Page 1

LG

Multi Type Air Conditioner

SERVICE MANUAL

LG

CAUTION

website http://www.lgservice.com

e-mail http://www.lgeservice.com/techsup.html

• BEFORE SERVICING THE UNIT, READ THE SAFETY

PRECAUTIONS IN THIS MANUAL.

• ONLY FOR AUTHORIZED SERVICE PERSONNEL.

MODEL: Indoor Unit: Wall Mounted Type

TMNC092DYAA

TMNC122DYAA

TMNC182D5AA

TMNC242D5AA

TMNC092TYAA

TMNC122TYAA

TMNC182T5AA

TMNC242T5AA

TMNH092DYAA

TMNH122DYAA

TMNH182D5AA

TMNH242D5AA

TMNH092TYAA

TMNH122TYAA

TMNH182T5AA

TMNH242T5AA

Outdoor Unit: T2UC182FAA

T2UC242FAA

T2UC362FAA

T2UC482FAA

T2UH242FAA

T2UH362FAA

T2UH482FAA

T2UH182FAA

Page 2

2 Multi Air Conditioner

Multi Air Conditioner Service Manual

TABLE OF CONTENTS

Safety Precautions ......................................................................................................................................3

Product Specifications ...............................................................................................................................7

Dimensions ..................................................................................................................................................9

Refrigeration Cycle Diagram ....................................................................................................................12

Wiring Diagram ..........................................................................................................................................13

Electronic Control Device .........................................................................................................................14

Schematic Diagram ...................................................................................................................................17

Functions ...................................................................................................................................................19

Operation Details ......................................................................................................................................22

Disassembly ..............................................................................................................................................26

2-way, 3-way Valve ....................................................................................................................................29

Cycle Troubleshooting Guide ..................................................................................................................33

Installation .................................................................................................................................................39

Flaring work and connection of piping ...................................................................................................42

Connecting the Cable Between Indoor Unit and Outdoor Unit .............................................................47

Exploded View and Replacement Parts List ...........................................................................................49

Page 3

Service Manual 3

Safety Precautions

Safety Precautions

To prevent injury to the user or other people and property damage, the following instructions must

be followed.

Incorrect operation due to ignoring instruction will cause harm or damage. The seriousness is

classified by the following indications.

Meanings of symbol used in this manual are as shown below.

WARNING

CAUTION

This symbol indicates the possibility of death or serious injury.

This symbol indicates the possibility of injury or damage.

WARNING

Installation

Be sure not to do.

Be sure to follow the instruction.

Do not use a defective or

underrated circuit breaker.

Use this appliance on a dedicated circuit.

• There is risk of fire or electric shock.

Do not let the air conditioner

run for a long time when the

humidity is very high and a

door or a window is left open.

• Moisture may condense and wet or

damage furniture.

Always ground the product.

• There is risk of fire or electric shock.

Install the panel and the cover

of control box securely.

• There is risk of fire or electric shock.

Always install a dedicated circuit and breaker.

• Improper wiring or installation may

cause fire or electric shock

Use the correctly rated breaker or fuse.

• There is risk of fire or electric shock.

Page 4

4 Multi Air Conditioner

Safety Precautions

Operational

Do not modify or extend the

power cable.

• There is risk of fire or electric shock.

Do not install, remove, or reinstall the unit by yourself

(customer).

• There is risk of fire, electric shock,

explosion, or injury.

Be cautious when unpacking

and installing the product.

• Sharp edges could cause injury. Be

especially careful of the case edges

and the fins on the condenser and

evaporator.

For installation, always contact the dealer or an

Authorized Service Center.

• There is risk of fire, electric shock,

explosion, or injury.

Do not install the product on a

defective installation stand.

• It may cause injury, accident, or damage to the product.

Be sure the installation area

does not deteriorate with age.

• If the base collapses, the air conditioner could fall with it, causing property

damage, product failure, and personal

injury.

Do not touch(operate) the

product with wet hands.

• There is risk of fire or electrical shock.

Do not place a heater or other

appliances near the power

cable.

• There is risk of fire and electric shock.

Do not allow water to run into

electric parts.

• It may cause There is risk of fire, failure of the product, or electric shock.

Page 5

Service Manual 5

Safety Precautions

Do not open the inlet grille of the product during operation. (Do not touch the electrostatic

filter, if the unit is so equipped.)

• There is risk of physical injury, electric shock, or product failure.

Be cautious that water could not enter the

product.

• There is risk of fire, electric shock, or product damage.

Do not store or use flammable gas or combustibles near the product.

• There is risk of fire or failure of product.

If strange sounds, or smell or smoke comes

from product. Turn the breaker off or disconnect the power supply cable.

• There is risk of electric shock or fire.

Gasolin

Page 6

6 Multi Air Conditioner

Operational

Safety Precautions

Use two or more people to lift

and transport the product.

• Avoid personal injury.

Use a soft cloth to clean. Do

not use harsh detergents, solvents, etc.

• There is risk of fire, electric shock, or

damage to the plastic parts of the product.

Do not touch the metal parts

of the product when removing

the air filter. They are very

sharp!

• There is risk of personal injury.

Do not step on or put anyting on the product.

(outdoor units)

• There is risk of personal injury and failure of product.

Do not insert hands or other objects through

the air inlet or outlet while the product is operated.

• There are sharp and moving parts that could cause personal

injury.

CAUTION

Installation

Wax

Thinner

check for gas (refrigerant)

leakage after installation or

repair of product.

• Low refrigerant levels may cause failure of product.

Install the drain hose to

ensure that water is drained

away properly.

• A bad connection may cause water

leakage.

Keep level even when

installing the product.

• To avoid vibration or water leakage.

90Û

Page 7

Service Manual 7

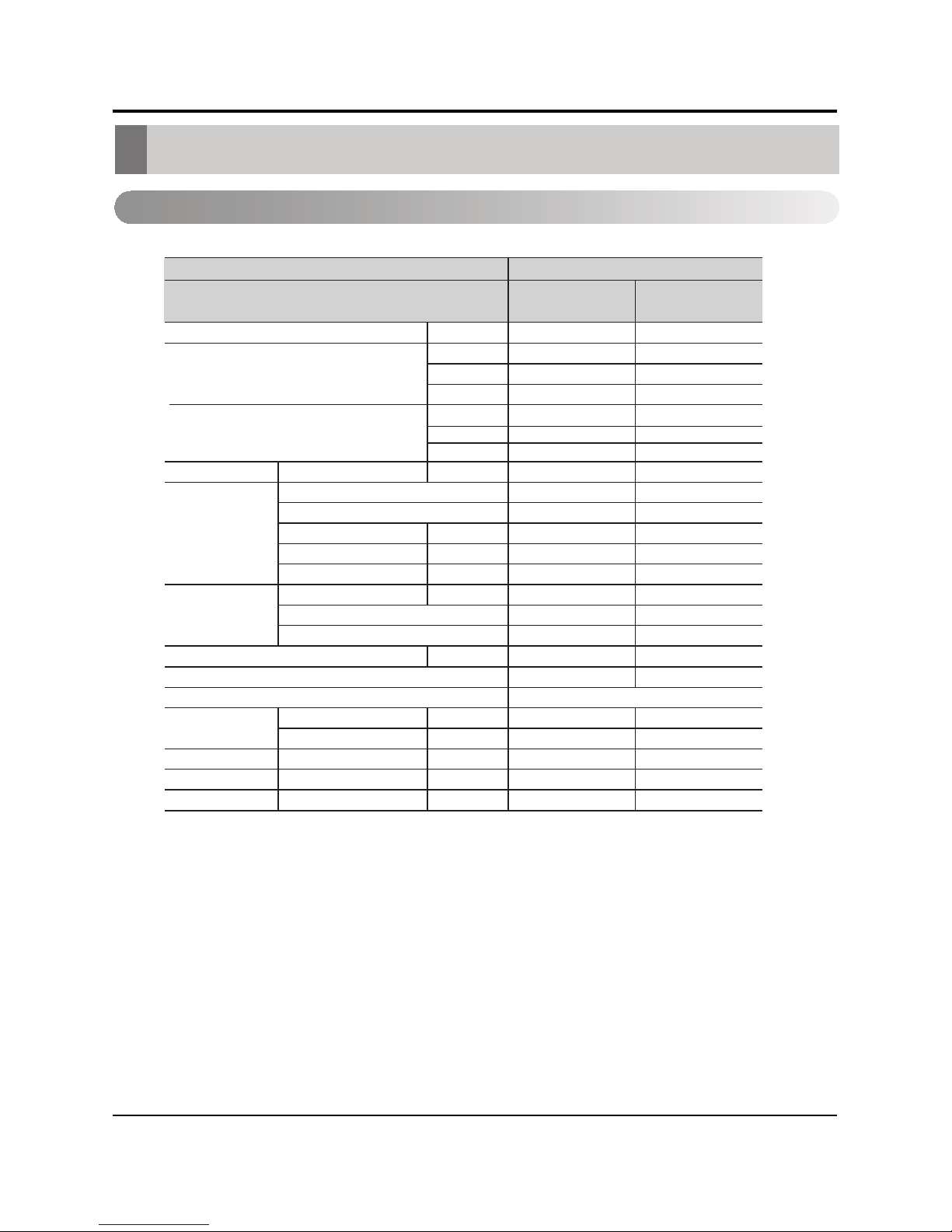

Product Specifications

Product Specifications

Indoor Unit

Power Supply Ø,V,Hz

rh/utByticapaC gnilooC

yticapaCHeating

W

kcal/hr

rh/utB

W

kcal/hr

Current Normal running current A

Fan Model

Fan Type

Motor Output W

Air Flow Rate CMM(CFM)

Capacitor µF/Vac

Coil Tube Size (OD) mm(inch)

Fins per inch

No. of Rows & Column/No.

