( ) Preliminary Specification

(●) Final Specification

Title 55.0” WUXGA TFT LCD

LC550DUJ

Product Specification

SPECIFICATION

FOR

APPROVAL

BUYER KONKA

MODEL

APPROVED BY

/

/

/

SIGNATURE

DATE

SUPPLIER LG Display Co., Ltd.

*MODEL LC550DUJ

SUFFIX SGK1 (RoHS Verified)

*When you obtain standard approval,

please use the above model name without suffix

APPROVED BY

Y.S. Park / Team Leader

REVIEWED BY

K.Y. Chong / Project Leader

PREPARED BY

H.G. Kang / Engineer

SIGNATURE

DATE

Please return 1 copy for your confirmation with

your signature and comments.

Ver. 1.0

TV Product Development Dept.

LG Display Co., Ltd.

0 /40

LC550DUJ

Product Specification

CONTENTS

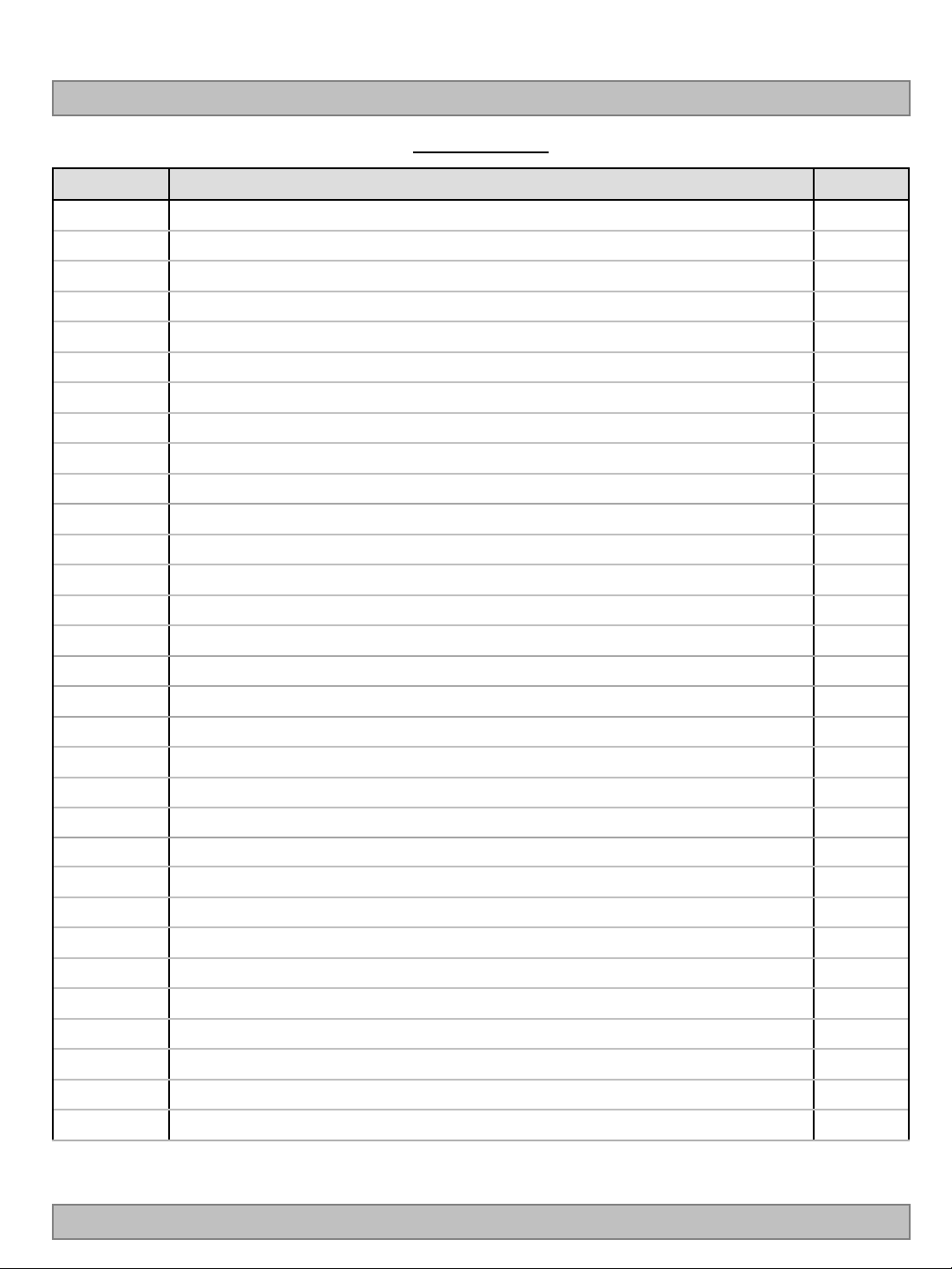

Number ITEM Page

COVER

CONTENTS

RECORD OF REVISIONS

1 GENERAL DESCRIPTION

2 ABSOLUTE MAXIMUM RATINGS

3 ELECTRICAL SPECIFICATIONS

3-1 ELECTRICAL CHARACTERISTICS

3-2 INTERFACE CONNECTIONS

3-3 SIGNAL TIMING SPECIFICATIONS

3-4 LVDS SIGNAL SPECIFICATIONS

3-5 INTARA INTERFACE SIGNAL SPECIFICATION

3-6 COLOR DATA REFERENCE

3-7 POWER SEQUENCE

4 OPTICAL SPECIFICATIONS

5 MECHANICAL CHARACTERISTICS

6 MECHANICAL DIMENSION

6-1 BOARD ASSEMBLY DIMENSION

0

1

2

3

4

5

5

6

7

9

12

13

14

15

20

21

21

6-2 CONTROL BOARD ASSEMBLY DIMMENSION

7 RELIABILITY

8 INTERNATIONAL STANDARDS

8-1 SAFETY 24

8-2 ENVIRONMENT 24

9 PACKING

9-1 PACKING FORM

10 PRECAUTIONS

10-1 ASSEMBLY PRECAUTIONS

10-2 OPERATING PRECAUTIONS

10-3 ELECTROSTATIC DISCHARGE CONTROL

10-4 PRECAUTIONS FOR STRONG LIGHT EXPOSURE

10-5 STORAGE

10-6 OPERATING CONDITION GUIDE

Ver. 1.0

22

23

24

25

25

26

26

26

27

27

27

27

1 /40

Product Specification

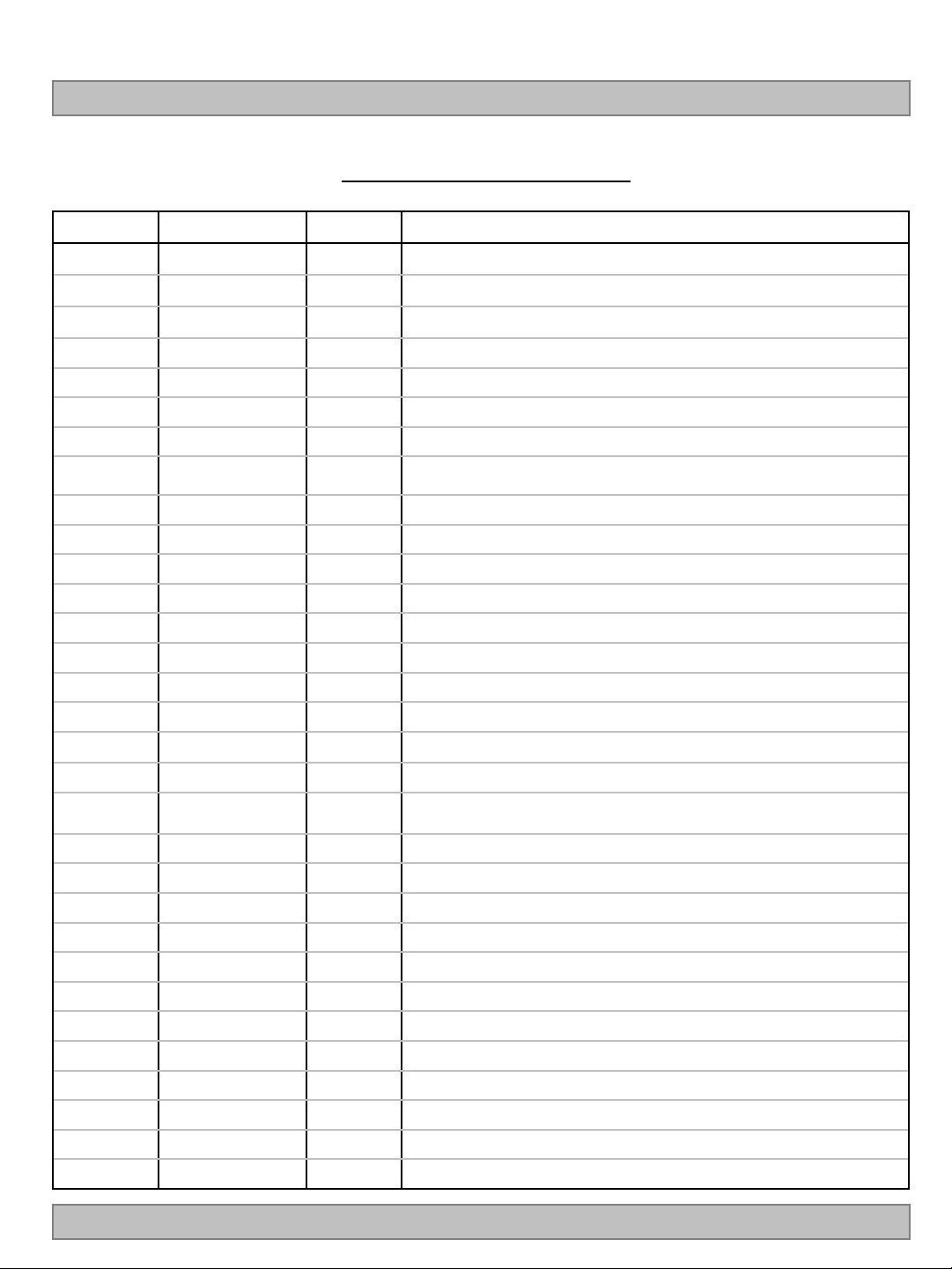

RECORD OF REVISIONS

Revision No. Revision Date Page Description

0.1 Apr, 19, 2013 - Preliminary Specification(First Draft)

0.2 May, 16. 2013 - Parts of spec was updated.

1.0 May, 29, 2013 - CAS Version 1.0 Release

- Final Specification

LC550DUJ

Ver. 1.0

2 /40

LC550DUJ

Product Specification

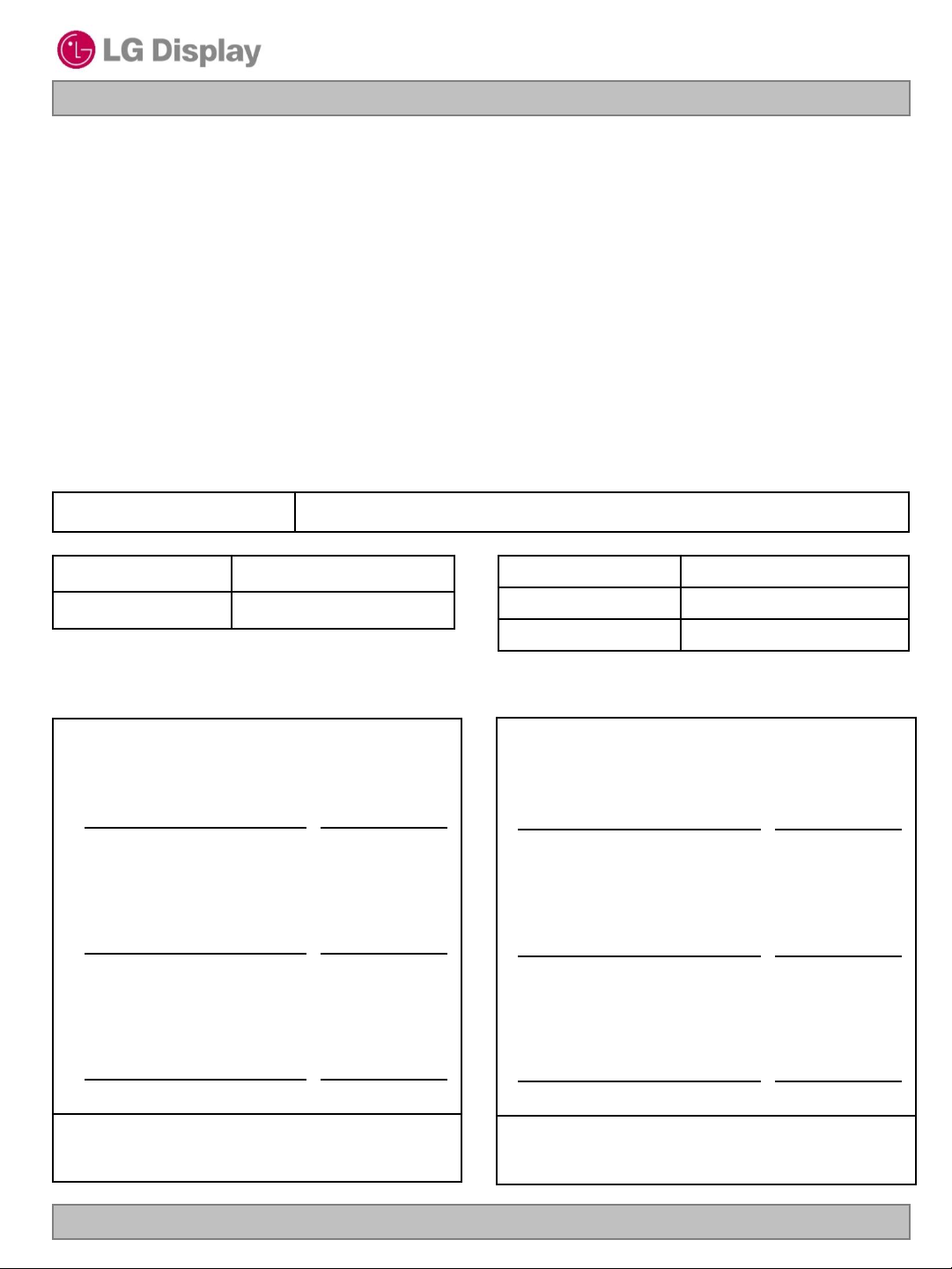

1. General Description

The LC550DUJ is a Color Active Matrix Liquid Crystal Display with an integral the Source PCB and Gate

implanted on Panel (GIP). The matrix employs a-Si Thin Film Transistor as the active element.

It is a transmissive type display operating in the normally black mode. It has a 54.64 inch diagonally measured

active display area with WUXGA resolution (1080 vertical by 1920 horizontal pixel array).

Each pixel is divided into Red, Green and Blue sub-pixels or dots which are arranged in vertical stripes.

Gray scale or the luminance of the sub-pixel color is determined with a 8-bit gray scale signal for each dot.

Therefore, it can present a palette of more than 16.7Million colors.

It has been designed to apply the 8-bit 2-port LVDS interface.

It is intended to support LCD TV, PCTV where high brightness, super wide viewing angle, high color gamut,

high color depth and fast response time are important.

EPI(RGB)

Control

Signals

Power Signals

Source Driver Circuit

S1 S1920

G1

TFT - LCD Panel

