Page 1

Liebert iTRUST UPS System

User Manual

E1-20020516-C-1.0

Liebert Corporation

Page 2

Page 3

Contents

Chapter 1 Introduction .....................................................................................................................1

1.1 Basics.................................................................................................................................1

1.2 Configuration ......................................................................................................................1

1.3 Operation Theory................................................................................................................2

1.4 Structure and Layout ..........................................................................................................3

1.5 Operation Modes................................................................................................................4

1.6 Basic Functions ..................................................................................................................8

1.7 Specifications .....................................................................................................................8

Chapter 2 Cabinet Installation .......................................................................................................13

2.1 Environmental Conditions.................................................................................................13

2.2 Unpacking.........................................................................................................................13

2.3 Dimensions.......................................................................................................................13

2.4 Transportation ..................................................................................................................16

2.5 Positioning of UPS............................................................................................................16

2.6 Cable Access....................................................................................................................18

2.7 Ventilation.........................................................................................................................19

2.8 Layout of Cabinet .............................................................................................................20

Chapter 3 Electrical Assembly.......................................................................................................23

3.1 Selection of cables ...........................................................................................................23

3.1.1 Current carrying capacity of cables ........................................................................23

3.1.2 Selection of power cables.......................................................................................23

3.1.3 Selection of signal cables.......................................................................................24

3.2 Cable connections............................................................................................................24

3.2.1 Power cables..........................................................................................................24

3.2.2 Signal cable............................................................................................................28

3.3 Connection of Single UPS System ...................................................................................35

Chapter 4 Commissioning of UPS.................................................................................................37

4.1 Startup Procedure ............................................................................................................37

4.1.1 Explanation of Circuit Breakers ..............................................................................37

4.1.2 Startup....................................................................................................................37

4.2 Setting the functions.........................................................................................................38

4.3 Functional checks.............................................................................................................40

4.3.1 Check the function of the display panel..................................................................41

4.3.2 Switching between operation mode........................................................................41

Chapter 5 Operation of Display Panel ...........................................................................................43

5.1 Display panel....................................................................................................................43

5.1.1 Layout of Display Panel..........................................................................................43

5.1.2 LED Indication........................................................................................................44

5.1.3 Functional Keys......................................................................................................45

Page 4

5.1.4 Alarm Buzzer..........................................................................................................46

5.1.5 LCD and Menu Keys .............................................................................................. 46

5.2 The displayed information ................................................................................................ 48

5.2.1 Opening display ......................................................................................................48

5.2.2 Main Menu Display.................................................................................................48

5.2.3 UPS Basic Information...........................................................................................48

5.2.4 Menu Keys Display Window...................................................................................49

5.2.5 Information of main menu.......................................................................................50

5.3 Function Setup .................................................................................................................54

5.3.1 Language setup .....................................................................................................54

5.3.2 Address setup ........................................................................................................55

5.3.3 Time setup .............................................................................................................55

5.3.4 Manual battery self-test..........................................................................................58

5.3.5 Contrast adjustment ...............................................................................................59

5.3.6 History log ..............................................................................................................59

5.3.7 background communication setup.......................................................................... 60

5.3.8 Call-back number setup ..........................................................................................61

5.4 Prompt window.................................................................................................................63

5.5 Events and State Information: .......................................................................................... 66

Chapter 6 Maintenance ................................................................................................................. 69

6.1 Setup procedures.............................................................................................................69

6.1.1 Start up...................................................................................................................69

6.1.2 Shutdown ............................................................................................................... 70

6.1.3 Transferring between operation modes..................................................................71

6.1.4 Emergency shutdown and recovery.......................................................................71

6.1.5 Mute .......................................................................................................................72

6.1.6 Fault clear ..............................................................................................................72

6.1.7 Monitoring system..................................................................................................73

6.1.8 Input and output contacts........................................................................................75

6.1.9 Temperature measuring.........................................................................................76

6.2 Maintenance.....................................................................................................................76

6.2.1 Daily maintenance..................................................................................................76

6.2.2 Battery maintenance .............................................................................................. 78

6.2.3 Shutdown maintenance..........................................................................................80

Chapter 7 Troubleshooting............................................................................................................81

7.1 UPS system troubleshooting............................................................................................81

7.1.1 Basics.....................................................................................................................81

7.1.2 Procedures............................................................................................................. 81

7.2 LED indicator....................................................................................................................81

7.2.1 LED display............................................................................................................81

7.2.2 LED indicator of lightning protection device ...........................................................82

7.3 Buzzer alarm ....................................................................................................................82

7.4 LCD indication for fault information .................................................................................. 83

Page 5

Chapter 8 Parallel System.............................................................................................................87

8.1 System Introduction..........................................................................................................87

8.1.1 Basics.....................................................................................................................87

8.1.2 Theory of Operation...............................................................................................88

8.1.3 Operation modes....................................................................................................90

8.2 Installation ........................................................................................................................91

8.2.1 Cabinet installation .................................................................................................91

8.2.2 Electrical installation...............................................................................................92

8.3 External Power Distribution ..............................................................................................93

8.4 Start up of Parallel Operation System ..............................................................................93

8.5 Using the Parallel Operation System ................................................................................94

8.5.1 Switch on the Parallel System................................................................................94

8.5.2 Shutdown the Parallel Operation System...............................................................95

8.5.3 Transferring between Operation Modes .................................................................96

8.5.4 Repairing the failed UPS unit in parallel operation system .....................................97

8.5.5 Emergency shutdown.............................................................................................98

8.5.6 Fault and Fault Process Methods...........................................................................99

Chapter 9 Optional Parts .............................................................................................................101

9.1 Battery ............................................................................................................................101

9.1.1 Capacity selection ................................................................................................101

9.2 Battery cabinet................................................................................................................102

9.2.1 External Dimensions.............................................................................................102

9.2.2 Installation of battery cabinet................................................................................103

9.2.3 Wiring of the batteries...........................................................................................103

9.3 SNMP Card and the Software ........................................................................................106

9.3.1 Product structure and ports ..................................................................................106

9.3.2 Technical features ................................................................................................106

9.4 Network Software ...........................................................................................................107

9.5 MODEM..........................................................................................................................107

9.6 Temperature sensor TMP12Z.........................................................................................108

9.7 Level C Lightning Protection System SPD24Z...............................................................108

9.7.1 Introduction of SPD24Z ........................................................................................109

9.7.2 Installation procedures of SPD24Z.......................................................................109

9.7.3 Using and Maintenance.........................................................................................111

9.8 Bypass Isolation Transformer.........................................................................................111

Chapter 10 Service after Sales....................................................................................................112

10.1 Abnormal Fault Handling..............................................................................................112

10.2 Technical support ............................................................. Error! Bookmark not defined.

10.3 Warranty.......................................................................................................................115

Page 6

Page 7

1.1 Basics

The Liebert iTrust UPS System is connected between the utility source and the

critical load to provide uninterruptible power to the load. The power from the UPS

being free of voltage and frequency variation and disturbances from utility. The UPS

has an output isolation transformer to provide galvanic isolation between the load

and utility. The UPS also uses the latest in high frequency double conversion

PWM technology and a fully digital control.

It also has advanced network management functions.

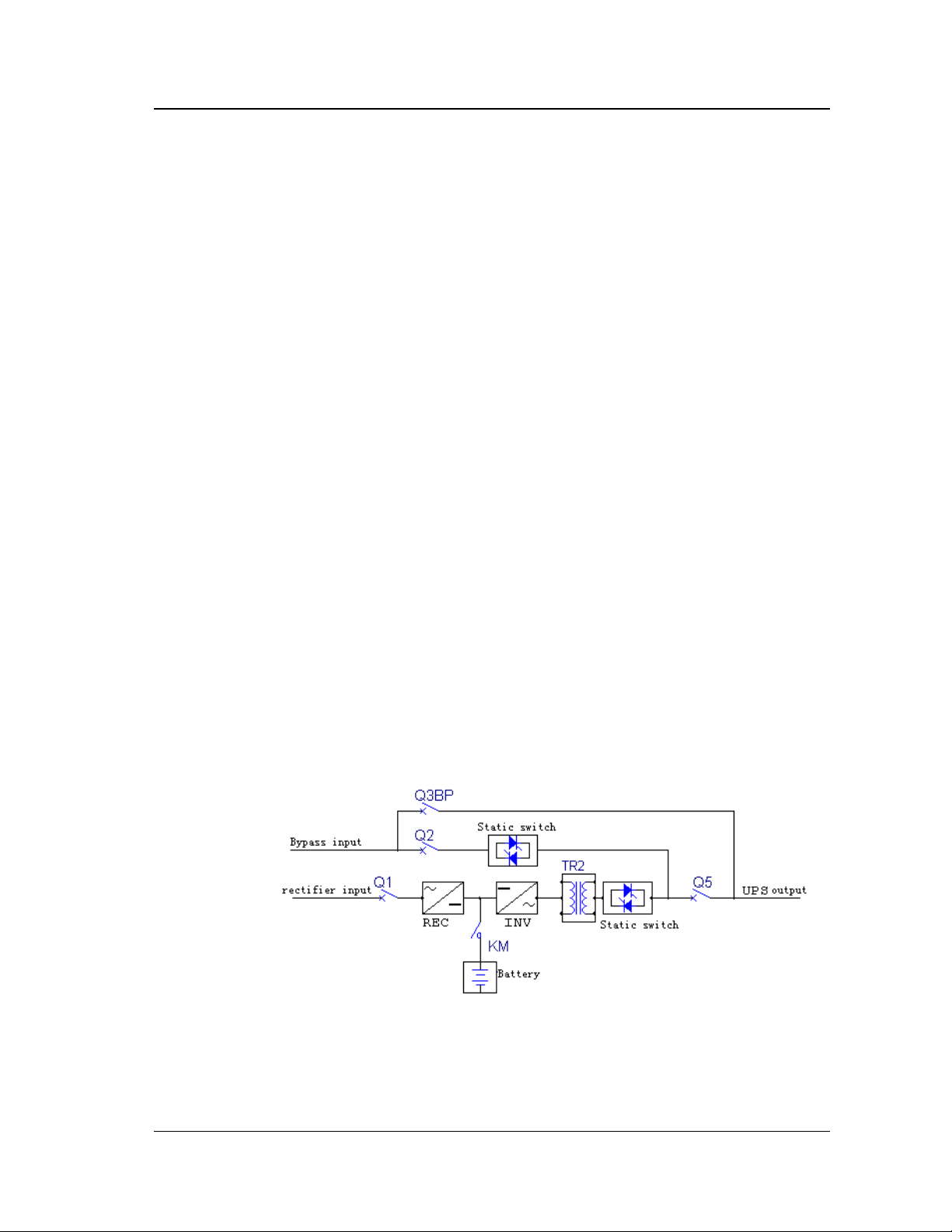

1.2 Configuration

The UPS consists of the following modules : rectifier, inverter, static bypass,

maintenance bypass, output isolation transformer, inverter static switch, battery and

input and output circuit breakers.

Chapter 1 Introduction

Chapter 1 Introduction

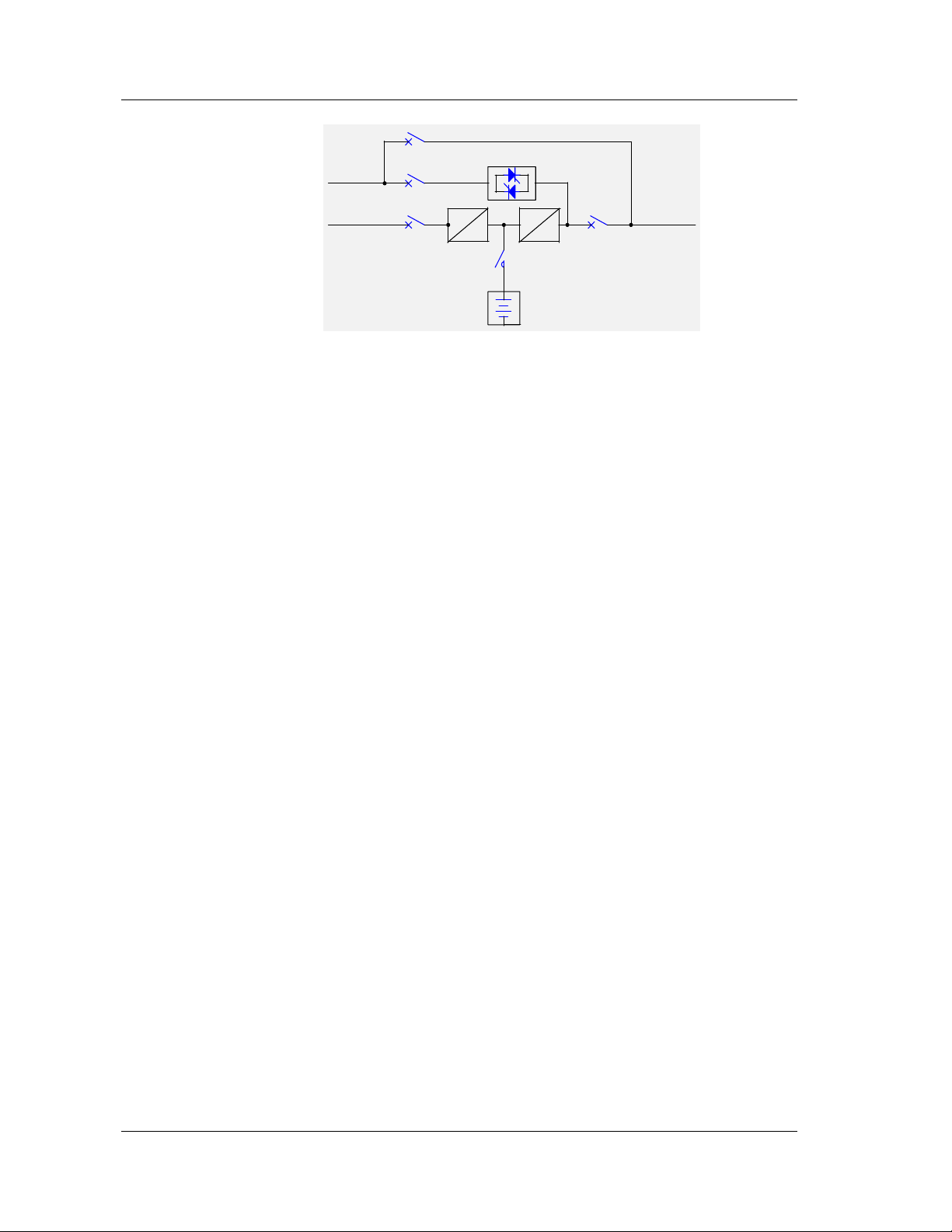

As shown in Figure 1-1, the AC utility source is input at Q1 and the rectifier

converts the AC Utility into DC source. The Inverter will convert the DC source or

the DC source from the batteries into AC source that is output from the isolation

transformer. The battery will power the load through the inverter in case of a power

failure. The utility source can also power the load through the static bypass.

Besides this, if maintenance or repair of the UPS is necessary, the UPS can

support the load through the maintenance bypass without interrupting the load.

