Page 1

THE INFORMATION CONTAINED HEREIN IS THE PROPERTY OF APPLE, INC. THE POSSESSOR AGREES TO THE FOLLOWING:

(i) TO MAINTAIN THIS DOCUMENT IN CONFIDENCE (ii) NOT TO REPRODUCE OR COPY IT (iii) NOT TO REVEAL OR PUBLISH IT IN WHOLE OR IN PART

Apple Inc.

Size: Letter

Scale: NONE

Page 1 of 67

Title: ERIS, DSPL, LCD MODULE, LGD, X34 DWG Number: 069-8326 ___Rev. B___

Revision

ECO#

Approved By

Date

Revision History

B

xxxxxx

Per ECO Approvals

08/14/2012

See Last Page for Revision History

LGD LCD Module Specification for X34

13.3” (2560X1600) TFT-LCD

Page 2

THE INFORMATION CONTAINED HEREIN IS THE PROPERTY OF APPLE, INC. THE POSSESSOR AGREES TO THE FOLLOWING:

(i) TO MAINTAIN THIS DOCUMENT IN CONFIDENCE (ii) NOT TO REPRODUCE OR COPY IT (iii) NOT TO REVEAL OR PUBLISH IT IN WHOLE OR IN PART

Apple Inc.

Size: Letter

Scale: NONE

Page 2 of 67

Title: ERIS, DSPL, LCD MODULE, LGD, X34 DWG Number: 069-8326 ___Rev. B___

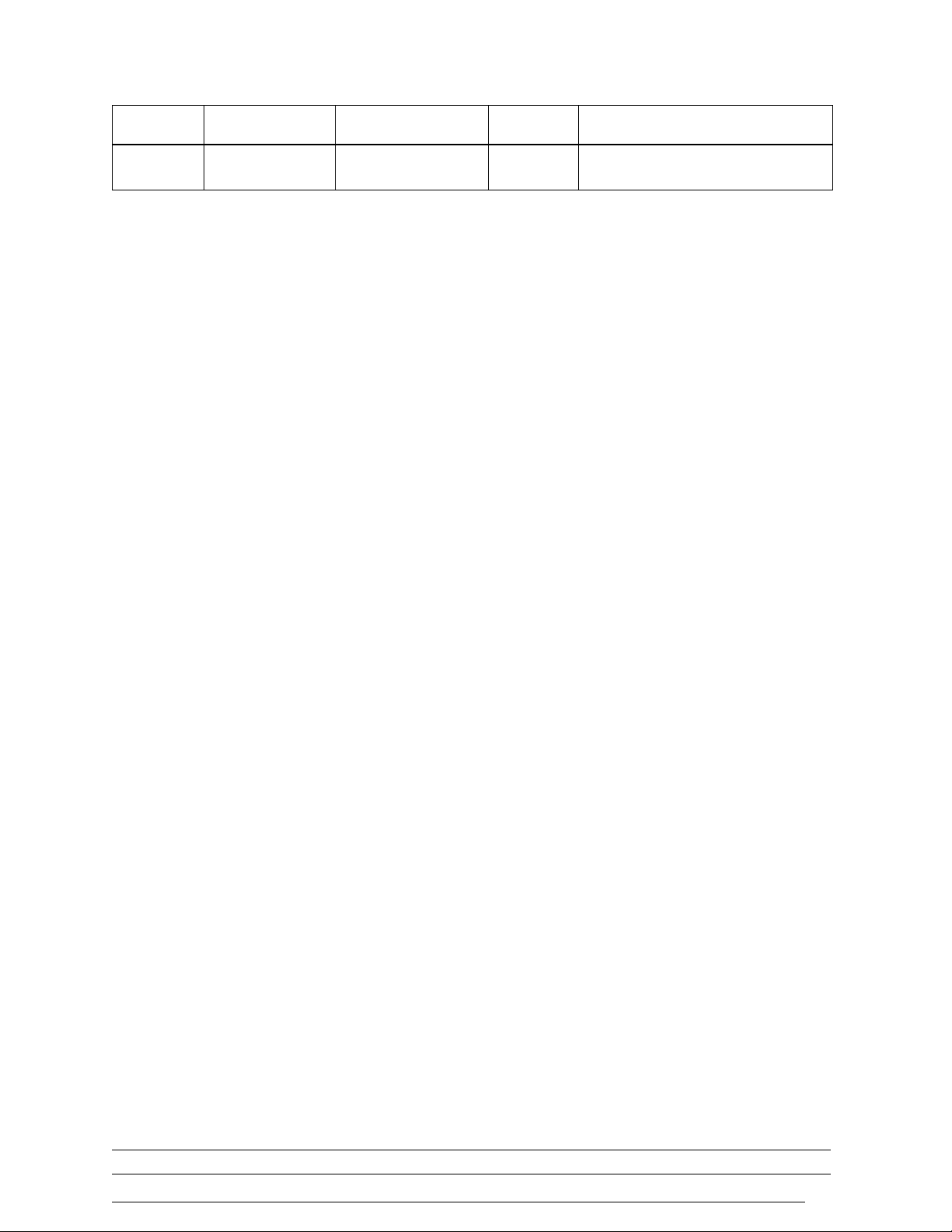

Revision History

Revision

Date

ECO

Author

Comments

1

09/16/11

Eric Benson

Initial Engineering Release

2

12/12/11

Eric Benson

Light Leakage and Testing Updates

3

8/8/11

Eric Benson

Optical, Mechanical, and Testing Updates

4

4/24/12

Eric Benson

Optical, Mechanical, Grinding, Electrical, Reliability

Updates

5

5/28/12

Eric Benson

Optical, Electrical, Mechanical, Reliability Updates.

Removed light leakage requirement

6

6/7/2012

Eric Benson

Added LCD edge ink spec.

A

8/06/2012

Eric Benson

Production Release

B

8/14/2012

Eric Benson

Added V-Com tuning requirement. Transmittance minimum

updated.

Page 3

THE INFORMATION CONTAINED HEREIN IS THE PROPERTY OF APPLE, INC. THE POSSESSOR AGREES TO THE FOLLOWING:

(i) TO MAINTAIN THIS DOCUMENT IN CONFIDENCE (ii) NOT TO REPRODUCE OR COPY IT (iii) NOT TO REVEAL OR PUBLISH IT IN WHOLE OR IN PART

Apple Inc.

Size: Letter

Scale: NONE

Page 3 of 67

Title: ERIS, DSPL, LCD MODULE, LGD, X34 DWG Number: 069-8326 ___Rev. B___

TABLE OF CONTENTS

!"! #$%&$'#(')$&*&%&+*&'#(',-*./&+0102-+'3.04-$205'""""""""""""""""""""""""""""""""""""""""""""""""""""""""""'6!

7"! 8&(&$&+*&',-*./&+09'"""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""':!

;"! <&+&$1=',&9*$2>02-+'""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""'!?!

@"! A.+*02-+1='8&B.2$&/&+09'""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""'!!!

@"!"! ,29>=15'C-%&='""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""'!!!

@"7"! )2D&='E-+(2F.$102-+'""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""'!7!

@";"! )2D&=')20*4'"""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""'!7!

@"@"! 8&9-=.02-+'"""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""'!7!

@"G"! 8.HH2+F',2$&*02-+'""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""'!7!

@"I"! J+0&$(1*&'1+%',$2K2+F'L*4&/ &'""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""'!;!

@"M"! A$-+0'L.$(1*&'N$&10/&+0'""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""'!;!

G"! C&*41+2*1='8&B.2$&/&+09'""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""'!;!

G"!"! O+K&=->&',2/&+92-+9'1+%'N-=&$1+*&9'""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""'!;!

G"7"! 3*02K&'3$&1'""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""'!;!

G";"! C199'"""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""'!;!

G"@"! P+20'A=10+&99'""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""" '!;!

5.4.1.! Flatness!Measurement!Requirements!................................................................................................!13!

G"G"! OD>-9&%'3$&1'1+%'8&90$2*02-+9'""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""'!;!

G"I"! O%F&'Q.1=205'8&B.2$&/&+09'""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""'!;!

5.6.1.! Surface!Finish!Requirements!..................................................................................................................!14!

5.6.2.! Edge!Defect!Requirements!.......................................................................................................................!15!

5.6.3.! Ground!Surface!Profile!...............................................................................................................................!16!

G"M"! )-=1$2R&$'O%F&'8&B.2$&/&+0'""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""'!M!

G"6"! C&*41+2*1='L01*ST.>'""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""'!6!

G":"! ,$2K&$'JE'C&*41+2*1='8&B.2$&/&+09'""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""'!6!

5.9.1.! Driver!IC!Edge!Quality!................................................................................................................................!18!

5.9.2.! Driver!IC!Top!Surface!Requirement!.....................................................................................................!19!

G"!?"! P+20'O%F&'J+S'8&B.2$&/&+0'""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""'!:!

I"! N4&$/1='8&B.2$&/&+09'""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""'!:!

M"! O=&*0$2*1='8&B.2$&/&+09'""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""'!:!

M"!"! U=-*S',21F$1/'"""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""'!:!

M"7"! ,29>=15')EU'L*4&/102*9'""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""'7?!

M";"! ,29>=15')EU'V15-.0'""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""'7!!

M"@"! 3*02K&'E-/>-+&+09'""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""'7!!

7.4.1.! Electrical!Interface!Requirements!........................................................................................................!21!

7.4.2.! Extended!Display!Identification!Data!(EDID)!Interface!..............................................................!22!

7.4.3.! Power!Supply!Requirements!..................................................................................................................!25!

7.4.4.! Signal!Timing!.................................................................................................................................................!25!

7.4.5.! Power!Requirements!(W/O!backlight)!...............................................................................................!27!

7.4.6.! Display!Pattern!Requirements!...............................................................................................................!27!

M"G"! )-W&$'-+T-(('9&B.&+*&'"""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""'76!

M"I"! X**'X-=01F&',$->'8&B.2$&/&+0'""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""'76!

M"M"! Y&1$TA2&=%'Y-29&'""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""'76!

M"6"! &,)'U20TO$$-$T810&'ZUO8['8&B.2$&/&+0'"""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""'76!

M":"! E#<'U20'O$$-$'810&'ZUO8['8&B.2$&/&+0'""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""'76!

M"!?"! )$-F$1//1H=&'<1//1'L&002+F9'"""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""'76!

Page 4

THE INFORMATION CONTAINED HEREIN IS THE PROPERTY OF APPLE, INC. THE POSSESSOR AGREES TO THE FOLLOWING:

(i) TO MAINTAIN THIS DOCUMENT IN CONFIDENCE (ii) NOT TO REPRODUCE OR COPY IT (iii) NOT TO REVEAL OR PUBLISH IT IN WHOLE OR IN PART

Apple Inc.

Size: Letter

Scale: NONE

Page 4 of 67

Title: ERIS, DSPL, LCD MODULE, LGD, X34 DWG Number: 069-8326 ___Rev. B___

M"!!"! U1*S=2F40'L.H9590&/'"""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""'7:!

7.11.1.! General!Information!.................................................................................................................................!29!

7.11.2.! Backlight!Electrical!Characteristics!...................................................................................................!29!

7.11.3.! LED!Connection!..........................................................................................................................................!31!

7.11.4.! LED!string!to!string!current!variation!..............................................................................................!32!

7.11.5.! LED!Driver!Requirement!........................................................................................................................!32!

M"!7"! JN#'O=&*0$2*1='L42&=%2+F'""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""';7!

6"! #>02*1='8&B.2$&/&+09'"""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""';@!

6"!"! <&+&$1='#>02*1='L>&*2(2*102-+9'"""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""';@!

6"7"! #>02*1='C&19.$2+F'E-+%202-+9'""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""';G!

8.2.1.! Center!Point!Luminance!............................................................................................................................!36!

8.2.2.! Average!Luminance!.....................................................................................................................................!37!

8.2.3.! Brightness!Uniformity!................................................................................................................................!37!

8.2.4.! Contrast!Ratio!................................................................................................................................................!37!

8.2.5.! White!Color!Uniformity!.............................................................................................................................!37!

8.2.6.! Panel!to!Panel!White!Color!Uniformity!..............................................................................................!38!

8.2.7.! Max!Color!Difference!with!respect!to!the!center!within!a!panel!.............................................!38!

8.2.8.! Max!Color!Difference!between!any!two!points!within!the!panel!............................................!38!

8.2.9.! Average!Color!Difference!between!top!and!bottom!......................................................................!38!

8.2.10.! Max!Color!Difference!between!two!neighbors!.............................................................................!39!

8.2.11.! RGB!Color!Chromaticity!..........................................................................................................................!39!

8.2.12.! Viewing!Angle!.............................................................................................................................................!39!

8.2.13.! Gray!Scale!Inversion!.................................................................................................................................!39!

8.2.14.! Response!Time!...........................................................................................................................................!40!

8.2.15.! Gray!Scale!Linearity!or!Gamma!Value!..............................................................................................!41!

6";"! A=2*S&$'"""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""'@!!

6"@"! E$-99T01=S'""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""'@!!

6"G"! L.$(1*&'8&(=&*02-+'"""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""'@7!

6"I"! <&+&$1='8&B.2$&/&+0'(-$'E1/&$1'1+%'EJV\3VL'3$&1'"""""""""""""""""""""""""""""""""""""""""""""""""""""""""""'@;!

6"M"! E1/&$1\3VL\EJV'#>02*1=')1$1/&0&$',&(2+202-+'"""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""'@@!

8.7.1.! Camera!Window!Transmittance!............................................................................................................!44!

8.7.2.! Camera!Window!Parallelism!...................................................................................................................!44!

8.7.3.! Camera!Window!Transmitted!Wavefront!Distortion!...................................................................!44!

8.7.4.! Haze!....................................................................................................................................................................!44!

8.7.5.! Color!Shift!........................................................................................................................................................!44!

8.7.6.! ALS!and!CIL!Transmittance!.....................................................................................................................!44!

6"6"! J/1F&'8&0&+02-+'""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""'@G!

8.8.1.! Quick!Check!Image!Retention!.................................................................................................................!46!

8.8.2.! Short!Term!Image!Retention!...................................................................................................................!46!

8.8.3.! Middle!Term!...................................................................................................................................................!46!

8.8.4.! Long!Term!.......................................................................................................................................................!46!

6":"! E-//-+'X-=01F&'ZX*-/['N.+2+F'8&B.2$&/&+09'"""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""'@I!

