Page 1

Precision Cooling

For Business-Critical Continuity™

Liebert XDK™ Rack Enclosure With Integrated Water-Based Cooling

User Manual–17kW

Page 2

IMPORTANT SAFETY INSTRUCTIONS

SAVE THESE INSTRUCTIONS

Liebert engineers will provide comprehensive support on how to install the XDK.

Extensive material, function and quality checks ensure that you fully benefit from product functions

and a long service life. Nevertheless, this product can produce hazards if it is used incorrectly by

untrained personnel or is not used for the correct purpose.

Read these operating instructions carefully before commissioning the XDK.

The electrical equipment complies with the applicable VDE and accident prevention regulations. Hazardous voltages (higher than 50 VAC or higher than 100 VDC) are present:

• inside the electric box in the unit's housing

• behind the fan cover on the outside of the rear door

Shut down the unit immediately if there are problems with electrical input or cold water supply.

WARNING

!

Risk of electric shock. Can cause injury or death.

Disconnect all local and remote electric power supplies before working within.

Only qualified personnel may perform repair, maintenance, and cleaning operations.

NOTE

Cleaning and servicing must be performed by qualified personnel. To ensure that the unit

remains safe to use and has a long service life, observe the maintenance and cleaning intervals.

Operate the XDK correctly within the stipulated ratings and with approved equipment.

During all work on and with the unit, observe:

• All applicable regulations (e. g., VDE regulations and other applicable national regulations)

• All applicable accident prevention instructions (BGV)

• All applicable laws on environmental protection

Operate the XDK only if it is in proper working condition. If a malfunction or fault occurs, you must

shut down the unit immediately and notify the responsible facility official or employee.

Resume operating the unit only after the malfunction or fault has been rectified and the XDK’s function has been re-established.

CAUTION

!

Risk of contact with hot surfaces. Can cause burn injury.

Fans, power supplies, PC boards, and other components become extremely hot during unit

operation. Allow sufficient time for them to cool before working within the unit.

Use extreme caution and wear protective gloves and arm protection when working on or near

hot components.

Page 3

TABLE OF CONTENTS

IMPORTANT SAFETY INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . INSIDE FRONT COVER

1.0 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

2.0 OPERATING CONDITIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

2.1 Proper Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

3.0 DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

3.1 General function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

3.2 Principle of Cooling Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3.2.1 Data Overview—XDK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3.3 Control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.4 Automatic Door Opening . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.4.1 Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.4.2 Initial Commissioning: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.4.3 Manual Closing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.4.4 Manual Opening . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4.0 EQUIPMENT INSPECTION, HANDLING AND STORAGE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4.1 Packaging Material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4.2 Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4.3 Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4.4 Returning the Unit in Case of Damage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

5.0 INSTALLATION AND COMMISSIONING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

5.1 Preparation for Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

5.2 Positioning the XDK. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

5.2.1 Remove Recirculation Air Duct Transport Lock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

5.3 Water Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5.3.1 Preparing Heat Exchanger for Initial Commissioning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5.4 Condensed Water Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5.5 Electrical Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.6 Sealing the Cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

6.0 SERVICING AND MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

6.1 General Inspection on Fans—Annual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

6.1.1 Fan Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

6.2 Inspect the Heat Exchanger—Annual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

6.3 Replacing the Heat Exchanger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

7.0 DISMANTLING AND DISPOSAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

8.0 WATER PURITY REQUIREMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

8.1 Unit Installation Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

8.2 Commissioning Certificate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

i

Page 4

FIGURES

Figure 1 Cooling airflow, top view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Figure 2 Cooling airflow, side view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

