Page 1

LG

Room Air Conditioner

SERVICE MANUAL

LG

MODELS: TS-C096EMA0

TS-H096EMA0

TS-C126EMA0

TS-H126EMA0

TS-C096YDA0

TS-H096YDA0

TS-C126TDA0

TS-H126TDA0

CAUTION

website http://www.lgservice.com

• BEFORE SERVICING THE UNIT, READ THE SAFETY

PRECAUTIONS IN THIS MANUAL.

• ONLY FOR AUTHORIZED SERVICE PERSONNEL.

Page 2

Air Conditioner Service Manual

TABLE OF CONTENTS

LG Model Name ...............................................................................................................................................3

Safety Precautions..........................................................................................................................................5

Dimensions....................................................................................................................................................10

Symbols Used in this Manual...................................................................................................................10

Indoor Unit................................................................................................................................................10

Outdoor Unit.............................................................................................................................................13

Product Specifications .................................................................................................................................14

Installation .....................................................................................................................................................18

Selection of the Best Location..................................................................................................................18

Piping Length and Elevation.....................................................................................................................18

How to Fix Installation Plate.....................................................................................................................19

Drill a Hole in the Wall..............................................................................................................................19

Drain hose junction...................................................................................................................................19

Flaring work and connection of piping.......................................................................................................20

Flaring work..............................................................................................................................................20

Connection of Piping Indoor.....................................................................................................................20

Connection of the Pipes-Outdoor.............................................................................................................24

Connecting the cable between indoor unit and outdoor unit...................................................................25

Connect the Cable to the Indoor Unit.......................................................................................................25

Connect the Cable to the Outdoor Unit ....................................................................................................26

Checking the drainage and forming the pipings........................................................................................27

Checking the Drainage.............................................................................................................................27

Form the Piping........................................................................................................................................27

AIR PURGING ................................................................................................................................................28

Air purging................................................................................................................................................28

Air purging with vacuum pump.................................................................................................................28

Test Running .................................................................................................................................................30

Operation .......................................................................................................................................................31

Function of Controls.................................................................................................................................31

Display Function ......................................................................................................................................35

Self-diagnosis Function............................................................................................................................35

Remote Control Operations......................................................................................................................36

Disassembly ..................................................................................................................................................37

Indoor Unit................................................................................................................................................37

Schematic Diagram.......................................................................................................................................40

Electric Control Device.............................................................................................................................40

Wiring Diagram.........................................................................................................................................41

Components Location ..............................................................................................................................44

Troubleshooting Guide.................................................................................................................................46

Refrigeration Cycle Diagram ....................................................................................................................46

2-way, 3-way Valve .................................................................................................................................47

Cycle Parts...............................................................................................................................................53

Electronic Parts........................................................................................................................................54

Exploded View...............................................................................................................................................61

Replacement Parts List ................................................................................................................................63

2 Room Air Conditioner

Page 3

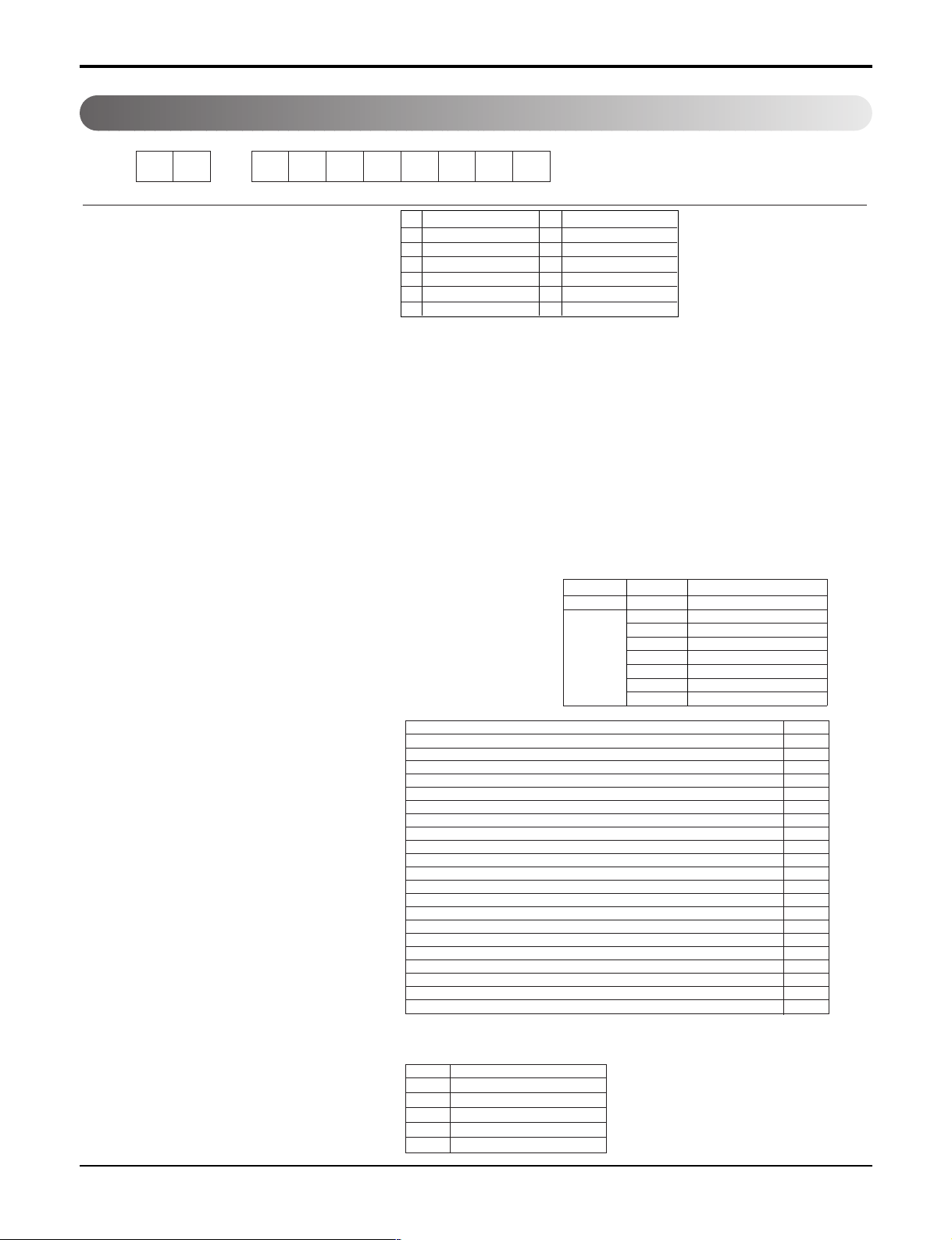

LG Model Name

12 - 345678910

Code Type Code of Model Meaning

1 Producing Center, A~Z L: Chang-won R22 N: India

Refrigerant A: Chang-won R410A Z: Brazil

C: Chang-won R407C D: Indonesia

T: China M: Mexico

K: Turkey R22 V: Vietnam

E: Turkey R410A S: Out Sourcing

H: Thailand

2 Product Type A~Z S: Split Type Air Conditioner

3 Cooling/Heating/Inverter A~Z C: Cooling only

H: Heat pump

X: C/O + E/Heater

Z: H/P + E/Heater

V: AC Inverter C/O

N: AC Inverter H/P

Q: DC Inverter C/O

W: DC Inverter H/P

4, 5 Capacity 0~9 Cooling/Heating Capacity

Ex. "09" → 9,000 Btu/h

6 Electric Range 1~9 1: 115V/60Hz, A: 220V, 50Hz, 3Phase

A~Z 2: 220V/60Hz B: 208~230V, 60Hz, 3Phase

3: 208-230V/60Hz C: 575V, 50Hz, 3Phase

5: 200-220V/50Hz D: 440~460, 60Hz, 3Phase

6: 220-240V/50Hz E: 265V, 60Hz

7: 110V, 50/60Hz F: 200V, 50/60Hz

8: 380-415V/50Hz

9: 380-415V/60Hz

7 Chassis A~Z Name of Chassis of Unit

Ex. LSP → SP Chassis

8 Look A~Z Look,

Color (Artcool Model)

9 Function A~Z

10 Serial No. 1~9 LG Model De

* ARTCOOL COLOR

velopment Serial No.