6"!?"! E-=-$']194-.0'"""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""'@M!

8.10.1.! Testing!Method!and!Condition!............................................................................................................!47!

8.10.2.! Observation!and!Pass!Criteria!.............................................................................................................!48!

6"!!"! #,A'A2=='3/-.+0'1+%'L.*02-+'E.>'N&902+F'"""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""'@6!

6"!7"! A#L'L42//&$2+F'L>&*2(2*102-+9'"""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""'@6!

:"! OYXJ8#YCOYN3V'"""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""'@:!

:"!"! L4-*S'8&B.2$&/&+09'""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""'@:!

:"7"! L2+&'X2H$102-+'8&B.2$&/&+09'"""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""'@:!

Page 5

THE INFORMATION CONTAINED HEREIN IS THE PROPERTY OF APPLE, INC. THE POSSESSOR AGREES TO THE FOLLOWING:

(i) TO MAINTAIN THIS DOCUMENT IN CONFIDENCE (ii) NOT TO REPRODUCE OR COPY IT (iii) NOT TO REVEAL OR PUBLISH IT IN WHOLE OR IN PART

Apple Inc.

Size: Letter

Scale: NONE

Page 5 of 67

Title: ERIS, DSPL, LCD MODULE, LGD, X34 DWG Number: 069-8326 ___Rev. B___

:";"! N&/>&$10.$&'1+%'^./2%205'""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""'@:!

:"@"! Y-+T->&$102-+1='O+K2$-+/&+01='8&B.2$&/&+09'""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""'@:!

9.4.1.! Low!Temperature!........................................................................................................................................!49!

9.4.2.! High!Temperature!.......................................................................................................................................!49!

9.4.3.! High!Temperature!and!High!Humidity!...............................................................................................!50!

9.4.4.! Thermal!Shock!...............................................................................................................................................!50!

:"G"! #>&$102-+1='N&902+F'"""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""'G?!

9.5.1.! Low!Temperature!........................................................................................................................................!50!

9.5.2.! High!Temperature!.......................................................................................................................................!50!

9.5.3.! Heat!Soak!.........................................................................................................................................................!50!

9.5.4.! High!Temperature!and!High!Humidity!...............................................................................................!50!

9.5.5.! Four!Corner!Test!(72!hrs!–!operating)!...............................................................................................!50!

:"I"! 3=020.%&'""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""'G?!

:"M"! E-=%'L-1S'"""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""'G?!

!?"! A8OQPOYE_'C38<JY'""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""'G!!

!!"! 8OVJ3UJVJN_'""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""'G7!

!!"!"! @TE-$+&$')&&=2+F'N&90''ZE-=-$'A2=0&$'ZEA['`'NAN['"""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""'G7!

11.1.1.! 4^Corner!Peel!Test!Procedure!..............................................................................................................!53!

!!"7"! VE,'399&/H=5'U1==T-+T82+F'N&90'"""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""'G;!

11.2.1.! BOR!Test!Configuration!..........................................................................................................................!54!

11.2.2.! BOR!Test!Procedure!.................................................................................................................................!55!

!!";"! VE,'399&/H=5'@T)-2+0'U&+%'N&90'""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""'GI!

11.3.1.! 4^Point!Bend!Test!Setup!.........................................................................................................................!56!

11.3.2.! 4^Point!Bend!Test!Procedure!...............................................................................................................!58!

!!"@"! )-=1$2R&$')&$2/&0&$',&=1/2+102-+'N&90'""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""" 'I?!

!!"G"! VE,',29>=15'E-=./+'L>1*&$'N&90'""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""'I?!

!!"I"! A=&D2H=&')$2+0&%'E2$*.20'ZA)E['L0$12+'8&=2&('""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""'I!!

!!"M"! 82F2%'A=&D'U&+%2+F'N&909'"""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""'I!!

!!"6"! A=&D'E1H=&'0-'<=199'U-+%2+F'L0$&+F04'""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""'I7!

!!":"! L>1*&$'82F2%205'N&902+F'""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""'I7!

!!"!?"! L42&=%2+F'JN#'L4&&0'8&92901+*&'^&10'L-1S'""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""'I;!

!!"!!"! O=&*0$-90102*',29*41$F&'ZOL,['N&90'""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""'I@!

!!"!7"! CNUA'""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""'I@!

!7"! E#LCONJE'8OQPJ8OCOYNL'""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""'IG!

!;"! ,JL)V3_'LO8J3V'YPCUO8L'3Y,'V3UOVJY<'""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""'IG!

!@"! 8O<PV3N#8_'""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""'IG!

!@"!"! )$-%.*0'L1(&05'ZO+K2$-+/&+01=a'O$F-+-/2*9a'L1(&05'1+%'^&1=04['"""""""""""""""""""""""""""""""""'IG!

!@"7"! 8-^L'E-/>=21+*&'1+%'-04&$'L.H901+*&'8&F.=102-+9'"""""""""""""""""""""""""""""""""""""""""""""""""""""""""'IG!

!@";"! ^1=-F&+'A$&&'""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""'II!

!@"@"! O+K2$-+/&+01='C1$S2+F9'1+%'8&*5*=2+F'""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""'II!

!@"G"! )$-%.*0'L1(&05'"""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""'II!

!@"I"! O$F-+-/2*9'""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""'II!

!@"M"! O=&*0$-/1F+&02*'E-/>102H2=205'ZOCE['""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""'II!

14.7.1.! Electromagnetic!Emissions!Requirements!....................................................................................!66!

14.7.2.! Electromagnetic!Immunity!Requirements!.....................................................................................!66!

14.7.3.! EMC!Production!Audit!Procedure!......................................................................................................!66!

!G"! 3*$-+5/9'""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""'IM!

Page 6

THE INFORMATION CONTAINED HEREIN IS THE PROPERTY OF APPLE, INC. THE POSSESSOR AGREES TO THE FOLLOWING:

(i) TO MAINTAIN THIS DOCUMENT IN CONFIDENCE (ii) NOT TO REPRODUCE OR COPY IT (iii) NOT TO REVEAL OR PUBLISH IT IN WHOLE OR IN PART

Apple Inc.

Size: Letter

Scale: NONE

Page 6 of 67

Title: ERIS, DSPL, LCD MODULE, LGD, X34 DWG Number: 069-8326 ___Rev. B___

Table of Figures

FIGURE!1!LCD!ASSEMBLY!OVERVIEW! 10!

FIGURE!2!RESOLUTION!OVERVIEW! 12!

FIGURE!3!RUBBING!DIRECTIONS! 12!

FIGURE!4!SURFACE!ROUGHNESS!MEASUREMENT!AREA! 14!

FIGURE!5!SURFACE!ROUGHNESS!MEASUREMENT!TEST!CONFIGURATIONS! 14!

FIGURE!6!GRINDING!ZONE!DEFINITIONS! 16!

FIGURE!7!GLASS!CHIP!PROFILE!DEFINITION! 16!

FIGURE!8!CHAMFER!OF!GRINDING!EDGE!PROFILE! 17!

FIGURE!9!GRINDING!PROFILE!ZONE!DEFINITIONS! 17!

FIGURE!10!POLARIZER!OVERHANG!REQUIREMENT! 18!

FIGURE!11!DRIVER!IC!EDGE!QUALITY! 19!

FIGURE!12!UNIT!ELECTRICAL!BLOCK!DIAGRAM!(FOR!REFERENCE!ONLY)! 20!

FIGURE!13!CONNECTOR!DRAWING!(PCB!SIDE)! 21!

FIGURE!14!WHITE!SCREEN!DISPLAY! !!FIGURE!15!MOSAIC!PATTERN!DISPLAY! 28!

FIGURE!16!VERTICAL!STRIPE!PATTERN!DISPLAY! 28!

FIGURE!17!LED!CONTROLLER!BLOCK!DIAGRAM! 30!

FIGURE!18!LED!CONTROLLER!REFERENCE!APPLICATION!CIRCUITS! 30!

FIGURE!19!DISPLAY!BACKLIGHT!CONTROL!DIAGRAM! 31!

FIGURE!20!ITO!TRANSMITTANCE! 33!

FIGURE!21!OPTICAL!MEASUREMENT!SET^UP! 36!

FIGURE!22!OPTICAL!MEASUREMENT!POINTS! 36!

FIGURE!23!NEIGHBORING!POINTS! 37!

FIGURE!24!VIEWING!ANGLE!DEFINITION! 39!

FIGURE!25!RESPONSE!TIME!MEASUREMENT! 40!

FIGURE!26!GRAY!TO!GRAY!RESPONSE!TIME! 41!

FIGURE!27!CROSS!TALK!MEASUREMENT! 42!

FIGURE!28!SURFACE!REFLECTION!MEASUREMENT! 43!

FIGURE!29!CAMERA/ALS/CIL!PATTERN!MEASUREMENT! 45!

FIGURE!30!IMAGE!RETENTION!CHECKING!CONDITION! 45!

FIGURE!31!IMAGE!RETENTION!CHECKING!PATTERNS! 46!

FIGURE!32!COLOR!WASHOUT!TEST!LOCATIONS! 47!

FIGURE!33!4^CORNER!PEEL!TEST!SETUP! 52!

FIGURE!34!4^CORNER!PEEL!TEST!EXAMPLE! 53!

FIGURE!35!BALL!AND!SUPPORT!RING!GEOMETRY! 54!

FIGURE!36!EXAMPLE!OF!BALL!ON!RING!TEST!CONFIGURATION!(INSTRON)! 55!

FIGURE!37!MODULE!TEST!LOCATIONS!FOR!BALL!ON!RING!TEST! 55!

FIGURE!38!4!POINT!BEND!90%!SURVIVAL!RATE!ON!WEIBULL!PROBABILITY!PLOT! 56!

FIGURE!394!POINT!BEND!TEST!SETUP! 57!

FIGURE!40!4^POINT!BEND!HORIZONTAL!GLASS!CONFIGURATION! 57!

FIGURE!41!4^POINT!BEND!VERTICAL!GLASS!CONFIGURATION! 58!

FIGURE!42!4^POINT!BEND!FAILURE!CASE!OVERVIEW! 59!

FIGURE!43!STRAIN!RELIEF!ON!THE!FPC! 61!

FIGURE!44!FPC!LEVEL!BENDING!TEST! 62!

FIGURE!45!FISHERSCOPE!HM2000! 63!

FIGURE!46!SPACER!RIGIDITY!TEST! 63!

Page 7

THE INFORMATION CONTAINED HEREIN IS THE PROPERTY OF APPLE, INC. THE POSSESSOR AGREES TO THE FOLLOWING:

(i) TO MAINTAIN THIS DOCUMENT IN CONFIDENCE (ii) NOT TO REPRODUCE OR COPY IT (iii) NOT TO REVEAL OR PUBLISH IT IN WHOLE OR IN PART

Apple Inc.

Size: Letter

Scale: NONE

Page 7 of 67

Title: ERIS, DSPL, LCD MODULE, LGD, X34 DWG Number: 069-8326 ___Rev. B___

Table of Tables

TABLE!1!UNIFIED!DISPLAY!FOR!X34!GENERAL!DESCRIPTION! 11!

TABLE!2!DISPLAY!SUBSYSTEM!CONNECTOR!PIN!ASSIGNMENT!(FOR!REFERENCE!ONLY)! 22!

TABLE!3!EDID!DATA!(FOR!REFERENCE!ONLY)! 23!

TABLE!4!COLOR!DATA!REFERENCE! 26!

TABLE!5!LED!REQUIREMENTS!(CHARACTERIZED!AT!20!MA)! 29!

TABLE!6!LED!CONNECTION!DATA! 31!

TABLE!7!LED!CONNECTOR!ASSIGNMENTS!(FOR!REFERENCE!ONLY)! 31!

TABLE!8!ITO!LAYER!CHARACTERISTICS! 32!

TABLE!9!GENERAL!OPTICAL!CHARACTERISTICS! 34!

TABLE!10!CAMERA!AND!CIL/ALS!REQUIREMENTS! 43!

TABLE!11!COLOR!WASHOUT!TEST!CONDITIONS! 47!

TABLE!12!APPLE!DEVELOPMENT!DISPLAY!LABEL!REQUIREMENTS! 65!

Page 8

THE INFORMATION CONTAINED HEREIN IS THE PROPERTY OF APPLE, INC. THE POSSESSOR AGREES TO THE FOLLOWING:

(i) TO MAINTAIN THIS DOCUMENT IN CONFIDENCE (ii) NOT TO REPRODUCE OR COPY IT (iii) NOT TO REVEAL OR PUBLISH IT IN WHOLE OR IN PART

Apple Inc.

Size: Letter

Scale: NONE

Page 8 of 67

Title: ERIS, DSPL, LCD MODULE, LGD, X34 DWG Number: 069-8326 ___Rev. B___

!" #$%&$'#(')$&*&%&+*&'#(',-*./&+0102-+'3.04-$205'

In the case of any conflict in any specification related to these parts, this order of precedence of

authority shall apply:

• The Purchase Order

• This Specification

• Reference Documents

Page 9

THE INFORMATION CONTAINED HEREIN IS THE PROPERTY OF APPLE, INC. THE POSSESSOR AGREES TO THE FOLLOWING:

(i) TO MAINTAIN THIS DOCUMENT IN CONFIDENCE (ii) NOT TO REPRODUCE OR COPY IT (iii) NOT TO REVEAL OR PUBLISH IT IN WHOLE OR IN PART

Apple Inc.