Figure 1-1 Theory of UPS

1

Page 8

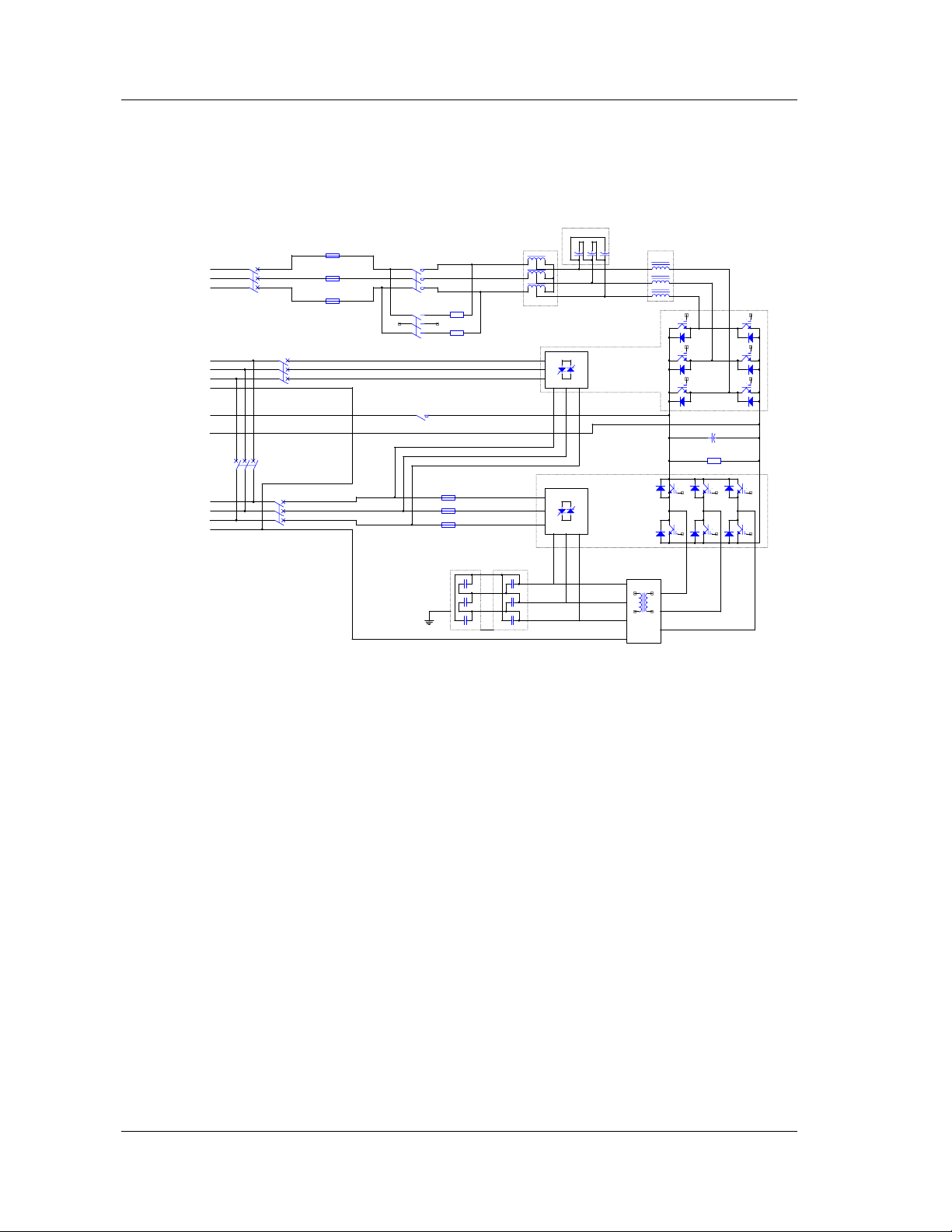

1.3 Operation Theory

The UPS circuit diagram is shown in Figure 1-2.

A1

B1

C1

A2

B1

C1

N2

BP

BN

U

V

W

N

Q1

Q2

Q3BP

Q5

FU1

FU2

FU3

Chapter 1 Introduction

KM1

KA1

Res1

Res2

KM2

FU4

FU5

FU6

AC2

TR1

L1

DC1

+

Res3

AC4

AC3

TR2

DZN6

Figure 1-2 Main circuit of UPS

The utility source is input at Q1 and flows through the fuse, the transformer,

inductor and into the high frequency rectifier which will convert the AC power into

DC power. The rectifier has PFC and charger function and make use of soft start

and DSP digital technology to improve the system immunity against surge, improve

the stability of the DC bus voltage, reduce the charging current ripple and prolongs

the battery life.

The battery is connected to the UPS through contactor. If the DC bus voltage drop

through certain threshold, then the contactor will activate to connect the battery to

the DC bus. The battery will supply the DC power to the inverter through a filtering

circuit.

The inverter uses digital vector control technology based on DSP to modulate six

IGBTs through SVPWM and invert DC power to AC three phase power.

The output is isolated from the load by Delta/Zig-Zag transformer, static switch,

fuse and circuit breakers.

The bypass source is input at Q2 and output through the bypass static switch.

2

Page 9

The double DSP and MCU form the full digital control system to realize the powerful

function of the UPS. The switching between the operation modes is realized by

controlling the bypass static switch and the inverter static switch. Advanced battery

management prolongs battery life.

Multi-communication ports and management software make it possible for the

customer to monitor the UPS performance locally or remotely. The Liebert UPS

uses full digital, discrete and on-line parallel operation technology. In parallel

operation, several UPS units input parallel logic signals and cross current detection

signals through parallel operation boards to enable a maximum of four UPS units to

operate in parallel. (N+X) redundancy parallel operation, capacity expansion and

hot-standby configuration can be realized. If an additional UPS is required to be

added to the system, no auxiliary equipment is required and power to the load

need not be interrupted.

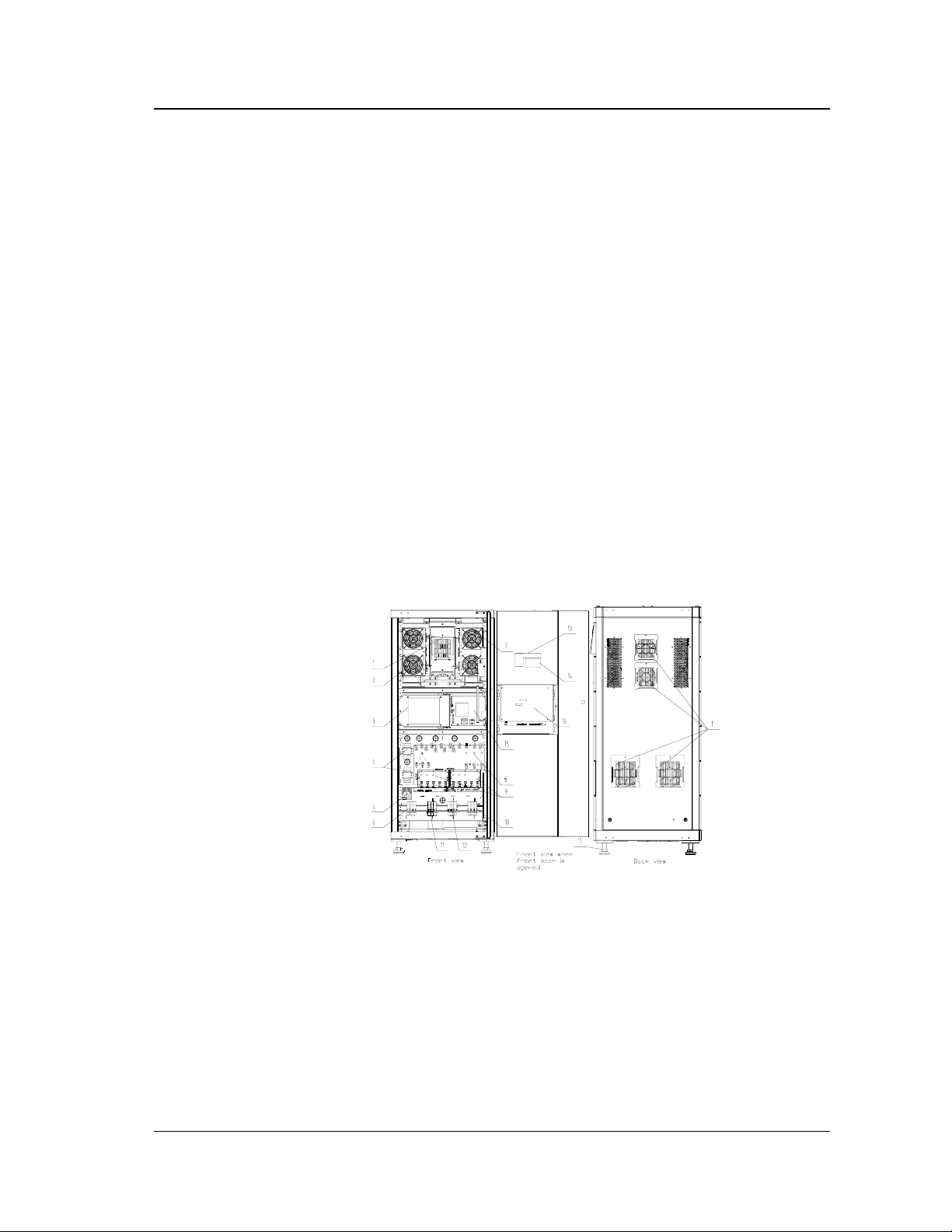

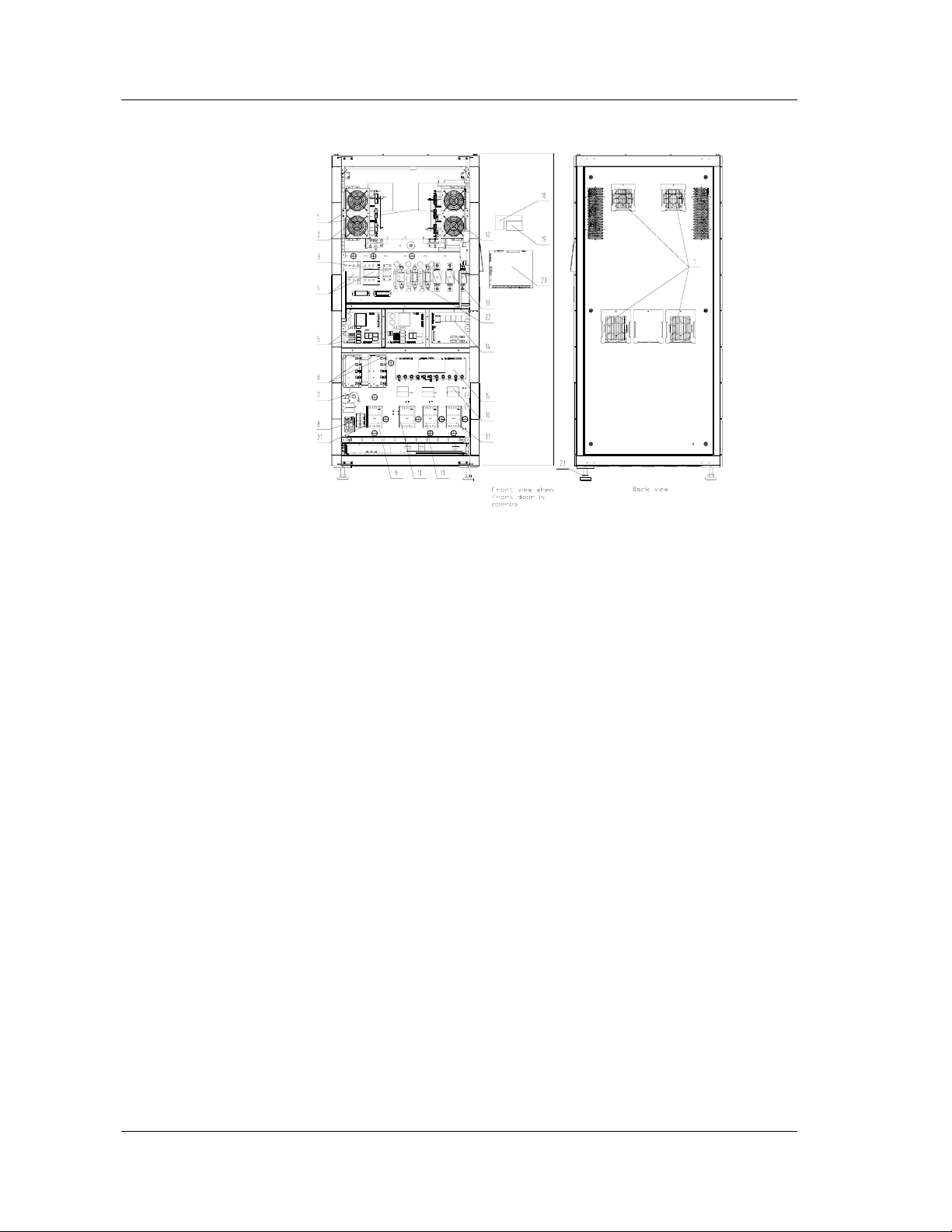

1.4 Structure and Layout

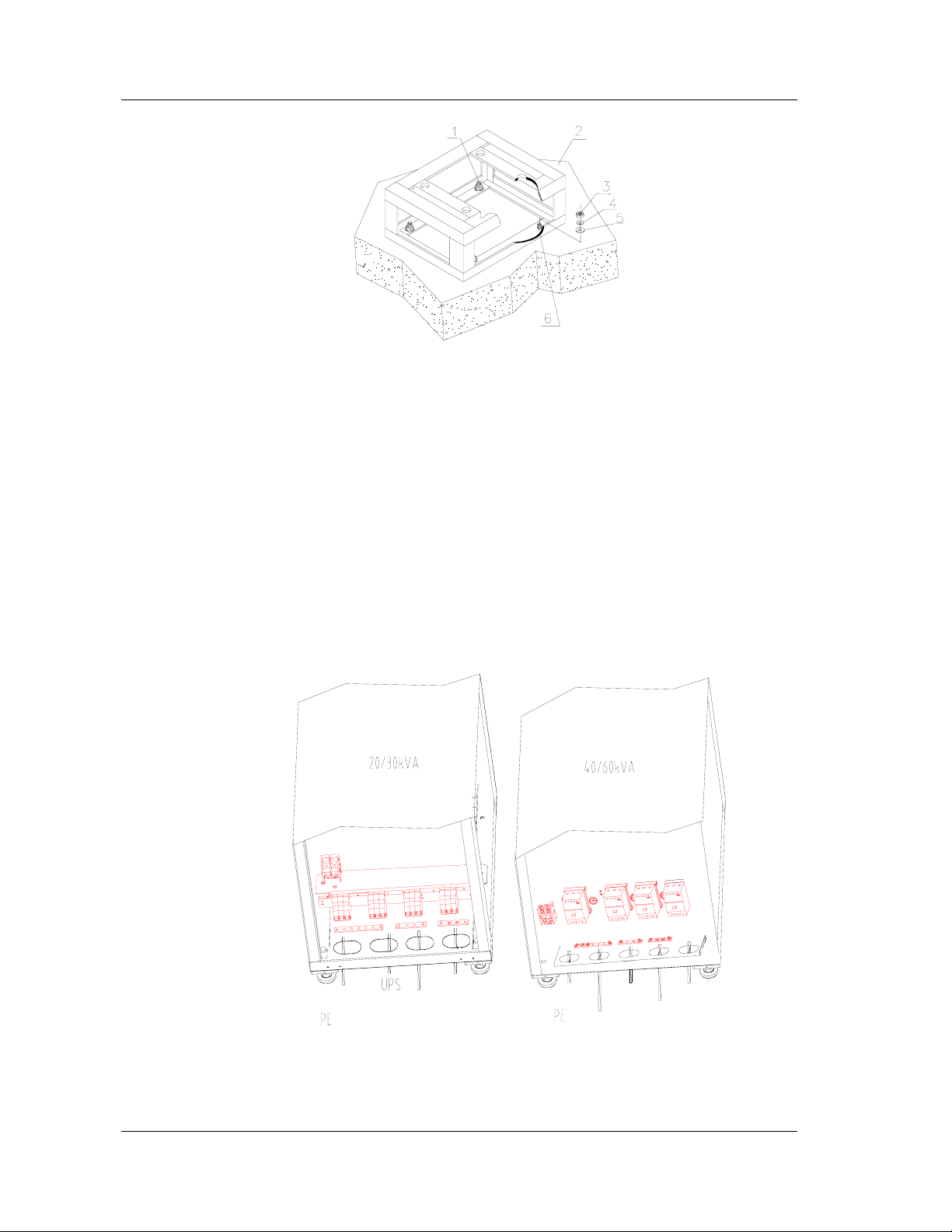

The structure and layout of the system is shown on Figures 1-3 and 1-4. The

system consists of the rectifier, inverter, auxiliary power supply, input and output

power distribution, monitoring system, parallel control system, lightning protection

unit, EMI filter, fan and input and output isolation filters.

