Page 1

COLOR MONITOR

SERVICE MANUAL

Website:http://biz.LGservice.com

E-mail:http://www.LGEservice.com/techsup.html

CAUTION

BEFORE SERVICING THE UNIT,

READ THE SAFETY PRECAUTIONS IN THIS MANUAL.

MODEL:

T530B

(T530BL-AL****)

CHASSIS NO. : CA-138

( ) **Same model for Service

*Same looking with new chassis.

Issue Date; 2004. 9.

T530S

(T530SL-AL****)

Page 2

1. PICTURE TUBE

Size : 15 inch

DefIection Angle : 90¡

Neck Diameter : 29.4 mm

Stripe Pitch : 0.28 mm

Face Treatment : W-ARASC (Anti-Reflection and

Anti-Static Coating)

Internal : Anti-Glare

2. SIGNAL

2-1. Horizontal & Vertical Sync

1) Input Voltage Level : Low=0~1.2V, High=2.5~5.5V

2) Sync Polarity : Positive or Negative

2-2. Video Input Signal

1) Voltage Level : 0 ~ 0.7 Vp-p

a) Color 0, 0 : 0 Vp-p

b) Color 7, 0 : 0.467 Vp-p

c) Color 15, 0 : 0.7 Vp-p

2) Input Impedance : 75

3) Video Color : R, G, B Analog

4) Signal Format : Refer to the Timing Chart

2-3. Signal Connector

3 row 15-pin Connector (Attached)

2-4. Scanning Frequency

Horizontal : 30 ~ 56 kHz

Vertical : 50 ~ 120 Hz

3. POWER SUPPLY

3-1. Power Range

AC 100-240V~ 50/ 60Hz, 1.0A

3-2. Power Consumption

4. DISPLAY AREA

4-1. Active Video Area :

Max Image Size :284.5 x 213.4 mm (11.20" x8.46")

Preset Image Size : 270 x 200 mm (10.63" x 7.87")

4-2. Display Color : Full Colors

4-3. Display Resolution : 1024 x 768 / 70Hz(Max)

(Non-Interlace)

4-4. Video Bandwidth : 75 MHz

5. ENVIRONMENT

5-1. Operating Temperature: 0¡C ~ 40¡C

(Ambient)

5-2. Relative Humidity : 10%~ 80%

(Non-condensing)

5-3. Altitude : 5,000 m

6. DIMENSIONS (with TILT/SWIVEL)

Width : 356.0 mm (14.02 inch)

Depth : 388.5 mm (15.30 inch)

Height : 347.0 mm (13.66 inch)

7. WEIGHT (with TILT/SWIVEL)

Net Weight : 11.5 kg (25.35 lbs.)

Gross Weight : 13.7 kg (30.20 lbs.)

CONTENTS

- 2 -

SPECIFICATIONS ................................................... 2

SAFETY PRECAUTIONS ........................................

3

TIMING CHART ....................................................... 7

WIRING DIAGRAM ................................................. 9

DISASSEMBLY ....................................................... 8

BLOCK DIAGRAM ...................................................

10

DESCRIPTION OF BLOCK DIAGRAM................... 11

ADJUSTMENT ....................................................... 13

TROUBLESHOOTING GUIDE .............................. 19

EXPLODED VIEW...................................................34

REPLACEMENT PARTS LIST ............................... 36

SCHEMATIC DIAGRAM......................................... 40

PRINTED CIRCUIT BOARD................................... 42

SPECIFICATIONS

MODE

MAX

NORMAL (ON)

STAND-BY

SUSPEND

DPMS OFF

POWER CONSUMPTION

75 W

63 W

less than 4 W

less than 4 W

less than 4 W

LED COLOR

GREEN

GREEN

FLASH

FLASH

FLASH

SERVICE PRECAUTION.......................................... 4

Low Radiation :MPR-II,NOM MPRII

Page 3

SAFETY PRECAUTIONS

- 3 -

SAFETY-RELATED COMPONENT WARNING!

There are special components used in this color monitor

which are important for safety. These parts are marked

on the schematic diagram and the replacement

parts list. It is essential that these critical parts should be

replaced with the manufacturer's specified parts to prevent

X-radiation, shock, fire, or other hazards. Do not modify

the original design without obtaining written permission

from manufacturer or you will void the original parts and

labor guarantee.

CAUTION:

No modification of any circuit should be

attempted.

Service work should be performed only after

you are thoroughly familiar with all of the

following safety checks and servicing

guidelines.

SAFETY CHECK

Care should be taken while servicing this color monitor

because of the high voltage used in the deflection circuits.

These voltages are exposed in such areas as the

associated flyback and yoke circuits.

FIRE & SHOCK HAZARD

An isolation transformer must be inserted between the

color monitor and AC power line before servicing the

chassis.

• In servicing, attention must be paid to the original lead

dress specially in the high voltage circuit. If a short

circuit is found, replace all parts which have been

overheated as a result of the short circuit.

• All the protective devices must be reinstalled per the

original design.

• Soldering must be inspected for the cold solder joints,

frayed leads, damaged insulation, solder splashes, or

the sharp points. Be sure to remove all foreign

materials.

IMPLOSION PROTECTION

All used display tubes are equipped with an integral

implosion protection system, but care should be taken to

avoid damage and scratching during installation. Use only

same type display tubes.

X-RADIATION

The only potential source of X-radiation is the picture tube.

However, when the high voltage circuitry is operating

properly there is no possibility of an X-radiation problem.

The basic precaution which must be exercised is keep the

high voltage at the factory recommended level; the normal

high voltage is about 25.8kV. The following steps describe

how to measure the high voltage and how to prevent Xradiation.

Note : It is important to use an accurate high voltage

meter calibrated periodically.

• To measure the high voltage, use a high impedance

high voltage meter, connect (–) to chassis and (+) to

the CDT anode cap.

• Set the brightness control to maximum point at full

white pattern.

• Measure the high voltage. The high voltage meter

should be indicated at the factory recommended level.

• If the meter indication exceeds the maximum level,

immediate service is required to prevent the possibility

of premature component failure.

• To prevent X-radiation possibility, it is essential to use

the specified picture tube.

Leakage Current Hot Check Circuit

CAUTION:

Please use only a plastic screwdriver to protect yourself

from shock hazard during service operation.

1.5 Kohm/10W

To Instrument's

exposed

METALLIC PARTS

Good Earth Ground

such as WATER PIPE,

CONDUIT etc.

AC Volt-meter

Page 4

- 4 -

SERVICING PRECAUTIONS

CAUTION: Before servicing receivers covered by this

service manual and its supplements and addenda, read

and follow the SAFETY PRECAUTIONS on page 3 of this

publication.

NOTE: If unforeseen circumstances create conflict

between the following servicing precautions and any of the

safety precautions on page 3 of this publication, always

follow the safety precautions. Remember: Safety First.

General Servicing Precautions

1. Always unplug the receiver AC power cord from the AC

power source before;

a. Removing or reinstalling any component, circuit

board module or any other receiver assembly.

b. Disconnecting or reconnecting any receiver electrical

plug or other electrical connection.

c. Connecting a test substitute in parallel with an

electrolytic capacitor in the receiver.

CAUTION: A wrong part substitution or incorrect

polarity installation of electrolytic capacitors may

result in an explosion hazard.

d. Discharging the picture tube anode.

2. Test high voltage only by measuring it with an

appropriate high voltage meter or other voltage

measuring device (DVM, FETVOM, etc) equipped with

a suitable high voltage probe.

Do not test high voltage by "drawing an arc".

3. Discharge the picture tube anode only by (a) first

connecting one end of an insulated clip lead to the

degaussing or kine aquadag grounding system shield

at the point where the picture tube socket ground lead

is connected, and then (b) touch the other end of the

insulated clip lead to the picture tube anode button,

using an insulating handle to avoid personal contact

with high voltage.

4. Do not spray chemicals on or near this receiver or any

of its assemblies.

5. Unless specified otherwise in this service manual,

clean electrical contacts only by applying the following

mixture to the contacts with a pipe cleaner, cottontipped stick or comparable non-abrasive applicator;

10% (by volume) Acetone and 90% (by volume)

isopropyl alcohol (90%-99% strength)

CAUTION: This is a flammable mixture.

Unless specified otherwise in this service manual,

lubrication of contacts in not required.

6. Do not defeat any plug/socket B+ voltage interlocks

with which receivers covered by this service manual

might be equipped.

7. Do not apply AC power to this instrument and/or any of

its electrical assemblies unless all solid-state device

heat sinks are correctly installed.

8. Always connect the test receiver ground lead to the

receiver chassis ground before connecting the test

receiver positive lead.

Always remove the test receiver ground lead last.

9. Use with this receiver only the test fixtures specified in

this service manual.

CAUTION: Do not connect the test fixture ground strap

to any heat sink in this receiver.

Electrostatically Sensitive (ES) Devices

Some semiconductor (solid-state) devices can be

damaged easily by static electricity. Such components

commonly are called Electrostatically Sensitive (ES)

Devices. Examples of typical ES devices are integrated

circuits and some field-effect transistors and

semiconductor "chip" components. The following

techniques should be used to help reduce the incidence of

component damage caused by static by static electricity.

1. Immediately before handling any semiconductor

component or semiconductor-equipped assembly, drain

off any electrostatic charge on your body by touching a

known earth ground. Alternatively, obtain and wear a

commercially available discharging wrist strap device,

which should be removed to prevent potential shock

reasons prior to applying power to the unit under test.

2. After removing an electrical assembly equipped with

ES devices, place the assembly on a conductive

surface such as aluminum foil, to prevent electrostatic

charge buildup or exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or

unsolder ES devices.

4. Use only an anti-static type solder removal device.

Some solder removal devices not classified as "antistatic" can generate electrical charges sufficient to

damage ES devices.

5. Do not use freon-propelled chemicals. These can

generate electrical charges sufficient to damage ES

devices.

6. Do not remove a replacement ES device from its

protective package until immediately before you are

ready to install it. (Most replacement ES devices are

packaged with leads electrically shorted together by

conductive foam, aluminum foil or comparable

conductive material).

7. Immediately before removing the protective material

from the leads of a replacement ES device, touch the

protective material to the chassis or circuit assembly

into which the device will be installed.

CAUTION: Be sure no power is applied to the chassis

or circuit, and observe all other safety precautions.

8. Minimize bodily motions when handling unpackaged

replacement ES devices. (Otherwise harmless motion

such as the brushing together of your clothes fabric or

the lifting of your foot from a carpeted floor can

generate static electricity sufficient to damage an ES

device.)

Page 5

- 5 -

General Soldering Guidelines

1. Use a grounded-tip, low-wattage soldering iron and

appropriate tip size and shape that will maintain tip

temperature within the range or 500

F to 600 F.

2. Use an appropriate gauge of RMA resin-core solder

composed of 60 parts tin/40 parts lead.

3. Keep the soldering iron tip clean and well tinned.

4. Thoroughly clean the surfaces to be soldered. Use a

mall wire-bristle (0.5 inch, or 1.25cm) brush with a

metal handle.

Do not use freon-propelled spray-on cleaners.

5. Use the following unsoldering technique

a. Allow the soldering iron tip to reach normal

temperature.

(500

F to 600 F)

b. Heat the component lead until the solder melts.

c. Quickly draw the melted solder with an anti-static,

suction-type solder removal device or with solder

braid.

CAUTION: Work quickly to avoid overheating the

circuitboard printed foil.

6. Use the following soldering technique.

a. Allow the soldering iron tip to reach a normal

temperature (500

F to 600 F)

b. First, hold the soldering iron tip and solder the strand

against the component lead until the solder melts.

c. Quickly move the soldering iron tip to the junction of

the component lead and the printed circuit foil, and

hold it there only until the solder flows onto and

around both the component lead and the foil.

CAUTION: Work quickly to avoid overheating the

circuit board printed foil.

d. Closely inspect the solder area and remove any

excess or splashed solder with a small wire-bristle

brush.

IC Remove/Replacement

Some chassis circuit boards have slotted holes (oblong)

through which the IC leads are inserted and then bent flat

against the circuit foil. When holes are the slotted type,

the following technique should be used to remove and

replace the IC. When working with boards using the

familiar round hole, use the standard technique as

outlined in paragraphs 5 and 6 above.

Removal

1. Desolder and straighten each IC lead in one operation

by gently prying up on the lead with the soldering iron

tip as the solder melts.

2. Draw away the melted solder with an anti-static

suction-type solder removal device (or with solder

braid) before removing the IC.

Replacement

1. Carefully insert the replacement IC in the circuit board.

2. Carefully bend each IC lead against the circuit foil pad

and solder it.

3. Clean the soldered areas with a small wire-bristle

brush. (It is not necessary to reapply acrylic coating to

the areas).

"Small-Signal" Discrete Transistor

Removal/Replacement

1. Remove the defective transistor by clipping its leads as

close as possible to the component body.

2. Bend into a "U" shape the end of each of three leads

remaining on the circuit board.

