Page 1

2

F.F

CUE

TIME LAPSE VCR

SERVICE MANUAL

APRIL, 2006

Printed in Korea

CAUTION

BEFORE SERVICING THE UNIT, READ THE “SAFETY PRECAUTIONS”

IN THIS MANUAL.

POWER/ TIMER

MOVE SEL

DOWN

TRACKING

REC/ PBSPEED

MENU

REC

UP

REW

REV

ALARM

PAUSE / STILL

KEY

LOCK

STOP / EJECTPLAY / REC CHK

Page 2

TABLE OF CONTENTS

SECTION 1

SUMMARY

• SPECIFICATIONS......................................................1-1

• LOCATION OF CUSTOMER CONTROLS.................1-2

• CRITICAL PARTS REPLACING TIME TABLE...........1-5

• CRITICAL PARTS DESCRIPTION.............................1-5

SECTION 2

CABINET & MAIN FRAME

EXPLODED VIEWS........................................................2-1

1. Cabinet and Main Frame Section ............................2-1

2. Packing & Accessory Section..................................2-3

SECTION 3

ELECTRICAL

ELECTRICAL ADJUSTMENT PROCEDURES .............3-1

1. PG ADJUSTMENT..................................................3-1

ELECTRICAL TROUBLESHOOTING GUIDE ...............3-2

1. POWER(SMPS) CIRCUIT......................................3-2

2. SERVO CIRCUIT....................................................3-4

3. Y/C CIRCUIT ..........................................................3-6

4. AUDIO CIRCUIT.....................................................3-9

5. SYSTEM/KEY CIRCUIT .........................................3-11

6. OSD CIRCUIT.........................................................3-12

BLOCK & CIRCUIT DIAGRAMS....................................3-13

1. OVERALL WIRING DIAGRAM...............................3-13

2. POWER BLOCK DIAGRAM ...................................3-15

3. POWER CIRCUIT DIAGRAM.................................3-17

4. AUDIO BLOCK DIAGRAM......................................3-19

5. Y/C BLOCK DIAGRAM...........................................3-20

6. A/V CIRCUIT DIAGRAM.........................................3-21

7. SYSTEM BLOCK DIAGRAM..................................3-24

8. SYSTEM CIRCUIT DIAGRAM................................3-27

9. JACK CIRCUIT DIAGRAM .....................................3-29

10. KEY-BOARD CIRCUIT DIAGRAM..........................3-31

PRINTED CIRCUIT DIAGRAMS....................................3-33

1. MAIN P.C.BOARD..................................................3-33

2. KEY 1 P.C.BOARD.................................................3-35

3. KEY 2 P.C.BOARD.................................................3-35

4. JACK P.C.BOARD..................................................3-35

SECTION 4

MECHANISM

SECTION 5

REPLACEMENT PARTS LIST

• Mechanical Section.....................................................5-1

• Electrical Section ........................................................5-3

NOTE) The table of contents for this section is edited

separately.

Page 3

SECTION1 SUMMARY

SPECIFICATIONS

1-1

GENERAL

Head System Four head helical scan azimuth system

Power Source AC 100-240V, 50/60Hz

Power Consumption Approx. 15 Watts

Back up time (clock) 30 days

Dimensions (WxHxD) 14.2” x 3.7” x 10.7” (360 x 94 x 273 mm)

Operating Temperature 41 °F~105 °F (5 °C~40 °C)

Operating Humidity Less than 80% RH

Timer 24-hour display type

Weight Approx. 8.4 lb (3.8 kg)

Tape Speed (NTSC) 11.12 mm/sec (6H) , 3.70 mm/sec (18H),

2.22 mm/sec (30H), 72H ~ 960H

Tape Speed (PAL) 11.695 mm/sec (6H) , 3.89 mm/sec (18H),

2.33 mm/sec (30H), 72H ~ 960H

Maximum Recording Time 6 hours (NT:T-120/PAL:E-180, 6H),

18 hours (NT:T-120/PAL:E-180, 18H),

30 hours (NT:T-120/PAL:E-180, 30H), 72H ~ 960H

Tape Width 0.5 in. (12.7 mm)

Rewind Time About 65 seconds (NT:T-120)(PAL:E-180)

Video Signal System(PAL) CCIR Standard (625 lines, 50 fields)

PAL type color signal

Video Signal System(NTSC) EIA Standard (525 lines, 60 fields)

NTSC type color signal

Video Input 1.0 Vp-p 75 ohms unbalanced

Video Output 1.0 Vp-p 75 ohms unbalanced

Signal to Noise Ratio More than 43 dB (6H mode)

Conventional audio

Input (LINE) -6.0 dBm more than 47 kohms

Output (LINE) -6.0 dBm less than 1.5 kohms

S/N Ratio More than 43 dB (6H mode)

Frequency Range 200 Hz to 10kHz (6H mode)

* Designs and specifications are subject to change without notice.

* Weight and dimensions shown are approximate.

Page 4

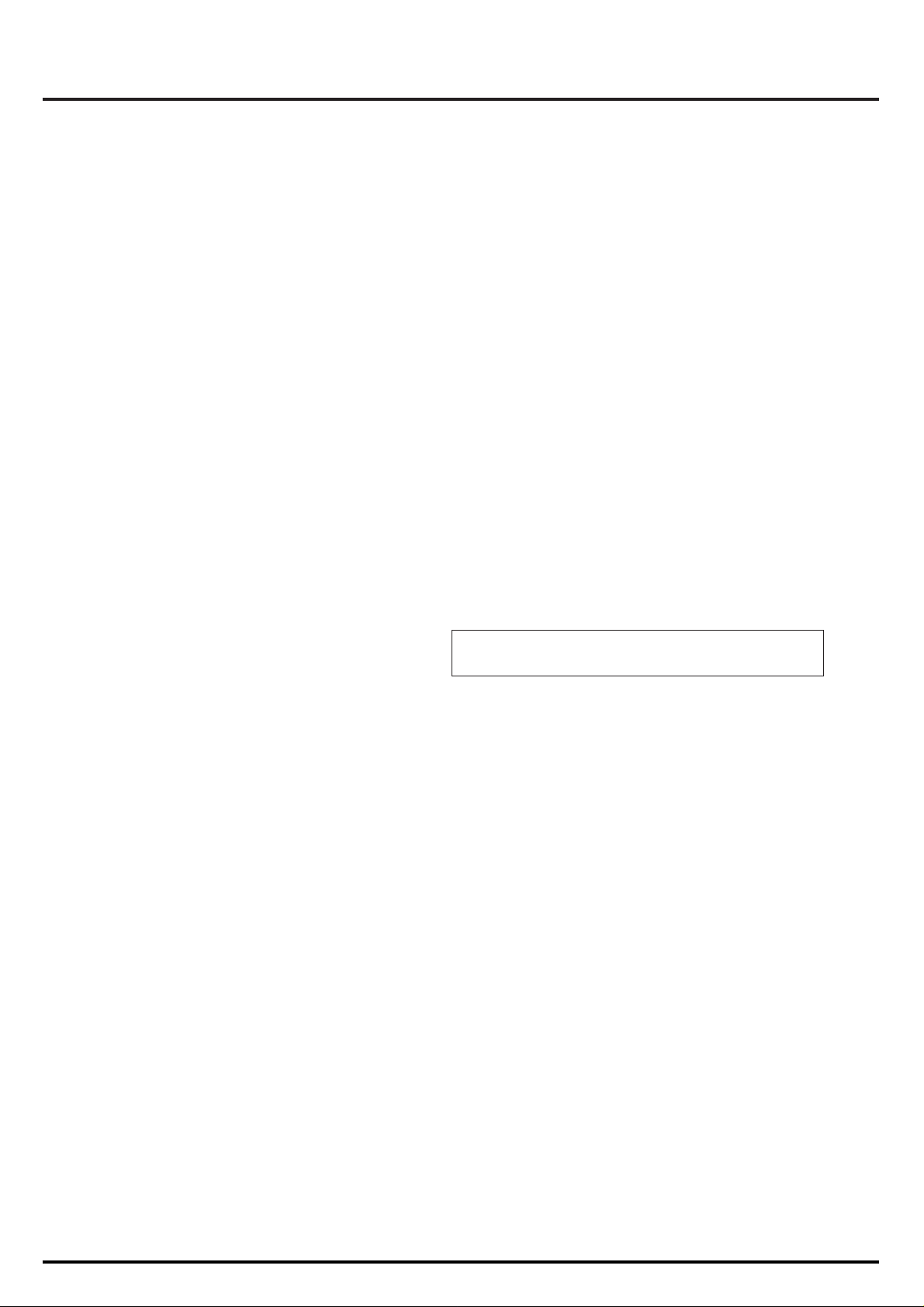

SECTION1 SUMMARY

LOCATION OF CUSTOMER CONTROLS

1-2

1 POWER/TIMER BUTTON

2 MENU BUTTON

3 REC (RECORD) BUTTON

4 MOVE BUTTON

5 SEL (SELECT) BUTTON

6 DOWN BUTTON

7 UP BUTTON

8 ALARM INDICATOR

9 KEY LOCK INDICATOR

10 CASSETTE LOADING SLOT

11 CLEAR, KEY LOCK OFF, BUZZER OFF

12 CLOCK, COUNT, REMAIN

13 SHUTTLE RING

14 JOG RING

15 PAUSE/STILL BUTTON

16 PLAY/REC CHECK BUTTON

17 STOP/EJECT BUTTON

FRONT

REAR

1 POWER CORD

2 AUDIO IN/OUT JACK

3 VIDEO IN/OUT JACK

4 RESET BUTTON

5 12-PIN TERMINAL BLOCK

Page 5

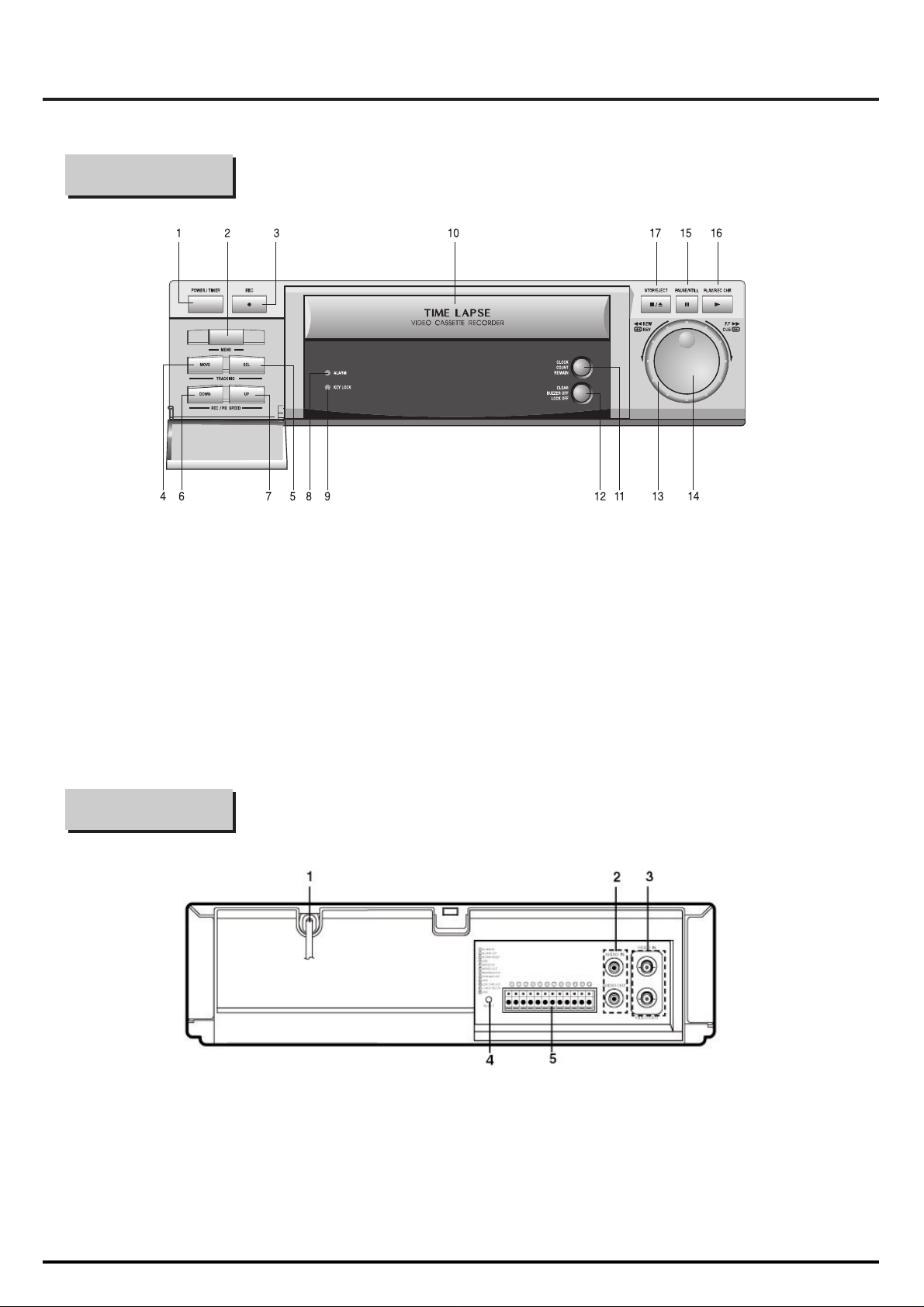

1-3

1 TIME LAPSE VCR TIME INDICATION

2 ALARM INDICATION

3 SERIES INDICATION

4 RECORD INDICATION

5 TIMER INDICATION

6 CASSETTE INDICATION

7 INDEX INDICATION

8 POWER FAILURE INDICATION

9 KEY LOCK INDICATION

10 REPEAT INDICATION

11 FUNCTION INDICATION

12 VCR FUNCTION INDICATION

INDICATOR PANEL

VCR FUNCTION INDICATION

SECTION1 SUMMARY

LOCATION OF CUSTOMER CONTROLS

Page 6

1-4

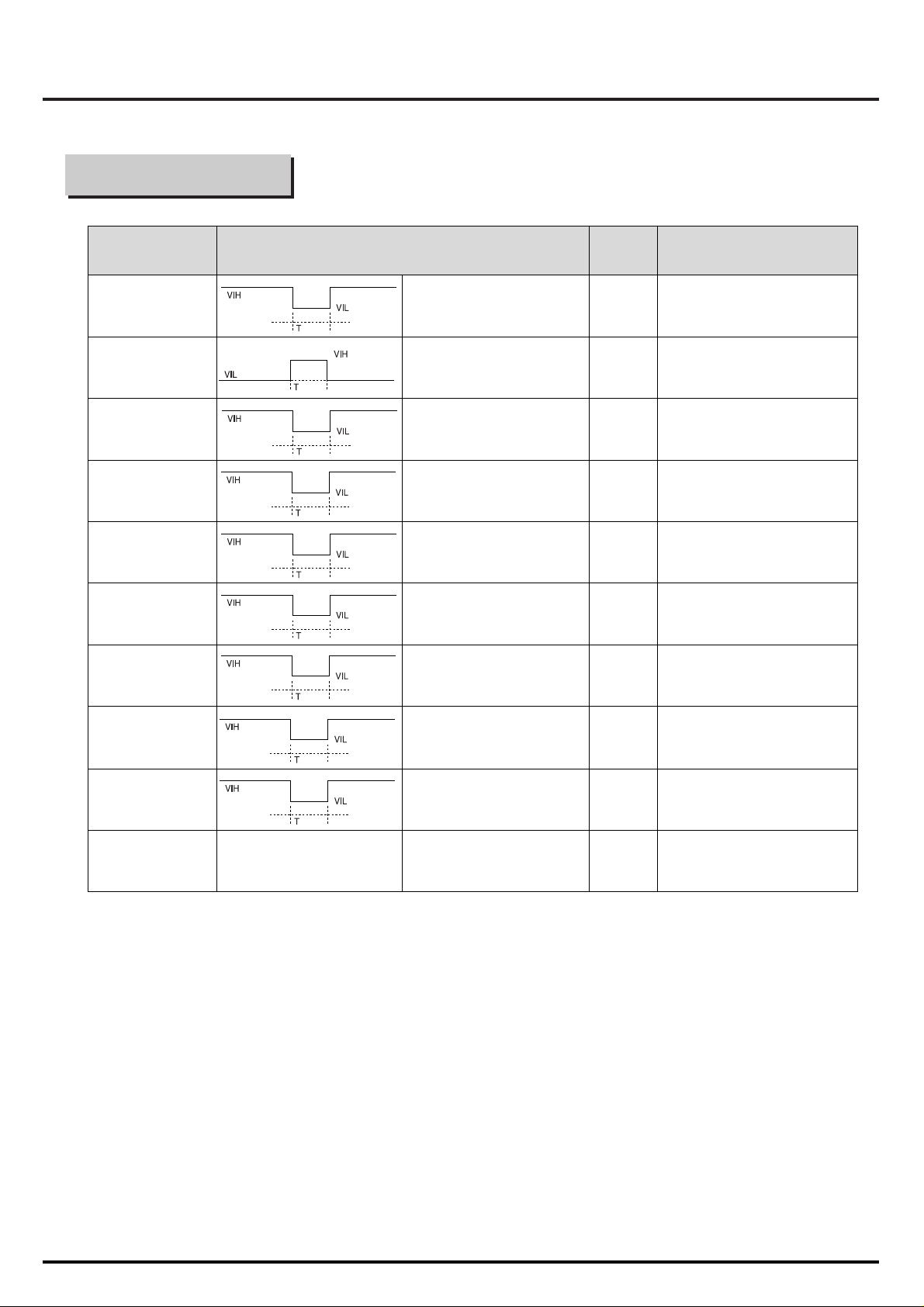

TERMINAL SIGNAL LEVELS

SECTION1 SUMMARY

LOCATION OF CUSTOMER CONTROLS

INPUT

OUTPUT

INPUT

INPUT

OUTPUT

OUTPUT

OUTPUT

OUTPUT

INPUT

COMMON

The input signal that makes

‘Alarm Record’ work

Output signal appears when the

tape reaches to end or deck is

error in recording.

Outputs whether VCR deck is

error.

The terminal that makes ‘1-short

Record’ work in Auto mode

As the terminal that outputs that tape

remains less than 5 minutes in

recording, it isn’t output in ‘1-shot

Record’.

The signal is output which is used by

switching several cameras in

general space with using camera

multi-plexer.