Chapter 1 Introduction

1:Fan 2:rectifier 3:two auxiliary power supply boards ULW2L61M5

4:contactor 5:battery input terminals 6:circuit breaker Q3BP for maintenance

7:Inverter 8:Power distribution board ULK2L61R1

9:D level lightning protection device SPD12Z

10: Output circuit breaker Q5 11:rectifier input circuit breaker Q1

12:bypass input circuit breaker Q2 13:operation keypad board ULW2L61K1

14:LCD 15:parallel board ULW2L61M3

16:monitoring board ULW2L61U2 17:4 leveling feet (M20)

Figure 1-3 Components of 20/30kVA UPS

3

Page 10

Chapter 1 Introduction

Front view

1:Fan 2:rectifier 3: softstart relays 4:contactor

5: two auxiliary power supply boards ULW2L61M5

6: D level lightning protection device SPD12Z 7: Hall current sensor

8:battery input terminals 9:circuit breaker Q3BP for maintenance

10:rectifier input circuit breaker Q1 11:bypass input circuit breaker Q2

12:Inverter 13: fast fuse

14: parallel board ULW2L61M3 15: EMI board ULW2L61M4

16: magnetic core 17: output circuit breaker

18:operation keypad board 19: LCD

20: monitoring board ULW2L61U2 21: Battery EMI board

22: Fuse NT100 23: 4 leveling feet (M20)

1.5 Operation Modes

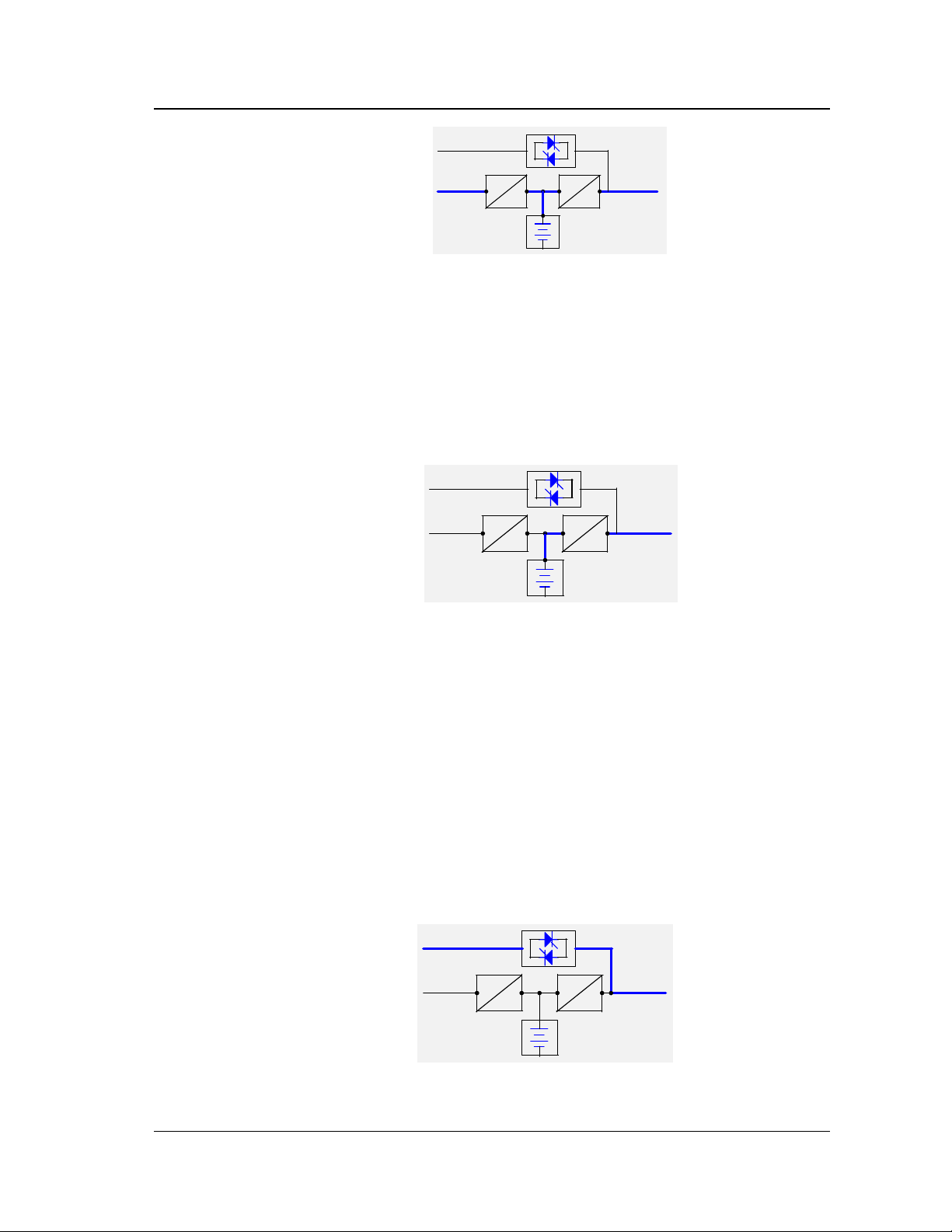

1. Normal mode

When the utility is normal, the UPS powers the load through the rectifier and

inverter and charges the batteries at the same time, as shown in Figure 1-5. This is

called the Normal Mode.

Figure 1-4 Components of 40/60kVA UPS

4

Page 11

Chapter 1 Introduction

-

~

-

output

Bypass

Mains output

2. Battery Mode

When the utility fails, the UPS system will switch to battery mode without

interruption and the battery will power the load through the inverter.

The UPS can return to normal mode automatically when the utility returns to normal,

as shown in Figure 1-6.

Bypass

Mains

~

Figure 1-5 Normal mode

~

-~

Figure 1-6 battery mode

3. Bypass Mode

In the event of an inverter overload which last longer than the typical time, an

output short circuit or a fault on the inverter, the UPS will transfer the load to bypass.

There are two kinds of bypass modes. In the first kind, the UPS can be set to

return to normal mode automatically when the fault is cleared. In the second kind,

the UPS is set to return to normal mode only with a manual transfer.

When the main UPS circuit fails, the battery is depleted or a severe fault occurs,

the inverter will be shut down and the system will remain in the bypass mode. The

system can return to normal mode only with a manual reset after the fault is cleared,

as shown in Figure 1-7.

Bypass

Mains

~-

output

~-

Figure 1-7 bypass mode

5

Page 12

Chapter 1 Introduction

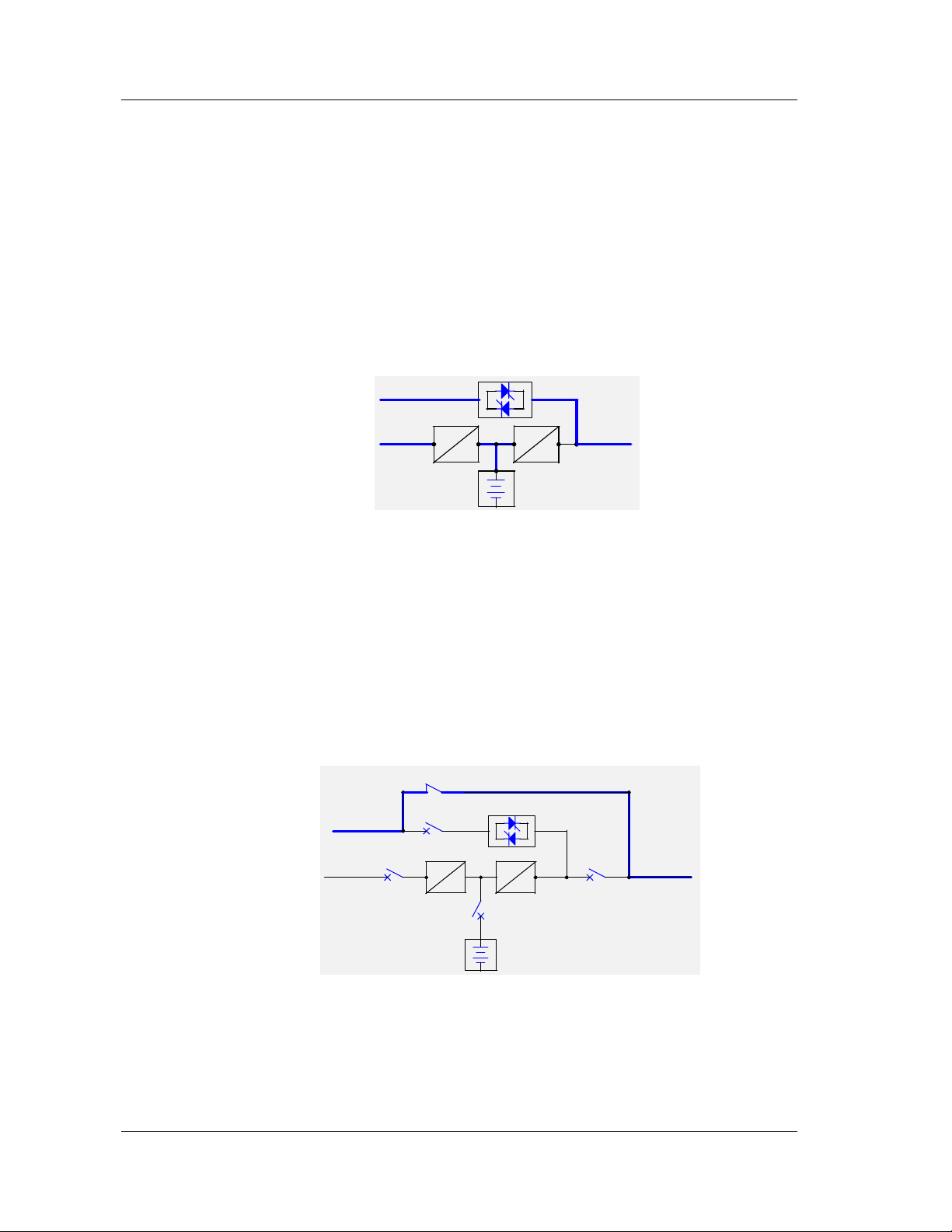

4. ECO Mode

If the load has no requirement for power quality but has a high requirement for

efficiency, then the UPS can be set in ECO mode. In this mode, the system will

power the load through the static bypass switch and the rectifier will charge the

batteries. When the bypass source fails or out of normal range, the UPS will revert

back to normal mode and powers the load through the batteries. The total transfer

time will be less than 15 msecs. When the bypass source recovers back to normal,

the system will return to ECO mode automatically and the system efficiency is

greatly improved, as shown in Figure 1-8. Note that the ECO mode function can

only be set by qualified personnel and applies to single UPS modules only.

-

-~

outputMains

~

Bypass

Figure 1-8 ECO mode

5. Maintenance Mode

When the UPS has to be repaired or has to undergo routine maintenance, the UPS

can be set to maintenance mode by switching on the maintenance bypass circuit

breaker. The load will be powered from the maintenance bypass supply without

interruption.

During maintenance, the circuit breakers Q1, Q2, QF1 and Q5 should be switched

off to ensure the safety of maintenance personnel. See Figure 1-9.

Q3BP

-

-~

QF1

~

Q5

OutputMains

Bypass

Q1

Q2

6

Figure 1-9

Page 13

Chapter 1 Introduction

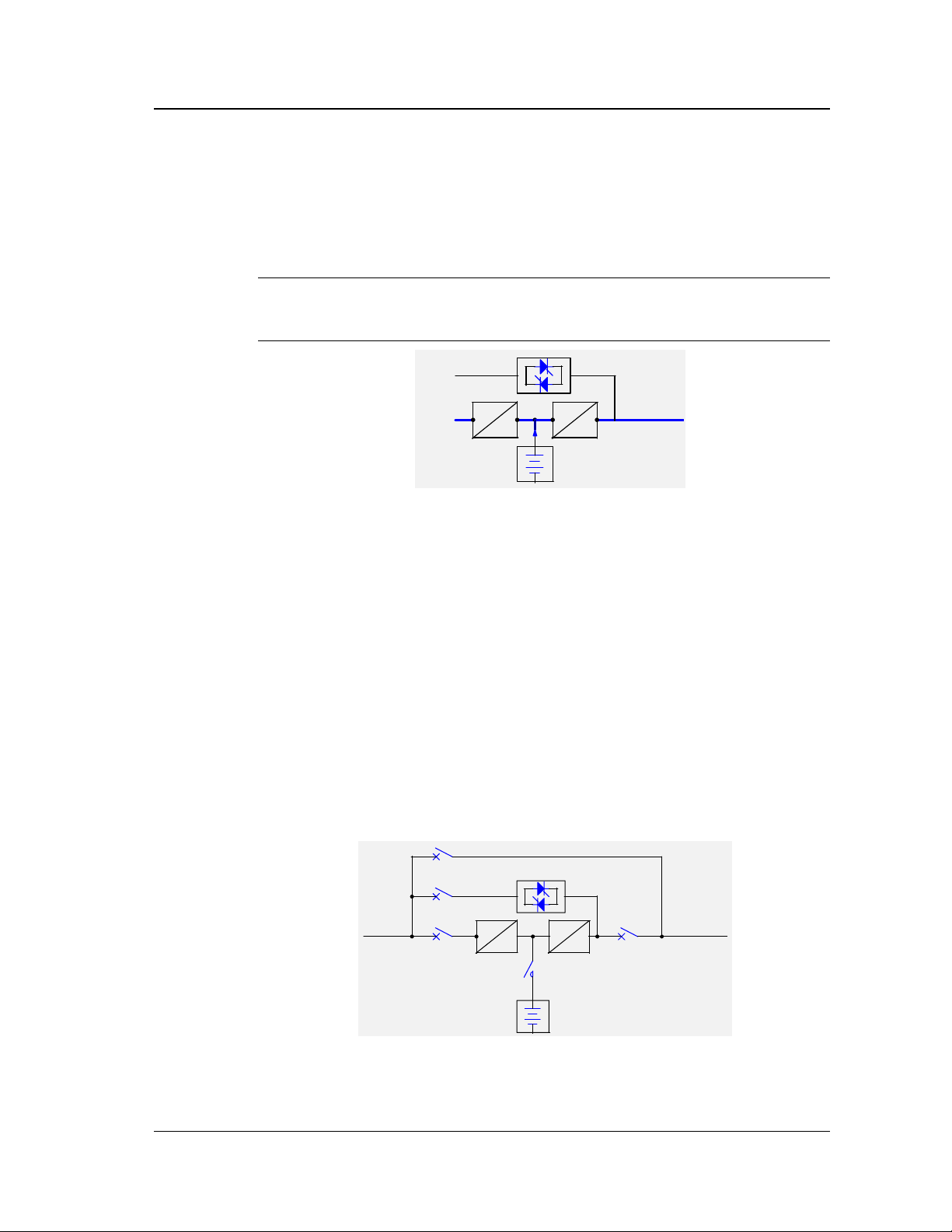

6. United Power Mode

When the utility is not available and the capacity of the generator set is inadequate

to support the load, the battery will power the load together with the generator

automatically. The operating time under this mode should not exceed the autonomy

time of the batteries, as shown in Figure 1-10

Note :

This mode can only be set by qualified personnel only.

-

-

outputMains

~

Bypass

~

Figure 1-10

7. Parallel Operation mode

When several UPS units (maximum four units) are in parallel operation mode, they

will share the load automatically amongst themselves. If one unit fails, this unit will

be shut down automatically and the remaining units will share the load equally. If

overload occurs, the UPS will transfer to bypass operation mode. Parallel operation

mode also has normal mode, battery mode, bypass mode, maintenance mode and

united power mode.

8. Dual Input Mode

The main circuit and the bypass can use the same or different sources. The input

methods are shown in Figure 1-11 and Figure 1-12.

7

-

Fig 1-11

~

Mains output

~

Page 14

Bypass

Mains

Chapter 1 Introduction

~

-~

-

output

1.6 Basic Functions

Battery Management Function - The UPS has advanced battery management

functions including battery fault detection and backup time forecast.

Soft Start Function - Complete delay soft start function can reduce the surge to the

UPS unit and utility source.

Alarm and Protection Function - The UPS can generator audible and visual alarm

through LCD, input/output contacts and network transmission. It can help

maintenance personnel to locate and clear the faults that are sent out in time,

accurately and in detail.

Dark Start Function - When the utility is unavailable, the UPS can start from battery

that is connected to the DC Bus.

Automatic Re-start when Utility returns - This function only applies to the UPS that

has batteries. The UPS shuts down due to low battery, and restart automatically

when the utility returns. At this time , its operation mode is the one before the utility

fails.

Fig 1-12

Monitoring Functions - The UPS monitoring system has an advanced monitoring

function and parallel control functions. It supports flexible network monitoring to

satisfy different customer requirements.