3. Bend into a "U" shape the replacement transistor leads.

4. Connect the replacement transistor leads to the

corresponding leads extending from the circuit board

and crimp the "U" with long nose pliers to insure metal

to metal contact then solder each connection.

Power Output, Transistor Device

Removal/Replacement

1. Heat and remove all solder from around the transistor

leads.

2. Remove the heat sink mounting screw (if so equipped).

3. Carefully remove the transistor from the heat sink of the

circuit board.

4. Insert new transistor in the circuit board.

5. Solder each transistor lead, and clip off excess lead.

6. Replace heat sink.

Diode Removal/Replacement

1. Remove defective diode by clipping its leads as close

as possible to diode body.

2. Bend the two remaining leads perpendicular y to the

circuit board.

3. Observing diode polarity, wrap each lead of the new

diode around the corresponding lead on the circuit

board.

4. Securely crimp each connection and solder it.

5. Inspect (on the circuit board copper side) the solder

joints of the two "original" leads. If they are not shiny,

reheat them and if necessary, apply additional solder.

Fuse and Conventional Resistor

Removal/Replacement

1. Clip each fuse or resistor lead at top of the circuit board

hollow stake.

2. Securely crimp the leads of replacement component

around notch at stake top.

3. Solder the connections.

CAUTION: Maintain original spacing between the

replaced component and adjacent components and the

circuit board to prevent excessive component

temperatures.

Page 6

- 6 -

Circuit Board Foil Repair

Excessive heat applied to the copper foil of any printed

circuit board will weaken the adhesive that bonds the foil

to the circuit board causing the foil to separate from or

"lift-off" the board. The following guidelines and

procedures should be followed whenever this condition is

encountered.

At IC Connections

To repair a defective copper pattern at IC connections use

the following procedure to install a jumper wire on the

copper pattern side of the circuit board. (Use this

technique only on IC connections).

1. Carefully remove the damaged copper pattern with a

sharp knife. (Remove only as much copper as

absolutely necessary).

2. carefully scratch away the solder resist and acrylic

coating (if used) from the end of the remaining copper

pattern.

3. Bend a small "U" in one end of a small gauge jumper

wire and carefully crimp it around the IC pin. Solder the

IC connection.

4. Route the jumper wire along the path of the out-away

copper pattern and let it overlap the previously scraped

end of the good copper pattern. Solder the overlapped

area and clip off any excess jumper wire.

At Other Connections

Use the following technique to repair the defective copper

pattern at connections other than IC Pins. This technique

involves the installation of a jumper wire on the

component side of the circuit board.

1. Remove the defective copper pattern with a sharp

knife.

Remove at least 1/4 inch of copper, to ensure that a

hazardous condition will not exist if the jumper wire

opens.

2. Trace along the copper pattern from both sides of the

pattern break and locate the nearest component that is

directly connected to the affected copper pattern.

3. Connect insulated 20-gauge jumper wire from the lead

of the nearest component on one side of the pattern

break to the lead of the nearest component on the

other side.

Carefully crimp and solder the connections.

CAUTION: Be sure the insulated jumper wire is

dressed so the it does not touch components or sharp

edges.

Page 7

- 7 -

TIMING CHART

VIDEO

SYNC

* No Composite Mode.

<< Dot Clock (MHz), Horizontal Frequency (kHz), Vertical Frequency (Hz), Horizontal etc... (µs), Vertical etc... (ms) >>

MODE

1 2 3 4

VESA

Polarity - - - +

H H-Frequency KHz 31.470 37.500 48.363 53.680

O H-Active(A) uS 31.780 26.670 20.677 18.630

R H-Video(B) uS 25.420 20.320 15.754 14.220

I H-blanking(C) uS 6.360 6.350 4.923 4.410

Z

H-frontporch(D)

uS 0.640 0.510 0.369 0.570

H-synctime(E) uS 3.810 2.030 2.092 1.140

H-backporch(F)

us 1.910 3.810 2.462 2.700

Polarity - - - +

V-Frequency Hz 59.940 74.990 60.004 85.070

V-Active(A) mS 16.684 13.335 16.666 11.755

V V-Video(B) mS 15.254 12.802 15.880 11.178

E V-blanking(C) mS 1.430 0.533 0.786 0.577

R

V-frontporch(D)

mS 0.318 0.026 0.062 0.018

T V-synctime(E) mS 0.063 0.080 0.124 0.056

V-backporch(F)

mS 1.049 0.427 0.600 0.503

Resolution 640* 640* 1024* 800*

480 480 768 600

RECALL YES YES YES YES

A

BCDEF

Page 8

- 8 -

DIS AS S E MB LY

1. T ILT/S WIV E L & B ACK C OVE R R E MOV A L

1) S et the monitor face downward.

2) C arefully remove the T ilt/S wivel by pulling it upward.

3) Remove the screw (b), Back cover by pushing it upward.

4) R eleas e the latch (c). (S ee T ip S pec. )

5) S lide the B ack C over away from the F ront C abinet of the monitor.

Tip S pec .

A(W idth) : 5. 0~15.0mm

B (Depth) : 0. 6~0. 9mm

C (Height) : 12.0mm

B a

ck

C ov e

r

(c )

C abin et

(b)

(a )

C

T ip

B

A

Page 9

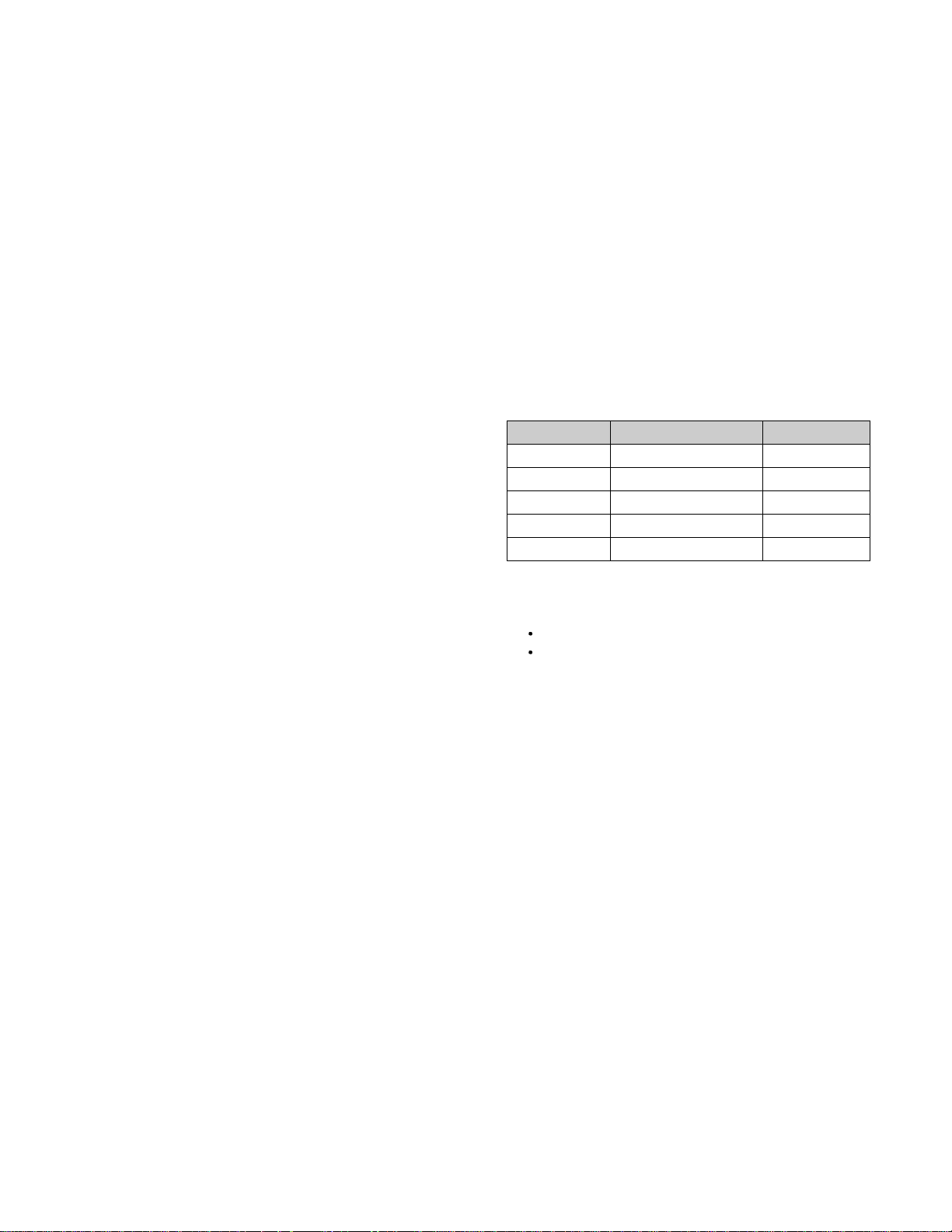

WIR ING DIA G R AM

- 9 -

P 501

P 201

P 405

P 301

P 302

G 2

P 702

P 701

T1

P 402

P 902

S

+

S

S ignal

C able

AC

S ocket

F B T

P 203

P 202

Page 10

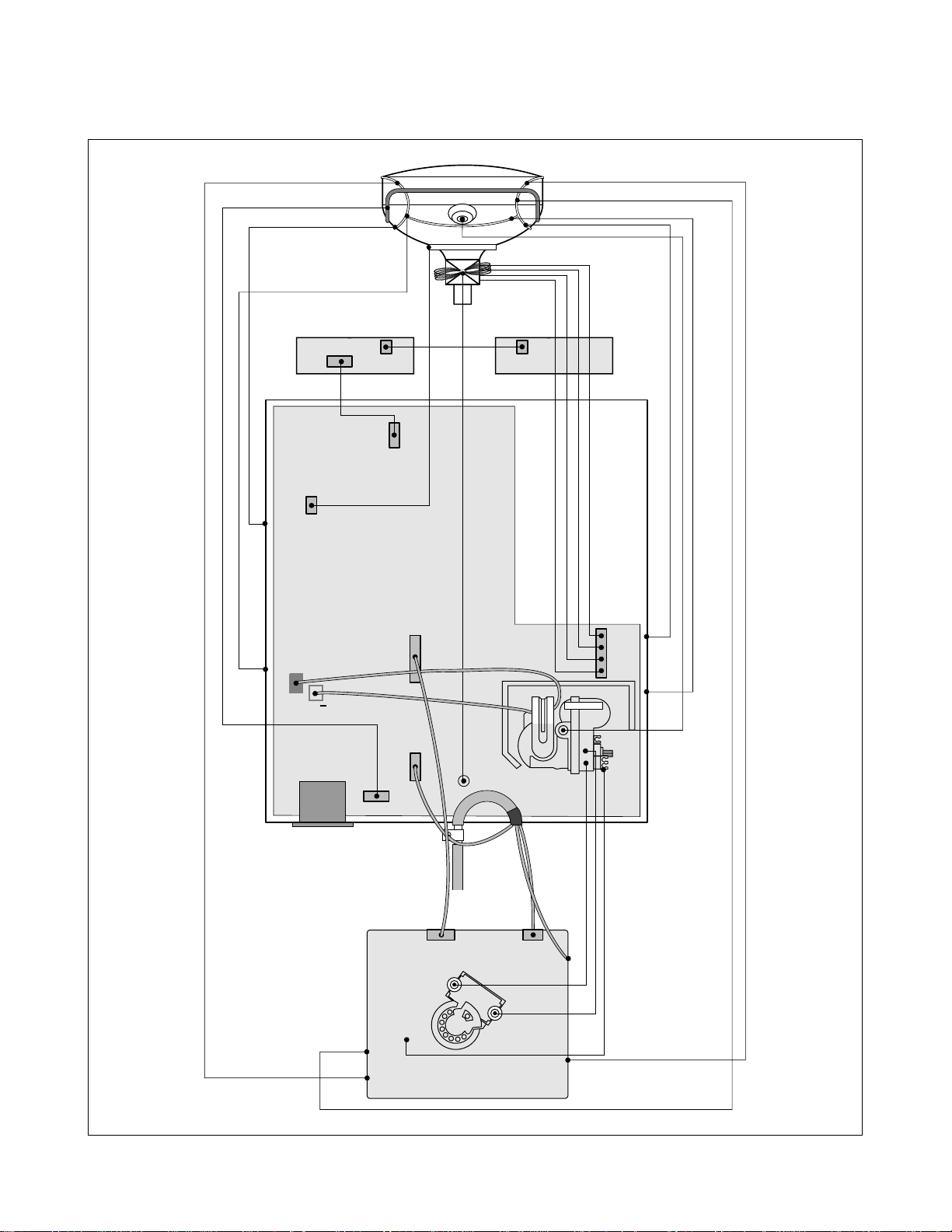

BLOCK DIAGRAM

- 10 -

H.V

Dyn ami c Foc us

Stat ic Foc us

DY CDT

Scr een

Heater ( 6.3V )

