Page 1

Large Systems

iCOM

Environmental Training and Service Manual

Microprocessor

TM-10098: Rev. 02/06

Page 2

Training & Service

iCOM

Control Training and Service Manual

iCOM

Manual

1

Page 3

iCOM

Controls Training and Service Manual

Disclaimer of Warranties and Limitations of Liabilities

The authors and editors have taken every precaution to ensure accuracy and completeness

in this manual. The authors and editors make no expressed or implied warranty of any

kind with regard to the documentation in this manual. Liebert Corporation assumes no

responsibility, and disclaims all liability for incidental or consequential damages resulting

from the use of this information or from errors or omissions. Liebert Corporation may

make improvements and/or changes in the product(s) described in this manual at any time.

Information in this manual is subject to change at any time and does not represent a

commitment on the part of Liebert Corporation.

Liebert® and the Liebert logo are registered trademarks of Liebert Corporation.

Emerson® and the Emerson logo are registered trademarks of Emerson Electric Co.

Copyright © 2004 by Liebert Corporation

All rights reserved throughout the world.

Specifications subject to change without notice.

Printed in the United States of America

2

Page 4

iCOM

Control Training and Service Manual

Table of Contents

Chapter 1: Temperature/ Humidity Control 6

Temperature Control Types

Intelligent Control

Proportional Control

Proportional + Integral (PI) Control

Proportional + Integral + Derivative (PID) Control

Temperature Control

Operations and Charts

2 Stage Compressorized

4 Stage Compressorized Cooling

Dual Compressor Digital Scroll Operation

Glycool Cooling

Dual Source Cooling

Staged Reheat

Humidity Control

Absolute (Predictive) Humidity Control

Relative Humidity Control

Humidifier Operation

Autoflush Control for Infrared

Dehumidification Operation

1 Stage Dehumidification, Compressorized Operation

2 Stage Dehumidification, Compressorized Operation

Reheat During Dehumidification

Additional Programs

Next Maintenance Calculation

Shared Parameters an Understanding

Networking and Functions

Teamwork

Unit Lead/ Lag or Running/ Standby Fuctions

6

6

8

8

9

11

11

11

13

18

18

20

21

25

25

27

27

29

31

31

32

33

35

38

40

41

48

49

3

Page 5

iCOM

Controls Training and Service Manual

Chapter 2: Programming Functions 52

Programming Functions

iCOM Display Components and Functions

iCOM Keypad Layout Descriptions

iCOM Display Symbols/ Icons

Programming Functions

Status Display Screens

Menu Screens – Icons/ Parameter Names

User Menu Icons and Descriptions

Service Menu Icons and Descriptions

Advanced Menu Icons and Descriptions

User Menu Parameters

Service Menu Parameters

Advanced Menu Parameters

Event Notifications Parameters

Event ID Number, Description and Function

52

53

54

55

56

56

57

58

59

60

60

67

84

90

92

Chapter 3: iCOM Hardware Connections 100

Introduction

Display Boards

Unit Control Board Switches and Jumpers

Large Display Switches and Jumpers

Small Display Switches and Jumpers

Temperature/ Humidity Board Switches and Jumpers

Unit Control Board Plug Connectors

Fuse Board Connectors

Temperature/ Humidity Board Connectors

100

101

102

104

105

106

107

111

112

Chapter 4: General Troubleshooting Data 114

Introduction

Isolation

Basic Operation of the Triac

Basic Operation of the Opto-Isolator

Troubleshooting the Opto-Isolator

114

115

116

118

119

4

Page 6

iCOM

Control Training and Service Manual

Unit Control Board: Opto-Isolator/ Triac Legends

iCOM Diagnostics/ Service Mode Programs

Basic Troubleshooting Steps

Moisture Content Charts

Suction Transducer Information

Digital Scroll High Temperature Sensor Chart

Unit Code Description

Troubleshooting Checklist

Glossary of Unit/ Systems Parameters

121

123

124

126

143

144

145

146

147

Glossary of Terms 156

Computer and Network Terms 160

Network Information 165

How To Use The Schematics 169

Electrical Schematics 170

5

Page 7

iCOM

Controls Training and Service Manual

Chapter 1

Temperature and Humidity

Control Programs

This section provides details on how your Liebert iCOM control responds to the

user programmed inputs values and room conditions. Refer to this section when

you need specific information control operation. This section includes details on

four (4) user selectable temperature control programs and two (2) user selectable

and humidity control programs.

Cooling and/ or Heating Required, in Percent (%)

The temperature control programs for the iCOM microprocessor is based on a

calculated percent (%) requirement for cooling and/ or heating. This percent (%)

requirement is determined by the control type (algorithm) selected by the user.

The four (4) user selectable temperature control programs are:

• Intelligent

• Proportional (P)

• Proportional + Integral (PI)

• Proportional + Integral + Derivative (PID)

Temperature Control Program Types

Intelligent Control – Factory Default Setting

The Intelligent Control operates from a set of general rules that defines how the

control output should be adjusted for different system conditions. The rules are

designed to duplicate the actions that an experienced human operator would take

if manually controlling the system.

Basically, this is done in a three-function process that differs from earlier

mathematically defined strict type data, hence, fuzzy logic. The on and off, true or

6

Page 8

iCOM

untrue type of statement is not used. The consideration now is how to set the

input value into a membership set, qualify this membership with rules, then decide

on the output consequence for action. It is not really that simple, but it is basically

how it works. The process:

Membership

• Measure value of input variables

• Map and transfer data into range of set domain

• Assign input membership into sets

Knowledge Base/Decision Making

• Provide a data base of definitions for rules base

• Provide a rules base and define function and domain

• Simulate human decision making based on concepts and actions

defined by implications and rules

Control Training and Service Manual

Consequence

• Convert defined range of knowledge to a corresponding output

variable

• Define a non-intelligent action from a deduced intelligent action

Just as an operator might take several things into consideration before making a

temperature control decision, the intelligent control can be programmed to do

likewise. For example, not only is the current temperature used in making

temperature control decisions, but also conditions such as:

• How fast is the temperature changing?

• What direction is the temperature changing?

• What is the cooling output now?

• What was the cooling output in the past?

• How long ago was the cooling output changed?

• Other factors

Any number of rules can be used in an intelligent control to define the controls

operation under various operating conditions. Hence, several advantages are

gained from this type of control over a more standard control approach that uses a

fixed mathematical equation to define the operation of the control for all conditions

(such as a Proportional or PID Control). You can expect Intelligent Control to be

7

Page 9

iCOM

more efficient and precise for most applications, but system performance based on

room conditions is not as predictable as standard approaches that use a fixed

equation.

The Liebert Intelligent Control includes rules that significantly enhance the

performance of the system, both from a standpoint of precision control and system

reliability.

Rules are included that:

Controls Training and Service Manual

• Cause the control to ignore very small or temporary temperature/

humidity deviations. This eliminates unnecessary control adjustments

that contribute to control instability.

• Help limit the frequency of control adjustments thus extending the life of

system components that are susceptible to mechanical wear or cycling.

• Recognize undesired modes of control operation such as hunting, and

make adjustments to the control response to eliminate them.

• Estimate the present load on the system and then tend to force the

control output to the appropriate state.

• Recognizes conditions, which indicate a large load change and allows

the control to temporarily respond more quickly than normal.

• Cause the control to anticipate the need for reheat during

dehumidification and activates reheats when overcooling occurs.

Proportional (P) Control

The proportional control is the standard control method that maintains the room at

a temperature proportional to the load. The temperature maintained increases as

the room load increases. At full load the room would be controlled at a

temperature equal to the temperature set point (TSP) plus ½ of the temperature

proportional band (PB). The operator programmed inputs are the temperature set

point (TSP) and temperature proportional band (PB) adjustments. The operator

may also program a temperature dead band (DB) adjustment.

Proportional + Integral (PI) Control

The PI control combines two (2) individual terms to determine the control output

for a given set of conditions. Note that PI control is used only for temperature. If

PI control is selected, the humidity control will be in percent relative humidity

(%RH).

The proportional (P) term is determined by the difference between the current

temperature and the control set point. This term is expressed in % cooling

(heating desired for each degree above (below) the set point. It is adjustable from

0% to 100% per degree. The purpose of this term is to adjust the control output

for any deviation between the current temperature and the control set point.

8

Page 10

iCOM

The integral (I) term is determined by two things: the difference between the return

air temperature and control set point and the amount of time this difference has

existed. This term is expressed in % cooling (heating) desired for each minute

and degree above (below) the set point. It is adjustable from 0% - 100% per

degree/minute. The purpose of this term is to force the control to maintain the

temperature around the set point by slowly but continuously adding (subtracting) a

small amount of cooling (heating) to the total control output until the temperature is

at the set point.

Control Training and Service Manual

Proportional + Integral + Derivative (PID) Control

The PID control combines three (3) individual terms to determine the control

output for a given set of conditions. Note that PID control is used only for

temperature. If PID control is selected, the humidity control will be in percent

relative humidity (%RH).

The proportional (P) term is determined by the difference between the current

temperature and the control set point. This term is expressed in % cooling

(heating desired for each degree above (below) the set point. It is adjustable from

0% to 100% per degree. The purpose of this term is to adjust the control output

for any deviation between the current temperature and the control set point.

The integral (I) term is determined by two things: the difference between the return

air temperature and control set point and the amount of time this difference has

existed. This term is expressed in % cooling (heating) desired for each minute

and degree above (below) the set point. It is adjustable from 0% - 100% per

degree/minute. The purpose of this term is to force the control to maintain the

temperature around the set point by slowly but continuously adding (subtracting) a

small amount of cooling (heating) to the total control output until the temperature is

at the set point.

The derivative (D) term is determined by the rate of change of temperature. This

term is expressed in % cooling (heating) desired for each degree per minute rise

(fall) in temperature. It is adjustable from 0% to 100% per degree/minute. The

purpose of this term is to adjust the control output for quickly changing

temperatures, thus providing an anticipation control.

All three terms are adjusted by selecting the “Setpoints” icon in either the USER or

SERVICE Menu screen. If PID control is selected, the temperature proportional

band value (and optional temperature dead band value) is not used by the control.

For optimum performance, a PID control must be adjusted or tuned according to

the characteristics of the particular space and load to be controlled. Improper

tuning can cause the control to exhibit poor response and/ or hunting. The

characteristics of the space and load may change seasonally, so occasional

returning is required for optimum performance.

9

Page 11

iCOM

A suggested tuning procedure is as follows:

Controls Training and Service Manual

1. Initially adjust the integral and derivative settings to 0% / degree-min

and 0% / degree / min..

2. Starting with 20% / degree, adjust the proportional setting in small

increments (10% steps) until the control sustains a constant hunting

action (the temperature swings are approximately the same amplitude

from one peak to the next).

3. Note the time in minutes between peaks of adjacent temperature

swings and the amplitude of the temperature swing (degrees above the

set point).

4. Adjust the proportional control setting to about l/2 the value obtained in

Step 2.

5. Adjust the integral setting to a value calculated by the following

equation: approximate room load (in % full load) time between

peaks x peak amplitude x 4.

Note: If calculation results in a value of less than 1%, then set the

integral to 1%.

6. Adjust the derivative to a value calculated by the following equation:

time between peaks x 5%.

The above tuning procedure is only an approximation for an initial set of

adjustments and are based on the "average" room characteristics. Your particular

settings may need to be further adjusted for optimum PID control performance.

Some suggestions for additional tuning are as follows:

• If cooling output overshoot is occurring on load changes, decrease

the proportional setting or the derivative setting.

• If system hunting occurs with constant room load, decrease the

integral setting.

• If the control responds too slowly, resulting in large temperature

excursions on a load change, increase the proportional setting or

the derivative setting.

• If a constant temperature deviation exists between the

temperature and set point, increase the integral setting.

10

Page 12

iCOM

Control Training and Service Manual

Temperature Control

Operations and Charts

The temperature proportional control band value is divided into two parts: the

temperature set point plus ½ of the temperature proportional band for cooling

operation and the temperature set point minus ½ of the temperature proportional

band for heating operation. A temperature dead band can also be programmed

into the control to shift the cooling and/ or heating on/ off operations away from the

temperature set point.

This programmed temperature dead band value is divided into two parts: the

temperature set point plus ½ of the dead band – no cooling operation and the

temperature set point minus ½ of the band – no heating operation.

The temperature set point range is adjustable from 41 - 104°F in increments of

1°F. The temperature proportional band range is adjustable from 2 - 54°F in

increments of 1°F. The temperature dead band range is adjustable from 0 - 36°F

in increments of 1°F.

Standard 2 Stage Compressorized Cooling

The basic temperature cooling control band is established at the temperature set

point with the length equal to ½ of the programmed temperature proportional band

divided by the number of cooling stages.

The Liebert DS units are supplied with two (2) compressors, each compressor is

rated at ½ of the unit capacity. The two (2) compressors will be either the

semi-hermetic or scroll type and will operate in an on/ off configuration to cool the

space.

The temperature controller activates the first cooling stage (lead compressor)

when the return air temperature increases to 50% of the cooling proportional band

and the second cooling stage (lag compressor) at 100% of the cooling proportional

band. The optional hot gas bypass solenoid valve, supplied with each compressor

when ordered, is also energized on a call for cooling.

11

Page 13

iCOM

The temperature controller deactivates the second stage of cooling (lag

compressor) when the return air temperature decreases to 50% of the cooling

proportional control band value. The first cooling stage (lead compressor) is

deactivated when the return air temperature decreases to the temperature set

point value or 0% of the cooling proportional control band value.

