LG XLDK225 Service Manual

XL-DK225

SERVICE MANUAL

No. S7734XLDK225/

MICRO COMPONENT SYSTEM

EO

VID

UX

A

/

MODEL

XL-DK225 Micro Component System consisting of

XL-DK225 (main unit) and CP-DK225 (speaker system).

• In the interests of user-safety (Required by safety regulations in

some countries) the set should be restored to its original condition

and only parts identical to those specified be used.

XL-DK225

CONTENTS

PRECAUTIONS FOR USING LEAD-FREE SOLDER

CHAPTER 1. GENERAL DESCRIPTION

[1] Important Service Safety Precaution ........... 1-1

[2] Specifications............................................... 1-1

[3] Names Of Parts ........................................... 1-2

CHAPTER 2. ADJUSTMENTS

[1] CD Section .................................................. 2-1

[2] Test Mode.................................................... 2-2

[3] Standard Specification Of Stereo System

Error Message Display Contents ................. 2-4

CHAPTER 3. MECHANICAL DESCRIPTION

[1] Removing And Reinstalling The Main Parts

..................................................................... 3-1

[2] Disassembly ................................................ 3-2

CHAPTER 4. BLOCK DIAGRAM

[1] Block Diagram ............................................. 4-1

Parts marked with " " are important for maintaining the safety of the set. Be sure to replace these parts with

specified ones for maintaining the safety and performance of the set.

!

CHAPTER 5. CIRCUIT DESCRIPTION

[1] Waveforms Of Servo Circuit ........................ 5-1

[2] IC Voltage .................................................... 5-3

CHAPTER 6. CIRCUIT SCHEMATICS AND PARTS

LAYOUT

[1] Notes On Schematic Diagram ..................... 6-1

[2] Types Of Transistor And LED ...................... 6-1

[3] Schematic Diagram ..................................... 6-2

[4] Charts Of Connecting Wires ...................... 6-10

[5] Wiring Side of PWB ................................... 6-12

CHAPTER 7. FLOWCHART

[1] Troubleshooting ........................................... 7-1

CHAPTER 8. OTHER

[1] Function Table Of IC .................................... 8-1

[2] FL Display.................................................... 8-9

PARTS GUIDE

SHARP CORPORATION

– 1

This document has been published to be used for

after sales service only.

The contents are subject to change without notice.

XL-DK225

AudioXL-MP150Service ManualXLMP150MarketE

PRECAUTIONS FOR USING LEAD-FREE SOLDER

1. Employing lead-free solder

"MAIN, POWER, SPEAKER, TRANSIT iPOD, DISPLAY, HEADPHONE, RE-FLASH, VOLUME LED, iPOD,

CD MP3 PWB" of this model employs lead-free solder.

The LF symbol indicates lead-free solder, and is attached on the PWB and service manuals. The alphabetical

character following LF shows the type of lead-free solder.

Example:

Indicates lead-free solder of tin, silver and copper.

2. Using lead-free wire solder

When fixing the PWB soldered with the lead-free solder, apply lead-free wire solder. Repairing with

conventional lead wire solder may cause damage or accident due to cracks.

As the melting point of lead-free solder (Sn-Ag-Cu) is higher than the lead wire solder by 40 C, were

commend you to use a dedicated soldring bit, if you are not familiar with how to obtain lead-free wire solder or

soldering bit, contact our service station or service branch in your area.

3. Soldering

As the melting point of lead-free solder (Sn-Ag-Cu) is about 220 C which is higher than the conventional lead

solder by 40 C, and as it has poor solder wettability, you may be apt to keep the soldering bit in contact with the

PWB for extended period of time. However, since the land may be peeled off or the maximum heat-resistance

temperature of parts may be exceeded, remove the bit from the PWB as soon as you confirm the steady

soldering condition.

Lead-free solder contains more tin, and the end of the soldering bit may be easily corrected. Make sure to turn on

and off the power of the bit as required.

If a different type of solder stays on the tip of the soldering bit, it is alloyed with lead-free solder. Clean the bit

after every use of it.

When the tip of the soldering bit is blackened during use, file it with steel wool or fine sandpaper.

Be careful when replacing parts with polarity indication on the PWB silk.

Lead-free wire solder for servicing

Ref No.

PWB-A

PWB-B

PWB-C

PWB-D 92LPWB6894CDUS

Parts No.

92LPWB6895MANS

92LPWB6894DPLS

92LPWB6894PODS

MAIN (A1), POWER (A2), SPEAKER (A3), TRANSIT iPOD (A4)

DISPLAY (B1), HEADPHONE (B2), RE-FLASH (B3), VOLUME LED (B4)

iPOD

CD MP3

Description

– 2

i

XL-DK225

CHAPTER 1.

GENERAL DESCRIPTION

[1] Important Service Safety Precaution

CAUTION : “These servicing instructions are for use by qualified service personnel only. To reduce

the risk of electric shock do not perform any servicing other than that contained in the operating

instructions unless you are qualified to do so”.

WARNING

1. For continued safety, no modification of any circuit should be attempted.

2. Disconnect AC power before servicing.

CAUTION: FOR CONTINUED

PROTECTION AGAINST FIRE

HAZARD, REPLACE ONLY WITH

SAME TYPE F801, F802, 3.15A, 125V/

F803, F804 2A, 125V/

F805 1.6A, 125V FUSES.

ATTENTION: POUR ASSURER

UNE LONGUE PROTECTION CONTRE

UN INCENDIE, REMPLACER SEULEMENT

PAR UN FUSIBLE DE

TYPE F801, F802, 3.15A, 125V/

F803, F804 2A, 125V/

F805 1.6A, 125V FUSES.

