Page 1

Global LCD Panel Exchange Center

www.panelook.com

Specification Rev. 0.5

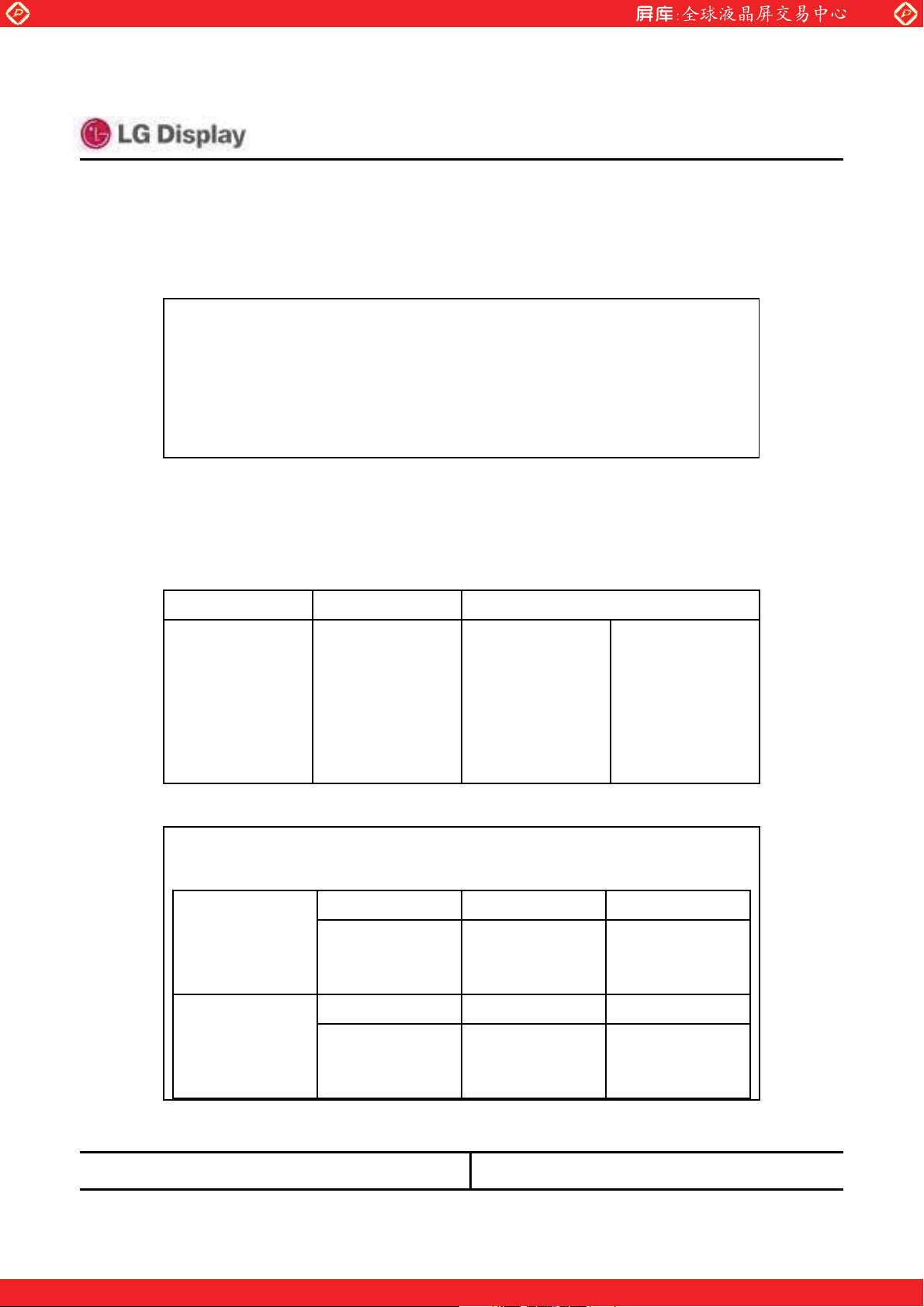

Specification of 13.3” TFT/LCD

MODEL: LP133WH2 (TLM4)

1/ 56

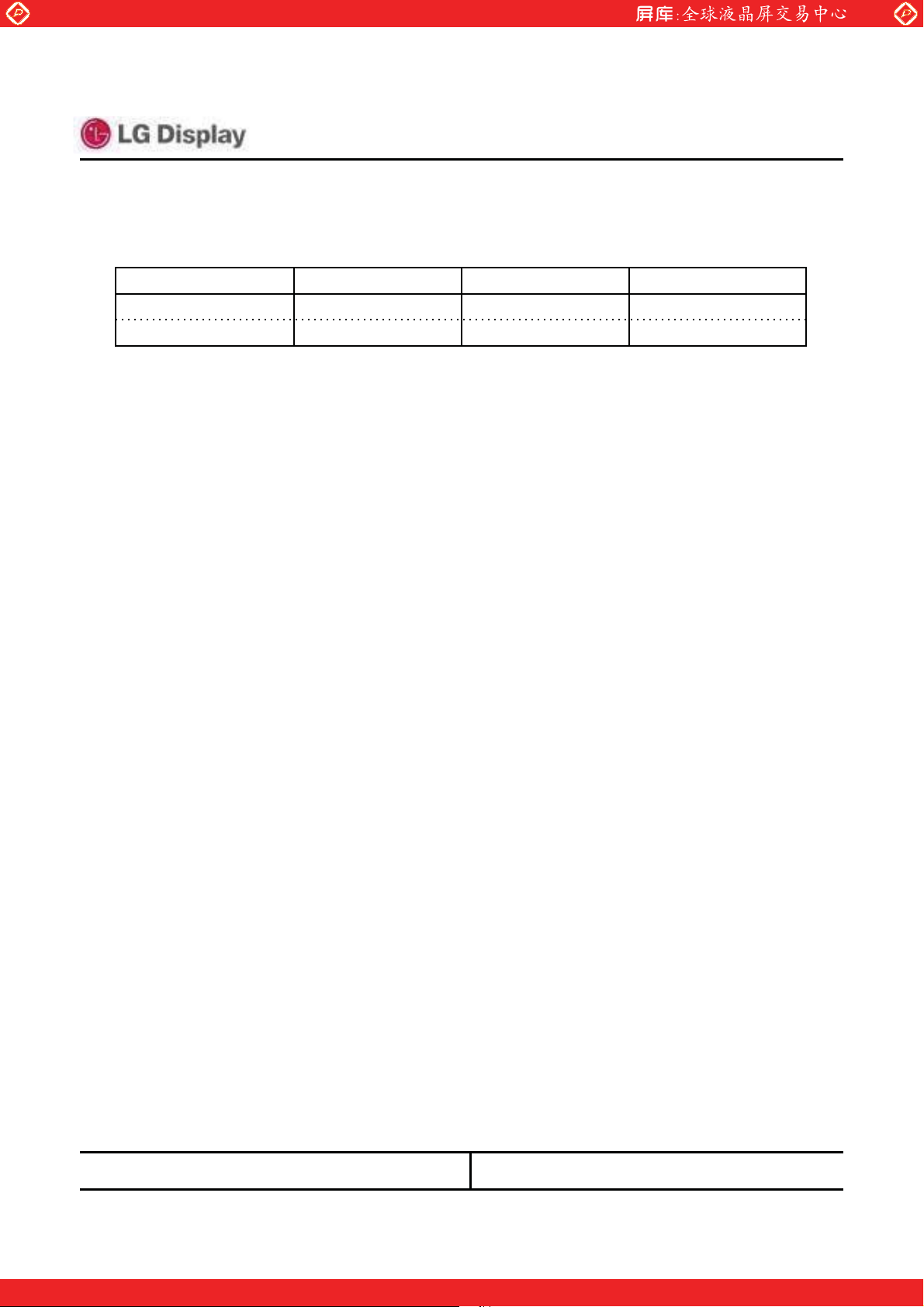

ApprovedCheckedPrepared

K.Y.Kwon

/Eng. Dept.

/Engineer

NOTICE of RECEIPT

We accepted this specification. OME Operations, TOSHIBA Corp.

Purchasing

Dept.

PC

Hardware

Dept.

Y.S.Ha

/Eng. Dept.

/Manager

Hans.Kim

/Eng. Dept.

/Senior Mgr

Brian Yoon

/CS. Dept.

/Senior Mgr

Senr. MgrSenr. Eng.Eng.

Senr. MgrSenr. Eng.Eng.

LG Display Co., Ltd.

Date: 2010. 08.11

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 2

Global LCD Panel Exchange Center

www.panelook.com

Specification Rev. 0.5

- CONTENTS -

Record of Revision --------------------------------------------------------------- 4

1. Scope --------------------------------------------------------------- 4

2. General Specifications --------------------------------------------------------------- 4

2.1. Features

2.2. Dimensional Outline

3. Absolute Maximum Ratings --------------------------------------------------------------- 9

3.1. Absolute Ratings of Environment

3.2. Electrical Absolute Maximum

3.3. Mechanical ratings

3.4. The others

4. Optical Characteristics --------------------------------------------------------------- 16

4.1 Test Conditions

4.2 Optical Specifications

5. Electrical Characteristics --------------------------------------------------------------- 21

5.1. TFT LCD module

5.2. Backlight Unit

5.3. Regulation

6. Block Diagram --------------------------------------------------------------- 25

7. Input Terminal Pin Assignment --------------------------------------------------------------- 26

7.1 TFT LCD module

7.2 Backlight Unit

7.3 LVDS Transmitter

7.4 Timing Diagrams of LVDS for Transmission

7.5 Input Signal, Basic Display Colors and Gray Scale of Each Colors

8. Interface timing --------------------------------------------------------------- 31

8.1 Timing Parameters

8.2 Timing diagrams of interface signal

8.3 Power On / Off Sequence

9. Cosmetic Specification --------------------------------------------------------------- 33

9.1 Sampling

9.2 Conditions of Inspections

9.3 Defect modes

9.4 Mechanical inspection

9.5 Visual Inspection

9.6 Electrical inspection

10. Packing --------------------------------------------------------------- 37

11. Labels and Other parts Exchange --------------------------------------------------------------- 39

12. General Precaution --------------------------------------------------------------- 47

2/ 56

Appendix --------------------------------------------------------------- 49

LG Display Co., Ltd.