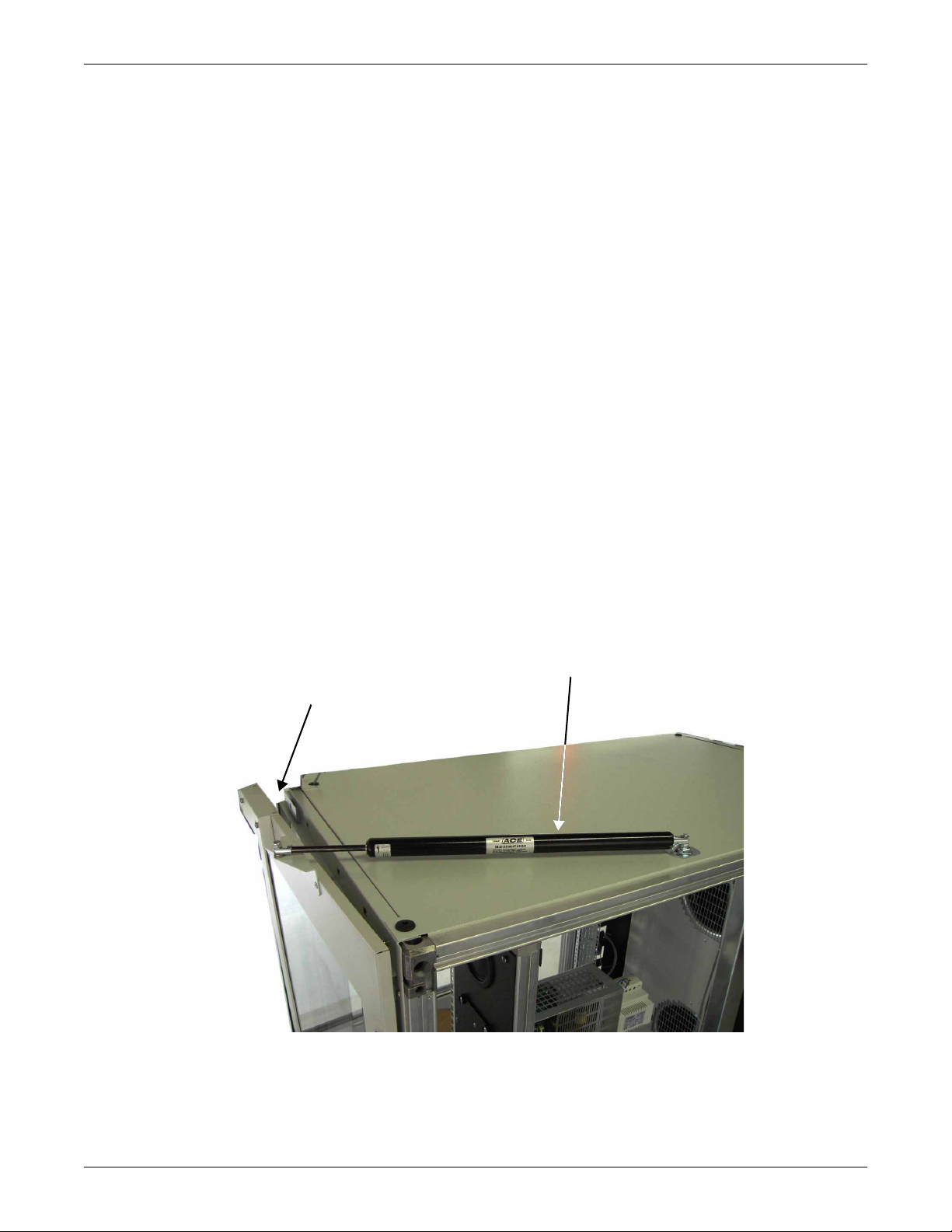

Figure 3 XDK door and automatic opening mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Figure 4 Door locking mechanisms, opening switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Figure 5 Remove the transport lock screws . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Figure 6 Heat exchanger access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Figure 7 Control valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Figure 8 Heat exchanger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Figure 9 Heat exchanger connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Figure 10 Bottom plate with cutouts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Figure 11 Replacing a fan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Figure 12 Heat exchanger replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

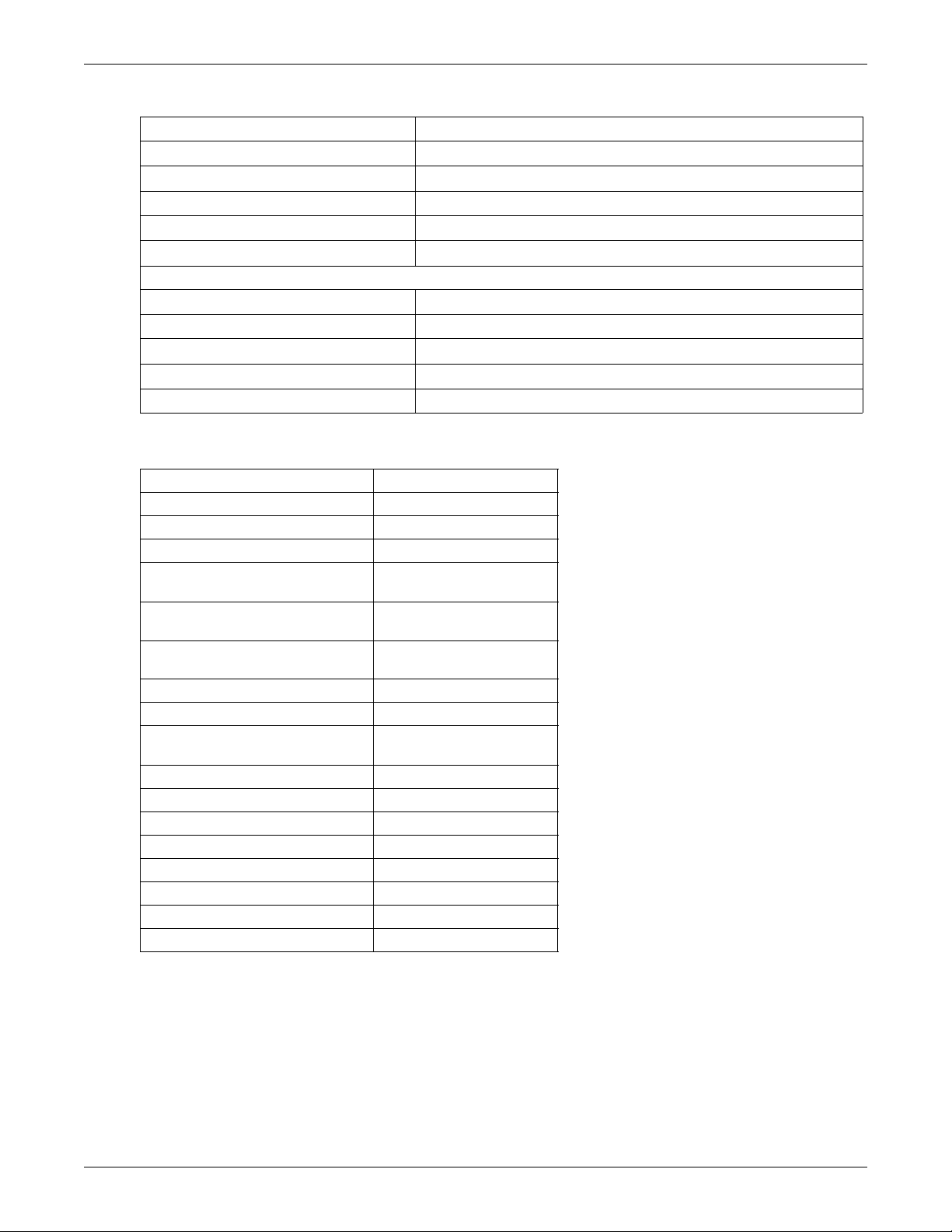

TABLES

Table 1 General operating data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Table 2 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Table 3 XDK general data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Table 4 Prevalent impurities and removal methods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Table 5 Suggested hydrologic levels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Table 6 XDK – Commissioning certificate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Table 7 Nominal values at setup site . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Table 8 Type of cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Table 9 Control of status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Table 10 Cold water facility on site . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Table 11 Electrical data / documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Table 12 Function check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

ii

Page 5

1.0 INTRODUCTION

The Liebert XDK provides the dissipation of heat loads up to 17kW.

The server rack is closed to the installation area, that means no heat load will dissipate to the environment. (see also chapter 2.) The cooling is provided by a closed cooling system via an air-to-water

heat exchanger. The cooling capacity adapts to the heat load.

19" (483mm) rails are designed for components as well as rails and shelves.

Cable entry is possible from the bottom and from the top.

Introduction

1

Page 6

2.0 OPERATING CONDITIONS

2.1 Proper Application

The XDK is a water-cooled enclosure and is intended for removing heat from electronic equipment

inside the cabinet. The cooling system in the cabinet is thermally independent of the room air. Water

is used to cool equipment installed in the XDK. No additional cooling of the server room is required.

NOTE

Under certain conditions, a small amount of heat, (approximately 0.5kW), can escape into the

room.

CAUTION

!