[2] Specifications

General

Power source AC 120 V - 60 Hz

Power

consumption

Dimensions

Weight 10.5 lbs (4.78 kg)

105 W

Width: 6-3/4" (175 mm)

Height: 9-1/2" (240 mm)

Depth: 12-1/5" (315 mm)

Amplifier

Output power 20 watts minimum RMS per channel into

Output terminals Speakers: 6 ohms

Input terminals Video/Auxiliary (audio signal):

6 ohms from 100 Hz to 20 kHz, 10% total

harmonic distortion

Headphones: 16 - 50 ohms

(recommended: 32 ohms)

Subwoofer pre-out (audio signal):

200 mV/10 k ohms at 70 Hz

500 mV/47 k ohms

CD player

Typ e 5-disc multi-play compact disc player

Signal readout Non-contact, 3-beam semiconductor laser

D/A converter Multi bit D/A converter

Frequency

response

Dynamic range 90 dB (1 kHz)

pickup

20 - 20,000 Hz

Tune r

Frequency range FM: 87.5 - 108 MHz

AM: 530 - 1,720 kHz

Speaker

Typ e 2-way type speaker system

2" (5 cm) tweeter

4-3/4" (12 cm) woofer

Maximum input

power

Rated input power 20 W

Impedance 6 ohms

Dimensions Width: 5-13/16" (148 mm)

Weight 4.93 lbs. (2.24 kg)/each

40 W

Height: 10-1/4" (260 mm)

Depth: 6-7/8" (175.5 mm)

1 – 1

1 – 3

XL-DK225

[3] Names Of Parts

10

10

Front panel

1. iPod Terminal

2. Disc Trays

3. Timer Indicator

4. Remote Sensor

5. Disc Stop Button

6. Disc or iPod Play or Pause Button

7. Power On/Standby Button

8. CD Button

9. Tuner (Band) Button

10. Video/Auxiliary/iPod Button

11. Headphone Jack

12. Volume Control

13. Disc Number Select Buttons

14. Disc Tray Open/Close Button

12 3 45 67

13 14

9 10 11

8

15

16

12

3

4

5

6

7

1

8

9

2

Display

1. Disc Number Indicators

2. MP3/WMA Folder Indicator

3. MP3/WMA Title Indicators

4. MP3 Indicator

5. WMA Indicator

6. Sleep Indicator

7. Timer Play Indicator

8. MP3/WMA Total Indicator

9. Daily Timer Indicator

10. FM Stereo Mode Indicator

11. FM Stereo Receiving Indicator

12. Memory Indicator

13. Extra Bass Indicator

14. Disc Repeat Play Indicator

15. Disc Pause Indicator

16. Disc Play Indicator

Rear panel

1. Speaker Terminals

2. AC Power Cord

3. FM 75 Ohms Antenna Jack

4. AM Antenna Ground Terminal

5. AM Loop Antenna Terminal

6. Video/Auxiliary (Audio Signal) Input Jacks

7. Video Out Jack

8. Cooling Fan

9. Subwoofer Pre-output Jack

Speaker system

1. Tweeter

2. Woofer

3. Bass Reflex Duct

4. Speaker Wire

1

3

1 – 4

1 – 2

2

4

XL-DK225

Remote control

1

11

13

7

8

12

2

9

14

15

10

16 17

20

1918

21 22

23

3

4

5

6

1. Remote Control Transmitter

2. Disc Number Select Buttons

3. Disc Direct Search Buttons

4. Equalizer Mode Select Button

5. Extra Bass/Demo Button

6. Volume Up and Down Buttons

7. Power On/Stand-by Button

8. CD Button

9. Tuner (Band) Button

10. Video/Auxiliary/iPod Button

11. Disc Clear/Dimmer Button

12. Disc Stop Button

13. Memory Button

14. Disc Play or Pause Button

15. iPod Play or Pause Button

16. Tuning Up Button

17. CD Track Up or Fast Forward, Tuner Preset Up,

Time Up Button

18. CD Track Down or Fast Reverse, Tuner Preset Down,

Time Down Button

19. Tuning Down Button

20. Play Mode Button

21. Display Button

22. Folder Button

23. Clock/Timer Button

1 – 5

1 – 3

XL-DK225

CHAPTER 2. ADJUSTMENTS

[1] CD Section

1. CD SECTION

• Adjustment

Since this CD system incorporates the following

automatic adjustment functions, readjustment is not

needed when replacing the pickup. Therefore,

different PWBs and pickups can be combined freely.

Each time a disc is changed, these adjustments are

performed automatically. Therefore, playback of

each disc can be performed under optimum

conditions.

Items adjusted automatically

1) Offset adjustment (The offset voltage between the

head amplifier output and the VREF reference

voltage is compensated inside the IC.)

* Focus offset adjustment

* Tracking offset adjustment

2) Tracking balance adjustment

3) Gain adjustment (The gain is compensated inside

the IC so that the loop gain at the gain crossover

frequency will be 0 dB.)

* Focus gain adjustment

* Tracking gain adjustment

2. CD ERROR CODE DESCRIPTION

Error Explanation

10* CAM error. Can't detect CAM switch when CAM is moving.

11* When it detect cam operation error during initialize process.

20* TRAY error. Can't detect TRAY switch when TRAY is

moving.

21* When it detect TRAY operation error during initialize

process.