3±)A(Bd)L/M/H(leveL dnuoS

Referigerant

Referigerant Control

)hcni(mmdiuqiLnoitcennoC gnipiP

)hcni(mmsaG

)sbl(gkroodnIthgieW teN

)hcni(mmD*H*WsnoisnemiD

)hcni(mmD*H*W noisnemiD gnikcaP

Model

TMNH092DYAA

TMNH122DYAA

detnuom llaWepyt tinu roodnI

1Ø, 220V, 60Hz 1Ø, 220V, 60Hz

0.270.20

CFF

RP15C-1 WEILINGRP15C-1 WEILING

42

8.4/7.6/6.4(296.5/268.3/225.9) 7/6/5(247.1/211.8/176.5)

0.9/400

20FPI S-FIN

2R 15C

R-22R-22

6.35(1/4)

12.7(1/2)

7/9

840*270*161

6.35(1/4)

9.52(3/8)

7/9

840*270*161

892*322*198 892*322*198

5

CFF

37

0.9/400

20FPI S-FIN

2R 15C

34/31/29 40/37/34

Thermistor

5

12,000

3,517

3,024

9,000

2,638

2,268

12,000

3,517

3,024

9,000

2,638

2,268

Page 8

8 Multi Air Conditioner

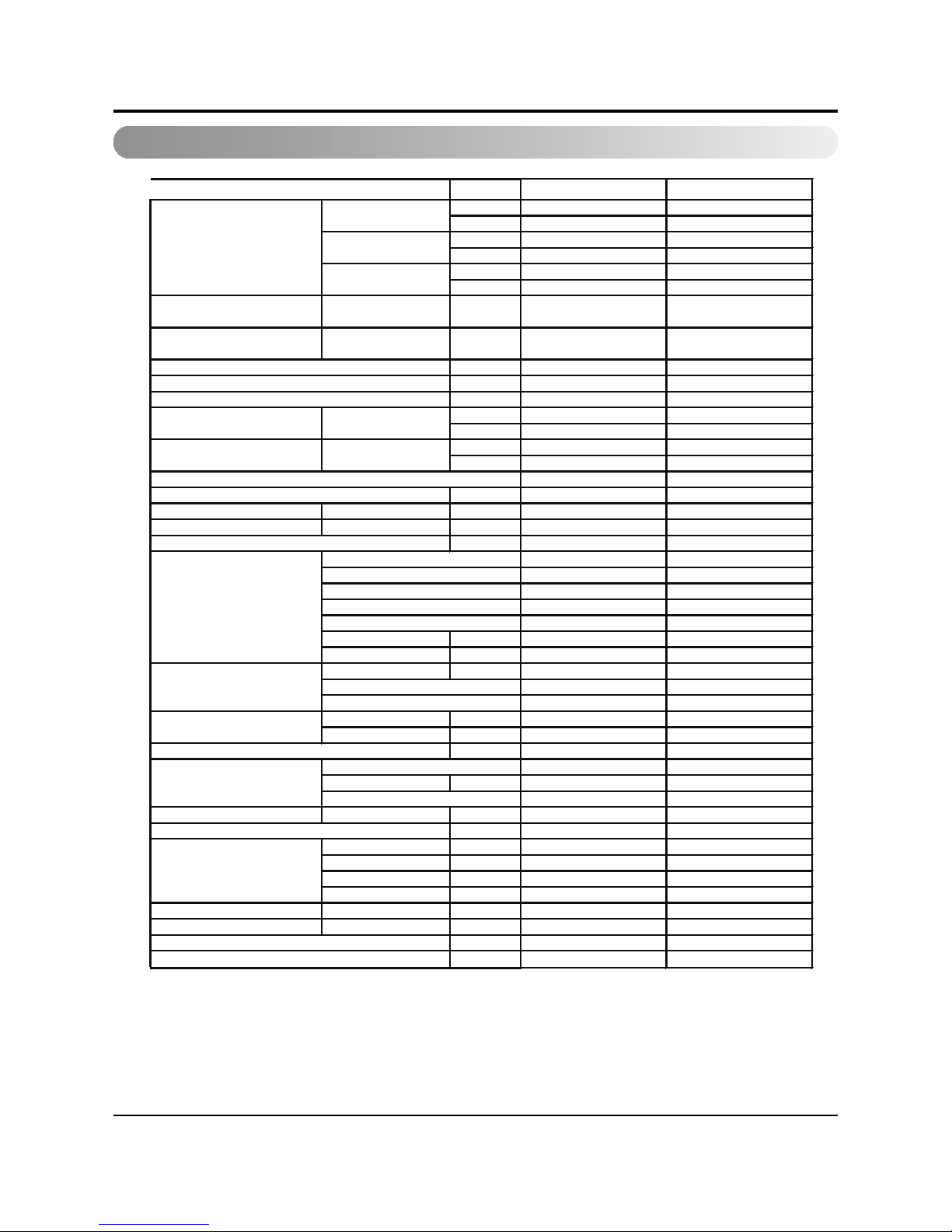

Product Specifications

Note :

1. Capacities are based on the following conditions:

Cooling: - Indoor Temperature 26.7°C(80°F) DB / 19.4°C(67°F) WB

- Outdoor Temperature 35°C(95°F) DB / 23.9°C(75°F) WB

Piping Length - Interconnecting Piping Length 7.5m

- Level Difference of Zero.

2. Due to our policy of innovation some specifications may be changed without notification.

3. At least two indoor units should be connected.

Outdoor Unit

Unit T2UH182FAA T2UH242FAA

W 3077/ 3077 3517 / 3517

Btu/hr 10500 / 10500 12000 / 12000

W 3077/ 3077 3517 / 3517

Btu/hr 10500 / 10500 12000 / 12000

W 5275 / 5275 7034

Btu/hr 18,000 / 18,000 24,000

Power input

(Cooling/heating)

A+B W 1850/1650 2380/2420

Running current

(Cooling/heating)

A+B A 8.6/ 7.6 11/11.3

f,V,Hz 1,220,60 1,220,60

No. * mm

2

3*2.5 3*2.5

No. * mm

2

4*0.75 4*0.75

W/W 2.85 2.96

Btu/hr W 9.7 10.1

W/W 3.20 2.91

Btu/hr W 10.9 9.9

Capillary Capillary

g(oz), type 1050, R22 A: 650 /B: 650 R22

Dimensions (W*H*D)

Outdoor unit mm 801*555*262 870*655*320

Packing dimensions (W*H*D)

Outdoor unit mm 960*610*384 1002*700*422

kg (lbs) 50 (110) 63 (139)

Rotary Rotary

1 2

QJ278KDF QK185KBK

LG LG

SUNISO 4GSI SUNISO 4GSI

MOTOR TYPE PSC PSC

Oil charge cc 410 350

Tube size (OD) inch (mm) 0.276 (7.0) 0.276 (7.0)

18 18

2R 24C 2R 28C

Model YGK25-6A-9 KFD-60K11

No. of poles 6 6

CMM (CFM) 49 (1398) 40 (1142)

Propeller Propeller

No. used / dia.

1 / 18.1(460) 1 / 18.1(460)

Side discharge Side discharge

RPM ±30 1020 880

dB +3(dB+1) 54(56) 54(56)

Liquid A inch (mm) 1/4 (6.35) 1/4 (6.35)

Gas A inch (mm) 3/8 (9.52) 1/2 (12.7)

Liquid B inch (mm) 1/4 (6.35) 1/4 (6.35)

Gas B inch (mm) 3/8 (9.52) 1/2 (12.7)

Max piping length total

m 30 30

Std. Piping length m 7.5 7.5

m 15 / 7.5 15 / 7.5

Stuff Quantity (Set) 20FT/40FT/40FT(H) 80/168/192 65/138/156

Power supply

Power supply cable

Connecting cable

Item

Capacity

(Cooling/heating)

A (SY 9K)

B (SY 9K )

A+B (9K+9K)