Size: Letter

Scale: NONE

Page 9 of 67

Title: ERIS, DSPL, LCD MODULE, LGD, X34 DWG Number: 069-8326 ___Rev. B___

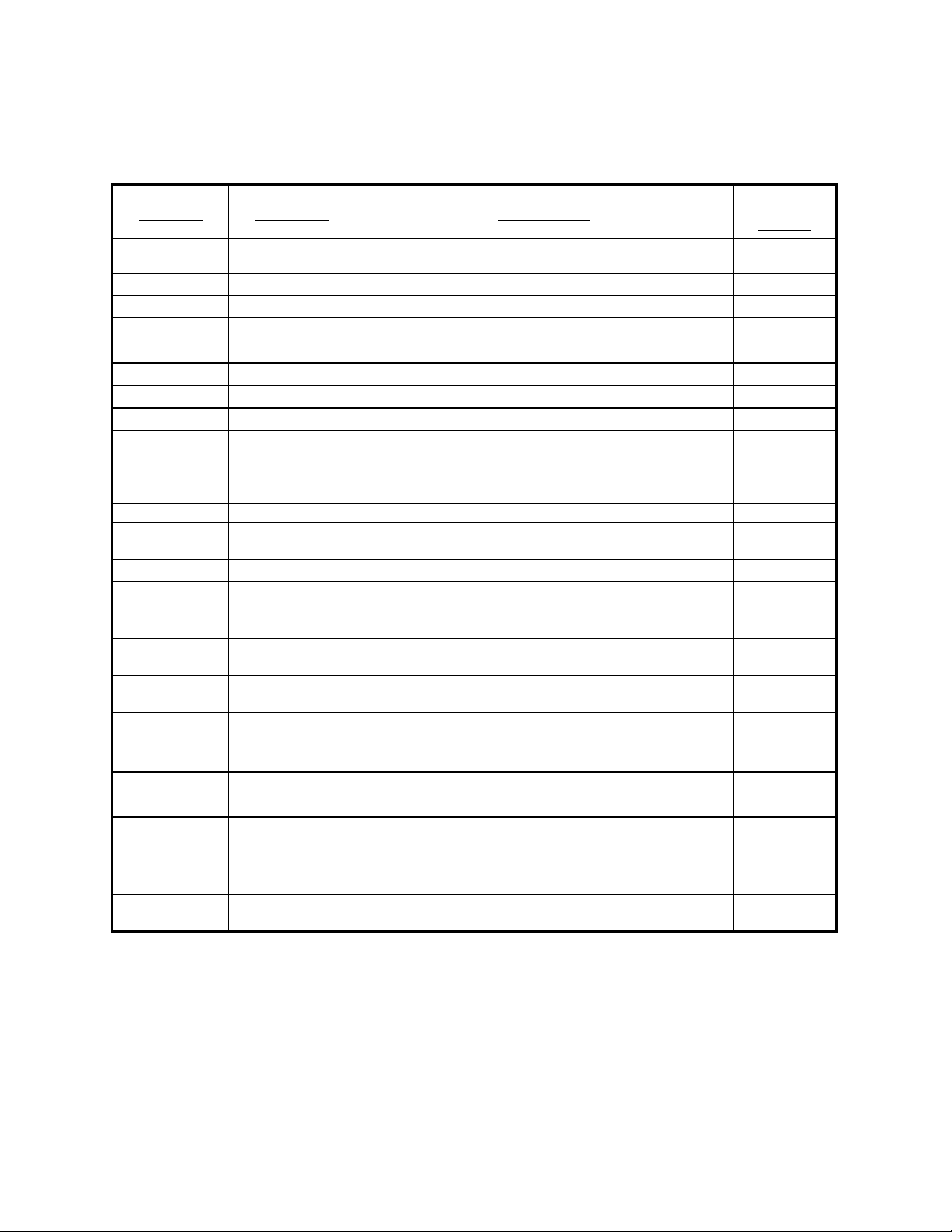

6" 7&(&$&+*&',-*./&+08'

NUMBER

TITLE

069-7821

LCD, MCO, X34

070-1191

Supplier Quality and Business Requirements, Apple

070-0385

Apple Service Requirements

069-7366

LCD Engineering Cosmetic Specification

069-7370

X34 Unified Backlight Specification

080-0855

Drop, Shock and Vibration

080-0854

Four-Corner Temperature and Humidity Test

062-0087

Packaging Finished Goods Shock and Vibration

062-7993

Electromagnetic Emissions Requirements

062-7994

Electromagnetic Immunity Requirements

080-0840

EMC Production Audit Procedure

062-2082

Vendor Packaging Procedure

062-0585

FG Labeling Specification

062-2111

Manufacturing Bar Code Specification

062-2208

Static Breakage Test

070-0371

Service: Packaging Standard

070-0385

Service: Product Quality Requirements

070-1191

Supplier Quality and Business Requirement

070-1193

Barcode Label Specification

074-0321

ESD Anti-static Label Specification

13406-2.3

ISO Specification

062-0093

Apple Corporate Specification, Mandatory Requirements for Product Safety

IEC60950

Safety of Information Technology Equipment (International Standard)

EN 60950

Safety of Information Technology Equipment (European Standard based on

IEC 60950)

UL 1950

Safety of Information Technology Equipment . Third Edition (US Standard

based on IEC 60950) C22.2 No. 950 Safety of Information Technology

Equipment. Third Edition (Canadian Standard based on IEC 60950)

UL 94

Tests for Flammability of Plastic Materials for Parts in Devices and

Appliances (UL standard for flame testing plastics. Includes test

requirements for HB, V-2, V-1 and V-0 flame ratings)

JIS K 5401

Pencil Scratch Tester for Coated Film 13406-2.3

069-0279

Product Safety Requirements for Component Flat Panel Display Assemblies

069-1111

Apple RoHS Compliance Specification

080-2153

Apple’s RoHS Declaration of Conformity Procedure

Page 10

THE INFORMATION CONTAINED HEREIN IS THE PROPERTY OF APPLE, INC. THE POSSESSOR AGREES TO THE FOLLOWING:

(i) TO MAINTAIN THIS DOCUMENT IN CONFIDENCE (ii) NOT TO REPRODUCE OR COPY IT (iii) NOT TO REVEAL OR PUBLISH IT IN WHOLE OR IN PART

Apple Inc.

Size: Letter

Scale: NONE

Page 10 of 67

Title: ERIS, DSPL, LCD MODULE, LGD, X34 DWG Number: 069-8326 ___Rev. B___

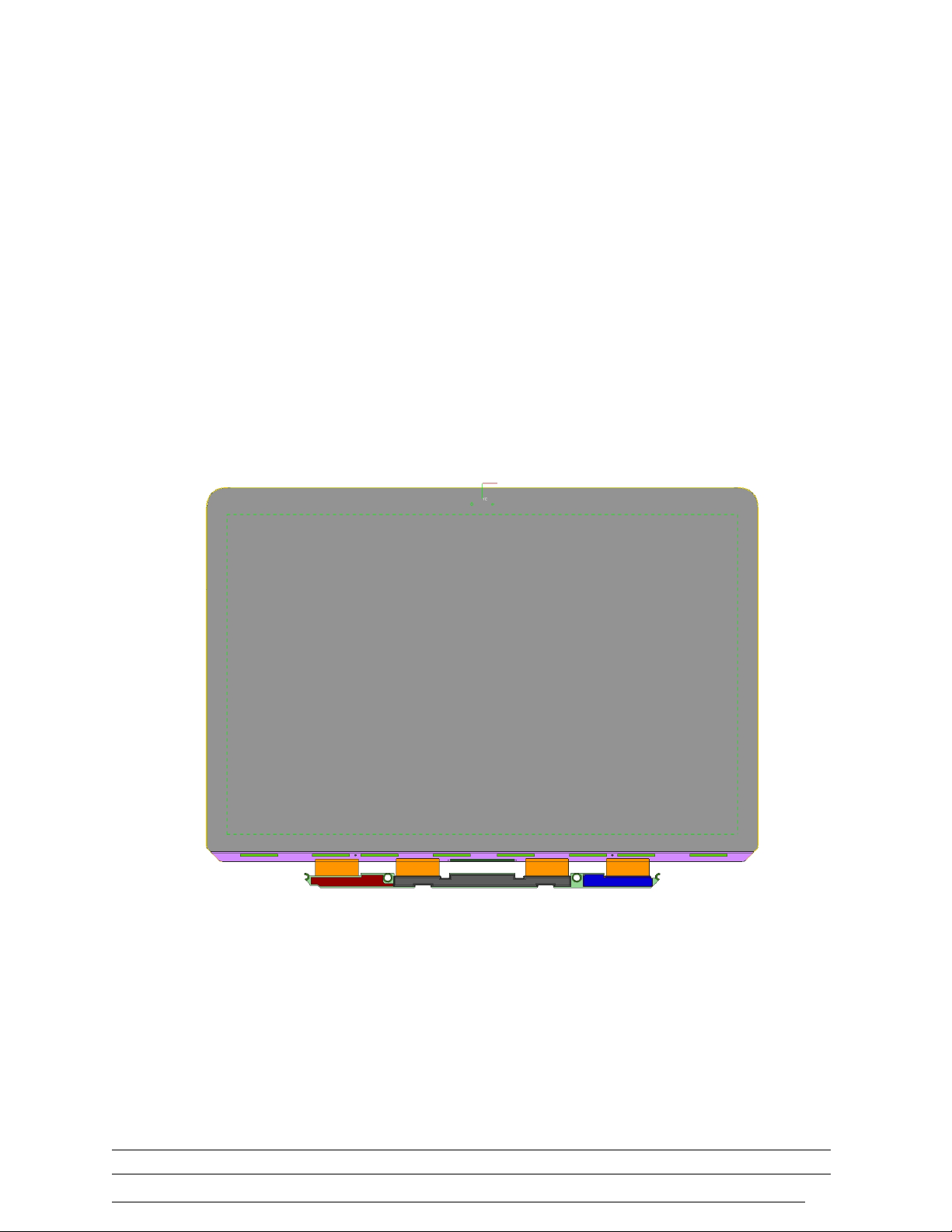

9" :&+&$1;',&8*$2<02-+'

The board assembly drawing for X34 is shown in Figure 1. The LCD Module contains the

following hardware. From this point forward the complete Unified Display for X34 13.3”

TFT-LCD will be referred to as the unit.

• 2x 0.3 mm glass (TFT and CF)

• Liquid Crystal

• Front and Rear Polarizers

• IC Drivers on glass

• PCB with rigid flex cables

• COG Spacer

• ITO Tape

• PCB Label / Insulation Tape

Figure 1 LCD Assembly Overview

Page 11

THE INFORMATION CONTAINED HEREIN IS THE PROPERTY OF APPLE, INC. THE POSSESSOR AGREES TO THE FOLLOWING:

(i) TO MAINTAIN THIS DOCUMENT IN CONFIDENCE (ii) NOT TO REPRODUCE OR COPY IT (iii) NOT TO REVEAL OR PUBLISH IT IN WHOLE OR IN PART

Apple Inc.

Size: Letter

Scale: NONE

Page 11 of 67

Title: ERIS, DSPL, LCD MODULE, LGD, X34 DWG Number: 069-8326 ___Rev. B___

=" >.+*02-+1;'7&?.2$&/&+08'

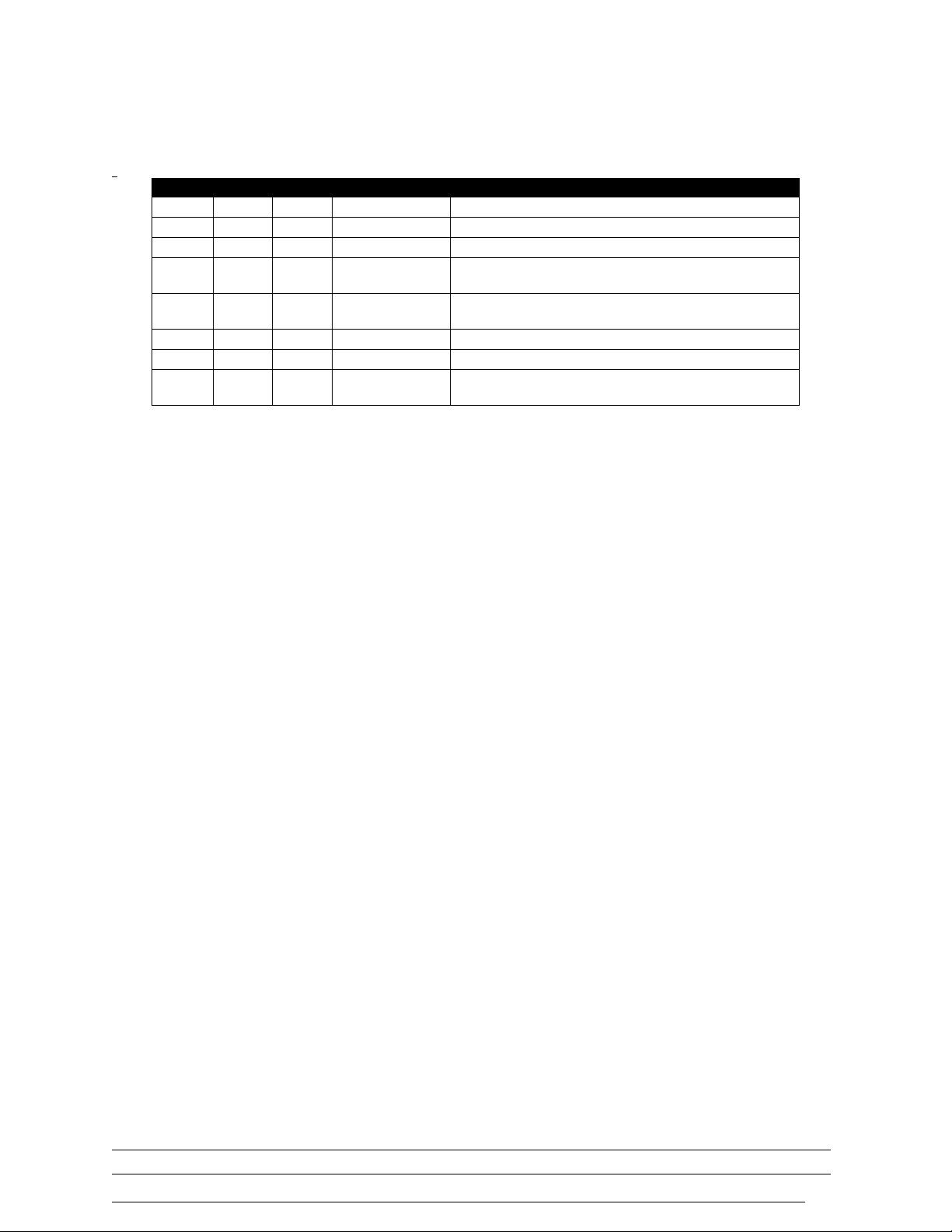

Table 1 provides a summary of the functionality and requirements of the LCD Module.