Date: 2010. 08.11

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 3

Global LCD Panel Exchange Center

www.panelook.com

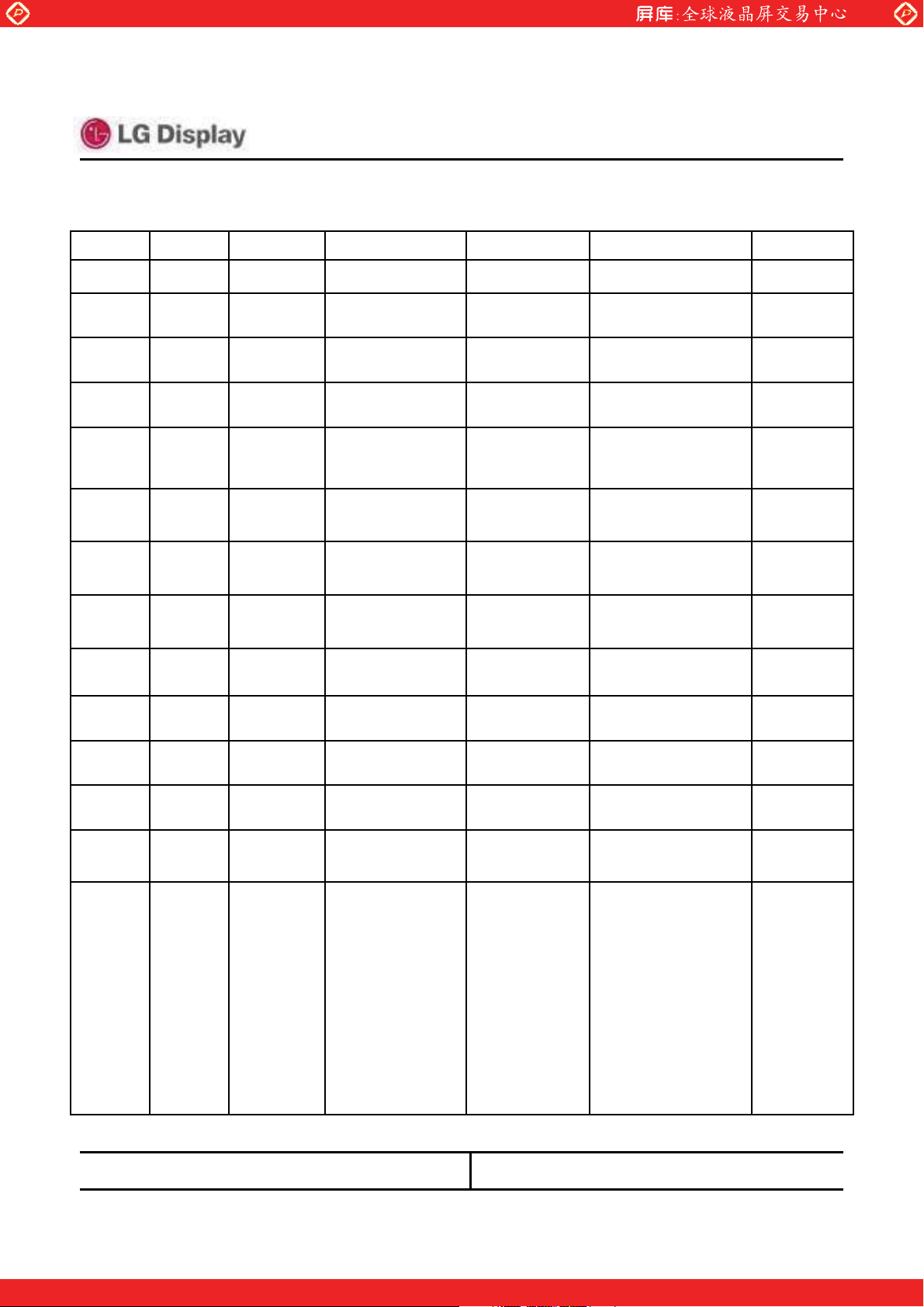

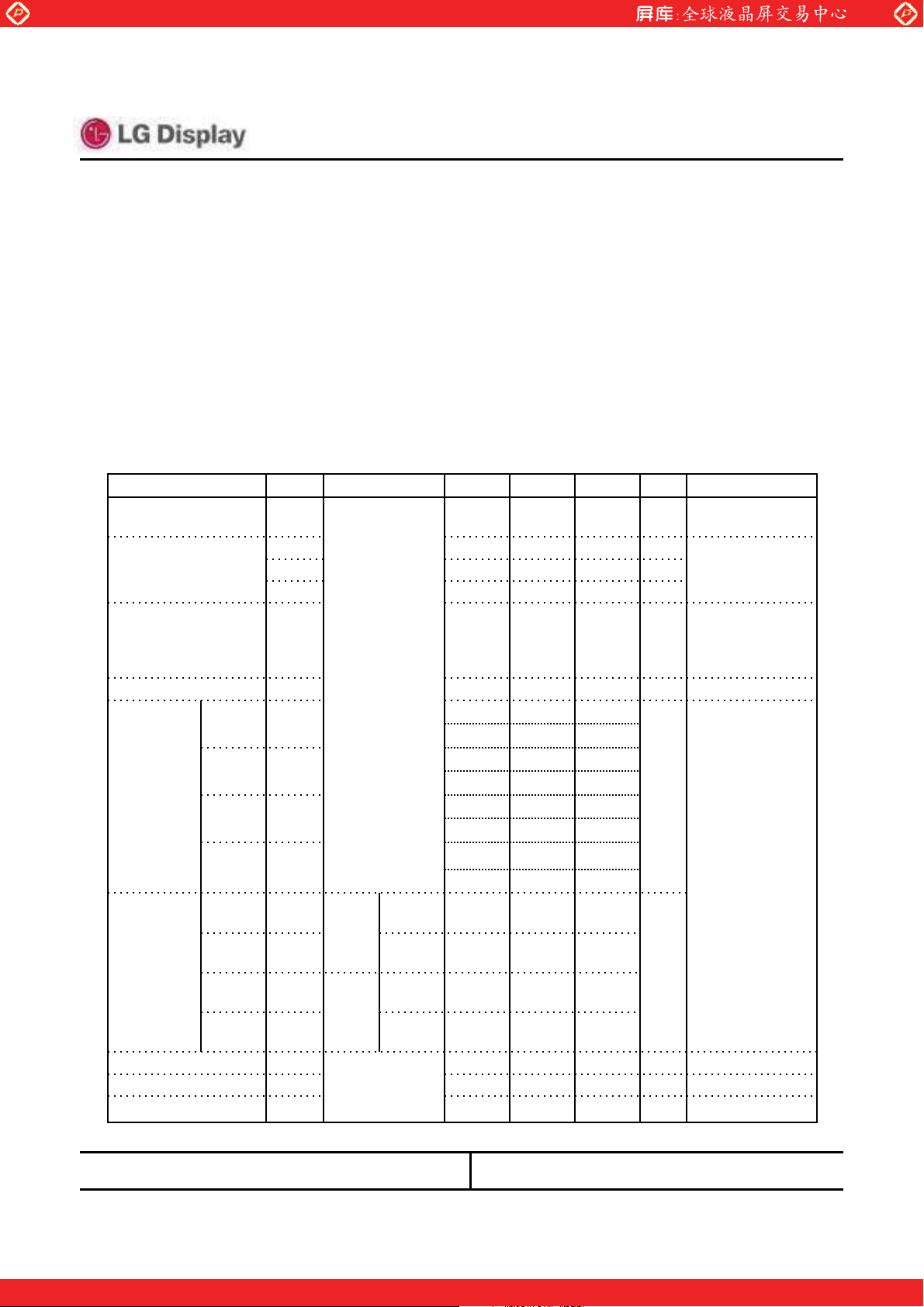

Record of Revision

’10.5.17

’10.6.11

0.1

Specification Rev. 0.5

Sheet(New)Rev. No.Date

Update Power

Sequence (t4, t6)

Update Color

Coordinate

Update Gray

scale Spec.

Update

Mechanical

Drawing

Update EDID

Data

All0.2

New Format for

Custormer

3/ 56

ReasonNewOldItem

First Edition---All0.0’10.4.9

’10.6.28

’10.8.2

’10.8.11

300.3

10

30

38

250.5

Update Timing

table

40.4

Update the LED

Quantity

Update Connector

tension test

Update Timing

table

Update the

Toshiba G-Code

Update the

Connector maker

“Backlight

connector ~”

G33C00067110

-

-

Add the LED Quantity

Delete the “Backlight

connector ~”

Add Refresh rate

40Hz

G33C00068110

LG Display Co., Ltd.

Date: 2010. 08.11

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 4

Global LCD Panel Exchange Center

www.panelook.com

Specification Rev. 0.5

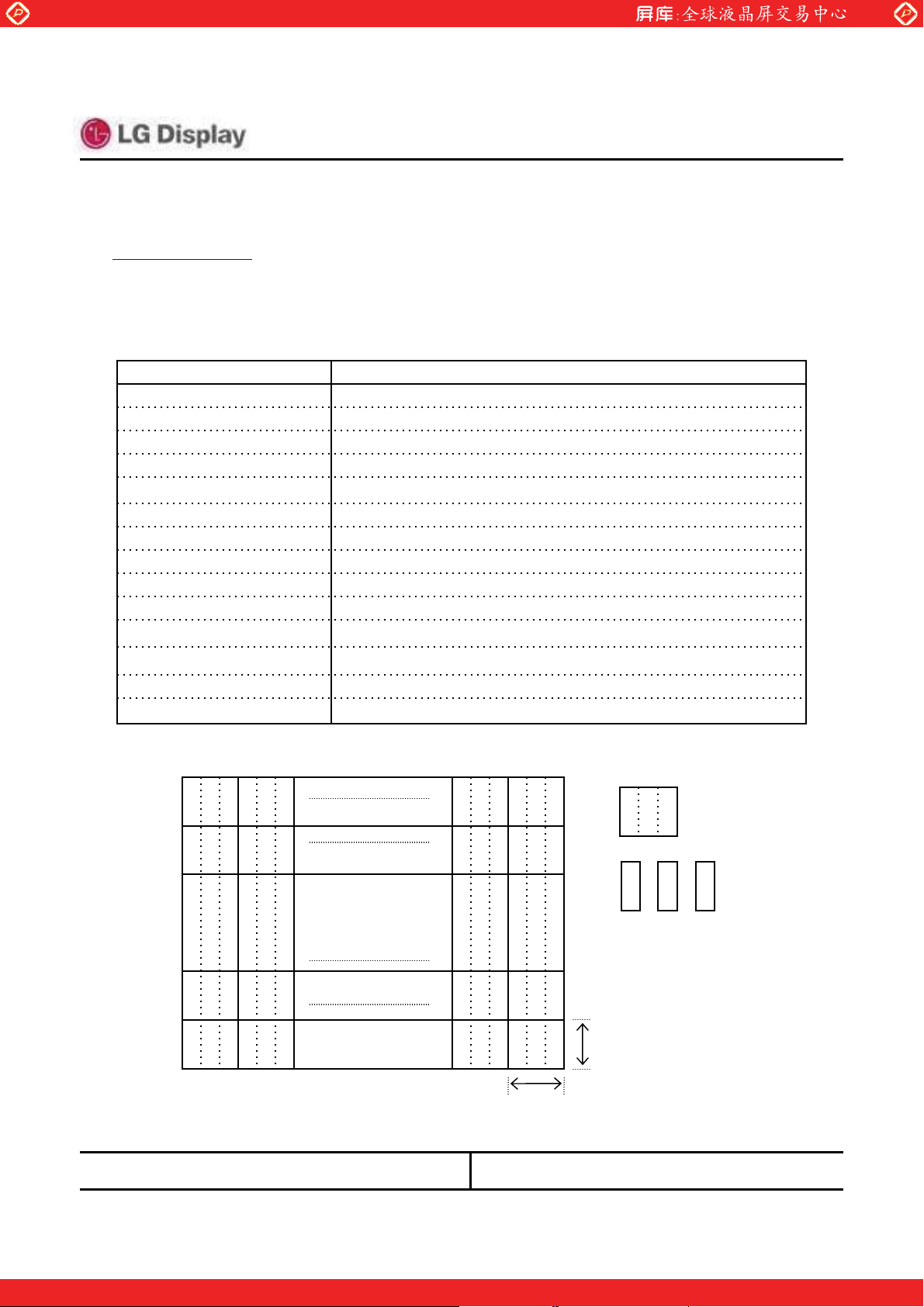

1. Scope

This specification is applicable to LCD manufacturer’s 13.3” diagonal size TFT-LCD module

"LP133WH2(TLM4)"

designed for Personal Computer.

2. General Specification

2.1. Features

SpecificationsItem

293.42(H, typ.) ϧ 164.97 (V, typ.) (13.3 inches diagonal )Display area ( Active area)

TFT active matrixDriving Method

Number of Pixels

Pixel pitch

Pixel Arrangement

1366 (W) u 768 (H) u R,G,B (HD) (pixels)

0.2148mm Ý 0.2148 mm

RGB vertical stripes

1)

1)

262,144 (colors)Display color

Transmissive mode, Normally whiteDisplay Mode

6 o'clock (in direction of maximum contrast)Viewing Direction

Anti-glare treatment of the front polarizer Surface Treatment

LVDSInterface

Single light emitting diode for side-lighting (LED Quantity : 36ea)Backlight

1)

4/ 56

Note 1)

767

768

306.3ρ0.5 (H) u 177.7 ρ0.5 (W) / 3.6(Max) (D) (mm)Dimensional Outline

297.42(H) u168.57ρ0.5 (W) (mm)Bezel Opening

290g ( Typ.) / 300g ( Max.)Weight

1 2 1365 1366

1

2

BGRBGRBGRBGR

BGRBGRBGRBGR

BGRBGRBGRBGR

BGRBGRBGRBGR

0.2148mm

R G B

0.2148mm

BGR

: Pixel

: Sub-pixel

(Dots)

LG Display Co., Ltd.