Controls Training and Service Manual

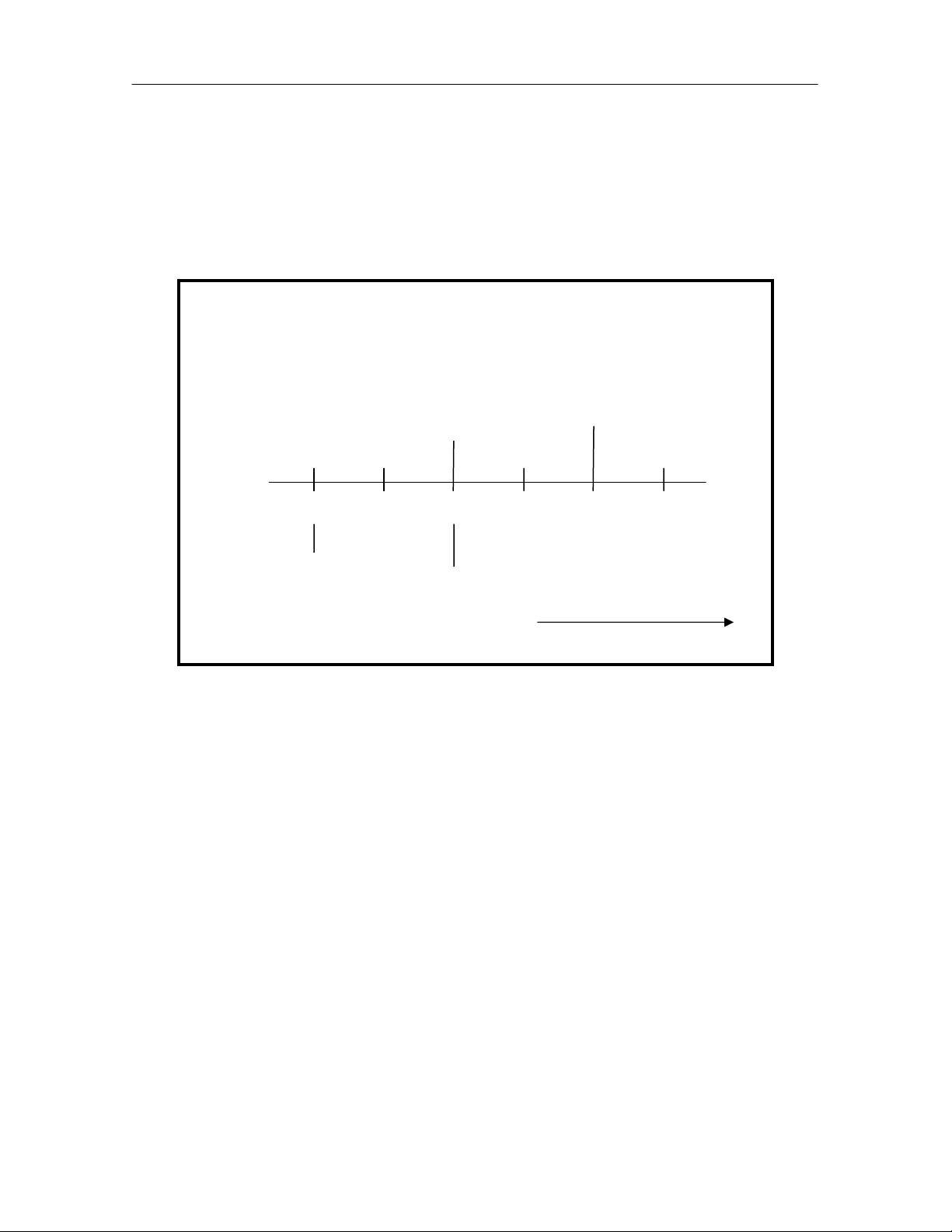

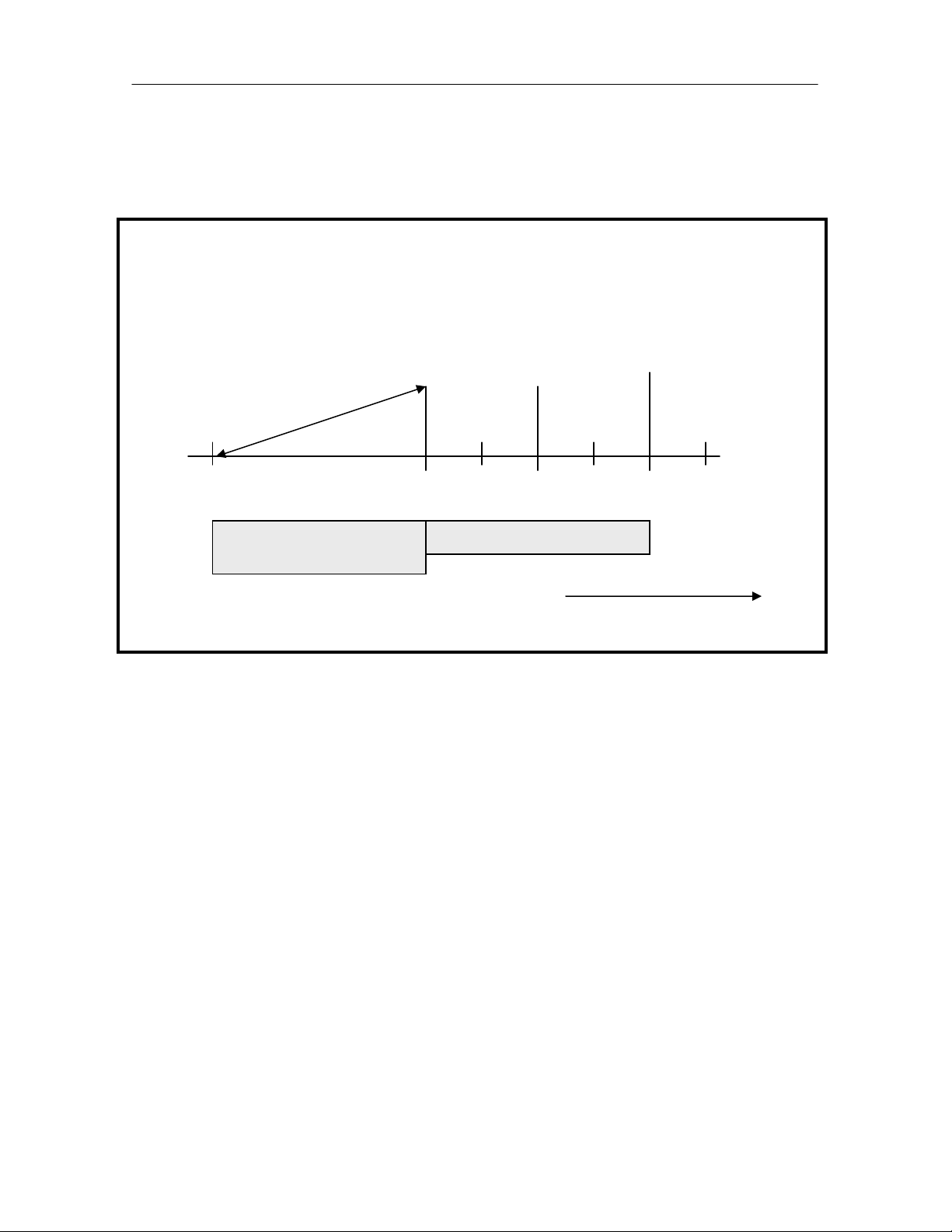

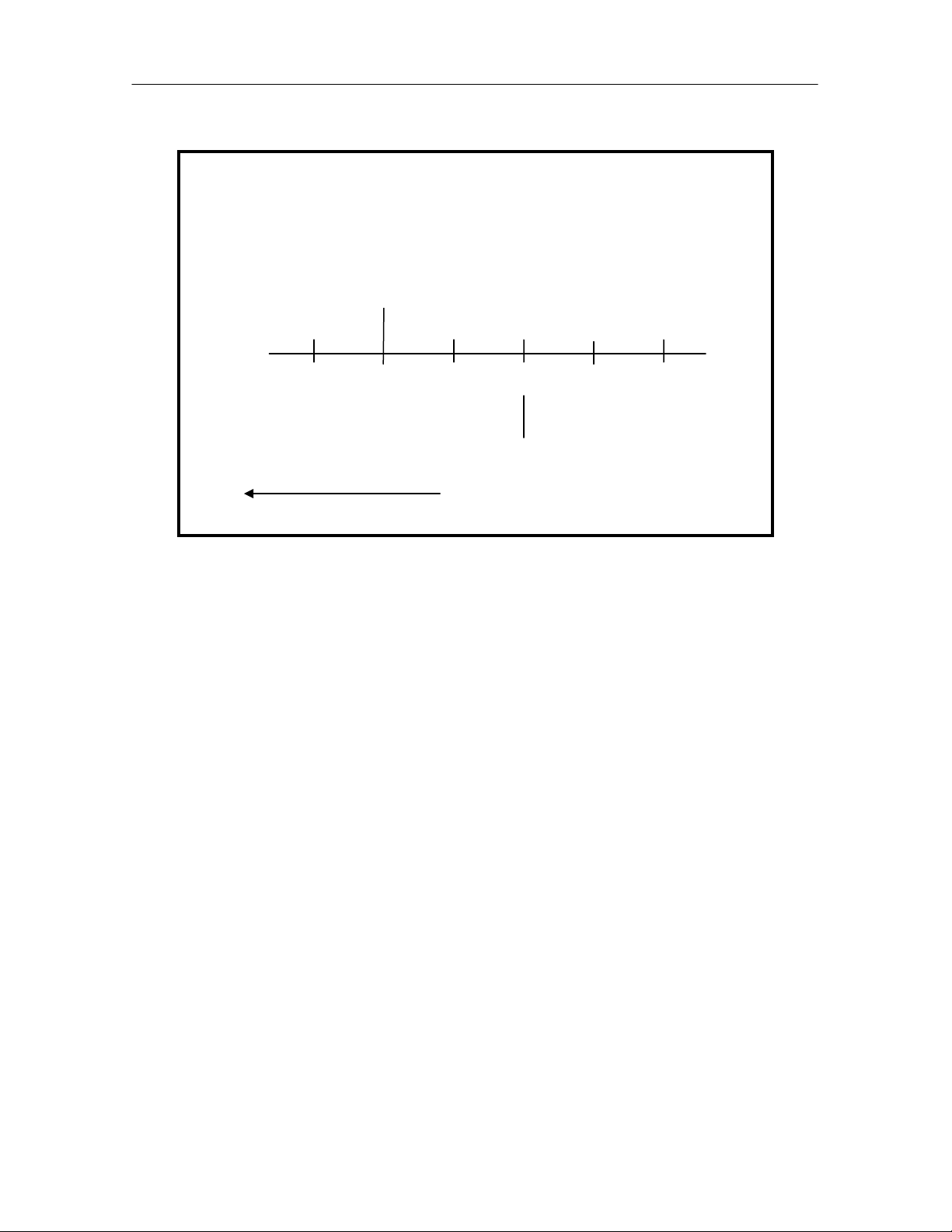

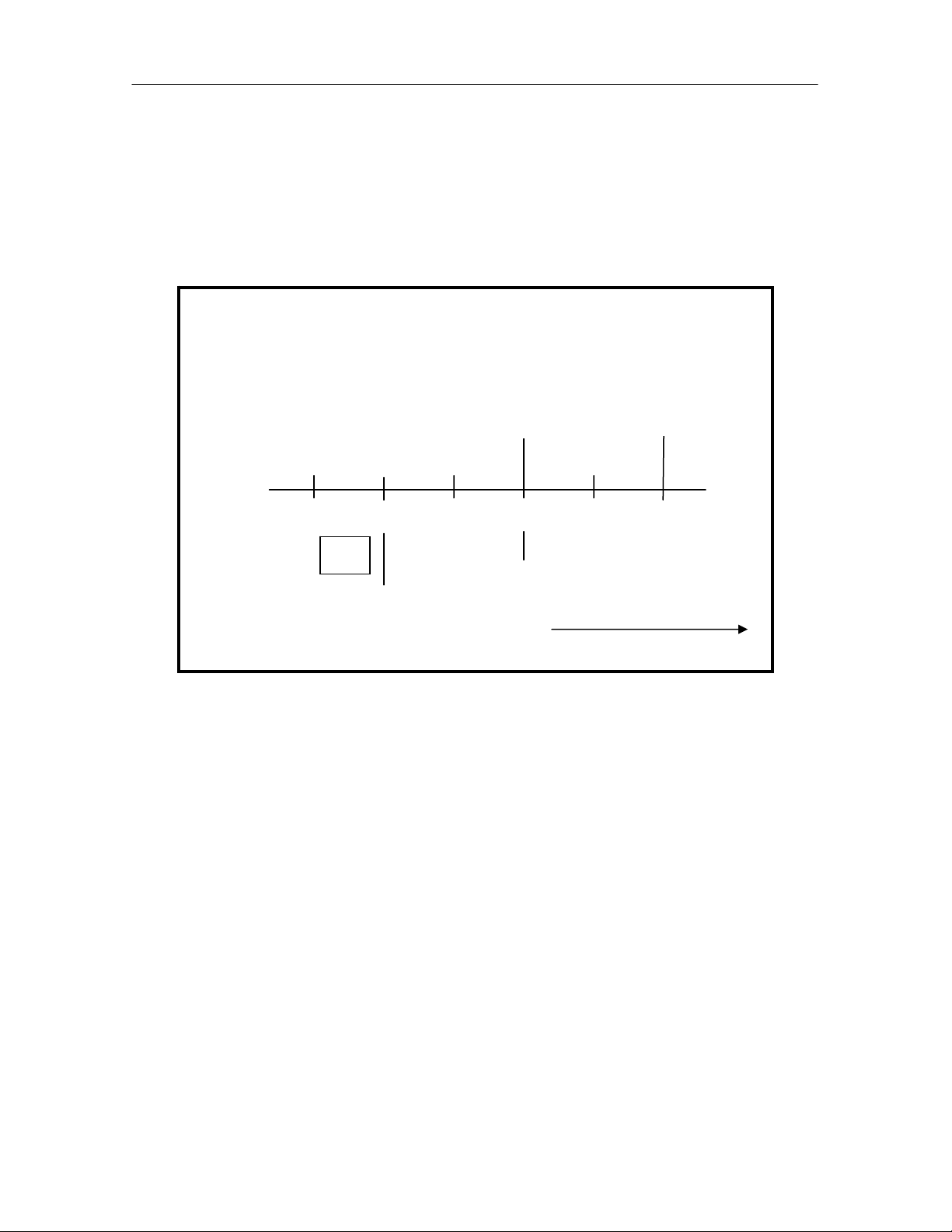

2 Stage Compressorized Cooling – No Dead Band

Note: in the above example that the control band begins at the 70°F temperature

set point and has a length of 4°F, which is ½ of the programmed temperature

proportional band value.

As the return air temperature increases Cooling 1 (lead compressor) is activated at

72°F or 50% of the cooling control band. If the return air temperature continues to

increase Cooling 2 (lag compressor) will activate at 74°F or 100% of the cooling

control band.

When the return air temperature starts to decrease, Cooling 2 (lag compressor) is

deactivated at 72°F or 50% of the cooling control band and Cooling 1 (lead

compressor) is deactivated at the temperature set point of 70°F or 0% of the

cooling control band.

Temp Set Point: 70°F

Proportional Band: 8°F

Temp Set Point + (1/2 Proportional Band)

Cool 1 On

70 71 72 73 74 75

Cool 1 Off

Cool 2 Off

Cool 2 On

Increasing Temperature

12

Page 14

iCOM

Control Training and Service Manual

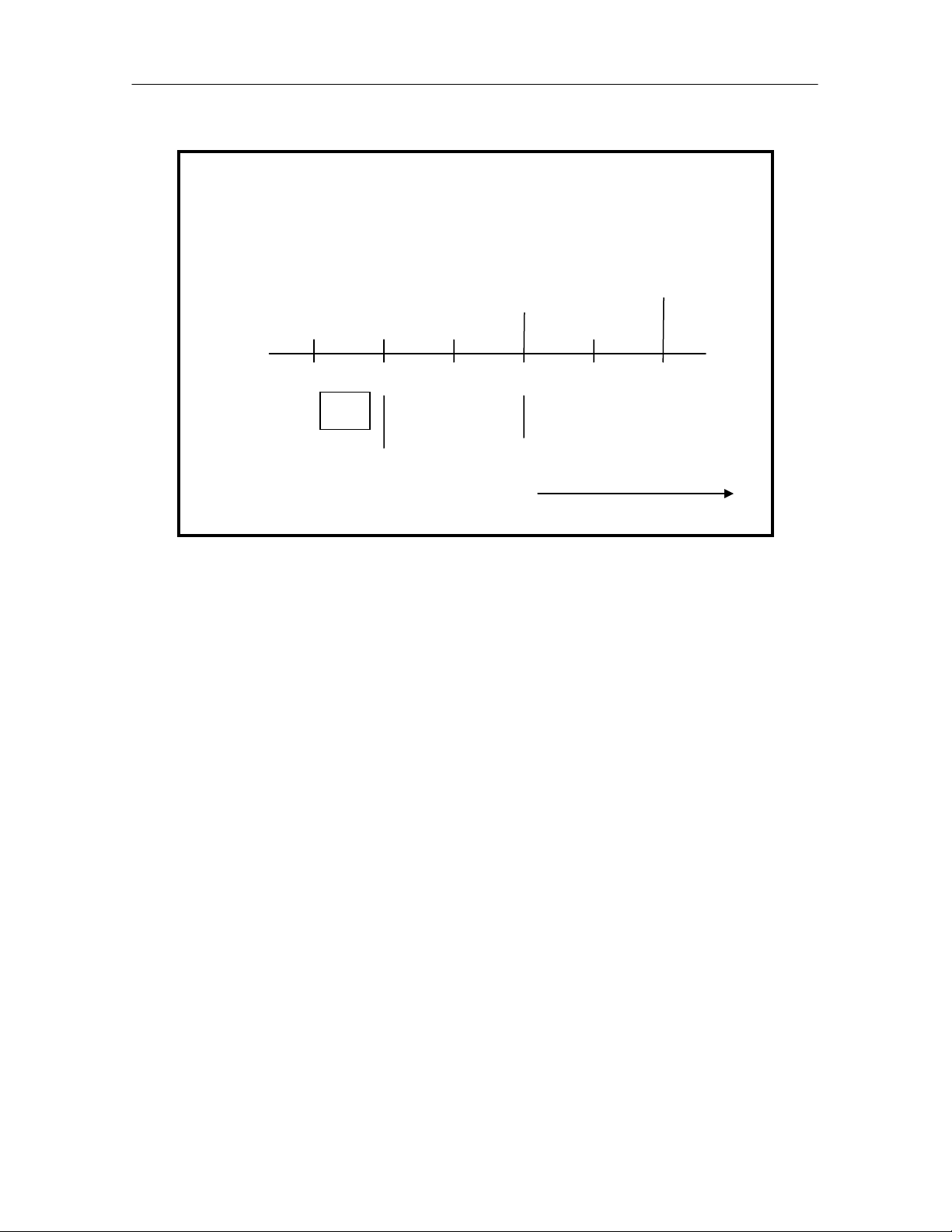

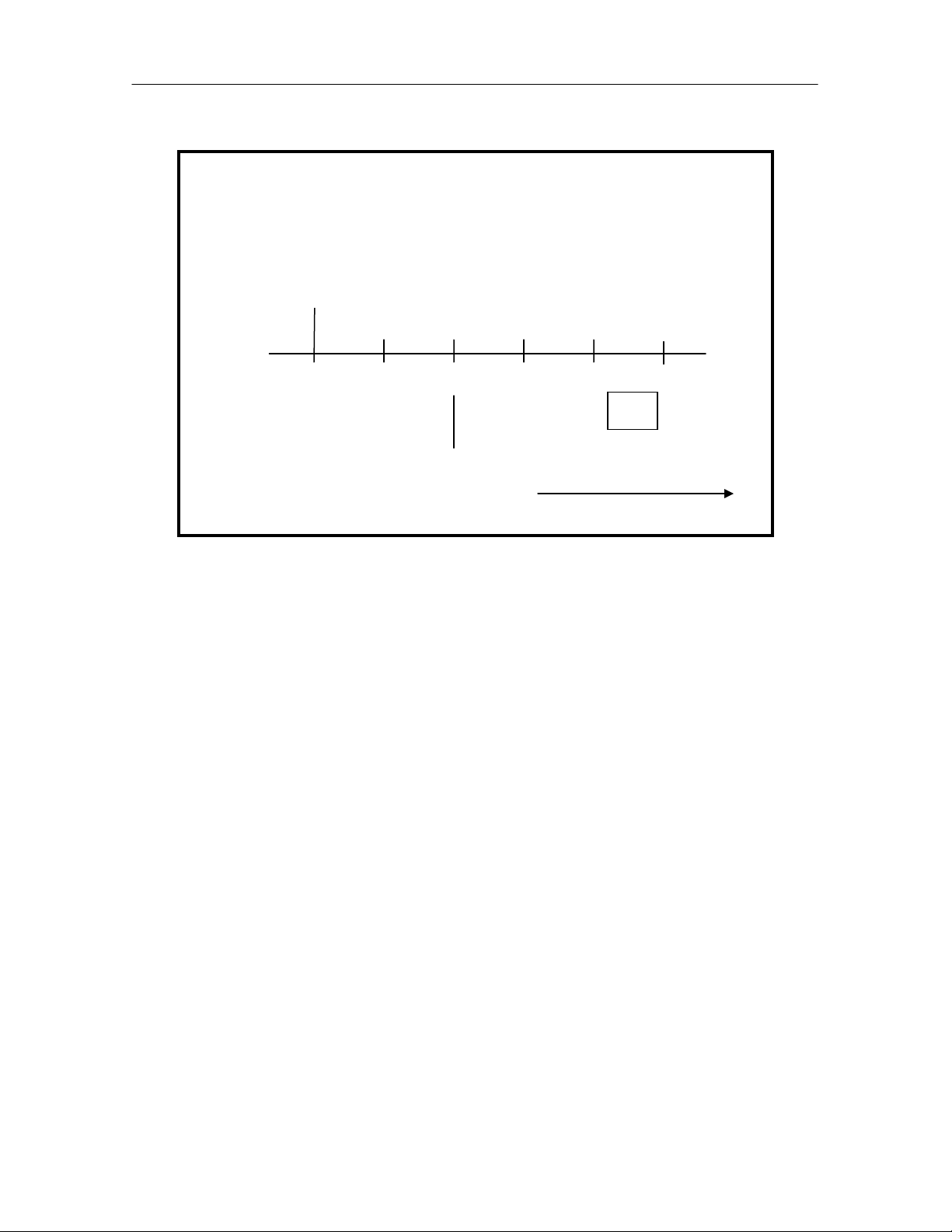

2 Stage Compressorized Cooling – With Dead Band

Note: in the above example that the control band begins at the 70°F temperature

set point and has a length of 5°F, which is ½ of the programmed temperature dead

band value plus ½ of the programmed temperature proportional band value.

As the return air temperature increases Cooling 1 (lead compressor) is activated at

73°F or ½ of the dead band value plus 50% of the cooling control band. If the

return air temperature continues to increase Cooling 2 (lag compressor) will

activate at 75°F or ½ of the dead band value plus 100% of the cooling control

band.

When the return air temperature starts to decrease, Cooling 2 (lag compressor) is

deactivated at 73°F or ½ of the dead band value plus 50% of the cooling control

band and Cooling 1 (lead compressor) is deactivated at 71°F or ½ of the dead

band value plus 0% of the cooling control band.

Remember the temperature dead band value is used by the control to shift the

cooling on/ off operations away from the temperature set point.

Temp Set Point + (1/2 Dead Band + 1/2 Proportional Band)

Temp Set Point: 70°F

Proportional Band: 8°F

Dead Band: 2°F

Cool 1 On

70 71 72 73 74 75

DB

Cool 1 Off

Cool 2 Off

Increasing Temperature

Cool 2 On

Optional 4 - Stage Cooling, Two (2) Compressors with Unloaders

The basic temperature cooling control band is established at the temperature set

point with the length equal to ½ of the programmed temperature proportional band

divided by the number of cooling stages.

The Liebert DS units are supplied with two (2) compressors, each compressor is

rated at ½ of the unit capacity. Each compressor will be the semi-hermetic type

13

Page 15

iCOM

and will be supplied with an electrical cylinder unloader valve. The electrical

solenoid valve used to unload or reduce the cooling capacity of the compressor.

The compressors will operate in an on/ off - loaded/ unloaded configuration

method to cool the space. The hot gas bypass solenoid valve option is not

available on 4 stage systems.

The temperature controller activates the first cooling stage, lead compressor

unloaded, when the return air temperature increases to 25% of the cooling

proportional band. The second cooling stage, lag compressor unloaded, is

activated when the return air temperature increases to 50% of the cooling

proportional band.

The temperature controller activates the third cooling stage, the lead compressor

loaded, when the return air temperature increases to 75% of the cooling

proportional band. The fourth cooling stage, the lag compressor loaded, is

activated when the return air temperature increases to 100% of the cooling

proportional band.

The temperature controller deactivates the fourth cooling stage, lag compressor

loaded, when the return air temperature decreases to 75% of the cooling

proportional control band value. The third cooling stage, lead compressor loaded,

is deactivated when the return air temperature decreases to 50% of the cooling

proportional control band value.

The temperature controller deactivates the second cooling stage, lag compressor

unloaded, when the return air temperature decreases to 25% of the cooling

proportional control band value. The first cooling stage, lead compressor

unloaded, is deactivated when the return air temperature decreases to the

temperature set point value or 0% of the cooling proportional control band value.

