LG RCWW008CA1B,RCWW010CA1B,RCWW011CA1B,RCWW012CA1B,RCWW014CA1B,RCWW016CA1B,RCWW018CA1B,RCWW020CA1B,RCWW022CA1B,RCWW020CA2B,RCWW022CA2B,RCWW024CA2B,RCWW026CA2B,RCWW028CA2B,RCWW032CA2B,RCWW036CA2B,RCWW040CA2B,RCWW044CA2B,RCWW008CA1B,RCWW010CA1B,RCWW011CA1B,RCWW012CA1B,RCWW014CA1B,RCWW016CA1B,RCWW019CA1B,RCWW020CA2B,RCWW022CA2B,RCWW024CA2B,RCWW028CA2B,RCWW032CA2B,RCWW038CA2B User Manual

LG Electronics, Home appliance & Air solution company

56, Digital-ro 10-gil, Geumcheon-gu, Seoul, Republic of Korea (153-801)

www.lg.com

www.lgeaircon.com

Ver. 202004

LG HVAC SOLUTION

WATER COOLED

SCREW CHILLER

For continual product development, LG reserves the right to

change specifications or designs without notice.

© 2020 LG Electronics. Printed in Korea. Apr. 2020

Distributed by

Line upNomenclature

Introduction

R : Korea(R134a)

M : China(R134a)

C: Chiller

Contents

02 Nomenclature

03 Line up & Introduction

04 Equipment overview

06 Control

08 Accessories and options

09 Specication

15 Electrical data

22 Outline drawing

24 Foundation

26 Piping diagram

28 Control wiring

30 Power wiring

32 Installation

34 Guide specication

W: Water-cooled

(Cooling only)

W: Screw

compressor

Nominal ton:

100RT ⇨ 010

380RT ⇨ 038

Water working pressure:

A: Chilled water : 10kgf/cm²G

Cooling water : 10kgf/cm²G

B: Chilled water : 16kgf/cm²G

Cooling water : 16kgf/cm²G

C: Chilled water : 20kgf/cm²G

Cooling water : 20kgf/cm²G

030R C W W C A 2 B

Develop-

A: Flooded type

C: Falling film type

Number of

compressors

ment

sequence

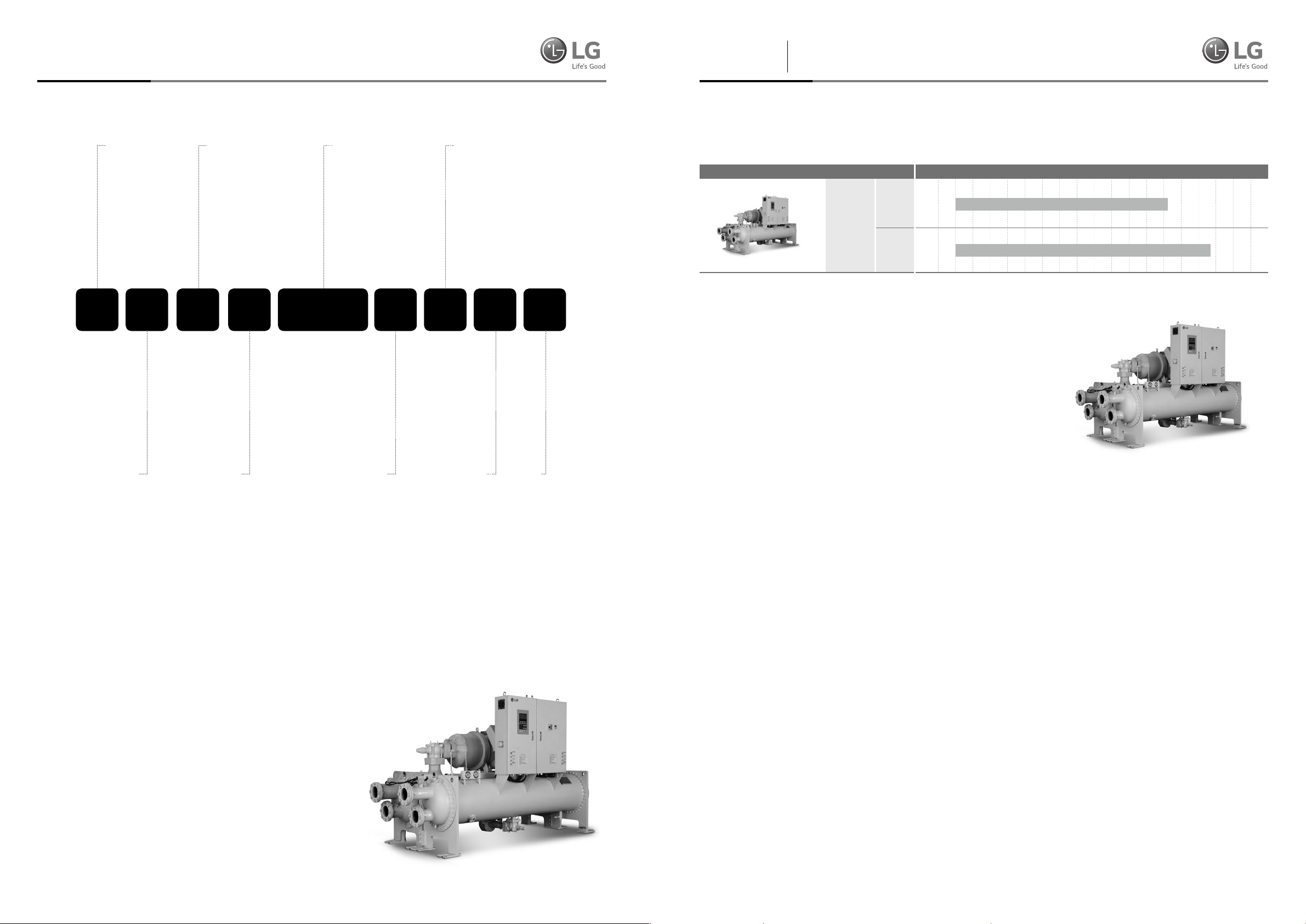

Line up

Model

50Hz

R-134a

60Hz

LG’s latest Water cooled screw chiller offers excellent operational efciency

thanks to the company’s advanced technologies and unrivalled air conditioning

expertise. The new model’s advanced capacity control system valve help to

improve performance and efciency. LG’s proprietary PID(Proportional, Integral,

Differential control), which controls hydraulic-head loss rate, helps to minimize

energy loss even further.