Basic A

Basic+4Way B

Plasma Filter C

Plasma Filter+4 Way D

Tele+LCD E

Tele+LCD+Nano plasma+4Way F

Nano Plasma F+(A/changeove)+A/clean+Low A G

Nano Plasma F+(A/changeove)+A/clean+4way+Low A H

Tele+LED+4way I

Internet J

Plasma F+4Way+Oxy generator K

Nano Plasma F+(A/changeove)+A/clean L

Nano Plasma F+(A/changeove)+A/clean+4way M

Nano Plasma F+(A/changeove)+A/clean+PTC N

Nano Plasma F+(A/changeove)+Autoclean+4way+PTC P

Nano Plasma F+(A/changeove)+A/clean+4way+Low A+PTC Q

Negative ION+A/Clean R

(Nano)Plasma+Negative ION+A/Clean S

4way+(Nano)Plasma F+Negative ION+Healthy dehumidification+A/Clean

T

Nano Plasma F+4Way+(A/changeove)+A/clean+ U

R Mirror

W White

B Blue

D Wood

M Metal

C Cherry

2003

Service Manual 3

Page 4

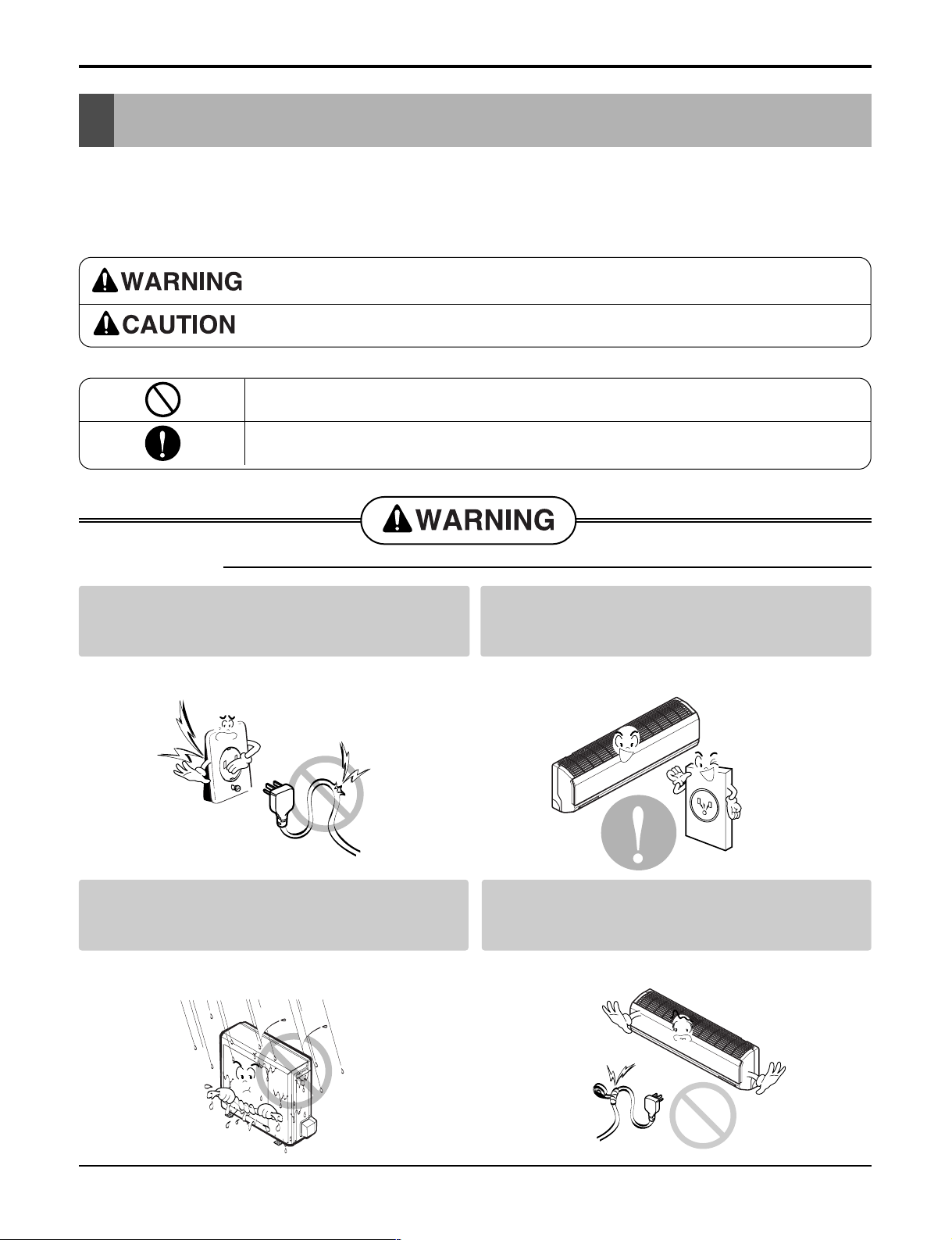

2004~

12 - 345678910

Code Type Code of Model Meaning

1 Producing Center, A~Z

L Chang_won R22

A Chang_won R410A

C Chang_won R407C

T China

K Turkey R22

E Turkey R410A

H Thailand

N India

Z Brazil

D Indonesia

X Mexico

V Vietnam

S Out sourcing

Refrigerant

2 Product Type A~Z S: Split Type Air Conditioner

3 Cooling/Heating/Inverter A~Z C: Cooling only

H: Heat pump

X: C/O + E/Heater

Z: H/P + E/Heater

V: AC Inverter C/O

N: AC Inverter H/P

Q: DC Inverter C/O

W: DC Inverter H/P

4, 5 Capacity 0~9 Cooling/Heating Capacity

Ex. "09" → 9,000 Btu/h

6 Electric Range 1~9 1: 115V/60Hz, A: 220V, 50Hz, 3Phase

A~Z 2: 220V/60Hz B: 208~230V, 60Hz, 3Phase

3: 208-230V/60Hz C: 575V, 50Hz, 3Phase

5: 200-220V/50Hz D: 440~460, 60Hz, 3Phase

6: 220-240V/50Hz E: 265V, 60Hz

7: 110V, 50/60Hz F: 200V

CHASSIS Look

D

K

L

G

M

N

D

P

Division

Panel Type(Deluxe)

Fighting 'Look'

(LG1)

(LG2)-SEMI PANEL

OEM1

OEM2

Panel Type(Deluxe)

LG3

, 50/60Hz

8: 380-415V/50Hz

9: 380-415V/60Hz

7 Chassis A~Z Name of Chassis of Unit

Ex. LSP → SP Chassis

8 Look A~Z Look,

Color (Artcool Model)

9 Function A~Z

10 Serial No. 1~9 LG Model De

* ARTCOOL COLOR

velopment Serial No.

R Mirror

W White

B Blue

D Wood

M Metal

C Cherry

S4/S5

S6

SQ

SR

ST

Basic A

Basic+4Way B

Plasma Filter C

Plasma Filter+4 Way D

Tele+LCD E

Tele+LCD+Nano plasma+4Way F

NBF F+(A/changeove)+A/clean+Low A G

NBF F+(A/changeove)+A/clean+4way+Low A H

Tele+LED+4way I

Internet J

Plasma F+4Way+Oxy generator K

NBF F+(A/changeove)+A/clean L

NBF F+(A/changeove)+A/clean+4way M

NBF F+(A/changeove)+A/clean+PTC N

NBF F+(A/changeove)+Autoclean+4way+PTC P

NBF F+(A/changeove)+A/clean+4way+Low A+PTC Q

(Nano)Plasma+ION+A/Clean S

4way+(Nano)Plasma F+

Negative ION+Healthy dehumidification

+A/Clean T

Nano Plasma F+4Way+(A/changeove)+A/clean+Oxy generator U

4way+(Nano)Plasma F+Negative ION+Healthy dehumidification+A/Clean+Oxy generator

V

Dry contact W

Wire remocon 8

4 Room Air Conditioner

Page 5

Safety Precautions

Safety Precautions

To prevent injury to the user or other people and property damage, the following instructions must

be followed.

■ Incorrect operation due to ignoring instruction will cause harm or damage. The seriousness is

classified by the following indications.

This symbol indicates the possibility of death or serious injury.

This symbol indicates the possibility of injury or damage to properties only.

■ Meanings of symbols used in this manual are as shown below.

Be sure not to do.

Be sure to follow the instruction.

■ Installation

Do not use damaged power cords, plugs, or a

loose socket.

• There is risk of fire of electric shock. • There is risk of electric shock.

Install the panel and the cover of control box

securely.

• There is risk of fire of electric shock. • No grounding may cause electric shock.

Always use the power plug and socket with the

ground terminal.

.Do not modify or extend the power cord.

Service Manual 5

Page 6

Safety Precautions

For re-installation of the installed product,

always contact a dealer or an authorized service center.

• There is risk of fire, electric shock, explosion, or

injury.

Be cautious when unpacking and installing the

product.

• Sharp edges could cause injury. Be especially care-

ful of the case edges and the fins on the condenser

and evaporator.

Do not install, remove, or re-install the unit by

yourself.

• There is risk of fire, electric shock, explosion, or

injury.

For installation, always contact the dealer or

an Authorized service center

•

There is risk of fire, electric shock, explosion, or injury.

Do not install the product on a defective installation stand.

• It may cause injury, accident, or damage to the

product.

6 Room Air Conditioner

Be sure the installation area does not

deteriorate with age.

• If the base collapses, the air conditioner could fall

with it, causing property damage, product failure,

and personal injury.

Page 7

■ Operation

Wax

Thinner

Safety Precautions

Do not turn the air-conditioner ON or OFF by

Use a dedicated outlet for this appliance.

plugging or unplugging the power plug.

• There is risk of fire or electrical shock. • There is risk of fire or electrical shock.

Grasp the plug to remove the cord from the

outlet. Do not touch it with wet hands.

• There is risk of fire or electrical shock. • There is risk of fire and electric shock.

Do not place a heater or other appliances near

the power cable.

Do not allow water to run into electrical parts. Do not store or use flammable gas or com-

bustibles near the air conditioner.

• There is risk of fire, failure of the product, or electric

shock.

• There is risk of fire or failure of product.

Service Manual 7

Page 8

90˚

Safety Precautions

Unplug the unit if strange sounds, odors, or

smoke comes from it.

• There is risk of electric shock or fire. • There is risk of fire, electric shock, or product dam-

Be cautious that water could not enter the

product.

age.

■ Installation

Always check for gas (refrigerant) leakage after

installation or repair of product.

Install the drain hose to ensure that water is

drained away properly.

• Low refrigerant levels may cause failure of product. • A bad connection may cause water leakage.

Keep level even when installing the product. Use two or more people to lift and transport

the air conditioner.

• To avoid vibration or water leakage. • Avoid personal injury.

8 Room Air Conditioner

Page 9

■ Operation

Wax

Safety Precautions

Use a soft cloth to clean. Do not use harsh

detergents, solvents, etc.

• There is risk of fire, electric shock, or damage to the

plastic parts of the product.

Do not step on or put anyting on the product.

(outdoor units)

Do not touch the metal parts of the product

when removing the air filter. They are very

sharp!

• There is risk of personal injury.

Do not insert hands or other objects through

the air inlet or outlet while the air conditioner

is plugged in.

• There is risk of personal injury and failure of product. • There are sharp and moving parts that could cause

personal injury.

Service Manual 9

Page 10

Dimensions

Installation plate

D

H

W

Indoor Unit

This symbol alerts you to the risk of electric shock.

This symbol alerts you to hazards that could cause harm to the

air conditioner.

This symbol indicates special notes.

Indoor Unit

This symbol alerts you to the risk of electric shock.

This symbol alerts you to hazards that could cause harm to the

air conditioner.

This symbol indicates special notes.

Dimensions

Symbols Used in this Manual

NOTICE

Model

Dimension

W mm 915

H mm 171

D mm 282

10 Room Air Conditioner

SE Chassis

Page 11

Dimensions

Installation plate

D

H

W

Model

Dimension

W mm 840

H mm 270

D mm 161

SY Chassis

Service Manual 11

Page 12

Dimensions

Installation plate

D

H

W

Dimensions

Model

Dimension

W mm 895

H mm 282

D mm 166

ST Chassis

Service Manual 12

Page 13

MODEL

DIM unit

W mm

H mm

D mm

Dimensions

Service Manual 13

Outdoor Unit

D

W

H

TS-C096EMA0

TS-C096YDA0

575

520

Gas side

(3-way valve)

Liquid side

(2-way valve)