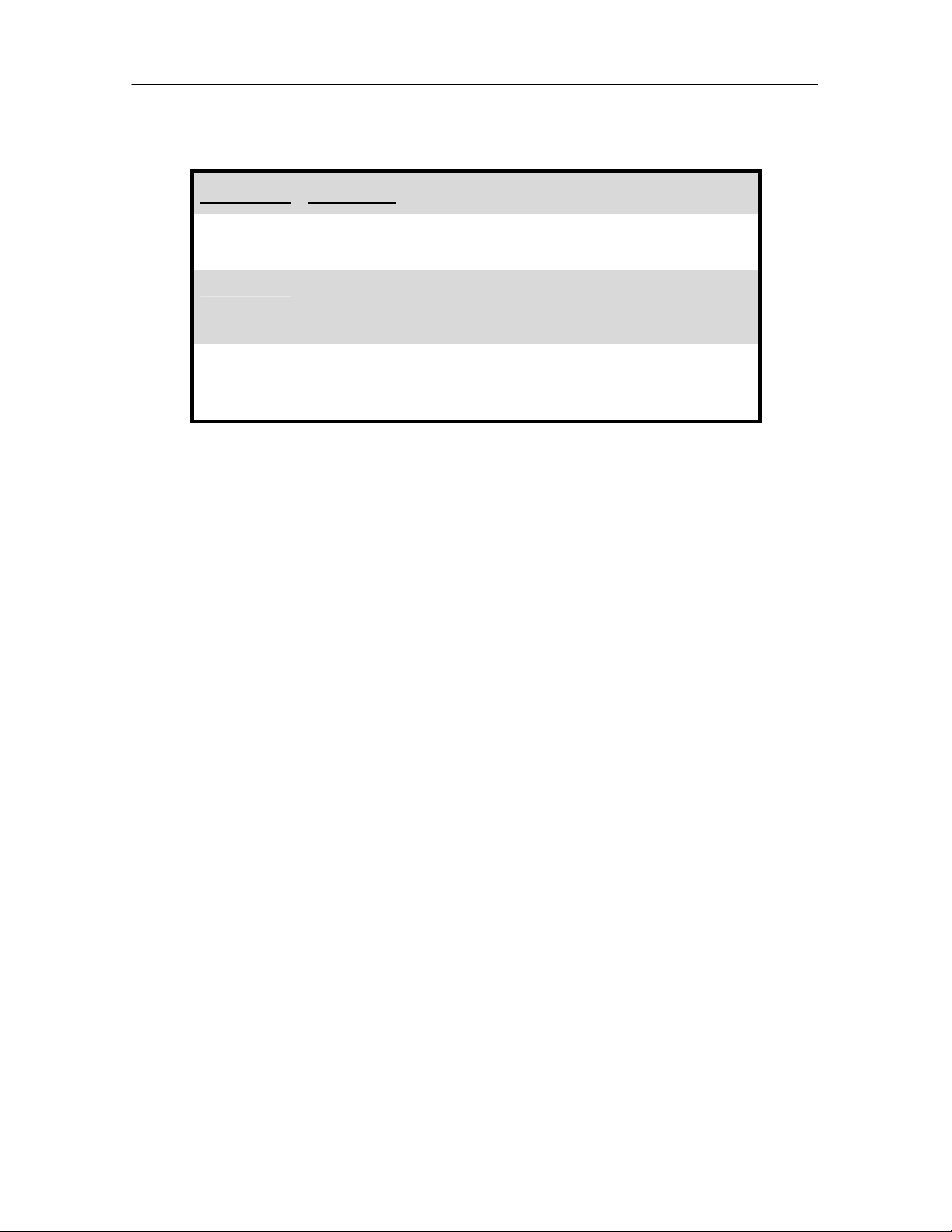

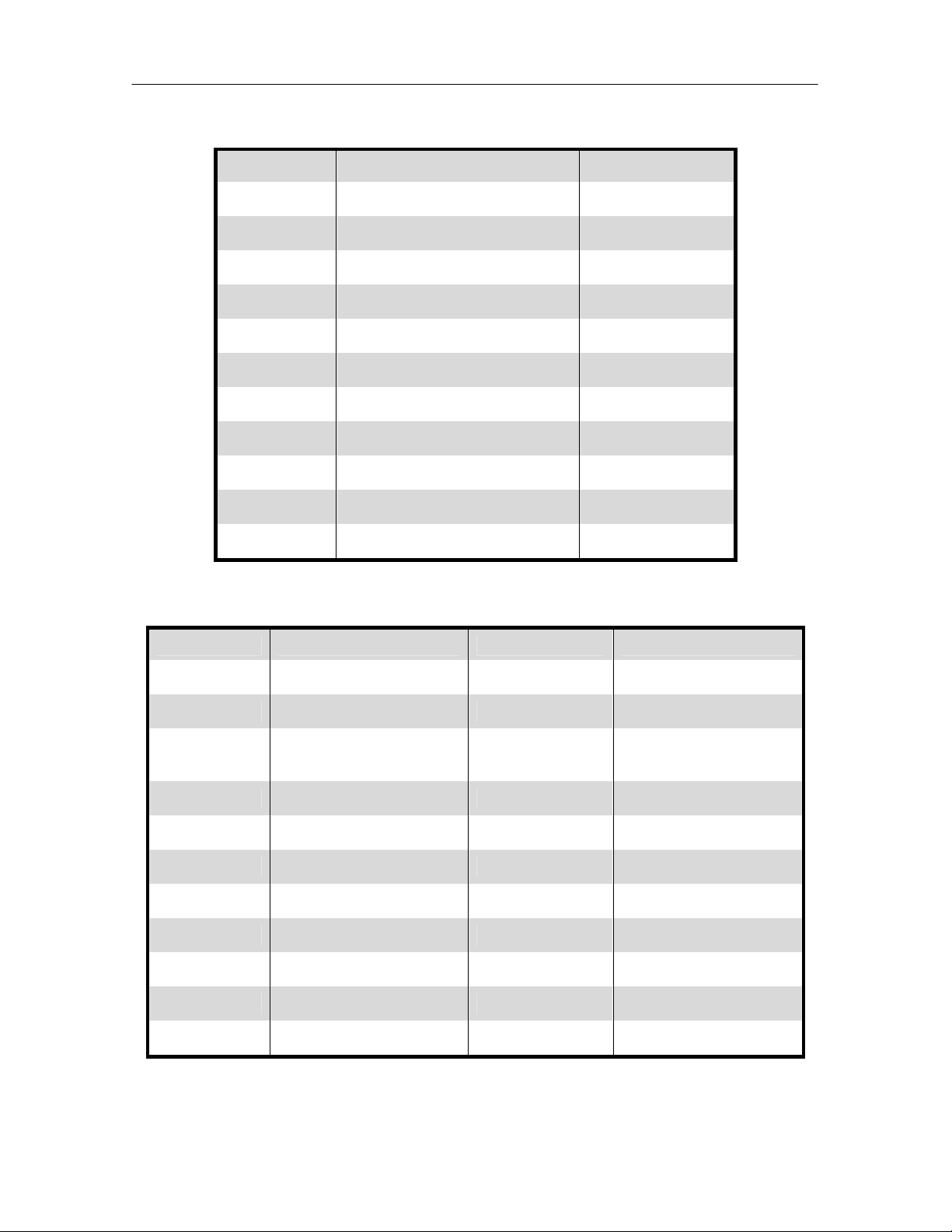

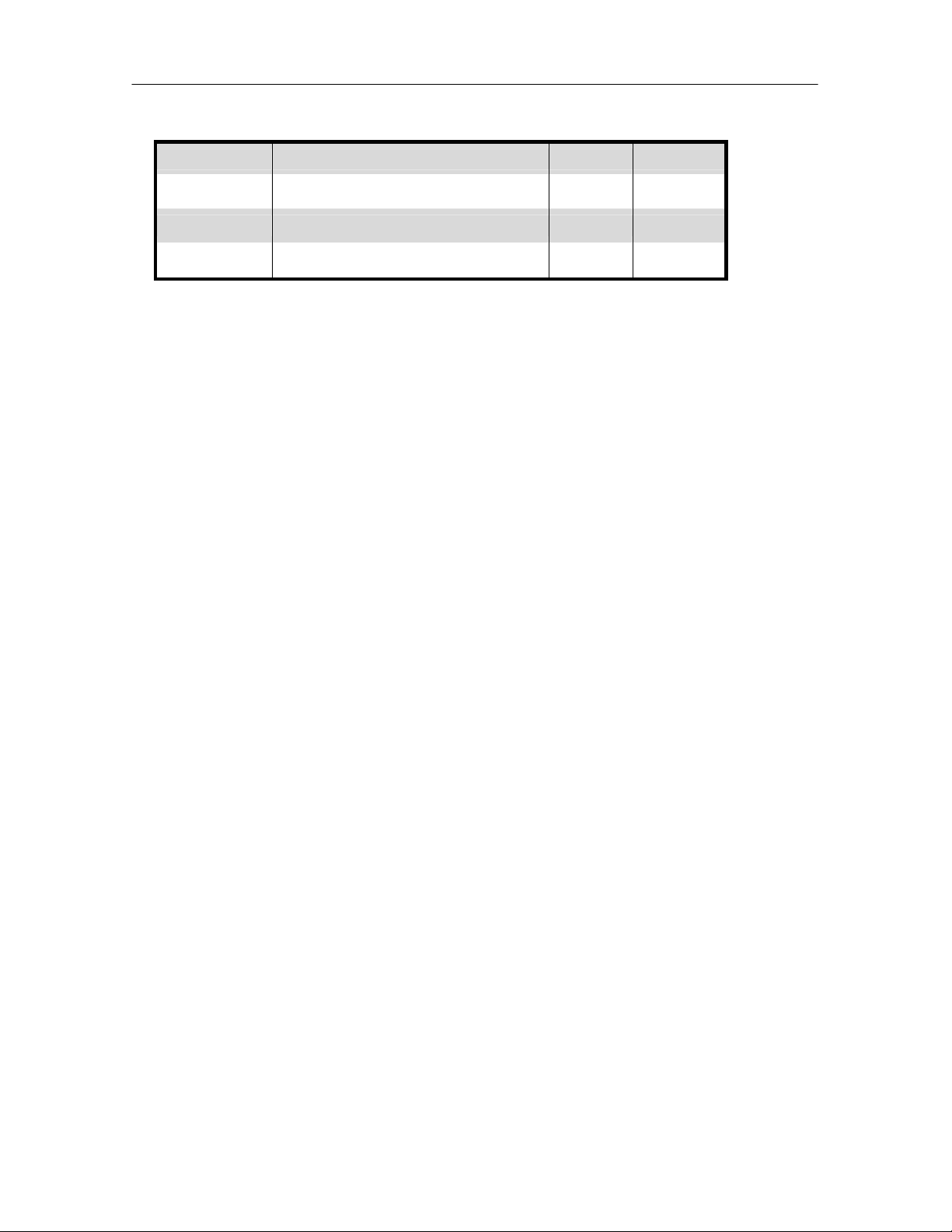

The table below shows the devices activated by each of the four cooling stages.

Controls Training and Service Manual

STAGE COMPRESSORS, UNLOADER STATE

1

2

3

4

Compressor 1 On, Unloader On (Energized)

Compressor 2 Off, Unloader Off (De-Energized)

Compressor 1 On, Unloader On (Energized)

Compressor 2 Off, Unloader On (Energized)

Compressor 1 On, Unloader Off (De-Energized)

Compressor 2 On, Unloader On (Energized)

Compressor 1 On, Unloader Off (De-Energized)

Compressor 2 On, Unloader Off (De-Energized)

14

Page 16

iCOM

Control Training and Service Manual

4 Stage Compressorized Cooling – No Dead Band

Note: in the above example that the control band begins at the 70°F temperature

set point and has a length of 4°F, which is ½ of the programmed temperature

proportional band value.

As the return air temperature increases Cooling 1, the lead compressor unloaded,

is activated at 71°F or 25% of the cooling control band. If the return air

temperature continues to increase Cooling 2, the lag compressor unloaded is

activated at 72°F or 50% of the cooling control band. If the return air temperature

continues to increase Cooling 3, the lead compressor is loaded at 73°F or 75% of

the cooling control band. If the return air temperature continues to increase

Cooling 4, the lag compressor is loaded at 74°F or 100% of the cooling control

band.

When the return air temperature starts to decrease, Cooling 4 is deactivated at

73°F or 75% of the cooling control band. If the return air temperature continues to

decrease Cooling 3 is deactivate at 72°F or 50% of the cooling control band. If the

return air temperature continues to decrease Cooling 2 is deactivate at 71°F or

25% of the cooling control band and Cooling 1 is deactivated at the temperature

set point of 70°F or 0% of the cooling control band.

Temp Set Point: 70°F

Proportional Band: 8°F

Temp Set Point + (1/2 Proportional Band)

Cool 2 On

Cool 1 On

70 71 72 73 74 75

Cool 1 Off

Cool 3 Off

Cool 3 On

Cool 4 OffCool 2 Off

Cool 4 On

Increasing Temperature

15

Page 17

iCOM

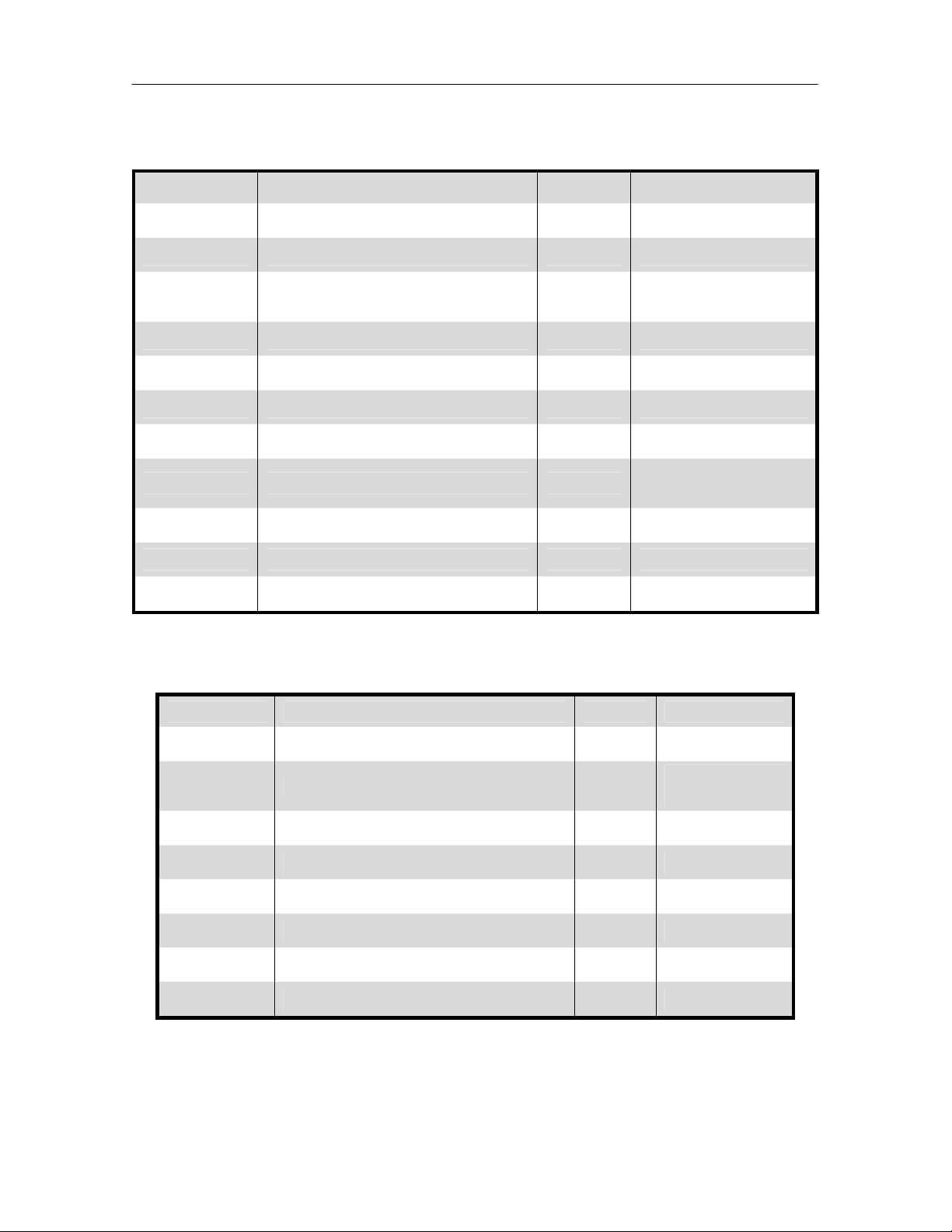

The example below is based on a temperature set point of 70°F with a control

band length of 4°F, which is ½ of the programmed temperature proportional band

value.

Controls Training and Service Manual

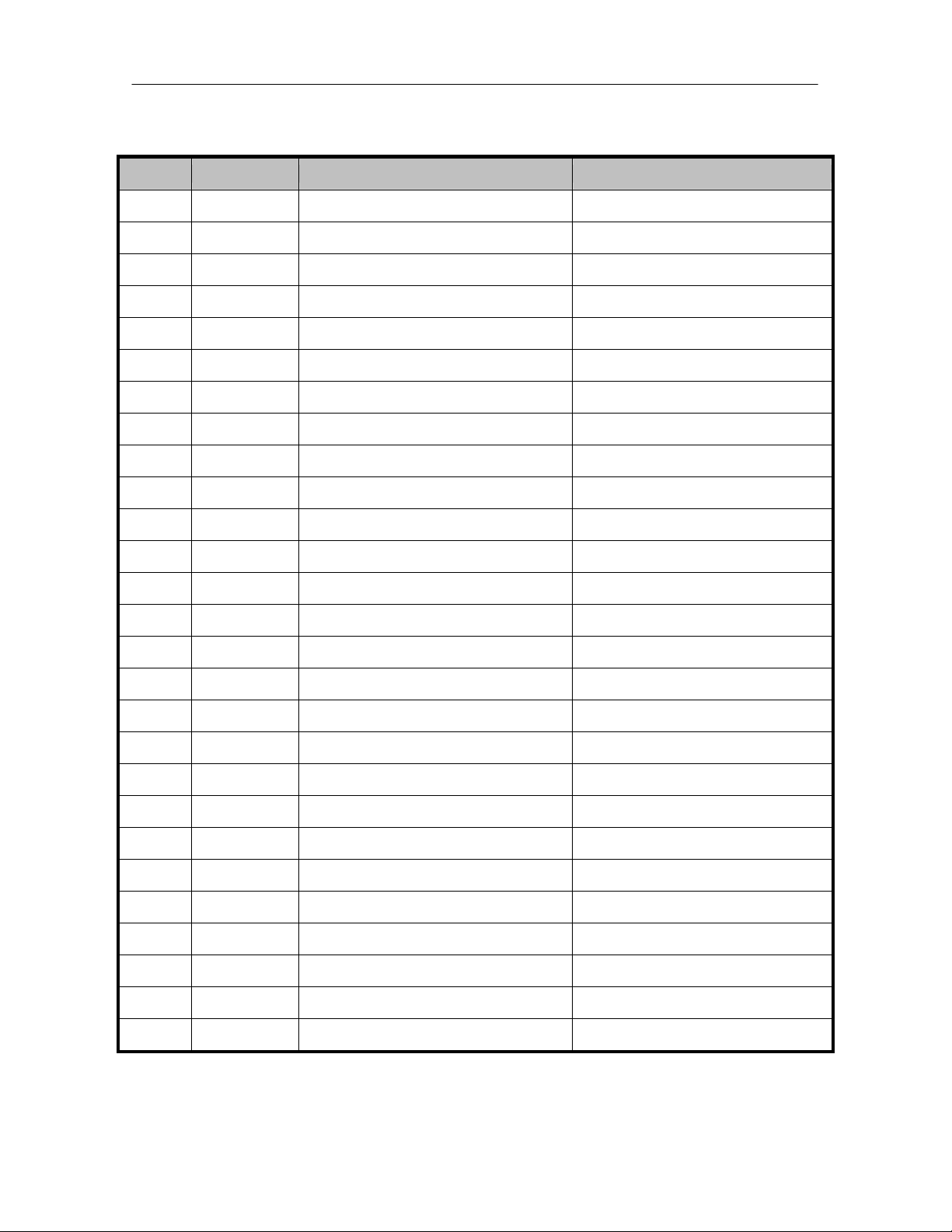

STAGE TEMPERATURE

Cool 1 ON

Cool 2 ON

Cool 3 ON

Cool 4 ON

Cool 4 OFF

Cool 3 OFF

Cool 2 OFF

Cool 1 OFF Set point

Set point plus 1°F

Set point plus 2°F

Set point plus 3°F

Set point plus 4°F

Set point plus 3°F

Set point plus 2°F

Set point plus 1°F

4 Stage Compressorized Cooling – With Dead Band

Note: in the above example that the control band begins at the 70°F temperature

set point and has a length of 5°F, which is ½ of the programmed temperature dead

band value plus ½ of the programmed temperature proportional band value.