G1

G2

- 160V

Bri ght nes s Control

FBT

( T701 )

13V

Au to

Beam

Limi t

D/D

Feed B ack

Cir cu it

Regul atio n

8V 80V

5V

Video

H-Sync

VIDEO

VIDEO

Pre-AMP /

RGB

Signa l

V-Sync

40V

13V

CUT OFF Cir cu it

80V

SCL / SDA

(IC304)

Bias

R/G/B

X-RAY

H-Sync /V-Syn c

PWM Cont rol Signal

( IC401 )

SAA4 849

MICOM & H/V Sync Processor

13V

V-Out

Cir cu it

Prot ect ion

( IC601)

TDA4867J

C

2

I

(IC303)

Main AMP

OSD

(IC302)

C CLOCK(SCL)

2

I

C DATA(SDA)

2

I

B+

H-Out

( Q706 )

H - Dri ve

80V

Cor rect ion

H-Lineari ty

50V

DC/DC Converter

B-Drive

DPM

Contr ol

Cir cu it

50V

13V

6.3V

5V

PROM

2

E

(IC402)

5V

SPCC

MOIRE

CONTRAST

BRIGHTNESS

H / V SIZE

DEGAUSSING

H / V POSITION

TRAPEZOID

PIN BAL ANCE

PARALLE LOGRAM

COLOR

RECALL / RESET

INFORMATION

LANGUAGE

TOP/BOTTOM CORNER

VIDEO LEVEL

OSD CONTROL L OCK

[ OSD Cont ro l ]

13V

Cir cu it

Degaus sing

SMPS

(T901)

Degaussing

Coi l

Line

Volt age

feedba ck

SMPS

Contr ol

(IC901)

Filt er

(50/60Hz)

Power Inpu t

100~240VAC

Page 11

DESCRIPTION OF BLOCK DIAGRAM

- 11 -

1. SMPS(Switching Mode Power Supply)

When you turn on the power switch, the operating

fprocedure is as follows:

.

6. X-RAY Protection Circuit

When the high Voltage reaches to 29kV in an abnormal case,

the high voltage detector circuit, R818,D721,C739-1 R416,

C409 start operation to shut down high voltage circuit.

7. Horizontal S-correction Circuit.

This circuit corrects the horizontal linearity for each horizontal

sync frequency.

8. Horizontal drive and Output Circuit.

This circuit is a horizontal deflection amplifier for raster scan.

9. ABL Circuit

This circuit limits the beam-current for the reliability of CDT

10. Vertical Output Circuit

This circuit takes the vertical ramp wave from the TDA4867J

(IC601) and perform the vertical deflection by supplying the

saw-tooth wave current to the vertical deflection yoke.

11. Blanking and Brightness Control Circuit.

Blanking circuit eliminates the retrace line by supplying

a negative pulse wave to the G1 of the CDT.

Brightness control circuit is used for control of the screen

brightness by changing the DC level G1.

12. Image Rotation (Tilt) Circuit.

This circuit corrects the tilt of the screen by supplying

the image rotation signal to the tilt coil which is

attached near the deflection yoke of the CDT.

13. OSD (On Screen Display) Circuit.

This circuit displays information of the monitor`s status

on the screen.

14. Video Processor Circuit.

Video processor circuit consists of the video drive output

block. The video drive IC(IC302) receives the video

signal from PC. The gain of each channel is controlled

by MICOM through IIC.

The cut-off circuit compensate different voltage of each

channel between the cathode and the G1 of the CDT.

1) The AC line voltage is rectified by the bridge diode

D900.

2) The control IC(IC901) starts switching and generates

switch pulse in the primary turn of the SMPS

transformer(T901)

3) The switching pulses of the primary turns are induced

to the secondary turns of the transformer by the turn

ratio. This pulses are rectified by each diode(D971,

D961(D962),D951,D942,D941)

4) Each rectified DC voltage(80V, 50V, 15V,

13V,6.3Vand 5V)

2. Over Voltage Protection Circuit

When the input of IC901 Vin (pin 4) is more than 22V, all the

secondary voltages of the SMPS transformer (T901) down

to low value

3. Display Power Management Circuit(DPM)

1) STAND-BY & SUSPEND Mode

When no input of horizontal or vertical sync Q951,

Q941 are turned off and Q952,Q942 are turned off.

Then input power consumption is below 5 watts.

2) OFF Mode

When no input of horizontal and vertical sync Q951,

Q941 are turned off and Q952, Q942 are turned off.

Then input power consumption is below 5 watts.

4. Microprocessor Control & Horizontal and Vertical Sync

Processor Circuit

The operating procedure is as follows ;

1) There is Horizontal & Vertical process function in

Microprocessor.(IC401)

2) Microprocessor (IC401) discriminates the operating mode

from the sync polarity and resolution.

3) After microprocessor reads these adjusted mode data

stored at EEPROM, it controls operating mode data through

IIC

4) Users can control screen condition by the OSD Select,Up,

Down, Left, Right, Exit.

5. D/D Converter Circuit.

To obtain constant high voltage, this circuit supplies

controlled DC voltage for FBT and horizontal deflection

circuit according to the horizontal sync frequency.

Page 12

- 12 -

15. Video Pre-Amp Circuit.

This circuit amplifies the analog video signal from 0~0.7 V

to 0~4 V. It is operated by taking the clamp, R,G,B drive

and contrast signal from the MICOM (IC401)

16. Video Output Amp Circuit.

This circuit amplifies the video signal which comes from the

video pre-amp circuit and amplified it to applied the CDT

cathode

Page 13

1. Preparation for Service Adjustment

GENERAL INFORMATION

All adjustment are thoroughly checked and corrected

when the monitor leaves the factory, but sometimes

several adjustments may be required.

Adjustment should be following procedure and after

warming up for a minimum of 30 minutes.

• Alignment appliances and tools.

- IBM compatible PC.

- Programmable Signal Generator.

(eg. VG-819 made by Astrodesign Co.)

- EPROM or EEPROM with saved each mode data.

- Alignment Adaptor and Software.

- Digital Voltmeter.

- White Balance Meter.

- Luminance Meter.

- High-voltage Meter.

AUTOMATIC AND MANUAL DEGAUSSING

The degaussing coil is mounted around the CDT so that

automatic degaussing when turn on the monitor. But a

monitor is moved or faced in a different direction, become

poor color purity cause of CDT magnetized, then press

DEGAUSSING on the OSD menu.

ADJUSTMENT PROCEDURE & METHOD

- Install the cable for adjustment such as Figure 1and run

the alignment program on the DOS for IBM

compatible PC.

- Set external Brightness and Contrast volume to max

position.

1. Adjustment for B+ Voltage.

1) Display cross hatch pattern at Mode 4.

2) Check D961 cathode voltage within 50V ± 1V .

2. Adjustment for High-Voltage.

1) Display cross hatch pattern at Mode 4.

2) Enter the SVC SUB menu as the following instruction.

3) Adjust H/Voltage to 24.5kV±0.1 kV by adjust 1-P value.

2. Adjustment by Service Hot key

How to enter SVC HOT KEY

1. Press Menu and OSD window will appear.

2. While OSD window is displayed,

is seen on the

left bottom of OSD window.

3. Press + power switch simultaneously and the

screen will immediately refresh.

4. Press Menu and make sure that is changed to

1 2.

5. Follow the menu on the left of OSD window to find 12

and OSD will change as shown in the figure.

6. Select Degauss in the above figure and then press

Select and

to enter the screen of the SUB menu.

(Back Raster for Pattern)

FOS SPEC

1. Size

H : 270

4mm

V : 200

4mm

Scanning frequency : All Mode (Mode 1~4)

Display image : Cross hatch pattern

2. Centering

Scanning frequency : All Mode (Mode 1~4)

Display image : Crosshatch pattern

Horizontal : 10 Row

Vertical : 8 Row

H :

L-R 4mm, V : U-D 4mm

3. Tilt

Scanning frequency : All Mode (Mode 1~4)

Display image : Crosshatch pattern

Horizontal : 10 Row

Vertical : 8 Row

Tilt :

E-F 2.0mm

- 13 -

ADJUSTMENT

U

D

L

R

EF

Page 14

- 14 -

4. Distortion

Scanning frequency : All Mode (Mode 1~4)

Display image : Crosshatch pattern

Horizontal : 10 Row

Vertical : 8 Row

A-B 2.0mm, C-D 2.0mm

E-F 2.0mm, G-H

2.0mm

5. Displa Size drift

4mm : 25 Standard, 10 35

0.5mm : 180V ~ 264V

6. Linearity

Formula :

(Max - Min) / Max

x 100(%)

Criteria : H - 10% Max. (Upper 40kHz)

14% Max. (Less 40kHz)

V - 8% Max.

7. Regulation

Luminance

2mm

Dynamic(lode) 2mm

Scanning frequency : All Mode (Mode 1~4)

8. Trapezoid

9. Pin Balance

10.Parallelogram

11. Adjustment of white balance (Adjustment of

chromaticity diagram)

*(Adjustment of white balance must be made after

entering Hot Key Mode and DEGAUSS.)

CONDITIONS

Signal: 54 kHz / 85 Hz

Display image: Back raster (Color 0,0)

Contrast: Maximum

Brightness: Maximum

Color temperature: 9300K

11-1. Adjustment of cut off (Adjustment of back raster)

11-1(a). Before adjustment, press Menu and Degauss

to remove.

=> Enter hot key mode.

Adjust Brightness and Contrast to Max in OSD

window.

(1)Adjust cut off (back raster) first. Enter DEGAUSS in

the Menu and modify the following data.

Modify RCUT to Min ,

Modify GCUT To Min ,

Adjust to BCUT Data = 127 (7F (h)) ,

Adjust to SBRT Data = 205 ( CD (h)).

(2)Turn FBT screen volume on "CRT COLOR

ANALYZER CA-100" equipment to adjust

Brightness to 0.4

0.05FL.

(3)Adjust RCUT, GCUT, and SBRT to set chromaticity

diagram at :

x: 0.283

0.005

y: 0.298 0.005

Y: 0.40

0.05FL

* If color values would not be matched desirable values,

repeat sequence 1 and 2 after readjusting “GREEN

CUTOFF” control a little different.

U

D

D

U

U-D

< 4mm

L1 R1

2.0mm

L1

R1 L1

R1

Y1

Y2

Y3

Y4

X1 X2 X3 X4

4mm

A B

DC

EG

FH

Page 15

11-2. Adjustment of White Balance

After finishing adjustment of cut off (back raster),

approve "Color(15.0) Full white pattern".

Adjust BDRV Data = 85(55)

SCON=127.

Adjust RDRV and GDRV to set chromaticity diagram at :

x: 0.283 0.005

y: 0.298 0.005

Approve "Window pattern (70x70mm)" to adjust

S-CON to Y : 50 1FL.

Approve "Color (15.0) Full white pattern" again and

adjust ABL Data to Y : 32 1FL

12. Focus Adjustment

PROCEDURE

For trained and experienced service technicians only.

Use the following procedure to correct minor color

purity problems:

1. Make sure the display is not affected by external

magnetic fields.

2. Very carefully break the glue seal between the 2-pole

purity convergence magnets (PCM), the band and

the spacer.

3. Make sure the spacing between the PCM assembly

and the CRT stem is 29 mm

1 mm.

CONDITIONS

Scanning frequency : All Mode (Mode 1~4)

Display image: character pattern

"H"

Brightness: Cut off point

Contrast: Maximum

PROCEDURE

1. Adjust the Focus VR on the FBT to display the

sharpest image possible.

2. Use Locktite to seal the Focus VR in position.

13. Color Purity Adjustment

Color purity is the absence of undesired color.

Conspicuous mislanding (unexpected color in a uniform

field) within the display area shall not be visible at a

distance of 50 cm from the CRT surface.

CONDITIONS

Orientation: Monitor facing east

Scanning Frequency: 800 x 600(54kHz/85Hz)

Display image: White flat field

Luminance: Cut off point at the center of the

display area

Note: Color purity adjustments should only be

attempted by qualified personnel.

4. Display a green pattern over the entire display area.

5. Adjust the purity magnet rings on the PCM assembly

to display a pure green pattern.

(Optimum setting: x = 0.295

0.015,

y = 0.594 0.015)

6. Repeat steps 4 and 5 using a red pattern and then

again, using a blue pattern.

Table 4-6. Color Purity Tolerances

Red: x=0.620 0.015 y=0.334 0.015

Green: x=0.620 0.015 y=0.334 0.015

Blue: x=0.620 0.015 y=0.334 0.015

(For 9300K color adjustment: x = 0.283 0.02,

y = 0.298 0.02)

7. When you have the PCMs properly adjusted,

carefully glue them together to prevent their

movement during shipping.

- 15 -

Page 16

- 16 -

3. Adjustment Using Service software Program

(Adjustment Program)

1. Adjustment for Factory Mode (Preset Mode).

1) Display cross hatch pattern at Mode All.