(1920 × RGB × 1080 pixels)

[Gate In Panel]

G1080

LVDS

2Port

LVDS

Select

+12.0V

CN1

(51pin)

LVDS 1,2

Option

signal

I2C

EEPROM

SCL

Timing Controller

LVDS Rx + DGA

Power Circuit

SDA

Integrated

Block

General Features

Active Screen Size 54.64 inches(1387.80mm) diagonal

Outline Dimension 1225.2 (H) x 696.7 (V) x 1.3mm(D) (Typ.)

Pixel Pitch 0.630 mm x 0.630 mm

Pixel Format 1920 horiz. by 1080 vert. Pixels, RGB stripe arrangement

Color Depth 8-bit, 16.7 Million colors

Drive IC Data Interface

Transmittance (With POL) 7.10 %(Typ.)

Viewing Angle (CR>10) Viewing angle free ( R/L 178 (Min.), U/D 178 (Min.))

Weight 2.6Kg (Typ.)

Display Mode Transmissive mode, Normally black

Surface Treatment (Top) Hard coating(2H), Anti-glare treatment ,Haze 1%(Typ.),

Ver. 1.0

Source D-IC : 8-bit EPI, gamma reference voltage, and control signals

Gate D-IC : Gate In Panel

3 /40

LC550DUJ

Product Specification

2. Absolute Maximum Ratings

The following items are maximum values which, if exceeded, may cause faulty operation or permanent damage

to the LCD module.

Table 1. ABSOLUTE MAXIMUM RATINGS

Parameter Symbol

Unit Note

Min Max

Power Input Voltage LCD Circuit VLCD -0.3 +14.0 VDC

T-Con Option Selection Voltage VLOGIC -0.3 +4.0 VDC

Value

Operating Temperature TOP 0 +50

Storage Temperature TST -20 +60

Panel Front Temperature TSUR - +68

°C

°C

°C

Operating Ambient Humidity HOP 10 90 %RH

Storage Humidity HST 5 90 %RH

Note

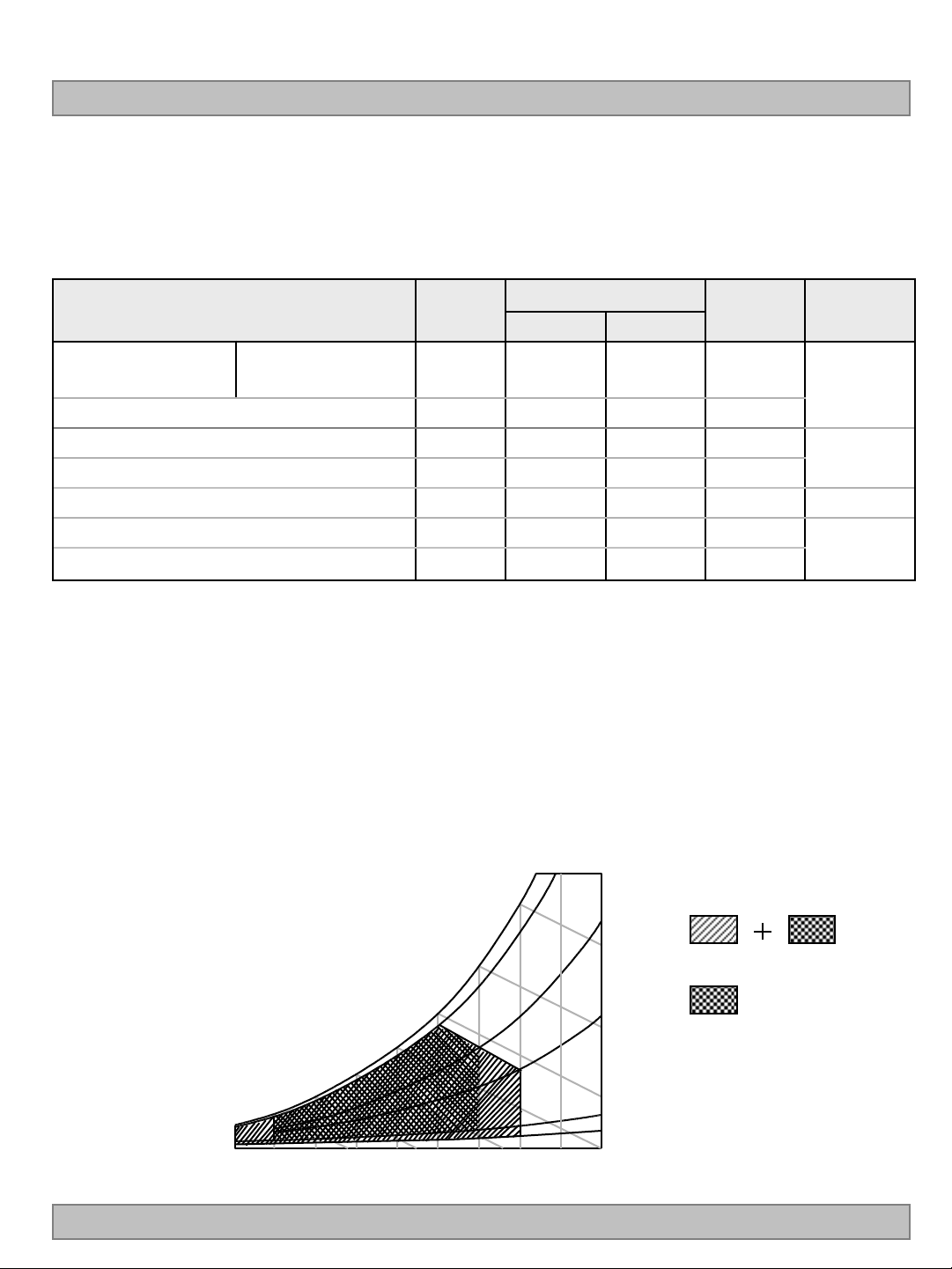

1. Ambient temperature condition (Ta = 25 2 °C )

2. Temperature and relative humidity range are shown in the figure below.

Wet bulb temperature should be Max 39°C, and no condensation of water.

3. Gravity mura can be guaranteed below 40°C condition.

4. The maximum operating temperatures is based on the test condition that the surface temperature

of display area is less than or equal to 68°C with LCD module alone in a temperature controlled chamber.

Thermal management should be considered in final product design to prevent the surface temperature of

display area from being over 68℃. The range of operating temperature may be degraded in case of

improper thermal management in final product design.

1

2,3

4

2,3

Ver. 1.0

Wet Bulb

Temperature [°C]

20

10

0

10 20 30 40 50 60 70 800-20

Dry Bulb Temperature [°C]

30

40

50

60

90%

60%

40%

10%

5%

Storage

Operation

Humidity

[(%)RH]

4 /40

Product Specification

3. Electrical Specifications

3-1. Electrical Characteristics

Table 2. ELECTRICAL CHARACTERISTICS

LC550DUJ

Parameter Symbol

Min Typ Max

Circuit :

Power Input Voltage VLCD 10.8 12.0 13.2 VDC

Power Input Current ILCD

T-CON Option

Selection Voltage

Power Consumption PLCD - 7.4 9.6 Watt 1

Rush current IRUSH - - 5.0 A 3

1. The specified current and power consumption are under the V

Note

Input High Voltage V

Input Low Voltage V

IH

IL

- 614 795 mA 1

- 936 1215 mA 2

2.7 - 3.6

0 - 0.7

Value

=12.0V, Ta=25 2°C, fV=60Hz

LCD

Unit Note

VDC

VDC

condition, and mosaic pattern(8 x 6) is displayed and fVis the frame frequency.

