Page 1

Supplemental Installation Manual

7247000C

MODEL

ALM-P1

Product Description

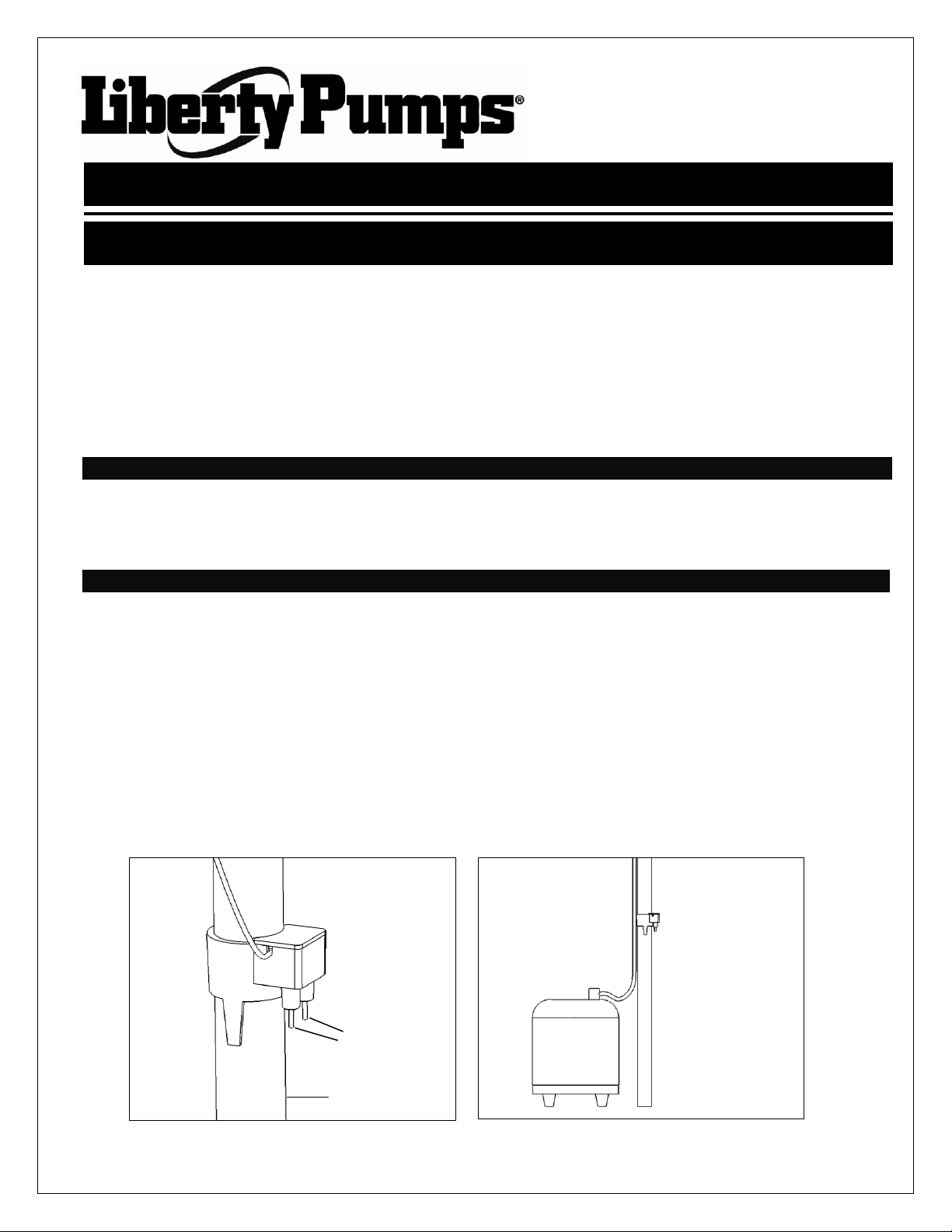

Installation of the Water Sensor Probe on discharge pipe

Probe level

1-1/4” or 1-1/2”

discharge

Figure 1

Figure 2

1-1/4” or 1-1/2”

discharge

Probe level

Supplemental Installation Instructions for your ALM-P1 Alarm

The ALM-P1 is an alarm system that utilizes a water sensor connected to an alarm panel to detect a high water

situation in a sump pump application. The sensor clamps on to 1-1/4” or 1-1/2” PVC pipe. When water bridges the

probes, the alarm box will activate an alarm light and horn. The horn can be silenced by switching the rocker switch on

the side. The alarm light will still function even when the horn is silenced.

1. The water sensor for the ALM-P1 was designed to be installed directly onto a pump discharge pipe. The clamp will

only fit onto 1-1/4” or 1-1/2” pipe. See figures 1 and 2.

2. Determine correct height for the water sensor. The alarm will turn on when the bottom of the probes detect water.

The correct height for these probes should be above the turn on point of the pump and well below the top of the

sump pit.

3. Connect wires from water sensor to the alarm panel. Red wire must be connected to the “left” terminal, labeled

R/W. The black wire must be connected to the “right” terminal, labeled B. Wire up to the panel can be secured to

the pipe with the included zip tie.

4. Test the pump and the turn on level of the alarm. When satisfied with the probe position, mark the level on the

discharge pipe. For added security, slide the probe clamp away from intended position and apply a small amount

of PVC glue to the discharge pipe. Return the alarm probe to desired position. The PVC glue will bond the pipe

and clamp to prevent accidental movement.

