Page 1

MODEL: RCD406 (RCD406, RCS606F)SERVICE MANUAL

Internal Use Only

Website http://biz.lgservice.com

Mini Hi-Fi System

SERVICE MANUAL

P/NO : AFN74972261 FEBRUARY, 2011

MODEL:

RCD406

(RCD406, RCS606F)

CAUTION

BEFORE SERVICING THE UNIT, READ THE “SAFETY PRECAUTIONS”

IN THIS MANUAL.

Page 2

CONTENTS

SECTION 1 ........ GENERAL

SECTION 2 ........ CABINET & MAIN CHASSIS

SECTION 3 ........ ELECTRICAL

SECTION 4 ........ REPLACEMENT PARTS LIST

1-1

Page 3

SECTION 1

SUMMARY

CONTENTS

SERVICING PRECAUTIONS ................................................................................................................... 1-3

ESD PRECAUTIONS .................................................................................................................................. 1-5

SERVICE INFORMATION FOR EEPROM .......................................................................................... 1-6

PROGRAM DOWNLOAD GUIDE ........................................................................................................... 1-7

SPECIFICATIONS ..................................................................................................................................... 1-10

1-2

Page 4

SERVICING PRECAUTIONS

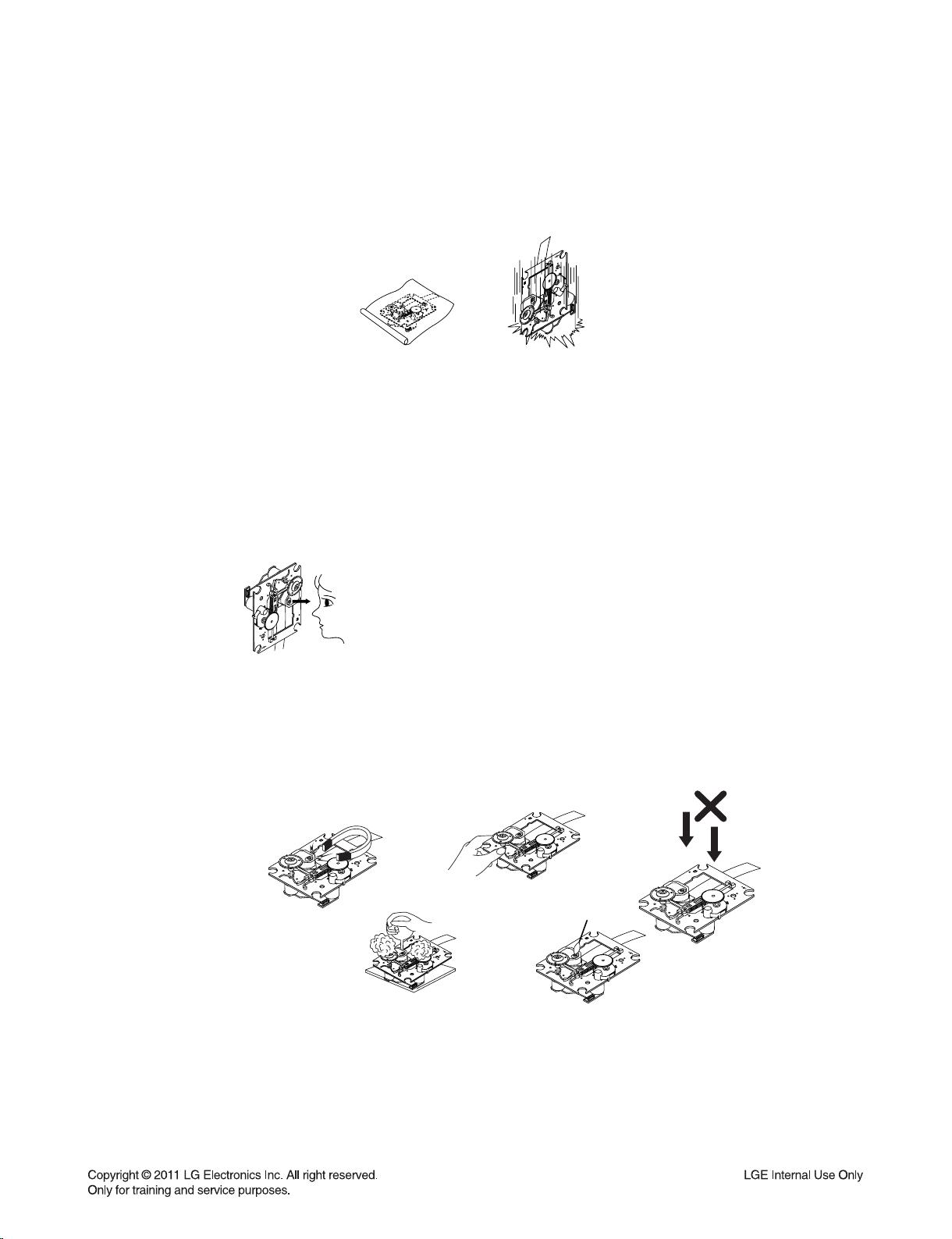

NOTES REGARDING HANDLING OF THE PICK-UP

1. Notes for transport and storage

1) The pick-up should always be left in its conductive bag until immediately prior to use.

2) The pick-up should never be subjected to external pressure or impact.

Storage in conductive bag

Drop impact

2. Repair notes

1) The pick-up incorporates a strong magnet, and so should never be brought close to magnetic materials.

2) The pick-up should always be handled correctly and carefully, taking care to avoid external pressure and

impact. If it is subjected to strong pressure or impact, the result may be an operational malfunction and/or

damage to the printed-circuit board.

3) Each and every pick-up is already individually adjusted to a high degree of precision, and for that reason

the adjustment point and installation screws should absolutely never be touched.

4) Laser beams may damage the eyes!

Absolutely never permit laser beams to enter the eyes!

Also NEVER switch ON the power to the laser output part (lens, etc.) of the pick-up if it is damaged.

NEVER look directly at the laser beam, and don’t allow

contact with fingers or other exposed skin.

5) Cleaning the lens surface

If there is dust on the lens surface, the dust should be cleaned away by using an air bush (such as used

for camera lens). The lens is held by a delicate spring. When cleaning the lens surface, therefore, a cotton

swab should be used, taking care not to distort lens.

Pressure

Magnet

How to hold the pick-up

Cotton swab

Conductive Sheet

6) Never attempt to disassemble the pick-up.

Spring has excess pressure. If the lens is extremely dirty, apply isopropyl alcohol to the cotton swab.

(Do not use any other liquid cleaners, because they will damage the lens.) Take care not to use too much

of this alcohol on the swab, and do not allow the alcohol to get inside the pick-up.

1-3

Pressure

Page 5

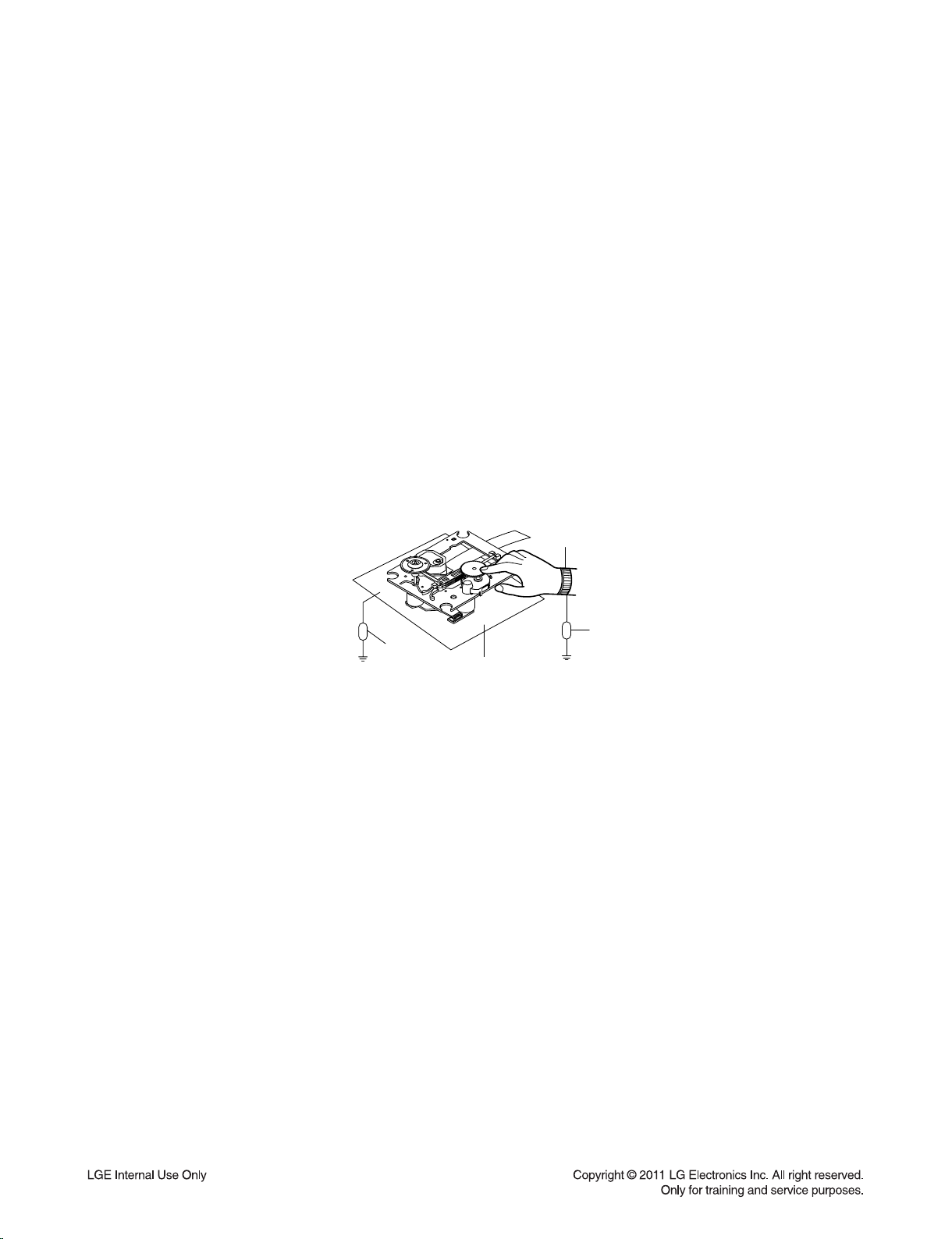

NOTES REGARDING COMPACT DISC PLAYER REPAIRS

1. Preparations

1) Compact disc players incorporate a great many ICs as well as the pick-up (laser diode). These components

are sensitive to, and easily affected by, static electricity. If such static electricity is high voltage, components

can be damaged, and for that reason components should be handled with care.

2) The pick-up is composed of many optical components and other high-precision components. Care must be

taken, therefore, to avoid repair or storage where the temperature or humidity is high, where strong magnetism is present, or where there is excessive dust.

2. Notes for repair

1) Before replacing a component part, first disconnect the power supply lead wire from the unit

2) All equipment, measuring instruments and tools must be grounded.

3) The workbench should be covered with a conductive sheet and grounded.

When removing the laser pick-up from its conductive bag, do not place the pick-up on the bag. (This is

because there is the possibility of damage by static electricity.)

4) To prevent AC leakage, the metal part of the soldering iron should be grounded.

5) Workers should be grounded by an armband (1 MΩ)

6) Care should be taken not to permit the laser pick-up to come in contact with clothing, in order to prevent static electricity changes in the clothing to escape from the armband.

7) The laser beam from the pick-up should NEVER be directly facing the eyes or bare skin.

Armband

Resistor

(1 MΩ)

Resistor

(1 MΩ)

Conductive

Sheet

1-4

Page 6

ESD PRECAUTIONS

Electrostatically Sensitive Devices (ESD)

Some semiconductor (solid state) devices can be damaged easily by static electricity. Such components

commonly are called Electrostatically Sensitive Devices (ESD). Examples of typical ESD devices are integrated

circuits and some field-effect transistors and semiconductor chip components. The following techniques should

be used to help reduce the incidence of component damage caused by static electricity.

1. Immediately before handling any semiconductor component or semiconductor-equipped assembly, drain off

any electrostatic charge on your body by touching a known earth ground. Alternatively, obtain and wear a

commercially available discharging wrist strap device, which should be removed for potential shock reasons

prior to applying power to the unit under test.

2. After removing an electrical assembly equipped with ESD devices, place the assembly on a conductive surface

such as aluminum foil, to prevent electrostatic charge buildup or exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder ESD devices.

4. Use only an anti-static solder removal device. Some solder removal devices not classified as "anti-static" can

generate electrical charges sufficient to damage ESD devices.

5. Do not use freon-propelled chemicals. These can generate electrical charges sufficient to damage ESD

devices.

6. Do not remove a replacement ESD device from its protective package until immediately before you are

ready to install it. (Most replacement ESD devices are packaged with leads electrically shorted together by

conductive foam, aluminum foil or comparable conductive materials).

7. Immediately before removing the protective material from the leads of a replacement ESD device, touch the

protective material to the chassis or circuit assembly into which the device will by installed.

CAUTION : BE SURE NO POWER IS APPLIED TO THE CHASSIS OR CIRCUIT, AND OBSERVE ALL OTHER

SAFETY PRECAUTIONS.

8. Minimize bodily motions when handing unpackaged replacement ESD devices. (Otherwise harmless motion

such as the brushing together of your clothes fabric or the lifting of your foot from a carpeted floor can generate

static electricity sufficient to damage an ESD device).

CAUTION. GRAPHIC SYMBOLS

THE LIGHTNING FLASH WITH APROWHEAD SYMBOL. WITHIN AN EQUILATERAL TRIANGLE, IS

INTENDED TO ALERT THE SERVICE PERSONNEL TO THE PRESENCE OF UNINSULATED

“DANGEROUS VOLTAGE” THAT MAY BE OF SUFFICIENT MAGNITUDE TO CONSTITUTE A RISK OF

ELECTRIC SHOCK.

THE EXCLAMATION POINT WITHIN AN EQUILATERAL TRIANGLE IS INTENDED TO ALERT THE

SERVICE PERSONNEL TO THE PRESENCE OF IMPORTANT SAFETY INFORMATION IN SERVICE

LITERATURE.

1-5

Page 7

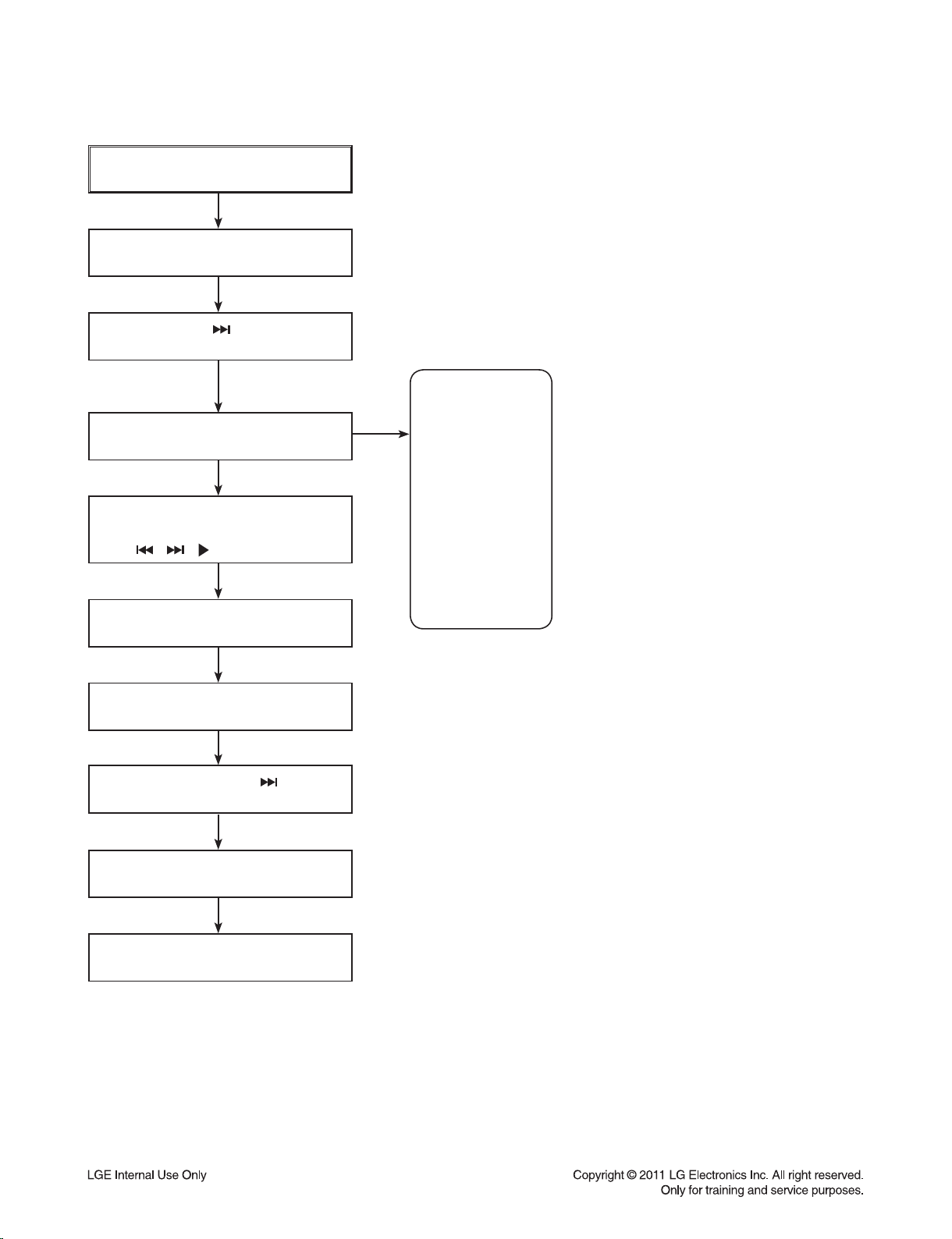

SERVICE INFORMATION FOR EEPROM

POWER ON

FLD no disc status

Remote control ‘

’ + Front ‘STOP’

push same timing during 5s

FLD ‘OP-0….