* 'CHECKING'

If Error is detected, 'CHECKING' will be displayed

instead of 'ER-CD**'. 'ER-CD**' display will only be

displayed when error had been detected for the 5

times.

th

2 – 1

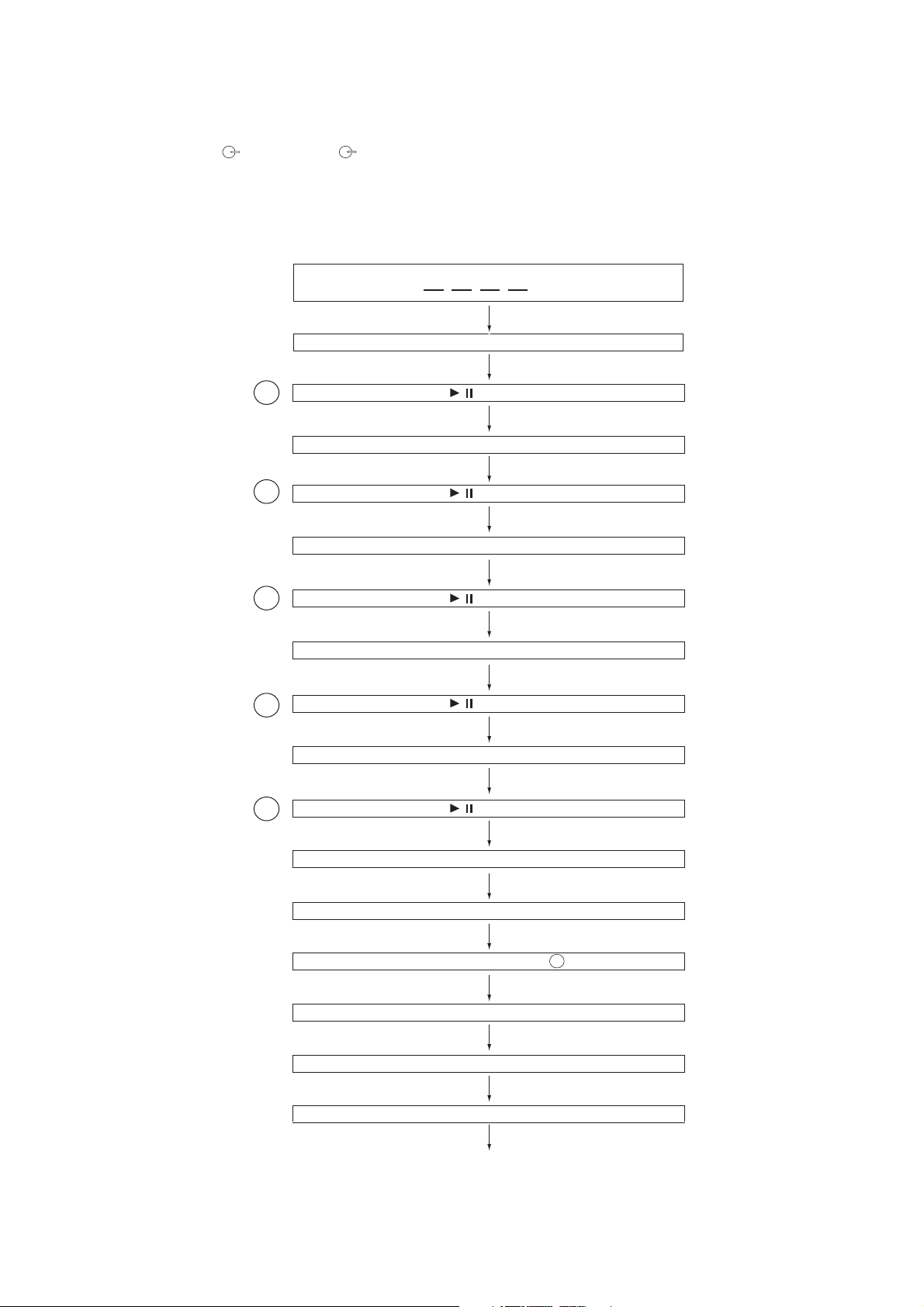

[2] Test Mode

• Setting the test mode

During stand-by mode, press STOP button while

pressing down the button and button. Then,

3

press the CD button to enter the test mode.

4

4

\

XL-DK225

Step

Step

Step

Step

C DTEST

OPEN/CLOSE operation is using manual. IL isn’t done

/

1

2

3

4

<< >> key input.

Laser ON.

/

<< >> key input.

Focus ON

/

<< >> key input.

CLV Servo ON

/

<< >> key input.

IL isn’t done

Step

Tracking Servo ON

/

5

Hold down << CD >> key for more than 2 sec.

Start Auto Adjustment at current pick-up location.

<< >> key input.

Reading Sub-code and Display

<<STOP>> key input.

STOP and return to Step

<<STOP>> key input.

1

2 – 2

XL-DK225

Note

STOP and return to Step

Everytime << DISPLAY >> key input

a) Focus Balance = FB : XX

b) Focus Gain = FG : XX

c) Tracking Balance = TB : XX

d) Tracking Gain = TG : XX

e) Focus Offset = FOFF : XX

f) Tracking Offset = TOFF : XX

g) RFRP = RFRP : XX

h) Focus Error

(RW Judgement) = RW : XX - XXXX

i) Focus Error

(Other than RW Judgement) = DA : XX - XXXX

<<STOP>> key input.

STOP and return to Step

1

1

Sliding the PICKUP with << >>, << >> button can be set

in STOP mode or play mode.

During at Step , if press << >> for more than 1 sec, it directly

goes to step .

