Page 1

POWER AVAILABILITY

GXT2-6000RT230™ & GXT2-4500RT230

USER MANUAL

™

230VAC

Page 2

Page 3

TABLE OF CONTENTS

IMPORTANT SAFETY INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

GLOSSARY OF SYMBOLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

1.0 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

2.0 S

2.1 Transient Voltage Surge Suppression (TVSS) and EMI/RFI Filters. . . . . . . . . . . . . . . . . . . . 4

2.2 Rectifier/Power Factor Correction (PFC) Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.3 Inverter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.4 Battery Charger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.5 DC-to-DC Converter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.6 Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.7 Dynamic Bypass . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

YSTEM DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3.0 MAJOR COMPONENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

3.1 Main Frame and Electronics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.2 Internal Battery Packs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.3 Removable Power Distribution Box. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4.0 WHAT’S INCLUDED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

5.0 INSTALLATION AND CONFIGURATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

5.1 Install the Main Cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

5.1.1 Tower UPS Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

5.1.2 Rack-Mount UPS Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

5.1.3 Installing the Adjustable Rack-Mount Kit—Sold Separately . . . . . . . . . . . . . . . . . . . . . . . . . 11

5.2 External Battery Cabinet Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5.3 Connect the Internal Batteries Using the External Connector . . . . . . . . . . . . . . . . . . . . . . . 14

5.3.1 Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5.4 Connect Input/Output Power. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5.4.1 Distribution Box Electrical Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

6.0 INITIAL START-UP AND ELECTRICAL CHECKS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

7.0 C

7.1 GXT2-6000RT230 and GXT2-4500RT230 Configuration Program Features . . . . . . . . . . . . 17

ONFIGURATION PROGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

7.1.1 What You Will Need . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

8.0 CONTROLS AND INDICATORS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

8.1 ON/Alarm Silence/Manual Battery Test Button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

8.2 Standby/Manual Bypass Button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

8.3 Load Level Indicators (4 Green, 1 Amber) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

8.4 Battery Level Indicators (5 Green) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

8.5 Fault Indicator LED (Red) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

i

Page 4

8.6 Bypass Indicator LED (Amber) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

8.7 UPS ON Indicator LED (Green) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

8.8 Battery Indicator LED (Amber). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

8.9 AC Input Indicator LED (Green). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

9.0 OPERATING INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

9.1 Normal Mode Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

9.2 Battery Mode Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

9.3 Bypass Mode Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

9.4 Battery Recharge Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

10.0 COMMUNICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

10.1 Communications Interface Port. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

10.2 Pin 4 - Remote Shutdown on Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

10.3 UPS Intelligent Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

10.4 Remote Emergency Power Off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

11.0 MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

11.1 Internal Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

11.1.1 Internal Battery Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

11.2 AC Power Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

11.2.1 PD-CEHDWR—Manual Bypass Switch Available . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

12.0 TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

12.0.1 Auto-Learning Battery Run Times . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

13.0 SPECIFICATIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

FIGURES

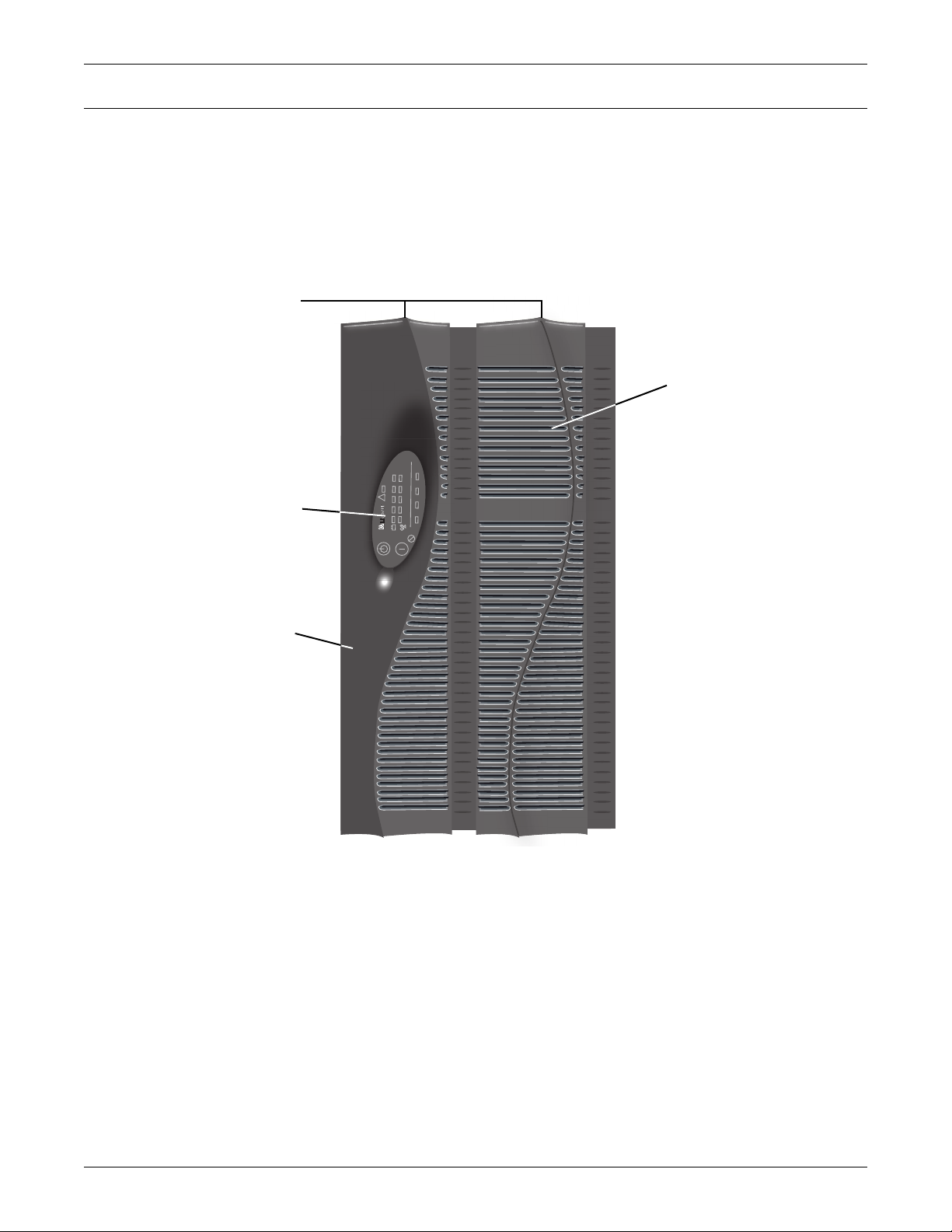

Figure 1 GXT2, front view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

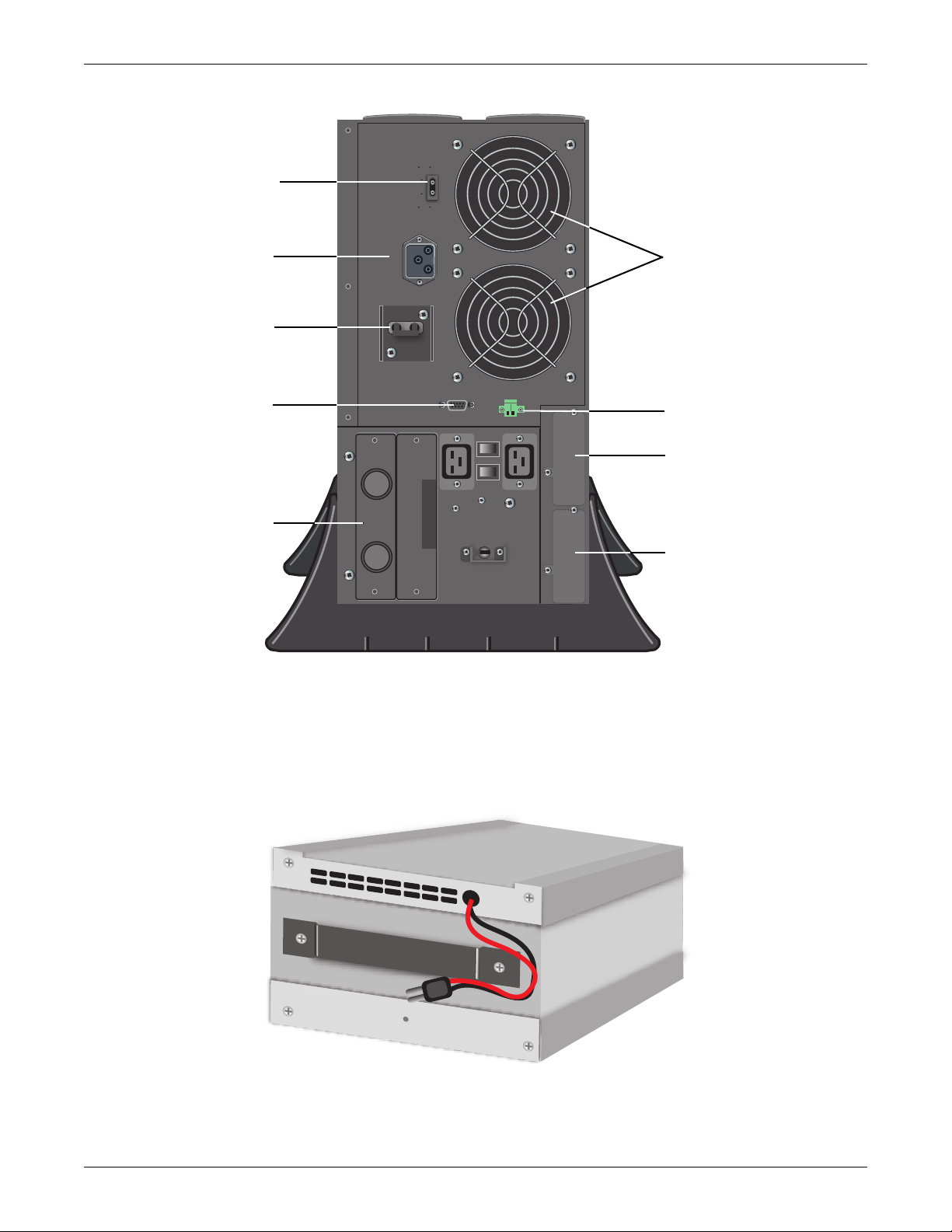

Figure 2 GXT2, rear view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Figure 3 Internal battery pack with connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