5. To test the water sensor, immerse both probes in water or place a wet rag or sponge across the probes. The

alarm panel should activate. Completely wipe and dry the probes before putting the unit back into service.

©Copyright 2012 Liberty Pumps Inc. All rights reserved 1

Page 2

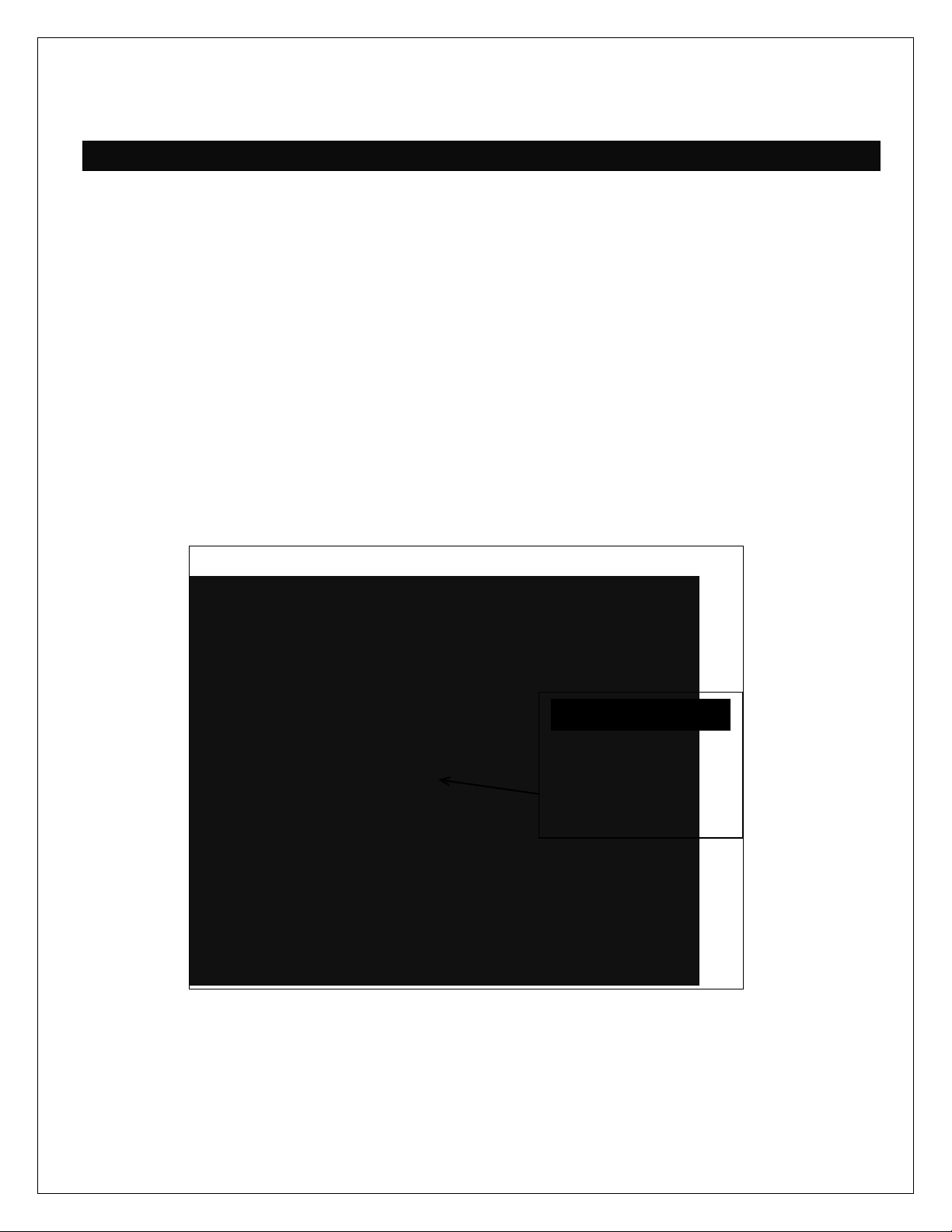

Important .

For proper installation

height, probe clamp

must be touching the

top of the foot valve.

SJ10 Float

SJ10 Foot

Valve

ALM-P1

Installation of the Water Sensor Probe with SumpJet® Model SJ10

Figure 3

The ALM-P1 was specifically designed for use with the SJ10 water-powered backup sump pump. With the water

sensor probe in the correct position, the alarm will activate before the pump activates, to let you know when the SJ10

backup is in use. During a power outage, the rocker switch can be deployed to the “silence” position to eliminate the

alarm from going off multiple times. The switch should be returned to the “on” position after the power outage has

ended, for normal operation.

1. The correct position for the water sensor clamp is already determined on the SJ10, to trigger just before the

pump activates. The clamp should be placed on the intake pipe of the SJ10 pump, with the bottom of the

clamp touching the top of the pump’s foot valve. If the clamp is not positioned directly against the foot valve,

the alarm may not function properly. The clamp should be rotated so that the probes face away from the SJ10

float. See figure 3.

2. Connect wires from water sensor to the alarm panel. Red wire must be connected to the “left” terminal, labeled

R/W. The black wire must be connected to the “right” terminal, labeled B. Wire up to the panel can be secured

to the pipe with the included zip tie.

3. For added security, slide the probe clamp away from intended position and apply a small amount of PVC glue

to the discharge pipe. Return the alarm probe to desired position. The PVC glue will bond the pipe and clamp

to prevent accidental movement.