Date: 2010. 08.11

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 5

Global LCD Panel Exchange Center

www.panelook.com

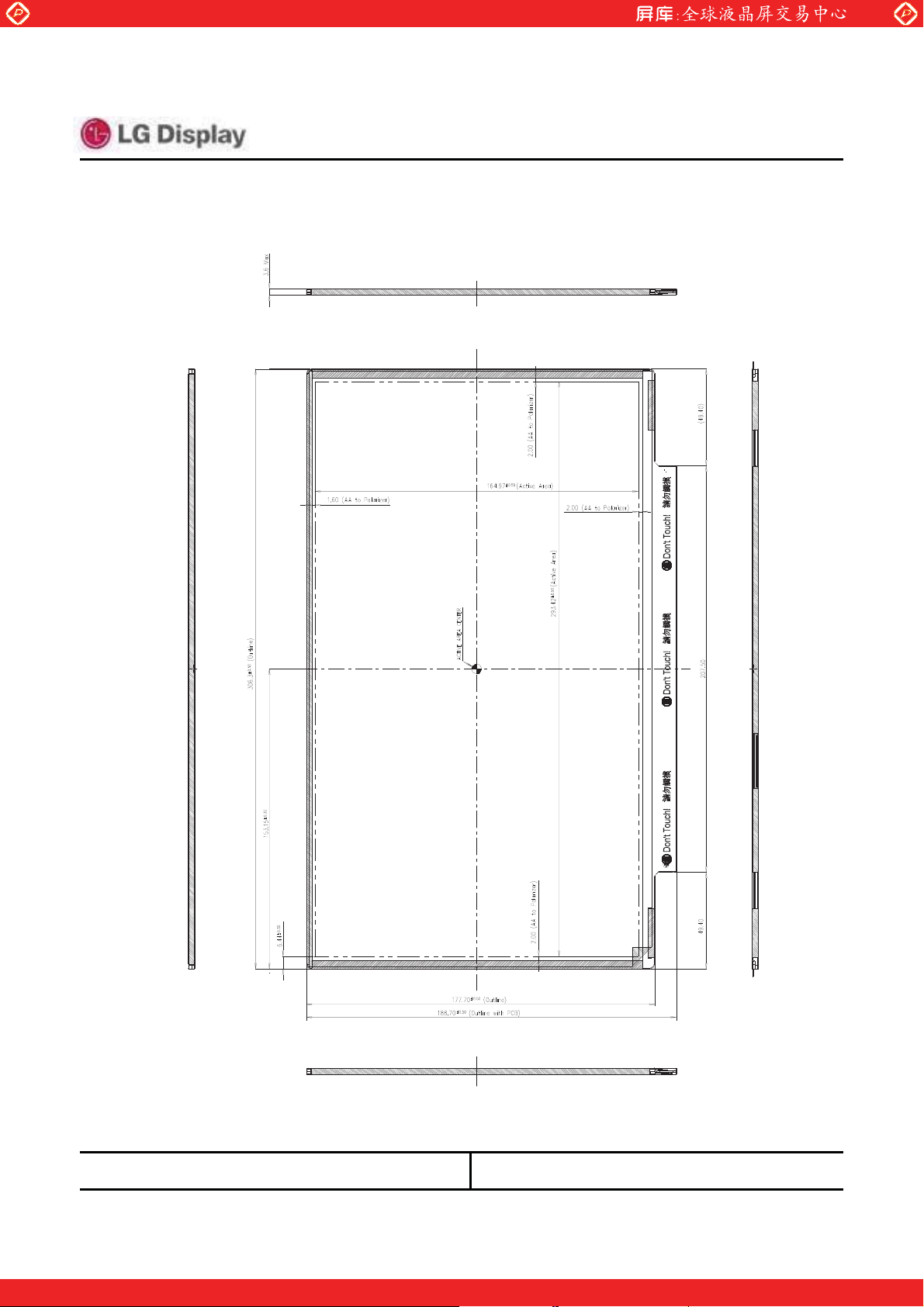

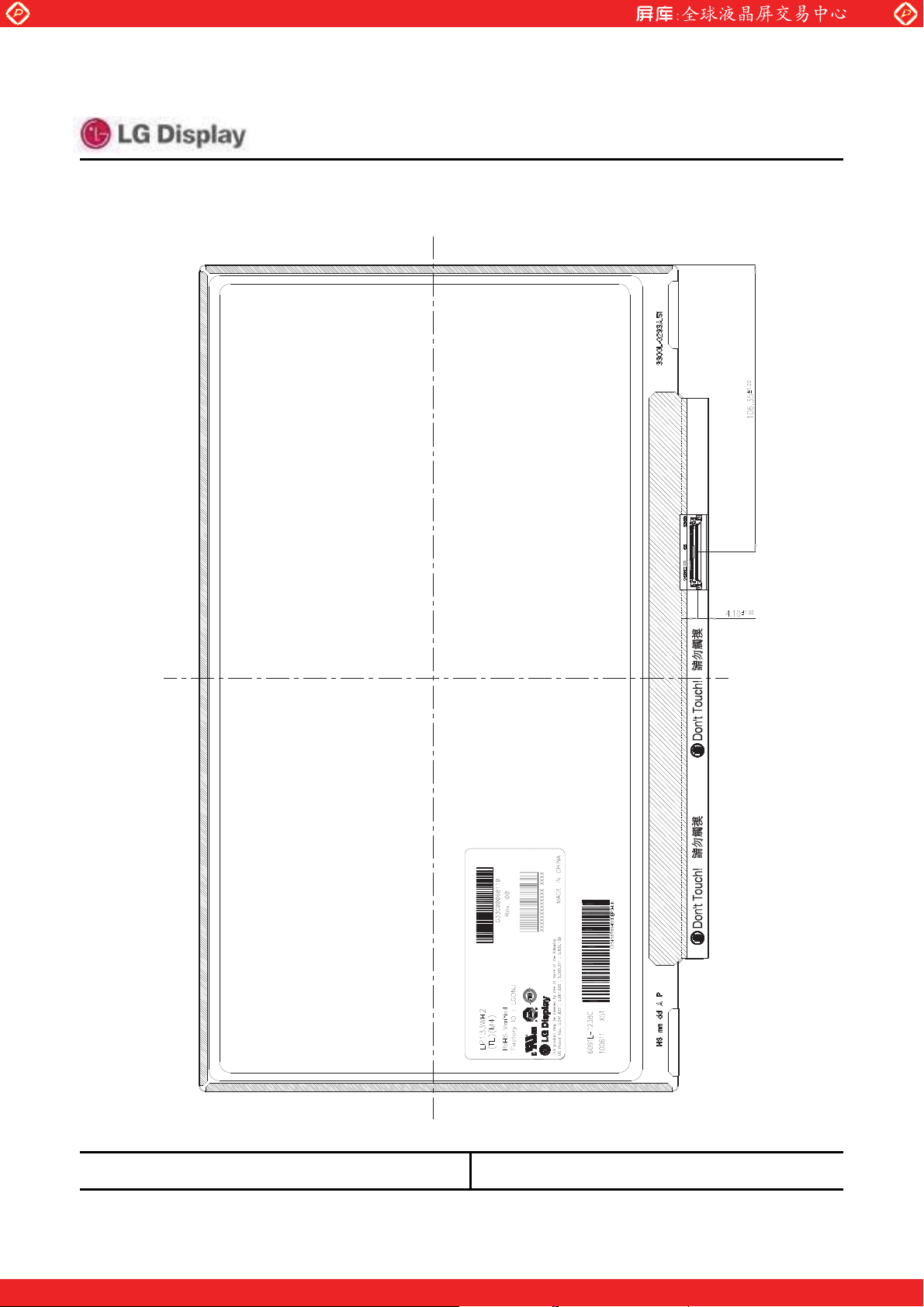

2.2. Dimensional Outline

( Front figure )

Specification Rev. 0.5

Note) Unit:[mm], General tolerance: r 0.5mm

5/ 56

UP

Down

* The size that related with metal bezel includes tape thickness (0.05mm)

LG Display Co., Ltd.

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

Date: 2010. 08.11

www.panelook.com

Page 6

Global LCD Panel Exchange Center

www.panelook.com

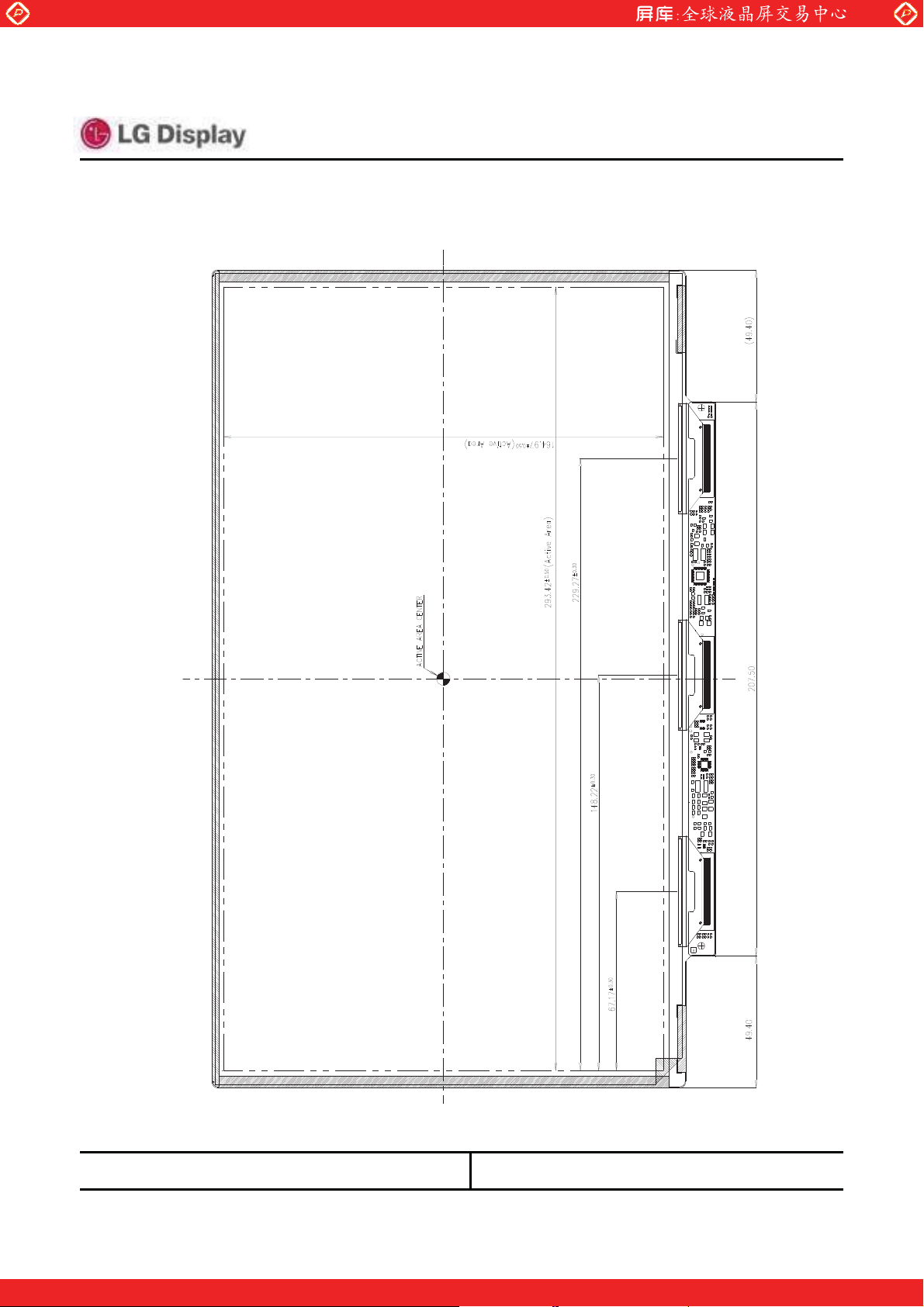

( Rear figure )

Specification Rev. 0.5

Note) Unit:[mm], General tolerance: r 0.5mm

6/ 56

LG Display Co., Ltd.

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

Date: 2010. 08.11

www.panelook.com

Page 7

Global LCD Panel Exchange Center

www.panelook.com

Specification Rev. 0.5

( Detail description of height of LCM back side & TAB Zone)

Note) Unit:[mm], General tolerance: r 0.5mm

7/ 56

LG Display Co., Ltd.

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

Date: 2010. 08.11

www.panelook.com

Page 8

Global LCD Panel Exchange Center

www.panelook.com

Specification Rev. 0.5

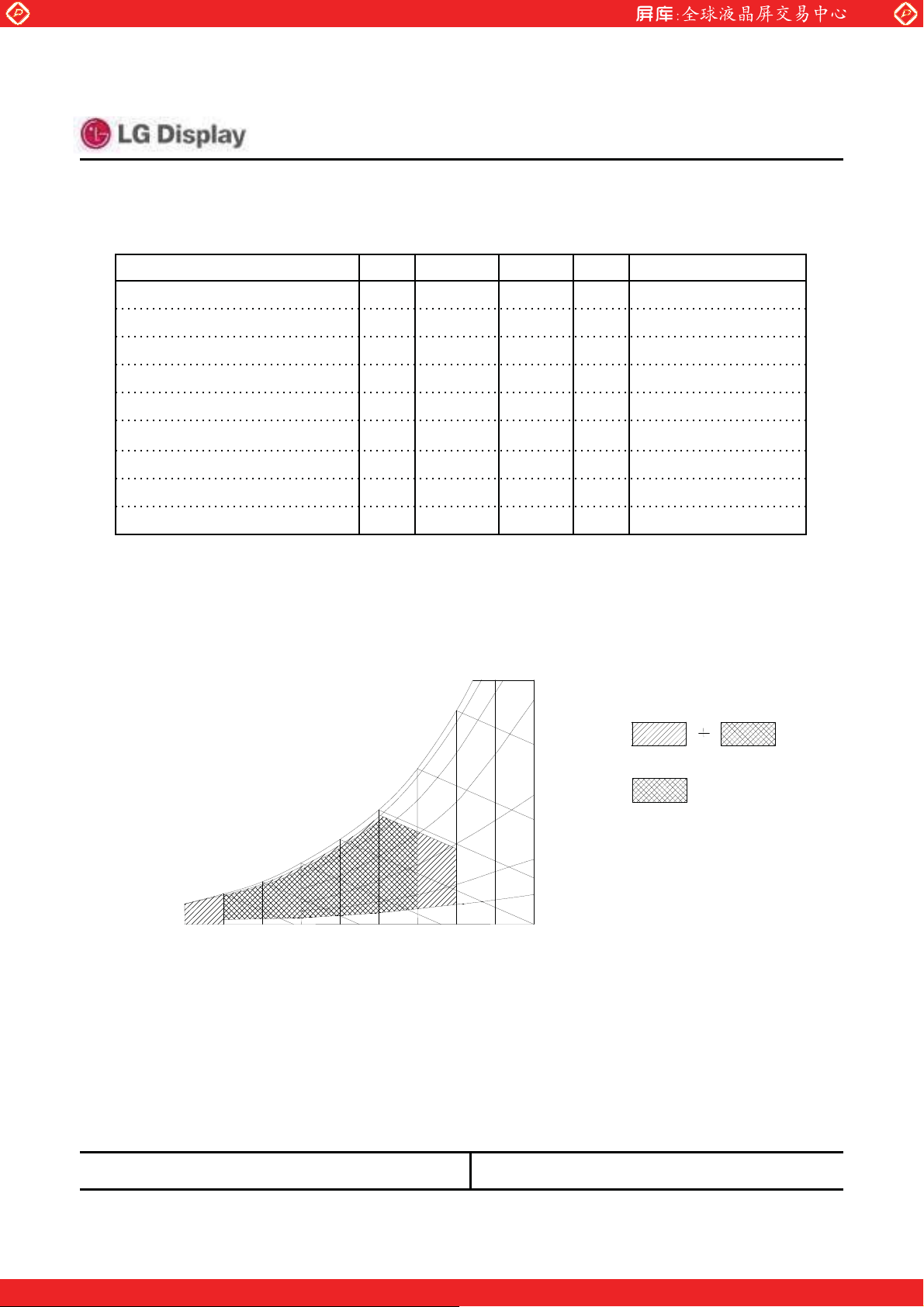

3. Absolute Maximum Ratings

3.1. Absolute Ratings of Environment

MaxMinItem NoteSymbol

Operating Ambient Temperature

Operating Temperature for Panel

Storage Temperature

Operating Ambient Humidity

Storage Humidity

Air Pressure

Air Pressure

Altitude

Altitude

-

-

Note 1) Temperature and relative humidity range are shown in the figure below.