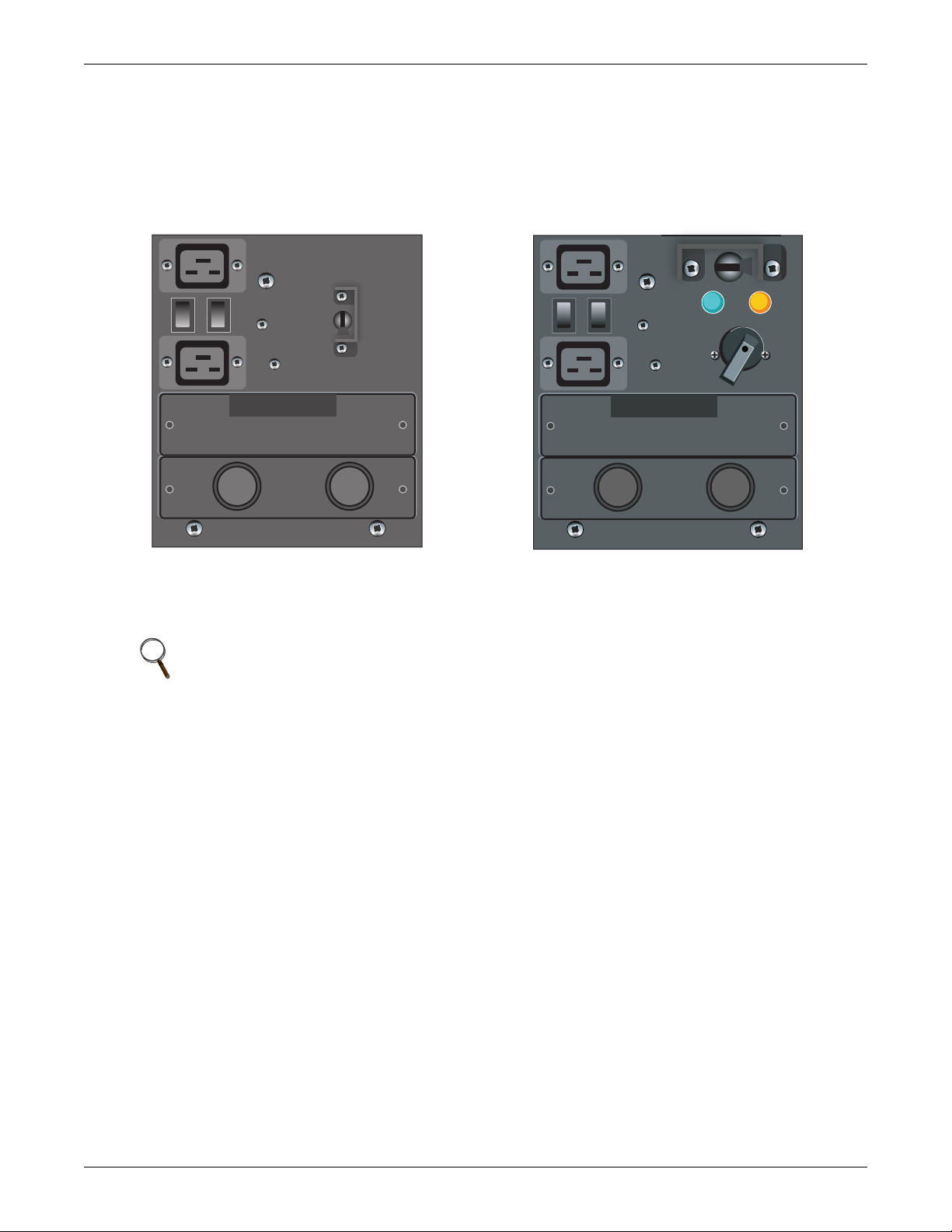

Figure 4 Power distribution boxes, basic, optional . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Figure 5 Tower-use support bases, spacers for external battery cabinets . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Figure 6 Distribution box electrical connections diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

TABLES

Table 1 Electrical specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Table 2 DB-9 pin assignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Table 3 Indicator meanings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Table 4 Troubleshooting guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Table 5 Alarm conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Table 6 Battery run times . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Table 7 UPS specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Table 8 Power distribution specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Table 9 External battery cabinet specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

ii

Page 5

IMPORTANT SAFETY INSTRUCTIONS

SAVE THESE INSTRUCTIONS

This Manual Contains Important Safety Instructions. Read all safety and operating instructions

before operating the Uninterruptible Power Supply (UPS). Adhere to all warnings on the unit and in

this manual. Follow all operating and user instructions. This equipment can be operated by individuals without previous training.

This product is designed for Commercial/Industrial use only. It is not intended for use with life support and other designated “critical” devices. Maximum load must not exceed that shown on the UPS

rating label. The UPS is designed for data processing equipment. If uncertain, consult your dealer.

See Limited Warranty.

This UPS is designed for use on a properly earthed (grounded), 220-240 VAC, 50Hz or 60Hz supply,

for installation by qualified personnel. A qualified electrician must review and approve customer supplied wiring, circuit breakers, intended loads, and verify correct input, output and earth connections

to ensure compliance with technical standards and local electrical codes of practice. Installation

instructions and warning notices only for use by qualified personnel are located after the UPS operator instructions in this manual.

WARNING

!

This UPS should not be supplied from electrical power systems of the “IT” (Impédance à

Terre) type. (IEC 364-ELECTRICAL INSTALLATION OF BUILDINGS)

ELECTROMAGNETIC COMPATIBILITY—This UPS complies with the requirements of the EMC

Directive 89/336/EEC and the published technical standards. Continued compliance requires installation in accordance with these instructions and the use of manufacturer approved accessories only.

WARNING

!

This is a product for restricted sales distribution to informed partners. Installation

restrictions or additional measures may be needed to prevent radio interference.

Operate the UPS in an indoor environment only in an ambient temperature range of 0-40°C

(32-104°F). Install it in a clean environment, free from moisture, flammable liquids, gases and corrosive substances.

This UPS contains no user serviceable parts. The UPS ON/OFF push buttons do not electrically isolate internal parts. Under no circumstances attempt to gain access internally, due to the risk of electric shock or burn.

Do not continue to use the UPS if the front panel indications are not in accordance with these operating instructions, or the UPS performance alters in use. Refer all faults to your dealer.

Only trained engineers authorized by Liebert should perform troubleshooting. To replace batteries,

refer all servicing to qualified service personnel. Proper disposal of batteries is required. Refer to your

local laws and regulations for disposal requirements.

Never block or insert any object into the ventilation holes or other openings.

DO NOT CONNECT equipment that could overload the UPS or demand DC current from the UPS,

for example: electric drills, vacuum cleaners, laser printers, hairdryers or any appliance using half

wave rectification.

Storing magnetic media on top of the UPS may result in data loss or corruption.

Turn the off UPS and isolate the UPS before cleaning. Use only a soft cloth, never liquid or aerosol

cleaners.

1

Page 6

GLOSSARY OF SYMBOLS

Risk of electrical shock

!

R

i

-

PbH2SO4

Indicates caution followed by important instructions

AC input

AC output

Requests the user to consult the manual

+

Indicates the unit contains a valve-regulated lead acid battery

Recycle

DC voltage

Equipment grounding conductor

Bonded to ground

AC voltage

ON/Alarm Silence/Battery Test

OFF/Bypass

Indicates the position of a fuse

2

Page 7

1.0 INTRODUCTION

Congratulations on your choice of the Liebert UPStation GXT2-6000RT230 and GXT2-4500RT230

Uninterruptible Power System (UPS). It provides conditioned power to microcomputers and other

sensitive electronic equipment.

Upon generation, AC power is clean and stable. However, during transmission and distribution it

may be subject to voltage sags, spikes, or complete power failure that may interrupt computer operations, cause data loss, or even damage equipment. The UPStation GXT2 protects equipment from

these disturbances.

The UPStation GXT2 comes in nominal power ratings of 4500 VA and 6000 VA. Complete model specifications appear at the end of this manual.

The UPStation GXT2 is a compact, on-line UPS. An on-line UPS continuously conditions and regulates its output voltage, whether mains power is present or not. It supplies connected equipment with

clean sinewave power. Sensitive electronic equipment operates best from sinewave power.

For ease of use, the UPStation GXT2 features a light-emitting diode (LED) display to indicate both

load percentage and battery capacity. It also provides self-diagnostic tests, a combination ON/Alarm

Silence/Manual Battery Test button, a Standby button, user configurable program, and two levels of

alarms when the unit is operating on battery.