4. To test the water sensor, immerse both probes in water or place a wet rag or sponge across the probes. The

alarm panel should activate. Completely wipe and dry the probes before putting the unit back into service.

_

©Copyright 2012 Liberty Pumps Inc. All rights reserved 2

Page 3

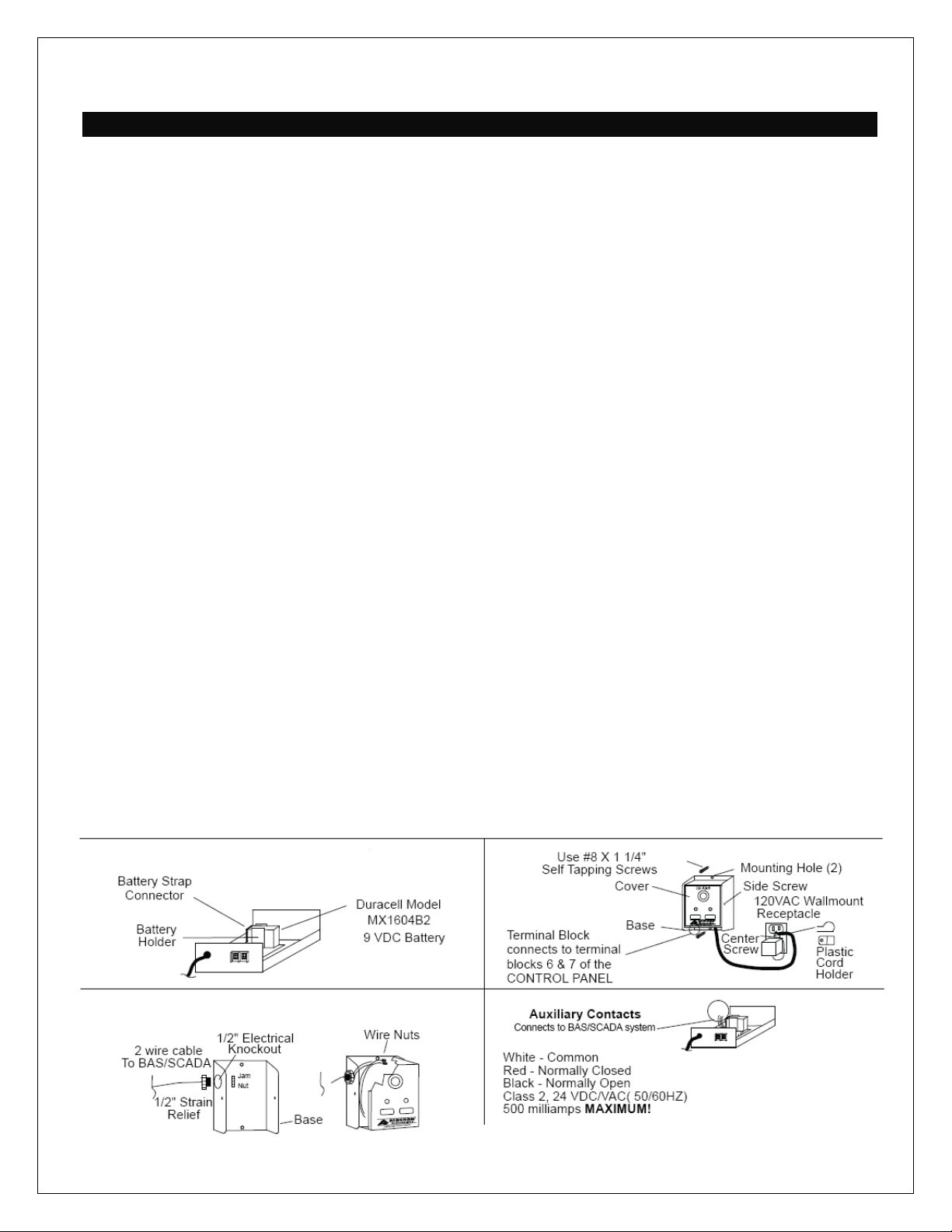

Installation of the Alarm Panel

Figure 4

Figure 5

Figure 6

Figure 7

The ALM-P1 alarm panel is powered by 120 VAC coming from standard wall outlets which is transformed to 9VDC.

A 9 Volt battery provides battery back-up power so that the alarm will function in the event of a power failure.

When the water bridges the two probes, the alarm horn and light will turn “on” and the alarm panel’s auxiliary contacts

will be activated. The rocker switch on the side of the alarm panel can be used to silence the horn.

Test product weekly. Make sure the green “power on” light is “on”. Press the “Test” switch”; the red alarm light and

horn should turn “on”. If the battery back-up system is utilized, unplug the wall mount power supply (the green light

will be off). Now press the “ Test” switch; the red alarm light and buzzer will “on”. If the buzzer sounds less loud ly

than when tested with the normal power supply, then the battery should be replaced.

1. To install/replace the battery for the backup power feature, remove the two side screws and install 9 VDC

battery. After installing battery, press the test button to activate the alarm to make sure the battery works

properly. Reinstall side screws. See figure 4.

2. Determine mounting location for the Alarm Panel. Make sure power outlet is within 6 feet of the alarm. Make

sure the outlet is on a separate circuit breaker from any other device and not on a switched receptacle to

maintain power integrity. Mount the alarm using two #8 x 1-1/4” self tapping screws (not included). Use #8

plastic anchor if mounting to sheet rock. See figure 5.