EER

cooling

COP

heating

Refrigerant control

Refrigerant charge

Net weight

Compressor

Type

Quantity

Model name

Maker

Oil type

Outdoor coil

FPI

No. of rows & columns

Noise level +3

SVC valves

Max. piping length per each room / elevation

Outdoor Motor

Air circulation

Outdoor fan

Type

Dischage

Page 9

Service Manual 9

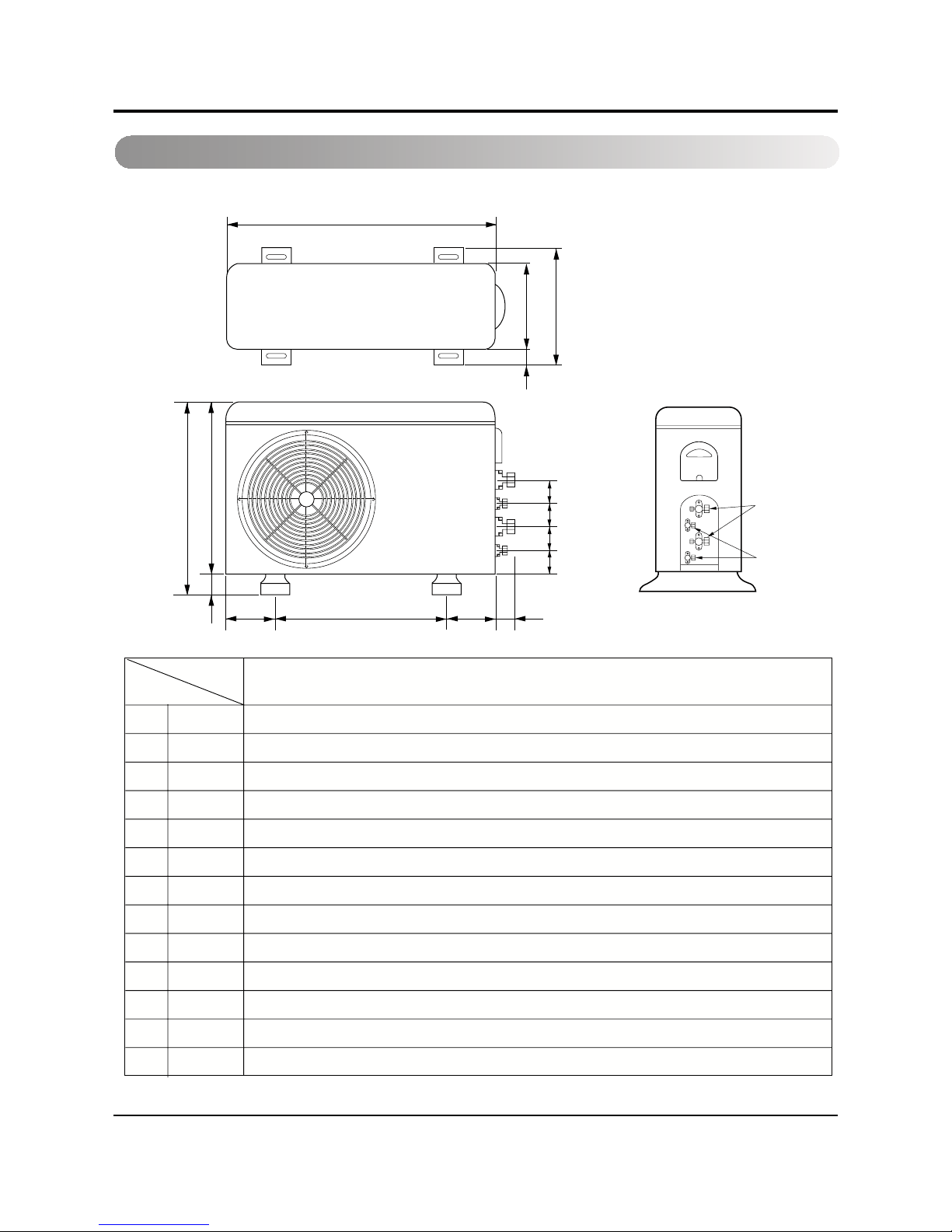

Dimensions

Dimensions

Installation plate

D

H

W

mmW

mmH

mmD

Model

Dimension

Indoor Unit

TMN 122DYAATMNH092DYAA

840

270

161

840

270

161

H

Page 10

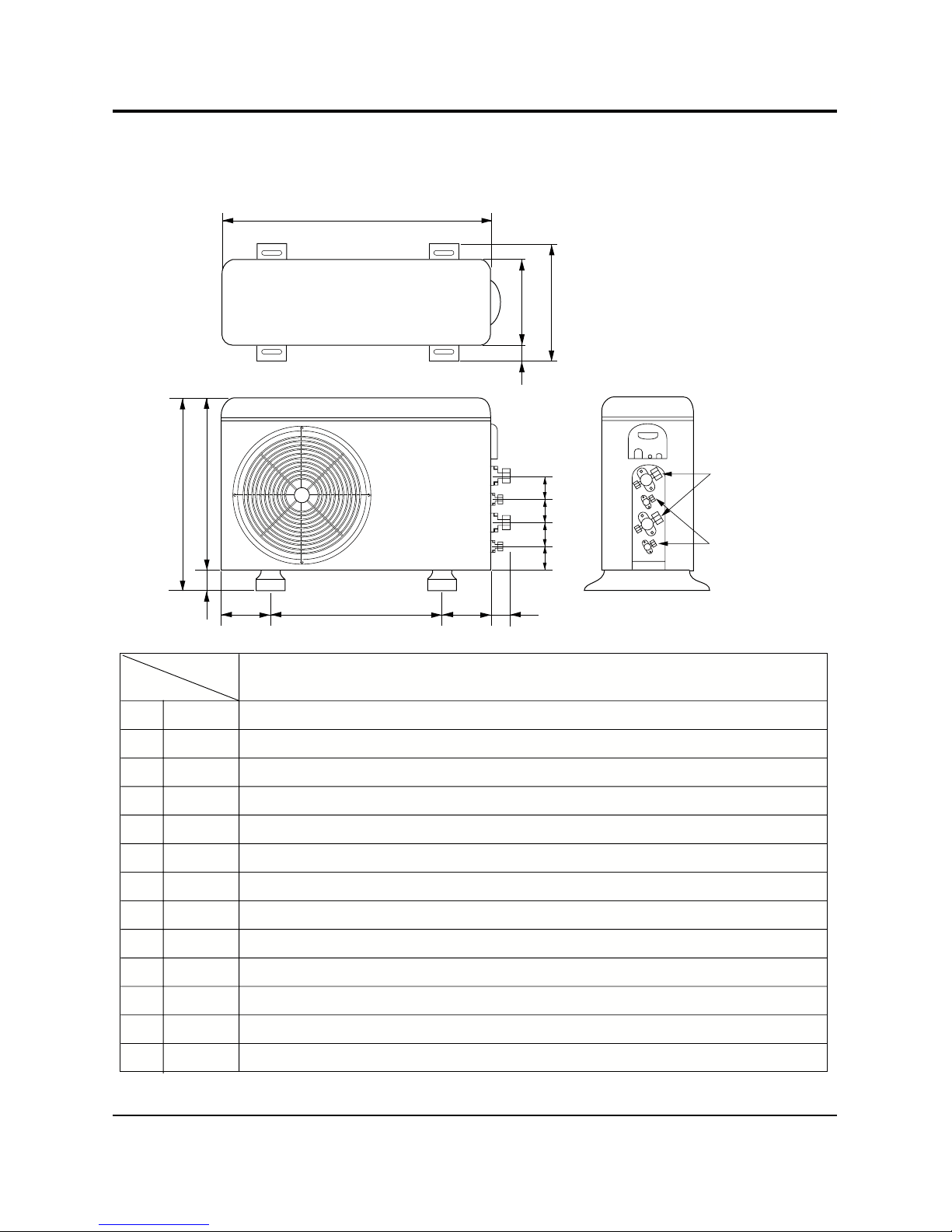

10 Multi Air Conditioner

Dimensions

Outdoor Unit

Model: T2UH182FAA

W

D

L1

L2

L9

L4

L3

H

L10

L10

L10

L8

L7L5L6

801mmW

555mmH

262mmD

339mm1L

37mm2L

543.6mm3L

11.4mm4L

591mm5L

105mm6L

105mm7L

72.5mm8L

74.5mm9L

79mm01L

T2UH182FAA

MODEL

DIM

Gas side

3-way valve

Liquid side

2-way valve

Page 11

Service Manual 11

Dimensions

Model : T2UH242FAA

W

D

L1

L2

L9

L4

L3

H

L10

L10

L10

L8

Gas side

3-Way valve

Liquid side

2-Way valve

L7L5L6

870mmW

655mmH

023mmD

073mm1L

52mm2L

630mm3L

52mm4L

645mm5L

061mm6L

061mm7L

55mm8L

80mm9L

05mm01L

T2UH242FAA

MODEL

DIM

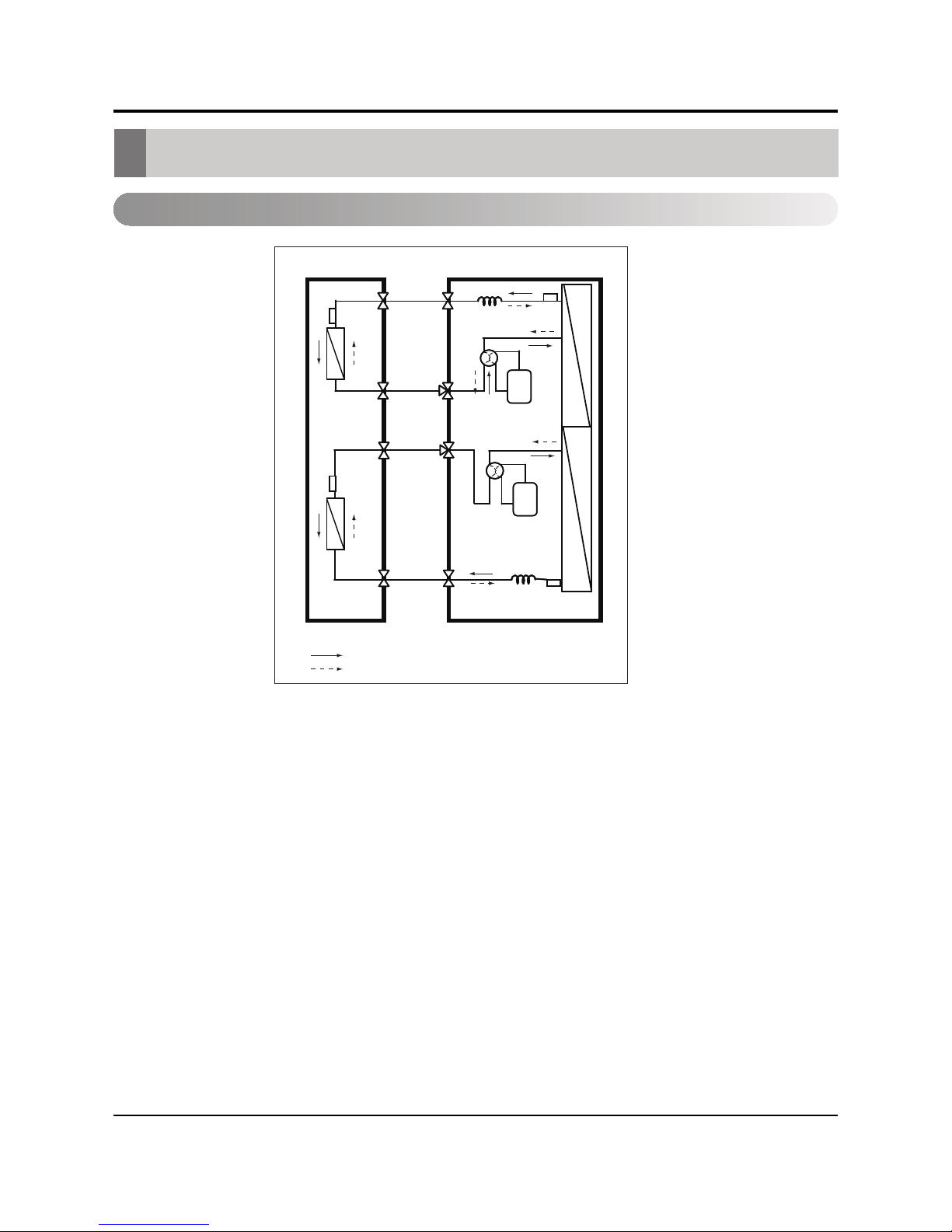

Page 12

12 Multi Air Conditioner

Refrigeration Cycle Diagram

Refrigeration Cycle Diagram

T2UH182FAA / T2UH242FAA

12K

12K

A

B

Indoor Side

Outdoor Side

A

Comp

B

Comp

Refrigerent Flow

Cooling

Heating

Page 13

13Service Manual

Wiring Diagram

Wiring Diagram

Indoor Unit

Outdoor Unit

T2UH242FAA.2T2UH182FAA.1

FAN

B/P1

B/P2

BC

EBY49965301

RD BRYL

2

BKWH

1

BLRD

BL

RD

WH BL

BK

BL

OR

BL

BL

BL

WH

TB

BC

BL

BR

BR

BR

BR

BK

EBY49965302

3

4

TB

LN

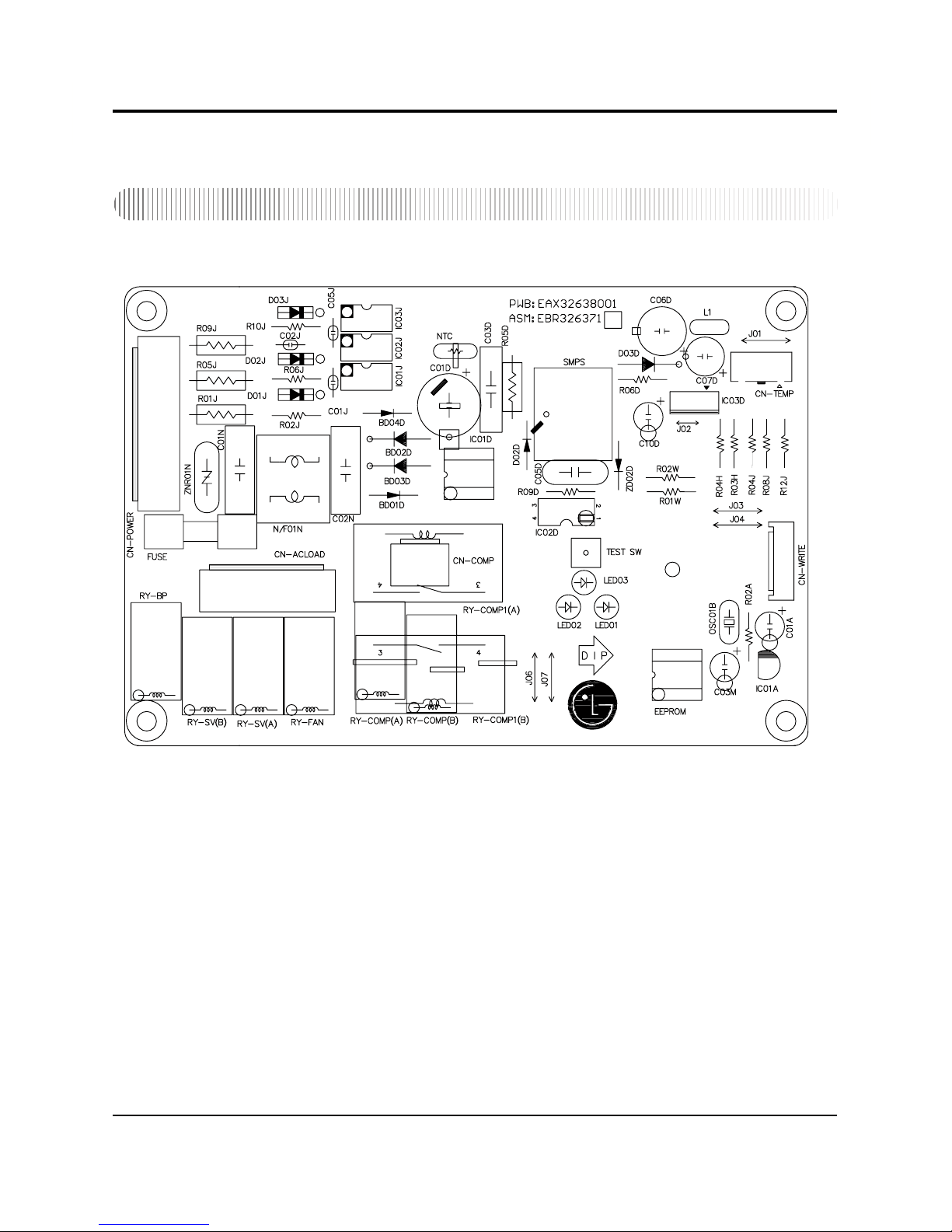

Page 14

14 Multi Air Conditioner

Electronic Control Device

Electronic Control Device

Indoor Unit

• MAIN P.C.B ASM

• TOP VIEW

• BOTTOM VIEW

Page 15

Service Manual

Electronic Control Device

Outdoor Unit

15

Page 16

Multi Air Conditioner

Electronic Control Device

Display P.C.B ASM

16

Page 17

Service Manual

Schematic Diagram

Schematic Diagram

Indoor Unit

42

28

15

16

22

20

19

18

17

21

26

25

23

24

27

11

12

13

14

9

8

10

34

33

32

29

30

31

38

37

36

35

41