The UPStation GXT2 has an interface port for communication between the UPS and a network server

or other computer systems. This port provides detailed operating information including voltages, currents, and alarm status to the host system when used in conjunction with Liebert MultiLink™ software. MultiLink software can also remotely control UPS operation.

Introduction

3

Page 8

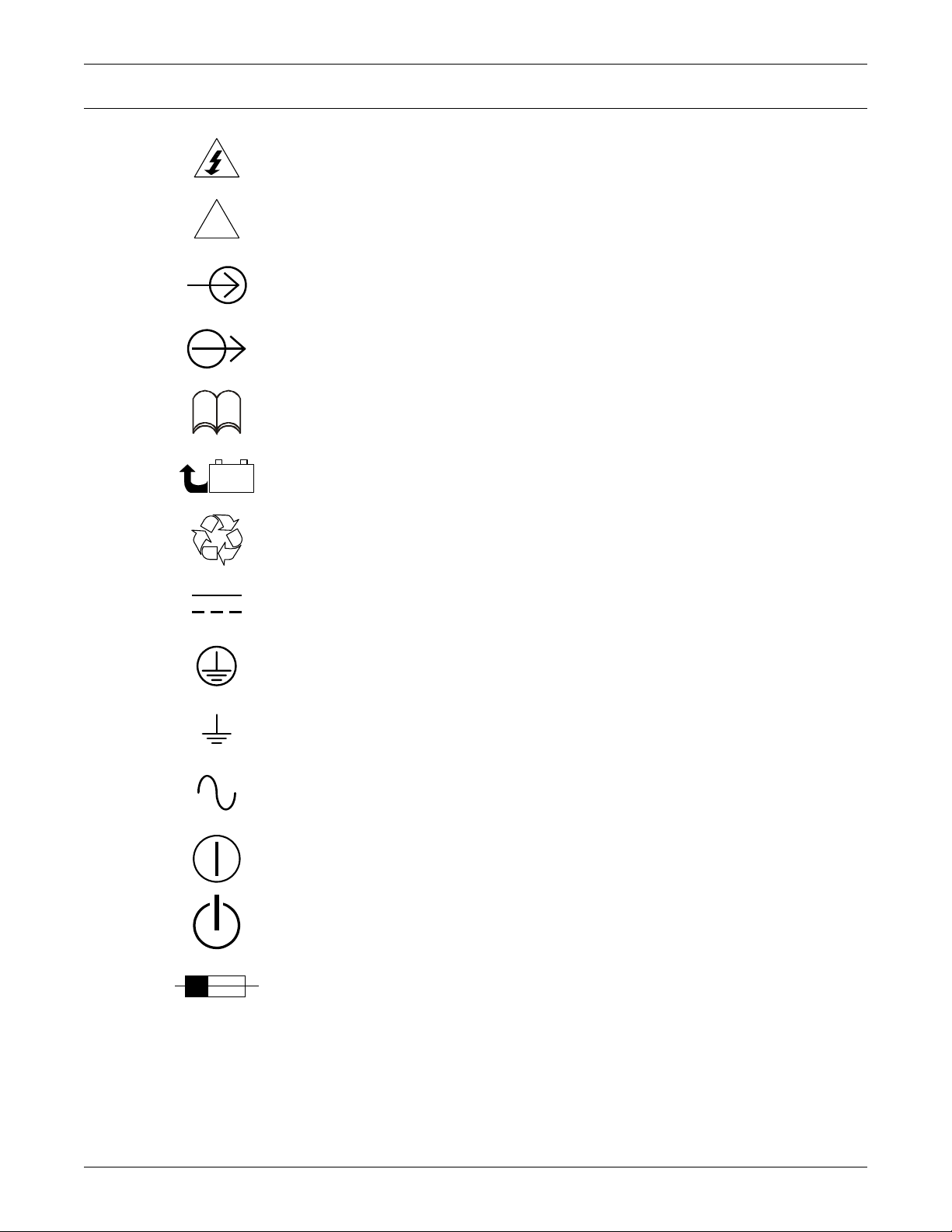

2.0 SYSTEM DESCRIPTION

System Description

Input Output

L1

N

G G

TVSS &

EMI/RFI

Filters

Rectifier

/PFC

DC-to-DC

Converter

Battery

Charger

Dynamic

Bypass

Inverter

Battery

L1

N

2.1 Transient Voltage Surge Suppression (TVSS) and EMI/RFI Filters

These UPS components provide surge protection and filter both electromagnetic interference (EMI)

and radio frequency interference (RFI). They minimize any surges or interference present in the

mains line and keep the sensitive equipment protected.

2.2 Rectifier/Power Factor Correction (PFC) Circuit

In normal operation, the rectifier/power factor correction (PFC) circuit converts mains AC power to

regulated DC power for use by the inverter while ensuring that the waveshape of the input current

used by the UPS is near ideal. Extracting this sinewave input current achieves two objectives:

• The mains power is used as efficiently as possible by the UPS.

• The amount of distortion reflected on the mains is reduced.

This results in cleaner power being available to other devices in the building not being protected by

the UPStation GXT2.

2.3 Inverter

In normal operation, the inverter utilizes the DC output of the power factor correction circuit and

inverts it into precise, regulated sinewave AC power. Upon a mains power failure, the inverter

receives its required energy from the battery through the DC to DC converter. In both modes of operation, the UPS inverter is on-line and continuously generating clean, precise, Regulated Ac Output

Power.

2.4 Battery Charger

The battery charger utilizes energy from the mains power and precisely regulates it to continuously

float charge the batteries. The batteries are being charged whenever the UPStation GXT2 is connected to mains power.

4

Page 9

2.5 DC-to-DC Converter

The DC to DC converter utilizes energy from the battery system and raises the DC voltage to the optimum operating voltage for the inverter. This allows the inverter to operate continuously at its optimum efficiency and voltage, thus increasing reliability.

2.6 Battery

The UPStation GXT2 utilizes valve-regulated, nonspillable, lead acid batteries. To maintain battery

design life, operate the UPS

in an ambient temperature of 20°C to 25°C (68°F to 77°F). Optional external battery cabinets are

available to extend battery run times.

2.7 Dynamic Bypass

The UPStation GXT2 provides an alternate path for mains power to the connected load in the

unlikely event of a UPS malfunction. Should the UPS have an overload, overtemperature, or UPS

failure condition, the UPS automatically transfers the connected load to bypass. Bypass operation is

indicated by an audible alarm and illuminated amber Bypass LED (other LEDs may be illuminated to

indicate the diagnosed problem). To manually transfer the connected load from the inverter to bypass,

press the Standby button once.

NOTE

The bypass power path does NOT protect the connected equipment from disturbances

in the mains supply.

System Description

5

Page 10

3.0 MAJOR COMPONENTS

The GXT2 is composed of three major assemblies to provide easier handling, installation, and versatility.

3.1 Main Frame and Electronics

This 5U cabinet is shipped with internal batteries installed and a basic, hardwire distribution box

attached and ready to install.

Figure 1 GXT2, front view

Top Trim

(2 pieces;

tower use

only)

Major Components

Lower Bezel &

Battery Access

Door

Status

Indicators

& Controls

Upper

Bezel

!

UPStation GXT

6

Page 11

Figure 2 GXT2, rear view

Battery

Disconnect

Major Components

External Battery

Connector

UPS Output

Circuit Breaker

DB-9

Communication

Port

Removable Power

Distribution Box

Fans

REPO Connector

Relay Card Slot

Serial Card Slot

(SNMP, OCWEB, USB)

3.2 Internal Battery Packs

The UPS has two internal battery packs behind a battery access door on the front of the unit. Each

pack is fitted with a connector to link to the UPS.

Figure 3 Internal battery pack with connector

7

Page 12

3.3 Removable Power Distribution Box

The UPS arrives with a basic hardwire power distribution pack installed. This box always contains

the UPS input circuit breaker.

Optional versions may be available to replace the standard box for custom installations.

Major Components

Figure 4

Power distribution boxes, basic, optional

Basic Hardwire Power Distribution Box

PD-CEHDWR

NOTE

Hardwire and hardwire/receptacle boxes that include a manual bypass switch allow

AC power to continue to flow from the mains input to the load while the box is removed

from the UPS. For details, refer to 11.2 - AC Power Connections.

Optional Hardwire Power Distribution

Box with Maintenance Bypass Switch

PD-CEHDWRBYP

8

Page 13

4.0 WHAT’S INCLUDED

The GXT2 are shipped with the following items:

• GXT2-6000RT230 and GXT2-4500RT230 user manual

• Vertical display overlay

• Top bezels - 2

• MultiLink software CD

• MultiLink serial cable, 10 ft (3m)

• Rack mount handles

• Support base - 2

• Mounting hardware

• Configuration program disk

•DB9 port cover

What’s Included

Top bezels

(tower use)

Vertical

display

overlay

Support base

with spacers

Rack mount

handles

MultiLink

software CD

Mounting hardware

DB9 port cover

MultiLink

serial cable

10 ft (3m)

www.liebert.com

GXT2™ Configuration

Program

For use with LiebertGXT 2U model UPS

systems

Versi on 1. 6

For Windows 95/98/NT

To Install:

Choose the Start button on the Taskbar

and select Run

Configuration

disk

9

Page 14

5.0 INSTALLATION AND CONFIGURATION

Do NOT attempt to start the UPS, turn on any circuit breaker or energize the input power until

instructed to do so in 6.0 - Initial Start-Up and Electrical Checks.