2) Run alignment program for T530BL/T530SL on

the IBM compatible PC.

3) EEPROM→ ALL CLEAR → Y(Yes) command.

<Caution> Do not run this procedure unless the

EEPROM is changed. All data in EEPROM (mode

data and color data) will be erased.

4) COMMAND → PRESET START → Y(Yes)

command.

5) DIST. ADJ. → FOS. ADJ command.

6) Adjust H-POSITION as arrow keys to center of the

screen.

7) Adjust H-SIZE as arrow keys to 270 ± 2mm.

8) Adjust V-POSITION as arrow keys to center of the

screen.

9) Adjust V-SIZE as arrow keys to 200 ± 2mm.

10) Adjust TRAPEZOID as arrow keys to be the best

condition.

11) Adjust SIDE PINCUSHON as arrow keys to be the

best condition.

12) Adjust TILT as arrow keys to be the best condition.

13) Display cross hatch pattern at Mode 4.

14) DIST. ADJ. → BALANCE DATA command.

15) Adjust balance of Pin-Balance as arrow keys to be

the best condition.

16) Adjust parallelogram as arrow keys to be the best

condition.

17) Save of the Mode.

18) Save of the System.

19) Display from Mode 4 and repeat above from number

6) to 16).

20) COMMAND → PRESET EXIT → Y (Yes) command.

2. Adjustment for White Balance and Luminance.

1) Set the White Balance Meter.

2) Press the DEGAUSSING on the OSD menu for

demagnetization of the CDT.

3) Display color 0,0 pattern at Mode 4.

4) COMMAND → PRESET START → Y(Yes)

command.

5) Set Bightness and Contrast to max position.

6) COLOR ADJ. → LUMINANCE command of the

alignment program.

7) COLOR ADJ. → BIAS ADJ. command of the

alignment program.

8) Check whether blue color or not at R-BIAS and GBIAS to min position, Sub-Brightness to 205

(CD(h))position, B-Bias to 127(7F(h))position. If it's not

blue color, the monitor must repair.

9) Adjust Screen control on the FBT to 0.4 ± 0.05FL

of the raster luminance.

10) Adjust R-BIAS and G-BIAS command to x=0.283 ±

0.006 and y=0.298 ± 0.006 on the White Balance

Meter with PC arrow keys.

11) Display color 15,0 Full White(70x70mm) at mode 4.

12) DRIVE ADJ command.

13) Set B-DRIVE to 85(55(h)) at DRIVE of the aligment

program.

14) Adjust R-DRIVE and G-DRIVE command to white

balance x=0.283 ± 0.003 and y=0.298 ± 0.003 on

the White Balance Meter with PC arrow keys.

15) Adjust SUB-CONTRAST command to 50±1FL of the

raster luminance.

16) Display color 15,0 full white patten at Mode 4.

17) COLOR ADJ. → LUMINANCE → ABL command.

18) Adjust ABL to 32 ± 1FL of the luminance.

19) Exit from the program.

Page 17

4. EDID Data Edit Using Service soft ware Program

00 01 02 03 04 05 06 07 08 09 0A 0B 0C 0D 0E 0F

00 | 00 FF FF FF FF FF FF 00 1E 6D #A8 #3B *01 *01 *01 *01

10 |**01 ***0F 01 03 78 1C 15 B0 EA 60 59 A4 54 46 9B 24

20 | 10 48 4C BF E8 00 31 59 45 59 61 4A 01 01 01 01

30 | 01 01 01 01 01 01 64 19 00 40 41 00 26 30 18 88

40 | 36 00 0E C8 10 00 00 18 F9 15 20 F8 30 58 1F 20

50 | 20 40 13 00 0E C8 10 00 00 1E 00 00 00 FD 00 32

60 | 78 1E 38 08 00 0A 20 20 20 20 20 20 00 00 00 FC

70 | 00 54 35 33 30 42 0A 20 20 20 20 20 20 20 00 ****

00 01 02 03 04 05 06 07 08 09 0A 0B 0C 0D 0E 0F

00 | 00 FF FF FF FF FF FF 00 1E 6D #A9 #3B *01*00 *00 *00

10 | **01***0F 01 03 78 1C 15 B0 EA 60 59 A4 54 46 9B 24

20 | 10 48 4C BF E8 00 31 59 45 59 61 4A 01 01 01 01

40 | 36 00 0E C8 10 00 00 18 F9 15 20 F8 30 58 1F 20

50 | 20 40 13 00 0E C8 10 00 00 1E 00 00 00 FD 00 32

60 | 78 1E 38 08 00 0A 20 20 20 20 00 00 00 FC

70 | 00 54 35 33 30 53 0A 20 20 20 20 20 20 20 00 ***

4.1 Read and Modify EDID Data

1) Connector the monitor and adjust device as Figure1

2) Display color 15,0 cross hatch pattern at Mode 4.

3) Use EDIT – MODEL SEL. command to select the right model info file.

4) Use EDIT – EDID INFO command and return to read the EDID Data.

5) Modify the EDID Data if needed and using F10 to save the change and exit.

4.2 Write EDID Data.

1) Display color 15,0 cross hatch pattern at Mode 4.

2) Use EEPROM -- Write EDID command and confirm

“EDID Write OK!!” message of monitor.

3) Exit from the alignment program.

4) Power switch OFF/ON for EDID data save.

T530BL

T530SL

30 | 01 01 01 01 01 01

64 19 00 40 41 00 26 30 18 88

20 20

- 17 -

Page 18

Figure 1. Cable Con nect ion Figure 1. Cable Con nect ion

VIDEO

SIGNAL

GENERATOR

Control Line

IBM

Compatible PC

Power inlet (required)

22

0

Power Select Switch

(110V/220V)

Power LED

E

ST Switch

- 18 -

PARALLEL PORT

5V

OFF ON

F

d

se

u

C

2

3

Not

2

RS

C

RALLEL

PA

VG

S

A

POWER

ST

MO

N

NC

I

T

O

SY

R

V-

B

F

V-Sync On/Off Switch

(Switch must be ON.)

A

69

1

15

10

5

5

11

6

1

13

25

ON

OFF

5V

E

74LS06

C

1

14

5V

4.7K

4.7K

74LS06

4.7K

B

- 18 -

Page 19

1 2

CHECK

D900 BRIDGE DIODE?

CHECK

C908(+) VOLTAGE

145VDC at 110V input

310VDC at 220V input

IC901, Q901

CHECK

D971, D961, D951, D904

D941, D942, D906 ?

CHECK

FUSE OK?(F901)

- 19 -

TROUBLESHOOTING GUIDE

1. NO POWER

NO POWER

(POWER INDICATOR OFF)

NO

NO

NO

NO

TROUBLE IN

Q951, Q952, Q941, Q942,

TROUBLE

IN FUSE (F901)

SMPS Switch (ON, OFF)

Waveforms

TROUBLE IN

BRIDGE DIODE (D900)

TROUBLE IN

IC901, Q901

TROUBLE IN

D971, D961, D951, D904

D941, D942, D906

YES

YES

YES

YES

Q901, Drain IC901, #6

21

Page 20

26

2. NO CHARACTER

NO CHARACTER

NO

NO

NO

NO

TROUBLE IN

CDT SOCKET

TROUBLE IN

P301, SIGNAL CABLE,

PC SIGNAL

TROUBLE IN

IC302, P301

TROUBLE IN

IC303

TROUBLE IN

IC304

YES

YES

YES

YES

- 20 -

CHECK

IC302 PIN 5,6,7

CHECK

IC302 PIN 1, 24, 23, 19, 20, 21

PIN 18 (5V) ?

CHECK

IC303 PIN 1, 2, 3

PIN8 (8V),

PIN 4 (80V) ?

CHECK

R, G, B CATHODE

VOLTAGE?

IC302, #5, 6, 7

IC302, #23 IC302, #19, 20, 21

IC302, #1 IC302, #24

CDT, RK, GK, BK

Waveforms

2827

30

31

26 27 28

29 30 31

29

Page 21

CHECK

SCREEN CONTROL

KNOB OF FBT

CHECK

VOLTAGE AT

D961 CATHODE (50V)

D971 CATHODE (80V)

D951 CATHODE (13V)

D941 CATHODE

(6.3V)?

CHECK

IC401 (MICOM) PIN 16

5V (HIGH), IC401 PIN 18

PIN20, PIN21

CHECK

POWER INDICATOR

GREEN or FLASH ?

- 21 -

3. NO RASTER

FLASH

NO

NO

NO

TROUBLE IN

IC401 (MICOM),

TROUBLE IN

P302 SIGNAL CABLE

ROTATE SCREEN CONTROL

KNOB TO CLOCKWISE

or COUNTER CLOCKWIES

TROUBLE IN PRIMARY

CIRCUIT OF T901

TROUBLE IN

CDT SOCKET, BOARD

GREEN

YES

YES

YES

NO VIDEO

(POWER INDICATOR

GREEN or FLASH)

IC401, #18 IC401, #20 IC401, #21

14

7

5

5 14 7

Waveforms

Page 22

CHECK

IC601 PIN 7 (45V)?

CHECK

IC401 PIN 33, 34

(SAWTOOTH WAVE)?

CHECK

IC601 Pin 3 (13V) ?

- 22 -

4. NO VERTICAL DEFLECTION

NO V-DEFLECTION

(ONE HORIZONTAL LINE)

NO

NO

NO

TROUBLE IN

IC601, V-CIRCUIT

TROUBLE IN

T901

13V Line

Waveforms

TROUBLE IN

T701 40V line

TROUBLE IN

IC401

YES

YES

YES

IC401, #33 IC401, #34

98

8 9

Page 23

3

CHECK

IC401 PIN 45, 46

WAVEFORM?

CHECK

IC401 PIN 10, 50 ?

CHECK B+ LINE

CHECK

IC401 (MICOM)

PIN 52, 53 (H/V INPUT)

SIGNAL?

- 23 -

5. TROUBLE IN DPM

4

Stand-by/SUSPEND/

DPMS OFF MODE FAILURE

INPUT H/V SYNC SIGNAL

NO

NO

NO

TROUBLE IN

T901 or PC

CHECK PC,

(PC IS NOT GOING INTO DPM

MODE)

TROUBLE IN

X401, IC401

TROUBLE IN

IC401

TROUBLE IN

IC401

NO

TROUBLE IN

Q941, Q951

NO H/V SYNC SIGNAL

YES

YES

YES

YES

DPMS TABLE

NORMAL ON/ON NORMAL GREEN

STAND-BY OFF/ON OFF(0V) FLASH

SUSPEND ON/OFF OFF(0V) FLASH

OFF OFF/OFF OFF(0V) FLASH

H/V SYNC VIDEO LED

MODE

ITEM

C401, #45 IC401, #46

CHECK

IC401 PIN 16 (5V, HIGH)?

43

Waveforms

(50V,13V,80V,5V)?

Page 24

CHECK

Q953 COLLECTOR

VOLTAGE (0.5V)?

CHECK

P902?

CHECK

RL901?

CHECK

IC401 PIN 4 (5V)?

6. NO DEGAUSSING

NO DEGAUSSING

NO

NO

NO

NO

TROUBLE IN

TH901,

DEGAUSSING COIL

TROUBLE IN

IC401 (MICOM)

TROUBLE IN

D953

TROUBLE IN

P902

TROUBLE IN

RL901

YES

YES

YES

YES

- 24 -

Page 25

5 18

20 21

19

Q705 drain

waveform is right?

Q706 base, collector

waveforms are right?

Q719 drain

waveform is right?

IC401 Pin 18 waveform is

right?

- 25 -

7. H_Deflection Failure

NO

NO

NO

NO

1. Check IC401 Pins 39,40,41

2. Replace IC401.

Check Q720,50V LINE

D710

Check Q704

Check 13V Line.

Check and replace T703

and Q706.Check DY connector

connection.

YES

YES

YES

IC401, #18

Q706, Base Q706, Collector

Q719, Drain Q705, Drain

5

18

19

2120

Waveforms

8. Invariable H_Size

NO

Check and replace IC401.

Check if DC voltage of

IC401 PIN 35

wave is Variable.

6

IC401, #35

6

Page 26

- 26 -

9. TROUBLE IN H-LINEARITY

UNBALANCED OF H-LIN.

CHECK

IC401

PIN 11, 12

CHECK

Q711~Q716?

CHECK

L703?

TROUBLE IN

IC401 (MICOM)

TROUBLE IN

Q711 ~ Q716

TROUBLE IN

L703

TROUBLE IN

C722, C726, C729

NO

NO

NO

YES

YES

YES

Cs SIGNAL TABLE

HORIZONTAL

FREQUENCY(fH)

30K ~ 33.9K

34K ~ 38.9K

39K ~ 43.9K

44K ~ 48.9K

49K ~ 51.9K

52K ~ 57.9K

Cs1

L

L

H

H

H

H

Cs2

L

H

L

H

H

H

Page 27

Check if AC

Voltage of IC401 Pin 35

waveform is Variable

T701 pin 2 voltage

is change with H frequency?