Wet bulb temperature should be 39qC Max, and no condensation of water.

Unit

8/ 56

(1)qC+500TOP

(2)qC+500-

(1)qC+60-20TSTG

(1)%RH9010HOP

(1)%RH9010HSTG

OperationkPa101.357-

Non-operationkPa101.312-

OperationKm3-

Non-operationKm12-

90% 80%

60%

Humidity[(%)RH]

Storage

40%

Operation

20%

10%

Wet Bulb

Temperature [

0

-20

]

20

10

10

20 30 40 50

60

50

40

30

60 70 800

Dry Bulb Temperature []

Note 2) The surface temperature caused by self heat radiation of cell itself is specified on this item.

LG Display Co., Ltd.

Date: 2010. 08.11

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 9

Global LCD Panel Exchange Center

www.panelook.com

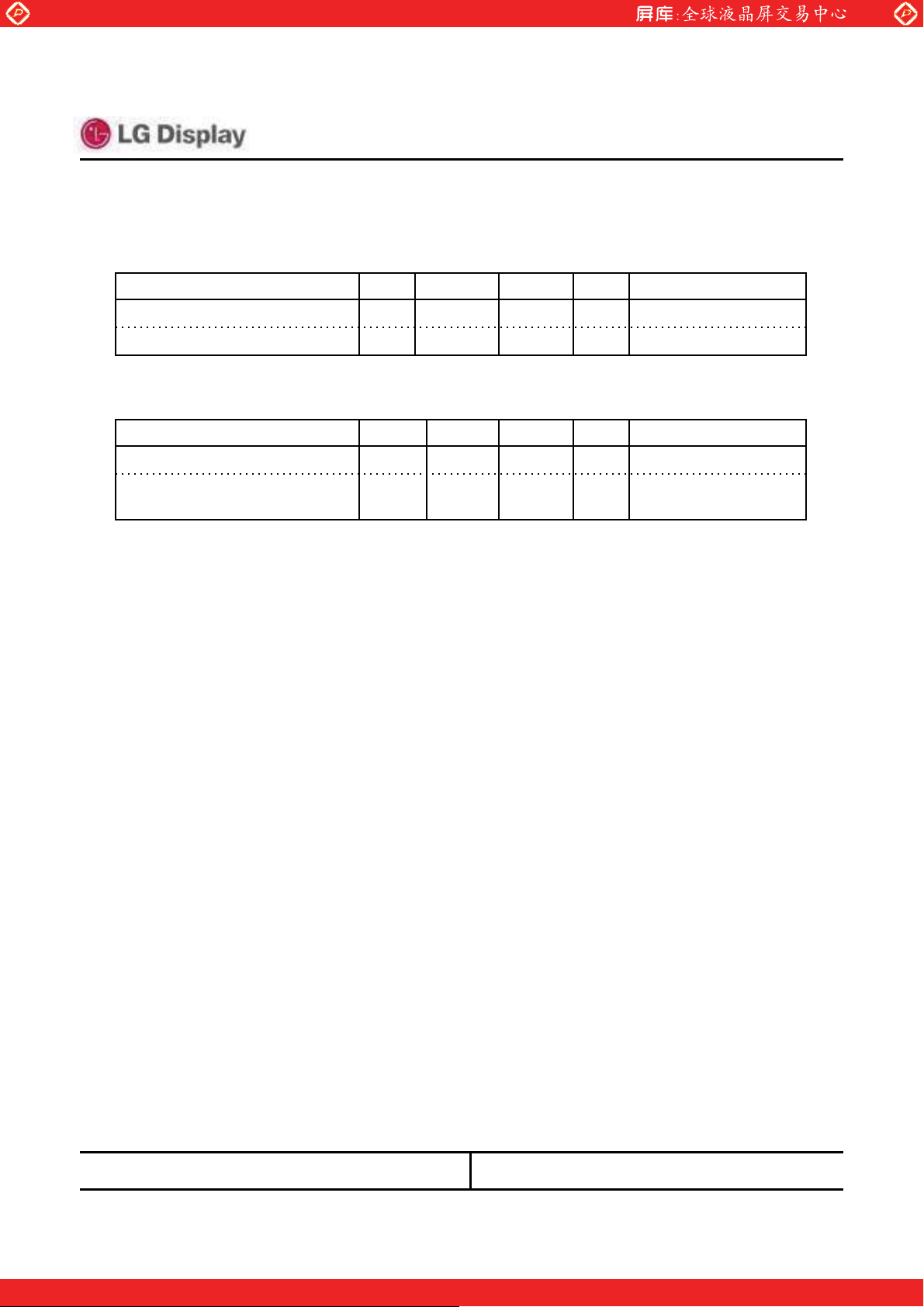

3.2. Electrical Absolute Maximum

(1) TFT LCD Module

Power Supply Voltage

Logic Input Voltage

(2) Back Light Unit

LED Driver Supply Voltage

LED PWM / LED_EN Voltage

Specification Rev. 0.5

IN

V

PWM

V

LED_EN

9/ 56

MaxMinItem NoteSymbol

Unit

at 25 r 5qCV+4.0-0.3VDD

LVDS interfaceVVDD+0.3-0.3V

UnitMaxMinItem NoteSymbol

damage to the device V23-0.3VL

V6.0-0.3

LG Display Co., Ltd.

Date: 2010. 08.11

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 10

Global LCD Panel Exchange Center

www.panelook.com

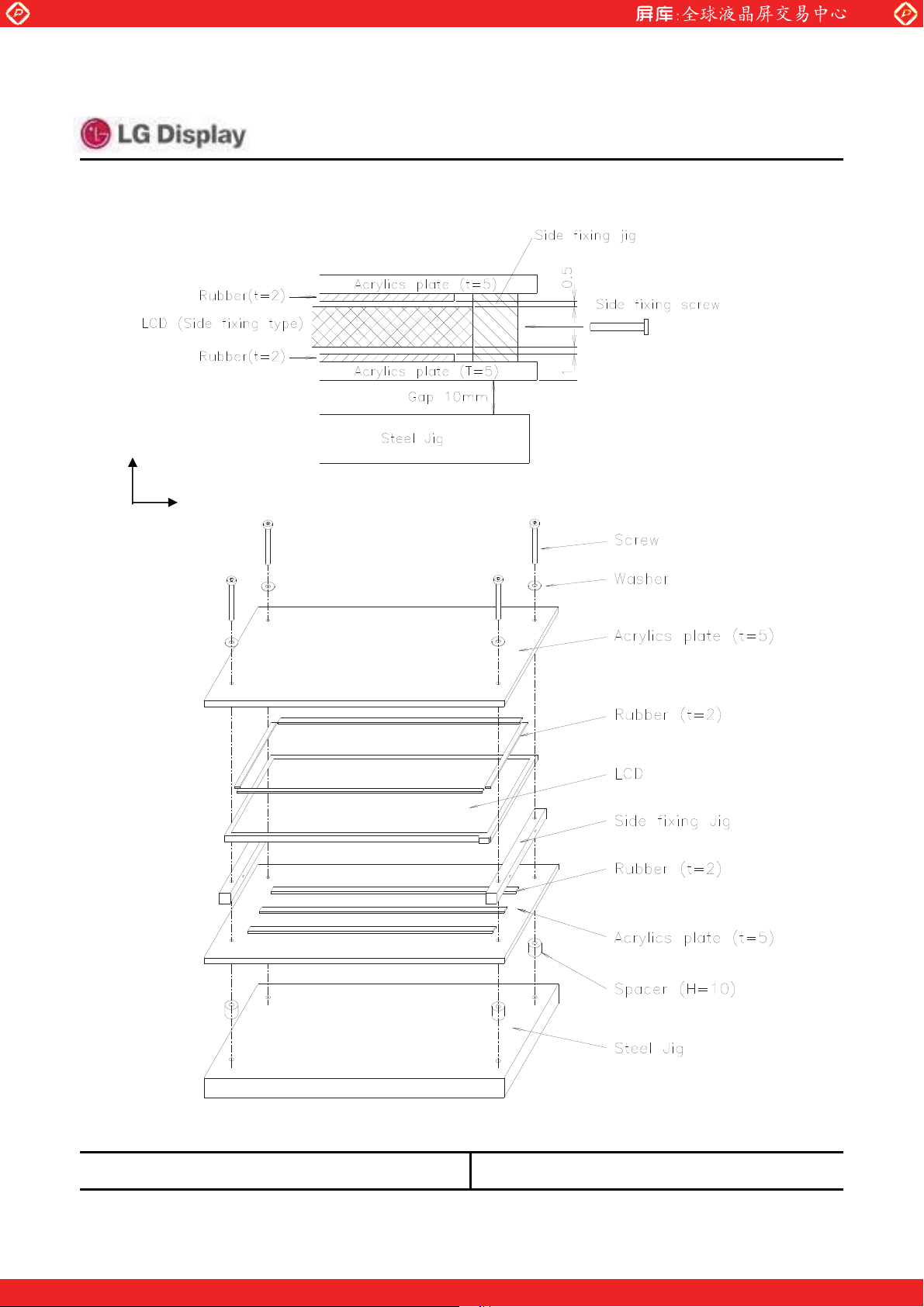

3.3. Mechanical Ratings

Test Item NoteTest Conditions

Frequency Range 5 - 500 Hz, 14.7m/s

Mechanical Vibration

Mechanical Shock

LCD fix condition

-> See Note (2)

Pressure Resistanace

-> See Note (1)

at side-mout part

0.5Hrs each axis (X, Y, Z direction).

Frequency Range 5 - 500 Hz, 4.9m/s2( 0.5G) constant,

0.5Hrs each axis (X, Y, Z direction).

No Destruction with the force 196 N (20 kgf, 16 mm in diameter) to

the display surface at the vertical direction.

No Destruction with the force 294.2 N (30 kgf, 30 mm in diameter)

to the back of the display surface at the vertical direction.

Only the breakage of below items will not happen after test.

( Glass.LED & Circuit parts)

Input connector : With 50 times of connector trial there must be no

damage to the shape and functionaly.

M2 : Max 2.5 kgfAssured torque value

Specification Rev. 0.5

2

1.5G) constant,

70G, Pulse width 11ms, Sine Wave rX, rY, rZ direction.

* Note) Normal function is only checking points.

2

(10G), Pulse width 11 ms, Sine Wave, rX, rY, rZ direction.

10 / 56

Non Operation

Operation

Non Operation* 240G, Pulse width 2 ms, Sine Wave, rX, rY, rZ direction.

Operation98 m/s

Non Operation

Fig 1-1

Fig 1-2

Fig 1-3

Non OperationConnector tension test

Non Operation

Tapping area : All bezel(Metal cover) side,

Tapping test

LCD: Full-screen gray (L32).

“Ripple (Pooling )” can not be seen in Active Area

Tapping Force: Max 3kgf.cm

Definitions of failure for judgment shall be as follows:

(1) Function of the module should be maintained.

(2) Current consumption should be smaller than the specified value.

(3) Appearance and display quality should not have distinguished degradation.

(4) Luminance should be larger than the minimum value specified in optical specification.

Non Operation15 times under Max. torqueRescrewed test

Operation

LG Display Co., Ltd.