1.7 Specifications

1. Functional Parameters

8

Page 15

Chapter 1 Introduction

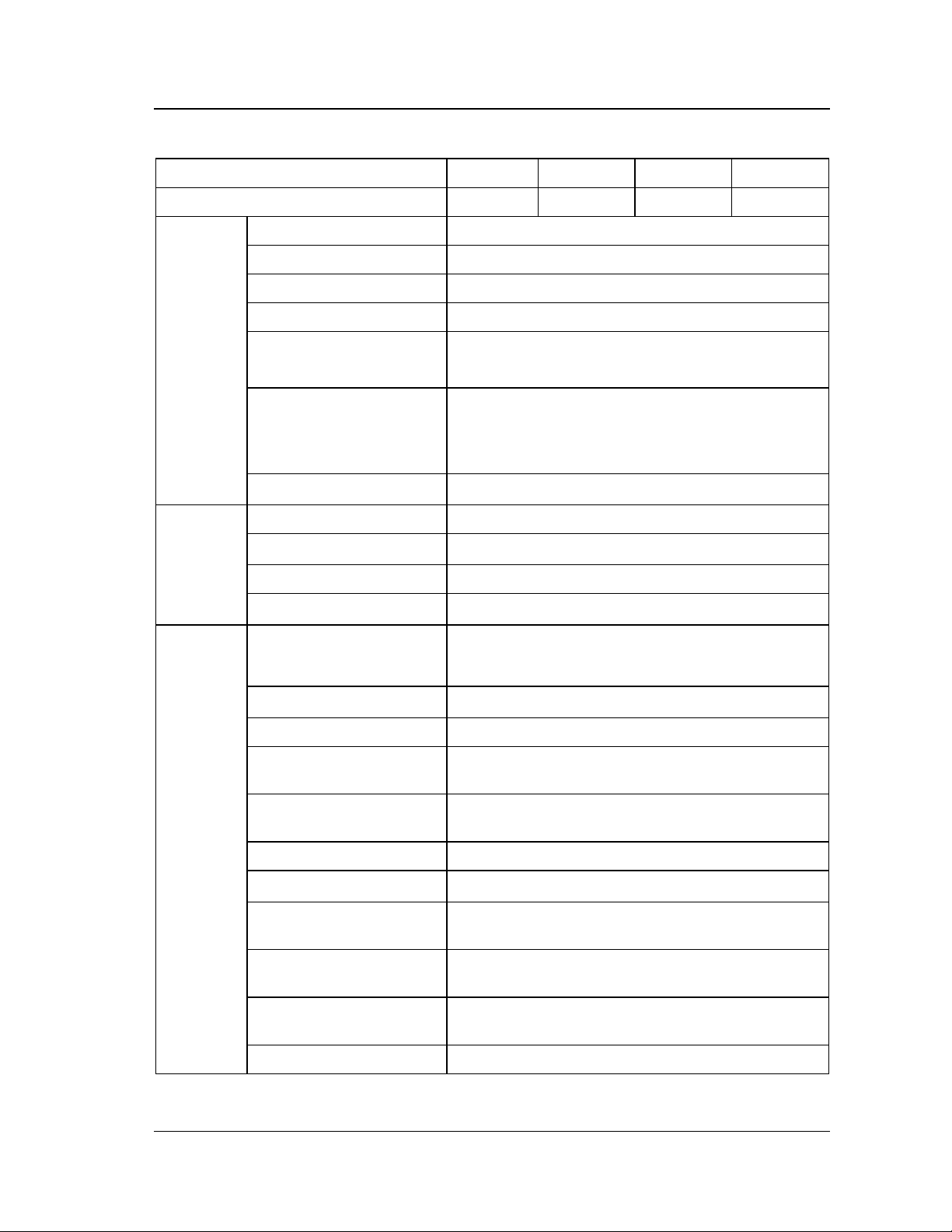

Parameters of Liebert iTrust UPS are given in Table1-1

Capacity 20kVA 30kVA 40kVA 60kVA

Model UL33-0200L UL33-0300L UL33-0400L UL33-0600L

Input Voltage 380/400/415V(line-to-line voltage)

AC Power Input Three-phase three-wire

Power Factor >0.99

Harmonic Current <4%(Voltage distortion lower than 2% at rated load)

Rectifier

input

Bypass input

Voltage Range

Input current limiting

frequency range

Input Voltage 380/400/415V(line-to-line voltage)

Input Voltage Range

AC Power Input Three-phase four-wire

Frequency range

Voltage regulation

(balanced load)

Voltage transient response

Transient recovery time <60ms

Voltage distortion(linear load)

+15%~-20%

Lowest operating voltage: -45%

Input Current: <115%In for continuous operation; 115~140%In

for 5 minutes; 140~165%In for 1minute; Current limiting at

current over 165%In(In is the rated output current without

deration)

50Hz ±10%

10%

±

50Hz±10%

380/400/415V±1%

(±5% adjustable)

5%(0~100%linear load)

±

THD<2%(line-to-neutral voltage)(battery float charge state,

rated balance load)

Output

Voltage distortion(nonlinear

load)

Power Factor 0.8(lagged)

Frequency Syn. Range

Frequency regulation(Battery

mode)

Phase Displacement (ThreePhase)

Voltage unbalance rate at

100% unbalance load

Frequency slew rate <1Hz/s

THD<5%(line-to-neutral voltage)(battery float charge state,

rated balance load)

50Hz±2Hz

0.1%

±

120± 1°(balanced load or unbalanced load)

2%(battery float charge state)

±

9

Page 16

Chapter 1 Introduction

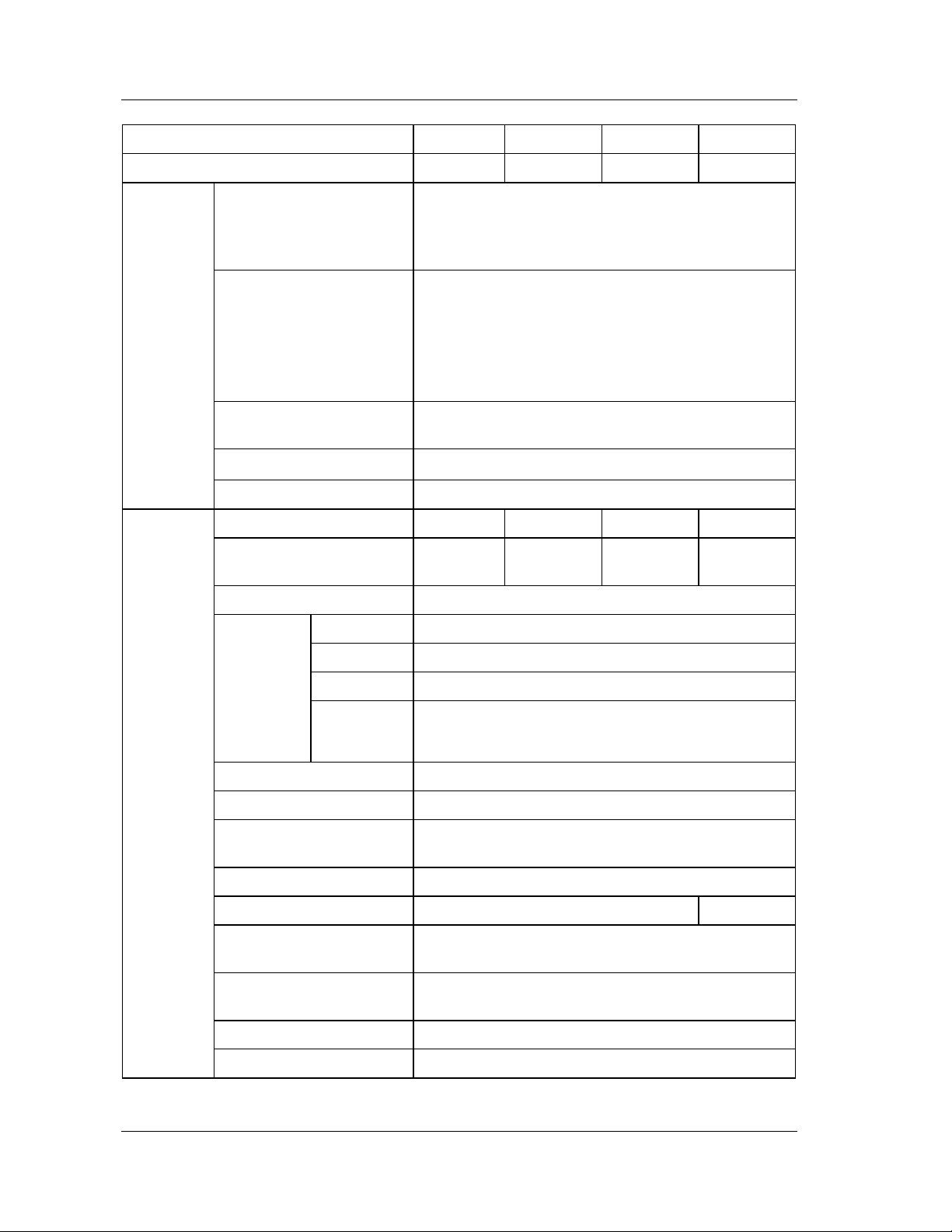

Capacity 20kVA 30kVA 40kVA 60kVA

Model UL33-0200L UL33-0300L UL33-0400L UL33-0600L

105% < load 125% , transfer to bypass mode after 10±0.1min;

Output

System

Overload capability(inverter)

125% < load 150% , transfer to bypass mode after 1 minute;

When load > 150%, transfer to bypass mode after 200ms

135% Rated Current continuously

135%~170% for 1 minute

Overload capability(bypass)

>170%, shutdown in 2s

1000% rated current for 20ms(a standard for selecting static

switch)

Ratio of output current peak

value to RMS value

Transfer time(normal mode)

3: 1

0(uninterrupted transfer),15ms(interrupted transfer)

Transfer time(ECO mode) 15ms

System efficiency(linear load) 87% 87% 88% 89%

Efficiency in battery

mode(linear load)

92% 93% 93% 94%

Display LCD+LED

Conduction EN50091-2

Radiation EN50091-2 CLASS-A

EMC/EMI

Harmonic IEC1000-3-4

EN 61000-4-2.3.4..6.8.9.11 Level III,

Immunity

EN 61000-4-5 Level Ⅳ

MTBF(inverter) 30,000 hours

MTBF(Single UPS) 150,000 hours

MTBF(1+1 parallel operation

system)

400,000 hours

Safety CCEE

Audible noise at 2m <60dB <65dB

Cross current without

load(1+1)

Cross current without

load(3+1)

<3A

<4A

current unbalance rate(1+1) <3%

current unbalance rate(3+1) <4%

10

Page 17

Chapter 1 Introduction

Capacity 20kVA 30kVA 40kVA 60kVA

Model UL33-0200L UL33-0300L UL33-0400L UL33-0600L

Insulation Resistance >2M(500VDC)

Dielectric Strength

Surge Immunity

System

Protection index IP20

Number of battery cells 30 battery cells(12V)

Installation Cable access mode top/bottom cable access modes optional

(input to earth, output to earth)2820Vdc, leakage current lower

than 3.5mA, 1min without arc

Satisfy the class IV requirements specified by IEC60664-1, the

ability to withstand 1.2/50us+8/20us not lower than 6kV/3kA

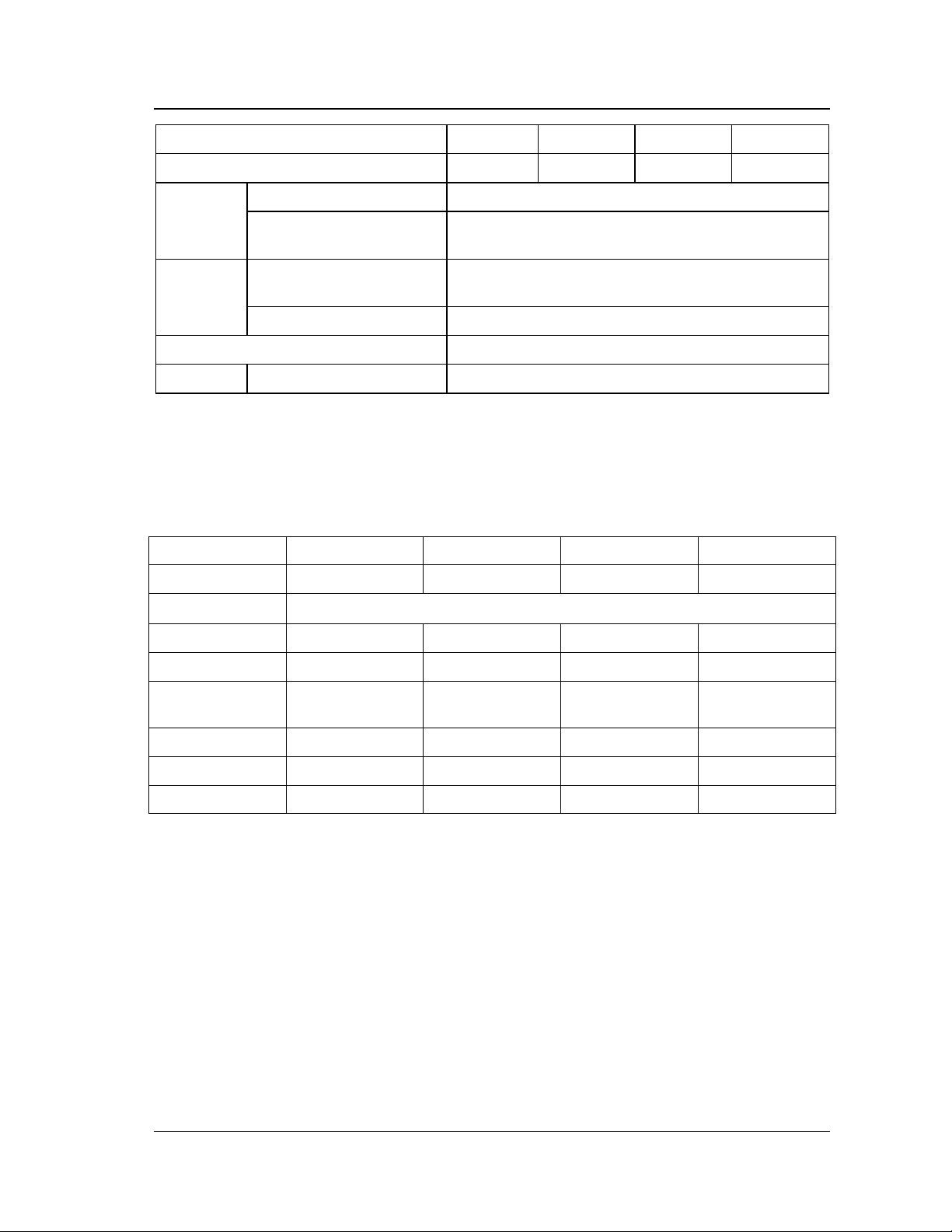

2. Electrical Parameters

For designing of utility power source, air-conditioner, input and output power

distribution and cable selection, please refer to Table 1-2

Table 1-2 electrical parameters

Model UL33-0200L UL33-0300L UL33-0400L UL33-0600L

UPS rated power 20kVA 30kVA 40kVA 60kVA

AC input

Rated loss 2.40kW 3.60kW 4.37kW 5.94kW

Air intake(m3/hour) 500 800 1400 2200

Rectifier: 380/400/415V+15%~(3¢3W), Bypass: 380/400/415V±10%(3¢4W)

Rectifier input

current

Bypass input current 37A 56A 74A 112A

UPS output current 37A 56A 74A 112A

Battery input current 56A 84A 112A 168A

44A 66A 88A 132A

11

Page 18

Page 19

Chapter 2 Cabinet Installation

Chapter 2 Cabinet Installation

2.1 Environmental Conditions

Operating Temperature : 0~ 40°C

Storage Temperature: -40~ 70°C(with no battery)

-20~ 55°C(with battery)

Relative Humidity:5%

Cooling method : Fan cooling

Elevation:1500m

Maximum Tilt : 5 degrees

Pollution :Class II

The UPS should be installed in a cool place with good ventilation, low humidity and

free of dust. The recommended operating temperature is 20 – 25 degree C, and

the humidity should be controlled at 50% RH.

Note :

The UPS room should not be stored with flammable, corrosive or explosive

materials. It is not advisable to install the UPS in areas with conductive dust.

2.2 Unpacking

Unpack the UPS only at the installation site and check the equipment for

completeness and damage. Keep accessories for later use.

~95

%, no condensation

Unpacking method is illustrated on the carton. For reliable operation of the UPS,

the installation method should be based on the actual environment condition and

site design standard.