3. If auxiliary contacts used, continue; otherwise go to step 4. Remove cover from base and remove ½”

electrical knockout from base. Use 16-2 AWG stranded wire – make sure there is at least 6’” of wire inside of

enclosure. Install a ½” strain relief with jam nut. Connect wires for required application using wire nuts.

Caution! – When installing wires, route all wires away from sharp objects & internal components. See figures

6 & 7.

4. There are two terminals on the bottom of the alarm panel. The red wire from the water sensor probe must be

connected to the “left” terminal, labeled R/W. The black wire from the water sensor probe must be connected

to the “right” terminal, labeled B.

5. Plug the power supply into a 120 VAC standard wall outlet. For UL applications, remove center screw on

receptacle and place cord from wall mount transformer inside the plastic cord holder. Secure plastic cord

holder to the receptacle by reinstalling screw to the center hole of receptacle. See figure 5. For Canadian

applications DO NOT INSTALL plastic cord holder! The green “Normal” light should come on.

6. Test the system by pressing the “Test” button. The horn and the red warning light will be “on”. The green

“Normal” light will be “off’. While holding the “Test” button, switch the side rocker switch to the “Silence”

position. The horn will silence, but the alarm light will stay “on”. Let go of the “Test” button and the alarm light

will turn “off” and the green “Normal” light will turn “on”. Switch the rocker switch back into the “normal”

position and the system is now in operating condition.

©Copyright 2012 Liberty Pumps Inc. All rights reserved 3

Page 4

7000 Apple Tree Avenue

Bergen, NY 14416

Phone 800-543-2550

www.libertypumps.com

Liberty Pumps, 3 Year Limited Warranty

Liberty Pumps, Inc. warrants that pumps of its manufacture are free from all factory defects in material and workmanship for a period of

3 years from the date of purchase. The date of purchase shall be determined by a dated sales receipt noting the model and serial

number of the pump. The dated sales receipt must accompany the returned pump if the date or return is more than 3 years from the

“CODE” (date of manufacture) number noted on the pump nameplate.

The manufacturer’s obligation under this Warranty shall be limited to the repair or replacement of any parts found by the man ufacturer

to be defective, provided the part or assembly is returned freight prepaid to the manufacturer or its authorized service center, and

provided that none of the following warranty-voiding characteristics are evident:

The manufacturer shall not be liable under this Warranty if the product has not been properly installed; if it has been disassembled,

modified, abused or tampered with; if the electrical cord has been cut, damaged, or spliced; if the pump discharge has been reduced

in size; if the pump has been used in water containing sand, lime, cement, gravel or other abrasives; if the product has been used to

pump chemicals or hydrocarbons; if a non-submersible motor has been subjected to excessive moisture; or if the label bearing the

serial, model, and code number has been removed.

Liberty Pumps, Inc. shall not be liable for any loss, damage or expenses resulting from installation or use of its products, or for

consequential damages, including costs of removal, reinstallation or transportation.

There is no other express warranty. All implied warranties, including those of merchantability and fitness for a particular purpose, are

limited to three years from the date or purchase.

This warranty contains the exclusive remedy of the purchaser, and, where permitted, liability for consequential or incidental damages

under any and all warranties are excluded.

©Copyright 2012 Liberty Pumps Inc. All rights reserved 4

Page 5

Manual de Instalación Suplementario

7247000C

MODELO

ALM-P1

Descripción del producto

Instalación de la sonda detectora de agua en la tubería de desagüe

Nivel de la

sonda

Desagüe de 1-1/4

pulg. o 1-1/2 pulg.

Figura 1

Figura 2

Desagüe de 1-1/4

pulg. o 1-1/2 pulg.

Nivel de la

sonda

Instrucciones de instalación suplementarias para su alarma ALM-P1

El sistema de alarma ALM-P1 utiliza un sensor de agua conectado a un panel de alarma a fin de detectar una situación

de alto nivel de agua en una aplicación con bomba de drenaje. El sensor se fija con una abrazadera a un tubo de PVC

de 1-1/4 pulg. o 1-1/2 pulg. Cuando el agua llegue a las sondas, la caja de la alarma activará una luz y una bocina de

alarma. Se puede silenciar la bocina si se conmuta el interruptor basculante que se encuentra al costado de la caja. La

luz de la alarma seguirá funcionando aunque se haya silenciado la bocina.

1. El sensor de agua del sistema ALM-P1 se ha diseñado para instalarse directamente en la tubería de desagüe de

una bomba. La abrazadera sólo encajará en un tubo de 1-1/4 pulg. o de 1-1/2 pulg. Vea las Figuras 1 y 2.

2. Determine la altura correcta para el sensor de agua. La alarma se activará cuando la parte inferior de las sondas

detecte agua. La altura correcta para dichas sondas debe ser por encima del punto de encendido de la bomba y

muy por debajo de la parte superior del sumidero de agua.

3. Conecte los alambres del sensor de agua al panel de alarma. El alambre rojo debe conectarse al terminal

“izquierdo”, rotulado R/W. El alambre negro debe conectarse al terminal “derecho”, rotulado B. El cableado que va

al panel puede fijarse al tubo con el amarre que se incluye.

4. Pruebe la bomba y el nivel de activación de la alarma. Cuando esté satisfecho con la ubicación de la sonda, marque el

nivel en la tubería de desagüe. Para mayor seguridad, deslice la abrazadera de la sonda fuera de la ubicación prevista y

aplique una pequeña cantidad de pegamento para PVC a la tubería de desagüe. Vuelva a colocar la sonda de la alarma

en la ubicación deseada. El pegamento para PVC fijará la abrazadera al tubo para prevenir su movimiento accidental.