Table 1 Unified Display for X34 General Description

Category

Parameter

Specification

Reference

Section

General

LCD TYPE

Normally-Black Transmissive, Mobile-IPS a-SI TFT-LCD

4.1

Product Code

TBA

N/A

Manufacturer

LGD

N/A

Manufacturer P/N

TBD

N/A

Diagonal

13.3”

Pixel Format

2560 (RGB stripe, H) x 1600 (V)

4.4

Pixel Pitch

0.03725(V) x 3 x 0.11175(H) mm

4.3

Color Depth

24-bits (8R, 8G, 8B)

Packaging

Protective film on front & back polarizer w/ pull tab. LCD

board packaged and sealed in ESD protection bags in class

10k or better clean room with all the glass edge & flex/ PCB

protections

Electrical

Interface

5V input power, 4 lane DisplayPort interface

7.4.3

Power

Consumption

2.0W Typical (Web Black/White/Mosaic)

2.6W Worse Case (R/G/B)

7.4.5

Inversion

Z-inversion (1-dot)

4.6

Color Filter ITO

Sheet Resistance

2.0 kΩ / square typical

2.5 kΩ / square maximum

7.12

Mechanical

Active Area

286.08 mm (H) X 178.80 mm (V)

5.2

Minimum Viewing

Area

354.11 mm x 231.70 mm

Module Outline

Size

354.49 mm x 237.30 mm

5.1

LCD Panel

Receptacle

iPEX:CAB CA 30 pins: 20525-130E-02

7.4.1

Cable Plug

iPEX:CAB CA 30 pins: 20523-130T-01

7.4.1

Perimeter Flatness

0.3 mm

Vertical Bending

-5 to 15

Mass

125 (typical), max 130 g

5.3

Environmental

Operating

Temperature

(functioning)

0°C to +60°C

9.5

Storage

Temperature

25 +/- 3 0C and 60% +/- 5% relative humidity to maintain

panel flatness

="!" ,28<;15'@-%&;'

The unit shall be Normally-Black, Transmissive, Mobile-IPS a-SI TFT-LCD with

compensation film polarizer.

Page 12

THE INFORMATION CONTAINED HEREIN IS THE PROPERTY OF APPLE, INC. THE POSSESSOR AGREES TO THE FOLLOWING:

(i) TO MAINTAIN THIS DOCUMENT IN CONFIDENCE (ii) NOT TO REPRODUCE OR COPY IT (iii) NOT TO REVEAL OR PUBLISH IT IN WHOLE OR IN PART

Apple Inc.

Size: Letter

Scale: NONE

Page 12 of 67

Title: ERIS, DSPL, LCD MODULE, LGD, X34 DWG Number: 069-8326 ___Rev. B___

="6" )2A&;'B-+(2C.$102-+'

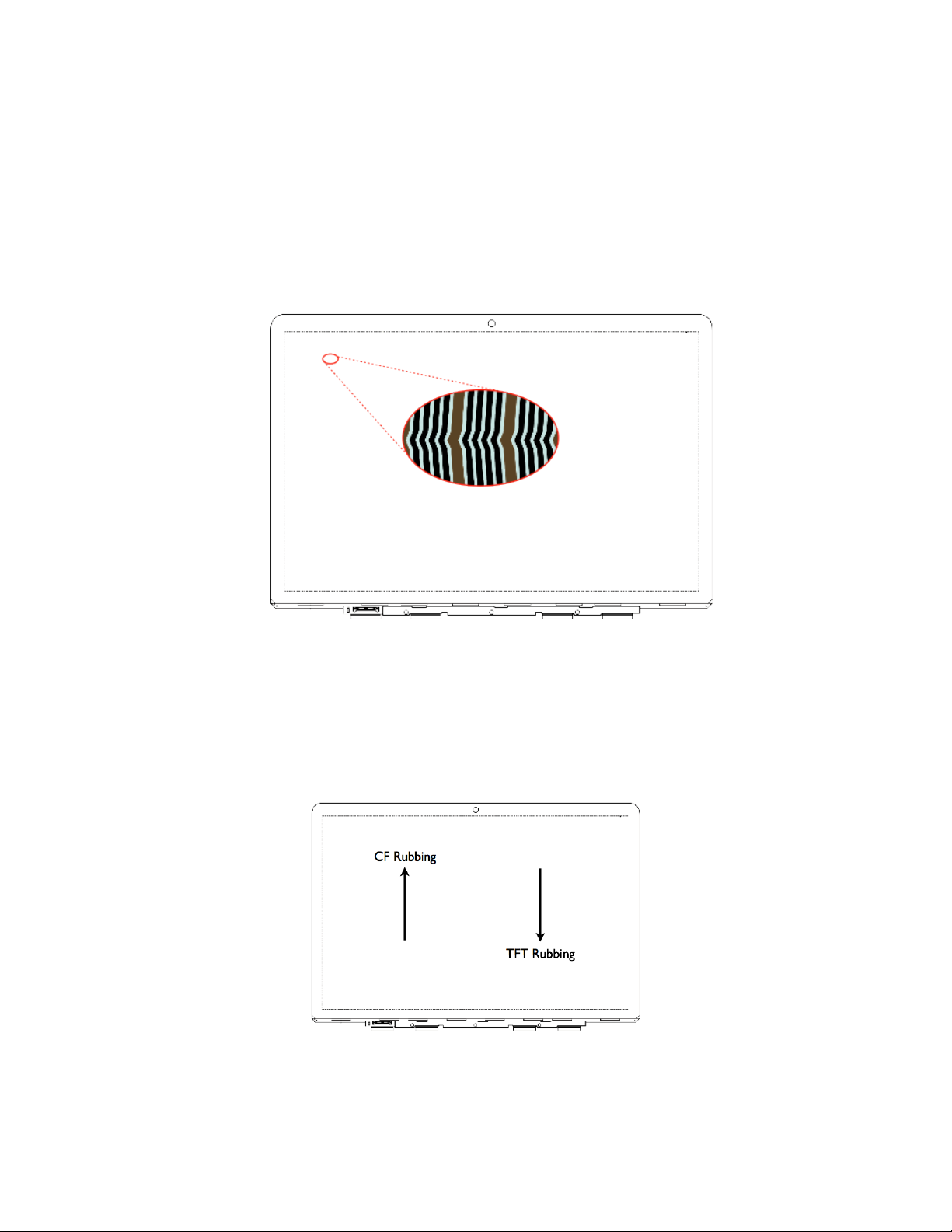

The unit shall be configured using a RGB Vertical Stripe, Vertical Chevron Dual Domain.

="9" )2A&;')20*4'

The unit shall provide a sub pixel pitch no greater than 0.03725 mm x 0.11175 mm

="=" 7&8-;.02-+'

The unit shall be no less than 2560 (RGB stripe, H) x 1600 (V).

Figure 2 Resolution Overview

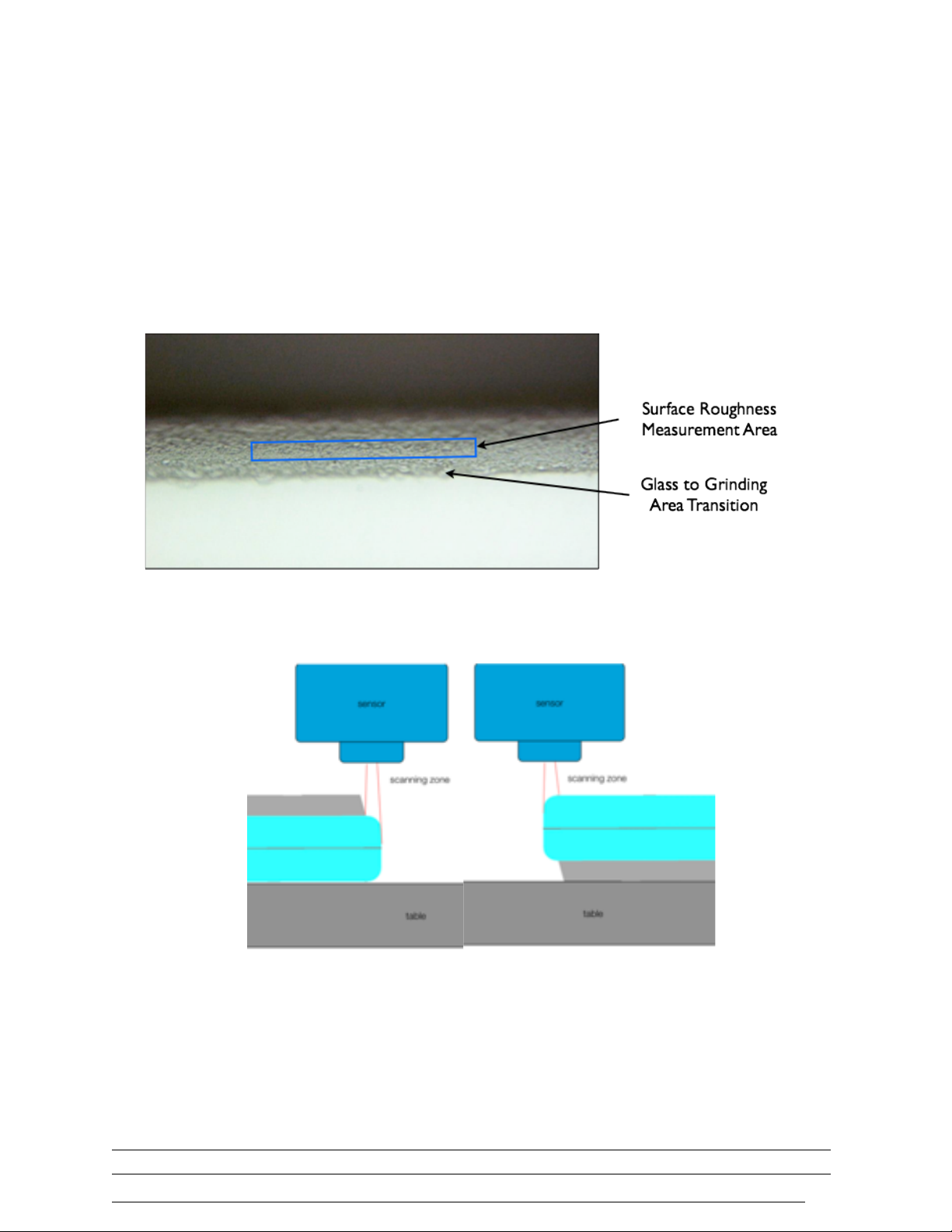

="D" 7.EE2+C',2$&*02-+'

The unit shall have Color Filter (CF) Rubbing from the bottom of the module to the top and

shall have TFT Rubbing from the top of the module to the bottom as shown in Figure 3.

Figure 3 Rubbing Directions

Page 13

THE INFORMATION CONTAINED HEREIN IS THE PROPERTY OF APPLE, INC. THE POSSESSOR AGREES TO THE FOLLOWING:

(i) TO MAINTAIN THIS DOCUMENT IN CONFIDENCE (ii) NOT TO REPRODUCE OR COPY IT (iii) NOT TO REVEAL OR PUBLISH IT IN WHOLE OR IN PART

Apple Inc.

Size: Letter

Scale: NONE

Page 13 of 67

Title: ERIS, DSPL, LCD MODULE, LGD, X34 DWG Number: 069-8326 ___Rev. B___

="F" G+0&$(1* & '1 + %',$2H2+C'I*4&/&'

The unit shall provide a 5V 4-lane DisplayPort interface, requiring Hsync and Vsync

signals, along with DE (Data Enable) mode, 1-dot Z-inversion scheme.

="J" >$-+0'I.$(1*&'K$&10/&+0'

The front surface of the unit shall provide a Dry AR1.5 coating that meets the requirements

specified herein.

D" @&*41+2*1;'7&?.2$&/&+08'

D"!" L+H&;-<&',2/&+82-+8'1+%'K-;&$1+*&8'

The unit shall meet the dimensional requirements specified in 069-7821 LCD, MCO, X34.

D"6" 3*02H&'3$&1'

The unit shall meet the active area requirement specified in 069-7821 LCD, MCO, X34.

D"9" @188'

The unit mass shall not exceed the mass specified in 069-7821 LCD, MCO, X34.

D"=" M+20'>;10+&88'

The LCD module shall meet the flatness requirement specified in 069-7821 LCD, MCO,

X34.

D"="!" >;10+&88'@&18.$&/&+0'7&?.2$&/&+08'

All units shall require a flatness measurement after aging that meet the following

requirements:

• Flatness measurement shall be completed within 24 hours after removal from

aging chamber

• Post aging, unit shall be stored in 25 +/- 3 0C and 60% +/- 5% relative humidity

D"D" LA<-8&%'3$&1'1+%'7&80$2*02-+8'

The display module shall not have exposed edges or components, which may cause injury or

damage during handling, inspection, assembly, and service. Exposed areas of the display

module (those not protected or shielded by construction) must be insulated and otherwise

protected to eliminate the possibility of electrical shorting or destructive ESD discharges

(per Section 7.2) during handling, inspection, assembly, and service.

D"F" L%C&'N.1;205'7&?.2$&/&+08'

The edge quality of the module shall be measured using an optical profiler such as the

Keyence VK-9700 or equivalent.

Page 14

THE INFORMATION CONTAINED HEREIN IS THE PROPERTY OF APPLE, INC. THE POSSESSOR AGREES TO THE FOLLOWING:

(i) TO MAINTAIN THIS DOCUMENT IN CONFIDENCE (ii) NOT TO REPRODUCE OR COPY IT (iii) NOT TO REVEAL OR PUBLISH IT IN WHOLE OR IN PART

Apple Inc.

