LG RCWW008CA1B,RCWW010CA1B,RCWW011CA1B,RCWW012CA1B,RCWW014CA1B,RCWW016CA1B,RCWW018CA1B,RCWW020CA1B,RCWW022CA1B,RCWW020CA2B,RCWW022CA2B,RCWW024CA2B,RCWW026CA2B,RCWW028CA2B,RCWW032CA2B,RCWW036CA2B,RCWW040CA2B,RCWW044CA2B,RCWW008CA1B,RCWW010CA1B,RCWW011CA1B,RCWW012CA1B,RCWW014CA1B,RCWW016CA1B,RCWW019CA1B,RCWW020CA2B,RCWW022CA2B,RCWW024CA2B,RCWW028CA2B,RCWW032CA2B,RCWW038CA2B User Manual

Page 1

LG Electronics, Home appliance & Air solution company

56, Digital-ro 10-gil, Geumcheon-gu, Seoul, Republic of Korea (153-801)

www.lg.com

www.lgeaircon.com

Ver. 202004

LG HVAC SOLUTION

WATER COOLED

SCREW CHILLER

For continual product development, LG reserves the right to

change specifications or designs without notice.

© 2020 LG Electronics. Printed in Korea. Apr. 2020

Distributed by

Page 2

Line upNomenclature

Introduction

R : Korea(R134a)

M : China(R134a)

C: Chiller

Contents

02 Nomenclature

03 Line up & Introduction

04 Equipment overview

06 Control

08 Accessories and options

09 Specication

15 Electrical data

22 Outline drawing

24 Foundation

26 Piping diagram

28 Control wiring

30 Power wiring

32 Installation

34 Guide specication

W: Water-cooled

(Cooling only)

W: Screw

compressor

Nominal ton:

100RT ⇨ 010

380RT ⇨ 038

Water working pressure:

A: Chilled water : 10kgf/cm²G

Cooling water : 10kgf/cm²G

B: Chilled water : 16kgf/cm²G

Cooling water : 16kgf/cm²G

C: Chilled water : 20kgf/cm²G

Cooling water : 20kgf/cm²G

030R C W W C A 2 B

Develop-

A: Flooded type

C: Falling film type

Number of

compressors

ment

sequence

Line up

Model

50Hz

R-134a

60Hz

LG’s latest Water cooled screw chiller offers excellent operational efciency

thanks to the company’s advanced technologies and unrivalled air conditioning

expertise. The new model’s advanced capacity control system valve help to

improve performance and efciency. LG’s proprietary PID(Proportional, Integral,

Differential control), which controls hydraulic-head loss rate, helps to minimize

energy loss even further.

• High-performance compressor manufactured by specialized

manufacturer is adopted to ensure that the chiller is

economical and durable with low vibration and low noise.

• Highly integrated motherboard is adopted and hence the

function is strong and reliable.

• Advanced control algorithm is adopted to control chiller in

advance and hence avoid frequent stoppage protection of chiller.

• We have set complete safety protection function in order to

make chiller safely and reliably run.

• The linkage control and remote monitoring function of

peripheral equipment ensure that the chiller can run safely

and the operation and monitoring are convenient.

• The selection of excellent raw materials and ttings is the key

to guaranteeing chiller quality.

High efciency, High reliability

The RCWW & MCWW series is a kind of water-cooled spray

screw chiller produced by LGE Corporation. Because of the

special structure design, the chiller has high efciency and

high reliability.

Optimized dedicated motor

R134a with high efciency

Made of premium grade, low-loss core steel with the special

slot design, the motors of R134a dedicated compressors

50 100 150 200 250 300 350 400 450 500

75RT 380RT

75RT 440RT

can gain the highest efciency with low power consumption.

Besides, different winding for specic voltage and frequency

requirement contributes to the best power factor and

excellent performance.

Constructional design of

dedicated screw compressor

The screw compressor is characterized by a very compact

design. Most of inner dimensions have been totally modied

considering displacement volume, size of compression

chamber, length & prole of rotors, oil separator specication

and oil piping rearrangement, etc. to ensure consistency and

cost effectiveness of the compressor.

Compressor

• Semi-hermetical twin-rotor screw compressor.

• Direct-drive, low speed/RPM for high efciency and high reliability.

• Only three moving parts, resulting in high reliability with

simple solution.

• Field serviceable compressor and easy maintenance.

• Precise rotor tip clearance.

• The world’s advanced patent screw tooth with low noise,

smooth operation long life advantages.

• A refrigerant dispersing cooling device is set internally for

compressor cooling, which uses return-refrigerant cooling.

• Years of research and testing. The LG screw chiller has

amassed thousands of hours of testing, and conditions

* The above range is based on the nominal tonnage.

02 | 2020 LG Water Cooled Screw 2020 LG HVAC Solution | 03

Page 3

Features Features

Equipment overviewEquipment overview

beyond normal air conditioning applications.

Unit performance testing

LG began promoting factory performance tests for air-cooled

chillers and water-cooled chillers, to show we stand behind the

products we design and build.

The bene ts of a performance test include veri cation of performance, prevention of operational problems, and assurance of a

smooth start-up.

Only a performance test conducted in a laboratory or laboratory

grade facility will con rm both performance and operation of a

speci c chiller.

Mostly factory performance tests go smoothly. If a problem

occurs, LG personnel easily correct them and chiller is shipped

to job site.

When a factory performance test is requested, the test can be

conducted at the speci ed, design conditions. The test facility

has the capability to control ambient test conditions to assure

our customers that our chillers will perform as predicted.

AHRI certi cation program

and standards and codes

Chillers conform to the following Standards and Codes:

• AHRI 550/590 - water chilling

packages using the vapor

compression cycle.

• ANSI/ASHRAE 34 -

number designation and safety

classi cation of refrigerants.

• ASME Section VIII(Option) - boiler and pressure vessel.

• GB/T 18430.1 - water chilling(heat pump) packages using the

vapor compression cycle - part 1: water chilling(heat pump)

packages for industrial & commercial and similar applications.

(This code is only applied to product manufactured in China)

Equipment Overview

Semi-hermetic twin compressor

The semi-hermetic screw compressor is developed especially

for applications in air-conditioning and refrigeration. With high

operating load design, each compressor is of high ef ciency

and reliability in all operating conditions. Each compressor has

the latest and advanced 5-to-6 Patented Screw Rotor Pro le

designed to ensure high capacity and ef ciency in all operating

conditions.

The compressor is equipped with separated radial and axial

bearings, liquid injection and economizer connection, PTC

motor temperature thermistors and discharge temperature

thermistors, a motor protector, and oil level switch and

oil pressure differential switch and other accessories. The

complete accessories and their new designs guarantee the

compressor has the best reliability, longest bearing life during

heavy duty running and strict operating conditions.

The slide valve for capacity control is located in the compressor

chamber. The slide valve is actuated by injection of pressurized

oil into the cylinder from the oil sump as well as bypass of

oil through solenoid valves in each oil lines with pressure

differential.

The screw compressors are equipped with either 3-step/4step capacity control system or continuous(stepless) capacity

control system. Both of the capacity control systems consist

of a modulation slide valve, piston rod, cylinder, piston and

piston rings. The slide valve and the piston are connected by a

piston rod. The principle of operation is using the oil pressure

to drive the piston in the cylinder. The lubrication oil ows from

the oil sump through the oil lter cartridge and capillary then

lls into the cylinder due to the positive oil pressure bigger

than the right side of spring force plus the high pressure

gas. The positive pressure differential causes the piston to

move toward the right side in the cylinder. When the slide

valve moves toward the right side, the effective compression

volume in the compression chamber increases. This means the

displacement of refrigerant gas also increases, as a result the

refrigeration capacity also increases.

However, when any of the step solenoid valve(for 4-step

capacity control system) is opened, the high pressure oil in the

cylinder bypasses to the suction port, which causes the piston

and the slide valve to move toward the left side, and then

some of the refrigerant gas bypasses from the compression

chamber back to the suction end. As a result, the refrigeration

capacity decreases because of the reduction of displacement

of refrigerant gas owing in the system. The piston spring

is used to push the piston back to its original position, i.e.

minimum load position in order to reduce the starting current

for the next starting.

4-steps capacity control

Component

No

1 Suction filter 10 Lubricant

2

Gas in(low pressure) 11 Oil separator cartridge

Motor 12

3

4 Oil filter cartridge 13 Capillary

5 Suction bearings 14 Solenold valve, SV2

6 Male rotor 15 Solenold valve, SV1

7 Discharge bearings 16 Orifice

8 Oil separator baffle 17 Slide valve

9

Gas out(high pressure with oil)

Step-less capacity control

Component

No

1 Suction filter 10 Lubricant

2 Gas in(low pressure) 11 Oil separator demister

3 Motor 12 Gas out(high pressure without oil)

4 Oil filter cartridge 13 Capillary

5 Suction bearings 14

6 Male rotor 15

7 Discharge bearings 16

8 Oil separator baffle 17 Slide valve

9 Gas out(high pressure with oil) *

Component

No

Gas out

(high pressure without oil)

Component

No

Solenold valve(min. %),

SV 25% / 33%

Solenold valve

(50% of full load), SV 50%

Solenold valve(75% / 66% of

full load), SV 75% / 66%

For RC2-100, 140 & 180 the SV50% omitted

Heat exchanger

Evaporator

Falling lm type

“Falling lm” shell and tube type evaporator having refrigerant

in the shell and chilled water inside the tubes.

Advantage of this type evaporator is higher heat transfer

performance and reduced refrigerant charge.

Distributer located on the top side of inside shell makes

uniform ow of refrigerant, this refrigerant ows downward

by gravity as a continuous lm.

The shell is of welded carbon steel construction with steel

tube sheets and copper heat exchange tubes. Removable steel

water boxes at both ends of the cooler allow tube cleaning

without disturbing the refrigerant circuit.

Tubes are mechanically expanded into tube sheets with double

grooves to ensure leak tight and trouble free operation.

Multiple compressor/ circuit chillers have coolers with separate

refrigeration circuits for each compressor.

Each refrigeration circuit is provided with its own pressure

relief valve. All chillers are tted with drain valves on the

removable heads and shell. All coolers are factory insulated

with 19mm of closed cell expanded synthetic rubber with all

joints vapor sealed.

Expansion device

Expansion unit consists of butter y valve and ori ce. At 100%

load situation, the pressure loss at the ori ce is smaller than

the refrigerant pressure loss in the condenser, thus the super-

cooled refrigerant passes through the ori ce.

At this stage the maximum amount of refrigerant is owing

into the evaporator. As the load reduces gradually, the

circulating amount of refrigerant also reduces and accordingly

the refrigerant level in the condenser is getting low.

When the amount of liquid refrigerant reduces, the gas

amount in the ori ce is getting larger, raising the resistance

thus controlling the ow rate.

