LG Display LP140WH2-TLF1 Specification

Global LCD Panel Exchange Center

www.panelook.com

LP140WH2

Liquid Crystal Display

Product Specification

SPECIFICATION

FOR

APPROVAL

()Preliminary Specification

() Final Specification

Title 14.0” HD TFT LCD

Customer LENOVO

MODEL

/

/

SUPPLIER LG Display Co., Ltd.

*MODEL LP140WH2

Suffix TLF1

*When you obtain standard approval,

please use the above model name without suffix

APPROVED BY

SIGNATUREAPPROVED BY

APPROVED BY

S. R. Kim / Manager

REVIEWED BY

REVIEWED BY

N. J. Seong / Manager

SIGNATURE

SIGNATURE

/

Please return 1 copy for your confirmation with

your signature and comments.

Ver. 1.0 Dec. 26, 2011

PREPARED BY

PREPARED BY

J. T. Kim / Engineer

J. K. Han / Engineer

Products Engineering Dept.

LG Display Co., Ltd

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

1 / 28

www.panelook.com

Global LCD Panel Exchange Center

www.panelook.com

LP140WH2

Liquid Crystal Display

Product Specification

Contents

No

1

2

3

4

COVER

CONTENTS

RECORD OF REVISIONS

GENERAL DESCRIPTION

ABSOLUTE MAXIMUM RATINGS

ELECTRICAL SPECIFICATIONS

ELECTRICAL CHARACTREISTICS

3-1

INTERFACE CONNECTIONS

3-2

LVDS SIGNAL TIMING SPECIFICATION

3-3

SIGNAL TIMING SPECIFICATIONS

3-4

SIGNAL TIMING WAVEFORMS

3-5

COLOR INPUT DATA REFERNECE

3-6

POWER SEQUENCE

3-7

OPTICAL SFECIFICATIONS

ITEM

Page

1

2

3

4

5

6-7

8

9-10

11

11

12

13

14-16

5

6

7

8

9

Ver. 1.0 Dec. 26, 2011

MECHANICAL CHARACTERISTICS

RELIABLITY

INTERNATIONAL STANDARDS

SAFETY

7-1

EMC

7-2

Environment

7-3

PACKING

DESIGNATION OF LOT MARK

8-1

PACKING FORM

8-2

Label Description

8-3

PRECAUTIONS

A APPENDIX. Enhanced Extended Display Identification Data

17-19

20

21

21

21

22

22

23

24-25

26-28

2 / 28

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Global LCD Panel Exchange Center

www.panelook.com

LP140WH2

Liquid Crystal Display

Product Specification

RECORD OF REVISIONS

Revision

No

0.0 Jun. 24. 2011 - First Draft (Preliminary Specification) 0.1

0.1 Sep. 30. 2011

0.2 Nov. 23. 2011

1.0 Dec. 26. 2011

Revision Date Page Description

6

8 Delete “or equivalent” Comment

13 Delete T

14 Update the Color Coordinates

15 Update the Gray Scale specification

17-19 Update the LCM Drawing

23 Change the Label Description (H/C)

26-28 Change the EDID Data (Update the Color Coordinates)

4 Update Power Consumption

6 Update Power Consumption

13 Update Power Sequence

14 Update Viewing Angle

6

11

Change the PWM Duty Ratio (min. 1%)

Change the PWM & LED_EN Voltage Level

max. Timing

13

Update Power Consumption (Window Bliss, Max Pattern)

Add the Text of Slow refresh confirmation

EDID

ver

0.2

0.2

1.0

13 Change T12 Spec. 0.5ms to 0.3ms

Ver. 1.0 Dec. 26, 2011

3 / 28

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Global LCD Panel Exchange Center