The Voltage

waveform Q706 Collector

is right?

- 27 -

10. Abnormal H_Size

NO

NO

Repeat the troubleshooting

Guide of H_deflection failure.

Check D/D converter circuit

Check IC401 B+ control circuit.

YES

11. Side Pin or Trap Failure

NO

12. Para. or Pin Balance Failure

Replace IC401.

Check and replace IC401.

Q706, Collector IC401, #35

21

6

21 6

Waveforms

Page 28

8 9

98

Q501 Emitter output varies

with different DAC values?

IC401 Pin 33, 34

output varies with different

DAC values?

IC401 Pin 26

output duty varies with

different DAC values?

13. Tilt Failure(optional)

Check tilt connector

connection

Check and replace CRT.

NO

NO

Check and replace IC401.

Check Q503,Q501,Q502.

YES

YES

14. V Size or Pos. Variation Failure

Check and replace IC401

and IC601.

NO

Check some parts around IC401.

YES

- 28 -

IC401, #33 IC401, #34

Waveforms

Page 29

Q706 collecter waveform

is right?

15. High Voltage Failure

NO

NO

Replace T701

Check Q719,Q720

Check 50V line

Repeat the troubleshooting

Guide of H_deflection failure.

YES

YES

16. ABL Failure

YES

NO

Check and replace CRT

Input full white pattern to monitor.

Check P302, D801,

R801~803, R798.

Check and replace IC302

Check and replace T701

NO

YES

- 29 -

Q719, Drain Q706,Collector

IC302 Pin22

input exists and varies

with different patterns?

T701 Pin 6 Voltage exists?

18

18

Waveforms

21

21

YES

waveform is right?

Q719 drain

Page 30

3 4

43

IC401 Pin 23 input is

High Active?

All in/output values are

right?

IC401 Pin 45 and 46

inputs are right?

IC401 Pin 16 input is over

4.2V?

17. Micom Failure

18. OSD Failure

NO

NO

NO

NO

Done.

Change IC302

Check Q903,D908,ZD902

Check X401

Check and replace

R451,C408

Replace IC401.

YES

YES

YES

YES

- 30 -

IC401, #45

IC401, #46

Waveforms

Page 31

Proper Video levels are

on P301 Pin 1, 3 and 5.

IC401 Pins 27 and 28

inputs are right at

each function?

19. User Control Failure

Check connector Ass’y.

NO

Done.

Check and replace IC401.

Check and replace function key.

YES

20. Missing Color

NO

Change the CRT.

Check signal generator and

signal cable.

NO

Refer to 2 No Charcter.

NO

Check and replace IC303

and IC304

NO

Check C341, C346 and G2 wire.

Check around FBT circuits also.

YES

YES

YES

YES

- 31 -

Proper AC voltage are

on all cathodes?

Proper DC voltage are

on all cathodes?

G2 voltage is right?

Page 32

Blank pedestal is on

Pin 19, 20 and 21 of IC302

Is V_FLB and DC_bias on

G1 Pin at CRT socket?

G2 voltage is right?

21. Visible Retrace

Check white balance adjustment.

NO

NO

NO

Done.

Check G2 control volume and FBT.

Check IC302

and related components.

Check Q799

and related components.

YES

YES

YES

- 32 -

Degaussing circuit is right?

Purity is right?

22. Purity Failure

Degaussing

YES

NO

Replace CRT and verify purity.

Done.

Refer to 6 NO Degaussing.

NO

YES

Page 33

Improved focus?

Adjust Pole4,Pole6

to improve the misconvergence

23. Misconvergence

Degauss the CDT

Done.

Change CRT and readjust

convergence.

Yes

Done

No

24. Poor Focus

Adjust focus VR.

Check focus leads from

FBT to CRT Socket.

Check the CRT Socket.

YES

Aging monitor and

check for focus change.

NO

- 33 -

Page 34

EXPLODED VIEW

- 34 -

10

12

12

13

11-2

11-1

7

B

A

2

6

5

a

b

b

1

d

12

3

4

8

15

c

14

15

9

Page 35

EXPLODED VIEW PARTS LIST

- 36 -

Description

CDT(CIRC), M36QFP503X01 QDDD LG-PHILIPS DISPLAY 54KHZ 29.1MM FCDT EQUATOR NON-MPR WITHOUT TILT

TILT SWIVEL ASSEMBLY, T530 B046 T051 320T-8C358A

SCREW ASSEMBLY, PHP+5*30BP(FZMY)+GW18

FBT (FLY BACK TRANSFORMER), C93 BSC24-1445 FUJIAN FURI(HIACHI) 15''

SOCKET(CIRC),POWER, SA-4S-061P-LF HUA JIE AC UNIVERSAL 3PIN BLACK

CABLE,D-SUB, UL20276-9C(5.8MM) AT 1560MM GRAY(85964) T710BJ DM

PWB(PCB) ASSEMBLY,SUB, T530SL CONTROL TOTAL BRAND CA-138

METAL, SHIELD T530

BRACKET, CB773D SUPPORTER CDT

SCREW, PTP+4*20BP(MSWR/FZMY)

BRACKET, T530 HOLDER FBT

MAIN TOTAL ASSEMBLY, T530BL KLANML BRAND CA-138

PWB(PCB) ASSEMBLY,MAIN, T530SL KLEUALD BRAND CA-138 TOTAL

SCREW,DRAWING, D3.5 L10.0 MSWR/FZMY +SW3.5+RW3.5

SCREW ASSEMBLY, TAPTITE P TYPE D3.0 L10.0 MSWR/FZMY SW3+RW10

SCREW,DRAWING, PZP+3*10(MSWR/FZMY)

Part No.

3091TKB055D

6318L15022C

3043TKK071S

339-002D

6174T11006D

6620TKB003B

6850TA9012A

6871TST985C

4950TKS331C

4810TKK153A

4810TKK154A

332-102F

4810TKK204K

3313T15104D

6871TMTA38C

332-112F

4001TKK004E

332-095B

Ref. No.

1

2

3

4

5

6

7

8

9

10

11-1

11-2

12

13

A

B

a

b

c

3091TKB055C

3091TKB055A

3091TKB055E

6318L15022A

3809TKB028F

3809TKB028B

3043TKK071P

3043TKK071T

6850TA9012C

CABINET ASSEMBLY, T530 BRAND 043A(SILVER APRAY FOR DI)

CABINET ASSEMBLY, T530 BRAND 043A(FOR LGEDI BLACK)

CABINET ASSEMBLY, T530 BRAND TKB043A(FOR NT)

CABINET ASSEMBLY, T530 BRAND 043A(FOR SP)

CDT(CIRC), M36QFP803X01 NDDD LG-PHILIPS DISPLAY 54KHZ 29.1MM FCDT MPR WITHOUT TILT

BACK COVER ASSEMBLY, T530 B032 320T 8C358

BACK COVER ASSEMBLY, 505EL B032 320T 92166 BK

TILT SWIVEL ASSEMBLY, CB553H B046/T051 60HR 92166BK

TILT SWIVEL ASSEMBLY, T530 B046 T051 320T(RUBBER PUSH)

CABLE,D-SUB, UL20276-9C(5.8MM) AT 1500MM BLACK 9930 700BJ DM

6871TST985A

6871TST985E

14

15

4930TKK036A

4930TKK031C

3313T15104C

3313T15104A

3313T15104L

6871TMTA38A

6871TMTA38G

d

332-110A

PWB(PCB) ASSEMBLY,SUB, T530EL CONTROL TOTAL BRAND CA-138

PWB(PCB) ASSEMBLY,SUB, T530SSL KLPAALM CONTROL TOTAL BRAND CA-138

BRACKET, CB773D SUPPORTER CDT

HOLDER,PCB FIX FB770G

HOLDER,PCB FIX,PC+ABS

MAIN TOTAL ASSEMBLY, T530SL BRAND CA-138

MAIN TOTAL ASSEMBLY, T530EL BRAND CA-138

MAIN TOTAL ASSEMBLY, T530SL.BR BRAND CA-138

PWB(PCB) ASSEMBLY,MAIN, T530EL KLRDMT BRAND CA-138 TOTAL

PWB(PCB) ASSEMBLY,MAIN, T530SL BRAZIL BRAND CA-138 TOTAL

SCREW, PZS+3*6(MSWR/FZMY)

Page 36

REPLACEMENT PARTS LIST

CAUTION: BEFORE REPLACING ANY OF THESE COMPONENTS,

READ CAREFULLY THE SAFETY PRECAUTIONS IN THIS MANUAL.

* NOTE : S SAFETY Mark

AL ALTERNATIVE PARTS

MODEL :T530BL/T530SL DATE:2005.03.11

*S *AL LOC NO. PART NO. DESCRIPTION/SPECIFICATON

C A P A C I T O R s

C 3 0 1 6 8 7 1 T M A A 0 4 C 0.001UF D 100V 5% PE TP5

C 3 0 2 6 8 7 1 T M A A 0 4 C "10UF SHL,SD 16V M FM5 TP 5"

C 3 0 3 6 8 7 1 T M A A 0 4 C 56P 50V J NP0 TP

C 3 0 4 6 8 7 1 T M A A 0 4 C 56P 50V J NP0 TP

C 3 0 5 6 8 7 1 T M A A 0 4 C "47UF SHL,SD 16V M FM5 TP 5"

C 3 0 6 6 8 7 1 T M A A 0 4 C ECQB1H103JF3 MATSUSHITA 50V

10000PF 5% TAPING 103J

C 3 0 7 6 8 7 1 T M A A 0 4 C 56P 50V J NP0 TP

C 3 0 8 6 8 7 1 T M A A 0 4 C 1000PF 50V K B TR

C 3 0 9 6 8 7 1 T M A A 0 4 C 0.1UF 50V Z F TR

C 3 1 1 6 8 7 1 T M A A 0 4 C 0.1UF 50V Z F TR

C 3 1 2 6 8 7 1 T M A A 0 4 C 0.1UF 50V Z F TR

C 3 1 3 6 8 7 1 T M A A 0 4 C 0.1UF 50V Z F TR

C 3 1 4 6 8 7 1 T M A A 0 4 C 47PF 500V J SL TP

C 3 1 5 6 8 7 1 T M A A 0 4 C 47UF KMG 16V M FM5 TP 5

C 3 1 7 6 8 7 1 T M A A 0 4 C 0.1UF 50V Z F TR

C 3 1 8 6 8 7 1 T M A A 0 4 C 0.1UF 50V Z F TR

C 3 1 9 6 8 7 1 T M A A 0 4 C 0.1UF 50V Z F TR

C 3 2 0 6 8 7 1 T M A A 0 4 C 1000PF D 2KV 10% TR B(Y5P)

C 3 2 1 6 8 7 1 T M A A 0 4 C "2.2UF SHL,SD 50V M FM5 TP 5"

C 3 2 3 6 8 7 1 T M A A 0 4 C "47UF SHL,SD 16V M FM5 TP 5"

C 3 2 4 6 8 7 1 T M A A 0 4 C 0.1UF 50V Z F TR

C 3 2 5 6 8 7 1 T M A A 0 4 C MKT 100V 104JTR PHS26104

C 3 2 6 6 8 7 1 T M A A 0 4 C 22PF 500V J NP0 TR

C 3 2 7 6 8 7 1 T M A A 0 4 C MKT 100V 104JTR PHS26104

C 3 2 8 6 8 7 1 T M A A 0 4 C 22UF KMG 100V M FM5 TP 5

C 3 2 9 6 8 7 1 T M A A 0 4 C MKT 100V 104JTR PHS26104

C 3 3 0 6 8 7 1 T M A A 0 4 C MKT 100V 104JTR PHS26104

C 3 3 1 6 8 7 1 T M A A 0 4 C MKT 100V 334JTR PHS26334

C 3 3 2 6 8 7 1 T M A A 0 4 C MKT 100V 334JTR PHS26334

C 3 3 3 6 8 7 1 T M A A 0 4 C MKT 100V 334JTR PHS26334

C 3 3 4 6 8 7 1 T M A A 0 4 C MKT 100V 104JTR PHS26104

C 3 3 5 6 8 7 1 T M A A 0 4 C MKT 100V 104JTR PHS26104

C 3 3 9 6 8 7 1 T M A A 0 4 C 1500P 500V K B TS

C 3 4 0 6 8 7 1 T M A A 0 4 C MKT 100V 104JTR PHS26104

C 3 4 1 6 8 7 1 T M A A 0 4 C 1000PF D 2KV 10% TR B(Y5P)