Control

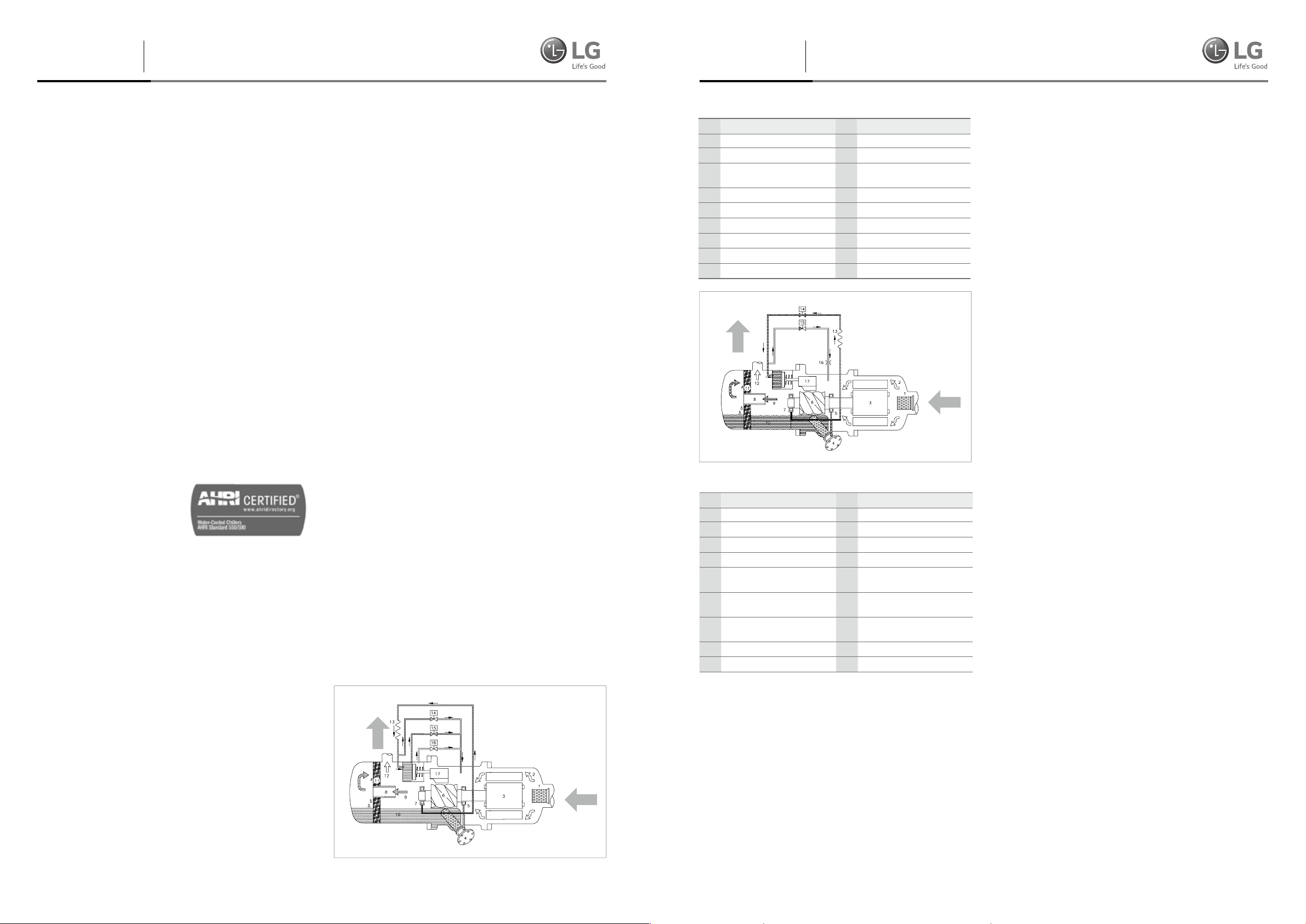

Controller system information

Generally controller consist of Display, Master, Slave and Relay

board. Each board connect with RS485 communication and

include analog input/output, digital input/output channel.

• 7 and 10.2-inch color LCD touch screen with high resolution

(1,024 x 600)

• Operation scheduling function

• Real time trend display

• Web Access(Additional accessory)

• Running data acquisition

• Easy-to-read display of operational data

• Certi ed EMI/EMS

• Communication supported: Modbus, RS485(standard)

• Language: English / Chinese / Korean

04 | 2020 LG Water Cooled Screw 2020 LG HVAC Solution | 05

Page 4

Features

Control

Features

Accessories and options

①

Machine type

selection indicator

②

Date and time

indicator

⑦

Menu bar

③

Operation method

selection indicator

④

Message

display

⑤

Operation mode

selection indicator

⑥

Displayed categories

Controller front view

① Machine type selection indicator

It show the currently selected model. You can check detail

from 'Control Information set' part.

② Date and time indicator

It show the current time. You can check detail from 'Sys.

Info.(System information)' part.

③ Operation method selection indicator

It show the currently selected control mode. You can

check detail from 'User set' part.

④ Message display

It show the message about status of product.

⑤ Operation mode selection indicator

It show the currently selected run mode. You can check

detail from 'User set' part.

⑥ Displayed categories

It show the currently information of product.

⑦ Menu bar

It show the functions for menu operation button.

Features of control unit

The Control unit of LG chiller controls temperature, pressure,

current and capacity control valve using high capacity

microprocessor. It is constructed to provide the high reliability

chiller operation using LG's unique optimum control algorithm.

Controller system composition diagram

Master board and slave board have the same hardware and

they are set as master or slave by DIP switch setting. This

board consist of analog input/output, digital input/output and

communication connections.

• Protocol and communication method

- Standard : Modbus, RS-485

- Option : BACnet, TCP/IP, Lonwork

RS485

TCP/IP

Serial to LAN

converter

Protocol

converter

The chillers can be managed up to 255 units when using communication of RS485 or TCP/IP.

Multi-Drop

RS485

Converter

Connecting to max 8 units

Detailed diagrams of BMS

NFB(Non-Fused Breaker)

power disconnect switch

A non-fused disconnect is available as a factory-installed option

for all units with single point power connection units. This option

is that power supply is disconnected during service & repair.

Suction service isolation valve

Service suction isolation valve is installed with unit for each

refrigerant circuit as a standard.

General options

Vibration isolation

For installation on building roofs or in sensitive noise areas

(hospitals, studios and some residential areas) pre-selected

spring type isolators with 1” or 2” de ection are available as a

factory option – shipped loose part for eld installation.

Power factor correction

Provide equipment with power factor correction capacitors as

required to maintain a displacement power factor of 95% at all

load conditions.

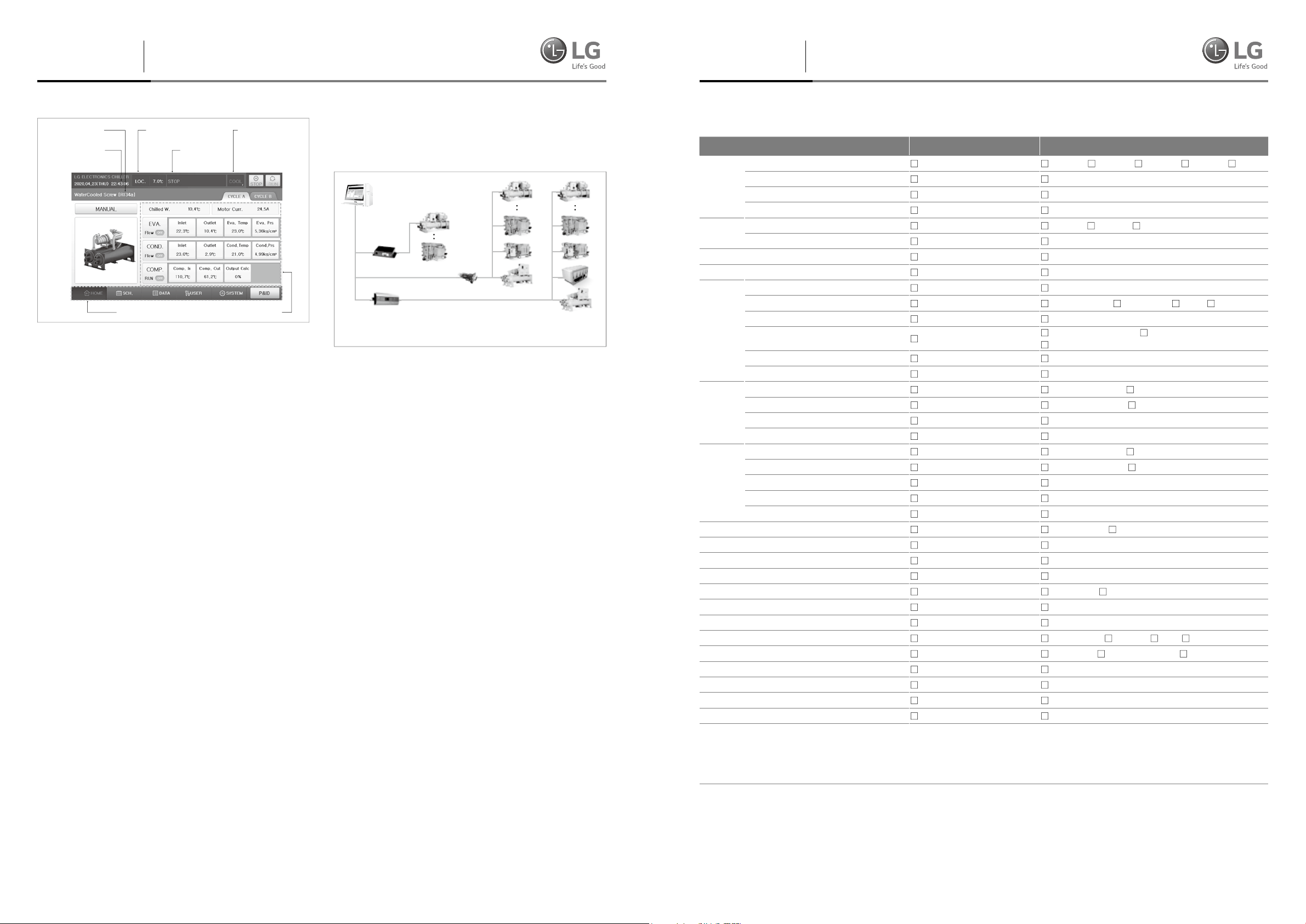

Water-Cooled Screw chiller standard summary

Items Standard Option

Power Supply(3Ph)

Comp.

Control

Panel

Power Connection

Factory Wiring

Starter

Panel

EVAP.

COND.

Refrigerant Charge

Packing

Insulation

Sound attenuator

Isolation

Anchor Bolt for Foundation

Counter Pipe Flange

Certification

Factory Performance Test&Process inspec.

Operating Training

Warranty-Compressor

Warranty-Ass'y

Labor warranty

Standard specification

Hertz

Capacity Control type

Angle Valve

Communication

Protection Grade

Supplied by

Starter type

Mounted type

Misc. Options

Power Access

Protection Grade

Waterbox Pressure

Nozzle Type

Flow proof type(Ref.)

Pipe direction(C.B Front st.)

Waterbox Pressure

Nozzle Type

Flow proof type(Water)

Flow proof type(Ref.)

Pipe direction(C.B Front st.)