Risk of improper operation. Can cause equipment damage. For reliable function of the XDK,

cold water must be available in the correct amount, and at the correct temperature and

pressure. Observe water quality specified in VGB-R 455 P. (see 8.0 - Water Purity

Requirements ).

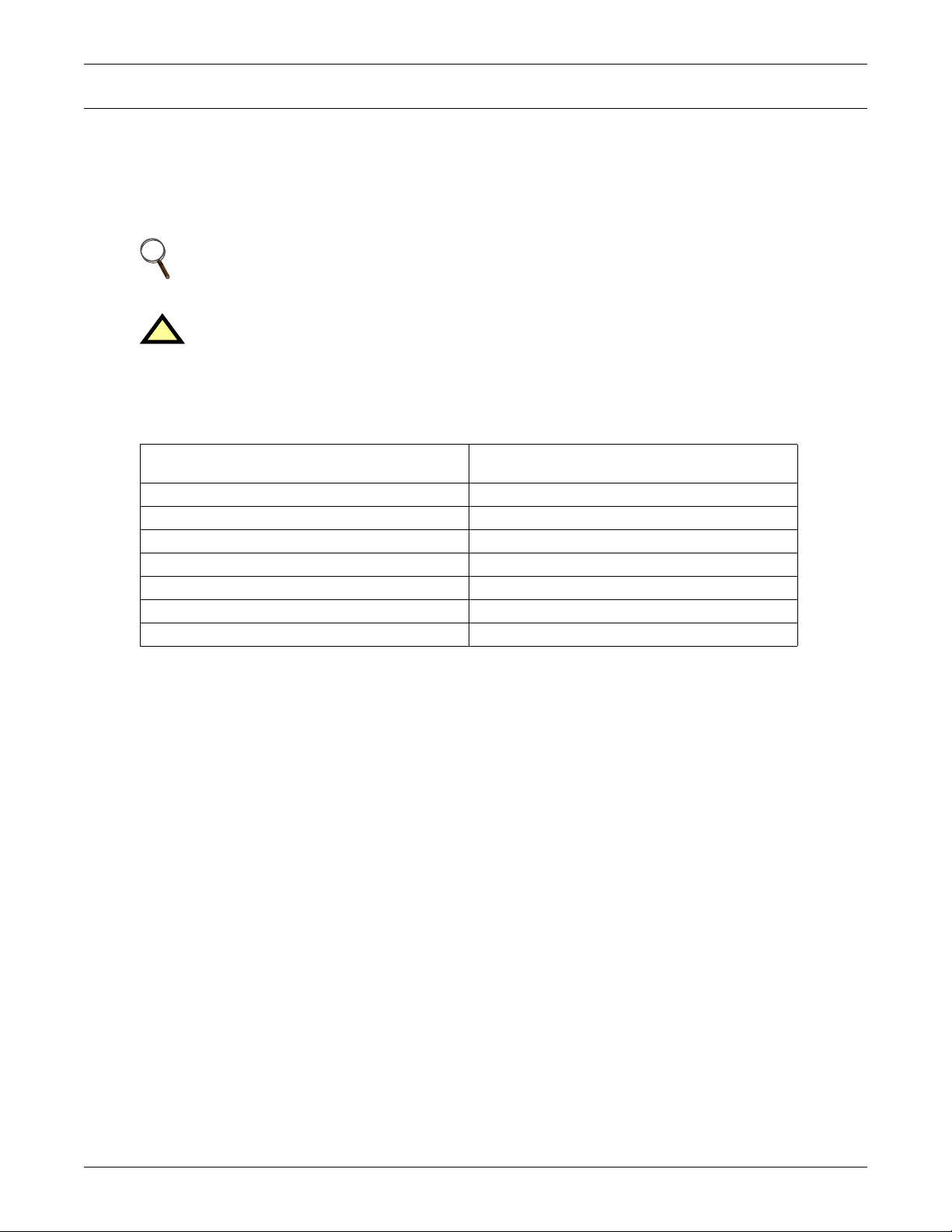

Table 1 General operating data

Ambient temperature

Absolute humidity in the installation location 8g H

Water temperature, supply 54°F (12°C); other temperatures upon request

Water temperature, return 64°F (18°C); other temperatures upon request

Water connection from below

Condensed water connection from below

Nominal voltage 200V to 264V (50Hz and 60 Hz)

Maximum operating pressure 145 PSI (10 bar)

50°F to 95°F (10°C to 35°C)

(other temperatures upon request)

O/ kg air maximum

2

Operating Conditions

2

Page 7

3.0 DESCRIPTION

3.1 General function

The modular design facilitates the installation of 19-inch-wide equipment of varying depth.

Heat produced by equipment in the cabinet, such as servers, is removed by the cold water system

integrated into the server cabinet. The cooling system is isolated from the server area, protecting the

sensitive equipment from water damage.

The cooling system comprises a high-performance air/water heat exchanger, fans with fan control

unit, fan-speed according to heat load.

The air circuit is closed such that no heat is emitted to the environment.

CAUTION

!

Risk of improper operation. Can cause equipment damage.

The XDK works only if cold server feed air and heated server outlet air are fully separated.

Height units not in use must be sealed with blanking panels.

