LG RCWW-1 Maintenance Manual

P/NO : MFL63281107

OPERATION &

MAINTENANCE MANUAL

Chiller

Water-cooled Screw R134a

• Please read this Operation & Maintenance Manual completely before Operating &

Maintenance the product.

• Operating & Maintenance must be performed in accordance with the national wiring

standards by authorized personnel only.

• Please retain this Operating & Maintenance for future reference after reading it thoroughly.

MODELS: RCWW-1 Compressor

www.lg.com

- 2 -

Chiller Water-cooled Screw

WARNING/CAUTION

Warning...................................................................................................................................3

Caution....................................................................................................................................7

GENERAL

HMI (Human Machine Interface) Operation ..........................................................................11

CONTROLS

Control Panel ........................................................................................................................25

PLC and HMI Unit .................................................................................................................26

Power Panel..........................................................................................................................33

Machine On/Off Control ........................................................................................................34

START UP

Pre Start-up ..........................................................................................................................35

Operating Procedure ............................................................................................................36

Operation Limit......................................................................................................................37

OPERATION

Operation Sequence .............................................................................................................41

Sensors.................................................................................................................................42

SERVICE

Cycle Part .............................................................................................................................43

Control System .....................................................................................................................57

Maintenance .........................................................................................................................65

TROUBLE SHOOTING............................................................................................................66

APPENDIX

Wiring Diagram .....................................................................................................................72

Cycle Diagram ......................................................................................................................73

Check List .............................................................................................................................74

Water cooled Screw Operation & Maintenance Manual

TABLE OF CONTENTS

- 3 -

Operation & Maintenance Manual

The installation, operation and maintenance service of the product can potentially be dangerous depending on

the system pressure, electric device, location of installation (Roof, lifting structure) etc. Only the well experienced and qualified installation or service engineer can install or operate the product. While operating the product, always check the warning/caution sticker or label on the product and comply with the details. Always wear

safety goggles and gloves. Always be careful when installing or operating all electric devices.

The following directions must be followed to prevent any injury to the user or others or any property damage.

n Improper use operation of the product that does not comply with the directions described in the manual can

lead to injury or damage. The severity is classified as follows.

n LG is not responsible for problems out of the warranty period, problems from mishandling by the consumer,

problems from natural disaster and power cord defect.

n The details included in the user manual can change without prior notice to improve the product.

n The meanings of the symbols used in this manual are as follows.

This symbol means that there is a possibility of death or major injury.

This symbol means that there is a possibility of property damage or minor injury.

Strictly prohibited.

Follow the direction.

All wiring must comply with local requirements

and the instructions given in this manual.

• If the power capacity is improper or the electrical

work is defective, it can cause a fire and electric

shock.

Product must be installed only by the service

provider with the installation certificate.

• Improper installation can cause a leakage, fire

and electric shock.

WARNING/CAUTION

To move or reinstall the product, consult the

installation service provider.

• It can ca use a fire, electric shock, explosion or

injury.

You must install the leakage current circuit

breaker and exclusive switch.

• If not installed, it can cause a fire and electric

shock.

- 4 -

Chiller Water-cooled Screw

Do not disassemble, repair or reconfigure the

product on your own.

• It can cause a fire and electric shock.

The product must be grounded properly.

• If not grounded properly, it can cause electric

shock.

Do not use damaged circuit breaker or exclusive switch.

• It can cause a fire, an electric shock, an explosion

or an injury.

Do not arbitrarily operate the product.

• Incorrect installation can lead to a fire, electric

shock or water leakage to cause an injury. Always

consult the installation service provider.

If the product is submersed under water,

always consult the installation service

provider.

• It can cause a fire and electric shock.

Be careful not to let water get inside the product (Controller). Especially, do not wash the

controller with water.

• It can cause electric shock and problems to the

product.

When install the product or moving the product to a different location, do not chart the

designated refrigerant (R134a) with a different

one.

• If a different refrigerant is mixed with original

refrigerant, it can cause problems in the refrigerant cycle and damage the product.

Use the exclusive cable for the product.

• It can cause electric shock and problems to the

product.

Install the product where the weight of the

product can be supported.

• If the product is installed at location with inappropriate hardness, it can fall over to cause damage.

When the product is installed in a small space

and the refrigerant is leaked, you must take

action to limit the concentration of the refrigerant not to exceed the safety limit.

• For appropriate action to prevent the product from

exceeding the safety limit, please consult the distributor. If the leakage of the refrigerant exceeds

the safety limit, it can cause a dangerous situation

due to lack of oxygen.

Do not store or use combustible gas or flammable substance near the product.

• It can cause a fire or a problem to the product.

Do not reconfigure or change the setting of

the protector.

• If other protective devices such as pressure

switch and temperature switch are disconnected

or operated by force, or when a different part is

used, it can cause a fire or an explosion.

- 5 -

Operation & Maintenance Manual

When explosive has leaked, immediately lock

the valve and open the window to ventilate the

room before operating the product.

• At this time, do not use the telephone or the

power switch. It can cause a fire or an explosion.

Do not operate the circuit breaker or main

power switch with wet hands.

• It can cause a fire and electric shock.

Comply with the permitted pressure.

• Comply with the regulated pressure for cold water

supply, cooling water and refrigerant etc.

• It can cause a fire and electric shock.

Do not change the setting.

• Do not change the setting of the controller and

safety device.

• If the product is operated with inappropriate setting, it can cause a defect, a fire or an explosion.

• When changing the control setting, always consult with the expert of the applicable field.

Do not put heavy objects or climb on top of

the product.

• It can cause a problem or an injury.

Be careful of the rotating part.

• Do not insert your finger or rod into the rotating

part of the pump and fan. It can cause a damage.

Be careful in case of a fire, earthquake or

lightning.

• In case of natural disasters including fire, earthquake or lightning or if there is a risk of lightning

strike, immediately stop operating the product.

• If you continue to operate the product it can

cause a fire or electric shock.

Comply with all the safety regulations.

• When the chiller is operating, follow the precautions indicated on the manual, tag, sticker and

label.

Always use fuse and circuit breaker of rated

capacity.

• If rated fuse or circuit breaker not used, It can

cause a fire or problem to the product.

Reconfiguring the control panel is prohibited.

•

Lock the control panel with a locking device, if possible, and when you have to open the control panel,

always shut down the main power switch first.

•

Do not touch the wiring or parts within the control panel.

• It can cause an electric shock, a fire or a problem

to the product.