380V

50Hz

Step

N/A

Modbus

IP4X

Standard(Single)

Open Wiring

Factory

Y-Delta(Open)

Unit Mounted

N/A

From the Top

IP4X

150psig(10kg/cm

ANSI-Flange

Relief V/V(Single)

Left

150psig(10kg/cm

ANSI-Flange

N/A

Relief V/V(Single)

Left

Separated Shipping

Shrink film

Yes

N/A

Neoprene PAD

N/A

N/A

Standard(KGS)

N/A

N/A

1yr

1yr

N/A

1) Factory Wiring : Open Wiring

2) Color : Dawn Gray

- Starter / Control Panel : Warm Gray

3) Standard provide Emergency stop switch

4) Flow proof type : DP Switch(Evaporator)

400V 415V 440V 460V 480V

60Hz

Stepless

Yes

BACnet TCP/IP etc( )

etc( )

Multi power Connection

Flexible Wiring

Supplied by customer

Y-Delta(Closed) Soft Starter

Stand Alone

Ground Fault Protection Power Factor Correction Capacitor

Integrating Watt-meter

From the Bottom

etc( )

2

)

2

)

230psig(16kg/cm

ANSI-Victaulic(AGS) ANSI-Victaulic(OGS)

Relief V/V(Dual)

Right

230psig(16kg/cm

ANSI-Victaulic(AGS) ANSI-Victaulic(OGS)

DP switch

Relief V/V(Dual)

Right

Factory Charge Customer supplied

Wooden packing

N/A

Yes

Spring 1Inch Spring Rubber Pad

Yes

Yes

ASME Ⅶ Only CE(PED) PED (C)UL(ETL)

Report Only Customer Wintness Process inspection

Yes

etc( )

etc( )

etc( )

2

)

2

)

300psig(20kg/cm

300psig(20kg/cm

SPG

Direct

2

2

)

)

BMS support function

Screw chiller’s basic communication protocol is Modbus protocol,

and it is compatible with the higher level communication methods.

Communication protocol support

06 | 2020 LG Water Cooled Screw 2020 LG HVAC Solution | 07

Page 5

Specification

60Hz

Specification

60Hz

R134a(60Hz)

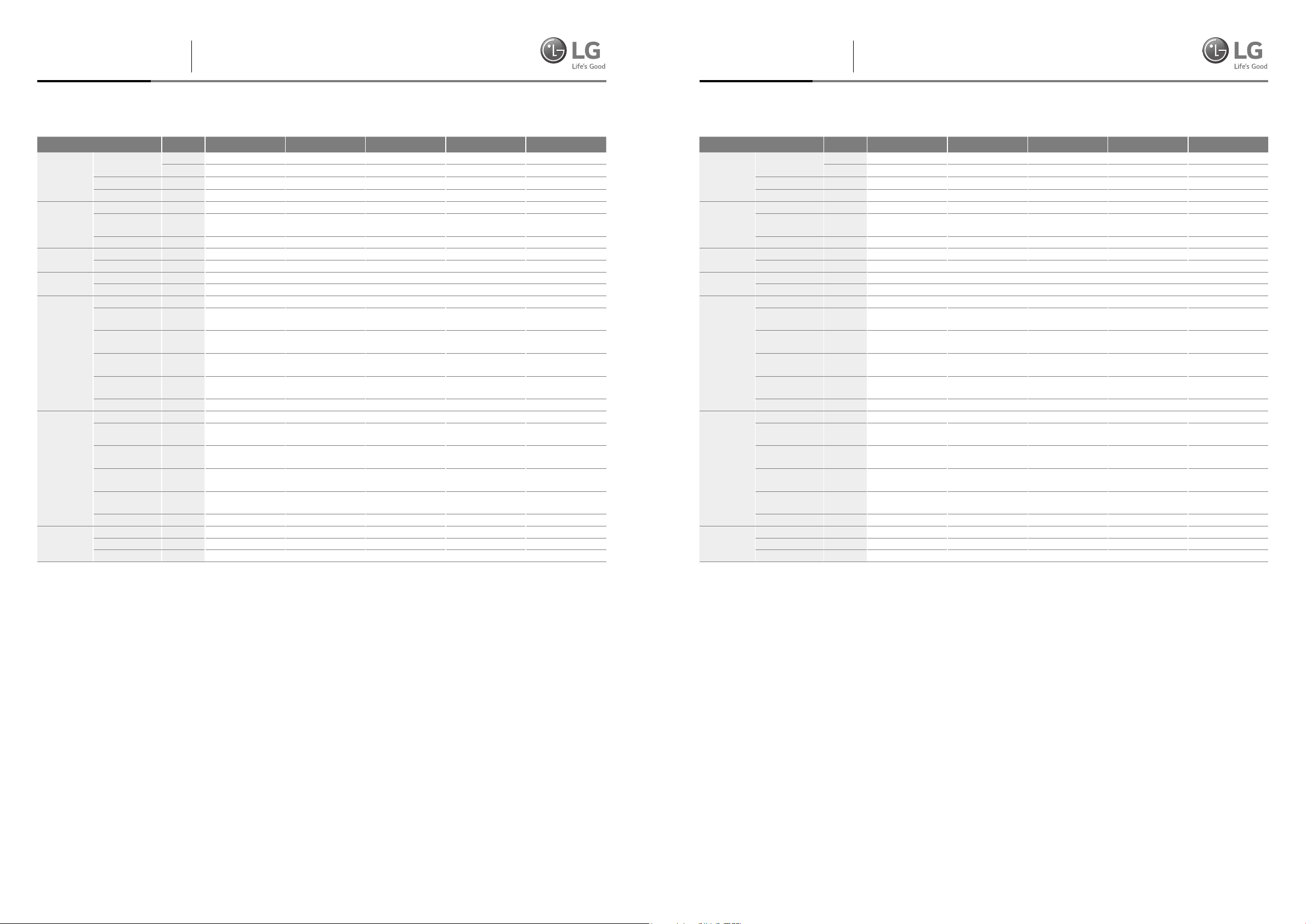

Model Units RCWW008CA1B RCWW010CA1B RCWW011CA1B RCWW012CA1B RCWW014CA1B

AHRI

Condition

Number of Circuits 1 1 1 1 1

General Unit

Data

Weight

Compressors

Condenser

Evaporator

Dimension

Operating Weight kg 2,810 3,020 3,120 3,120 3,460

Water Connections DN 100 100 100 100 125

Water Connections DN 100 100 100 100 125

Cooling capacity

Input Power kW 51.6 62.3

COP 5.35 5.33 5.34 5.35 5.58

Refrigerant,

R-134a

Oil Charge l 16 16 18 20 20

Shipping Weight kg 2,670 2,860 2,950 2,940 3,230

Compressor type Semi-hermetic twin screw

Quantity EA 1 1 1 1 1

Condenser type Shell and Tube

Max. Water

Pressure

Max. Refrigerant

Pressure

Min. Cooling

Water Flow Rate

Max. Cooling

Water Flow Rate

Evaporator type Shell and Tube

Max. Water

Pressure

Max. Refrigerant

Pressure

Min. Chilled

Water Flow Rate

Max. Chilled

Water Flow Rate

Length mm 3,040 3,040 3,040 3,040 3,145

Width mm 1,435 1,435 1,435 1,435 1,480

Height mm 1,860 1,865 1,865 1,865 2,080

kW 276.0 332.2 376.4 407.0 472.2

usRT 78.5 94.5

107.0

70.5

kg 110 110 110 110 140

MPa 1.0 1.0 1.0 1.0 1.0

MPa 1.0 1.0 1.0 1.0 1.0

l/s 6.6 7.5 8.5 8.5 10.8

l/s 26.5 30.0 34.2 34.2 43.2

MPa 1.0 1.0 1.0 1.0 1.0

MPa 0.9 0.9 0.9 0.9 0.9

l/s 5.6 7.7 7.7 8.4 10.1

l/s 22.3 30.7 30.7 33.5 40.5

115.7 134.3

76.1 84.7

R134a(60Hz)

Model Units RCWW016CA1B RCWW018CA1B RCWW020CA1B RCWW022CA1B RCWW020CA2B

AHRI

Condition

Number of Circuits 1 1 1 1 2

General Unit

Data

Weight

Compressors

Condenser

Water Connections DN 125 125 125 125 150

Evaporator

Water Connections DN 125 125 125 125 150

Dimension

Cooling capacity

Input Power kW 105.0 114.7

COP 5.44 5.52 5.47 5.61 5.35

Refrigerant,

R-134a

Oil Charge l 28 28 28 1 16 / 16

Shipping Weight kg 3,560 3,680 3,780 3,880 5,140

Operating Weight kg 3,810 3,960 4,060 4,160 5,410

Compressor type Semi-hermetic twin screw

Quantity EA 1 1 1 1 2

Condenser type Shell and Tube

Max. Water

Pressure

Max. Refrigerant

Pressure

Min. Cooling

Water Flow Rate

Max. Cooling

Water Flow Rate

Evaporator type Shell and Tube

Max. Water

Pressure

Max. Refrigerant

Pressure

Min. Chilled

Water Flow Rate

Max. Chilled

Water Flow Rate

Length mm 3,145 3,145 3,145 3,365 3,855

Width mm 1,480 1,605 1,605 1,750 1,565

Height mm 2,080 2,105 2,105 2,150 2,175

kW 571.6 632.8 681.1 795.9 667.6

usRT 162.6 180.0

193.7

124.6

kg 140 165 165 200 120 x 2

MPa 1.0 1.0 1.0 1.0 1.0

MPa 1.0 1.0 1.0 1.0 1.0

l/s 12.0 13.6 13.6 13.6 12.0

l/s 48.1 54.4 54.4 54.4 48.1

MPa 1.0 1.0 1.0 1.0 1.0

MPa 0.9 0.9 0.9 0.9 0.9

l/s 11.2 12.6 12.6 12.6 11.2

l/s 44.6 50.2 50.2 50.2 44.6

226.4 189.8

142.0 124.7

Note:

1. 1usRT = 3,024kcal/hr = 3.517kW, 1mH

2. AHRI conditions :

Leaving chilled water temperature is 6.7 ˚C(44 ˚F). Water flow is 0.043 L/s per kW(2.4 gpm/ton)

Entering cooling water temperature is 29.4 ˚C(85 ˚F). Water flow is 0.054 L/s per kW(3.0 gpm/ton)

Fouling factor of water in evaporator is 0.018 m²·˚C/kW(0.00001 h·ft2·˚F/Btu)

Fouling factor of water in condenser is 0.044 m²·˚C/kW(0.00025 h·ft2·˚F/Btu)

3. Due to our policy of innovation some specification may be changed without prior notification.

O = 9.8kPa

2

Note:

1. 1usRT = 3,024kcal/hr = 3.517kW, 1mH

2. AHRI conditions :

Leaving chilled water temperature is 6.7 ˚C(44 ˚F). Water flow is 0.043 L/s per kW(2.4 gpm/ton)

Entering cooling water temperature is 29.4 ˚C(85 ˚F). Water flow is 0.054 L/s per kW(3.0 gpm/ton)

Fouling factor of water in evaporator is 0.018 m²·˚C/kW(0.00001 h·ft2·˚F/Btu)