• High-performance compressor manufactured by specialized

manufacturer is adopted to ensure that the chiller is

economical and durable with low vibration and low noise.

• Highly integrated motherboard is adopted and hence the

function is strong and reliable.

• Advanced control algorithm is adopted to control chiller in

advance and hence avoid frequent stoppage protection of chiller.

• We have set complete safety protection function in order to

make chiller safely and reliably run.

• The linkage control and remote monitoring function of

peripheral equipment ensure that the chiller can run safely

and the operation and monitoring are convenient.

• The selection of excellent raw materials and ttings is the key

to guaranteeing chiller quality.

High efciency, High reliability

The RCWW & MCWW series is a kind of water-cooled spray

screw chiller produced by LGE Corporation. Because of the

special structure design, the chiller has high efciency and

high reliability.

Optimized dedicated motor

R134a with high efciency

Made of premium grade, low-loss core steel with the special

slot design, the motors of R134a dedicated compressors

50 100 150 200 250 300 350 400 450 500

75RT 380RT

75RT 440RT

can gain the highest efciency with low power consumption.

Besides, different winding for specic voltage and frequency

requirement contributes to the best power factor and

excellent performance.

Constructional design of

dedicated screw compressor

The screw compressor is characterized by a very compact

design. Most of inner dimensions have been totally modied

considering displacement volume, size of compression

chamber, length & prole of rotors, oil separator specication

and oil piping rearrangement, etc. to ensure consistency and

cost effectiveness of the compressor.

Compressor

• Semi-hermetical twin-rotor screw compressor.

• Direct-drive, low speed/RPM for high efciency and high reliability.

• Only three moving parts, resulting in high reliability with

simple solution.

• Field serviceable compressor and easy maintenance.

• Precise rotor tip clearance.

• The world’s advanced patent screw tooth with low noise,

smooth operation long life advantages.

• A refrigerant dispersing cooling device is set internally for

compressor cooling, which uses return-refrigerant cooling.

• Years of research and testing. The LG screw chiller has

amassed thousands of hours of testing, and conditions

* The above range is based on the nominal tonnage.

02 | 2020 LG Water Cooled Screw 2020 LG HVAC Solution | 03

Features Features

Equipment overviewEquipment overview

beyond normal air conditioning applications.

Unit performance testing

LG began promoting factory performance tests for air-cooled

chillers and water-cooled chillers, to show we stand behind the

products we design and build.

The bene ts of a performance test include veri cation of performance, prevention of operational problems, and assurance of a

smooth start-up.

Only a performance test conducted in a laboratory or laboratory

grade facility will con rm both performance and operation of a

speci c chiller.

Mostly factory performance tests go smoothly. If a problem

occurs, LG personnel easily correct them and chiller is shipped

to job site.

When a factory performance test is requested, the test can be

conducted at the speci ed, design conditions. The test facility

has the capability to control ambient test conditions to assure

our customers that our chillers will perform as predicted.

AHRI certi cation program

and standards and codes

Chillers conform to the following Standards and Codes:

• AHRI 550/590 - water chilling

packages using the vapor

compression cycle.

• ANSI/ASHRAE 34 -

number designation and safety

classi cation of refrigerants.

• ASME Section VIII(Option) - boiler and pressure vessel.

• GB/T 18430.1 - water chilling(heat pump) packages using the

vapor compression cycle - part 1: water chilling(heat pump)

packages for industrial & commercial and similar applications.

(This code is only applied to product manufactured in China)

Equipment Overview

Semi-hermetic twin compressor

The semi-hermetic screw compressor is developed especially

for applications in air-conditioning and refrigeration. With high

operating load design, each compressor is of high ef ciency

and reliability in all operating conditions. Each compressor has

the latest and advanced 5-to-6 Patented Screw Rotor Pro le

designed to ensure high capacity and ef ciency in all operating

conditions.

The compressor is equipped with separated radial and axial

bearings, liquid injection and economizer connection, PTC

motor temperature thermistors and discharge temperature

thermistors, a motor protector, and oil level switch and

oil pressure differential switch and other accessories. The

complete accessories and their new designs guarantee the

compressor has the best reliability, longest bearing life during

heavy duty running and strict operating conditions.

The slide valve for capacity control is located in the compressor

chamber. The slide valve is actuated by injection of pressurized

oil into the cylinder from the oil sump as well as bypass of

oil through solenoid valves in each oil lines with pressure

differential.

The screw compressors are equipped with either 3-step/4step capacity control system or continuous(stepless) capacity

control system. Both of the capacity control systems consist

of a modulation slide valve, piston rod, cylinder, piston and

piston rings. The slide valve and the piston are connected by a

piston rod. The principle of operation is using the oil pressure

to drive the piston in the cylinder. The lubrication oil ows from

the oil sump through the oil lter cartridge and capillary then

lls into the cylinder due to the positive oil pressure bigger

than the right side of spring force plus the high pressure

gas. The positive pressure differential causes the piston to

move toward the right side in the cylinder. When the slide

valve moves toward the right side, the effective compression

volume in the compression chamber increases. This means the

displacement of refrigerant gas also increases, as a result the

refrigeration capacity also increases.