Move to appropriate position and

make changes with remote control.

( , , /■ , REPEAT )

Press STOP key

FLD ‘write ok’

DETECT NEW EEPROM

(OPTION EDIT SCREEN)

NAME

OP0

OP1

OP2

OP3

OP4

OP5

OP6

OP7

OP8

OP9

HEX

09

00

00

00

00

69

90

05

60

08

Remote control ‘

’ +

Front ‘STOP’ push same timing

FLD ‘E2P CLR’

Completed

1-6

Page 8

PROGRAM DOWNLOAD GUIDE

1. AUDIO PROGRAM

Download program file name must be RCD406_YYMMDDX.HEX

If security program (Water Wall) is activated on your PC, you must save the file to the usb storage

device and disable the security software, then download the file to your set.

Caution: When downloading the file, you should neither unplug the usb device, change to the other

function, nor power off the device. Usb device must be unplugged when the downloading

process is completed.

ON VFD DISPLAY SCREEN

NO USB

↓← Insert usb device at usb function

READ

↓

FIRMWARE

↓

WRITE 00 .. 100

↓

UPDATED

↓

POWER OFF AUTOMATICALLY

←

When completed, remove usb device.

1-7

Page 9

2. CD PROGRAM

Download program file name must be HD003_DATE_00.BIN

If security program (Water Wall) is activated on your PC, you must save the file to the usb storage

device and disable the security software, then download the file to your set.

Caution: When downloading the file, you should neither unplug the usb device, change to the other

function, nor power off the device. Usb device must be unplugged when the downloading

process is completed.

ON VFD DISPLAY SCREEN

NO USB

↓← Insert usb device at usb function

READ

↓

FIRMWARE

↓

FINISH

↓

UPDATED

↓

POWER OFF AUTOMATICALLY

←

When completed, remove usb device

.

1-8

Page 10

3. BEAT BOX PROGRAM

Download program file name must be BEAT_BIN_DATE_00.BIN

If security program (Water Wall) is activated on your PC, you must save the file to the usb storage

device and disable the security software, then download the file to your set.

Caution: When downloading the file, you should neither unplug the usb device, change to the other

function, nor power off the device. Usb device must be unplugged when the downloading

process is completed.

ON VFD DISPLAY SCREEN

NO USB

↓← Insert usb device at usb function

READ

↓

FIRMWARE

↓

FINISH

↓

UPDATED

↓

POWER OFF AUTOMATICALLY

←

When completed, remove usb device

.

1-9

Page 11

SPECIFICATIONS

• GENERAL

Power requirements Refer to main label

Power consumption Refer to main label

Dimensions (W x H x D) 285 x 350 x 380 mm without foot

Net Weight (Approx.) 6.6 kg

Operating temperature 5 °C to 35 °C (41 °F to 95 °F)

Operating humidity 5 % to 90 %

Bus Power Supply USB DC 5 V 500 mA

iPod DC 5 V 1 A

• INPUTS/ OUTPUTS

ANALOG AUDIO IN 1.2 Vrms (1 kHz, 0 dB), 600 Ω, RCA jack (L, R) x 1

PORT. IN 0.5 Vrms (3.5 mm stereo jack)

ANALOG AUDIO OUT 800 mVrms (1 kHz, 0 dB), 600 Ω, RCA jack (L, R) x 1

• TUNER

FM Tuning Range 87.5 to 108.0 MHz or 87.50 to 108.00 MHz

AM Tuning Range 522 to 1 620 kHz, 520 to 1 710 kHz or 522 to 1 710 kHz

• AMPLIFIER

Stereo mode 200 W + 200 W (4 Ω at 1 kHz)

• CD

Frequency Response 40 to 20 000 Hz

Signal-to-noise ratio 75 dB

Dynamic range 80 dB

• SPEAKERS

Front speaker

Type 2 Way 2 speaker

Impedance 4 Ω

Rated Input Power 200 W

Max. Input power 400 W

Net Dimensions (W x H x D) 239 x 400 x 335 mm

Net Weight 5 kg

• Design and specifications are subject to change without notice.

1-10

Page 12

SECTION 2

CABINET & MAIN CHASSIS

CONTENTS

DISASSEMBLY AND ASSEMBLY FOR MECHANISM DECK (CDM-H1803) ........................ 2-2

1. ORDER OF DISASSEMBLY FOR MECHANISM DECK .......................................................................... 2-2

2. ORDER OF ASSEMBLY FOR MECHANISM DECK ................................................................................ 2-6

EXPLODED VIEWS ................................................................................................................................... 2-11

1. CABINET AND MAIN FRAME SECTION (RCD406) .............................................................................. 2-11

2. MECHANISM DECK SECTION (CDM-H1803) ....................................................................................... 2-13

3. PACKING ACCESSORY SECTION ....................................................................................................... 2-15

4. SPEAKER SECTION .............................................................................................................................. 2-16

2-1

Page 13

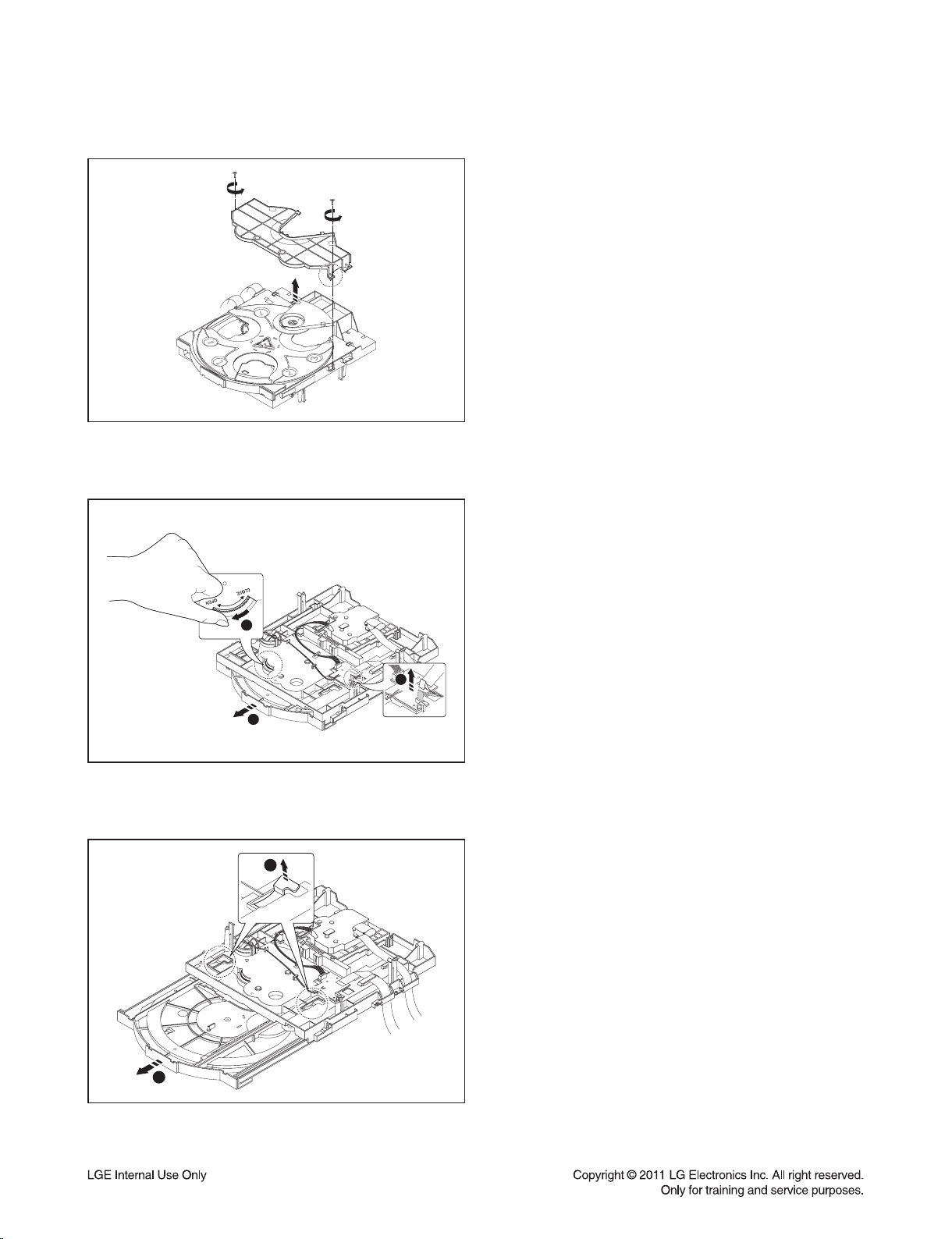

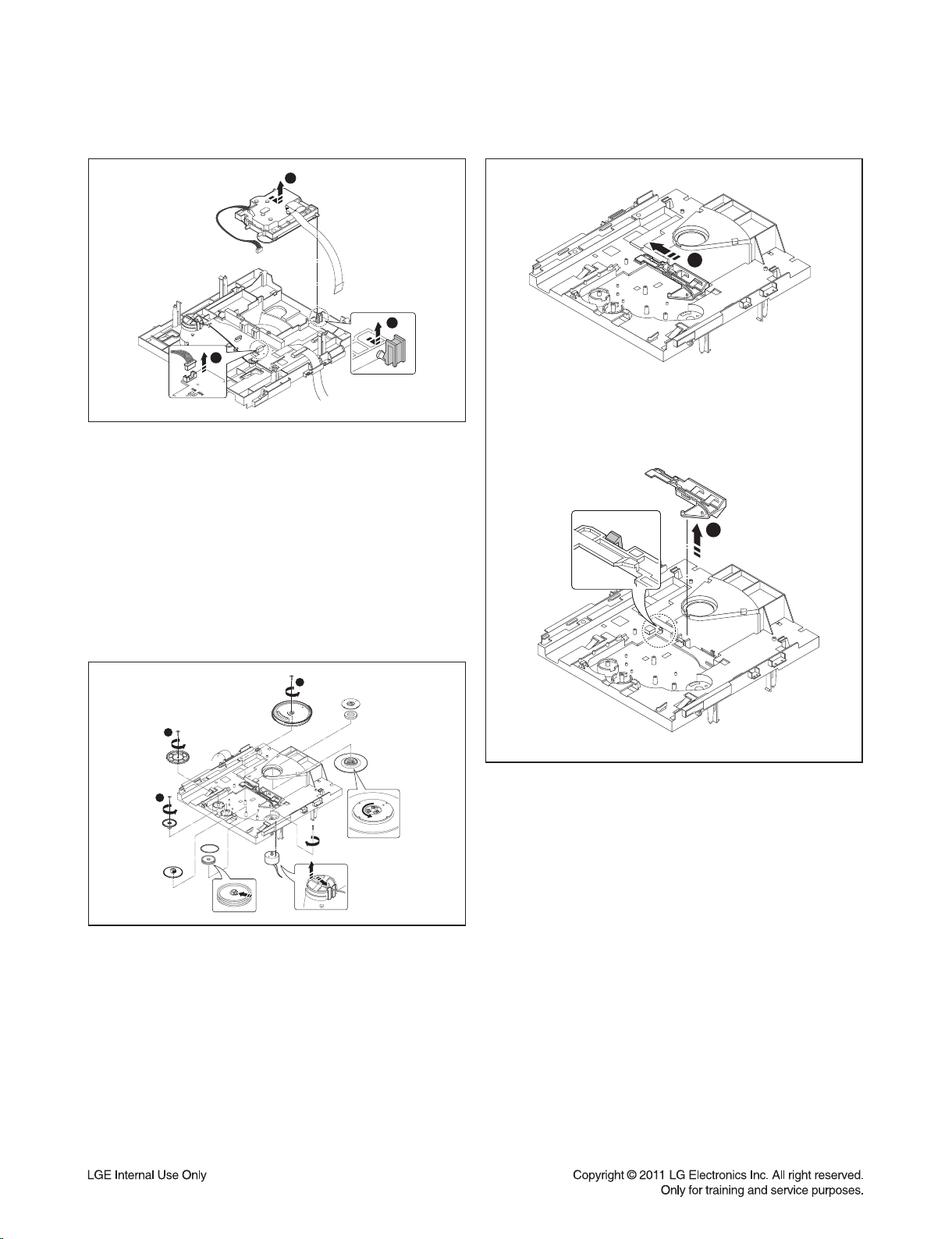

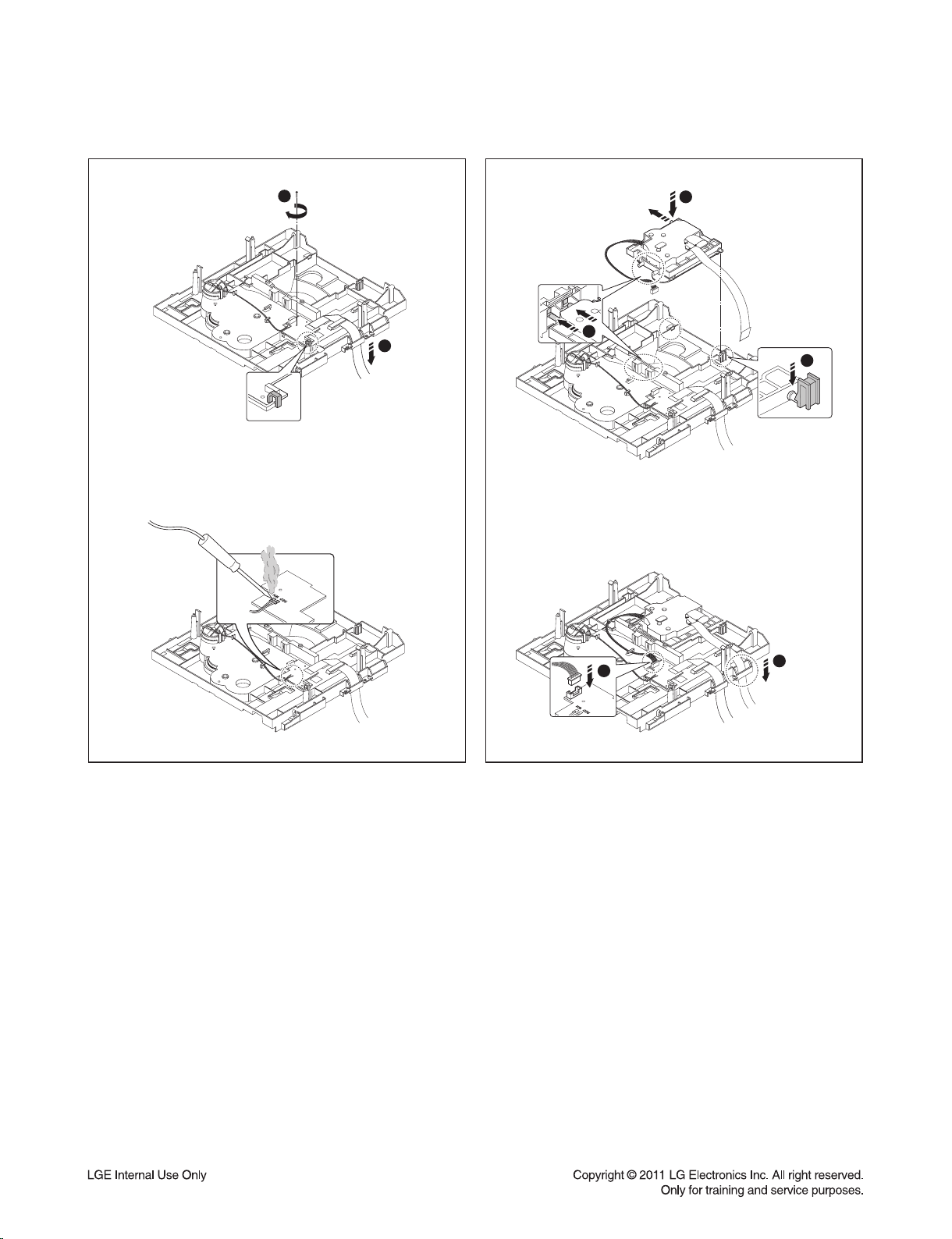

DISASSEMBLY AND ASSEMBLY FOR MECHANISM DECK (CDM-H1803)

1. ORDER OF DISASSEMBLY FOR MECHANISM DECK

1) Disassemble the Cover Guide Disc.