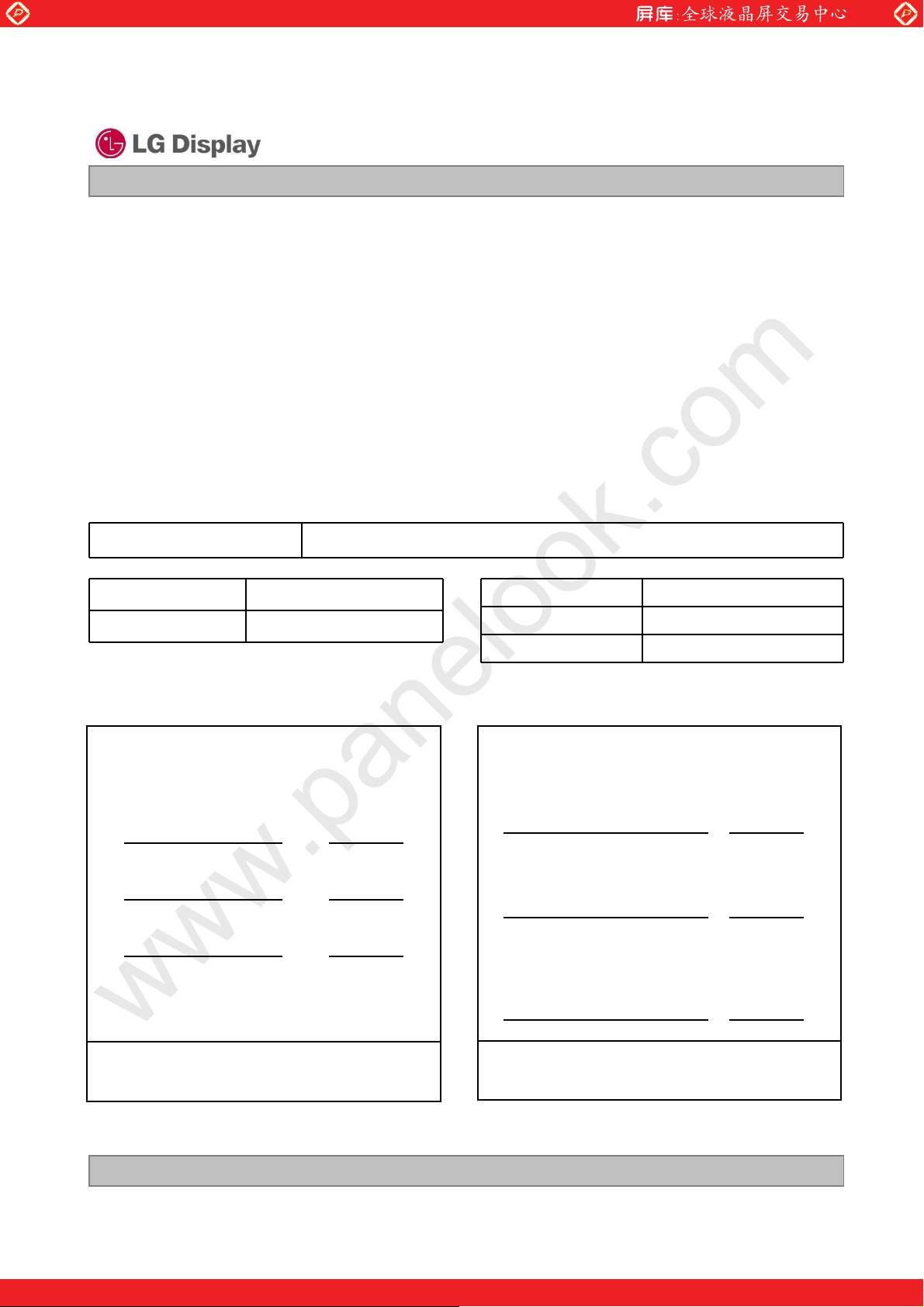

1. General Description

The LP140WH2 is a Color Active Matrix Liquid Crystal Display with an integral LED backlight system. The

matrix employs a-Si Thin Film Transistor as the active element. It is a transmissive type display operating in

the normally white mode. This TFT-LCD has 14.0 inches diagonally measured active display area with HD

resolution (1366 horizontal by 768 vertical pixel array). Each pixel is divided into Red, Green and Blue subpixels or dots which are arranged in vertical stripes. Gray scale or the brightness of the sub-pixel color is

determined with a 6-bit gray scale signal for each dot, thus, presenting a palette of more than 262,144

colors. The LP140WH2 has been designed to apply the interface method that enables low power, high

speed, low EMI. The LP140WH2 is intended to support applications where thin thickness, low power are

critical factors and graphic displays are important. In combination with the vertical arrangement of the subpixels, the LP140WH2 characteristics provide an excellent flat display for office automation products such

as Notebook PC.

www.panelook.com

LP140WH2

Liquid Crystal Display

Product Specification

EEPROM Block

EEPROM Block

for EDID

for EDID

EEPROM Block

EEPROM Block

for Tcon Operating

User connector

for Tcon Operating

1

1366

Gate Driver

TFT-LCD Panel

40

Pin

Timing Control

LVDS

1port

VCC

VLED

LED_EN

PWM

Timing Control

(Tcon) Block

(Tcon) Block

DVCC

Power

Block

LED Driver

LED Driver

Block

TCLKs

Power

Block

Block

VGH, VGL, GMA

Gate Signals, DSC

Control & Data Power

E

PI

DVCC, AVDD

VOUT_LED

FB1~3

(HD, GD-IC, TN)

Source Driver

(Bottom)

LED Backlight Ass’y

EDID signal & Power

General Features

Active Screen Size 14.0 inches diagonal

Outline Dimension 320.4(H, typ) Ý 198.1(V, typ) Ý 3.6(D,max) [mm] (with PCB Board)

Pixel Pitch 0.2265mm Ý 0.2265 mm

Pixel Format 1366 horiz. by 768 vert. Pixels RGB strip arrangement

Color Depth 6-bit, 262,144 colors

Luminance, White 200 cd/m

Power Consumption Total 3.06W(Typ.) Logic : 0.36W (Typ.@ Mosaic), B/L : 2.7W (Typ.@ VLED 12V )

Weight 320g (Max.)