40

39

53

55

56

58

57

54

61

63

62

64

60

59

5

4

7

6

1

3

2

49

51

52

50

44

45

43

48

46

47

FAN

12V

4WAY

COMP

OUTDOOR FAN

L(AC)

COMP

4WAY

LOAD

2. The unit of undefined capacitors is uF.

1. The unit of undefined resistance is ohm, 1/8W, 5%.

NOTE

Direct type

123

PCB outside

12

Angle type

CN-MOTOR

321

CN-4WAY

SH-CAPACITOR

22

680

33

CN-12V

2

1

1

2

2

1

12V

AC PART

3

TLP421(V4 BL)

IC01L

VOLTAGE GND

DC LOW

INT

4

1N4148

VOLTAGE GND

2

DC HIGH

300K

1/2W

NF01J

40mH/1A

1IN4007

1N4007

D05J

R03L

300K

1/2W

27k

1/6W

D01L

1

R02L

R01L

1N4007

5V

1N4007

D03J

C02J

100nF/275V/436D

METAL FILM

D02J

1N4007

D01J

D04J

12V

INDOOR FAN

R01F

560

1/4W

100,1/2W

250V/T2A

100nF/275V/436D

C01J

METAL FILM

ZNR01J

TVR10561

FUSE

RY- FAN

RY-4 WAY

3

434

TLP762JF

SM1L43

T1

R03F

1/2W

5

1

2

4

IC01F

3

TR01F

TRAICS

T2

METAL FILM

100nF/275V/436D

C01F

TVR10561

120, 1/2W

R04F

ZNR01F

COMPRESSOR

11

CN-N1

RY-COMP

G4A-1A-E-LG

3

N

50/60Hz

AC220~240V

L

MOTOR

4

11

33

11

22

3

1

2

3

1

2(N)

1(L)

2

TERMINAL

5

4

5

FAN MOTOR

OUTDOOR

4-WAY

4

11

2

4

3

5

Vout

GND

Vcc

RECEIVER

DISPLAY

C

CAB

B

KTC3198-Y

1

1

11

20K

(2012)

R01P

10V

2

2

HVB

33

1

CN-HVB

1

Option

HVB OUT

6

3

A0

A1

M24C01-MN6T SGS-THOMSON 8PIN SOP TRAY EEPROM IIC

EEPROM

4

SCL

SDA

5

G

A2

1

2

8

Vcc

7

WP

receiver

5555

C13L

SW(FORCE)

104

2 2

11

22

11

44

3

3

44

3

3

R01G~R04G1220 1/8W

7

7

6 6

77

66

8 8 88

CN-DISP1

KRA107S

Q02G

KRA107S

Q03G

220uF SD

Force

+

C12L

5V

Q01G

KRA107S

5V

KID65004AF

9

IC01G

5V

5V

20K

R02P

(2012)

OR4HOR6HOR5H

Hi Med Low

OR3H OR1HOR2H

O/L F2 F1

R26H

R21H

5V

d

5V

s1s

V

d

Force

20K

R15L

5V

C08D,AXIAL

103,50V

A

V

A

Vss0

Vdd0

AVref

R24H

R23H

R25H

12.1K, 1%

R21H~R26H

R22H

5V

RESET

AVdd

C07D,AXIAL

103,50V

X2

X1

CRTL8.00MSOT

CSTS0800MG03-T2

R01B

1M

OSC01B

2SC5343

R03G

OUTDOOR

OPERATION

LED2

SLEEP

LED1

A

TIMER

LED3

R02G

R01G

3

3

2 2

3

3

2

2

6644

55

6

6

5

5

4

4

LED4

R04G

77

7

7

11 6

16

15

14

1

2

3

13

12

4

5

12V

10 7

KID65004AF

IC01M

BL

OR

4

5

RD

4

5

2

1

3

PK

YL

2

1

3

STEPPING MOTOR

(UP/DOWN)