TS-H096EMA0 TS-H096YDA0

0

TS-C126EMA0 TS-C126TDA0

TS-H126EMA0 TS-H126TDA0

770

540

260

245

Page 14

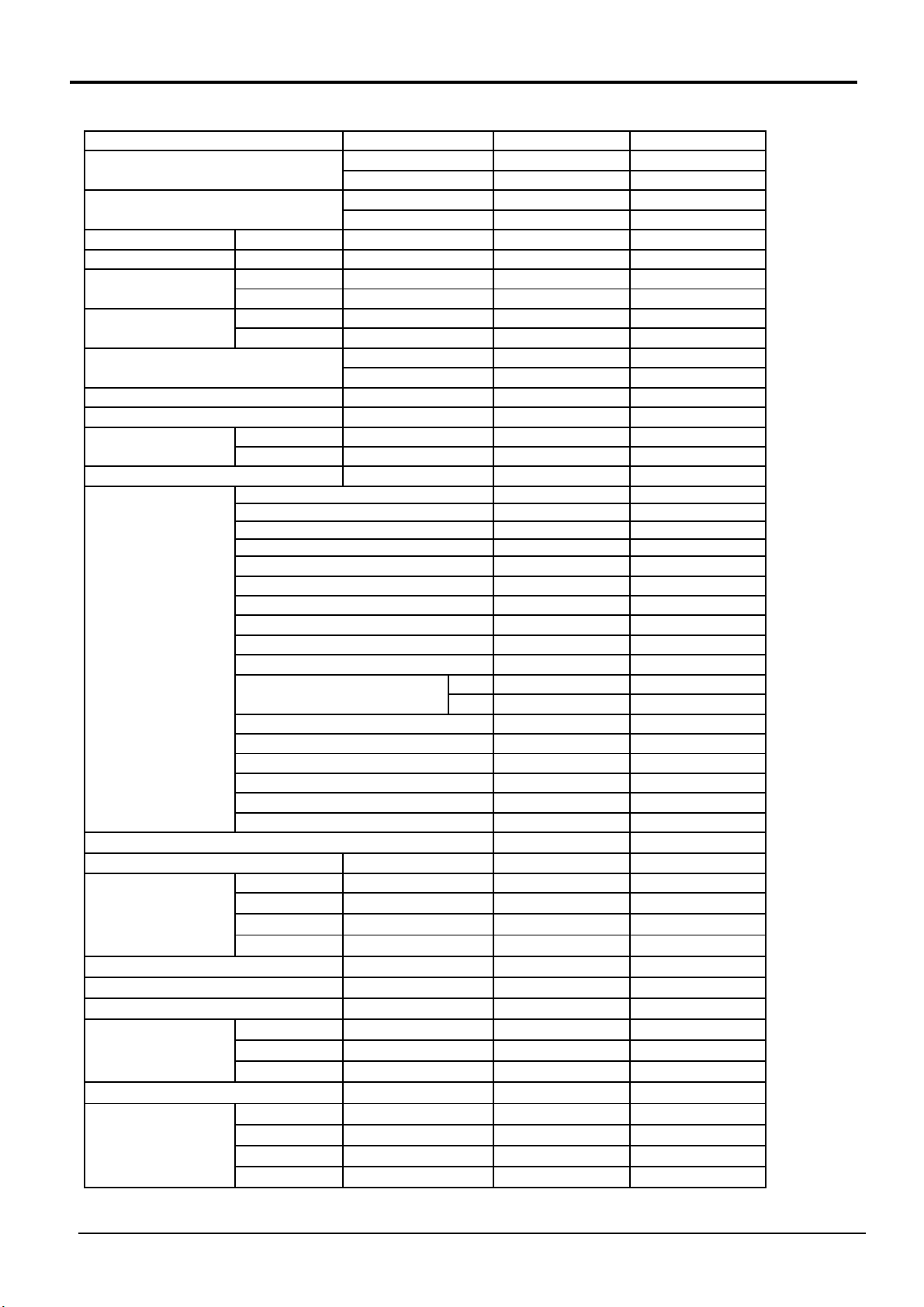

Models TS-C096EMA0 TS-H096EMA0

Product Specifications

Service Manual 14

Cooling Capacity

Heating Capacity -

Power Input Cooling 930 950

Heating - 940

Running Current Cooling 4.5 4.5

Heating - 4.5

Starting Current Cooling 6 6

Heating - 6

EER 2.44(2.84) 2.39(2.78)

COP - 2.8

Power Supply 1Φ,220-240,50 1Φ,220-240,50

Air Circulation Indoor,Max

Outdoor,Max 1680 1680

Moisture Removal

Features Temperature Control

Plasma Filter - Nano Plasma Filter - Deodorizing Filter Optional Optional

CHAOS Wind(Auto Wind)

Airflow Direction(4-Way:Optional)

Steps, Fan/Cool 3/4 3/4

Airflow Direction Contorl(up&down)

Airflow Direction Contorl(left&right)

Remocon Type Wireless Simple Wireless Simple

Setting Temperature Range Cool

Temperature Increment

Self Diagnosis

Timer

Sleep Operation

Soft Dry Operation

Restart Delay(minute) 3 3

Special Function

Refrigerant(R22)Charge 490g 780g

Blower Motor Input 29 29

Output 11 11

Motor Input 52 66.6

Motor Output 36 27

Circuit Breaker A

Power Cord 3*0.75 3*0.75

Connecting Cable 3*0.75 3*0.75

Connecting Tube Liquid Side 6.35(1/4) 6.35(1/4)

(φ. Socket Flare) Gas Side 9.52(3/8) 9.52(3/8)

Length,std 5 5

Drain Hose (O.D , I.D) 21.5,16(0.85,0.63) 21.5,16(0.85,0.63)

Dimension Indoor 171*915*282 171*915*282

Outdoor520*575*260 540*770*245

Net Weight Indoor

Outdoor 33 25

Unit

kcal/h.(W)

Btu/h.

kcal/h.(W)

Btu/h.

W

W

A

A

A

A

kcal/h.W(W/W)

Btu/h.W

W/W

Φ,V,Hz

㎥/min(CFM)

㎥/min(CFM)

ℓ/h.(pts/h.)

g

W

W

W

W

AWG#:P*㎟

AWG#:P*㎟

mm(in)

mm(in)

m(in)

mm(in)

mm

mm

kg

kg

Heat

2268(2637) 2268(2637)

9,000 9,000

- 9,000

9.68 9.47

430 430

0.95 0.95

Thermistor Thermistor

Yes Yes

4-Way 4-Way

Auto Auto

Manual Manual

18 - 30 18 - 30

- 16 - 30

11

Yes Yes

24h, Off 24h, Off

Yes Yes

Yes Yes

--

--

10 9

2268(2637)

Page 15

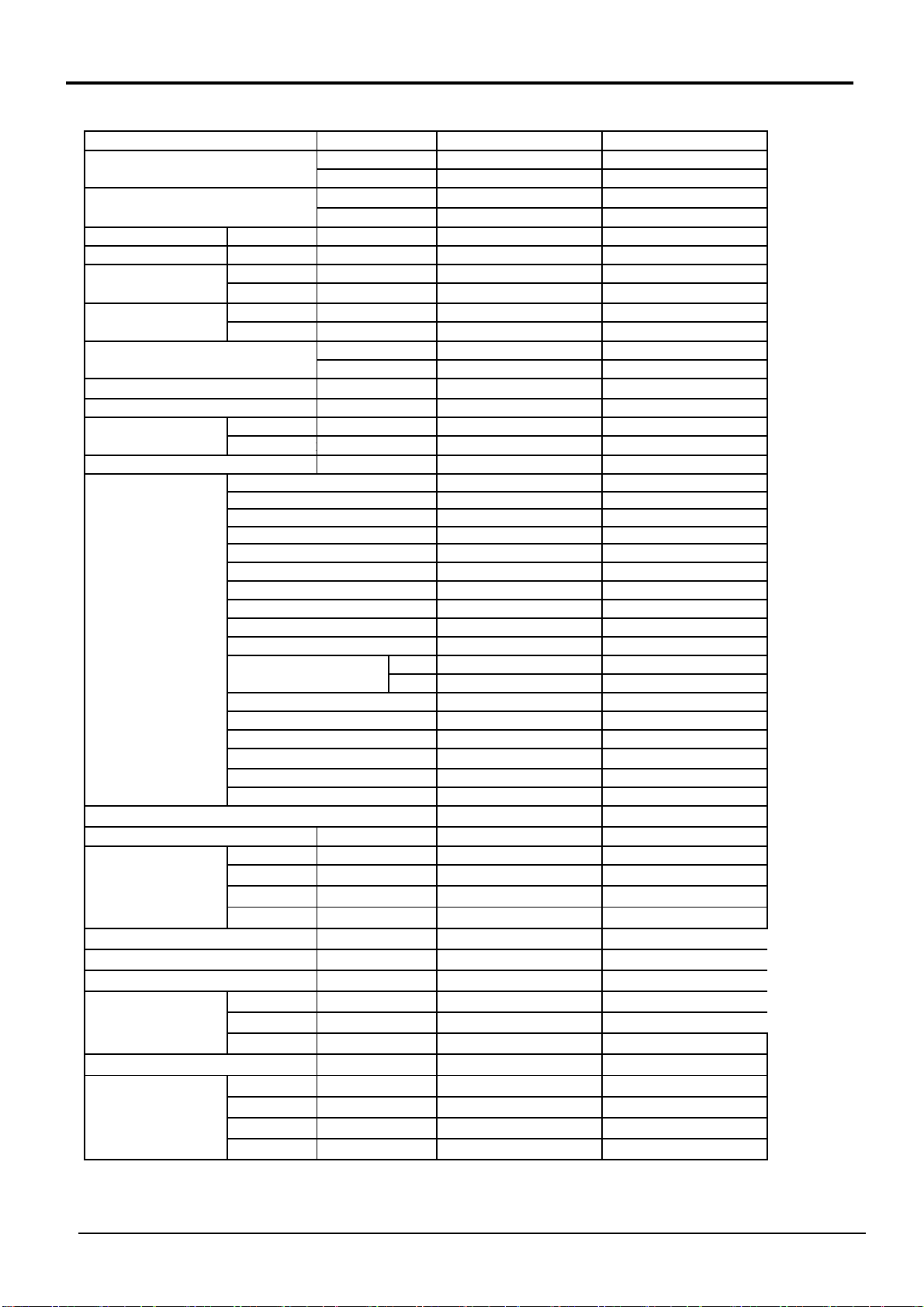

Models TS-C126EMA0 TS-H126EMA0

Product Specifications

Service Manual 15

Cooling Capacity

Heating Capacity

Power Input Cooling 1290 1280

Heating - 1280

Running Current Cooling 6.3 6.1

Heating - -

Starting Current Cooling 10.1 9.6

Heating 7.35 7.7

EER 2.35(2.73) 2.36(2.75)

COP - 2.8

Power Supply 1Φ,220-240,50 1Φ,220-240,50

Air Circulation Indoor,Max

Outdoor,Max 1680 1680

Moisture Removal

Features Temperature Control

Plasma Filter - Nano Plasma Filter - Deodorizing Filter Optional Optional

CHAOS Wind(Auto Wind)

Airflow Direction(4-Way:Optional)

Steps, Fan/Cool 3/4 3/4

Airflow Direction Contorl(up&down)

Airflow Direction Contorl(left&right)

Remocon Type Wireless Simple Wireless Simple

Setting Temperature Range Cool

Temperature Increment

Self Diagnosis

Timer

Sleep Operation

Soft Dry Operation

Restart Delay(minute) 3 3

Special Function

Refrigerant(R22)Charge 680g 930g

Blower Motor Input 29 29

Output 11 11

Motor Input 66.6 109

Motor Output 27 42

Circuit Breaker A

Power Cord 3*1.0 3*1.0

Connecting Cable 3*1.0 3*1.0

Connecting Tube Liquid Side 6.35(1/4) 6.35(1/4)

(φ. Socket Flare) Gas Side 12.7(1/2) 12.7(1/2)

Length,std 5 5

Drain Hose (O.D , I.D) 21.5,16(0.85,0.63) 21.5,16(0.85,0.63)

Dimension Indoor 171*915*282 171*915*282

Outdoor 245*540*770 245*540*770

Net Weight Indoor

Outdoor 33 33

Unit

kcal/h.(W)

Btu/h.

kcal/h.(W)

Btu/h.