Figure 1

2) Disassemble the Loading FFC from the Main PCB

Assy.

Turn the Gear in OPEN direction as shown in Figure 2

to take out the Tray Loading Assy in 3 direction.

2

1

3

Figure 2

3) Pull up the Holder 1 to completely disassemble the

1

2

Tray Loading Assy from the Base Main Assy.

Figure 3

2-2

Page 14

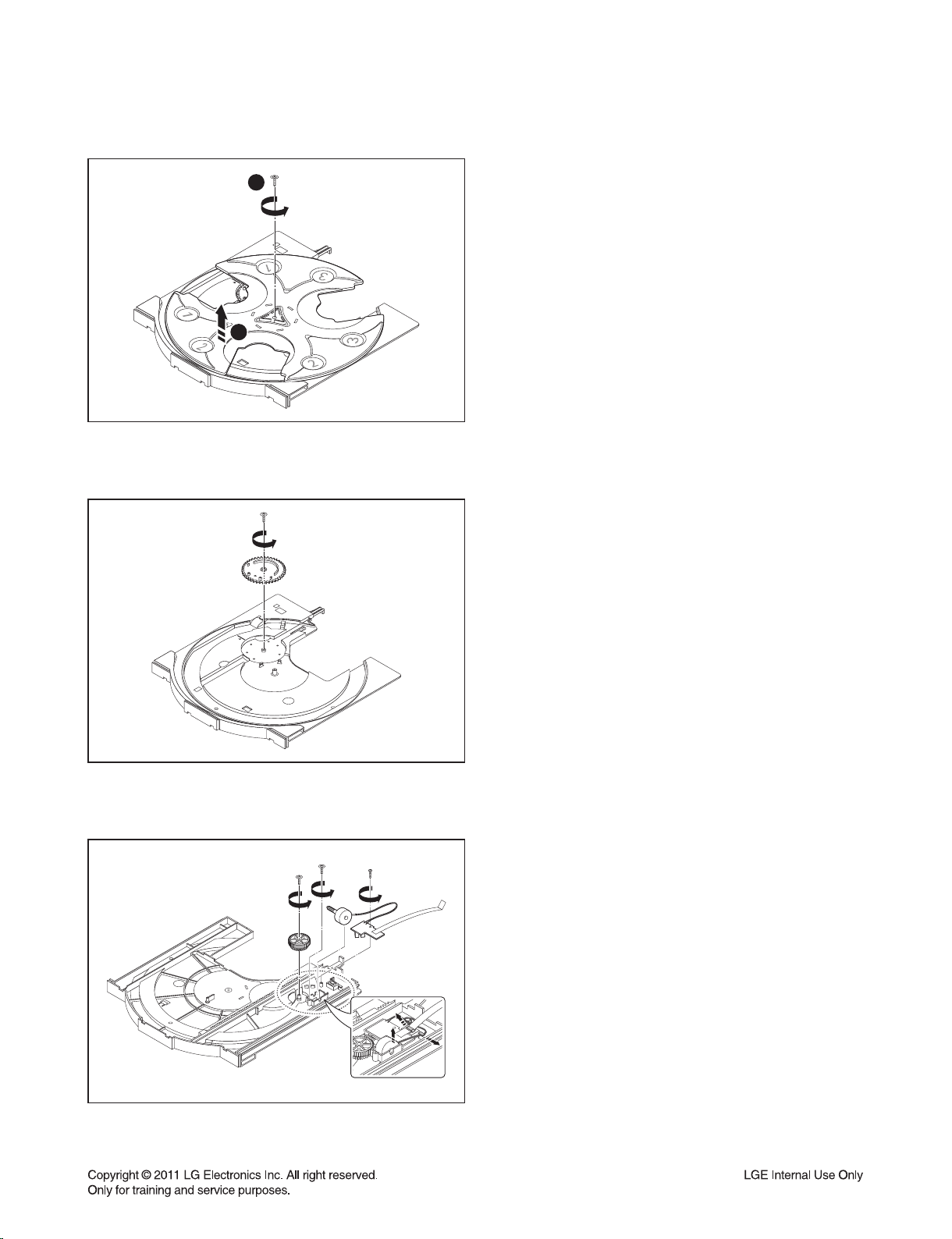

ORDER OF DISASSEMBLY FOR MECHANISM DECK

4) Loosen the screw to pull up and disassemble the

1

2

Figure 4

Tray Disc.

5) Loosen the screw to pull up and disassemble the

Gear Tray CAM.

Figure 5

Figure 6

6) Disassemble the Gear Tray, Tray Motor Assy and

Loading PCB Assy from the Tray Loading.

2-3

Page 15

ORDER OF DISASSEMBLY FOR MECHANISM DECK

3

2

1

Figure 7

7) Disassemble the Harness Cable from the Base

Main.

Disassemble the Base Sled Assy from the Base Main

by referring to Figure.

1

2

3

1

2

Figure 8

8) Disassemble each gear part, Clamp Disc, Clamp

Magnet and Cover Plate from the Base Main.

Disassemble the Loading Motor Assy by being careful

of the hook on the surface of the Base Main.

Figure 9

9) Push the Guide UD in direction 1 to disassemble it

from the Base Main.

2-4

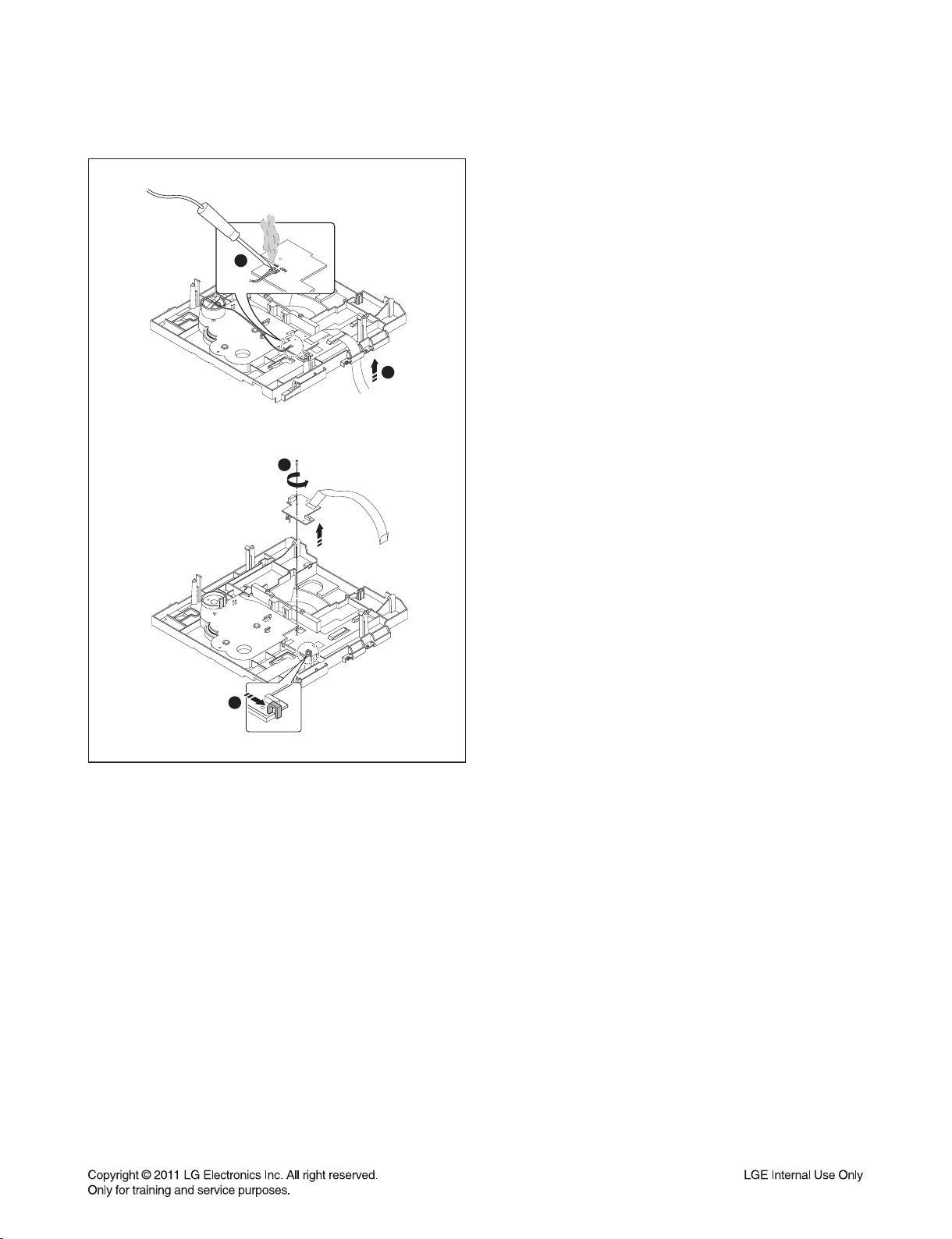

Page 16

ORDER OF DISASSEMBLY FOR MECHANISM DECK

10) Use a solder to remove the Motor Jump Wire from

the Main PCB Assy and then disassemble the FFC

Cable.

Loosen the screw to disassemble the Main PCB Assy.

1

2

4

3

Figure 10

2-5

Page 17

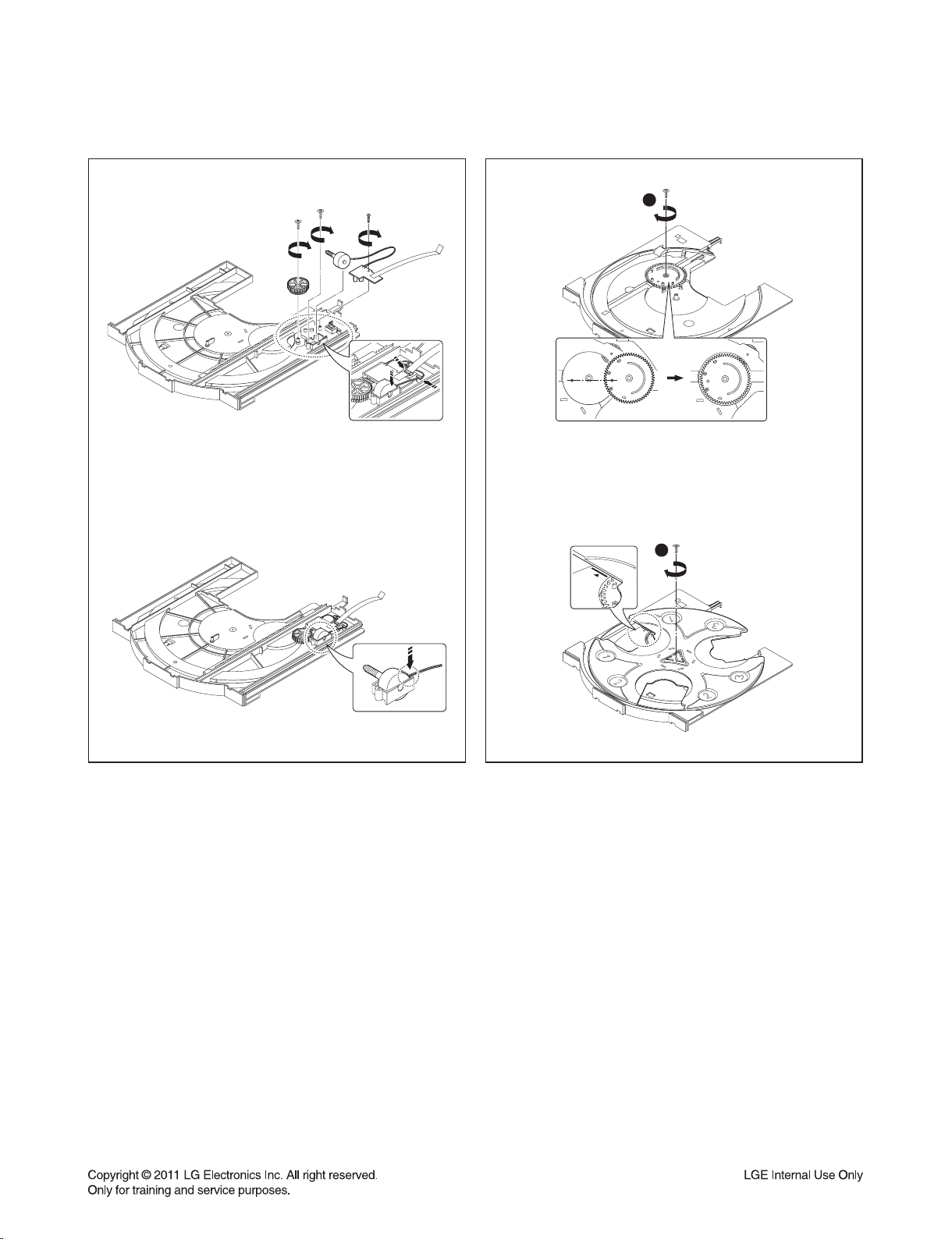

2. ORDER OF ASSEMBLY FOR MECHANISM DECK

1) Assemble the Loading Motor Assy to the Base

Main.

(When assembling the Motor Assy, use the hook on

the surface of the Base Main to preassemble, and then

tighten the screws.)

Figure 1

2) Set the Guide UD on the Base Main.

After setting the part, push it in direction 3.

2

3

1

Figure 2

2-6

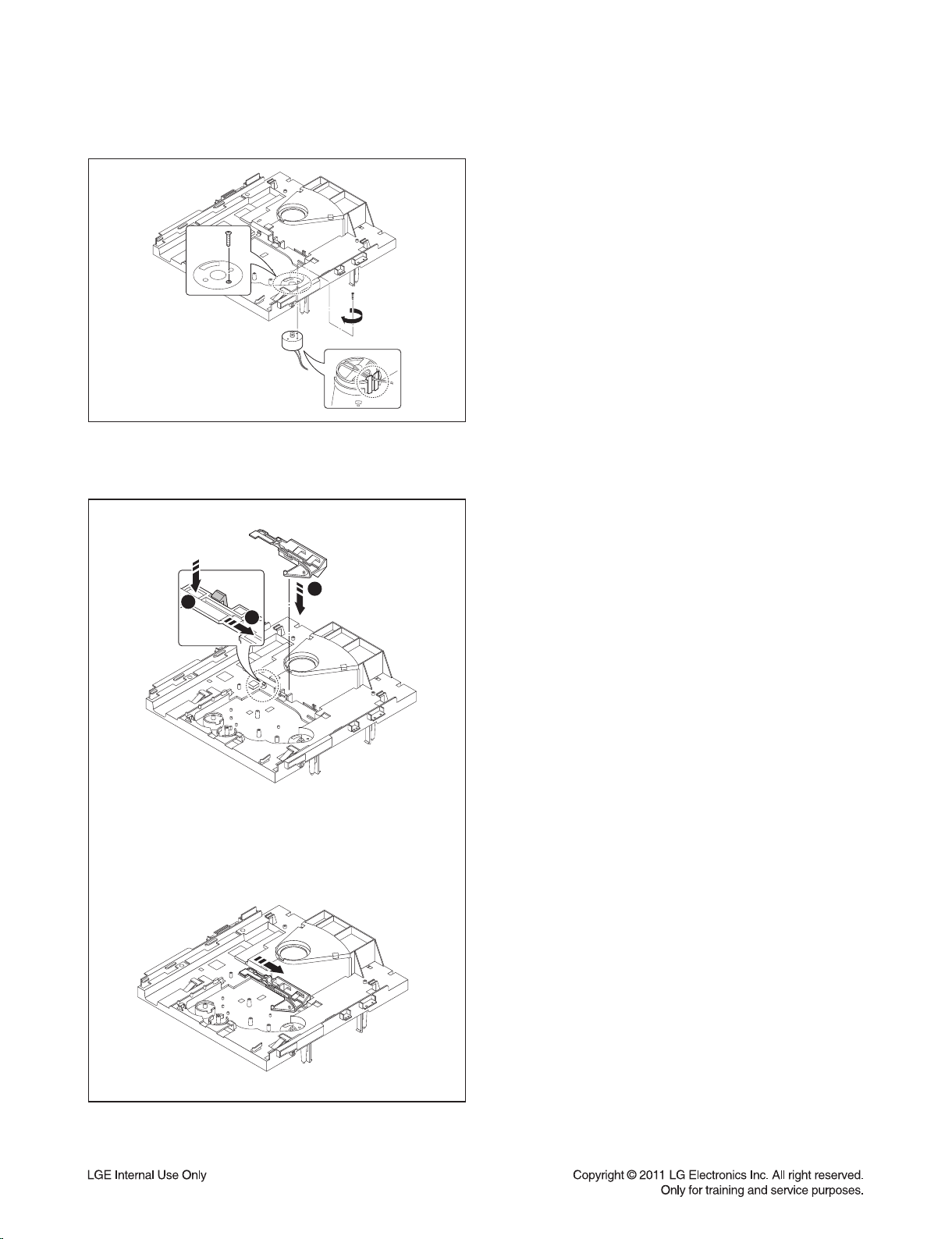

Page 18

ORDER OF ASSEMBLY FOR MECHANISM DECK

3) Set the Gear Loading 1 and Gear Pulley 2 on the

2

1

Figure 3

Base Main.