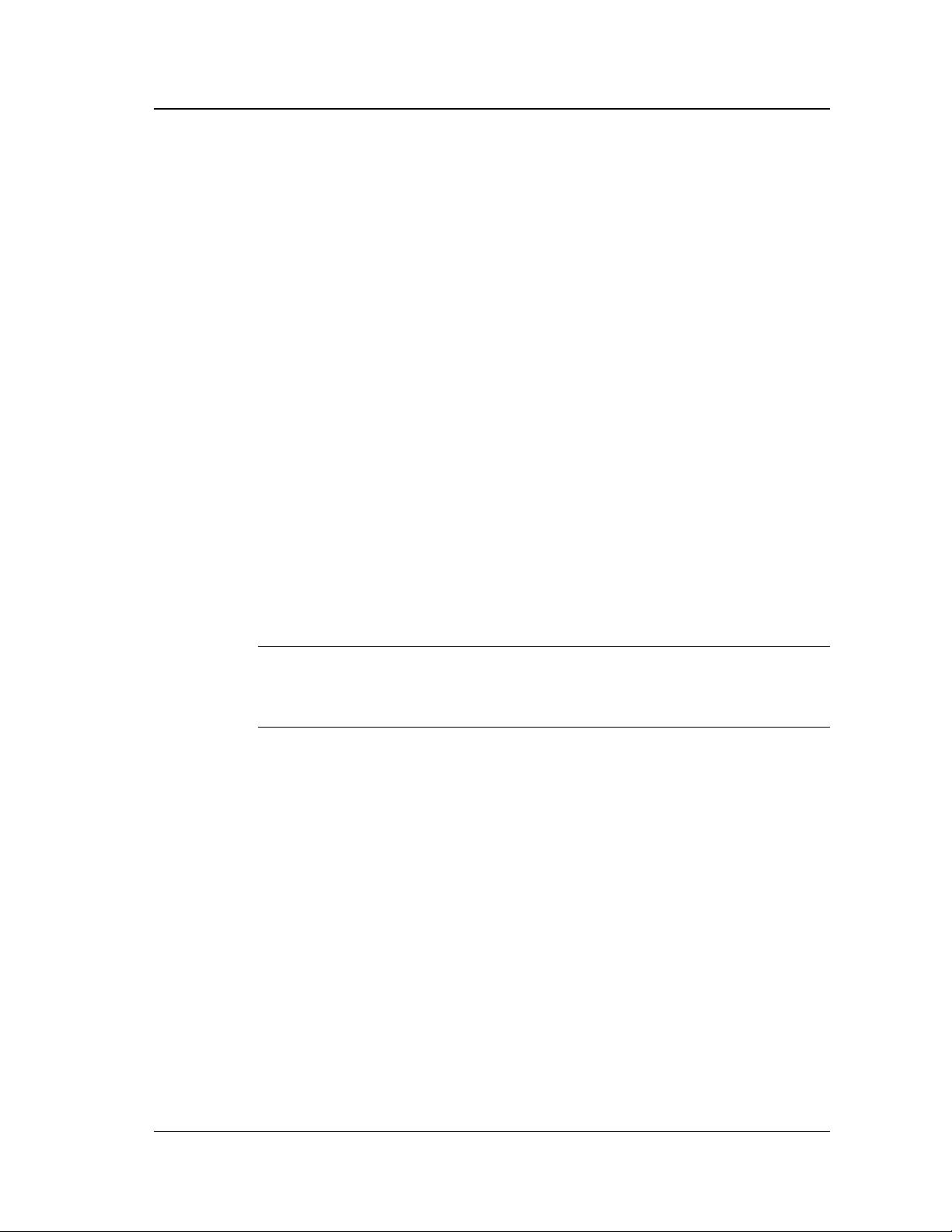

2.3 Dimensions

The dimensions of the UPS are listed in Table 2-1

13

Page 20

Chapter 2 Cabinet Installation

Figure 2-1

4 fixing holes

4 screws for levelling feet

Figure 2-2

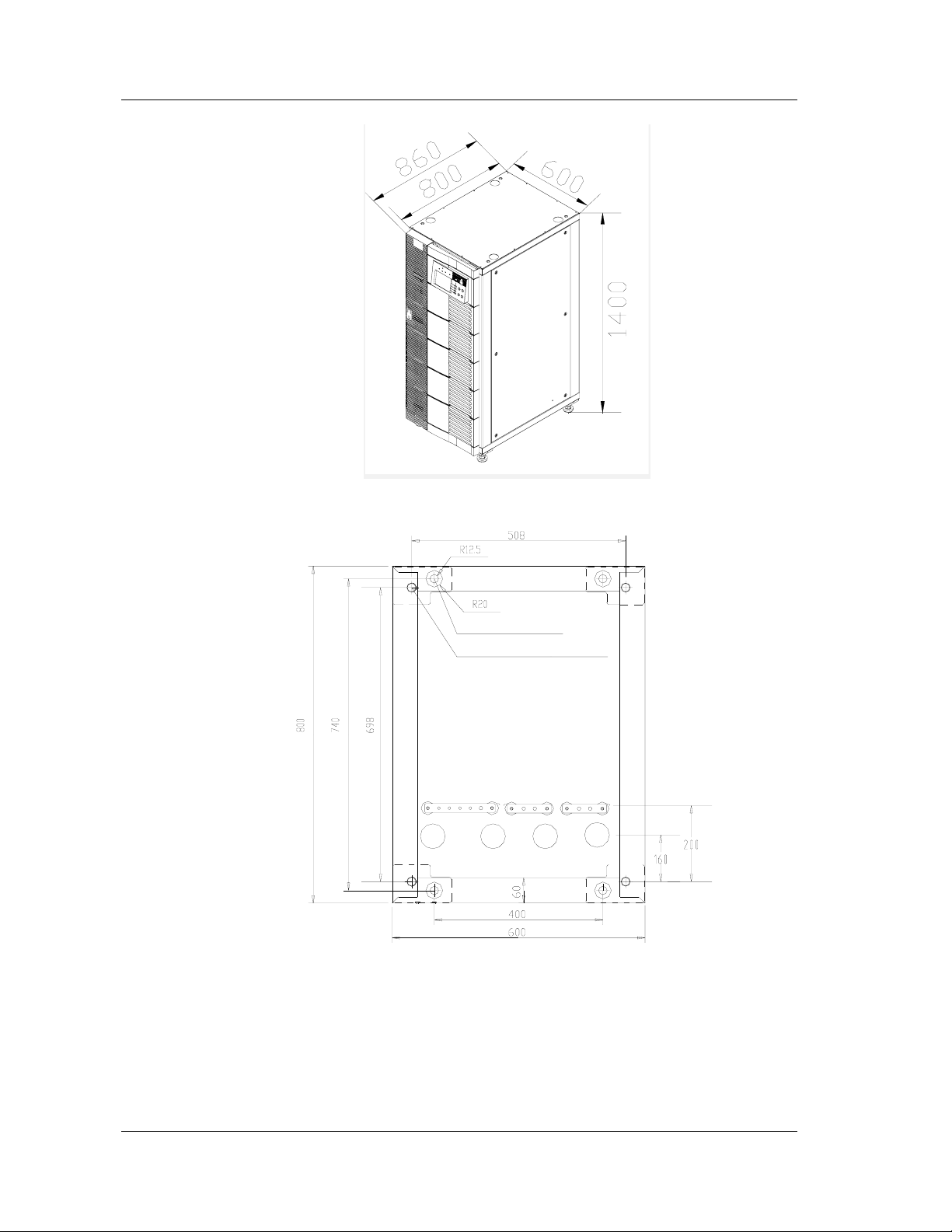

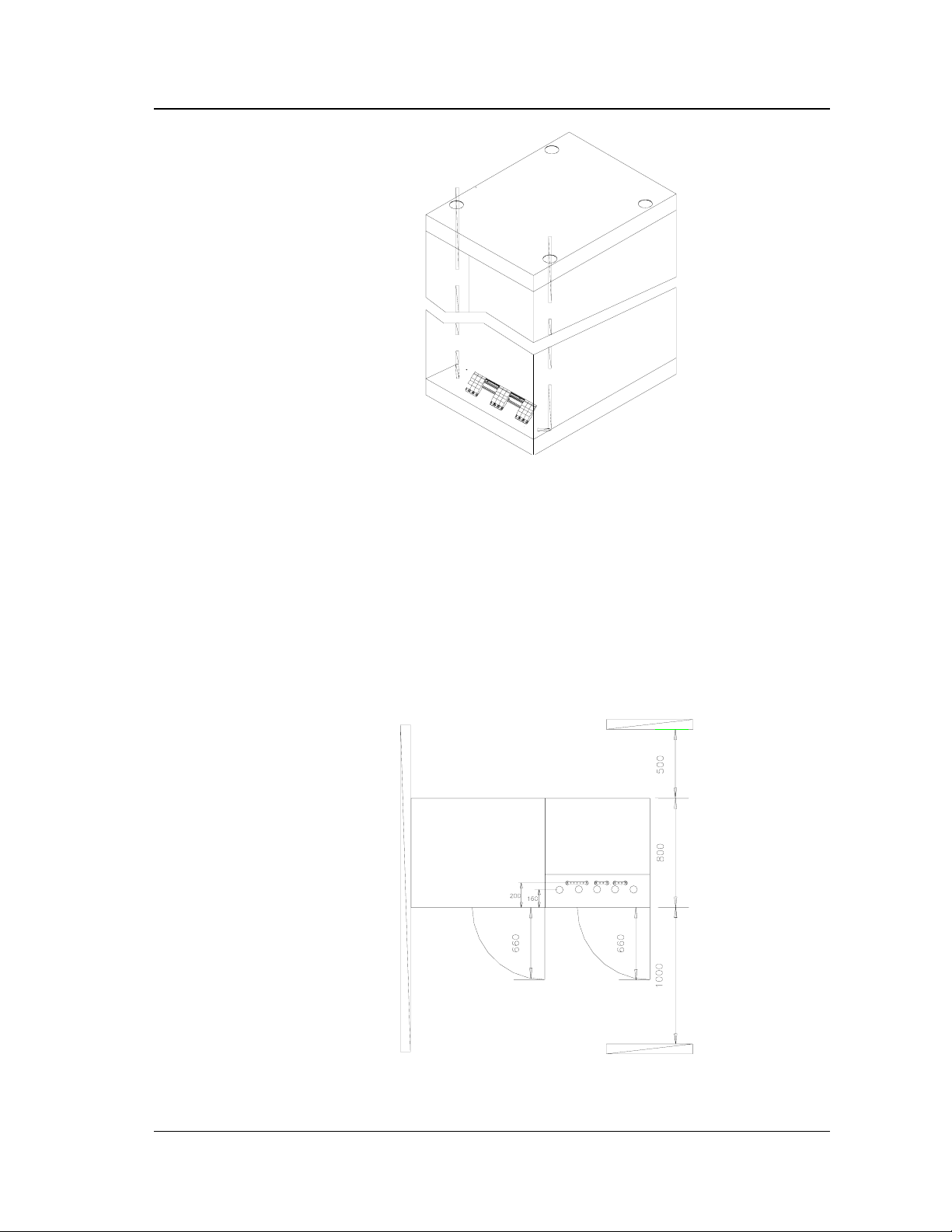

External Dimensions of 40/60kVA UPS are shown in Fig. 2-3 and its installation

position is shown in Fig. 2-4.

14

Page 21

Chapter 2 Cabinet Installation

Figure 2-3 40/60kVA UPS Outline Dimension

4 fixing holes

4 screws for levelling feet

Figure 2-4 40/60kVA UPS Fixing Holes

15

Page 22

2.4 Transportation

1. Hoisting the UPS

Prepare four cables of length 1.5 m and the weight bearing capacity of each cable

of 1.5 tons. The UPS has four lifting rings and should be installed at the top of the

UPS

2. Transportatio with Forklift

The UPS can be raised by forklift in four directions – front, back, left and right. But

the transportation distance should not exceed 10 m.

2.5 Positioning of UPS

The UPS cabinet exerts its weight on the floor through four castors. If the load

bearing capacity of the floor is inadequate, add auxiliary equipment to distribute

the weight over a larger area, such as a big iron sheet or increasing the number of

supporting castor wheels.

Chapter 2 Cabinet Installation

Note

As the UPS is cooled from the bottom, at least 10 cm space should be left at the

bottom of the UPS for ventilation

There are three kinds of positioning methods:

1. Non-Fixed position

Place the UPS directly on the flat ground . The ground should be made of Industrial

cement. Level the UPS by lowering and adjusting the leveling bolt at the base of

the UPS.

4 M20 screws for

levelling feet

16

Figure 2-5

Page 23

Chapter 2 Cabinet Installation

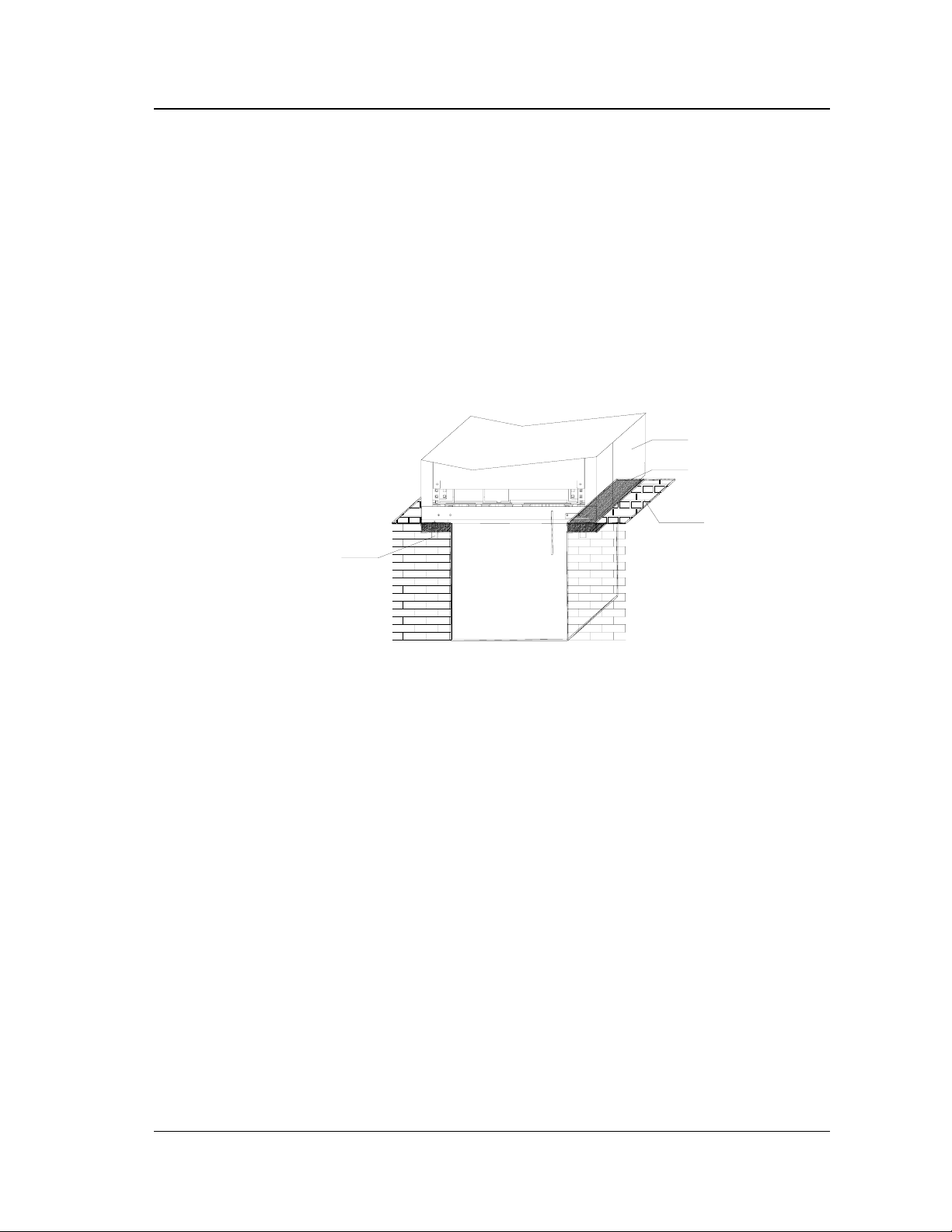

2. Fixed position without a base

In earthquake prone areas, place UPS on a conduit as shown in Figure 2-6.

1. At the edge of the conduit, drill holes for fixing expansion bolts

2. Hoist the cabinet at least 250 mm to remove the four leveling bolts. Take off

the plastic cover of the installation holes on the beam.

3. Position the cabinet at the right position and align the holes on the beam and

the holes on the expansion bolts.

4. Insert the expansion bolts into the installation holes. Adjust the tilt of the

cabinet and screw the expansion bolts to fix the cabinet.