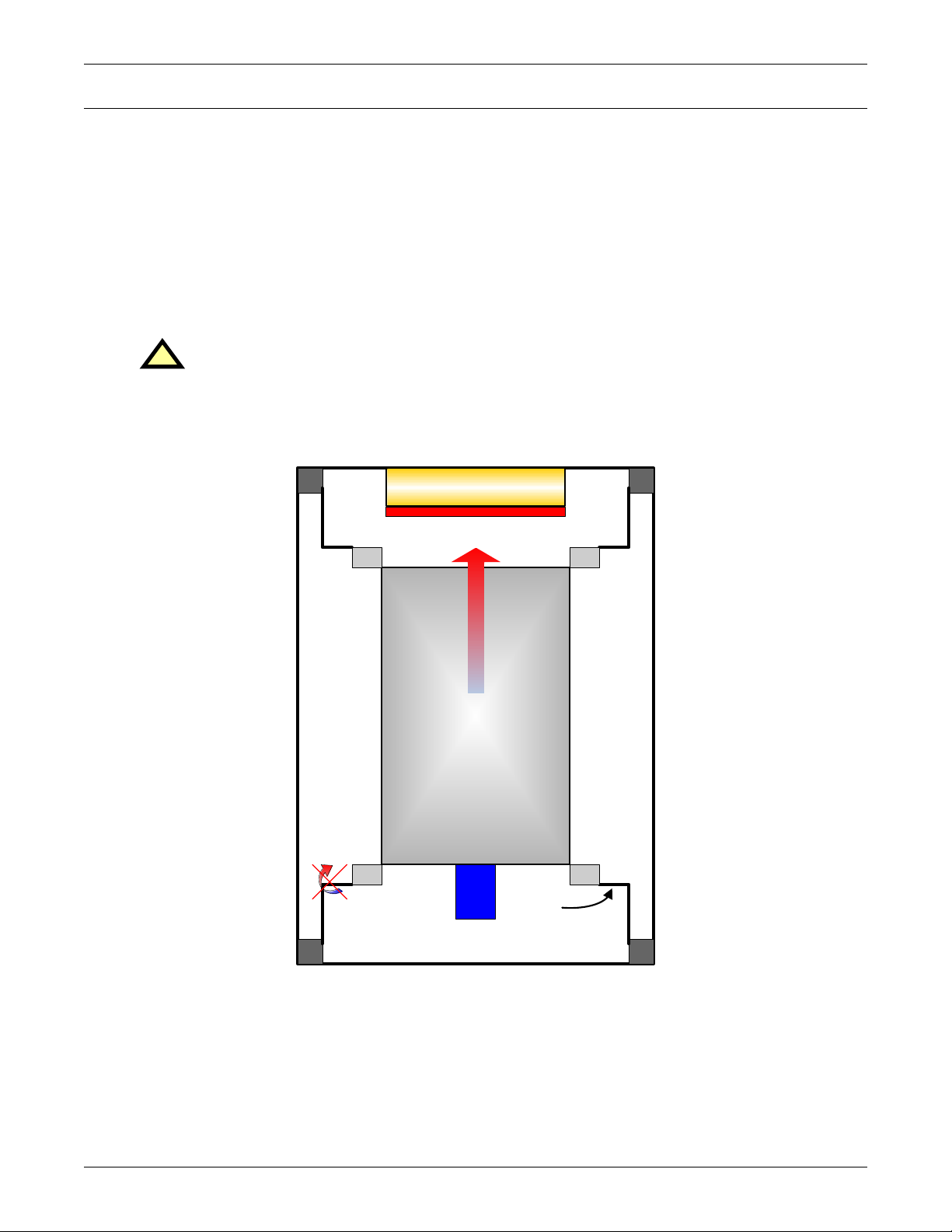

Figure 1 Cooling airflow, top view

Description

Air Duct

WarmWarm

Warm Warm

Server

Cold

Air

Separation

Cold

Front

3

Page 8

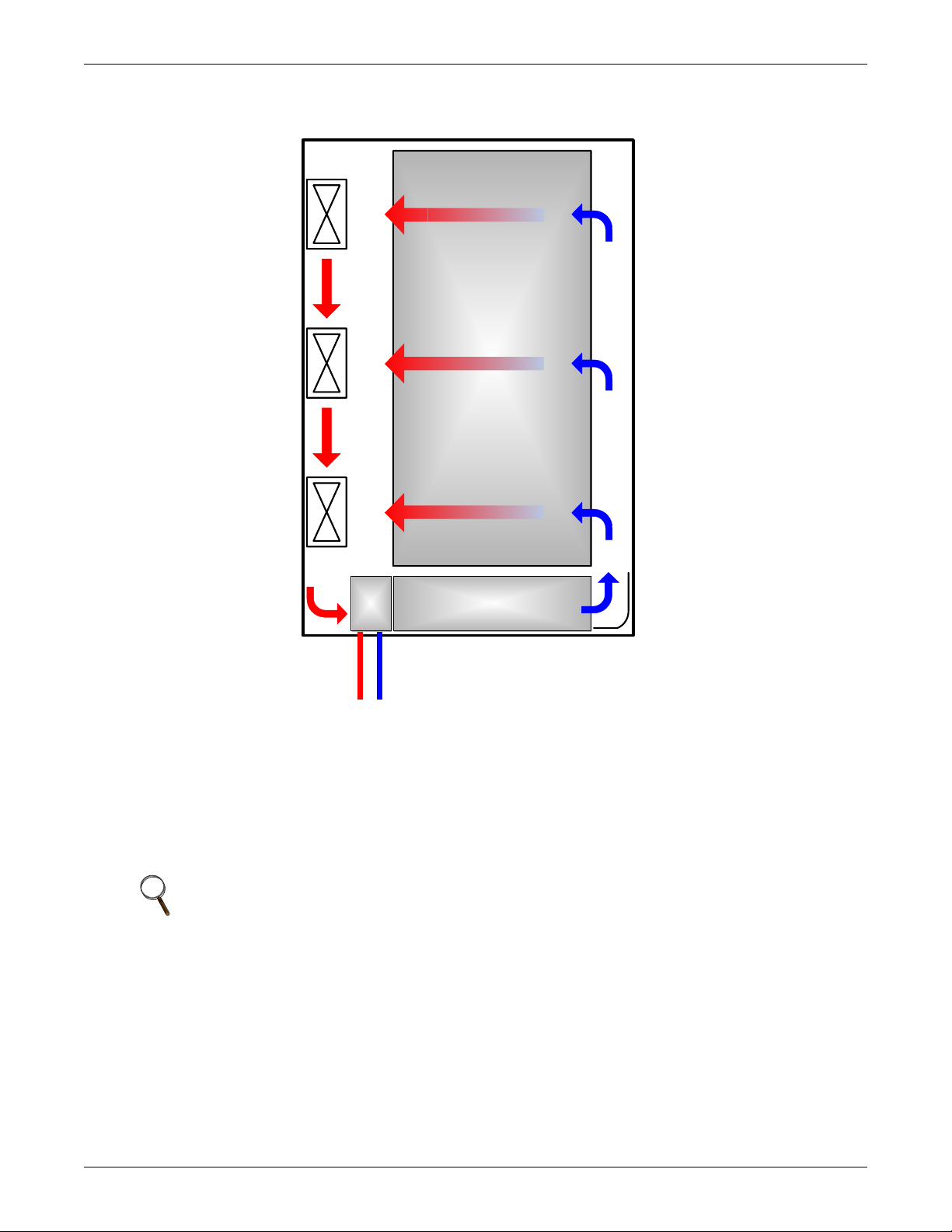

3.2 Principle of Cooling Operation

Figure 2 Cooling airflow, side view

Fan

Bank

Description

Rear

of

XDK

19" Equipment

Front

of

XDK

Air / Water

Heat Exchanger

Cold Water Supply

Side of XDK

Air that has been heated by the servers to 95°F (35°C), for example, is circulated to a specially

designed air/water heat exchanger by high-performance fans. The heated air is cooled to 68-77°F

(20-25°C) and fed to the front of the server.