W

W

A

A

A

A

kcal/h.W(W/W)

Btu/h.W

W/W

Φ,V,Hz

㎥/min(CFM)

㎥/min(CFM)

ℓ/h.(pts/h.)

g

W

W

W

W

AWG#:P*㎟

AWG#:P*㎟

mm(in)

mm(in)

m(in)

mm(in)

mm

mm

kg

kg

Heat

3024(3516) 3024(3516)

12,000 12,000

- 3024(3516)

- 12,000

9.30 9.38

550 550

1.5 1.5

Thermistor Thermistor

Yes Yes

4-Way 4-Way

Auto Auto

Manual Manual

18 - 30 18 - 30

- 16 - 30

11

Yes Yes

24h, Off 24h, Off

Yes Yes

Yes Yes

--

--

10 10

Page 16

Models TS-C096YDA0 TS-H096YDA0

x

y

y

&

&

R

,

u

Product Specifications

Service Manual 16

Cooling Capacity

Heating Capacity -

Power Input Cooling 900 900

Heating - 900

Running Current Cooling 4.4 4.4

Heating --

Starting Current Cooling 6 6

Heating - -

EER 2.52(2.93) 2.52(2.93)

COP - 2.9

Power Supply 1Φ,220-240,50 1Φ,220-240,50

Air Circulation Indoor,Max

Outdoor,Ma

Moisture Removal

Features Temperature Control

Plasma Filter - Nano Plasma Filter - -

Deodorizing Filter Optional Optional

CHAOS Wind(Auto Wind)

Airflow Direction(4-Way:Opti

Steps, Fan/Cool 3/4 3/4

Airflow Direction Contorl(up

Airflow Direction Contorl(left

Remocon Type Wireless Simple Wireless Simple

Setting Temperature

Temperature Increment

Self Diagnosis

Timer

Sleep Operation

Soft Dry Operation

Restart Delay(minute) 3 3

Special Function

Refrigerant(R22)Charge 430g 630g

Blower Motor Input 29 29

Output 11 11

Motor Input 52 66.6

Motor Outp

Circuit Breaker A

Power Cord 3*0.75 3*0.75

Connecting Cable 3*0.75 3*0.75

Connecting Tube Liquid Side 6.35(1/4) 6.35(1/4)

(φ. Socket Flare) Gas Side 9.52(3/8) 9.52(3/8)

Length,std 5 5

Drain Hose (O.D , I.D) 21.5,16(0.85,0.63) 21.5,16(0.85,0.63)

Dimension Indoor 161*270*840 161*270*840

Outdoor 520

Net Weight Indoor

Outdoor 22 33

Unit

kcal/h.(W)

Btu/h.

kcal/h.(W)

Btu/h.

W

W

A

A

A

A

kcal/h.W(W/W)

Btu/h.W

W/W

Φ,V,Hz

㎥/min(CFM)

㎥/min(CFM)

ℓ/h.(pts/h.)

Cool

Heat

g

W

W

W

W

AWG#:P*㎟

AWG#:P*㎟

mm(in)

mm(in)

m(in)

mm(in)

mm

mm

kg

kg

2268(2637) 2268(2637)

9,000 9,000

- 9,000

10.00 10.00

450 450

1560 1560

1.1 1.1

Thermistor Thermistor

Yes Yes

4-Wa

Auto Auto

Manual Manual

18 - 30 18 - 30

- 16 - 30

11

Yes Yes

7h

Off 7h, Off

Yes Yes

Yes Yes

--

36 27

--

*575*260 540*770*245

77

2268(2637)

4-Wa

Page 17

Models TS-C126TDA0 TS-H126TDA0

x

y

y

&

&

R

,

u

Product Specifications

Service Manual 17

Cooling Capacity

Heating Capacity

Power Input Cooling 1260 1180

Heating - 1350

Running Current Cooling 6 5.6

Heating - 6.1

Starting Current Cooling 10.7 9

Heating - 8

EER 2.4(2.79) 2.56(2.98)

COP - 2.6

Power Supply 1Φ,220-240,50 1Φ,220-240,50

Air Circulation Indoor,Max

Outdoor,Ma

Moisture Removal

Features Temperature Control

Plasma Filter - Nano Plasma Filter - -

Deodorizing Filter Optional Optional

CHAOS Wind(Auto Wind)

Airflow Direction(4-Way:Opti

Steps, Fan/Cool 3/4 3/4

Airflow Direction Contorl(up

Airflow Direction Contorl(left

Remocon Type Wireless Simple Wireless Simple

Setting Temperature

Temperature Increment

Self Diagnosis

Timer

Sleep Operation

Soft Dry Operation

Restart Delay(minute) 3 3

Special Function

Refrigerant(R22)Charge 770g 860g

Blower Motor Input 42 42

Output 11 11

Motor Input 109 109

Motor Outp

Circuit Breaker A

Power Cord 3*1.0 3*1.0

Connecting Cable 3*1.0 3*1.0

Connecting Tube Liquid Side 6.35(1/4) 6.35(1/4)

(φ. Socket Flare) Gas Side 12.7(1/2) 12.7(1/2)

Length,std 5 5

Drain Hose (O.D , I.D) 21.5,16(0.85,0.63) 21.5,16(0.85,0.63)

Dimension Indoor 166*282*895 166*282*895

Outdoor 245*540*770 245*540*770

Net Weight Indoor

Outdoor 33 33

Unit

kcal/h.(W)

Btu/h.

kcal/h.(W)

Btu/h.

W

W

A

A

A

A

kcal/h.W(W/W)

Btu/h.W

W/W

Φ,V,Hz

㎥/min(CFM)

㎥/min(CFM)

ℓ/h.(pts/h.)

Cool

Heat

g

W

W

W

W

AWG#:P*㎟

AWG#:P*㎟

mm(in)

mm(in)

m(in)

mm(in)

mm

mm

kg

kg

3024(3516) 3024(3516)

12,000 12,000

-

- 12,000

9.52 10.17

450 450

1680 1680

1.5 1.5

Thermistor Thermistor

Yes Yes

4-Wa

Auto Auto

Manual Manual

18 - 30 18 - 30

- 16 - 30

11

Yes Yes

7h

Off 7h, Off

Yes Yes

Yes Yes

--

42 42

--

88

3024(3516)

4-Wa

Page 18

Installation

More than 10cm

More than

5cm

More than 2.3m

More than

5cm

Outdoor unit

Indoor unit

A

B

Outdoor unit

Indoor unit

A

B

A

Oil trap

Outdoor unit

Indoor unit

B

I

More than 10cm More than 10cm

More

than 60cm

More than 60cm

More than 70cm

Installation

Selection of the Best Location

Indoor unit

• Do not have any heat or steam near the unit.

• Select a place where there are no obstacles in front of the

unit.

• Make sure that condensation drainage can be conveniently

routed away.

Do not install near a doorway.

• Ensure that the space around the left and right of the unit is

more than "A". The unit should be installed as high on the

wall as possible, allowing a minimum of "B" from ceiling.

• Use a stud finder to locate studs to prevent unnecessary

damage to the wall.

Install the indoor unit on the wall where the height

from the floors more than 2.3 meters.

Grade

5K~28K 10 5

30K~38K 30 12

Clearance(cm)

AB

Rooftop Installations:

• If the outdoor unit is installed on a roof structure, be

sure to level the unit. Ensure the roof structure and

anchoring method are adequate for the unit location.

• Consult local codes regarding rooftop mounting.

Piping Length and Elevation

Max.

(m)

Max.

Elevation

B (m)

Capacity

(Btu/h)

5k~14k

18k~28k 5/8"(Ø15.88) 1/4"(Ø6.35) 4 or 7.5 15 30 20

30k~38k

Pipe Size

GAS LIQUID

3/8"(Ø9.52) 1/4"(Ø6.35) 4 or 7.5 7 15 20

1/2"(Ø12.7) 1/4"(Ø6.35) 4 or 7.5 7 15 20

1/2"(Ø12.7) 1/4"(Ø6.35) 4 or 7.5 15 30 20

5/8"(Ø15.88) 3/8"(Ø9.52) 4 or 7.5 15 30 30

5/8"(Ø15.88) 3/8"(Ø9.52) 7.5 15 30 30

3/4"(Ø19.05) 3/8"(Ø9.52) 7.5 15 30 50

Standard

Length

Length

A (m)

Additional

Refrigerant

(g/m)

Outdoor unit

• If an awning is built over the unit to prevent direct sunlight

or rain exposure, make sure that heat radiation from the

condenser is not restricted.

• Ensure that the space around the back and sides is more

than 10cm. The front of the unit should have more than

70cm of space.

• Do not place animals and plants in the path of the warm air.

• Take the air conditioner weight into account and select a

place where noise and vibration are minimum.

• Select a place so that the warm air and noise from the air

conditioner do not disturb neighbors.

18 Room Air Conditioner

If case more than 5m

• Capacity is based on standard length and maximum allowance length is on the basis of reliability.

• Oil trap should be installed every 5~7 meters.