Display Operating Mode Transmissive mode, normally white

Surface Treatment Anti glare treatment of the front Polarizer

RoHS Compliance Yes

BFR / PVC / As Free Yes for all

2

1

768

Gate Signals,

DSC

Ver. 1.0 Dec. 26, 2011

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

4 / 28

www.panelook.com

Global LCD Panel Exchange Center

2. Absolute Maximum Ratings

The following are maximum values which, if exceeded, may cause faulty operation or damage to the unit.

www.panelook.com

LP140WH2

Liquid Crystal Display

Product Specification

Table 1. ABSOLUTE MAXIMUM RATINGS

Parameter Symbol

Power Input Voltage

Operating Temperature

Storage Temperature

Operating Ambient Humidity

Storage Humidity

VCC -0.3 4.0 Vdc at 25 r 5qC

TOP 050qC1

HST -20 60 qC1

HOP 10 90 %RH 1

HST 10 90 %RH 1

Values

Units Notes

Min Max

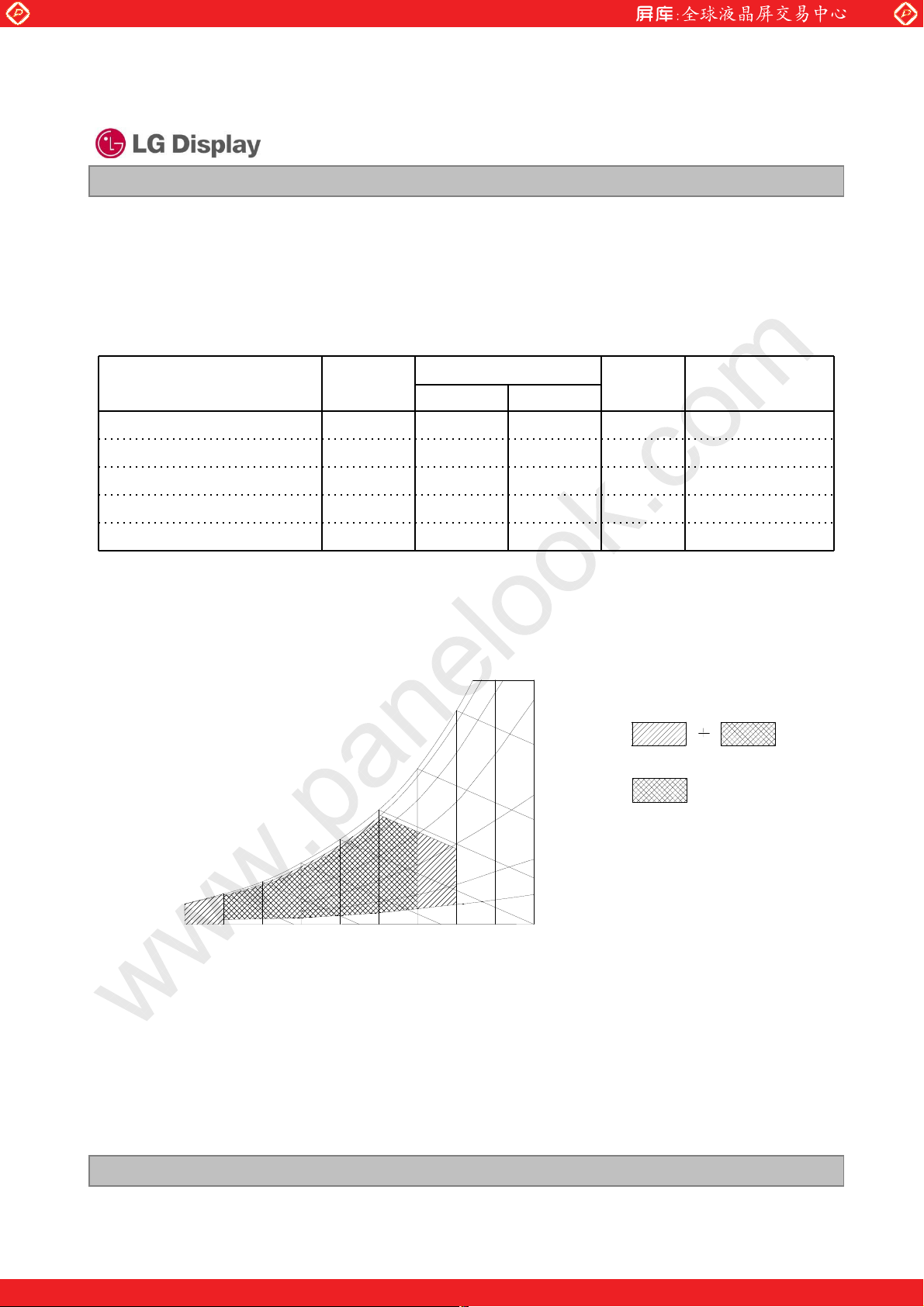

Note : 1. Temperature and relative humidity range are shown in the figure below.

Wet bulb temperature should be 39

Wet Bulb

Temperature [

10

0

20

]

30

qC Max, and no condensation of water.