5. Para probar el sensor de agua, sumerja ambas sondas en agua o envuélvalas con un paño o una esponja

empapada en agua. El panel de alarma deberá activarse. Seque bien las sondas con un paño antes de volver a

poner la unidad en servicio.

©Copyright 2012 Liberty Pumps Inc. Todos los derechos reservados 1

Page 6

Importante .

Para que la altura de la

instalación sea adecuada,

la abrazadera de la

sonda debe tocar la

parte superior de la

válvula de aspiración.

Flotador de la

Válvula de aspiración

de la SJ10

ALM-P1

Instalación de la sonda detectora de agua con SumpJet® modelo SJ10

Figura 3

El sistema ALM-P1 se diseñó específicamente para usarse con la bomba auxiliar de drenaje impulsada con agua

modelo SJ10. Si la sonda detectora de agua está en la posición correcta, la alarma se activará antes de que se active

la bomba, a fin de indicarle que la bomba auxiliar SJ10 está en uso. Durante un corte del suministro eléctrico, el

interruptor basculante puede colocarse en la posición “Silence” (Silencio) para evitar que se dispare varias veces la

alarma. Es necesario volver a colocar el interruptor en la posición de “encendido” cuando haya terminado el corte

eléctrico para que la unidad funcione normalmente.

1. La ubicación correcta de la abrazadera del sensor de agua ya está determinada en el modelo SJ10, para que

se dispare justo antes de activarse la bomba. Hay que colocar la abrazadera en el tubo de entrada de la

bomba SJ10, de manera que la parte inferior de la abrazadera toque la parte superior de la válvula de

aspiración de la bomba. Si no se coloca la abrazadera directamente contra la válvula de aspiración, es posible

que la alarma no funcione correctamente. Hay que rotar la abrazadera para que las sondas apunten en

sentido contrario al flotador de la bomba SJ10. Vea la Figura 3.

2. Conecte los alambres del sensor de agua al panel de alarma. El alambre rojo debe conectarse al terminal

“izquierdo”, rotulado R/W. El alambre negro debe conectarse al terminal “derecho”, rotulado B. El cableado que

va al panel puede fijarse al tubo con el amarre que se incluye.

3. Para mayor seguridad, deslice la abrazadera de la sonda fuera de la ubicación prevista y aplique una pequeña

cantidad de pegamento para PVC a la tubería de desagüe. Vuelva a colocar la sonda de la alarma en la

ubicación deseada. El pegamento para PVC fijará la abrazadera al tubo para prevenir su movimiento

accidental.

4. Para probar el sensor de agua, sumerja ambas sondas en agua o envuélvalas con un paño o una esponja

empapada en agua. El panel de alarma deberá activarse. Seque bien las sondas con un paño antes de volver

a poner la unidad en servicio.

_

©Copyright 2012 Liberty Pumps Inc. Todos los derechos reservados 2

Page 7

Instalación del panel de alarma

Figura 4

Figura 5

Figura 6

Figura 7

El panel de alarma ALM-P1 se alimenta con 120 VCA provenientes de tomacorrientes estándar de pared; dicho voltaje se

transforma a 9 VCC. Una batería de 9 voltios proporciona energía de reserva para que funcione la alarma en caso de un

corte del suministro eléctrico.

Cuando el agua llegue a las dos sondas, sonará la bocina, se encenderá la luz de la alarma y se activarán los contactos auxiliares

del panel de alarma. Se puede silenciar la bocina si se conmuta el interruptor basculante que se encuentra al costado del panel.

Pruebe el producto cada semana. Compruebe que esté encendida la luz verde de “encendido”. Oprima el interruptor “Test”

(Prueba); deberá encenderse la luz roja de alarma y sonar la bocina. Si se utiliza el sistema de reserva con batería,

desenchufe la fuente de alimentación montada en la pared. (Se apagará la luz verde.) Ahora oprima el interruptor “Test”

(Prueba); se encenderá la luz roja de alarma y sonará la bocina. Si la bocina suena con menor potencia que cuando se

prueba con la fuente de alimentación normal, hay que reemplazar la batería.

1. Para instalar o reemplazar la batería del sistema eléctrico de reserva, retire los dos tornillos laterales e instale

una batería de 9 VCC. Después de instalar la batería, oprima el botón “Test” (Prueba) para activar la alarma y

comprobar que la batería funcione correctamente. Vuelva a instalar los tornillos laterales. Vea la Figura 4.

2. Determine la ubicación de montaje para el panel de alarma. Compruebe que el tomacorriente esté como máximo

a 1.80 m (6 pies) de la alarma. Para conservar la integridad eléctrica, verifique que el tomacorriente esté

conectado a un disyuntor separado de todo otro dispositivo y que no esté sujeto a un interruptor de toma. Monte

la alarma con dos tornillos autorroscantes No. 8 x 1-1/4 pulg. (no se incluyen). Si monta la unidad sobre un panel

de yeso, utilice anclajes de plástico No. 8. Vea la Figura 5.