Date: 2010. 08.11

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 11

Global LCD Panel Exchange Center

www.panelook.com

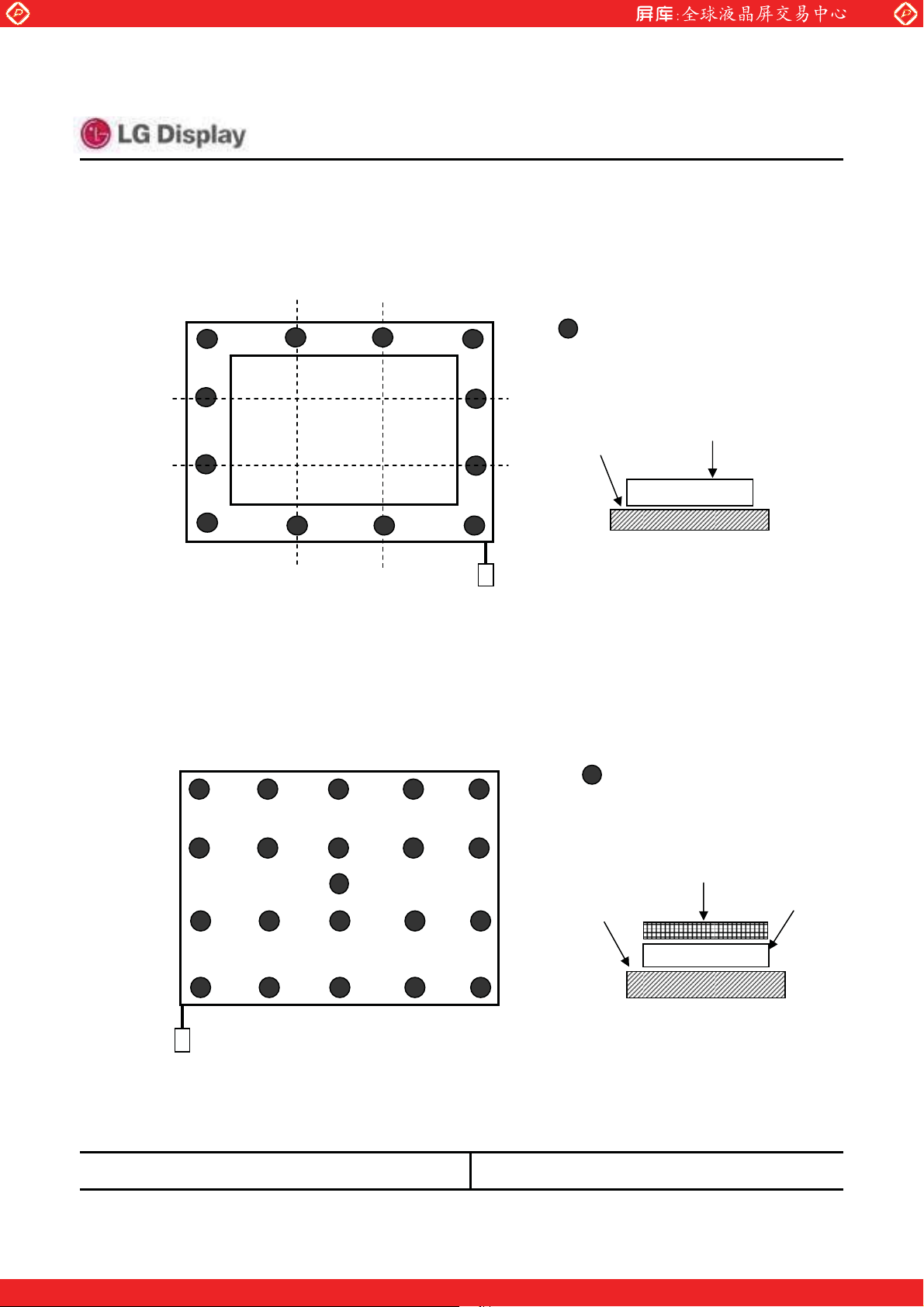

Note 1)

Specification Rev. 0.5

(1) The compression condition of front side

(a) Compression point : 12 points ( refer to Fig 1-1)

(b) Compression condition: 20kgf, 3 sec, Tool diameter: 16 mm in diameter (refer to Fig 1-3)

COMPRESSION POINT

LCDFlat plate

11 / 56

[ Fig 1-1 ]

(2) The compression condition of rear side

(a) Compression point : 21 points ( refer to Fig 1-2 )

(b) Compression condition : 30kgf, 3 sec, Tool radius: 30 mm in diameter ( refer to Fig 1-3)

COMPRESSION POINT

ABS natural 2.0t

Flat plate

LCD

[ Fig 1-2 ]

LG Display Co., Ltd.

Date: 2010. 08.11

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 12

Global LCD Panel Exchange Center

www.panelook.com

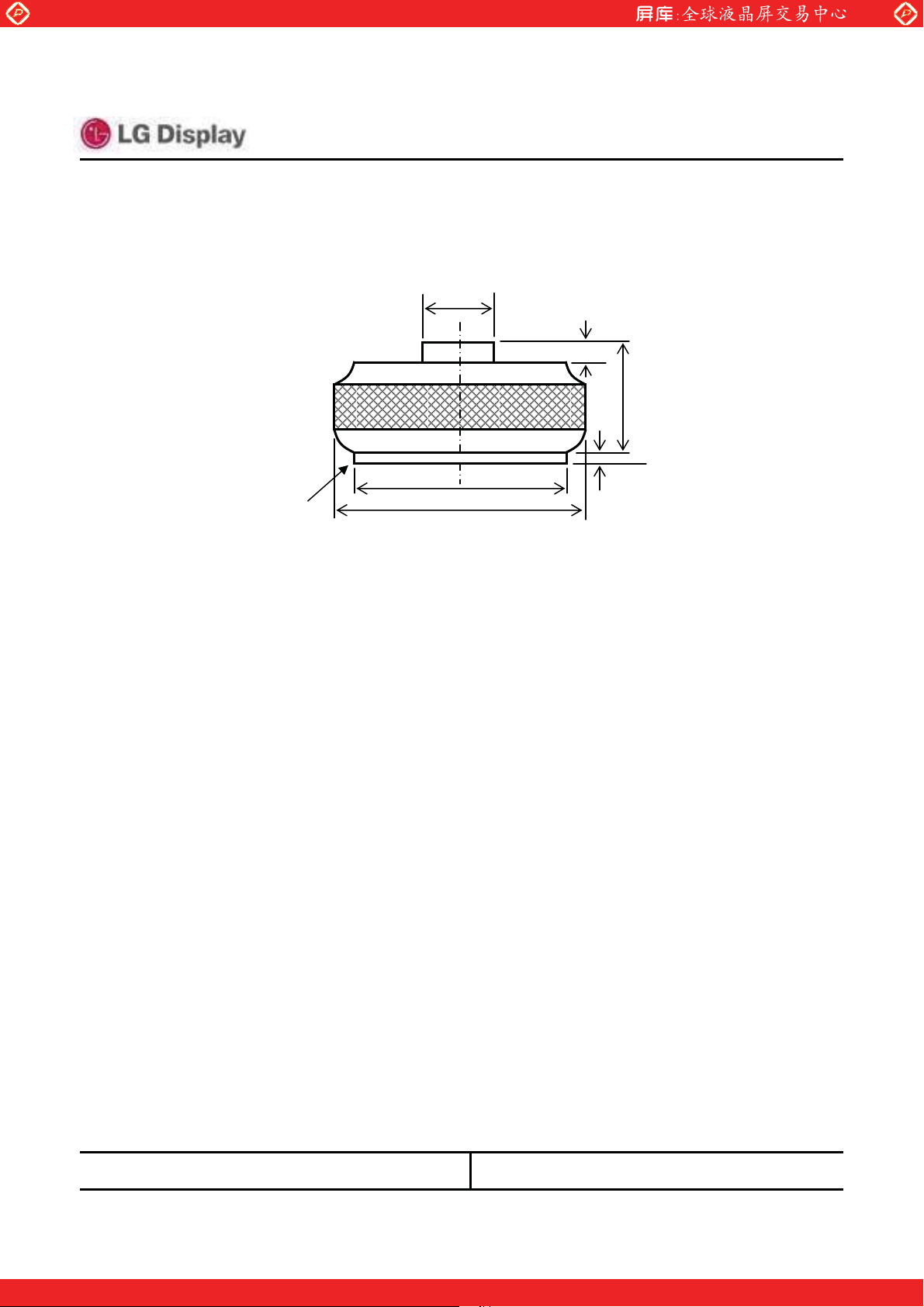

Rubber sheet

Specification Rev. 0.5

10mm in diameter

B

A

[ Fig 1-3 ]

12 / 56

10

16

1.5

(3) Dimension of the compression jig

(a) compression jig for front side A = 16 mm in diameter

B = 16 mm in diameter

(b) compression jig for rear side A = 30 mm in diameter

B = 28 mm in diameter

LG Display Co., Ltd.

Date: 2010. 08.11

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 13

Global LCD Panel Exchange Center

www.panelook.com

Note 2) LCD fixing condition for z direction.

Z

Y X

Specification Rev. 0.5

13 / 56

LG Display Co., Ltd.

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

Date: 2010. 08.11

www.panelook.com

Page 14

Global LCD Panel Exchange Center

www.panelook.com

3.4. The Others

(1) Static electricity pressure resistance

(2) Sound noise

There should be no uncomfortable noise.

Being used under whatever surrounds, when power on/off, the panel should not generate

uncomfortable noise. And regarding specified values are negotiated if it is needed.

(3) Open / Short

No smoke, no fiery at any open/ short test

(4) MTBF : 50,000 Hr (except for backlight LED)

Specification Rev. 0.5

14 / 56

Non OperationOperationItem Testing conditions

r 10 kV8KV150pF, 330 ohmContact discharge

20 KV15KV150pF, 330 ohmAir discharge

LG Display Co., Ltd.

Date: 2010. 08.11

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 15

Global LCD Panel Exchange Center

www.panelook.com

Specification Rev. 0.5

15 / 56

4. Optical Characteristics

4.1. Test Conditions

Ambient Temperature : Ta 25r5qC

Ambient Humidity : Ha 65r20%RH

Supply Voltage : VDD 3.3V

Input Signal : According to typical value in "Electrical Characteristics"

LED Driver Supply Voltage : VLED = 12V

LED PWM Duty : DPWM = 100%

The measuring method is shown in 4.2. The following items are measured under stable conditions. The opti

cal characteristics should be measured in a dark room ( Screen illuminance < 2 lx ) or equivalent state with t

he methods shown in Note (6).

4.2. Optical Specifications

NoteUnitMax.Typ.Min.ConditionsSymbolItem

Contrast Ratio

(Center 1 Point)

Response Time

Average luminance

(5 Point Average)

Cross Modulation

Red

Luminance

Uniformity

Chromaticity

Viewing

Angle

13 Points CR Variation

Green

Blue

White

Hor.

Ver.

Hor.

Ver.

ON+tOFF

ON

t

OFF

L

SHA

Rx

Ry

Gx

Gy

Bx

By

Wx

Wy

T

L

T

R

T

up

T

Low

T

L

T

R

T

up

T

Low

ǬW13 Points White Variation

R

T=0q, I=0q

Viewing

normal angle

CR>=10

CR>=5

T=0q, I=0q

Viewing

normal angle

I = 180

I = 0q

I = 90q

I = -90q

I = 180

I = 0q

I = 90q

I = -90q

40

40

10

30

50

50

10

30

45

45

15

35

55

55

15

35

ms2516t

95.5t

-200170Y

ms (3)

ms1610.5

2

cd/m

0.6070.5770.547

0.3770.3470.317

0.3680.3380.308

0.5910.5610.531

0.1890.1590.129

-

0.1570.1270.097

0.3430.3130.283

0.3590.3290.299

-

-

-

deg.

-

-

-

-

(2), (6)--350300CR

=12V

*V

LED

=100%

D

PWM

Gray Scale Level

= L63 (White)

(5)%2.0--D

(1), (6)

PR650

Only for

Color

Coordinate

(Color Coordinate of

the R,G,B is based

on LGD’s equipment,

and Color Coordinate

of the W is based on

LGD’s equipment)

(7)1.6--

(7)2.0--ǬC

(8)2.0--dLWhite Variation

LG Display Co., Ltd.

Date: 2010. 08.11

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 16

Global LCD Panel Exchange Center

www.panelook.com

Specification Rev. 0.5

16 / 56

Attach the LED current – Luminance characteristics. The range of LED current is shown in 3.2 (2)

A. Present CR Variation(13Point) Spec is based on PR-880 Equipment and can be changed by the

measuring equipment.

NoteUnitMax.Typ.Min.ConditionsGray levelItem

100100100

88746055

6852.4936.847

50

33

21.5

11.6

4.9

0.90.120.000

%

(1), (6)

(Center 1 Point)

Normalized luminance

at each gray level

63

T=0q, I=0q

Viewing

normal angle

34.822039

21.019.531

12.213.523

5.360.9515

1.450.097

At normal viewing direction, during displaying the L0-L63 gray scale bar, luminance intensity inversion

can not be seen.

Note 1) Definition of viewing angle T and I

I

= 180

q

I

= 270

,

Left

q

Down

,

Note 2) LCD fixing condition for z direction.

The contrast ratio can be calculated by the following expression.

Contrast Ratio (CR) = L63 / L0

L63 : Luminance on the white raster (gray scale level L63)

L 0 : Luminance on the black raster (gray scale level L0)

Normal

T

Measurement

Direction

I

Y

I

= 90q, Up

I

q

= 0

,

Right

LG Display Co., Ltd.

Date: 2010. 08.11

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 17

Global LCD Panel Exchange Center

www.panelook.com

Specification Rev. 0.5

Note 3) Definition of response time

%

100

90

Optical

Response

10

0

Bright Bright

Note 4) Definition of surface luminance of white

Measure the luminance of white at Center point. Surface luminance of white Y

Ton

17 / 56

Toff

Dark

L

Note 5) Definition of Cross Modulation (D

= | YB–YA| / YAu100 (%)

D

SHA

Where:

= Luminance of measured location without darkest gray pattern (cd/m2)

Y

A

Y

= Luminance of measured location with darkest gray pattern (cd/m2)

B

(0, 0)

Gray Level 42

VIEW AREA

YA(683, 192)

(1366, 768)

SHA

)

Gray Level 0

Gray Level 42

(0, 0)

VIEW AREA

(106, 96)

YA(683, 192)

(342, 384)

(1366, 768)

LG Display Co., Ltd.