HVB OUT

15 2

8

16

9

1

13

14

3

4

INDOOR FAN

COMP

10

11

12

5

6

7

UPD780023AGC-C

NEC

INT1

Vss1

INT0

B

Z

Q01L

R11L,1/6W

FAN

12

4

1

2

3

16 15 14 13

2

4

3

5

4WAY

KID65004AF

8

7

5

6

91011

IC02M

1

CN-L/R

DC PART

STEPPING MOTOR

(LEFT/RIGHT)

Option

1

INT

RELAY CONNECTION

CN-TH1

10K

R05H

R02H

12.1K

1%

R04H

6.2K

1%

5V

PIPE-TH

R02F

114422

33

ROOM-TH

50V

5V

3

10uF

C02A

IC01A

1

3.6V

S71362KIA7036P

R05L

56K

R02A,4.7K

CN-MOTOR

33

FAN

INDOOR

MOTOR

3

4

R12L 5.1K

receiver

680pF,50V

12K

R04L,1/6W

5V

C11L ,AXIAL

5V

PKM13EPY-4002

R02E,20

R01E

1K

BZ01E

IC01J

DMR40 EE1916S

Lp=4.50mH,+-8%,40Khz

158T

VOLTAGE GND

DC LOW

+

5V

C04D

C05D

10V SD

104,AXAIL

50V

220

S78L05L 1WIIC01D

O

7805

D01D

UF4004

ZBF503D-TA-K TDK TP 12uH

L01D,IMD

1/6W

104,AXIAL

C03D

R01D

4.7K

50V

100uF

C02D

25V

12V

28T

220UF

C01D

25V

SMPS

450V/SD

1N4937

DC HIGH

VOLTAGE GND

100,1/6W

R02J

50V

C05J

0.1uF

100V

RO1J

1/4W,1%

27K

DO6J

1uF

C04J

LNK500P

S

D

C

+

10uF

C03J

NTC SCK-102

CI-B2012-100KJT R/TP 100nH

L02D

2

5

4

5

4

3

1

3

1

2

12V

5V

GND

R14L

1K

C01P,AXIAL,103,50V

X

RT

X

DD

R01A,1K

R03A,100

AXIAL

C01A

103

222,400V

C06J,AXIAL

+

1

2

1

2

33

12V

CN-P/O

+

R01H,1/6W,10K

R03H,1/6W,10K

C14L

C02H

C01H

R13L

100 1/4W

12V

BLPKYLORRD

8

PLASMA

CHIP

RXD

TXD

C03T

CHIP

R06H,1/6W,10K

C03H

231

231

CN-TH2

6.2K

R07H

1%

5V

113322

77

66

55

44

CN-OPTION

GND

OR1H (PIN 33)

OR2H (PIN 32)

OR3H (PIN 31)

OR4H (PIN 30)

OR5H (PIN 29)

OR6H (PIN 28)

C01L

AXIAL

33

CN-RF

5V

1122

CHIP(104) or 10K ohm resistor

C01T

R01T,1K,AXIAL

CHIP(681)

C02T

1

38

6

Metal film

+

LINK SWICH

CN-4WAY

CN-N2

CN-LIVE

WIRE-N

R02D

C06D,AXIAL

4.7K,1/6W

102,400V

WIRE-N

3

4

CN-LIVE

PTC-HEATER

RF

Transmitter

on artworking,Eyelet pattern

10M,1W,5% noise character increasing thing

R03J

103

103

103

YW396-03AV(WH)

YW396-03AV(YL)

103

1K

102 or 10K ohm resistor

AXIAL AXIAL

50V 50V

AXIAL

50V

50V

103

50V

CN-DISP2

CN-U/D

CN-CENT

SMD

BARE PCB:6870A90238A

ASM PCB:6871A20572

DISPLAY BARE PCB : 6870A90240A

DISPLAY ASM PCB : 6871A20574A

If CN-CENT don't use,this use resistor 10K(2012).

OR1H

OR2H

OR3H

OR4H

OR5H

OR6H

PCB ASM : 6871A20577

If CN-RF don't use,this use resistor 10K(2012).

2UEW0.14 TIW0.25

Option : only This is applied the H/P SRAC.

P/no:6200JB8010P WRAC APPLIED

OPTION : noise character increasing thing

OPTION : noise character increasing thing

PWB:6870A90243A

10K

47K

47K

10K

47K

10K

Only no low temporature detection function.

10K+-5%

5K+-5%

15pF

15pF

GLASS TYPE

R11H

R12H

5V

0J1H0J2H

5V

OPTION : import or export operation option

R11H~R12H

20K,2012

1-4 79T

4-3 79T

R04D

0 ohm

0 ohm

R03D

C09D

open

C10D

open

Anti Surge Res.

Anti Surge Res.

Anti Surge Res.

17

Page 18

Schematic Diagram

18 Multi Air Conditioner

Page 19

Service Manual

Functions

Function of Indoor Unit

• Room temperature sensor. (THERMISTOR)

• Maintains the room temperature in accordance with the Setting Temp.

• Indoor fan is delayed for 5 seconds at the starting.

• Restarting is inhibited for approx. 3 minutes.

• High, Med, Low, Chaos

--- Lights up in operation

--- Lights up in Sleep Mode

--- Lights up in Energy Saving Mode

--- Lights up in Defrost Mode(for Heating model)

--- Lights up in Compressor operation(for Cooling model)

• Intermittent operation of fan at low speed.

• The fan is switched to low(Cooling), med(Heating) speed.

• The unit will be stopped after 1, 2, 3, 4, 5, 6, 7 hours.

• The fan is switched to intermittent or irregular operation

•

The fan speed is automatically switched from high to low speed.

• The louver can be set at the desired position or swing

up and down automatically.

Wall mounted type

Operation ON/OFF by Remote controller

Sensing the Room Temperature

Room temperature control

Starting Current Control

Time Delay Safety Control

Indoor Fan Speed Control

Operation indication Lamps (LED)

OUT

DOOR

Health Dehumidification Operation

Sleep Mode Auto Control

Natural Air Control by CHAOS Logic

Airflow Direction Control

19

Page 20

Multi Air Conditioner

Functions

Healthy Dehumidification Operation Mode.

( )

Remote Controller

Operation ON/OFF

Operation Mode Selection

Temperature Setting

JET COOL

Sleep Operation

Airflow Direction Control

(Cooling

model only)

TEMPERATURE

LOW HIGH

Cooling Operation Mode.( )

Heating Operation Mode.( )

Fan Operation Mode

Energy Saving Mode

Fan Speed Selection

(Low) (Med) (High) (CHAOS)

: Cancel Sleep Mode, Timer ON or Timer OFF

: 1, 2, 3, 4, 5, 6, 7, Off Timer

: Fan Operates without cooling or heating.

Cooling

Down to 18°C

Up to 30°C

20

Page 21

Service Manual 2

Function

Display Function

Self-diagnosis Function

• Cooling, Soft Dry, Fan

• Sleep Mode

Operation Indicator

Energy Saving Mode

Sleep Timer Indicator

Compressor on Indicator

OUT

DOOR

Error Indicator

• The function is to self-diagnoisis airconditioner and express the troubles identifically if there is any trouble.

• Error mark is ON/OFF for the operation LED of evaporator body in the same manner as the following table.

• If more than two troubles occur simultaneously, primarily the highest trouble fo error code is expressed.

• After error occurrence, if error is released, error LED is also released simultaneously.

• To operate again on the occurrence of error code 12, be sure to pull out power cord and then re-insert.

• Having or not of error code is different from Model.

ledoM gnilooC

3sec 3sec 3sec

(once)

Error

Code

1

Error Display LED

(Indoor body operation LED)

Error contents

• Indoor room temperature

thermistor open/short

• Indoor pipe temperature

thermistor open/short.

• Indoor Thermistor

assembly check

SVC check point

1

Page 22

2 Multi Air Conditioner

Operation Details

Operation Details

Function of Controls

• DISPLAY

C/O Model

Operation Indicator

• ON while in appliance operation, OFF while in appliance pause.

•

Sleep Mode

Comp. Running Incidator

•

Cooling Mode Operation

• Whenthe intake air temperature reaches0.5 °C below the setting temp, the compressorand the outdoor fan

stop.

• When itreaches0.5 °C above the setting temp, they start to operate again.

Compressor ON Temp

Setting Temp+0.5°C

Compressor OFF Temp

Setting Temp-0.5°C

• Whilein compressorrunning, operating with the

speedset by the remote control. While in compressor

Health

•Whenthe operation input by the remote control is received,the intake air temperature is

detected and the setting temp is automatically set according to the intake air temperature.

26°C Intake Air Temp

25°C

24°C Intake Air Temp<26°C

Intake Air Temp-1°C

18°C Intake Air Temp<24°C

Intake Air Temp-0.5°C

Intake Air Temp<18°C

18°C

•

• Whilethe intakeair temp isbetween compressoron temp. and compressor temp.,10-min

Compressor ON Temp. Setting Temp+0.5°C

Compressor OFF Temp.

Setting Temp-0.5°C

•

Energy Saving Mode

2

Page 23

Operation Details

Airflow Speed Selection

• The airflow speed of the indoor fan is set to high, medium, low, or chaos (auto) by the input of the airflow

speed selection key on the remote control.

Sleep Timer Operation

• When the sleep time is reached after <1,2,3,4,5,6,7,0(cancel) hr> is input by the remote control while in appliance operation, the operation of the appliance stops.

• While the appliance is on pause, the sleep timer mode cannot be input.