The server fans can draw in the air and feed it over internal components.

Cold water is provided by a separate Liebert XD Pumping unit.

A condensate tray with a 5/8" outlet is below the heat exchanger.

NOTE

If the rear door (with fans) is opened, the front door must be opened. If the front door is opened,

it is not necessary to open the rear door.

4

Page 9

Table 2 Technical data

Housing material Aluminium sheet, sheet steel, galvanized and coated

Operating Temperature range 50°F to 95°F (10°C to 35°C)

Abs. atmospheric humidity 8g / kg maximum

Temperature difference across server approx. 15K

Cold Water

Cooling capacity 17kW

Supply temperature 54°F (12°C) (other temperatures upon consultation)

Return temperature 64°F to 72°F (18°C to 22°C) (other temperatures upon consultation)

Max. operating pressure 145 PSI (10 bar)

Water supply connection 1"

3.2.1 Data Overview—XDK

Table 3 XDK general data

Nominal Cooling Capacity 17kW @ 54°F (12°C) EFT

Height, in (mm) 86.6 (2200)

Width, in (mm) 31.5 (800)

Depth, in (mm) 47 (1200)

Usable Height for Electronic

Equipment

Maximum Electronic

Equipment Depth, in (mm)

Electronic Equipment

Air Temperature, In/Out, °F (°C)

Weight, Empty, lb (kg) 683 (310)

Maximum Weight, Filled 2,800 (1310)

Maximum Operating

Water Pressure, psi (bar)

Water Flow Rate, GPM (m

Water Pressure Drop, psi (bar) 10 (0.7)

Water Connections, in 1

Maximum Air Flow, CFM ( m

Sound Pressure Level 55 dB(A) at 3 ft (1m)

Input Voltage 200-264 V, 1 ph, 50/60 Hz

Maximum Power Draw 1400W

Options Leveling Feet or Casters

Noise level 55 dB(A) sound pressure at a distance of 3 ft. (1m)

Useful load 2204 lb (1000kg)

40 U

29 (740)

68/98 (20/37

145 (10)

3

/h) 10.7 (2.44)

3

/h) 1800 (3,100)

Description

5

Page 10

3.3 Control

The server cabinet temperature is controlled by the fan control board

A temperature sensor continuously measures the temperature of the server cabinet (server feed air).

The air circulation flow rate is controlled by the fan speed according to the current thermal load.

At temperatures lower than 70°F (21°C) fans rotate at 75% of maximum speed.

Between 68°F and 73°F (20 and 23°C), speed increases proportionally to the temperature up to 96% of

maximum speed.

The failure of the temperature sensor set the fans to maximum speed.

The water flow rate is controlled by a three-way valve depending on thermal load. In case of failure,

the valve opens and the all the chilled water flows through the heat exchanger.

From 61°F to 66°F (16°C to 19°C), the three-way valve controls the water flow rate from 0% to 100% of

the nominal flow rate.

The programming of the control is factory-set and protected with a password.

The failure of the temperature sensor or one of the fans will set off an alarm using a potential free

contact.

The outgoing alarms with potential free contact are:

• sensor error

• fan malfunction

• high-temperature / low-temperature

Description

The fans are automatically shut down if the server cabinet rear door is opened.

3.4 Automatic Door Opening

Figure 3 XDK door and automatic opening mechanism

Upper magnet

and retaining

plate

Gas pressure spring

6

Page 11

3.4.1 Function

Front and rear door are kept closed with two electromagnets. The door will be pushed open smoothly

by a gas pressure spring if power to the electromagnets fails.

If the doors are opened, the thermal load can escape into the room, preventing the servers from overheating.

The inflow of air with water droplets can also be prevented (Door opening due to humidity alarm).

When the rear door is opened, the fans shut down automatically.

Figure 4 Door locking mechanisms, opening switch

Description

Upper and lower

transport-lock

screw

3.4.2 Initial Commissioning:

___ 1. Loosen the upper and lower transport lock screw

___ 2. Connect inlet power to the power supply (See 3.4.3 - Manual Closing.)

Door opening switch

with LED (green)

NOTE

If the power supply fails during initial commissioning, the front door opens automatically. If

the transport lock screws are reinstalled, both transport lock screws must be reinserted or the

door could be damaged

7

Page 12

3.4.3 Manual Closing

1. Press LED switch for electromagnet activation

2. The LED lights up

3. Push door evenly shut. Both magnetic locks must latch.

3.4.4 Manual Opening

1. Press LED switch - green LED doesn’t light

2. Rack door opens itself

Description

8

Page 13

Equipment Inspection, Handling And Storage

4.0 EQUIPMENT INSPECTION, HANDLING AND STORAGE

Upon arrival of the unit, and before unpacking, verify that the labeled equipment matches the bill of

lading. Inspect all items for damage, either visible or concealed. Damage should be immediately

reported to the carrier and a damage claim filed with a copy sent to your local sales representative.

4.1 Packaging Material

All material used to package this unit is recyclable. Please save for future use or

dispose of the material appropriately.

SAFETY INFORMATION

WARNING

!

Risk of top-heavy unit falling over. Improper handling can cause equipment damage, injury or

death! Read all of the following instructions before attempting to move, lift, remove packaging

from or preparing unit for installation.

WARNING

!

Risk of sharp edges, splinters and exposed fasteners. Can cause personal injury.

Only properly trained personnel wearing appropriate safety headgear, gloves, shoes and

glasses should attempt to move, lift, remove packaging from or prepare unit for installation.

R

CAUTION

!

Risk of overhead interference. Can cause unit and/or structure damage.

Refer to the installation plans prior to moving the unit to verify clearances.

CAUTION

!

Risk of damage from fork lift! Improper handling with the forklift can cause exterior and/or

underside damage! Keep tines of the fork lift level and at a height suitable to fit below the

skid.

4.2 Handling

When possible, transport the unit using a forklift or pallet jack. Otherwise use a crane with belts or

cables.

• When using a forklift or pallet jack, make sure the forks (if adjustable) are spread to the widest

allowable distance that will fit under the skid.