Date: 2010. 08.11

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 18

Global LCD Panel Exchange Center

www.panelook.com

Note 6) Measuring setup

The measurement suppose to be executed after stabilized the panel at given temperature during 30

min. The measurement shall be executed 30 minutes after lighting at rating. The luminance of white

should be typical luminance ( Typical Condition IL=6.0mA ). In order to stable the luminance, LCD s

hall not be got winds.

LCD module

LCD panel

Center of the screen

Specification Rev. 0.5

( Field of view = 1 deg)

500 mm

18 / 56

Light Shield Room

( Screen luminance < 2 lx)

Photometer

(Prichard 880 or equivalent)

Note 7) Definition of 13 points white variation GW, CR variation GC

GW = Maximum luminance of 13 points / Minimum luminance of 13 points

GC

= Maximum CR 13 points / Minimum CR of 13 points

R

Horizontal Line number [pixel]

Vertical Line number [pixel]

0

192

384

576

768

45

723

0

45

6

9

11

342 683 1025 1366

7 8

2

1

4

12

3

5

Active area

R

1321

: test point

10

13

LG Display Co., Ltd.

Date: 2010. 08.11

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 19

Global LCD Panel Exchange Center

www.panelook.com

Specification Rev. 0.5

Note 8) Definition of White Variation dL : measure the luminance of white at 13 u11 points.

dL = [ | L(x,y) – L(x+I, y+j) | / ( L(x,y) u D(x+I, y+j) ) ] u 100 (%/mm)

where 2 d x d 15, 2 d y d 11, I = r 1, j = r 1

2.14mm

10.9mm

17.5mm

11.6mm

17.5mm

L(x-1,y-1)

12

D(x+1,y-1)

L(x,y)

19 / 56

L(x+1,y-1)

L(x+1,y+1)

Active area

Measuring Spot 16

( Field of View : 2deg. Measuring Distance : 500 mm )

I17.5

LG Display Co., Ltd.

Date: 2010. 08.11

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 20

Global LCD Panel Exchange Center

www.panelook.com

Specification Rev. 0.5

20 / 56

5. Electrical Characteristics

5.1. TFT LCD module

NoteUnitMax.Typ.Min.SymbolItem

Power Supply Voltage

Differential Input

Threshold Voltage

Rush Current

Power Supply

Current

High

Low

White(L63)

Mosaic

Max. Pattern

DD

RUSH

I

DD

255225195

Note 1) The module should be always operated within these ranges. The "Typ." shows the recommendable

value.

Note 2) Recommended LVDS transmitter : SN75LVDS84 (made by TI )

LVDS receiver included in this module is SW0617.(1 chip)

Note 3) Typical condition as follows. : fV= 60Hz, fDCLK = 69.3 MHz, V

= 3.3V, DC current.

DD

Note 4) Power dissipation check pattern.

V3.63.33.0V

mV+100-Vth

mV---100Vtl

mA

(5)A1.5--I

(3), (4) (a)

(3), (4) (b)365315265

(3), (4) (c)470410350

(a) White pattern

Active Area

(C) Max. pattern

Active Area

(b) Mosaic pattern

Display Brightest Gray scale

Display Darkest Gray scale

G BR

LG Display Co., Ltd.

Date: 2010. 08.11

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 21

Global LCD Panel Exchange Center

www.panelook.com

Specification Rev. 0.5

Note 5) Measuring condition of rush current.

21 / 56

rising time is 500us

V

DD

GND

LG Display Co., Ltd.

0.1 V

DD

0.9 V

3.3V

DD

Date: 2010. 08.11

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 22

Global LCD Panel Exchange Center

www.panelook.com

5.2. Backlight Unit

BACKLIGHT : ( with LED Driver)

PWM Jitter

PWM High Level Voltage

PWM Low Level Voltage

Specification Rev. 0.5

SymbolParameter

LEDLED Power Input Voltage

LEDLED Power Input Current

LEDLED Power Consumption

LED_PLED Power Inrush Current

-

PWMPWM Impedance

PWMPWM Frequency

PWM_H

PWM_L

PWMLED_EN Impedance

22 / 56

Values

NotesUnit

MaxTypMin

1V21.012.07.0V

2mA220200-I

3W2.62.4-P

4mA1000--I

5%100-5PWM Duty Ratio

6%0.2-0

kȳ604020Z

7Hz20001000200F

V5.3-3.0V

V0.3-0V

kȳ604020Z

LED_EN_HLED_EN High Voltage

LED_EN_LLED_EN Low Voltage

V5.3-3.0V

V0.3-0V

8Hrs--12,000Life Time

1. This impedance value is needed for proper display and measured form LVDS Tx to the mating connector.

2. The measuring position is the connector of LCM and the test conditions are under 25.

3. The current and power consumption with LED Driver are under the Vled = 12.0V , 25, Dimming of

Max luminance and White pattern with the normal frame frequency operated(60Hz).

4. The below figures are the measuring Vled condition

and the Vled control block LGD used.

VLED control block is same with Vcc control block.

Rising time

LED

V

0V

10%

90%

12.0V

0.5ms

5. The operation of LED Driver below minimum dimming ratio may cause flickering or reliability issue.

6. If Jitter of PWM is bigger than maximum, it may induce flickering.

7. This Spec. is not effective at 100% dimming ratio as an exception because it has DC level equivalent

to 0Hz. In spite of acceptable range as defined, the PWM Frequency should be fixed and stable for

more consistent brightness control at any specific level desired.

8. The life time is determined as the time at which the typical brightness of LCD is 50% compare to that of

initial value at the typical LED current. These LED backlight has 4 strings on it and the typical current of

LED’s string is base on 18mA.

LG Display Co., Ltd.

Date: 2010. 08.11

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 23

Global LCD Panel Exchange Center

ൎ

www.panelook.com

Specification Rev. 0.5

5.3. Regulation

The set (which LCD module is assembled into) should conform to the regulations below.

(1) EMC Regulations.

a) ANSI C63.4

b) CISPR 22

c) CISPR 13

(2) Safety Regulations (Only LCD)

a) UL 60950-1, Second Edition, Underwriters Laboratories Inc.

b) CAN/CSA C22.2 No.60950-1-07, Second Edition, Canadian Standards Association.

c) EN 60950-1:2006 + A11:2009, European Committee for Electrotechnical Standardization (CENELEC).

d) IEC 60950-1:2005, Second Edition, The International Electrotechnical Commission (IEC).

(3) Environment

a) RoHS, Directive 2002/95/EC of the European Parliament and of the council of 27 January 2003

(4) Material list concerning

23 / 56

TCON

DC/DC

LED

Driver

TCON OUTPUT

(Data Output)

Power

V

(2.5V)

cc

Control IC for

Power supply

Switching

Diode

Schottky

Barrier Diode

Control IC for

LED

R12, R13,

R14, R15

NRS4012T100ML2, L3Inductor

NRS4012T100ML4Inductor

Resistor

SW5024US1

DAN217UD11

ADD5201US3

100

2.5VTCONUC1

SW5024, Siliconworks, NBPC,

Boost+LDO+L/S+OP-Amp+PVcom+D/C+GPM,

TQFN (6x6), R/TP, 48 pin

DC/DC Switching frequency

(400Khz ~ 1200Khz)

0.75ABAT750-7-FD3, D10

10 uH20% (Inductance)

0.310ೱ20% (DC Resistance)

0.95A Max (Rated DC Current)

ADD5201, ANALOG DEVICE, 21V, 8CH, -,

LFCSP, R/TP, 28, NBPC

10 uH20% (Inductance)

0.310ೱ20% (DC Resistance)

0.95A Max (Rated DC Current)

MakerRatingProductSilkItem

ROHM,

Samsung

Elec., Walsin

Siliconworks

Siliconworks

DIODES

DIODES

KTY

Analog

Device

KTY

LG Display Co., Ltd.

Date: 2010. 08.11

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 24

Global LCD Panel Exchange Center

www.panelook.com

6. Block Diagram

User connector

LVDS

1port

40

Pin

VCC

VLED

LED_EN

PWM

Specification Rev. 0.5

EEPROM Block

EEPROM Block

for EDID

for EDID

EEPROM Block

EEPROM Block

for Tcon Operating

for Tcon Operating

Timing Control

Timing Control

(Tcon) Block

(Tcon) Block

DVCC

Power

Power

Block

Block

LED Driver

LED Driver

Block

Block

TCLKs

M

i

n

i

-

L

V

D

S

AVCC, AVDD

VGH, VGL, GMA

GIP CLKs, DSC

VOUT_LED

FB1~4

ࣿࣜࣜ ࣜࣜࣜ

1

TFT-LCD Panel

(HD, GIP, TN)

768

Source Driver

(Flat)

LED Backlight Ass’y

24 / 56

1366

LG Display Co., Ltd.

Date: 2010. 08.11

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 25

Global LCD Panel Exchange Center

www.panelook.com

Specification Rev. 0.5

25 / 56

7. Input Terminal Pin Assignment

7.1. TFT LCD module

This LCD employs two interface connections, a 40 pin connector is used for the module electronics interface

and the other connector is used for the integral backlight system.

Table 3. MODULE CONNECTOR PIN CONFIGURATION (CN1)

NotesDescriptionSymbolPin

20

23

24

26

27

29

30

31

32

33

34

35

36

37

38

39

40

NC

NC

NC

NC

NC

NC

NC

NC

GND

GND

GND

NC

LED_EN

NC

No Connection`NC1

LCD Logic and driver power (3.3V Typ.)VCC2

LCD Logic and driver power (3.3V Typ.)VCC3

DDC Power (3.3V)V EEDID4

No ConnectionNC5

DDC ClockClk EEDID6

DDC DataDATA EEDID7

Negative LVDS differential data inputORX0-8

Positive LVDS differential data inputORX0+9

LCM Ground GND10

Negative LVDS differential data inputORX1-11

Positive LVDS differential data inputORX1+12

LCM Ground GND13

Negative LVDS differential data inputORX2-14

Positive LVDS differential data inputORX2+15

LCM Ground GND16

Negative LVDS differential clock inputORXC-17

Positive LVDS differential clock inputORXC+18

LCM Ground GND19

No Connection

No Connection21

LCM Ground GND19

No Connection

No Connection

LCM Ground GND19

No Con

No Connection

LCM Ground GND19

No Connection

No Connection

LCM Ground (LED Backlight Ground)

LCM Ground (LED Backlight Ground)

LCM Ground (LED Backlight Ground)

No Connection

System PWM Signal input for dimmingPWM

LED Backlight On/Off

No Connection

LED Backlight Power (7V-21V)VLED

LED Backlight Power (7V-21V)VLED

LED Backlight Power (7V-21V)VLED

nection

1. Interface chips

1.1 LCD : SW, SW0617 (LCD Controller)

including LVDS Receiver

1.2 System : THC63LVDF823A

* Pin to Pin compatible with LVDS

2. Connector

2.1 LCD : UJU IS050-L40B-C10

2.2 Mating : 20453-#40E-## series

2.3 Connector pin arrangement

or equivalent

or equivalent

[LCD Module Rear View]

LG Display Co., Ltd.

Date: 2010. 08.11

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 26

Global LCD Panel Exchange Center

www.panelook.com

Specification Rev. 0.5

7.3. LVDS Transmitter

LVDS Transmitter : SN75LVDS84 (made by TI ) or compatible.

Pin Name

D1720

21

D1822

23

26 / 56

Require SignalsPin NamePin #Require SignalsPin #

R3D348R4D41

R2D247VccVcc2

GNDGND46R5D53

R1D145G0D64

R0D044GNDDND5

NCNC43G1D76

LVDS GNDLVDS GND42G2D87

Y0M41VccVcc8

Y2M35NCNC14

A0M

A0PY0P40G3D99

A1MY1M39G4D1010

A1PY1P38GNDGND11

LVDS VccLVDS Vcc37G5D1112

LVDS GNDLVDS GND36B0D1213

A2M

A2PY2P34B1D1315

CLKMCLKOUTM33B2D1416

CLKPCLKOUTP32GNDGND17

LVDS GNDLVDS GND31B3D1518

PLL GNDPLL GND30B4D1619

PLL VccPLL Vcc29B5

PLL GNDPLL GND28VccVcc

SHDNSHDN27HSYNC

DclkCLKIN26VSYNCD19

DE(Data Enable)D2025GNDGND24

LG Display Co., Ltd.