Outputs whether ‘Alarm

Recording’ is working

The terminal that stops ‘Alarm

Record’ in Auto mode

The input terminal to make

‘Series Record’ work

1. ALARM IN

2. ALARM OUT

3.ALARM RESET

5. SERIES IN

6. SERIES OUT

7. WARNING OUT

8. TRIGGER OUT

10. LOW TAPE OUT

11. 1-SHOT REC IN

4, 9, 12. GND

VIH : 4 ~ 5V

VIL : 0 ~ 0.6V

T : above 250 msec

VIH : 4 ~ 5V

VIL : 0 ~ 0.6V

T : ALARM REC STATE

VIH : 4 ~ 5V

VIL : 0 ~ 0.6V

T : above 250 msec

VIH : 4 ~ 5V

VIL : 0 ~ 0.6V

T : above 250 msec

VIH : 4 ~ 5V

VIL : 0 ~ 0.6V

T : above 250 msec

VIH : 4 ~ 5V

VIL : 0 ~ 0.6V

T : above 250 msec

0V-

VIH : 4 ~ 5V

VIL : 0 ~ 0.6V

T : until any-key is pressed

VIH : 4 ~ 5V, VIL : 0 ~ 0.6V

8 msec : NTSC

10 msec : PAL

VIH : 4 ~ 5V

VIL : 0 ~ 0.6V

T : below 5 min, end of tape

TERMINAL SIGNAL LEVEL IN/OUT DESCRIPTION

Page 7

1-5

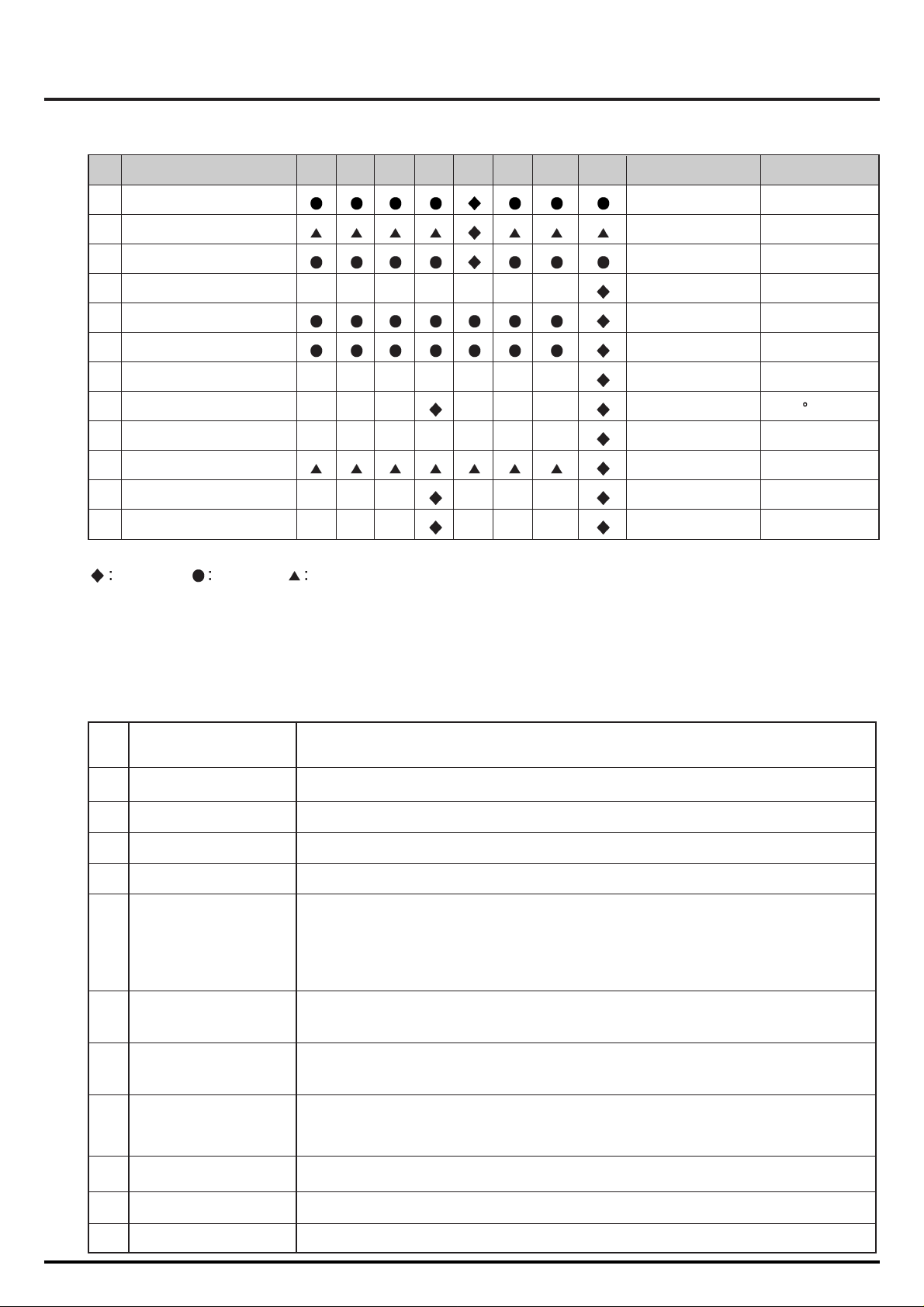

No. DESCRIPTION 1500 3000 5000 6000 7500 9000 10000 12000 Test freatures Specification

1 DRUM ASSY RF out level -4dB and below

2 ARM ASSY CLEANER Wear status

3 MOTOR CAPSTAN (D-35) W/F(WTD) 0.4% and below

4 BELT CAPSTAN Belt tension

5 BASE ASSY A/C -6dB and below

6 HEAD F/E 45dB min

7 ARM ASSY IDLER 4~12 g

8 HOLDER ASSY PINCH 60~90

9 BAND ASSY TENSION Back Torque 40~70 g

10 HOUSING ASSY CST loading status

11 CAPSTAN SOFT BRAKE Felt wear

12 CLUTCHAY Torque(Play, Rev)

there shouldn’t be any space

betwween CST and compartment

whether there is

touch noise

40~140gcm, 100~210gcm

1. Drum Ass’y

Consists of video head, rotary trans and motor. records video and audio information on

the tape, and play the tape back.

(Audio information is recorded only on the Hi-Fi models)

2. Arm Ass’y Cleaner Cleans video head and rotation head automatically.

4. Motor Capstan Moves the tape with regular speed.

5. Belt Capstan Transfers rotative energy of capstan motor to the driving system.

6. Brake Ass’y Capstan Brakes rotative energy of capstan motor.

7. Base Ass’y A/C Consists of three head.

Audio erase head in the left upper erases audio signal in dubbing.

Audio head in the right upper records and playes the audio signal.

CTL head in the right lower records and detects CTL pulse to control tape speed.

8. Head F/E Is abbreviation of Full Erased Head.

erases the signal recorded on a tape clearly and absorb vibration of tape.

12. Arm Ass’y Idler Is located between T/UP reel and supply reel.

Transfers ratative energy of capstan motor to T/UP reel or supply reel.

13. Holder Ass’y Pinch Sticks a video tape to capstan motor and has the tape played without being

slipped from capstan motor axle.

14. Band Ass’y Tension Has supply reel loosened properly with giving it some tensile force.

15. Arm Ass’y Makes the cassette tape inserted be loaded and ejected precisly and safely.

16. Clutch Ass’y Plays the tape with trasfering rotative energy of capstan motor to idler reel.

SECTION1 SUMMARY

CRITICAL PARTS REPLACING TIME TABLE

Audio and CTL out

level

Whether extraneous

matters come out

Variation amount :

within 40%

The rate of erasing

(1KHz)

The capacity of ldler

for moving

Surrace solidity of

Roller

Reference :

Changing Cleaning Checking

Notes :

• Check the running path adjustment when you change the itens 1, 3, 5, 6 and 10.

• Check the back tension when you change Band Assy Tension.

CRITICAL PARTS DESCRIPTION

Page 8

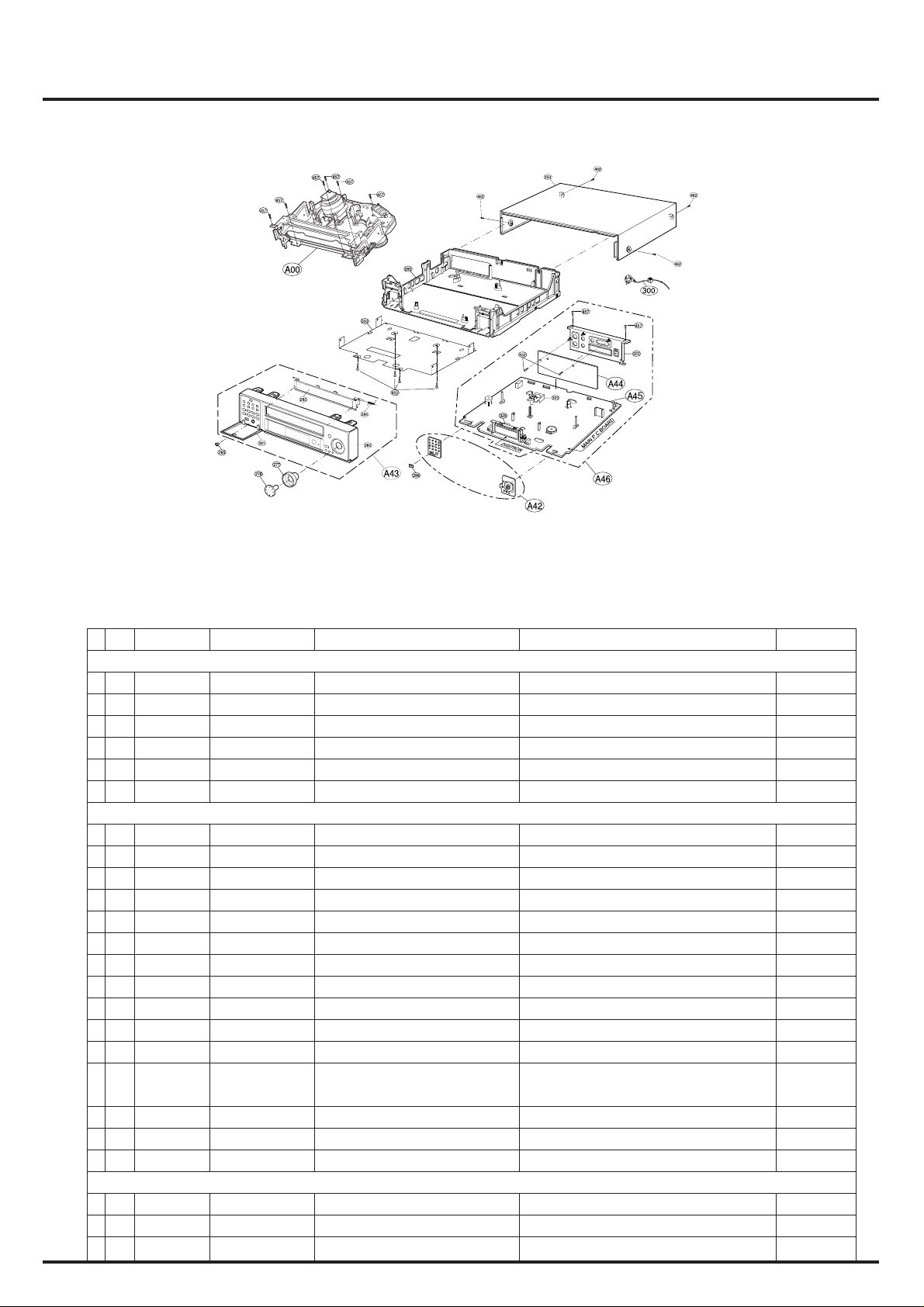

2-1

SECTION2 CABINET & MAIN FRAME

EXPLODED VIEWS

1. Cabinet and Main Frame Section

Cabinet & Main Frame Section Parts list

MODEL : TL-AT130M

S AL LOCA.NO. PART NO DESCRIPTION SPECIFICATION REMARKS

ASSEMBLY SECTION

A00 6721R-0771U DECK ASSEMBLY,VIDEO DECK/MECHA D35 LG T/L (4HD(ALL

A42 6871R-8283A PWB(PCB) ASSEMBLY,TOTAL T/L VCR KEY2 JOG/SHUTTLE

A43 3721R-F826D PANEL ASSEMBLY,FRONT CCD TIME LAPSE PANEL FRONT ASS

A44 6871R-4462A PWB(PCB) ASSY,TOTAL TL-AR30 (SERIES) - W. RS232C A45 6871R-7050B PWB(PCB) ASSEMBLY,TOTAL T/L VCR TL-AT130M MAIN

A46 3501R-7050B BOARD ASSEMBLY VCR TL-AT130M MAIN

PARTS SECTION

250 3110R-S040F CASE LV-TL1960 2960 MOLD AIRHALL BA

260 3210R-0023A FRAME VCR - MAIN

277 4940R-Z075A KNOB SHUTTLE(TL-AR30M)

278 4940R-Z076B KNOB CCD TL-AT130 MOLD

280 3720R-F721D PANEL,VIDEO CCD LV-TL1960 S MOLD HIPS 40AF

281 524-013A MAGNET VCR - ASSY DOOR

283 3580R-V090A DOOR CCD TIME LAPSE MOLD DOOR CST

284 442-681A SPRING DOOR

285 4940R-Z086A KNOB CCD LV-TL124 MOLD

286 4940R-S017A KNOB SLIDE (LV-TL24)

300 6410RZHV01A POWER CORD IT10S2(6A/250V) VOLEX IMMETRO

320 3721R-D031N PANEL ASSEMBLY, LV-TL1960S 2960S NEW ASSY (RS-

DISTRIBUTOR[NOR

323 3111R-0089B CASE ASSY PRE-AMP (PBSB-SH)

325 4931R-0024D HOLDER ASSEMBLY DIGI(MONO-ENABLE)

330 3550R-0210A COVER BOTTOM(LARGE)

SCREW

452 353-051A SCREW,DRAWING SPECIAL

457 353-051E SCREW,DRAWING SPECIAL (3X12)

462 353-136A SCREW,DRAWING SPECIAL(FBK) (353S353A)

RUN DATE : 2004.03.12

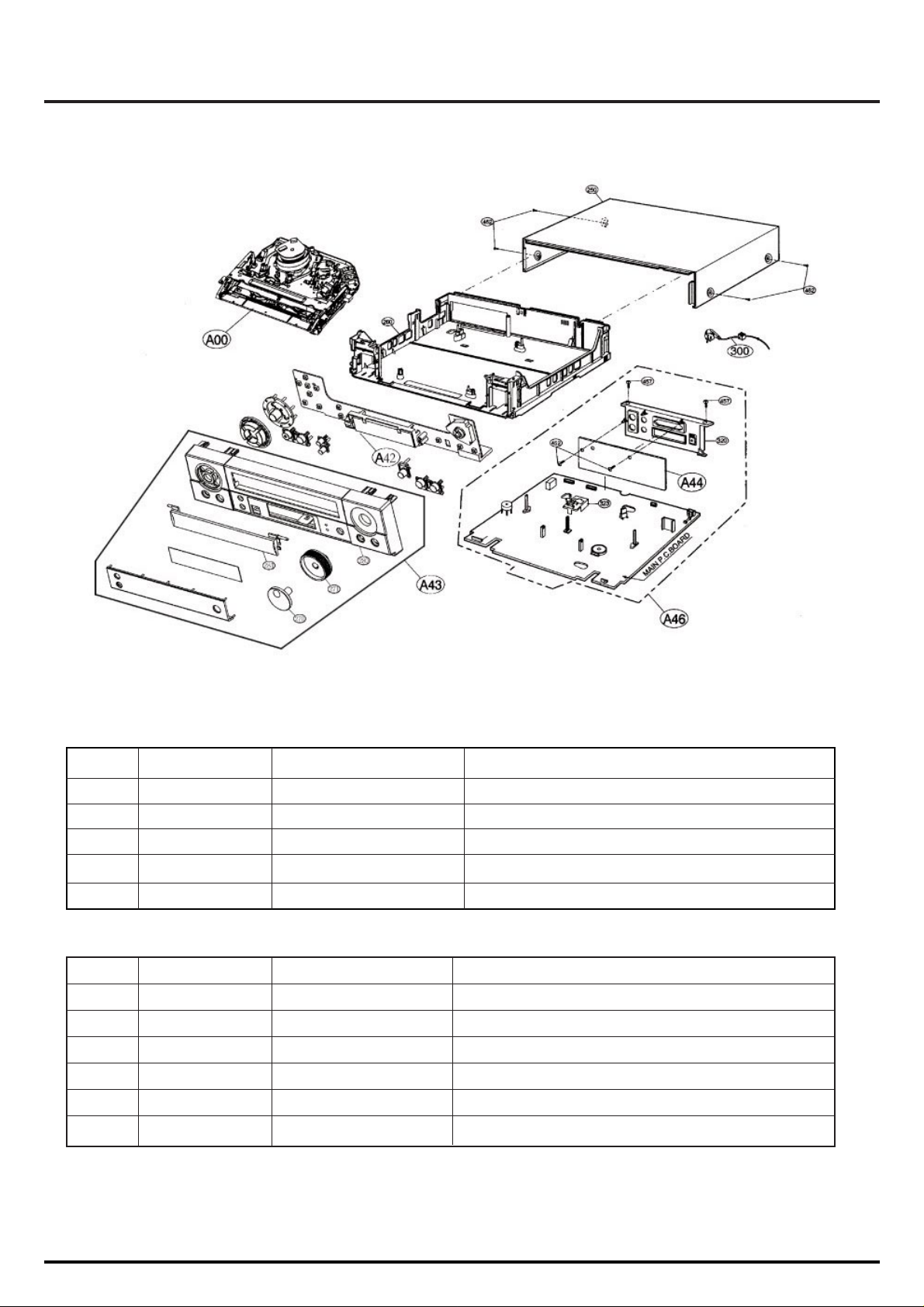

Page 9

1-1. Cabinet and Main Frame Section

2-2

Cabinet & Main Frame Section Parts list

ASSEMBLY PARTS SECTION

A42 6871RK5700K Ass'y Front PCB SNILN4T3526

A43 05503805 ASS'Y FRONT CAVINET NTH960 C-TYPE

A44 6871R-4462A Ass'y Ant. PCB TL-AR30(SERIES)

A46 3501RK3200B Ass'y Main PCB CCD LV-TL1960

SECTION2 CABINET & MAIN FRAME

EXPLODED VIEWS

Page 10

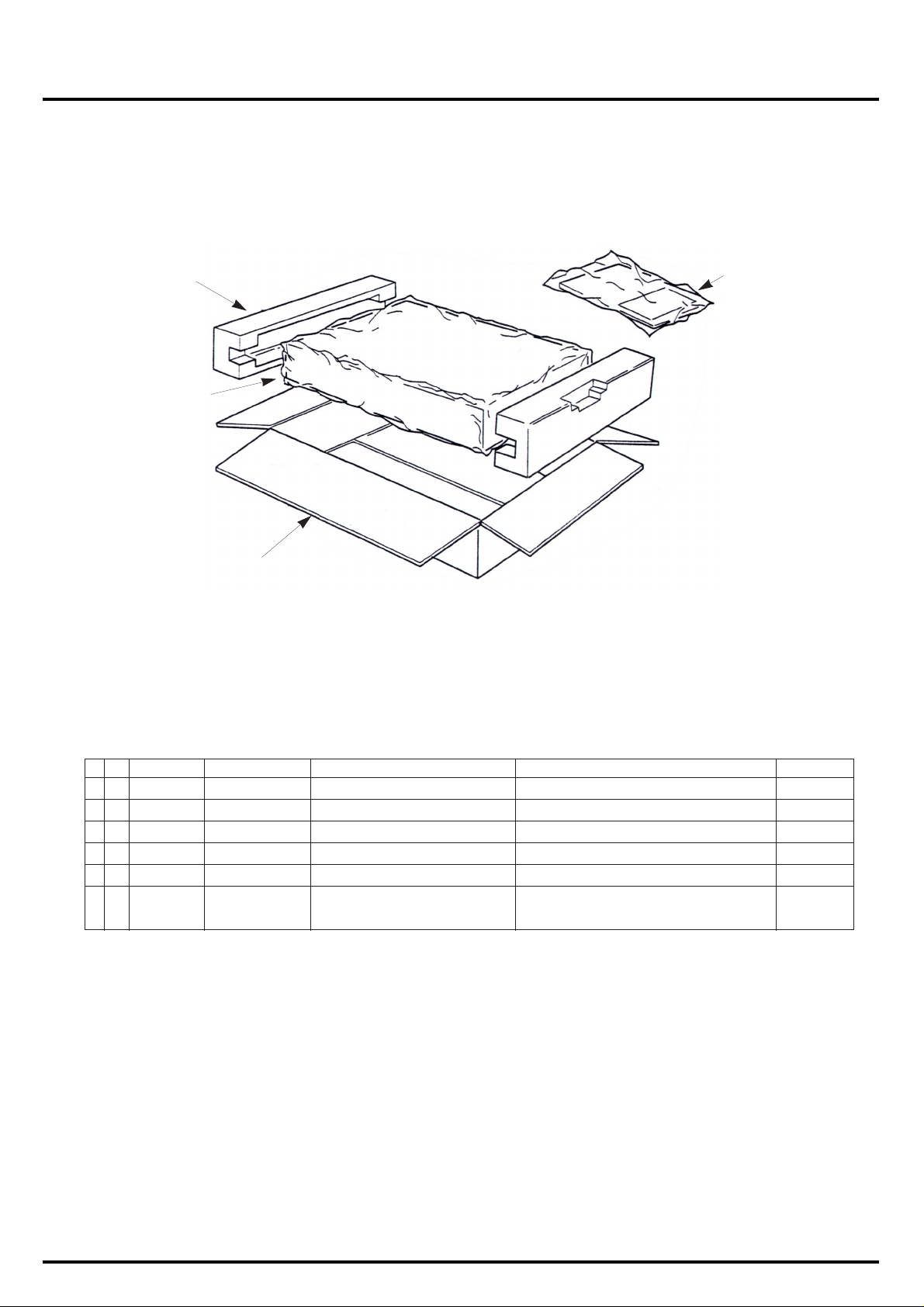

2-3

2. Packing & Accessory Section

✒

NOTE

NOTE

Refer to “REPLACEMENT PARTSLIST” in order to look

for the part number of each part.