• Ensure that the fork length is suitable for the unit length.

• When using a forklift while moving the packaged XDK, do not lift it higher than 6" (152mm).

• If circumstances require the XDK to be lifted higher than 6" (152mm), great care must be exercised. Personnel not involved in moving the unit must be at least 20' (5m) from the lift point of the

unit.

• Belts or cables must be used when the XDK is moved with a crane.

• The XDK’s net weight is 749 lb. (340 kg).

• Avoid twisting the housing or other damage during handling.

• Ensure that the XDK’s doors are closed prior to lifting.

• Do not stand under an XDK while it is suspended.

• Hooks used to attach to the unit must be of appropriate tensile strength.

• The XDK must not be lifted at an angle.

9

Page 14

4.3 Storage

• If the XDK’s packaging has been removed, cover it with tarpaulins to protect against particulates,

such as sand and dust, and from moisture.

• Keep storage temperature between -22°F and 104°F (-30°C and +40°C).

• The heat exchanger must be completely drained to prevent the risk of freezing damage.

• When stored for more than 12 months, turn fans by hand to check the fan bearings prior to installation.

4.4 Returning the Unit in Case of Damage

If the XDK is not returned in its original packaging, the packaging used for return must comply with

the following:

• There must be at least 1-3/16" (30mm) space between the unit and the packaging.

• Footprint of the skid shall extend at least 2-1/2" (64mm) from the perimeter of the unit.

• The XDK must be attached to the skid using original metal brackets or steel banding.

If steel banding is used to hold unit to the skid, place reinforced protective material between the

banding and the XDK.

• Ensure proper shipping information is affixed to the exterior of the packaging.

Equipment Inspection, Handling And Storage

10

Page 15

5.0 INSTALLATION AND COMMISSIONING

5.1 Preparation for Installation

CAUTION

!

Risk of improper installation. Can cause equipment damage.

Before installing the unit, a number of points must be checked for safety and to ensure the

correct function of the server cabinet. Take care when performing these checks to ensure that

the unit functions correctly.

CAUTION

!

Risk of improper installation. Can cause equipment damage.

The XDK must be installed on a level surface. For this reason, check the horizontal alignment

with a spirit level prior to starting installation. The floor must be able to support a rack load

of 307 lb/ft² (1500 kg/m²) (with installed equipment per XDK).

To achieve good air circulation, ensure that there is no packaging material or other equipment that

could hinder or prevent air circulation in the area of the equipment, in the area of the heat exchanger,

in the air inlet or in the air outlet.

5.2 Positioning the XDK

Installation and Commissioning

After positioning, the XDK’s feet must be adjusted to make the cabinet vertical. When positioned the

doors must close easily.

5.2.1 Remove Recirculation Air Duct Transport Lock

The Liebert XDK is shipped without the gas pressure springs for the front and rear automatic door

openers installed. The springs should be installed according to separate instructions before the Liebert XDK is connected and turned on.

After positioning, remove the transport lock screws at the sides of the recirculation air duct (see

Figure 5).

The recirculation air duct may be pulled out to remove items that fall into the heat exchanger tray.

Figure 5 Remove the transport lock screws

Remove both screws

11

Page 16

5.3 Water Connection

The heat exchanger can be pulled out for servicing

Water pipes should be connected so that the heat exchanger can be pulled out when the connection is

undone. If the heat exchanger is connected to the water circuit using threaded fittings, the pipe fitting

must be supported on tightening.

Before commissioning the server cabinet, the pipe connections should be checked for leaks according

to local codes.

5.3.1 Preparing Heat Exchanger for Initial Commissioning

Check the mechanical installation and the supply pipe connection.

Figure 6 Heat exchanger access

Remove this air duct

for bleeding, draining the

heat exchanger and

checking the valve

Installation and Commissioning

1. Carefully bleed heat exchanger when filling the system.

2. Open the air bleed valve until the water coming out has no bubbles.

3. Close this valve after bleeding.

Figure 7 Control valve

Water return

Water supply

4. If necessary, retighten threaded fittings.

5. After an extended period without use, and particularly in case of risk of freezing temperatures,

the heat exchanger and the supply pipe must be drained of all fluid.

6. Drain completely by blowing out with compressed air and remove all bleed and drain plugs.

Air bleed valve

Drain valve

12

Page 17

Figure 8 Heat exchanger

(850mm)

33-7/16"

27-3/8"

(695mm)

2"

(50mm)

Top View

Installation and Commissioning

Space

for

Cabling

9- 7/ 8"

(150mm)

2"

(50mm)

Figure 9 Heat exchanger connection

Water return

Water supply

Liebert recommends insulating the cold water pipes with waterproof insulation to prevent condensation and losses.

13

Page 18

Figure 10 Bottom plate with cutouts

Installation and Commissioning

Network

Cable

Entry

Condensed

Water Cutouts

Front

Cable and pipe openings must be sealed air-tight on completion of work.

5.4 Condensed Water Connection

If the XDK is operated below dew point, condensed water may occur. As standard there is a water connection, 5/8" diameter, in the condensed water tray for drainage.

Sealed Cable Cutout

Rear

Cutout for

Water Pipes

Preparations for Connecting

Step 1):

Remove

the air

duct

Step 2):

Remove

the cap

Condensate

connection

Step 3.)

Connect the

nipple with a drain

hose 5/8"

Step 4.)

Move and snap the

nipple with hose

into the hole

When connecting to the condensate tray, ensure that the condensed water pipe is connected to a selffilling siphon with return protection and that the condensate drain is properly sloped.

The height of the siphon must be designed for an underpressure or overpressure of 0.11psi (800 Pa) so

that air is not drawn into or blown out of the waste pipe.

14

Page 19

The condensate drain is not pressurized; a condensate pump can be used.

5.5 Electrical Connection

The wiring diagram is enclosed in the unit.

WARNING

!

Risk of electric shock. Can cause injury or death.

Disconnect all local and remote electric power supplies before working within. Prior to

beginning installation, shut down the server cabinet, disconnect it and secure it against

unauthorized startup.

As soon as all preparations for installation have been made, you can start electrical installation.

WARNING

!

Risk of electric shock. Can cause injury or death.

Disconnect all local and remote electric power supplies before working within.

The XDK unit must be connected by a licensed and qualified electrician only. Ensure that the

server cabinet is electrically isolated for the duration of the connection operation and is

secured against unauthorized startup

Check whether voltage and frequency at installation site as well as fuse ratings match the specifications on the rating plate.