Page 19

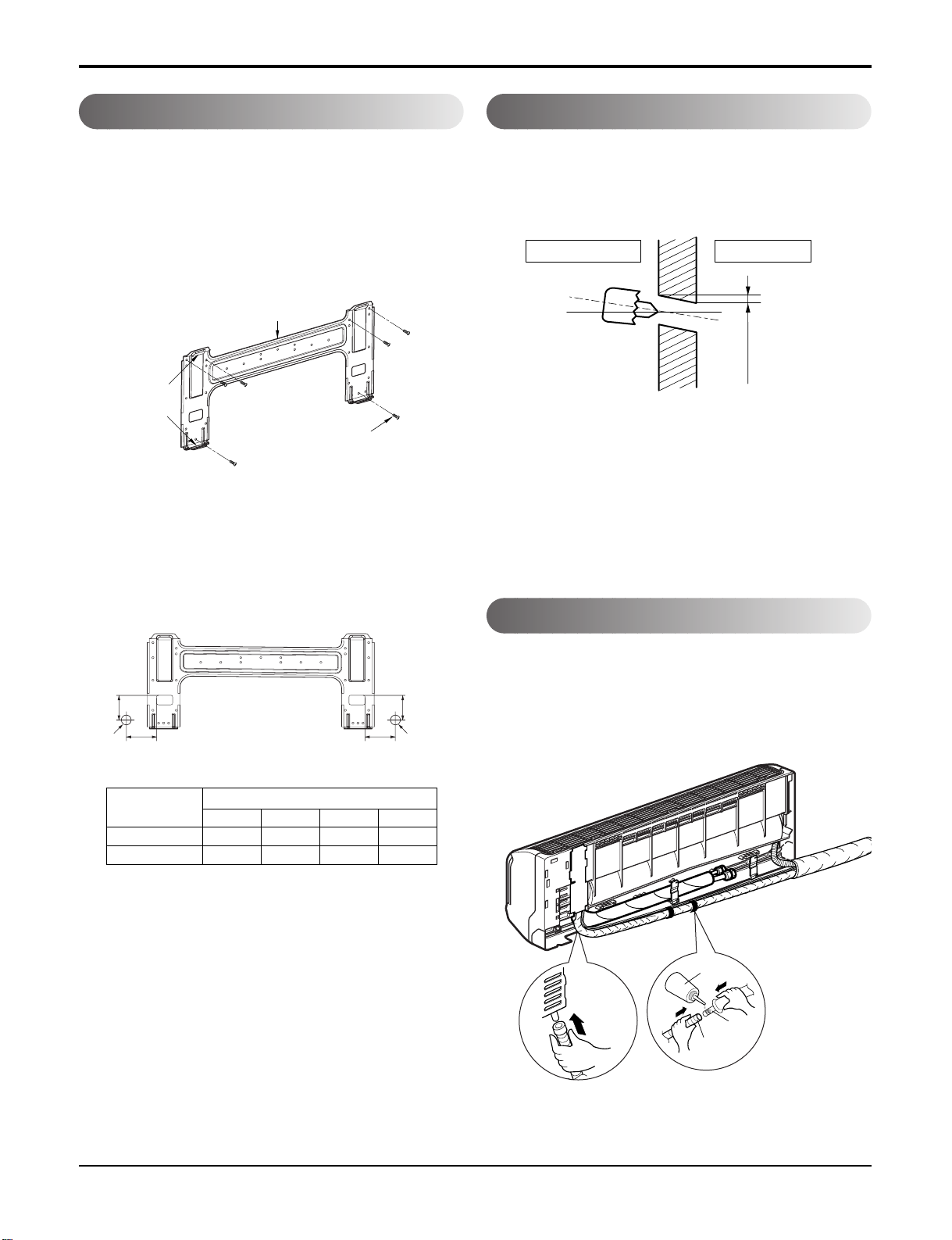

How to Fix Installation Plate Drill a Hole in the Wall

Installation Plate

Type "A" screw

Chassis

Hook

5-7mm

(3/16"~5/16")

Indoor

WALL

Outdoor

Installation plate

Left rear piping Right rear piping

Ø70mm

Ø70mm

DB

A

C

Connecting

part

Adhesive

Drain

hose

Only the

desired direction

Installation

The wall you select should be strong and solid

enough to prevent vibration

1. Mount the installation plate on the wall with four

type A screws. If mounting the unit on a concrete

wall, use anchor bolts.

• Mount the installation plate horizontally by aligning

the centerline using a level.

2. Measure the wall and mark the centerline. It is

also important to use caution concerning the

location of the installation plate-routing of the

wiring to power outlets is through the walls typically. Drilling the hole through the wall for piping connections must be done safely.

• Drill the piping hole with a ø70mm hole core drill.

Drill the piping hole at either the right or the left

with the hole slightly slanted to the outdoor side.

• Open the Front Grille.

• Pass Telephone Control Cord Wire through the hole

which the power cord goes through.

• Connect Telephone Control Cord Wire to the phone jack

of telephone PCB of Control Box.

• Fix Telephone Control Cord Wire inside Control box so

as not to disconnect.

• Close the Front Grille.

CHASSIS

(Grade)

7k, 9k, 12k 75 65 105 65

18k, 24k 105 65 260 65

ABCD

Distance (mm)

Drain hose junction

• Remove the rubber stopple in the desired drain direction.

• Insert drain hose into the handle of drain pan, and join

drain hose and connecting hose according to the figure

by.

Service Manual 19

Page 20

Flaring work and connection of piping

Bar

Copper pipe

Clamp handle

Red arrow mark

Cone

Yoke

Handle

Bar

"A"

Inclined

Inside is shiny without scratches

Smooth all round

Even length

all round

Surface

damaged

Cracked Uneven

thickness

= Improper flaring =

Drain hose

Pipe

Reamer

Point down

Flare nut

Copper tube

Flaring work and connection of piping

Flaring work

• Carry out flaring work using flaring tool as shown below.

Flaring work

Main cause for refrigerant leakage is due to defect in the

flaring work. Carry out correct flaring work using the following procedure.

Cut the pipes and the cable.

• Use the piping kit accessory or pipes purchased locally.

• Measure the distance between the indoor and the outdoor unit.

• Cut the pipes a little longer than the measured distance.

• Cut the cable 1.5m longer than the pipe length.

Copper

pipe

Slanted Uneven Rough

90°

Check

• Compare the flared work with figure below.

• If flare is noted to be defective, cut off the flared sec-

tion and re-flare it.

Burr removal

• Completely remove all burrs from the cut cross section of

pipe/tube.

• Put the end of the copper tube/pipe in a downward direction as you remove burrs in order to avoid dropping burrs

into the tubing.

Outside diameter A

mm inch mm

Ø6.35 1/4 0~0.5

Ø9.52 3/8 0~0.5

Ø12.7 1/2 0~0.5

Ø15.88 5/8 0~1.0

Ø19.05 3/4 1.0~1.3

Putting nut on

• Remove flare nuts attached to indoor and outdoor unit,

then put them on pipe/tube having completed burr removal.

(not possible to put them on after flaring work)

Flaring work

• Firmly hold copper pipe in a die in the dimension shown in

the table above.

20 Room Air Conditioner

Connection of piping -- Indoor

• Preparing the indoor unit's piping and drain hose for installation through the wall.

• Remove the plastic tubing retainer(see illustration below)

and pull the tubing and drain hose away from chassis.

• Replace the plastic tubing holder in the original

position.(Optional)

When install, make sure that the

remaining parts must be removed

clearly so as not to damage the piping and drain hose, especially power

cord and connecting cable.

Page 21

Flaring work and connection of piping

Drain hose

Connecting

cable

Vinyl tape(narrow)

Connection

pipe

Connecting cable

Vinyl tape

(wide)

Wrap with vinyl tape

Indoor

unit pipe

Pipe

Plastic bands

Insulation material

Vinyl tape(narrow)

Adhesive

Drain pipe

Indoor unit drain hose

Wrench

Indoor unit tubing

Open-end wrench (fixed)

Connection pipe

Flare nut

Indoor unit tubing Flare nut Pipes

Drain hose

Connecting

pipe

Connecting cable

Tape

Drain hose

For right rear piping

Route the indoor tubing and the drain hose in the direction of

rear right.

Insert the connecting cable into the indoor unit from the outdoor unit through the piping hole.

• Do not connect the cable to the indoor unit.

• Make a small loop with the cable for easy connection later.

Tape the tubing, drain hose, and the connecting cable. Be

sure that the drain hose is located at the lowest side of the

bundle. Locating at the upper side can cause drain pan to

overflow inside the unit.

Connecting the pipings to the indoor unit and

drain hose to drain pipe.

• Align the center of the pipes and sufficiently tighten

the flare nut by hand.

• Tighten the flare nut with a wrench.

Outside diameter Torque

mm inch kg.m

Ø6.35 1/4 1.8

Ø9.52 3/8 4.2

Ø12.7 1/2 5.5

Ø15.88 5/8 6.6

Ø19.05 3/4 6.6

• When extending the drain hose at the indoor unit, install the

drain pipe.

NOTE: If the drain hose is routed inside the room, insulate

the hose with an insulation material* so that dripping from

"sweating"(condensation) will not damage furniture or floors.

*Foamed polyethylene or equivalent is recommended.

Indoor unit installation

• Hook the indoor unit onto the upper portion of the installation plate.(Engage the two hooks of the rear top of the

indoor unit with the upper edge of the installation plate.)

Ensure that the hooks are properly seated on the installation plate by moving it left and right.

Press the lower left and right sides of the unit against the

installation plate until the hooks engage into their slots(clicking sound).

Wrap the insulation material around the connecting portion.

•Overlap the connection pipe insulation material and the

indoor unit pipe insulation material. Bind them together with

vinyl tape so that there is no gap.

• Wrap the area which accommodates the rear piping hous-

ing section with vinyl tape.

Service Manual 21

Page 22

Flaring work and connection of piping

Drain pipe

Connecting cable

Wrap with vinyl tape

Drain hose

Pipe

Vinyl tape(wide)

Indoor unit tubing Flare nut Pipes

Installation plate

Spacer

Indoor unit

8cm

Plastic bands

Insulation material

Vinyl tape

Adhesive

Drain hose

Indoor unit drain hose

(narrow)

Wrench

Indoor unit tubing

Connection pipe

Flare nut

Open-end wrench (fixed)

• Bundle the piping and drain hose together by wrapping

them with vinyl tape for enough to cover where they fit into

the rear piping housing section.

For left rear piping

Route the indoor tubing and the drain hose to

the required piping hole position.

Insert the piping, drain hose, and the connecting cable into the piping hole.

Connecting the pipings to the indoor unit and

the drain hose to drain pipe.

• Align the center of the pipes and sufficiently tighten the

flare nut by hand.

• Tighten the flare nut with a wrench.

Outside diameter Torque

mm inch kg.m

Ø6.35 1/4 1.8

Ø9.52 3/8 4.2

Ø12.7 1/2 5.5

Ø15.88 5/8 6.6

Ø19.05 3/4 6.6

Insert the connecting cable into the indoor unit.

• Don't connect the cable to the indoor unit.

• Make a small loop with the cable for easy connection later.

Tape the drain hose and the connecting cable.

• Connecting cable

Indoor unit installation

• Hang the indoor unit from the hooks at the top of the installation plate.

• Insert the spacer etc. between the indoor unit and the

installation plate and separate the bottom of the indoor unit

from the wall.

• When extending the drain hose at the indoor unit, install the

drain pipe.

Wrap the insulation material around the connecting portion.

• Overlap the connection pipe heat insulation and the indoor

unit pipe heat insulation material. Bind them together with

vinyl tape so that there is no gap.

22 Room Air Conditioner

Page 23

Flaring work and connection of piping

Vinyl tape(narrow)

Connection

pipe

Connecting cable

Indoor

unit piping

Pipe

Vinyl tape

(wide)

Wrap with vinyl tape

Drain hose

Vinyl tape(narrow)

Pipe

Wrap with

vinyl tape(wide)

Piping for

passage through

piping hole

Tubing holder

Drain hose

Connecting

cable

• Wrap the area which accommodates the rear piping housing section with vinyl tape.