- 6 -

Chiller Water-cooled Screw

Do not use undesignated refrigerant or oil.

•

Do not use undesignated refrigerant, cooling oil or brine.

•

It can have severe effect on compressor and part defect.

• If you would like to use a substitute refrigerant,

please contact LG.

Always shut down the power during installation and repair service.

• Electric shock can lead to injury or death.

• There could be more than one circuit breaker

switches. Indicate and check all switches blocked

so that the power will not be recovered until the

task is completed.

Wear protective gear.

• Wear protective goggles and gloves.

• Always be careful when installing and operating

the chiller and when operating electric parts.

When providing the service, do not take off

the brazing on the existing joint. If necessary,

put the pipe with the pipe cutter during the

service.

•

Compressor oil is combustible and there is no

method of detecting the flux in the refrigerant pipe.

•

Check the oil within the pipe and use the pan to

measure the amount of oil to be added to the cycle.

When charging/removing the refrigerant, always

let the water flow on the heat exchanger.

• It can prevent potential damage of the tube within

the heat exchanger.

• When the chiller is exposed to temperature below

0°C, use the brine appropriately within the water

circulating pipe to prevent the heat exchanger

from freezing.

Do not exhaust refrigerant inside the building

through the refrigerant exhaust valve.

•

Outlet of the exhaust valve must be directed to outdoors.

• Leakage of refrigerant in closed space can

remove the oxygen to cause suffocation.

•

Closed space or space with low ceiling must be ventilated appropriately. Suction of refrigerant is hazardous and can cause irregular heart beat, unconsciousness and death. Abuse of refrigerant is critical.

Refrigerant is heavier than air and reduces the

amount of oxygen. It can stimulate the eye and skin.

Be careful of leakage.

• If a leakage is spotted at the joints including

pump and pipe, immediately stop the operation.

• It can cause an electric shock, a leakage or a

problem to the product.

Be careful of electric shock.

• After installing the chiller, always make sure to

ground the product.

• There is a risk of electric shock.

Do not leave the cooling system in standby

condition for more than necessary.

• When the repair cannot be completed, close the

cycle to prevent the oil from being contaminated

and charge the dry nitrogen.

Do not reuse the compressor oil.

• It can damage the product.

- 7 -

Operation & Maintenance Manual

After installing or repairing the product,

always check for gas leakage.

• It can cause problems to the product.

Do not install the product at a location where

combustible gas is leaking.

• It can cause property damage.

Do not let children touch the product.

• It can cause a burn or an injury.

Install the product so that the noise does not

affect the neighbors.

• It may cause conflict with neighbors.

Do not use the product in special environment.

• Oil, steam, sulfuric smoke can reduce the performance of the product or damage the parts.

Be careful when transporting the product.

• When transporting the chiller, always consult with

the special expert.

• When transporting the chiller, always follow the

regulated method described in the manual. If not,

it can fall over or fall down.

Prevent the product from rusting from sea wind

(Salt) or install the blocking fence if necessary.

•

It can cause deformation or problem to the product.

Install the product so that the tension is not

applied to the cable of the product.

• If tension is applied, the cable can be disconnected or generate heat to cause a fire.

• When the power cable is damaged, do not

exchange the cable directly. Contact the service

center for replacement.

When installing the product, make sure to

level the product.

• Purpose of preventing vibration or leakage.

Do not install the product for special

usage/location including preservation of animal/plant, precision device, artifact etc.

• It can cause property damage.

Use exclusive cable of the product. Use rated

power cable with sufficient capacity over the

permitted current.

• It can cause a fire and electric shock.

When installing the product at the hospital or

communication tower, provide sufficient protective device for the noise.

•

Inverter, personal generator, high frequency medical device and electronic communication device

can cause malfunction or problem to the product.

On the other hand, the product can generate noise

to interfere with the medical device or video device.

- 8 -

Chiller Water-cooled Screw

Check whether the installation board has been

damaged from long use.

• When the base breaks down, the product can fall

over to cause property damage, problem in product or injury.

Safely remove the packaging.

• Metal objects such as nail or other wooden packaging can cause skin cut or other injury.

•

Rip any plastic or vinyl bags so that children would

not play with them, and dispose them safely.

Playing with plastic bags can cause suffocation.

Do not touch the refrigerant during or after the

operation.

•

The pipe during or after the operation can be hot or

cold depending on the condition of the refrigerant

passing through the refrigerant pipe, compressor,

refrigerant cycle parts etc. If you touch the pipe at

this time, it can cause burns or frostbite.

Turn on the main power 12 hours prior to

starting the operation.

• If you start to operate the product immediately

after turning on the main power, it can severely

damage the internal part. Keep the main power

turned on while operating the product.

Do not turn off the main power immediately

after stopping the operation.

• Always wait at least 5 minutes before turning off

the main power. If not, it can cause shortage of oil

supply or other problems.

Do not operate the product with the panel or

safety device removed.

• Rotating, hot or high pressure parts can cause a

safety accident.

Be careful when disposing the product.

• When disposing the chiller, request to the special

service provider.

When cleaning or repairing the chiller, use a

firm chair or ladder.

• It can cause an injury.

Be careful of high temperature.

• Be careful not to have any body parts touch the

hot part of the chiller.

• It can cause a burn.

Be careful of high pressure.

• Always install the power through a separate cable

and use exclusive power. Always install exclusive

circuit breaker for the power.

• It can cause an electric shock or a fire.

Be careful when installing the chiller.

• Be careful of the extra service space for the

product during the installation and specially

remove any surrounding obstacles for the water

cooling type. Install the product where it is well

ventilated.

Do not use strong chemical, household bleach

or acid solvent to clean the chiller.

• Use proper cleaner which is safe for environment.

- 9 -

Operation & Maintenance Manual

Be careful during re-operation.

• When the safety device of the product is operating, remove the cause and operate again.

• If you repeat the operation arbitrarily, it can

cause a fire or a problem.

Use appropriate tools.

• Use tools appropriate for repair and accurate for

measurement.

• Using inappropriate tools can cause an accident.

Be careful of sound or noise.

• If you hear a weird sound or smell something

weird, immediately stop the operation and contact the service center.

• It can cause a fire, an explosion or an injury.

Be careful of injury.

• Check the safety label of the safety device.

• Follow the above precaution and details on the

label. It can cause a fire or an injury.

• To prevent the generation of condensed water,

the pipe connected to the evaporator, as well as

the evaporator, must be insulated.