• While in cooling mode operation, 30 min later since the start of the sleep timer, the setting temperature

increases by 1°C. After another 30 min elapse, it increases by 1°C again.

• When the sleep timer mode is input while in cooling cycle mode, the airflow speed of the indoor fan is set to

the low.

• When the sleep timer mode is input while in heating cycle mode, the airflow speed of the indoor fan is set to

the medium.

Chaos Natural Wind Mode

• When the Chaos Natural Wind mode is selected and then operated, the high, medium, or low speed of the airflow mode is operated for 2~15 sec. randomly by the Chaos Simulation.

Jet Cool Mode Operation (C/O Model)

• If the Jet Cool key is input at any operation mode while in appliance operation, the Jet Cool mode operates.

• In the Jet Cool mode, the indoor fan is operated at super-high speed for 30 min at cooling mode operation.

• In the Jet Cool mode operation, the room temperature is controlled to the setting temperature, 18°C

• When the sleep timer mode is input while in the Jet Cool mode operation, the Jet Cool mode has the priority.

• When the Jet Cool key is input, the upper/lower vanes are reset to those of the initial cooling mode and then

operated in order that the air outflow could reach further.

Forced Operation

• Operation procedures when the remote control can't be used.

• The operation will be started if the power button is pressed.

• If you want to stop operation, re-press the button.

• While in forced operation, the key input by the remote control has no effect and the buzzer sounds 10 times to

indicate the forced operation.

Heat pump Model

Cooling Model

Room Temp. 24°C 21°C Room Temp. < 24 °C Room Temp. < 21 °C

Operating mode Cooling Cooling Healthy Dehumidification Heating

Indoor FAN Speed

High High High High

Setting Temperature

22°C 22°C 23°C 24°C

Test operation

•

During the TEST OPERATION, the unit operates in cooling mode at high speed fan, regardless of room temperature and resets in 18±1 minutes.

•

During test operation, if remote controller signal is received, the unit operates as remote controller sets.

If you want to use this operation, open the front panel upward and Press the power button let it be pressed for

about 3 seconds.

•

If you want to stop the operation, re-press the button.

Service Manual 23

Page 24

Operation Details

Auto restart

•

In case the power comes on again after a power failure, Auto Restarting Operation is the function to operate

procedures automatically to the previous operating conditions.

Protection of the evaporator pipe from frosting

• If the indoor pipe temp is below 0°C in 7 min. after the compressor operates without any pause while in cooling cycle operation mode, the compressor and the outdoor fan are turned off in order to protect the indoor

evaporator pipe from frosting.

• When the indoor pipe temp is 7°C or higher after 3 min. pause of the compressor, the compressor and the

outdoor fan is turned on according to the condition of the room temperature.

Buzzer Sounding Operation

• When the appliance-operation key is input by the remote control, the short "beep-beep-" sounds.

• When the appliance-pause key is input by the remote control, the long "beep—" sounds.

24

Multi Air Conditioner

Page 25

25Service Manual

Operation Details

Remote Control Operations

Page 26

Disassembly

Disassembly

Indoor Unit

Disconnect the unit from power supply before making any checks.

Be sure the power switch is set to “OFF ”.

To remove the Grille from the Chassis.

• Set the up-and-down air discharge louver to open

position (horizontally) by nger pressure.

• Remove the securing screws.

• To remove the Grille, pull the lower left and right

side of the grille toward you (slightly tilted) and lift it

straight upward.

1. Before removing the control box, be sure to

take out the wire screwed at the other end.

Earth

Conductor

26 Multi Air Conditioner

Page 27

Disassembly

2. To remove the Control Box.

• Remove securing screws.

• Pull the control box out from the chassis

carefully.

3. To remove the Discharge Grille.

• Unhook the discharge grille and pull the

discharge grille out from the chassis carefully.

4. To remove the Evaporator.

• Remove 3 screws securing the evaporator(at the

left 2EA in the Eva Holder, at the right 1EA).

Screw

• When repair, do not damage the Caution label.

Service Manual 27

Page 28

Disassembly

• Unhook the tab on the right inside of the chassis

at the same time, slightly pull the evaporator

toward you until the tab is clear of the slot.

5. To remove the Motor Cover

• Remove 2 securing screw.

• Pull the motor cover out from the chassis

carefully.

6. To remove the Cross-Flow Fan

• Loosen the screw securing the cross-flow fan to

the fan motor (do not remove).

• Lift up the right side of the cross-flow fan and the

fan motor, separate the fan motor from the

cross-flow fan.

• Remove the left end of the cross-flow fan from

the self-aligning bearing.

Motor cover

Bearing

Cross-flow fan

28 Multi Air Conditioner

Page 29

2-way, 3-way Valve

2-way, 3-way Valve

2-way Valve (Liguid Side) 3-way Valve (Gas Side)

Works Shaft position Shaft position Service port

Shipping Closed Closed Closed

(with valve cap) (with valve cap) (with cap)

Air purging Open Closed Open

(Installation) (counter-clockwise) (clockwise) (push-pin or with

vacuum pump)

Operation Open Open Closed

(with valve cap) (with valve cap) (with cap)

Pumping down Closed Open Open

(Transfering) (clockwise) (counter-clockwise) (connected

manifold gauge)

Evacuation Open Open Open

(Servicing) (with charging

cylinder)

Gas charging Open Open Open

(Servicing) (with charging

cylinder)

Pressure check Open Open Open

(Servicing) (with charging

cylinder)

Gas releasing Open Open Open

(Servicing) (with charging

cylinder)

3.

2.

1.

4.

5.

6.

Flare nut

To

piping

connection

Open position

Closed position

Flare nut

Valve cap

To

piping

connection

Open position

Closed position

Hexagonal wrench

(4mm)

To outdoor unit

Pin

Service

port

Service

port cap

To outdoor unit

Service Manual 29

Page 30

2-way, 3-way Valve

•

Procedure

1. Confirm that both the gas side and liquid side

valves are set to the open position.

- Remove the valve stem caps and confirm that

the valve stems are in the raised position.

- Be sure to use a hexagonal wrench to operate

the valve stems.

2. Operate the unit for 10 to 15 minutes.

3. Stop operation and wait for 3 minutes, then connect the manifold gauge to the service port of

the gas side valve.

- Connect the hose of the gauge with the push

pin to the service port.

4. Air purging of the charge hose.

- Open the Low-handle valve on the gauge

slightly to air purge from the hose.

5. Set the liquid side valve to the closed position.

6. Operate the air conditioner at the cooling cycle

and stop it when the gauge indicates 1kg/cm

2

g.

7. Immediately set the gas side valve to the closed

position.

- Do this quickly so that the gauge ends up indi-

cating 1kg/

g.

8. Disconnect the charge set, and mount the liquid

side and gas side valve caps and the service

port nut.

- Use torque wrench to tighten the service port

nut to a torque of 1.8kg.m.(4.2kg*m/5.5kg*m)

- Be sure to check for gas leakage.

Indoor unit

Outdoor unit

Liquid side

Close

Gas side

2-Way

valve

Open

3-Way

valve

manifold gauge

Hi- handle

(CLOSE)

Low-handle

(CLOSE)

(1) Pumping down

30 Multi Air Conditioner

Page 31

2-way, 3-way Valve

(2) Evacuation

(All amount of refrigerant leaked)

• Procedure

1. Confirm that both the liguid side valve and gas

side valve are set to the opened position.

2. Connect the vaccum pump to the center hose of

the manifold gauge.

3. Connect the service port of the gas side valve to

the low side of the gauge.

4. Connect power supply to outdoor unit.

5. Evacuation for approximately one hour.

- Confirm that the gauge needle has moved

toward-76 cmHg (vacuum of 4 mmHg or less).

6. Close the Low handle of the gauge turn off the

vacuum pump, and confirm that the gauge needle does not move(approximately 5 minutes

after turning off the vacuum pump).

7. Disconnect the charge hose from the vacuum

pump.

- Vacuum pump oil.

If the vacuum pump oil becomes dirty or depleted,replenish as needed.

8. Mount the valve caps and the service port caps.

Indoor unit

Outdoor unit

Liquid side

Close

Gas side

2-Way

valve

Open

3-Way

valve

manifold gauge

Vacuum pump

Hi- handle

(CLOSE)

Lowhandle

(OPEN)

Service Manual 31

Page 32

2-way, 3-way Valve

(3) Gas Charging

(After Evacuation)

• Procedure

1. Connect the gauge to the charging cylinder.

- Connect the charge hose which you disconnected from the vacuum pump to the valve at the

bottom of the cylinder.

- If you are using a gas cylinder, also use a scale

and reverse the cylinder so that the system can

be charged with liquid.

2. Purge the air from the charge hose.

-

Open the valve at the bottom of the cylinder and

press the check valve on the charge set to purge

the air. (Be careful of the liquid refrigerant). The

procedure is the same if using a gas cylinder.

3. Open the low handle on the gauge and charge

the system with liquid refrigerant.

- If the system can not be charged with the specified amount of refrigerant, it can be charged

with a little at a time (approximately 150g each

time) while operating the air conditioner in the

cooling cycle; however, one time is not sufficient, wait approximately 1 minute and then

repeat the procedure(pumping down-pin).

4. Immediately disconnect the charge hose from

the gas side valve's service port.

- Stopping partway will allow the gas to be dis-

charged.

- If the system has been charged with liquid

refrigerant while operating the air conditioner

turn off the air conditioner before disconnecting

the hose.

5. Mount the valve stem nuts and the service port

nut.

- Use torque wrench to tighten the service port

nut to a torque of 1.8 kg.m.(4.2kg.m/5.5kg.m.)

- Be sure to check for gas leakage.