Hang the belt between the Gear Pulley and Motor Pulley.

Assemble the Clamp Disc, Clamp Magnet and Cover

Plate to the Base Main.

4) After setting the Gear Main 2, Gear Pu Up 3 and Gear

Pu Down 4 on the Base Main, tighten the screws.

After assembling the Gear Main, align the location as

shown in Figure.

1

2

4

3

Figure 4

2-7

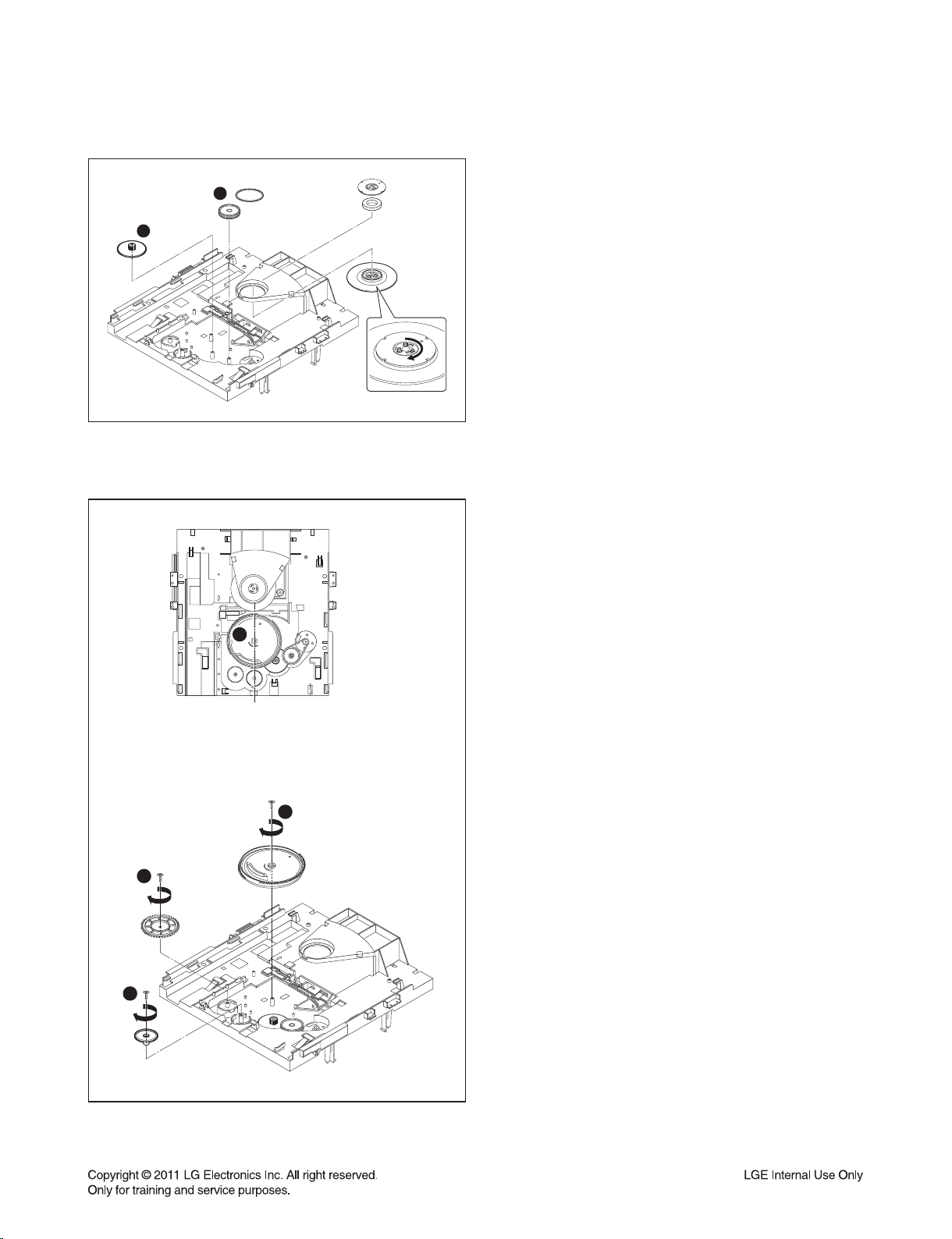

Page 19

ORDER OF ASSEMBLY FOR MECHANISM DECK

1

1

2

2

3

Figure 5

5) After setting the Main PCB Assy on the Base Main,

tighten the screw.

(Set the part accurately on the hook)

Solder the Motor Jump Wire on the PCB set on the

Base Main.

5

4

Figure 6

6) Set the Base Sled Assy on the Base Main.

(When setting the part, assemble with the CAM part of

the Guide UD inserted in two locations of the Boss of

Frame UD)

Align the FFC to the Guide and connect the Harness

Cable.

2-8

Page 20

ORDER OF ASSEMBLY FOR MECHANISM DECK

1

2

Figure 7

7) After setting the Gear Tray, Tray Motor Assy and

Loading PCB Assy on the Tray Loading, tighten the

screw.

Figure 8

8) Assemble the Gear Tray CAM on the Tray Loading

and set the Tray Disc.

(When assembling, check the location of the Gear Tray

CAM and Tray Disc as shown in the Figure)

2-9

Page 21

ORDER OF ASSEMBLY FOR MECHANISM DECK

1

2

3

Figure 9 Figure 10

9) Assemble the Tray Loading Assy on the Base Main

Assy as shown in the Figure.

After assembling, insert the Loading FFC to the 5 Pin

Wafer of Main PCB Assy.

10) After setting the Cover Guide Disc, tighten the

screw.

2-10

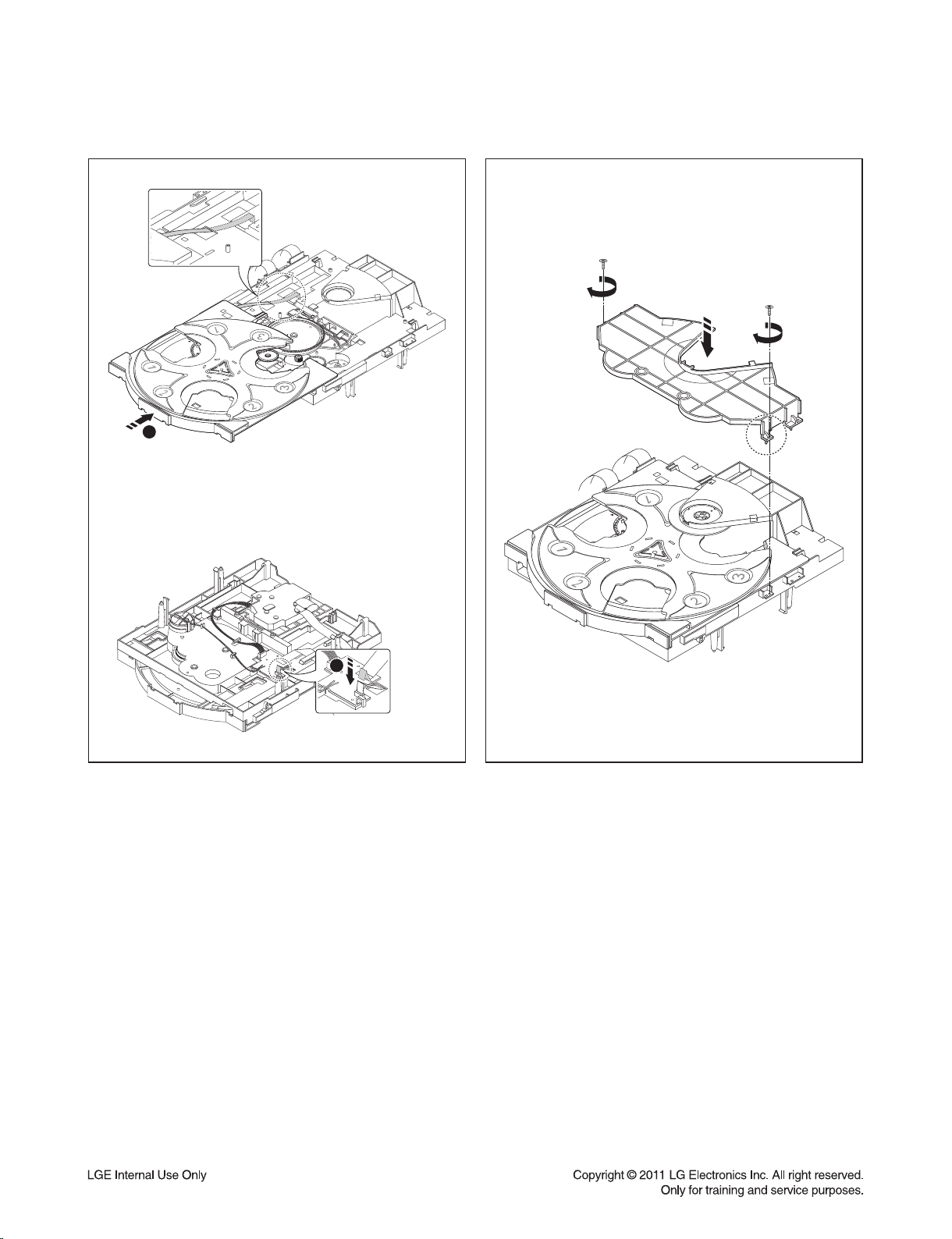

Page 22

EXPLODED VIEWS

1. CABINET AND MAIN FRAME SECTION (RCD406)

464

A49

CABLE1

A42

E

iPod

464

464

264

A45

A43

VOLUME

CABLE2

CN302

CABLE7

464

480

NOTES) THE EXCLAMATION POINT WITHIN AN

EQUILATERAL TRIANGLE IS INTENDED

TO ALERT THE SERVICE PERSONNEL

TO THE PRESENCE OF IMPORTANT

SAFETY INFORMATION IN SERVICE

LITERATURE.