801 INSTRUCTION ASS’Y

803 : PACKING

804: SHEET ROLL

802: BOX CARTON

SECTION2 CABINET & MAIN FRAME

EXPLODED VIEWS

S AL LOCA.NO. PART NO DESCRIPTION SPECIFICATION REMARKS

801 3835RS0069N INSTRUCTION ASSEMBLY CCD TL-AT330M-AABBDL1_ENG_POR_

802 3890R-C065K BOX,MASTER TL-AT330M AABBDL . 1

803 3920R-E016A PACKING Packing LV-TL24I 0.02 0 EPS 10

804 3858R-S001A SHEET (MECH) Packing LDPE 600M 630MM 0.5 VC

808 534-008C BATTERY,MANGANESE AAAM(R03) SEOTONG 1-5 V - 1PA

900 6711R1P041H REMOTE CONTROLLER P9 LV-TL1960

ASSEMBLY

MODEL : TL-AT130M

• Packing Accessory Section Parts list

RUN DATE : 2004.03.12

Page 11

3-1

SECTION3 ELECTRICAL

ELECTRICAL ADJUSTMENT PROCEDURES

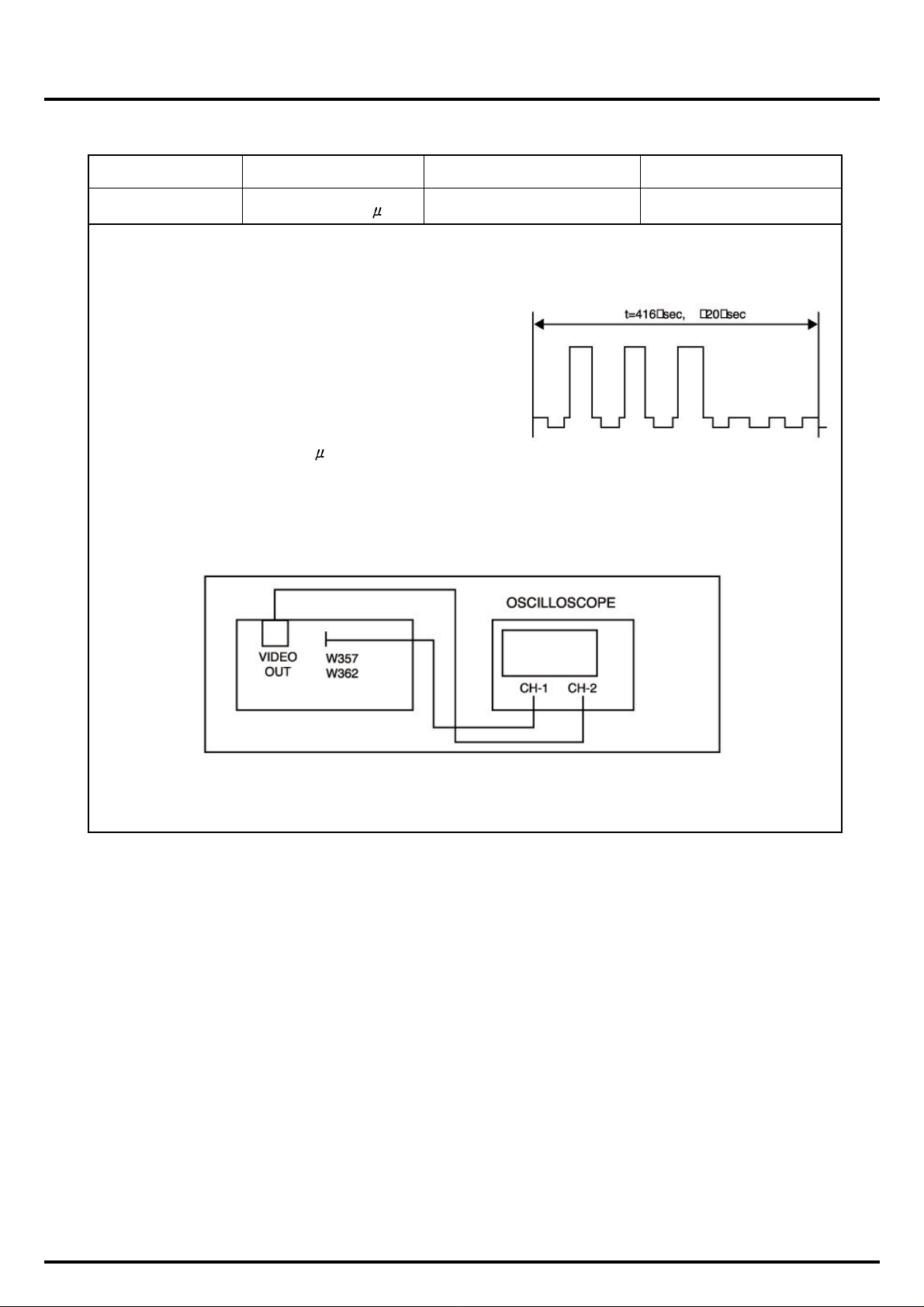

1. PG ADJUSTMENT

MODE SPECIFICATION OBJECT MEASURED OBJECT ADJUSTED

PLAYBACK IN SP PG : 416 ± 20

sec

V.OUT JACK VR501

1. Connect CH-1 of the oscilloscope to W357 and W362,

and adjust it to 1Vp-p as TRIGGER.

(In case of 10:1 Probe, adjust it 50m Vp-p)

2. Connect CH-2 of the oscilloscope to V.OUT JACK and

adjust it to 0.5Vp-p.

(In case of 10:1 Probe, adjust it 50 Vp-p)

3. Adjust time of the oscilloscope to 0.1 msec.

4. Adjust the range between FLLING EDGE part of video

vertical trigger signal and video vertical trigger signal

to the specification(416±20

sec

) with changing VR501.

WAVEFORM

• CONNECTION CHART OF MAIN PWB

Fig 3-1. Connection chart of PG adjustment

✒

Caution

Caution

When repairing the power part just after pulling out the power code, there is hazard of electical shock caused by the

charged electricity at the peripheral circuit component(primary power) such as condenser C807(150µF). So begin

repairing after doing procedure below.

1. Set the volt meter up to resistance measurement.(In case of digital volt meter, set it up to over 20MΩ.)

2. Discharge electicity with putting the measuring terminal lines(+, 1 probe) of volt meter at the ends of condenser

C103.(You don’t have to put the polarity of the measuring terminal lines on the same polarity of the condenser.)