1

5

/

To cancel: Power OFF

2 – 3

XL-DK225

[3] Standard Specification Of Stereo System Error Message Display Contents

Error Contents DISPLAY Notes

CD CD Changer Mechanism Error. ‘ER-CD**’ (*) 10: CAM SW Detection NG during normal operation

11: CAM SW Detection NG during initialize process

20: TRAY SW Detection NG during normal operation

21: TRAY SW Detection NG during initialize process

Focus Not Match/IL Time Over. ‘NO DISC’

TUNER PLL Unlock.

87.50

FM MHz

(*) CHECKING:

If CD changer mechanism error is detected, 'CHECKING' will be display instead of 'ER-CD**'. 'ER-CD**' will only be

display when error had been detected for the 5

th

times.

Speaker abnormal detection and +B PROTECTION display

In case speaker abnormal detection or +B PROTECTION had occurred, the unit will automatically enter to stand-by

mode and Timer indicator will flashing as below.

Example: In case of speaker abnormal

PLL Unlock.

ON

FLASHING FLASHING

ON ON ON

TIMER

LED OFF OFF

NO NO. 1.1

NO. 2

1

FRAME

OFF

OFF OFF OFF OFF

NO. 2

(REPEAT)

NO. 1 : +B PROTECTION

NO. 2 : Speaker abnormal

BEFORE TRANSPORTING THE UNIT

The following process need to be taken after set tapering/parts replacement.

1. Press the POWER ON/STAND-BY button to enter stand-by mode.

2. While pressing down the button and the button, press the button. The Micro Computer version

3

4

number will be displayed as "X5U_10**".

3. Press the button until "WAIT"--> "FINISHED" appears.

4

4. Unplug the AC cord and the unit is ready for transporting.

2 – 4

XL-DK255

CHAPTER 3.

MECHANICAL DESCRIPTION

[1] Removing And Reinstalling The Main Parts

1. CHANGER MECHANISM SECTION

Perform steps 1, 2, 9 and 10 of the disassembly

method to remove the CD changer mechanism.

1.1 How to remove CD Disc (See Fig. 1-4)

1. When CD is at play position (Figure 1), rotate

reduction gear C clock-wise as shown in Figure 2

until disc tray is at stock position, then rotate further

to eject the disc tray so that CD can be removed

from the tray.

Disc Tray

Guide Tray

CD Disc

CD Disc

CD at play position.

Gear up down board

Reduction gear D

Up Down

Figure 3

Mark 1

(DISC 1)

Mark 2

(DISC 2)

Figure 4

Mark 3

(DISC 3)

Mark 4

(DISC 4)

Mark 5

(DISC 5)

CD at stalk position.

Figure 1

Reduction gear C

Front Rear

Figure 2

2. In another case, if CD mechanism is at tray No.1

play position and to remove CD located in tray No.3,

the procedure is as follows:

If the gear up down board is located at tray No.1

position, then rotate gear clock-wise until it is at

stock postiiton. Rotate reduction gear D clockwise

(Figure 3) to move the CD mechanism to tray No.3

position. This is confirmed by checking the gear up

down board position by the marking as indicated on

the main chassis as shown in Figure 4.