Check.

• Periodically check the product. When an issue is

identified, stop the operation and contact the

service center.

• Insufficient check can cause a fire, an explosion

or a problem.

Do not remove or change the cable connection when delivering the chiller.

• Operation of the compressor in the opposite

direction can cause a problem to the compressor

and must be replaced.

When shorting the part using jumper or other

tools, do not bypass by deviating from the

specified procedure.

• Grounding the control board and short circuiting

other cables can lead to electric module or part

damage.

• Insufficient check can cause a fire, an explosion

or a problem.

The flux must be within the designed range

and must be processed cleanly.

• This assures the product performance and

reduces the possibility of damage to the tube

including corrosion, sediment, scaling etc.

• LG is not responsible for any damage in chiller

and condenser from unprocessed or inappropriately processed cooling water.

Consult with the expert on the appropriate

cooling water processing method.

• Chemical processing may be required to prevent

or remove sediments or corrosions etc.

Do not overcharge the system.

• Overcharging increases the compressor discharge pressure and increases the consumption

of refrigerant. Also it can damage the compressor

and increase the power consumption.

- 10 -

Chiller Water-cooled Screw

Welding the evaporator head or nozzle part is

not recommended.

• When you need to weld a part, you must remove

the flux switch and coolant water inlet/outlet thermometer.

• After the welding is completed, the flux switch and

the thermometer must be reinstalled. If the flux

switch and thermometer are not removed, it can

damage the parts.

Install the device only on the heat exchanger.

• When the device is installed on the lower heat

exchanger, the device may not be lifted safely.

• It can cause an injury or damage to the chiller.

Do not add different type of oil.

• It can lead to abnormal operation of chiller.

Before receiving the service, the controller

power must be shut down.

• Ensure the safety and prevent the damage of the

controller.

Maintain the compressor oil pressure to normal level.

•When reducing the pressure, follow the precaution.

- 11 -

Operation & Maintenance Manual

GENERAL

This manual consists of information about control, operation, start, service and problem solving of

water-cooling chiller.

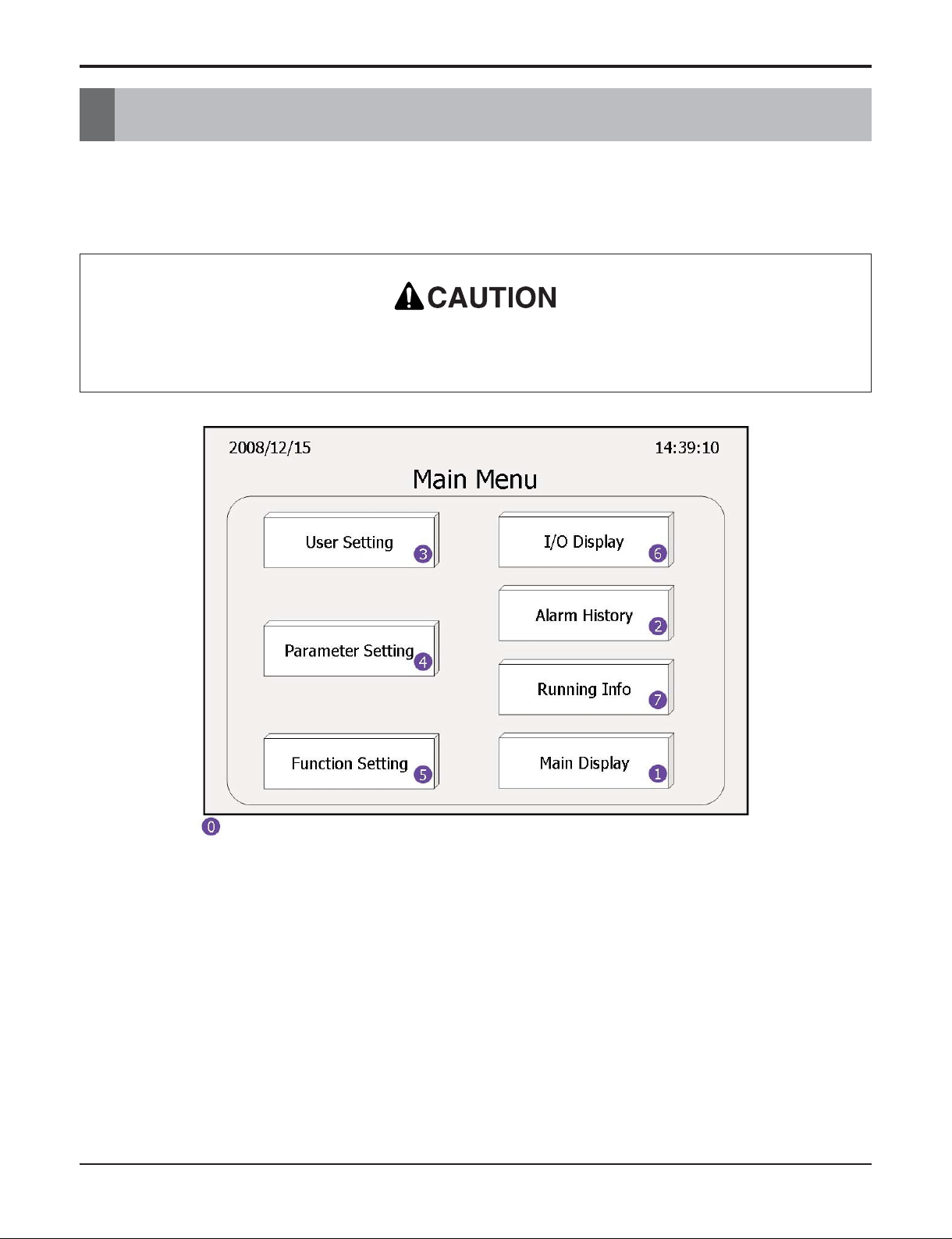

n HMI (Human Machine Interface) Operation

You should not change the program without consulting LGE service agent. Wrong program

can harm the machine.

Menu structure of HMI machine is indicated Fig. 1 above. It consists of 7 menus about User interface. HMI is touch screen, and you can move to the menu you want if you click the menu item with

your hand. User Setting, Parameter Setting and Function Setting of menu limit is accessed by certification code system.

Especially Parameter Setting limits access of operator, and operator only has authority to access to

User Setting.

In case of approval after power is OFF, basically Main Display screen would show up and operator

can move to Main Menu by operating menu item.