However, when any of the step solenoid valve(for 4-step

capacity control system) is opened, the high pressure oil in the

cylinder bypasses to the suction port, which causes the piston

and the slide valve to move toward the left side, and then

some of the refrigerant gas bypasses from the compression

chamber back to the suction end. As a result, the refrigeration

capacity decreases because of the reduction of displacement

of refrigerant gas owing in the system. The piston spring

is used to push the piston back to its original position, i.e.

minimum load position in order to reduce the starting current

for the next starting.

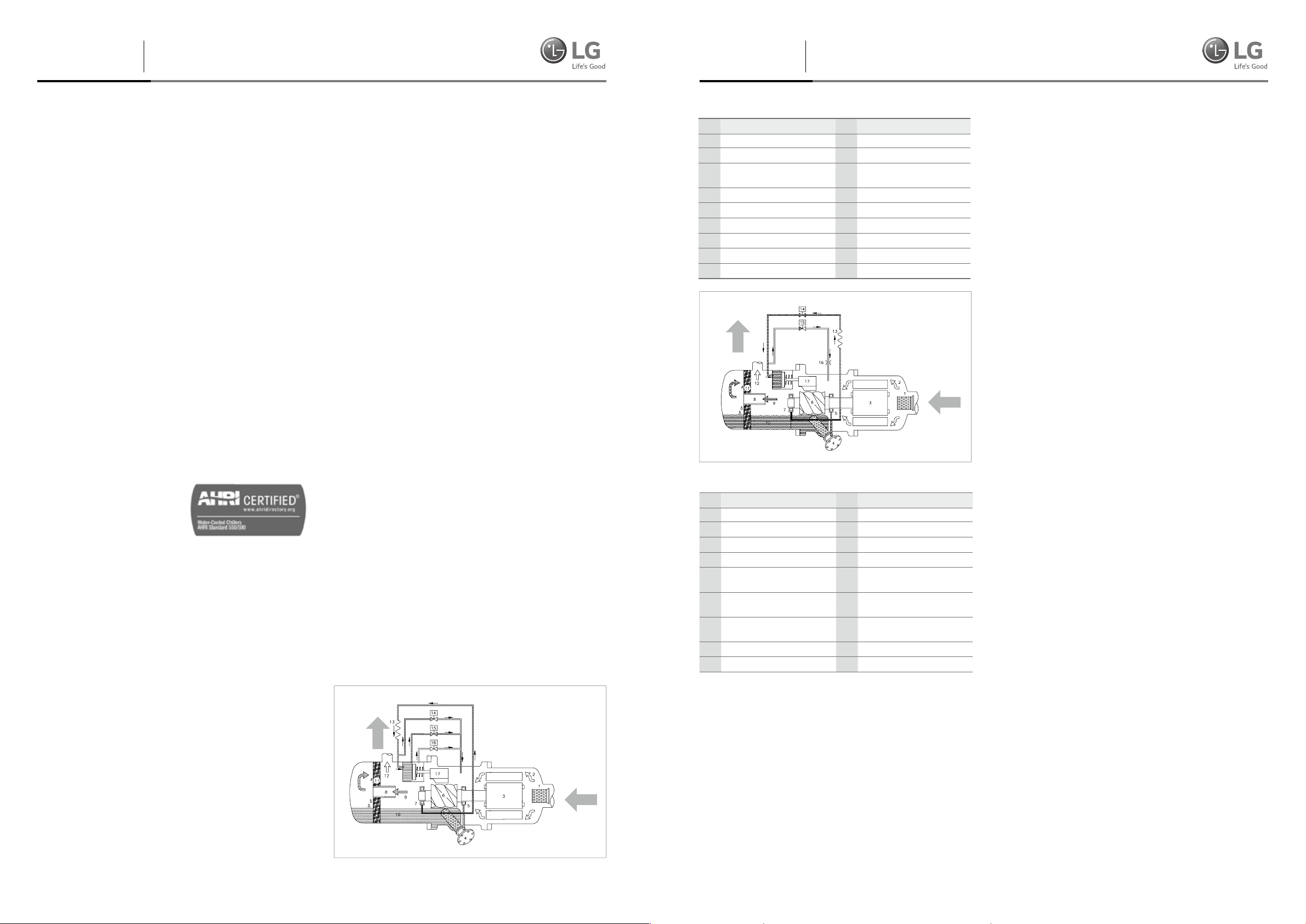

4-steps capacity control

Component

No

1 Suction filter 10 Lubricant

2

Gas in(low pressure) 11 Oil separator cartridge

Motor 12

3

4 Oil filter cartridge 13 Capillary

5 Suction bearings 14 Solenold valve, SV2

6 Male rotor 15 Solenold valve, SV1

7 Discharge bearings 16 Orifice

8 Oil separator baffle 17 Slide valve

9

Gas out(high pressure with oil)