464

268

464

CABLE6

270

464

VFD

464

464

269

I

464

K

463

C

464

F

H

J

A26

D

SMPS

A47

A

B

251

255A

255C

464

K

USB+MIC

463

267

C

G

464

464

265

A44

300

463

D

E

266

F

G

J

271

272

MAIN

464

A46

H

B

CN102

I

CN101

464

A

2-11 2-12

Page 23

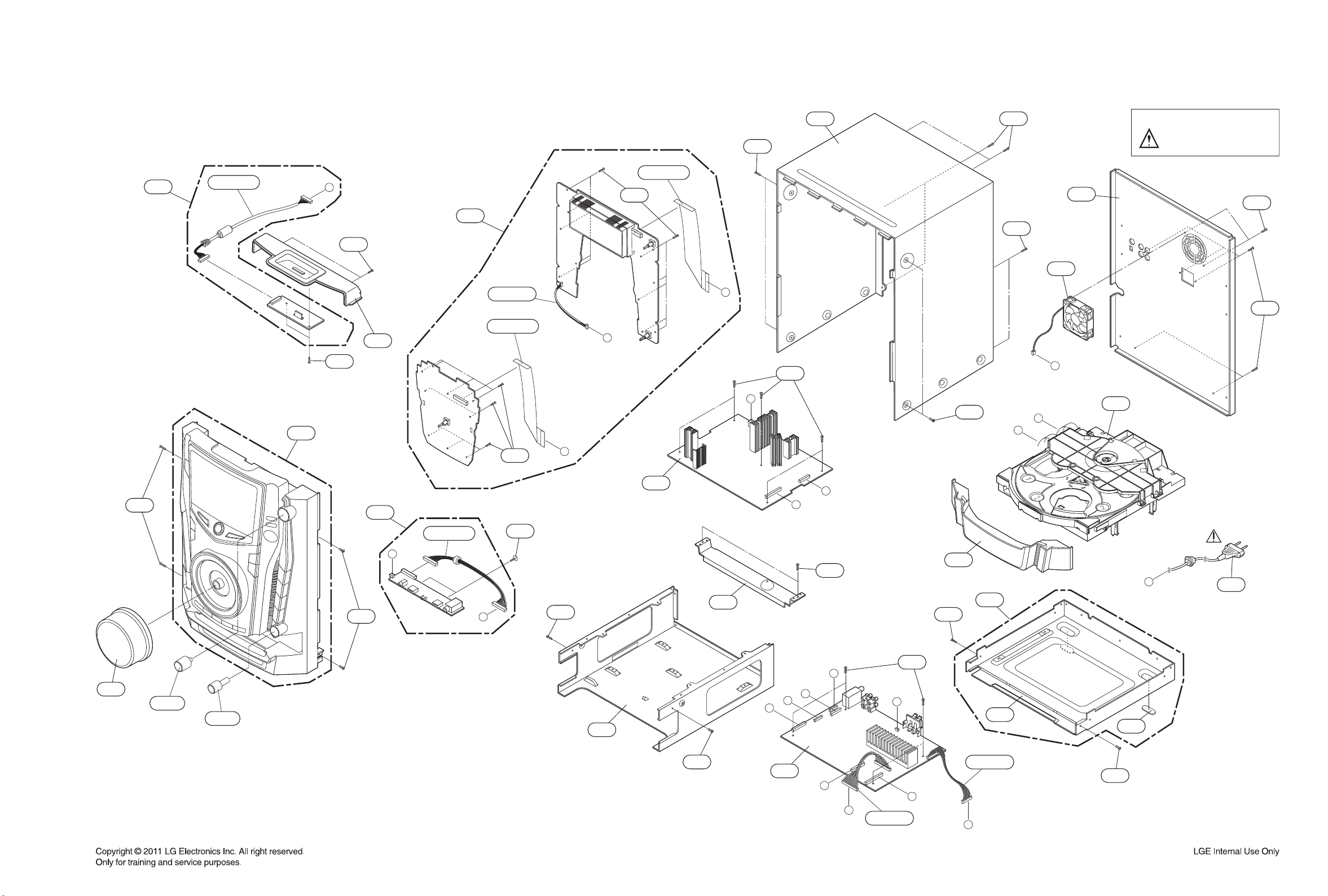

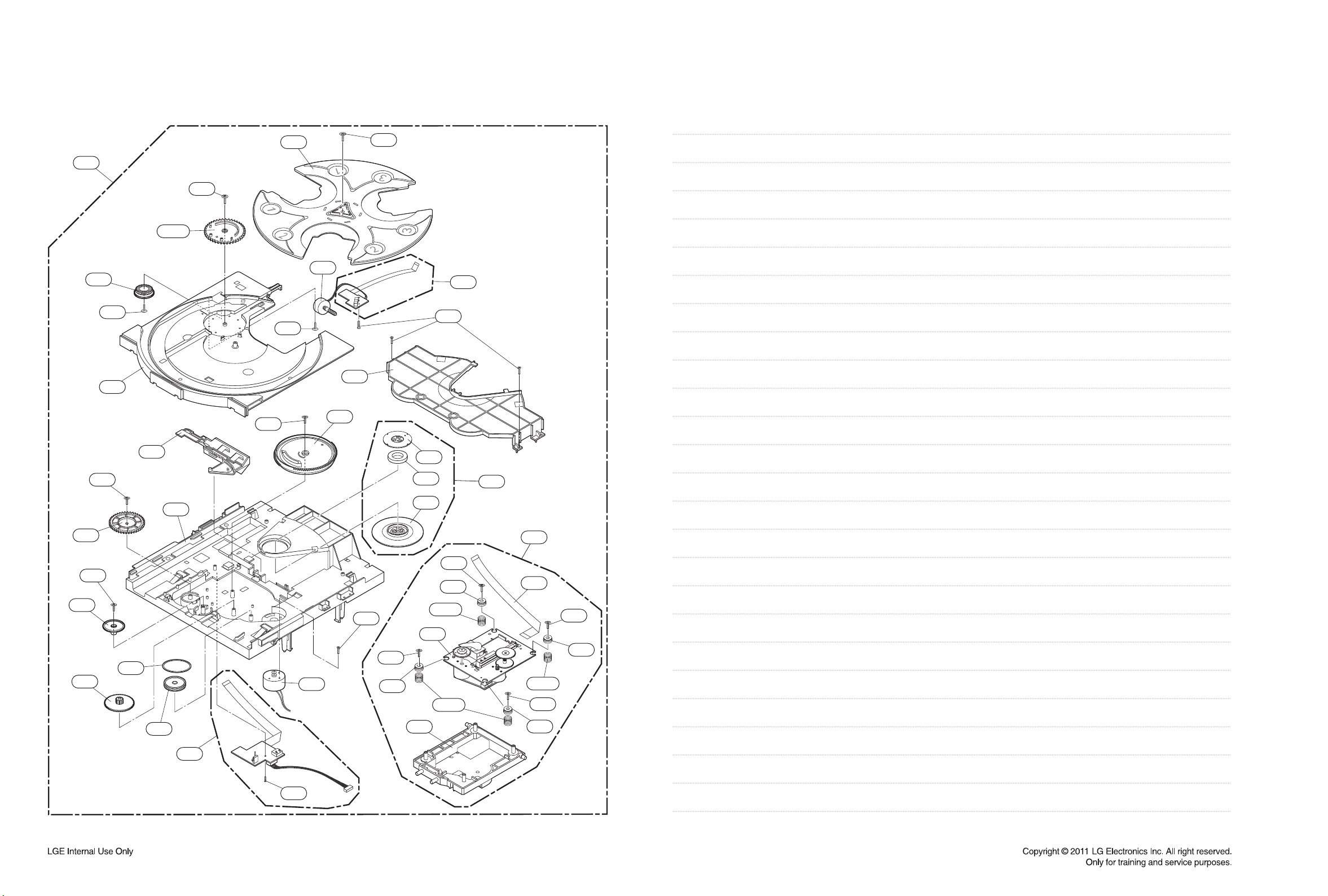

2. MECHANISM DECK SECTION (CDM-H1803)

MEMO

A26

153

443

159

173

153A

443

416

151

443

416

155

156

422

182

177

001

166

167

164

417

417

162

163

172

165

422

175

440

421

012

002

003

180

012B

137

421

012

012A

A02

A01

010

421

012

012B

421

012

2-13 2-14

Page 24

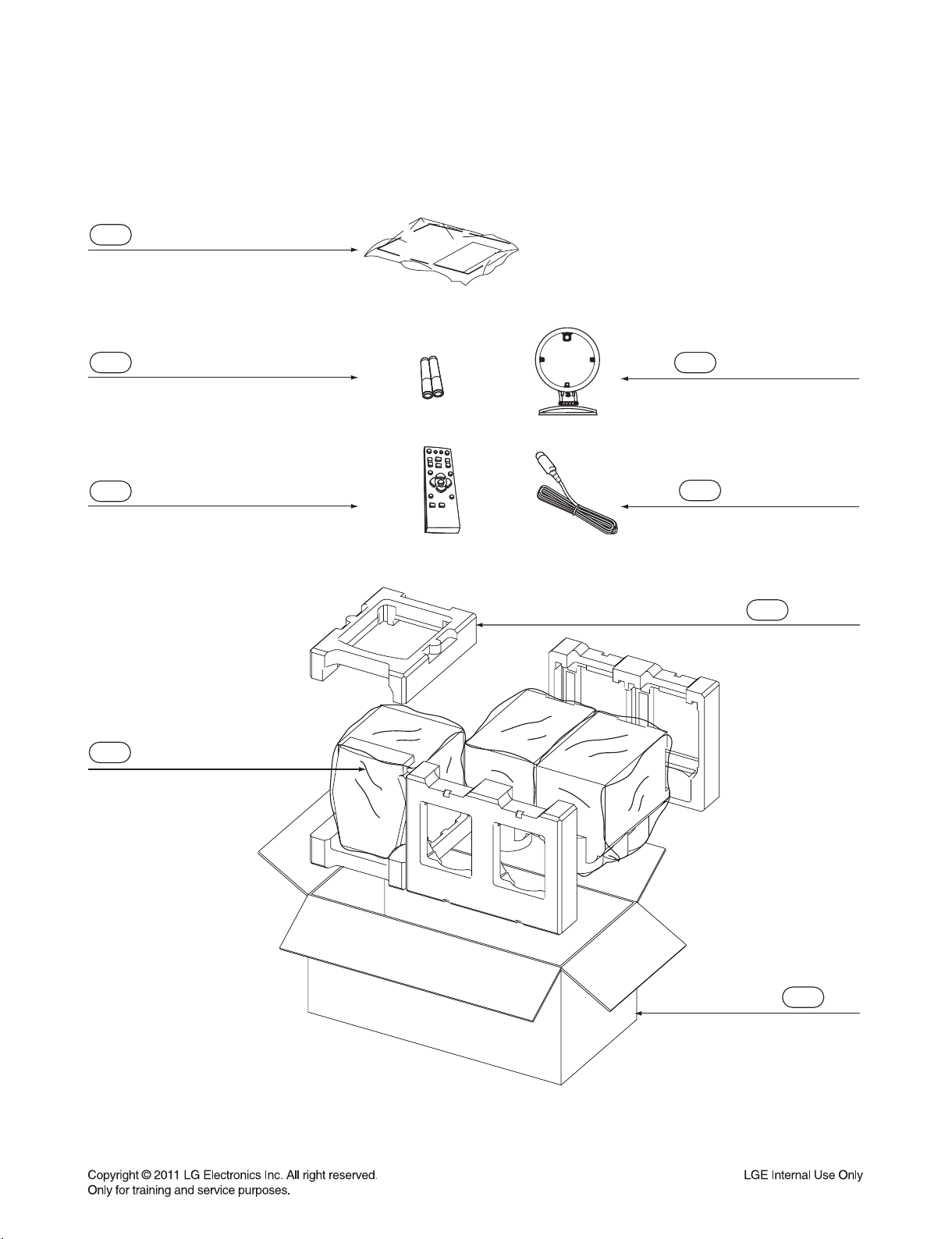

3. PACKING ACCESSORY SECTION

801 Owner’s Manual

AAA

808 Battery

AAA

824 AM Loop Antenna

900 Remote Control

804 Bag

825 FM Wire Antenna

803 Packing

2-15

802 Box

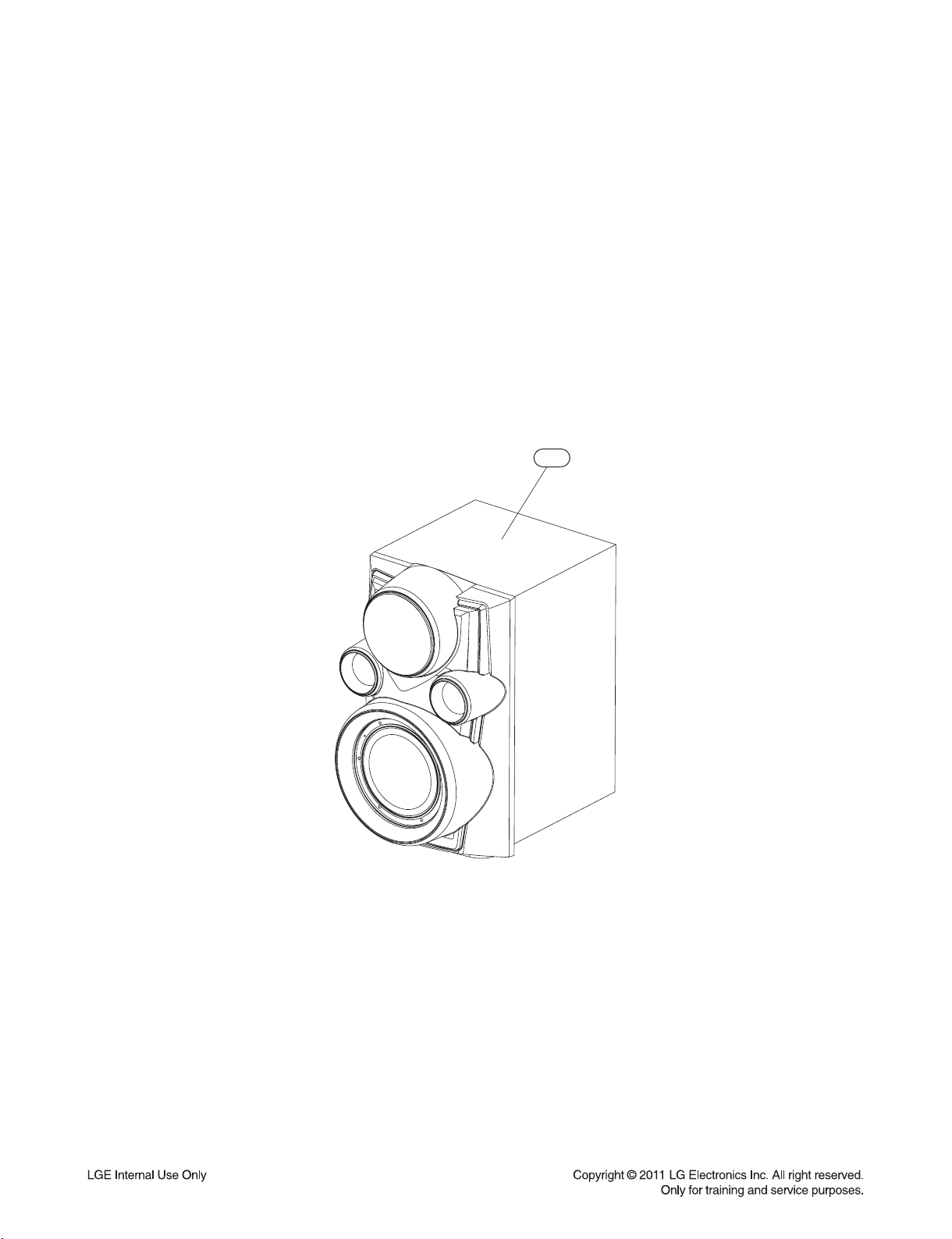

Page 25

4. SPEAKER SECTION

4-1. FRONT SPEAKER (RCS606F)

A60

2-16

Page 26

SECTION 3 ELECTRICAL

CONTENTS

TRAINING MASTER ................................................................................................................................... 3-2

1. NO SOUND FROM SPEAKERS ............................................................................................................ 3-2

2. NO SOUND IN AUX FUNCTION ............................................................................................................ 3-3

3. NO SOUND IN PORT. IN FUNCTION ................................................................................................... 3-4

4. NO SOUND IN IPOD FUNCTION .......................................................................................................... 3-5

5. NO SOUND IN AM/FM FUNCTION ....................................................................................................... 3-6

6. NO SOUND IN CD FUNCTION .............................................................................................................. 3-7

7. NO SOUND IN USB FUNCTION ............................................................................................................ 3-9

8. NO POWER .......................................................................................................................................... 3-10

ONE POINT REPAIR GUIDE ................................................................................................................. 3-11

1. NO POWER .......................................................................................................................................... 3-11

2. NO BOOTING WHEN POWER ON THE SET ..................................................................................... 3-13

3. VFD IS NOT DISPLAYED WHEN POWER ON THE SET ................................................................... 3-14

4. NO OPERATION OF MD ..................................................................................................................... 3-15

5. NO SOUND .......................................................................................................................................... 3-21

ELECTRICAL TROUBLESHOOTING GUIDE .................................................................................. 3-29

1. POWER SUPPLY ON SMPS BOARD ................................................................................................. 3-29

2. SYSTEM PART .................................................................................................................................... 3-33

3. NO AUDIO PART ................................................................................................................................. 3-34

4. DIGITAL AUDIO AMP CHECK ............................................................................................................. 3-39

WAVEFORMS ............................................................................................................................................. 3-40

WIRING DIAGRAM ................................................................................................................................... 3-43

BLOCK DIAGRAMS ................................................................................................................................. 3-45

1. OVERALL BLOCK DIAGRAM .............................................................................................................. 3-45

2. SMPS BLOCK DIAGRAM..................................................................................................................... 3-47

3. POWER BLOCK DIAGRAM ................................................................................................................. 3-49

CIRCUIT DIAGRAMS ............................................................................................................................... 3-51

1. SMPS CIRCUIT DIAGRAM .................................................................................................................. 3-51

2. MICOM CIRCUIT DIAGRAM ................................................................................................................ 3-53

3. PWM CIRCUIT DIAGRAM .................................................................................................................... 3-55

4. AMP CIRCUIT DIAGRAM ..................................................................................................................... 3-57

5. DSP CIRCUIT DIAGRAM ..................................................................................................................... 3-59

6. RF SERVO CIRCUIT DIAGRAM .......................................................................................................... 3-61

7. ADC CIRCUIT DIAGRAM ..................................................................................................................... 3-63

8. BEAT BOX CIRCUIT DIAGRAM .......................................................................................................... 3-65

9. VFD CIRCUIT DIAGRAM ..................................................................................................................... 3-67

10. VOLUME CIRCUIT DIAGRAM ............................................................................................................. 3-69

11. USB & MIC CIRCUIT DIAGRAM .......................................................................................................... 3-71

12. IPOD CIRCUIT DIAGRAM .................................................................................................................... 3-73

CIRCUIT VOLTAGE CHART ................................................................................................................. 3-75

PRINTED CIRCUIT BOARD DIAGRAMS ......................................................................................... 3-79

1. MAIN P.C.BOARD ................................................................................................................................ 3-79

2. SMPS P.C.BOARD ............................................................................................................................... 3-83

3. VFD P.C.BOARD .................................................................................................................................. 3-85

4. VOLUME P.C.BOARD .......................................................................................................................... 3-87

5. USB & MIC P.C.BOARD ...................................................................................................................... 3-89

6. IPOD P.C.BOARD ................................................................................................................................ 3-89

3-1

Page 27

TRAINING MASTER

1. NO SOUND FROM SPEAKERS

Are the speaker cables connected correctly

between the speaker terminals on the unit

and the speakers?

YES

Does the customer select correctly

the input function he or she wants to listen to?

YES

After pressing FUNCTION,

is “CD, USB, AUX, IPOD, AM or FM” displayed?

YES

Turn the master volume clockwise

for the volume up.

YES

NO

NO

NO

NO

Make sure to connect the cables to each specified

connector tightly on the unit.

Connect the woofer cables to the WOOF SYSTEM

connectors on the rear panel.

Make sure to connect some cables like A/V cables

and FM/AM antenna cables.

Make sure to select the desired input function

pressing FUCTION button.

The volume level LEDs around the master volume

will be turned on more and more

while turning it clockwise for the volume up.

Is there any sound from the selected input source?

(AUX IN, USB, TUNER or CD Disc)

YES

Are the sound spectrum level LEDs

on the left and right side of the front panel

being changed up and down

according to the sound input gain?

YES

The sound is output from the speakers.

YES

Sound OK

NO

NO

Refer to a device’s instruction manual

and then check if there is sound output from it

connecting another audio system.

The sound spectrum level LEDs will be turned on/off

repeatedly at regular intervals. The speakers cables

might be short-circuited with the chassis ground.

Be careful not to be shorted each other.

3-2

Page 28

TRAINING MASTER

2. NO SOUND IN AUX FUNCTION

Does the customer select correctly

the AUX function he or her wants to listen to?

YES

After pressing the FUNCTION,

is “AUX” displayed on VFD?

YES

Turn the master volume clockwise

for the volume up.

YES

Is there any sound

from the selected input source?

YES

NO

NO

NO

NO

Make sure to connect some cables

between the AUX IN jacks of the unit

and the Audio output jacks of a external Audio device.

Make sure to select the AUX IN function

pressing the AUX/IPOD/PORT. IN button.

The volume level LEDs around the master volume

will be turned on more and more

while turning it clockwise for the volume up.

Refer to a device’s instruction manual

and then check if there is sound output

from it connecting another audio system

Are the sound spectrum level LED’s

on the left and right side of the front panel

being changed up and down

according to the sound input gain?

YES

Are the speaker cables connected correctly

between the speaker terminals on the unit

and the speakers?

YES

The sound is output

from the speakers.

YES

Sound OK

NO

NO

The sound spectrum level LED’s will be turned on/off

repeatedly at regular intervals. A speaker cable

might be short-circuited with the chassis ground.

Be careful not to be shorted each other.

Make sure to connect the cables to each specified

connector tightly on the unit.

Connect the woofer cables to the WOOF SYSTEM

connectors on the rear panel.

3-3

Page 29

TRAINING MASTER

3. NO SOUND IN PORT. IN FUNCTION

Does the customer select correctly

the PORT. IN function he or her wants to listen to?

YES

Is “PORT. IN” displayed on VFD?

YES

Turn the master volume clockwise

for the volume up.