Front door

Steel of conduit

floor of machine

room

Expansive

bolts

Cabinet

Cables

Cement

floor

Figure 2-6 Install UPS on a Conduit

Conduit

Cement

floor

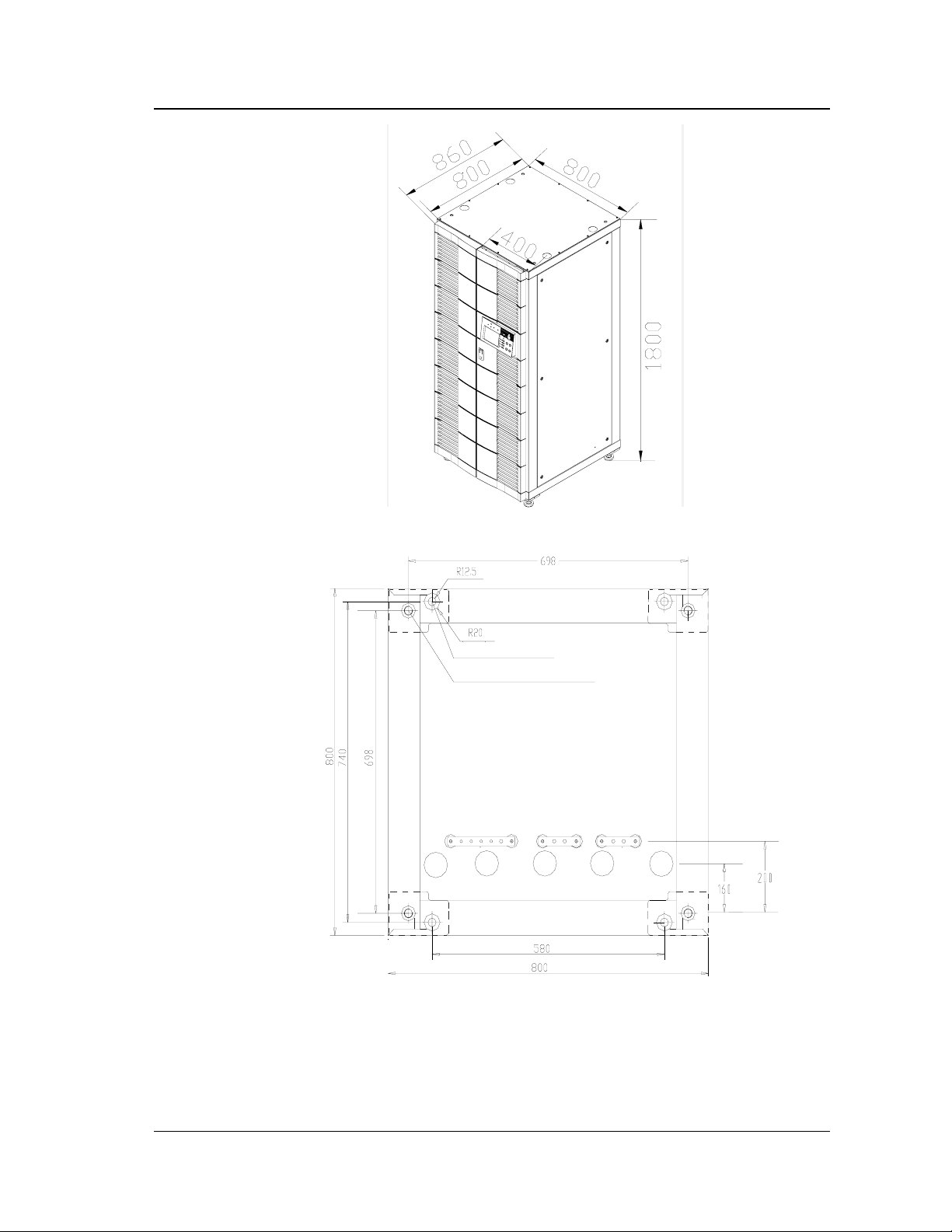

3. Fixed cabinet position on a base

If the UPS is place in a ESD proof floor, a support rack should be designed to

support the cabinet. The design of the rack is illustrated in Figure 2-4 and Figure 27 considering the load carrying capacity of the floor. Level the cabinet according to

section 2.5 – 1

17

Page 24

2.6 Cable Access

Chapter 2 Cabinet Installation

Figure 2-7 Install the UPS on a support rack

1. Finished state 2. Concrete floor

3. Nut 4. Spring washer

5. Flat washer 6. Supporting frame

The UPS has various methods of cable access. One is bottom access where the

cables are routed in conduit from the bottom of the UPS. This is shown in Figure 2-

8.

Another is top access where the cables are routed on cable trays from the top and

into the UPS as shown in Figures 2-9.

Battery

cables

input N

Cabinet

Signal cables

UPS output

output N

Battery

cables

Rectifier

input

Cabinet

Bypass input

input N

Signal cables

UPS output

output N

Fig. 2-8 UPS input/output cables

18

Page 25

2.7 Ventilation

Chapter 2 Cabinet Installation

Input cable

Battery cable

Output cable

Signal cable

Fig. 2-9 UPS top cable output

The cooling air comes into the UPS from the bottom and the fan circulates the cool

air inside the UPS. The air is expelled out of the UPS from the back.

Table 2-3 shows the relationship between the power consumed and air intake.

The rear clearance required by the UPS is 500 mm. The front clearance required is

1 m for the convenient of door opening and maintenance, shown in Figure 2-10.

Battery cabinet

UPS cabinet

bottom board

Fig. 2-10 Relative position of cabinet

19

Page 26

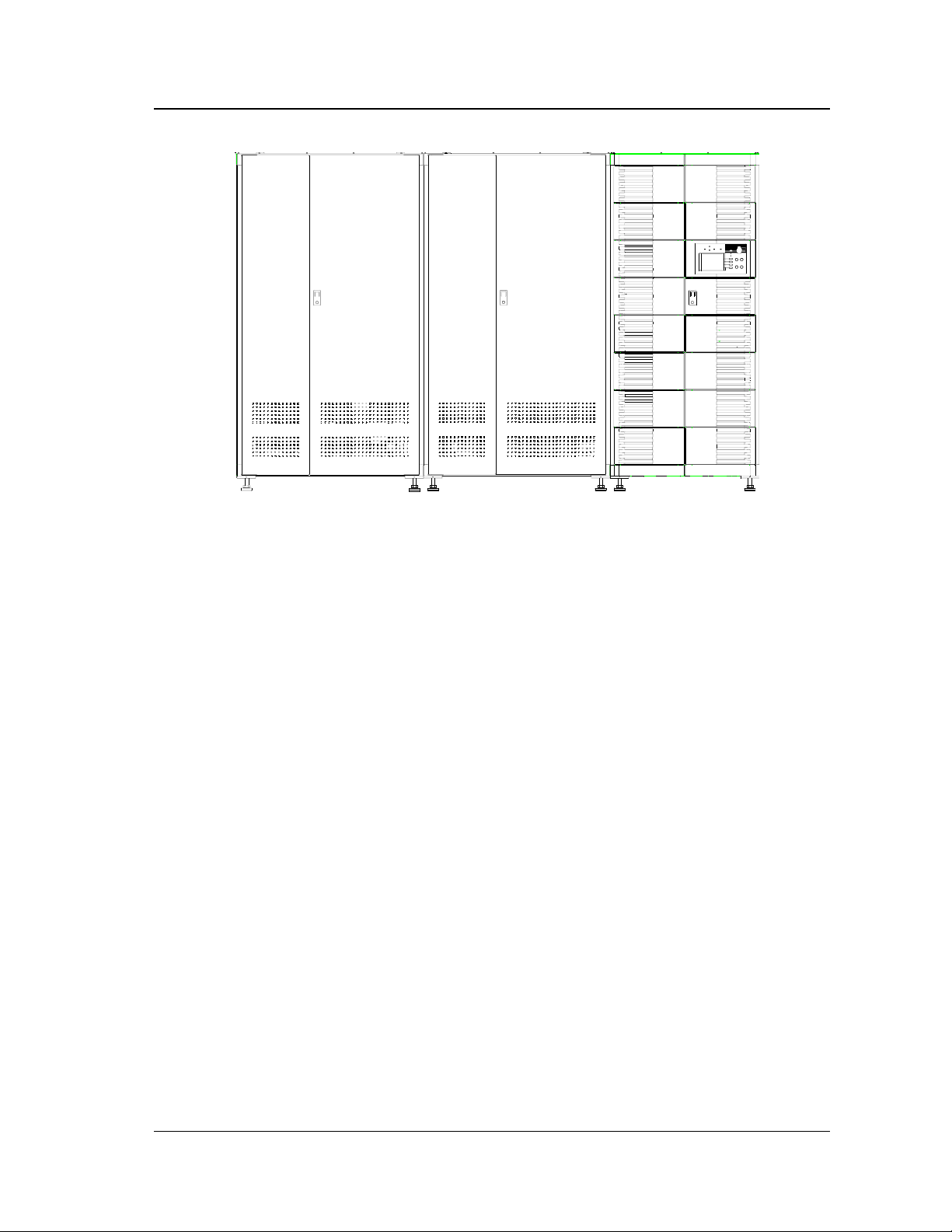

2.8 Layout of Cabinet

Besides the UPS cabinet, there are also battery cabinets, input/output distribution

cabinet and cabinet for bypass transformer. All these cabinets should be laid out

correctly. The layout of battery cabinet and UPS cabinet is shown below.

1. One UPS cabinet and one battery cabinet

If the required battery backup time is 15 – 16 minutes, one battery cabinet is

required to hold all the required batteries. There is no strict requirement for the

relative position of the UPS and the battery cabinet. Figure 2-11 shows this kind of

layout.

Capacity expansion must be considered into layout design.

Chapter 2 Cabinet Installation

Battery cabinet

Fig. 2-11 Layout 1

UPS cabinet

2. One UPS cabinet and several battery cabinets

More than one UPS cabinet should be used if the required backup time is more

than 30 minutes. Please refer to Chapter 9 for the relationship between the battery

backup time and the battery capacity.

The battery cabinets should be placed side-by-side and the UPS cabinet can be

placed on the left or right side, in front of or behind the battery cabinets. Be sure to

leave space for maintenance.

20

Page 27

Chapter 2 Cabinet Installation

Battery cabinet 1

Battery cabinet 2

Fig. 2-12 Layout 2

UPS cabinet

21

Page 28

Page 29

Chapter 3 Electrical Assembly

Chapter 3 Electrical Assembly

This chapter introduces the connection methods of the power and signal cables.

3.1 Selection of cables

3.1.1 Current carrying capacity of cables

The current carrying capacity can be selected according to the voltage drop and

permissible temperature increase.

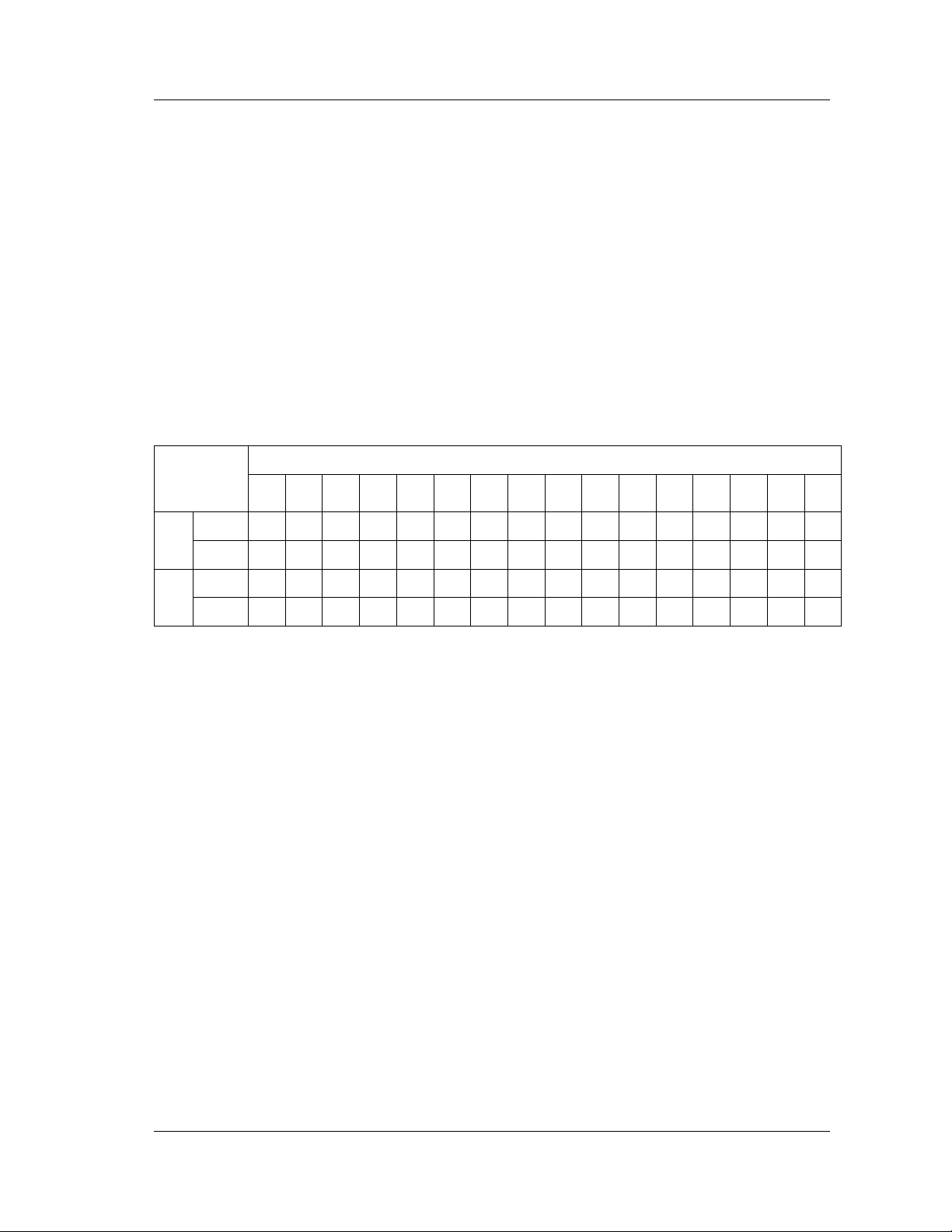

Table 3-1 Current carrying capacity of cables

Cross sectional area(mm

carrying

capacity (A)

1 1.5 2.5 4 6 10 16 25 35 50 70 95 120 150 185 240

2

) Current

Rubber

25°C

Rubber

35°C

21 27 35 45 58 85 110 145 180 230 285 345 400 470 540 660

Plastic

19 24 32 42 55 75 105 138 170 215 265 325 / / / /

20 25 33 42 54 80 103 136 168 215 267 323 374 439 505 617

Plastic

18 22 30 39 51 70 96 129 159 201 248 304 / / / /

3.1.2 Selection of power cables

The power cables include input power cables of main circuit and that of the bypass,

the UPS output cables, battery input cables, protective earth cables and the

lightning protection cables.

1. Calculation of current of power cables

The first calculation method is done according to the following formula:

If the power factor is 0.80, the efficiency is 0.9, the minimum input voltage is 176

volts, output line to neutral voltage is 220V, minimum battery voltage is 324 V,

bypass overload capability is 135% and that of the inverter is 125%,

2. Selection of cable cross sectional areas

2

Power cables are selected according to two factors - 3 – 5 A/mm

current density

and the maximum voltage drop be less than 3 W.

The cross-sectional areas of bypass input neutral cable and UPS output neutral

cable should be 1.5 times of the phase cable. The cross sectional area of the

23

Page 30

Chapter 3 Electrical Assemble

protective earth cable and lightning protection earth cable, should be 0.5 times of

phase cable.

The relationship between the current and cross-sectional area is shown in Table 3-

2.