90% 80%

60

50

40

60%

Humidity[(%)RH]

40%

20%

10%

Storage

Operation

-20

10

20 30 40 50

60 70 800

Dry Bulb Temperature []

Ver. 1.0 Dec. 26, 2011

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

5 / 28

www.panelook.com

Global LCD Panel Exchange Center

3. Electrical Specifications

3-1. Electrical Characteristics

The LP140WH2 requires two power inputs. The first logic is employed to power the LCD electronics and to

drive the TFT array and liquid crystal. The second backlight is the input about LED BL with LED Driver.

www.panelook.com

LP140WH2

Liquid Crystal Display

Product Specification

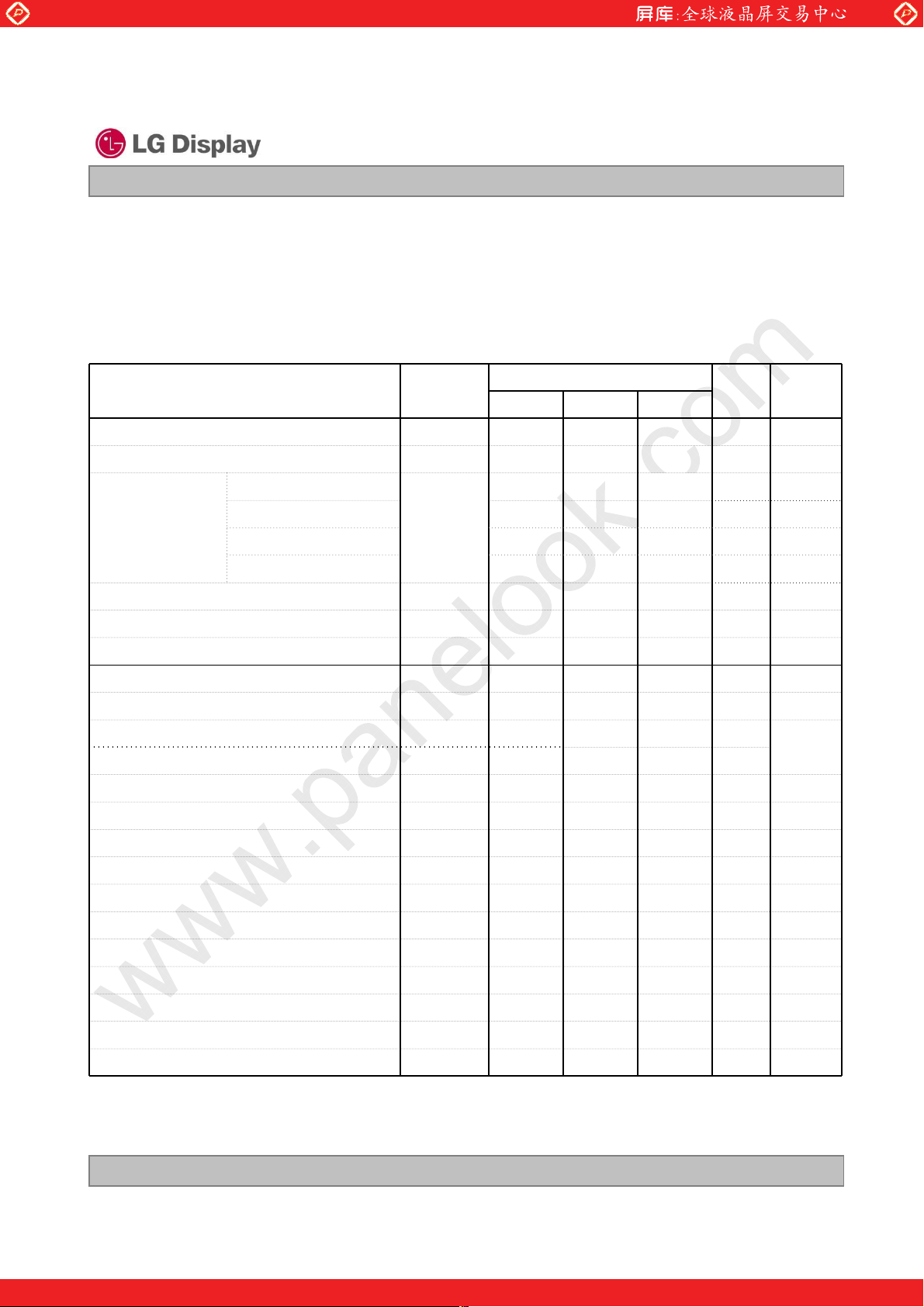

Table 2. ELECTRICAL CHARACTERISTICS

Parameter Symbol

Unit Notes

Min Typ Max

LOGIC :

Values

Power Supply Input Voltage V

Mosaic

Power Supply

Input Current

Window Bliss (Buyer) - 121

Black - 109

Red (Max Pattern) - 160

Power Consumption P

Power Supply Inrush Current I

LVDS Impedance Z

CC 3.0 3.3 3.6 V 1

- 109 126 mA 2

126 mA

CC

I

140 mA

185 mA

CC 0.36 0.42 W 2

CC_P - - 1500 mA 3

LVDS 90 100 110

ȳ

BACKLIGHT : ( with LED Driver)

LED Power Input Voltage V

LED Power Input Current I

LED Power Consumption P

LED Power Inrush Current I

LED 6.0 12.0 21.0 V 5

LED - 226 242 mA

LED -2.72.9W

LED_P - - 2000 mA 7

PWM Duty Ratio 1 - 100 % 8

PWM Jitter

-

0-0.2%9

4

6

PWM Impedance Z

PWM Frequency F

PWM High Level Voltage V

PWM Low Level Voltage V

LED_EN Impedance Z

LED_EN High Voltage V

LED_EN Low Voltage V

PWM 20 40 60 kȳ

PWM 200 - 1000 Hz 10

PWM_H

PWM_L

PWM 20 40 60 kȳ

LED_EN_H 2.2 - 5.3 V

LED_EN_L 0-0.3V

2.2 - 5.3 V

0-0.3V

Life Time 12,000 - - Hrs 11

Ver. 1.0 Dec. 26, 2011

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

6 / 28

www.panelook.com

Global LCD Panel Exchange Center

Note)

1. The measuring position is the connector of LCM and the test conditions are under 25, fv = 60Hz,

Black pattern.