Date: 2010. 08.11

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 27

Global LCD Panel Exchange Center

www.panelook.com

Specification Rev. 0.5

7.4. Timing Diagrams of LVDS Transmission

Switching Characteristic

VCC = 3.0 ~ 3.6V, Ta = -10 ~ +70

Transmitter

Parameter UnitMax.Typ.Min.Symbol

27 / 56

ns5--CLK IN Transition TimetTCIT

ns32.4T14.7CLK IN PeriodtTCP

ns0.6T0.5T0.4TCLK IN High TimetTCH

ns0.6T0.5T0.4TCLK IN Low TimetTCL

ns-14.2-CLK IN to TCLK +/- DelaytTCD

ns--3.0TTL Data Setup to CLK INtTS

ns--1.5TTL Data Hold from CLK INtTH

ns1.50.70.26LVDS Transition TimetLVT

ns0.20-0.2Output Data Position 0 (T= 15.38ns)tTOP1

nsT/7 + 0.2T/7T/7 - 0.2Output Data Position 1 (T= 15.38ns)tTOP0

ns2T/7 + 0.22T/72T/7 - 0.2Output Data Position 2 (T= 15.38ns)tTOP2

ns3T/7 + 0.23T/73T/7 - 0.2Output Data Position 3 (T= 15.38ns)tTOP3

ns4T/7 + 0.24T/74T/7 - 0.2Output Data Position 4 (T= 15.38ns)tTOP4

ns5T/7 + 0.25T/75T/7 - 0.2Output Data Position 5 (T= 15.38ns)tTOP5

ns6T/7 + 0.26T/76T/7 - 0.2Output Data Position 6 (T= 15.38ns)tTOP6

ns10--Phase Lock Loop SettTPLL

LG Display Co., Ltd.

Date: 2010. 08.11

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 28

Global LCD Panel Exchange Center

www.panelook.com

AC Timing Diagrams

Transmitter Device

CLK IN

TxD - Tx6

Tx +/-

tTCP

tTCH tTCL

2.0V

tTS

2.0V

0.8V

DATA VALID

Specification Rev. 0.5

2.0V

0.8V

tTH

2.0V

0.8V

tTCD

2.0V 2.0V

0.8V

0.8V

28 / 56

Tx0Tx1Tx4 R G B Tx2Tx5Tx6

TCLK+

V diff=0V

tTOP1

tTOP0

tTOP6

tTOP5

tTOP4

tTOP3

tTOP2

LG Display Co., Ltd.

Date: 2010. 08.11

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 29

Global LCD Panel Exchange Center

www.panelook.com

Specification Rev. 0.5

7.5. Input Signal, Basic Display Colors and Gray Scale of each Color

Input Color Data

Color

MSB LSB

RED

Black

Red

Green

Basic

Color

Blue

Cyan

Magenta

Yellow

White

RED (00)

RED (01)

RED

…

RED (62)

RED (63)

GREEN (00)

GREEN (01)

GREEN

...

GREEN (62)

GREEN (63)

BLUE (00)

BLUE (01)

BLUE

…

BLUE (62)

BLUE (63)

Note 1) 0: Low level voltage, 1: High level voltage

MSB LSB

GREEN

29 / 56

BLUE

MSB LSB

B5 B4 B3 B2 B1 B0G5 G4 G3 G2 G1 G0R5 R4 R3 R2 R1 R0

0 0 0 0 0 00 0 0 0 0 00 0 0 0 0 0

0 0 0 0 0 00 0 0 0 0 01 1 1 1 1 1

0 0 0 0 0 01 1 1 1 1 10 0 0 0 0 0

1 1 1 1 1 10 0 0 0 0 00 0 0 0 0 0

1 1 1 1 1 11 1 1 1 1 10 0 0 0 0 0

1 1 1 1 1 10 0 0 0 0 01 1 1 1 1 1

0 0 0 0 0 01 1 1 1 1 11 1 1 1 1 1

1 1 1 1 1 11 1 1 1 1 11 1 1 1 1 1

0 0 0 0 0 00 0 0 0 0 00 0 0 0 0 0

0 0 0 0 0 00 0 0 0 0 00 0 0 0 0 1

………

0 0 0 0 0 00 0 0 0 0 01 1 1 1 1 0

0 0 0 0 0 00 0 0 0 0 01 1 1 1 1 1

0 0 0 0 0 00 0 0 0 0 00 0 0 0 0 0

0 0 0 0 0 00 0 0 0 0 10 0 0 0 0 0

………

0 0 0 0 0 01 1 1 1 1 00 0 0 0 0 0

0 0 0 0 0 01 1 1 1 1 10 0 0 0 0 0

0 0 0 0 0 00 0 0 0 0 00 0 0 0 0 0

0 0 0 0 0 10 0 0 0 0 00 0 0 0 0 0

………

1 1 1 1 1 00 0 0 0 0 00 0 0 0 0 0

1 1 1 1 1 10 0 0 0 0 00 0 0 0 0 0

LG Display Co., Ltd.

Date: 2010. 08.11

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 30

Global LCD Panel Exchange Center

www.panelook.com

Specification Rev. 0.5

8. Interface Timing

8.1. Timing Parameters

This is the signal timing required at the input of the User connector. All of the interface signal timing should be

satisfied with the following specifications and specifications of LVDS Tx/Rx for its proper operation

Hsync

Vsync

Data

Enable

FrequencyDCLK

Slow Refresh RateDCLK

Period

Width

Width-Active

Period

Width

Width-Active

Horizontal back porch

Horizontal front porch

Vertical back porch

Vertical front porch

CLK

CLK

HP

WH

VP

WV

HBP

HFP

VBP

VFP

HA

VA

167416421450t

12411228t

136613661366tw

792786775t

532t

768768768tw

13612828t

483628t

12104t

751t

.

tCLK

tHP

tCLK

tHP

30 / 56

NoteUnitMax.Typ.Min.SymbolITEM

@ 60HzMHz79.577.467.4f

@ 40HzMHz5351.6244.95f

Appendix) All reliabilities are specified for timing specification based on refresh rate of 60 Hz.

Even though actual performance in 50Hz and 40Hz for low power is displayed normally,

remark and inform to user that display quality in 40 Hz and 50 Hz is out of guarantee range.

Data Enable, Hsync, Vsync

tCLK

DCLK

Hsync

t

WH

t

HBP

0.5 Vcc

t

HP

High: 0.7VCC

Low: 0.3VCC

tWHA

Condition : VCC =3.3V

t

HFP

Data Enable

t

VP

t

WV

Vsync

t

VBP

tWVA

t

VFP

Data Enable

LG Display Co., Ltd.

Date: 2010. 08.11

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 31

Global LCD Panel Exchange Center

www.panelook.com

8.3. Power On/Off Sequence

Power Supply Input

VCC

0V

Interface Signal, V

LVDS

LED BL

On/Off Control Signal

LED_EN

i

0V

0V (Off)

90%

Specification Rev. 0.5

T

T

1

2

T

5

T

9

Valid Data

3.0V

3.0V

31 / 56

90%

10%10%

T

T

3

7

T

6

T

10

T

4

8

T

12

Valid Data

T

11

90%

T

10%

13

LED BL

Dimming Control Signal

PWM

LED Driver Input Voltage

VLED

0V (Low)

0V

T

90%

10%

Table 6. POWER SEQUENCE TABLE

Logic

Parameter

1

2

3

4

5

6

7

Value

Max.Typ.Min.

Units

ms10-0.5T

ms50-0T

ms50-0T

ms--200T

ms--200T

ms--0T

LED

Parameter

8

9

10

11

12

13

ms10-0.5T

Value

Note)

1. Do not insert the mating cable when system turn on.

2. Valid Data have to meet “3-3. LVDS Signal Timing Specifications”

3. LVDS, LED_EN and PWM need to pull-down condition on invalid status.

4. LGD recommend the rising sequence of VLED after the Vcc and valid status of LVDS turn on.

Max.Typ.Min.

Units

ms--10T

ms--10T

ms--10T

ms--10T

ms--0.5T

ms5000-0.1T

LG Display Co., Ltd.

Date: 2010. 08.11

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 32

Global LCD Panel Exchange Center

www.panelook.com

Specification Rev. 0.5

9. Cosmetic Specification

9.1. Sampling

A.Q.L (Acceptable Quality Level ): MIL-STD, 105E Level II,

Major: 0.65 , Minor: 1.5

9.2. Conditions of Inspections

(1) Ambient Temperature : 25r5qC

(2) Ambient Humidity : 65r20%RH

(3) Illumination : 200 – 500 Lux ( nominal 350 Lux ) under the fluorescent Lamp.

(4) Viewing Distance: Approximately 30cm by the eyes of the inspector from the module

(5) Viewing angle : The surface of the module and the inspector’s line shall be at 90 r 45 degrees.

(6) Display pattern: Pure Red, Green, Blue, Black, White, Gray level 0 - 63

9.3. Defect modes

DescriptionDefect Mode

Points on the display which appear dark / bright and remain unchanged in sizeDark / Bright spots

Lines on the display which appear dark / bright and remain unchanged in sizeDark / Bright lines

Polarizer scratch

Polarizer dent

Ripple (Pooling )

When the unit is lit a light , line is seen across a darker background; line does not vary

in size

When the unit is lit a light, light (white) spots appear against a darker background, and

do not vary in size

A sub-pixel (R,G,B dot) stuck off / onBright / dark dot

Diagonal lines that appear gray with the display patterns dark and vary in sizeRubbing line

When the unit lights, lines in the minor (Vertical ) or major (Horizontal) axis appear dimDim line

When the unit lights, lines in the both minor and major axis do not appearCross line

Interference can not be seen with any bright plane display at any viewing angleInterference

When displaying sub-pixel checker(gray level and darkest gray), flicker can not be seenFlicker

Tapping Test, Tapping area : All bezel(Metal cover) side, LCD: Full-screen gray (L32)

“Ripple (Pooling )” can not be seen in Active Area

32 / 56

9.4. Mechanical Inspection

(1) Light leakage: No light leakage between metal chassis (bezel) and glass

(2) No sharp edge

(3) The mounting holes: No Changed (Side fixed type)

(4) PCB Appearance: No pattern peeling snapping / No electrically short

If there are repair portions, the repair portions on PCB is covered by epoxy resign

(5) Soldering: No cold solder joint, lead move when pulled

(6) Bezel, Frame, Connectors: No distinct stain, rust or scratch, no pin bending

LG Display Co., Ltd.

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

Date: 2010. 08.11

www.panelook.com

Page 33

Global LCD Panel Exchange Center

www.panelook.com

9.5. Visual Inspection

Dark / bright spot

Dark / Bright lines

L

Polarizer scratch

L

Specification Rev. 0.5

Reject (mm)Count (mm)Defect type

D

W

W

0.2 < D d 0.5

N d 3

0.05 < W d 0.1

0.3 < L d 3.0

N d 3

0.01 < W d 0.1

0.3 < L d 0.5

N d 3

D > 0.5

W > 0.1

L > 3.0

W > 0.1

L > 0.5

33 / 56

Polarizer dent / bubble

D

0.2 d D d 0.5

N d 3

Not allowedRubbing defect

Not allowedDim line

D > 0.5

N > 7N d 7Maximum allowable number of defects

[ D : diameter, W : width, L : length, N : count ]

Note 1) Inspection area should be within bezel opening.

Note 2) Dusts which are bigger not less than 0.10mm (0.1dW) shall be judged by "Average Diameter".

Note 3) Scratches which are bigger not less than 0.05mm (0.05dW) shall be judged by "Average Diameter".

Average Diameter D = (a+b)/2 (mm)

a

b

LG Display Co., Ltd.

Date: 2010. 08.11

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 34

Global LCD Panel Exchange Center

www.panelook.com

Specification Rev. 0.5

9.6. Electrical Inspection

(1) Dot defect

Defect type

Bright dots

Three or more adjacent

Dark dots

Maximum distance

between defects

Not allowedTwo adjacent

Not allowed

Not allowedThree or more adjacent

1) Inspection patterns for dot defect are Pure Red, Green, Blue, Black, and White.

2) Adjacent two dots will be counted as two dots.

3) The distribution of dot defects should be below. Average value of dot defect s should be less than 1.

RejectCount

N > 3N d 2Random

N > 5N d 4Random

N > 2N d 1Two adjacent

N > 6N d 5Maximum allowable number of dot defect

L d 15mmL>15.1mmBright - to - bright dot

L d 10mmL>10.1mmDark - to - dark dot

34 / 56

Quantity of LCD

0 1 2 3 4 5 6 7 8

Count of dot defect in a LCD

Required distribution of dot defect

4) The definition of 2 adjacent dots.

RGBRGBRG RGBRGBRG RGBRGBRG

LG Display Co., Ltd.

Average dot defect N

< 1

AVE

Date: 2010. 08.11

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 35

Global LCD Panel Exchange Center

www.panelook.com

Specification Rev. 0.5

(2) Light leakage

Light leakage can not be seen between metal chassis (bezel) and glass when displaying black plane.

(3) Image sticking

Image sticking pattern shall not be to persist longer than 1second after displaying following pattern 8

hours in the room temperature condition.

35 / 56

(4) Glue/stain/dirt

Glue, non-removable stain and dirt which are visible in the inspection area are not acceptable.

LG Display Co., Ltd.

Date: 2010. 08.11

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 36

Global LCD Panel Exchange Center

ྙ

ྚ

ྛ

ྜ

ྜྷ

ྡ

www.panelook.com

10. Packing

10.1. Carton

(1) Packing Form

Corrugated cardboard box and EPS Packing

(2) Packing Method

Packing Material : EPS (Expanded Polystyrene)

Packing Weight: : 1.3Kg

(1Box/30Module)

Packing weight, 30 pcs modules included :10.5kg

Specification Rev. 0.5

36 / 56

[^Z

Z][

ZZ_

͵Ͷ΄ʹͺ΅ͺͿͿ

ͽʹ͵;ΠΕΦΝΖ

ͳͲ

;Ͳ΅ͶͺͲͽ

ͽ͵Ͷ

;Ͳ΄ͼͺͿ;;Ή;΅ͲͶ

Ͷ΄ͲʹͼͺͿ΅ΣΒΪ΅

Ͷ΄ͲʹͼͺͿ΅ΣΒΪͳ΅΅;

΄ΈͳΉ

;;Ή;΅ͲͶ

Ͳ΅ΉͽͲͳͶͽ

ͲͽͲͽͳΒΘ

LG Display Co., Ltd.