Temp Set Point + (1/2 Dead Band + 1/2 Proportional Band)

Temp Set Point: 70°F

Proportional Band: 8°F

Dead Band: 2°F

70 71 72 73 74 75

DB

Cool 1 Off

Cool 2 On

Cool 1 On Cool 3 On

Cool 2 Off

Cool 3 Off

Cool 4 Off

Increasing Temperature

Cool 4 On

16

Page 18

iCOM

As the return air temperature increases Cooling 1, lead compressor unloaded, is

activated at 72°F or ½ of the dead band value plus 25% of the cooling control

band. If the return air temperature continues to increase Cooling 2, lag

compressor unloaded, will activate at 73°F or ½ of the dead band value plus 50%

of the cooling control band. If the return air temperature continues to increase

Cooling 3, lead compressor unloaded, is activated at 74°F or ½ of the dead band

value plus 75% of the cooling control band. If the return air temperature continues

to increase Cooling 4, lag compressor loaded, will activate at 75°F or ½ of the

dead band value plus 100% of the cooling control band.

When the return air temperature starts to decrease, Cooling 4 is deactivated at

74°F or ½ of the dead band value plus 75% of the cooling control band. If the

return air temperature continues to decrease Cooling 3 will be deactivate at 73°F

or ½ of the dead band value plus 50% of the cooling control band. If the return air

temperature continues to decrease Cooling 2 will be deactivate at 72°F or ½ of the

dead band value plus 25% of the cooling control band and Cooling 1 is

deactivated at 71°F or 1/2 the dead band value plus 0% of the cooling control

band.

Remember the temperature dead band value is used by the control to shift the

cooling on/ off operations away from the temperature set point.

Control Training and Service Manual

17

Page 19

iCOM

p

f

p

d

Controls Training and Service Manual

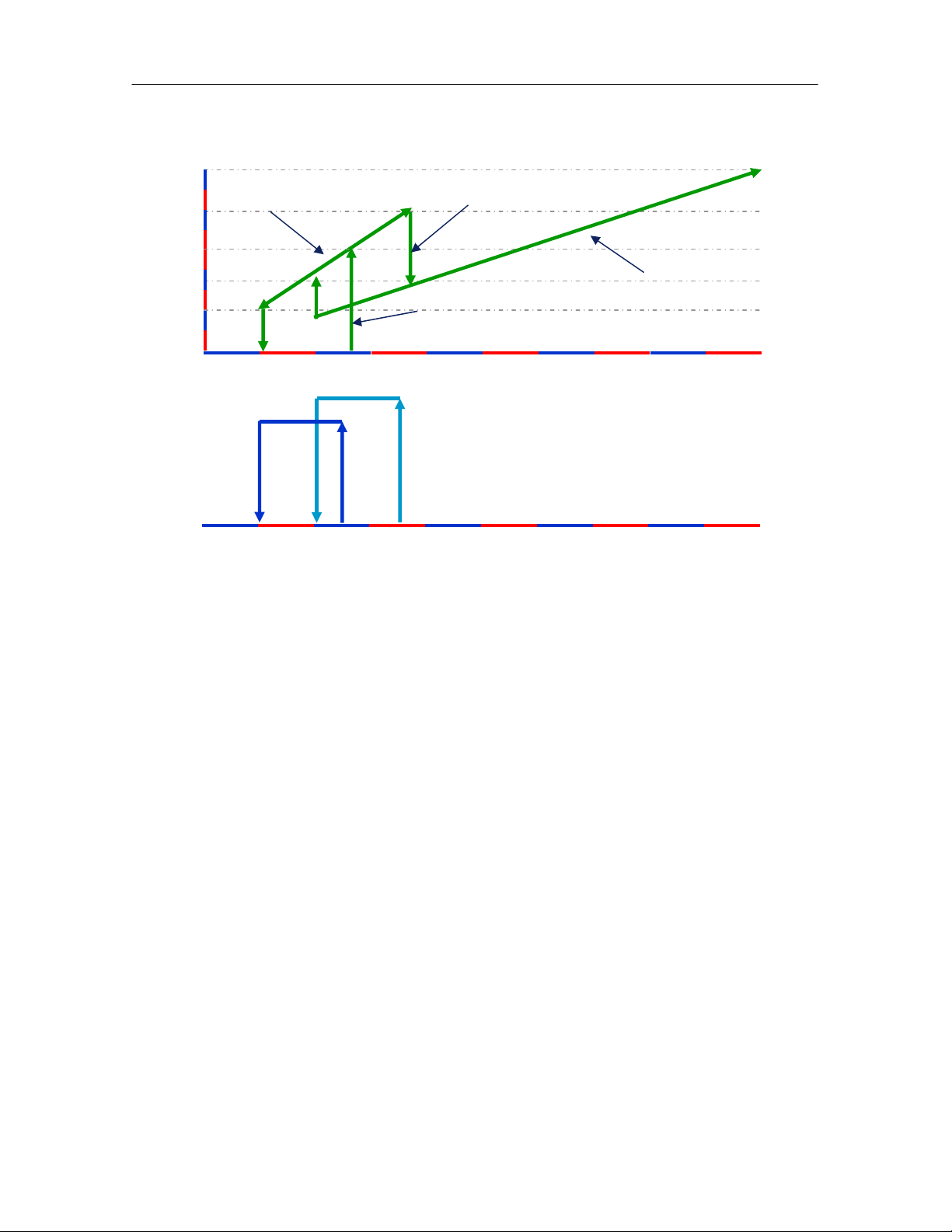

Optional Dual Compressor Digital Scroll Operation

100

1 compressor operation

Switch 2

n

70

50

PWM

35

20

st

2 compressor operation

ressor ONSwitch 1 com

Off

Of

C1

On

C2

On

Start/ sto

10

20

25

35 700%

In the chart above we are defining the Digital Compressor start and stop at the

capacity need and how the compressors load and unload with the PWM from the

controller and the unit setting for temperature control.

Note that the Digital Scroll will run continuously while the head is raised and

lowered as the need for cooling is required from 10% to 100% and vise versa.

Optional Glycool (Econ-O-Cycle) Cooling

When supplied with the Glycool option, the basic unit is supplied with an additional

coil, piping, valve and a Glycol Fluid Sensor (AQ), which is mounted to the unit

supply fluid line and serves as control interface in determining the system

operation. Selection of the glycool or compressorized operation is controlled by

microprocessor using this aquastat to sense the glycol temperature.

The Glycool (Econ-O-Cycle) Cooling program establishes two distinct control

bands for cooling control operation. The first band controls the operation of the

chilled glycol valve and the second controls the operation of the compressors,

either 2-stage or 4-stage.

The microprocessor checks the return air temperature and the entering glycol fluid

temperature to determine a cooling capacity. In order to reduce compressor

cycling and to prevent chilled glycol valve hunting, Glycool (Econ-o-Cycle) cooling

capacity does not become available until the entering chilled glycol fluid

18

Page 20

iCOM

Control Training and Service Manual

temperature is at least 8°F below the return air temperature, or 3°F lower than the

return air temperature for two consecutive hours.

When the microprocessor decides that the return glycol fluid temperature is cold

enough the first cooling band is the modulating valve control method, and the

second band, added to the first band, is for the compressors as in the normal

2-Stage or 4-Stage control method. If the chilled glycol fluid temperature is not

cold enough the valve control band is replaced by the compressor band. If the

chilled glycol cooling capacity is reduced by a rise in the glycol fluid temperature,

the control band shrinks proportionally. This allows the compressor band to move

down as well. The following shows the Glycool operation at 100% capacity and

the Glycool at 50% capacity.

Glycool at 100% Capacity – No Dead Band

Temp Set Point + (1/2 Proportional Band + 1/2 Proportional Band)

Temp Set Point: 70°

Proportional Band: 8°

Valve

Closed

70 71 72 73 74 75 76 77 78 79

Band 1 Glycool Valve Band 2 Compressors

100%

Open

Cool 1 On

Cool 2 On

Increasing Temperature

19

Page 21

iCOM

Controls Training and Service Manual

Glycool at 50% Capacity – No Dead Band

Temp Set Point + (1/2 Proportional Band + 1/2 Proportional Band)

Temp Set Point: 70°

Proportional Band: 8°

Valve

Closed

100%

Open

Cool 1 On

Cool 2 On

70 71 72 73 74 75 76 77 78 79

Band 1

Band 2 Compressors

Glycool

Valve

Increasing Temperature

Dual Source Cooling

When supplied with the Dual Cooling option, the basic unit is supplied with an

additional coil, piping, valve and a Glycol Fluid Sensor (AQ), which is mounted to

the unit supply fluid line and serves as control interface in determining the system

operation. Selection of the chilled water or compressorized operation is controlled

by microprocessor using this aquastat to sense the water temperature.

The Dual Source Cooling program establishes two distinct control bands for

cooling control operation in the same method as Glycool. The first band controls

the operation of the chilled water valve and the second controls the operation of

the compressors, either 2-stage or 4-stage.

The microprocessor checks the return air temperature and the entering chilled

water fluid temperature to determine a cooling capacity. The chilled water cooling

capacity is considered to be 100% if the entering Chilled Water fluid temperature is

8°F lower than the return air temperature.

When the microprocessor decides that the return chilled water temperature is cold

enough the first cooling band is the modulating valve control method, and the

second band, added to the first band, is for the compressors as in the normal

20

Page 22

iCOM

Control Training and Service Manual

2-Stage or 4-Stage control method. If the chilled water temperature is not cold

enough the valve control band is replaced by the compressor band.

Dual Cooling at 100% Capacity – No Dead Band

Temp Set Point + (1/2 Proportional Band + 1/2 Proportional Band)

Temp Set Point: 70°

Proportional Band: 8°

Valve

Closed

100%

Open

Cool 1 On

Cool 2 On

70 71 72 73 74 75 76 77 78 79

Band 1 Chilled Water

Valvel

Band 2 Compressors

Increasing Temperature

An addition program available with the Dual Cooling option is called Minimum

Chilled Water Temperature. This program allows the end user to select the

minimum chilled water temperature that permits simultaneous operation of the

chilled water control and compressor control. When the supply chilled water

temperature decreases to this programmed value ONLY the chilled water valve

control is operational, the compressors are locked out.

Staged Electric Reheat

The basic temperature heating control band is established at the temperature set

point with the length equal to ½ of the programmed temperature proportional band

divided by the number of reheat stages.

The Liebert DS units are supplied with three (3) reheat stages (elements), each

stage is rated at 1/3 of the unit capacity. The three (3) stages will operate in an

on/ off configuration to reheat the unit discharge air as it enters the space.

The temperature controller activates the first electric heating stage when the return

air temperature decreases to 33% of the heating proportional band. The second

electric heating stage activates when the return air temperature decreases to 66%

21

Page 23

iCOM

of the heating proportional band. The third electric heating stage activates when

the return air temperature decreases to 100% of the heating proportional band.

The temperature controller deactivates the third heating stage when the return air

temperature increases to 66% of the heating proportional control band value. The

second heating is deactivated when the return air temperature increases to 33% of

the heating proportional control band value. The first heating stage is deactivated

when the return air temperature increases to the temperature set point value or

0% of the heating proportional control band value.

Controls Training and Service Manual

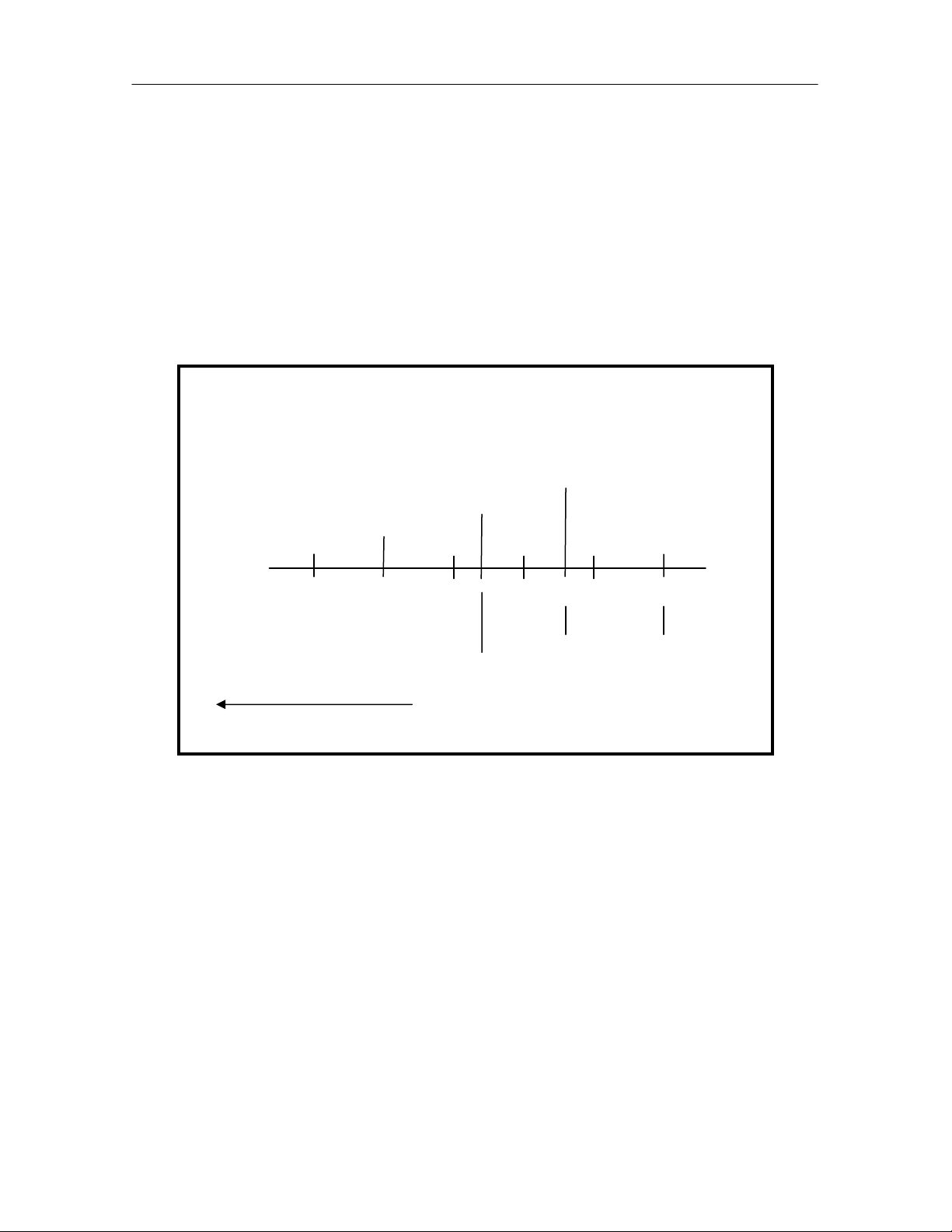

3 Stage Electric Reheat – No Dead Band

Note: in the above example that the control band begins at the 70°F temperature

set point and has a length of 4°F, which is ½ of the programmed temperature

proportional band value.

As the return air temperature decreases Reheat 1 is activated at 68.7°F or 33% of

the heating control band. If the return air temperature continues to decrease

Reheat 2 will activate at 67.4°F or 66% of the heating control band. If the return

air temperature continues to decrease Reheat 3 will activate at 66°F or 100% of

the heating control band.

When the return air temperature starts to increase, Reheat 3 is deactivated at

67.4°F or 66% of the heating control band, Reheat 2 is deactivated at 68.7°F or

33% of the heating control band and Reheat 1 is deactivated at the temperature

set point of 70°F or 0% of the heating control band.

Temp Set Point: 70°F

Proportional Band: 8°F

Decreasing Temperature

Temp Set Point - (1/2 Proportional Band)

Reheat 1 On

Reheat 2 On

Reheat 3 On

65 66 67 68 69 70

Reheat

3 Off

Reheat

2 Off

Reheat

1 Off

22

Page 24

iCOM

Control Training and Service Manual

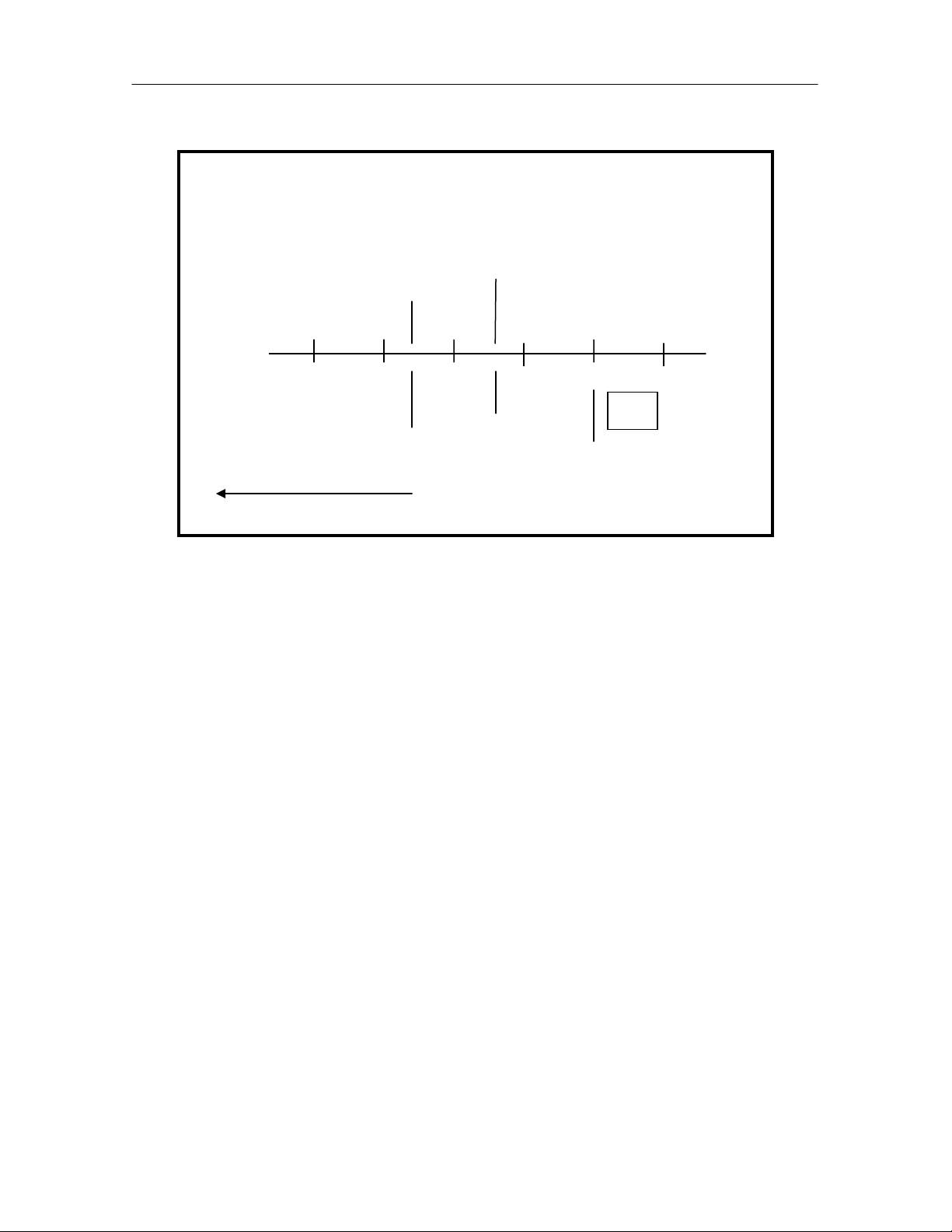

3 Stage Electric Reheat – With Dead Band

Note: in the above example that the control band begins at the 70°F temperature

set point and has a length of 5°F, which is ½ of the programmed temperature dead

band value plus ½ of the programmed temperature proportional band value.

As the return air temperature decreases Reheat 1 is activated at 67.7°F or ½ of

the dead band value plus 33% of the heating control band. If the return air

temperature continues to decrease Reheat 2 will activate at 66.4°F or ½ of the

dead band value plus 66% of the heating control band. If the return air

temperature continues to decrease Reheat 3 will activate at 65°F or ½ of the dead

band value plus 100% of the heating control band.

When the return air temperature starts to increase, Reheat 3 is deactivated at

66.4°F or ½ of the dead band value plus 66% of the heating control band. Reheat

2 is deactivated at 67.7°F or ½ of the dead band value plus 33% of the heating

control band. Reheat 1 is deactivated at 69°F or ½ of the dead band value plus

0% of the heating control band.

Remember the temperature dead band value is used by the control to shift the

cooling on/ off operations away from the temperature set point.