YES

Is there any sound

from the selected input source?

YES

NO

NO

NO

NO

Make sure to connect a cable

between the PORT. IN jack of the unit and the Audio

output jack of a portable device like a MP3 player.

Make sure to select the PORT. IN function

pressing the AUX/IPOD/PORT. IN button.

The volume level LEDs around the master volume

will be turned on more and more

while turning it clockwise for the volume up.

Refer to a portable device’s instruction manual

and then check if there is sound output

from it connecting another audio system.

Are the sound spectrum level LED’s

on the left and right side of the front panel

being changed up and down

according to the sound input gain?

YES

Are the speaker cables connected correctly

between the speaker terminals on the unit

and the speakers?

YES

The sound is output

from the speakers.

YES

Sound OK

NO

NO

The sound spectrum level LED’s will be turned on/off

repeatedly at regular intervals. A speaker cable

might be short-circuited with the chassis ground.

Be careful not to be shorted each other.

Make sure to connect the cables to each specified

connector tightly on the unit.

Connect the woofer cables to the WOOF SYSTEM

connectors on the rear panel.

3-4

Page 30

TRAINING MASTER

4. NO SOUND IN IPOD FUNCTION

Does the customer select correctly

the iPod function he or she wants to listen to?

YES

Does the customer use the compatible iPod?

YES

After displaying “Loading”,

is “IPOD” displayed on VFD?

YES

After selecting desired songs

using the user interface of a iPod or a iPhone,

press PALY button and turn the master volume

clockwise for the volume up.

YES

NO

NO

NO

NO

Make sure to put a iPod or a iPhone

on the docking system on the top of the unit.

Make sure that The unit supports the models

as follows/iPod nano 1 G, 2 G, 3 G, 4 G, 5 G, 6 G/

iPod classic/ iPod 4 G, 5 G/

iPod touch 2 G, 3 G, 4 G/ iPhone 3 G, 4 G/.

If “ERROR”message is displayed, make sure firmly to put a

iPod or a iPhone on the docking system on the top of the unit.

When the battery of a iPod or a iPhone is fully discharged, the

unit can not detect IPOD function, Please wait for a moment

and then it will work after charging a little.

The volume level LEDs around the master volume

will be turned on more and more

while turning it clockwise for the volume up.

Refer to a device’s instruction manual

and then check if there is sound output

from it connecting another audio system.

Is there any sound from iPod or iPhone?

NO

YES

Are the sound spectrum level LED’s

on the left and right side of the front panel

being changed up and down

according to the sound input gain?

NO

The sound spectrum level LED’s will be turned on/off

repeatedly at regular intervals. A speaker cable might

be short-circuited with the chassis ground.

Be careful not to be shorted each other.

YES

Are the speaker cables connected correctly

between the speaker terminals on the unit

and the speakers?

NO

Connect the woofer cables to the WOOF SYSTEM

Maker sure to connect the cables

to each specified connector tightly on the unit.

connectors on the rear panel.

YES

The sound is output from the speakers. Sound OK

YES

3-5

Page 31

TRAINING MASTER

5. NO SOUND IN AM/FM FUNCTION

Does the customer select correctly

the AM/FM function he or she wants to listen to?

NO

Make sure to connect AM/FM antennas

on the rear panel of the unit.

YES

Is “AM or FM” displayed on VFD?

NO

Make sure to select AM or FM function

pressing the FUNC button.

YES

After tuning a desired channel

using the TUNING± button,

is the sound quality good to listen to the music?

NO

To prevent noise pickup, keep the AM Loop

antenna away from the unit and other components.

Be sure to fully extend the FM wire antenna. After

connecting the FM wire antenna, keep it horizontal.

YES

Is the signal strength of the radio station too week? Make sure to tune the station manually.

NO

YES

Are the sound spectrum level LED’s

on the left and right side of the front panel

being changed up and down

according to the sound input gain?

YES

Are the speaker cables connected correctly

between the speaker terminals on the unit

and the speakers?

YES

The sound is output

from the speakers.

YES

Sound OK

NO

NO

The sound spectrum level LED’s will be turned on/off

repeatedly at regular intervals. A speaker cable might

be short-circuited with the chassis ground.

Be careful not to be shorted each other.

Make sure to connect the cables to each specified

connector tightly on the unit.

Connect the woofer cables to the WOOF SYSTEM

connectors on the rear panel.

3-6

Page 32

TRAINING MASTER

6. NO SOUND IN CD FUNCTION

Does the customer select correctly

the CD function he or she wants to listen to?

NO

Make sure to put on a CD disc on the tray.

YES

Is a CD disc put on the tray correctly? Make sure to insert the CD disc upside down.

NO

YES

Does the unit display “NO DISC” on VFD

when a disc is inserted on the tray?

NO

Place the disc with the label

or printed side facing upwards.

YES

Does the customer use

the supported mp3 or WMA music files on the disc?

NO

Check the playable disc.

Make sure that the file extensions

are “.mp3” or “.wma”.

YES

When the unit searches music files in a CD disc,

are the following messages displayed on VFD?

“SELECTED” “TRACKING #” and “TIME”

YES

After selecting a track number using the SCAN or

DISC# button, press PLAY button and turn the master

volume clockwise for the volume up.

YES

Is the sound quality good to listen to the music?

YES

Are the sound spectrum level LED’s

on the left and right side of the front panel

changed up and down

according to the sound input gain?

YES

NO

NO

NO

NO

Make sure to check

the supported MP3/WMA music file on the CD disc.

Refer to the owner’s manual.

The volume level LEDs around the master volume

will be turned on more and more

while turning it clockwise for the volume up.

Make sure to clean CD discs with a commercially

available cleaner. If the surface of the disc is polluted

or scratched, the sound quality can become bad

or the customer can not listen to the music.

The sound spectrum level LED’s will be turned on/off

repeatedly at regular intervals. A speaker cable

might be short-circuited with the chassis ground.

Be careful not to be shorted each other.

3-7

Page 33

YES

TRAINING MASTER

Are the speaker cables connected correctly

between the speaker terminals on the unit

and the speakers?

YES

YES

The sound is output from the speakers. Sound OK

NO

NO

NO

NO

Connect the woofer cables to the WOOF SYSTEM

Maker sure to connect the cables

to each specified connector tightly on the unit.

connectors on the rear panel.

3-8

Page 34

TRAINING MASTER

7. NO SOUND IN USB FUNCTION

Does the customer select correctly

the USB function he or she wants to listen to?

YES

Is “USB” displayed on VFD?

YES

Does the unit display “SELECTED” on VFD

when a USB is inserted into the USB port?

YES

Does the customer use the supported

mp3 or WMA music files on the disc?

YES

NO

NO

NO

NO

Make sure to insert a USB on the USB ports

on the bottom of the unit.

Make sure to select the USB function

pressing the CD/USB button.

When “No USB” is displayed,

make sure that the customer uses the recommended

USB which support USB2.0 or USB1.1.

Check if it is the playable disc or not.

Make sure that the file extensions are

“.mp3”or “.wma”.

When the unit searches music files in a USB,

are the following messages displayed on VFD?

“SELECTED” “TRACKING #” and “TIME”

YES

After selecting a track number using the SCAN button,

press PLAY button and turn the master volume

clockwise for the volume up.

YES

Are the sound spectrum level

on the left and right side of the front panel

being changed up and down

according to the sound input gain?

YES

Are the speaker cables connected correctly

between the speaker terminals on the unit

and the speakers?

YES

NO

NO

NO

NO

Make sure to check the compatible USB device

and the supported MP3/WMA music file requirement.

Refer to the owner’s manual.

The volume level LEDs around the master volume

will be turned on more and more

while turning it clockwise for the volume up.

The sound spectrum level will be turned on/off

repeatedly at regular intervals. A speaker cable

might be short-circuited with the chassis ground.

Be careful not to be shorted each other.

Make sure to connect the cables

to each specified connector tightly on the unit.

Connect the woofer cables to the WOOF SYSTEM

connectors on the rear panel.

3-9

Page 35

YES

TRAINING MASTER

The sound is output from the speakers. Sound OK

8. NO POWER

Is the power cord plugged

into a electrical outlet?

Does the Standby LED light

YES

in red color?

YES

NO

NO

NO

Make sure to plug the power cord of the unit

into a electrical outlet.

If the customer can not see the red light

on the front panel, the SMPS might have any problem.

Please solve the problem

referring to the service manual.

Is the Standby LED turned off

after pressing the Power button

on the remote control?

YES

Are the messages displayed

in the following order on VFD?

“HELLOW” “VOLUME 15” “FUNCTION”

YES

Is there any sound

from the speakers each input function?

YES

Power & Sound OK

NO

NO

NO

Replace the batteries with new ones

if the remote control doesn’t work.

The SMPS might be not able to supply the power

to drive the VFD.

Refer to the service manual to fix it.

Make sure to connect speaker cables.

3-10

Page 36

ONE POINT REPAIR GUIDE

1. NO POWER

If the unit doesn’t work by no power problem, repair the set according to the following

guide.

1-1. FUSE & BRIDGE DIODE

1-1-1. Solution

Please check and replace F901, BD901, TH901, TH903 on SMPS board.

1-1-2. How to troubleshoot (Countermeasure)

1) Check if the fuse F901 is open or short-circuit.

2) Check if the bridge diode DB901 is short-circuit by over current with a digital multi meter.

3) Check if the NTC thermistor TH901 and TH902 is normal or open.

1-1-3. Service hint (Any picture / Remark)

< F901 >

If F901 is not short-circuit,

replace it with a same

specifi cations one.

replace it with a new one.

< BD901 >

If BD901 is short-circuit,

< TH901, TH903 >

If TH901 or TH902 is open,

replace it with a new one.

3-11

Page 37

ONE POINT REPAIR GUIDE

NO POWER

If the unit doesn’t work by no power problem, repair the set according to the following

guide.

1-2. D951, ZD951

1-2-1. Solution

Please check and replace D951, ZD951 on SMPS board.

1-2-2. How to troubleshoot (Countermeasure)

1) Check the Anode-Cathod Voltage of D951 with a digital multi-meter, it is normally 0.2 ~ 0.3 V.

If it doesn’t have any voltage, it’s destroyed. Replace it with a new one.

2) Check if ZD951 is short-circuit.

If it is short-circuit, and then replace it with a new one.

1-2-3. Service hint (Any picture / Remark)

< SMPS schematic diagram >

3-12

Page 38

ONE POINT REPAIR GUIDE

2. NO BOOTING WHEN POWER ON THE SET

The set doesn’t work when press the power button on the front board or the remote

control.

2-1. FLASH MEMORY

2-1-1. Solution

Please check and replace IC101 on MAIN board.

2-1-2. How to troubleshoot (Countermeasure)

1) Check the 3.7VA to CN102, CN103, and CN104 in standby mode.

If there is no 3.7 VA, check the SMPS.

2) Check 5.6 V, 12 VA, FL+, FL- and 32 V when power on the set.

- If the set doesn’t work regardless of what the KEY1 changes high to low while pressing the power

button. X100 and X101 work normally but, if you can not power on the set, replace the IC101 with a new

one on the main board.

2-1-3. Service hint (Any picture / Remark)

w~yj{ys

OyX[`P

rlX

OX[P

XWW

O`UZ_ZWto¡P

XWX

OZYU^]_ro¡P

< Signal check point >

3-13

Page 39

ONE POINT REPAIR GUIDE

3. VFD IS NOT DISPLAYED WHEN POWER ON THE SET

When power on the set, any icons or characters on VFD are not displayed.

3-1. VFD

3-1-1. Solution

Please check and replace DIG301 on FRONT board.

3-1-2. How to troubleshoot (Countermeasure)

1) Check if 32 V, FL+ and FL- are output from SMPS to VFD via the MAIN board.

2) Check if the IC101 outputs VFD_RST, VFD_CLK, VFD_STB, and VFD_STB to the FRONT board.

3) Check if the VFD grid current amplifier circuit (Q301, Q303, Q304) on the FRONT board.

Check the drive signal to the transistor’s base.

If the control signals from VFD (TP302, TP303, TP304) isn’t output, replace VFD with a new one.

If the transistor doesn’t work, replace it.

3-1-3. Service hint (Any picture / Remark)

kpn ZWXG} mk

{w ZWYSG

{w ZWZSG

{wZW[

xZWX xZW[xZWZ

yZY^O{w ZW[P

xZWXGl

j G G SGG GGG

GU

j GGGGU

< Waveform of the grid current driver >

G

ZW} T

3-14

Page 40

ONE POINT REPAIR GUIDE

4. NO OPERATION OF MD

When no sound output in the CD function, you can not listen to music reading data

from a CD disc if the servo motors in MD don’t work. This step is for checking the

SPINDLE MOTOR among them.

4-1. SPinDLE MOTOR

4-1-1. Solution

Please check and replace IC407, IC408 on MAIN board.

4-1-2. How to troubleshoot (Countermeasure)

1) Check the SPDO signal from Pin16 of IC407.

If no signal, check 3.3V(RF) and X402.

2) Check the SP- & SP+ from IC408 to CN405 for driving SPinDLE motor. It is about 3.6 Vp-p.

If no signal, check +1.8 V and +5 V for IC408.

3) Check if the FFC cable is solidly connected between CN405 and MD.

4) Check the MD.

If the sPindle motor is sort-circuit or has any trouble, it can not rotate CD discs.

Please check the function after changing another MD.

4-1-3. Service hint (Any picture / Remark)

G

ZU]} T

zwTGju[W\

zwRGGju[W\

< Waveform of SP- & SP+

for driving SPinDLE motor >

zwR

YGGju[W\

zwT

XGGju[W\

< Signal check point >

pj[W_

3-15

Page 41

ONE POINT REPAIR GUIDE

NO OPERATION OF MD

When no sound output in the CD function, you can not listen to music reading data

from a CD disc if the servo motors in MD don’t work. This step is for checking the

SLED MOTOR among them.

4-2. SLED MOTOR

4-2-1. Solution

Please check and replace IC407, IC408 on MAIN board.

4-2-2. How to troubleshoot (Countermeasure)

1) Check the SLDO signal from Pin15 of IC407.

If no signal, check 3.3V(RF) and X402.

2) Check the SLED+ & SLED-from IC408 to CN405 for driving SPinDLE motor. It is about 2.9 Vp-p.

If no signal, check +1.8V and +5V for IC408.

3) Check if the FFC cable is solidly connected between CN405 and MD.

4) Check the MD.

If the sled motor is sort-circuit or has any trouble, it can not move the pickup module.

Please check the function after changing another MD.

4-2-3. Service hint (Any picture / Remark)

hG

YU`} T

zsTGju[W\

zwT G ju[W\

z sRGGju[W\

zwRGGju[W\

< Waveform of SLED- & SLED+

for driving SLED motor >

zsR

[GGju[W\

zsT

ZGGju[W\

< Signal check point >

pj[W_

3-16

Page 42

ONE POINT REPAIR GUIDE

NO OPERATION OF MD

When no sound output in the CD function, you can not listen to music reading data

from a CD disc if the servo motors in MD don’t work. This step is for checking the

TRAY MOTOR among them.

4-3. TRAY MOTOR

4-3-1. Solution

Please check and replace IC407, IC408 on MAIN board.

4-3-2. How to troubleshoot (Countermeasure)

1) Check TUR+ & TUR-signals from Pin56 & 57 of IC501 to IC406.

If no signal, check +5 V to IC406.

2) Check TUR_M+ & TUR_M- from IC406 to CN405 for driving TRAY motor. It is about 3.8 Vp-p.

If no signal, check +5 V to IC406. If it has any trouble, replace it with a new one.

3) Check if the FFC cable is solidly connected between CN405 and MD.

4) Check the MD.

If the tray motor is sort-circuit or has any trouble, it can not rotate the tray.

Please check the function after changing another MD.

4-3-3. Service hint (Any picture / Remark)

hG

ZU_} T

{| ytRG Gju[W\

{| ytTGju[W\

< Waveform of TUR_M±

for driving TRAY motor >

{|ytT

_GGju[W\

{|ytR

^GGju[W\

< Signal check point >

pj[W_

3-17

Page 43

ONE POINT REPAIR GUIDE

NO OPERATION OF MD

When no sound output in the CD function, you can not listen to music reading data

from a CD disc if the servo motors in MD don’t work. This step is for checking the

TRAY OPEN/CLOSE MOTOR among them.

4-4. TRAY OPEN / CLOSE MOTOR

4-4-1. Solution

Please check and replace IC407, IC408 on MAIN board.

4-4-2. How to troubleshoot (Countermeasure)

1) Check MOT_OPEN & MOT_CLOSE signals from Pin104 & 105 of IC501 to IC408.

If no signal, check +1.8 V & + 5 V to IC408.

2) Check LOAD± from IC406 to CN405 for driving the tray open / close motor. It is about 3.85 Vp-p.