Fig. 1

- 12 -

Chiller Water-cooled Screw

Main Display

Main Display consists of one screen, and it is the screen showing up when power is ON in the first

stage. Operator can check the present condition of chiller in Main display. Also, operator can start/stop

in main display. If pressing Start/Stop button on screen over 3 seconds, chiller may Start/Stop.

Operator can check the condition of pump and system in Main display.

If pump is ON, it means that it is operating and Pump State would be indicated as black oval. If

chiller is ON, it means that it is operating and System State would be flickering twice in a second.

Actual operating condition of pump can be different from Pump State indication depending upon

which part conduct the pump control. Pump state indication in the Fig. 2 above would be applied

when the pump is controlled by control signal of chiller.

Operator can check the present existence of alarm. It can be checked because there are indications

of kinds of alarm in the bottom of screen. When alarm is ON, alarm box on the top would be flickering twice in a second, and it can be eliminated by pushing the alarm box on the top. It would move

to Alarm display menu to eliminate it.

Operator can check the date and day on the top of the screen. The date and time is changeable

function of setting menu.

Temperature of cold water outlet and cooling water outlet would be indicated in the main display,

and operator can check the operation condition of chiller by checking the indication of temperature

sensor input on chiller.

Also, operator can check the cooling power of chiller when operating in main display. Cooling power

will be indicated as 0~100% by the result of actual compressor capacity control.

Fig. 2

- 13 -

Operation & Maintenance Manual

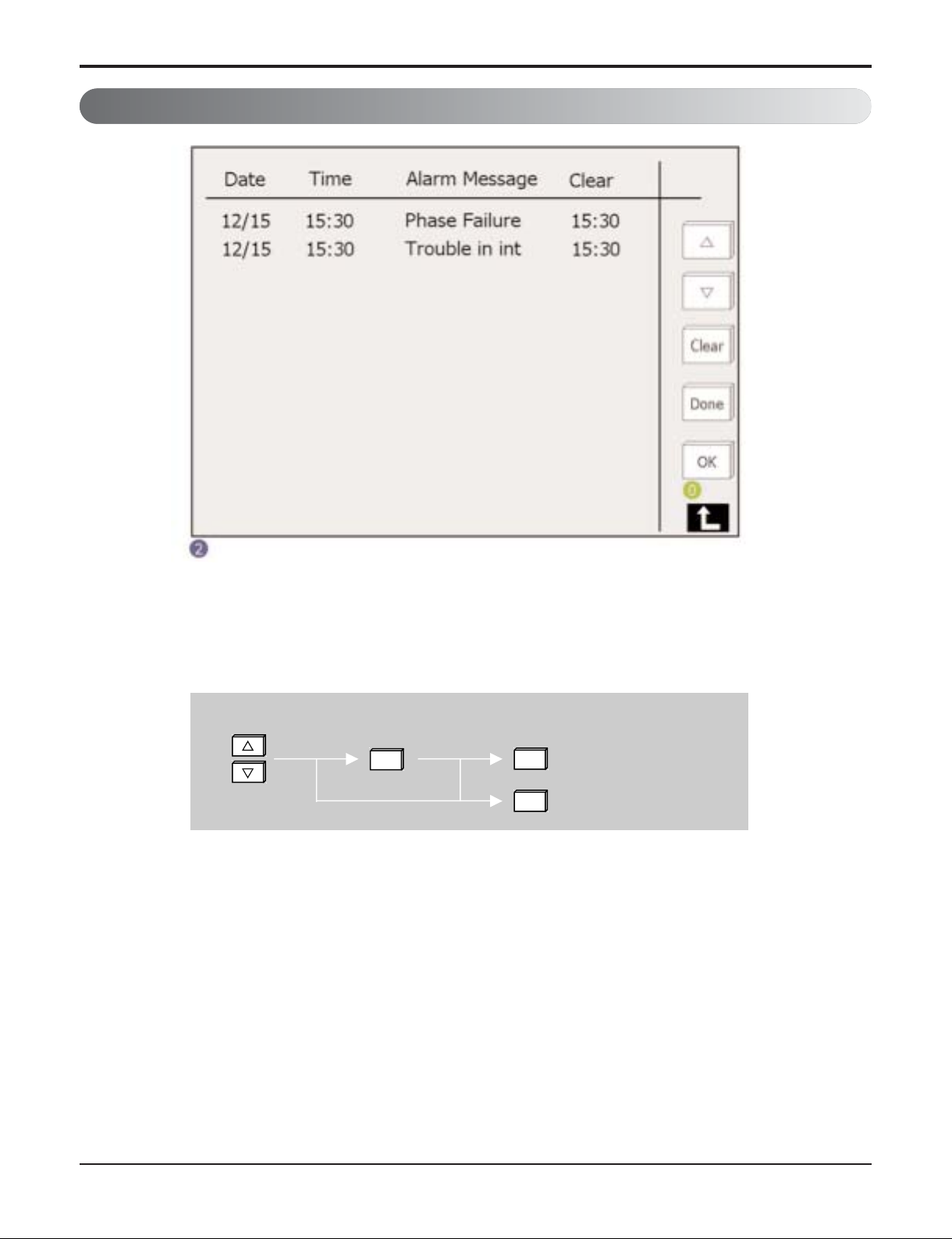

Alarm History

Last operated alarm will be indicated on Alarm display with time. Also, operator can cancel alarm on

the screen. See the Fig4 below for cancellation of alarm.

As explained in the Fig4 above, click the arrow ▽△ to move to the alarm contents which operator

wants to eliminate, and select the alarm by clicking OK. Cancel the alarm by clicking Clear.

Canceled alarm would be eliminated in the alarm display screen.

If operator does not cancel the alarm after alarm is ON, Chiller would not work even if actual alarm

situation is complete. After alarm is ON, always cancel the alarm and re-start it for operation.

Alarm elimination (Reset)

OK

Clear

Alarm elimination (Reset)

Done

Cancellation

Fig. 3

Fig. 4

- 14 -

Chiller Water-cooled Screw

User Setting

Fig. 5

- 15 -

Operation & Maintenance Manual

User setting consists of 2 screens. Movement can be done with clicking arrow ▽, △ Through user

setting, operator can make up the control parameter of chiller.

Operator basically can check and change the control setting condition of cold water outlet temperature. Among temperature setting items, target temperature of cold water outlet temperature and control range can be set by operator in user setting screen. Also by setting preheat function, operator

can set machine to operate only after ranged preheat time when power is ON.