2. The current is specified at the maximum current pattern.

3. The duration of rush current is about 2ms and rising time of power input is 0.5ms (min.).

4. Ripple voltage level is recommended under ± 5% of typical voltage

White : 255 Gray

Black : 0 Gray

Ver. 1.0

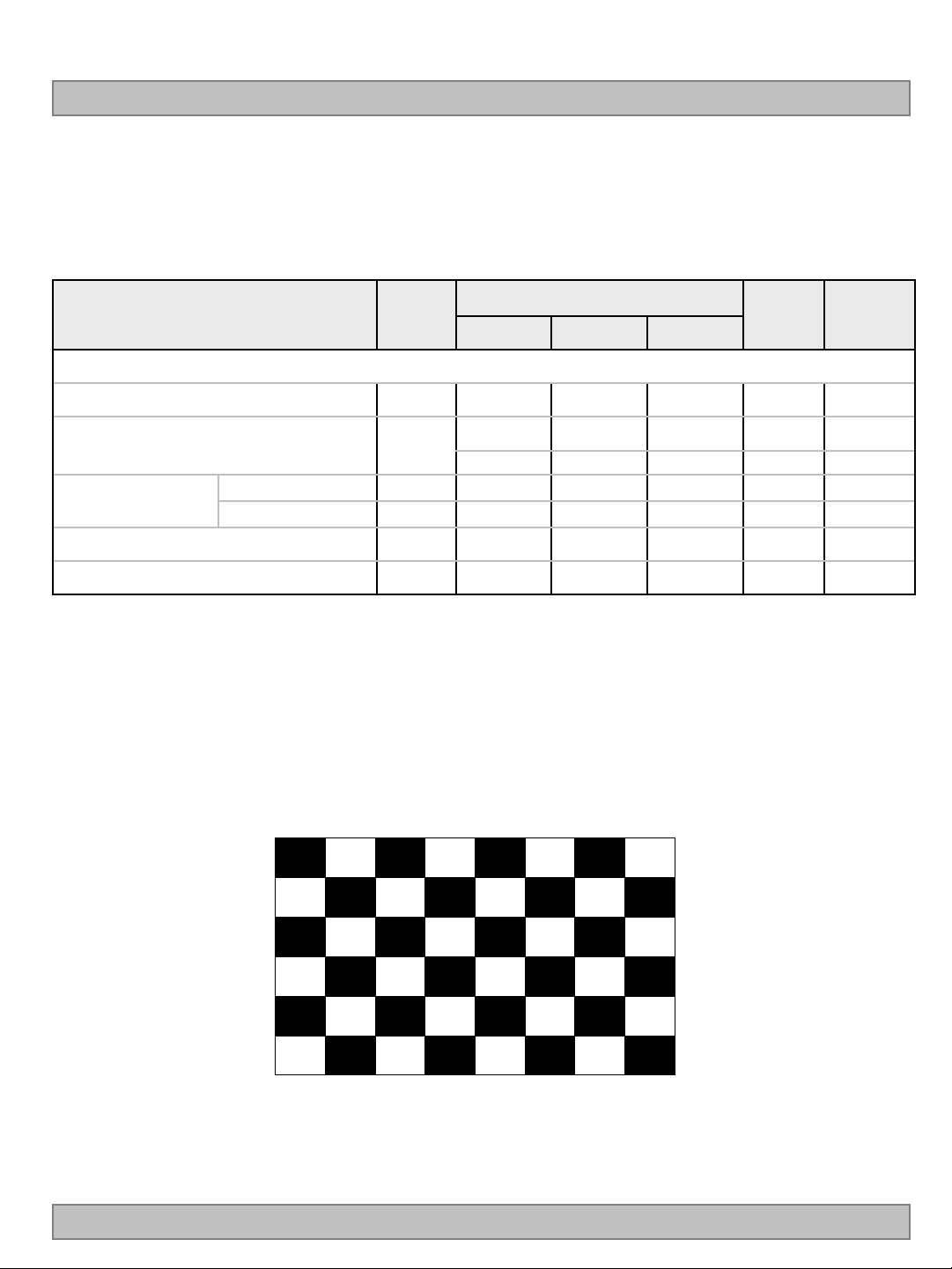

Mosaic Pattern(8 x 6)

5 /40

LC550DUJ

Product Specification

3-2. Interface Connections

This LCD module employs two kinds of interface connection, 51-pin connector is used for the module

electronics.

3-2-1. LCD Module

- LCD Connector(CN1): FI-RE51S-HF(manufactured by JAE) or GT05P-51S-H38(manufactured by LSM)

or IS050-C51B-C39(manufactured by UJU)

- Mating Connector : FI-R51HL(JAE) or compatible

Table 3. MODULE CONNECTOR(CN1) PIN CONFIGURATION

No Symbol Description No Symbol Description

1

2

3

4

5

6

7

8

9

10

11 GND

12 R1AN

13 R1AP

14 R1BN

15

16 R1CN

17 R1CP

18 GND

19 R1CLKN

20

21 GND

22 R1DN

23 R1DP

24

25

26

NC

NC

NC

NC

NC

NC

LVDS Select

NC

NC

NC

R1BP

R1CLKP

NC No connection

NC No connection

NC or GND

No Connection (Note 4)

No Connection (Note 4)

No Connection (Note 4)

No Connection (Note 4)

No Connection (Note 4)

No Connection (Note 4)

‘H’ =JEIDA , ‘L’ or NC = VESA

No Connection (Note 4)

No Connection (Note 4)

No Connection (Note 4)

Ground

FIRST LVDS Receiver Signal (A-)

FIRST LVDS Receiver Signal (A+)

FIRST LVDS Receiver Signal (B-)

FIRST LVDS Receiver Signal (B+)

FIRST LVDS Receiver Signal (C-)

FIRST LVDS Receiver Signal (C+)

Ground

FIRST LVDS Receiver Clock Signal(-)

FIRST LVDS Receiver Clock Signal(+)

Ground

FIRST LVDS Receiver Signal (D-)

FIRST LVDS Receiver Signal (D+)

No Connection or Ground

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

- - -

NC No connection

R2AN

R2AP

R2BN

R2BP

R2CN

R2CP

GND

R2CLKN

R2CLKP

GND

R2DN

R2DP

NC No connection

NC No connection

NC or GND

NC or GND

GND Ground (Note 5)

GND Ground

GND Ground

NC No connection

VLCD Power Supply +12.0V

VLCD Power Supply +12.0V

VLCD Power Supply +12.0V

VLCD Power Supply +12.0V

SECOND LVDS Receiver Signal (A-)

SECOND LVDS Receiver Signal (A+)

SECOND LVDS Receiver Signal (B-)

SECOND LVDS Receiver Signal (B+)

SECOND LVDS Receiver Signal (C-)

SECOND LVDS Receiver Signal (C+)

Ground

SECOND LVDS Receiver Clock Signal(-)

SECOND LVDS Receiver Clock Signal(+)

Ground

SECOND LVDS Receiver Signal (D-)

SECOND LVDS Receiver Signal (D+)

No Connection or Ground

No Connection or Ground

Note

Ver. 1.0

1. All GND(ground) pins should be connected together to the LCD module‟s metal frame.

2. All VLCD (power input) pins should be connected together.

3. All Input levels of LVDS signals are based on the EIA 644 Standard.

4. #1~#6 & #8~#10 NC (No Connection): These pins are used only for LGD (Do not connect)

5. Specific pin No. #44 is used for “No signal detection” of system signal interface.

It should be GND for NSB(No Signal Black) during the system interface signal is not.

If this pin is “H”, LCD Module displays AGP(Auto Generation Pattern).

6 /40

LC550DUJ

Product Specification

3-3. Signal Timing Specifications

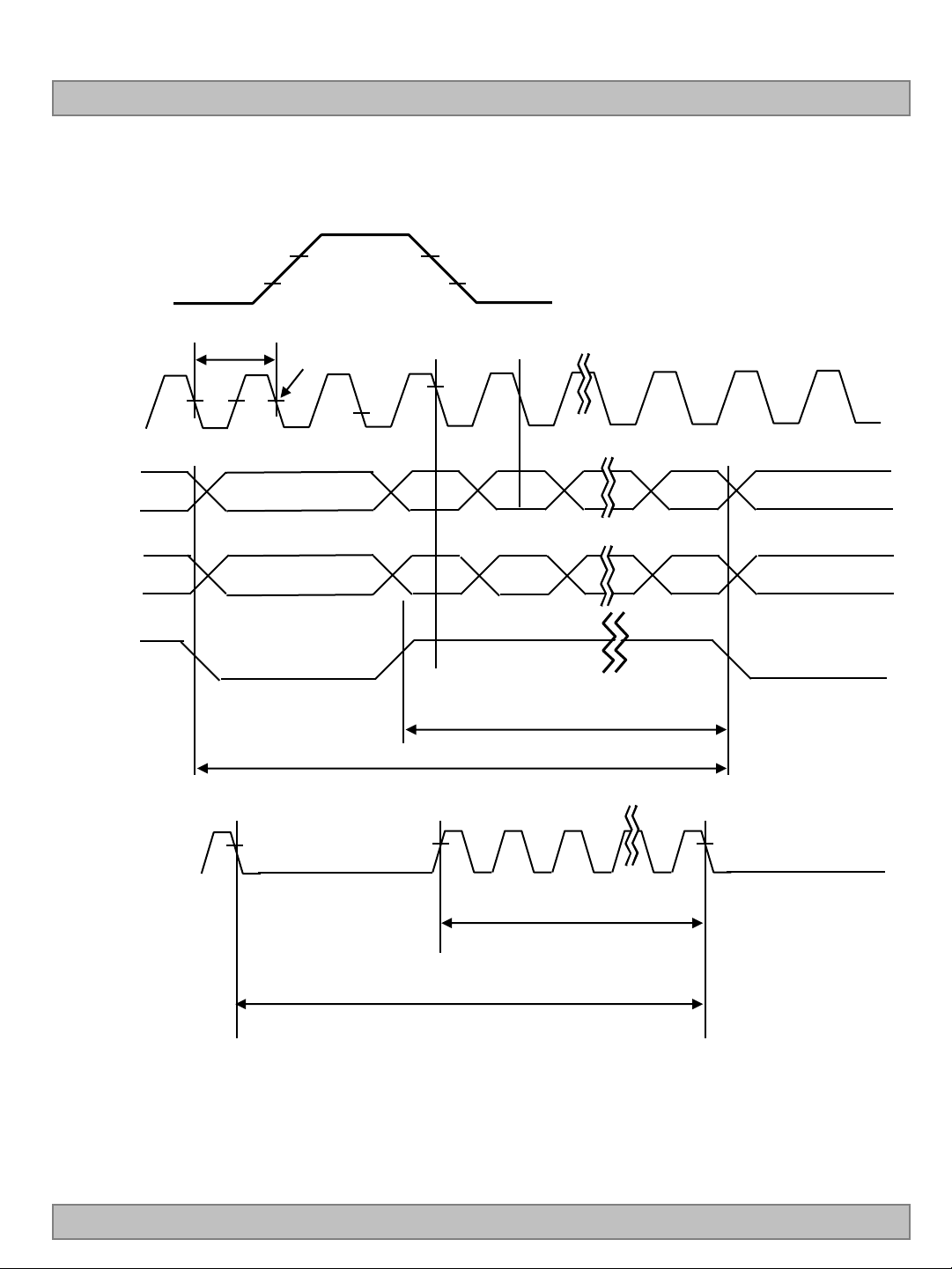

Table 6 shows the signal timing required at the input of the LVDS transmitter. All of the interface signal

timings should be satisfied with the following specification for normal operation.