Visually inspect the UPS for freight damage. Report any damage to the carrier and your local dealer

or Liebert representative.

CAUTION

!

The UPS is heavy (see 13.0 - Specifications). Take proper precautions

when lifting or moving it.

Install the GXT2 indoors in a controlled environment, where it cannot be accidentally turned off.

Place it where air flows unrestricted around the unit. The installation location must be free of water,

flammable liquids, gases, corrosives and conductive contaminants. Maintain a minimum clearance of

100mm (4 inches) in the front and rear of the UPS. Maintain an ambient temperature range of 0 to

40°C (32 -104°F).

NOTE

UPS operation in sustained temperatures above 25°C (77°F) reduces battery life.

This device is intended for use in an Installation Category II environment.

Installation and Configuration

5.1 Install the Main Cabinet

The GXT2 may be installed in either a tower configuration or in a rack, depending on available space

and use considerations. Determine the type of installation and follow the appropriate instructions in

either 5.1.1 - Tower UPS Installation or 5.1.2 - Rack-Mount UPS Installation.

5.1.1 Tower UPS Installation

When using the GXT2 in a tower configuration, use the included support base (shown below, left) to

stabilize the UPS. If any external battery cabinets are added, they will include spacers to accommodate the additional cabinets (shown below, right).

Figure 5 Tower-use support bases, spacers for external battery cabinets

3U

5U support base for GXT2

End bases and 3U spacer

5.1.2 Rack-Mount UPS Installation

When using the GXT2 in a rack-mount configuration, the UPS must be supported by a slide kit, fixed

rails or a shelf.

When using the optional Adjustable Rack Mount Kit, you will use the following instructions. The figures accompanying 5.1.3 - Installing the Adjustable Rack-Mount Kit—Sold Separately shows

the positioning of the rack-mounting brackets. Liebert recommends taking the internal batteries out

of the UPS during rack installation. This will make the UPS cabinet lighter and easier to handle.

Spacers added to support base

to accommodate additional battery cabinets

3U

3U

2U

2U

2U

2U

CAUTION

!

Only three (3) M4 screws are used on the side of the GXT2 where the Power Distribution Box

is located. The fourth mounting hole is above the Power Distribution Box and is not used.

10

Page 15

5.1.3 Installing the Adjustable Rack-Mount Kit—Sold Separately

This kit contains parts needed to mount several different models of UPS and external battery cabinets into EIA310-D standard four-post racks that are 18-32" deep (457-813mm). The weight limit per

pair of adjustable rack-mounting brackets is 91 kg (200lbs.).

Parts included are:

Item Quantity

Rear bracket members 2

Front bracket members 2

Inner bracket members 2

M4 x 8mm machine screws 16

M4 locking hex nuts 8

M5 x 16 mm machine screws 12

Grease packet. 1

Tools needed for installation are:

• one Phillips screwdriver

• one 7mm wrench

The adjustable rack-mounting brackets (Part#: RMKIT18-32) feature retaining latches to prevent

users from inadvertently sliding the UPS or battery cabinet out of the rack.

Installation and Configuration

To install the rack mount brackets:

1. Unpack two (2) rack-mounting bracket assemblies and

mounting hardware from this kit. Bracket assemblies are

interchangeable between left-hand or right-hand.

Remove inner member of each bracket assembly as shown

at right by extending it to its outermost position, depressing the retaining latch and then pulling the inner member

out of the bracket assembly.

2. Determine the height position inside the rack enclosure

where you want to mount the UPS or battery cabinet.

CAUTION

!

Reduce the risk of tipping the rack enclosure by

placing the UPS or battery cabinet in the lowest

possible rack position.

3. Install the rear member of each bracket assembly into the

rack enclosure with two (2) M5 screws provided in this kit

(see figure at right). The return flanges on the bracket

assembly fit to the inside of rack mounting rails. Insert

screws loosely (finger-tight) into the top and bottom holes of

the return flange on the rear member. Extend the bracket

assembly by sliding the front member forward until it

touches the front rack mounting rail. Insert two (2) M5

screws loosely (finger-tight) into the top and bottom holes of

the return flange on each front member. Make sure that the

bracket assemblies are at the same mounting height on all

four (4) rack mounting rails.

Retaining

Latches

Inner

members

Front rack

mounting rails

M5 screws

Return

flanges

Front

members

M5 screws

Rear rack

mounting

rails

11

Page 16

Installation and Configuration

4. Get eight (8) M4 screws and eight (8) M4 nuts from the

hardware pack in this kit. Each nut has a locking, nylon

M4 nuts

M4

screws

insert that begins gripping the screw when it is halfway

tight. Make sure to tighten the nut and screw completely to

ensure locking action. Fasten the rear member and the front

member together using (4) screws and (4) nuts per bracket

assembly as shown in at right. For maximum support, insert

fasteners for each bracket assembly as far apart as possible,

depending on rack depth, while still joining both members

(see figures at right). Check alignment of bracket assemblies

and TIGHTEN ALL SCREWS FROM Steps 2 and 3.

5. Prepare the UPS or battery cabinet (the “equipment”) for

rack mounting by following instructions in the equipment’s

457mm

(18")

rack

depth

M4 nuts

M4 nuts

M4

screws

user manual. The equipment may require additional parts to

be added or parts to be removed for rack mounting. After it is

prepared, lay the equipment in rack-mounting position.

Fasten the inner members from Step 1 to the equipment on

both sides as shown at right with eight (8) M4 screws

provided in the kit. Make sure retaining latch is near the rear

813mm

(32") rack

depth

M4 nuts

of the equipment as shown (see figure at right).

6. Open the grease packet provided in the kit. Apply a bead of

M4 screws

Retaining latch

grease 25mm (1") long at four (4) places inside the bottom,

curved tracks of the front members as shown below right. The

grease will allow the equipment to slide into the bracket

assemblies more easily.

CAUTION

!

6.

Lifting equipment into the rack may be a two-person

job, depending on the weight of the equipment.

Liebert recommends taking the internal batteries

Front

UPS or battery

cabinet

out of the UPS during rack installation. This will

make the UPS cabinet lighter and easier to handle.

M4 screws

The GXT2 weighs 67kg (151lb). For the battery

cabinet’s weight, see the unit’s user manual.

7. Insert the equipment, with inner members attached in

Step 5, into the bracket assemblies by inserting the top and

bottom edges of the inner members into the top and bottom

curved tracks of the front members and sliding the

UPS or

battery

cabinet

Apply

grease

equipment into the rack (see figure at right). Ends of inner

members are tapered to allow the rear of the equipment to be

angled upward before insertion, if space allows.

Then the rear, bottom edges of the inner members can be

placed into the front edge of the bottom tracks and the front

Apply

grease

(inside)

of the equipment can be tipped up so they are level to insert

the top edges of the inner members before sliding the equipment into the rack (see figure below right). The equipment

should move smoothly into the bracket assemblies. If it does

not, recheck the alignment of the front and rear members

... and push it

into the rack.

from Steps 2 and 3.

8. Secure the front of the equipment to the rack mounting rails

to prevent the equipment from sliding out of position. If

securing holes are provided on the front of the equipment

that align with the center holes on the return flange of the

front members, you can use the four (4) extra M5 screws

provided in the kit to secure the equipment. Otherwise, the

Insert the UPS into the front

members, lift the front .. .

equipment should be secured to the front of the rack with

four (4) customer-supplied fasteners.

12

Page 17

5.2 External Battery Cabinet Installation

Optional Liebert external battery cabinets may be connected to the UPS to provide additional battery

run time. External battery cabinets are designed to be placed on one side of the UPS or stacked

beneath the UPS.

CAUTION

!

The external battery cabinet(s) are heavy (see 13.0 - Specifications). External battery

cabinets can be used in rack-mount or tower configuration. Take proper precautions when

lifting them.

1. Visually inspect the external battery cabinet for freight damage. Report damage to the carrier

and your local dealer or Liebert representative.

2. For slide rail installations, first remove the top/side fin. Top/side fin slides forward and then lift

up to remove. Optional rack-mount handles are shipped with the external battery cabinet and

may be installed at this time if desired.

3. Securing hardware and slide rails are sold separately. Please contact your local dealer or Liebert

representative for these additional options and any assistance needed. Fasten the slides into

position with the screws per the instructions included with the slide rails.

4. Use the enclosed support bases for the tower option to prevent tip-over. One additional set of

support base extensions ships with each external battery cabinet.

5. Connect the supplied external battery cabinet cable to the rear of the external battery cabinet,

then to the rear of the UPS.

6. The UPS is now equipped with additional backup battery run time. For approximate battery run

times, refer to Table 6.

Installation and Configuration

NOTE

You must use the included configuration program to program the UPS for the number

of external battery cabinets connected. Instructions for the configuration program are in

7.0 - Configuration Program.

3U

2U

Spacers added to support

base to accommodate

additional battery cabinets

2U

13

Page 18

5.3 Connect the Internal Batteries Using the External Connector

The internal connectors of the internal battery packs will be connected when shipped. However, the

internal batteries will be disconnected from the UPS using a rear panel connector. The connector

attaches to the UPS in both the open and closed position using two screws. The picture on the left

shows the connector in the open position, as shipped.

When the UPS is installed, remove the two screws to release the connector. Plug the connector into

the socket. The internal batteries are now connected to the UPS electronics. Install the two screws to

secure the connector in the closed position.