Installation and Commissioning

To connect the unit to the power supply:

1. Shut down the server cabinet.

2. See the wiring diagram for information on the connections to be made.

3. Connect the supply cable in the computer room.

4. Check the secure connection of the earth wire.

To return the server cabinet to operation, switch on the fuse-protected power supply.

NOTE

The unit's fans will rotate clockwise.

5.6 Sealing the Cabinet

To ensure the optimal cooling function the cabinet must be sealed:

• Pipe entrances should be cut into the foam and properly closed with a extra foam if required.

• Cable entrances should be closed with the pivoting plate and foamed material.

• Air flows on the warm and cold sides of the cabinet must be separated from each other.

15

Page 20

6.0 SERVICING AND MAINTENANCE

WARNING

!

Risk of high speed rotating fan blades. Can cause serious injury.

Disconnect all local and remote electric powers supplies and assure that fan blades have

stopped rotating before working within the unit.

WARNING

!

Risk of electric shock. Can cause injury or death.

Disconnect all local and remote electric power supplies before working within the unit.

CAUTION

!

Risk of explosive discharge of water under pressure. Can cause injury or equipment damage.

Shut off the water supply and relieve pressure before working with piping.

NOTE

Service and maintenance work must be performed only by properly trained personnel and in

accordance with applicable regulations as well as with manufacturers’ specifications.

NOTE

Use only original spare parts that have been tested and approved by the manufacturer. If

necessary, request a comprehensive spare parts list from the manufacturer. For cleaning, use

commercially available cleaning agents only. Follow the stipulated safety measures and do not

use any tools that may cause scratching or tools for scraping (surfaces will be irreversibly

damaged).

Servicing and Maintenance

6.1 General Inspection on Fans—Annual

• Check for unusual bearing noises. (Check for excessive bearing play.)

6.1.1 Fan Replacement

The expected service life is approximately 40,000 operating hours at a temperature of 40°C (104°F).

1. Remove the housing cover from the unit (with earth cable).

2. Determine which fan has failed.

3. Check the surface temperature of the fan and switch off the circuit breaker.

4. Disconnect supply cable at the fan terminal block.

5. Loosen the four fastening nuts for the fan to be replaced.

6. Remove the failed fan.

Figure 11 Replacing a fan

Step 3:

Disconnect

supply cable

at the fan

terminal

block

One of four

fastening nuts

Step 4: Undo

the four

fastening

nuts

Slot to

insert

wrench to

remove

nut

16

Page 21

Reinstall the fan by reversing the steps to remove the fan.

1. Tighten the fan fastening bolts.

2. Connect the power supply cable to the fan.

WARNING

!

Risk of electric shock. Can cause injury or death.

Reconnect the earth ground cable to the sheet metal panel to prevent a potentially hazardous

open circuit in case of loose or disconnected electrical wiring or a fan motor short circuit.

3. Switch on the circuit breaker.

4. Dispose of the old fans correctly.

6.2 Inspect the Heat Exchanger—Annual

The efficiency of heat exchangers is sharply reduced by dirt and debris; retaining high efficiency

requires regular cleaning. Use a vacuum cleaner, compressed air or a soft brush to clean the fins.

Do not bend the fins during cleaning—this will interfere with proper air flow through the unit.

• Check heat exchanger on air side for soiling, damage and corrosion.

• Check feed and return for correct function.

• If necessary clean the air side.

• Regularly check odor trap (external) for correct function.

• Heat exchanger can be pulled out for improved cleaning.

• Regularly visually inspect the water circuit for leaks.

Servicing and Maintenance

17

Page 22

6.3 Replacing the Heat Exchanger

Figure 12 Heat exchanger replacement

Step 1: Lift the air

duct off the flange

to remove it.

Step 4: Remove screws

Servicing and Maintenance

Step 5: Pull

out the heat

exchanger

Step 3:

Remove condensate

connection

Reinstall the heat exchanger by reversing the reverse order of removal.

NOTE

Regularly check the condensed water drain and clean if necessary

18

Step 2:

Remove

the grounding

cable

Page 23

7.0 DISMANTLING AND DISPOSAL

The XDK may be dismantled by qualified personnel only.

WARNING

!

Risk of electric shock. Can cause injury or death.

Disconnect all local and remote electric power supplies before working within the unit.

Disconnect the unit from the external water circuit by closing the shutoff valves and drain the unit’s

water circuit.

Transport the unit as described in 4.0 - equipment Inspection, Handling And Storage, using a

lifting device with sufficient load-bearing capacity.

Dispose of the air conditioner in accordance with the locally applicable disposal and safety instructions. Liebert recommends using a specialist recycling organization.

All parts can be stripped down and consist of:

• aluminium, steel, brass, copper

• labelled plastic parts

• electronic parts

Dismantling and Disposal

19

Page 24

8.0 WATER PURITY REQUIREMENTS

To ensure the maximum service life of the air/water heat exchangers, water must comply with the

VGB water regulations (VGB-R 455 P). The water used must be soft enough to prevent deposits, but it

must not be so soft that heat exchanger corrosion occurs.

The following table contains the most important impurities and methods for removing them.

Table 4 Prevalent impurities and removal methods

Water Impurity Method of Removal

Mechanical pre-treatment (dp < 1 mm) Filtering the water

Excessive hardness Soften the water using ion exchange

Moderate content of mechanical impurities and hardness formers Addition of dispersing or stabilizing agents

Moderate content of chemical impurities Addition of passivation agents and inhibitors

Biological impurities (bacteria and algae) Addition of biocides

It is recommended to achieve the following hydrological data as far as possible:

Table 5 Suggested hydrologic levels

Hydrological Data Suggested

pH values 7 - 8.5

Carbonate hardness >3 <8 °dH

Free carbon dioxide 8 - 15 mg/dm

Bound carbon dioxide 8 - 15 mg/dm

Aggressive carbon dioxide 0 mg/dm

Sulfides < 10 mg/dm

Oxygen < 50 mg/dm

Chloride ions < 250 mg/dm

Sulfate ions < 10 mg/dm

Nitrates and nitrides < 7 mg/dm

CSB < 5 mg/dm

Ammonia < 5 mg/dm

Iron < 0.2 mg/dm

Manganese < 0.2 mg/dm

Conductivity < 2200 μS/cm

Solid evaporation residue < 500 mg/dm

Potassium permanganate consumption < 25 mg/dm

Suspended matter < 3 mg/dm

(Partial flow cleaning is recommended) > 3 < 15 mg/dm

(Continuous cleaning) > 15 mg/dm

Water Purity Requirements

Units

Amount

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

20

Page 25

8.1 Unit Installation Checklist

___ 1. Check unit for damage on delivery

___ 2. Check for level floor

___ 3. Check maximum floor load

___ 4. XDK feet adjusted, if applicable

___ 5. XDK is level

___ 6. No remains of packaging in the XDK

___ 7. All installation tools removed

___ 8. Cable entries into the unit correct and air-tight

___ 9. Cable connections checked

___ 10. Cold water connection does not leak

___ 11. Pressure test performed

___ 12. Water circuit bled

___ 13. Water flow rate adjusted

___ 14. Condensed water pipe clear

___ 15. Water system odor trap in order

___ 16. Heat exchanger tray connected to condensed water pipe

___ 17. Fan function checked

___ 18. All front panels closed (separation of air flows)

Water Purity Requirements

Comments

Signature Date

Checker

21

Page 26

8.2 Commissioning Certificate

Table 6 XDK – Commissioning certificate

General Data

Client/Setup Site

Client Name

Client Address

Contact Persons

Phone Number

Setup Site / Room Number

Water Purity Requirements

Table 7 Nominal values at setup site

Air Humidity

at Setup Site % Relative Humidity

Ambient

Temperature °C (°F)

Nominal Values

at Setup Site

Temperature

°F (°C)

Maximum Relative

Humidity %

50

(10)59(15)64(18)66(19)68(20)70(21)72(2273(2375(2477(2579(2681(2782(2886(3095(35

100 76 62 58 55 52 48 46 43 40 38 36 34 30 23

Nominal values kept

___ 1. Yes

___ 2. No

22

Page 27

Configuration

Table 8 Type of cabinet

XDK 17kW

Cabinet Number

Serial Number

Date Shipped

Fan

Type

Table 9 Control of status

General Condition

Load Carrying Capacity Checked Yes No

Level Alignment Checked Yes No

Transportation Damages of Cabinet Yes No

Comments

Water Purity Requirements

Damages on Heat Exchanger/Connections Yes No

Front Door Closing Easily Yes No

Comments:

Rear Door Closing Easily Yes No

Comments:

Cable Entries Closed Yes No

Comments

Condensate Drain Open / Connected Yes No

Comments

Trap Filled Up Yes No

Packaging Removed Yes No

Installation Tools Removed Yes No

Air Separation

(Front Panels Closed)

Cable Entries Air Tight Yes No

Yes No

23

Page 28

Water Purity Requirements

Table 10 Cold water facility on site

Cold Water

XDK Connected To

Water Temperature Feed °C/°F Return

Water Pressure Feed PSI (Pa) Return PSI (Pa)

Water Differential Pressure Pa

Table 11 Electrical data / documents

Wiring Scheme Attached Yes No

Comments

Cable Connections Checked: Yes No

Electrical Acceptance Certificate

by Approved Staff

Comments

Yes No

.

Table 12 Function check

Function of All Fans

(Air Blowing Direction)

Fans Shut Down When Rear Door

is Opened

Comments

Function Three Way Valve Yes No

Comments

Door Opens When ____ °F (°C) is

Reached

Comments

Yes No

Yes No

Yes No

24

Page 29

Table 12 Function check (continued)

Malfunction Indicator Function Yes No

Comments

Water Purity Requirements

Condensate Occurrence at Heat

Exchanger

Comments

Pressure Test Water Circuit Yes

Water Flow Rate Adjusted Yes No

Flow Rate

(Possible Only Externally)

Water Feed °F (°C)

Water Return °F (°C)

Air Temperature in the Cabinet

At The Heat Exchanger Inlet °F (°C)

Air Temperature in the Cabinet

At the Heat Exchanger Outlet °F (°C)

Yes No

GPM

Commissioning performed by day to day operating.

Correctness of function check protocol certified by:

Approved Staff Date Signature

Client Date Signature

25

Page 30

Water Purity Requirements

26

Page 31

Page 32

Ensuring The High Availability

0f Mission-Critical Data And Applications.

Emerson Network Power, the global leader in enabling business-critical

continuity, ensures network resiliency and adaptability through

a family of technologies—including Liebert power and cooling

technologies—that protect and support business-critical systems.

Liebert solutions employ an adaptive architecture that responds

to changes in criticality, density and capacity. Enterprises benefit

from greater IT system availability, operational flexibility and

reduced capital equipment and operating costs.

While every precaution has been taken to ensure the accuracy

and completeness of this literature, Liebert Corporation assumes no

responsibility and disclaims all liability for damages resulting from use of

this information or for any errors or omissions.

© 2007 Liebert Corporation

All rights reserved throughout the world. Specifications subject to change

without notice.

® Liebert and the Liebert logo are registered trademarks of Liebert

Corporation. All names referred to are trademarks

or registered trademarks of their respective owners.

Technical Support / Service

Web Site

www.liebert.com

Monitoring

800-222-5877

monitoring@emersonnetworkpower.com

Outside the US: 614-841-6755

Single-Phase UPS

800-222-5877

upstech@emersonnetworkpower.com

Outside the US: 614-841-6755

Three-Phase UPS

800-543-2378

powertech@emersonnetworkpower.com

Environmental Systems

800-543-2778

Outside the United States

614-888-0246

Locations

United States

1050 Dearborn Drive

P.O. Box 29186

Columbus, OH 43229

Europe

Via Leonardo Da Vinci 8

Zona Industriale Tognana

35028 Piove Di Sacco (PD) Italy

+39 049 9719 111

Fax: +39 049 5841 257

Asia

7/F, Dah Sing Financial Centre

108 Gloucester Road, Wanchai

Hong Kong

852 2572220

Fax: 852 28029250

SL-16681_REV0_04-07

Emerson Network Power.

The global leader in enabling Business-Critical Continuity.

AC Power

Connectivity

DC Power

Business-Critical Continuity, Emerson Network Power and the Emerson Network Power logo are trademarks and service marks of Emerson Electric Co.

©2007 Emerson Electric Co.

Embedded Computing

Embedded Power Power Switching & Controls

Monitoring

Outside Plant

Precision Cooling

EmersonNetworkPower.com

Racks & Integrated Cabinets

Services

Surge Protection

Loading...

Loading...