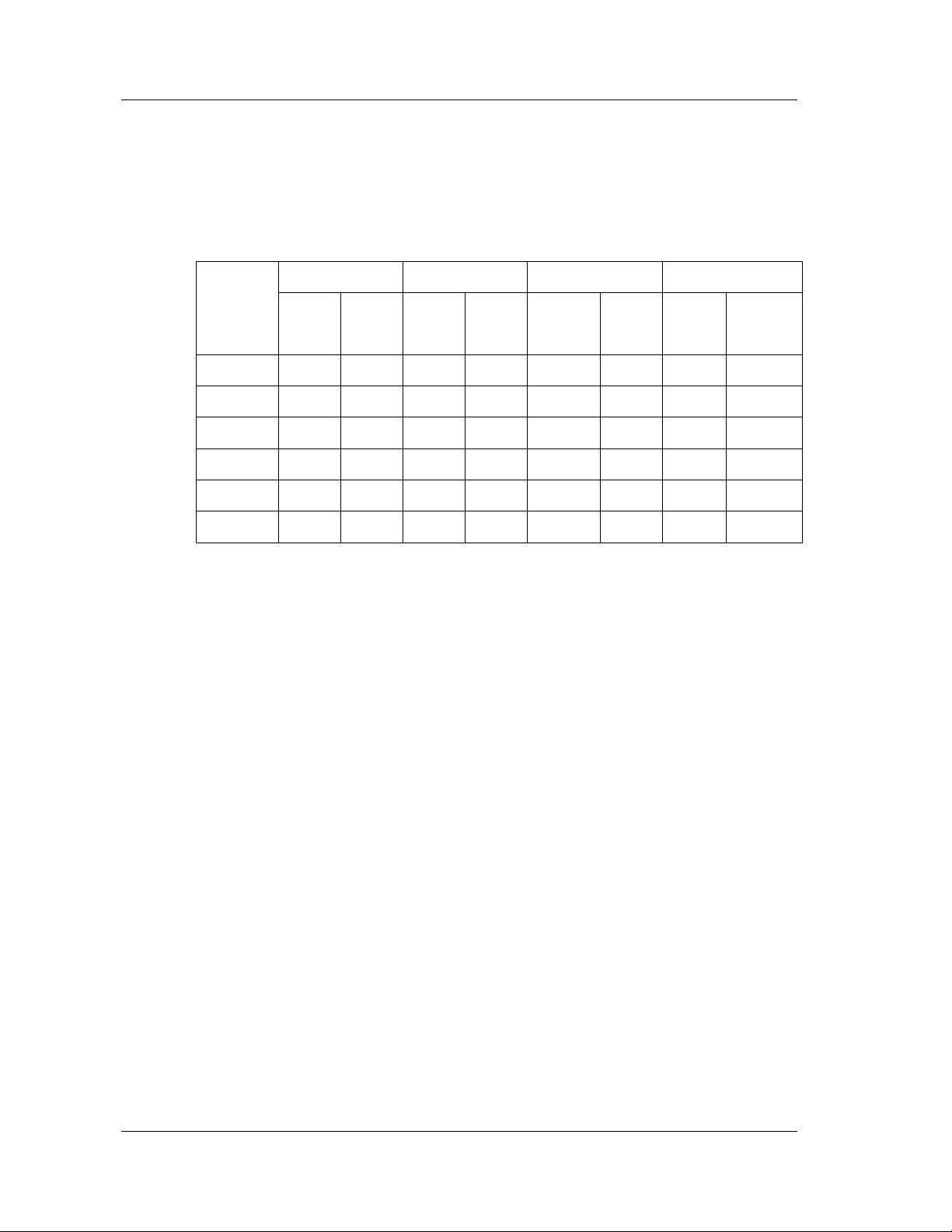

Table3-2 Recommended cross sectional area of cables

20kVA 30kVA 40kVA 60kVA

Name

Battery 56 25 84 25 112 35 168 50

Bypass 37 16 56 16 74 25 112 35

Output 37 16 56 16 74 25 112 35

Input 44 16 66 16 88 25 132 35

Neutral line 25

Earth cable 16

Current

(A)

Cable

(mm

3.1.3 Selection of signal cables

Signal cables should use shielded multi-conductor cables. But if cable with single

conductor is used, the different cables should be bonded together to increase the

mechanical strength. The number of the bonded cables should not exceed 30. The

cross-sectional area of the cable with single conductor should be at least 0.5 sqmm. Serial communication cables should use 3 or 5 shielded conductor cables.

3.2 Cable connections

2

)

Current

(A)

Cable

(mm2)

25

16

Current

(A)

Cable

(mm2)

35

25

Current

(A)

Cable

(mm2)

50

25

3.2.1 Power cables

1. Cabling layout

Cabling layout is shown in Figures 3-1 and 3-2. For single input UPS, the rectifier

input and bypass input are connected together.

24

Page 31

Chapter 3 Electrical Assembly

Battery

cables

UPS input

input N

UPS output

output N

Fig. 3-1 20/30kVA UPS bottom cable output

Battery cables

Rectifier input

Bypass input

Bypass N

UPS output

Output N

Fig. 3-2 40/60kVA UPS cable connection at bottom

2. Cable routing

1. Bottom entry configuration – the cables are input and output from the bottom of

the UPS

2. Top entry configuration – the cables are input and output from the top of the

UPS. To do this, punch out the cable entry cut-outs on the top of the UPS,

and feed the cables through the cutouts and guide them through the metal

conduit to the bottom of the UPS. From the front view, the battery cable, the

input power cables of rectifier and bypass input cables should be input from

the left. The output cable and signal cables should be input from the right.

The layout of the cables is shown in Figure 2-8.

25

Page 32

Chapter 3 Electrical Assemble

3. Cable connection

Note

All the switches should be switched off during cable connection.

1. Feed cables

Feed cables according to the cable entry mode, with reference to Figures 2-7, 2-8,

3-1, 3-2

2. Assembling cable lugs to cables

First strip the insulation layer 20 mm from the end. Then insert the conductor into

the cable lug. Then press the cable lug against the cable till tight.

The parameters of the cable lugs are given in Table 3-3

20kVA 30kVA 40kVA 60kVA

Name

terminal

Battery

Bypass H16/24

Output H16/24

Input H16/24

Neutral

line

Earth

cable

GTNR25-8

GTNR25-8

GTNR25-8

3. Connecting the rectifier input to utility

Connect the three phase cables of phase A1, B1 and C1 to the circuit breaker Q1

4.Connecting the bypass input to utility

Connect the three phase cables of phase A2, B2 and C2 to the circuit breaker Q2.

Note :

Cable

)

terminal

GTNR25-8

H16/24

H16/24

H16/24

GTNR25-8

GTNR25-8

2

(mm

25

16

16

16

25

16

Cable

terminal

2

)

(mm

25

16

16

16

25

16

GTNR50-8

H35/30

H35/30

H35/30

GTNR50-8

GTNR25-8

Cable

terminal

2

)

(mm

35

25

25

25

35

25

GTNR50-8

H35/30

H35/30

H35/30

GTNR50-8

GTNR25-8

Cable

2

)

(mm

50

35

35

35

50

25

In single input system, jumper the respective terminals on Q1 to Q2 with a 300mm

length cable. The utility will be connected to Q1 as described in 3.

26

Page 33

Chapter 3 Electrical Assembly

Wire terminal

Input power cable

Parallel power cable

Fig. 3-3 Power cable connection of One branch utility source

5. Connect the Load to the U, V, W terminals of UPS output breaker Q5.

6.Connection of battery cables

The positive and negative cables of batteries are connected to the Positive and

Negative terminals of JX3 respectively.

7. Connection of Neutral cable

The neutral cable of bypass source is connected to the JX5 copper bar, that is

marked with “N/INPUT”. The neutral cable of UPS output source is connected to

copper bar JX4, that is marked with “N/OUTPUT”.

Note

The phase rotation of circuit breakers Q1, Q2, Q5 cannot be wrong and the phase

rotation is shown in Figure 3-4.

ABC

TRS

UWV

L1 L2 L3

ABC

RTS

WUV

L1 L3L2

Q1

B

A

C

T

SR

U

W

V

L1

L2

L3

BC

A

TRS

UWV

L1 L2 L3

Q2

R

U

L1

A

R

L1

BUA

C

S

T

WWV

L3

L2

C

B

ST

V

L2

L3

Q5

Fig. 3-4 Phase rotation

27

Page 34

Chapter 3 Electrical Assemble

4. Earthing Method

The UPS rectifier source has no neutral cable. The bypass and output source have

neutral cables and the input and output neutral cables are short circuited.

The lightning protection earth PE and the protection earth of the cabinet are

connected as shown in Figure 3-5. The user can decide whether to use a

connection cable according to his earthing requirement.

PE for lightning protection

PE inside cabinet

Protective earth

Fig. 3-5 Wiring inside cabinet

Generally, the separated neutral mode is better for human safety. The united

connection mode is better for the UPS system. If there is C-level lightning

protection unit inside the UPS, the cabinet protection earth and the lightning

protection earth should be connected together.

In the bottom cable entry mode, the protection earth cable should be connected

with a copper terminal on the beam inside the cabinet or connected to the copper

busbar marked with PE. User board M8x12 to fix the cable.

The leakage current of the UPS should be less than 1 ampere.

The earthing resistance of the UPS cabinet should be less than 1 ohm.

3.2.2 Signal cable

The Signal cable includes serial communication cables, control cables of

input/output contacts, logic and load sharing cables.

1. Routing the signal cable

Note

The signal cables should be routed according to Figure 3-6

28

Page 35

Chapter 3 Electrical Assembly

Fig. 3-6 Layout of signal cables of 20/30/40/60kVA UPS

2. Connection method

1.Parallel connection method

Open the door of the UPS to see a circuit board ULW2L61M3. On the board, 15pin connectors P1 and P2 are used to connect the parallel logic cables. 9-pin

connectors P3 and P4 are used for connecting the load sharing cables. Each UPS

system has two pieces of 15 meters length cables.

Parallel logic cable

Parallel load sharing cable

Fig. 3-7 Parallel Board ULW2L61M3

29

Page 36

Chapter 3 Electrical Assemble

2.Connection of serial connection cables

The monitoring board ULW2L61U2 is shown in Figure 3-8, where the locations of

RS232, RS485 and input and output contacts are marked. The user can connect

the cables with reference to this board.

communication cable RS485-

communication cable RS485+

r

o

s

r

r

o

o

t

a

r

e

n

e

g

r

o

f

A

.

C

.

D

e

A

t

B

c

a

r

p

r

p

u

o

e

o

t

t

o

n

e

g

r

o

f

B

.

C

.

D

s

s

s

V

r

y

y

4

c

e

c

2

n

n

w

r

e

e

o

o

g

g

p

f

r

r

.

e

e

V

C

4

m

.

m

2

E

D

E

+

e

e

c

e

e

e

r

u

l

a

v

t

V

n

4

e

2

m

r

n

o

f

o

r

.

i

v

C

.

n

e

D

u

l

u

u

u

l

l

a

o

a

a

v

s

v

v

t

r

t

t

V

n

V

e

n

n

2

e

4

e

e

1

w

2

m

r

o

m

m

r

n

o

p

n

n

f

o

o

f

o

o

r

.

V

i

r

r

.

i

i

2

v

C

v

v

.

C

1

n

.

n

n

D

e

+

D

e

e

n

e

t

s

u

r

p

o

f

n

i

e

e

c

r

r

u

u

t

t

o

a

n

s

r

e

e

r

i

p

e

b

w

m

m

o

e

A

t

p

r

r

r

a

a

a

l

l

l

r

a

a

a

e

e

r

u

r

t

o

a

r

s

e

n

p

e

s

m

f

e

t

o

y

d

r

n

e

t

u

t

o

a

r

b

g

w

w

w

w

o

o

o

o

l

l

l

p

y

y

y

y

r

r

r

r

e

e

e

e

t

t

t

t

a

b

r

o

f

C

.

N

t

t

t

t

t

a

a

a

a

b

b

b

b

r

r

r

r

o

o

o

f

o

f

f

f

.

.

.

.

C

C

O

.

C

.

.

.

C

C

N

N

r

r

r

r

r

e

w

o

p

y

r

e

t

r

e

e

e

e

e

w

w

v

w

w

o

o

o

o

o

p

p

t

p

p

r

r

n

r

y

e

e

e

e

r

i

t

t

t

r

r

e

r

b

t

e

e

t

e

v

v

m

v

a

a

n

n

n

b

i

i

i

r

r

r

r

r

o

o

o

o

f

o

f

f

f

f

.

.

.

.

.

C

C

O

C

.

C

.

.

.

.

N

N

N

N

C

p

p

o

r

r

t

o

t

e

e

s

s

v

v

t

t

o

o

n

n

t

t

e

e

n

n

g

g

r

e

e

r

i

i

e

b

e

b

e

e

r

e

m

r

r

m

m

m

u

e

u

t

u

a

e

a

t

t

r

a

a

r

r

r

r

a

o

r

r

f

o

o

o

e

f

f

f

e

e

.

p

.

.

.

p

p

C

m

.

C

C

O

m

.

m

.

.

e

N

e

t

e

t

C

C

N

t

m

m

p

m

r

r

r

o

a

a

t

l

l

a

l

s

a

a

a

t

n

n

n

n

o

o

e

o

g

m

m

r

m

e

m

m

m

o

o

m

o

c

c

e

c

r

r

r

r

o

o

o

o

f

f

f

f

.

.

.

.

C

O

O

C

.

.

.

.

C

N

N

N

m

m

m

r

r

r

e

e

e

w

w

w

o

o

o

p

p

p

r

d

r

r

d

d

o

a

t

o

o

a

a

o

o

l

l

r

r

e

e

v

v

o

o

r

r

o

o

f

f

.

.

C

C

.

.

C

N

t

t

o

a

l

a

a

r

r

r

r

e

e

e

e

n

n

n

v

e

e

e

o

g

g

g

r

r

r

r

o

o

f

f

o

o

f

f

.

.

.

.

O

C

.

.

C

O

.

.

N

N

C

N

Fig. 3-8 Monitoring Board ULW2L61U2

The length of the serial communication cables is different according to actual

conditions. The cables are not supplied with the UPS.

The communication modes of RS232, RS485, modem and SNMP can be used

together, but only one mode can be used at any time.

1) RS232 Connection

The J20 is the RS232 communication port. One end of the communication cables

should be connected to J20 and the other end should be connected to background

monitoring equipment. The meaning of each pin is shown in Figure 3-9.

Pin 2:receiving Pin 3:Transmitting Pin 5:Ground Other pins:Void

Fig. 3-9 RS232 Serial Port

30

Page 37

Chapter 3 Electrical Assembly

2) Connection of modem

MODEM or SNMP

SNMP cables

Monitoring board

20/30kVA Front view when

Front door is opened

Monitoring board

SNMP cables

MODEM or SNMP

40/60kVA Front view when

right door is opened

Fig. 3-10 Installation of MODEM or SNMP

1. Figure 3-10 shows the location of Modem and SNMP card. Before installing the

modem, the user should remove the iron box use for SNMP card and installed the

modem there.

communication port

serial pore

communication port

Power source

Communication port

Fig. 3-11 MODEM Connection Method

2.Connecting the communication cables. The communication cables of modem are

connected to J20.

3. Connection of power source cables. Connect the power source cables of modem

directly to J8. The Pin 1 of J8 is ground. Pin 2 is 12V power.

4.Connection of Telephone line. Connect the telephone line after connecting the

power source and communication cables to realize remote communication.

31

Page 38

Chapter 3 Electrical Assemble

3)Connection of SNMP Card

Installation of SNMP card

Unpack the SNMP card and place it in the iron case shown in Figure 3-10

Connect the cables

On the monitoring board, there is a jack J22 with a cable to plug in directly to the

SNMP card, after the SNMP Card is installed. Please do not remove this cable

even if the SNMP card is not used.

4)Connection of RS485

Connector J23 on the monitoring board is the RS485 communication port. One

end of the communication cable is connected to J23 while the other end is

connected to the user’s equipment.

RS485+

RS485-

SHIELD

J23

1

2

3

4

Pin 1:Signal + Pin 2:Signal Pin 4:Shielded ground

Fig. 3-12 RS485 Port

3. Connection of input and output voltage free contacts

The input and output contacts can be connected to shielded cables, and single

cables. One end of the cables are connected to J9 to J18. The other end is for

connection by user.

Note:

The contact should satisfy the SELV safety requirements.

The J9-J14 connectors on the monitoring board are monitoring dry contacts of

relays. The relays have a normally open, normally closed and a common terminal.

The capacity of the contacts are 0.3A/125VAC, 0.3A/110VDC and 1A/24DC.

The transmission distance of the dry contact signals are dependent on the voltage

level and the cross sectional area of the cables. J15 – J18 are the input contacts

for external signals.