If no signal, check +5 V to IC406. If it has any trouble, replace it with a new one.

3) Check if the FFC cable is solidly connected between CN405 and MD.

4) Check the MD.

If the tray motor is sort-circuit or has any trouble, it can not open or close the tray.

Please check the function after changing another MD.

4-4-3. Service hint (Any picture / Remark)

hG

ZU_\} T

tv{ vwlu

tv{ jsvzl

svT Gju[W[

svRGGju[W[

< Waveform

for driving TRAY open / close motor >

ju[W\

svR

XZGGju[W\

tv{vwlu

^GGpj[W_

tv{jsvzl

]GGpj[W_

svT

XYGGju[W\

< Signal check point >

pj[W_

3-18

Page 44

ONE POINT REPAIR GUIDE

NO OPERATION OF MD

When no sound output in the CD function, you can not listen to music reading data

from a CD disc if the pickup module in MD doesn’t work. This step is for checking the

LASER TRACKING ACTUATOR.

4-5. LASER TRACKING ACTUATOR

4-5-1. Solution

Please check and replace IC407, IC408 on MAIN board.

4-5-2. How to troubleshoot (Countermeasure)

The tracking actuator makes the laser beam be positioned in the center of a track on CD disc.

1) Check the TRD signal from Pin14 of IC407.

If no signal, check 3.3 V(RF) and X402.

2) Check T- & T+ from IC408 to CN404 for driving the tracking actuator.

If no signal, check +1.8 V and +5 V for IC408.

3) Check if the FFC cable is solidly connected between CN404 and MD.

4) Check the MD.

If the pickup module has any trouble, it can not move the laser beam on the left or right side.

Please check the function after changing another MD.

4-5-3. Service hint (Any picture / Remark)

{TGju[W[

{RGGju[W[

< Waveform of T±

for driving TRACKING actuator >

ju[W[

{R

ZG Gju[W[

{T

YG Gju[W[

< Signal check point >

3-19

Page 45

ONE POINT REPAIR GUIDE

NO OPERATION OF MD

When no sound output in the CD function, you can not listen to music reading data

from a CD disc if the pickup module in MD doesn’t work. This step is for checking the

LASER FOCUSING ACTUATOR.

4-6. LASER FOCUSING ACTUATOR

4-6-1. Solution

Please check and replace IC407, IC408 on MAIN board.

4-6-2. How to troubleshoot (Countermeasure)

The focusing actuator makes the laser beam keep a regular interval with the surface of a CD disc.

1) Check the FOD signal from Pin13 of IC407.

If no signal, check 3.3 V(RF) and X402.

2) Check F- & F+ from IC408 to CN404 for driving the focusing actuator.

If no signal, check +1.8 V and +5 V for IC408.

3) Check if the FFC cable is solidly connected between CN404 and MD.

4) Check the MD.

If the pickup module has any trouble, it can not move the laser beam on the top or bottom side.

Please check the function after changing another MD.

4-6-3. Service hint (Any picture / Remark)

{T

mRGGju[W[

mT Gju[W[

< Waveform of TR±

for driving FOCUSING actuator >

ju[W[

mR

[G Gju[W[

mT

XG Gju[W[

< Signal check point >

3-20

Page 46

ONE POINT REPAIR GUIDE

5. NO SOUND

There is no sound output in the CD FUNCTION, repair the set according to the following guide.

5-1. IN THE CD FUNCTION

5-1-1. Solution

Please check and replace IC501, IC602, IC801 on MAIN board.

5-1-2. How to troubleshoot (Countermeasure)

1) Check CD_BCK, CD_LRCK, & CD_DATA signals from IC407 to IC501.

If no signal, check if the RF & servo signals from MD is entered to IC407.

Refer to the “No operation of MD” guide on Item 4.

2) Check the following I2S signal flow. < I2S audio signal Interface >

- DAC_BCK: IC501_87Pin --> IC507_16Pin --> IC602_4Pin

- DAC_LRCK : IC501_88Pin --> IC507_5Pin --> IC602_4Pin (44.1 kHz)

- DAC_DATA : IC501_83Pin --> R817 next to IC01 --> IC602_6/9Pin

- DAC_MCLK : IC501_86Pin --> R818 next to IC801

If there is any trouble, check the power for each IC. The power is normal but, if the signal waveform to

the IC is distorted or no signal, replace it with a new one.

3) Check if “Digital audio AMP block” on Item 5-2 is normal.

5-1-3. Service hint (Any picture / Remark)

{T

IC407

BU9543KV

IC501

MLC9800

BEAT_ DATA DAC_MCLK

IC801

FS502B

BEAT BOX

DAC_BCK

DAC_LRCK

IC602

PS9850

PWM

< I2S Signal Flow >

AMP IC

TAS5631

khjtjsrGOX]U`Zto¡P

khjijrGOXU[to¡ P

khjkh{h

khjsyjrGO[[UXro¡ P

< Waveform of I2S audio interface signals >

3-21

Page 47

ONE POINT REPAIR GUIDE

NO SOUND

There is no sound output by DIGITAL AUDIO AMP DAMAGE, repair the set according

to the following guide.

5-2. BY DIGITAL AUDIO AMP DAMAGE (IN ALL FUNCTIONS)

5-2-1. Solution

Please check and replace IC701, IC702, IC703 on MAIN board.

5-2-2. How to troubleshoot (Countermeasure)

1) Check FL±, FR±, RL±, RR±, SW1±, & SW2± signals from IC602 to IC701, 702 & 703 each input

function.

If no signal, check if I2S audio signals are entered to IC602.

Refer to “I2S audio signal interface” on Item 5-1.

2) Check PVDD_48V.

If 48 V is abnormal, check the SMPS.

3) Check +12 for driving the gate of AMP IC.

a. All the powers are normal, but if +12 V is low, there is possible for AMP IC to be damaged.

b. Remove a ferrite bead among FB703, FB707 and FB713 one by one.

When removed a ferrite bead, if +12 V is recovered, the IC connected to it was damaged.

c. Replace the IC with a new one.

4) Check the impedance between SPK+ & GND and SPK- & GND.

a. If the impedance is 0 Ω, the IC must be damaged.

b. After removing the heat sink, replace it with a new one.

Comments !!

If a AMP IC among three is damaged, “AMP_PDN” to R103 changes HIGH to LOW at regular intervals.

The sound is not output by AMP power down function.

5-2-3. Service hint (Any picture / Remark)

pj^WX pj^WY pj^WZ

ilh k

< Signal check point >

yXWZOhtwwkuP

khjkh{h

pjXWX

3-22

Page 48

ONE POINT REPAIR GUIDE

NO SOUND

There is no sound output in the USB FUNCTION, repair the set according to the following guide.

5-3. IN THE USB FUNCTION

5-3-1. Solution

Please check and replace IC501, IC504 on MAIN board & IC3U01 on USB board.

5-3-2. How to troubleshoot (Countermeasure)

1) Check +5VU to USB board.

If the USB LEDs are turned on, the voltage is okay, if so not, check +5.6 V to Pin8 of CN602.

2) Check USB D± from main board to USB board.

a. Check USB_HUB_DN/DP signals to IC501(Pin116, 117)

b. Check USB1/2_DN/DP signals from IC504 to CN602 (Pin10, 11, 13, & 14)

If there is any trouble, check the power for each IC. The power is normal but , if the signal waveform to

the IC is distorted or no signal, replace it with a new one.

3) Check if “Digital audio AMP block” on item 5-2 is normal.

5-3-3. Service hint (Any picture / Remark)

{T

IC504

USB2512B

ADC_D ATADA C_MCLK

IC501

MLC9800

DAC_DAT A DAC_MCLK

IC801

FS502B

BEAT BOX

< USB function signal fl ow >

USB_D

DAC_BCK

DAC_L RCK

BEAT_ DATA

USB

Board

IC602

PS9850

USB

AMP IC

TAS5631

PWM

kT G XWG Gju]WY

kRGGGXXGGju]WY

< Waveform of USB D± signal >

3-23

Page 49

ONE POINT REPAIR GUIDE

NO SOUND

There is no sound output in the AUX FUNCTION, repair the set according to the following guide.

5-4. IN THE AUX FUNCTION

5-4-1. Solution

Please check and replace IC202 on MAIN board.

5-4-2. How to troubleshoot (Countermeasure)

1) Check AUX_L/R signals to IC202 (Pin7, 8).

2) Check if ADC_BCK, ADC_LRCK, & DAC_MCLK are entered from IC501 to IC202.

3) Check if ADC_DATA is entered from IC202 to IC501.

If no signal, check +5 V & +3.3 V(ADC) for IC202. If is NG, replace it a new one.

4) Check the following I2S signal flow from IC501 to IC602. (Refer to Item 5-1.)

If there is any trouble, check the power for each IC. The power is normal but, if the signal waveform to

the IC is distorted or no signal, replace it with a new one.

5) Check if the digital audio AMP block is okay. Refer to “Digital Audio AMP” guide on Item 5-2.

If AMP is damaged, replace it with a new one.

5-4-3. Service hint (Any picture / Remark)

{T

IC202

CS5346

ADC_D ATADAC_MCLK

IC501

MLC9800

DAC_DAT A DAC_MCLK

IC801

FS502B

BEAT BOX

< AUX function signal fl ow >

AUX_ L/R

DAC_BC K

DAC_L RCK

BEAT_ DATA

AUX

IC602

PS9850

PWM

AMP IC

TAS5631

pjYWY

h kj k h{hGG GyYX\

hkjijrGGyYX]

kRGGGXXGGju]WY

< Signal check point >

h| sGGyYWYh|yGGyYWZ

hkjtjsrGGyYYX

hkjsyjrGGyYX`

3-24

Page 50

ONE POINT REPAIR GUIDE

Y

y

`

NO SOUND

There is no sound output in the IPOD FUNCTION, repair the set according to the following guide.

5-5. IN THE IPOD FUNCTION

5-5-1. Solution

Please check and replace IC201, IC202, IC203 on MAIN board.

5-5-2. How to troubleshoot (Countermeasure)

1) Check USB VBUS_+5V to Pin3 of CN201 after inserting the iPod to IPOD Docking System.

If no power, check if IPOD_P_CTRL to Pin3 of IC203 change Low to High.

2) Check if IPOD Audio L/R signals are entered from Pin11 & 12 of CN201 to Pin10 & 6 of IC201.

3) Check if the IPOD Audio L/R that some noise is removed to IC201 are output from Pin1 & 5 of IC201.

If no signal, replace the IC with a new one.

4) Check IPOD_L/R signals from 1 & 5 of IC201 to IC202(Pin26, 27).

5) Check if ADC_BCK, ADC_LRCK & DAC_MCLK are entered from IC501 to IC202.

6) Check if ADC_DATA is entered from IC202 to IC501.

If there is no signal, check +5 V & +3.3 V(ADC) for IC202. If is NG, replace it a new one.

7) Check the following I2S signal flow from IC501 to IC602. (Refer to Item 5-1.)

If there is any trouble, check the power for each IC. The power is normal but , if the signal waveform to

the IC is distorted or no signal, replace it with a new one.

8) Check if the digital audio AMP block is okay. Refer to “Digital Audio AMP” guide on Item 5-2.

If an AMP is damaged, replace it with a new one

5-5-3. Service hint (Any picture / Remark)

{T

IC202

CS5346

IC501

MLC9800

DAC_DAT A DAC_MCLK

IC801

FS502B

BEAT BOX

IPOD_ L/R

ADC_D ATADAC_MCLK

DAC_BC K

DAC_L RCK

BEAT_ DATA

iPod

IC602

PS9850

PWM

< iPod function signal fl ow >

AMP IC

TAS5631

hkjtjsrGGyYYX

pjYWY

hkjs

GyYX

pw vksGGy YY]X hkjijrGGy

< Signal check point >

3-25

Page 51

ONE POINT REPAIR GUIDE

NO SOUND

There is no sound output in the PORT. IN FUNCTION, repair the set according to the

following guide.

5-6. IN THE PORT. IN FUNCTION

5-6-1. Solution

Please check and replace IC202 on MAIN board.

5-6-2. How to troubleshoot (Countermeasure)

1) Check PT_L/R signal from Main board to USB board.

2) Check if PT_LR is entered from Pin1 & 3 of CN3U01 to Pin1 & 3 to CN502.

3) Check POT_L/R signals to IC202(Pin21, 22).

4) Check if ADC_BCK, ADC_LRCK, & DAC_MCLK are entered from IC501 to IC202.

5) Check if ADC_DATA is entered from IC202 to IC501.

If no signal, check +5 V & +3.3 V(ADC) for IC202. If is NG, replace it a new one.

6) Check the following I2S signal flow from IC501 to IC602. (Refer to Item 5-1.)

If there is any trouble, check the power for each IC. The power is normal but , if the signal waveform to

the IC is distorted or no signal, replace it with a new one.

7) Check if the digital audio AMP block is okay. Refer to “Digital Audio AMP” guide on Item 5-2.

If AMP is damaged, replace it with a new one

5-6-3. Service hint (Any picture / Remark)

{T

IC202

CS5346

IC501

MLC9800

DAC_DAT A DAC_MCLK

IC801

FS502B

BEAT BOX

< PORT. IN function signal fl ow >

ADC_D ATADAC_MCLK

POT_L/R

DAC_BC K

DAC_L RCK

BEAT_ DATA

USB

Board

IC602

PS9850

PWM

POT . IN

AMP IC

TAS5631

w{sGGYX

w{yGGYY

kRGGGXXGGju]WY

h| sGGyYWY

hkjtjsrGGyYYX

pjYWY

h kj k h{hGG GyYX\

hkjijrGGyYX]

hkjsyjrGGyYX`

< Signal check point >

3-26

Page 52

ONE POINT REPAIR GUIDE

NO SOUND

There is no sound output in the TUNER FUNCTION, repair the set according to the

following guide.

5-7. IN THE TUNER FUNCTION

5-7-1. Solution

Please check and replace IC202, TU101 on MAIN board.

5-7-2. How to troubleshoot (Countermeasure)

1) Check if TUNER_LR is entered from Pin1 & 3 of T1U01 to IC202(Pin23, 24).

If no signals, Check +3.3 V for Tuner power.

Check if the Tuner control signals (CLK, DAT, CE, RST, GPO2) are entered from IC101 to TU101.

If it doesn’t work, replace TUNER with a new one.

2) Check if ADC_BCK, ADC_LRCK, & DAC_MCLK are entered from IC501 to IC202.

3) Check if ADC_DATA is entered from IC202 to IC501.

If no signal, check +5 V & +3.3 V(ADC) for IC202. If is NG, replace it a new one.

4) Check the following I2S audio signal flow from IC501 to IC602. (Refer to Item 5-1.)

If there is any trouble, check the power for each IC. The power is normal but, if the signal waveform to

the IC is distorted or no signal, replace it with a new one.

5) Check if the digital audio AMP block is okay. Refer to “Digital Audio AMP” guide on Item 5-2.

If AMP is damaged, replace it with a new one.

5-7-3. Service hint (Any picture / Remark)

{T

IC202

CS5346

IC501

MLC9800

DAC_DAT A DAC_MCLK

IC801

FS502B

BEAT BOX

< TUNER function signal fl ow >

ADC_D ATADAC_MCLK

TUNER _L/R

DAC_BC K

DAC_L RCK

BEAT_ DATA

IC602

PS9850

PWM

TUNER

AMP IC

TAS5631

{|ulysG

GYZ

{|ulyyG

GY[

h kj k h{hGG GyYX\

hkjijrGGyYX]

kRGGGXXGGju]WY

< Signal check point >

h| sGGyYWY

hkjtjsrGGyYYX

pjYWY

hkjsyjrGGyYX`

3-27

Page 53

ONE POINT REPAIR GUIDE

NO SOUND

There is no sound output in the MIC IN FUNCTION, repair the set according to the

following guide.

5-8. IN THE MIC IN FUNCTION

5-8-1. Solution

Please check and replace IC603, IC605 on MAIN board.

5-8-2. How to troubleshoot (Countermeasure)

1) Check MIC_SIG signal to Pin 27 of CN104.

If no signal, Check the signal to Pin 5 of CN3M01 on the MIC board. Check it from Pin5 of CN302 on

the VOLUME board. Check if the signal is entered from Pin3 of CN301 to MAIN board.

2) Check if MIC_SIG is entered from Pin27 of CN104 to Pin3 to IC605 (MIC AMP).

3) Check if the amplified signal is entered from Pin4 of IC605.

If no signal output, check +12 V for IC605, replace IC605 with a new one if it has a problem.

4) Check if MIC_BCK & MIC_LRCK is entered from IC507 to IC603 and DAC_MLCK from IC501 to IC603.

Check if MIC_DATA is entered from Pin 9 of IC603I to Pin 7 of IC602.

If no signal, check +5 V & +3.3 V for IC603. If it is abnormal, change replace it a new one.