C 3 4 4 6 8 7 1 T M A A 0 4 C MKT 100V 104JTR PHS26104

C 3 4 6 6 8 7 1 T M H A 7 2 C 0.01M 2KV Z F S

C 3 7 2 6 8 7 1 T M A A 0 4 C 0.1UF 50V Z F TR

C 4 0 1 6 8 7 1 T M A A 0 4 C 0.1UF 50V Z F TR

C 4 0 4 6 8 7 1 T M A A 0 4 C 0.1UF 50V Z F TR

C 4 0 5 6 8 7 1 T M A A 0 4 C 470UF SHL TYPE 16V M FM5 TP 5

C 4 0 6 6 8 7 1 T M A A 0 4 C 100PF D 2KV 10% B(Y5P) TR

C 4 0 7 6 8 7 1 T M A A 0 4 C 0.0047UF D 100V 5% PE TP5

C 4 0 8 6 8 7 1 T M A A 0 4 C 0.1UF 50V Z F TR

C 4 0 9 6 8 7 1 T M A A 0 4 C "10UF SHL,SD 16V M FM5 TP 5"

C 4 1 0 6 8 7 1 T M A A 0 4 C 100PF 50V K B TR

C 4 1 1 6 8 7 1 T M A A 0 4 C 100PF 50V K B TR

C 4 1 2 6 8 7 1 T M A A 0 4 C 1000PF 50V K B TR

C 4 1 3 6 8 7 1 T M A A 0 4 C 100PF 50V K B TR

C 4 1 4 6 8 7 1 T M A A 0 4 C "10UF SHL,SD 16V M FM5 TP 5"

C 4 1 5 6 8 7 1 T M A A 0 4 C 2200P 50V K B TS

C 4 1 6 6 8 7 1 T M A A 0 4 C 0.01U 100V J POLY TP

C 4 1 7 6 8 7 1 T M A A 0 4 C MKT 100V 104JTR PHS26104

C 4 1 9 6 8 7 1 T M A A 0 4 C 2200PF 100V J PE TP

C 4 2 0 6 8 7 1 T M A A 0 4 C 0.068U 100V K POLY TP

C 4 2 1 6 8 7 1 T M A A 0 4 C 1000PF 50V K B TR

MODEL :T530BL/T530SL DATE:2005.03.11

*S *AL LOC NO. PART NO. DESCRIPTION/SPECIFICATON

C 4 2 2 6 8 7 1 T M A A 0 4 C 2200P 50V K B TS

C 4 2 3 6 8 7 1 T M A A 0 4 C 2200P 50V K B TS

C 4 2 4 6 8 7 1 T M A A 0 4 C "4.7UF SHL,SD 50V M FM5 TP 5"

C 4 2 6 6 8 7 1 T M A A 0 4 C 470PF 50V K B TR

C 4 2 7 6 8 7 1 T M A A 0 4 C 470PF 50V K B TR

C 4 3 0 6 8 7 1 T M A A 0 4 C 0.1UF 50V Z F TR

C 6 0 1 6 8 7 1 T M A A 0 4 C "220UF KMG,RD 16V 20% TP 5 FM5"

C 6 0 2 6 8 7 1 T M A A 0 4 C MKT 100V 104JTR PHS26104

C 6 0 3 6 8 7 1 T M A A 0 4 C 100UF KMG 50V M FM5 TP 5

C 6 0 4 6 8 7 1 T M A A 0 4 C MKT 100V 333JTR PHS 86333

C 6 0 5 6 8 7 1 T M A A 0 4 C 1000PF D 500V 10% B(Y5P) TR

C 7 0 1 6 8 7 1 T M A A 0 4 C 0.1UF 50V Z F TR

C 7 1 2 6 8 7 1 T M A A 0 4 C 0.1UF 50V Z F TR

C 7 1 3 6 8 7 1 T M A A 0 4 C 220P 50V K B TS

C 7 1 4 6 8 7 1 T M A A 0 4 C "100UF SHL,SD 25V M FM5 TP 5"

C 7 1 5 6 8 7 1 T M A A 0 4 C MKT 100V 103JTR PHS86103

C 7 1 9 6 8 7 1 T M H A 7 2 C SHL-BP SYE / SWE 50V 3.3UF 20% BULK

E B 7 7 0 H

C 7 2 2 6 8 7 1 T M H A 7 2 C 224J 30.0*19.5*12.0*20.0 250V J PU FM20

C 7 2 4 6 8 7 1 T M A A 0 4 C 0.1UF 50V Z F TR

C 7 2 5 6 8 7 1 T M A A 0 4 C 680P 500V K B TS

C 7 2 6 6 8 7 1 T M H A 7 2 C 823J 20.0*17.5*10.0*10.0 250V J PU FM10

C 7 2 9 6 8 7 1 T M H A 7 2 C 304J 19.0*18.5*10.5*10.0 250V J MPP FM10

C 7 3 0 6 8 7 1 T M A A 0 4 C 0.1UF 50V Z F TR

C 7 3 1 6 8 7 1 T M H A 7 2 C 472J 29.0*20.0*9.0*20.0 2.5KV J BUP FM20

C 7 3 3 6 8 7 1 T M H A 7 2 C 682J 20.0*17.5*10.0*10.0 800V J PU FM10

C 7 3 9 - 1 6 8 7 1 T M A A 0 4 C "10UF SHL,SD 100V M FM5 TP 5"

C 7 4 0 6 8 7 1 T M H A 7 2 C 220UF KMG 63V 20% FM5 BULK

C 7 4 1 6 8 7 1 T M A A 0 4 C ECQV1H154JZ3 154J 50V TP5.0

M A T S U S H I T A

C 7 4 4 6 8 7 1 T M H A 7 2 C 684J 26.0*19.0*12.5*15.0 250V J MPP FM15

C 7 4 8 6 8 7 1 T M A A 0 4 C 150PF 500V K B TR

C 7 4 9 6 8 7 1 T M A A 0 4 C 4.7000UF SMS 200V M FM5 TP5

C 7 5 0 6 8 7 1 T M A A 0 4 C 0.1UF 50V Z F TR

C 7 5 6 6 8 7 1 T M A A 0 4 C 47PF D 50V 10% B(Y5P) TR

C 8 0 1 6 8 7 1 T M A A 0 4 C MKT 100V 104JTR PHS26104

C 9 0 1 6 8 7 1 T M H A 7 2 C BULK PCX2 335 474K

C 9 0 2 6 8 7 1 T M H A 7 2 C BULK PCX2 335 104M

C 9 0 3 6 8 7 1 T M H A 7 2 C BULK 7.5 CS E 102M 8.0 250V TDK

C 9 0 4 6 8 7 1 T M H A 7 2 C BULK 7.5 CS E 222M 10.5 250V TDK

C 9 0 5 6 8 7 1 T M H A 7 2 C BULK 7.5 CS E 222M 10.5 250V TDK

C 9 0 6 6 8 7 1 T M H A 7 2 C BULK 7.5 CS E 102M 8.0 250V TDK

C 9 0 7 6 8 7 1 T M H A 7 2 C BULK 7.5 CS E 472M 14.5 250V TDK

C 9 0 8 6 8 7 1 T M H A 7 2 C "150UF SMH,HC(25.4*30) 400V M VNSN

B U L K "

C 9 0 9 6 8 7 1 T M A A 0 4 C "10000PF D 1KV 80%,-20% F(Y5V) TR"

C 9 1 0 6 8 7 1 T M A A 0 4 C 100PF 1KV K B TR

C 9 1 1 6 8 7 1 T M A A 0 4 C "4.7UF SHL,SD 50V M FM5 TP 5"

C 9 1 2 6 8 7 1 T M A A 0 4 C 330P 50V K B TS

C 9 1 3 6 8 7 1 T M A A 0 4 C "47UF SHL,SD 50V M FM5 TP 5"

C 9 1 4 6 8 7 1 T M A A 0 4 C ECQB1H153JM3 153J 50V TP5.0

M A T S U S H I T A

C 9 1 5 6 8 7 1 T M A A 0 4 C 680P 50V K B TS

C 9 1 7 6 8 7 1 T M A A 0 4 C 1000PF 50V K B TR

C 9 1 8 6 8 7 1 T M A A 0 4 C 0.1UF 50V Z F TR

C 9 4 1 6 8 7 1 T M A A 0 4 C 1000UF SHL 10V M FL TP5

C 9 4 2 6 8 7 1 T M A A 0 4 C "100UF SHL,SD 16V M FM5 TP 5"

- 36 -

Page 37

MODEL :T530BL/T530SL DATE:2005.03.11

*S *AL LOC NO. PART NO. DESCRIPTION/SPECIFICATON

C 9 4 3 6 8 7 1 T M A A 0 4 C 560P 1KV K B TS

C 9 5 1 6 8 7 1 T M H A 7 2 C 1000UF SHL 16V M FM5 BULK

C 9 5 2 6 8 7 1 T M A A 0 4 C "100UF SHL,SD 16V M FM5 TP 5"

C 9 5 3 6 8 7 1 T M A A 0 4 C 470UF SHL TYPE 16V M FM5 TP 5

C 9 5 4 6 8 7 1 T M A A 0 4 C 1000UF KMG 10V M FL TP 5

C 9 7 1 6 8 7 1 T M A A 0 4 C 47UF KMG 50V M FM5 TP 5

C 9 9 8 6 8 7 1 T M H A 7 2 C 220UF KMG 63V 20% FM5 BULK

D I O D E s

D 3 0 1 6 8 7 1 T M A A 0 4 C 1N4148M PCTRONIX TP DO34 100V 75VA

2000MA 4NSEC 0.025UA

D 3 0 2 6 8 7 1 T M A A 0 4 C 1N4148M PCTRONIX TP DO34 100V 75VA

2000MA 4NSEC 0.025UA

D 3 0 3 6 8 7 1 T M A A 0 4 C 1N4148M PCTRONIX TP DO34 100V 75VA

2000MA 4NSEC 0.025UA

D 3 0 4 6 8 7 1 T M A A 0 4 C 1N4148M PCTRONIX TP DO34 100V 75VA

2000MA 4NSEC 0.025UA

D 3 0 5 6 8 7 1 T M A A 0 4 C 1N4148M PCTRONIX TP DO34 100V 75VA

2000MA 4NSEC 0.025UA

D 3 0 6 6 8 7 1 T M A A 0 4 C 1N4148M PCTRONIX TP DO34 100V 75VA

2000MA 4NSEC 0.025UA

D 3 0 7 6 8 7 1 T M A A 0 4 C 1N4148M PCTRONIX TP DO34 100V 75VA

2000MA 4NSEC 0.025UA

D 3 0 8 6 8 7 1 T M A A 0 4 C 1N4148M PCTRONIX TP DO34 100V 75VA

2000MA 4NSEC 0.025UA

D 3 0 9 6 8 7 1 T M A A 0 4 C 1N4148M PCTRONIX TP DO34 100V 75VA

2000MA 4NSEC 0.025UA

D 3 1 0 6 8 7 1 T M A A 0 4 C PSS244 PCTRONIX TP DO34 280V 625MA

1000MA 50NSSEC 10UA

D 3 1 1 6 8 7 1 T M A A 0 4 C PSS244 PCTRONIX TP DO34 280V 625MA

1000MA 50NSSEC 10UA

D 3 1 2 6 8 7 1 T M A A 0 4 C PSS244 PCTRONIX TP DO34 280V 625MA

1000MA 50NSSEC 10UA

D 3 1 3 6 8 7 1 T M A A 0 4 C PSS244 PCTRONIX TP DO34 280V 625MA

1000MA 50NSSEC 10UA

D 3 1 4 6 8 7 1 T M A A 0 4 C PSS244 PCTRONIX TP DO34 280V 625MA

1000MA 50NSSEC 10UA

D 3 1 5 6 8 7 1 T M A A 0 4 C PSS244 PCTRONIX TP DO34 280V 625MA

1000MA 50NSSEC 10UA

D 3 1 6 6 8 7 1 T M A A 0 4 C 1N4005-1021 TIWAN SEMI TP DO41 600V

1A 30A 2USSEC 5.0UA

D 4 0 1 6 8 7 1 T M A A 0 4 C 1N4148M PCTRONIX TP DO34 100V 75VA

2000MA 4NSEC 0.025UA

D 4 0 2 6 8 7 1 T M A A 0 4 C 1N4148M PCTRONIX TP DO34 100V 75VA

2000MA 4NSEC 0.025UA

D 4 0 3 6 8 7 1 T M A A 0 4 C 1N4148M PCTRONIX TP DO34 100V 75VA

2000MA 4NSEC 0.025UA

D 4 0 6 6 8 7 1 T M A A 0 4 C PSS244 PCTRONIX TP DO34 280V 625MA

1000MA 50NSSEC 10UA

D 7 0 3 6 8 7 1 T M H A 7 2 C MUR460(15MM) GULF BK DO201AD 600V

4A 150A 45NSSEC 10UA

D 7 0 4 4 9 2 1 T K K 4 5 7 C "FFPF04F150STU,LF FAIR CHILD ST

TO220F 1500V 4A 40A 170NSEC 5UA"