Remove these screws

to release connector

Installation and Configuration

5.3.1 Storage

If the UPS is to be shipped or stored for an extended time, the connector should be removed and

attached in the open position, as shown above. This will minimize any standby current drain on the

batteries.

5.4 Connect Input/Output Power

The UPS should arrive with the basic hardwire

box attached. If the box needs to be exchanged for

an optional model, remove and install the desired

box using the three captive screws marked in the

illustration at right.

To remove:

Loosen the screws about 20 turns until the box

can be pulled away from the UPS.

To install:

Align the connectors on the box and UPS. Push

the box into place. While holding the box firmly

against the UPS, tighten the three captive screws

until the box is secure. Do not over tighten.

5.4.1 Distribution Box Electrical Connections

Electrical connections are made through a removable power distribution box that attaches to the rear of the UPS.

The installer must provide a 32A branch circuit breaker. The Input circuit breaker on the distribution

box and the Output circuit breaker on the rear fixed-panel of the UPS disconnect all power between

the main cabinet and the distribution box.

Models equipped with a manual bypass switch pass bypass power directly to the bypass switch from

the input terminal block. The input circuit breaker on the distribution box does not disconnect power

from the manual bypass switch.

Unscrew

these

captive

screws

14

Page 19

Figure 6 Distribution box electrical connections diagram

PD-CEHDWR PD-CEHDWRBYP

Installation and Configuration

Mains

Input

32A

External

Branch

CB

Mains

Input

CB

30 30

30 30

Output

UPS

Output

CB

Input

32A

External

Branch

CB

Input

CB

UPS - PFC, Battery, InverterUPS - PFC, Battery, Inverter

Byp.

Output

Inv.

UPS

Output

CB

PD-CEHDWR and PD-CEHDWRBYP Terminal Block Connections

Conduit entry holes are provided on the rear and side of the box. Input and output wiring should not

share the same conduit.

Table 1 Electrical specifications

Input

Current

Rating

24A 32A 6-10mm2 (8-10AWG) 10mm2 (8AWG) 2.26 Nm (20 in-lb)

Recommended

(Maximum) External

Overcurrent Protection

Recommended Wire

(Including ground wire)

(758C copper wire)

Maximum Wire

Accepted by

Terminal Block

Terminal

Tightening

Torque

NNLL

OUTPUT INPUT

6-10mm2 - Use Copper Wire Only

32Amp Max Branch

Overcurrent Protection

NNLL

OUTPUT TO LOAD INPUT TO UPS

NOTE

1. Note1 The installer must provide circuit breaker protection according to local codes. The

mains disconnect should be within sight of the UPS or have appropriate an appropriate

lock-out. Maintain service space around the UPS or use flexible conduit.

2. Note 2 The installer must provide output distribution panels, circuit breaker protection, or

emergency disconnects according to local codes. Output circuits must not share a common

conduit with any other wiring.

15

Page 20

6.0 INITIAL START-UP AND ELECTRICAL CHECKS

1. Verify that the Input Output circuit breakers are off.

2. During initial system checks, disconnect all loads (open load disconnects).

3. Inspect all wiring, cables, and connection.

4. If external battery cabinets are used, verify that the battery interconnect cables are fully inserted

in the sockets.

5. If you are using a distribution box that includes a Manual Bypass Switch, place the switch in

BYPASS position.

6. Turn on the branch circuit disconnect to apply voltage to the input terminal block.

7. Using a voltmeter, verify the expected L1-N voltage.

If no Manual Bypass Switch is used, there will be no output voltage at this time. If a Manual

Bypass Switch is used, verify that the same voltages appear at the Output terminals. If a Manual

Bypass Switch is used, the Bypass lamp will light by the switch. If no manual bypass switch is

used, there will be no output voltage at this time.

8. After verifying proper input voltage to the UPS terminal block, turn off the branch circuit power,

close all access panels to the distribution box, and reapply input power.

9. Close the Input circuit breaker located on the distribution box. The green AC INPUT lamp should

illuminate on the front panel.

10. Press the ON button for 1 second. The BYPASS lamp will light for several seconds before the UPS

ON lamp turn on continuously. If the batteries are determined to charged above 80%, an

automatic battery test will run for about 15 seconds.

11. Close the Output circuit breaker on the rear of the UPS. If a Manual Bypass Switch is used, the

Inverter lamp by the switch will light. If a Manual Bypass Switch is used, transfer the switch to

the Inverter position. The output terminal block will be powered at this time.

12. Perform a Manual Battery Test - Press the ON button for 1 second. The front BATTERY lamp will

light for about 15 seconds and then return to only the UPS ON and AC INPUT lamps being on.

13. Review all setting option provided by the configuration program. Some changes require that the

UPS be OFF. If this is the case, these should be programmed before powering the loads. The

configuration program is described in the next section.

14. Connect all loads for normal operation.

Initial Start-Up and Electrical Checks

16

Page 21

Configuration Program

7.0 CONFIGURATION PROGRAM

The final step of installation may require custom configuration of your UPS using the enclosed configuration program. Some configuration settings may be changed only while the UPS is off. These should

be set before the UPS is put into full-time service powering the critical load.

For most users operating with 230VAC and with no external batteries, the factory default settings

will be adequate.

7.1 GXT2-6000RT230 and GXT2-4500RT230 Configuration Program Features

• Select one of three L-N output voltages to match local voltages.

• Enable/Disable Auto-Restart.

• Select frequency converter operation with a fixed output frequency of 50 or 60 Hz.

• Set the Low Battery Warning alarm time from 2 to 30 minutes.

• Enable/Disable the Auto-Battery test.

• Set the Auto-Battery test to 7, 14, 21, or 28 days.

• Specify the number of external battery cabinets connected to the UPS to adjust the remaining run

time calculations reported by Liebert software products.

• Modify the shutdown setting of DB-9 pin 6 (for information on pin assignments, see Table 2).

7.1.1 What You Will Need

In addition to the GXT2 UPS, you will need the configuration program diskette and serial cable (beige

or tan, 3-wire: GND, TX, RX; straight through 2-2, 3-3, 5-5) included in the UPS accessory box. A Windows 95® or later computer, desktop or laptop, is also required to set up and run the configuration

program.

17

Page 22

8.0 CONTROLS AND INDICATORS

Controls and Indicators

All indicators illuminated

for illustration only.

UPStation GXT

BATTERY UPS ON BYPASSAC INPUT

8.1 ON/Alarm Silence/Manual Battery Test Button

This button controls output power to connected load(s) and has three functions:

•ON

•Alarm Silence

•Manual Battery Test

ON - Pressing this button will start up the UPS in order to provide conditioned and

protected power.

Alarm Silence - To silence alarms, press this button for at least one Second. After the

alarm is silenced, the UPStation GXT2 will reactivate the alarm system to alert of

additional problems.

NOTE

The LOW BATTERY and BYPASS reminder alarms CANNOT be silenced.

Manual Battery Test - To initiate a manual battery test, press the ON button for at least one second

while operating from mains power with no alarm conditions present.

• If only three of the five Battery LEDs illuminate, allow the UPS to recharge the batteries for 24

hours.

• After 24 hours, retest the batteries.

• After the batteries have been retested, if only three of the five Battery LEDs illuminate, contact

your local dealer, Liebert representative or Liebert Worldwide Support Group.

8.2 Standby/Manual Bypass Button

This button controls output power to connected load(s) and has dual functions:

Standby and Manual Bypass.

CAUTION

!

Pressing the Standby/Manual Bypass button once will transfer the

load to bypass power. Pressing the Standby/Manual Bypass button a

second time within 4 seconds will cut off power to the output sockets

and connected loads. Perform all necessary shutdown procedures on

connected loads before pressing this button twice.

18

Page 23

8.3 Load Level Indicators (4 Green, 1 Amber)

The load level indicators display the approximate electrical load placed upon the UPS at all times.

8.4 Battery Level Indicators (5 Green)

The battery level indicators display approximate battery capacity at all times.

The UPStation GXT2 is equipped with automatic and remote battery test features. The automatic

test occurs every 14 days (this option is user configurable) if mains has not been interrupted. Should

the battery fail this test, the red Fault indicator LED along with the A and C diagnostic LEDs will

illuminate and an alarm will sound (refer to 12.0 - Troubleshooting). The remote test feature functions with MultiLink 3.x software and can remotely initiate the battery test.

8.5 Fault Indicator LED (Red)

The Fault indicator LED is illuminated if the UPS has detected a problem. Also, one or more of the

battery level indicators may be illuminated (refer to 12.0 - Troubleshooting).

8.6 Bypass Indicator LED (Amber)

The Bypass indicator LED is illuminated when the UPS is operating from bypass power. An alarm

will sound indicating the UPS detected a problem, or the manual bypass function has been activated.

Controls and Indicators

8.7 UPS ON Indicator LED (Green)

The UPS ON indicator LED is illuminated when the UPS inverter is operating and supplying power

to the connected loads.

8.8 Battery Indicator LED (Amber)

The Battery indicator LED is illuminated when the UPS is operating on battery.

8.9 AC Input Indicator LED (Green)

The AC Input indicator LED is illuminated when mains power is available and within the input specifications.

19

Page 24

9.0 OPERATING INSTRUCTIONS

AC I NPUT

9.1 Normal Mode Operation

During normal operation, mains power provides energy to the

UPS. The filters, power factor correction circuit and the inverter

process this power to provide computer grade power to connected

loads. The UPS maintains the batteries in a fully charged state.