Table 6. TIMING TABLE for NTSC & PAL(DE Only Mode)

ITEM Symbol Min Typ Max Unit notes

Horizontal

Vertical

Frequency

Display

Period

Blank tHB 100 140 240 tCLK 1

Total tHP 1060 1100 1200 tCLK

Display

Period

Blank tVB 20 45 300 Lines 1

Total tVP 1100 1125 1380 Lines

ITEM Symbol Min Typ Max Unit notes

DCLK fCLK 60.00 74.25 78.00 MHz

Horizontal fH 57.3 67.5 70 KHz 2

Vertical fV 47 60 63 Hz 2

tHV 960 960 960 tCLK 1920 / 2

tVV 1080 1080 1080 Lines

Note: 1. The input of HSYNC & VSYNC signal does not have an effect on normal operation (DE Only Mode).

If you use spread spectrum of EMI, add some additional clock to minimum value for clock margin.

2. The performance of the electro-optical characteristics may be influenced by variance of the vertical

refresh rate and the horizontal frequency

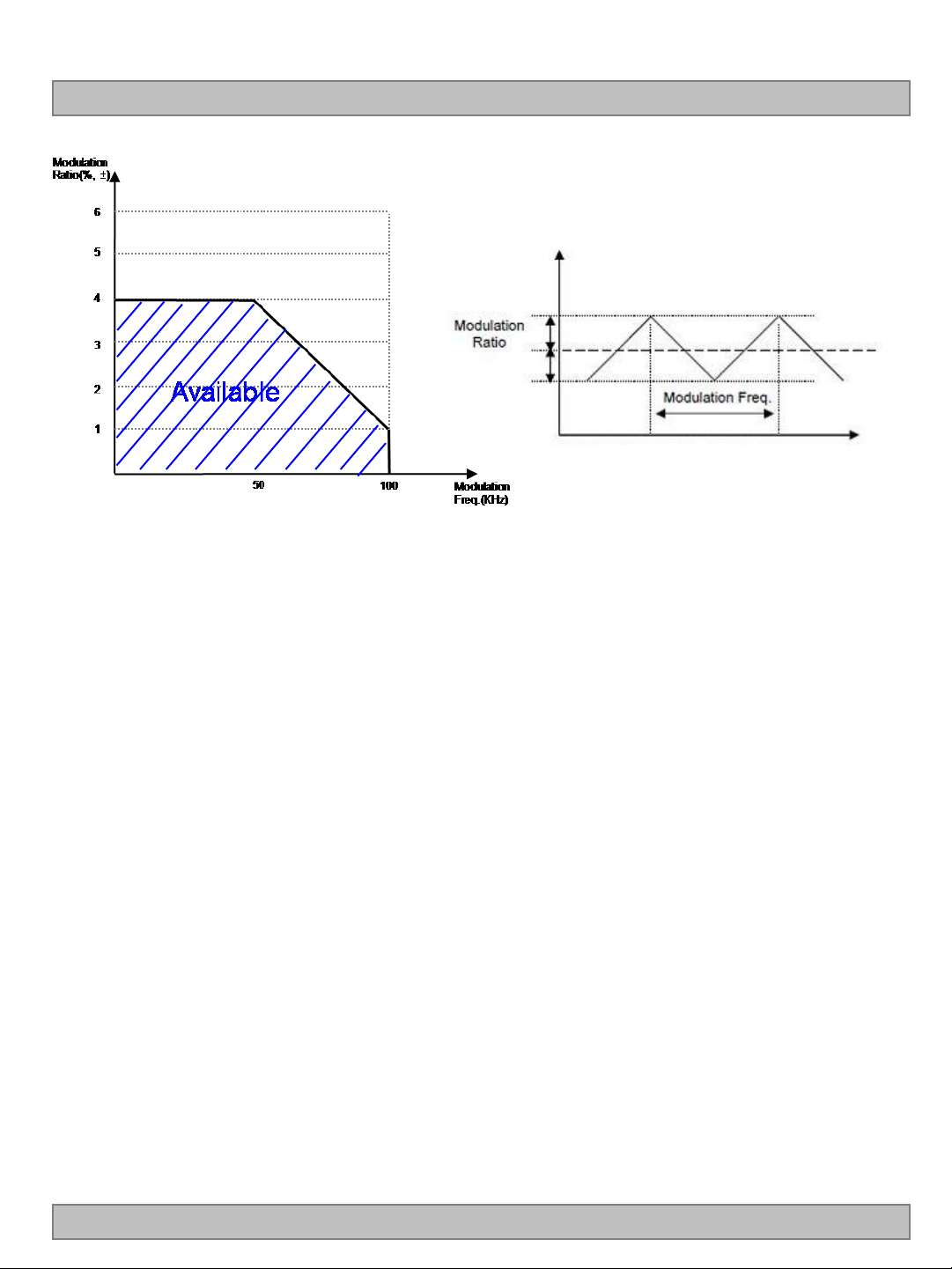

3. Spread Spectrum Rate (SSR) for 50KHz ~ 100kHz Modulation Frequency(FMOD) is calculated by

(7 – 0.06*Fmod), where Modulation Frequency (FMOD) unit is KHz.

LVDS Receiver Spread spectrum Clock is defined as below figure

※ Timing should be set based on clock frequency.

Ver. 1.0

7 /40

LC550DUJ

Product Specification

※ Please pay attention to the followings when you set Spread Spectrum Rate(SSR) and Modulation Frequency(FMOD)

1. Please set proper Spread Spectrum Rate(SSR) and Modulation Frequency (FMOD) of TV system LVDS output.

2. Please check FOS after you set Spread Spectrum Rate(SSR) and Modulation Frequency(FMOD) to avoid

abnormal display. Especially, harmonic noise can appear when you use Spread Spectrum under FMOD 30 KHz.

Ver. 1.0

8 /40

3-4. LVDS Signal Specification

3-4-1. LVDS Input Signal Timing Diagram

LC550DUJ

Product Specification

DE, Data

DCLK

First data

Second data

0.7VDD

0.3VDD

tCLK

DE(Data Enable)

0.5 VDD

Invalid data

Invalid data

Valid data

Pixel 0,0

Valid data

Pixel 1,0

tHP

Pixel 2,0

Pixel 3,0

Invalid data

Invalid data

tHV

DE(Data Enable)

Ver. 1.0

1 1080

tVV

tVP

9 /40

3-4-2. LVDS Input Signal Characteristics

1) DC Specification

LVDS -

LVDS +

LC550DUJ

Product Specification

# VCM= {(LVDS +) + ( LVDS - )}/2

0V

V

CM

V

IN _ MAXVIN _ MIN

Description Symbol Min Max Unit notes

LVDS Common mode Voltage V

LVDS Input Voltage Range V

CM

IN

1.0 1.5 V -

0.7 1.8 V -

Change in common mode Voltage ΔVCM - 250 mV -

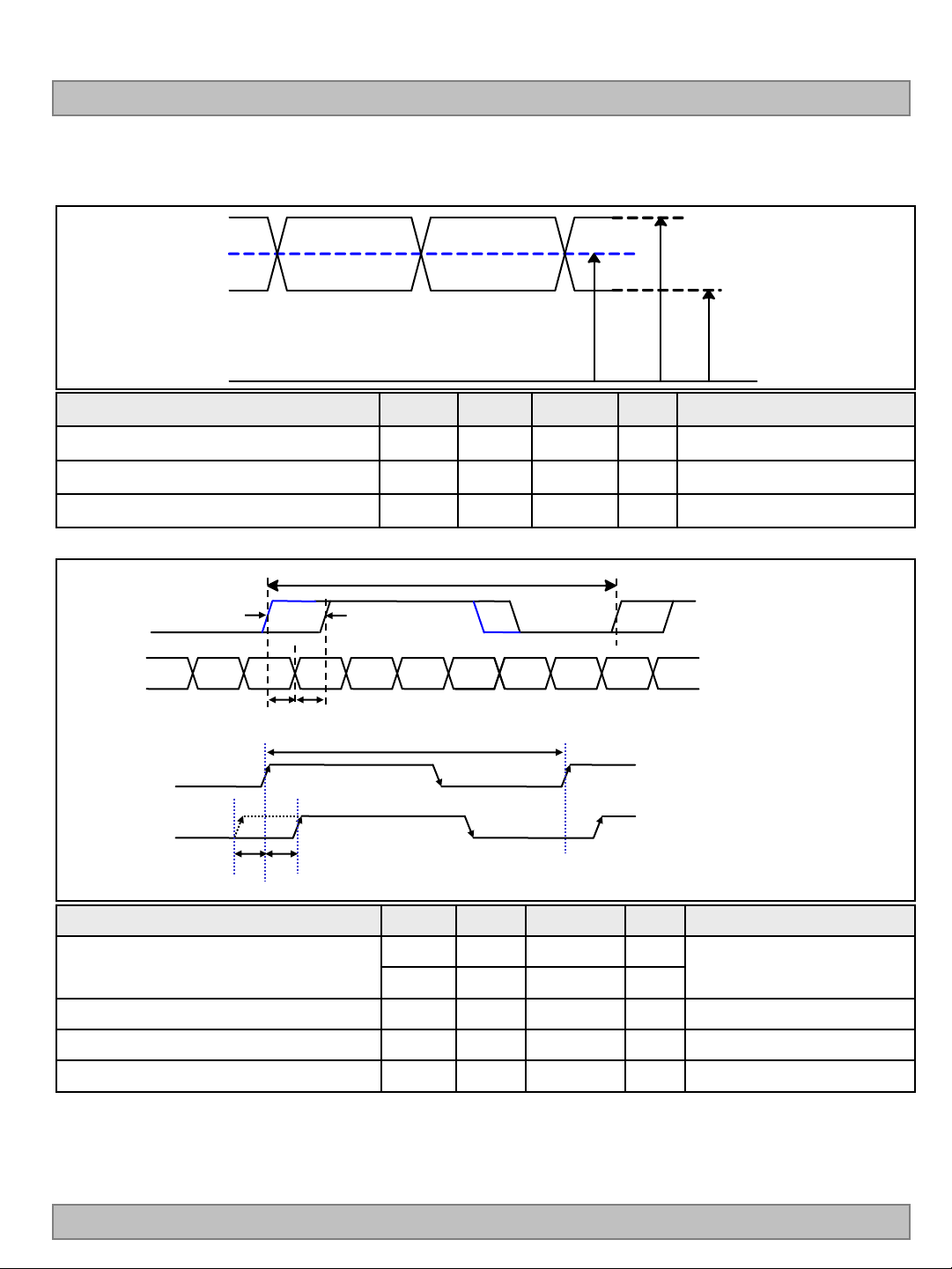

2) AC Specification

T

clk

LVDS Clock

LVDS Data

(F

= 1/T

)

clk

LVDS 1‟st Clock

LVDS 2ndClock

tSKEW

tSKEW

clk

T

clk

t

SKEW_mintSKEW_max

Description Symbol Min Max Unit notes

LVDS Differential Voltage

LVDS Clock to Data Skew t

Effective time of LVDS t

LVDS Clock to Clock Skew (Even to Odd) t

notes

1. All Input levels of LVDS signals are based on the EIA 644 Standard.

2. LVDS Differential Voltage is defined within t

Ver. 1.0

V

TH

V

TL

SKEW

eff

SKEW_EO

100 600 mV

-600 -100 mV

- |(0.2*T

|± 360|

- |1/7* T

eff

)/7| ps -

clk

- ps -

| ps -

clk

Tested with Differential Probe

2

10 /40

Product Specification

LC550DUJ

LVDS Data

0V

(Differential)