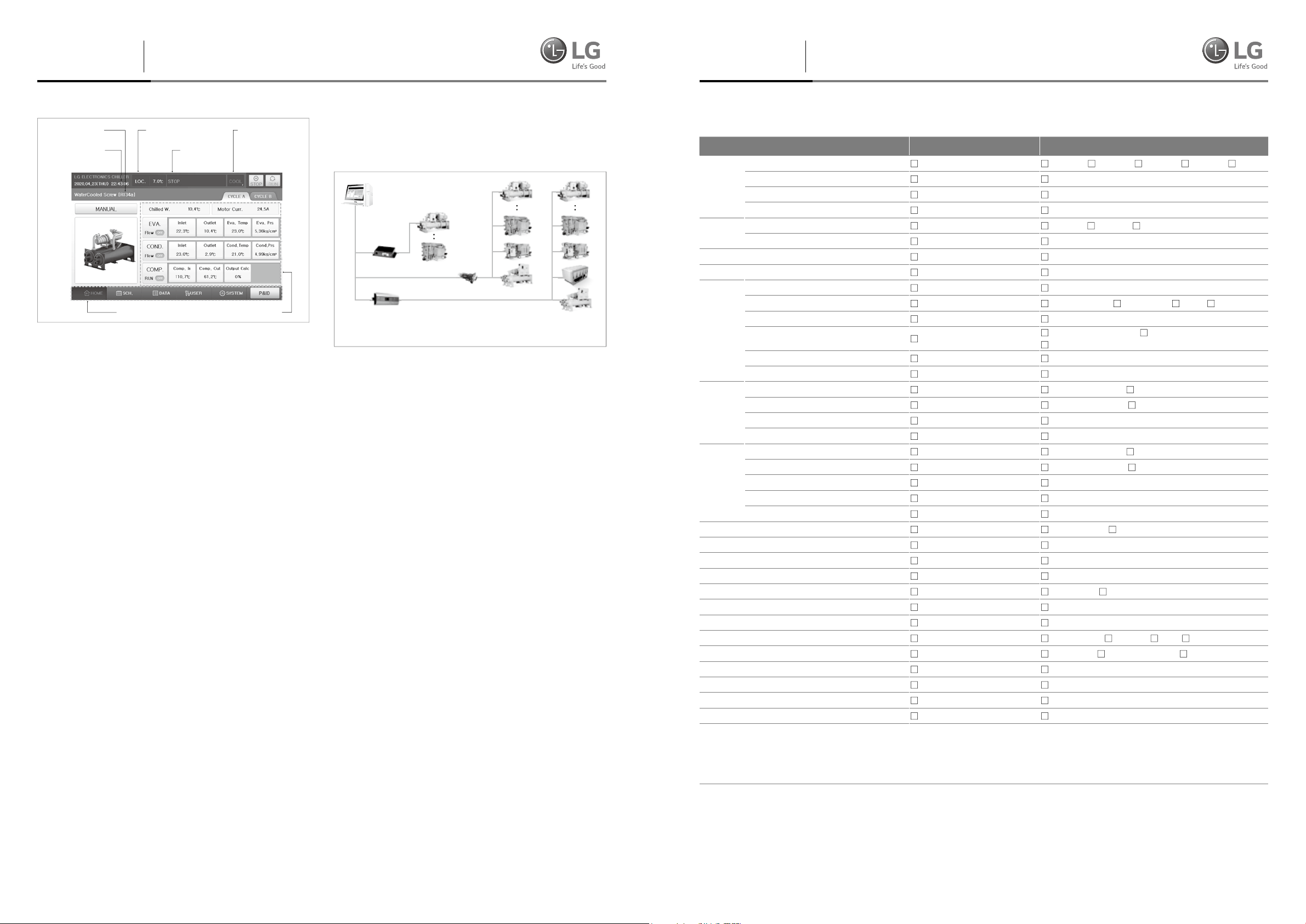

Step-less capacity control

Component

No

1 Suction filter 10 Lubricant

2 Gas in(low pressure) 11 Oil separator demister

3 Motor 12 Gas out(high pressure without oil)

4 Oil filter cartridge 13 Capillary

5 Suction bearings 14

6 Male rotor 15

7 Discharge bearings 16

8 Oil separator baffle 17 Slide valve

9 Gas out(high pressure with oil) *

Component

No

Gas out

(high pressure without oil)

Component

No

Solenold valve(min. %),

SV 25% / 33%

Solenold valve

(50% of full load), SV 50%

Solenold valve(75% / 66% of

full load), SV 75% / 66%

For RC2-100, 140 & 180 the SV50% omitted

Heat exchanger

Evaporator

Falling lm type

“Falling lm” shell and tube type evaporator having refrigerant

in the shell and chilled water inside the tubes.

Advantage of this type evaporator is higher heat transfer

performance and reduced refrigerant charge.

Distributer located on the top side of inside shell makes

uniform ow of refrigerant, this refrigerant ows downward

by gravity as a continuous lm.

The shell is of welded carbon steel construction with steel

tube sheets and copper heat exchange tubes. Removable steel

water boxes at both ends of the cooler allow tube cleaning

without disturbing the refrigerant circuit.

Tubes are mechanically expanded into tube sheets with double

grooves to ensure leak tight and trouble free operation.

Multiple compressor/ circuit chillers have coolers with separate

refrigeration circuits for each compressor.

Each refrigeration circuit is provided with its own pressure

relief valve. All chillers are tted with drain valves on the

removable heads and shell. All coolers are factory insulated

with 19mm of closed cell expanded synthetic rubber with all

joints vapor sealed.

Expansion device

Expansion unit consists of butter y valve and ori ce. At 100%

load situation, the pressure loss at the ori ce is smaller than

the refrigerant pressure loss in the condenser, thus the super-

cooled refrigerant passes through the ori ce.

At this stage the maximum amount of refrigerant is owing

into the evaporator. As the load reduces gradually, the

circulating amount of refrigerant also reduces and accordingly

the refrigerant level in the condenser is getting low.

When the amount of liquid refrigerant reduces, the gas

amount in the ori ce is getting larger, raising the resistance

thus controlling the ow rate.

Control

Controller system information

Generally controller consist of Display, Master, Slave and Relay

board. Each board connect with RS485 communication and

include analog input/output, digital input/output channel.

• 7 and 10.2-inch color LCD touch screen with high resolution

(1,024 x 600)

• Operation scheduling function

• Real time trend display

• Web Access(Additional accessory)

• Running data acquisition

• Easy-to-read display of operational data

• Certi ed EMI/EMS

• Communication supported: Modbus, RS485(standard)

• Language: English / Chinese / Korean

04 | 2020 LG Water Cooled Screw 2020 LG HVAC Solution | 05

Features

Control

Features

Accessories and options

①

Machine type

selection indicator

②

Date and time

indicator

⑦

Menu bar

③

Operation method

selection indicator

④

Message

display

⑤

Operation mode

selection indicator

⑥

Displayed categories

Controller front view

① Machine type selection indicator

It show the currently selected model. You can check detail

from 'Control Information set' part.

② Date and time indicator

It show the current time. You can check detail from 'Sys.

Info.(System information)' part.