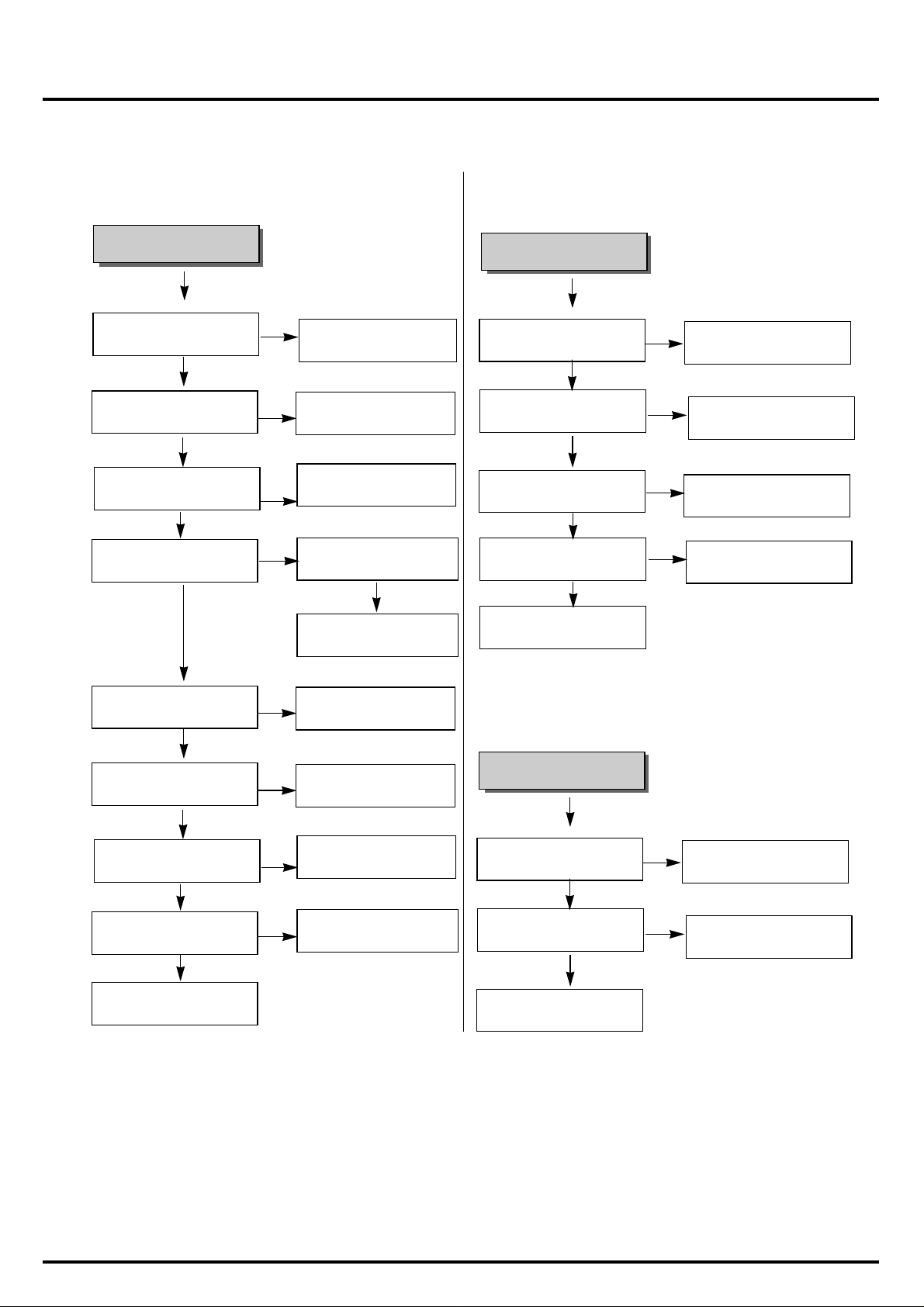

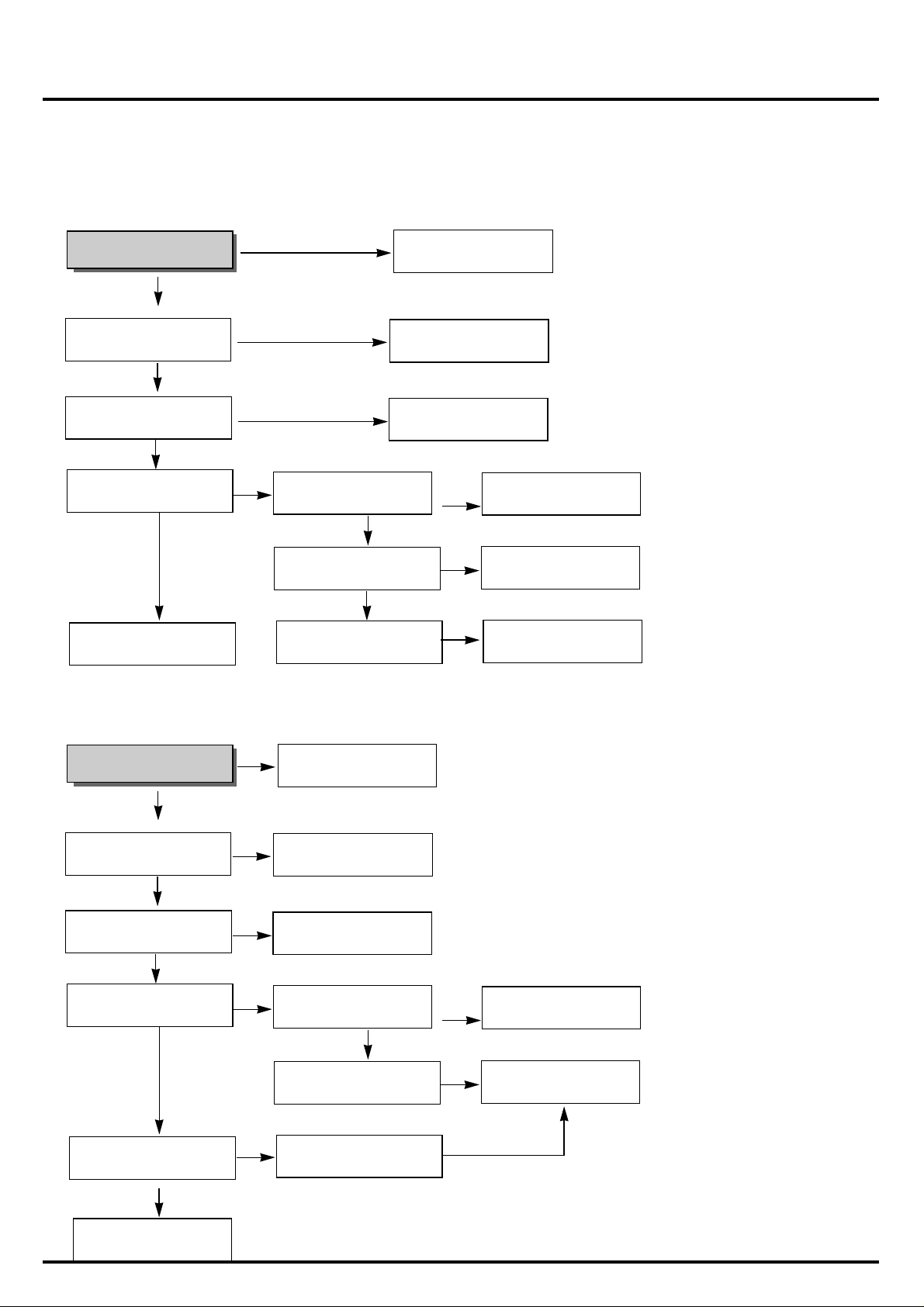

Page 12

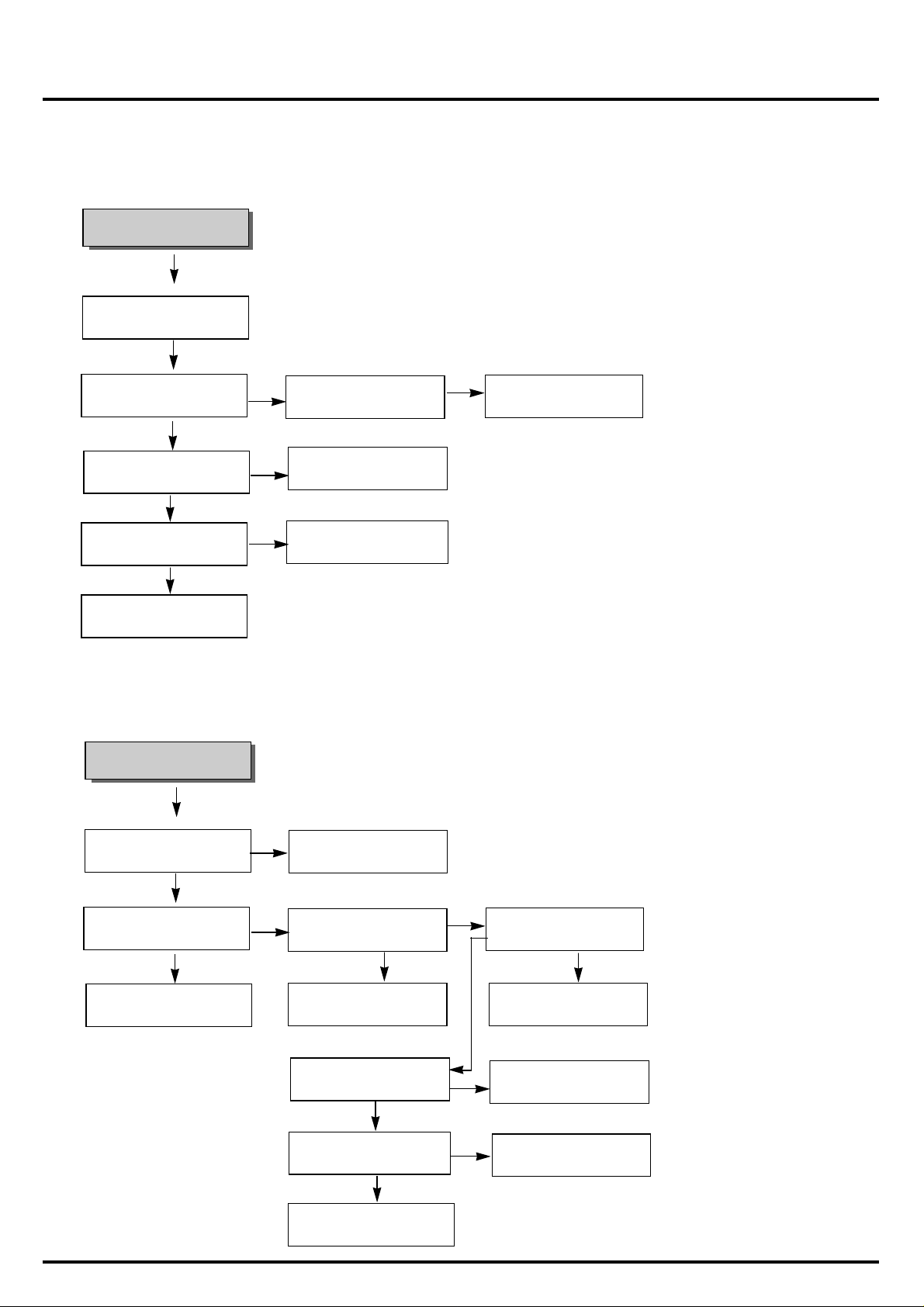

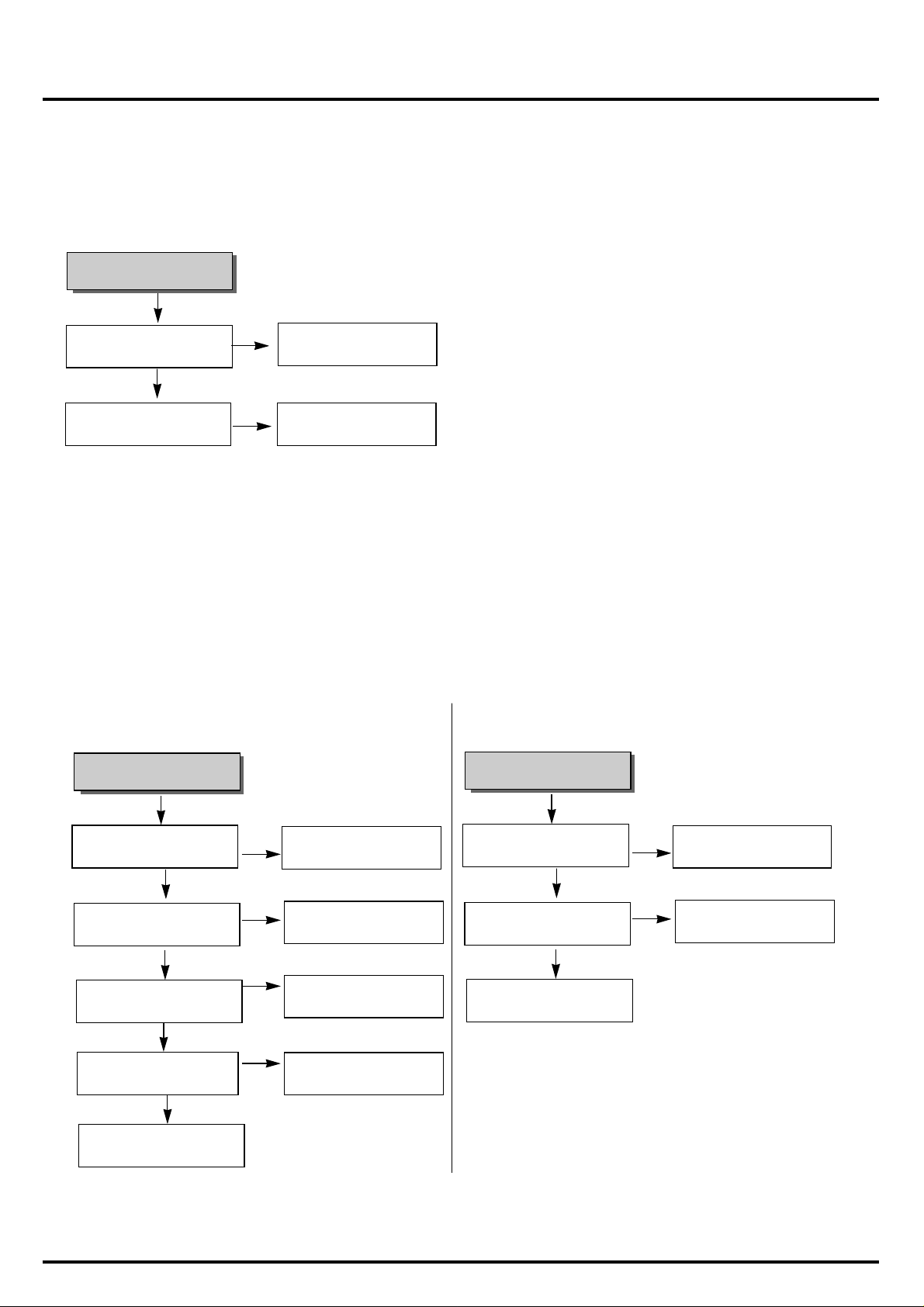

3-2

SECTION3 ELECTRICAL

ELECTRICAL TROUBLESHOOTING GUIDE

1. Power Circuit(SMPS)

(1) No 5.3 A

(2) No 9V

Is R101 normal?

YES

NO

NO

NO

NO

YES

YES

Is there Vcc (about 13~19V) at

IC101 pin 5?

Is Q170 normal?

Is D110 normal?

Is Q152 normal?

Replace F101(Use a specified

fuse).

NO

Replace BD101.

Replace R101.

Is D103 normal?

Check/

Replace D103

No 5.3V

Is F101 normal?

Check/Replace D109

No 12V

Is D109 normal?

YES

Is BD101 normal?

Replace D110

NO

YES

YES

NO

Replace Q170

NO

Replace Q152

NO

Check/ Replace Q163

YES

YES

YES

Is Q159 normal?

Check ‘H’ signal at Q161

Base terminal

Check/Replace D110

No 24V

Is D110 normal?

NO

Check/Replace Q152

NO

(3) No 24 V

Is D109 normal?

YES

NO

NO

Is L103 normal?

NO

Replace IC103.

Replace D109.

Is L103 normal?

YES

Is there about 2.5V at

IC103 pin 1?

YES

NO

Replace D106.

YES

Is D106 normal?

YES

Check the power terminal at main

PCB short.

Page 13

3-3

(4) No 5.2 A (TO AVCP, BIAS) (5) No 10V

Is there voltage (about 0V)

at Q157 collector.

NO

NO

YES

YES

Is Q170 normal?, Is there about

13.5V at Q107 Base?

Check/ Replace

D155, D156, D157/\.

Replace D106.

NO

Replace Q153.

Replace Q157.

No 5.2V

Is D106 normal?

Replace D109

No 10V

Is D109 normal?

YES

Is Q153 normal?

YES

Check/

Replace Q156

YES

NO

Check/ Replace

Q107, ZD103

NO

SECTION3 ELECTRICAL

ELECTRICAL TROUBLESHOOTING GUIDE

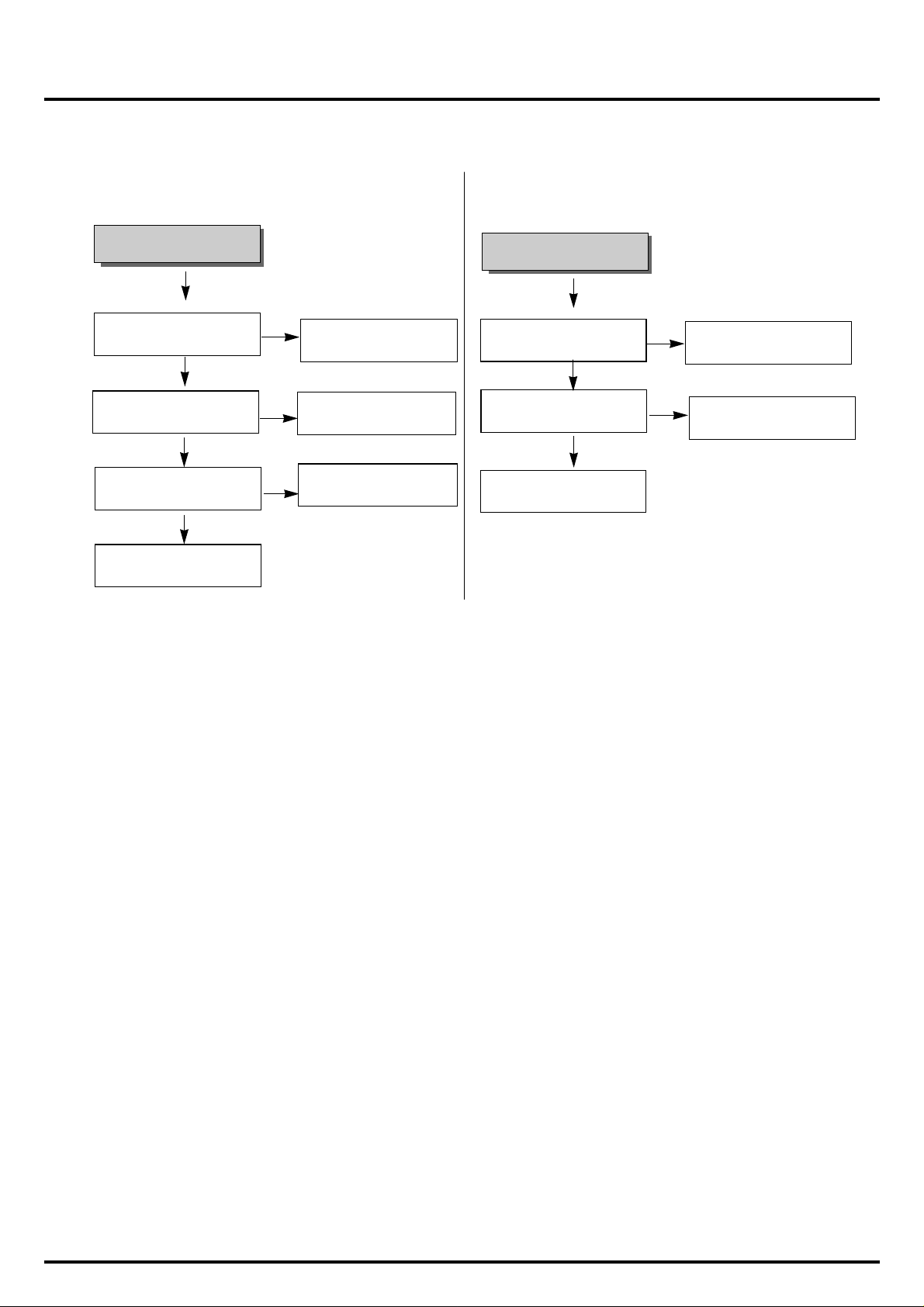

Page 14

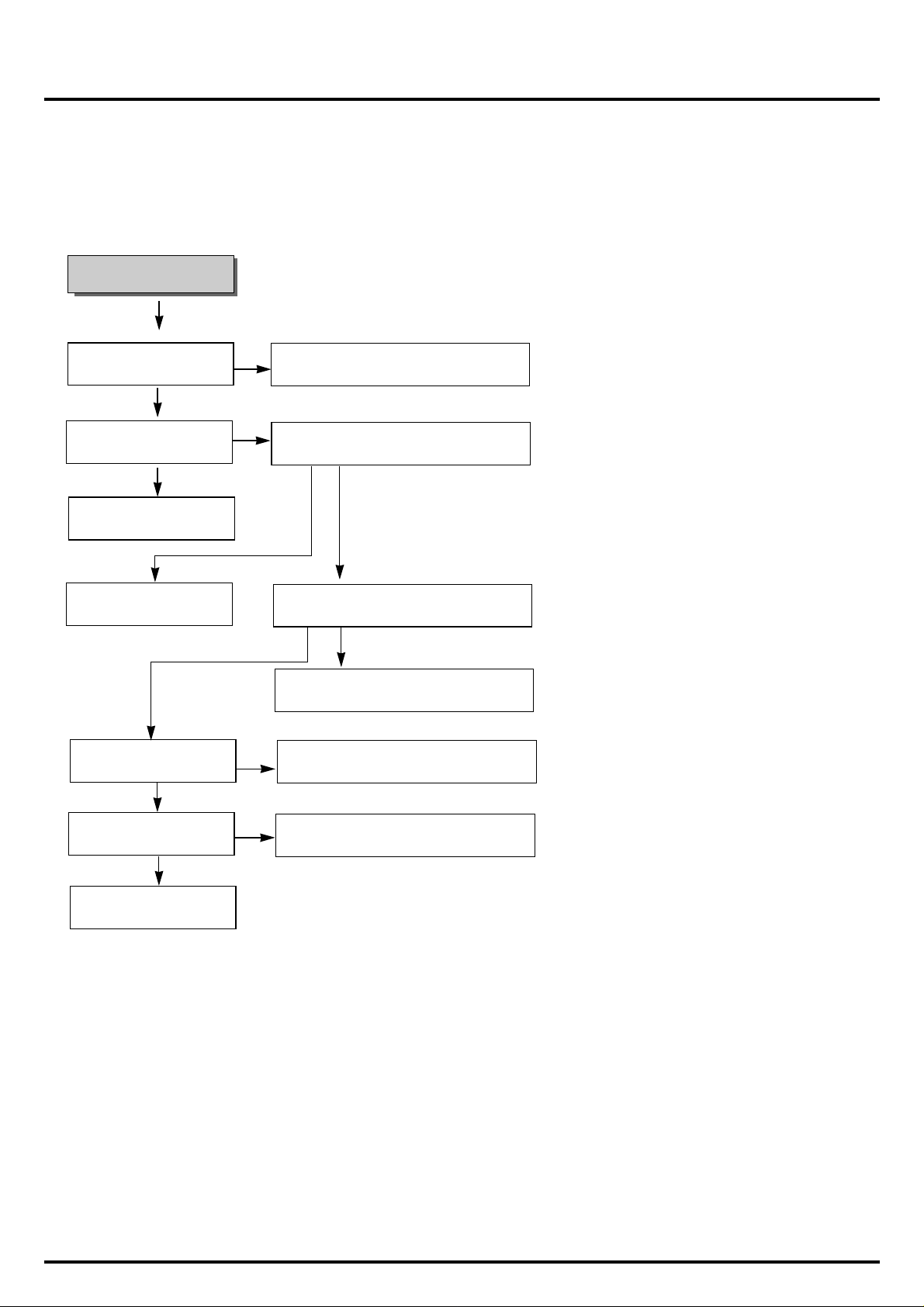

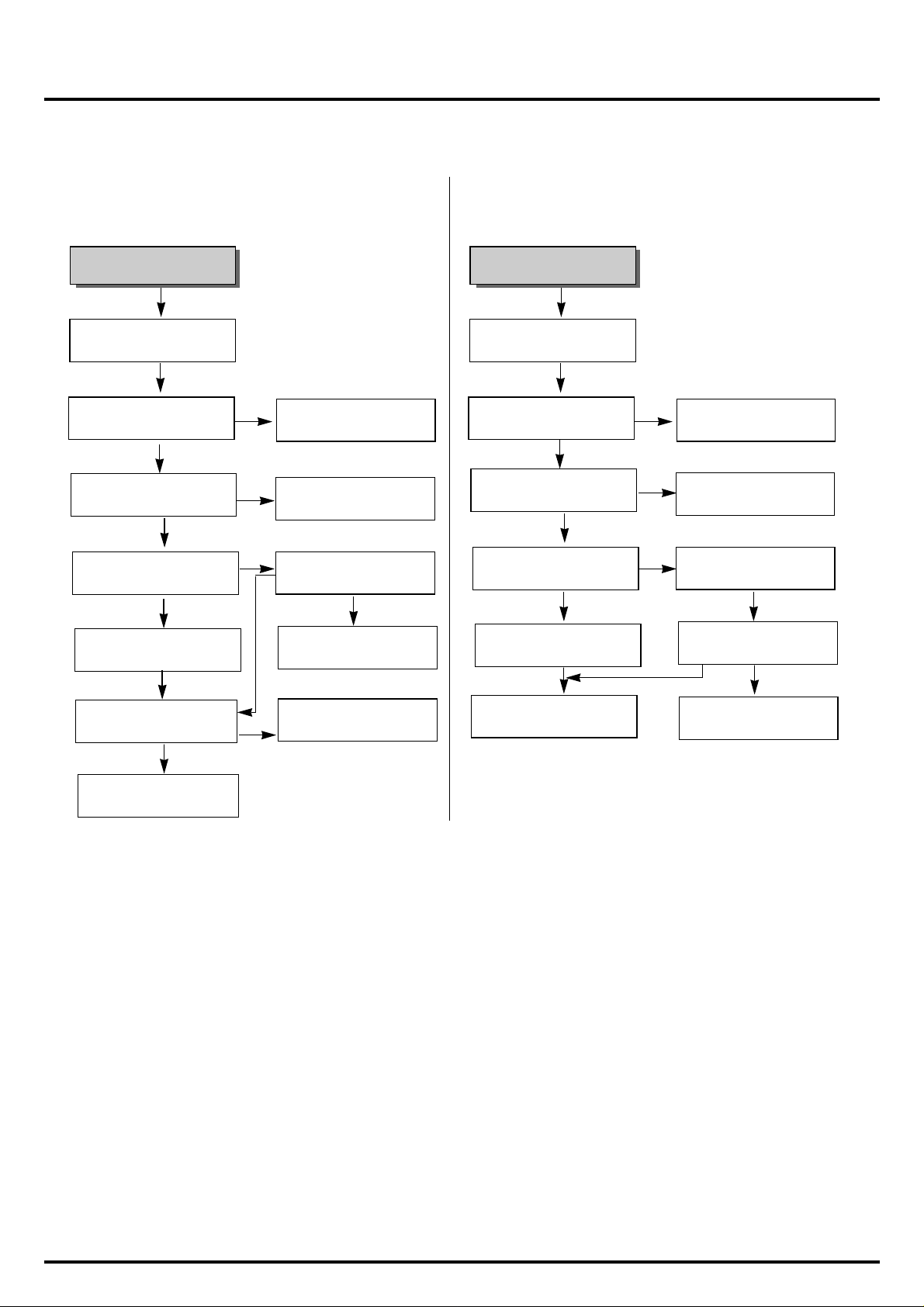

3-4

SECTION3 ELECTRICAL

ELECTRICAL TROUBLESHOOTING GUIDE

2. SERVO CIRCUIT

(1) Video is unstable in PB mode

Does CTL pulse move on tracking?

YES

NO

NO

Does Video Envelope wave form

appear at IC501 pin 86?

YES

Replace IC501.

NO

Is adjusting height of CTL

head accurate?

Replace IC501.

Check the Pre-Amp circuit

In PB mode

Does noise level on the screen

change periodically?

YES

Does CTL pulse appear at

IC501 Pin 76?

YES

NO

Readjust the height

of CTL fead.

(2) Drum motor stops

Check the Ass’s between

connector(PMC01) and Drum motor

YES

NO

NO

Aren’t pattern or componets between

IC501 Pin34 and PMC01 Pin12 short?

NO

Does Drum PWM pulse

appear at IC501 Pin34?

Does DFG pulse appear at

IC501 Pin65?

Does Drum PWM pulse appear

at IC501 Pin34?

When the drum moter stop

Is there 12V at PMC01 Pin8?

YES

Is there 2.8V at PMC01 Pin12?

YES

NO

Does DFG pulse appear at

PMC01 Pin3?

Check Power circuit

YES

YES

Aren’t pattern or componets between

IC501 Pin34 and PMC01 Pin12 short?

YES

Replace IC501

Check the Ass’y between

junction PCB and Drum motor

Aren’t pattern or componets between

IC501 Pin34 and PMC12 Pin1 short?

NO

NO

Page 15

(3) Capstan motor stops

3-5

SECTION3 ELECTRICAL

ELECTRICAL TROUBLESHOOTING GUIDE

Check the Ass’y between PMC01

and Capstan motor

YES

NO

Aren’t pattern or componets between

IC501 Pin33 and PMC01 Pin9 short?

NO

Check Power circuit

Does CFG signal appear at PMC01 Pin1?

Check the Ass’y of Capstan motor

When the capstan motor stops

Is it 12VA at PMC01 Pin2?

YES

Is there 2.8V at PMC01 Pin9?

YES

NO

Does PWM signal appear at IC501 Pin 33?

NO

NO

Aren’t pattern or componets between IC501 Pin67 and

PMC01 Pin1 short?

Replace IC501

YES

NO

YES

Check CFG signal appear at IC501

Pin67?

Does Capstan PWM signal appear

at IC501 Pin33?

YES

Aren’t pattern or componets between

IC501 Pin33 and PMC01 Pin1 short?