LVDS CLK

0.5tui

360ps

tui

VTH

VTL

360ps

teff

tui : Unit Interval

0V

(Differential)

* This accumulated waveform is tested with differential probe

Ver. 1.0

11 /40

LC550DUJ

Product Specification

3-5. Intra interface Signal Specification

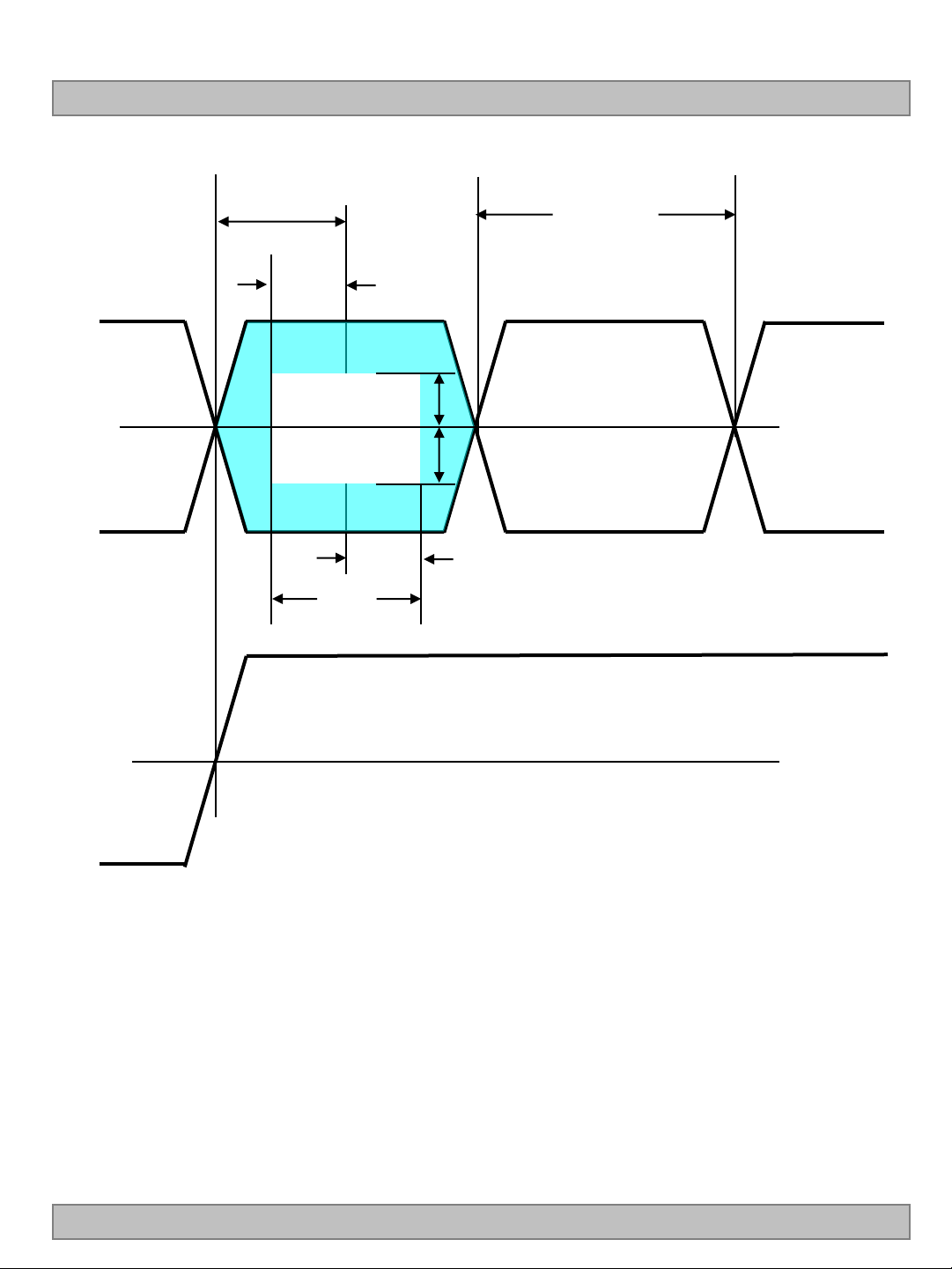

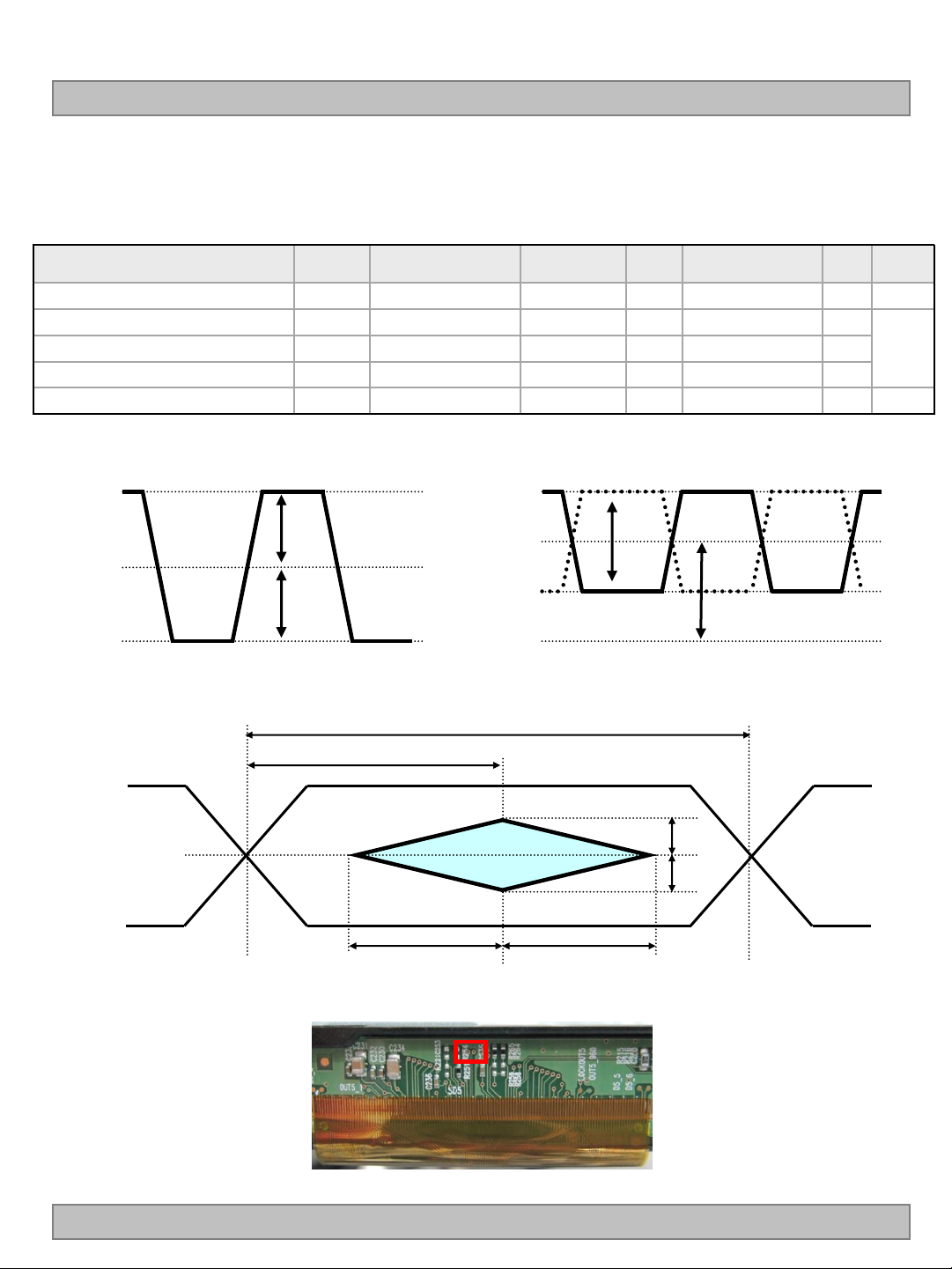

3-5-1. EPI Signal Specification

Table 5. ELECTRICAL CHARACTERISTICS

Parameter Symbol Condition MIN TYP MAX Unit notes

Logic & EPI Power Voltage VCC - 1.62 1.8 1.98 VDC

EPI input common voltage VCM LVDS Type 0.8 VCC/2 1.3 V

EPI input differential voltage Vdiff - 150 - 500 mV

EPI Input eye diagram Veye - 90 - - mV

Effective Veye width time B1&B2 0.25 - - UI

EPI +

0 V

0 V

(Differential Probe)

Vdiff

Vdiff

(Differential Probe)

EPI Differential signal characteristics

*Source PCB

EPI -

0 V

1 UI

0.5 UI

B1 B2

Eye Pattern of EPI Input

Vdiff

Vcm

(Active Probe)

Veye

Veye

Ver. 1.0

FIG. 3 Measure point

12 /40

LC550DUJ

Product Specification

3-6. Color Data Reference

The brightness of each primary color(red,green,blue) is based on the 8bit gray scale data input for the color.

The higher binary input, the brighter the color. Table 6 provides a reference for color versus data input.

Table 6. COLOR DATA REFERENCE

Input Color Data

Basic

Color

RED

Color

RED

MSB LSB

MSB LSB

GREEN

BLUE

MSB LSB

R7 R6 R5 R4 R3 R2 R1 R0 G7 G6 G5 G4 G3 G2 G1 G0 B7 B6 B5 B4 B3 B2 B1 B0

Black 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

Red (255) 1 1 1 1 1 1 1 1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

Green (255) 0 0 0 0 0 0 0 0 1 1 1 1 1 1 1 1 0 0 0 0 0 0 0 0

Blue (255) 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 1 1 1 1 1 1 1 1

Cyan 0 0 0 0 0 0 0 0 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

Magenta 1 1 1 1 1 1 1 1 0 0 0 0 0 0 0 0 1 1 1 1 1 1 1 1

Yellow 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 0 0 0 0 0 0 0 0

White 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

RED (000) 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

RED (001) 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

... ... ... ...