Fouling factor of water in condenser is 0.044 m²·˚C/kW(0.00025 h·ft2·˚F/Btu)

3. Due to our policy of innovation some specification may be changed without prior notification.

O = 9.8kPa

2

08 | 2020 LG Water Cooled Screw 2020 LG HVAC Solution | 09

Page 6

Specification

60Hz

Specification

60Hz

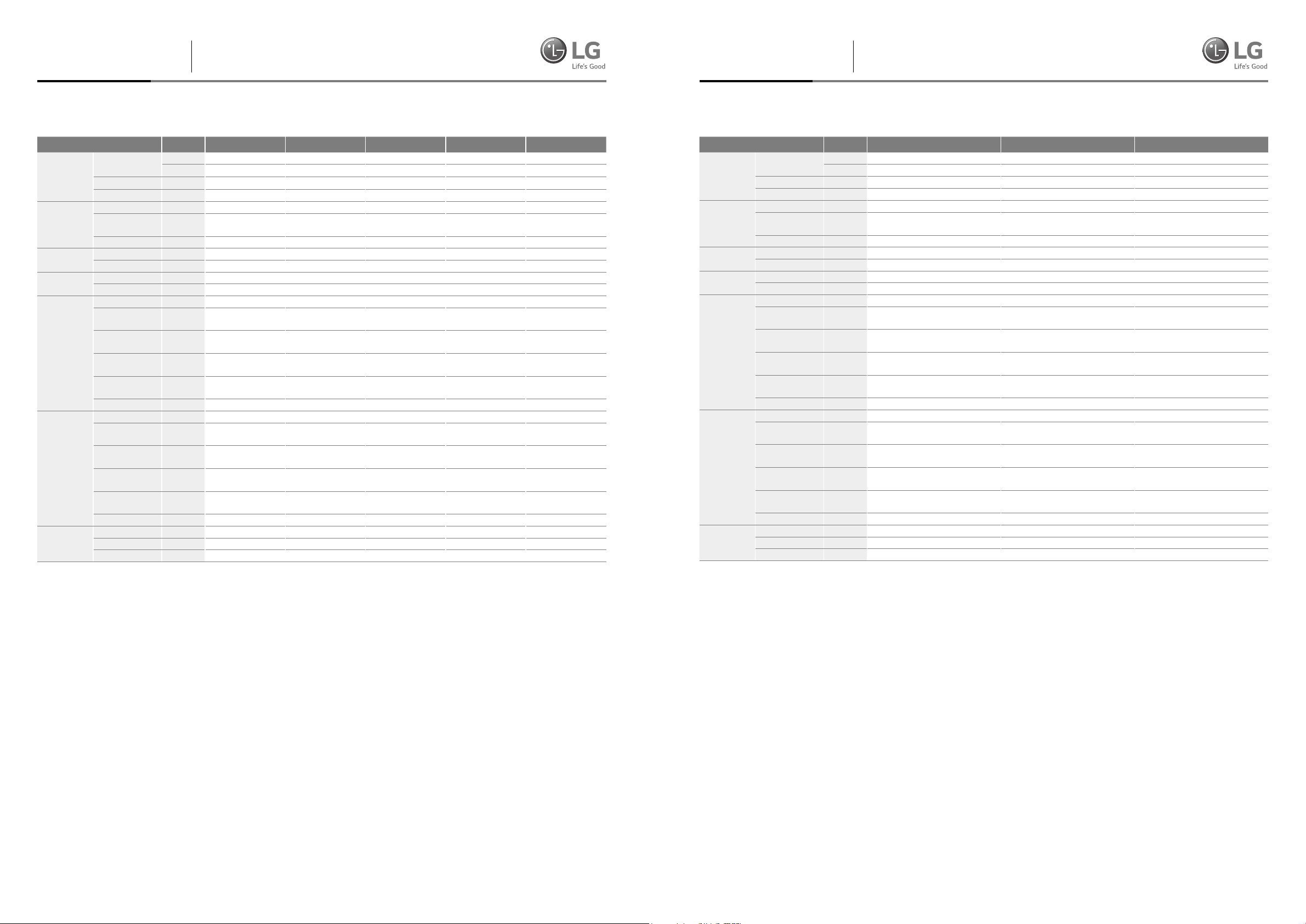

R134a(60Hz)

Model Units RCWW022CA2B RCWW024CA2B RCWW026CA2B RCWW028CA2B RCWW032CA2B

AHRI

Condition

Number of Circuits 2 2 2 2 2

General Unit

Data

Weight

Compressors

Condenser

Evaporator

Dimension

Operating Weight kg 5,780 5,940 6,080 6,150 7,040

Water Connections DN 150 150 150 150 200

Water Connections DN 150 150 150 150 200

Cooling capacity

Input Power kW 140.9 152.4

COP 5.35 5.34 5.38 5.56 5.42

Refrigerant,

R-134a

Oil Charge l 18 / 18 20 / 20 23 / 23 20 / 20 28 / 28

Shipping Weight kg 5,460 5,600 5,720 5,770 6,580

Compressor type Semi-hermetic twin screw

Quantity EA 2 2 2 2 2

Condenser type Shell and Tube

Max. Water

Pressure

Max. Refrigerant

Pressure

Min. Cooling

Water Flow Rate

Max. Cooling

Water Flow Rate

Evaporator type Shell and Tube

Max. Water

Pressure

Max. Refrigerant

Pressure

Min. Chilled

Water Flow Rate

Max. Chilled

Water Flow Rate

Length mm 3,855 3,855 3,855 3,855 3,855

Width mm 1,565 1,565 1,565 1,685 1,685

Height mm 2,175 2,175 2,175 2,225 2,225

kW 754.6 814.0 886.8 945.3 1,141.1

usRT 214.6 231.5

252.2

164.7

kg 120 x 2 120 x 2 120 x 2 145 x 2 145 x 2

MPa 1.0 1.0 1.0 1.0 1.0

MPa 1.0 1.0 1.0 1.0 1.0

l/s 13.6 14.6 14.6 16.9 19.0

l/s 54.4 58.6 58.6 67.7 76.0

MPa 1.0 1.0 1.0 1.0 1.0

MPa 0.9 0.9 0.9 0.9 0.9

l/s 12.6 13.8 13.8 15.7 18.0

l/s 50.2 55.1 55.1 62.8 71.8

268.8 324.5

169.9 210.5

R134a(60Hz)

Model Units RCWW036CA2B RCWW040CA2B RCWW044CA2B

AHRI

Condition

Number of Circuits 2 2 2

General Unit

Data

Weight

Compressors

Condenser

Water Connections DN 200 200 200

Evaporator

Water Connections DN 200 200 200

Dimension

Cooling capacity

Input Power kW 230.0 249.8 284.7

COP 5.51 5.44 5.58

Refrigerant,

R-134a

Oil Charge l 28 / 28 28 / 28 28 / 28

Shipping Weight kg 6,910 6,930 7,430

Operating Weight kg 7,430 7,480 7,980

Compressor type Semi-hermetic twin screw

Quantity EA 2 2 2

Condenser type Shell and Tube

Max. Water

Pressure

Max. Refrigerant

Pressure

Min. Cooling

Water Flow Rate

Max. Cooling

Water Flow Rate

Evaporator type Shell and Tube

Max. Water

Pressure

Max. Refrigerant

Pressure

Min. Chilled

Water Flow Rate

Max. Chilled

Water Flow Rate

Length mm 4,550 4,550 4,550

Width mm 1,795 1,795 1,910

Height mm 2,275 2,275 2,300

kW 1,267.5 1,357.7 1,589.0

usRT 360.5 386.1 451.9

kg 165 x 2 165 x 2 190 x 2

MPa 1.0 1.0 1.0

MPa 1.0 1.0 1.0

l/s 21.6 21.6 21.6

l/s 86.5 86.5 86.5

MPa 1.0 1.0 1.0

MPa 0.9 0.9 0.9

l/s 20.2 20.2 20.2

l/s 80.9 80.9 80.9

Note:

1. 1usRT = 3,024kcal/hr = 3.517kW, 1mH

2. AHRI conditions :

Leaving chilled water temperature is 6.7 ˚C(44 ˚F). Water flow is 0.043 L/s per kW(2.4 gpm/ton)

Entering cooling water temperature is 29.4 ˚C(85 ˚F). Water flow is 0.054 L/s per kW(3.0 gpm/ton)

Fouling factor of water in evaporator is 0.018 m²·˚C/kW(0.00001 h·ft2·˚F/Btu)

Fouling factor of water in condenser is 0.044 m²·˚C/kW(0.00025 h·ft2·˚F/Btu)

3. Due to our policy of innovation some specification may be changed without prior notification.

O = 9.8kPa

2

Note:

1. 1usRT = 3,024kcal/hr = 3.517kW, 1mH

2. AHRI conditions :

Leaving chilled water temperature is 6.7 ˚C(44 ˚F). Water flow is 0.043 L/s per kW(2.4 gpm/ton)

Entering cooling water temperature is 29.4 ˚C(85 ˚F). Water flow is 0.054 L/s per kW(3.0 gpm/ton)

Fouling factor of water in evaporator is 0.018 m²·˚C/kW(0.00001 h·ft2·˚F/Btu)

Fouling factor of water in condenser is 0.044 m²·˚C/kW(0.00025 h·ft2·˚F/Btu)

3. Due to our policy of innovation some specification may be changed without prior notification.

O = 9.8kPa

2

10 | 2020 LG Water Cooled Screw 2020 LG HVAC Solution | 11

Page 7

Specification

50Hz

Specification

50Hz

R134a(50Hz)

Model Units

AHRI

Condition

Number of Circuits 1 1 1 1 1 1

General Unit

Data

Weight

Compressors

Condenser

Evaporator

Dimension

Operating Weight kg 2,940 3,050 3,140 3,210 3,660 3,860

Water Connections DN 100 100 100 100 125 125

Water Connections DN 100 100 100 100 125 125

RCWW008CA1B RCWW010CA1B RCWW011CA1B RCWW012CA1B RCWW014CA1B RCWW016CA1B

Cooling capacity

Input Power kW 51.8 63.2

COP 5.36 5.35 5.42 5.45 5.43 5.48

Refrigerant,

R-134a

Oil Charge l 16 16 18 20 20 28

Shipping Weight kg 2,800 2,890 2,970 3,030 3,430 3,610

Compressor type Semi-hermetic twin screw

Quantity EA 1 1 1 1 1 1

Condenser type Shell and Tube

Max. Water

Pressure

Max. Refrigerant

Pressure

Min. Cooling

Water Flow Rate

Max. Cooling

Water Flow Rate

Evaporator type Shell and Tube

Max. Water

Pressure

Max. Refrigerant

Pressure

Min. Chilled

Water Flow Rate

Max. Chilled

Water Flow Rate

Length mm 3,040 3,040 3,040 3,040 3,145 3,145

Width mm 1,435 1,435 1,435 1,435 1,480 1,480

Height mm 1,860 1,865 1,865 1,865 2,080 2,080

kW 277.4 337.9 370.1 414.9 473.9 567.2

usRT 78.9 96.1

105.2

68.3

kg 110 110 110 110 140 140

MPa 1.0 1.0 1.0 1.0 1.0 1.0

MPa 1.0 1.0 1.0 1.0 1.0 1.0

l/s 6.6 7.5 8.5 8.5 10.8 12.0

l/s 26.5 30.0 34.2 34.2 43.2 48.1

MPa 1.0 1.0 1.0 1.0 1.0 1.0

MPa 0.9 0.9 0.9 0.9 0.9 0.9

l/s 5.6 7.7 7.7 8.4 10.1 11.2

l/s 22.3 30.7 30.7 33.5 40.5 44.6

118.0 134.8 161.3

76.2 87.3 103.6

R134a(50Hz)