③ Operation method selection indicator

It show the currently selected control mode. You can

check detail from 'User set' part.

④ Message display

It show the message about status of product.

⑤ Operation mode selection indicator

It show the currently selected run mode. You can check

detail from 'User set' part.

⑥ Displayed categories

It show the currently information of product.

⑦ Menu bar

It show the functions for menu operation button.

Features of control unit

The Control unit of LG chiller controls temperature, pressure,

current and capacity control valve using high capacity

microprocessor. It is constructed to provide the high reliability

chiller operation using LG's unique optimum control algorithm.

Controller system composition diagram

Master board and slave board have the same hardware and

they are set as master or slave by DIP switch setting. This

board consist of analog input/output, digital input/output and

communication connections.

• Protocol and communication method

- Standard : Modbus, RS-485

- Option : BACnet, TCP/IP, Lonwork

RS485

TCP/IP

Serial to LAN

converter

Protocol

converter

The chillers can be managed up to 255 units when using communication of RS485 or TCP/IP.

Multi-Drop

RS485

Converter

Connecting to max 8 units

Detailed diagrams of BMS

NFB(Non-Fused Breaker)

power disconnect switch

A non-fused disconnect is available as a factory-installed option

for all units with single point power connection units. This option

is that power supply is disconnected during service & repair.

Suction service isolation valve

Service suction isolation valve is installed with unit for each

refrigerant circuit as a standard.

General options

Vibration isolation

For installation on building roofs or in sensitive noise areas

(hospitals, studios and some residential areas) pre-selected

spring type isolators with 1” or 2” de ection are available as a

factory option – shipped loose part for eld installation.

Power factor correction

Provide equipment with power factor correction capacitors as

required to maintain a displacement power factor of 95% at all

load conditions.

Water-Cooled Screw chiller standard summary

Items Standard Option

Power Supply(3Ph)

Comp.

Control

Panel

Power Connection

Factory Wiring

Starter

Panel

EVAP.

COND.

Refrigerant Charge

Packing

Insulation

Sound attenuator

Isolation

Anchor Bolt for Foundation

Counter Pipe Flange

Certification

Factory Performance Test&Process inspec.

Operating Training

Warranty-Compressor

Warranty-Ass'y

Labor warranty

Standard specification

Hertz

Capacity Control type

Angle Valve

Communication

Protection Grade

Supplied by

Starter type

Mounted type

Misc. Options

Power Access

Protection Grade

Waterbox Pressure

Nozzle Type

Flow proof type(Ref.)

Pipe direction(C.B Front st.)

Waterbox Pressure

Nozzle Type

Flow proof type(Water)

Flow proof type(Ref.)

Pipe direction(C.B Front st.)

380V

50Hz

Step

N/A

Modbus

IP4X

Standard(Single)

Open Wiring

Factory

Y-Delta(Open)

Unit Mounted

N/A

From the Top

IP4X

150psig(10kg/cm

ANSI-Flange

Relief V/V(Single)

Left

150psig(10kg/cm

ANSI-Flange

N/A

Relief V/V(Single)

Left

Separated Shipping

Shrink film

Yes

N/A

Neoprene PAD

N/A

N/A

Standard(KGS)

N/A

N/A

1yr

1yr

N/A

1) Factory Wiring : Open Wiring

2) Color : Dawn Gray

- Starter / Control Panel : Warm Gray

3) Standard provide Emergency stop switch

4) Flow proof type : DP Switch(Evaporator)

400V 415V 440V 460V 480V

60Hz

Stepless

Yes

BACnet TCP/IP etc( )

etc( )

Multi power Connection

Flexible Wiring

Supplied by customer

Y-Delta(Closed) Soft Starter

Stand Alone

Ground Fault Protection Power Factor Correction Capacitor

Integrating Watt-meter

From the Bottom

etc( )

2

)

2

)

230psig(16kg/cm

ANSI-Victaulic(AGS) ANSI-Victaulic(OGS)

Relief V/V(Dual)

Right

230psig(16kg/cm

ANSI-Victaulic(AGS) ANSI-Victaulic(OGS)

DP switch

Relief V/V(Dual)

Right

Factory Charge Customer supplied

Wooden packing

N/A

Yes

Spring 1Inch Spring Rubber Pad

Yes

Yes

ASME Ⅶ Only CE(PED) PED (C)UL(ETL)

Report Only Customer Wintness Process inspection

Yes

etc( )

etc( )

etc( )

2

)

2

)

300psig(20kg/cm

300psig(20kg/cm

SPG

Direct

2

2

)

)

BMS support function

Screw chiller’s basic communication protocol is Modbus protocol,

and it is compatible with the higher level communication methods.

Communication protocol support

06 | 2020 LG Water Cooled Screw 2020 LG HVAC Solution | 07

Specification

60Hz

Specification

60Hz

R134a(60Hz)