YES

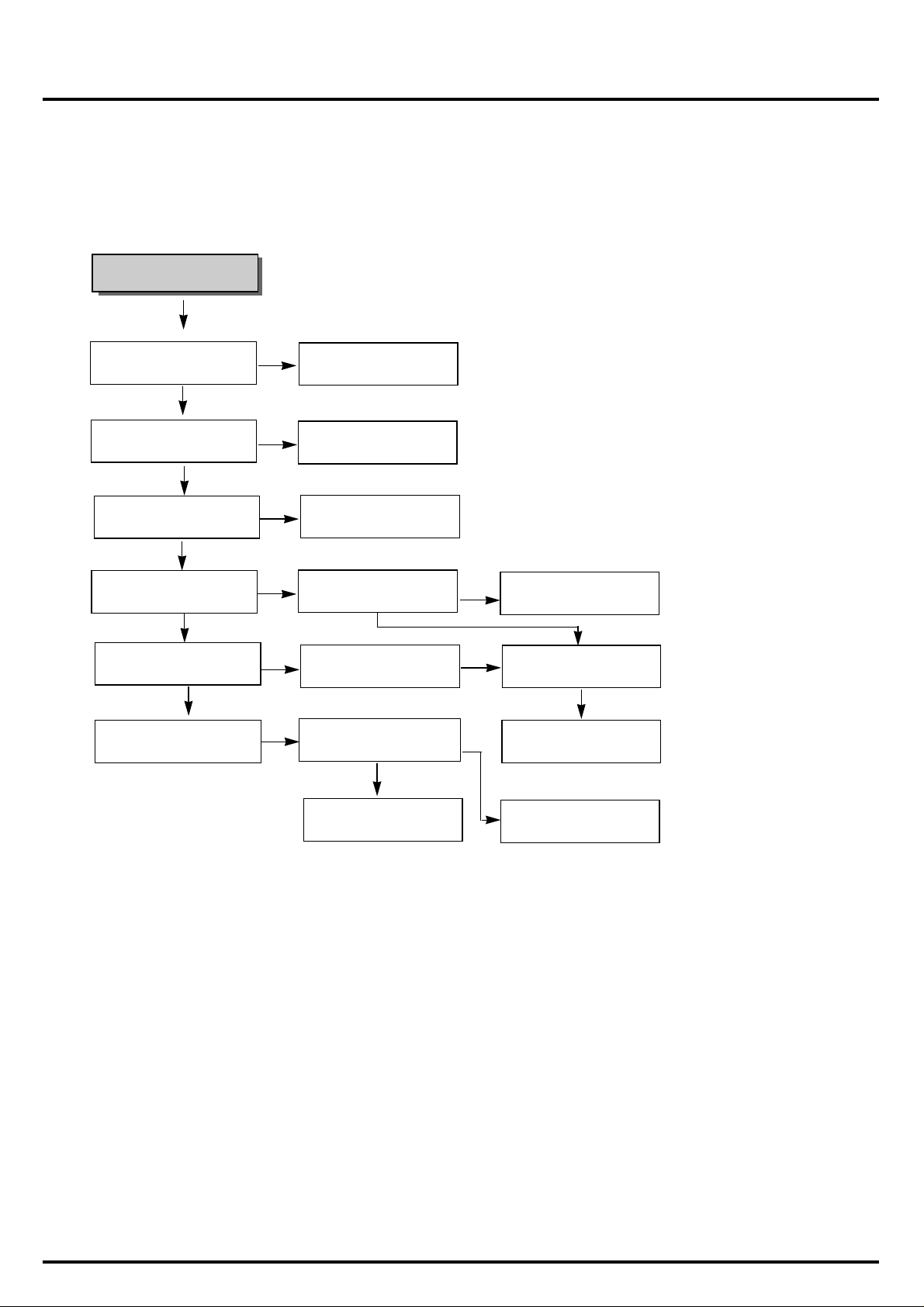

Page 16

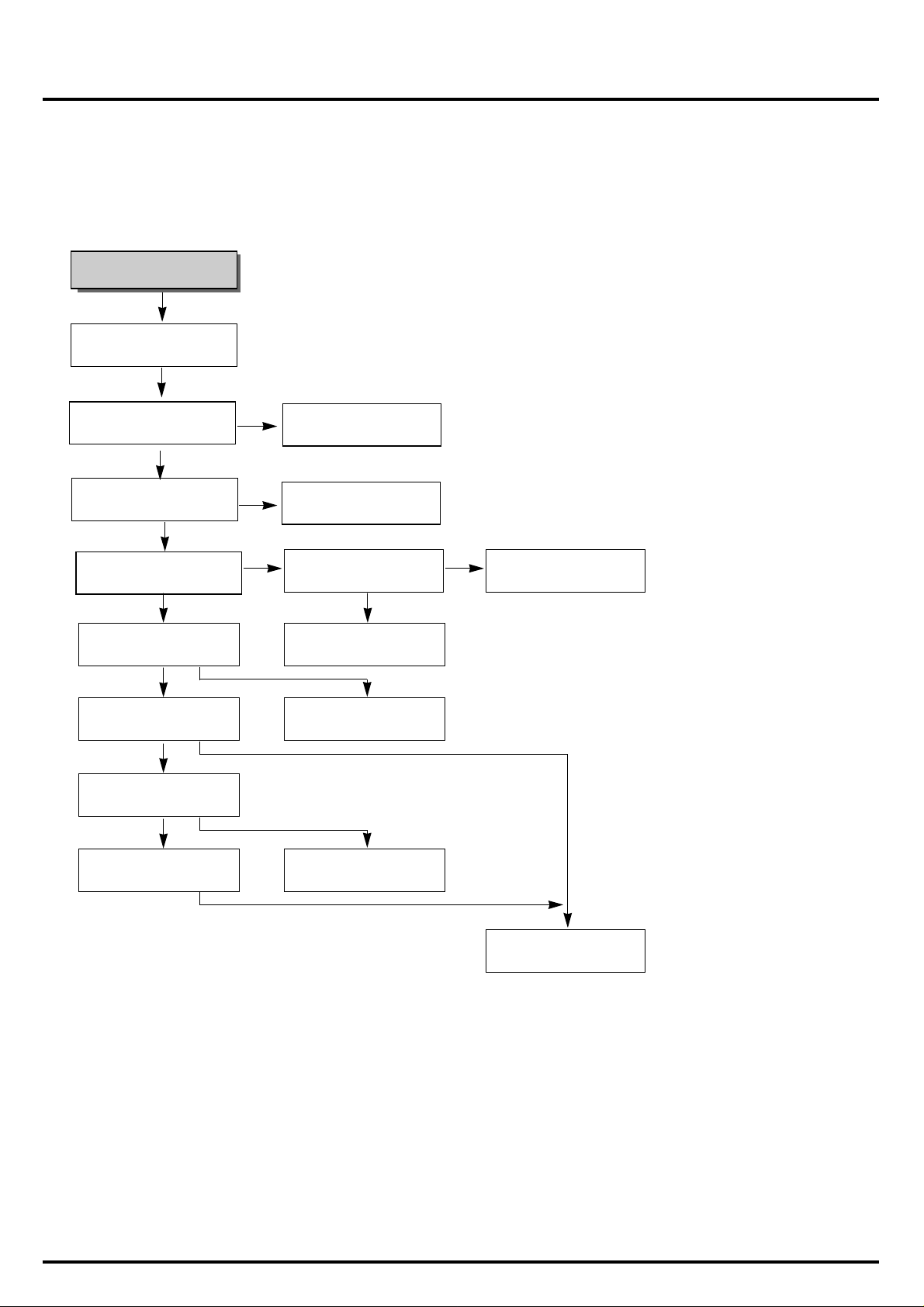

3-6

SECTION3 ELECTRICAL

ELECTRICAL TROUBLESHOOTING GUIDE

3. Y/C CIRCUIT

(1) No Video in EE Mode

Does the Video signal appear

at the IC301 Pin29?

NO

NO

NO

Check the IC3G1 Pin14

and Q3G1 emitter.

Check the path of the signal between

the IC301 Pin29 and IC501 Pin49.

Is there 9V on the plus

terminal of the C381?

No Video in EE Mode

Does the Video signal appear at the

IC3G1 Pin9?

YES

Does the Video signal appear

at the IC301 Pin38?

YES

Check the Video input Jack &

jack Board connection.

YES

Is I2C BUS signal applied to the

IC301 Pin 23, 24?

Check C316.(AGC)

Replace the Q380.

Check the System Circuit. (Refer to

‘SYSTEM I2C BUS Trouble Shooting’)

NO

Does the Video signal appear

at the IC501 Pin 47?

YES

Does the Video signal appear at

the Emitter terminal of the Q380?

YES

NO

NO

NO

YES

Replace the IC301.

YES

Check the 9V Line.

(Power Circuit)

NO

Is 5V applied to the

IC301 Pin16, 40, 55, 58, 75, 87?

YES

Check the 5VA Line.

(Power Circuit)

NO

Page 17

(2) When the Y(Luminance)signal doesn’t appear on the screen in PB Mode.

3-7

Clean the Drum.

NO

NO

Is the V.H.S/W "H" about

3.4V to the IC301 Pin11 ?

Check the path of the Y(Luminance)

RF signal.(Check the Q301)

Check the path of the Y(Luminance)

RF signal.(Check Q302, Q303)

Is 5V applied to the IC301

Pin 16, 40, 55, 58, 87?

Is the I2C Bus signal applied

to the IC301 Pin 23, 24?

YES

Does the normal RF signal

appear at the IC301 Pin74?

YES

Check the System Circuit. (Refer to

‘SYSTEM I

2

C BUS Trouble Shooting’)

YES

YES

Replace the IC301.

Replace the IC301.

Does the Y(Luminance) RF signal

appear at the IC301 Pin 17?

YES

Is the Y(Luminance) Video waveform

showed up at the IC301 Pin 41?

YES

YES

Check the System Circuit.

(IC501 Pin 23)

NO

NO

NO

NO

Is V.H.S/W "H" about 3.4V at the

IC301 Pin 11?

YES

Check the V.H.S/W level.

(Check R304, R305)

NO

NO

Check the line of the 5.3VA

Line. (Power Circuit)

SECTION3 ELECTRICAL

ELECTRICAL TROUBLESHOOTING GUIDE

Page 18

3-8

SECTION3 ELECTRICAL

ELECTRICAL TROUBLESHOOTING GUIDE

(3) When the C(Color) signal doesn't appear on the screen in PB Mode

Check the circuit of the

IC301 Pin 35, 62.

NO

NO

Check the Color Rotary level.

(Check the R302, R303)

Is 5V applied to the IC301

Pin 16, 40, 55, 58, 87?

Is the Color Rotary signal applied to

the IC301 Pin 10?

YES

Is Color Rotary "H" about

1.6V?

YES

Check the Color Rotary

Circuit. (IC501 pin 98)

Replace the IC301.

Does the Color signal appear at

the IC301 Pin 71?

Replace the IC301.

YES

YES

NO

Does the Color signal appear

at the IC301 Pin 61?

Check the Color Pass.

(Check the Q304)

NO

NO

Check the line of the 5.3VA

Line. (Power Circuit)

Replace the X301 or the X302.

NO

NO

Does the X301(4.43MHz) or

X302(3.58MHz) oscillate?

YES

(4) When the Video signal doesn't appear on the screen in REC Mode.

Check the circuit of the

IC301 Pin 90, 92, 94

NO

NO

Check PB Mode.

Is the EE signal normal?

Is 5V applied to the IC301

Pin 16, 40, 55, 58, 87?

YES

Does PB Mode operate

normally?

YES

Check the line of the 5.3VA

Line.(Power Circuit)

Check the Drum &

Drum Connector

Does the RF signal appear at

the IC301 Pin 12?

Does the REC RF signal appear at

the IC301 Pin90?

YES

YES

NO

Check REC Luminance

Pass & Color Pass.

Replace the IC301.

YES

NO

Check EE Mode.

Check the System of REC 'H'

(the IC501 Pin 30 / the D301)

NO

NO

Is the REC 'H' signal (about

4V)applied to the IC301 Pin 30?

YES

YES

Page 19

3-9

SECTION3 ELECTRICAL

ELECTRICAL TROUBLESHOOTING GUIDE

4. AUDIO CIRCUIT

(1) No sound in EE Mode

Is the Audio signal applied to the

IC301 Pin 76?

NO

NO

Check the path of

LINE/AUDIO.

Check the IC501 Pin 2.

(Audio Mute "H".)

Check the IC501 Pin18(CLK),

17(Data) Line.

Does the CLK/Data signal(I2C)

appear at the IC301 Pin 23, 24?

No sound in EE Mode.

No sound.

YES

Is 5V applied to the IC301

Pin 75?

YES

Check the line of the 5V Line.

(Power Circuit)

YES

YES

Is the Audio Mute "High" signal applied

to the IC301 Pin 10?

Check the connection of the Audio

out Jack.

NO

NO

NO

YES

Does the Audio signal appear

at the IC301 Pin 96?

YES

Replace the IC301

YES

YES

(2) No sound in PB MODE

Does the CLK/Data signal(I2C)

appear at the IC301 Pin 23, 24?

NO

NO

Check the IC501 Pin 18(CLK),

17(Data) Line.

Is the Audio Mute "H" applied to

the IC301 Pin 10?

No sound in PB Mode.

No sound.

YES

Is 5V applied to the

IC301 Pin 75?

YES

Check the line of the 5V Line.

(Power Circuit)

YES

NO

Check the connecting State between

the P3D02 Pin 6 and A/C Head.

Does the Audio signal appear

at the IC301 Pin 96?

NO

YES

Does the Audio signal appear

at the IC301 Pin 1?

YES

YES

NO

Replace the IC301

Check the IC501 Pin2.

YES

Page 20

3-10

SECTION3 ELECTRICAL

ELECTRICAL TROUBLESHOOTING GUIDE

(3) No sound in REC Mode.

Is the Audio signal applied

to the IC301 Pin 76?

NO

NO

Check the path of Line Audio.

Is the “High” signal applied to the

IC301 Pin 10?

Is 5V applied to the FL401

Pin 2?

NO sound in REC Mode.

Sound is not recorded.

YES

Is Playback O.K.?

YES

Refer to "No sound in PB

Mode,".

YES YES

Does the Audio waveform appear

at the IC301 Pin 7?

NO

NO

Check the CLK/Date line and

replace the IC301

Check the Audio R/P/E

connector and Head.

NO

YES

Check the IC501 Pin 96

(Audio Mute “H”).

Is 3.0~4.5V applied to the Emitter

of the Q481?

YES

NO

NO

NO

Check the line of the 5V

Power Circuit.

Does the Erase signal

appear at the FL401 Pin 6?

YES

Is the Voltage level of the IC301

Pin6 850mVp-p?

YES

Replace the FL401 or the

Q405.

YES

Page 21

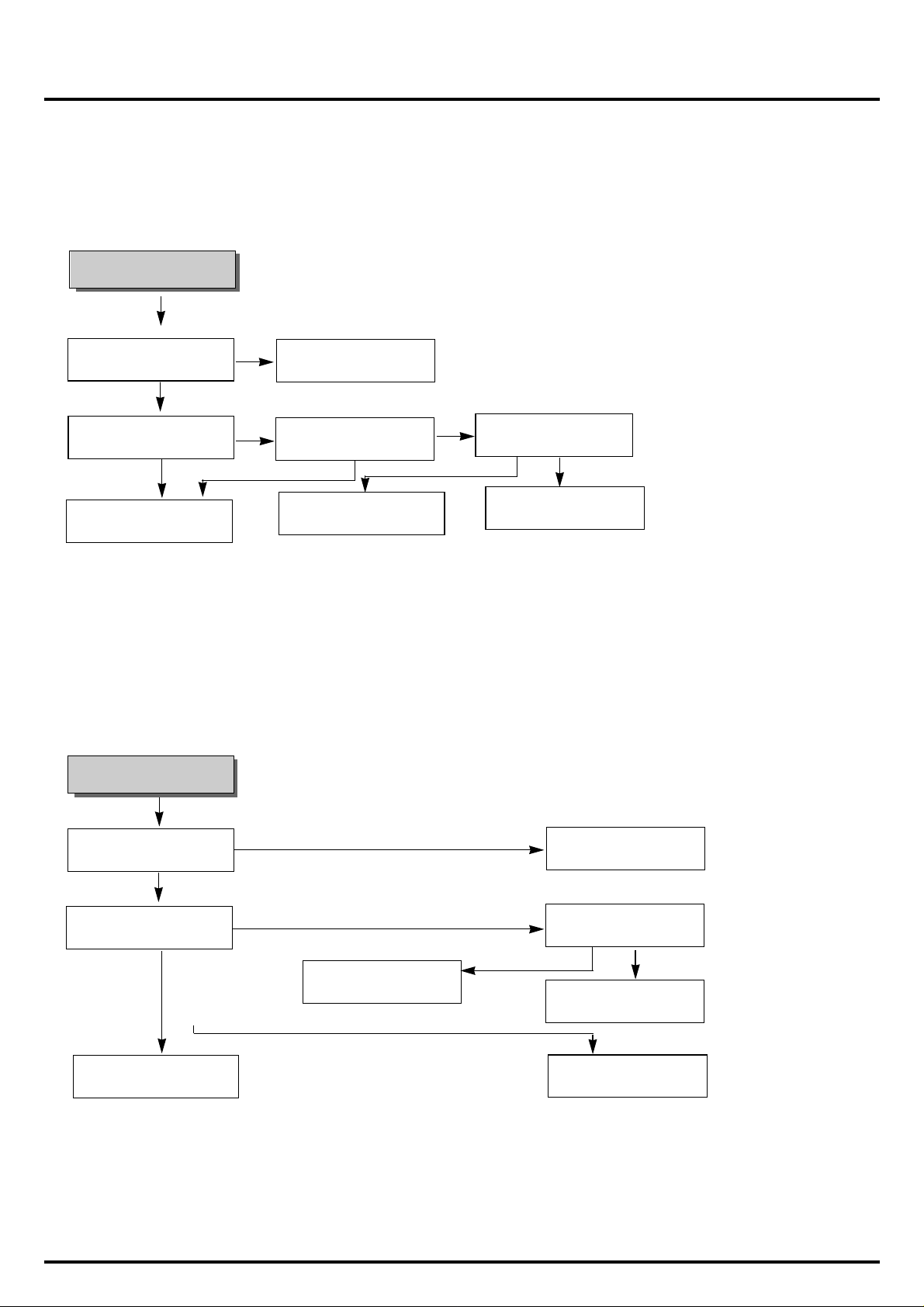

3-11

SECTION3 ELECTRICAL

ELECTRICAL TROUBLESHOOTING GUIDE

5. SYSTEM/KEY CIRCUIT

(1) AUTO STOP

NO

NO

Does T/up reel pulse appear

at Q514 Base terminal?

Auto Stop

Does SW waveform appear at IC501

pin23?

YES

YES

Does T/up reel pulse appear

at IC501 Pin27?

Check Drum motor signal

YES

Is there 5.3V at RS501?

NO

Replace T/up reel sensor of deck

Check power circuit

YES

Check DP06, LP03

Replace IC501

NO

YES

(2) No cassette tape loading

NO

NO

Is there 5.3V at IC501 Pin73?

Check IC501 Pin7, 8, 9, 10

No cassette tape loading

Is there REG. 12V at PMCQ1

Pin8?

YES

Does 'H' signal appear at IC501

Pin62 while inserting CST?

Check power circuit L104.

Check power circuit

Check D106, L103.

Check Deck mechanism

NO

NO

YES

YES

Check CST SW and peripheral circuit

YES

*Caution : Auto stop can occur because Grease or Oil is dried up

Page 22

3-12

SECTION3 ELECTRICAL

ELECTRICAL TROUBLESHOOTING GUIDE

(2) No F.OSD display.

(3) No Key display

Is there 5.3V IC501 Pin 51?

NO

NO

Replace bad switches

Replace X502.

No Key display

Is there 5.2VA at IC501

Pin79, 80, 81?

YES

As pressing the byttons doeseach

function work properly?

YES

Check power circuit

Check 5.3V Line of power

circuity.

Does oscillation appear at the

IC501 Pins 40, 41?

NO

NO

NO

YES

Does oscillation appear at the

IC501 PIns 37, 38?

YES

Check peripheral circuit and

replace X501

YES

No OSD display.

6. OSD CIRCUIT

(1) No OSD display.

Does Video signal appear at the

IC501 Pin 47?

YES

NO

Check the signal between

IC501 Pin47 and V.out Jack.

Replace IC501.