D 7 0 5 6 8 7 1 T M A A 0 4 C SRT14(1021) TIWAN SEMI TP NON 40V 1A

25A .SEC 0.5MA

D 7 0 6 6 8 7 1 T M H A 7 2 C "FFPF04F150STU,LF FAIR CHILD ST

TO220F 1500V 4A 40A 170NSEC 5UA"

D 7 1 0 6 8 7 1 T M A A 0 4 C UF4004 GULF TP DO41 400V 1A 30A

50NSEC 10UA

D 7 1 2 6 8 7 1 T M A A 0 4 C RGP10G-1021 TIWAN SEMI TP DO41 400V

1A 30A 150NSEC 5UA

D 7 1 4 6 8 7 1 T M A A 0 4 C 1N4148M PCTRONIX TP DO34 100V 75VA

2000MA 4NSEC 0.025UA

D 7 1 5 6 8 7 1 T M A A 0 4 C 1N4148M PCTRONIX TP DO34 100V 75VA

2000MA 4NSEC 0.025UA

D 7 1 6 6 8 7 1 T M A A 0 4 C 1N4005-1021 TIWAN SEMI TP DO41 600V

MODEL :T530BL/T530SL DATE:2005.03.11

*S *AL LOC NO. PART NO. DESCRIPTION/SPECIFICATON

1A 30A 2USSEC 5.0UA

D 7 1 7 6 8 7 1 T M A A 0 4 C 1N4005-1021 TIWAN SEMI TP DO41 600V

1A 30A 2USSEC 5.0UA

D 7 1 9 6 8 7 1 T M A A 0 4 C RGP10J-1021 TIWAN SEMI TP DO41 600V

1A 30A 250NSEC 5UA

D 7 2 1 6 8 7 1 T M A A 0 4 C RGP10G-1021 TIWAN SEMI TP DO41 400V

1A 30A 150NSEC 5UA

D 7 2 3 6 8 7 1 T M A A 0 4 C 1N4148M PCTRONIX TP DO34 100V 75VA

2000MA 4NSEC 0.025UA

D 7 2 4 6 8 7 1 T M A A 0 4 C 1N4005-1021 TIWAN SEMI TP DO41 600V

1A 30A 2USSEC 5.0UA

D 8 0 1 6 8 7 1 T M A A 0 4 C 1N4148M PCTRONIX TP DO34 100V 75VA

2000MA 4NSEC 0.025UA

D 9 0 0 6 8 7 1 T M H A 7 2 C D2SB60-1121 TIWAN SEMI ST GBL 600V

2A 80A _SEC 10UA

D 9 0 4 6 8 7 1 T M A A 0 4 C RGP10G-1021 TIWAN SEMI TP DO41 400V

1A 30A 150NSEC 5UA

D 9 0 5 6 8 7 1 T M A A 0 4 C UF4007-1021 TIWAN SEMI TP DO204AL

1000V 1A 30A 75NSEC 10UA

D 9 0 6 6 8 7 1 T M A A 0 4 C RGP10G-1021 TIWAN SEMI TP DO41 400V

1A 30A 150NSEC 5UA

D 9 0 8 6 8 7 1 T M A A 0 4 C 1N4148M PCTRONIX TP DO34 100V 75VA

2000MA 4NSEC 0.025UA

D 9 1 0 6 8 7 1 T M A A 0 4 C 1N4148M PCTRONIX TP DO34 100V 75VA

2000MA 4NSEC 0.025UA

D 9 1 1 6 8 7 1 T M A A 0 4 C 1N4148M PCTRONIX TP DO34 100V 75VA

2000MA 4NSEC 0.025UA

D 9 4 1 6 8 7 1 T M A A 0 4 C UF4004 GULF TP DO41 400V 1A 30A

50NSEC 10UA

D 9 4 2 6 8 7 1 T M A A 0 4 C UF4004 GULF TP DO41 400V 1A 30A

50NSEC 10UA

D 9 5 1 6 8 7 1 T M H A 7 2 C UF5404 GULF BK DO201AD 400V 3.0A

150A 50NSSEC 10.0UA

D 9 5 2 6 8 7 1 T M A A 0 4 C 1N4148M PCTRONIX TP DO34 100V 75VA

2000MA 4NSEC 0.025UA

D 9 6 1 6 8 7 1 T M H A 7 2 C 31GF6 GULF BK DO201AD 600V 3A 90A

30NSEC 10UA

D 9 7 1 6 8 7 1 T M A A 0 4 C UF4007-1021 TIWAN SEMI TP DO204AL

1000V 1A 30A 75NSEC 10UA

Z D 3 0 1 6 8 7 1 T M A A 0 4 C UZ-4.3BSB PCTRONIX TP52 DO34 500MW

4.3BV 5MA PF

Z D 4 0 2 6 8 7 1 T M A A 0 4 C UZ-5.6BSB PCTRONIX TP52 DO34 500MW

5.6BV 5MA PF

Z D 4 0 3 6 8 7 1 T M A A 0 4 C UZ-5.6BSB PCTRONIX TP52 DO34 500MW

5.6BV 5MA PF

Z D 4 0 4 6 8 7 1 T M A A 0 4 C UZ-5.6BSB PCTRONIX TP52 DO34 500MW

5.6BV 5MA PF

Z D 4 0 5 6 8 7 1 T M A A 0 4 C UZ-5.6BSB PCTRONIX TP52 DO34 500MW

5.6BV 5MA PF

Z D 4 0 6 6 8 7 1 T M A A 0 4 C UZ-5.6BSB PCTRONIX TP52 DO34 500MW

5.6BV 5MA PF

Z D 9 0 2 6 8 7 1 T M A A 0 4 C UZ-5.1BSB PCTRONIX TP52 DO34 500MW

5.1BV 5MA PF

C O I L s & C O R E s

L 7 0 2 6 8 7 1 T M H A 7 2 C "- - H-SIZE,DR12*20-C6.0,150UH 700BJ"

L 7 0 3 6 8 7 1 T M H A 7 2 C 14*5T 12UH 0.12*30MM 23.5T

L 7 0 5 6 8 7 1 T M H A 7 2 C DR15*18-C9.8 100UH 0.1*30MM 40.5T D/D

C H O K E

F B 3 0 2 6 8 7 1 T M A A 0 4 C BAS3580T BO SUNG 3580MM AXIAL52MM

F B 3 0 5 6 8 7 1 T M A A 0 4 C BRS2550B BO SUNG 2550MM RADIAL

F B 3 0 6 6 8 7 1 T M A A 0 4 C BAS3580T BO SUNG 3580MM AXIAL52MM

F B 3 0 7 6 8 7 1 T M A A 0 4 C BRS3580B BO SUNG 3580MM RADIAL

F B 3 0 8 6 8 7 1 T M A A 0 4 C BAS2550T BO SUNG 2550MM AXIAL52MM

F B 3 0 9 6 8 7 1 T M A A 0 4 C BAS2550T BO SUNG 2550MM AXIAL52MM

F B 3 1 0 6 8 7 1 T M A A 0 4 C BRD3510B BO SUNG 3510MM RADIAL

- 37 -

Page 38

MODEL :T530BL/T530SL DATE:2005.03.11

*S *AL LOC NO. PART NO. DESCRIPTION/SPECIFICATON

F B 3 1 3 6 8 7 1 T M A A 0 4 C BAS2550T BO SUNG 2550MM AXIAL52MM

F B 7 0 1 6 8 7 1 T M A A 0 4 C BAS3580T BO SUNG 3580MM AXIAL52MM

F B 9 0 3 6 8 7 1 T M A A 0 4 C BRS2550B BO SUNG 2550MM RADIAL

F B 9 0 5 6 8 7 1 T M A A 0 4 C BAS2550T BO SUNG 2550MM AXIAL52MM

F B 9 0 6 6 8 7 1 T M A A 0 4 C BRS2550B BO SUNG 2550MM RADIAL

F B 9 2 1 6 8 7 1 T M A A 0 4 C BRD3510B BO SUNG 3510MM RADIAL

F B 9 2 2 6 8 7 1 T M A A 0 4 C BRD3510B BO SUNG 3510MM RADIAL

L 9 0 3 6 8 7 1 T M A A 0 4 C BAS3550T BO SUNG 3550MM AXIAL52MM

I c s

I C 3 0 2 6 8 7 1 T M H A 7 2 C "LM1246DDC/NA,NOPB NATIONAL

SEMICONDUCTOR 24,DIP ST LF,ONE

CHIP (VIDEO+OSD)"

I C 3 0 3 4 9 2 1 T K K 4 6 7 C "LM2470TA,NOPB NATIONAL

SEMICONDUCTOR 9PIN TA09A

ST LF,MONOLITHIC TRIPLE 7.0NS CRT

D R I V E R "

I C 3 0 4 6 8 7 1 T M H A 7 2 C "LM2480NA,NOPB NATIONAL

SEMICONDUCTOR 8P,DIP ST LF,80V

TRIPLE BIAS CLAMP"

I C 4 0 1 0 I Z Z T S Z 6 8 9 A SAA4849(OTP) PHILIPS 56PIN SDIP -

DEFLECTION AND MICOM

I C 4 0 2 6 8 7 1 T M H A 7 2 C "M24C08-WBN6(P),LF STM 8PIN PDIP ST

SERIAL IIC EEPROM"

I C 6 0 1 4 9 2 1 T K K 4 4 9 C "TDA4867J PHILIPS 9PIN,ST DIP VERTICAL

OUTPUT IC"

I C 9 0 1 6 8 7 1 T M H A 7 2 C KA3842B (PWM)

T R A N S I S T O R s

Q 7 0 3 4 9 2 1 T K K 4 5 7 C FQPF10N20C FAIRCHILD ST TO220F 200V

9 . 5 A

Q 7 0 4 6 8 7 1 T M A A 0 4 C FAIRCHILD 2N3904(TA) TP TO-92 60V 0.2A

Q 7 0 5 6 8 7 1 T M A A 0 4 C KTC200-Y TP KEC TO92 NPN

Q 7 0 6 4 9 2 1 T K K 4 5 7 C FJAF6810A FAIRCHILD ST TO3PF 1550V

1 0 A / 2 0 A

Q 7 1 1 4 9 2 1 T K K 4 5 1 C "IRF630MFP,LF SGS-T(STM) ST TO220F

200V 5A"

Q 7 1 3 4 9 2 1 T K K 4 5 1 C "IRF630MFP,LF SGS-T(STM) ST TO220F

200V 5A"

Q 7 1 5 6 8 7 1 T M A A 0 4 C KTC3198-Y(KTC1815) TP KEC TO92 NPN

Q 7 1 6 6 8 7 1 T M A A 0 4 C KTC3198-Y(KTC1815) TP KEC TO92 NPN

Q 7 1 9 4 9 2 1 T K K 4 5 5 C FQPF10N20C FAIRCHILD ST TO220F 200V

9 . 5 A

Q 7 2 0 6 8 7 1 T M A A 0 4 C FAIRCHILD 2N3904(TA) TP TO-92 60V 0.2A

Q 7 9 9 6 8 7 1 T M A A 0 4 C MPSA92 KEC TP TO92 -300V -500MA

Q 9 0 1 4 9 2 1 T K K 4 6 8 C "STP9NK65ZFP,LF SGS-T(STM) ST TO220F

650V 6.4A"