2. The specified Icc current and power consumption are under the Vcc = 3.3V , 25, fv = 60Hz condition

and Mosaic pattern.

3. This Spec. is the max load condition for the cable impedance designing.

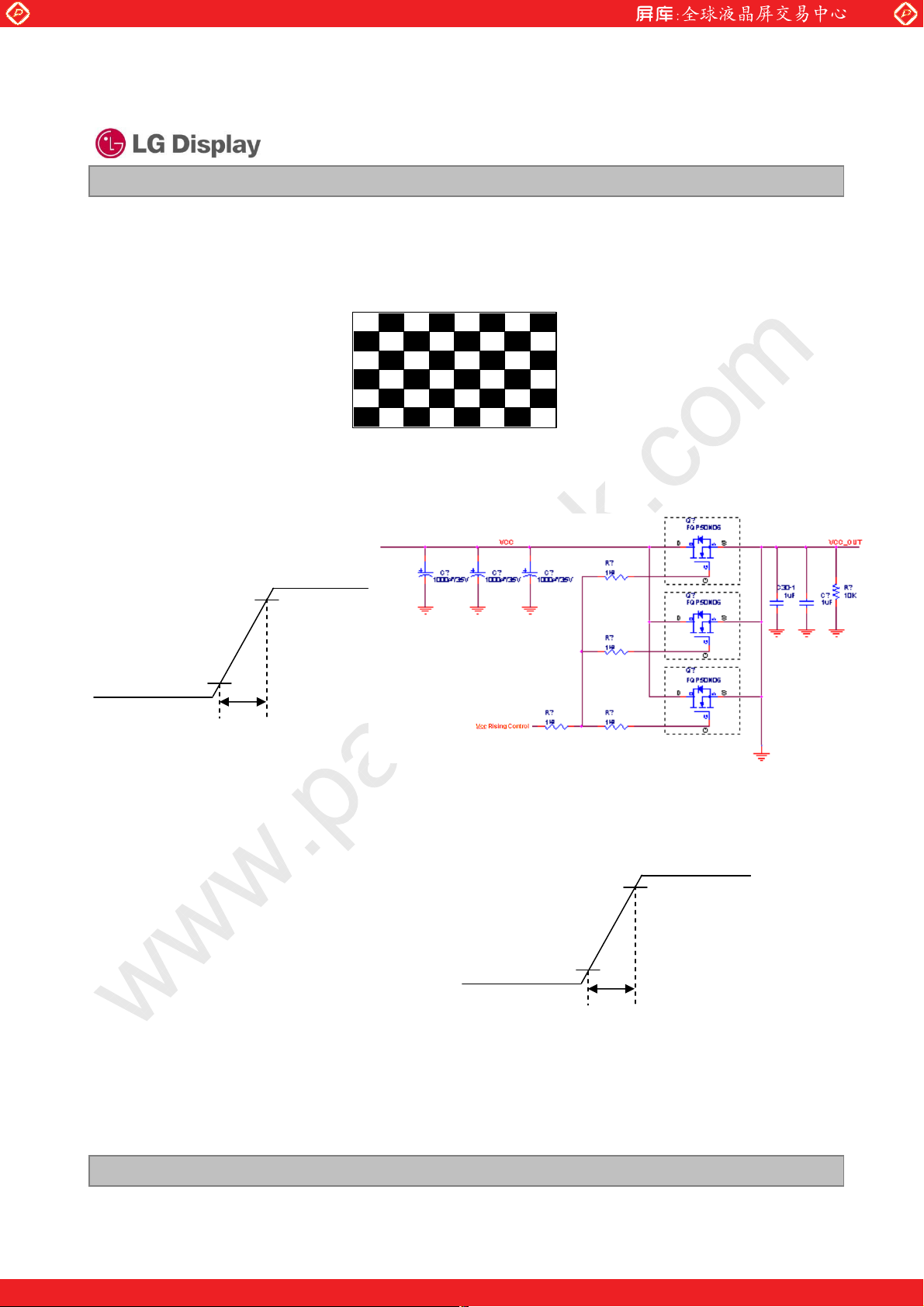

4. The below figures are the measuring Vcc condition and the Vcc control block LGD used.

The Vcc condition is same as the minimum of T1 at Power on sequence.

www.panelook.com

LP140WH2

Liquid Crystal Display

Product Specification

Rising time

Vcc

0V

5. This impedance value is needed for proper display and measured form LVDS Tx to the mating connector.

6. The measuring position is the connector of LCM and the test conditions are under 25.

7. The current and power consumption with LED Driver are under the Vled = 12.0V , 25, Dimming of

Max luminance and White pattern with the normal frame frequency operated(60Hz).

8. The below figures are the measuring Vled condition

and the Vled control block LGD used.

VLED control block is same with Vcc control block.