3. Si se usan contactos auxiliares, prosiga; en caso contrario, siga con el paso 4. Retire la tapa de la base y quite el

troquelado eléctrico de ½ pulg. de la base. Utilice un cable trenzado tipo 16-2 AWG; compruebe que haya por lo

menos 15 cm (6 pulg.) de alambre dentro de la caja. Instale una protección contra tirones de ½ pulg. con

contratuerca. Conecte los alambres con empalmes plásticos para el uso requerido. ¡Precaución! – Al instalar

alambres, tiéndalos alejados de objetos cortantes y componentes internos. Vea las figuras 6 y 7.

4. Hay dos terminales en la parte inferior del panel de alarma. El alambre rojo de la sonda detectora de agua debe

conectarse al terminal “izquierdo”, rotulado R/W. El alambre negro de la sonda detectora de agua debe

conectarse al terminal “derecho”, rotulado B.

5. Enchufe la fuente de alimentación en un tomacorriente estándar de pared de 120 VCA. Para las aplicaciones tipo

UL, retire el tornillo del centro del tomacorriente y coloque el cable del transformador de montaje en la pared

dentro del sujetador plástico del cable. Vuelva a instalar el tornillo en el orificio del centro del tomacorriente para

fijar el sujetador plástico del cable al tomacorriente. Vea la Figura 5. Para las aplicaciones canadienses: ¡NO

INSTALE el sujetador plástico del cable! Deberá encenderse la luz verde “Normal”.

6. Oprima el botón “Test” (Prueba) para probar el sistema. Sonará la bocina y se encenderá la luz de la alarma. Se apagará la

luz verde “Normal”. Mientras mantiene oprimido el botón “Test” (Prueba), coloque el interruptor basculante lateral en la

posición “Silence” (Silencio). Se silenciará la bocina, pero se mantendrá encendida la luz de la alarma. Suelte el botón “Test”

(Prueba); se apagará la luz de la alarma y se encenderá la luz verde “Normal”. Vuelva a colocar el interruptor basculante en

la posición “normal”; ahora el sistema ya está en condiciones normales de operación.

©Copyright 2012 Liberty Pumps Inc. Todos los derechos reservados 3

Page 8

Garantía limitada de 3 años de Liberty Pumps

Liberty Pumps, Inc. garantiza que las bombas que fabrica están libres de defectos en los materiales y la mano de obra por un período

de 3 años a partir de la fecha de compra. La fecha de compra se determinará con el recibo de compra fechado, que incluya el modelo

y el número de serie de la bomba. El recibo fechado de la compra deberá adjuntarse a la bomba si la fecha de devolución ocurre más

de 3 años después de la fecha de fabricación (código-CODE) indicada en la placa de la unidad.

Las obligaciones del fabricante bajo esta garantía se limitarán a la reparación o reemplazo de las piezas que el fabricante determine

que son defectuosas, siempre que la pieza, o ensamblaje de piezas, sea devuelta con el porte pagado al fabricante o a uno de sus

centros autorizados, y que no se evidencie ninguna de las siguientes características, lo que supondría la anulación de la garantía:

El fabricante no tendrá obligación alguna bajo esta garantía si el producto no ha sido instalado correctamente; si ha sido de smontado,

modificado, maltratado o forzado; si el cable eléctrico se ha cortado, dañado o empalmado; si se redujo el tamaño de la descarga de la

bomba; si la bomba se usó con agua que contenía arena, cal, cemento, grava u otros elementos abrasivos; si se utilizó para bo mbear

productos químicos o hidrocarburos; si un motor no sumergible fue sometido a exceso de humedad; o si se retiró la etiqueta con el

número de serie, modelo y código.

Liberty Pumps, Inc. no se hace responsable de pérdidas, daños o gastos que resulten por la instalación o uso de sus productos, o por

daños emergentes, incluidos los costos de desmontaje, reinstalación o transporte de la unidad.

No se ofrece ninguna otra garantía expresa. Todas las garantías implícitas, incluidas las de comerciabilidad e idoneidad para un

propósito determinado, están limitadas a un plazo de trois años a partir de la fecha de compra.

Esta garantía representa el único recurso del comprador y, siempre que se permita, se excluye toda responsabilidad por daños

consecuentes y fortuitos bajo cualquier otra garantía.

©Copyright 2012 Liberty Pumps Inc. Todos los derechos reservados 4

Page 9

Manuel d'installation supplémentaire

7247000C

MODÈLE

ALM-P1

Description du produit

Installation du capteur d'eau sur la conduite d'évacuation

Niveau du

capteur

Conduite d’évacuation

de 1½ po ou de 1¼ po

Illustration 1

Illustration 2

Conduite d’évacuation

de 1½ po ou de 1¼ po

Niveau du

capteur

Directives d'installation supplémentaires pour l'alarme ALM-P1

Le modèle ALM-P1 est un système d'alarme qui utilise un capteur d'eau raccordé à un panneau d'alarme afin de

détecter une élévation excessive du niveau d'eau là où une pompe d'assèchement est installée. Le capteur se fixe sur

une conduite d’évacuation de 1½ po ou de 1¼ po. Lorsque l'eau relie les sondes, la boîte d'alarme active une alarme

lumineuse et sonore. Il est possible de désactiver l'alarme sonore à l'aide du commutateur à bascule situé sur le côté.

L'alarme lumineuse fonctionne même lorsque l'alarme sonore est désactivée.

1. Le capteur d'eau de l'ALM-P1 a été conçu pour s'installer directement sur la conduite d'évacuation d'une pompe.

La pince ne s'adapte qu'à une conduite d’évacuation de 1½ po ou de 1¼ po. Voir illustrations 1 et 2.