YES

Refer to “(5) No OSD picture”

Check the signal between IC301

Pin 29 and IC501 Pin 49.

YES

Check power Vcc 9V

Replace IC501

NO

NO

YES

Does video signal appear at

IC501 Pin 50?

YES

No F.OSD display.

Page 23

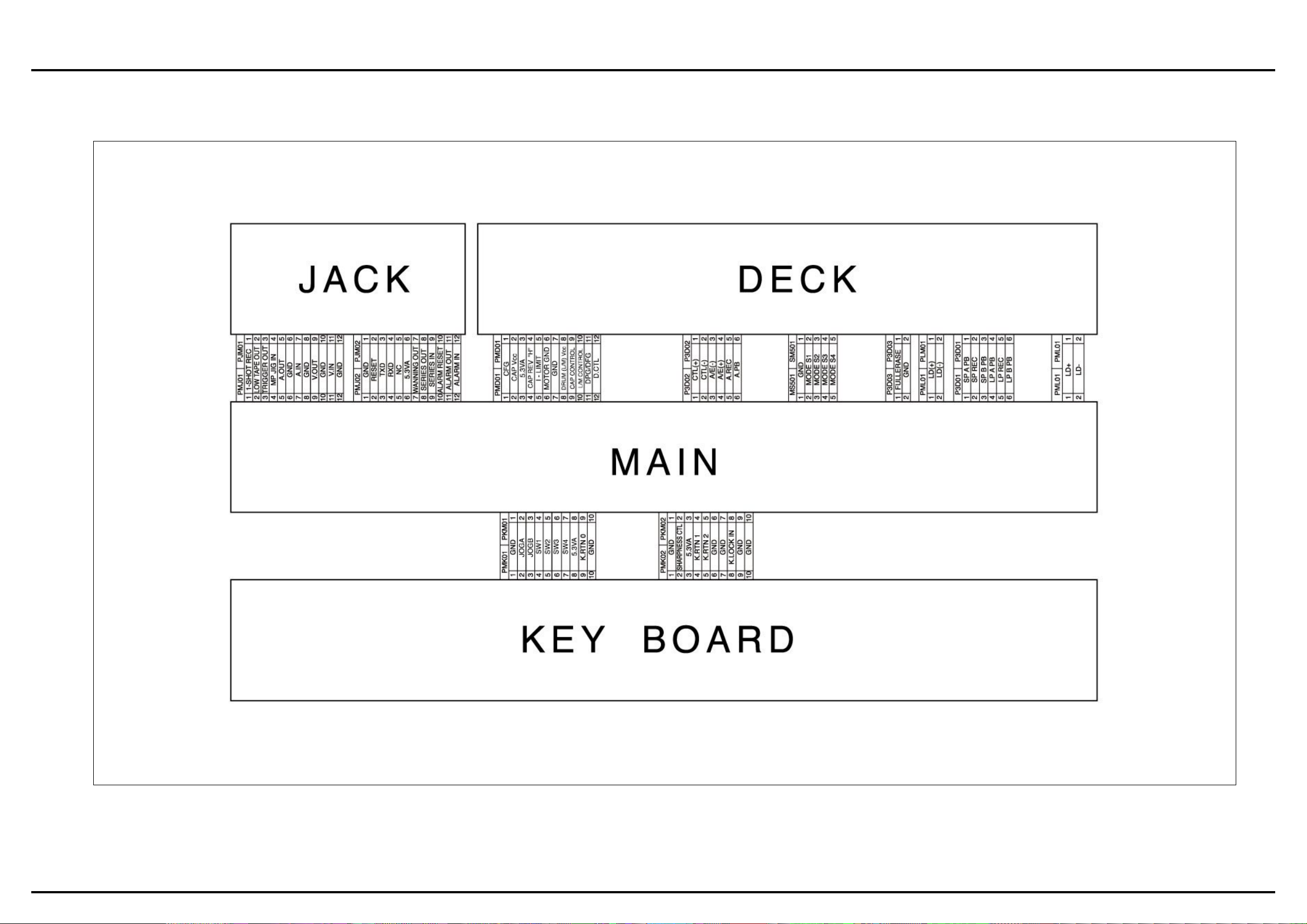

3-143-13

SECTION3 ELECTRICAL

BLOCK & CIRCUIT DIAGRAMS

1. OVERALL WIRING DIAGRAM

Page 24

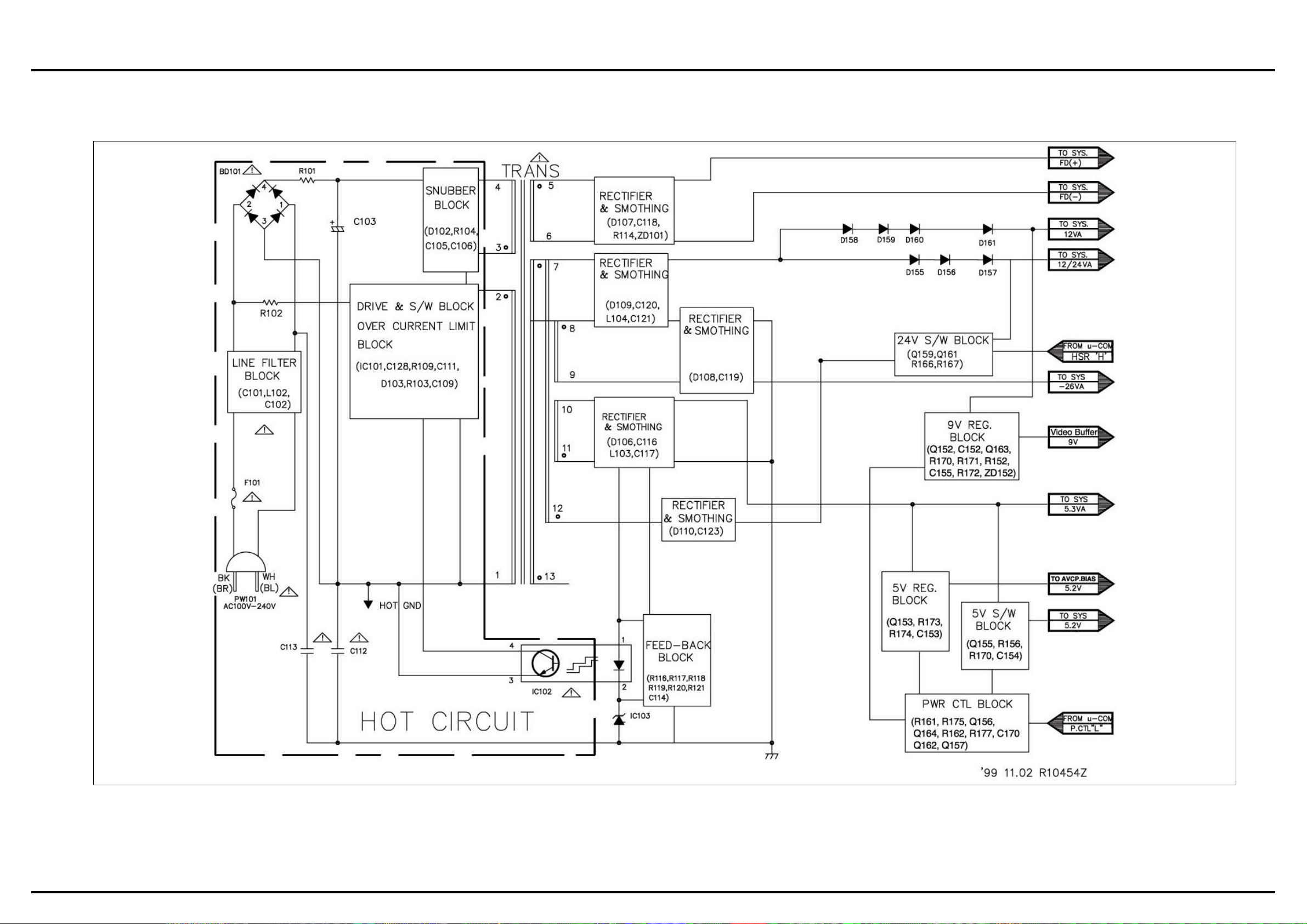

3-163-15

SECTION3 ELECTRICAL

BLOCK & CIRCUIT DIAGRAMS

2. POWER

BLOCK DIAGRAM

Page 25

3-183-17

SECTION3 ELECTRICAL

BLOCK & CIRCUIT DIAGRAMS

3. POWER

CLRCUIT DIAGRAM

Page 26

3-19

SECTION3 ELECTRICAL

BLOCK & CIRCUIT DIAGRAMS

4. AUDIO BLOCK DIAGRAM

Page 27

3-20

SECTION3 ELECTRICAL

BLOCK & CIRCUIT DIAGRAMS

5. Y/C BLOCK DIAGRAM

Page 28

3-223-21

SECTION3 ELECTRICAL

BLOCK & CIRCUIT DIAGRAMS

6. A/V

CIRCUIT DIAGRAM

Page 29

3-23

SECTION3 ELECTRICAL

BLOCK & CIRCUIT DIAGRAMS

Page 30

3-253-24

SECTION3 ELECTRICAL

BLOCK & CIRCUIT DIAGRAMS

7. SYSTEM

BLOCK DIAGRAM

Page 31

3-26

SECTION3 ELECTRICAL

BLOCK & CIRCUIT DIAGRAMS

Page 32

3-283-27

SECTION3 ELECTRICAL

BLOCK & CIRCUIT DIAGRAMS

8. SYSTEM

CLRCUIT DIAGRAM

Page 33

3-303-29

SECTION3 ELECTRICAL

BLOCK & CIRCUIT DIAGRAMS

9. JACK

CLRCUIT DIAGRAM

Page 34

3-323-31

SECTION3 ELECTRICAL

BLOCK & CIRCUIT DIAGRAMS

10. KEY-BOARD

CLRCUIT DIAGRAM

Page 35

3-343-33

SECTION3 ELECTRICAL

PRINTED CIRCUIT DIAGRAMS

1. MAIN P.C.BOARD

Page 36

3-35

SECTION3 ELECTRICAL

PRINTED CIRCUIT DIAGRAMS

PRINTED CIRCUIT BOARD DIAGRAMS

2. KEY 1 P.C.BOARD 3. KEY 2 P.C.BOARD

4. JACK P.C.BOARD

Page 37

DECK MECHANISM PARTS

LOCATIONS

• Top View......................................................4-1

• Bottom View ...............................................4-1

DECK MECHANISM

DISASSEMBLY

1. Drum Assembly .........................................4-2

2. Plate Top ...................................................4-4

3. Holder Assembly CST ...............................4-4

4. Opener Door .............................................4-4

5. Bracket Assembly L/D Motor.....................4-4

6. Gear Assembly Rack F/L ..........................4-4

7. Arm Assembly F/L .....................................4-4

8. Lever Assembly S/W .................................4-4

9. Arm Assembly Cleaner..............................4-5

10.Head F/E ...................................................4-5

11. Base Assembly A/C Head .........................4-5

12.Brake Assembly T .....................................4-6

13.Brake Assembly RS ..................................4-6

14.Arm Assembly Tension..............................4-6

15.Reel S / Reel T..........................................4-6

16.Base Assembly P4 ....................................4-7

17.Opener Lid ................................................4-7

18.Arm Assembly Pinch .................................4-7

19.Lever T/up / Arm T/up ...............................4-7

20.Belt Capstan/Motor Capstan.....................4-8

21.Lever F/R ..................................................4-8

22.Clutch Assembly D35 ................................4-8

23. Brake Assembly Capstan .........................4-8

24.Gear Drive/Gear Cam ...............................4-9

25.Gear Sector...............................................4-9

26.Plate Slider................................................4-9

27.Lever Tension............................................4-9

28.Lever Spring..............................................4-9

29.Gear Assembly P2/

Gear Assembly P3 ..................................4-10

30.Base Assembly P2/

Base Assembly P3 ..................................4-10

31.Base Loading ..........................................4-11

32.Base Tension...........................................4-11

33.Arm Assembly Idler .................................4-11

DECK MECHANISM ADJUSTMENT

• Tools and Fixtures for Service ...............4-12

1. Mechanism Alignment Position Check....4-13

2. Preparation for Adjustment......................4-14

3. Checking Torque .....................................4-14

4. Guide Roller Height Adjustment..............4-15

4-1. Preliminary Adjustment....................4-15

4-2. Precise Adjustment..........................4-15

5. Audio/Control (A/C) Head Adjustment ....4-16

5-1. Preliminary Adjustment....................4-16

5-2. Confirmation of Tape Path between

Pinch Roller and Take-up Guide......4-17

5-3. Precise Adjustment(Azimuth Adjustment)

.........................................................4-17

6. X-Value Adjustment.................................4-17

7. Adjustment after Replacing Drum Assembly

(Video Heads) .........................................4-18

8. Check the Tape Travel after Reassembling

Deck Mechanism.....................................4-18

8-1. Checking Audio and RF Locking Time

during Playback after CUE or REV

.........................................................4-18

8-2. Checking for Tape Curling or

Jamming ..........................................4-18

MAINTENANCE/INSPECTION

PROCEDURE

1. Check before starting Repairs ................4-19

2. Required Maintenance ............................4-20

3. Scheduled Maintenance..........................4-20

4. Supplies Required for Inspection and

Maintenance............................................4-20

5. Maintenance Procedure ..........................4-20

5-1. Cleaning...........................................4-20

5-2. Greasing ..........................................4-21

MECHANISM TROUBLESHOOTING

GUIDE

1. Deck Mechanism.....................................4-23

2. Front Loading Mechanism.......................4-26

EXPLODED VIEWS

1. Front Loading Mechanism Section .........4-28

2. Moving Mechanism Section (1)...............4-29

3. Moving Mechanism Section (2)...............4-30

SECTION 4 MECHANISM

CONTENTS

Page 38

DECK MECHANISM PARTS LOCATIONS

4-1

• Top View

• Bottom View

20

24

23

20

24

22

21

29

30

29

30

25

32

27

26

28

NOTE : When reassembly perform the

procedure in the reverse order.

1 Drum Assembly 3 Screw A-1 T

2 Plate Top 2 Hook A-2 T

2 3 Holder Assembly CST Chassis Hole A-2 T

2 4 Opener Door Chassis Hole A-2 T

5 Bracket Assembly 3 Hook A-2 T

L/D Motor

2,3,4 6 Gear Assembly Rack F/L 1 Hook, Chassis Hole A-2 T

2,3,4,6 7 Arm Assembly F/L Chassis Hole A-2 T

8 Lever Assembly S/W 1 Hook A-2 T

9 Arm Assembly Cleaner Chassis Embossing A-3 T

10 Head F/E Chassis Embossing A-3 T

11 Base Assembly A/C Head 1 Screw A-3 T

2,3 12 Brake Assembly T 1 Hook A-4 T

2,3 13 Brake Assembly RS 1 Hook A-4 T

2,3 14 Arm Assembly Tension 2 Hook A-4 T

2,3,12,13, 15 Reel S/Reel T A-4 T

14

16 Base Assembly P4 Chassis Embossing A-5 T

17 Opener Lid Chassis Embossing A-5 T

17 18 Arm Assembly Pinch Shaft A-5 T

17 19 Lever T/Up / Arm T/Up 1 Hook A-5 T

17,18 20

Belt Capstan/Motor Capstan

3 Screw A-6 B

21 Lever F/R Locking Tab A-6 B

20, 21 22 Clutch Assembly D35 Washer A-6 B

23 Brake Assembly Capstan Locking Tab A-6 B

24 Gear Drive/Gear Cam Washer/Hook A-7 B

25 Gear Sector 1 Hook A-7 B

20,21,23, 26 Plate Slider Shaft Guide A-7 B

24,25

20,21,23, 27 Lever Tension 1 Hook A-7 B

24,25,26

2,3,14,20, 28 Lever Spring Locking Tab A7 B

21,25,23,

24,26

25 29

Gear Assembly P2/Gear Assembly P3

Boss A-8 B

2,3,14,25, 30

Base Assembly P2/Base Assembly P3

Chassis Slot A-8 B

29

2,3,14,25, 31 Base Loading 1 Screw A-9 T

29

2,3,14 32 Base Tension Chassis Embossing A-9 B

2,3,20,21, 33 Arm Assembly Idler Locking Tab A-9 T

22

Starting

No.

Procedure

Part Fixing Type

Fig-

ure

View

1) When reassembling, confirm Mechanism and Mode

Switch Alignment Position (Refer to Page 4-13)

2) When disassembling, the Parts for Starting No. Should

be removed first.

T:Top, B:Bottom

2

7

10

1

31

14

15

8

6

3

4

9

5

11

18

16

17

19

19

12

33

13

15

Page 39

4-2

DECK MECHANISM DISASSEMBLY

(S3)

(S2)

(S2)

(S3)

(A)

Stator

Carbon Brush

Drum Motor

Rotor

Drum Sub Assembly

Drum FPC

(S1)

(S1)

(S1)

Holder FPC

H1

H2

1. Drum Assembly (Fig. A-1-1)

1) Unplug the Drum FPC Connector.

2) Remove three Screws(S1) on bottom side and separate

the Drum assembly.

3) Unhook (H1), (H2) and separate the Holder FPC and

Cap FPC.

1-1. Drum Motor

1) Remove two Screws(S2) and disassemble the Stator of

the Drum Motor.

2) Remove two Screws(S3) and separate the Rotor of the

Drum Motor from the Drum Sub assembly.

NOTE

When reassembling, confirm (A) portion of the Drum Sub

assembly whether the Carbon Brush is in there or not.

Fig. A-1

(Fig. B-1)

Holder FPC

Drum FPC

Cap FPC

Figure in the opposite direction

(Fig. A-1-1)

Page 40

DECK MECHANISM DISASSEMBLY

4-3

(B)

(E)

(C1)

(C)

Plate Top

Arm Assembly F/L

Spring Lever S/W

Gear Assembly Rack F/L

Chassis

Opener Door

Bracket Assembly L/D Motor

Holder Assembly CST

(B')

(C')

(D)

(E')

(H6)

(A)

(B)

Lever Assembly S/W

(H8)

Fig. A-2

(Fig. A-2-1)

(Fig. A-2-2)

(Fig. A-2-6)

(Fig. A-2-7)

(Fig. A-2-5)

(Fig. A-2-3)

(Fig. A-2-4)

Page 41

4-4

DECK MECHANISM DISASSEMBLY

2. Plate Top (Fig. A-2-1)

1) Pull the (B) portion of the Plate Top back in direction of

arrow and separate the right side of it.

2) pull the (B’) portion of the Plate Top back in direction of

arrow and separate the left side of it.

(Used tools : (-) type driver, anything tool with sharp

point or flat point.)

NOTE

(1) When reassembling, push the Plate Top after alignment

the two position(C), (C’) as below Fig.

3. Holder Assembly CST (Fig.A-2-2)

1) Move the Holder Assembly CST in direction of arrow and

separate the left side of it first through the (D) position of

the Chassis.

2) Disassemble the right side of the Holder Assembly CST

from each guided hole of the Chassis.

NOTE

When reassembling, insert the (E) part of the Holder

Assembly CST in the (E’) hole of the Chassis first and

assemble the left side of it.

4. Opener Door (Figure. A-2-3)

1) Turn the Opener Door clockwise and remove it through

the guide hole of the Chassis.

5. Bracket Assembly L/D Motor

(Fig. A-2-4)

1) Unplug the Connector(C1).

2) Unhook three Hooks(H3, H4, H5) on bottom side of the

Chassis, lift up the Bracket Assembly L/M and disassemble the Bracket Assembly L/D Motor.

6. Gear Assembly Rack F/L (Fig. A-2-5)

1) Move the Gear Assembly Rack F/L in direction of

arrow(A) and unhook the Hook(H6) pulling back in front.

2) Separate the Gear Rack F/L in direction of arrow(B).