For changing value, select the part which indicates the value and select the number which operator

wants to change to. If operator wants to cancel the change, select CLR, it would be cancelled. Stop

and Re-start temperature would be set automatically by setting Stop temperature Dt, Re-start Dt in

parameter setting. Stop temperature means the temperature at which compressor would be

stopped. Setting condition is 5.0ʼC. Re-start temperature means the temperature in case that compressor should be re-started after Stop. Setting condition is 9.0ʼC. Difference of Stop temperature

and Re-start temperature prevent often re-start of compressor.

Oil preheat can be set as Use/Nonuse, by minute unit. In the region where outdoor temperature is

low, oil needs to be preheated to ensure proper thickness of oil.

Control mode consists of Local Control/Tele Control, Hand Control/Auto control and MODBUS

Use/Nonuse. In case of Local Control, chiller may be operated by key controlling of operator. If

mode is changed to tele control, Start and Stop of chiller may be done by the condition of tele contact part.

In case of Auto control, chiller would Start and Stop automatically by operator setting operation

schedule. Schedule setting can be done in function setting menu. Contrarily, in case of Hand

Control, chiller would be operated by key control of operator or tele signals.

MODBUS would be used to conduct the control after connecting chiller to BMS and MODBUS

through network.

Operator can change password in second screen. Some function of HMI would be protected by

password. Password change can be done by selecting New Password , re-input it and complete it

by clicking OK.

Setting range of user setting value is specified below.

Table 1

Indication

Target Temp

Control Range

Preheat Function

Local Control/

Tele Control

Hand Control/

Auto Control

MODBUS

Code

Meaning

Setting temperature

of cold water outlet

Control Range

Preheat function

Local Control/

Tele control

Hand Control/

Auto Control

MODBUS Use

User input Password

Setting Range

5°C~12°C

0.6°C~1.5°C

Use/Nonuse

Local Control/

Tele Control

Hand Control/

Auto Control

Use/NonUse

XXXX

Basics

7°C

0.6°C

Use

Local Control

Hand Control

NonUse

6666

- 16 -

Chiller Water-cooled Screw

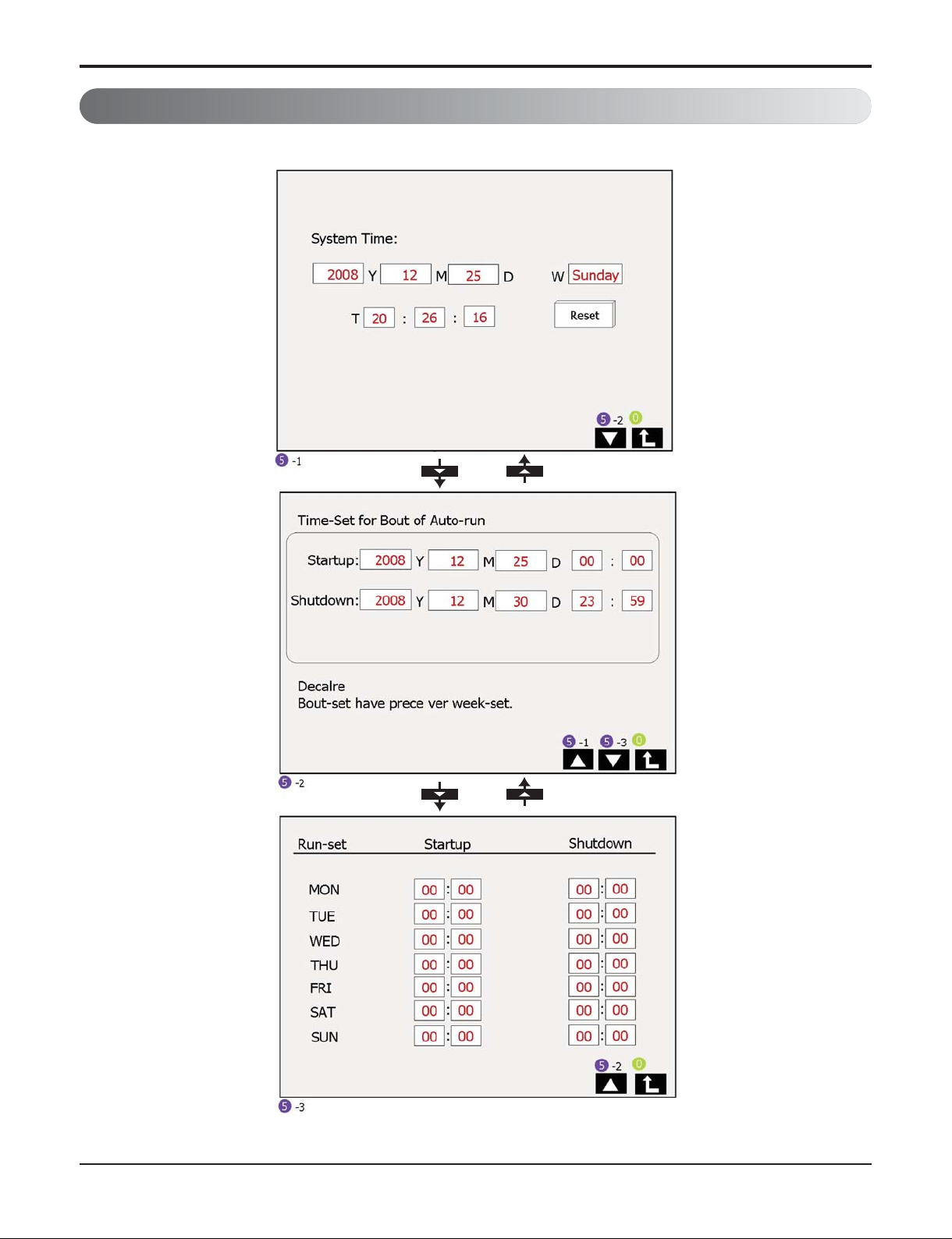

Function Setting

Fig. 6

- 17 -

Operation & Maintenance Manual

Function setting menu consists of 3 screens, and screen movement can be done by using arrow ▽,

△.

Operator can set the present time in the first screen. It can be done by selecting date and time box

which operator wants.

Resting 2nd screens enable operator to set the operation schedule of chiller. In the second screen,

operator would set the period to operate the chiller. Input the first start date, time of chiller and input

the stop date and time. If operator inputs 00 for the time of operation, it means that it would not be

operated. It can be changed by selecting box as explained earlier. Setting operation schedule is

used for efficient process operation schedule setting of manufacturing facilities.