Temp Set Point - (1/2 Dead Band + 1/2 Proportional Band)

Temp Set Point: 70°F

Proportional Band: 8°F

Dead Band: 2°F

Reheat 2 On

Reheat 3 On

65 66 67 68 69 70

Reheat

3 Off

Decreasing Temperature

Reheat 1 On

Reheat

2 Off

DB

Reheat

1 Off

23

Page 25

iCOM

Controls Training and Service Manual

Humidity Control

Humidification and/ or Dehumidification Required, in

Percent (%)

The humidity control programs for the iCOM microprocessor is based on a

calculated percent (%RH) requirement for humidification and/ or dehumidification.

This percent (%RH) requirement is determined by the control type (algorithm)

selected by the user.

The two (2) user selectable humidity control programs are:

• Absolute Humidity, grains of moisture in the air

• Relative Humidity (%RH)

Humidity Control Program Types

Absolute (predictive) Humidity Control – Factory Default Setting

Absolute (predictive) humidity control is based on the moisture content in the

return air. The iCOM microprocessor control automatically adjusts the humidity

control as the return air temperature deviates from the programmed temperature

set point. This calculation converts the return temperature and humidity values to

a moisture content value defined as either grains per cubic foot or grains per

pound. This recalculated content value is compared to the content control band

that is determined by the:

• Programmed temperature set point

• Programmed humidity set point in %RH

• Programmed humidity proportional band in %RH

This automatic adjustment results in a predictive humidity control response. With

absolute humidity control, the humidity control program is automatically adjusted

approximately 2% RH for each degree difference between the return air

temperature and the temperature set point. Note the following example:

24

Page 26

y

y

y

Temperature

Set Point

Humidity

Set Point

iCOM

Proportional

Control Training and Service Manual

Humidity

Band = 6%

Content Level

Grains per LB.

75°F

75°F

The Absolute (Predictive) Humidity Control Flowchart shows what the program is

doing and why.

Programmed Values

Temp Set Point

Humidity Set Point

Humidit

The program can be analyzed using the Moisture Content Charts supplied in a

later chapter of this manual. It is important to remember that the display provides

the humidity value in %RH, not moisture content. The moisture content (grains)

values are used only in the internal control program calculation. The LCD display

will indicate relative humidity percentage for both methods of control. If the

absolute method of control is selected, the adjusted humidity reading will be

shown.

When utilizing the absolute (predictive) humidity control program feature,

the humidity level is automatically adjusted ~ 2% RH for each degree

difference between the return air temperature and the temperature set point.

When absolute humidity control is used, over dehumidification is avoided in the

space. When overcooling occurs, causing an increase in the relative humidity

reading, the humidity control program “predicts” what the RH will be when the

dehumidification cycle ends and the temperature returns to the programmed set

point. This allows the dehumidification cycle to end at the proper time.

Proportional Band

Present

Room Temperature

Room Humidity

50% +3% 59.2

50% -3% 52.5

Calculates Band

Calculates Content

Humidif

Dehumidif

Compares

Moisture

Content to

Band and

Makes

Decision

25

Page 27

iCOM

Controls Training and Service Manual

Relative Humidity Control

Relative humidity control is based on the humidity content in the return air. The

iCOM microprocessor control determines the unit humidification/ dehumidification

operation by comparing the return air humidity value to the control band that is

determined by the:

• Programmed humidity set point in %RH

• Programmed humidity proportional band in %RH

Operations and Charts

The humidity proportional control band value is divided into two parts: the humidity

set point plus ½ of the programmed humidity proportional band for

dehumidification operation and the humidity set point minus ½ of the programmed

humidity proportional band for humidification operation.

A humidity dead band can also be programmed into the control to shift the

humidification and/ or dehumidification on/ off operations away from the humidity

set point.

This programmed humidity dead band value is divided into two parts: the humidity

set point plus ½ of the dead band – no dehumidification operation and the humidity

set point minus ½ of the band – no humidification operation.

The humidity set point range is adjustable from 1 – 80% RH in increments of 1%

RH. The humidity proportional band range is adjustable from 1 – 20% RH in

increments of 1% RH. The humidity dead band range is adjustable from

0 – 50% RH in increments of 1% RH.

Humidifier Operation

The Relative Humidity control program is used to illustrate the humidification

operation in the following examples. The basic humidification control band is

established at the humidity set point with the length equal to ½ of the programmed

humidity proportional band value. The Liebert DS units are supplied with an

infrared humidifier rated at the unit capacity.

The humidity controller activates the infrared humidifier when the return air

humidity level decreases to 100% of the humidity proportional band. The

humidifier makeup water solenoid valve also operates during humidification

operation based on a timing sequence.

The humidity controller deactivates the infrared humidifier and makeup water

solenoid valve when the return air humidity level increases to 50% of the humidity

proportional control band value.

26

Page 28

iCOM

Control Training and Service Manual

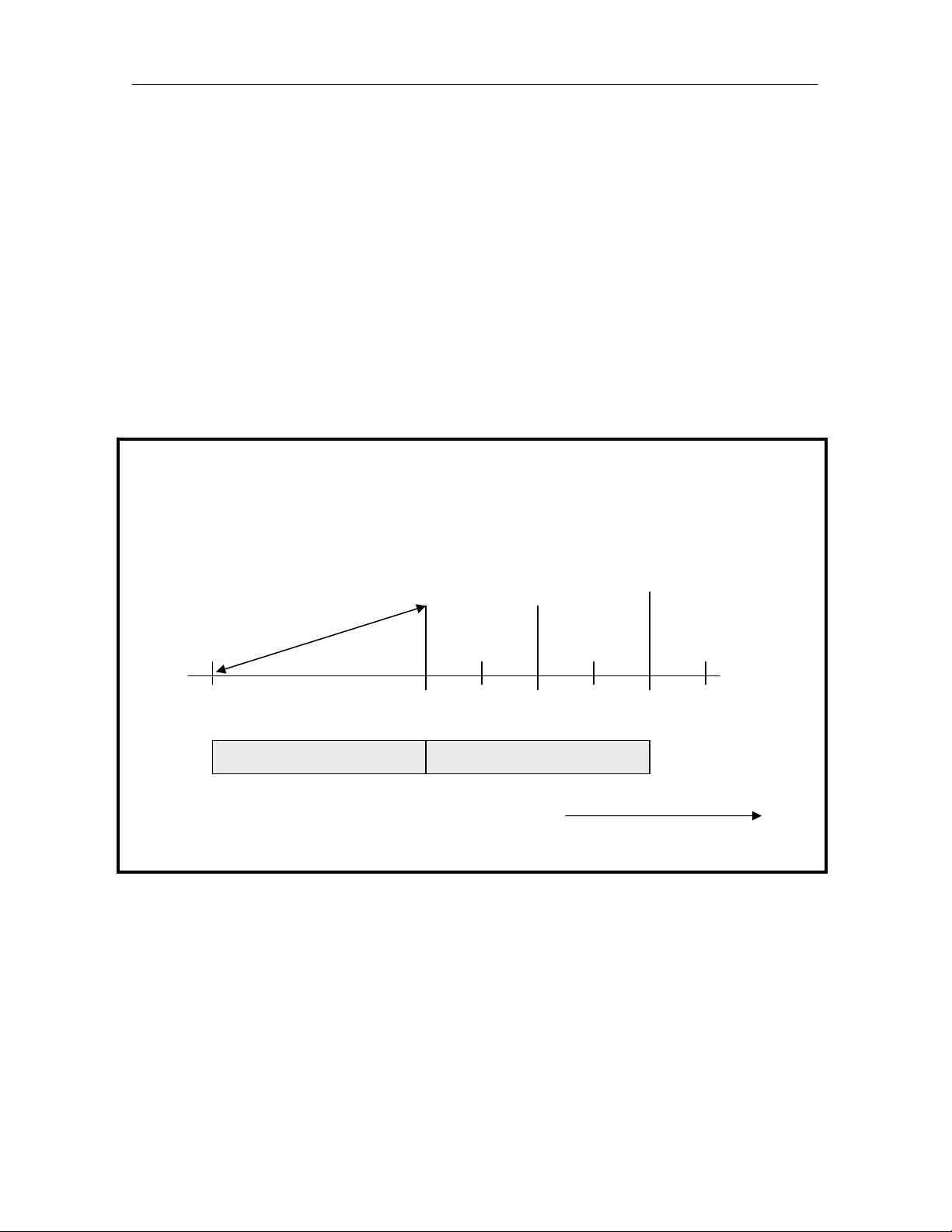

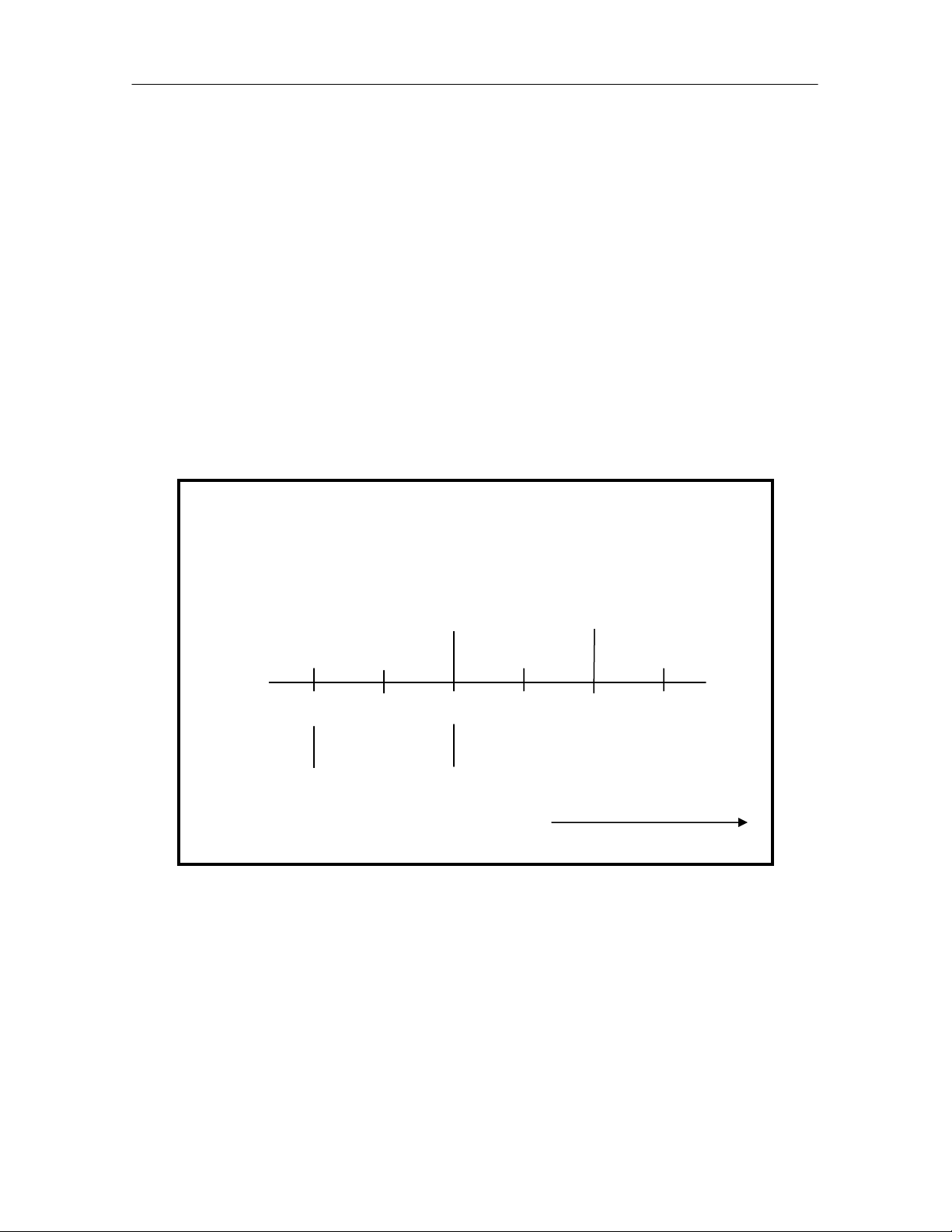

Infrared Humidification – No Dead Band

Note: in the above example that the control band begins at the 50% humidity set

point and has a length of 4%, which is ½ of the programmed humidity proportional

band value.

As the return air humidity decreases the infrared humidifier is activated at 46%RH

or 100% of the humidification control band. When the return air humidity starts to

increase, the infrared humidifier is deactivated at 48%RH or 50% of the

humidification control band.

Humid Set Point: 50%

Proportional Band: 8%

Humidity Set Point - (1/2 Proportional Band)

Humidification On

45 46 47 48 49 50

Humidification Off

Decreasing Humidity

27

Page 29

iCOM

Controls Training and Service Manual

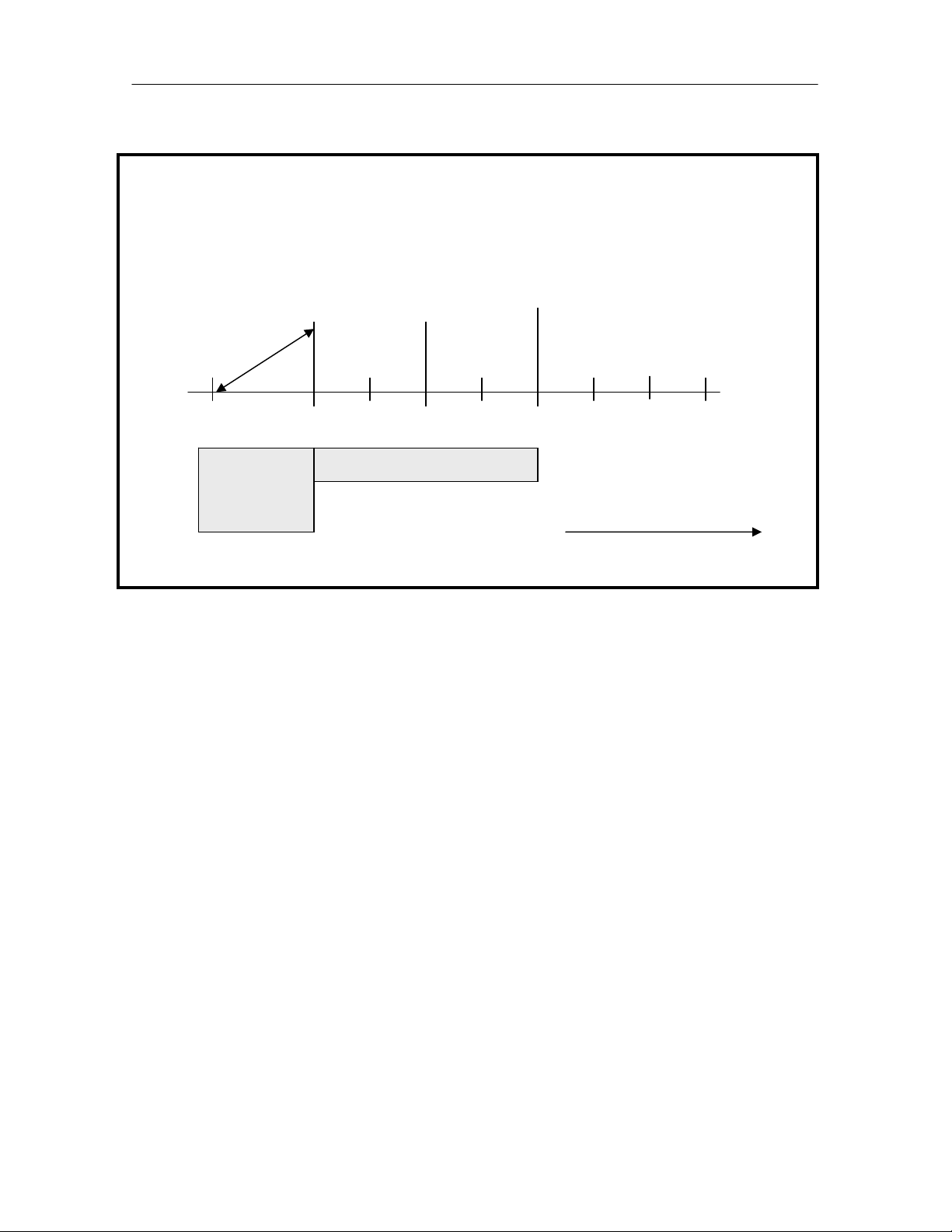

Infrared Humidification – With Dead Band

Note: in the above example that the control band begins at the 50% humidity set

point and has a length of 5%, which is ½ of the programmed dead band value plus

½ of the programmed humidity proportional band value.

As the return air humidity decreases the infrared humidifier is activated at 45%RH

or ½ of the dead band value plus 100% of the humidification control band. When

the return air humidity starts to increase, the infrared humidifier is deactivated at

47%RH or ½ of the dead band value plus 50% of the humidification control band.

Humidity Set Point - (1/2 Dead Band + 1/2 Proportional Band)

Humid Set Point: 50%

Proportional Band: 8%

Dead Band: 2%

Humidification On

45 46 47 48 49 50

DB

Humidification Off

Increasing Temperature

Autoflush Control for Infrared Large (IFL) or Small (IFS)

Pans

The Autoflush Water-Level Control software program is an integral part of the

infrared humidifier system. The program automatically controls a water makeup

valve to maintain the proper water level in the humidifier pan during operation.

When a call for humidification exists, the program performs a series of checks.

The first check to see how long the infrared humidifier has been off. If the off time

is equal to or greater than the programmed value (factory default is 15 hours), it is

assumed that the pan is dry and a program called pre-fill is initiated to add water to

the pan. During the pre-fill operation the infrared lamps are inactive. The pre-fill

time is programmable with an adjustable range of 1 to 120 seconds for either pan

size. The factory default for a large (IFL) pan is 60 seconds and for a small (IFS)

pan is 30 seconds.

28

Page 30

iCOM

–

If the off time is less than 15 hours (or user programmed value) the pre-fill program

is bypassed and the infrared lamps and water valve are activated at the same time

to fill the pan to the proper water level and initiate humidification.

During normal infrared humidification operation the water makeup valve is

periodically closed (no pan fill) and opened (pan fill) based on a timing sequence

to allow for the evaporation of water from the pan (see flow chart below).

With the humidifier water flush rate set at the factory default value of 150% the

water makeup valve will open for 7 minutes of fill time with an off time of 45

seconds between fill cycles for a small pan. For a large pan water makeup valve

will open for 10 minutes of fill time with an off time of 80 seconds between fill

cycles. The user can modify the percentage from 110% to a maximum of 500% in

1% increments.