3 – 1

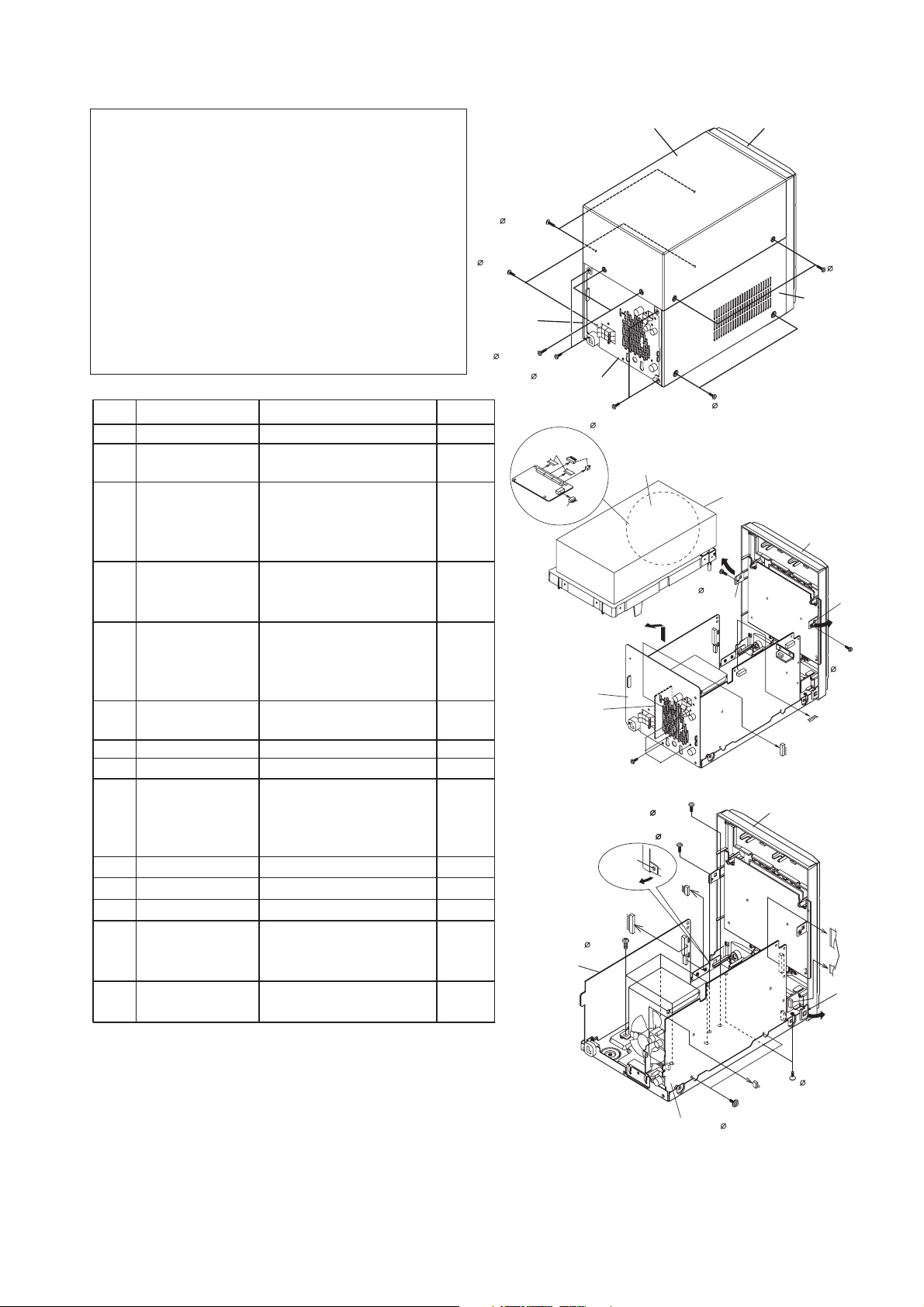

[2] Disassembly

XL-DK255

Caution on disassembly

Follow the below-mentioned notes when disassembling

the unit and reassembling it, to keep it safe and ensure

excellent performance:

1) Take cassette tape and compact disc out of the unit.

2) Be sure to remove the power supply plug from the

wall outlet before starting to disassemble the unit.

3) Take off nylon bands or wire holders where they

need to be removed when disassembling the unit.

After servicing the unit, be sure to rearrange the

leads where they were before disassembling.

4) Take sufficient care on static electricity of integrated

circuits and other circuits when servicing.

STEP REMOVAL PROCEDURE FIGURE

1 Top Cabinet 1

2 Side Panel

(Left/Right)

3 CD Changer unit 2

4 Rear Panel with 2

Speaker PWB

5 Front Panel 3

6 Main PWB 3

7 Power PWB 3

8 Speaker PWB 4

9 Display PWB 5

10 USB PW B / SUB PWB 5

11 Jack PWB 5

12 Re-Flash PWB 6

13 CD MP3 PW B 7

14 CD Mechanism 7

1. Screw ............................(A1) X 6

1. Screw ............................(B1) X 8

1. Screw ............................(C1) X 2

2. Hook ..............................(C2) X 2

3. Socket ...........................(C3) X 3

4. Flat Cable ...................... (C4) X 2

1. Screw ............................(D1) X 4

2. Socket ...........................(D2) X 1

3. Flat Cable ...................... (D3) X 1

1. Screw ............................(E1) X 3

2. Flat Cable ...................... (E2) X 2

3. Socket ...........................(E3) X 1

4. Hook .............................. (E4) X 2

1. Screw ............................(F1) X 3

2. Socket ........................... (F2) X 2

1. Screw ............................(G1) X 4

1. Screw ............................(H1) X 2

1. Knob ...............................(J1) X 1

2. Nut..................................(J2) X 1

3. Washer...........................(J3) X 1

4. Screw .............................(J4) X 6

1. Screw ............................(K1) X 2

1. Screw ............................ (L1) X 1

1. Screw ........................... (M1) X 1

1. Screw ............................(N1) X 3

2. Flat Cable ...................... (N2) X 2

3. Socket ...........................(N3) X 1

1. Screw ............................(P1) X 4

2. Screw ............................(P2) X 4

1

8

(A1)x2

3x12mm

(B1)x2

3x10mm

Side Panel

(Right)

(A1)x2

3x12mm

(B1)x2

3x10mm

(C4)x2

(C3)x1

Rear Panel

Speaker PWB

Power PWB

Rear Panel

(C3)x2

(G1)x4

4x6mm

(B1)x2

3x10mm

(D1)x4

3x10mm

(E4)x1

PULL

(F2)x1

Top Cabinet

Figure 1

CD MP3 PWB

Figure 2

(E1)x1

3x6mm

(F1)x1

3x6mm

CD Changer Unit

(C1)x1

3x10mm

(E3)x1

(B1)x2

3x10mm

PULL

Hook

(C2)x1

Front Panel

(D2)x1

Front panel

Side Panel

(Left)

Front Panel

(D3)x1

PULL

(A1)x2

3x12mm

Hook

(C2)x1

PULL

(C1)x1

3x10mm

(E2)x2

Hook

(E4)x1

Note:

After removing the connector for the optical pickup from

the connector, wrap the conductive aluminium foil around

the front end of the connector so as to protect the optical

pickup from electrostatic damage.