NOTE

When reassembling, align the gear part of the Gear

Assembly Rack F/L with the Gear Drive as below Fig.

7. Arm Assembly F/L (Fig. A-2-6)

1) Move the Arm Assembly F/L in direction of arrow and

separate the left side of it first.

2) Disassemble the Arm Assembly F/L from each guided

hole of the Chassis.

8. Lever Assembly S/W(Fig. A-2-7)

1) Unhook the Hook(H8) in the left side of the Chassis and

remove the Lever Assembly S/W.

(B')

(C')

(C)

(B)

(H4)

(H3)

(H5)

Bracket assembly L/M

Gear Rack F/L

Holder assembly CST

(D)

Chassis

Gear Drive

Chassis

(H8)

Page 42

DECK MECHANISM DISASSEMBLY

4-5

9. Arm Assembly Cleaner (Fig. A-3-1)

1) Breakaway the (A) portion as Fig. A-3-1 from the

embossing of the Chassis, turn the Arm assembly

Cleaner to clockwise direction and lift it up.

10. Head F/E (Fig. A-3-2)

1) Breakaway the (A) portion of the Head F/E from the

embossing of the Chassis, turn it to counterclockwise

direction and lift it up.

11. Base Assembly A/C Head (Fig. A-3-3)

1) Remove the Screw(S4) and lift the Base Assembly A/C

Head up.

(A)

Arm Assembly

Cleaner

Base Assembly A/C Head

(S4)

Head F/E

(A)

Chassis

Fig. A-3

(Fig. A-3-1)

(Fig. A-3-3)

(Fig. A-3-2)

Page 43

4-6

DECK MECHANISM DISASSEMBLY

Brake Assembly T

Spring TB

(H9)

Reel T

Brake Assembly RS

Spring RS

Arm Assembly Tension

Spring Tension

Reel S

Base Tension

(H11)

(H12)

Chassis

(H10)

Fig. A-4

12. Brake Assembly T (Fig. A-4-1)

1) Unhook the Spring TB from the Hook(H9) of the Chassis.

2) Lift the Brake Assembly T up.

13. Brake Assembly RS (Fig. A-4-2)

1) Unhook the Spring RS from the Hook(H10) of the

Chassis.

2) Lift the Brake Assembly T up.

14. Arm Assembly Tension (Fig. A-4-3)

1) Unhook the Spring Tension from the Hook(H11) of the

Arm Assembly Tension.

2) Unhook the Hook(H12) of the Base Tension and lift the

Arm Assembly Tension up.

NOTE

Difference for Springs

15. Reel S / Reel T (Fig. A-4-4)

1) Difference for Reel S / Reel T

Spring TB

Spring RS Color (Black)

Spring Tension

Reel S Reel T

(Fig. A-4-1)

(Fig. A-4-3)

(Fig. A-4-4)

(Fig. A-4-4)

(Fig. A-4-2)

Page 44

DECK MECHANISM DISASSEMBLY

4-7

Opener Lid

Arm

Assembly

Pinch

Base Assembly P4

Arm T/up

Lever T/up

(A)

(B)

(C)

(C)

(H13)

(B)

(H13)

Chassis

Fig. A-5

16. Base Assembly P4 (Fig. A-5-1)

1) Breakaway the (A) portion of the Base Assembly P4 from

the embossing of the Chassis.

2) Turn the Base Assembly P4 to counterclockwise direction

and lift it up.

17. Opener Lid (Fig. A-5-2)

1) Breakaway the (B) portion of the Opener Lid from the

embossing of the Chassis.

2) Turn the Opener Lid to clockwise direction and lift it up.

18. Arm Assembly Pinch (Fig. A-5-3)

1) Lift the Arm Assembly Pinch up.

NOTE

When reassembling, confirm the (C) portion of the Arm

Assembly Pinch is inserted to the Chassis hole correctly as

Fig.

19. Lever T/up (Fig. A-5-4)/

Arm T/up (Fig. A-5-5)

1) Unhook the Hook(H13) of the bottom Chassis and lift the

Lever T/up up.

2) Lift the Arm T/up up.

(Fig. A-5-2)

(Fig. A-5-1)

(Fig. A-5-3)

(Fig. A-5-5)

(Fig. A-5-4)

Page 45

4-8

DECK MECHANISM DISASSEMBLY

Chassis

(S5)

Belt Capstan

Motor Capstan

Washer(W1)

Lever F/R

Clutch Assembly D35

Brake Assembly Capstan

(L1)

(L2)

(L1)

Fig. A-6

20. Belt Capstan (Fig. A-6-1)/

Motor Capstan (Fig. A-6-2)

1) Remove the Belt Capstan.

2) Remove the three Screws(S5) on bottom Chassis and lift

the Motor Capstan up.

21. Lever F/R (Fig. A-6-3)

1) Unlock the Locking Tab(L1) as Fig. A-6-3 and lift the

Lever F/R up.

22. Clutch Assembly D35 (Fig. A-6-4)

1) Remove the Washer(W1) and lift the Clutch Assembly

D35 up.

23. Brake Assembly Capstan

(Fig. A-6-5)

1) Pull the Locking Tab(L2) back in direction of arrow and lift

it up.

(Fig. A-6-1)

(Fig. A-6-2)

(Fig. A-6-3)

(Fig. A-6-5)

(Fig. A-6-4)

Page 46

DECK MECHANISM DISASSEMBLY

4-9

Gear Drive

Washer (W2)

Gear Cam

Plate Slider

Lever Tension

Lever spring

Base Loading

Gear Sector

(L3)

(H15)

(H16)

(H14)

(A)

Chassis

Gear Drive Hole(C)

Gear Cam Hole(B)

Gear Drive Hole(A)

Fig. A-7

24. Gear Drive (Fig. A-7-1)/

Gear Cam (Fig. A-7-2)

1) Remove the Washer(W2) and lift the Gear Drive up.

2) Unhook the Hook(H14) of the Gear Cam and lift the Gear

Cam up.

NOTE

When reassembling, align the Gear Drive Hole(A) and the

Gear Cam Hole(B) in a straight line after the Gear Drive

Hole(C) is aligned with the Chassis Hole as Fig.

25. Gear Sector (Fig. A-7-3)

1) Unhook the Hook(H15) of the Base Loading on bottom

Chassis and lift the Gear Sector up.

26. Plate Slider (Fig. A-7-4)

1) Just lift the Plate Slider up.

27. Lever Tension (Fig. A-7-5)

1) Unhook the (A) portion of the Lever Tension from the

Hook(H16) of the Chassis.

2) Turn the Lever Tension to counterclockwise direction and

lift it up.

28. Lever Spring (Fig. A-7-6)

1) Unlock the Locking Tab(L3) of the bottom Chassis and lift

the Lever Spring up.

(Fig. A-7-4)

(Fig. A-7-5)

(Fig. A-7-6)

(Fig. A-7-1)

(Fig. A-7-2)

(Fig. A-7-3)

Page 47

4-10

DECK MECHANISM DISASSEMBLY

Gear Assembly P3

Gear Assembly P2

Base Assembly P2

Base Assembly P3

(A)

(B)

Chassis

Gear Assembly P2 Hole

Gear Sector Hole(A)

Plate Slider Hole(B)

Lever Spring Boss

Gear Assembly P3 Hole

Fig. A-8

29. Gear Assembly P2 (Fig. A-8-1)/

Gear Assembly P3 (Fig. A-8-2)

1) Just lift the Gear Assembly P2 up.

2) Just lift the Gear Assembly P3 up.

NOTE

When reassembling, align the two holes of the Gear

Assembly P2 and P3 in a straight line after confirmation

whether the Gear Sector Hole(A) and the Plate Slider

Hole(B) are aligned or not as Fig.

30. Base Assembly P2 (Fig. A-8-3)/

Base Assembly P3 (Fig. A-8-4)

1) Move the Base Assembly P2 in direction of arrow(A)

along the guide hole of the Chassis and disassemble it

on bottom side.

2) Move the Base Assembly P3 in direction of arrow(B)

along the guide hole of the Chassis and disassemble it

on bottom side.

(Fig. A-8-1)

(Fig. A-8-2)

(Fig. A-8-3)

(Fig. A-8-4)

Page 48

DECK MECHANISM DISASSEMBLY

4-11

(A)

(B) (C)

(S7)

Arm Assembly Idler

Base Loading

Base Tension

Chassis

(D)

Fig. A-9

31. Base Loading (Fig. A-9-1)

1) Remove the Screw(S7).

2) Lift the Base Loading up.

32. Base Tension (Fig. A-9-2)

1) Breakaway the (A) portion of the Base Tension from the

embossing of the Chassis.

2) Turn the Base Tension to counterclockwise direction and

lift it up.

33. Arm Assembly Idler (Fig. A-9-3)

1) Make narrower the two parts, (B) and (C), as Fig. A-9-3.

2) Lift the Arm assembly Idler up.

NOTE

When disassembling, be careful not to be caught the (D) part

by the Chassis as Fig.

(Fig. A-9-1)

(Fig. A-9-2)

(Fig. A-9-3)

Page 49

DECK MECHANISM ADJUSTMENT

4-12

• Tools and Fixfures for Service

1. Cassette Torque Meter

1. SRK-VHT-303(Not SVC part)

1. Parts No: D00-D006

4. Torque Gauge Adaptor

Parts No:D09-R001

5. Post Height Adjusting Driver

Parts No:DTL-0005

6. + Type Driver (ø 5)

2. Alignment Tape

Parts No NTSC: DTN-001

PAL:DTN-0002

3. Torque Gauge

3. 600g.Cm ATG

3. Parts No:D00-D002

SRK

VIDEO

CASSETTE

TORQUE

METER

VHT-303

S

R

K

-

V

H

T

-

S

S

R

K

-

V

H

T

T

300

250

200

150

50

0

300

250

200

150

50

0

100

Page 50

DECK MECHANISM ADJUSTMENT

4-13

Purpose:To determine if the Mechanism is in the correct position, when a Tape is ejected.

1. Mechanism Alignment Position Check

1) Turn the Power S/W on and eject the Cassette by pressing the Eject Button.

2) Remove the Top Cover and Plate Assembly Top, visually check if the Gear Cam Hole is aligned with the

Chassis Hole as below Fig. C-2.

3) IF not, rotate the Shaft of the Loading Motor to either

clockwise or counterclockwise until the alignment is as

below Fig. C-2.

4) Remove the Screw which fixes the Deck Mechanism and

Main Frame and confirm if the Gear Cam is aligned with

the Gear Drive as below Fig. C-1(A).

5) Confirm if the Mode S/W on the Main P.C.Board is

aligned as below Fig. C-1(B).

6) Remount the Deck Mechanism on the Main P.C.Board

and check each operation.

Gear Cam

Gear Drive

(A)

Mode S/W

(B)

Test Equipment/ Fixture

• Blank tape

Test Conditions (Mechanism

Condition)

• Eject Mode (with Cassette ejected)

Check Point

• Mechanism and Mode Switch Position

Fig. C-1

Fig. C-2

CHECK DIAGRAM

BOTTOM VIEW

TOP VIEW

Gear Cam (o) and Gear Drive (o) groove alignment

L/D Motor Assembly

(A')

(B')

Gear Cam

Chassis Hole

(A)

Gear Cam Hole

Gear Drive Hole

(B)

Page 51

4-14

DECK MECHANISM ADJUSTMENT

Purpose: To insure smooth transport of the tape during each mode of operation.

If the tape transport is abnormal, then check the torque as indicated by the chart below.

2. Preparation for Adjustment (To set the

Deck Mechanism of the loading state

without inserting a cassette tape).

1) Unplug the power cord from the AC outlet.

2) Disassemble the Top Cover and Plate Assembly Top.

3) Plug the power cord into the AC outlet.

4) Turn the power S/W on and push the Lever Stopper of

the Holder Assembly CST to the back for loading the

cassette without tape.

Cover the holes of the End Sensors at the both sides of

the Chassis to prevent a light leak.

Then the Deck Mechanism drives to the Stop Mode.

In this case, the Deck Mechanism can accept inputs of

each mode, however the Rewind and Review operation

can not be performed for more than a few seconds

because the Take-up Reel Table is in the Stop State

and can not be detected the Reel Pulses.

3. Checking Torque

NOTE:

The values are measured by using a Torque Gauge and

Torque Gauge Adaptor with the Torque Gauge affixed.

NOTE:

The torque reading to measure occurs when the tape

abruptly changes direction from Fast Forward to Rewind

Mode, when quick braking is applied to both Reels.

SRK

VIDEO

CASSETTE

TORQUE

METER

VHT-303

S

R

K

-

V

H

T

-

S

S

R

K

-

V

H

T

T

300

250

200

150

50

0

300

250

200

150

50

0

100

Test Equipment/ Fixture

• Torque Gauge(600g/cm ATG)

• Torque Gauge Adaptor

• Cassette Torque Meter

SRK-VHT-303

Checking Method

• Perform each Deck Mechanism mode without

inserting a cassette tape(Refer to above No.2

Preparation for Adjustment).

• Read the measurement of the Take-up or Supply

Reels on the Cassette Torque Meter(Fig. C-3-2).

• Attach the Torque Gauge Adaptor to the Torque

Gauge and then read the value of it(Fig. C-3-1).

Fig. C-3-2Fig. C-3-1

Torque Gauge

Torque Gauge

Adaptor

Reel Table

Item

Fast Forward Torque

Rewind Torque

Play Take-Up Torque

Review Torque

Mode

Fast Forward

Rewind

Play

Review

Test Equipment

Cassette Torque Gauge

Cassette Torque Gauge

Cassette Torque Meter

Cassette Torque Meter

Measurement Reel

Take-Up Reel

Supply Reel

Take-Up Reel

Supply Reel

Measurement Values

More than 400g/cm

More than 400g/cm

40~100g/cm

120~210g/cm

Test Conditions

(Mechanism Condition)

• Play (FF) or Review (REW) Mode

• Cassette Torque Meter (SRK-VHT-303)• Torque Gauge (600g.cm ATG)

Page 52

DECK MECHANISM ADJUSTMENT

4-15

4.Guide Roller Height Adjustment

Adjustment Procedure

1) Confirm if the tape runs along the tape guide line of the

Lower Drum.

2) If the tape runs the bottom of the guide line, turn the

Guide Roller Height Adjustment Screw to clockwise

direction.

3) If it runs the top, turn to counterclockwise direction.

4) Adjust the height of the Guide Roller to be guided to the

guide line of the Lower Drum from the starting and ending point of the Drum.

Purpose: To regulate the height of the tape so that the bottom of the tape runs along the

tape guide line on the Lower Drum.

Test Equipment/ Fixture

• Post Height Adjusting Driver

Test Conditions (Mechanism Condition)

• Play or Review Mode

Adjustment Point

• Guide Roller Height Adjustment

screws on the Supply and Take-Up

Guide Rollers.

Fig. C-4-1

Upper Flange

Guide Roller

Retaining Screw

Guide Roller Height

Adjustment screw

ADJUSTMENT DIAGRAM

Test Equipment/Fixture

• Oscilloscope

• Alignment Tape

• Post Height Adjusting

Driver

Test Equipment Connection Points

• CH-1:PB RF Envelope

• CH-2:NTSC: SW 30Hz

PAL: SW 25Hz

• Head Switching Output

Point

• RF Envelope Output

Point

Test Conditions VCR(VCP) State

• Play an Alignment Tape

Adjustment Point

• Guide Roller Height

Adjustment Screws

Fig. C-4-2

Fig. C-4-3

P3 POST

ADJUSTMENT

P2 POST

ADJUSTMENT

Turn the Roller Guide Height

Adjustment Screw slightly

to flatten the waveform.

Tracking Control at center

RF ENVELOPE OUTPUT TEST POINT

OSCILLOSCOPE

HEAD SWITCHING OUTPUT TEST

POINT

Turn(Move) the Tracking

Control to both directions

4-1. Preliminary Adjustment

4-2. Precise Adjustment

Adjustment Procedure

1) Play an Alignment Tape after connecting the probe of the

Oscilloscope to the RF Envelope Output Test Point and

Head Switching Output Test Point.

2) Tracking Control(in PB Mode) : Center Position(When

this adjustment is performed after the Drum Assembly

has been replaced, set the Tracking Control so that the

RF Output is Maximum).

3) Height Adjustment Screw : Flatten the RF waveform.

(Fig. C-4-2)

4) Turn(Move) the Tracking Control(in PB Mode) clockwise

and counterclockwise.(Fig. C-4-3)

5) Check that any drop of RF Output is uniform at the start

and end of the waveform.

NOTE

If the adjustment is excessive or insufficient the tape will

jam or fold.

Waveform Diagrams

Connection Diagram

Page 53

4-16

DECK MECHANISM ADJUSTMENT

5. Audio/Control (A/C) Head Adjustment

10.9

Purpose: To insure that the tape passes accurately over the Audio and Control Tracks in

exact alignment of the both Record and Playback Modes.

Test Equipment/ Fixture

• Blank Tape

• Screw Driver(+) Type 5mm

• Play the blank tape

Test Conditions (Mechanism Condition)

Adjustment Point

• Tilt Adjustment Screw(C)

• Height Adjustment Screw(B)

• Azimuth Adjustment Screw(A)

Fig. C-5-1

A/C Head Base

Fig. C-5-2

Height Adjustment

Screw(B)

Tilt Adjustment

Screw(C)

Azimuth Adjustment

Screw(A)

X-Value Adjustment

Hole

Fixed Screw

Fig. C-5-3

A/C Head

Tape

Tape

0.2~0.25mm

P4

5-1. Preliminary Adjustment (Height and Tilt Adjustment)

Perform the Preliminary Adjustment, when there is no Audio Output Signal with the Alignment Tape.

1) Initially adjust the Base Assembly A/C Head as shown

Fig. C-5-1 by using the Height Adjustment Screw(B).

2) Play a blank tape and observe if the tape passes accurately over the A/C Head without tape curling or folding.

3) If folding or curling is occured then adjust the Tilt

Adjustment Screw(C) while the tape is running to resemble Fig. C-5-3.

4) Reconfirm the tape path after Playback about 4~5 seconds.

NOTE

Ideal A/C head height occurs when the tape runs between

0.2~0.25mm above the bottom edge of the A/C Head core.

Adjustment Procedure/Diagrams

A/C Head Assembly

Page 54

DECK MECHANISM ADJUSTMENT

4-17

Purpose: To obtain compatibility with the other VCR(VCP) Models.

5-2. Confirm that the tape passes smoothly

between the Take-up Guide and Pinch

Roller(using a mirror or the naked eye).

1) After completing Step 5-1.(Preliminary Adjustment), check

that the tape passes around the Take-up Guide and Pinch

Roller without folding or curling at the top or bottom.

(1) If folding or curling is observed at the bottom of the

Take-up Guide then slowly turn the Tilt Adjustment

Screw(C) in the clockwise direction.

(2) If folding or curling is observed at the top of it then

slowly turn the Tilt Adjustment Screw(C) in the

counterclockwise direction.

NOTE:

Check the RF envelope after adjusting the A/C Head, if the

RF waveform differs from Fig. C-5-4, performs Precise

Adjustment to flat the RF waveform.

Test Equipment/ Fixture

• Oscilloscope

• Alignment Tape(SP)

• Screw Driver(+) Type 5mm

Connection Point

• Audio output jack

Test Conditions

(Mechanism Condition)

• Play an Alignment Tape

1KHz, 7KHz Sections

Adjustment Point

• Azimuth Adjustment Screw(A)

• Height Adjustment Screw(B)

1) Connect the probe of the oscilloscope to Audio Output

Jack.

2) Alternately adjust the Azimuth Adjustment Screw(A) and

the Tilt Adjustment Screw(C) for maximum output of the

1KHz and 7KHz segments, while maintaining the flattest

envelope differential between the two frequencies.