Date: 2010. 08.11

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 37

Global LCD Panel Exchange Center

www.panelook.com

Specification Rev. 0.5

(3) Packing Specification

ConditionsItem

Random=1.50Grms, Non-Operating LCM, To driving way / 1hrPacking Vibration

Refer to below tablePacking Drop Test

Vibration frequency Drop Height

Bottom

side

Left

side

Front

side

Right

side

Rear

side

Top

side

drop test, repeat 3x.

Drop height according table.

drop test from 0.30 m

drop test from 0.30 m

drop test from 0.30 m

drop test from 0.30 m

drop test from 0.30 m

37 / 56

M a ss He i gh t M a ss He i gh t

[kg] [cm ] [kg] [cm]

170 15 43

270 16 42

367 17 41

463 18 40

560 19 39

657 20 38

755 21 38

853 22 37

951 23 37

10 49 24 36

11 48 25 36

12 46 26 36

13 45 27 36

14 44 28 – 50 35

(4) Package Label

Package label should be at least shown the following information.

a) TOSHIBA code name(G33C00068110) which will be numbered by Toshiba

b) Revision number which be numbered by LCD maker

c) Quantity

d) LCD maker

e) Model number which be numbered by LCD maker

f) Production Year / Month

(5) Location of Package label : 1 points ( Side )

1 Side (LABEL Position)

LG Display Co., Ltd.

Date: 2010. 08.11

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 38

Global LCD Panel Exchange Center

www.panelook.com

Specification Rev. 0.5

11. Labels and Other parts Exchange

11.1. LCD code Label on LCD

LCD code label should be at least shown the following information.

(1) TOSHIBA code name (G33C00068110) which will be numbered by Toshiba & Bar code

(Bar code : CODE-39 High-density )

(2) LGPL Serial number CODE ( numbered by LCD maker , less than equal 13 digits)

ABCDEFGHI JKLM

A,B,C : SIZE(INCH) D : YEAR

E : MONTH F ~ M : SERIAL NO.

Note

1. YEAR

Year

Mark

321

200452005

4

200320022001

2006720078200892009

6

38 / 56

2010

0

2. MONTH

Month

Mark

Apr5May

4

Jun7Jul8Aug9Sep

6

b) Location of Lot Mark

Serial No. is printed on the label. The label is attached to the backside of the LCD module.

This is subject to change without prior notice.

Oct

A

Nov

B

DecMarFebJan

C321

LG Display Co., Ltd.

Date: 2010. 08.11

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 39

Global LCD Panel Exchange Center

www.panelook.com

Example >

LABEL : 78mm X 37mm

Specification Rev. 0.5

TOSHIBA CODE

39 High-density

39 / 56

TOSHIBA

Revision Code

LGD Serial Number Code

128 High-density

The revision code is inserted in the label by Toshiba request. If the contents of the specification need to be

change under mass-production, the code can be revised after Toshiba’s approval. Although there is not

items in the contents of the specification, Toshiba can requests LGD to change the revision code.

11.2. Caution Texture and Labels on LCD

[Disposal of BL label]

LG Display Co., Ltd.

Date: 2010. 08.11

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 40

Global LCD Panel Exchange Center

www.panelook.com

11.3. Label Locations on LCD

Specification Rev. 0.5

40 / 56

11.4. Others

(1) Backlight repair parts kit : 6091L-1238C

PartNo.

Plate Bottom1

Cover Shield(S)2

Cover Shield(T)3

Cover Shield(L,R)4

Product Code

3300L-0332A

3550S-1024A

3550S-0910A

3550S-0921B

Geo rim

Geo rim

Geo rim

Maker

Qt’y

1

1

1

2

2Hwa sung7250L-0082ATape Adhesive5

36SSC6915L-0070ALED6

Note

LG Display Co., Ltd.

Date: 2010. 08.11

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 41

Global LCD Panel Exchange Center

www.panelook.com

Specification Rev. 0.5

(2) Package specification of Backlight repair parts kit

a) Individual packing

41 / 56

b) Master carton Packing method

c) Label

70

100

LG Display Co., Ltd.

Date: 2010. 08.11

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 42

Global LCD Panel Exchange Center

ᐭ

ᐭ

ᐭ

ᐭ

www.panelook.com

11.5. Instruction of changing the parts

11.5.1. Disassembly of Cover Shield

(1) ྙ Disassembly of Cover Shield (4 Point)

Caution: Pressure or stress should not be given on Source COF.

Cover Shield(L)

3550-0921B

Specification Rev. 0.5

42 / 56

Cover Shield(R)

3550-0910A

Cover Shield(R)

3550-0921B

Cover Shield(S)

3550S-1024A

LG Display Co., Ltd.

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

Date: 2010. 08.11

www.panelook.com

Page 43

Global LCD Panel Exchange Center

ᐭ

www.panelook.com

11.5.2. Disassembly of Source PCB

(1) ྙ Disassembly of Source PCB.

Caution: Pressure or stress should not be given on PCB and COF.

Specification Rev. 0.5

43 / 56

SOURCE

PCB

LG Display Co., Ltd.

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

Date: 2010. 08.11

www.panelook.com

Page 44

Global LCD Panel Exchange Center

www.panelook.com

Specification Rev. 0.5

11.5.3. Disassembly of Case top, Board Ass’y, Tape Adhesive, Light guide, Cover Ass’y

(1) ྙ Disassembly of Cover Shield (4Point)

(2) ྚ Disassembly of Screw for PCB fixing (2Point)

Caution: Maximum value of torque with Screw should be below 1.5kg.

(3) ྛ Disassembly of Board Ass’y.

Caution: This process should be made in Clean room with no scratch nor particle on Polarizer and

B/L Ass’y.

(4) ྜ Disassembly of Tape Adhesive used for Sheets fixing (4Point).

(5) ྜྷ Disassembly of Sheets, Light guide.

Caution: No penetration of foreign body is indispensable with no scratch on the surface of each

Sheets.

(5) ྞ Disassembly of Plate Ass’y

44 / 56

LED Array Ass’y

Plate Bottom

Reflector

Light Guide Panel

Supporter Main

Sheet

Board Ass’y

Cover Shield

Screw

PartNo.

LGP1

Diffuser Up2

Prism Up3

Prism Down4

Maker

Coretronic

KEIWA

Suntech

Suntech

Maker P/N

5150L-0308A(PMMA)

PBS-631S

SPX2-5SHK

SPX2-5SHK

Note

Toray SaehanDiffuser Down5

LG Display Co., Ltd.

TDA10N

UX150DupontReflector6

Date: 2010. 08.11

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 45

Global LCD Panel Exchange Center

www.panelook.com

Specification Rev. 0.5

11.5.4. Assembly of Cover Ass’y, Sheets, Light guide, Tape Adhesive, Board Ass’y and Case top.

(1) ྙ Assembly of Cover Ass’y

(2) ྚ Assembly of Light Guide and Sheets.(Reflector Sheet fixing with one Double Tape)

Caution: No penetration of foreign body is indispensable with no scratch on the surface of each

Sheet and Light guide.

(3) ྛ Assembly of Tape adhesive used for Sheets fixing(4Point)

(4) ྜ Assembly of Board Ass’y.

Caution: Pressure or stress should not be given on PCB and COF.

(5) ྜྷ Assembly of Screw for PCB fixing

Caution: Maximum value of torque with Screw should be below 1.5kg

(6) ྜྷ Assembly of Cover Shield (4Point)

45 / 56

LED Array Ass’y

Plate Bottom

Reflector

Light Guide Panel

Supporter Main

Sheet

Board Ass’y

Screw

PartNo.

LGP1

Diffuser Up2

Prism Up3

Prism Down4

Maker

Coretronic

KEIWA

Suntech

Suntech

Maker P/N

5150L-0308A(PMMA)

PBS-631S

SPX2-5SHK

SPX2-5SHK

Cover Shield

Note

Toray SaehanDiffuser Down5

LG Display Co., Ltd.

TDA10N

UX150DupontReflector6

Date: 2010. 08.11

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 46

Global LCD Panel Exchange Center

www.panelook.com

Specification Rev. 0.5

12. General Precaution

Please pay attention to the followings when you use this TFT LCD module.

12.1. Mounting Precautions

(1) You must mount a module using holes arranged in four corners or four sides.

(2) You should consider the mounting structure so that uneven force (ex. twisted stress) is not applied

to the module. And the case on which a module is mounted should have sufficient strength so that

external force is not transmitted directly to the module.

(3) Please attach a transparent protective plate to the surface in order to protect the polarizer.

Transparent protective plate should have sufficient strength in order to resist external force.

(4) You should adopt radiation structure to satisfy the temperature specification.

(5) Acetic acid type and chlorine type materials for the cover case aren’t desirable because the former

generates corrosive gas of attacking the polarizer at high temperature and the latter causes circuit

break by electro-chemical reaction.

(6) Do not touch, push or rub the exposed polarizers with glass, tweezers or anything harder than HB

pencil lead. And please do not rub with dust clothes with chemical treatment. Do not touch the surface

of polarizer for bare hand or greasy cloth. (Some cosmetics are detrimental to the polarizer.)

(7) When the surface becomes dusty, please wipe gently with absorbent cotton or other soft materials

like chamois soaked with petroleum benzene. Normal-hexane is recommended for cleaning the

adhesives used to attach front / rear polarizers. Do not use acetone, toluene and alcohol because

they cause chemical damage to the polarizer.

(8) Wipe off saliva or water drops as soon as possible. Their long time contact with polarizer causes

deformations and color fading.

(9) Do not open the case because inside circuits do not have sufficient strength.

46 / 56

12.2. Operating Precautions

(1) The spike noise causes the mis-operation of circuits. It should be lower than following voltage

: V = r 200mV (Over and under shoot voltage).

(2) Response time depends on the temperature. (In lower temperature, it becomes longer.)

(3) Brightness depends on the temperature. (In lower temperature, it becomes lower.) And in lower

temperature, response time (required time that brightness is stable after turned on ) becomes longer.

(4) Be careful for condensation at sudden temperature change. Condensation makes damage to

polarizer or electrical contacted parts. And after fading condensation, smear or spot will occur.

(5) When fixed patterns are displayed for a long time, remnant image is likely to occur.

(6) A module has high frequency circuit. If you need to shield the electromagnetic noise, please co-

work. When a Back-light unit is operating, it sounds. If you need to shield the noise, please co-work.

12.3. Electrostatic Discharge Control

Since a module is composed of electronic circuits, it is not strong to electrostatic discharge. Make

certain that treatment persons are connected to ground through wrist band etc . And don’t touch

interface pin directly.

LG Display Co., Ltd.

Date: 2010. 08.11

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 47

Global LCD Panel Exchange Center

www.panelook.com

Specification Rev. 0.5

12.4. Precautions for Strong Light Exposure

Strong light exposure causes degradation of polarizer and color filter.

12.5. Storage

When storing modules as spares for a long time, the following precautions are necessary.

(1) Store them in a dark place. Do not expose the module to sunlight or fluorescent light. Keep the

temperature between 5 and 35 at normal humidity.

(2) The polarizer surface should not come in contact with any other object. It is recommended that they

be stored in the container in which they were shipped.

12.6. Handling Precautions for Protection Film

(1) When the protection film is peeled off, static electricity is generated between the film and polarizer.

This should be peeled off slowly and carefully by people who are electrically grounded and with well

ion- blown equipment or in such a condition, etc.

(2) The protection film is attached to the polarizer with a small amount of glue. If some stress is applied

to rub the protection film against the polarizer during the time you peel off the film, the glue is apt to

remain on the polarizer. Please carefully peel off the protection film without rubbing it against the

polarizer.

(3) When the module with protection film attached is stored for a long time, sometimes there remains a

very small amount of glue still on the polarizer after the protection film is peeled off.

(4) You can remove the glue easily. When the glue remains on the polarizer surface or its vestige is

recognized, please wipe them off with absorbent cotton waste or other soft material like chamois

soaked with normal-hexane.

47 / 56

LG Display Co., Ltd.

Date: 2010. 08.11

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 48

Global LCD Panel Exchange Center

www.panelook.com

Specification Rev. 0.5

48 / 56

APPENDIX A. Enhanced Extended Display Identification Data (EEDIDTM) 1/3

LG Display Co., Ltd.

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

Date: 2010. 08.11

www.panelook.com

Page 49

Global LCD Panel Exchange Center

www.panelook.com

Specification Rev. 0.5

49 / 56

APPENDIX A. Enhanced Extended Display Identification Data (EEDIDTM) 2/3

LG Display Co., Ltd.

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

Date: 2010. 08.11

www.panelook.com

Page 50

Global LCD Panel Exchange Center

www.panelook.com

Specification Rev. 0.5

50 / 56

APPENDIX A. Enhanced Extended Display Identification Data (EEDIDTM) 3/3

LG Display Co., Ltd.

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

Date: 2010. 08.11

www.panelook.com

Loading...

Loading...