Model Units

AHRI

Condition

Number of Circuits 1 2 2 2 2 2 2

General Unit

Data

Weight

Compressors

Condenser

Water Connections DN 125 150 150 150 150 200 200

Evaporator

Water Connections DN 125 150 150 150 150 200 200

Dimension

RCWW019CA1B RCWW020CA2B RCWW022CA2B RCWW024CA2B RCWW028CA2B RCWW032CA2B RCWW038CA2B

Cooling capacity

Input Power kW 118.2 126.5

COP 5.57 5.37 5.43 5.44 5.42 5.45 5.56

Refrigerant,

R-134a

Oil Charge l 28 16 / 16 18 / 18 20 / 20 20 / 20 28 / 28 28 / 28

Shipping Weight kg 3,720 5,220 5,500 5,780 6,180 6,680 6,990

Operating Weight kg 4,000 5,490 5,860 6,120 6,560 7,140 7,510

Compressor type Semi-hermetic twin screw

Quantity EA 1 2 2 2 2 2 2

Condenser type Shell and Tube

Max. Water

Pressure

Max. Refrigerant

Pressure

Min. Cooling

Water Flow Rate

Max. Cooling

Water Flow Rate

Evaporator type Shell and Tube

Max. Water

Pressure

Max. Refrigerant

Pressure

Min. Chilled

Water Flow Rate

Max. Chilled

Water Flow Rate

Length mm 3,145 3,855 3,855 3,855 3,855 3,855 4,550

Width mm 1,605 1,565 1,565 1,565 1,685 1,685 1,795

Height mm 2,105 2,175 2,175 2,175 2,225 2,225 2,275

kW 657.9 679.3 741.2 829.9 948.9 1,132.3 1,317.9

usRT 187.1 193.2

210.8

136.6

kg 165 120 x 2 120 x 2 120 x 2 145 x 2 145 x 2 165 x 2

MPa 1.0 1.0 1.0 1.0 1.0 1.0 1.0

MPa 1.0 1.0 1.0 1.0 1.0 1.0 1.0

l/s 13.6 12.0 13.6 14.6 16.9 19.0 21.6

l/s 54.4 48.1 54.4 58.6 67.7 76.0 86.5

MPa 1.0 1.0 1.0 1.0 1.0 1.0 1.0

MPa 0.9 0.9 0.9 0.9 0.9 0.9 0.9

l/s 12.6 11.2 12.6 13.8 15.7 18.0 20.2

l/s 50.2 44.6 50.2 55.1 62.8 71.8 80.9

236.0 269.9 322.0 374.8

152.5 175.1 207.6 237.0

Note:

1. 1usRT = 3,024kcal/hr = 3.517kW, 1mH

2. AHRI conditions :

Leaving chilled water temperature is 6.7 ˚C(44 ˚F). Water flow is 0.043 L/s per kW(2.4 gpm/ton)

Entering cooling water temperature is 29.4 ˚C(85 ˚F). Water flow is 0.054 L/s per kW(3.0 gpm/ton)

Fouling factor of water in evaporator is 0.018 m²·˚C/kW(0.00001 h·ft2·˚F/Btu)

Fouling factor of water in condenser is 0.044 m²·˚C/kW(0.00025 h·ft2·˚F/Btu)

3. Due to our policy of innovation some specification may be changed without prior notification.

O = 9.8kPa

2

Note:

1. 1usRT = 3,024kcal/hr = 3.517kW, 1mH

2. AHRI conditions :

Leaving chilled water temperature is 6.7 ˚C(44 ˚F). Water flow is 0.043 L/s per kW(2.4 gpm/ton)

Entering cooling water temperature is 29.4 ˚C(85 ˚F). Water flow is 0.054 L/s per kW(3.0 gpm/ton)

Fouling factor of water in evaporator is 0.018 m²·˚C/kW(0.00001 h·ft2·˚F/Btu)

Fouling factor of water in condenser is 0.044 m²·˚C/kW(0.00025 h·ft2·˚F/Btu)

3. Due to our policy of innovation some specification may be changed without prior notification.

O = 9.8kPa

2

12 | 2020 LG Water Cooled Screw 2020 LG HVAC Solution | 13

Page 8

Electrical data

380V / 60Hz

Electrical data

440V / 60Hz

380V / 60Hz

Model Voltage

RCWW008CA1B Circuit 1

RCWW010CA1B Circuit 1 820 112 273 122 273 165 296

RCWW011CA1B Circuit 1 985 125 328 135 328 181 325

RCWW012CA1B Circuit 1 985 134 328 145 328 195 350

RCWW014CA1B Circuit 1 1,115 150 372 162 372 217 390

RCWW016CA1B Circuit 1 1,750 188 583 203 583 270 486

RCWW018CA1B Circuit 1 1,930 200 643 218 643 294 529

RCWW020CA1B Circuit 1 2,185 217 728 236 728 316 569

RCWW022CA1B Circuit 1 2,470 248 823 269 823 360 647

RCWW020CA2B

RCWW022CA2B

RCWW024CA2B

Circuit 1 820 112 273

Circuit 2 820 112 273

Circuit 1 985 125 328

Circuit 2 985 125 328

Circuit 1 985 134 328

Circuit 2 985 134 328

380

LRA RLA Start Current

810 88 270 96 270 129 232

Compressor

Total

RLA

224 385 329 592

249 453 362 651

267 462 389 700

Max Current MCA MOCP

440V / 60Hz

Model Voltage

RCWW008CA1B Circuit 1

RCWW010CA1B Circuit 1 700 97 233 97 233 142 256

RCWW011CA1B Circuit 1 810 108 270 108 270 156 281

RCWW012CA1B Circuit 1 810 115 270 115 270 168 302

RCWW014CA1B Circuit 1 875 130 292 130 292 187 337

RCWW016CA1B Circuit 1 1,340 162 447 162 447 233 420

RCWW018CA1B Circuit 1 1,430 173 477 173 477 254 457

RCWW020CA1B Circuit 1 1,565 188 522 188 522 273 491

RCWW022CA1B Circuit 1 1,990 214 663 214 663 310 559

RCWW020CA2B

RCWW022CA2B

RCWW024CA2B

Circuit 1 700 97 233

Circuit 2 700 97 233

Circuit 1 810 108 270

Circuit 2 810 108 270

Circuit 1 810 115 270

Circuit 2 810 115 270

440

LRA RLA Start Current

690 77 230 77 230 111 200

Compressor

Total

RLA

194 331 284 511

215 378 312 562

231 385 336 605

Max Current MCA MOCP

RCWW026CA2B

RCWW028CA2B

RCWW032CA2B

RCWW036CA2B

RCWW040CA2B

RCWW044CA2B

Circuit 1 1,115 146 372

Circuit 2 1,115 146 372

Circuit 1 1,115 150 372

Circuit 2 1,115 150 372

Circuit 1 1,750 188 583

Circuit 2 1,750 188 583

Circuit 1 1,930 200 643

Circuit 2 1,930 200 643

Circuit 1 2,185 217 728

Circuit 2 2,185 217 728

Circuit 1 2,470 248 823

Circuit 2 2,470 248 823

293 518 422 759

300 522 434 781

376 771 541 973

400 843 588 1,058

434 945 632 1,138

496 1,071 719 1,294

RCWW026CA2B

RCWW028CA2B

RCWW032CA2B

RCWW036CA2B

RCWW040CA2B

RCWW044CA2B

Circuit 1 875 126 292

252 418 364 656

Circuit 2 875 126 292

Circuit 1 875 130 292

259 421 375 675

Circuit 2 875 130 292

Circuit 1 1,340 162 447

325 609 467 840

Circuit 2 1,340 162 447

Circuit 1 1,430 173 477

346 650 508 914

Circuit 2 1,430 173 477

Circuit 1 1,565 188 522

375 709 546 982

Circuit 2 1,565 188 522

Circuit 1 1,990 214 663

429 878 621 1,117

Circuit 2 1,990 214 663

Note:

1. AHRI conditions :

Leaving chilled water temperature is 6.7˚F(44°C)

Entering cooling water temperature is 29.4˚F(85°C)

2. Symbols :

LRA : Locked Rotor Ampere

RLA : Rated Load Ampere

MCA : Minimum Circuit Ampere

MOCP : Maximum OverCurrent Protection

Total RLA : Current when all compressor running

Start Current : Starting current of one compressor

Max current : Start current(Circuit 1) + RLA(Circuit 2)

Note:

1. AHRI conditions :

Leaving chilled water temperature is 6.7˚F(44°C)

Entering cooling water temperature is 29.4˚F(85°C)

2. Symbols :

LRA : Locked Rotor Ampere

RLA : Rated Load Ampere

MCA : Minimum Circuit Ampere

MOCP : Maximum OverCurrent Protection

Total RLA : Current when all compressor running

Start Current : Starting current of one compressor

Max current : Start current(Circuit 1) + RLA(Circuit 2)