2. Déterminer la hauteur adéquate où installer le capteur d'eau. L'alarme se mettra en marche lorsque le bas des sondes détectera

de l'eau. Ces sondes doivent être installées au-dessus du niveau de mise en marche de la pompe et sous le haut du puisard.

3. Raccorder les fils du capteur d'eau au panneau d'alarme. Le fil rouge doit toujours être relié à la borne de gauche,

identifiée par R/W. Le fil noir doit toujours être relié à la borne de droite, identifiée par un B. Les fils raccordant le

capteur au panneau peuvent être attachés à la conduite à l'aide de l'attache mono-usage fournie.

4. Tester la pompe et le niveau de déclenchement de l'alarme. Une fois la position du capteur satisfaisante, indiquer le

niveau sur la conduite d'évacuation. Pour plus de sécurité, glisser la pince du capteur loin de l'emplacement prévu et

appliquer une petite quantité de colle à PVC sur la conduite d'évacuation. Remettre le capteur de l'alarme à

l'emplacement prévu. La colle à PVC fixera la pince au tuyau afin de prévenir tout mouvement accidentel de la pince.

5. Pour tester le capteur d'eau, immerger les deux sondes dans l'eau ou encore placer un linge mouillé ou une

éponge entre les sondes. Le panneau de l'alarme devrait s'activer. Essuyer et assécher à fond les sondes avant

de remettre l'appareil en marche.

©Copyright 2012 Liberty Pumps Inc. Tous droits réservés 1

Page 10

Important .

Pour que l'installation

soit à la bonne hauteur,

la pince du capteur doit

toucher le sommet du

clapet de pied.

Flotteur SJ10

Clapet de

pied SJ10

ALM-P1

Installation du capteur d'eau avec la pompe SumpJetMD, modèle SJ10

Illustration 3

L'ALM-P1 a été spécialement conçu pour fonctionner avec la pompe d'assèchement de secours alimentée à l'eau SJ10.

Lorsque la sonde du capteur est dans la bonne position, l'alarme s'active avant que la pompe de secours SJ10 se mette

en marche, afin d'en informer l'utilisateur. Lors d'une panne de courant, il est possible de désactiver l'alarme sonore à

l'aide du commutateur à bascule afin de prévenir son déclenchement à répétition. Une fois la panne terminée, il suffit de

remettre le commutateur à la position de marche pour que l'alarme se remette à fonctionner normalement.

1. Le positionnement adéquat de la pince du capteur d'eau est déjà déterminé sur la pompe SJ10, afin de se

déclencher juste avant l'activation de la pompe. La pince doit être placée sur le tuyau d'entrée de la pompe

SJ10, le bas de la pince touchant le sommet du clapet de pied de la pompe. Si la pompe n'est pas placée

directement contre le clapet de pied, l'alarme risque de mal fonctionner. Il faut faire pivoter la pince afin que les

sondes soient orientées dans la direction opposée au flotteur de la SJ10. Voir illustration 3.

2. Raccorder les fils du capteur d'eau au panneau d'alarme. Le fil rouge doit toujours être relié à la borne de

gauche, identifiée par R/W. Le fil noir doit toujours être relié à la borne de droite, identifiée par un B. Les fils

raccordant le capteur au panneau peuvent être attachés à la conduite à l'aide de l'attache mono-usage fournie.

3. Pour plus de sécurité, glisser la pince du capteur loin de l'emplacement prévu et appliquer une petite quantité

de colle à PVC sur la conduite d'évacuation. Remettre le capteur de l'alarme à l'emplacement prévu. La colle à

PVC fixera la pince au tuyau afin de prévenir tout mouvement accidentel de la pince.

4. Pour tester le capteur d'eau, immerger les deux sondes dans l'eau ou encore placer un linge mouillé ou une

éponge entre les sondes. Le panneau de l'alarme devrait s'activer. Essuyer et assécher à fond les sondes

avant de remettre l'appareil en marche.

_

©Copyright 2012 Liberty Pumps Inc. Tous droits réservés 2

Page 11

Installation du panneau de l'alarme

Illustration 4

Illustration 5

Illustration 6

Illustration 7

Le panneau de l'alarme ALM-P1 est alimenté par du courant de 120 Vca provenant des prises murales transformé en courant

9 Vcc. Une pile de 9 volts assure une alimentation de secours afin que l'alarme fonctionne même en cas de panne de secteur.

Lorsque l'eau relie les sondes, l'alarme lumineuse et sonore se met en marche et les contacts auxiliaires du panneau de l'alarme

sont activés. Il est possible de désactiver l'alarme sonore à l'aide du commutateur à bascule situé sur le côté de l'appareil.

Il est recommandé de tester le produit chaque semaine. S'assurer que le témoin lumineux d'alimentation vert est allumé.

Appuyer sur le commutateur « Test »; l'alarme lumineuse rouge et l'alarme sonore doivent être en marche. Pour vérifier

le système de pile de sécurité, débrancher le bloc d'alimentation de la prise murale (le voyant vert sera éteint). Appuyer

maintenant sur le commutateur « Test »; l'alarme lumineuse rouge et l'alarme sonore se mettront en marche. Si le

niveau de l'alarme sonore est plus faible que lors du test avec le bloc d'alimentation, il faut remplacer la pile.

1. Pour installer/remplacer la pile de secours en cas de panne de secteur, retirer les deux vis latérales et installer la

pile 9 Vcc. Après avoir installé la pile, appuyer sur le bouton de test pour activer l'alarme afin de s'assurer que la

pile fonctionne bien. Réinstaller les vis latérales. Voir illustration 4.