The last screen enable operator to set the operation schedule of chiller by a week unit. Input

detailed operation time schedule from Monday to Sunday. Time can be set in minute unit. If operator

inputs start and stop time as 00:00, it would not be operated. This operation schedule setting would

be efficient in the situation where load change happens often like in the normal office building.

In case that 2 schedules are overlapped, schedule in the second screen would take precedence

over the others.

- 18 -

Chiller Water-cooled Screw

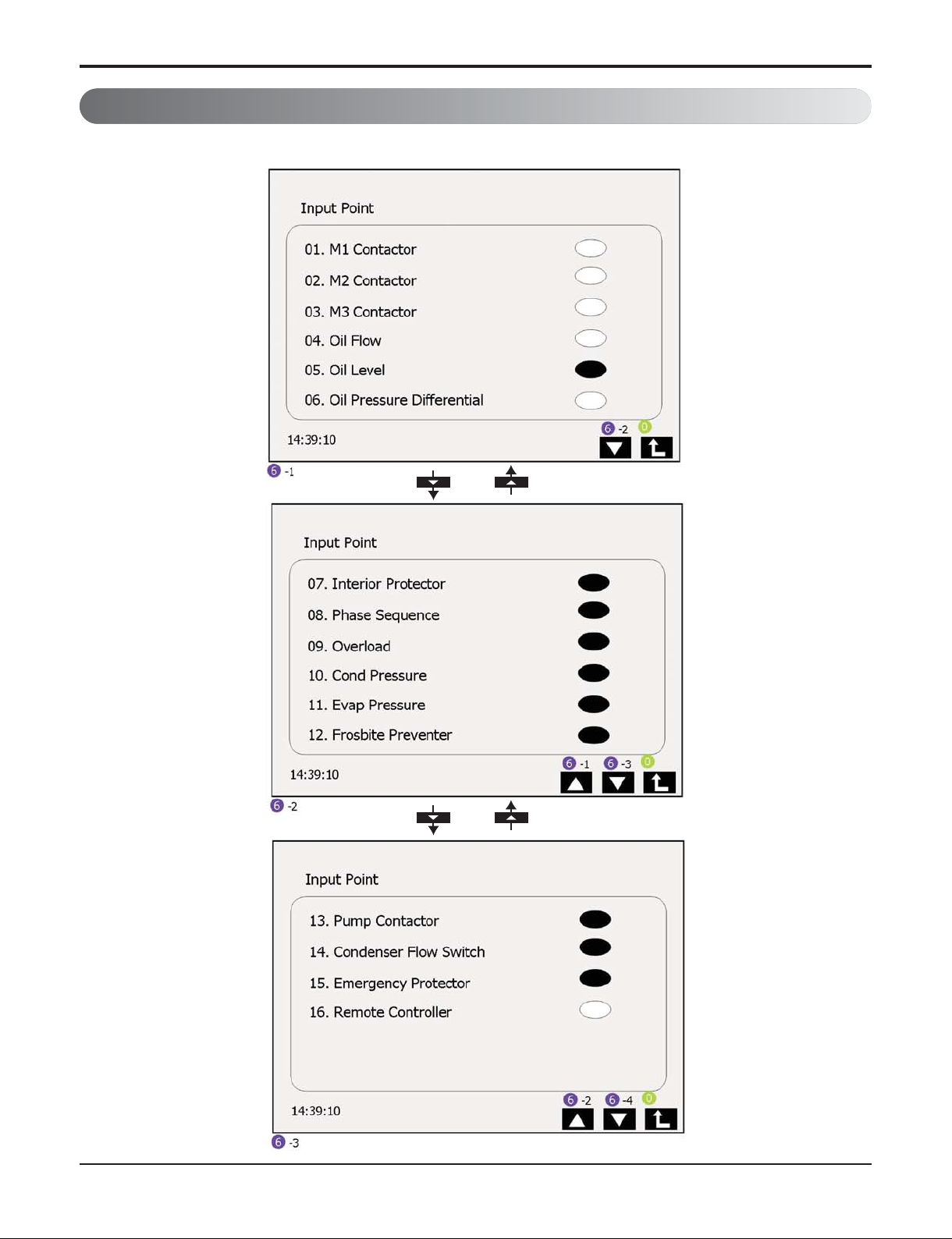

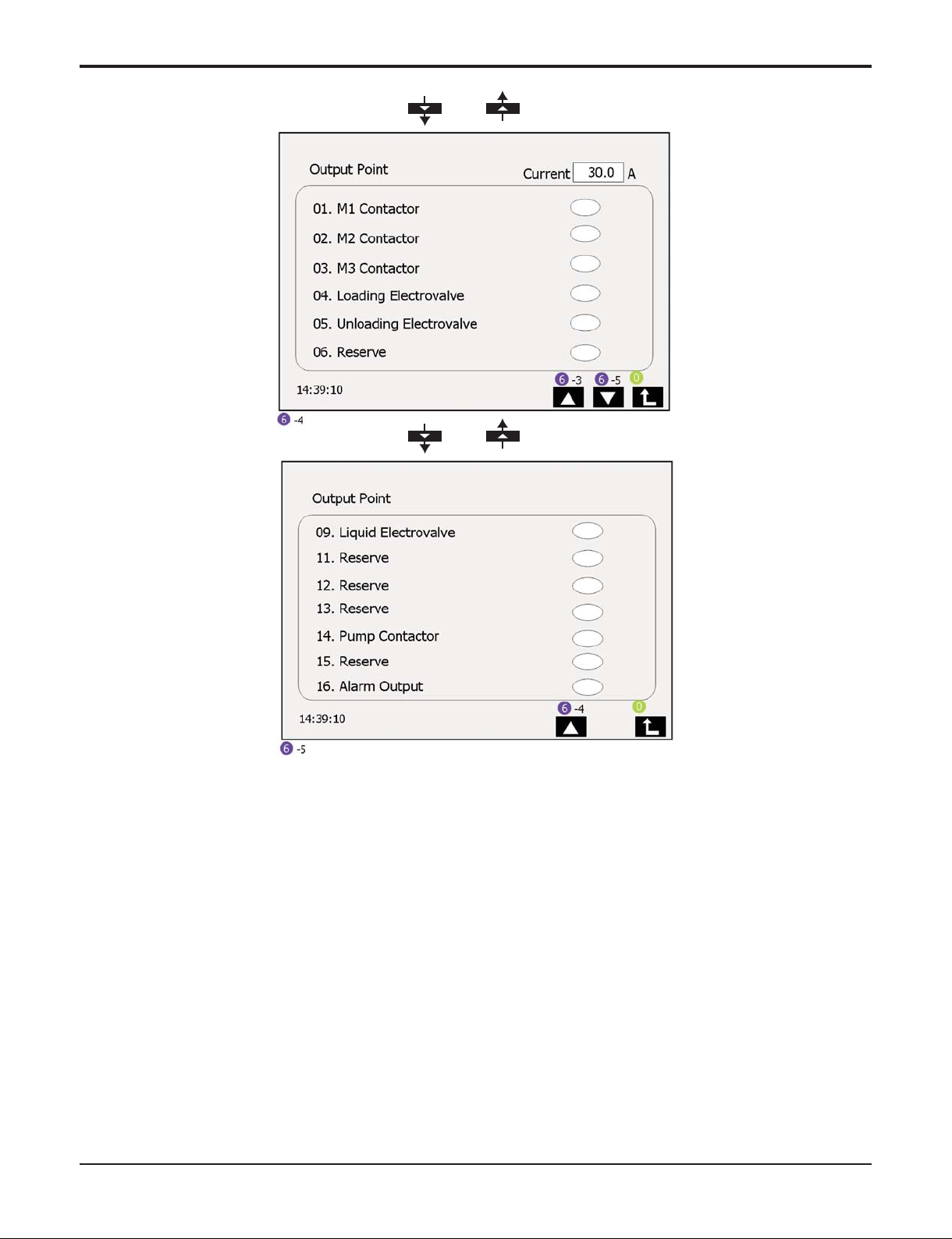

I/O Display

- 19 -

Operation & Maintenance Manual

Fig. 7

Input/Output display consists of total 5 screens including 3 screens for expressing the input condition and 2 screens for expressing the output condition. Input/Output display has input information

that means switch data that chiller control is inputted, and output information that means output signal approval of load equipment that conduct chiller controller output. Black oval of input/output signal means ON, white oval means OFF.

- 20 -

Chiller Water-cooled Screw

Indication value and meaning of input display, and normal value is specified above in the table.

Especially when operating if value is inputted other than the value specified above, PLC judge the wrong

value and alarm generated which would stop the chiller.

M3 contractor of input value is electron contactor of Y short of compressor motor and it would be change

to OFF after ON about for 5 seconds in the beginning of the compressor operation. After M3 Contactor is

Off, compressor would be operated normally through that M2 Contactor , which is electron contactor for

△ short. M1 contactor would be kept ON during operation as Main contactor for power approval.

Oil Flow and Oil Pressure Differential input would be inputted for checking normal function of lubrication

with Oil Level during operation. Oil level input always keeps being on during operation and stop which is

input for getting the oil level of oil separator. Oil Flow switch monitors actual oil flow from oil separator to

compressor, Oil Pressure differential is input for checking the pressure difference between low pressure

refrigerant and high pressure of compressor which is power for making oil flow, both inputs are ON when

compressor operation is stabilized. Therefore it check if it powers on normally in 5 minutes of compressor operation and it judge if it operates alarm. If it is not ON in 5 minutes of compressor operation, PLC

may recognize it alarm and stop the chiller safely.

Delay time is changeable through Parameter Setting, and contact LGE service agent when change is

needed because of alarm operation.

Table 2

Normal

Indication Meaning condition Normal condition

when when operating

stopping

M1 Contactor Main electron contactor ON ON

M2 Contactor Electron contactor for △ short OFF OFF → ON

M3 Contactor Electron contactor for Y short OFF ON → OFF

Oil Flow Oil flow switch OFF

ON