The four green load level LEDs indicate an approximate level of

load in 25% increments. If the UPS becomes loaded beyond full

rating, the fifth (amber) LED indicator will illuminate and the

UPS will sound an audible alarm. The display template indicates

the percentage of load (10% of load shown in example) on the UPS

output.

9.2 Battery Mode Operation

Battery mode occurs in event of an extreme input voltage condition

or complete mains failure. The battery system supplies power

through the DC to DC converter to the inverter to generate power

for the connected load. During battery mode an alarm sounds

every 10 seconds. This will change to two beeps every 5 seconds

when the battery runs low (approximately 2 minutes remaining,

but this is user configurable). The AC Input LED will extinguish,

and the Battery LED will illuminate to warn that a mains problem

has occurred. Each battery level indicator represents a 20% capacity level. As capacity decreases, fewer indicators remain illuminated. Refer to 12.0 - Troubleshooting. For approximate battery

run times, refer to Table 6. These times are approximate, based on resistive load and an ambient

temperature of 25°C (77°F). To increase this time, turn off non-essential pieces of equipment (such as

idle computers and monitors) or add the optional external battery cabinet.

Operating Instructions

BATTERY UPS ON BYPASSAC I NPUT

Normal Mode Operation

Batteries at 100% Charge

Load at 10%

Battery Mode Operation

Batteries at 30% Charge

Load at 50%

CAUTION

!

Turning OFF the UPS while in it is battery mode will cut off output power.

9.3 Bypass Mode Operation

Bypass mode occurs when the OFF button is pressed once while

the UPS is in Normal Mode. During bypass operation, mains

power provides energy to the UPS. The mains power bypasses the

inverter and provides power for the connected load.

The four green load level LEDs indicate an approximate level of

load in 25% increments. If the UPS becomes loaded beyond full

rating, the fifth (amber) LED indicator will illuminate and the

UPS will sound an audible alarm. The display template indicates

the percentage of load (26-50% of load shown in the example above) on the UPS output.

9.4 Battery Recharge Mode

Once mains power is restored, the UPS resumes normal operation. At this time, the Battery Charger

begins recharging.

UPS ON BYPASS

20

Page 25

10.0 COMMUNICATIONS

r

10.1 Communications Interface Port

The UPStation GXT2 UPS has a standard DB-9 serial port female connector located on the rear of the

UPS unit. Several signals are provided on this port and are assigned as follows:

Table 2 DB-9 pin assignment

DB-9

Assignment Description

Pin

1 Low Battery (open collector)

2 UPS TxD (typically RS-232 levels)

3 UPS RxD (typically RS-232 levels)

4 Remote Shutdown (5-12VDC, 10-24mA max; battery operation)

5 Common

6 Remote Shutdown (short to pin 5); all modes of operation

7 Low Battery (open emitter)

8 Mains Fail (open emitter)

9 Mains Fail (open collector)

Communications

Pin Assignment Collector to Emitter*

6789

54321

* Maximum voltage and current on pins 1, 7, 7 and 9 are 60VDC and 10.0 mA

10.2 Pin 4 - Remote Shutdown on Battery

1. 1. This pin is functional only when the UPS is in battery mode. If the UPS is being powered by the

mains, Pin 4 will ignore any signal on this pin.

2. 2. Pin 4 requires a 5-12 VDC signal to shutdown. This normally comes form the serial port using

Liebert's contact closure cable. It cannot be used with just a contact closure unless the relay is

used to switch a voltage source. A 5-12 VDC signal for 1.5 seconds or greater is required to signal

a shutdown. Signals for less than 1.5 seconds will be ignored. After Pin 4 receives a shutdown

signal for 1.5 seconds, the command cannot be canceled.

3. 3. A battery shutdown signal on Pin 4 will NOT cause an immediate Shutdown. A shutdown

signal will start a 2-minute shutdown timer. The timer cannot be stopped. After 2 minutes, the

UPS will shut down.

4. 4. If the mains returns during the 2-minute timer countdown, the shutdown timer will continue

until the end of 2 minutes and the UPS will turn OFF. The UPS must remain OFF for at least

10 seconds even if AC input power Returns before the UPS turns OFF. This serves to reset and

restart the server.

330 Ohms

(+)

(-)

Open

Collecto

Open

Emitter

Whether the UPS turns back ON when power is restored depends on the auto-restart setting: enabled

or disabled.

If the auto-restart is disabled, the UPS will not restart after performing the 2-minute shutdown

delay.

21

Page 26

10.3 UPS Intelligent Communications

The UPStation GXT2 is equipped with two Intellislot® ports to provide advanced communication and

monitoring options.

The Intellislot port closer to the corner of the UPS chassis is the serial card slot. This Intellislot port is

used for the OCWEBCARD and the USBCARD. The other Intellislot port is used for

RELAYCARD-INT or the MULTIPORT Card.

Liebert’s OCWEBCARD

Communications

DB9 (RS232) port

covered

NOTE

The OCWEBCARD DB9 serial port cable should be used only for the initial card setup. Remove

the cable after setup is complete.

When the DB9 OCWEBCARD serial port cable is removed, the OCWEBCARD DB9 connector

needs to be covered. The DB9 cover is included with the UPS.

Liebert's MultiLink software continually monitors the UPS and can shut down your computer or

server in the event of an extended power failure.

MultiLink can also be configured for use without the serial cable when the Intellislot SNMP/Web card

is installed in the UPS. Additionally, MultiLink can be configured to coordinate shutdown across the

network with other computers running MultiLink when you purchase a MultiLink License Kit. For

more information about the Intellislot SNMP/Web Card and MultiLink license Kits, visit our Web site

(www.liebert.com) or contact your local dealer or Liebert representative.

Several option cards are available for use in the Intellislot port of the UPStation GXT2. The Intellislot

SNMP/Web Card provides SNMP and Web-based monitoring and control of the UPS across the network.

The Intellislot MultiPort 4 Card allows you to install MultiLink software on four computers and coordinate shutdown in the event of a power failure.

The Intellislot Relay Card provides dry contact relay outputs for custom wired applications and delivers support for built-in shutdown for AS/400 systems.

CAUTION

!

To maintain safety (SELV) barriers and for electromagnetic compatibility, signal cables

should be segregated and run separate from all other power cables, where applicable.

22

Page 27

10.4 Remote Emergency Power Off

The UPS is equipped with a Remote Emergency Power Off (REPO) connector.

The user must supply a means of interfacing with the REPO circuit to allow disconnecting the UPS

input feeder breaker to remove all sources of power to the UPS and connected equipment to comply

with national and local wiring codes and regulations.

REPO switch connection diagram

UPS ships with REPO jumper

installed allowing the UPS

to operate

Communications

Opening the REPO connection will disable the UPS.

Manual restart using the front panel is required after

the REPO connection is closed again.

12

Normally closed switch system

(fail-safe)

CAUTION

!

To maintain safety (SELV) barriers and electromagnetic compatibility, signal cables should

be segregated and run separately from power cables.

12

23

Page 28

11.0 MAINTENANCE

11.1 Internal Battery

The UPStation GXT2 requires very little maintenance. The batteries are valve-regulated, non-spillable, flame retardant, lead acid, and should be kept charged to obtain their designed life. The UPS

continuously charges the batteries when connected to the mains supply.

When storing the UPS for any length of time, it is essential to plug the UPS in for at least 24 hours

every four to six months to ensure full recharge of the batteries. Failure to recharge the batteries periodically will result in permanent degradation of battery capacity.

UPStation GXT

- +

AC INPUT

Maintenance

!

BATTERY UPS ON BYPASS

The UPStation GXT2 is designed to allow the user to safely replace the internal batteries. Read the

safety cautions before proceeding. Contact your local dealer or Liebert representative to obtain the

appropriate replacement battery kit part number and pricing.

24

Page 29

11.1.1 Internal Battery Replacement

CAUTION

!

A battery can present a risk of electrical shock and high short circuit current. Observe the

following precautions before replacing the batteries:

• Remove rings, watches and other metal objects.

• Use a Phillips (cross-head) screwdriver with insulated grips.

• Do not lay tools or other metal objects on top of the batteries.

• If the battery replacement kit is damaged in any way or shows signs of leakage, contact

your local dealer or Liebert representative immediately.

• Do not dispose of batteries in a fire. The batteries may explode.

• Do not open or mutilate batteries. Released electrolyte is harmful to the skin and eyes. It is

toxic.

Maintenance

1. Remove the 3U battery access panel on the front of

the UPS by loosening the two captive screws

located between the bezels (see illustration at

right).

2. Once the captive screws are loosened, tip the panel

forward and lift to remove it from the main

cabinet.

3. Use a Phillips (cross-head) screwdriver to remove

the screw in the battery retaining bracket on each

battery pack (see illustration at right). Remove the

retaining brackets.

4. Disconnect the battery connectors in the front of

each battery pack.

5. Lift the internal connector out of the way and slide

the battery out of the UPS. Support the weight of

the battery to prevent it from falling.

6. Unpack the new battery assembly, taking care not

to destroy the packing. Compare new and old

battery assemblies to make sure they are the

same. If so, proceed with Step 7; otherwise STOP

and contact your local dealer, Liebert

representative or the Liebert Worldwide Support

Group.

7. Line up and slide in the new replacement battery

pack while holding the internal connector out of

the way.

8. Reconnect the electrical connections for each

battery pack.

9. Install the battery retaining brackets using the

Phillips removed earlier.

10. Install the battery access panel and tighten the

captive screws.

Battery Door Captive Screws

!