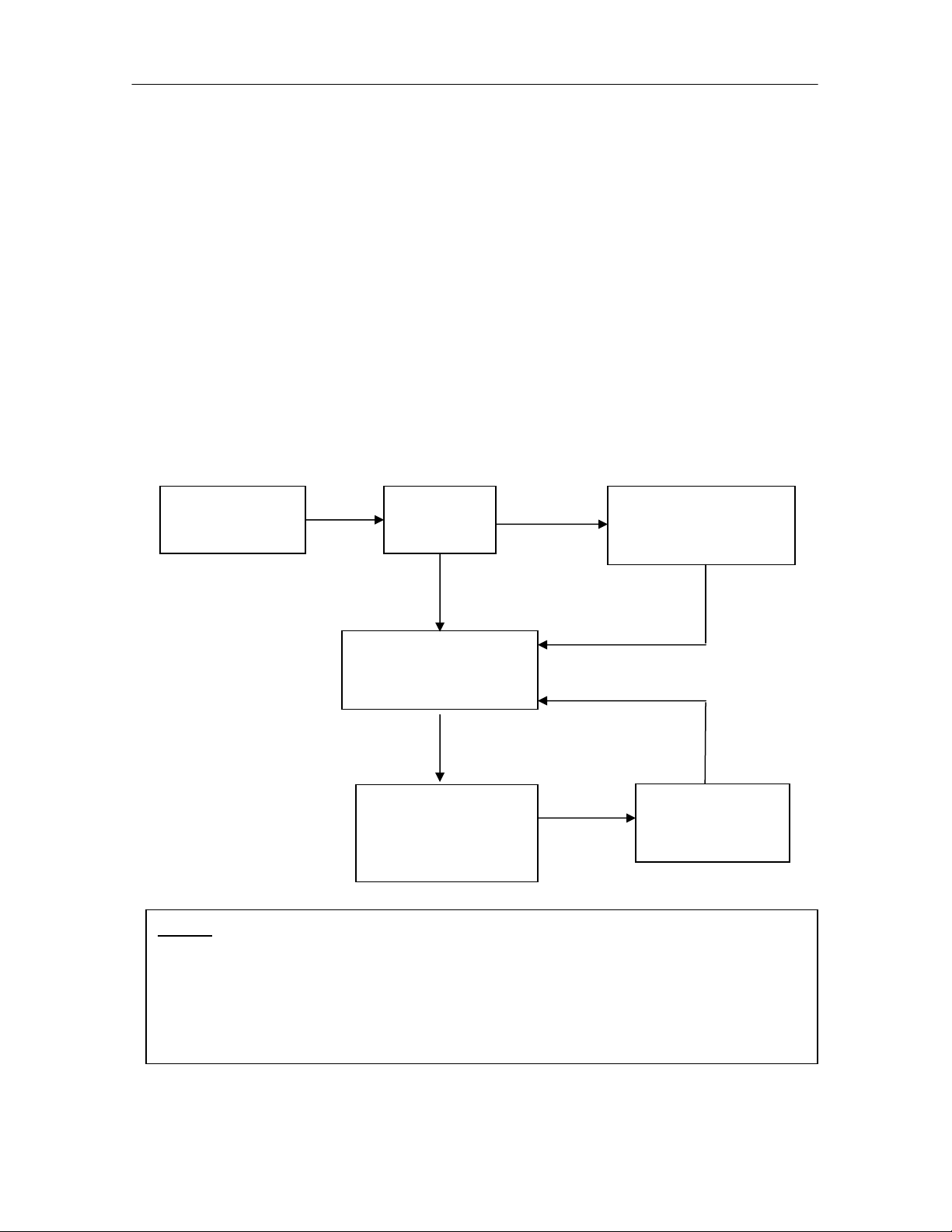

Autoflush Control Flow Chart

Control Training and Service Manual

Call for

Humidification

On in last

15 Hours?

YES

NO

HMV Pre-fill

30 sec – small pan

60 sec – large pan

HMV and Lamps on

4 min – small pan

7 min – large pan

Humidification

Lamps only

8 min – small pan

10 min

large pan

Refill

110% to 500%

Notes:

1. IFL: Infra-red Large and IFS: Infra-red Small

2. Last 15 Hours is programmable from 1-120hours.

3. Pre-fill time is programmable from 1-120 seconds on Large or Small pans

4. Normal Fill is programmable from 1-120 seconds

5. Refill is programmable in 1% increments

29

Page 31

iCOM

Controls Training and Service Manual

Dehumidification Operation

The Relative Humidity control program is used to illustrate the dehumidification

operation in the following examples. The basic dehumidification control band is

established at the humidity set point with the length equal to ½ of the programmed

humidity proportional band value.

The humidity controller activates dehumidification operation when the return air

humidity level increases to 100% of the humidity proportional band. The humidity

controller deactivates dehumidification operation when the return air humidity level

decreases to 0% of the humidity proportional control band value.

1-Stage Dehumidification, Compressorized Direct Expansion (DX)

Systems

The Liebert DS unit is supplied with two (2) compressors. Under normal

operation, the lead compressor is used for sensible cooling and the lag

compressor is used for either additional cooling or for dehumidification control.

The optional hot gas bypass solenoid valve is de-energized during

dehumidification.

If single compressor dehumidification is selected, the lag compressor is activated

by the humidity controller when the return air humidity level increases to 100% of

the humidity proportional band.

The humidity controller deactivates the lag compressor when the return air

humidity level decreases to 50% of the humidity proportional control band value.

1 Stage Compressorized Dehumidification – No Dead Band

Humid Set Point: 50%

Proportional Band: 8%

Humidity Set Point - (1/2 Proportional Band)

Dehumidification On

50 51 52 53 54 55

Dehumidification Off

Increasing Humidity

30

Page 32

iCOM

Note: in the above example that the control band begins at the 50% humidity set

point and has a length of 4%, which is ½ of the programmed humidity proportional

band value.

As the return air humidity increases, dehumidification operation is activated at

54%RH or 100% of the dehumidification control band. When the return air

humidity starts to decrease, dehumidification operation is deactivated at 52%RH or

50% of the humidity proportional control band.

Control Training and Service Manual

1 Stage Compressorized Dehumidification – With Dead Band

Note: in the above example that the control band begins at the 50% humidity set

point and has a length of 5%, which is ½ of the programmed dead band value plus

½ of the programmed proportional band value.

As the return air humidity increases, dehumidification operation is activated at 55%

RH or ½ of the dead band value plus 100% of the dehumidification control band.

When the return air humidity starts to decrease, dehumidification operation is

deactivated at 53%RH or ½ of the dead band value plus 50% of the humidity

proportional control band.

Humidity Set Point - (1/2 Dead Band +1/2 Proportional Band)

Humid Set Point: 50%

Proportional Band: 8%

Dead Band: 2%

Dehumidification On

50 51 52 53 54 55

DB

Dehumidification Off

Increasing Humidity

2-Stage Dehumidification, Compressorized Direct Expansion (DX)

Systems

The basic dehumidification control band is established at the humidity set point

with the length equal to ½ of the programmed humidity proportional band value.

When 2 stage dehumidification is selected, the controller works as follows.

31

Page 33

iCOM

The humidity controller activates the first stage of dehumidification operation when

the return air humidity level increases to 50% of the humidity proportional band.

The second stage of dehumidification is activated when the return air humidity

level increases to 100% of the humidity proportional band.

The humidity controller deactivates the second stage of dehumidification operation

when the return air humidity level decreases to 50% of the humidity proportional

control band value. The first stage of dehumidification is deactivated when the

return air humidity level decreases to the humidity set point of 50% or 0% of the

humidity proportional band.

If the compressors have unloading capability (4-stage cooling), then the

compressors are activated in the fully loaded condition for each stage of

dehumidification.

Controls Training and Service Manual

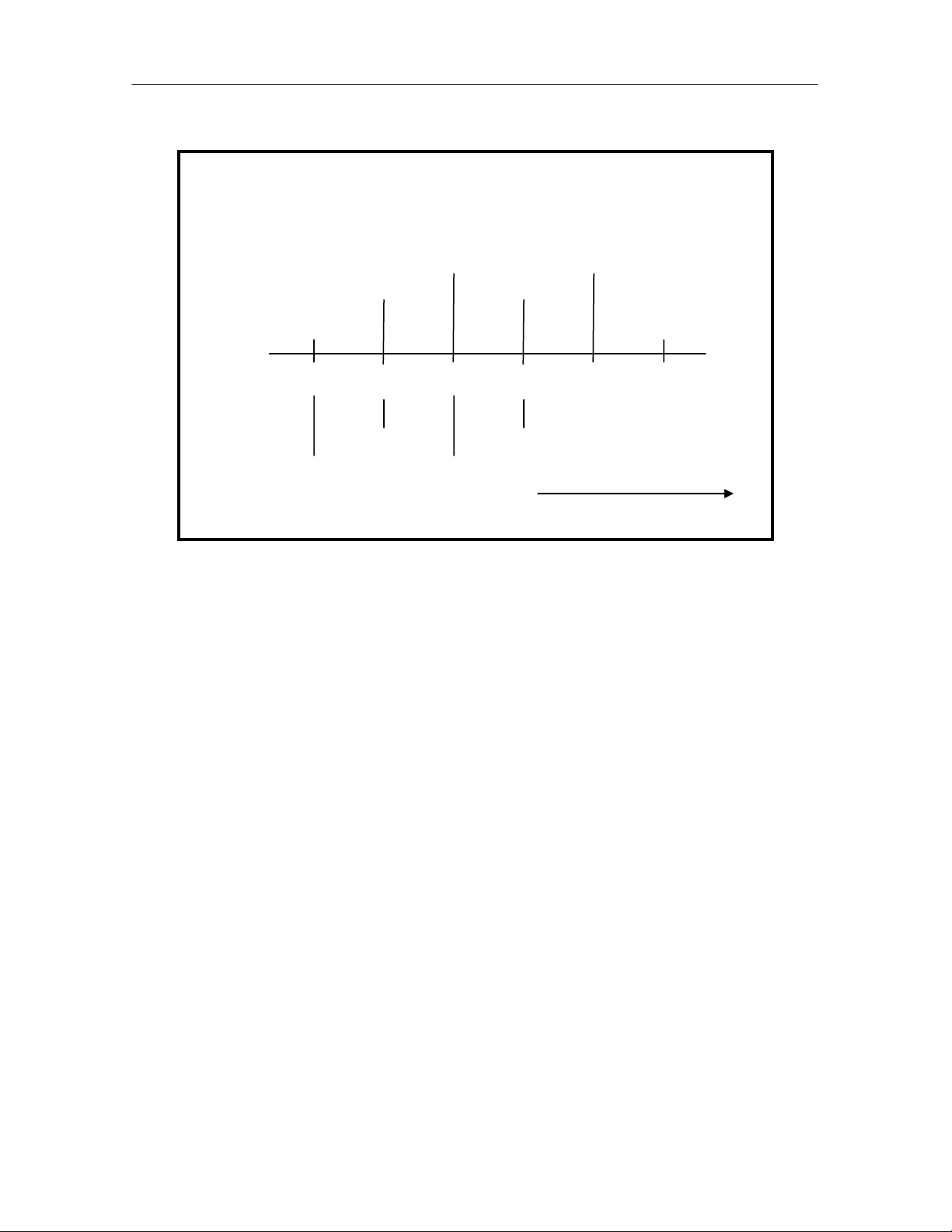

2 Stage Compressorized Dehumidification – No Dead Band

Note: in the above example that the control band begins at the 50% humidity set

point and has a length of 4%, which is ½ of the programmed humidity proportional

band value.

As the return air humidity level increases, first stage dehumidification operation is

activated at 52%RH or 50% of the dehumidification control band. If the return air

humidity level continues to increase the second dehumidification stage actives at

54%RH, which 100% of the dehumidification control band.

Humid Set Point: 50%

Proportional Band: 8%

Humidity Set Point + (1/2 Proportional Band)

Dehumid

Stage 1 On

50 51 52 53 54 55

Dehumid

Stage 1 Off

Dehumid

Stage 2 Off

Dehumid

Stage 2 On

Increasing Humidity

32

Page 34

iCOM

When the return air humidity level decreases to 52%RH or 50% of the

dehumidification control band the second dehumidification stage is deactivated.

When the return air humidity level decreases to the humidity set point of 50% or

0% of the humidity proportional band the first dehumidification stage is

deactivated.

Control Training and Service Manual

2 Stage Compressorized Dehumidification – With Dead Band

Note: in the above example that the control band begins at the 50% humidity set

point and has a length of 5%, which is ½ of the programmed dead band value plus

½ of the programmed humidity proportional band value.

As the return air humidity level increases, first stage dehumidification operation is

activated at 53%RH or ½ of the programmed dead band value plus 50% of the

dehumidification control band. If the return air humidity level continues to increase

the second dehumidification stage actives at 54%RH or ½ of the programmed

dead value plus 100% of the programmed humidity proportional control band.

When the return air humidity level decreases to 53%RH or ½ of the programmed

dead band value plus 50% of the programmed proportional control band the

second dehumidification stage is deactivated. When the return humidity level

decreases to 51%RH or ½ of the dead band value plus 0% of the programmed

proportional control band the first stage dehumidification deactivated.

Humidity Set Point + (1/2 Dead Band +1/2 Proportional Band)

Humid Set Point: 50%

Proportional Band: 8%

Dehumid

Stage 1 On

50 51 52 53 54 55

DB

Dehumid

Dehumid

Stage 1 Off

Stage 2 Off

Increasing Humidity

Dehumid

Stage 2 On

Reheating during Dehumidification

The Parameter Electric Reheat Enabled defines how the reheats react when the

return air temperature decreases below the temperature set point during the

33

Page 35

iCOM

dehumidification process. The end user can choose to select from the following

selections:

Controls Training and Service Manual

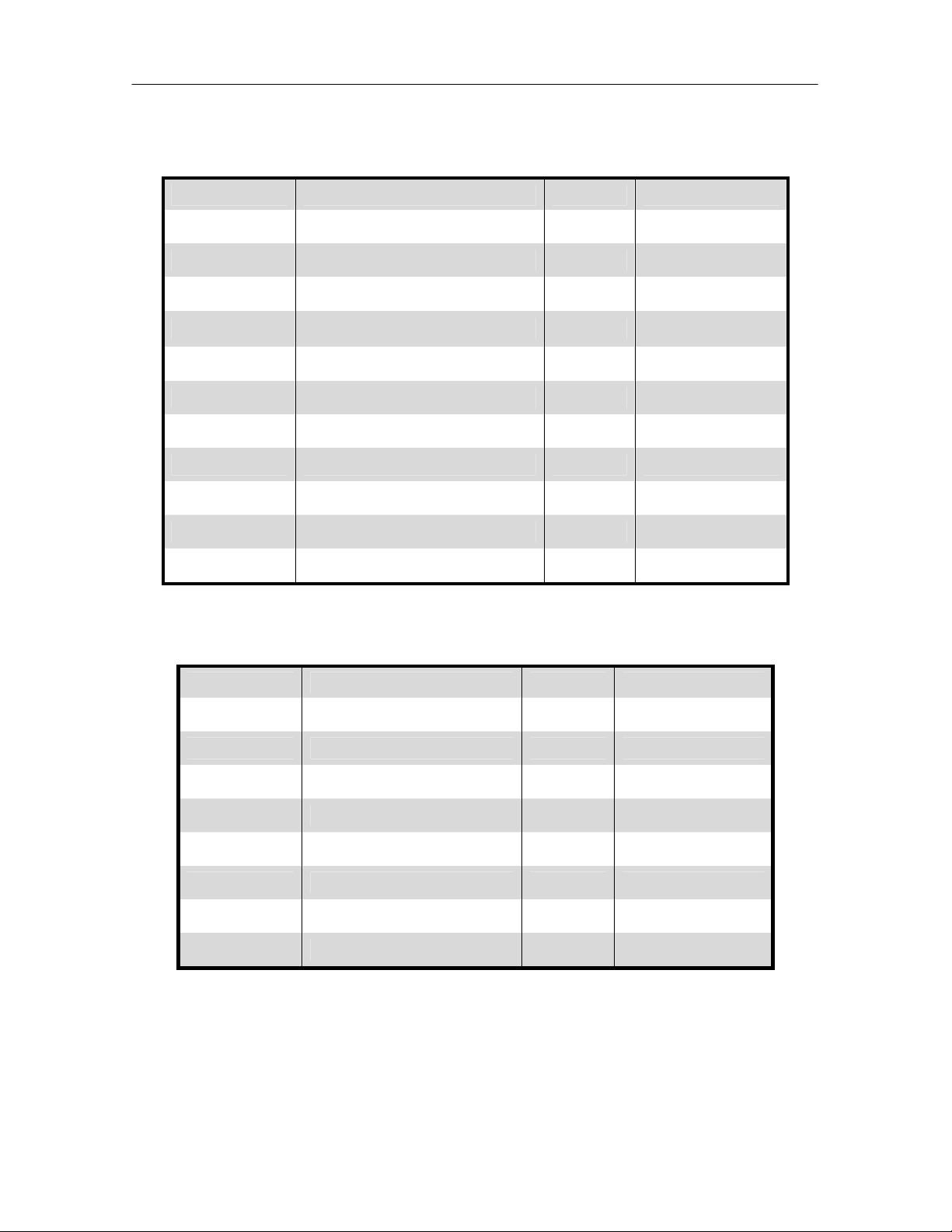

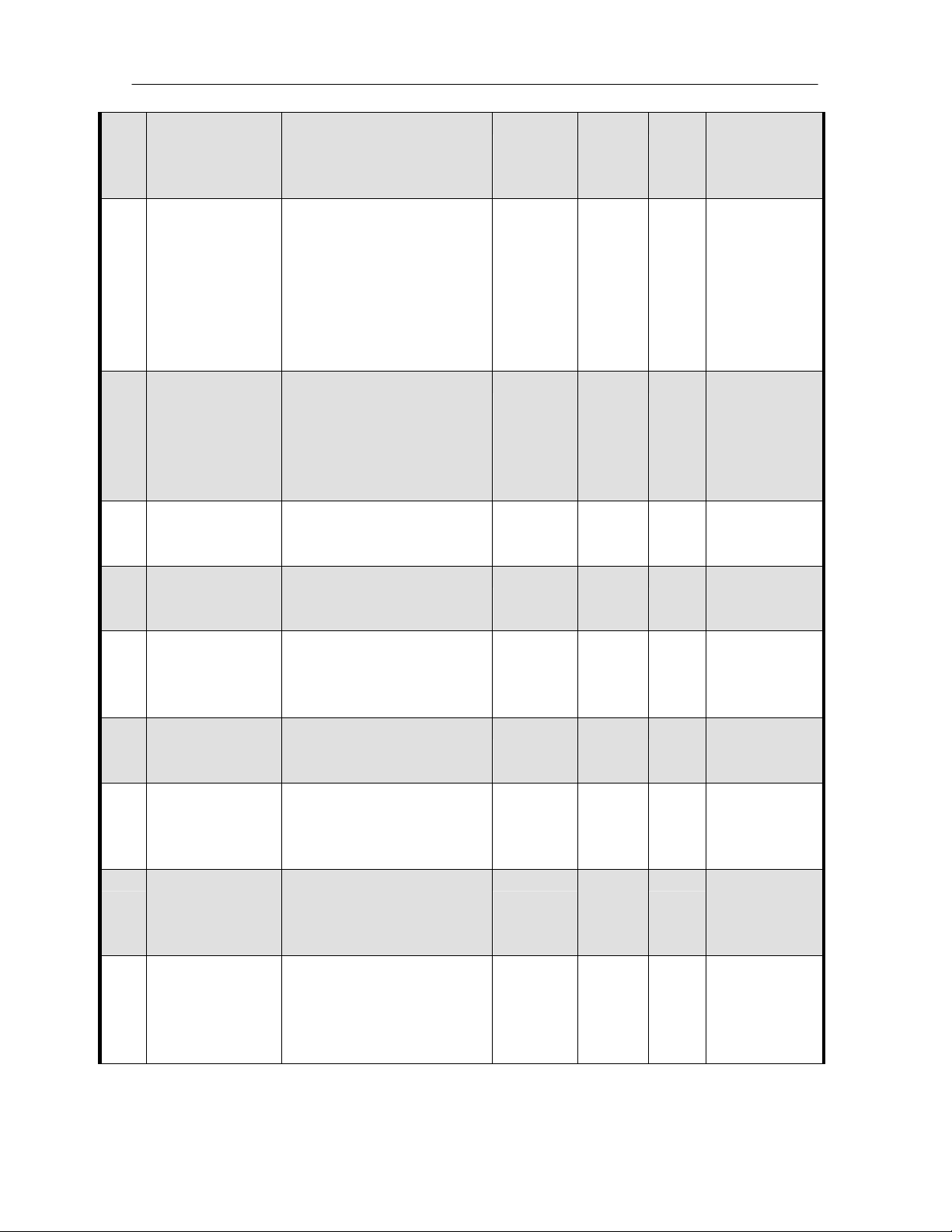

Parameter Operation

No

Normal

Delayed

No electric reheat allowed during compressorized

dehumidification operation.

Electric reheat operates as normal. A decrease in

return air temperature below set point will start

reheats as described previously in his chapter.

No low limit reached / low limit reset: heaters

disabled. Only one of two compressors operating in

dehum or low limit 1 reached: heaters enabled

Normal or Delayed Reheat (2-Stage Dehumidification Only)

When normal reheat (factory default) control is selected, the unit reheats are not

disabled during dehumidification, even if both compressors are operating. As the

return air temperature decreases below the temperature set point the reheats will

stage on and off as described earlier in this chapter.

If delayed reheat is selected and both compressors are operating for

dehumidification control, the reheats are disabled until only one compressor is

required. If, during reheat disable, the return air temperature decreases far

enough below the temperature set point to require 150% total available reheat

capacity, then dehumidification is disabled and reheats are activated.