90%

10%

0.5ms

3.3V

Rising time

LED

V

0V

10%

12.0V

90%

0.5ms

9. The operation of LED Driver below minimum dimming ratio may cause flickering or reliability issue.

10. If Jitter of PWM is bigger than maximum, it may induce flickering.

11. This Spec. is not effective at 100% dimming ratio as an exception because it has DC level equivalent

to 0Hz. In spite of acceptable range as defined, the PWM Frequency should be fixed and stable for

more consistent brightness control at any specific level desired.

12. The life time is determined as the time at which brightness of LCD is 50% compare to that of minimum

value specified in table 7. under general user condition.

Ver. 1.0 Dec. 26, 2011

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

7 / 28

www.panelook.com

Global LCD Panel Exchange Center

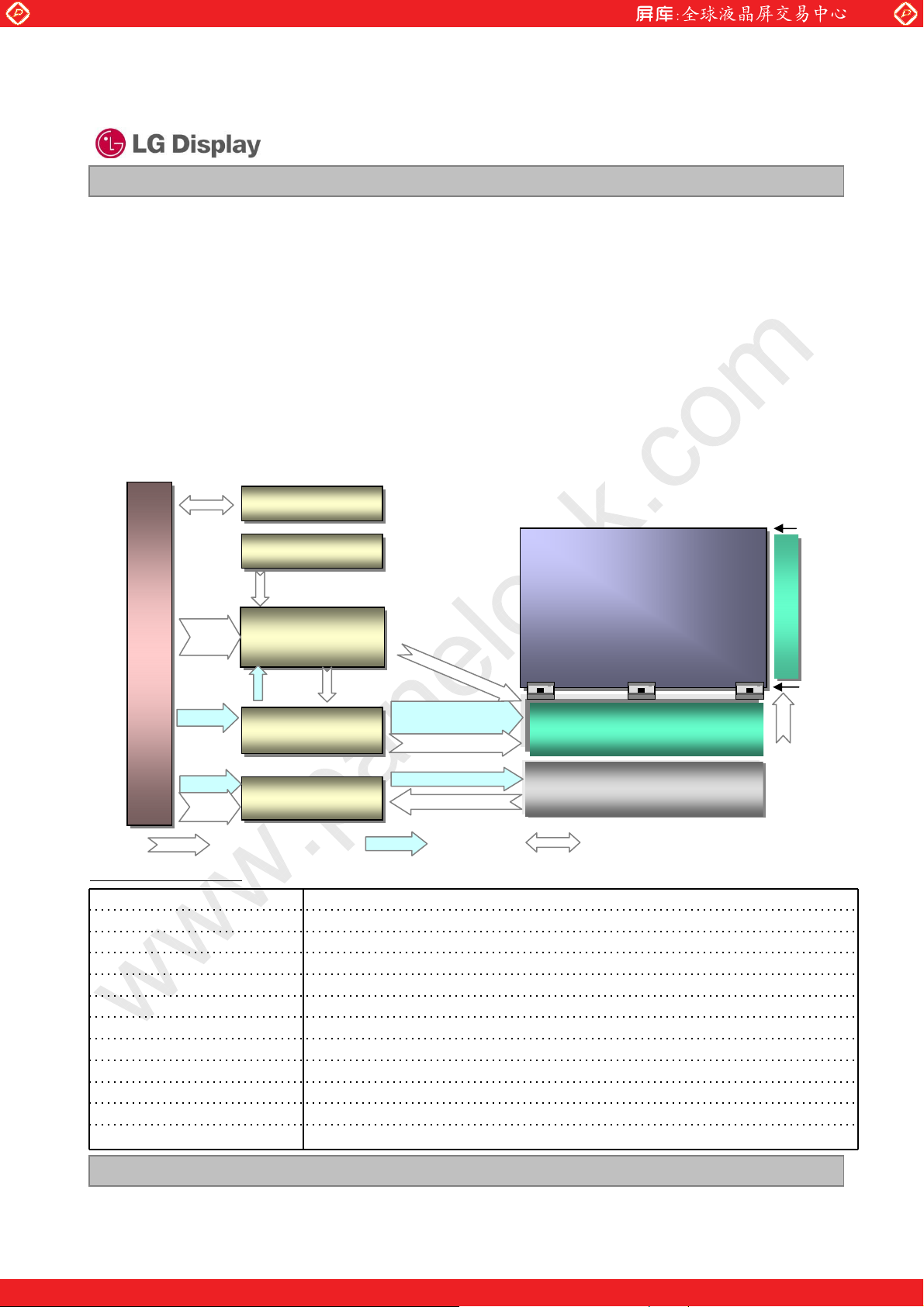

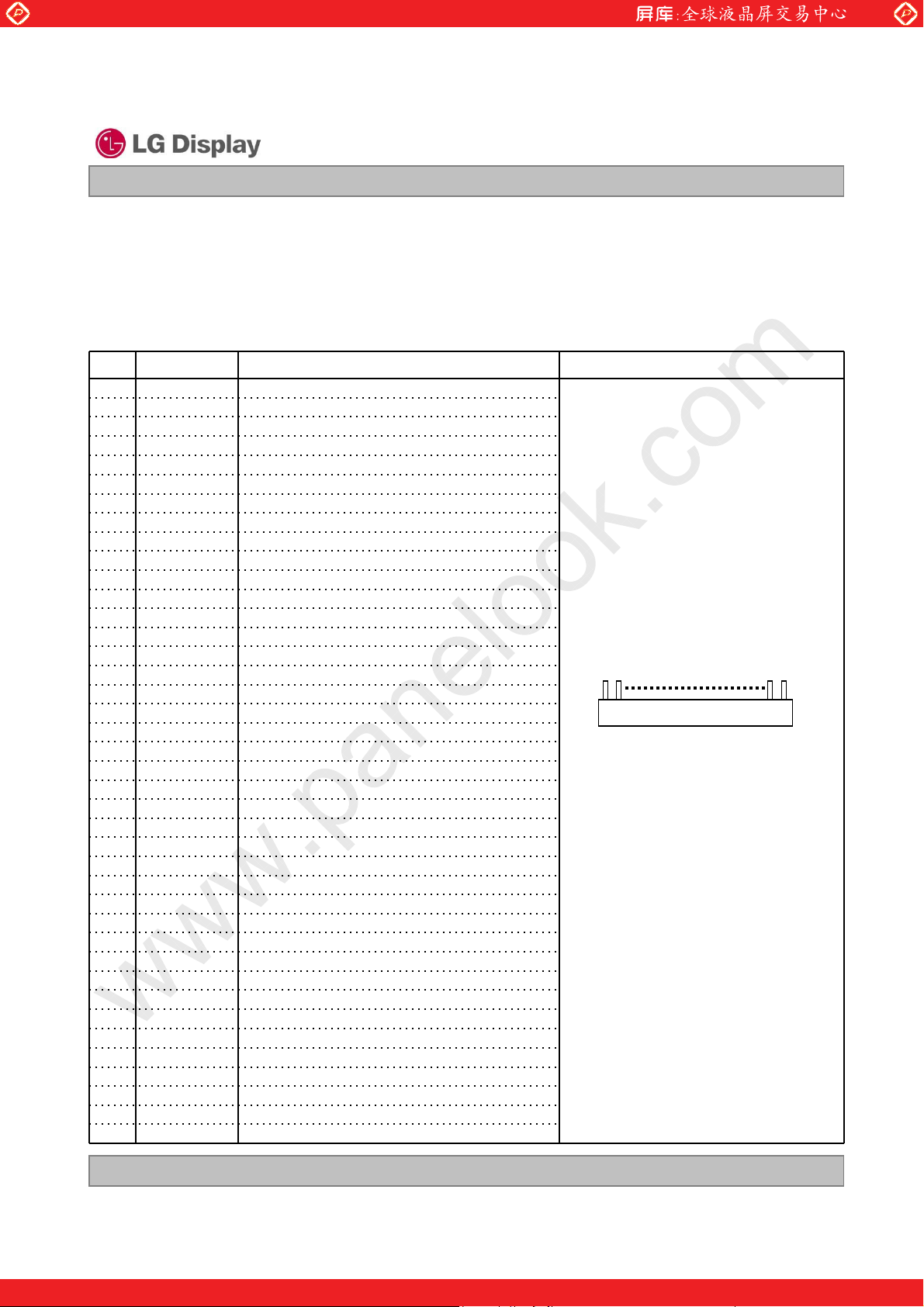

3-2. Interface Connections

This LCD employs two interface connections, a 40 pin connector used for the module electronics interface and

the other connector used for the integral backlight system.

Table 3. MODULE CONNECTOR PIN CONFIGURATION (CN1)

Pin Symbol Description Notes

1 NC No Connection

2 VCC LCD Logic and driver power (3.3V Typ.)

3 VCC LCD Logic and driver power (3.3V Typ.)