Adjustment Procedure

5-3. Precise Adjustment (Azimuth adjustment)

6. X-Value Adjustment

Fig. C-5-4

1KHZ

• Oscilloscope

• Alignment Tape(SP only)

• Screw Driver(+) Type 5mm

• CH-1: PB RF Envelope

• CH-2: NTSC: SW 30Hz

PAL: SW 25Hz

• Head Switching Output

Test Point

• RF Envelope Output Test

Point

Test Conditions

(Mechanism Condition)

• Play an Alignment Tape

Adjustment PointConnection PointTest Equipment/ Fixture

Adjustment Procedure

1) Release the Automatic Tracking to run long enough for

tracking to complete it’s cycle.

2) Loosen the Fixed Mounting Screw and move the Base

Assembly A/C Head in the direction as shown in the diagram to find the center of the peak that allows for the maximum waveform envelope.

This method should allow the 31µm Head to be centrally

located over the 58µm tape track.

3) Tighten the Base Assembly A/C Head mounting Screw.

7KHZ

A:Maximum

B:Maximum

Left

Right

Groove at the

Base A/C

Height Adjustment Screw(B)

Tilt Adjustment Screw(C)

Azimuth Adjustment

Screw(A)

X-Value Adjustment Hole

Fixed Screw

RF ENVELOPE OUTPUT TEST POINT

OSCILLOSCOPE

HEAD SWITCHING OUTPUT TEST POINT

Connection Diagram

Adjustment Diagram

CH-1

CH-2

Page 55

4-18

DECK MECHANISM ADJUSTMENT

Purpose: To correct for shift in the Roller Guide and X value after replacing the Drum.

8-2. Checking for tape curling or jamming

Test Equipment/ Fixture

• T-160 Tape

• T-120 Tape

Specification

• Be sure there is no tape jamming or curling at

the begining, middle or end of the tape.

VCR(VCP) State

•

Run the CUE, REV, Play mode at the

beginning and the end of the tape.

Test Conditions (Mechanism Condition)

1) Confirm that the tape runs smoothly around the roller

guides, Drum and A/C Head Assemblies while abruptly

changing operating modes from Play to CUE or REV.

This is to be checked at the begining, middle and end

sections of the tape.

2) Confirm that the tape passes over the A/C Head

Assembly as indicated by proper audio reproduction and

proper tape counter performance.

Checking Procedure

7. Adjustment after Replacing Drum Assembly (Video Heads)

Test Equipment/ Fixture

• Oscilloscope

• Alignment Tapes

• Blank Tape

• Post Height Adjusting Driver

• Screw Driver(+) Type 5mm

Connection Point

• CH-1: PB RF Envelope

• CH-2: NTSC: SW 30Hz

PAL: SW 25Hz

• Head Switching Output

Test Point

• RF Envelope Output Test Point

Test Conditions

(Mechanism Condition)

• Play the Blank Tape

• Play an Alignment Tape

Adjustment Points

• Guide Roller Precise

Adjustment

• Switching Point

• Tracking Preset

• X-Value

Checking/Adjustment Procedure

Play a blank tape and check for tape curling or creasing around

the Roller Guide. If there is a problem then follow the procedure

4. "Guide Roller Height" and 5. "Audio Control(A/C) Head

Adjustment".

RF ENVELOPE OUTPUT TEST POINT

OSCILLOSCOPE

HEAD SWITCHING OUTPUT TEST

POINT

Connection Diagram

Waveform

V1/V MAX EE0.7

V2/V MAX EE0.8

RF ENVELOPE OUTPUT

Fig. C-7

8. Check the Tape Travel after Reassembling Deck Assembly.

8-1. Checking Audio and RF Locking Time during playback and after CUE or REV (FF/REW)

Test Equipment/ Fixture

• Oscilloscope

• Alignment Tapes(with 6H

3KHz Color Bar Signal)

• Stop Watch

Specification

• RF Locking Time: Less than 5

sec.

• Audio Locking Time:Less than

10sec

Test Equipment

Connection Points

• CH-1: PB RF Envelope

• CH-2: Audio Output

• RF Envelope Output Point

• Audio Output Jack

Test Conditions

(Mechanism Condition)

• Play an Alignment Tape

(with 6H 3kHz Color Bar

Signal)

Checking Procedure

Play an Alignment Tape then change the operating mode to

CUE or REV and confirm if the unit meets the above listed

specifications.

NOTES:

1) CUE is the forward search mode

2) REV is the backward search mode

3) Refer to the Play mede

V1

V

V2

CH1 CH2

Connection Points

Page 56

MAINTENANCE/INSPECTION PROCEDURE

4-19

(3) F/E Head

(5) Drum Assembly

(Video Head)

(4) Base

Assembly P2

(2) Tension Post

(1) Supply Reel

(6) Base Assembly P3

1. Check before starting repairs

The following faults can be remedied by cleaning and oiling. Check the needed lubrication and the conditions of

cleanliness in the unit.

Check with the customer to find out how often the unit is

used, and then determine that the unit is ready for inspection and maintenance. Check the following parts.

Phenomenon Inspection

Replace-

ment

Color beats Dirt on Full-Erase Head

o

Poor S/N, no color Dirt on Video Head

Vertical or

Horizontal jitter

Dirt on Audio/Control Head

Dirt on Pinch Roller

NOTE

If locations marked with o do not operate normally after

cleaning, check for wear and replace.

See the EXPLODED VIEWS at the end of this manual as

well as the above illustrations and see the Greasing (Page

4-21, 22) for the sections to be lubricated and greased.

o

o

o

o

Dirt on Video Head

Dirt on tape transport system

Low volume,

Sound distorted

Tape does not run.

Tape is slack

o

In Review and

Unloading (off mode),

the tape is rolled up

loosely.

Clutch Assembly D35

torque reduced

Cleaning Drum and

transport system

Fig. C-9-3

(7) A/C Head

(8) P4 Post

(10) Pinch Roller

(11) Take-up Guide Post

(9) Capstan Shaft

(12) Take-up Reel

* No. (1)~(12) Indicates the Tape Path to be traveled from Supply Reel to Take-up Reel.

Fig. C-9-1 Top View

Fig. C-9-2 Bottom View

F/E Head

Video Head

A/C Head

Pinch Roller

Belt Capston

Clutch

Assembly D35

Fig. C-9-3 Tape Transport System

Page 57

MAINTENANCE/INSPECTION PROCEDURE

4-20

2. Required Maintenance

The recording density of a VCR(VCP) is much higher than

that of an audio tape recorder. VCR(VCP) components must

be very precise, at tolerances of 1/1000mm, to ensure compatibility with the other VCRs. If any of these components are

worn or dirty, the symptoms will be the same as if the part is

defective. To ensure a good picture, periodic inspection and

maintenance, including replacement of worn out parts and

lubrication, is necessary.

3. Scheduled Maintenance

Schedules for maintenance and inspection are not fixed

because they vary greatly according to the way in which the

customer uses the VCR(VCP), and the environment in which

the VCR(VCP) is used.

But, in general home use, a good picture will be maintained

if inspection and maintenance is made every 1,000 hours.

The table below shows the relation between time used and

inspection period.

Table 1

4. Supplies Required for Inspection and

Maintence

(1) Grease : Kanto G-311G (Blue) or equivalent

(2) Isopropyl Alcohol or equivalent

(3) Cleaning Patches

(4) Grease : Kanto G-381(Yellow)

5. Maintenance Procedure

5-1) Cleaning

(1) Cleaning video head

First use a cleaning tape. If the dirt on the head is too

stubborn to remove by tape, use the cleaning patch. Coat

the cleaning patch with Isopropyl Alcohol. Touch the

cleaning patch to the head tip and gently turn the

head(rotating cylinder) right and left.

(Do not move the cleaning patch vertically. Make sure

that only the buckskin on the cleaning patch comes into

contact with the head. Otherwise, the head may be damaged.)

Thoroughly dry the head. Then run the test tape. If lsopropyl Alcohol remains on the video head, the tape may

be damaged when it comes into contact with the head

surface.

(2) Clean the tape transport system and drive system, etc, by

wiping with a cleaning patch wetted with Isopropyl

Alcohol.

NOTES:

1 It is the tape transport system which comes into contact

with the running tape. The drive system consists of those

parts which moves the tape.

2 Make sure that during cleaning you do not touch the tape

transport system with excessive force that would cause

deformation or damage to the system.

About 1

year

One hour

Two hours

Three hours

When

inspection is

necessary

Average

hours used

per day

About 18

months

About 3

years

Fig. C-9-4

Drum

(Rotating Cylinder)

Head Tip

Coat With Isopropyl Alcohol

Touch this section of cleaning

patch to the head tip and gently

turn the Drum (Rotating Cylinder)

Cleaning Patch

Page 58

MAINTENANCE/INSPECTION PROCEDURE

4-21

5-2) Greasing

(1) Greasing guidelines

Apply grease, with a cleaning patch. Do not use excessive grease. It may come into contact with the tape

transport or drive system. Wipe excessive grease and

clean with cleaning patch wetted in Isopropyl Alcohol.

(2) Periodic greasing

Grease specified locations every 5,000 hours.

NOTE:Greasing Points

3

5

7

6

1

7

2

4

1) Loading Path Inside & Top side

2) Base Assembly P2, P3 stopper

3) Shaft

4) L/D Motor Gear Wheel Part

5) Arm Take-up Rubbing Sections

6)Reel S,T shaft(G381:Yellow)

7) Arm Assembly F/L Rotating

Sections

Base Loading

Gear Drive

Gear Sector

Gear Cam

Gear Part

Chassis (Left Side)

Chassis (Right Side)

5

7

8

1

2

6

4

3

Slider Guide

Slider Guide

1) Loading Path Inside & Top side

2) Base Assembly P2,P3 stopper

3) Shaft

4) Shaft

5) Clutch Assembly D35 Shaft

6) Plate Slider Guide Sections

7) Plate Slider Guide Sections

8) Gear Assembly P2, P2 Rubbing

Sections

Chassis (Top)

Chassis (Bottom)

Gear Rack F/L

Plate Slider

Guide Rail

Page 59

MAINTENANCE/INSPECTION PROCEDURE

4-22

Lever, F/R, Base, Tension GEAR AY, P2 & P3

Lever, F/R Base, Tension

Arm Tension

Guide Hole

Clutch

(G-754. Yellow)

Boss Cam

Page 60

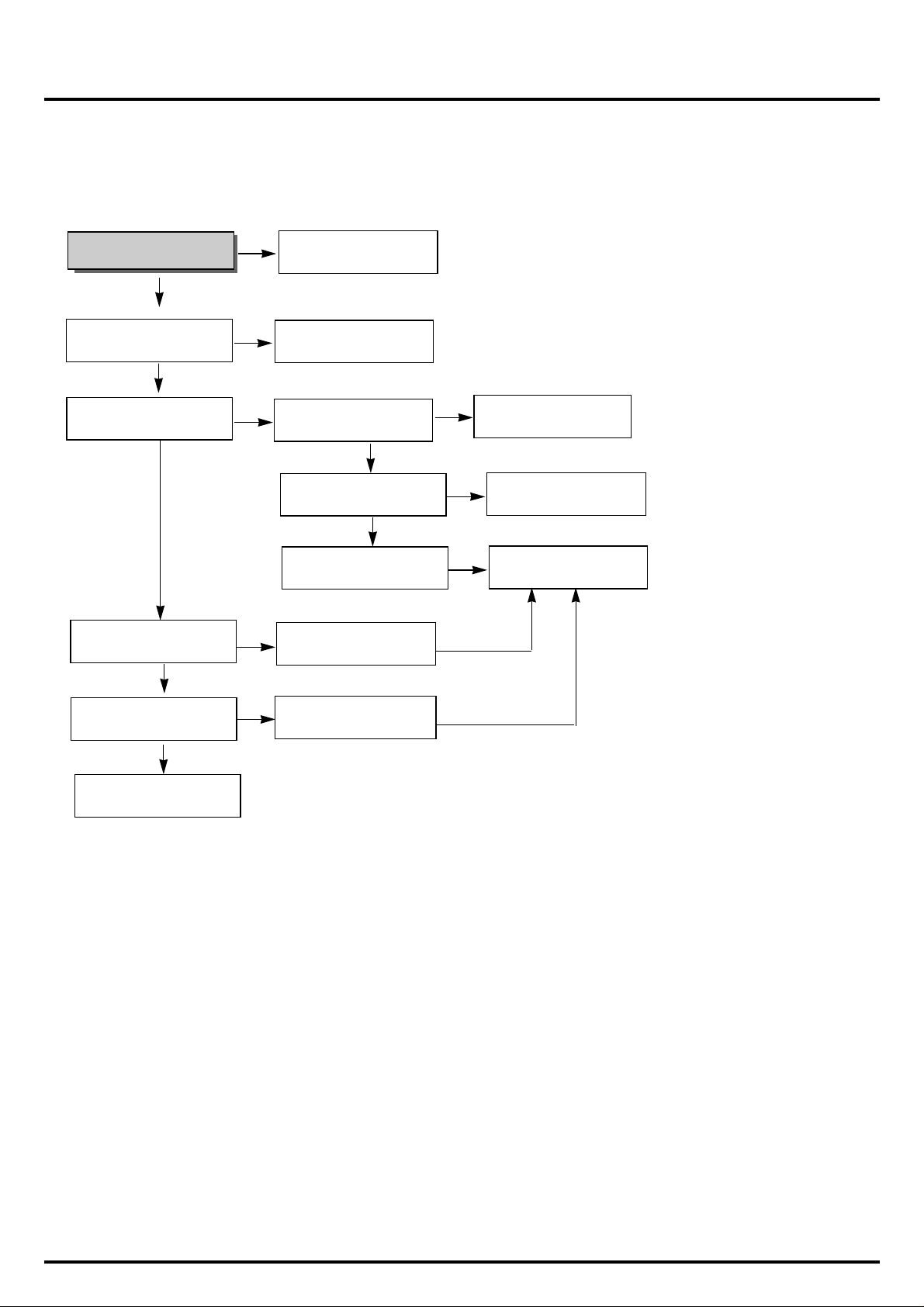

MECHANISM TROUBLESHOOTING GUIDE

4-23

Auto REW doesn't work.

Is the output of END sensor of

supply side "H"?

“H”: more than 3.5V

“L”: less than 0.7V~1V

Is the voltage across IR LED

between 0.8~1.5V?

Replace the IR LED.

Is the Vcc. voltage of End

sensor 5V?

Check the syscon power.

Replace the End sensor.

Check the syscon circuit.

NO

YES

YES

YES

YES

NO

NO

1.Deck Mechanism

A.

NO

NO

NO

No F/R modes.

Is the present mode

F/R Mode?

Is the mode SW assembled

correctly? (refer to page 4-13.)

Is the normal voltage supplied to

the Capstan Motor Vcc1, Vcc2?

Does terminal voltage(Vctl) of

Capstan Motor supply side more

than 4V?

Check the servo, power

circuits.

Replace the Capstan Motor.

Does the Capstan Motor rotate?

Do the T/Up, Supply Reel

rotate?

Check the syscon circuit.

YES

YES

YES

YES

YES

YES

B.

Page 61

4-24

MECHANISM TROUBLESHOOTING GUIDE

AUTO STOP.

(PLAY/CUE/REV)

Are there T/up and Supply Reel

pulses.

In Play/Cue/Rev, Is the Pinch

Roller in contact with the

Capstan Shaft?

Replace the Reel Sensor.

Is the output of DFG, DPG OK?

Check alignment positions

(page 4-13).

Replace the Drum Motor.

Check the Servo, Syscon.

Check the Syscon, µ-COM.

Cassette doesn’t load.

Insert the cassette.

Check Lever Assembly S/W.

Is there variation for CST IN S/W

Output?

(In Tape with REC Tab

“L”→“H”→“L”)

(In Tape without REC Tab

“L”→“H”→“L”→“H”)

Does the CST IN S/W work

normally?

Does the Lever Assembly S/W

work normally?

Check the Syscon Circuit.

Check the Syscon Circuit.

Replace the CST IN S/W.

YES

YES

YES

YES

YES

YES

NO

NO

NO

NO

NO

NO

NO

YES

C.

D.

Page 62

4-25

MECHANISM TROUBLESHOOTING GUIDE

In PB mode Tape Presence

not sensed.

Is the Pinch Roller attached

to the Capstan Motor Shaft?

Check Alignment positions

(page 4-13).

Does the T/Up Reel turn?

Replace the Belt.

Is the Belt ok?

Does the Drum Motor turn?

Are there DPG, DFG pulses?

Are the T/Up and Supply Reel

Sensors ok?

Check the Syscon, Circuit.

Check the Syscon, Circuit.

Check the Servo, Syscon.

Does the Capstan Motor turn?

Is the terminal voltage(vctl) of the

Drum Motor more than 4V?

Replace the

Drum Motor.

Is the Vcc voltage of the Drum

Motor normal?

Check the Clutch and Idler

Assembly.

YES

YES

YES

YES

YES

YES

YES

YES

NO

NO

NO

NO

NO

Is the terminal voltage(vctl) of

Capstan Motor supplied more

than 4V?

Replace the Capstan Motor.

Is the voltage supplied to the

Capstan Motor Vcc1,Vcc2 each?

YES

YES

YES

Check the Servo, Power.

NO

NO

NO

E.

Page 63

MECHANISM TROUBLESHOOTING GUIDE

4-26

Cassette cannot be inserted.

Does the Lever Assembly

Switch work?

Is the Lever Assembly Switch

Spring damaged or omitted?

Does the CST IN Switch work

normally?

Replace or add the Lever

Assembly Switch Spring.

Is the Vcc of Main P.C.Board

5V?

YES

YES

Check the syscon circuit.

YES

Check the power circuit.

NO

Is the voltage between cassette

switch and GND on Main

P.C.Board 5V??

YES

Is there a short circuit between cassette

switch and GND on main P.C.Board?

Remove the short circuit part or

Replace the main P.C.Board.

NO

Check the Mode switch location

and syscon circuit.

Replace the CST IN Switch.

YES

NO

YES

NO

NO

Replace the CST IN Switch.

NO

NO

Cassette does not eject.

Does the L/D Motor rotate in reverse?

Check the L/D Motor or Drive IC.

Replace the Lever Assembly Switch.

Does the Lever Assembly Switch work?

YES

NO

NO

Does the Arm Assembly F/L work normally?

YES

NO

Does the Opener Door work?

YES

Replace the Arm Assembly F/L.

Replace the Opener Door.

2. Front Loading Mechanism

A.

B.

Page 64

MECHANISM TROUBLESHOOTING GUIDE

4-27

Cassette does not load.

Does the cassette insert?

Does the Opener Lid work?

Check the opener Door assembled

correctly.

Replace the Opener Lid.

Replace the Arm Assembly F/L.

Check the power of L/D Motor.

Check the Holder Assembly Cassette

assembled correctly.

Replace the Gear Rack F/L.

Does the Gear Assembly Rack F/L

work?

Does the Opener Door work?

Does the Arm Assembly F/L work?

Does the L/D Motor work?

Does the Holder Assembly Cassette

move the Arm Assembly F/L?

Replace the Front Loading

Mechanism Assembly.

YES

YES

YES

YES

NO

NO

NO

YES

NO

YES

NO

YES

NO

C.

Page 65

4-28

EXPLODED VIEWS

117

103

105

117

100

106

107

A21

114

113

112

110

115

A24

116

102

A23

032

A22

109

054

054A

100A

100B

1. Front Loading Mechanism Section

Page 66

EXPLODED VIEWS

4-29

401

402

001

008

011

031

079

017

032

024

406

020

021

028

019

018

029

030

026

A03

A04

A01

002

002A

025

027

022

003

004

006

007

010

405

014

015

009

409