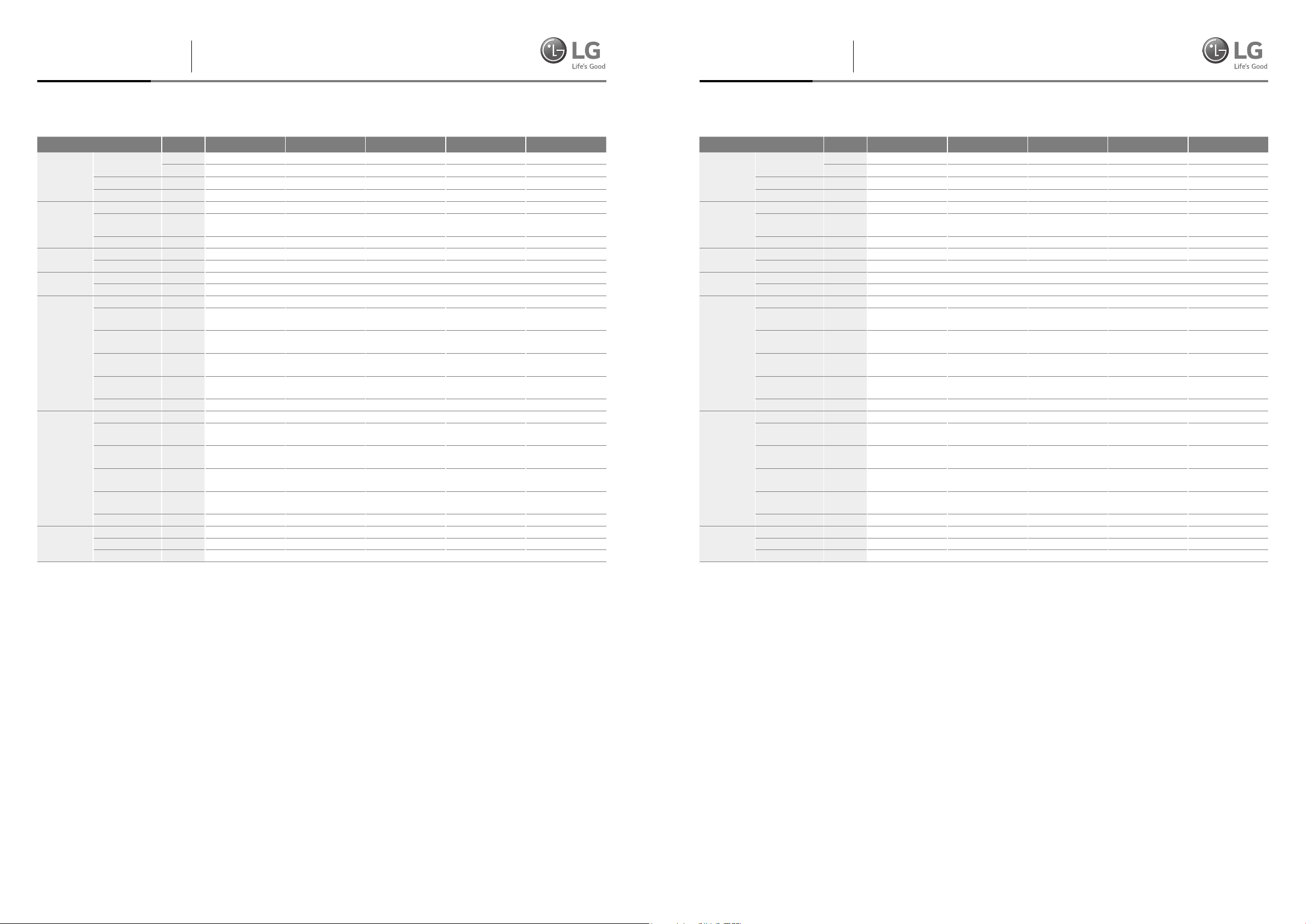

Model Units RCWW008CA1B RCWW010CA1B RCWW011CA1B RCWW012CA1B RCWW014CA1B

AHRI

Condition

Number of Circuits 1 1 1 1 1

General Unit

Data

Weight

Compressors

Condenser

Evaporator

Dimension

Operating Weight kg 2,810 3,020 3,120 3,120 3,460

Water Connections DN 100 100 100 100 125

Water Connections DN 100 100 100 100 125

Cooling capacity

Input Power kW 51.6 62.3

COP 5.35 5.33 5.34 5.35 5.58

Refrigerant,

R-134a

Oil Charge l 16 16 18 20 20

Shipping Weight kg 2,670 2,860 2,950 2,940 3,230

Compressor type Semi-hermetic twin screw

Quantity EA 1 1 1 1 1

Condenser type Shell and Tube

Max. Water

Pressure

Max. Refrigerant

Pressure

Min. Cooling

Water Flow Rate

Max. Cooling

Water Flow Rate

Evaporator type Shell and Tube

Max. Water

Pressure

Max. Refrigerant

Pressure

Min. Chilled

Water Flow Rate

Max. Chilled

Water Flow Rate

Length mm 3,040 3,040 3,040 3,040 3,145

Width mm 1,435 1,435 1,435 1,435 1,480

Height mm 1,860 1,865 1,865 1,865 2,080

kW 276.0 332.2 376.4 407.0 472.2

usRT 78.5 94.5

107.0

70.5

kg 110 110 110 110 140

MPa 1.0 1.0 1.0 1.0 1.0

MPa 1.0 1.0 1.0 1.0 1.0

l/s 6.6 7.5 8.5 8.5 10.8

l/s 26.5 30.0 34.2 34.2 43.2

MPa 1.0 1.0 1.0 1.0 1.0

MPa 0.9 0.9 0.9 0.9 0.9

l/s 5.6 7.7 7.7 8.4 10.1

l/s 22.3 30.7 30.7 33.5 40.5

115.7 134.3

76.1 84.7

R134a(60Hz)