4 V EEDID DDC Power (3.3V)

5

6 Clk EEDID DDC Clock

7 DATA EEDID DDC Data

8 ORX0- Negative LVDS differential data input

9 ORX0+ Positive LVDS differential data input

10

11 ORX1- Negative LVDS differential data input

12 ORX1+ Positive LVDS differential data input

13

14 ORX2- Negative LVDS differential data input

15 ORX2+ Positive LVDS differential data input

16

17 ORXC- Negative LVDS differential clock input

18 ORXC+ Positive LVDS differential clock input

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

NC Reserved (BIST)

GND LCM Ground

GND LCM Ground

GND LCM Ground

NC

NC

NC

No Connection

No Connection

No Connection

GND LCM Ground

NC

NC

No Connection

No Connection

GND LCM Ground

NC

NC

No Connection

No Connection

GND LCM Ground

NC

NC

GND

GND

GND

NC

PWM System PWM Signal input for dimming

LED_EN

1& 5HVHUYHG

VLED LED Backlight Power (7V-21V)

VLED LED Backlight Power (7V-21V)

VLED LED Backlight Power (7V-21V)

No Connection

No Connection

LCM Ground (LED Backlight Ground)

LCM Ground (LED Backlight Ground)

LCM Ground (LED Backlight Ground)

No Connection

LED Backlight On/Off

www.panelook.com

Product Specification

LP140WH2

Liquid Crystal Display

[Interface Chip]

1. LCD :

SiW, SW0645A(LCD Controller)

Including LVDS Receiver.