3 – 2

Main PWB

Figure 3

(F1)x2

3x10mm

(F2)x1

(E1)x2

3x10mm

XL-DK255

Speaker PWB

Display PWB

(J4)x6

Ø2.6x10mm

SUB PWB

USB PWB

(K1)x2

Ø2.6x10mm

Rear Panel

Figure 4

Jack PWB

(L1)x1

Special

Figure 5

Front Panel

(J2)x1

(J3)x1

(H1)x2

Ø3x10mm

(J1)x1

(P2)x4

Special

CD Mechanism

CD Changer Unit

Figure 8

STEP PROCEDURE FIGURE

1 Woofer 1. Net Frame Ass’y............ (A1) X 1

2 Tweeter 1. Screw ............................ (B1) X 2

REMOVAL

9, 10

2. Catching Holder............. (A2) X 4

3. Screw ............................ (A3) X 4

4. Screw ............................ (A4) X 4

10

Speaker Box

Re-Flash PWB

(M1)x1

CD Changer

Unit

(P1)x2

Ø3x10mm

Ø3x10mm

Main Chassis

Figure 6

(N1)x3

Ø3x10mm

Figure 7

(N2)x2

(P1)x2

Ø3x10mm

(N3)x1

Net Frame Ass’y

(A1) x1

Tweeter Ring

Woofer

Woofer Ring

(A2)x4

Tweeter

(A3)x4

Ø4x20mm

Figure 9

Front Board

Figure 10

(B1)x2

Ø3x14mm

(A4)x4

Ø3.5x14mm

3 – 3

-MEMO-

XL-DK255

3 – 4

XL-DK225

CHAPTER 4. DIAGRAMS

[1] Main Block Diagram

Figure 4-1: MAIN BLOCK DIAGRAM (1/2)

4 – 1

XL-DK225

Figure 4-2: MAIN BLOCK DIAGRAM (2/2)

4 – 2

XL-DK225

[2] CD Block Diagram

Figure 4-3: CD BLOCK DIAGRAM (1/2)

4 – 3

XL-DK225

Figure 4-4: CD BLOCK DIAGRAM (2/2)