Model Units RCWW016CA1B RCWW018CA1B RCWW020CA1B RCWW022CA1B RCWW020CA2B

AHRI

Condition

Number of Circuits 1 1 1 1 2

General Unit

Data

Weight

Compressors

Condenser

Water Connections DN 125 125 125 125 150

Evaporator

Water Connections DN 125 125 125 125 150

Dimension

Cooling capacity

Input Power kW 105.0 114.7

COP 5.44 5.52 5.47 5.61 5.35

Refrigerant,

R-134a

Oil Charge l 28 28 28 1 16 / 16

Shipping Weight kg 3,560 3,680 3,780 3,880 5,140

Operating Weight kg 3,810 3,960 4,060 4,160 5,410

Compressor type Semi-hermetic twin screw

Quantity EA 1 1 1 1 2

Condenser type Shell and Tube

Max. Water

Pressure

Max. Refrigerant

Pressure

Min. Cooling

Water Flow Rate

Max. Cooling

Water Flow Rate

Evaporator type Shell and Tube

Max. Water

Pressure

Max. Refrigerant

Pressure

Min. Chilled

Water Flow Rate

Max. Chilled

Water Flow Rate

Length mm 3,145 3,145 3,145 3,365 3,855

Width mm 1,480 1,605 1,605 1,750 1,565

Height mm 2,080 2,105 2,105 2,150 2,175

kW 571.6 632.8 681.1 795.9 667.6

usRT 162.6 180.0

193.7

124.6

kg 140 165 165 200 120 x 2

MPa 1.0 1.0 1.0 1.0 1.0

MPa 1.0 1.0 1.0 1.0 1.0

l/s 12.0 13.6 13.6 13.6 12.0

l/s 48.1 54.4 54.4 54.4 48.1

MPa 1.0 1.0 1.0 1.0 1.0

MPa 0.9 0.9 0.9 0.9 0.9

l/s 11.2 12.6 12.6 12.6 11.2

l/s 44.6 50.2 50.2 50.2 44.6

226.4 189.8

142.0 124.7

Note:

1. 1usRT = 3,024kcal/hr = 3.517kW, 1mH

2. AHRI conditions :

Leaving chilled water temperature is 6.7 ˚C(44 ˚F). Water flow is 0.043 L/s per kW(2.4 gpm/ton)

Entering cooling water temperature is 29.4 ˚C(85 ˚F). Water flow is 0.054 L/s per kW(3.0 gpm/ton)

Fouling factor of water in evaporator is 0.018 m²·˚C/kW(0.00001 h·ft2·˚F/Btu)

Fouling factor of water in condenser is 0.044 m²·˚C/kW(0.00025 h·ft2·˚F/Btu)

3. Due to our policy of innovation some specification may be changed without prior notification.

O = 9.8kPa

2

Note:

1. 1usRT = 3,024kcal/hr = 3.517kW, 1mH

2. AHRI conditions :

Leaving chilled water temperature is 6.7 ˚C(44 ˚F). Water flow is 0.043 L/s per kW(2.4 gpm/ton)

Entering cooling water temperature is 29.4 ˚C(85 ˚F). Water flow is 0.054 L/s per kW(3.0 gpm/ton)

Fouling factor of water in evaporator is 0.018 m²·˚C/kW(0.00001 h·ft2·˚F/Btu)

Fouling factor of water in condenser is 0.044 m²·˚C/kW(0.00025 h·ft2·˚F/Btu)

3. Due to our policy of innovation some specification may be changed without prior notification.

O = 9.8kPa

2

08 | 2020 LG Water Cooled Screw 2020 LG HVAC Solution | 09

Specification

60Hz

Specification

60Hz

R134a(60Hz)