Q 9 0 3 6 8 7 1 T M A A 0 4 C KSC1008C-Y TP SAMSUNG TO92 NPN

Q 9 4 1 6 8 7 1 T M A A 0 4 C KTC3198-Y(KTC1815) TP KEC TO92 NPN

Q 9 4 2 6 8 7 1 T M A A 0 4 C KTA1273-Y(KTA966A) TP KEC TO92L PNP

Q 9 5 1 6 8 7 1 T M A A 0 4 C KTC3198-Y(KTC1815) TP KEC TO92 NPN

Q 9 5 2 6 8 7 1 T M A A 0 4 C KTA1273-Y(KTA966A) TP KEC TO92L PNP

Q 9 5 3 6 8 7 1 T M A A 0 4 C KTC3198-Y(KTC1815) TP KEC TO92 NPN

R E S I S T O R s

L 3 0 1 6 8 7 1 T M A A 0 4 C 47 1/4W(3 5% TA52

L 3 0 2 6 8 7 1 T M A A 0 4 C 47 1/4W(3 5% TA52

L 3 0 3 6 8 7 1 T M A A 0 4 C 47 1/4W(3 5% TA52

R 2 0 1 6 8 7 1 T S A 7 2 4 C 1K 1/4W(3 5% TA52

R 2 0 2 6 8 7 1 T S A 7 2 4 C 91 OHM 1/4 W (3.4) 5% TA52

R 2 0 3 6 8 7 1 T S A 7 2 4 C 220 1/4W(3 5% TA52

R 2 0 4 6 8 7 1 T S A 7 2 4 C 430 OHM 1/4 W(3.4) 5.00% TA52

R 2 0 5 6 8 7 1 T S A 7 2 4 C 1K 1/4W(3 5% TA52

R 2 0 6 6 8 7 1 T S A 7 2 4 C 91 OHM 1/4 W (3.4) 5% TA52

R 2 0 7 6 8 7 1 T S A 7 2 4 C 430 OHM 1/4 W(3.4) 5.00% TA52

R 2 0 8 6 8 7 1 T S A 7 2 4 C 220 1/4W(3 5% TA52

R 2 0 9 6 8 7 1 T S A 7 2 4 C 910 1/4W(3 5% TA52

R 2 1 1 6 8 7 1 T S A 7 2 4 C 220 1/4W(3 5% TA52

MODEL :T530BL/T530SL DATE:2005.03.11

*S *AL LOC NO. PART NO. DESCRIPTION/SPECIFICATON

R 3 0 1 6 8 7 1 T M A A 0 4 C 75 1/4W(3 5% TA52

R 3 0 2 6 8 7 1 T M A A 0 4 C 75 1/4W(3 5% TA52

R 3 0 3 6 8 7 1 T M A A 0 4 C 75 1/4W(3 5% TA52

R 3 0 5 6 8 7 1 T M A A 0 4 C 6.20K 1/6W 1% TA52

R 3 1 4 6 8 7 1 T M A A 0 4 C 100 1/4W(3 5% TA52

R 3 1 5 6 8 7 1 T M A A 0 4 C 100 1/4W(3 5% TA52

R 3 1 9 6 8 7 1 T M A A 0 4 C 4.70K 1/4W(3 5% TA52

R 3 2 0 6 8 7 1 T M A A 0 4 C 4.70K 1/4W(3 5% TA52

R 3 2 6 6 8 7 1 T M A A 0 4 C 2.20K 1/4W(3 5% TA52

R 3 2 7 6 8 7 1 T M A A 0 4 C 1K 1/4W(3 5% TA52

R 3 2 8 6 8 7 1 T M A A 0 4 C 1K 1/4W(3 5% TA52

R 3 2 9 6 8 7 1 T M A A 0 4 C 1K 1/4W(3 5% TA52

R 3 3 0 6 8 7 1 T M A A 0 4 C 1K 1/4W(3 5% TA52

R 3 3 1 6 8 7 1 T M A A 0 4 C 200 1/4W(3 5% TA52

R 3 3 2 6 8 7 1 T M A A 0 4 C 200 1/4W(3 5% TA52

R 3 3 3 6 8 7 1 T M A A 0 4 C 150 1/4W(3 5% TA52

R 3 3 4 6 8 7 1 T M A A 0 4 C 330K 1/4W(3 5% TA52

R 3 3 5 6 8 7 1 T M A A 0 4 C 330K 1/4W(3 5% TA52

R 3 3 6 6 8 7 1 T M A A 0 4 C 330K 1/4W(3 5% TA52

R 3 3 7 6 8 7 1 T M A A 0 4 C 100 1/4W(3 5% TA52

R 3 3 8 6 8 7 1 T M A A 0 4 C 10 1/4W(3 5% TA52

R 3 4 0 6 8 7 1 T M A A 0 4 C 10K 1/6W 1 TA52

R 3 4 1 6 8 7 1 T M A A 0 4 C 33 OHM 1/2 W (7.0) 5% TA52

R 3 4 2 6 8 7 1 T M A A 0 4 C 33 OHM 1/2 W (7.0) 5% TA52

R 3 4 3 6 8 7 1 T M A A 0 4 C 33 OHM 1/2 W (7.0) 5% TA52

R 3 4 4 6 8 7 1 T M A A 0 4 C 33 1/4W(3 5% TA52

R 3 4 5 6 8 7 1 T M A A 0 4 C 33 1/4W(3 5% TA52

R 3 4 6 6 8 7 1 T M A A 0 4 C 33 1/4W(3 5% TA52

R 3 4 7 6 8 7 1 T M A A 0 4 C 20 1/4W(3 5% TA52

R 4 0 1 6 8 7 1 T M A A 0 4 C 220 1/4W(3 5% TA52

R 4 0 2 6 8 7 1 T M A A 0 4 C 100 1/4W(3 5% TA52

R 4 0 3 6 8 7 1 T M A A 0 4 C 100 1/4W(3 5% TA52

R 4 0 4 6 8 7 1 T M A A 0 4 C 100 1/4W(3 5% TA52

R 4 0 5 6 8 7 1 T M A A 0 4 C 2.20K 1/4W(3 5% TA52

R 4 0 6 6 8 7 1 T M A A 0 4 C 2.20K 1/4W(3 5% TA52

R 4 0 7 6 8 7 1 T M A A 0 4 C 4.70K 1/4W(3 5% TA52

R 4 0 8 6 8 7 1 T M A A 0 4 C 100 1/4W(3 5% TA52

R 4 0 9 6 8 7 1 T M A A 0 4 C 100 1/4W(3 5% TA52

R 4 1 1 6 8 7 1 T M A A 0 4 C 100 1/4W(3 5% TA52

R 4 1 2 6 8 7 1 T M A A 0 4 C 100 1/4W(3 5% TA52

R 4 1 3 6 8 7 1 T M A A 0 4 C 100 1/4W(3 5% TA52

R 4 1 4 6 8 7 1 T M A A 0 4 C 16K 1/4W(3 5% TA52

R 4 1 6 6 8 7 1 T M A A 0 4 C 1.5K 1/6W 1 TA52

R 4 1 7 6 8 7 1 T M A A 0 4 C 100 1/4W(3 5% TA52

R 4 1 9 6 8 7 1 T M A A 0 4 C 47K 1/6W 1% TA52

R 4 2 0 6 8 7 1 T M A A 0 4 C 2K 1/4W(3 5% TA52

R 4 2 1 6 8 7 1 T M A A 0 4 C 1.50K 1/4W(3 5% TA52

R 4 2 2 6 8 7 1 T M A A 0 4 C 2K 1/4W(3 5% TA52

R 4 2 3 6 8 7 1 T M A A 0 4 C 100 1/4W(3 5% TA52

R 4 2 4 6 8 7 1 T M A A 0 4 C 100 1/4W(3 5% TA52

R 4 2 5 6 8 7 1 T M A A 0 4 C 100 1/4W(3 5% TA52

R 4 2 6 6 8 7 1 T M A A 0 4 C 100 1/4W(3 5% TA52

R 4 2 7 6 8 7 1 T M A A 0 4 C 10K 1/4W(3 5% TA52

R 4 3 0 6 8 7 1 T M A A 0 4 C 100 1/4W(3 5% TA52

R 4 3 1 6 8 7 1 T M A A 0 4 C 18K 1/4W(3 5% TA52

R 4 3 3 6 8 7 1 T M A A 0 4 C 2K 1/4W(3 5% TA52

R 4 3 4 6 8 7 1 T M A A 0 4 C 33K 1/4W(3 5% TA52

R 4 3 6 6 8 7 1 T M A A 0 4 C 3.60K 1/4W(3 5% TA52

R 4 3 7 6 8 7 1 T M A A 0 4 C 27K OHM 1/2 W (7.0) 5% TA52

R 4 3 8 6 8 7 1 T M A A 0 4 C 130K 1/4W(3 5% TA52

R 4 3 9 6 8 7 1 T M A A 0 4 C 560 1/6W 1% TA52

R 4 4 0 6 8 7 1 T M A A 0 4 C 1K 1/6W 1% TA52

R 4 4 1 6 8 7 1 T M A A 0 4 C 33K 1/4W(3 5% TA52

R 4 4 2 6 8 7 1 T M A A 0 4 C 3.90K 1/6W 1% TA52

R 4 4 3 6 8 7 1 T M A A 0 4 C 220 1/4W(3 5% TA52

- 38 -

Page 39

*S *AL LOC NO. PART NO. DESCRIPTION/SPECIFICATON

R 4 4 4 6 8 7 1 T M A A 0 4 C 470 OHM 1/4 W (3.4) 5% TA52

R 4 4 5 6 8 7 1 T M A A 0 4 C 470 OHM 1/4 W (3.4) 5% TA52

R 4 4 6 6 8 7 1 T M A A 0 4 C 100 1/4W(3 5% TA52

R 4 4 7 6 8 7 1 T M A A 0 4 C 100 1/4W(3 5% TA52

R 4 4 9 6 8 7 1 T M A A 0 4 C 7.50K 1/6W 1% TA52

R 4 5 0 6 8 7 1 T M A A 0 4 C 120K OHM 1/4 W (3.4) 2% TA52

R 4 5 1 6 8 7 1 T M A A 0 4 C 1K 1/4W(3 5% TA52

R 4 5 2 6 8 7 1 T M A A 0 4 C 10K 1/4W(3 5% TA52

R 4 5 3 6 8 7 1 T M A A 0 4 C 2K 1/4W(3 5% TA52

R 4 5 4 6 8 7 1 T M A A 0 4 C 2K 1/4W(3 5% TA52

R 4 5 5 6 8 7 1 T M A A 0 4 C 10K 1/4W(3 5% TA52

R 4 5 6 6 8 7 1 T M A A 0 4 C 100 1/4W(3 5% TA52

R 4 6 1 6 8 7 1 T M A A 0 4 C 390 1/4W(3 5% TA52

R 4 6 2 6 8 7 1 T M A A 0 4 C 2K 1/4W(3 5% TA52

R 4 6 3 6 8 7 1 T M A A 0 4 C 4.70K 1/4W(3 5% TA52

R 6 0 1 6 8 7 1 T M A A 0 4 C 100 1/4W(3 5% TA52

R 6 0 2 6 8 7 1 T M A A 0 4 C 100 1/4W(3 5% TA52

R 6 0 3 6 8 7 1 T M A A 0 4 C 0.22 1/2W 5% TA52

R 6 0 4 6 8 7 1 T M A A 0 4 C 1 OHM 1/2 W (7.0) 5% TA52

R 6 0 5 6 8 7 1 T M A A 0 4 C 150 OHM 1/2 W (7.0) 5% TA52

R 6 0 6 6 8 7 1 T M A A 0 4 C 100 1/4W(3 5% TA52

R 6 0 7 6 8 7 1 T M A A 0 4 C 3.90K 1/6W 1% TA52

R 6 0 8 6 8 7 1 T M A A 0 4 C 220 OHM 1/2 W (7.0) 5% TA52

R 7 0 1 6 8 7 1 T M A A 0 4 C 470 OHM 1/4 W (3.4) 5% TA52

R 7 0 2 6 8 7 1 T M A A 0 4 C 620 1/4W(3 5% TA52

R 7 0 3 6 8 7 1 T M A A 0 4 C 5.60K 1/4W(3 5% TA52

R 7 0 4 6 8 7 1 T M A A 0 4 C 10K 1/4W(3 5% TA52

R 7 0 5 6 8 7 1 T M A A 0 4 C 10 1/4W(3 5% TA52

R 7 0 6 6 8 7 1 T M A A 0 4 C 62K OHM 1/2 W (7.0) 5% TA52

R 7 2 7 6 8 7 1 T M H A 7 2 C 100 OHM 2 W 5% SF

R 7 2 8 6 8 7 1 T M A A 0 4 C 1K 1/4W(3 5% TA52

R 7 2 9 6 8 7 1 T M A A 0 4 C 10K 1/4W(3 5% TA52

R 7 3 6 6 8 7 1 T M A A 0 4 C 2.2KOHM 1 W 5% TA52

R 7 3 7 6 8 7 1 T M A A 0 4 C 0.56 1/2W 5 TA52

R 7 3 8 6 8 7 1 T M A A 0 4 C 0.56 1/2W 5 TA52

R 7 3 9 6 8 7 1 T M A A 0 4 C 2.70K 1/4W(3 5% TA52

R 7 4 0 6 8 7 1 T M A A 0 4 C 2.7 OHM 1/2 W (7.0) 5% TA52

R 7 4 4 6 8 7 1 T M A A 0 4 C 220 OHM 1/2 W (7.0) 5% TA52

R 7 4 7 6 8 7 1 T M A A 0 4 C 3K 1/4W(3 5% TA52

R 7 4 8 6 8 7 1 T M A A 0 4 C 47K 1/4W(3 5% TA52

R 7 4 9 6 8 7 1 T M A A 0 4 C 2.20K 1/4W(3 5% TA52

R 7 5 0 6 8 7 1 T M A A 0 4 C 3K 1/4W(3 5% TA52

R 7 5 1 6 8 7 1 T M A A 0 4 C 22 OHM 1/2 W (7.0) 5% TA52

R 7 5 2 6 8 7 1 T M A A 0 4 C 2.20K 1/4W(3 5% TA52

R 7 5 4 6 8 7 1 T M A A 0 4 C 680 OHM 1/2 W (7.0) 5% TA52

R 7 5 6 6 8 7 1 T M A A 0 4 C 22K OHM 1/2 W (7.0) 5% TA52

R 7 6 1 6 8 7 1 T M A A 0 4 C 3K 1/4W(3 5% TA52

R 7 6 2 6 8 7 1 T M A A 0 4 C 3K 1/4W(3 5% TA52