4 – 4

XL-DK225

CHAPTER 5. CIRCUIT DESCRIPTION

[1] Waveforms Of CD Circuit

1

IC1

22

FDO

1

IC1

2

IC1 IC1

1

IC1 IC1

23

22

TDO

FDO

5

6

7

IC1

3

IC1

16

TE

1

IC1

22

25

28

27

22

FDO

SPDO

PDOUT 0

PDOUT 1

FDO

3

IC1

IC1

TE

16

4

IC1

2

4

2

RFOUT

RFOUT

5 – 1

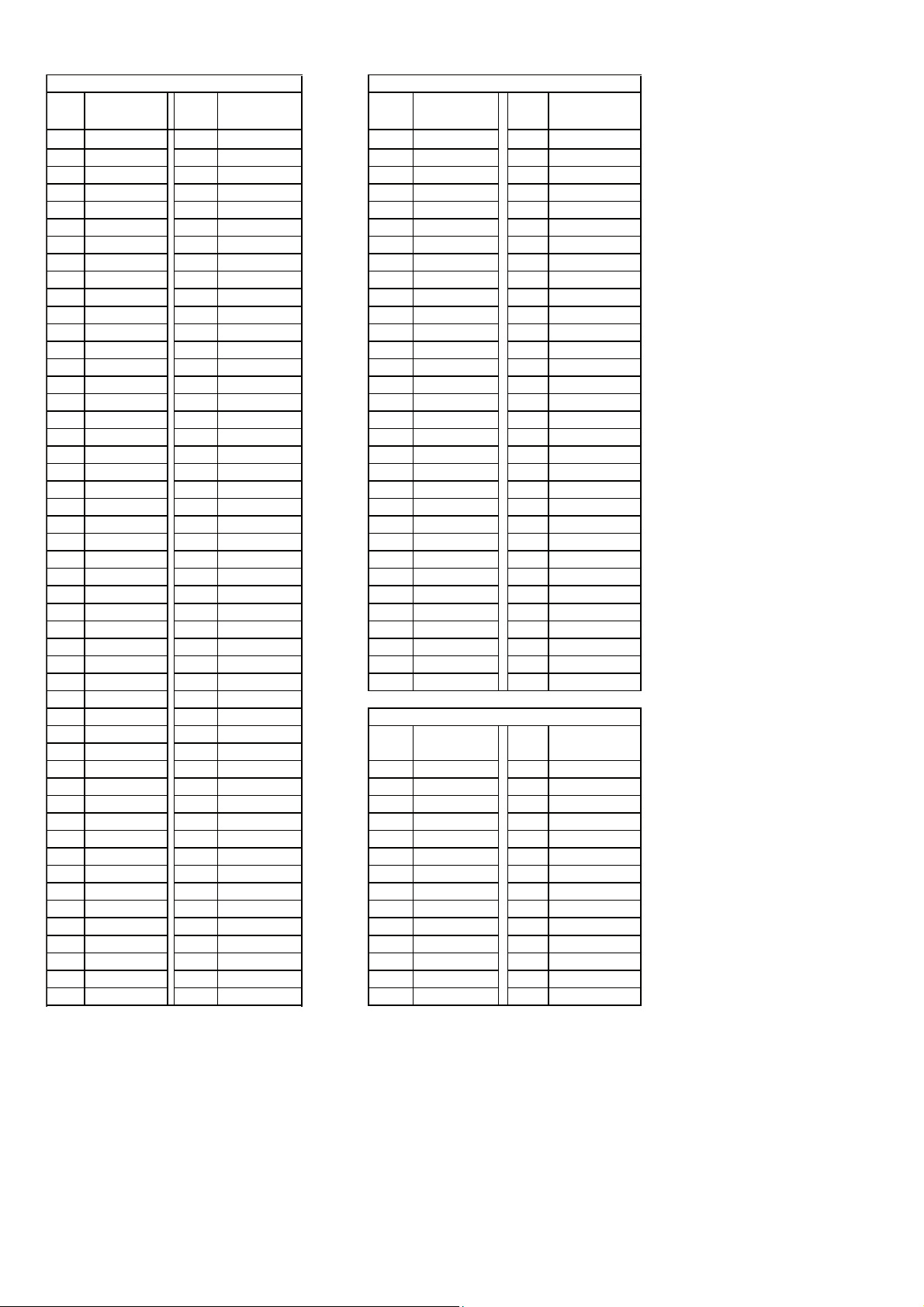

[2] Voltage

IC1

PIN

VOLTAGE

NO

1 0.02 26 0.01 51 1.53 76 3.26

2 1.63 27 1.52 52 0.03 77 1.63

3 0.76 28 3.03 53 3.27 78 0.98

4 0.70

5 0.59 30 1.52 55 0.03 80 1.74

6 0.70

7 1.63 32 3.27 57 1.53 82 1.63

8 3.27 33 0.03 58 3.27 83 1.68

9 1.63 34 4.53 59 0.04 84 1.63

10 1.63 35 1.53 60 3.27 85 1.62

11 1.63 36 0.01 61 0.03 86 1.64

12 1.63 37 3.25 62 0.03 87 1.66

13 1.63 38 2.41 63 0.03 88 1.62

14 0.01 39 2.14 64 0.03 89

15 0.52 40 2.59 65 1.62 90 3.27

16 0.55 41 2.25 66 1.65 91 3.25

17 0.01 42 0.61 67 3.24 92 0.01

18 0.01 43 3.25 68 1.49 93 0.02

19 1.11 44 0.04 69 0.02 94 1.63

20 0.36 45 0.04 70 1.63 95 1.63

21 0.26 46 0.04 71 3.26 96 1.63

22 0.01 47 0.04 72 1.61 97 1.63

23 0.26 73 1.31 98 1.63

24 0.34 49 1.64 74 0.02 99 1.64

25 0.54 50 1.65 75 1.38 100 1.63

PIN

VOLTAGE

NO

29 1.52 54 0.03 79 0.02

31 0.01 56 3.27 81 1.63

48 0.10

PIN

NO

VOLTAGE

PIN

NO

XL-DK225

VOLTAGE

0.50

IC2

PIN

VOLTAGE

NO

1 3.18 10 3.27 19 3.20 28 7.09

2 3.17 11 1.63 20 3.20 29 0.01

3 3.19 12 1.63 21 0.01 30 1.63

4 3.20 13 1.63 22 0.01 31 2.24

5 3.19 14 1.63 23 0.01 32 3.15

6 3.18 15 1.63 24 0.01 33 3.16

7 0.00 16 1.63 25 0.00 34 2.69

8 4.39 17 1.62 26 7.03 35 3.16

9 7.08 18 1.62 27 7.08 36 3.16

Q1 Q2 Q3 Q4

PIN

VOLTAGE

NO

E 3.26 E 5.05 E 1.48 E 0.01

C 0.89 C 3.26 C 3.26 C 0.02

B 4.37 B 4.37 B 2.17 B 3.11

Q5

PIN

VOLTAGE

NO

E 5.08

C 5.05

B 4.37

PIN

VOLTAGE

NO

PIN

VOLTAGE

NO

Q8

PIN

VOLTAGE

NO

E 0.00

C 0.04

B 2.98

PIN

NO

PIN

NO

VOLTAGE

VOLTAGE

PIN

NO

PIN

NO

VOLTAGE

VOLTAGE

5 – 2

XL-DK225

VOLTAGE

PIN

NO

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

IC701 IC702

VOLTAGE

(V)

3.22

3.22

0.00

0.00

0.00

3.22

0.00

0.00

0.00

0.47

0.63

3.19

1.54

0.00

0.00

3.24

3.24

1.05

0.00

3.18

0.00

0.00

0.00

0.00

0.71

0.00

0.00

3.24

0.00

0.00

3.24

0.00

3.24

3.24

3.24

3.28

3.27

0.00

0.00

0.00

0.00

0.00

0.76

0.63

0.00

3.23

0.00

0.58

0.00

0.00

PIN

NO

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

(V)

3.30

3.14

3.31

3.31

3.15

3.23

3.24

3.23

3.24

3.24

3.31

3.24

0.00

0.00

0.00

0.00

3.14

0.00

0.00

3.22

3.31

0.00

0.00

3.24

3.24

3.24

0.00

0.00

0.00

0.00

3.24

3.22

3.28

0.00

3.31

3.24

0.00

0.00

0.00

0.00

3.31

3.28

3.28

3.28

3.28

0.00

3.28

3.30

3.24

0.00

PIN

NO

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

PIN

NO

1

2

3

4

5

6

7

8

9

10

11

12

13

14

VOLTAGE

(V)

-26.44

-26.40

-26.40

-26.40

3.24

3.20

3.24

3.24

0.00

0.00

3.29

1.51

1.51

0.00

-24.10

-28.77

-28.78

-28.77

-28.77

-28.75

-28.77

-28.77

-21.70

-28.97

-26.40

-28.77

-28.76

-28.76

21.71

-24.06

-24.07

-24.07

VOLTAGE

(V)

4.62

4.62

4.63

4.63

4.62

4.62

4.63

4.65

4.61

4.65

4.61

4.65

4.65

4.64

PIN

NO

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

IC601

PIN NOVOLTAGE

15

16

17

18

19

20

21

22

23

24

25

26

27

28

VOLTAGE

(V)

-26.42

-28.77

-26.41

-26.40

-26.41

-24.06

-17.00

-26.40

-24.07

-9.89

-26.40

-9.98

-17.00

-12.34

-9.94

-26.40

-26.42

-24.06

-14.67

-12.36

-28.76

-28.76

-28.76

-28.75

-26.45

-26.41

-26.41

-26.40

-26.40

-26.40

-26.40

-26.40

(V)