RED (254) 1 1 1 1 1 1 1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

RED (255) 1 1 1 1 1 1 1 1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

GREEN (000) 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

GREEN

BLUE

Ver. 1.0

GREEN (001) 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 0

... ... ... ...

GREEN (254) 0 0 0 0 0 0 0 0 1 1 1 1 1 1 1 0 0 0 0 0 0 0 0 0

GREEN (255) 0 0 0 0 0 0 0 0 1 1 1 1 1 1 1 1 0 0 0 0 0 0 0 0

BLUE (000) 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

BLUE (001) 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 1

... ... ... ...

BLUE (254) 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 1 1 1 1 1 1 1 0

BLUE (255) 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 1 1 1 1 1 1 1 1

13 /40

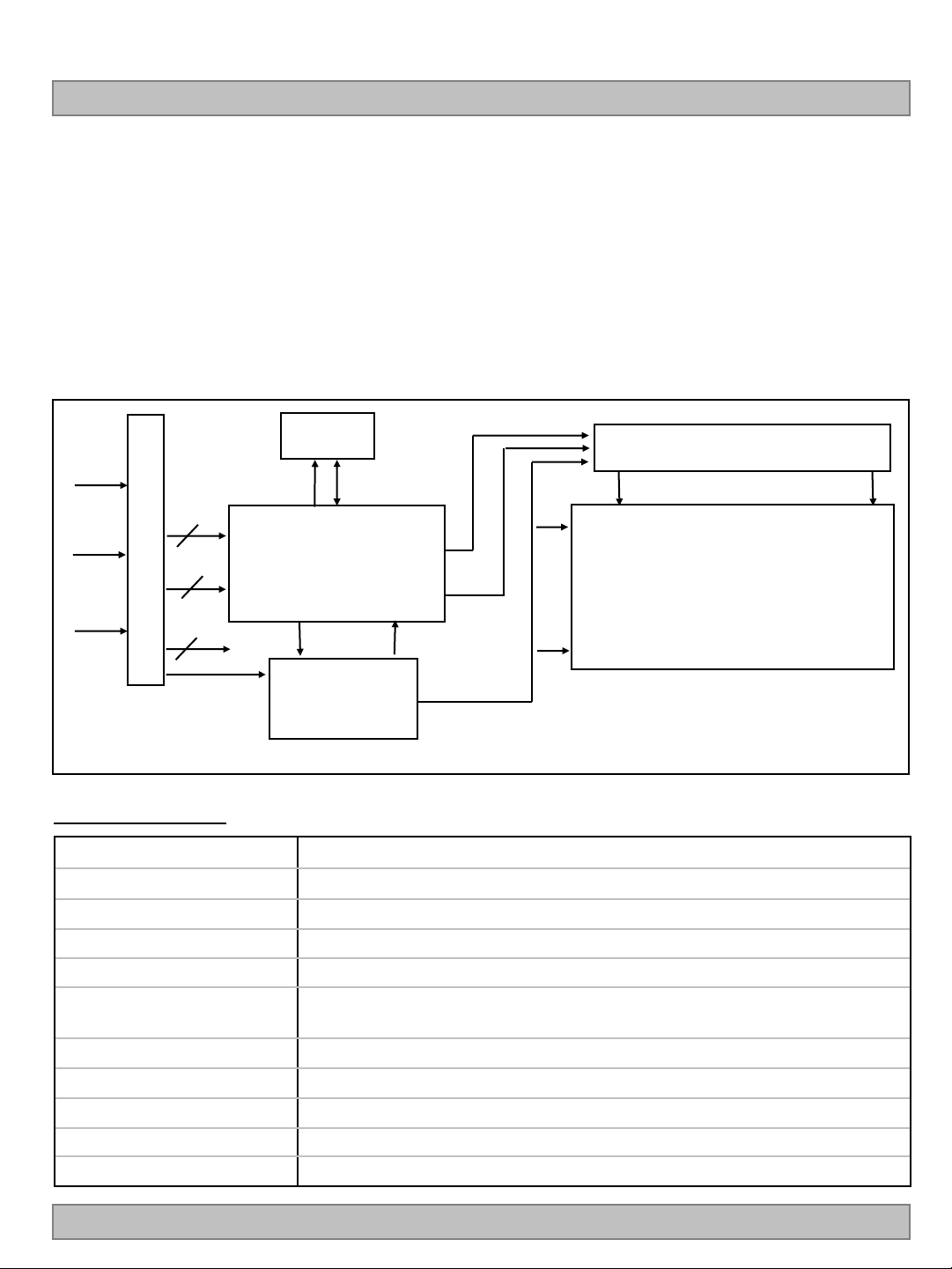

3-7. Power Sequence

3-7-1. LCD Driving circuit

LC550DUJ

Product Specification

Power Supply For LCD

V

LCD

Interface Signal (Tx_clock)

User Control Signal

(LVDS_select)

Power for LED

Table 7. POWER SEQUENCE

Parameter

90%

10%

0V

T1

T2

30%

0V

100%

T6

Valid Data

T3 T4

LED ON

Value

Min Typ Max

90%

10%

T7

T5

Vcm : LVDS Common mode Voltage

Unit Notes

10%

Note :

Ver. 1.0

T1 0.5 - 20 ms 1

T2 0 - - ms 2

T3 400 - - ms 3

T4 100 - - ms 3

T5 1.0 - - s 4

T6 0 - T2 ms 5

T7 0 - - ms 6

1. Even though T1 is over the specified value, there is no problem if I2T spec of fuse is satisfied.

2. If T2 is satisfied with specification after removing LVDS Cable, there is no problem.

3. The T3 / T4 is recommended value, the case when failed to meet a minimum specification,

abnormal display would be shown. There is no reliability problem.

4. T5 should be measured after the Module has been fully discharged between power off and on period.

5. If the on time of signals (Interface signal and user control signals) precedes the on time of Power (V

it will be happened abnormal display. When T6 is NC status, T6 doesn‟t need to be measured.

6. It is recommendation specification that T7 has to be 0ms as a minimum value.

※ Please avoid floating state of interface signal at invalid period.

※ When the power supply for LCD (VLCD) is off, be sure to pull down the valid and invalid data to 0V.

LCD

),

14 /40

LC550DUJ

Product Specification

4. Optical Specification

Optical characteristics are determined after the unit has been „ON‟ and stable in a dark environment at 25± 2°C.

The values are specified at 50cm from the LCD surface at a viewing angle of and equal to 0 °.

FIG. 1 shows additional information concerning the measurement equipment and method.

Optical Stage(x,y)

LCD Module

Pritchard 880 or

equivalent

50cm

FIG. 1 Optical Characteristic Measurement Equipment and Method

Ta= 25± 2°C, V

Table 8. OPTICAL CHARACTERISTICS

Parameter Symbol

Contrast Ratio CR 800 1200 - 1

Response Time

Color Coordinates

[CIE1931]

Viewing

Angle

Gray Scale - 2.2 - 5

2D

(CR>10)

3D

(CT≤10%)

Variation G to G

Gray to Gray (BW) G to GBW 9 13

RED

GREEN

BLUE

right(=0°)

left (=180°)

up (=90°)

down (=270°)

up + down

u (y axis) 89 - -

d (y axis) 89 - -

u (y axis)

σ

Rx

Ry

Gx

Gy

Bx

By

r (x axis) 89 - -

l (x axis) 89 - -

+d (y axis)

Back Light : LGD B/L

Value

Min Typ Max

6 9

0.649

0.333

Typ

-0.03

11 - degree 6

0.308

0.585

0.148

0.066

=12.0V, fV=60Hz, Dclk=74.25MHz,

LCD

Unit Note

ms 2

Typ

+0.03

degree 4

3

Ver. 1.0

15 /40

Product Specification

Note : 1. Contrast Ratio(CR) is defined mathematically as :

LC550DUJ

Contrast Ratio =

Surface Luminance with all white pixels

Surface Luminance with all black pixels

It is measured at center 1-point.

2. Response time is the time required for the display to transit from any gray to white (Rise Time, TrR)

and from any gray to black (Decay time, TrD). For additional information see the FIG. 3.

※ G to GBWSpec stands for average value of all measured points.

Photo Detector : RD-80S / Field : 2 °

3. G to G σ is Variation of Gray to Gray response time composing a picture

G to G (σ) =

√

Σ(Xi- u)

N

2

Xi = Individual Data

u = Data average

N : The number of Data

4. Viewing angle is the angle at which the contrast ratio is greater than 10. The angles are

determined for the horizontal or x axis and the vertical or y axis with respect to the z axis which

is normal to the LCD module surface. For more information, see the FIG. 4.

5. Gray scale specification

Gamma Value is approximately 2.2. For more information, see the Table 9.

6. 3D performance specification is expressed by 3D luminance and 3D viewing angle.

Table 9. GRAY SCALE SPECIFICATION

Gray Level Luminance [%] (Typ)

L0 L15 0.27

L31 1.04

L47 2.49

L63 4.68

L79 7.66

L95 11.5

L111 16.1

L127 21.6

L143 28.1

L159 35.4

L175 43.7

L191 53.0

L207 63.2

L223 74.5

L239 86.7

L255 100

Ver. 1.0

16 /40

Dimension of viewing angle range

Normal

Y

E

= 0, Right

= 180, Left

= 270, Down

= 90, Up

LC550DUJ

Product Specification

Response time is defined as the following figure and shall be measured by switching the input signal for

“Gray(N)” and “Black or White”.

100

Optical

Response

90

10

FIG. 4 Viewing Angle

Tr

Tf

0

Gray(N)

White

N = 0(Black)~255(White)

Gray(N)

Black

Ver. 1.0

FIG. 3 Response Time

17 /40

Product Specification

LC550DUJ

LW-RW

LW-RB

LB-RW

LB-RB

(a) Test pattern image

< FIG. 6. Positioning eyeglass >

2

6

4 5

7

1

9

3

8

3D display

(b) Measurement

position

< FIG. 5. Measurement configuration>

Luminance

Lum( LE or RE, test pattern, number )

Measurement through

Left or Right eyeglass

< FIG. 7. Notation of luminance measurement >

LMS

Right or left eyeglass

( Circular polarizer )

(c) Setup

measurement

position

In order to measure 3D crosstalk and 3D viewing angle, it need to be prepared as below;

1) Measurement configuration

4-Test pattern images. Refer to FIG 5.

-. LW-RW : White for left and right eye

-. LW-RB : White for left eye and Black for right eye

-. LB-RW : Black for left eye and white for right eye

-. LB-RB : Black for left eye and right eye

Image files where black and white lines are displayed on even or odd lines.

Luminance measurement system (LMS) with narrow FOV (field of view) is used. Refer to FIG 1.

2) Positioning Eyeglass (refer to appendix-VII for standard specification of eyeglass)

Find angle of minimum transmittance.

This value would be provided beforehand or measured by the following steps;

(i) Test image (LB-RW) is displayed.