2020 LG HVAC Solution | 1514 | 2020 LG Water Cooled Screw

Page 9

Electrical data

460V / 60Hz

Electrical data

480V / 60Hz

460V / 60Hz

Model Voltage

RCWW008CA1B Circuit 1

RCWW010CA1B Circuit 1 730 93 243 93 243 136 245

RCWW011CA1B Circuit 1 845 103 282 103 282 149 269

RCWW012CA1B Circuit 1 845 110 282 110 282 161 289

RCWW014CA1B Circuit 1 915 124 305 124 305 179 322

RCWW016CA1B Circuit 1 1,400 155 467 155 467 223 402

RCWW018CA1B Circuit 1 1,495 166 498 166 498 243 437

RCWW020CA1B Circuit 1 1,635 179 545 179 545 261 470

RCWW022CA1B Circuit 1 2,080 205 693 205 693 297 534

RCWW020CA2B

RCWW022CA2B

RCWW024CA2B

Circuit 1 730 93 243

Circuit 2 730 93 243

Circuit 1 845 103 282

Circuit 2 845 103 282

Circuit 1 845 110 282

Circuit 2 845 110 282

460

LRA RLA Start Current

720 73 240 73 240 107 192

Compressor

Total

RLA

186 336 272 489

206 384 299 537

221 392 321 578

Max Current MCA MOCP

480V / 60Hz

Model Voltage

RCWW008CA1B Circuit 1

RCWW010CA1B Circuit 1 690 89 230 89 230 130 234

RCWW011CA1B Circuit 1 795 99 265 99 265 143 257

RCWW012CA1B Circuit 1 795 106 265 106 265 154 277

RCWW014CA1B Circuit 1 850 119 283 119 283 172 309

RCWW016CA1B Circuit 1 1,295 149 432 149 432 214 385

RCWW018CA1B Circuit 1 1,370 159 457 159 457 233 419

RCWW020CA1B Circuit 1 1,485 172 495 172 495 250 450

RCWW022CA1B Circuit 1 1,850 197 617 197 617 285 512

RCWW020CA2B

RCWW022CA2B

RCWW024CA2B

Circuit 1 690 89 230

Circuit 2 690 89 230

Circuit 1 795 99 265

Circuit 2 795 99 265

Circuit 1 795 106 265

Circuit 2 795 106 265

480

LRA RLA Start Current

655 70 218 70 218 102 184

Compressor

Total

RLA

178 319 261 469

197 364 286 515

212 371 308 554

Max Current MCA MOCP

RCWW026CA2B

RCWW028CA2B

RCWW032CA2B

RCWW036CA2B

RCWW040CA2B

RCWW044CA2B

Circuit 1 915 121 305

Circuit 2 915 121 305

Circuit 1 915 124 305

Circuit 2 915 124 305

Circuit 1 1,400 155 467

Circuit 2 1,400 155 467

Circuit 1 1,495 166 498

Circuit 2 1,495 166 498

Circuit 1 1,635 179 545

Circuit 2 1,635 179 545

Circuit 1 2,080 205 693

Circuit 2 2,080 205 693

241 426 349 627

248 429 358 645

311 622 447 804

331 664 485 873

359 724 522 940

410 898 594 1,069

RCWW026CA2B

RCWW028CA2B

RCWW032CA2B

RCWW036CA2B

RCWW040CA2B

RCWW044CA2B

Circuit 1 850 116 283

231 399 334 601

Circuit 2 850 116 283

Circuit 1 850 119 283

238 402 344 618

Circuit 2 850 119 283

Circuit 1 1,295 149 432

298 580 428 770

Circuit 2 1,295 149 432

Circuit 1 1,370 159 457

317 615 465 837

Circuit 2 1,370 159 457

Circuit 1 1,485 172 495

344 667 500 900

Circuit 2 1,485 172 495

Circuit 1 1,850 197 617

393 813 569 1,024

Circuit 2 1,850 197 617

Note:

1. AHRI conditions :

Leaving chilled water temperature is 6.7˚F(44°C)

Entering cooling water temperature is 29.4˚F(85°C)

2. Symbols :

LRA : Locked Rotor Ampere

RLA : Rated Load Ampere

MCA : Minimum Circuit Ampere

MOCP : Maximum OverCurrent Protection

Total RLA : Current when all compressor running

Start Current : Starting current of one compressor

Max current : Start current(Circuit 1) + RLA(Circuit 2)

Note:

1. AHRI conditions :

Leaving chilled water temperature is 6.7˚F(44°C)

Entering cooling water temperature is 29.4˚F(85°C)

2. Symbols :

LRA : Locked Rotor Ampere

RLA : Rated Load Ampere

MCA : Minimum Circuit Ampere

MOCP : Maximum OverCurrent Protection

Total RLA : Current when all compressor running

Start Current : Starting current of one compressor

Max current : Start current(Circuit 1) + RLA(Circuit 2)

16 | 2020 LG Water Cooled Screw 2020 LG HVAC Solution | 17

Page 10

Electrical data

380V / 50Hz

Electrical data

400V / 50Hz

380V / 50Hz

Model Voltage

RCWW008CA1B Circuit 1

RCWW010CA1B Circuit 1 810 113 270 113 270 164 295

RCWW011CA1B Circuit 1 875 125 292 125 292 179 322

RCWW012CA1B Circuit 1 1,220 134 407 134 407 194 350

RCWW014CA1B Circuit 1 1,340 160 447 160 447 230 415

RCWW016CA1B Circuit 1 1,565 182 522 182 522 266 478

RCWW019CA1B Circuit 1 1,990 209 663 209 663 304 547

RCWW020CA2B

RCWW022CA2B

RCWW024CA2B

RCWW028CA2B

Circuit 1 810 113 270

Circuit 2 810 113 270

Circuit 1 875 125 292

Circuit 2 875 125 292

Circuit 1 1,220 134 407

Circuit 2 1,220 134 407

Circuit 1 1,340 160 447

Circuit 2 1,340 160 447

380

LRA RLA Start Current

700 95 233 95 233 138 248

Compressor

Total

RLA

240 383 327 589

270 416 358 644

290 540 389 699

312 607 461 829

Max Current MCA MOCP

400V / 50Hz

Model Voltage

RCWW008CA1B Circuit 1

RCWW010CA1B Circuit 1 845 110 282 110 282 159 286

RCWW011CA1B Circuit 1 915 121 305 121 305 174 313

RCWW012CA1B Circuit 1 1,285 130 428 130 428 189 340

RCWW014CA1B Circuit 1 1,400 156 467 156 467 224 404

RCWW016CA1B Circuit 1 1,635 177 545 177 545 258 465

RCWW019CA1B Circuit 1 2,080 203 693 203 693 295 532

RCWW020CA2B

RCWW022CA2B

RCWW024CA2B

RCWW028CA2B

Circuit 1 845 110 282

Circuit 2 845 110 282

Circuit 1 915 121 305

Circuit 2 915 121 305

Circuit 1 1,285 130 428

Circuit 2 1,285 130 428

Circuit 1 1,400 157 467

Circuit 2 1,400 157 467

400

LRA RLA Start Current

730 92 243 92 243 134 241

Compressor

Total

RLA

220 392 318 573

242 426 348 627

260 558 378 680

313 623 449 807

Max Current MCA MOCP

RCWW032CA2B

RCWW038CA2B

Circuit 1 1,565 182 522

Circuit 2 1,565 182 522

Circuit 1 1,990 209 663

Circuit 2 1,990 209 663

390 704 531 956

418 872 608 1,094

RCWW032CA2B

RCWW038CA2B

Circuit 1 1,635 178 545

355 723 516 929

Circuit 2 1,635 178 545

Circuit 1 2,080 203 693

407 897 591 1,063

Circuit 2 2,080 203 693

Note:

1. AHRI conditions :

Leaving chilled water temperature is 6.7˚F(44°C)

Entering cooling water temperature is 29.4˚F(85°C)

2. Symbols :

LRA : Locked Rotor Ampere

RLA : Rated Load Ampere

MCA : Minimum Circuit Ampere

MOCP : Maximum OverCurrent Protection

Total RLA : Current when all compressor running

Start Current : Starting current of one compressor

Max current : Start current(Circuit 1) + RLA(Circuit 2)

Note:

1. AHRI conditions :

Leaving chilled water temperature is 6.7˚F(44°C)

Entering cooling water temperature is 29.4˚F(85°C)

2. Symbols :

LRA : Locked Rotor Ampere

RLA : Rated Load Ampere

MCA : Minimum Circuit Ampere

MOCP : Maximum OverCurrent Protection

Total RLA : Current when all compressor running

Start Current : Starting current of one compressor

Max current : Start current(Circuit 1) + RLA(Circuit 2)

18 | 2020 LG Water Cooled Screw 2020 LG HVAC Solution | 19

Page 11

Electrical data

415V / 50Hz

415V / 50Hz

Outline drawing

1 Compressor model

Model Voltage

RCWW008CA1B Circuit 1

RCWW010CA1B Circuit 1 795 104 265 104 265 150 270

RCWW011CA1B Circuit 1 850 114 283 114 283 164 295

RCWW012CA1B Circuit 1 1,160 122 387 122 387 178 320

RCWW014CA1B Circuit 1 1,295 147 432 147 432 211 380

RCWW016CA1B Circuit 1 1,485 167 495 167 495 243 438

RCWW019CA1B Circuit 1 1,850 191 617 191 617 278 501

RCWW020CA2B

RCWW022CA2B

RCWW024CA2B

RCWW028CA2B

RCWW032CA2B

Circuit 1 795 104 265

Circuit 2 795 104 265

Circuit 1 850 114 283

Circuit 2 850 114 283

Circuit 1 1,160 123 387

Circuit 2 1,160 123 387

Circuit 1 1,295 147 432

Circuit 2 1,295 147 432

Circuit 1 1,485 167 495

Circuit 2 1,485 167 495

415

LRA RLA Start Current

690 87 230 87 230 126 227

Compressor

Total

RLA

207 369 300 539

228 397 328 590

245 509 356 640

294 579 422 760

334 662 486 875

Max Current MCA MOCP

RCWW038CA2B

Circuit 1 1,850 192 617

Circuit 2 1,850 192 617

Note:

1. AHRI conditions :

Leaving chilled water temperature is 6.7˚F(44°C)

Entering cooling water temperature is 29.4˚F(85°C)

2. Symbols :

LRA : Locked Rotor Ampere

RLA : Rated Load Ampere

MCA : Minimum Circuit Ampere

MOCP : Maximum OverCurrent Protection

Total RLA : Current when all compressor running

Start Current : Starting current of one compressor

Max current : Start current(Circuit 1) + RLA(Circuit 2)