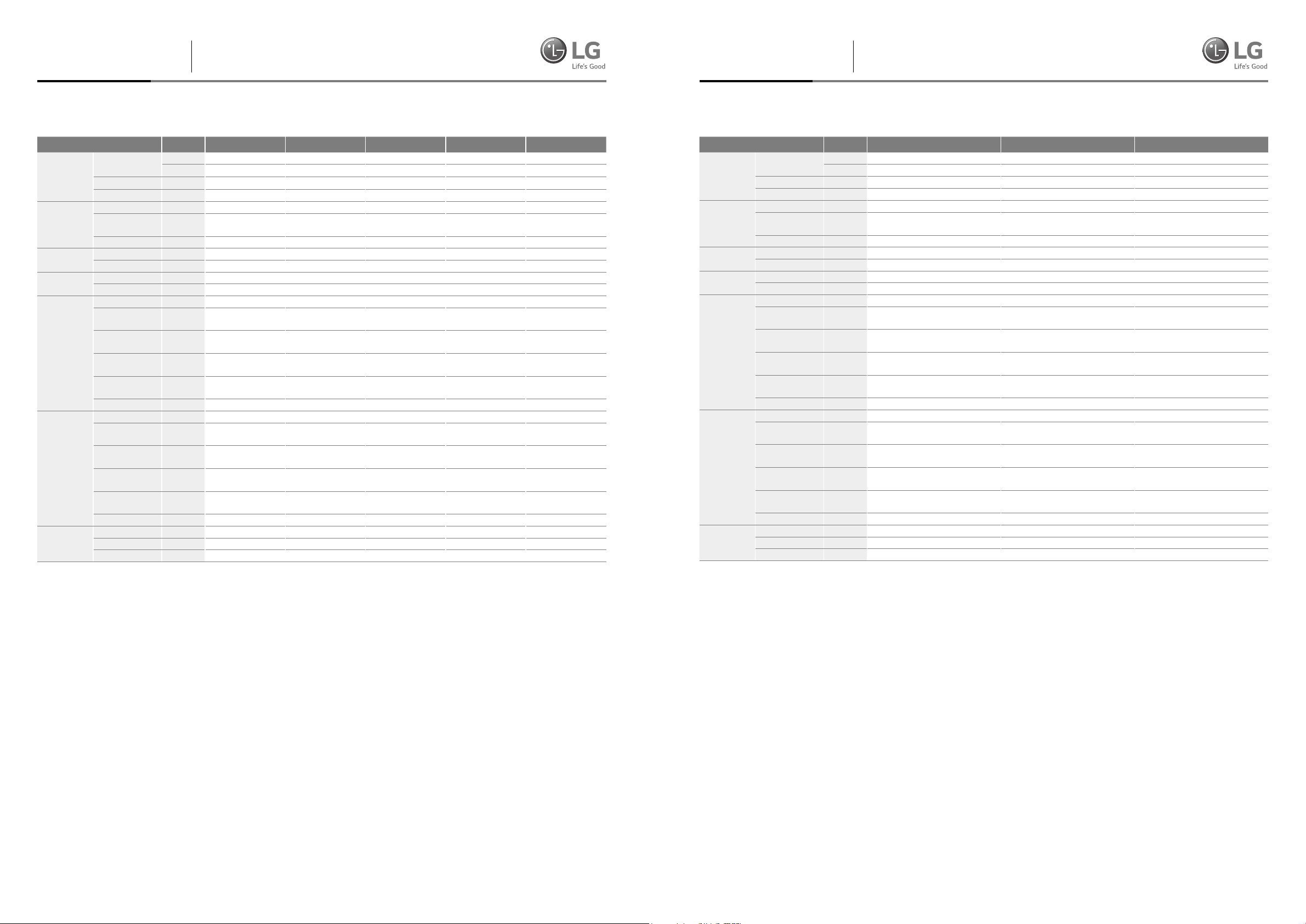

Model Units RCWW022CA2B RCWW024CA2B RCWW026CA2B RCWW028CA2B RCWW032CA2B

AHRI

Condition

Number of Circuits 2 2 2 2 2

General Unit

Data

Weight

Compressors

Condenser

Evaporator

Dimension

Operating Weight kg 5,780 5,940 6,080 6,150 7,040

Water Connections DN 150 150 150 150 200

Water Connections DN 150 150 150 150 200

Cooling capacity

Input Power kW 140.9 152.4

COP 5.35 5.34 5.38 5.56 5.42

Refrigerant,

R-134a

Oil Charge l 18 / 18 20 / 20 23 / 23 20 / 20 28 / 28

Shipping Weight kg 5,460 5,600 5,720 5,770 6,580

Compressor type Semi-hermetic twin screw

Quantity EA 2 2 2 2 2

Condenser type Shell and Tube

Max. Water

Pressure

Max. Refrigerant

Pressure

Min. Cooling

Water Flow Rate

Max. Cooling

Water Flow Rate

Evaporator type Shell and Tube

Max. Water

Pressure

Max. Refrigerant

Pressure

Min. Chilled

Water Flow Rate

Max. Chilled

Water Flow Rate

Length mm 3,855 3,855 3,855 3,855 3,855

Width mm 1,565 1,565 1,565 1,685 1,685

Height mm 2,175 2,175 2,175 2,225 2,225

kW 754.6 814.0 886.8 945.3 1,141.1

usRT 214.6 231.5

252.2

164.7

kg 120 x 2 120 x 2 120 x 2 145 x 2 145 x 2

MPa 1.0 1.0 1.0 1.0 1.0

MPa 1.0 1.0 1.0 1.0 1.0

l/s 13.6 14.6 14.6 16.9 19.0

l/s 54.4 58.6 58.6 67.7 76.0

MPa 1.0 1.0 1.0 1.0 1.0

MPa 0.9 0.9 0.9 0.9 0.9

l/s 12.6 13.8 13.8 15.7 18.0

l/s 50.2 55.1 55.1 62.8 71.8

268.8 324.5

169.9 210.5

R134a(60Hz)

Model Units RCWW036CA2B RCWW040CA2B RCWW044CA2B

AHRI

Condition

Number of Circuits 2 2 2

General Unit

Data

Weight

Compressors

Condenser

Water Connections DN 200 200 200

Evaporator

Water Connections DN 200 200 200

Dimension

Cooling capacity

Input Power kW 230.0 249.8 284.7

COP 5.51 5.44 5.58

Refrigerant,

R-134a

Oil Charge l 28 / 28 28 / 28 28 / 28

Shipping Weight kg 6,910 6,930 7,430

Operating Weight kg 7,430 7,480 7,980

Compressor type Semi-hermetic twin screw

Quantity EA 2 2 2

Condenser type Shell and Tube

Max. Water

Pressure

Max. Refrigerant

Pressure

Min. Cooling

Water Flow Rate

Max. Cooling

Water Flow Rate

Evaporator type Shell and Tube

Max. Water

Pressure

Max. Refrigerant

Pressure

Min. Chilled

Water Flow Rate

Max. Chilled

Water Flow Rate

Length mm 4,550 4,550 4,550

Width mm 1,795 1,795 1,910

Height mm 2,275 2,275 2,300

kW 1,267.5 1,357.7 1,589.0

usRT 360.5 386.1 451.9

kg 165 x 2 165 x 2 190 x 2

MPa 1.0 1.0 1.0

MPa 1.0 1.0 1.0

l/s 21.6 21.6 21.6

l/s 86.5 86.5 86.5

MPa 1.0 1.0 1.0

MPa 0.9 0.9 0.9

l/s 20.2 20.2 20.2

l/s 80.9 80.9 80.9

Note:

1. 1usRT = 3,024kcal/hr = 3.517kW, 1mH

2. AHRI conditions :

Leaving chilled water temperature is 6.7 ˚C(44 ˚F). Water flow is 0.043 L/s per kW(2.4 gpm/ton)

Entering cooling water temperature is 29.4 ˚C(85 ˚F). Water flow is 0.054 L/s per kW(3.0 gpm/ton)

Fouling factor of water in evaporator is 0.018 m²·˚C/kW(0.00001 h·ft2·˚F/Btu)

Fouling factor of water in condenser is 0.044 m²·˚C/kW(0.00025 h·ft2·˚F/Btu)

3. Due to our policy of innovation some specification may be changed without prior notification.

O = 9.8kPa

2

Note:

1. 1usRT = 3,024kcal/hr = 3.517kW, 1mH

2. AHRI conditions :

Leaving chilled water temperature is 6.7 ˚C(44 ˚F). Water flow is 0.043 L/s per kW(2.4 gpm/ton)

Entering cooling water temperature is 29.4 ˚C(85 ˚F). Water flow is 0.054 L/s per kW(3.0 gpm/ton)

Fouling factor of water in evaporator is 0.018 m²·˚C/kW(0.00001 h·ft2·˚F/Btu)

Fouling factor of water in condenser is 0.044 m²·˚C/kW(0.00025 h·ft2·˚F/Btu)

3. Due to our policy of innovation some specification may be changed without prior notification.

O = 9.8kPa

2

10 | 2020 LG Water Cooled Screw 2020 LG HVAC Solution | 11

Loading...

Loading...