(ii) Left eyeglass are placed in front of LMS and luminance is measured,

rotating right eyeglass such as FIG 6. The notation for luminance measurement is “Lum(LE, LB-RW,1)”.

(iii) Find the angle where luminance is minimum.

* Following measurements should be performed at the angle of minimum transmittance of eyeglass.

Ver. 1.0

18 /40

Product Specification

3) Measurement of 3D crosstalk

(i) Test image ( LB-RW, LW-RB and LB-RB ) is displayed.

(ii) Right or left eyeglass are placed in front of LMS successively and

luminance is measured for position 1.

with rotating LMS or sample vertically.

Lum(LE, LB-RW,1) - Lum(LE, LB-RB,1)

Lum(LE, LW-RB,1) - Lum(LE, LB-RB,1)

or

Lum(RE, LW-RB,1) - Lum(RE, LB-RB,1)

Lum(RE, LB-RW,1) - Lum(RE, LB-RB,1)

4) Measurement of 3D Viewing Angle

3D viewing angle is the angle at which the 3D crosstalk is under 10%. The angles are

determined for the vertical or y axis with respect to the z axis which is normal to the LCD

module surface and measured for position 1. For more information , see the Fig 8

LC550DUJ

y axis

LB-RW LW-RB

LCM

LB-RB

(a) Test pattern image

(b) Measurement of 3D viewing angle (up/down)

< FIG. 8. Measurement of 3D crosstalk and 3D viewing angle >

Φyu(up)

Φyd (down)

z axis

LMS

Ver. 1.0

19 /40

Product Specification

5. Mechanical Characteristics

Table 10 provides general mechanical characteristics.

Table 10. MECHANICAL CHARACTERISTICS

Item Value

Horizontal 1225.2 mm

Outline Dimension

(Only Glass)

Vertical 696.7mm

Thickness 1.3mm

LC550DUJ

Active Display Area

Vertical

Weight 2,600g(Typ.), 2,750g(Max)

Horizontal

Surface Treatment

Hard coating(2H), Anti-glare treatment of the front polarizer

: Haze 1%(typ.)

1209.6 mm

680.4 mm

Note : Please refer to a mechanical drawing in terms of tolerance at the next page.

Ver. 1.0

20 /40

6. Mechanical Dimension

6-1. Board Assembly Dimension

LC550DUJ

Product Specification

Ver. 1.0

21 /40

Product Specification

6-2. Control Board Assembly Dimension

LC550DUJ

Ver. 1.0

22 /40

Product Specification

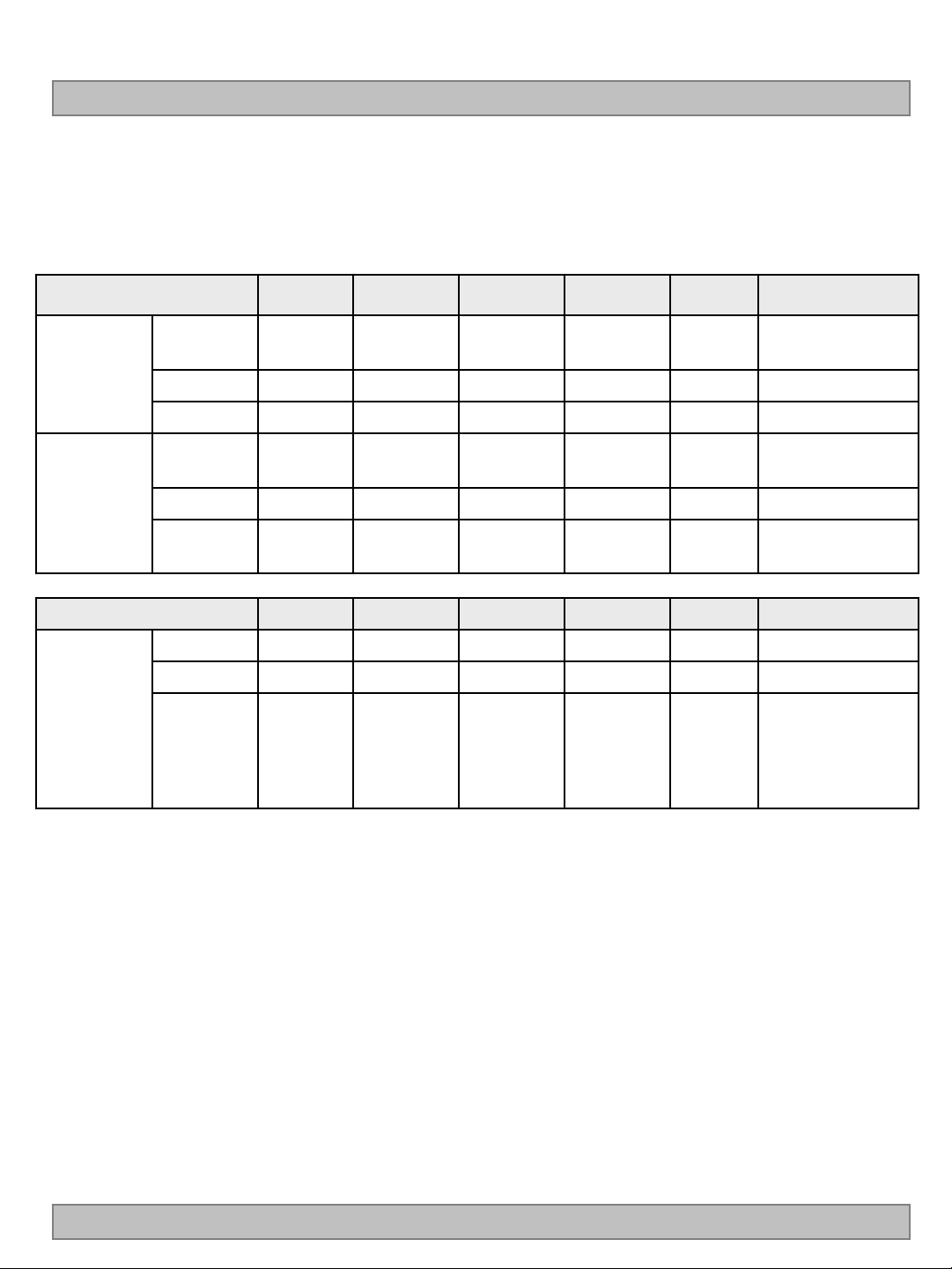

7. Reliability

Table 11. ENVIRONMENT TEST CONDITION

No. Test Item Condition

LC550DUJ

1 High temperature storage test

2 Low temperature storage test

3 High temperature operation test

4 Low temperature operation test

7 Humidity condition Operation

Altitude operating

8

storage / shipment

Ta= 60°C 90% 240h

Ta= -20°C 240h

Ta= 50°C 50%RH 500h

Ta= 0°C 500h

Ta= 40 °C ,90%RH

0 - 16,400 ft

0 - 40,000 ft

Note : Before and after Reliability test, LCM should be operated with normal function.

Ver. 1.0

23 /40

Product Specification

8. International Standards

8-1. Safety

a) UL 60065, Underwriters Laboratories Inc.

Audio, Video and Similar Electronic Apparatus - Safety Requirements.

b) CAN/CSA C22.2 No.60065:03, Canadian Standards Association.

Audio, Video and Similar Electronic Apparatus - Safety Requirements.

c) IEC 60065, The International Electrotechnical Commission (IEC).

Audio, Video and Similar Electronic Apparatus - Safety Requirements.

8-2. Environment

a) RoHS, Directive 2011/65/EU of the European Parliament and of the council of 8 June 2011

LC550DUJ

Ver. 1.0

24 /40

Product Specification

9. Packing

9-1. Packing Form

a) Package quantity in one Pallet : 70 pcs

b) Pallet Size : 1390 mm(W) X 890 mm(D) X 1080 mm(H)

LC550DUJ

Ver. 1.0

25 /40

LC550DUJ

Product Specification

10. Precautions

Please pay attention to the followings when you use this TFT LCD module.

10-1. Handling Precautions

(1) Please attach the surface transparent protective film to the surface in order to protect the polarizer.

Transparent protective plate should have sufficient strength in order to the resist external force.

(2) Acetic acid type and chlorine type materials for the cover case are not desirable because the former

generates corrosive gas of attacking the polarizer at high temperature and the latter causes circuit break

by electro-chemical reaction.

(3) Do not touch, push or rub the exposed polarizers with glass, tweezers or anything harder than HB

pencil lead. And please do not rub with dust clothes with chemical treatment.

Do not touch the surface of polarizer for bare hand or greasy cloth.(Some cosmetics are detrimental

to the polarizer.)

(4) After removing the protective film, when the surface becomes dusty, please wipe gently with absorbent

cotton or other soft materials like chamois soaks with petroleum benzine.

Do not use acetone, toluene and alcohol because they cause chemical damage to the polarizer.

(5) Wipe off saliva or water drops as soon as possible. Their long time contact with polarizer causes

deformations and color fading.

(6) Since a module is composed of electronic circuits, it is not strong to electrostatic discharge.

Make certain that treatment persons are connected to ground through wrist band etc. And don‟t touch

interface pin directly. Panel ground path should be connected to metal ground.

(7) Please make sure to avoid external forces applied to the Source PCB and D-IC during the process of

handling or assembling the TV set. If not, It causes panel damage or malfunction.

(8) Panel and BLU should be protected from the static electricity. If not, it causes IC damage.

(9) Do not pull or fold the source D-IC which connect the source PCB and the panel.

(10) Panel(board ass‟y) should be put on the BLU structure precisely to avoid mechanical impact.

(11) FFC Cable should be connected between System board and Source PCB correctly.

(12) Mechanical structure for backlight system should be designed for sustaining board ass‟y safely.

(13) Surface temperature of the Source D-IC should be controlled under 100℃ with TV Set status.

If not, problems such as IC damage or decrease of lifetime could occur.

10-2. Operating Precautions

(1) Response time depends on the temperature.(In lower temperature, it becomes longer.)

(2) Brightness depends on the temperature. (In lower temperature, it becomes lower.)

And in lower temperature, Stable time(required time that brightness is stable after turned on)

becomes longer

(3) Be careful for condensation at sudden temperature change. Condensation makes damage to polarizer or

electrical contacted parts. And after fading condensation, smear or spot will occur.

(4) When fixed patterns are displayed for a long time, remnant image is likely to occur.

(5) Module has high frequency circuits. Sufficient suppression to the electromagnetic interference shall be

done by system manufacturers. Grounding and shielding methods may be important to minimized the

interference.

Ver. 1.0

26 /40

LC550DUJ

Product Specification

10-3. Protection Film

(1) Please keep attaching the protection film before assembly.

(2) Please peel off the protection film slowly.

(3) Please peel off the protection film just like shown in the Fig.1

(4) Ionized air should be blown over during the peeling.

(5) Source PCB should be connected to the ground when peel off the protection film.

(6) The protection film should not be contacted to the source D-IC during peeling it off.

< Fig. 1 >

10-4. Storage Precautions

When storing modules as spares for a long time, the following precautions are necessary.

(1) Temperature : 5 ~ 40 ℃

(2) Humidity : 35 ~ 75 %RH

(3) Period : 6 months

(4) Control of ventilation and temperature is necessary.