4.65

0.00

0.00

4.64

4.64

0.00

0.00

0.00

4.63

9.28

0.00

4.65

4.65

4.63

5 – 3

IC703 IC705 IC901

PIN

VOLTAGE

NO

1 3.30 1 3.90 1 -0.10 9 -23.00

2 3.30 2 0.60 2 -0.10 10 0.00

3 0.00 3 5.60 3 - 11 0.00

4 - 4 21.90 12 -22.10

5 - 5 -20.70 13 0.00

(V)

PIN

NO

VOLTAGE

(V) (V) (V)

PIN

VOLTAGE

NO

60.00 14-0.10

70.00 15-0.10

823.10

PIN

NO

VOLTAGE

XL-DK225

IC852 IC853

PIN

VOLTAGE

NO

1 15.80 1 3.30 1 5.10 5 16.20

2 0.00 2 0.00 2 13.00 6 10.00

3 4.90 3 5.10 3 16.40 7 8.50

PIN NOVOLTAGE

1 5.60 1 0.00 1 0.00 1 2.20

2 0.60 2 0.00 2 0.00 2 2.20

3 13.90 3 0.70 3 0.70 3 0.00

PIN NOVOLTAGE

1 0.00 1 0.00 1 0.00 1 0.00

2 3.20 2 3.20 2 3.30 2 0.00

3 0.00 3 0.00 3 0.00 3 3.00

PIN NOVOLTAGE

1

2

3

(V)

IC854 Q603

(V)

Q701 Q702 Q704 Q706

(V)

Q801 Q841 Q860 Q901

(V)

-28.90

-29.50

-37.60

PIN

VOLTAGE

NO

PIN NOVOLTAGE

PIN NOVOLTAGE

PIN NOVOLTAGE

1 0.80 1 0.00 1 0.00

2 0.00 2 3.50 2 3.40

3 0.00 3 0.00 3 0.00

(V)

(V)

(V)

(V)

PIN

VOLTAGE

NO

40.00

PIN NOVOLTAGE

PIN

NO

PIN

NO

(V)

Q604 Q608

(V)

VOLTAGE

(V)

VOLTAGE

(V)

IC851

PIN

NO

PIN NOVOLTAGE

PIN NOVOLTAGE

PIN NOVOLTAGE

VOLTAGE

(V)

(V)

(V)

(V)

Q902 Q903 Q904 Q905

PIN

PIN NOVOLTAGE

(V)

1 0.00 1 0.00 1 0.00 1 0.00

2 3.30 2 3.10 2 3.10 2 0.00

3 0.00 3 0.00 3 0.00 3 0.70

Q906

PIN NOVOLTAGE

(V)

10.70

20.00

33.60

PIN NOVOLTAGE

(V)

NO

VOLTAGE

(V)

PIN NOVOLTAGE

5 – 4

(V)

XL-DK225

-MEMO-

5 – 5

XL-DK225

CHAPTER 6. CIRCUIT SCHEMATICS AND PARTS LAYOUT

[1] Notes On Schematic Diagram

•Resistor:

To differentiate the units of resistors, such symbol as

K and M are used: the symbol K means 1000 ohm

and the symbol M means 1000 kohm and the

resistor without any symbol is ohm-type resistor.

Besides, the one with “Fusible” is a fuse type.

• Capacitor:

To indicate the unit of capacitor, a symbol P is used:

this symbol P means pico-farad and the unit of the

capacitor without such a symbol is microfarad. As to

electrolytic capacitor, the expression “capacitance/

withstand voltage” is used.

(CH), (TH), (RH), (UJ): Temperature compensation

(ML): Mylar type

(P.P.): Polypropylene type

REF. NO DESCRIPTION POSITION

SW701 DISC4 ON—OFF

SW702 DISC5 ON—OFF

SW703 OPEN/CLOSE ON—OFF

SW704 DISC1 ON—OFF

SW705 DISC2 ON—OFF

SW706 DISC3 ON—OFF

SW707 POWER ON/STAND-BY ON—OFF

SW708 PLAY/REPEAT ON—OFF

SW709 STOP ON—OFF

SW710 VIDEO/AUX/USB ON—OFF

SW711 TUNER (BAND) ON—OFF

SW712 CD ON—OFF

VR701 VOLUME MAX—MIN

• Schematic diagram and Wiring Side of P.W.Board

for this model are subject to change for

improvement without prior notice.

• The indicated voltage in each section is the one

measured by Digital Multimeter between such a

section and the chassis with no signal given.

1. In the tuner section,

indicates AM

indicates FM stereo

2. In the CD section, the CD is stopped.

• Parts marked with “ ” ( ) are

important for maintaining the safety of the set. Be

sure to replace these parts with specified ones for

maintaining the safety and performance of the set.

[2] Types Of Transistor And LED

FRONT

VIEW

ECB

(S)(G)(D)

(1)(2)(3)

KTA1271 Y

KTA1274 Y

KIA78L05

KTC3199 GR

KTC3203 Y

TOP VIEW

KDS184

B

(3)

(1)

TOP

VIEW

E

KRA102 S

KRC107 S

KRC102 S

KRC104 S

KTA1504 GR

KTC3875 GR

KTA1544 T

KTC3265 Y

FRONT

VIEW

AC AC

10XB60F

S4B05GM

(2)

TOP VIEWTOP VIEW

C

HSS4148

FRONT

VIEW

343VC3F

503BC2E30

1N4004S

DRL204F

MA 111

FRONT

VIEW

123

KIA7805A

6 – 1

Loading...

Loading...