• Bundle the piping and drain hose together by wrapping

them with cloth tape over the range within which they fit

into the rear piping housing section.

Indoor unit installation

• Remove the spacer.

• Ensure that the hooks are properly seated on the installa-

tion plate by moving it left and right.

Press the lower left and right sides of the unit against the

installation plate until the hooks engage into their

slots(clicking sound).

Installation Information (For left piping)

• Good case

For left piping. Follow the instruction below.

• Press on the upper side of clamp. ( )

Reroute the pipings and the drain hose across

the back of the chassis.

Set the pipings and the drain hose to the back

of the chassis with the tubing holder.

• Hook the edge of tubing holder to tap on chassis and push

the bottom of tubing holder to be engaged at the bottom of

chassis.

• Unfold the tubing to downward slowly. ( )

• Bend the tubing to the left side of chassis.

Service Manual 23

Page 24

Flaring work and connection of piping

Outdoor unit

Gas side piping

(Bigger diameter)

Liquid side

piping

(Smaller

diameter)

Torque wrench

Connection of the pipes-Outdoor

• Bad case

• Following bending type from right to left could cause

problem of pipe damage.

Align the center of the pipings and sufficiently

tighten the flare nut by hand.

Finally, tighten the flare nut with torque wrench

until the wrench clicks.

• When tightening the flare nut with torque wrench, ensure

the direction for tightening follows the arrow on the wrench.

Outside diameter Torque

mm inch kg.m

Ø6.35 1/4 1.8

Ø9.52 3/8 4.2

Ø12.7 1/2 5.5

Ø15.88 5/8 6.6

Ø19.05 3/4 6.6

24 Room Air Conditioner

Page 25

Air

Conditioner

Main power source

NORMAL

CROSS-SECTIONAL

AREA 0.75mm

2

The power connecting cable connected to

the indoor and outdoor unit should be

complied with the following specifications

(Type "B" approved by HAR or SAA).

The power cord connected to the "A" unit

should be complied with the following

specifications(Type "B" approved by HAR or

SAA).

Connecting the cable between indoor unit and outdoor unit

Connect the cable to the Indoor unit.

• Connect the cable to the indoor unit by connecting the wires to the terminals on the control board individually according to

the outdoor unit connection. (Ensure that the color of the wires of the outdoor unit and the terminal No. are the same as

those of the indoor unit.). The earth wire should be longer than the common wires.

The above circuit diagram is subject to change without notice.

When installing, refer to the circuit diagram on the control box

inside Indoor Uint.

• When installing, refer to the circuit diagram on the

Control Box of Indoor Unit.

• When installing, refer to the wiring diagram on the

Control Cover Inside Outdoor Unit.

• The above circuit diagram is subject to change without

notice.

• Be sure to connect wires according to the wiring diagram.

• Connect the wires firmly, so that not to be pulled out easily.

• Connect the wires according to color codes by referring the

wiring diagram.

Connecting the cable between indoor unit and outdoor unit

(mm2)

NORMAL CROSS

-SECTIONAL AREA

Unit(A) Indoor Indoor Indoor Indoor Outdoor Outdoor

Cable Type(B) H05VV-F H05VV-F H05VV-F H05VV-F H05RN-F H05RN-F

5k~9k 12k 14K~18k 24k~28k 30k, 32k 36k, 38k

1.0 1.0 1.5 2.5 2.5 5.5

Grade

• If a power plug is not to be used, provide a circuit

breaker between power source and the unit as

shown below.

Circuit Breaker

Use a circuit

breaker or time

delay fuse.

(mm2)

NORMAL

CROSS

-SECTIONAL

AREA

Cable Type(B) H07RN-F H07RN-F H07RN-F

Grade

5k~12k 14k~18k 24k~28k

1.0 1.5 2.5

Service Manual 25

Page 26

Connecting the cable between indoor unit and outdoor unit

Terminal block

Over 5mm

Cover control

Connecting cable

Connecting cable

Connect the cable to the outdoor unit

Remove the control cover from the unit by

loosening the screw.

Connect the wires to the terminals on the control board individually.

Secure the cable onto the control board with

the cord clamp.

Refix the control cover to the original position

with the screw.

Use a recognized circuit breaker "A"

between the power source and the unit.

A disconnecting device to adequately disconnect all supply lines must be fitted.

Circuit

Breaker

(A)

5k~14k 18k 24k~28k 30k, 32k 36k, 38k

15 20 30 30 40

Grade

Outdoor Unit

After the confirmation of the above conditions, prepare the wiring as follows:

1) Never fail to have an individual power circuit specifically for the air conditioner. As for the method of wiring,

be guided by the circuit diagram posted on the inside of control cover.

2) The screw which fasten the wiring in the casing of electrical fittings are liable to come loose from vibrations

to which the unit is subjected during the course of transportation. Check them and make sure that they are

all tightly fastened. (If they are loose, it could cause burn-out of the wires.)

3) Specification of power source.

4) Confirm that electrical capacity is sufficient.

5) See to that the starting voltage is maintained at more than 90 percent of the rated voltage marked on the

name plate.

6) Confirm that the cable thickness is as specified in the power source specification.

(Particularly note the relation between cable length and thickness. (Refer to page 26))

7) Always install an earth leakage circuit breaker in a wet or moist area.

8) The following would be caused by voltage drop.

• Vibration of a magnetic switch, which will damage the contact point, fuse breaking, disturbance of the normal func-

tion of the overload.

9) The means for disconnection from a power supply shall be incorporated in the fixed wiring and have an air

gap contact separation of at least 3mm in each active(phase) conductors.

26 Room Air Conditioner

Page 27

Checking the drainage and forming the pipings

Pull the right and

the left side.

Downward slope

Do not raise

Accumulated

drain water

Tip of drain hose

dipped in water

Air

Waving

Water

leakage

Water

leakage

Ditch

Less than

50mm gap

Water

leakage

Taping

Drain

hose

Pipings

Connecting

cable

Trap is required to prevent water

from entering into electrical parts.

Seal small openings

around pipings with a

gum type sealer.

Seal a small opening

around the pipings

with gum type sealer.

Trap

Trap

Checking the drainage and forming the pipings

Checking the drainage Form the piping

To remove the front panel from the indoor unit.

• Set the air direction louvers up-and-down to the

position(horizontally) by hand.

• Remove the securing screws that retain the front panel.

Pull the lower left and right sides of the grille toward you

and lift it off.

To check the drainage.

• Pour a glass of water on the evaporator.

• Ensure the water flows through the drain hose of the indoor

unit without any leakage and goes out the drain exit.

Form the piping by wrapping the connecting

portion of the indoor unit with insulation material and secure it with two kinds of vinyl tapes.

• If you want to connect an additional drain hose, the end of

the drain outlet should be routed above the ground. Secure

the drain hose appropriately.

In cases where the outdoor unit is installed

below the indoor unit perform the following.

• Tape the piping, drain hose and connecting cable from

down to up.

• Secure the tapped piping along the exterior wall using saddle or equivalent.

Drain piping

• The drain hose should point downward for easy drain flow.

• Do not make drain piping.

In cases where the Outdoor unit is installed

above the Indoor unit perform the following.

• Tape the piping and connecting cable from down to up.

• Secure the taped piping along the exterior wall. Form a trap

to prevent water entering the room.

• Fix the piping onto the wall by saddle or equivalent.

Service Manual 27

Page 28

Air purgingd

Lo Hi

Indoor unit

Outdoor unit

Manifold valve

Charge hose

Nitrogen gas

cylinder(in vertical

standing position)

Pressure

gauge

AIR PURGING

Air purging

Air and moisture remaining in the refrigerant system have

undesirable effects as indicated below.

• Pressure in the system rises.

• Operating current rises.

• Cooling(or heating) efficiency drops.

• Moisture in the refrigerant circuit may freeze and block cap-

illary tubing.

• Water may lead to corrosion of parts in the refrigeration

system.

Therefore, the indoor unit and tubing between the indoor and

outdoor unit must be leak tested and evacuated to remove

any noncondensables and moisture from the system.

Air purging with vacuum pump

Preparation

• Check that each tube(both liquid and gas side tubes)

between the indoor and outdoor units have been properly

connected and all wiring for the test run has been completed. Remove the service valve caps from both the gas and

the liquid side on the outdoor unit. Note that both the liquid

and the gas side service valves on the outdoor unit are

kept closed at this stage.

Leak test

• Do a leak test of all joints of the tubing(both indoor and outdoor) and both gas and liquid side service valves.

Bubbles indicate a leak. Be sure to wipe off the soap with a

clean cloth.

• After the system is found to be free of leaks, relieve the

nitrogen pressure by loosening the charge hose connector

at the nitrogen cylinder. When the system pressure is

reduced to normal, disconnect the hose from the cylinder.

• Connect the manifold valve(with pressure gauges) and dry

nitrogen gas cylinder to this service port with charge hoses.

Be sure to use a manifold valve for air purging. If it is not

available, use a stop valve for this purpose. The "Hi" knob

of the manifold valve must always be kept close.

• Pressurize the system to no more than 150 P.S.I.G. with

dry nitrogen gas and close the cylinder valve when the

gauge reading reached 150 P.S.I.G. Next, test for leaks

with liquid soap.

To avoid nitrogen entering the refrigerant system in a liquid

state, the top of the cylinder must be higher than its bottom

when you pressurize the system. Usually, the cylinder is

used in a vertical standing position.

28 Room Air Conditioner

Page 29

Soap water method

Gas side

Liquid side

Cap

Hexagonal wrench

2-way valve

(Open)

3-way valve

(Close)

Indoor unit

Outdoor unit

Lo Hi

Manifold valve

Vacuum pump

Pressure

gauge

Open

Close

(1) Remove the caps from the 2-way and 3-way valves.

(2) Remove the service-port cap from the 3-way valve.

(3) To open the 2-way valve turn the valve stem counter-

clockwise approximately 90°, wait for about 2~3 sec, and

close it.

(4) Apply a soap water or a liquid neutral detergent on the

indoor unit connection or outdoor unit connections by a

soft brush to check for leakage of the connecting points

of the piping.

(5) If bubbles come out, the pipes have leakage.

Evacuation

• Connect the charge hose end described in the preceding

steps to the vacuum pump to evacuate the tubing and

indoor unit.

Confirm the "Lo" knob of the manifold valve is open. Then,

run the vacuum pump.

The operation time for evacuation varies with tubing length

and capacity of the pump. The following table shows the

time required for evacuation.