383 808 556 1,001

Frequency Model L W H A B C D E

RCWW008CA1B 3,040 1,435 1,860 543 283 559 299 595

RCWW010CA1B 3,040 1,435 1,860 543 283 559 299 595

RCWW011CA1B 3,040 1,435 1,860 543 283 559 299 595

RCWW012CA1B 3,040 1,435 1,860 543 283 559 299 595

60Hz

50Hz

RCWW014CA1B 3,145 1,480 2,080 632 392 667 407 655

RCWW016CA1B 3,145 1,480 2,080 632 392 667 407 655

RCWW018CA1B 3,145 1,605 2,105 657 357 642 342 715

RCWW020CA1B 3,145 1,605 2,105 657 357 642 342 715

RCWW022CA1B 3,365 1,750 2,150 692 432 717 458 775

RCWW008CA1B 3,040 1,435 1,860 543 283 559 299 595

RCWW010CA1B 3,040 1,435 1,860 543 283 559 299 595

RCWW011CA1B 3,040 1,435 1,860 543 283 559 299 595

RCWW012CA1B 3,040 1,435 1,860 543 283 559 299 595

RCWW014CA1B 3,145 1,480 2,080 632 392 667 407 655

RCWW016CA1B 3,145 1,480 2,080 632 392 667 407 655

RCWW019CA1B 3,145 1,605 2,105 657 357 642 342 715

20 | 2020 LG Water Cooled Screw 2020 LG HVAC Solution | 21

Page 12

Outline drawing

2 Compressor model

Foundation

1 Compressor model

1 Compressor model

Frequency Model L W H A B C D E

RCWW020CA2B 3,855 1,565 2,175 645 335 665 365 740

RCWW022CA2B 3,855 1,565 2,175 645 335 665 365 740

RCWW024CA2B 3,855 1,565 2,175 645 335 665 365 740

RCWW026CA2B 3,855 1,565 2,175 645 335 665 365 740

60Hz

50Hz

RCWW028CA2B 3,855 1,685 2,225 667 407 763 463 800

RCWW032CA2B 3,855 1,685 2,225 667 407 763 463 800

RCWW036CA2B 4,550 1,795 2,275 747 427 789 489 855

RCWW040CA2B 4,550 1,795 2,275 747 427 789 489 855

RCWW044CA2B 4,550 1,910 2,300 763 463 834 474 915

RCWW020CA2B 3,855 1,565 2,175 645 335 665 365 740

RCWW022CA2B 3,855 1,565 2,175 645 335 665 365 740

RCWW024CA2B 3,855 1,565 2,175 645 335 665 365 740

RCWW028CA2B 3,855 1,685 2,225 667 407 763 463 800

RCWW032CA2B 3,855 1,685 2,225 667 407 763 463 800

RCWW038CA1B 4,550 1,795 2,275 747 427 789 489 855

Frequency Model A B C D

RCWW008CA1B 2,500 1,035 2,530 2,870

RCWW010CA1B 2,500 1,035 2,530 2,870

RCWW011CA1B 2,500 1,035 2,530 2,870

RCWW012CA1B 2,500 1,035 2,530 2,870

60Hz

50Hz

RCWW014CA1B 2,500 1,150 2,530 2,870

RCWW016CA1B 2,500 1,150 2,530 2,870

RCWW018CA1B 2,500 1,275 2,530 2,870

RCWW020CA1B 2,500 1,275 2,530 2,870

RCWW022CA1B 2,500 1,395 2,530 2,870

RCWW008CA1B 2,500 1,035 2,530 2,870

RCWW010CA1B 2,500 1,035 2,530 2,870

RCWW011CA1B 2,500 1,035 2,530 2,870

RCWW012CA1B 2,500 1,035 2,530 2,870

RCWW014CA1B 2,500 1,150 2,530 2,870

RCWW016CA1B 2,500 1,150 2,530 2,870

RCWW019CA1B 2,500 1,275 2,530 2,870

22 | 2020 LG Water Cooled Screw 2020 LG HVAC Solution | 23

Page 13

Foundation

2 Compressor model

2 Compressor model

Piping diagram

1 Compressor model

Frequency Model A B C D

RCWW020CA2B 3,100 1,325 3,128 3,468

RCWW022CA2B 3,100 1,325 3,128 3,468

RCWW024CA2B 3,100 1,325 3,128 3,468

RCWW026CA2B 3,100 1,325 3,128 3,468

60Hz

50Hz

RCWW028CA2B 3,100 1,445 3,128 3,468

RCWW032CA2B 3,100 1,445 3,128 3,468

RCWW036CA2B 3,100 1,555 3,128 3,468

RCWW040CA2B 3,100 1,555 3,128 3,468

RCWW044CA2B 3,100 1,670 3,128 3,468

RCWW020CA2B 3,100 1,325 3,128 3,468

RCWW022CA2B 3,100 1,325 3,128 3,468

RCWW024CA2B 3,100 1,325 3,128 3,468

RCWW028CA2B 3,100 1,445 3,128 3,468

RCWW032CA2B 3,100 1,445 3,128 3,468

RCWW038CA1B 3,100 1,555 3,128 3,468

24 | 2020 LG Water Cooled Screw 2020 LG HVAC Solution | 25

Page 14

Piping diagram

2 Compressor model

Control wiring

1 Compressor model

26 | 2020 LG Water Cooled Screw 2020 LG HVAC Solution | 27

Page 15

Control wiring

2 Compressor model

Power wiring

1 Compressor model

28 | 2020 LG Water Cooled Screw 2020 LG HVAC Solution | 29

Page 16

Power wiring

2 Compressor model

Installation

Checking of the site information

Before installing the chiller unit, check the site in advance, review the necessary details and coordinate the followings with the site

personnel so that the installation can be performed safely and accurately.

1) Work scope and unit data: Check the site installation work scope and approved document

2) Installation location: Check the environmental condition to install according to the article 3-2.

3) Check the entrance size(width, length and height) to the installing site in advance not to have any trouble in moving. Then check

and review the detail method and order for moving the unit.

The environmental condition of installation site

The site space to install or store the product along with the following environmental condition should be considered.

1) Be careful not to damage the piping, insulation materials and wires of the chiller unit when storing and installing.

The site should have ventilation measures for the refrigerant leakage.

2) Select site where the temperature is below 40 °C all the time with good ventilation. When the unit is to be stored for long term,

pay a close attention to the temperature of the site to be maintained below 40 °C all the time. If the chiller unit is charged with

refrigerant and the pressure of the unit exceeds the limit, the pressure relief valve will be operated and discharge the refrigerant

gas resulting in the loss of refrigerant gas along with potential loss of lives. If the machine room temperature is over 40 °C,

the pressure vessel should be recongured. Check the set pressure for the relief valve of the chiller unit and maintain the room

below the relief valve operating temperature consulting the authorized service engineer of LG Electronics.

3) Store the chiller unit in dry and safe location without any vibration.

4) The oor surface to install the chiller unit should be at and of sufcient strength and mass to support the chiller operating

weight.

5) Avoid place of any re or ammable materials near. When installed in parallel to the heating object such as a boiler, sufcient

care to the radiation heat is required.

6) Be careful with high humidity as it causes the electric error and the corrosion of the chiller unit.

7) Select the site where less dust are as the dust cause electric error.

8) Provide enough space around the unit to allow the installation and maintenance personnel access to all service points such as

replacing heat exchanger tubes and waterbox to open.

9) Secure maximum or safe height to t to the crane for easy lifting and lowering of the chiller unit.

10) Secure good drainage from the machine room.

11) Secure sufcient lighting considering the repair and maintenance.

12) This chiller unit is manufactured for indoor use. Therefore avoid installing outdoors or a place under direct sunlight.

13) Protect the unit by vinyl cover form dust and rains.

14) When installing the chiller unit, plan appropriately in accordance with the installation of High Pressure Gas Safety Control Act.

(Local standard)

30 | 2020 LG Water Cooled Screw 2020 LG HVAC Solution | 31

Page 17

Installation

2020 LG HVAC Solution

|

33

Guide speci cation

Securing service space

1) Before installation, provide enough space for the service and maintenance as indicated on the foundation drawing.

This is the minimum required space for the maintenance.

2) The foundation to install the chiller unit should be of suf cient strength and mass to support the chiller operating weight.

3) Prepare a good drainage path to drain out the chilled water and cooling water when cleaning the heat exchanger tubes or before

shutting down.

4) To ensure stable operation of the chiller, level the chiller by adjusting the level plate within 1/16”

5) Floor foundation construction is out of scope of LG Electronics. Please work according to the approved foundation drawings.

LG Electronics is not responsible for any unit failure caused by the inappropriate design and construction of the foundation.

Ceiling

E

UNIT

Floor

Contents

Part 1 – General

1.01 Scope

1.02 System descriptions

1.03 Quality assurance

1.04 Delivery and handling

Part 2 – Products

2.01 General

2.02 Equipment description

2.03 Operating characteristics

2.04 Compressor

2.05 Heat exchanger

2.06 Expansion unit

2.07 Controller

2.08 Characteristics of the controller

2.09 Automatic safety device

2.10 Accessories and options

D: Reverse side

A:Left side

Provide space at either side of heat

exchanger for service of exchanging tubes.

UNIT

C:Front side

B:Right side

Figure 4. Minimum space requirement for installation

Model A B C D E

RCWW008CA11 ~ RCWW018CA11 2,500 1,500 1,500 1,500 1,000

RCWW020CA21 ~ RCWW040CA21

3,100 1,500 1,500 1,500 1,000

Part 3 - Execution

3.01 Installation

32 | 2020 LG Water Cooled Screw 2020 LG HVAC Solution | 33

Page 18

Guide specication

Guide specication

Part 1 – General

1.01 Scope

The requirements of the General Conditions, Supplementary

Conditions and Drawings apply to all work herein.

1.02 System descriptions

Microprocessor controlled water-cooled liquid chiller utilizing

screw compressor(s) and electronic expansion valves.

1.03 Quality assurance

• AHRI 550/590 - water chilling packages using the vapor

compression cycle.

• ANSI/ASHRAE 34 - number designation and safety

classication of refrigerants.

• ASME Section VIII - boiler and pressure vessel.

• GB/T 18430.1 - water chilling(heat pump) packages using

the vapor compression cycle - part 1: water chilling(heat

pump) packages for industrial & commercial and similar

applications.

• GB25131 - Safety requirements for water chillers(heat

pump) using the vapor compression cycle.

• GB150/151 - steel pressure vessels / Tubular heat

exchangers.

• ANSI/ASHRAE Standard 15 safety code.

• Manufactured in an EN ISO 9001 accredited organization.

• The packaged chiller shall be pressure and leak test.

• Chiller manufacturer shall have factory trained and supported

service organization local to the chiller installation to

provide commissioning and service support throughout the

manufacturer’s warranty period.

• Manufacturer shall warrant all equipment and material of

its supply against defects in workmanship and material for

a period of eighteen(18) months from date of shipment or

twelve(12) months from initial start-up, whichever occurs

rst.

1.04 Delivery and handling

Depending on the condition of the installation site, chiller is

shipped as a single unit or as separated unit, and as charged

with refrigerant or with nitrogen. If shipped as separated units,

contact the authorized LG Electronics dealers or LG Electronics

directly. For single unit type, the unit will be delivered to the

site as preassembled. Separated unit type will be delivered as

2 or 3 separated main pieces. Conrm and record that it is the

correct unit and that it is properly equipped as the submitted

packing list. When refrigerant is charged, refrigerant and oil

are charged together according to the specication of the

chiller unit. It needs special attention to high pressure inside

since the saturated refrigerant pressure is decided by the

external air temperature. When nitrogen is charged, the unit

is charged with 0.5kg/cm2 before shipment from the factory.

If the pressure is “0”, please record the condition and check for

any leakage, since there is leak possibility.

Unit shall be handled, transported and stored in accordance

with manufacturer’s instructions.

Shipping: Unit shall ship in one piece and shall require installer

to provide the evaporator and condenser inlet and outlet pipe

connections. If providing chiller model that ships in multiple

pieces, bid shall include all the material and eld labor costs

for factory authorized personnel to connect the pieces as well

as all interconnecting piping and wiring.

Part 2 – Products

2.01 General

The equipment shown on the drawings is based on the model

RCWW and MCWW series water cooled liquid chiller as

manufactured by the LG Electronics.

2.02 Equipment description

Supply and install and commission as shown on the drawings

and schedules complete factory assembled, charged and

operationally tested air cooled screw compressor chiller(s) as

specied herein. Chiller shall include one or more independent

refrigeration circuits, semi hermetic twin screw compressors(s),

shell and tube liquid cooler & condenser, Refrigerant R-134a,

lubrication system and oil, interconnecting piping and wiring

and lockable control center housing safety, operating and

capacity controls necessary for the safe automatic operation

of the liquid chiller.

2.03 Operating characteristics

- Chiller will be installed in an indoor location and shall be

capable of operating in room temperatures between 4.4°C

and 15.6°C(40F~60F)

- Provide capacity control system capable of reducing unit

capacity to min. 25% of full load.

2.04 Compressor

The semi-hermetic twin screw compressor with precision

machined cast iron housing and discharge shutoff valve.

