steht. Die Türen müssen nach Ausrichtung leicht zu schließen sein.

Die Einstellung der Füße erfolgt mit einem Schraubenschlüssel (SW65mm). Die Gewindelänge ist

zu beachten.

Optional ist es möglich die Schränke mit einander zu verbinden. Dazu sind die

Stopfen aus den Seitenwänden zu entfernen und mit Sechskantschraube, Art. Nr.

4000 1411 zu verbinden.

Abstand

Füße

B700 T1200

B800 T1200

B800 T1300

einstellbare Füße

B1

(mm)

600 1114

700 1114

700 1214

T1

(mm)

CoolTherm 01_998_330_0_k page / Seite 61/83

Page 64

CoolTherm

Manual / Bedienungsanleitung

Transportsicherung der Luftumlenkung entfernen

Nach Aufstellung sind die zwei als Transportsicherung dienenden Schrauben an den Seiten der

Luftumlenkung zu entfernen. So kann die Luftumlenkung selbst nach oben hinausgezogen werden

um eventuell hineingefallene Teile aus der Wärmetauscherwanne zu entfernen.

Schrauben entfernen

5.3 Anschluss Kühlwasser

Der Wärmetauscher ist ausziehbar. Die Kühlwasserrohre sind so anzuschließen,

dass beim Lösen der Wärmetauscherverbindung dieser herausgezogen werden kann.

Wird der Wärmetauscher über Gewinde an das Kühlwassernetz angeschlossen,

so muss der Rohrstutzen beim Festziehen gegengehalten werden.

Vor Inbetriebnahme des Schaltschrankes sind die Rohrverbindungen

auf Dichtheit zu überprüfen

Wärmetauscher zur Erstinbetriebnahme vorbereiten:

- Ordnungsgemäße mechanische Montage und Anschluss der Versorgungsleitung.

CoolTherm 01_998_330_0_k page / Seite 62/83

Page 65

CoolTherm

Manual / Bedienungsanleitung

Kanalteil entfernen zum

Entlüften, Entleeren und