When the return temperature raises to the point where reheat is no longer

required, then dehumidification operation is re-enabled. However, if the amount of

time that both compressors were operating prior to being disabled by the low

temperature condition was less than 10 minutes, then only one compressor is

allowed to operate for subsequent dehumidification requirements. This prevents

excessive system cycling, which can occur if the room heat load is small. Once

the requirement for dehumidification is no longer present, then both compressors

are enabled.

Caution:

Dehumidification with normal reheat allows for operating both compressors and

reheats simultaneously. It is very important that the electrical service to the unit be

sized and wired for this option if selected. If not sized properly the electrical

service could experience nuisance trips and or possible damage to building circuit

breakers (or Fuses) and wiring.

34

Page 36

iCOM

Control Training and Service Manual

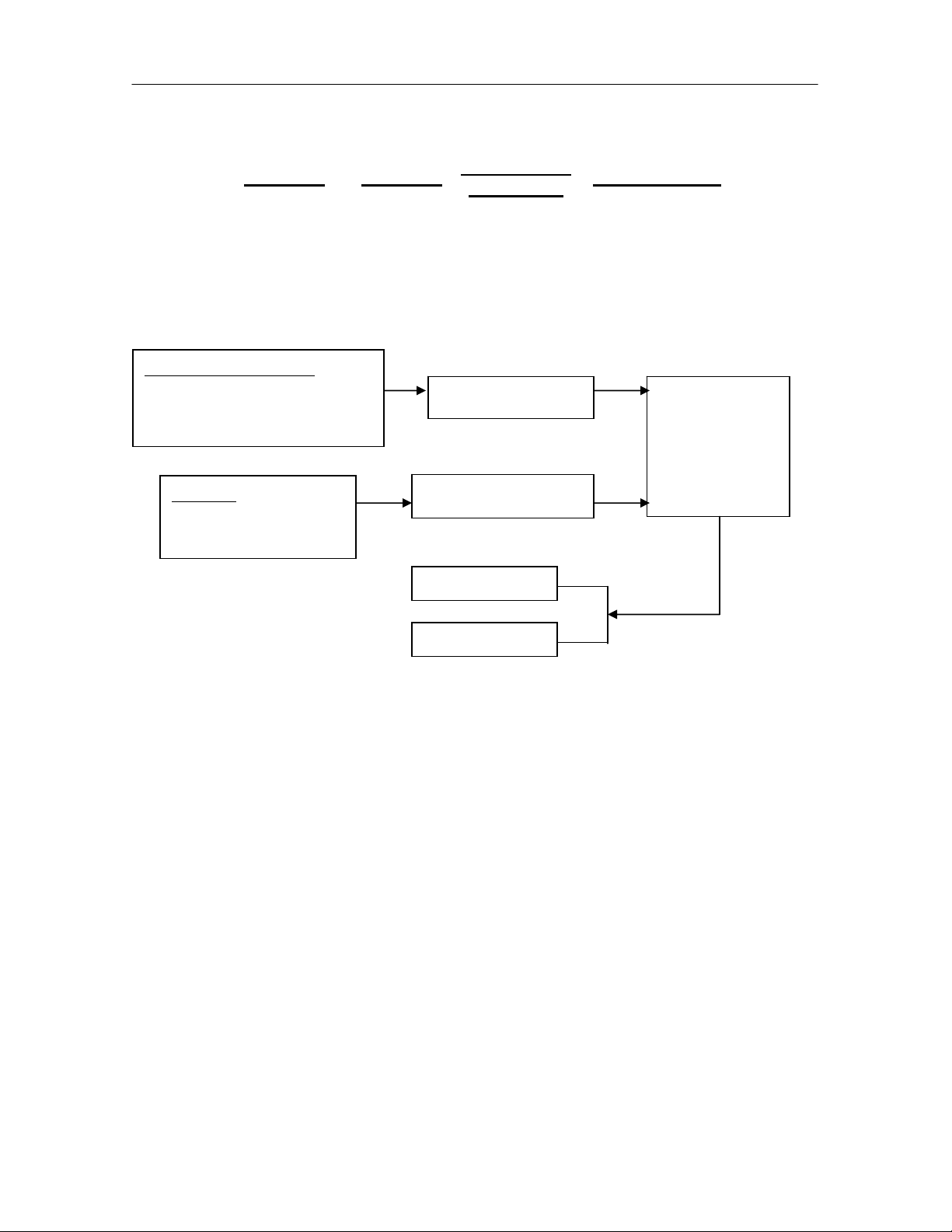

Additional Programs

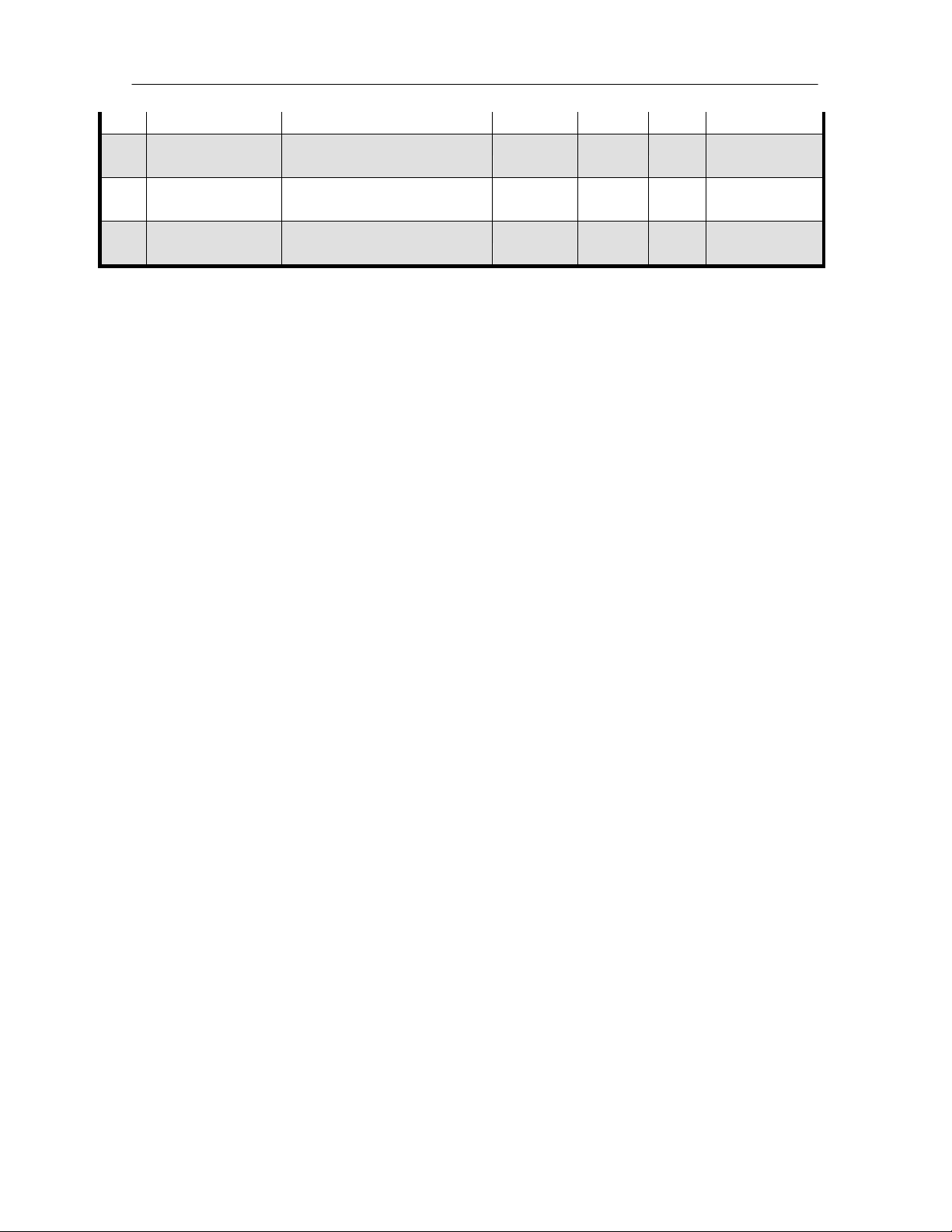

Start

The unit fan is activated. The unit can be switched on/ off from 2 inputs:

1. Remote on/ off input (RSD – Remote Shutdown Device)

2. Display button

Note: Switches 1 and 2 are in series; the unit will start only if both switches are in

the on position. If either switch is in the off position the unit will stop

Remon/off

Display button(s)

Auto restart

When there is a power outage the unit will provide an automatic restart on power

restoration when programmed. The unit will start and the loads will sequence on

with the Fan first, the first Cooling need and so forth until all loads are on as the

room requirement demands.

The Unit Auto Restart Sequence (customer programmable) takes place. Each

unit will restart by this program, however, with a network of units, the start loop will

start the next unit at each individual time when elapsed beginning with unit num

ber

ID #1. The unit control start sequence will start at this point as well.

Power on

Unit 1

on

Unit 2

on

Unit 3

on

Unit 4

on

Autorestart

Boot seque nce

Autorestart

Control 1

on

Autorestart

Control 2

on

35

Autorestart

Control 3

on

Control 4

on

Page 37

iCOM

Controls Training and Service Manual

Fan Alarm / Fan settings

The fan operation is controlled by two (2) digital devices: the Loss of Airflow

differential pressure switch and the Main fan Overload motor protection. The

time delay at the unit start is always 5 seconds shorter than the control delay.

High Pressure Cutout

The control uses high head lockout functionality. If one compressor trips or is

locked out on high head, the other compressor turns on when the space

temperature increases 1°F. Pressing the alarm button on the display twice can

reset high head Alarm. A lockout condition occurs on the third trip and must be

reset by turning the main power switch to off then back on

.

Suction Pressure Transducer

The suction pressure transducer operation is only on air conditioning products (not

chiller applications). Transducer measurements are made at least once every 1

second. With all other operating times for all compressors, additional

measurements, shall be taken based on operation “at limit conditions” for 5

seconds and shall not include readings taken during Pumpdown or Winter Start

Kit (WSK) timeout

.

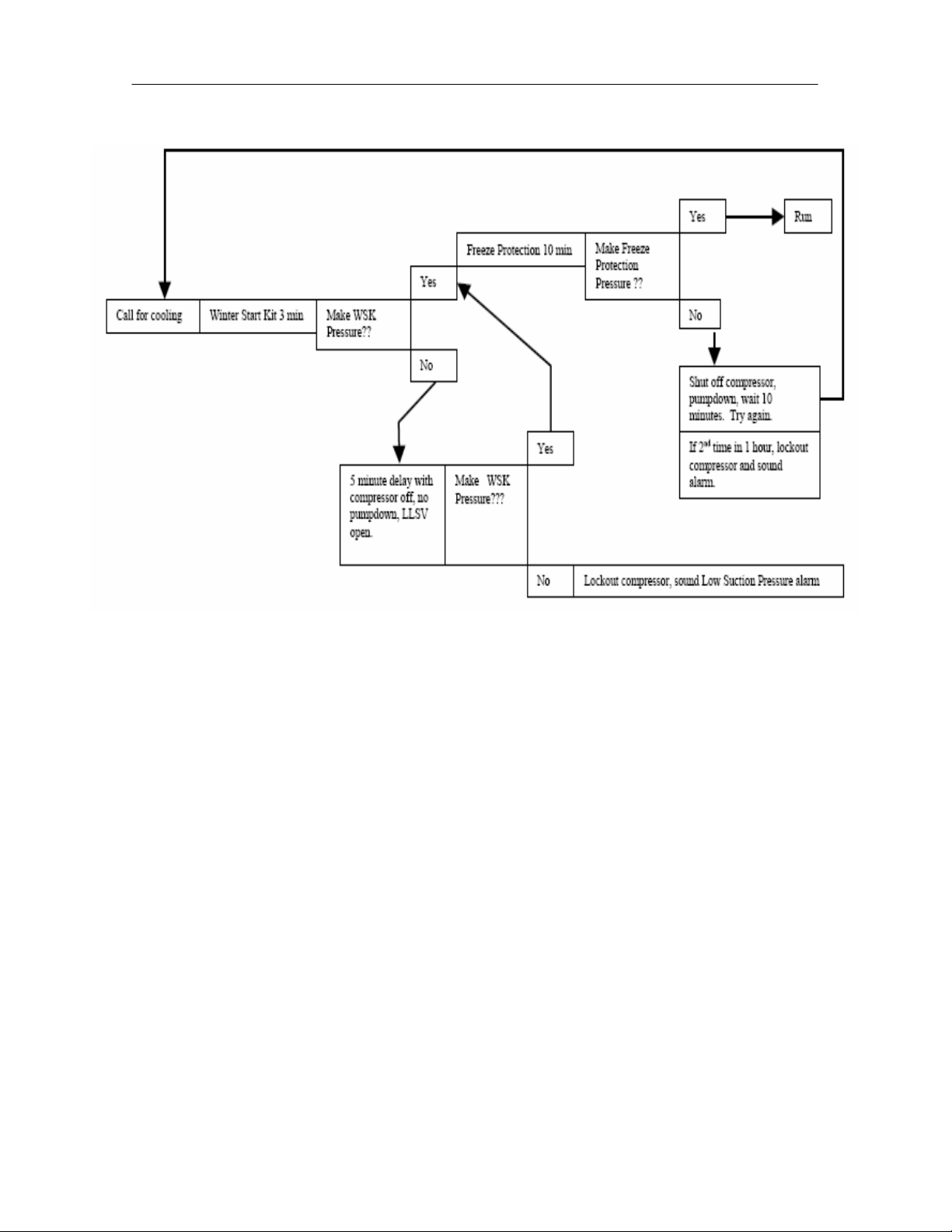

Call for Cooling

The following applies for both R22 and R407C systems and applies to all

compressor types. The call for cooling opens the Liquid Line Solenoid Valve

(LLSV). Note: on units with Digital Scroll Compressors the unloader is energized

0.1 second before the compressor contactor is energized. On air-cooled units with

fan speed type condenser (FSC) the low pressure start threshold is 35psiG

(50psiA). On air-cooled units with lee-temp control (LT) and all fluid cooled

units the low-pressure start threshold is 60psiG (75psiA).

All compressorized units use the following start

sequence:

Open LLSV, if WSK is set to 0, wait for suction pressure to reach setting, then start

compressor and freeze protection timer.

If WSK is set greater than 0, operate the compressor for the WSK override time

and monitor suction transducer value.

If pressure is achieved the compressor is allowed to operate, and the freeze

protection timer is started.

If pressure is not achieved, turn compressor off and leave LLSV open.

If pressure is achieved within next 30 seconds the compressor is allowed to

operate, and the freeze protection timer is started.

36

Page 38

iCOM

Control Training and Service Manual

The Startup and Freeze Protection Program

The sequence for the call for cooling with the program features is as follows:

The need for cooling is defined by the control setting for the temperature setpoint,

proportional band, and deadband (if used). At this point the Winter Start Kit (WSK)

time delay is the wait period for the compressor to run without the indication of the

low-pressure condition (also known as LP bypass). The WSK time delay is

programmable with a range of 0 - 5 minutes. If the LP switch setting is achieved in

this time then full cooling is in process with the Freeze Protection (FP) now

watching the LP for an additional 10 minutes (fixed). If the LP remains closed the

cooling process continues.

If the WSK is not made in the set time period the cooling process stops and waits

an additional 5 minutes with the compressor off (no pumpdown). The liquid line

solenoid valve will remain open during this time period. If the LP switch is made

the control will now advance and wait for the freeze protection time delay as stated

as above. If the LP switch does not prove in the WSK time delay period plus the 5

minute wait period, the compressor is locked off and the Low Suction Pressure

Alarm will activate. A power off/ on reset is required to reset the cooling function.

If the WSK is made and the control is in the 10 minute Freeze Protection (FP) wait

time period and this function does not prove the LP the control will go into

additional 10 minute wait (fixed), with the compressor off (no pumpdown) and the

liquid line solenoid valve to remain open. If the freeze protection does not make

37

Page 39

iCOM

Controls Training and Service Manual

during the second time frame the cooling process locks off and will require a

power off sequence.

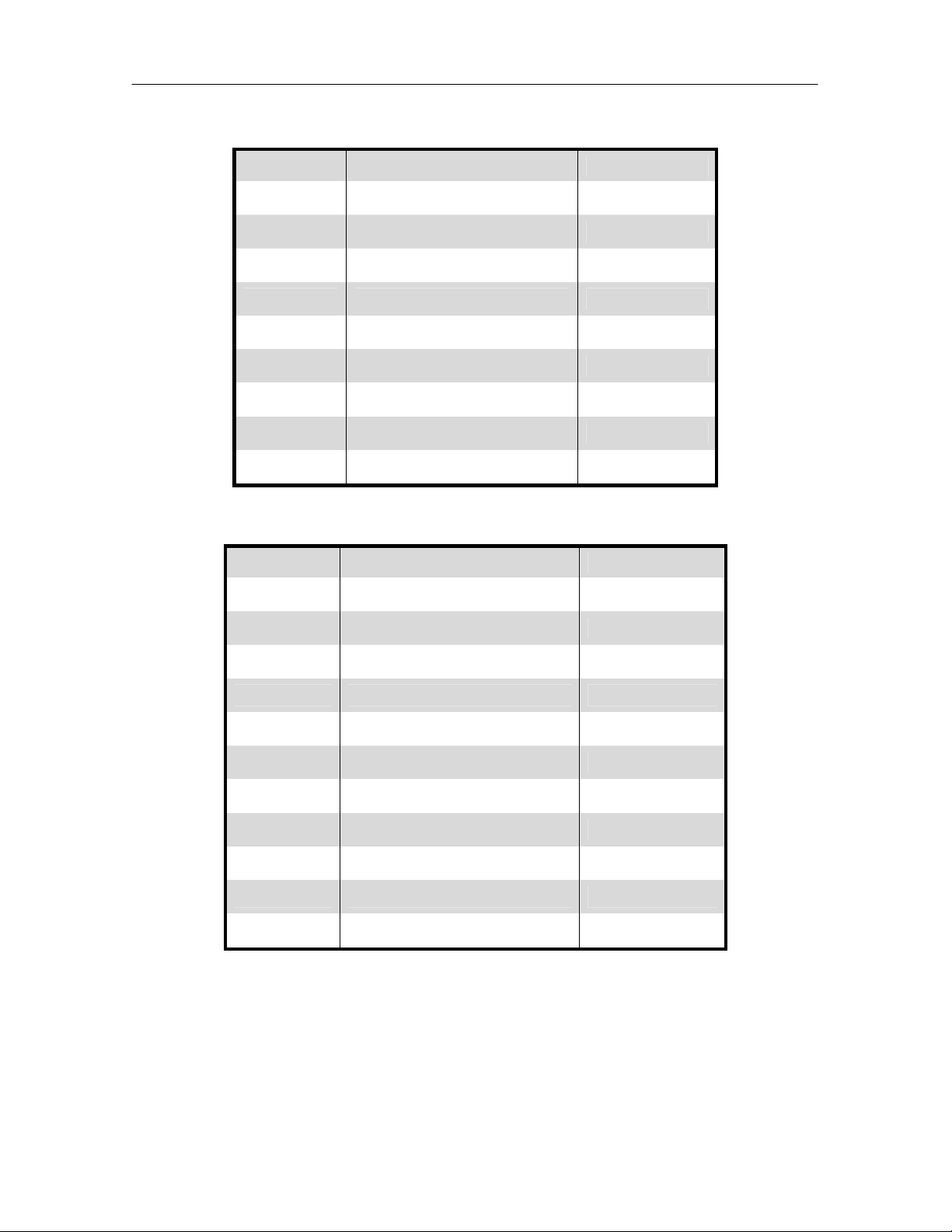

Next Maintenance Calculation

Foreword

The next maintenance calculation will help run the Liebert Environmental unit in an

optimum way, to ensure minimum components stress resulting in increased

reliability.