Indoor unit

Outdoor unit

Liquid side

Close

Gas side

2-Way

valve

Open

3-Way

valve

manifold gauge

Charging

cylinder

Hi- handle

(CLOSE)

Low-handle

(OPEN)

Check valve

This is different from previous procedures.

Because you are charging with liquid refrigerant

from the gas side, absolutely do not attempt to

charge with larger amounts of liquid refrigerant

while operating the air conditioner.

32 Multi Air Conditioner

Page 33

Cycle Troubleshooting Guide

Cycle Troubleshooting Guide

Trouble analysis

1. Check temperature difference between intake and discharge air and operating current.

All amount of refrigerant leaked out.

Check refrigeration cycle.

Refrigerant leakage

Clog of refrigeration cycle

Defective compressor

Excessive amount of refrigerant

Normal

Notice:

Temperature difference between intake and discharge air depends on room air humidity. When the room air

humidity is relativery higher, temperature difference is smaller. When the room air humidity is relatively lower

temperature difference is larger.

2. Check temperature and pressure of refrigeration cycle.

Notice:

1. The suction pressure is usually 4.5~6.0 kg/cm

2

G at normal condition.

2. The temperature can be measured by attaching the thermometer to the low pressure tubing and wrap it with

putty.

Temp. difference : approx. 0°C

Current : less than 80% of

rated current

Temp. difference : approx. 8°C

Current : less than 80% of

rated current

Temp. difference : less than 8°C

Current : over the rated

current

Temp. difference : over 8°C

Temp. Difference

Operating Current

Suction pressure Temperature

(Compared with (Compared with Cause of Trouble Description

the normal value) the normal value)

High Defective compressor Current is low.

Normal Excessive amount of High pressure does not quickly

refrigerant rise at the beginning of operation.

Insufficient amount of Current is low.

Lower Higher refrigerant(Leakage)

Clogging Current is low.

Higher

Service Manual 33

Page 34

Cycle Troubleshooting Guide

Electronic Parts

Product does not operate at all.

(* Refer to Electronic Control Device drawing and Schematic diagram.)

Turn off Main Power

Turn on Main Power

Does "beeping" sound is made from the Indoor Unit?

Primarily, the operating condition of Micom is OK.

Check the voltage of power (About AC 220V, 60Hz)

• Main power's voltage

• Voltage applied to the unit

• Connecting method of Indoor/Outdoor connecting

cable

• Check PWB Assembly

- Fuse

- Pattern damage

- Varistor(ZNR01J)

Check the connection housing for contacting

• Connector related to CN-NI, RY-COMP NO.3

• Connector related to CN-MOTOR

• Connector contacting of Outdoor Fan/Compressor

• Display PCB Assembly Check

Check each load(Indoor/Outdoor Fan Motor,

Compressor, Stepping Motor) and contacting

condition of related connector

Main PCB Board Operation Check

Items

• SMPS Transformer

(Indoor unit)

- Input Voltage

- Output Voltage(C03D)

• IC01D(7805) Output

(Indoor/Outdoor unit)

• IC01A(KIA7036, Reset IC)

OSC01B(8MHz)

• Replace Trans

• Replace IC01D

• Replace faulty parts

- About AC220V/240V±10% - Check the power voltage

- About DC12V

• DC +5V

• Voltage of IC No.1,

(DC +4.5V over) and Soldering condition.

Content Remedy

NO

YES

(After 10 seconds)

34

Multi Air Conditioner

Page 35

Cycle Troubleshooting Guide

The product is not operate with the remote controller.

Turn on Main Power

While the compressor has been stopped, the compressor does not

operate owing to the delaying function for 3 minutes after stopped.

Caused by other parts except the remote control

Cause by the remote control

When the mark( ) is displayed in LCD screen, replace

battery.

Check the contact of CN-DISP1 connector.

When the compressor stopped Indoor Fan is driven by a low speed.

At this point the wind speed is not controlled by the remote controller.

(When operated in the Sleeping Mode, the wind speed is set to the

low speed by force.)

Check Display PCB Assembly

- Voltage between CN DISP1

- : DC +5V

Check the connecting circuit between the remote controller

MICOM (No.

) - R16(1.5k) - IR LED - TR - R17(1Ω).

or

MICOM (No. ) - R1(1.5k) - IR LED - TR - R2(1Ω).

Check point

• Check the connecting circuit between CN-DIS1

-

R11L(100Ω) - C01A(100nF) - MICOM PIN

• Check Receiver Assembly

61

Service Manual 35

Page 36

Cycle Troubleshooting Guide

Compressor/Outdoor Fan are unable to drive.

Turn on Main Power

Operate "Cooling Mode( )" by setting the desired temperature of the

remote controller is less than one of the indoor temperature by 1°C at least.

When in Air Circulation Mode, Compressor/Outdoor Fan is stopped.

Check the sensor for indoor temperature is attached as close as to be

effected by the temperature of Heat Exchanger(EVA).

When the sensor circuit for indoor temperature and connector are in bad

connection or are not engaged, Compressor/Outdoor Fan is stopped.

• Check the related circuit of RY-FAN.

• Check the indoor temperature sensor is disconnected or not(About 10kΩ / at 25°C).

Turn off Main Power

• Check the electrical wiring diagram of outdoor side.

• Check the abnormal condition for the component of

Compressor/Outdoor Fan Motor.

• Check the "open" or "short" of conmecting wires between indoor and

outdoor.

Check Relay(RY - COMP) for driving compressor.

• When the power(About AC220V/240V) is applied to the connecting wire

terminal support transferred to compressor, PWB Assembly is normal.

• Check the circuit related to the relay.

Check point COMP ON COMP OFF

Between Micom(No.

DC5V DC0V

59) and GND

Between IC01M(No. 15) Below DC 1V

About DC12V

and GND (app)

36 Multi Air Conditioner

Page 37

Cycle Troubleshooting Guide

Check the TRIAC high speed operation by remote control.

(The Indoor Fan Motor is connected)

Turn off Main power

Check the connection of CN-MOTOR

Check the Fan Motor

Check the Fuse(AC250V/T2A)

Turn ON Main Power

Check the related circuit of indoor Fan Motor.

• The pin NO 58 of Micom, and the part for driving TRIAC(the input and

output signal of IC01M, PIN NO 1, 16)

• Check the pattern

• Check the TRIAC

- TRIAC Open: Indoor Fan Motor never operate

- TRIAC short: Indoor Fan Motor always operates in case of ON or OFF.

When indoor Fan does not operate.

The voltage of PIN NO 1(orange) and 3(yellow) of CN-MOTOR.

About AC 180V over About AC 50V over

TRIAC is not damaged TRIAC Check

Service Manual 37

Page 38

Cycle Troubleshooting Guide

• Confirm that the Vertical Louver is normally geared with the shaft of

Stepping Motor.

• If the regular torque is detected when rotating the Vertical Louver with

hands

Normal

• Check the connecting condition of CN-U/D Connector

• Check the soldering condition(on PWB) of CN-U/D Connector

If there are no problems after above checks

• Confirm the assembly conditions that are catching and interfering parts

in the rotation radial of the Vertical Louver

When Vertical Louver does not operate.

Check the operating circuit of the Vertical Louver

• Confirm that there is DC +12V between pin

(RED) of CN-U/D and

GND.

• Confirm that there is a soldering short at following terminals.

- Between , , and of MICOM

- Between , , and of IC01M

- Between

, , and of IC01M

60 61 62 63

38 Multi Air Conditioner

Page 39

Installation

Installation

Select the best Location

1. If an awning is built over the unit to prevent

direct sunlight or rain exposure, make sure

that heat radiation from the condenser is not

restricted.

2. Ensure that the spaces indicated by arrows

around front, back and side of the unit.

3. Do not place animals and plants in the path

of the warm air.

4. Take the air conditioner weight into account

and select a place where noise and vibration

are minimum.

5. Select a place so that the warm air and noise

from the air conditioner do not disturb

neighbors.

Rooftop Installations:

If the outdoor unit is installed on a roof

structure, be sure to level the unit. Ensure the

roof structure and anchoring method are

adequate for the unit location. Consult local

codes regarding rooftop mounting.

more than

20cm

more than

70cm

more than

20cm

Service Manual 39

Page 40

Multi Air Conditioner

Installation

40

Page 41

Service Manual

Installation

Piping Length and Elevation

Indoor Unit Capacity Pipe Size Rated Max Additional

(Btu/h)

Gas Liquid

Length Length Refrigerant

• The maximun allowable level and piping length

18k

24k

Refrigerant Charge

Extra refrigerant = (Extended length - Rated length) x Additional refrigerant

7.5m

A

B

7.5m

Installation of the outdoor unit

on an upper position

Installation of the outdoor unit

on a lower position

A

B

7.5m

7.5m

Model

[Outdoor unit]

T2UH182FAA

7.5m 15m 15m - 30m (A+B)

T2UH242FAA

Standard length

A,B

Max. piping length of each indoor unit

ABC

Max. total piping length

1/2"(12.7mm) 1/4"(6.35mm) 7.5 15

3/8"(9.52mm) 1/4"(6.35mm) 7.5 15

20g/m

30g/m

41

Page 42

Flaring work and connection of piping

Flaring work and connection of piping

Flaring work

Flaring work

Main cause for refrigerant leakage is due to defect in the

flaring work. Carry out correct flaring work using the following procedure.

Cut the pipes and the cable.

• Use the piping kit accessory or pipes purchased locally.

• Measure the distance between the indoor and the outdoor unit.

• Cut the pipes a little longer than the measured distance.

• Cut the cable 1.5m longer than the pipe length.

Check

• Compare the flared work with figure below.

• If flare is noted to be defective, cut off the flared section and re-flare it.

• Preparing the indoor unit's piping and drain hose for instal-

lation through the wall.

• Remove the plastic tubing retainer(see illustration below)

and pull the tubing and drain hose away from chassis.