2. System : SiW LVDSRx or equivalent

* Pin to Pin compatible with LVDS

[Connector]

UJU IS050-L40B-C10

LSMtron GT05Q-40S-H10

[Mating Connector]

20345-#40E-## series or equivalent

[Connector pin arrangement]

40

[LCD Module Rear View]

1

Ver. 1.0 Dec. 26, 2011

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

8 / 28

www.panelook.com

Global LCD Panel Exchange Center

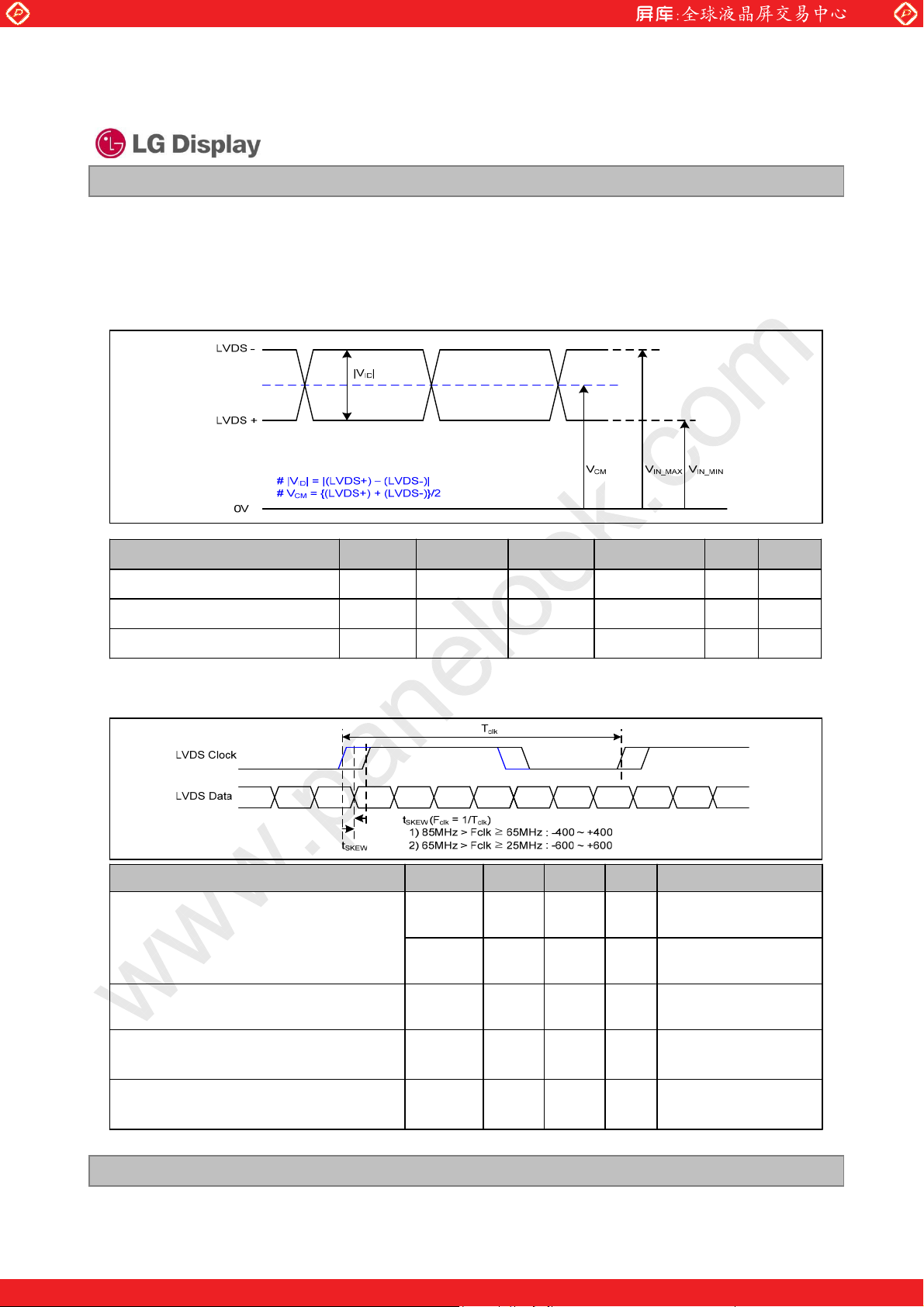

3-3. LVDS Signal Timing Specifications

3-3-1. DC Specification

www.panelook.com

LP140WH2

Liquid Crystal Display

Product Specification

VDD=1.8V

Description Symbol Min Typ Max Unit Notes

LVDS Differential Voltage |V

LVDS Common mode Voltage V

LVDS Input Voltage Range V

3-3-2. AC Specification

Description Symbol Min Max Unit Notes

LVDS Clock to Data Skew Margin

LVDS Clock to Clock Skew Margin (Even

to Odd)

| 100 - 600 mV -

ID

CM

IN

|VID| /2 1.2 VDD- |VID|/2 V -

0.3 - VDD V -

t

SKEW

t

SKEW

t

SKEW_EO

- 400 + 400 ps

- 600 + 600 ps

-1/7 + 1/7 T

clk

85MHz > Fclk ˻

65MHz

65MHz > Fclk ˻

25MHz

-

Maximum deviation

of input clock frequency during SSC

Maximum modulation frequency

of input clock during SSC

Ver. 1.0 Dec. 26, 2011

F

F

DEV

MOD

- · 3% -

- 200 KHz -

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

9 / 28

www.panelook.com

Loading...

Loading...