(in 5 minutes of operation)

Oil Level Oil Level switch ON ON

Oil Pressure Differential Oil Pressure differential switch OFF

ON

(in 5 minutes of operation)

Interior Protector Compressor interior protector ON ON

Phase Sequence Phase sequence voltage watcher ON ON

Overload Overload relay ON ON

Cond Pressure Condenser high-voltage switch ON ON

Evap pressure Evaporator low-voltage switch ON ON

Frosbite Preventer Freezing Preventer ON ON

Pump Contactor Pump operation input interlock OFF ON

Condenser Flow Switch Cold water/cooling water level switch OFF ON

Emergency Protector Emergency stop switch ON ON

Remote Controller Tele operation signal contact part ON/OFF ON/OFF

Input

- 21 -

Operation & Maintenance Manual

Compressor interior protector is equipment for sensing winding wire and discharge temperature of compressor which is installed on compressor. In case that compressor interior protector sense abnormal

high temperature from winding wire and discharge temperature, this signal change from ON to OFF, it is

kept ON in normal temperature condition.

Phase Sequence is Phase sequence voltage watcher which is installed on Power Panel, it watches input

power condition, if it detects abnormality, it change the signal from ON to OFF, if not it is in ON condition. The kinds of abnormal voltage that Phase Sequence can detect is 5, it includes over voltage, low

voltage, open, short, imbalance of between phase.

Overload is condition of overload relay for compressor, if it is normal it kept ON, if it is abnormal when

over-current flows it changes from ON to OFF.

Cond Pressure is input value of high-pressure switch that detect condenser high-pressure. It would be on in

high pressure abnormal condition, it would be On in normal pressure condition. Evap. Pressure also input

value of low-pressure switch that detects evaporator low-pressure. It would be OFF in evaporator low-pressure abnormal condition, it would be ON in normal pressure condition.

Frosbite Preventer is low temperature detect switch installed on evaporator, and it is used for preventing ice

formation. Low temperature detection would be done by the standard of cold water temperature 2ʼc, it would

be ON in normal temperature and it would be OFF if it is lower than 2ʼc.

Pump contactor input to the field wire is needed, contact part of electron contactor of cold water and cooling

water pump would be inputted to PLC in series. This signal should be ON when pump operation is needed.

Condenser Flow Switch is signal that is inputted into PLC after cold water and cooling water level switch

is connected in series. This signal should be ON when pump operation is needed.

Emergency Protector is the condition of Emergency switch that is installed on control. In case that emergency switch is cancelled, it is kept ON, in case that emergency switch is clicked, it is kept OFF.

Remote Controller is contact part signal input for tele controlling in tele control mode of chiller, when it is

ON, it operates chiller, when it is OFF, it stops chiller.