3U Battery Access Door and

UPStation GXT

- +

Battery Bezel

AC INPUT

BATTERY UPS ON BYPASS

Retaining screw

!

UPStation GXT

AC OUTPUT BATTERY UPS ON BYPASS

Retaining bracket

!

UPStation GXT

- +

AC INPUT

BATTERY UPS ON BYPASS

NOTE

These are hot-swappable replacement

batteries. However, caution should be

exercised because during this procedure the

load is unprotected from disturbances and

power outages.

25

Battery Connectors

Page 30

11.2 AC Power Connections

Power connections may be disconnected from the UPS cabinet via a removable distribution box. This

may be a convenient feature if the UPS must be moved a short distance or replaced. This box allows

power connections to be conveniently disconnection from the main UPS cabinet. A label is attached to

the UPS to describe these procedures.

Hardwire and Hardwire/Receptacle boxes that include a Manual Bypass Switch allow AC power to

continue to flow from the mains input to the load while the box is removed from the UPS.

11.2.1 PD-CEHDWR—Manual Bypass Switch Available

Disconnect

1. DO NOT turn off the branch circuit breaker feeding power the box unless you intend to disconnect

all power to the load.

2. Ensure that the Maintenance Bypass Lamp is ON.

3. Switch to the maintenance bypass position.

The Load is now unprotected from line disturbances or interruptions.

4. Turn off the UPS using the front panel controls.

a. If needed, push the OFF button for one second once to transfer the load to bypass.

b. Press the OFF button twice within four seconds to turn the UPS off.

5. Turn off the UPS input circuit breaker on the box at the rear of the UPS.

This input circuit breaker only cuts power to the connector between the box and UPS. The input

circuit breaker does not cut power to the manual bypass switch.

6. Turn off the output circuit breaker on the rear of the UPS.

7. Remove the distribution box from the UPS

a. Loosen all three captive screws until box releases.

b. Pull box away from the UPS and set the box aside on a padded surface.

Maintenance

CAUTION

!

Power is still passing through the box from mains to the load.

Reconnect

1. Align connectors and press the box onto the rear of the UPS.

2. 2. Hold the box firmly against the UPS and tighten the captive screws. Do not overtighten.

3. If the Mains branch circuit breaker and load is off, turn the branch breaker on now.

4. Turn on the output circuit breaker on the rear of the UPS.

5. Turn on the input circuit breaker on the box.

6. Start the UPS according to the startup instructions.

Press the ON button for one second.

7. Confirm that the UPS AVAILABLE lamp is lit beside the manual bypass switch.

8. Turn the manual bypass switch to the UPS position.

9. The UPS now protects the load.

26

Page 31

12.0 TROUBLESHOOTING

AC I NP UT

The information below indicates various symptoms a user may encounter in the event the UPStation

GXT2 develops a problem. Use this information to determine whether external factors caused the

problem and how to remedy the situation.

1. 1. The Fault indicator will illuminate, indicating the UPS detected a problem.

2. 2. An alarm will sound, alerting that the UPS requires attention.

3. 3. One or more additional battery level LED indicators will be illuminated to provide a diagnostic

aid to the operator, as described below:

Table 3 Indicator meanings

Troubleshooting

Fault

Example shows UPS

on bypass because

of output overload,

signified by amber

load indicator.

LED status Diagnosis/Audible alarm

All LEDs On bypass due to output overload; beep every half-second

A LED On bypass due to overtemperature condition; beep every 4 sec.

B LED On bypass due to DC bus overvoltage; beep every 4 sec.

C LED DC-DC failure during battery mode; beep every 4 sec.

D LED On bypass due to PFC failure; beep every 4 sec.

E LED On bypass due to inverter failure; beep every 4 sec.

A&C LEDs UPS failed battery test; long beep every minute

C&E LEDs UPS shutdown due to command from communication port (SNMP); no beep

Battery LED Flashing

A&E LEDs Fan locked

B&C REPO active. UPS cannot run with REPO loop open.

B&D UPS is OFF due to previous REPO shutdown. Autorestart disabled.

D&E Charger Malfunction

Internal Battery source not available (continuous horn). Check Battery connection,

completely power down and reboot UPS.

Under fault conditions, the Fault indicators will be illuminated indefinitely while battery charger is

operational, or for a maximum of 5 minutes while the battery charger is not operational.

If a problem persists, consult your local dealer, Liebert representative or contact the Liebert Worldwide Support Group. Please have the UPS model number and serial number available at the time of

your inquiry.

27

Page 32

Table 4 Troubleshooting guide

Problem

UPS fails to start when the

ON button is pressed.

Battery indicator LED is

illuminated.

UPS has reduced battery

time.

Fault and Bypass indicator

LEDs and all load level LEDs

are illuminated.

Fault and Bypass indicator

LEDs and diagnostic LED A

are illuminated.

Fault and Bypass indicator

LEDs and diagnostic LED B

are illuminated.

Fault indicator LED and

diagnostic LED C are

illuminated.

Fault and Bypass indicator

LEDs and diagnostic LED D

are illuminated.

Fault and Bypass indicator

LEDs and diagnostic LED E

are illuminated.

Fault indicator LED and

diagnostic LEDs A and C are

illuminated.

Fault and Bypass indicator

LEDs and diagnostic LED C

and E are illuminated.

Fault and LEDs A&E are

Illuminated

Fault and LEDs B&C are

Illuminated

Fault and LEDs B&D are

Illuminated

Cause Solution

UPS is short-circuited or

overloaded.

UPS not plugged in.

UPS input protection fuse

has blown/opened.

Mains voltage out of UPS

input range.

Batteries are not fully

charged.

UPS is overloaded. Check load level display and reduce the load on the UPS.

Batteries may not be able to

hold a full charge due to age.

UPS overloaded or load

equipment is faulty.

UPS internal fan has a

problem or UPS shutdown

due to temperature condition.

Load is on bypass power.

UPS internal DC bus

overvoltage.

DC-DC failure during battery

mode.

UPS PFC (Power Factor

Correction Circuit) fault.

UPS inverter fault.

UPS failed the battery test.

UPS shutdown due to a

command from the

communications port(s).

Fan locked

REPO active

UPS is OFF due to previous

REPO shutdown, but the

REPO has been connected

or reset. Autorestart

disabled.

Troubleshooting

Ensure UPS is OFF. Disconnect all loads and ensure nothing is

lodged in output receptacles.

Ensure loads are not defective or shorted internally.

UPS is operating from battery mode, make certain UPS is

securely plugged into the wall receptacle.

UPS is operating from battery mode. Save data and close

applications. Replace UPS input fuse, then restart UPS.

UPS is operating from battery mode. Save data and close

applications. Ensure mains supply voltage is within acceptable

limits for UPS.

Keep UPS plugged in continuously at least 24 hours to

recharge batteries.

Replace batteries. Contact your local dealer, Liebert

representative or the Liebert Worldwide Support Group for

replacement battery kit.

Check load level display and remove non-essential loads.

Recalculate the load and reduce number of loads connected to

UPS. Check load equipment for faults.

Ensure UPS is not overloaded, ventilation openings not

blocked, or room ambient temperature is not excessive. Wait

30 minutes to allow UPS to cool, then restart UPS. If UPS does

not restart, contact your local dealer, Liebert representative or

the Liebert Worldwide Support Group.

UPS requires service. Contact your local dealer, Liebert

representative or the Liebert Worldwide Support Group.

Bus voltage under 315VDC(O/P 220VAC) / 330VDC(O/P

230VAC) / 345VDC(O/P 240VAC). UPS requires service.

Contact your local dealer, Liebert representative or the Liebert

Worldwide Support Group.

UPS requires service. Contact your local dealer, Liebert

representative or the Liebert Worldwide Support Group.

UPS requires service. Contact your local dealer, Liebert

Representative or the Liebert Worldwide Support Group.

Replace batteries. Contact your local dealer, Liebert

representative or the Liebert Worldwide Support Group.

Your UPS has received a signal or command from the attached

computer. If this was inadvertent, ensure the communication

cable used is correct for your system. For assistance, contact

your local dealer, Liebert representative or the Liebert

Worldwide Support Group.

Check for external obstruction entering fan guard. UPS

requires service. Contact your local dealer, Liebert

representative or Liebert Worldwide Support Group.

circuit is closed. If not used, a wire jumper must connect the

REPO terminals.

Start the UPS using the front panel.

28

Page 33

Troubleshooting

Table 4 Troubleshooting guide (cont’d)

Problem

Fault and LEDs D&E are

Illuminated

Battery LED is flashing.

Cause Solution

If the charger is overvoltage, the UPS will shutdown. If the

Charger malfunction

Battery source is not

available; continuous horn.

charger is undervoltage and the batteries are nearly depleted,

this alarm will give a temporary warning before the UPS shuts

down. UPS requires service. Contact your local dealer, Liebert

representative or Liebert Worldwide Support Group.

Check battery connections, completely power down and restart

UPS.

NOTE: If the battery circuit

opens while the UPS is running,

it will be detected when the next

battery test is performed.