Compressor motor is cooled down by refrigerants. The

differential pressure type oil lubrication and a lterintegrated type should be used. A compressor integrated

type oil separator is used, a check valve should be installed

at the discharge side to prevent the backward owing of the

refrigerants. Design working pressure of entire compressor,

suction to discharge shall be 30 bar(435 psig) 4-step or

stepless control that can control the capacity from 25 % to

100 % using a capacity control slide valve. A discharge/suction

shut-off valve is installed.

To separate the oil from the refrigerant in which oil is mixed

together, the internal oil separator is designed to allow the oil

ow into the system to the minimum.

2.05 Heat exchanger

| Falling Film Type |

Evaporator shall be of the falling lm shell and tube type

with removable heads and mechanically cleanable tubes of

seamless copper with internally and externally enhanced

surface. Distributer located on the top side of inside shell,

this makes uniform ow of refrigerant. Through distributer

refrigerant ows downward by gravity as a continuous lm.

Tubes shall be mechanically expanded into multiple grooves

in tube sheets. Cooler will incorporate one, two independent

refrigerant circuits with a common chilled liquid multi-pass

circuit arrangement. Coolers will be factory insulated with

19mm(optional 38) closed cell insulation with all joints vapor

sealed and water drain and vent taps in cooler heads.

| Condenser |

The shall is manufactured Shell & Tube and shell be constructed

and tested in accordance with pressure vessel code for a

refrigerant and 10bar(150 psig) water-side pressure.

To increase efciency, sub-cooler is installed for over-cooling

of condenser liquid refrigerant.

2.06 Expansion unit

Expansion unit consists of buttery valve and orice. At 100%

load situation, the pressure loss at the orice is smaller than

the refrigerant pressure loss in the condenser, thus the super-

cooled refrigerant passes through the orice. At this stage the

maximum amount of refrigerant is owing into the evaporator.

As the load reduces gradually, the circulating amount of

refrigerant also reduces and accordingly the refrigerant level

in the condenser is getting low. When the amount of liquid

refrigerant reduces, the gas amount in the orice is getting

larger, raising the resistance thus controlling the ow rate.

| Refrigerant isolation v/v: Option |

Refrigerant isolation valves shall be provided to isolate the

referent into the condenser for standard water chilling

application.

2.07 Controller

| Composition of the control panel |

The control panel is composed of a Micom module(a main

module, an I/O module, a display and an operation key module),

a power supply unit that provides stable power, and a breaker

that performs other control jobs or ensures safety, magnetic

contact, and a relay for control. The major functions of these

modules are as follows.

| Main module |

A high-performance microprocessor is installed in the

main module and performs the control function optimized

to equipment. A high-precision analog/digital converter

measures sensor values in real time and displays them on the

screen or applies them for the equipment control. In addition,

the RS-485/232C communication port is integrated to

support customers’ remote monitoring. Customers can select

RS-485 or RS-232C with simple operation. Therefore, It can

be responded to the building automation easily.

| Display and operation key module |

The display and operation key module is composed of setting

values needed for various operation data and equipment

operation, a display unit that displays the malfunction

information in texts, a key input unit that enables operators

to input data or select menus, and a LED lamp display unit.

In particular, the convenience for operators is enhanced by

allowing them to use keys directly, if keys are used frequently,

or select menus. Operation keys are composed of four menu

handling keys, three manual control value handling keys, three

manual extraction pump handling keys and two run/stop keys

to run or stop the equipment operation. If the operation keys

are out of order, operators can handle the control valve and

the refrigerant value using the text display unit and the menu

selection key. In addition, the operation status(temperature,

running/stopping of the neighboring device, storage) can be

displayed in English, Chinese or Korean for users’ convenience.

| I/O module |

The I/O module is composed of a digital input unit which

checks the operational state of various switches, and a digital

output unit that controls the equipment operation. In addition,

a photo coupler is installed at the I/O unit to block noises. All

the I/O module data can be sent and received from the main

module. Therefore, the malfunction by the EMI, which can

occur when the data are transmitted using a regular cable, can

be prevented and high availability can be secured.

2.08 Characteristics of the controller

| Convenient management of the operation data |

The 7.1inch color LCD shows much operation information on

a screen. The analog data(e.g., temperature data) can be saved

for 300 times by intervals dened by customers. The data can

be used to keep operation logs or to perform maintenance

work. In addition, the temperature of the chilled water outlet

is displayed on a graph so that customers can understand the

trend of temperature changes conveniently.

| Safety controller algorithm |

The safety parts such as high and low pressure sensor,

2020 LG HVAC Solution | 3534 | 2020 LG Water Cooled Screw

Page 19

Guide specication

Guide specication

discharge temperature, current sensor can help product

operation without shutdown. This algorithm can be minimized

malfunction operations without manual reset.

| Self-diagnosis and malfunction history saving |

The microcomputer monitors the equipment state when

the equipment is stopped or running, and informs the state

to operators using text messages, alarm lamps and buzzers.

The advice function shows cause of malfunction and checking

point and troubleshooting. It can be saved in USB memory

with operation and malfunction history.

| Optimized articial intelligent control algorithm |

• Flexible Startup

To prevent excessive shocks to the equipment due to any

abrupt load at the time of startup, the input power will be

supplied gradually.

| Advanced digital PID control |

A digital PID control together with its smooth start-up

minimizes unnecessary chiller shut-downs by recognizing the

optimal PID control point automatically when the chiller is

started or the chiller operation mode is changed from manual

to automatic, and applying the point to the control formula.

Compared with existing analog controls, more stable and

accurate temperature control is possible.

※ A digital transmitter to show and monitor the evaporator

pressure/condenser pressure/ differential oil pressure.

※ A digital transmitter to show and monitor the current/

voltage.

※ PT 100 sensor a chilled water/Cooling water/Oil

temperature PT 100 Sensor installation.

| Scheduled operation function |

Customers can conveniently run the equipment using the

schedule operation function that allows customers to select

Run/Stop and control temperature setting values by weekday

or holiday for 11 times per day.

| Customer support function |

• Communication function for building automation, remote

surveillance and control The communication function

(RS232C/RS485, users can select) is integrated so that

the equipment can be connected to customers’ monitoring

system with ease. Also, no voltage I/O is provided so that

customers can run/stop the equipment or remotely monitor

the important operation state using a simple electric wiring.

MODBUS is basic specication , BACnet and Modem is

optional.

• Help function

If a malfunction occurs, the details thereabout will be logged

and operators can take measures using the help function.

• Three language support

36 | 2020 LG Water Cooled Screw 2020 LG HVAC Solution | 37

Users can select Korean, Chinese or English languages from

the operation menu.

• Pump down function

If the operation stops, the pump-down operation will be

started automatically and the refrigerants will be gathered

at the condenser. Therefore, the equipment can be operated

cost-effectively by its improved operation stability and by

preventing the liquid suction during the operation.

2.09 Automatic safety device

A double protection device that prevents reverse phase, phase

loss and overcurrents is installed. Therefore, the compressor

can be completely protected against external electric shocks.

Chilled water and cooling water safety device

• A chilled water pump interlock contact

• A cooling water pump interlock contact

• A chilled /cooling water ow switch: chilled /cooling water

level – under 50 %.

• Chilled water temperature(low): Chilled water out

temperature – under 2.5°C.

• Evaporator refrigerant temperature(low) – Refrigerant

temperature – under 2.5°C.

※A run/stop signal and interlock contact of the chilled water

and cooling water pump is a very important safety device

that can prevent freezing and bursting and safety incidents.

Therefore, make sure to connect the line in such a way that

the chiller, the chilled water pump and the cooling water

pump can be linked at the time of operation.

※ In addition, the automatic blocking value should be installed

to prevent the water ow on the cooling water pipe of the

chiller if several cooling water pipes are connected in parallel.

Then, the automatic blocking valve should be operated in line

with the LG control device. To link the automatic blocking

valve, the valve should be opened/closed in synchronization

with the cooling water pump run/stop signal provided by

the control panel.

• For more details, please contact LG service center in advance.

| Chiller protection device |

• Evaporator low pressure

• Condenser high pressure

• Differential oil pressure

• Low chilled water ow

• Evaporator low temperature

• Condenser high temperature

• Overcurrent protection

• Compressor overheat protection

| Motor/Compressor protector |

• A reverse phase/phase loss protection relay

• A three-phase wire-wound temperature monitoring S/W

• A compressor discharge temperature monitoring sensor

2.10 Accessories and options

Some accessories and options supersede standard product

features. All options are factory-mounted unless otherwise

noted.

| Gateway |

Provides communication for Building Automation Systems,

including BACnet(MS/ TP), Modbus,(Field Commissioned by

BAS Manufacturer)

| General Options |

1. Flow Switch: The water ow switch comes with SPDT output

function, 1.6MPa(232 psi) working pressure, -10°C to

120°C(-14°F to 248°F) with 1” NPT connection for upright

mounting in horizontal pipe(This ow switch or equivalent

must be furnished with each unit). Field mounted.

2. Differential Pressure Switch: 0.2-3 bar(3-45 psig) range

with 1/4” NPTE pressure connections.(Field Mounted by

Contractor.)

| Vibration Isolation(All Options Field Mounted by Contractor |

1” Deection Spring Isolators: Level adjustable, spring and

cage type isolators for mounting under the unit base rails.

| Compressor acoustic enclosure |

The compressor acoustic enclosure can be provided as a option

to reduce compressor sound levels.

| Single power point connection |

For models installed with 2, 3 and 4 compressors, to minimize

job site installation cost and time, single point power

connection can be provided as an option about the following

models. If optional single point power connection is required,

terminal block connections will be supplied at the point of

incoming single point connection.

| Power factor correction |

Provide equipment with power factor correction capacitors as

required to maintain a displacement power factor of 95% at

all load conditions.

| Double thickness insulation |

As a standard, the evaporator shell is insulated with 19mm

(3/4”). As a option, it can be insulated with 38mm(1-1/2”).

| NFB(Non-Fused Breaker) power disconnect switch |

A non-fused disconnect is available as a factory-installed

option for all units with single point power connection units.

This option is that power supply is disconnected during service

& repair work as well as door interlock.

| Suction service isolation valve |

Service suction isolation valve is installed with unit for each

refrigerant circuit as a standard.

| Pressure vessel(options) |

The evaporator and condenser can be provided with either

ASME or PED pressure vessel codes certication.

Part 3 – Execution

3.01 Installation

A. General: rig and install in full accordance with manufacturer’s

requirements, project drawings, and contract documents.

B. Location: locate chiller as indicated on drawings,

including cleaning and service maintenance clearance

per manufacturer instructions. Adjust and level chiller on

support structure.

C. Components: installing contractor shall provide and install

all auxiliary devices and accessories for fully operational

chiller.

D. Electrical: coordinate electrical requirements and

connections for all power feeds with electrical contractor.

E. Controls: coordinate all control requirements and

connections with controls contractor.

F. Finish: installing contractor shall paint damaged and abraded

factory nish with touch-up paint matching factory nish.

Page 20

MemoMemo

38 | 2020 LG Water Cooled Screw 2020 LG HVAC Solution | 39

Loading...

Loading...