32

Page 39

Chapter 3 Electrical Assembly

Table 3-4 Definitions of input/output contacts

Connector Name of contacts Board name input/output

Normally closed contacts for

battery low alarm

BLV-C output

J9

J10

J11

Central contacts for battery low

alarm

Normally open contacts for

battery low alarm

Normally closed contacts for

battery mode

Central contacts for battery

mode

Normally open contacts for

battery mode

Normally closed contacts for

inverter mode

Central contacts for inverter

mode

Normally open contacts for

inverter mode

Normally closed contacts for

ambient over-temperature

Central contacts for ambient

over-temperature

BLV-S output

BLV-O output

BAT-C output

BAT-S output

BAT-O output

INV-C output

INV-S output

INV-O output

TMP-C output

TMP-S output

J12

J13

J14

Normally open contacts for

ambient over-temperature

Normally closed contacts for

emergency shutdown

Central contacts for emergency

shutdown

Normally open contacts for

emergency shutdown

Normally closed contacts for

common alarm

Central contacts for common

alarm

Normally open contacts for

common alarm

Normally closed contacts for

overload

33

TMP-O output

URG-C output

URG-S output

URG-O output

WRN-C output

WRN-S output

WRN-O output

OVR-C output

Page 40

Chapter 3 Electrical Assemble

Connector Name of contacts Board name input/output

Central contacts for overload OVR-S output

J12

J13

J14

J17

J16

Normally open contacts for

overload

Normally closed contacts for

generator mode

Central contacts for generator

mode

Normally open contacts for

generator mode

+24V power for environmental

signal

24V power for environmental

signal 1

24V power for environmental

signal 2

24V power for environmental

signal 3

+12V power for environmental

signal

12V environmental signal ENV

OVR-O output

GEN-C output

GEN-S output

GEN-O output

+24V power output

ENV1

ENV2

ENV3

+12V power output

connect to dry

contacts

connect to dry

contacts

connect to dry

contacts

connect to dry

contacts

J18

J15

NC NC

Ambient temperature input V-AD 0~5V signal input

Dry contacts H of generator GEN-H connect to dry contacts

Dry contacts L of generator GEN-L

Emergency shutdown H UCTRH

Emergency shutdown L UCTRL

NC NC

12V

Power Source of Sensor

Battery Temperature BAT-T 0~5V signal input

GND of Sensor GND power output

+

connect to dry

contacts

connect to dry

contacts

connect to dry

contacts

power output

Terminals J9~J14 are the dry contacts for monitoring that can be used by users.

The relays have central contacts.

34

Page 41

Chapter 3 Electrical Assembly

4. Battery Temperature detection cable

When the user select the temperature compensation technology, he should select

the TMP12Z sensor that is installed inside the battery cabinet or battery room. Use

a cable to send a temperature signal to J15 on the monitoring board. Shield cable

is recommended to be used because the transmission distance is long.

The location of the temperature sensor is shown o Figure 3-13.

Fig. 3-13 Dry Contact

1. Circuit Breaker QF1 2. Temperature Sensor TMP12Z

Fig. 3-13 Installation of TMP12Z

3.3 Connection of Single UPS System

The circuit breaker of bypass source is selected according to its disconnecting

capacity and short circuit current. The selected circuit breaker should be able to

protect the static switch according to its maximum permissible current.

35

Page 42

Page 43

Chapter 4 Commissioning of UPS

Chapter 4 Commissioning of UPS

4.1 Startup Procedure

4.1.1 Explanation of Circuit Breakers

From the layout of Figure 1-3 and Figure 1-4, the startup of UPS has connections

with the following circuit breakers

Q1 : Connects rectifier to Utility source

Q2 : Connects bypass to Utility source

Q5 : Connects UPS output to the Load

Q3BP : Connects bypass input source to the load switch

4.1.2 Startup

QF1 : Battery Circuit Breaker

All the circuit breakers of the UPS should be switched off and phase rotation correct.

The battery cables are connected correctly. Q1 and Q2 are connected to utility.

Note

Before startup, do not connect the load

The UPS should be started up according to the following procedures:

Step 1 : Switch on Q2 and Q5. The power source indicator on the panel turns on

and the LCD displays information during startup.

Step 2 : Switch on Q1 and QF1. The sound of the relay closing should be heard.

After 2 secs, the main contactor closes. The rectifier starts after the soft start relay

opens. The rectifier indicator flashes several times and the rectifier enters normal

operation states after about 10 secs.

Step 3 : The battery input contactor closes automatically after the DC bus reaches

the pre-set value. The battery indicator illuminates before the battery contactor

closes and it turns off after the contactor closes.

Step 4 : Press the button “inverter start” for two seconds. The inverter will start up

and enters normal operating state when the inverter indicator flash.

37

Page 44

Step 5 : After the UPS transfers from bypass to inverter, the bypass indicator turns

off, and the inverter and the load indicator turns on. The transfer may fail if the

phase rotation of bypass and inverter output are different.

During operation, if the AC power recovers after failure, the rectifier will restart

automatically after some time. If the UPS transfer to generator power, the

monitoring system will determine the quality of the generator supply. The time it

takes to determine this, ranges from 1 second to 255 seconds.

After startup, use the keypad to set the functions of the UPS.

Note

Power failure means the line to neutral voltage is lower than 120V or the Line to

Line voltage is lower than 208V over 10 msecs.

4.2 Setting the functions

The methods of setting the functions will be described in details in Chapter 5.

Chapter 4 Commissioning of UPS

This chapter only introduces the setting that relates to commissioning.

The user enters the menu of “set functions” shown in the figure below.

UL33-0400L

Inv. On Units 2/4 ID: 1

Out

Local

System

Battery

Records

Settings

Input Breaker Closed

Byp. Breaker Closed

Mains Volt. Abnormal

UPS in Battery Mode

Battery low

2001-11-08

Language

Chinese

Com. Adress Set

1

Date & Time Set

2001£ -11 £ -08 12:50:30

English

11£ -08 12:09

11£ -08 12:09

11£ -08 12:28

11£ -08 12:28

11£ -08 12:50

12:50:30

Chinese

1

Fig. 4-1 Function Setup Menu

Language selection : select “Chinese” or “English” as shown in Figure 4-3

Address setup : set the address of this UPS in the monitoring system as shown in

Figure 4-3.

Date and Time setup : format is “YYYY-MM-DD” and “HH:MM:SS” as shown in

Figure 4-3

38

Page 45

Chapter 4 Commissioning of UPS

UL33-0400L

2001-11-08

12:50:30

Inv. On Units 2/4 ID: 1

Out

Local

System

Battery

Records

Settings

Input Breaker Closed

Byp. Breaker Closed

Mains Volt. Abnormal

UPS in Battery Mode

Battery low

Language

Chinese

Com. Adress Set

1

Date & Time Set

2001£ -11£ -08 12:50:30

11£ -08 12:09

11£ -08 12:09

11£ -08 12:28

11£ -08 12:28

11£ -08 12:50

English

Chinese

1

m

Fig. 4-2 Setup Language

Manual Battery Self Test : Select “start self test” or “stop self test”

Contrast Adjustment : Change the display contrast according to the 11 bars, as

shown in Figure 4-4.

UL33-0400L

2001-11-08

12:50:30

Inv. On Units 2/4 ID: 1

ÊÖ¶¯µç³Ø×Ô¼ì

Out

Local

System

Battery

Records

Settings

Input Breaker Closed

Byp. Breaker Closed

Mains Volt. Abnormal

UPS in Battery Mode

Battery low

Manual Batt Test

Start

Stop

Display contrast adjust

Record Query Range

0: all records

11£ -08 12:09

11£ -08 12:09

11£ -08 12:28

11£ -08 12:28

11£ -08 12:50

3 days

m

Fig. 4-4 Manual Battery Self-test

History Record : The set range is 1-30 days. If “0” is set, all records will be

available for viewing.

Background Communication Setup : select between modem and RS232, as shown

in Figure 4-5

Baud Rate setup : Select from available baud rates of 9600, 4800, 2400 or 1200,

as shown in Figure 4-5

Callback time setup : the available set range is from 1-5 times, as shown in Figure

4-5

39

Page 46

Chapter 4 Commissioning of UPS

UL33-0400L

2001-11-08

12:50:30

Inv. On Units 2/4 ID: 1

ÊÖ¶¯µç³Ø×Ô¼ì

Out

Local

System

Battery

Records

Settings

Input Breaker Closed

Byp. Breaker Closed

Mains Volt. Abnormal

UPS in Battery Mode

Battery low

Comm. Mode Set

MODEM

RS232

Comm. Baudrate Set 9600

4800

9600

Callback Times Set 3

3

11£ -08 12:09

11£ -08 12:09

11£ -08 12:28

11£ -08 12:28

11£ -08 12:50

2400

RS232

1200

m

Fig. 4-5 Background Communication

Callback number 1 : the first callback number can be a mobile phone number, a

fixed line phone number, a beeping pager or an extension telephone. The length of

the telephone number is 15 digits. Input the number from the first digit and any

remaining blanks digits has to be entered with an asterisk “*”

Callback number 2 : same as for callback number 1

Callback number 3 : same as for callback number 1

4.3 Functional checks

Check the functions of switching between operation modes, visual and audible

alarms and the display functions.

UL33-0400L

2001-11-08

12:50:30

Inv. On Units 2/4 ID: 1

ÊÖ¶¯µç³Ø×Ô¼ì

Out

Local

System

Battery

Records

Settings

Input Breaker Closed

Byp. Breaker Closed

Mains Volt. Abnormal

UPS in Battery Mode

Battery low

Comm. Mode Set

MODEM

RS232

Comm. Baudrate Set 9600

4800

9600

Callback Times Set 3

3

11£ -08 12:09

11£ -08 12:09

11£ -08 12:28

11£ -08 12:28

11£ -08 12:50

Fig. 4-6 Fault Call-back

2400

RS232

1200

m

40

Page 47

Chapter 4 Commissioning of UPS

4.3.1 Check the function of the display panel

Press the button “inverter shutdown” for 2 seconds and check that the inverter

stops.

Rectifier

indicator

Bypass

indicator

Battery

indicator

Inverter

indicator

Load

indicator

Alarm

indicator

Emergency

shutdown

UL33-0400L

UL33-0400L

Inv. On Units 2/4 ID: 1

Äæ±ä¿ªÆô ² ¢»ų́Êý 2/4

Out

Ö÷·ÊäÈë

Local

ÅÔ·ÊäÈë

System

½»Á÷Êä³ö

Battery

±¾»ú¸ºÔØ

Records

²¢»ú¸ºÔØ

Settings

µç³ØÊý¾Ý

Input Breaker Closed

ÊäÈë¿Õ¿ª±ÕºÏ

Byp. Breaker Closed

Mains Volt. Abnormal

Êä³ö¿Õ¿ª±ÕºÏ

UPS in Battery Mode

Ö÷·Äæ±ä¹©µç

Battery low

µç³Ø¾ù³ä

2001-11-08

2001-11-08

Language

A(B)

Chinese

Ïàµçѹ V

Com. Adress Set

µç Á ÷ A

Ƶ  ÊHz

Date & Time Set

¹¦ÂÊÒòÊý

Ïßµçѹ V

221

11. 8

1

50.2

0.99

2001£ -11£ -08 12:50:30

381 380 382

11£ -08 12:09

11£ -08 12:09

11£ -08 12:09

11£ -08 12:09

11£ -08 12:28

11£ -08 12:09

11£ -08 12:28

11£ -08 12:15

11£ -08 12:50

11£ -08 12:12

B(C) C(A)

English

220 221

12.3

50.1

0.99

12:50:30

12:50:30

Chinese

1

50.1

Alarm

F1

F2

Inverter

stare

F3

m

F4

Fault

clearing

Inverter

stop

Mute

Fig. 4-7 Display Panel

Press the button “Emergency shutdown” and check that the UPS shuts down

Press the button “fault clear” to restart the UPS

Simulate a fault to check the visual and audible alarm functions.

Press “Mute” button to silence the alarm

4.3.2 Switching between operation mode

t

Fig. 4-8 UPS Circuit Breaker Operation

41

Page 48

Chapter 4 Commissioning of UPS

1. Switch from normal mode to battery mode. Switch off Q1 to enter battery mode

and after a few seconds, switch on Q1 again to return to normal mode

2. Press “inverter shutdown” button to switch to bypass mode. After a short while,

start inverter again to return to normal mode.

3. In bypass mode, switch on Q1 and press “inverter start” button after the rectifier

starts. The UPS should switch to normal mode.

4. Switch from normal mode to maintenance bypass mode. Press “inverter

shutdown” button, switch off Q1, switch on Q3BP, switch off Q2, Q5, QF1. At this

time the bypass source will power the load through Q3BP.

5. Check that the generator set and the UPS battery can work together.

6. A parallel system can also switch between different operation mode.

42

Page 49

Chapter 5 Operation of Display Panel

Chapter 5 Operation of Display Panel

5.1 Display panel

5.1.1 Layout of Display Panel

The display panel of the UPS is shown in Figure 5-1.

Start

Shutdown

Faullt clear

1:LCD 2:Rectifier indicator

3:Battery operation indicator 4:Bypass source indicator

5:Inverter operation indicator 6:UPS output indicator

7:Buzzer 8:Alarm indicator

9: cover used for preventing wrong operation of Emergency shutdown button

10:Emergency shutdown button (EPO) 11:Inverter start button

12:Inverter shutdown button 13:Fault clear button

14:Alarm mute button 15:F1 Functional key

16:F2 Functional key 17:F3 Functional key 18:F4 Functional key

Fig. 5-1 Display Panel

Mute

The display panel is divided into three sections:

1.LED section

2.Functional Keys

3.LCD

43

Page 50

Chapter 5 Operation of Display Panel

Rectifier

indicator

UL33-0400L

Äæ±ä¿ªÆô ² ¢»ų́Êý 2/4

Ö÷·ÊäÈë

Local

ÅÔ·ÊäÈë

System

½»Á÷Êä³ö

Battery

±¾»ú¸ºÔØ

²¢»ú¸ºÔØ

µç³ØÊý¾Ý

Input Breaker Closed

ÊäÈë¿Õ¿ª±ÕºÏ

Byp. Breaker Closed

Êä³ö¿Õ¿ª±ÕºÏ

Ö÷·Äæ±ä¹©µç

Battery low

µç³Ø¾ù³ä

Bypass

indicator

UL33-0400L

Inv. On Units 2/4 ID: 1

Out

Ïàµçѹ V

Com. Adress Set

µç Á ÷ A

Records

Settings

Mains Volt. Abnormal

UPS in Battery Mode

Ƶ  ÊHz

¹¦ÂÊÒòÊý

Ïßµçѹ V

2001-11-08

2001-11-08

Language

A(B)

Chinese

1

Date & Time Set

2001£ -11£ -08 12:50:30

English

221

11. 8

50.2

0.99

381 380 382

11£ -08 12:09

11£ -08 12:09

11£ -08 12:09

11£ -08 12:09

11£ -08 12:28

11£ -08 12:09

11£ -08 12:28

11£ -08 12:15

11£ -08 12:50

11£ -08 12:12

Battery

indicator

12:50:30

12:50:30

Inverter

indicator

Alarm

Chinese

B(C) C(A)

220 221

1

12.3

50.1

50.1

0.99

m

Fig. 5-2 Function Dividing

F1

F2

F3

F4

Load

indicator

Alarm

indicator

Emergency

Inverter

stare

Fault

clearing

shutdown

Inverter

stop

Mute

5.1.2 LED Indication

There are six LEDs to indicate the operation state and fault.

Yellow – Normal

Red – Fault condition

Bypass LED

Yellow – Load on Bypass power

Red – Bypass Voltage out of normal range

Off – Bypass Normal

Rectifier LED

Yellow – Load on Rectifier

Flashing Yellow – Utility Normal, but rectifier not operating

Red – Rectifier fault

Off – Utility abnormal

Battery LED

Green – Battery powers the load

44

Page 51

Chapter 5 Operation of Display Panel

Flashing Green – End of battery discharge

Red – Battery Abnormal (overtemp, low battery, contactor fused)

Off – Battery Normal but not in operation

Inverter LED

Green – Inverter powers the load normally

Flashing Green - Inverter standby

Red – Inverter Fails

Off – Inverter Normal but not in operation

Load LED

Green – UPS output on

Red – UPS shuts down due to overload

Orange – UPS overload

Alarm LED: If the red LED turns on, that means the system itself has fault; If green

LED turns on, that means there is no alarm; If orange color(actually red and green

illuminate together) means there is a fault in the environment of the system, such

as rectifier input abnormal, bypass voltage abnormal and battery disconnected.

5.1.3 Functional Keys

There are five buttons.

Emergency shutdown – Use to totally shut down the UPS including the rectifier, the

inverter and the battery

Inverter Start-Use to start the inverter, but if the inverter is not ready, pressing this

key will have no use

Inverter Stop-use to shut down the Inverter during operation,

Fault clear – If the UPS shuts down due to a fault, press this key to restart the UPS