Table 5 Alarm conditions

Condition Alarm

Battery Mode (mains failure) One short beep every 10 seconds: more than 2 minutes of run time remaining

Low Battery Two short beeps every 5 seconds: less than 2 minutes of run time remaining

Output Overload (Bypass) One short beep every half second

Overtemperature (Bypass) A one-second beep every 4 seconds

DC Bus Overvoltage (Bypass) A one-second beep every 4 seconds

DC-DC failure during battery

mode

PFC Failure (Bypass) A one-second beep every 4 seconds

Inverter Failure A one-second beep every 4 seconds

Battery Test Failure A two-second beep every 1 minute

Fan Locked A one-second beep every 4 seconds

REPO Active A 0.25-second beep every 0.25 seconds

UPS OFF; Autorestart disabled

from previous REPO shutdown

Charger Malfunction A one-second beep every 4 seconds

A one-second beep every 4 seconds

A one-second beep every 4 seconds

29

Page 34

Troubleshooting

Table 6 Battery run times

Load% 4500VA 6000VA

10% 125 94

20% 66 46

30% 41 29

40% 30 21

Internal Battery

(minutes)

Internal Battery

+ 1 External Battery

Cabinet (minutes)

Internal Battery

+ 2 External Battery

Cabinets (minutes)

Internal Battery

+ 3 External Battery

Cabinets (minutes)

Internal Battery

+ 4 External Battery

Cabinets (minutes)

50% 24 17

60% 19 13

70% 16 11

80% 14 9

90% 12 8

100% 10 7

10% 296 222

20% 166 124

30% 114 81

40% 86 60

50% 70 49

60% 56 39

70% 48 33

80% 41 28

90% 35 24

100% 31 21

10% 467 350

20% 262 197

30% 180 135

40% 142 105

50% 120 85

60% 98 70

70% 83 58

80% 72 50

90% 62 43

100% 54 38

10% 638 478

20% 358 269

30% 247 185

40% 193 145

50% 164 123

60% 138 101

70% 120 85

80% 104 73

90% 90 63

100% 80 55

10% 809 606

20% 454 341

30% 313 235

40% 245 184

50% 208 156

60% 175 131

70% 153 113

80% 135 97

90% 120 85

100% 106 75

Using the configuration program, the user may specify the number of GXT2-240VBATT external battery cabinets attached to the UPS. The factory default is programmed for internal batteries only.

Table 6 above shows the estimated run times at different loads.

30

Page 35

12.0.1 Auto-Learning Battery Run Times

As batteries age, the estimated runtimes may become less accurate. The GXT2 is programmed to

“learn” from a full battery discharge and modify the estimated runtime for the measured battery

capacity. This can improve accuracy and compensate for aging batteries or batteries that operate at

different ambient temperatures.

The UPS will update the anticipated run time calculation only under certain conditions.

• The UPS must have a steady load that is greater than 20%.

• The UPS must be at 100% charge at the start of a battery discharge.

• The battery discharge must continue uninterrupted until the batteries reach their end-of-discharge voltage.

If all conditions are not met, the run time calculation will not be modified.

If the configuration program is used to change the number of battery cabinets, then the values in the

battery above table will be restored. This will override any value that is Auto-Learned.

Troubleshooting

31

Page 36

13.0 SPECIFICATIONS

Table 7 UPS specifications

Model Number GXT2-6000RT230 GXT2-4500RT230

Dimensions mm (in.)

Shipping, W x D x H 560 x 690 x 500 (22.05 x 27.17 x 19.7)

Weight kg (lbs)

Input AC Parameters

Nominal Operating Frequency 50 or 60Hz (Factory Default = 50)

Factory Default VAC 230VAC

User Configurable VAC

Operating Voltage Range Without

Battery Operation

Maximum Allowable VAC 276VAC

Input Frequency Without Battery

Input Power Connection PD-CEHDWR Standard (See 3.3 - Removable Power Distribution Box)

Output AC Parameters

Factory Default VAC 230VAC

Output Connections PD-CEHDWR Standard (See 3.3 - Removable Power Distribution Box)

Battery Parameters

Battery Mfr. / Part # Yuasa / REW 28-12

Recharge Time (Internal Batteries) 3 hrs. to 90% capacity after full discharge into 100% load

Bypass Protection Limits

Disable Bypass operation If input voltage exceeds ±15% of the nominal voltage

Re-enable Bypass operation If input voltage returns to within ±10% of nominal output voltage

Disable Bypass operation When the input frequency prevents synchronous operation

Environmental

Operating Temperature 0°C to +40°C (+32°F to +104° F)

Storage Temperature -15°C to +50°C (+5°F to +122° F)

Relative Humidity 0-95% non-condensing

Operating Elevation

Storage Elevation

Agency

EMI/EMC/C-Tick EMC EN50091-2 and AS 62040-2: 2002, Class A; CE EMC Directive

Radiated Susceptibility EN61000-4-3, Level 3, Criteria A

Electrical Fast Transient EN61000-4-4, Level 4, Criteria A

Model Rating 6KVA / 4,200W 4.5KVA / 3,150W

Unit, W x D x H 221 x 547 x 430 (8.7 x 21.5 x 16.9)

Unit 67 (151) 67 (151)

Shipping 79.5 (175.3) 79.5 (175.3)

(May be modified using configuration program)

Operation

Frequency 50Hz or 60Hz, Nominal

Waveform Sinewave

Main Mode

Overload

Type Valve-regulated, non-spillable, lead acid

Quantity x V 20 x 12V

Back-up Time See Table 6 - Battery run times

Audible Noise

Safety EN62040-1-1; TUV/GS

ESD EN61000-4-2, Level 4, Criteria A

Surge Immunity EN61000-4-5, Level 3, Criteria A

Transportation ISTA Procedure 1B

>200% for 96 milliseconds; 131 - 199% for 2 seconds;

112- 129% for 10 seconds with transfer to bypass

Up to 2000m (6600 ft) at 40°C (104° F) without derating

<55 dBA, at 1 meter from the rear

<50 dBA, at 1 meter from the front or sides

220/230/240VAC

176 – 276VAC

40 - 70Hz

15,000m (50,000 ft.) maximum

Specifications

32

Page 37

Table 8 Power distribution specifications

Model Number PD-CEHDWR PD-CEHDWRBYP

Amps Rating 32 Amps

2

Input Power Connection 3-Wire Hardwired, 6-10mm

Output Power Connection 3-Wire Hardwired, 6-10mm

Includes: Two IEC320 C19 16A/250V sockets

Manual Bypass Switch with Indicator Lamps

(8-10AWG)

2

(8-10AWG)

Two IEC320 C19 16A/250V sockets

Input Branch Circuit Breaker 32A, Supplied by User

Table 9 External battery cabinet specifications

Model Number GXT2-240VBATT

Used w/ UPS model GXT2-6000RT230, GXT2-4500RT230

Dimensions, W x D x H, mm (in.)

Unit (with bezel) 176 x 522 x 430 (6.9 x 20.55 x 16.9)

Shipping 560 x 690 x 455 (22 x 27.2 x 17.9)

Weight, kg (lbs)

Unit 65 (145)

Shipping 78.5 (173.1)

Battery Parameters

Type Valve-regulated, non-spillable, flame retardant, lead acid

Qty x V 20 x 12V

Battery Manufacturer, Part # Yuasa / REW 45-12

Backup Time See Battery Run Times charts

Environmental

Operating Temp 0°C to +40°C (+32°F to +104° F)

Storage Temp -15°C to +50°C (+5°F to +122° F)

Relative Humidity 0-95% non-condensing

Operating Elevation Up to 2000m (6600 ft.) at 40°C (104° F) without derating

Storage Elevation 15,000m (50,000 ft.) maximum

Agency

Safety EN62040-1-1; TUV/GS

Transportation ISTA Procedure 1B

Specifications

33

Page 38

Specifications

34

Page 39

Page 40

POWER AVAILABILITY

GXT2-6000RT230™ & GXT2-4500RT230

USER MANUAL

The Company Behind the Products

With over a million installations around the globe,

Liebert is the world leader in computer protection

systems. Since its founding in 1965, Liebert has

developed a complete range of support and

protection systems for sensitive electronics:

• Environmental systems—close-control air

conditioning from 1 to 60 tons

• Power conditioning and UPS with power

ranges from 300 VA to more than 1000 kVA

• Integrated systems that provide both

environmental and power protection in a

single, flexible package

• Monitoring and control—from systems of any

size or location, on-site or remote

• Service and support through more than 100

service centers around the world and a 24/7

Customer Response Center

While every precaution has been taken to ensure

the accuracy and completeness of this literature,

Liebert Corporation assumes no responsibility and

disclaims all liability for damages resulting from

use of this information or for any errors or

omissions.

© 2004 Liebert Corporation

All rights reserved throughout the world.

Specifications subject to change without notice.

® Liebert and the Liebert logo are registered

trademarks of Liebert Corporation. All names

referred to are trademarks or registered

trademarks of their respective owners.

SLI-23170 (7/04) Rev. 3

Technical Support/Service

Web Site

www.liebert.com

Monitoring

800-222-5877

monitoring@liebert.com

Outside the US: 614-841-6755

Single-Phase UPS

800-222-5877

upstech@liebert.com

Outside the US: 614-841-6755

Three-Phase UPS

800-543-2378

powertech@liebert.com

Environmental Systems

800-543-2778

Outside the United States

614-888-0246

Locations

United States

1050 Dearborn Drive

P.O. Box 29186

Columbus, OH 43229

Via Leonardo Da Vinci 8

Zona Industriale Tognana

35028 Piove Di Sacco (PD)

+39 049 9719 111

Fax: +39 049 5841 257

23F, Allied Kajima Bldg.

138 Gloucester Road

Wanchai

Hong Kong

+852 2 572 2201

Fax: +852 2 831 0114

™

Italy

Asia

Loading...

Loading...