(5) Please make sure to protect the product from strong light exposure, water or moisture. Be careful for

condensation.

(6) Please keep the modules at a circumstance shown below Fig. 2

No Baking

50℃, 10%, 24hr 50℃, 10%, 48hr

2 month

3 month

6 month

< Fig. 2 >

10-5. Packing Precautions

Product assembled into module should be stored in the Al-bag (cover case).

10-6. Operating condition guide

(1) The LCD product should be operated under normal conditions. Normal condition is defined as below;

- Temperature : 5 ~ 40 ℃, normal humidity

- Display pattern : continually changing pattern (Not stationary)

(2) If the product will be used in extreme conditions such as high temperature, display patterns or operation

time etc..,

It is strongly recommended to contact LGD for Qualification engineering advice. Otherwise, its reliability

and function may not be guaranteed. Extreme conditions are commonly found at Airports, Transit Stations,

Banks, Stock market, and Controlling systems. The LCD product should be applied by global standard

environment. (refer ETSI EN 300, IEC 60721)

Ver. 1.0

27 /40

# APPENDIX-I-1

■ Pallet Ass‟y

①

LC550DUJ

Product Specification

ⓑ

②

ⓐ

③

Desiccant X4

⑤

Ⓙ

ⓒ

ⓓ

ⓔ

④

No. Description Material

ⓐ

ⓑ

ⓒ

Pallet Plywood

Carton Plate Single Wall

PE Sheet Carbon

⑥

Ver. 1.0

ⓓ

ⓔ

ⓕ

ⓖ

ⓗ

ⓘ

Ⓙ

Top Packing EPS

Bottom Packing EPS

Angle Packing Single Wall

Tape OPP

Band PP

Clip Steel

Desiccant Power dry

28 /40

Product Specification

# APPENDIX-I-2

■ Control PCB Packing Ass’y

a) Control PCB Qty / Box : 70 pcs

b) Tray Qty / Box : 8Tray (Upperst Tray Is empty)

c) Tray Size : 353 X 353 X 16

d) Box size : 368 X 355 X 98

[10pcs/Tray]

LC550DUJ

[7 Tray+Empty Tray]

[7Tray]

[Inserting into Box]

NO. DESCRIPTION MATERIAL

1 PCB Packing A,ssy 2 Tray PET

3 Box SWR4

Ver. 1.0

29 /40

# APPENDIX- II-1

■ Serial Label

LC550DUJ

Product Specification

Model

Serial No.

Work Order

6060L-XXXX LC550DUJ-SGK1-XXX

XXXX

Ver. 1.0

30 /40

# APPENDIX- II-2

■ BOX Label

LC550DUJ

Product Specification

LC550DUJ-SGK1

QTY : 10

■ Pallet Label

LC550DUJ

SGK1

70 PCS

MADE IN KOREA

001/01-01

XXXXXXXXXXXXX XXX

RoHS Verified

Ver. 1.0

31 /40

Product Specification

# APPENDIX- III-1

■ Required signal assignment for Flat Link (Thine : THC63LVD103) Transmitter(Pin7= “L” or “NC”)

LC550DUJ

Host System

24 Bit

RED0

RED1

RED2

RED3

RED4

RED5

RED6

RED7

GREEN0

GREEN1

GREEN2

GREEN3

GREEN4

GREEN5

GREEN6

GREEN7

BLUE0

BLUE1

BLUE2

BLUE3

BLUE4

BLUE5

BLUE6

BLUE7

Hsync

Vsync

Data Enable

CLOCK

THC63LVD103

or Compatible

33

34

35

36

37

38

59

61

4

5

40

41

42

44

45

46

62

63

6

8

48

49

50

52

53

54

64

1

9

11

55

57

58

12

TCLK-

TCLK+

TA-

TA+

TB-

TB+

TC-

TC+

TD-

TD+

31

30

29

28

25

24

23

22

21

20

GND

FI-RE51S-HF

12

13

14

15

16

17

19

20

22

23

7

100Ω

100Ω

100Ω

100Ω

100Ω

LCM Module

Timing

Controller

RO0N

RO0P

RO1N

RO1P

RO2N

RO2P

ROCLKN

ROCLKP

RO3N

RO3P

VESA/ JEIDA

Note: 1. The LCD module uses a 100 Ohm[Ω] resistor between positive and negative lines of each receiver

input.

2. Refer to LVDS Transmitter Data Sheet for detail descriptions. (THC63LVD103 or Compatible)

3. „7‟ means MSB and „0‟ means LSB at R,G,B pixel data.

Ver. 1.0

32 /40

Product Specification

# APPENDIX- III-2

■ Required signal assignment for Flat Link (Thine : THC63LVD103) Transmitter(Pin7= “H” )

LC550DUJ

Host System

24 Bit

RED0

RED1

RED2

RED3

RED4

RED5

RED6

RED7

GREEN0

GREEN1

GREEN2

GREEN3

GREEN4

GREEN5

GREEN6

GREEN7

BLUE0

BLUE1

BLUE2

BLUE3

BLUE4

BLUE5

BLUE6

BLUE7

Hsync

Vsync

Data Enable

CLOCK

THC63LVD103

or Compatible

4

5

59

61

33

34

35

36

37

38

6

8

62

63

40

41

42

44

45

46

9

11

64

1

48

49

50

52

53

54

55

57

58

12

TCLK-

TCLK+

TA-

TA+

TB-

TB+

TC-

TC+

TD-

TD+

31

30

29

28

25

24

23

22

21

20

FI-RE51S-HF

VCC

12

13

14

15

16

17

19

20

22

23

Timing

Controller

100Ω

100Ω

100Ω

100Ω

100Ω

7

LCM Module

RO0N

RO0P

RO1N

RO1P

RO2N

RO2P

ROCLKN

ROCLKP

RO3N

RO3P

VESA /JEIDA

Note :1. The LCD module uses a 100 Ohm[Ω] resistor between positive and negative lines of each receiver

input.

2. Refer to LVDS Transmitter Data Sheet for detail descriptions. (THC63LVD103 or Compatible)

3. „7‟ means MSB and „0‟ means LSB at R,G,B pixel data.

Ver. 1.0

33 /40

Product Specification

# APPENDIX- IV

■ LVDS Data-Mapping Information (8 Bit )

1) LVDS Select : “H” Data-Mapping (JEIDA format)

RCLKP

RCLKM

LC550DUJ

RAP

RBP

RCP

RDP

R17 R16 R15 R14G12 R13R12’ R12R13’ G12”

B12 G17 G16 G15B13 G14G13’ G13G14’ B13”

V

SYNCHSYNC

B17 B16DE B15B14’ B14B15’ DE”

B11 B10 G11 G10X R11R10’ R10R11’ X”

2) LVDS Select : “L” Data-Mapping (VESA format)

RCLKP

RCLKM

RAP

RBP

R15 R14 R13 R12G10 R11R10’ R10R11’ G10”

B10 G15 G14 G13B11 G12G11’ G11G12’ B15”

Ver. 1.0

RCP

RDP

V

SYNCHSYNC

B15 B14DE B13B12’ B12B13’ DE”

B17 B16 G17 G16X R17R16’ R16R17’ X”

34 /40

Product Specification

# APPENDIX- V

■ Option Pin Circuit Block Diagram

1) Circuit Block Diagram of LVDS Format Selection pin

LVDS Select Pin : Pin 7

LC550DUJ

LVDS Select

1KΩ

(Pin 7)

60kΩ

System Side LCM Side

LVDS Select

ASIC

(TCON)

Ver. 1.0

35 /40

Product Specification

Polarizer

Retarder

Right eye

Left eye

+λ/4

-λ/4

Polarizer

Retarder

Right eyeRight eye

Left eyeLeft eye

+λ/4

-λ/4

a) Slow axis of retarder

Left Right

45˚

-45˚

a) Slow axis of retarder

Left Right

45˚

-45˚

b) Transmission axis of polarizer

Left Right

0˚

0˚

b) Transmission axis of polarizer

Left Right

0˚

0˚

0˚

90˚

45˚

135˚

Cell Patterned

retarder

Top

POL

Bottom

POL

0˚0˚

90˚90˚

45˚

135˚

45˚

135˚

Cell Patterned

retarder

Top

POL

Bottom

POL

# APPENDIX- VI

■ Standard specification of Eyeglasses

This is recommended data of Eyeglasses for LC550DUJ-SGK1 model. (details refer to table)

For each item, depending on the eyeglass manufacturer tolerances may occur, this tolerance can

affect 3D performance. (3D Crosstalk, 3D luminance, 3D viewing angle)

<Table. Standard specification of Eyeglasses>

Design item of Eyeglasses Left Right Remark

LC550DUJ

Optical

axis

Retardation

value

a) Slow axis of retarder

b) Transmission axis of polarizer

Retarder 125nm @550nm

※Recommended polarizer

Polarization efficiency: more than 99.90%

Patterned

Patterned

retarder

retarder

-45

45

135

45˚45

-45˚ 45˚

0˚ 0˚

˚

˚

˚

˚

Refer to

drawing

Direction from viewer

Ver. 1.0

(b) Configuration of Eyeglasses

<Drawing. Information of optical axis>

36 /40

Product Specification

# APPENDIX-Ⅶ-1

■ Flicker Adjustment

Parameter Unit Min Typ Max Note

Inversion Method - 2-Dot Inversion

LC550DUJ

Adjust Pattern /

Gray Level

Position - Center

Voltage range V

- G2Dot Full Flicker / 127Gray 60Hz

6.28 V

(149 LV)

(199 LV)

R G

Row 1

Row 2

Row 3

Row 4

7.05 V

B R G

(249 LV)

B

7.83 V

R G

B

R G

B

127 Gray

0Gray

Ver. 1.0

SCL

SDA

Adjustment JIG

A

PMIC

B

LCD Module

A : Pull-up Resistors

(If it is necessary)

B : I2C Connector

(Refer to Appendix IX)

37 /40

Product Specification

# APPENDIX-Ⅶ-2

Vcom Adjustment

MODULE 51 Pin CNT(CN1) PIN CONFIGURATION

LC550DUJ

Pin No

1~3

4

5

6~51

LC550DUJ-SGK1 Control PCB Assembly uses TI PWM IC(TPS65175A).

PWM IC (Slave) Address is 40h (01000000, LSB „0‟ means „Write‟),

Vcom Register address is 0x15 & 0x16.

If you need detailed information, Please refer to TI PWM IC(TPS65175A) Data Sheet or contact with TI

company.

Description Note

NC

SDA

SCL

-

Ver. 1.0

38 /40

Product Specification

# APPENDIX-Ⅷ

■ The reference method of BL dimming

It is recommended to use synchronous V-sync frequency to prevent waterfall

(Vsync * 2 =P-Dim Frequency)

LC550DUJ

Ver. 1.0

39 /40

# APPENDIX-IX

LC550DUJ

Product Specification

Ver. 1.0

- Material List

◈ Note

- Pad : GOLD Plating

- # ≥ Cpk 1.0

- ## ≥ Cpk 1.33

- Stiffener color : Sky Blue

- H-F

- Dimensions unit : mm

40 /40

Loading...

Loading...