2. Déterminer l'emplacement d'installation du panneau de l'alarme. S'assurer que la prise d'alimentation se trouve à

moins de 1,8 m (6 pi) de l'alarme. S'assurer que la prise murale est raccordée à un circuit indépendant muni d'un

disjoncteur et qu'elle n'est pas accompagnée d'un interrupteur pour assurer la stabilité de l'alimentation. Fixer

l'alarme à l'aide de deux vis autotaraudeuses nº 8 X 3,2 cm (1¼ po) non comprises. Utiliser les douilles d'ancrage

en plastique nº 8 lors d'une installation sur cloison sèche. Voir illustration 5.

3. Poursuivre l'installation si les contacts auxiliaires sont utilisés; sinon, passer à l'étape 4. Retirer le couvercle de la base et

libérer l'ouverture défonçable de 13 mm (1/2 po) pour câblage électrique. Utiliser un câble standard AWG 16-2; s'assurer

de laisser au moins 15 cm (6 po) de câble à l'intérieur de l'enceinte. Installer un réducteur de tension de 13 mm (1/2 po)

avec contre-écrou. Raccorder les câbles utilisés à l'aide d'écrous à câbles. Attention! – Lors de l'installation des câbles,

prendre soin de les diriger loin des objets effilés et des composants internes. Voir illustrations 6 et 7.

4. On trouve deux bornes situées en bas du panneau de l'alarme : le fil rouge du capteur à eau doit toujours être relié à la borne

de gauche, identifiée par R/W; le fil noir du capteur à eau doit toujours être relié à la borne de gauche, identifiée par B .

5. Raccorder le bloc d'alimentation à une prise murale 120 Vca standard. Dans les cas des installations UL, retirer la

vis centrale de la prise et placer le cordon du transformateur mural à l'intérieur de support à cordon en plastique.

Fixer le support à cordon en plastique à la prise en réinstallant la vis dans l'orifice central de la prise. Voir

illustration 5. NE PAS INSTALLER le support à cordon en plastique dans le cas d'installations effectuées au

Canada! Le témoin lumineux vert « Normal » devrait s'allumer.

6. Tester le système en appuyant sur la touche « Test ». L'alarme lumineuse rouge et l'alarme sonore se mettront.

Le témoin lumineux vert « Normal » devrait s'éteindre. Tout en maintenant la touche « Test » enfoncée, placer le

commutateur à bascule situé sur le côté de l'appareil sur « Silence ». L'alarme sonore sera désactivée, mais

l'alarme lumineuse continuera de fonctionner. Libérer la touche « Test ». L'alarme lumineuse s'éteindra et le

témoin lumineux vert « Normal » s'allumera. Remettre le commutateur à bascule en position « Normal ». Le

système est maintenant en état de marche.

©Copyright 2012 Liberty Pumps Inc. Tous droits réservés 3

Page 12

7000 Apple Tree Avenue

Bergen, NY 14416, USA

Téléphone : 1-800-543-2550

www.libertypumps.com

Liberty Pumps, garantie limitée de 3 ans

Liberty Pumps, Inc. garantit que les pompes sortant de son usine sont exemptes de tout défaut de matériau et de fabrication pour une

période de 3 ans à partir de la date d’achat. La date d'achat sera établie par une facture d’achat datée indiquant les numéros de

modèle et de série de la pompe. La pompe retournée doit être accompagnée de la facture d’achat datée si la date de retour se situe à

plus de 3 ans du numéro de « CODE » (date de fabrication) indiqué sur la plaque signalétique de la pompe.

L’obligation de garantie du fabricant se limite à la réparation ou au remplacement de toute pièce jugée défectueuse par le fabricant, à

condition que la pièce ou l’appareil soient retournés franco de port au fabricant ou à son centre de service autorisé et à condition qu’il

n’y ait aucune preuve que les critères suivants annulant la garantie sont en cause.

Le fabricant ne peut en aucun cas être tenu responsable, selon les dispositions de cette garantie, si le produit n’a pas été correctement

installé; s’il a été démonté, modifié, soumis à un usage abusif ou endommagé; si le cordon électrique a été coupé, endommagé ou

ligaturé; si la taille du tuyau d’évacuation de la pompe a été réduite; si la pompe a été utilisée pour pomper de l’eau d'une température

supérieure aux recommandations ci-dessus ou de l’eau contenant du sable, de la chaux, du ciment, du gravier ou autres matières

abrasives; si le produit a été utilisé pour pomper des produits chimiques ou des hydrocarbures; si un moteur non submersible a été

exposé à de l’humidité excessive; ou si l’étiquette portant le numéro de série, de modèle et de code a été retirée.

Liberty Pumps, Inc. ne pourra être tenue responsable des pertes, dommages, frais attribuables à l’installation ou l’utilisation de ses

produits ni pour les dommages accessoires ou consécutifs, y compris les coûts de retrait, de réinstallation ou de transport.

Il n’y a aucune autre garantie expresse. Toute garantie implicite, y compris celles de qualité marchande et d'aptitude à une fin

particulière est limitée à tres ans à partir de la date d’achat.

Cette garantie contient le recours exclusif de l’acheteur et exclut, lorsque permis par la loi, toute responsabilité pour dom mages

consécutifs ou accessoires en vertu de toutes autres garanties.

©Copyright 2012 Liberty Pumps Inc. Tous droits réservés 4

Loading...

Loading...