Air purgingd

Required time for evacuation when 30 gal/h vacuum

If tubing length is less than 10m (33 ft)

pump is used

if tubing length is longer than 10m (33 ft)

10 min. or more 15 min. or more

• When the desired vacuum is reached, close the "Lo" knob

of the manifold valve and stop the vacuum pump.

Finishing the job

• With a service valve wrench, turn the valve stem of liquid

side valve counter-clockwise to fully open the valve.

• Turn the valve stem of gas side valve counter-clockwise to

fully open the valve.

• Loosen the charge hose connected to the gas side service

port slightly to release the pressure, then remove the hose.

• Replace the flare nut and its bonnet on the gas side service

port and fasten the flare nut securely with an adjustable

wrench. This process is very important to prevent leakage

from the system.

• Replace the valve caps at both gas and liquid side service

valves and fasten them tight.

This completes air purging with a vacuum pump.

The air conditioner is now ready to test run.

Service Manual 29

Page 30

Test running

Bolt

Tubing connection

Discharge

temperature

Discharge air

Intake temperature

Power

button

TEST RUNNING

1. Check that all tubing and wiring have been properly con-

NOTE: If the actual pressure is higher than shown, the system is

nected.

2. Check that the gas and liquid side service valves are fully

open.

Settlement of outdoor unit

The air conditioner is now ready for use.

• Anchor the outdoor unit with a bolt and nut(ø10mm) tightly

and horizontally on a concrete or rigid mount.

• When installing on the wall, roof or rooftop, anchor the

mounting base securely with a nail or wire assuming the

influence of wind and earthquake.

• In the case when the vibration of the unit is conveyed to the

hose, secure the unit with an anti-vibration bushing.

1. Connect a low-pressure gauge manifold hose to the

2. Open the gas side service valve halfway and purge the air

3. Close the liquid side service valve(all the way in).

4. Turn on the unit's operating switch and start the cooling

Evaluation of the performance

5. When the low-pressure gauge reading becomes 1 to

Operate unit for 15~20 minutes, then check the system

refrigerant charge:

1. Measure the pressure of the gas side service valve.

2. Measure the temperature of the intake and discharge of air.

3. Ensure the difference between the intake temperature and

the discharge is more than 8°C(46°F) (Cooling) or

Power-Failure Compensation Function User Selection ON/OFF

1) Operation Sequence

(Heating).

most likely over-charged, and charge should be removed.

If the actual pressure are lower than shown, the system is

most likely undercharged, and charge should be added.

PUMP DOWN

This is performed when the unit is to be relocated or

the refrigerant circuit is serviced.

Pump Down means collecting all refrigerant in the outdoor

unit without loss in refrigerant gas.

CAUTION:

Be sure to perform Pump Down procedure with the unit

cooling mode.

Pump Down Procedure

charge port on the gas side service valve.

from the manifold hose using the refrigerant gas.

operation.

0.5kg/cm2 G(14.2 to 7.1 P.S.I.G.), fully close the gas side

valve stem and then quickly turn off the unit. At that time,

Pump Down has been completed and all refrigerant gas

will have been collected in the outdoor unit.

Press the forced switch until BUZZER sounds 2 times

(beep~beep~).

Release the forced switch if BUZZER sounds.

4. For reference; the gas side pressure of optimum condition

is as below.(Cooling)

Refrigerant

Outside ambient

TEMP.

The pressure of the gas side

service valve.

R-22 35°C (95°F) 4~5kg/cm2G(56.8~71.0 P.S.I.G.)

R-410A 35°C (95°F) 8.5~9.5kg/cm2G(120~135 P.S.I.G.)

30 Room Air Conditioner

Check the function selection ON/OFF with the operation LED.

2) Checking function-selection ON/OFF

- Function-Selection ON: One time blinking of operation LED

would repeat 4 times.

- Function-Selection OFF: Two times blinking of operation LED

would repeat 4 times.

Page 31

Operation

Function of Controls

• DISPLAY

1) C/O Model

Operation Indicator

• ON while in appliance operation, OFF while in appliance pause.

• Flashing while in disconnection or short in Thermistor. (3 sec off / 0.5 sec on)

Timer Indicator

• ON while in timer mode (on/off), OFF when timer mode is completed or canceled.

Comp. Running Incidator

• While in appliance operation, ON while in outdoor unit compressor running, OFF while in compressor off.

2) H/P Model

Operation Indicator

• ON while in appliance operation, OFF while in appliance pause.

• Flashing while in disconnection or short in Thermistor. (3 sec off / 0.5 sec on)

Operation

Timer Indicator

• ON while in timer mode (on/off), OFF when timer mode is completed or canceled.

Defrost Indicator

• OFF except when hot start during heating mode operation or while in defrost control.

■ Cooling Mode Operation

• When the intake air temperature reaches 0.5°C below the setting temp, the compressor and the outdoor fan

stop.

• When it reaches 0.5°C above the setting temp, they start to operate again.

Compressor ON Temp ➲ Setting Temp+0.5°C

Compressor OFF Temp ➲ Setting Temp-0.5°C

• While in compressor running, operating with the airflow speed set by the remote control. While in compressor

not running, operating with the low airflow speed regardless of the setting.

■ Healthy Dehumidification Mode

• When the dehumidification operation input by the remote control is received, the intake air temperature is

detected and the setting temp is automatically set according to the intake air temperature.

26°C ≤ Intake Air Temp ➲ 25°C

24°C ≤ Intake Air Temp<26°C ➲ Intake Air Temp-1°C

18°C ≤ Intake Air Temp<24°C ➲ Intake Air Temp-0.5°C

Intake Air Temp<18°C ➲ 18°C

Service Manual 31

Page 32

Operation

• While in compressor off, the indoor fan repeats low airflow speed and pause.

• While the intake air temp is between compressor on temp. and compressor off temp., 10-min dehumidification

operation and 4-min compressor off repeat.

Compressor ON Temp. ➲ Setting Temp+0.5°C

Compressor OFF Temp. ➲ Setting Temp-0.5°C

• In 10-min dehumidification operation, the indoor fan operates with the low airflow speed.

■ Heating Mode Operation

• When the intake air temp reaches +3°C above the setting temp, the compressor is turned off. When reaches

the setting temp, the compressor is turned on.

Compressor ON Temp. ➲ Setting Temp.

Compressor OFF Temp. ➲ Setting Temp.+3°C

• While in compressor on, the indoor fan is off when the indoor pipe temp. is below 20°C, when above 28°C , it

operates with the low or setting airflow speed. When the indoor pipe temp is between 20°C and 28°C, it operates with Super-Low(while in sleep mode, with the medium airflow speed).

• While in compressor off, the indoor fan is off when the indoor pipe temp is below 33°C, when above 35°C , it

operates with the low airflow speed.

• If overloaded while in heating mode operation, in order to prevent the compressor from OLP operation, the

outdoor fan is turned on/off according to the indoor pipe temp.

• While in defrost control, both of the indoor and outdoor fans are turned off.

■ Defrost Control

• While in heating mode operation in order to protect the evaporator pipe of the outdoor unit from freezing,

reversed to cooling cycle to defrost the evaporator pipe of the outdoor unit.

• After 40 min heating mode operation, at 4 min interval, whether to carry out defrost control or not and the time

of defrost control are determined according to the following conditions.

1) While in heating mode operation, the maximum of the indoor pipe temperature is measured and it is com-

pared with the present indoor pipe temperature to get the difference of the indoor pipe temperatures (=the

maximum temperature of indoor pipe ? the present temperature of indoor pipe), according to which, whether

to carry out defrost control or not is determined.

2) According to the need of defrost control shown above and the elapsed time of heating mode operation at that

moment, the defrost control time is determined.

3) When the determined time of defrost control is below 7 min, heating mode operation continues without carry-

ing out defrost control. According to the procedure stated above, the determination is made again. When the

defrost control time is 7 min or longer, defrost control is then carried out.

• While in defrost control, the minimum temp of the indoor pipe is measured and it is compared with the present

temp of the indoor pipe to get the difference of the indoor pipe temperatures (=the present temperature of the

indoor pipe ? the minimum temperature of the indoor pipe). When the difference is 5°C or higher, defrost control is completed and heating mode operation is carried out.

• While in defrost control, if the defrost time determined before the start of defrost control is completed, defrost

control stops and heating mode operation is carried out regardless of the above condition.

• When the indoor pipe temp is 42°C or above, defrost control is not carried out even if the condition is one of

the defrost conditions above.

• While in defrost control, the compressor is on and the indoor fan, the outdoor fan, and the 4 way valve are off.

32 Room Air Conditioner

Page 33

Operation

■ Airflow Speed Selection

• The airflow speed of the indoor fan is set to high, medium, low, or chaos (auto) by the input of the airflow

speed selection key on the remote control.

■ Sleep Timer Operation

• When the sleep time is reached after <1,2,3,4,5,6,7,0(cancel) hr> is input by the remote control while in appliance operation, the operation of the appliance stops.

• While the appliance is on pause, the sleep timer mode cannot be input.

• While in cooling mode operation, 30 min later since the start of the sleep timer, the setting temperature

increases by 1°C. After another 30 min elapse, it increases by 1°C again.

• When the sleep timer mode is input while in cooling cycle mode, the airflow speed of the indoor fan is set to

the low.

• When the sleep timer mode is input while in heating cycle mode, the airflow speed of the indoor fan is set to

the medium.

■ Chaos Natural Wind Mode

• When the Chaos Natural Wind mode is selected and then operated, the high, medium, or low speed of the airflow mode is operated for 2~15 sec. randomly by the Chaos Simulation.

■ Jet Cool Mode Operation (C/O Model)

• If the Jet Cool key is input at any operation mode while in appliance operation, the Jet Cool mode operates.

• In the Jet Cool mode, the indoor fan is operated at super-high speed for 30 min at cooling mode operation.

• In the Jet Cool mode operation, the room temperature is controlled to the setting temperature, 18°C

• When the sleep timer mode is input while in the Jet Cool mode operation, the Jet Cool mode has the priority.

• When the Jet Cool key is input, the upper/lower vanes are reset to those of the initial cooling mode and then

operated in order that the air outflow could reach further.

■ Jet Cool Mode Operation (H/P Model)

• While in heating mode or Fuzzy operation, the Jet Cool key cannot be input. When it is input while in the

other mode operation (cooling, dehumidification, ventilation), the Jet Cool mode is operated.

• In the Jet Cool mode, the indoor fan is operated at super-high speed for 30 min at cooling mode operation.

• In the Jet Cool mode operation, the room temperature is controlled to the setting temperature, 18°C.

• When the sleep timer mode is input while in the Jet Cool mode operation, the Jet Cool mode has the priority.

• When the Jet Cool key is input, the upper/lower vanes are reset to those of the initial cooling mode and then

operated in order that the air outflow could reach further.

■ Forced Operation

• Operation procedures when the remote control can't be used.

• The operation will be started if the power button is pressed.

• If you want to stop operation, re-press the button.