Size: Letter

Scale: NONE

Page 14 of 67

Title: ERIS, DSPL, LCD MODULE, LGD, X34 DWG Number: 069-8326 ___Rev. B___

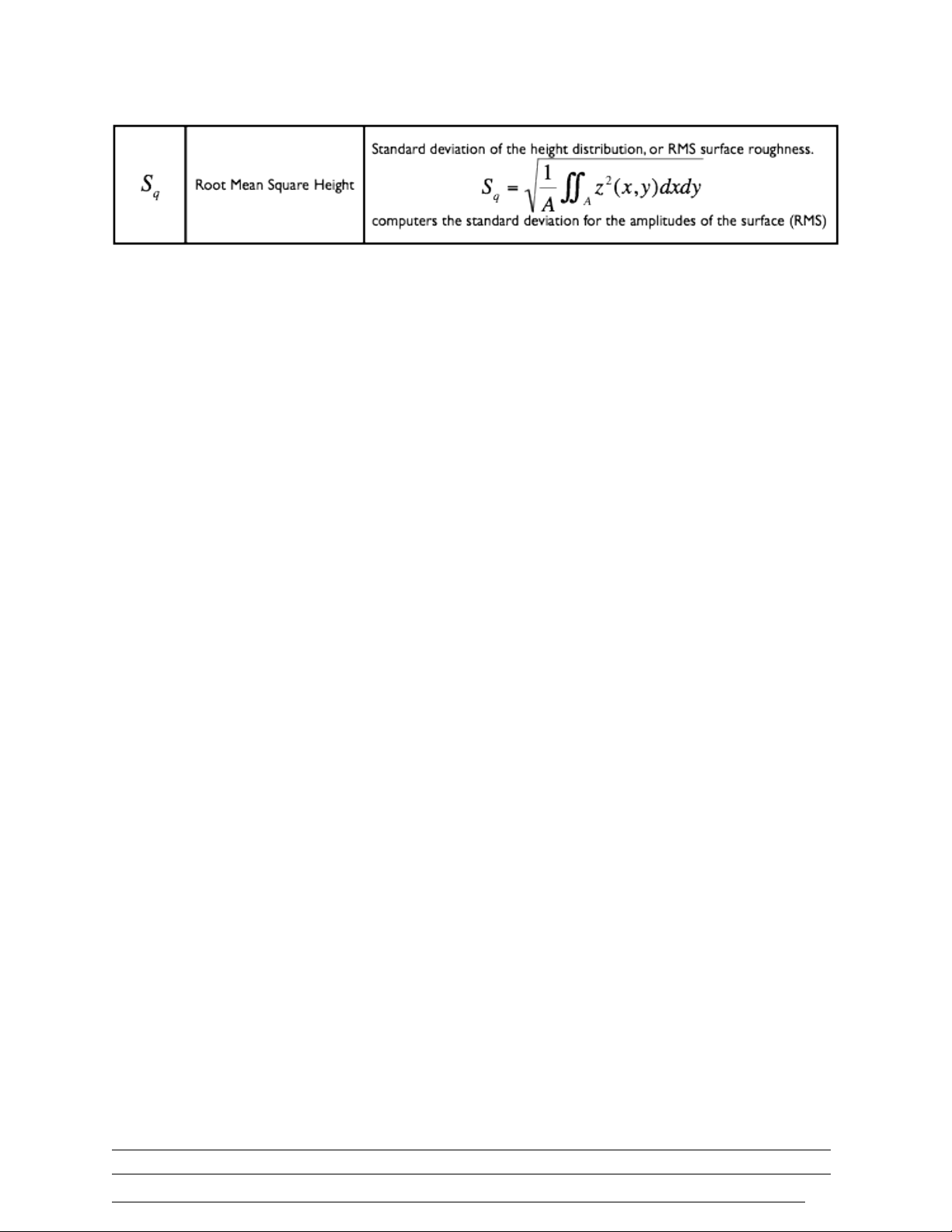

D"F"!" I.$(1*&'>2+284'7&?.2$&/&+08'

!"#"$"$" %&'()*&+&,-./&0)1*&+&,-(.

The following settings on the Keyence VK-9700 shall be used to measure the surface

finish requirements.

•

20x Objective

•

Measurement Area: 0.25 mm x 0.1 mm

•

Measurement Area distance from Glass Grinding Transition: 0.015 mm

Figure 4 Surface Roughness Measurement Area

Figure 5 Surface Roughness Measurement Test Configurations

!"#"$"2" ../33-.%&',.40)'*&.5/06.

The ground edge surface Root Mean Square shall not exceed 2.25 um.

Page 15

THE INFORMATION CONTAINED HEREIN IS THE PROPERTY OF APPLE, INC. THE POSSESSOR AGREES TO THE FOLLOWING:

(i) TO MAINTAIN THIS DOCUMENT IN CONFIDENCE (ii) NOT TO REPRODUCE OR COPY IT (iii) NOT TO REVEAL OR PUBLISH IT IN WHOLE OR IN PART

Apple Inc.

Size: Letter

Scale: NONE

Page 15 of 67

Title: ERIS, DSPL, LCD MODULE, LGD, X34 DWG Number: 069-8326 ___Rev. B___

Root Mean Square is defined as:

!"#"$"7" .%'81+)+.9&1:;-.5/<=+'86.

The ground edge Maximum Height shall not exceed 25 um where maximum height is

defined as distance between the highest peak and the lowest valley.

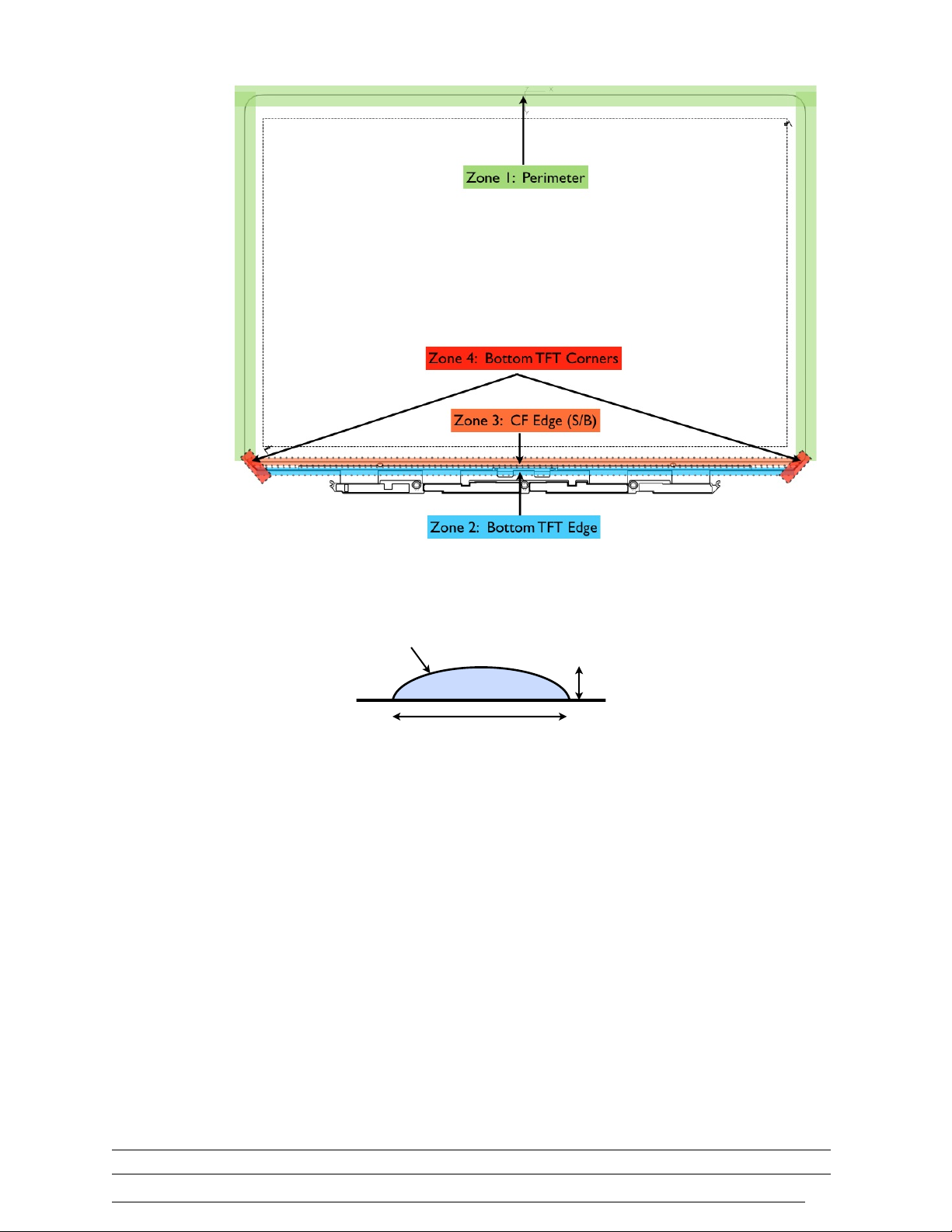

D"F"6" 'L%C&',&(&*0'7&?.2$&/&+08'

The module shall have an edge scan completed using the Meere Company X35 EDGE

INSPECTION SYSTEM Model No. EI-AGTT-17.3.

The ground edge surface shall not exceed the following chip size requirements as

specified for each grinding zone (see Figure 6).

• Zone 1: CF/TFT Glass Perimeter (0.6t)

o 0 defects greater than 50 um in any direction

• Zone 2: Bottom TFT Ledge (0.3t)

o 0 defects greater than 50 um in any direction

• Zone 3: CF Edge (Scribe / Break)

o X-Dimension: Defect shall not exceed 500 um

o Y-Dimension: Defect shall not exceed 500 um

• Zone 4: Bottom TFT Corners (0.3t)

o X- Dimension: No defect length requirement

o Y-Dimension: Defect shall not exceed 150 um

Page 16

THE INFORMATION CONTAINED HEREIN IS THE PROPERTY OF APPLE, INC. THE POSSESSOR AGREES TO THE FOLLOWING:

(i) TO MAINTAIN THIS DOCUMENT IN CONFIDENCE (ii) NOT TO REPRODUCE OR COPY IT (iii) NOT TO REVEAL OR PUBLISH IT IN WHOLE OR IN PART

Apple Inc.

Size: Letter

Scale: NONE

Page 16 of 67

Title: ERIS, DSPL, LCD MODULE, LGD, X34 DWG Number: 069-8326 ___Rev. B___

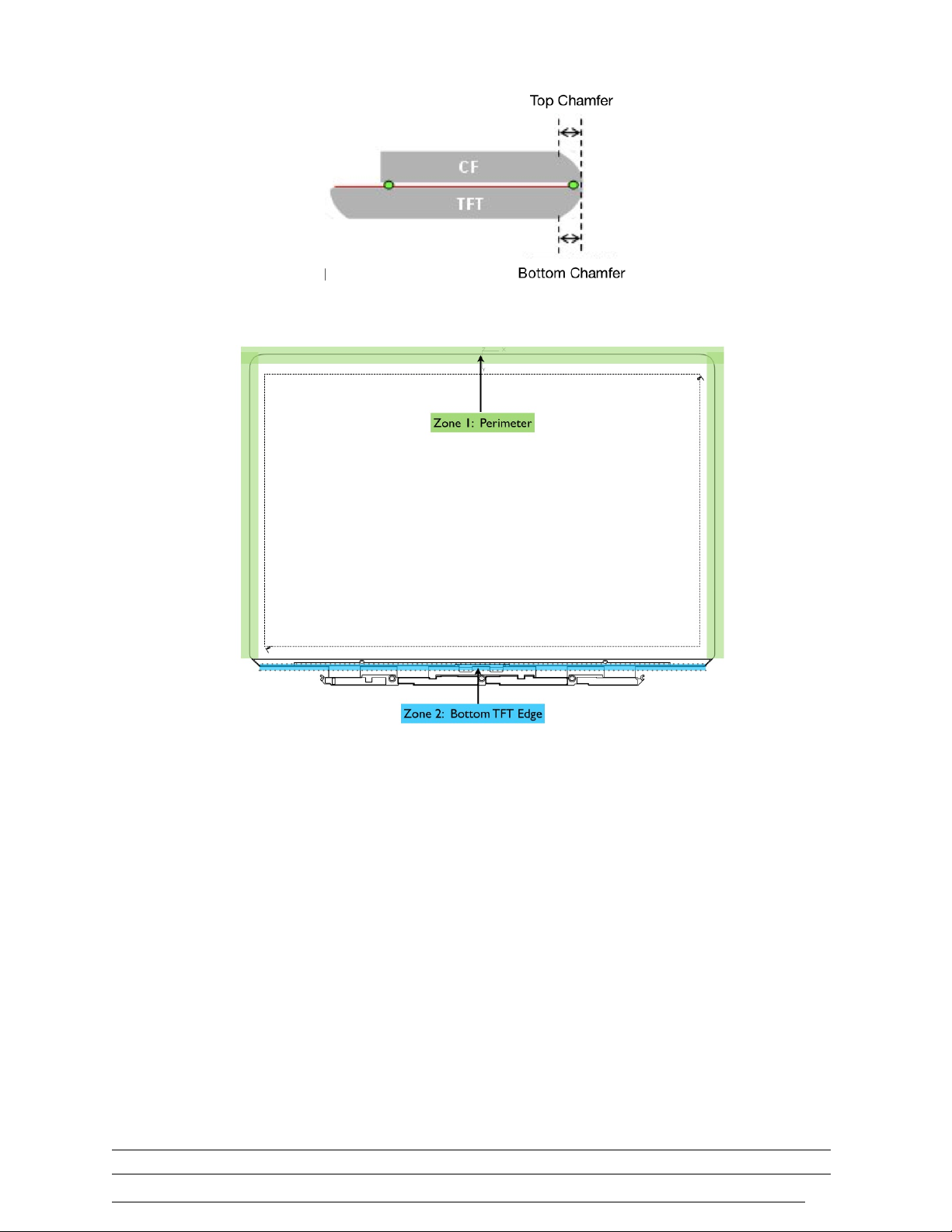

Figure 6 Grinding Zone Definitions

Figure 7 Glass Chip Profile Definition

D"F"9" :$-.+%'I.$(1*&')$-(2;&'

The top and bottom chamfer size (Figure 8) of the glass shall meet the following

requirements shown below in the specified zone (Figure 9):

• Zone 1: CF/TFT Glass Perimeter (0.6t):

o 200 um ≥ chamfer size ≥ 60 um

• Zone 2: Bottom TFT Ledge (0.3t)

o 200 um ≥ chamfer size ≥ 50 um

X-Dimension

Y-Dimension

Glass Chip

Page 17

THE INFORMATION CONTAINED HEREIN IS THE PROPERTY OF APPLE, INC. THE POSSESSOR AGREES TO THE FOLLOWING:

(i) TO MAINTAIN THIS DOCUMENT IN CONFIDENCE (ii) NOT TO REPRODUCE OR COPY IT (iii) NOT TO REVEAL OR PUBLISH IT IN WHOLE OR IN PART

Apple Inc.

Size: Letter

Scale: NONE

Page 17 of 67

Title: ERIS, DSPL, LCD MODULE, LGD, X34 DWG Number: 069-8326 ___Rev. B___

Figure 8 Chamfer of grinding edge profile

Figure 9 Grinding Profile Zone Definitions

D"J" )-;1$2O&$'L%C&'7&?.2$&/&+0'

The laser cut polarizer edge with release lines removed shall be inspected using a variable

pressure electron microscope to evaluate polarizer edge damage.