Table 3

Normal

Indication Meaning condition Normal condition

when when operating

stopping

Current Operation Current 0A Operation Current

M1 Contactor Main electron contactor ON ON

M2 Contactor Electron contactor for △ short OFF OFF → ON

M3 Contactor Electron contactor for Y short OFF ON → OFF

Loading Solenoid valve

Control valve for Sliding It changes depending on operation

Unloading Valve condition.

Solenoid valve

Liquid Solenoid valve Valve for Economizer ON

OFF/ON

(100% ON during operation)

Pump Contactor Pump control OFF ON

Alarm Output Alarm operation It changes depending on operation condition.

Output

- 22 -

Chiller Water-cooled Screw

M1 contactor, M2 contactor and M3 contactor indicates condition of electron contactor for compressor with input display. The value indicated on Output display is Output from actual PLC, the value

indicated on Input display is extra contact part condition which is inputted to PLC from electron contactor. Therefore, if wiring related to electron contactor is normal, the condition should be consistent.

If input condition and output condition is not same due to abnormality of electron contactor, it recognize the situation of alarm generation by PLC.

Loading Solenoid valve and Unloading Solenoid valve is used to control the sliding valve for volume

control of the compressor. Loading Valve and Unloading Valve is used to control Sliding Valve by

using oil pressure for compressor.

Liquid Solenoid valve is valve for Economizer operation, and it is installed at the pipe that sprays the

mid-pressure refrigerant to middle of compressor rotor, and it sprays when it is ON. If it is normal,

Liquid Solenoid valve is ON and spray refrigerant 100% in operating condition.

Pump contactor output is output signal for control cold water and cooling water, it should conduct

pump control of cold water and cooling water pump in field by field wiring. At least field pump should

be kept operating when this output signal is ON.

Alarm Output is the signal that operator can check the alarm operation of chiller in location where it

is far from chiller installation field and gives output when alarm is ON. If this signal is ON, chiller has

alarm operation, if the signal is OFF, chiller has normal condition.

- 23 -

Operation & Maintenance Manual

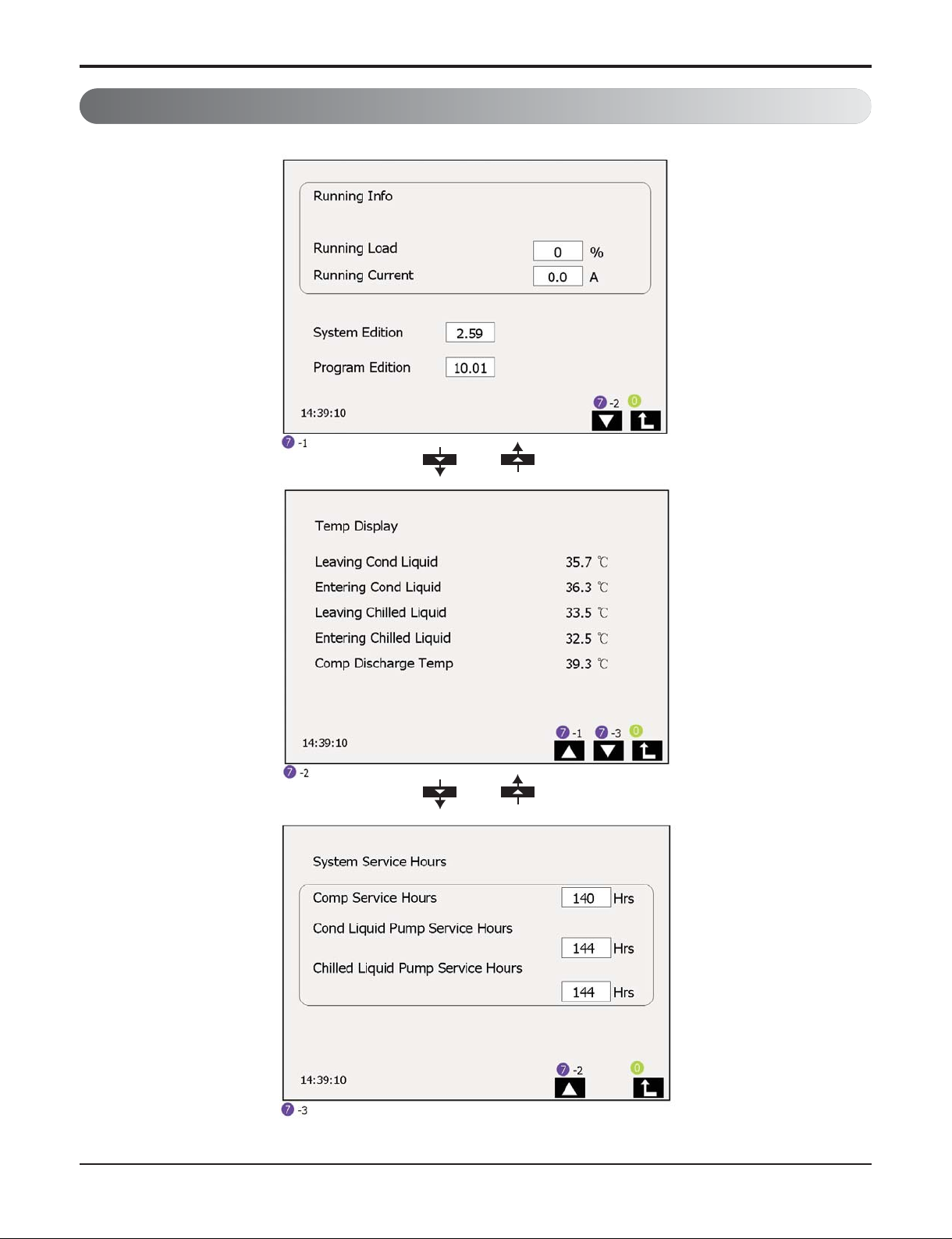

Running Information

Fig. 8

- 24 -

Chiller Water-cooled Screw

Operation Information screen indicates operation value state of chiller including chilling cycle, cold

water/cooling water temperature.

This operation value state includes chiller operation capability and operation current in present condition, also does accumulate operation time of cold water, cooling water pump and compressor.

Also, operation value state indicates refrigerant temperature of chilling cycle and cold water, cooling

water temperature. Indicated temperature would be shown to one place of decimal, and it includes

Leaving Cond. Liquid, Entering Cond. Liquid, Leaving Chilled Liquid, Entering Chilled Liquid, and

Comp. discharge Temp.

Loading...

Loading...