• Replace the plastic tubing holder in the original

position.(Optional)

• Carry out flaring work using flaring tool as shown below.

Burr removal

• Completely remove all burrs from the cut cross section of

pipe/tube.

• Put the end of the copper tube/pipe in a downward direction as you remove burrs in order to avoid dropping burrs

into the tubing.

Putting nut on

• Remove flare nuts attached to indoor and outdoor unit,

then put them on pipe/tube having completed burr removal.

(not possible to put them on after flaring work)

Flaring work

• Firmly hold copper pipe in a die in the dimension shown in

the table above.

Copper

pipe

90q

Slanted Uneven Rough

Bar

Copper pipe

Clamp handle

Red arrow mark

Cone

Yoke

Handle

Bar

"A"

Inclined

Inside is shiny without scratches

Smooth all round

Even length

all round

Surface

damaged

Cracked Uneven

thickness

= Improper flaring =

Drain hose

Pipe

Reamer

Point down

Flare nut

Copper tube

mm inch mm

Ø6.35 1/4 0~0.5

Ø9.52 3/8 0~0.5

Ø12.7 1/2 0~0.5

Ø15.88 5/8 0~1.0

Ø19.05 3/4 1.0~1.3

Outside diameter A

Connection of piping -- Indoor

When install, make sure that the

remaining parts must be removed

clearly so as not to damage the piping and drain hose, especially power

cord and connecting cable.

42 Multi Air Conditioner

Page 43

Flaring work and connection of piping

Route the indoor tubing and the drain hose in the direction of

rear right.

Drain hose

Connecting

cable

Vinyl tape(narrow)

Connection

pipe

Connecting cable

Vinyl tape

(wide)

Wrap with vinyl tape

Indoor

unit pipe

Pipe

Plastic bands

Insulation material

Vinyl tape(narrow)

Adhesive

Drain pipe

Indoor unit drain hose

Wrench

Indoor unit tubing

Open-end wrench (fixed)

Connection pipe

Flare nut

Indoor unit tubing Flare nut Pipes

Drain hose

Connecting

pipe

Connecting cable

Tape

Drain hose

Insert the connecting cable into the indoor unit from the outdoor unit through the piping hole.

• Do not connect the cable to the indoor unit.

• Make a small loop with the cable for easy connection later.

Tape the tubing, drain hose, and the connecting cable. Be

sure that the drain hose is located at the lowest side of the

bundle. Locating at the upper side can cause drain pan to

overflow inside the unit.

NOTE: If the drain hose is routed inside the room, insulate

the hose with an insulation material* so that dripping from

"sweating"(condensation) will not damage furniture or floors.

*Foamed polyethylene or equivalent is recommended.

Indoor unit installation

• Hook the indoor unit onto the upper portion of the installation plate.(Engage the two hooks of the rear top of the

indoor unit with the upper edge of the installation plate.)

Ensure that the hooks are properly seated on the installation plate by moving it left and right.

Press the lower left and right sides of the unit against the

installation plate until the hooks engage into their slots(clicking sound).

Connecting the pipings to the indoor unit and

drain hose to drain pipe.

• Align the center of the pipes and sufficiently tighten

the flare nut by hand.

• Tighten the flare nut with a wrench.

• When extending the drain hose at the indoor unit, install the

drain pipe.

Wrap the insulation material around the connecting portion.

•Overlap the connection pipe insulation material and the

indoor unit pipe insulation material. Bind them together with

vinyl tape so that there is no gap.

• Wrap the area which accommodates the rear piping housing section with vinyl tape.

mm inch kg.m

Ø6.35 1/4 1.8

Ø9.52 3/8 4.2

Ø12.7 1/2 5.5

Ø15.88 5/8 6.6

Ø19.05 3/4 6.6

Outside diameter Torque

For right rear piping

Service Manual 43

Page 44

Flaring work and connection of piping

• Bundle the piping and drain hose together by wrapping

them with vinyl tape for enough to cover where they fit into

the rear piping housing section.

Connecting the pipings to the indoor unit and

the drain hose to drain pipe.

• Align the center of the pipes and sufficiently tighten the

flare nut by hand.

• Tighten the flare nut with a wrench.

• When extending the drain hose at the indoor unit, install the

drain pipe.

Wrap the insulation material around the connecting portion.

• Overlap the connection pipe heat insulation and the indoor

unit pipe heat insulation material. Bind them together with

vinyl tape so that there is no gap.

Route the indoor tubing and the drain hose to

the required piping hole position.

Insert the piping, drain hose, and the connecting cable into the piping hole.

Insert the connecting cable into the indoor unit.

• Don't connect the cable to the indoor unit.

• Make a small loop with the cable for easy connection later.

Indoor unit installation

• Hang the indoor unit from the hooks at the top of the installation plate.

• Insert the spacer etc. between the indoor unit and the

installation plate and separate the bottom of the indoor unit

from the wall.

Tape the drain hose and the connecting cable.

• Connecting cable

Drain pipe

Connecting cable

Wrap with vinyl tape

Drain hose

Pipe

Vinyl tape(wide)

Indoor unit tubing Flare nut Pipes

Installation plate

Spacer

Indoor unit

8cm

Plastic bands

Insulation material

Vinyl tape

Adhesive

Drain hose

Indoor unit drain hose

(narrow)

Wrench

Indoor unit tubing

Connection pipe

Flare nut

Open-end wrench (fixed)

For left rear piping

mm inch kg.m

Ø6.35 1/4 1.8

Ø9.52 3/8 4.2

Ø12.7 1/2 5.5

Ø15.88 5/8 6.6

Ø19.05 3/4 6.6

Outside diameter Torque

44 Multi Air Conditioner

Page 45

Flaring work and connection of piping

Installation Information (For left piping)

• Good case

For left piping. Follow the instruction below.

• Press on the upper side of clamp. (

)

• Wrap the area which accommodates the rear piping housing section with vinyl tape.

Indoor unit installation

• Remove the spacer.

• Ensure that the hooks are properly seated on the installation plate by moving it left and right.

Press the lower left and right sides of the unit against the

installation plate until the hooks engage into their

slots(clicking sound).

• Bundle the piping and drain hose together by wrapping

them with cloth tape over the range within which they fit

into the rear piping housing section.

Reroute the pipings and the drain hose across

the back of the chassis.

Set the pipings and the drain hose to the back

of the chassis with the tubing holder.

• Hook the edge of tubing holder to tap on chassis and push

the bottom of tubing holder to be engaged at the bottom of

chassis.

Vinyl tape(narrow)

Connection

pipe

Connecting cable

Indoor

unit piping

Pipe

Vinyl tape

(wide)

Wrap with vinyl tape

Drain hose

Vinyl tape(narrow)

Pipe

Wrap with

vinyl tape(wide)

Piping for

passage through

piping hole

Tubing holder

Drain hose

Connecting

cable

• Unfold the tubing to downward slowly. ( )

• Bend the tubing to the left side of chassis.

Service Manual 45

Page 46

Flaring work and connection of piping

Align the center of the pipings and suciently

tighten the are nut by hand.

Finally, tighten the are nut with torque wrench

until the wrench clicks.

• When tightening the are nut with torque wrench, ensure

the direction for tightening follows the arrow on the wrench.

• Bad case

• Following bending type from right to left could cause

problem of pipe damage.

Connection of the pipes-Outdoor

mm inch kg.m

Ø6.35 1/4 1.8

Ø9.52 3/8 4.2

Ø12.7 1/2 5.5

Ø15.88 5/8 6.6

Ø19.05 3/4 6.6

Outside diameter Torque

Outdoor unit

Gas side piping

(Bigger diameter)

Liquid side

piping

(Smaller

diameter)

Torque wrench

46 Mutli Air Conditioner

Page 47

Connecting the cable between indoor unit and outdoor unit

Outdoor unit

Terminal block

Over 5mm

Cover control

Connecting cable

Power cord

Holder for

power supply

cord

Connection of the cable

1.

Remove the cover control from the unit by loosening the screw.

Connect the wires to the terminals on the control board individually as the following.

2.Secure the cable onto the control board with the holder (clamper).

3.

screw.

4.Use a recongnized circuit breaker between the power

source and the unit. A disconnection device to ade-

Connect the cable to the Indoor unit.

Connecting the cable between indoor unit and outdoor unit

Service Manual 47

Page 48

Connecting the cable between indoor unit and outdoor unit

The power cord connected to the outdoor unit should be complied with the following specifications

(ETL recognized and CSA certified).

The power connecting cable connected to the indoor and outdoor unit should be complied with

the following specifications.

GN/YL

20mm

GN/YL

20mm

GN/YL

20mm

0.75

Cable Type(B) H07RN-F

NORMAL CROSS

-SECTIONAL AREA

Grade

(mm2)

T2UH182FAA T2UH242FAA

2.5 2.5

Cable Type(B) H07RN-F H07RN-F

NORMAL CROSS

-SECTIONAL AREA

Grade

(mm2)

T2UH182FAA T2UH242FAA

48 Multi Air Conditioner

Page 49

Exploded View and Replacement Parts List

Exploded View and Replacement Parts List

342800

263230

359011

131410

135316

135311

35211B

346810

135516

354210-1

W0CZZ

267110

Indoor Unit

Service Manual 49

135515

354210-2

352111

352116

352115

267110

For model DYAA

For model D5AA

Page 50

53Service Manual

Exploded View and Replacement Parts List

•

649950

554160

554160

349600

554031

546810

559010

447910

435301

430410

435511

W6640-1

349480

552203-1

552203-2

552203-3

552116

552111-1

W6640-2

552111-2

435512

437211

437212

268711-1

268711-2

263230

Page 51

P/No.:

December, 2007

Printed in China

-

Loading...

Loading...