Cooling Model

Operating mode Cooling Cooling Healthy Dehumidification Heating

Indoor FAN Speed

Setting Temperature

High High High High

22°C22°C23°C24°C

Room Temp. ≥ 24°C 21°C ≤ Room Temp. < 24°C Room Temp. < 21°C

Heat pump Model

• While in forced operation, the key input by the remote control has no effect and the buzzer sounds 10 times to

indicate the forced operation.

Service Manual 33

Page 34

Operation

■ Test operation

•

During the TEST OPERATION, the unit operates in cooling mode at high speed fan, regardless of room temperature and resets in 18±1 minutes.

•

During test operation, if remote controller signal is received, the unit operates as remote controller sets.

If you want to use this operation, open the front panel upward and Press the power button let it be pressed for

about 3 seconds.

•

If you want to stop the operation, re-press the button.

■ Auto restart

•

In case the power comes on again after a power failure, Auto Restarting Operation is the function to operate

procedures automatically to the previous operating conditions.

■ Protection of the evaporator pipe from frosting

• If the indoor pipe temp is below 0°C in 7 min. after the compressor operates without any pause while in cooling cycle operation mode, the compressor and the outdoor fan are turned off in order to protect the indoor

evaporator pipe from frosting.

• When the indoor pipe temp is 7°C or higher after 3 min. pause of the compressor, the compressor and the

outdoor fan is turned on according to the condition of the room temperature.

■ Buzzer Sounding Operation

• When the appliance-operation key is input by the remote control, the short "beep-beep-" sounds.

• When the appliance-pause key is input by the remote control, the long "beep—" sounds.

34 Room Air Conditioner

Page 35

Display Function

3sec 3sec 3sec

(once)

1. Heating Model 2. Cooling Model

Operation

Operation Indicator

• Cooling, Soft Dry, Fan, Heating • Cooling, Soft Dry, Fan

Deicer Indicator

• Hot-start, Deice

Operation Indicator

Compressor on Indicator

Self-diagnosis Function

Error

Code

1

Error Display LED

(Indoor body operation LED)

Error contents

• Indoor room temperature

thermistor open/short

• Indoor pipe temperature

thermistor open/short.

OUT

DOOR

SVC check point

• Indoor Thermistor

assembly check

Service Manual 35

Page 36

36 Service Manual

3

4

Page 37

Disassembly

Earth

Conductor

Indoor Unit

Disconnect the unit from power supply before making any checks.

Be sure the power switch is set to “OFF”.

To remove the Grille from the Chassis.

• Set the up-and-down air discharge louver to open

position (horizontally) by finger pressure.

• Remove the securing screws.

• To remove the Grille, pull the lower left and right

side of the grille toward you (slightly tilted) and lift it

straight upward.

Disassembly

1. Before removing the control box, be sure to

take out the wire screwed at the other end.

Service Manual 37

Page 38

Disassembly

Screw

2. To remove the Control Box.

• Remove securing screws.

• Pull the control box out from the chassis

carefully.

3. To remove the Discharge Grille.

• Unhook the discharge grille and pull the

discharge grille out from the chassis carefully.

4. To remove the Evaporator.

• Remove 3 screws securing the evaporator(at the

left 2EA in the Eva Holder, at the right 1EA).

• When repair, do not damage the Caution label.

38 Room Air Conditioner

Page 39

• Unhook the tab on the right inside of the chassis

Motor cover

Bearing

Cross-flow fan

at the same time, slightly pull the evaporator

toward you until the tab is clear of the slot.

5. To remove the Motor Cover

• Remove 2 securing screw.

• Pull the motor cover out from the chassis

carefully.

Disassembly

6. To remove the Cross-Flow Fan

• Loosen the screw securing the cross-flow fan to

the fan motor (do not remove).

• Lift up the right side of the cross-flow fan and the

fan motor, separate the fan motor from the

cross-flow fan.

• Remove the left end of the cross-flow fan from

the self-aligning bearing.

Service Manual 39

Page 40

Schematic Diagram

Schematic Diagram

Electric Control Device

• Heat Pump Model(LED TYPE)

40 Room Air Conditioner

Page 41

Wiring Diagram

Indoor Unit

Models: SE 9k,12k Cooling only Model

Schematic Diagr am

POWER

YL

/

MOTOR

BL

BR

GN

BR

SH-CAPA

YL

/

BL

BR

GN

T/BLOCK

YL

/

BL

BR

GN

TO OUTDOOR UNIT

YL

OR

BK

PWB ASM

CN-MOTOR

CN-TAB2 CN-TAB1

RY-COMP

CN-DISPLAY

DISPLAY PWB ASM

CN-TH

SSR

ZNR

CN-U/D

FORCE

S/W

FUSE

)

(250V/2A

CN-FORCE

CN-SUB

INDOOR WIRING DIAGRAM

Models: SE 9k,12k Heat pump Model

POWER

YL

/

N

BL

BR

G

BR

K

C

O

L

1(L)32(N)

B

/

T

R

B

TO OUTDOOR UNIT

SH-CAPA

BL

L

B

MOTOR

BR

YL

/

N

G

YL

/

N

G

OR

PWB ASM

MOT

N

C

OR

BK

YL

BK

RD

BK

RD

4

B1

A

T

N

C

B2

N-TA

C

RY-COMP

RY-4WAY

RY-FAN

CN-DISPLAY

DISPLAY PWB ASM

SSR

FUSE

(250V/2A

ZNR

INDOOR WIRING DIAGRAM

THERMISTOR

N-TH

C

D

STEP

U/

MOTOR

NC

FORCE

S/W

)

CN-FORCE

UB

S

SUB PCB

NC

THERMISTOR

STEP

MOTOR

SUB PCB

CN-F/G

F/G

MOTOR

STEP

CN-F/G

R

G

TO

EP

F/

MO

ST

Service Manual 41

Page 42

Wiring Diagram

Indoor Unit

Models: SY 9k,ST 12k Cooling only Model

Schematic Diagr am

POWER

YL

/

MOTOR

BL

BR

GN

BR

SH-CAPA

BL

BR

2(N)1(L)

T/BLOCK

BL

BR

TO OUTDOOR UNIT

CN-MOTOR

CN-MOTOR

OR

BK

YL

CN-TAB1

CN-TAB2

YL

/

GN

DISPLAY PWB ASM

3

YL

/

GN

PWB ASM

SSR

ZNR

FUSE

4 3

(250V/2A

RY-COMP

)

INDOOR WIRING DIAGRAM

FORCE S/W

CN-TH

THERMISTOR

STEP

MOTOR

CN-U/D

Models: SY 9k,ST 12k Heat pump Model

POWER

L

Y

/

L

N

R

MOTOR

B

B

G

YL

BR

SH-CAPA

L

Y

/

R

BL

B

BK

GN

1(L)2(N)

T/BLOCK

YL

/

BK

BL

BR

GN

TO OUTDOOR UNIT

R

R

PWB ASM

O

O

T

OT

MO

N-

C

N-M

TRIAC

C

OR

BK

SSR

1

B

A

-T

N

C

2

B

A

-T

N

C

34

RY-COMP

RY-4WAY

RY-FAN

RD

DISPLAY PWB ASM

43

D

R

FORCE S/W

H

T

NC

THERMISTOR

ZNR

D

STEP

U/

-

MOTOR

N

C

FUSE

(250V/2A

)

INDOOR WIRING DIAGRAM

Service Manual 42

Page 43

Schematic Diagram

Outdoor Unit

Models: Cooling only Model

BLUE

CAPACITOR

H

C

F

BLUE

GREEN

R

C

BROWN

OVERLOAD

PROTECT

BROWN

TERMINAL BLOCK

RED

BLUE

S

COMP

YELLOW/GREEN

BROWN

BLUE

1(L)

2(N)

BLUE

BROWN

YELLOW

THE UNIT INDOOR

OUTDOOR DIAGRAM WIRING

Models: Heat pump Model

BLUE

RED

FAN

YELLOW

S

R

COMP

C

BROWN

YELLOW/GREEN

OVERLOAD

PROTECT

BROWN

1(L)

YELLOW/GREEN

OUTDOOR DIAGRAM WIRING

RED

BLUE

BROWN

BLUE

3

2(N)

BLUE

BROWN

THE UNIT INDOOR

H

VALVE,REVERSING

BLUE

4

RED

BLACK

CAPACITOR

C

BLUE

BLUE

TERMINAL BLOCK

RED

F

FAN

YELLOW

43 Room Air Conditioner

Page 44

Schematic Diagram

Components Location

MAIN P.W.B ASSEMBLY

• TOP VIEW

• BOTTOM VIEW

44 Room Air Conditioner

Page 45

DISPLAY ASSEMBLY

Schematic Diagram

Service Manual 45

Page 46

Troubleshooting Guide

INDOOR UNIT OUTDOOR UNIT

INDOOR UNIT OUTDOOR UNIT

HEAT

EXCHANGE

(EVAPORATOR)

HEAT

EXCHANGE

(EVAPORATOR)

HEAT

EXCHANGE

(CONDENSER)

HEAT

EXCHANGE

(CONDENSER)

COMPRESSOR

COMPRESSOR

ACCUMU

LATOR

GAS SIDE

GAS SIDE

3-WAY VALVE

LIQUID SIDE

LIQUID SIDE

3-WAY VALVE

CAPILLARY TUBE

CAPILLARY TUBE

CHECK VALVE

(Heating Model only)

COOLING

HEATING

REVERSING

VALVE

(Heating Model Only)

Troubleshooting Guide

Refrigeration Cycle Diagram

(1) Cooling Only Models

(2) Cooling & Heating Models

46 Room Air Conditioner

Page 47

2-way, 3-way Valve

Valve cap

Open position

Closed position

Pin

Service

port

Service

port cap

To outdoor unit

Flare nut

To

piping

connection

To outdoor unit

Hexagonal wrench (4mm)

Open position

Closed position

To

piping

connection

Flare nut

Troubleshooting Guide

2-way Valve (Liquid Side) 3-way Valve (Gas Side)

Works

Shipping

Air purging

1.

(Installation)

Operation

Pumping down

2.

(Transfering)

Evacuation

3.

(Servicing)

Gas charging

4.

(Servicing)

Pressure check

5.

(Servicing)

Gas releasing

6.

(Servicing)

Shaft position Shaft position Service port

Closed Closed Closed

(with valve cap) (with valve cap) (with cap)

Open Closed Open

(counter-clockwise) (clockwise) (push-pin or with

vacumm pump)

Open Open Closed

(with valve cap) (with valve cap) (with cap)

Closed Open Open

(clockwise) (counter-clockwise) (connected manifold

gauge)

Open Open Open

(with charging

cylinder)

Open Open Open

(with charging

cylinder)

Open

(with charging cylinder)

Open

(with charging cylinder)

Service Manual 47

Open Open

Open Open