Polarizer overhang on the edge of the polarizer caused from laser cutting shall not exceed 15

um as shown in Figure 10.

Page 18

THE INFORMATION CONTAINED HEREIN IS THE PROPERTY OF APPLE, INC. THE POSSESSOR AGREES TO THE FOLLOWING:

(i) TO MAINTAIN THIS DOCUMENT IN CONFIDENCE (ii) NOT TO REPRODUCE OR COPY IT (iii) NOT TO REVEAL OR PUBLISH IT IN WHOLE OR IN PART

Apple Inc.

Size: Letter

Scale: NONE

Page 18 of 67

Title: ERIS, DSPL, LCD MODULE, LGD, X34 DWG Number: 069-8326 ___Rev. B___

Figure 10 Polarizer Overhang Requirement

D"P" @&*41+2*1;'I01*QR.<'

The unit shall meet the stack-up requirements specified in 069-7821 LCD, MCO, X34.

Mechanical Stack-up

Part #

Nominal Thickness

(mm)

Top Polarizer

Nitto Denko NATZ-AR1.5

0.166

LCD Glass CF

-

0.30

LCD Glass TFT

-

0.30

Bottom Polarizer (glossy, APCF)

Nitto Denko APCFG3CVTT

0.162

Total

-

0.928

D"S" ,$2H&$'GB'@&*41+2*1;'7&?.2$&/&+08'

The driver IC shall meet the envelope requirements specified in 069-7821 LCD, MCO, X34.

D"S"!" ',$2H&$'GB'L%C&'N.1;205'

The Driver IC chip depth shall not exceed 35 um on any edge as shown in Figure 11.

Page 19

THE INFORMATION CONTAINED HEREIN IS THE PROPERTY OF APPLE, INC. THE POSSESSOR AGREES TO THE FOLLOWING:

(i) TO MAINTAIN THIS DOCUMENT IN CONFIDENCE (ii) NOT TO REPRODUCE OR COPY IT (iii) NOT TO REVEAL OR PUBLISH IT IN WHOLE OR IN PART

Apple Inc.

Size: Letter

Scale: NONE

Page 19 of 67

Title: ERIS, DSPL, LCD MODULE, LGD, X34 DWG Number: 069-8326 ___Rev. B___

Figure 11 Driver IC Edge Quality

D"S"6" ',$2H&$'GB'K-<'I.$(1*&'7&?.2$&/&+0'

The top surface of the driver IC shall meet the following requirements as defined in

ASME B.46.1-1995

• Ra ≤ 0.015 um

• Rmax ≤ 0.100 um

D"!T" M+20'L%C&'G+Q'7&?.2$&/&+0'

A black halogen free ink approved by Apple shall be applied to the edge of the unit in the

location specified in 069-7821 LCD, MCO, X34.

F" K4&$/1;'7&?.2$&/&+08'

The unit white point color shift over temperature shall meet ∆𝑢!𝑣!≤ 0.008 from 30 °C to 50

°C.

J" L;&*0$2*1;'7&?.2$&/&+08'

The unit shall meet the electrical requirements as specified in 069-8336, X34 Display TCON

PCBA Engineering Requirements Specification (ERS), LGD.

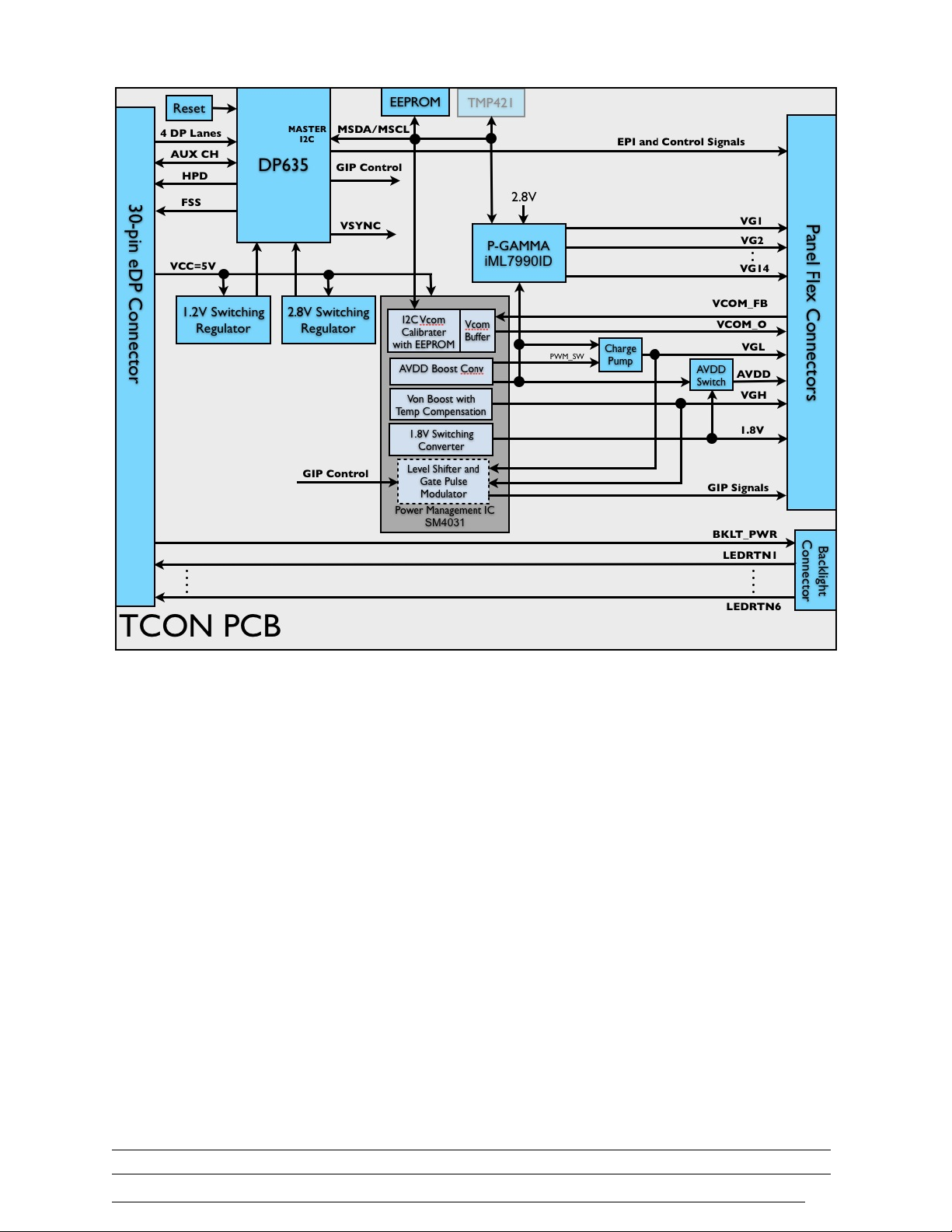

J"!" U;-*Q',21C$1/''

The unit shall meet the interface requirements as specified in 069-8336, X34 Display TCON

PCBA Engineering Requirements Specification (ERS), LGD.

The block diagram is shown in Figure 12 as reference only.

Page 20

THE INFORMATION CONTAINED HEREIN IS THE PROPERTY OF APPLE, INC. THE POSSESSOR AGREES TO THE FOLLOWING:

(i) TO MAINTAIN THIS DOCUMENT IN CONFIDENCE (ii) NOT TO REPRODUCE OR COPY IT (iii) NOT TO REVEAL OR PUBLISH IT IN WHOLE OR IN PART

Apple Inc.

Size: Letter

Scale: NONE

Page 20 of 67

Title: ERIS, DSPL, LCD MODULE, LGD, X34 DWG Number: 069-8326 ___Rev. B___

Figure 12 Unit Electrical Block Diagram (FOR REFERENCE ONLY)

J"6" ,28<;15')BU'I*4&/102*8'

The unit shall meet the schematic diagram as specified in 069-8336, X34 Display TCON

PCBA Engineering Requirements Specification (ERS), LGD.

• Schematics shall be provided with the following information:

• Numbered by version and date coding, PDF searchable

• Include signal-net page-number tags where signal-nets transfer to other pages

• Resistors to show the value, tolerance, and package information

• Capacitors to show the value, rating, tolerance, material, and package information

• Inductors to show the value, rating (current & power), tolerance, and package

information

• Fuses to show the rating and package information.

• ICs, Diodes, Inductors, Fuses, and Connectors must show the Manufacturer,

Manufacturer’s Part Number, and package information.

• Test points

Page 21

THE INFORMATION CONTAINED HEREIN IS THE PROPERTY OF APPLE, INC. THE POSSESSOR AGREES TO THE FOLLOWING:

(i) TO MAINTAIN THIS DOCUMENT IN CONFIDENCE (ii) NOT TO REPRODUCE OR COPY IT (iii) NOT TO REVEAL OR PUBLISH IT IN WHOLE OR IN PART

Apple Inc.

Size: Letter

Scale: NONE

Page 21 of 67

Title: ERIS, DSPL, LCD MODULE, LGD, X34 DWG Number: 069-8326 ___Rev. B___

J"9" ,28<;15')BU'V15-.0'

The unit shall meet PCB layout requirements specified in 069-8336, X34 Display TCON

PCBA Engineering Requirements Specification (ERS), LGD. .

The PCB CAD layout files shall be provided for Apple approval shall be an Allegro .brd file

format. The other acceptable format is Specctra format - AutoVue compatible.

J"=" 3*02H&'B-/<-+&+08'

The unit shall active components requirements as specified in 069-8336, X34 Display

TCON PCBA Engineering Requirements Specification (ERS), LGD.

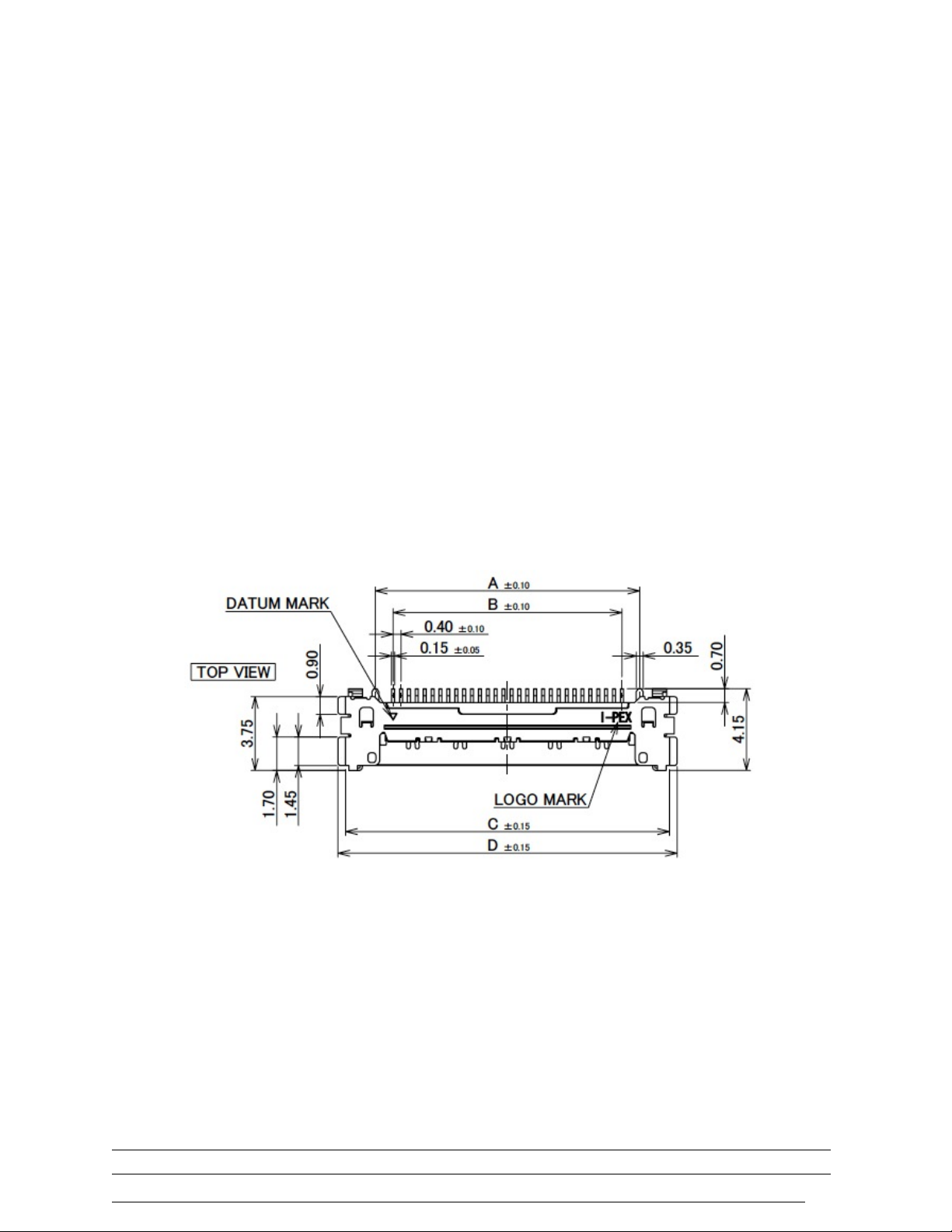

J"="!" L;&*0$2*1;'G+0&$(1*&'7&?.2$&/&+08''

>"?"$"$" @3,,&A-3*./&0)1*&+&,-(.

The unit shall provide an IPEX 20525-130E-02 connector (1.0 mm thickness, lock-in

type) as shown in Figure 13. Pin 1 on the connector is defined by the datum mark

(triangle) located on the connector (see Figure 73).

Apple will provide an IPEX 20523-130T-01 mating connector (micro-coax type).

The unit connector and mating connect shall have palladium-nickel plating (silver color).

Figure 13 Connector Drawing (PCB Side)

>"?"$"2" @3,,&A-3*.B1,.C((1:,+&,-(.

The unit shall meet connector pin assignments specified in 069-8336, X34 Display

TCON PCBA Engineering Requirements Specification (ERS), LGD.

Table 2 presents the connector pin assignments and is for reference only.