Calculation of next Maintenance Parameters

The following components are included in the calculation individually:

• Fan(s)

• Compressor 1

• Compressor 2

• Electric Heaters

• Humidifier

For each individual component the next maintenance will be calculated from

following parameters:

1. Standard service interval (1, 2, 4 or 6 times a year, to be programmed).

2. Working hours (counted).

3. Number of starts (counted).

4. Average running time (calculated).

5. Optimum number of starts per hour (to be programmed).

6. Maximum number of starts per hour (to be programmed).

7. Maximum bonus to enlarge time to next maintenance (to be programmed).

8. Maximum penalty to reduce time to next maintenance (to be programmed).

The Maintenance Calculation is done as follows:

Basic: maintenance frequency (1). The control counts the working hours of the

component, as well as the number of starts.

The working hours and the number of starts are compared with the programmed

optimum / maximum starts per hour. This results in “Wellness Factor”.

This factor, in accordance to the service interval, will add a “Bonus” to increase the

time before the next maintenance, or will add a “Penalty” to decrease the time

before the next maintenance. In simple words: If a component starts very often,

the time to next maintenance will be decreased, if it starts rarely, the time to next

maintenance will be increased.

38

Page 40

iCOM

Control Training and Service Manual

The control always takes the component with the most on/ off (cycling) as the

reference component, which asking for the nearest maintenance (example: if the

fan runs continuously, but the compressor switches on/off all the time, the next

maintenance will be calculated from the compressor).

Alarms or warnings (like clogged filter, high or low pressure, fans alarm etc.) will

decrease the time to next maintenance immediately to 0. If the alarm was reset,

the original situation will be displayed again, but the alarm will be counted in the

diagnostics window.

The display’s main window provides information about the next maintenance:

a bar graph (graphical display screen) will fill in, as the next maintenance gets

closer (the width of the graph equals to the standard maintenance Interval (1, 2, 4

or 6 times a year). The date of the next maintenance is also displayed.

Parameters for next Maintenance Calculation:

General Maintenance Settings:

Maintenance Frequency: can be set at 1, 2, 4 or 6 times a year. “NO” means

the maintenance calculation program is disabled.

Maximum Bonus: this value increases the time to next maintenance with the set

value, if all components run in optimum way (number of starts, average running

time).

Maximum Penalty: this value decreases the time to next maintenance with the

set value, if some components run in non-optimum way (number of starts, average

running time).

Last Maintenance: this date can be will be set by the calculations and the

service-engineer and others to view.

Service-Engineer: name can be added and edited.

Reset: puts all counters of all components (fans, compressors, ect.) to 0, and

starts new maintenance calculation (always reset after maintenance is completed).

Fans / Heaters / Humidifier Settings / Compressor 1 /2 Settings

Number of starts and Working hours: counted from the last maintenance. Total

working hours can be read in the standard working hours window (customer

window).

Average Working Hours: calculated by the number of starts and working hours

of each component.

39

Page 41

iCOM

Starts per Day Optimum: the number of individual component starts that is

considered as good or optimum. To be set by Service Engineer.

Starts per Day Worst: the number of individual component starts that is

considered as “hunting” or worst case. To be set by Service Engineer.

Number of Alarms: counts the number of alarms occurring between service

intervals.

Actual Bonus: calculated from “number of starts” and “average working time”

values. The result can be positive (for a bonus) or negative (for a penalty). This

value influences the time remaining to the next maintenance.

Controls Training and Service Manual

Shared Parameters an understanding

If we have multiple units in the same room (zone) they will need to communicate

with each other to avoid opposite operational functions. This will prevent the

cooling and heating functions from operating at the same time on different units.

This condition called “fighting “ often exists in the room due to imbalanced loads

and the crossing of airflow conditions. This is also considered when using the

Lead/ Lag and Cascade functions.

When a system is setup the parameters are shared by all units. The unit selected

as the Lead Unit (#1 unit) is used to program the system, if program parameters

are not set in this unit they will be ignored. This is true for all of the active units in

the system. However, if a unit in the system is not active it will be ignored until it is

active and the parameters will be shared within 2 minutes of activation.

Shared Temperature and Humidity parameters example:

Two units share the master Temperature Control (1/2) Proportional Band Setting

such as 10°F, and then each unit will use the master band divided by 2 (units) or

5°F proportional bands. To avoid the cooling hunting process or compressor

cycling too quickly, the primary temperature proportional band needs to be set

wide enough to compensate for the number of units in the system setup. Note that

shared parameters are not used on single unit applications.

Heating, humidification, and dehumidification will follow the same example with

each function starting in each unit one after the other or in sequence.

In Chilled Water units all valves operate are in parallel but this operation may be

overridden by the setting and use of the Supply Limit sensor. This parameter is

controlled by the individual unit. Here we may see uneven valve positioning

(operation) in some of the units.

40

Page 42

iCOM

Freecooling and Dual cooling will operate in the same manner as chilled water

with the supervision of the Supply Limit, again showing different valve positions on

the units

If in a Freecooling or Dual Cooling unit if the limit of the coil operation is detected

(no free cooling or no CW available) the valve will close off and unit will become

DX operation in the system.

Control Training and Service Manual

Networking and Functions

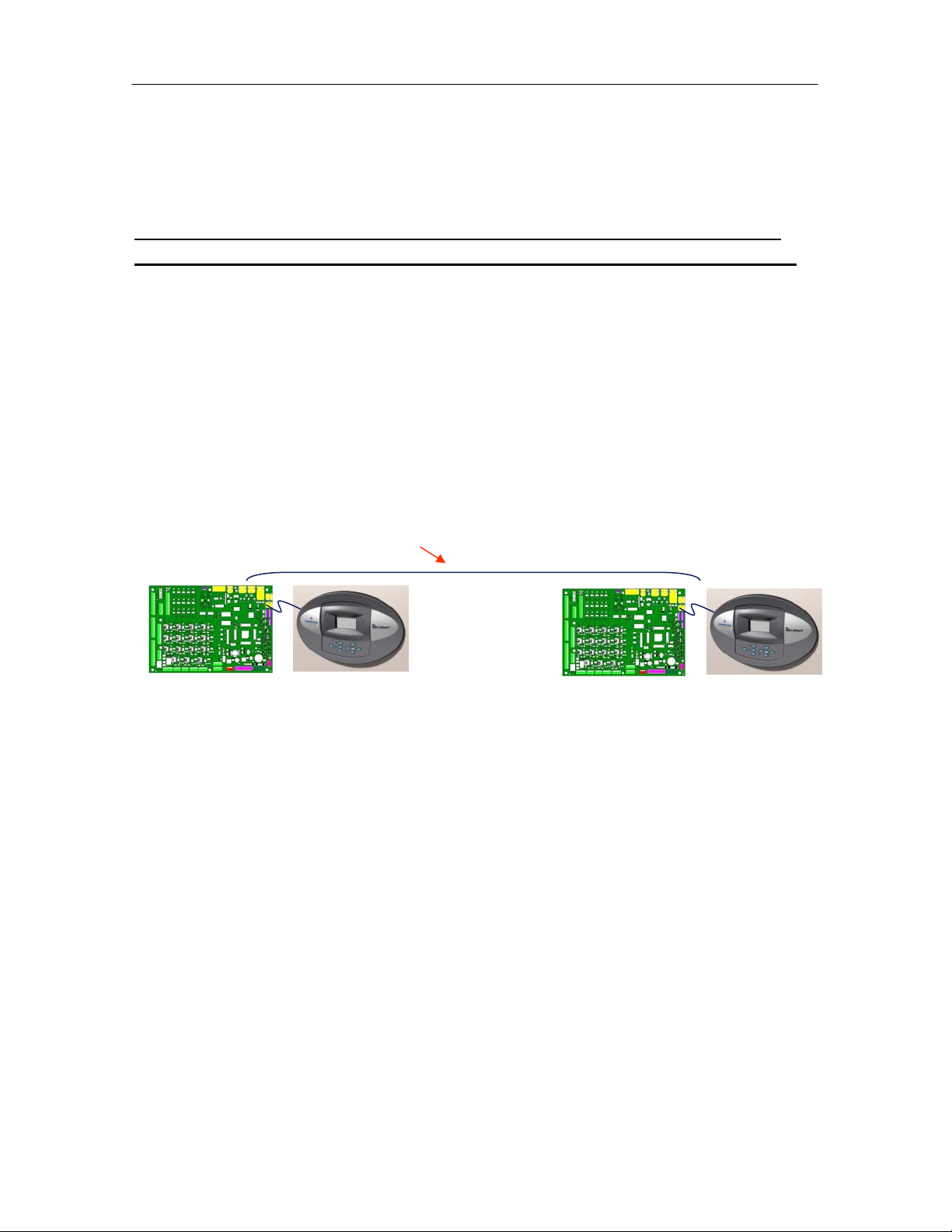

Unit 2 Unit (U2U) Communications by networking will allow the following

functions to be placed into operation when the requirements exist. The user

must install the correct hardware and properly program the units for the

functionality.

In the iCOM Network the owner may perform the following functions:

The Teamwork Mode functions, which allow multiple stages of Cooling/ Heating

and/ or Humidification/ Dehumidification. The ability to prevent the units fighting is

included in this feature.

The Lead/ Lag function, which allows one or more units to be set as “Running and

Standby” for activation in case of an alarm. This also has the ability to be

programmed in a rotation for assurance of functional standbys.

The Cascade function, which allows additional units to be staged on based on the

temperature or humidity requirement.

Understanding the iCOM Network setup process:

To setup a system network with the iCOM control requires a complete

understanding of the control processes and parameter programming to insure the

proper functional operation without incident. To insure the setup is correct and

that the operation will function as selected you need to map both the room layout

and the unit setup. First, read and record all programmed settings in all of the

single units. Second, document the network parameter settings that are needed

and identify the numerical order of the units to be networked. The order of the

setup process is very important.

41

Page 43

iCOM

Controls Training and Service Manual

The Basics for Cooling Unit Placement:

Installation instructions are found in the product manuals for the Cooling units.

Networking setup should include these additional factors for planning.

• Locations of heat loads in conditioned space.

• Air distribution for cooling.

• Number of operating units versus standby.

The Basics for Hardware:

Multi-unit networking requires the following hardware:

Minimum Network Switch Requirements:

• IEEE 802.3, IEEE 802.3u

• 10/100 Mbps speed

• Multiple RJ-45 ports – one shared RJ45 uplink

CAT 5 patch cables (straight through) in the proper lengths not to exceed

150 ft. maximum length each. One for each board and display added into

the iCOM network. Cable management will apply.

The Basic for Programming:

An IP address number will be used to identify each receiver/ sender of information.

(See Computer and Network Terms in Training and Service Manual)

The iCOM Network is a Class C Private Network and will use the 192.168.254.xxx

series of static IP address. This has nothing to do with the local building or owner

network. The iCOM Network may only be attached to these networks through a

WEB Card or 485 Card using the Liebert Intellislot.

A series of basic rules must be followed to connect and program the units for this

private iCOM Network. See the following rules.

1. Small Displays are CAN connections only, programming of single unit

parameters is required.

2. Small Displays CANNOT look at or program other iCOM Network functions.

3. Small Displays may be networked with a CAT 5 crossover cable (2 units).

4. All Large Displays and Control Boards will use a CAT 5 or greater straight

through (patch) cables to connect to the switch.

5. One large Display (Wall Mount) with a separate power adapter may be used

with multiple units (Control Boards and Small Displays) through the network

switch.

42

Page 44

iCOM

6. Each set of unit control boards must be set up individually, then connected to

the network switch and checked before the next board can be setup

6a. Large Displays and Control Boards must each be programmed with a

different IP Address.

Example: Display: 192.168.254.001

Example: Control Board: 192.168.254.010

6b. Each Display and Control Board in the iCOM network must have the

same Gateway IP address.

Example: Gateway IP: 192.168.254.75

6c. Each Display and Control Board in the iCOM network must have the

same Netmask IP address.

Example: Netmask IP = 255.255.255.000

6d. The Unit to Unit (U2U) address must be programmed in the necessary

order for setup.

Example: Unit Display: 33 – 64 and Unit Control Board: 1 - 32

Control Training and Service Manual

43

Page 45

iCOM

Controls Training and Service Manual

Setting Parameters

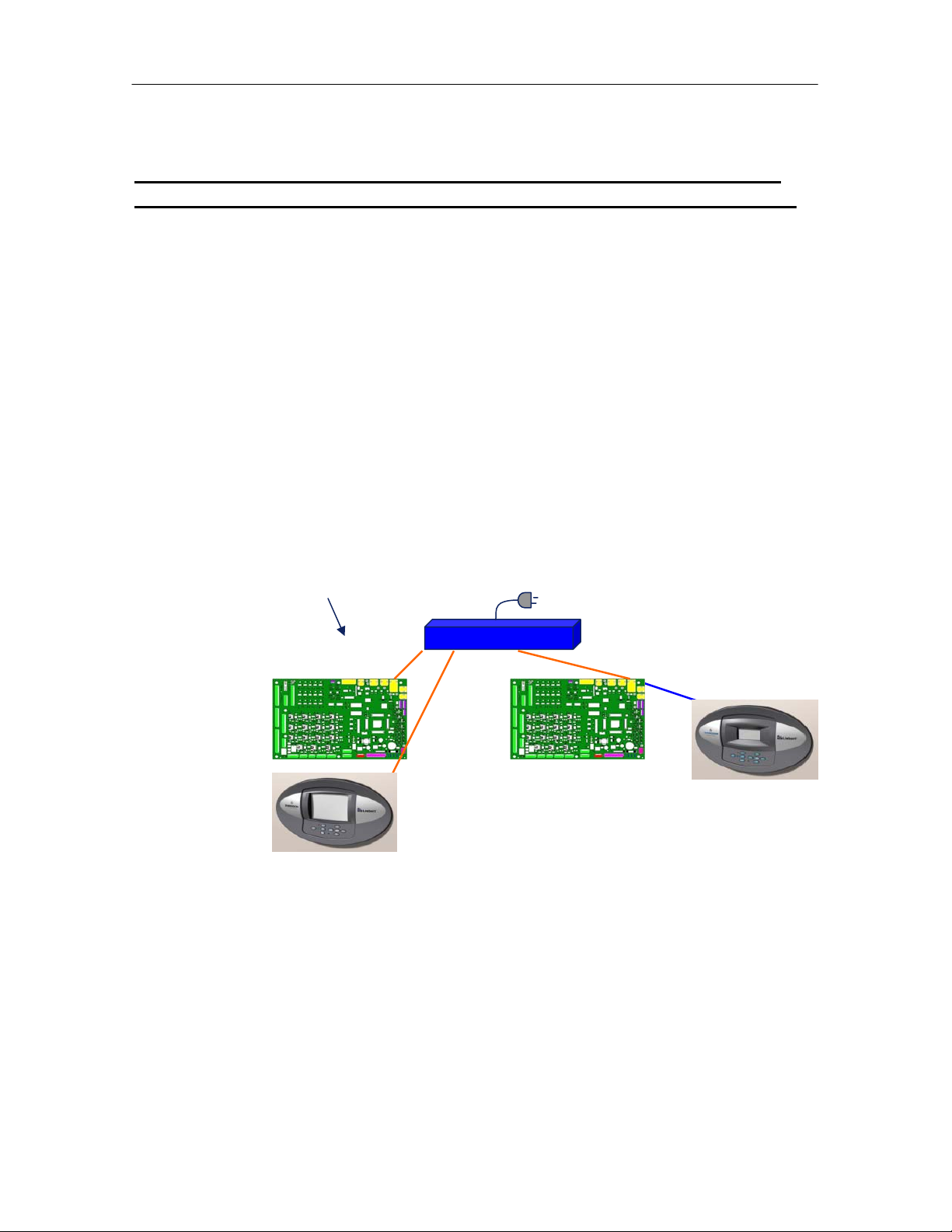

Example: 2 Units with Small Display’s

All Network parameters are viewed and programmed using the

Service Menu function and by selecting the Network Setup Icon

The following example references menu lines on the Network Setup screen:

Line S802: Number units connected: xx (2)

Line S803: Teamwork: xx (No, 1, 2)

Line S804: Control Board IP Address: 192.168.254. xxx (010, 011)

Line S805: Control Board Netmask IP the same for all units

Line S806: Control Board Gateway IP the same for all units

Line S808: U2U address Control Board #: xx (1-2)

Line S810: U2U group #: xx (1)

U2U: CAT5 (Crossover-cable)

Unit No. 1

Unit No. 2

44

Page 46

iCOM

Control Training and Service Manual

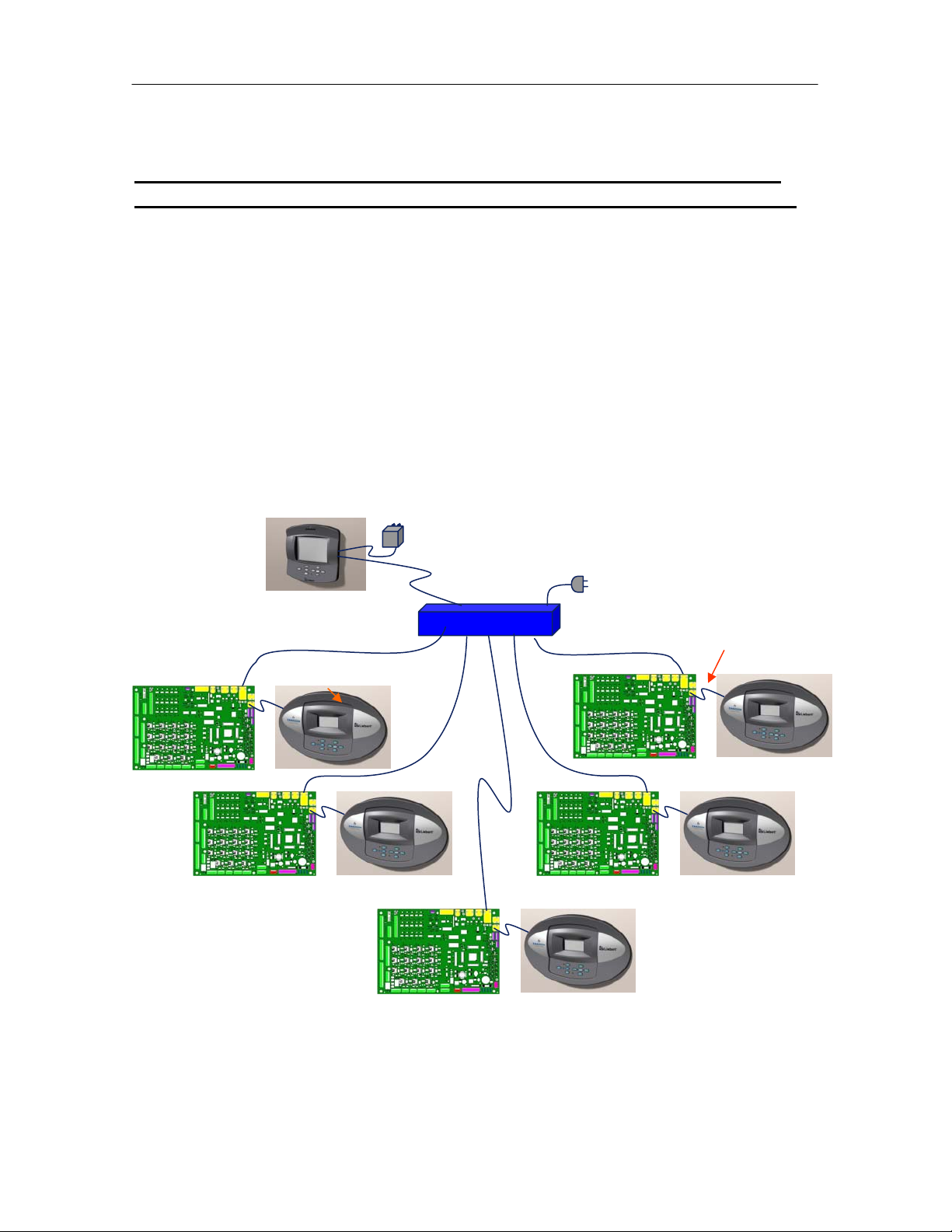

Example: 2 Units, One Large Display and One Small Display

All Network parameters are viewed and programmed using the

Service Menu function and by selecting the Network Setup Icon

The following example references menu lines on the Network Setup screen:

Line S802: Number units connected: xx (2)

Line S803: Teamwork: xx (No, 1, 2)

Line S804: Large Display Board IP Address: 192.168.254. xxx (001 - 049)