Page 22

THE INFORMATION CONTAINED HEREIN IS THE PROPERTY OF APPLE, INC. THE POSSESSOR AGREES TO THE FOLLOWING:

(i) TO MAINTAIN THIS DOCUMENT IN CONFIDENCE (ii) NOT TO REPRODUCE OR COPY IT (iii) NOT TO REVEAL OR PUBLISH IT IN WHOLE OR IN PART

Apple Inc.

Size: Letter

Scale: NONE

Page 22 of 67

Title: ERIS, DSPL, LCD MODULE, LGD, X34 DWG Number: 069-8326 ___Rev. B___

Table 2 Display Subsystem Connector Pin Assignment (FOR REFERENCE ONLY)

Pin

Signal

Description

Cable Gauge

1

BKLT_PWR

48V

Solid AWG36

2

N.C.

Arc prevention

-

3

LEDRTN6

Backlight Return Current

uCoax AWG42

4

LEDRTN5

Backlight Return Current

uCoax AWG42

5

LEDRTN4

Backlight Return Current

uCoax AWG42

6

LEDRTN3

Backlight Return Current

uCoax AWG42

7

LEDRTN2

Backlight Return Current

uCoax AWG42

8

LEDRTN1

Backlight Return Current

uCoax AWG42

9

HPD

Hot Plug

uCoax AWG42

10

FSS

Frame Sync mux

uCoax AWG42

11

AUX_P

eDP AUX

uCoax AWG42

12

AUX_N

eDP AUX

uCoax AWG42

13

GND

Shield

-

14

DP0_P

eDP pair 0

90Ω Twin-Ax AWG40

15

DP0_N

eDP Pair 0

16

GND

Shield

-

17

DP1_P

eDP pair 1

90Ω Twin-Ax AWG40

18

DP1_N

eDP pair 1

19

GND

Shield

-

20

DP2_P

eDP pair 2

90Ω Twin-Ax AWG40

21

DP2_N

eDP pair 2

22

GND

Shield

-

23

DP3_P

eDP pair 3

90Ω Twin-Ax AWG40

24

DP3_N

eDP pair 3

25

GND

Digital Ground

Solid AWG36

26

GND

Digital Ground

Solid AWG36

27

GND

Digital Ground

Solid AWG36

28

VCC

5V

Solid AWG36

29

VCC

5V

Solid AWG36

30

VCC

5V

Solid AWG36

J"="6" LA0&+%&%',28<;15'G%&+02(2*102-+',101'WL,G,X'G+0&$(1*&''

The unit shall meet EDID interface requirements specified in 069-8336, X34 Display

TCON PCBA Engineering Requirements Specification (ERS), LGD and shown in Table

3 (for reference only).

Page 23

THE INFORMATION CONTAINED HEREIN IS THE PROPERTY OF APPLE, INC. THE POSSESSOR AGREES TO THE FOLLOWING:

(i) TO MAINTAIN THIS DOCUMENT IN CONFIDENCE (ii) NOT TO REPRODUCE OR COPY IT (iii) NOT TO REVEAL OR PUBLISH IT IN WHOLE OR IN PART

Apple Inc.

Size: Letter

Scale: NONE

Page 23 of 67

Title: ERIS, DSPL, LCD MODULE, LGD, X34 DWG Number: 069-8326 ___Rev. B___

Table 3 EDID Data (FOR REFERENCE ONLY)

Field Name

#

Raw Hex

Interpretation

Header

0-7

0x00, 0xFF,

0xFF, 0xFF,

0xFF, 0xFF,

0xFF, 0x00

ID Manufacturer

Name

8-9

0x06, 0x10

APP

ID Product Code

1011

0x14, 0xA0

ID Serial Number

1215

0x00, 0x00,

0x00, 0x00

0l

Date of

Manufacture

1617

0x0A, 0x16

March 4, 2012

EDID Structure

Version/Revision

Number

1819

0x01, 0x04

1.4

Video Input

Definition

20

0xA5

Bit 7 = 1, Display accepts digital

input

Color bit depth is 8 bits per primary

color

DisplayPort is supported

Max Horizontal

Image Size

21

0x1D

29 cm

Max Vertical

Image Size

22

0x12

18 cm

Display Transfer

Characteristic

(Gamma)

23

0x78

2.20

Feature and DPMS

Support

24

0x02

Bit 7 = 0, Display doesn't support DPMS

Stand-by

Bit 6 = 0, Display doesn't support DPMS

Suspend

Bit 5 = 0, Display doesn't support DPMS

Active Off

Bits [4:3] = Supported Color Encoding

Formats, [0:0] = RGB 4:4:4 is supported

Bit 2 = 0, Display doesn't use the sRGB

standard default color space as its

primary color space

Bit 1 = 1, Display's preferred timing

is native

Bit 0 = 0, Multi-scan display

Color

Characteristics

2534

0x6F

0xB1

0xA7

0x55

0x4C

0x9E

0x25

0x0C

0x50

0x54

Red_x Value = 0.65236

Red_y Value = 0.33206

Green_x Value = 0.29692

Green_y Value = 0.61723

Blue_x Value = 0.14456

Blue_y Value = 0.04692

White_x Value = 0.31250

White_y Value = 0.32814

Established

Timing 1

35

0x00

Established

Timing 2

36

0x00

Page 24

THE INFORMATION CONTAINED HEREIN IS THE PROPERTY OF APPLE, INC. THE POSSESSOR AGREES TO THE FOLLOWING:

(i) TO MAINTAIN THIS DOCUMENT IN CONFIDENCE (ii) NOT TO REPRODUCE OR COPY IT (iii) NOT TO REVEAL OR PUBLISH IT IN WHOLE OR IN PART

Apple Inc.

Size: Letter

Scale: NONE

Page 24 of 67

Title: ERIS, DSPL, LCD MODULE, LGD, X34 DWG Number: 069-8326 ___Rev. B___

Manufacturer's

Timings

37

0x00

Standard Timing

Identification 1

3839

0x01, 0x01

not used

Standard Timing

Identification 2

4041

0x01, 0x01

not used

Standard Timing

Identification 3

4243

0x01, 0x01

not used

Standard Timing

Identification 4

4445

0x01, 0x01

not used

Standard Timing

Identification 5

4647

0x01, 0x01

not used

Standard Timing

Identification 6

4849

0x01, 0x01

not used

Standard Timing

Identification 7

5051

0x01, 0x01

not used

Standard Timing

Identification 8

5253

0x01, 0x01

not used

Detailed Timing

Description 1

5471

0xE2

0x68

0x00

0xA0

0xA0

0x40

0x2E

0x60

0x30

0x20

0x36

0x00

0x1E

0xB3

0x10

0x00

0x00

0x1A

Pixel Clock = 268.50 MHz

Horizontal Active = 2560 Pixels

Horizontal Blanking = 160 Pixels

Vertical Active = 1600 Lines

Vertical Blanking = 46 Lines

Horizontal Sync Offset (Front Porch) =

48 Pixels (from blanking start)

Horizontal Sync Pulse Width = 32 Pixels

Vertical Sync Offset = 3 lines

Vertical Sync Pulse Width = 6 Lines

Horizontal Image Size = 286 mm

Vertical Image Size = 179 mm

Horizontal Border = 0 Pixels

Vertical Border = 0 Lines

Flags:

Bit 7 = 0, Non-interlaced

Bit [6:5:0] = [0:0:x], Normal display

(non-stereo)

Bit [4:3] = [1:1], Digital Seperate

Syncs

Bit 2 = 0, negative true VSync

Bit 1 = 1, positive true HSync

Calculated Horizontal Refresh = 98.71

kHz

Calculated Vertical Refresh = 59.97 Hz

Monitor

Description 2

7289

0x00

0x00

0x00

0xFC

0x00

0x43

0x6F

0x6C

0x6F

0x72

0x20

0x4C

0x43

0x44

Monitor Name:

Color LCD

Page 25

THE INFORMATION CONTAINED HEREIN IS THE PROPERTY OF APPLE, INC. THE POSSESSOR AGREES TO THE FOLLOWING:

(i) TO MAINTAIN THIS DOCUMENT IN CONFIDENCE (ii) NOT TO REPRODUCE OR COPY IT (iii) NOT TO REVEAL OR PUBLISH IT IN WHOLE OR IN PART

Apple Inc.

Size: Letter

Scale: NONE

Page 25 of 67

Title: ERIS, DSPL, LCD MODULE, LGD, X34 DWG Number: 069-8326 ___Rev. B___

0x0A

0x20

0x20

0x20

Monitor

Description 3

90107

0x00

0x00

0x00

0x10

0x00

0x00

0x00

0x00

0x00

0x00

0x00

0x00

0x00

0x00

0x00

0x00

0x00

0x00

Dummy descriptor.

Monitor

Description 4

108

125

0x00

0x00

0x00

0x10

0x00

0x00

0x00

0x00

0x00

0x00

0x00

0x00

0x00

0x00

0x00

0x00

0x00

0x00

Dummy descriptor.

Extension Flag

126

0x00

0

Checksum

127

0x8D

141

J"="9" )-Y&$'I.<<;5'7&?.2$&/&+08'

The unit shall meet the internal power supply requirements in 069-8336, X34 Display

TCON PCBA Engineering Requirements Specification (ERS), LGD.

J"="=" I2C+1;'K2/2+C'

>"?"?"$" D+E&FF&F.G1(HI'JB3*-.5&GB6.41:,'I./&0)1*&+&,-.

The unit shall meet the digital communications interface specified in VESA DisplayPort

Standard, Version 1, Revision 1a and VESA Embedded DisplayPort Standard, Version

1.3.

Page 26

THE INFORMATION CONTAINED HEREIN IS THE PROPERTY OF APPLE, INC. THE POSSESSOR AGREES TO THE FOLLOWING:

(i) TO MAINTAIN THIS DOCUMENT IN CONFIDENCE (ii) NOT TO REPRODUCE OR COPY IT (iii) NOT TO REVEAL OR PUBLISH IT IN WHOLE OR IN PART

Apple Inc.

Size: Letter

Scale: NONE

Page 26 of 67

Title: ERIS, DSPL, LCD MODULE, LGD, X34 DWG Number: 069-8326 ___Rev. B___

>"?"?"2" G1(HI'J.K1+1,:.G'-'.

The unit shall meet display timing data requirements in 069-8336, X34 Display TCON

PCBA Engineering Requirements Specification (ERS), LGD.

>"?"?"7" @3I3*.L,H)-.G'-'./&M&*&,A&.

The color data reference specified in Table 4 shall be used for the reference for color

versus data input.

The brightness of each primary color (red, green and blue) is based on the 8-bit gray scale

data input for the color. The higher the binary input, the brighter the color.

Table 4 Color Data Reference

Input Color Data

Color

Red

MSB LSB

Green

MSB LSB

Blue

MSB LSB

R7

R6

R5

R4

R3

R2

R1

R0

G7

G6

G5

G4

G3

G2

G1

G0

B7

B6

B5

B4

B3

B2

B1

B0

Basic

Color

s

Black

Red(255)

Green(255)

Blue(255)

Cyan

Magenta

Yellow

White

0

1

0

0

0

1

1

1

0

1

0

0

0

1

1

1

0

1

0

0

0

1

1

1

0

1

0

0

0

1

1

1

0

1

0

0

0

1

1

1

0

1

0

0

0

1

1

1

0

1

0

0

0

1

1

1

0

1

0

0

0

1

1

1

0

0

1

0

1

0

1

1

0

0

1

0

1

0

1

1

0

0

1

0

1

0

1

1

0

0

1

0

1

0

1

1

0

0

1

0

1

0

1

1

0

0

1

0

1

0

1

1

0

0

1

0

1

0

1

1

0

0

1

0

1

0

1

1

0

0

0

1

1

1

0

1

0

0

0

1

1

1

0

1

0

0

0

1

1

1

0

1

0

0

0

1

1

1

0

1

0

0

0

1

1

1

0

1

0

0

0

1

1

1

0

1

0

0

0

1

1

1

0

1

0

0

0

1

1

1

0

1

Red

Red(00)

Dark

Red(01)

Red(02)

Red(253)

Red(254)

Red(255)

Bright

0

0

0

:

1

1

1

0

0

0

:

1

1

1

0

0

0

:

1

1

1

0

0

0

:

1

1

1

0

0

0

:

1

1

1

0

0

0

:

1

1

1

0

0

1

:

0

1

1

0

1

0

:

1

0

1

0

0

0

:

0

0

0

0

0

0

:

0

0

0

0

0

0

:

0

0

0

0

0

0

:

0

0

0

0

0

0

:

0

0

0

0

0

0

:

0

0

0

0

0

0

:

0

0

0

0

0

0

:

0

0

0

0

0

0

:

0

0

0

0

0

0

:

0

0

0

0

0

0

:

0

0

0

0

0

0

:

0

0

0

0

0

0

:

0

0

0

0

0

0

:

0

0

0

0

0

0

:

0

0

0

0

0

0

:

0

0

0

Gree

n

Green(00)

Dark

Green(01)

Green(02)

Green(253)

Green(254)

Green(255)

Bright

0

0

0

:

0

0

0

0

0

0

:

0

0

0

0

0

0

:

0

0

0

0

0

0

:

0

0

0

0

0

0

:

0

0

0

0

0

0

:

0

0

0

0

0

0

:

0

0

0

0

0

0

:

0

0

0

0

0

0

:

1

1

1

0

0

0

:

1

1

1

0

0

0

:

1

1

1

0

0

0

:

1

1

1

0

0

0

:

1

1

1

0

0

0

:

1

1

1

0

0

1

:

0

1

1

0

1

0

:

1

0

1

0

0

0

:

0

0

0

0

0

0

:

0

0

0

0

0

0

:

0

0

0

0

0

0

:

0

0

0

0

0

0

:

0

0

0

0

0

0

:

0

0

0

0

0

0

:

0

0

0

0

0

0

:

0

0

0

Blue

Blue(00)

Dark

Blue(01)

Blue(02)

Blue(253)

Blue(254)

Blue(255)

Bright

0

0

0

:

0

0

0

0

0

0

:

0

0

0

0

0

0

:

0

0

0

0

0

0

:

0

0

0

0

0

0

:

0

0

0

0

0

0

:

0

0

0

0

0

0

:

0

0

0

0

0

0

:

0

0

0

0

0

0

:

0

0

0

0

0

0

:

0

0

0

0

0

0

:

0

0

0

0

0

0

:

0

0

0

0

0

0

:

0

0

0

0

0

0

:

0

0

0

0

0

0

:

0

0

0

0

0

0

:

0

0

0

0

0

0

:

1

1

1

0

0

0

:

1

1

1

0

0

0

:

1

1

1

0

0

0

:

1

1

1

0

0

0

:

1

1

1

0

0

0

:

1

1

1

0

0

1

:

0

1

1

0

1

0

:

1

0

1

Page 27

THE INFORMATION CONTAINED HEREIN IS THE PROPERTY OF APPLE, INC. THE POSSESSOR AGREES TO THE FOLLOWING:

(i) TO MAINTAIN THIS DOCUMENT IN CONFIDENCE (ii) NOT TO REPRODUCE OR COPY IT (iii) NOT TO REVEAL OR PUBLISH IT IN WHOLE OR IN PART

Apple Inc.

Size: Letter

Scale: NONE

Page 27 of 67

Title: ERIS, DSPL, LCD MODULE, LGD, X34 DWG Number: 069-8326 ___Rev. B___

J"="D" )-Y&$'7&?.2$&/&+08'WZ[#'E1*Q;2C40X'

The unit (w/o backlight) shall meet the internal power requirements in 069-8336, X34

Display TCON PCBA Engineering Requirements Specification (ERS), LGD.

The unit with the backlight turned off shall meet the power requirements shown in Table

7.45 using the display pattern requirements specified in 7.4.6.

Table 7.45 Power Requirements (FOR REFERENCE ONLY)

Pattern

Nominal

Max

Unit

White

380

440

mA

Mosaic

380

440

mA

Horizontal Line -

One On / One Off

570

660

mA

Vertical Line –

One On / One Off

600

690

mA

Red

500

580

mA

Black

380

430

mA

Note: (1) Display data pins and timing signal pins should be connected (GND = 0V);

(2) Operation conditions: fV = 60 Hz, f

CLK

= 268.500 MHz, Vcc = 5 V;

J"="F" ,28<;15')100&$+'7&?.2$&/&+08'

The display patterns for system verification are defined below.

• White Pattern: All pixels in active area turned on at 100%

• Mosaic (checker) Pattern: Repeating pattern of 20 pixels x 20 pixels black an

white areas over entire active area. White area has all pixels turned on at 100%

and black area has all pixels turned off.

• Vertical Stripe Pattern: Sub-pixel vertical line alternating between power on and

power off as shown in Figure 16.

Page 28

THE INFORMATION CONTAINED HEREIN IS THE PROPERTY OF APPLE, INC. THE POSSESSOR AGREES TO THE FOLLOWING:

(i) TO MAINTAIN THIS DOCUMENT IN CONFIDENCE (ii) NOT TO REPRODUCE OR COPY IT (iii) NOT TO REVEAL OR PUBLISH IT IN WHOLE OR IN PART

Apple Inc.

Size: Letter

Scale: NONE

Page 28 of 67

Title: ERIS, DSPL, LCD MODULE, LGD, X34 DWG Number: 069-8326 ___Rev. B___

Figure 14 White Screen Display Figure 15 Mosaic Pattern Display

Figure 16 Vertical Stripe Pattern Display

J"D" )-Y&$'-+R-(('8&?.&+*&'

The unit shall meet the power on-off sequence requirements (TBD) in 069-8336, X34

Display TCON PCBA Engineering Requirements Specification (ERS), LGD.

J"F" \**'\-;01C&',$-<'7&?.2$&/&+0''

The unit shall operate as specified herein with a voltage drop (during power-on or normal

operation) specified (TBD) in 069-8336, X34 Display TCON PCBA Engineering

Requirements Specification (ERS), LGD.

J"J" ]&1$R>2&;%']-28&'

The panel vendor shall follow the noise characterization process outlined in Apple’s near

field noise spec (069-2794), and comply with noise emission limits.

Note: This spec compliance requirement is in addition to the legal EMI compliance

requirements.

J"P" &,)'U20RL$$-$R710&'WUL7X'7&?.2$&/&+0'

The unit shall meet the eDP Bit-Error rate requirements in 069-8336, X34 Display TCON

PCBA Engineering Requirements Specification (ERS), LGD.

J"S" B#:'U20'L$$-$'710&'WUL7X'7&?.2$&/&+0'

The unit COG chips shall meet the BER requirement in 069-8336, X34 Display TCON

PCBA Engineering Requirements Specification (ERS), LGD

J"!T" )$-C$1//1E;&':1//1'I&002+C8'

The programmable gamma settings for the unit are specified in 069-8336, X34 Display

TCON PCBA Engineering Requirements Specification (ERS), LGD.

Page 29

THE INFORMATION CONTAINED HEREIN IS THE PROPERTY OF APPLE, INC. THE POSSESSOR AGREES TO THE FOLLOWING:

(i) TO MAINTAIN THIS DOCUMENT IN CONFIDENCE (ii) NOT TO REPRODUCE OR COPY IT (iii) NOT TO REVEAL OR PUBLISH IT IN WHOLE OR IN PART

Apple Inc.

Size: Letter

Scale: NONE

Page 29 of 67

Title: ERIS, DSPL, LCD MODULE, LGD, X34 DWG Number: 069-8326 ___Rev. B___

J"!!" U1*Q;2C40'I.E8580&/'

J"!!"!" :&+&$1;'G+(-$/102-+'

Table 5 LED Requirements (Characterized at 20 mA)

LED Manufacturer

TG

LED Manufacturer Assembly P/N

E1S72-YW1L7-0F or Apple approved equivalent

Number of LEDs

42

LED Vf Ranks

5.3-5.5V, 5.5-5.7V

LED Forward Voltage Range for All 6

LED Series Lines

MAX: 42 V

(Characterized at Connector for 23 mA)

LED Forward Voltage Difference

between Strings

0.6V

J"!!"6" U1*Q;2C40'L;&*0$2*1;'B41$1*0&$2802*8'

>"$$"2"$" NDG.A3,-*3II&*.

The unit shall drive the LED subsystem shown in Figure 17, Figure 18, and Figure 19

Page 30

THE INFORMATION CONTAINED HEREIN IS THE PROPERTY OF APPLE, INC. THE POSSESSOR AGREES TO THE FOLLOWING:

(i) TO MAINTAIN THIS DOCUMENT IN CONFIDENCE (ii) NOT TO REPRODUCE OR COPY IT (iii) NOT TO REVEAL OR PUBLISH IT IN WHOLE OR IN PART

Apple Inc.

Size: Letter

Scale: NONE

Page 30 of 67

Title: ERIS, DSPL, LCD MODULE, LGD, X34 DWG Number: 069-8326 ___Rev. B___

Figure 17 LED Controller Block Diagram

Figure 18 LED Controller Reference Application Circuits

Page 31

THE INFORMATION CONTAINED HEREIN IS THE PROPERTY OF APPLE, INC. THE POSSESSOR AGREES TO THE FOLLOWING:

(i) TO MAINTAIN THIS DOCUMENT IN CONFIDENCE (ii) NOT TO REPRODUCE OR COPY IT (iii) NOT TO REVEAL OR PUBLISH IT IN WHOLE OR IN PART

Apple Inc.

Size: Letter

Scale: NONE

Page 31 of 67

Title: ERIS, DSPL, LCD MODULE, LGD, X34 DWG Number: 069-8326 ___Rev. B___

Figure 19 Display Backlight Control Diagram

J"!!"9" VL,'B-++&*02-+'

The display subsystem shall have a LED connection scheme as specified in Table 6.

Table 6 LED Connection Data

String

1 2 3 4 5 6 7

1

1 7 13

19

25

31

37

2

2 8 14

20

26

32

38

3

3 9 15

21

27

33

39 4 4

10

16

22

28

34

40

5

5

11

17

23

29

35

41

6

6

12

18

24

30

36

42

Table 7 LED Connector Assignments (FOR REFERENCE ONLY)

Pin

Symbol

Description

1

NC

NC

2

LEDRTN1

Backlight Return Current

3

NC

NC

4

LEDRTN2

Backlight Return Current

Page 32

THE INFORMATION CONTAINED HEREIN IS THE PROPERTY OF APPLE, INC. THE POSSESSOR AGREES TO THE FOLLOWING:

(i) TO MAINTAIN THIS DOCUMENT IN CONFIDENCE (ii) NOT TO REPRODUCE OR COPY IT (iii) NOT TO REVEAL OR PUBLISH IT IN WHOLE OR IN PART

Apple Inc.

Size: Letter

Scale: NONE

Page 32 of 67

Title: ERIS, DSPL, LCD MODULE, LGD, X34 DWG Number: 069-8326 ___Rev. B___

5

NC

NC

6

LEDRTN3

Backlight Return Current

7

NC

NC

8

LEDRTN4

Backlight Return Current

9

BKLT_PWR

Backlight Power (48V)

10

LEDRTN5

Backlight Return Current

11

BKLT_PWR

Backlight Power (48V)

12

LEDRTN6

Backlight Return Current

J"!!"=" VL,'80$2+C'0-'80$2+C'*.$$&+0'H1$2102-+'

LED current variation from string to string is defined as ⊗ = (I

max

- I

min

)/I

avg,

where I

max

and I

min

are the maximum and minimum current on any of the 6 strings, respectively.

LED current variation ⊗ should be within ±2.0% during the complete range of PWM

dimming from 20mA (100% duty) to 0.4mA (2% duty)

J"!!"D" VL,',$2H&$'7&?.2$&/&+0'

16-bit dimming control through Pulse Width Modulation (PWM) scheme with consistent

current on LED strings. The LED string PWM signal frequency is 8KHz or higher.

Between each string a 60 degree phase delay is implemented.

J"!6" 'GK#'L;&*0$2*1;'I42&;%2+C'

A transparent ITO layer shall be applied on the top surface of the CF Glass for electrical

shielding that meet the electrical requirements specified in Table 8 and Figure 20.

Table 8 ITO Layer Characteristics

Minimum

Typical

Maximum

ITO Sheet Resistance

-

2000 Ω/square

2500 Ω/square

Grounding Method

Black conductive tape connecting ITO on Color Filter Surface to ground

Module level ITO

transmittance (with polarizer)

98%

99%

-

Module level ITO white point

shift (delta x & delta y)

- - 0.001

Page 33

THE INFORMATION CONTAINED HEREIN IS THE PROPERTY OF APPLE, INC. THE POSSESSOR AGREES TO THE FOLLOWING:

(i) TO MAINTAIN THIS DOCUMENT IN CONFIDENCE (ii) NOT TO REPRODUCE OR COPY IT (iii) NOT TO REVEAL OR PUBLISH IT IN WHOLE OR IN PART

Apple Inc.

Size: Letter

Scale: NONE

Page 33 of 67

Title: ERIS, DSPL, LCD MODULE, LGD, X34 DWG Number: 069-8326 ___Rev. B___

Figure 20 ITO Transmittance

Glass

Glass

Tr (1) %

Tr (2) %

Tr% = Tr(2) /Tr(1)

Page 34

THE INFORMATION CONTAINED HEREIN IS THE PROPERTY OF APPLE, INC. THE POSSESSOR AGREES TO THE FOLLOWING:

(i) TO MAINTAIN THIS DOCUMENT IN CONFIDENCE (ii) NOT TO REPRODUCE OR COPY IT (iii) NOT TO REVEAL OR PUBLISH IT IN WHOLE OR IN PART

Apple Inc.

Size: Letter

Scale: NONE

Page 34 of 67

Title: ERIS, DSPL, LCD MODULE, LGD, X34 DWG Number: 069-8326 ___Rev. B___

P" #<02*1;'7&?.2$&/&+08' '

P"!" :&+&$1;'#<02*1;'I<&*2(2*102-+8'

The optical performance will be approved by Apple based on supplier’s measurement data,

visual inspection of the samples, verification measurements, and specification correlation.

Table 9 General Optical Characteristics

Parameter

Symbol

Condition

Min.

Typ.

Max.

Unit

Note

Spec

Iso-Contrast

Viewing Angle

$

CR ≥ 100

Horizontal and

Vertical

Directions

75

85

-- ° 1,2,3

8.15

CR ≥ 10

Horizontal and

Vertical

Directions

85

89

°

CR ≥ 100

@ any other

angle

35

40

--

°

No Gray Inversion

Angle

$

Any Angle

90 - -- ° 1,2,3

8.16

Contrast ratio

CR

Optimal

750

900

--

--

1,2,3

8.7

Color Shift

du’v’

White (255/255)

--

--

0.02

--

1,2,3

du’v’

Gray (127/255)

--

--

0.03

--

1,2,3

Transmittance

T

with standard

BLU

3.75

4.0

-- % 1,2,4,5

White Chromaticity

Wx

CIE 1931

0.298

0.313

0.328

--

1,2,3,5

8.14

Wy

0.314

0.329

0.344

--

1,2,3,5

Red Chromaticity

Rx

CIE 1931

0.625

0.640

0.655

--

1,2,3,5

Ry

0.320

0.330

0.340

--

1,2,3,5

Green Chromaticity

Gx

CIE 1931

0.285

0.300

0.315

--

1,2,3,5

Gy

0.580

0.600

0.620

--

1,2,3,5

Blue Chromaticity

Bx

CIE 1931

0.140

0.150

0.160

--

1,2,3,5

By

0.050

0.060

0.070

--

1,2,3,5

Black Chromaticity

No visible hue

on black screen

Blue Shift Over

Temperature

∆u’v’

30 °C to 50 °C

0.008

1,2,3,5

Max color

difference over a

cell

du’v’

white

--

--

0.0055

--

1,2

8.11

Max color

difference w.r.t.

Center

du’v’

white

--

--

0.0045

--

1,2

8.10

Page 35

THE INFORMATION CONTAINED HEREIN IS THE PROPERTY OF APPLE, INC. THE POSSESSOR AGREES TO THE FOLLOWING:

(i) TO MAINTAIN THIS DOCUMENT IN CONFIDENCE (ii) NOT TO REPRODUCE OR COPY IT (iii) NOT TO REVEAL OR PUBLISH IT IN WHOLE OR IN PART

Apple Inc.

Size: Letter

Scale: NONE

Page 35 of 67

Title: ERIS, DSPL, LCD MODULE, LGD, X34 DWG Number: 069-8326 ___Rev. B___

Parameter

Symbol

Condition

Min.

Typ.

Max.

Unit

Note

Spec

Max color

difference between

neighbors

du’v’

white

--

--

0.0022

--

1,2

8.13

Gamma

--

--

2.25

--

--

1,2,3

Flicker

F

No Visual

Flicker

--

--