6) Check the following I2S signal flow from IC603 to IC602.

If there is any trouble, check the power for each IC. If the signals are abnormal, replace it a new one.

7) Check if the digital audio AMP block is okay. Refer to “Digital Audio AMP” guide on Item 5-2.

If AMP is damaged, replace it with a new one.

5-8-3. Service hint (Any picture / Remark)

IC603

AK5358

MLC9800

DAC_DAT A DAC_MCLK

BEAT BOX

MIG_SIG

MIC_DATADAC_MCLK

IC501

IC801

FS502B

< MIC IN function signal fl ow >

IC605

S4308

DAC_BC K

DAC_L RCK

BEAT_ DATA

Board

IC602

PS9850

PWM

MIC

AMP IC

TAS5631

MIC IN

zkv|{X

Gy][\

tpjsyjrGGy][[

< Signal check point >

tpjz pnGGGXMYG

hkjtjsrGGy]_Y

tpjijrGGy][Z

3-28

Page 54

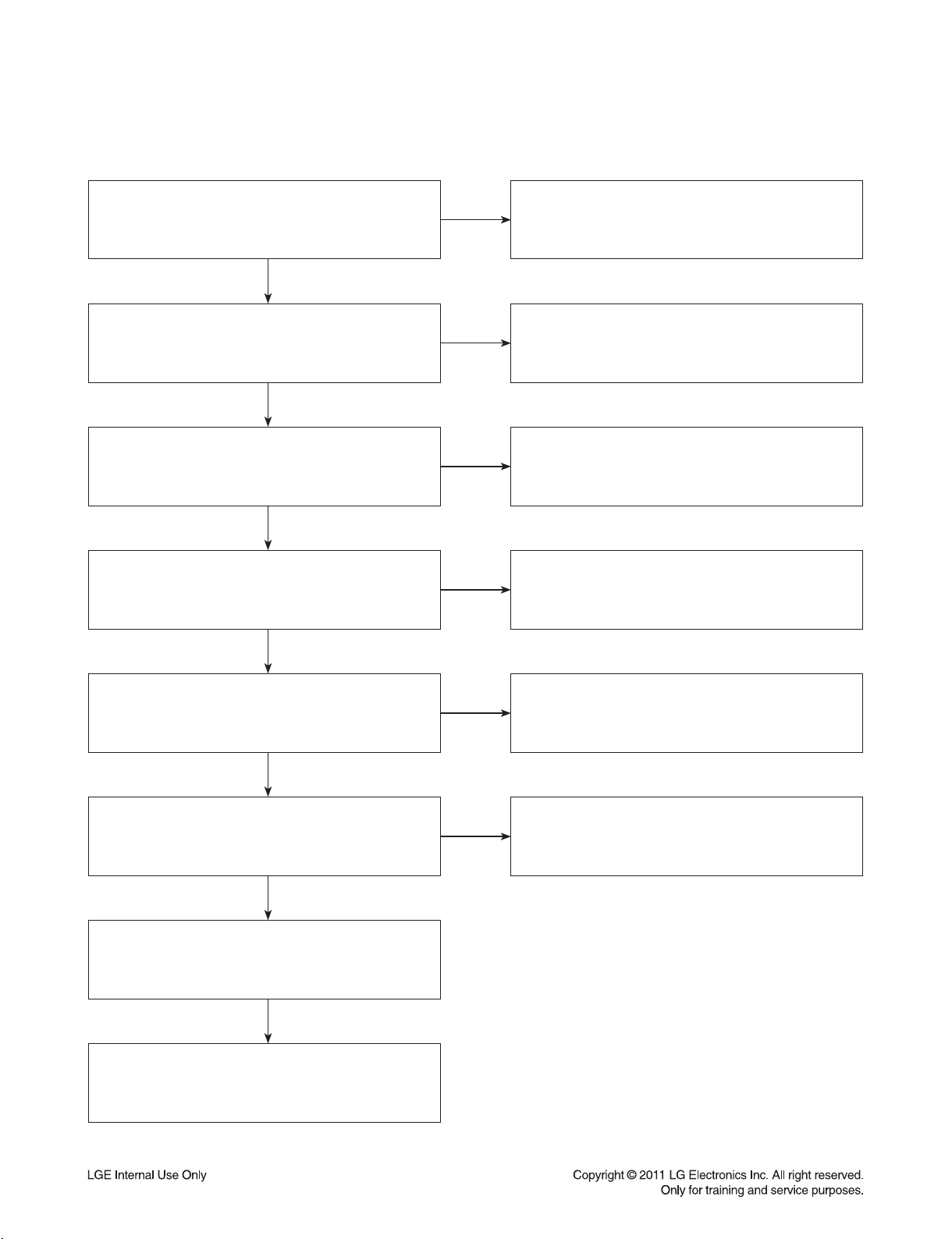

ELECTRICAL TROUBLESHOOTING GUIDE

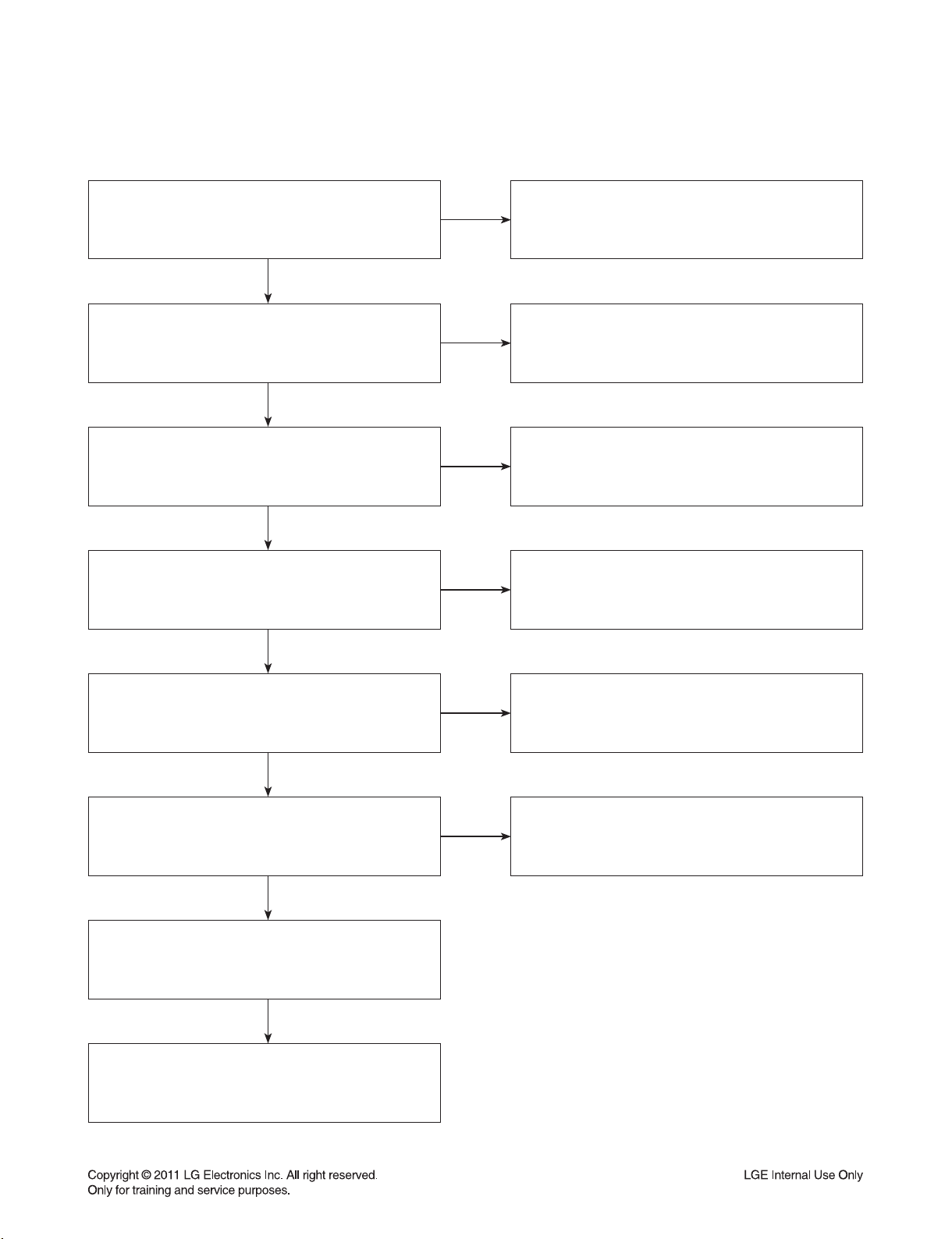

1. POWER SUPPLY ON SMPS BOARD

No output 3.7 / 5.6 VA

F901 normal?

YES

BD901 normal?

YES

D904 normal?

YES

IC934 normal?

YES

D933, D937 normal?

YES

NO

NO

NO

NO

NO

Replace F901 (same fuse).

Replace BD901.

Replace D904.

Replace IC934.

Replace D933, D937.

Power line of MAIN PCB is short.

3-29

Page 55

ELECTRICAL TROUBLESHOOTING GUIDE

No output 12 V

F901 normal?

YES

BD901 normal?

YES

D904 normal?

YES

D934, D935 normal?

YES

IC931 normal?

YES

NO

NO

NO

NO

NO

Replace F901 (same fuse).

Replace BD901.

Replace D904.

Replace D934, D935.

Replace IC931.

Power Line of Main PCB is short.

3-30

Page 56

ELECTRICAL TROUBLESHOOTING GUIDE

No output FL+/FL-

P-CTRL OK?

YES

D931, D932

OK?

YES

ZD931 OK?

YES

FR931 short?

YES

Check soldering of PN901.

NO

NO

NO

NO

Check 3.3 V Output & P-CTRL.

Replace D931, D932.

Replace ZD931.

Replace FR931.

3-31

Page 57

ELECTRICAL TROUBLESHOOTING GUIDE

No AMP Output

Is the

VCC supplied to

IC911 Pin7?

YES

ZD912, ZD913

OK ?

YES

D951, D952

OK ?

YES

Check soldering of CN902.

NO

NO

NO

P-CTRL OK?

YES

Q901,D904

OK?

YES

Replace ZD912, ZD913.

Replace D951, D952.

NO

NO

Check 3.3V & P-CTRL.

Replace D914/ Q900/ PC901.

3-32

Page 58

ELECTRICAL TROUBLESHOOTING GUIDE

2. SYSTEM PART

Power on.

“HELO”

Display on FLD

OK?

YES

Volume LED

(LD302~LD322)

Turn on?

NO

NO

CN301

cable connection

OK?

YES

CN301

Pin27, 28, 29 power

OK?

YES

Pin20, 21, 22 data signal

CN301

OK?

YES

Q301, 303, 304

grid voltage OK?

CN301 Pin18

+12 V OK?

NO

NO

NO

NO

NO

Check FFC cable (Pin29).

Check SMPS board.

Check MAIN board.

Replace DIG301.

Check SMPS board.

YES

When turn

the volume, count is

change?

YES

FRONT board OK.

NO

YES

CN301 Pin7, 9, 12

I2C data OK?

YES

Replace LED

(LD302 ~ LD322).

CN301 Pin13, 14

signal OK?

YES

Check MAIN board.

3-33

NO

NO

Check MAIN board.

Check FFC cable.

Page 59

ELECTRICAL TROUBLESHOOTING GUIDE

3. NO AUDIO PART

CD FUNCTION

Can

disc insert?

YES

Disc reading OK?

YES

Pin100,101,102 I2S input

IC501

signal OK?

NO

NO

LOAD +- ok ?

YES

Is motor impedance

about 12 Ω?

OPU driving

(Focusing & Tracking) OK?

Check OPU.

(Pick-up module)

NO

NO

NO

NO

Is motor_open/ close OK?

(IC408 Pin9,10)

YES

Check IC301.

Check Loading motor.

Check IC408.

NO

Focusing/

Tracking/ Sled Signal

OK?

YES

PD(CN404 Pin5)

about 180 mV?

YES

Pin34,35,36 I2S output

IC407

signal OK?

YES

Pin100,101,102 I2S input

IC501

signal OK?

YES

A

NO

NO

IC407

RF & Servo signal

OK?

YES

Check IC501.

3-34

NO

Check FFC cable

to CN404, CN405.

Page 60

ELECTRICAL TROUBLESHOOTING GUIDE

USB play

Pin116,117 USB_D output

IC501

signal OK?

YES

USB,IC502 Pin1,2,3,4 USB_D

When insert

signal OK?

YES

A

AUX

NO

NO

Check IC501.

IC3U01

USB power +5 V

OK?

YES

NO

Replace IC3U01.

Pin7,8 AUX input signal

IC202

OK?

YES

IC202

Pin42,43,44 I2S input signal

OK?

YES

IC202

Pin41 ADC data output signal

OK?

YES

A

NO

NO

NO

Check audio cable.

Check IC501.

Replace IC202.

3-35

Page 61

ELECTRICAL TROUBLESHOOTING GUIDE

POT. IN

Pin21,22 POT. IN input signal

IC202

OK?

YES

IC202

Pin42,43,44 I2S input signal

OK?

YES

IC202

Pin41 ADC data output signal

OK?

YES

A

iPod

NO

NO

NO

Check USB board.

Check IC501.

Replace IC202.

Pin25,26 iPod input signal

IC202

OK?

YES

Pin42,43,44 I2S input signal

IC202

OK?

YES

Pin41 ADC data output

IC202

signal OK?

YES

A

NO

NO

NO

Pin4 USB_VBUS 5 V

IC203

OK?

YES

Check IC501.

Replace IC202.

3-36

NO

Check USB_VBUS of IC203.

Page 62

ELECTRICAL TROUBLESHOOTING GUIDE

TUNER

Pin21,22 TUNER_L/R input

IC202

signal OK?

YES

Pin42,43,44 I2S input

IC202

signal OK?

YES

Pin41 ADC data output

IC202

signal OK?

YES

A

NO

NO

NO

TU101

TUNER_L/R output

signal OK?

YES

Check IC501.

Replace IC202.

NO

Check +3.3 V of TU101.

3-37

Page 63

ELECTRICAL TROUBLESHOOTING GUIDE

A

Pin83,87,88 I2S data output

IC501

signal OK?

YES

Pin2,17 DAC_BCK/LRCK input

IC507

signal OK?

YES

Pin7,14 BEAT_LRCK/BCK output

IC507

signal OK?

YES

Pin83 BEAT_DAC_DATA output

IC501

signal OK?

YES

Pin83 BEAT_DAC_DATA output

IC501

signal OK?

YES

NO

NO

NO

NO

NO

Replace IC501.

Check IC507.

Replace IC507.

Check IC501.

Check IC501.

IC801

I2S input signal

OK?

YES

BEAT_DATA output signal

IC801

OK?

YES

B

NO

NO

Check IC501.

Check IC801.

3-38

Page 64

ELECTRICAL TROUBLESHOOTING GUIDE

4. DIGITAL AUDIO AMP CHECK

B

IC602

I2S input signal

OK?

YES

PWM data output signal

IC602

OK?

YES

IC701

FL±/FR± input signal

OK?

YES

+12 VA, +48 V

Power voltage OK?

NO

NO

NO NO

Check IC602.

NO

Check IC801 & IC501.

Replace IC602.

SW1±/SW2± input signal

IC702

OK?

YES

Check SMPS.

Check IC602.

RL±/RR± input signal

IC703

OK?

YES

YES

SPK_FL±/FR± output

Check L701, L702, L704, L705. Check L708, L709, L710. Check L711, L714, L715, L717.

IC701

OK?

YES YES YES

Replace IC701. Replace IC702. Replace IC703.

NO NO

IC702

SPK_SW output

OK?

SPK_RL±/RR± output

IC703

OK?

NO

YES YES YES

Check speaker cable connection.

OK

3-39

Page 65

WAVEFORMS

1. WAVEFORM OF SP- & SP+ FOR

DRIVING SPINDLE MOTOR

zwT

zwR

2. WAVEFORM OF SL- / SL+ FOR

DRIVING SLED MOTOR

zsT

zsR

3. WAVEFORM OF TUR_M+ & TUR_

M- FOR DRIVING TRAY MOTOR

{|ytR

ZUY}

{|ytT

4. WAVEFORM OF LO- & LO+ FOR DRIVING PICKUP MODULE UP/DOWN MOTOR

svT

tv{jsvzl

svR

tv{vwlu

3-40

Page 66

5. WAVEFORM OF RF SERVO 6. WAVEFORM OF VFD GRID CURRENT DRIVER

joXa yZY^O {wZW[P

joYa xZWXGl

7. WAVEFORM OF USB_D±

kT

kR

3-41

Page 67

MEMO

3-42

Page 68

WIRING DIAGRAM

tkGtljoh

tkGwpjr|w

16P

tkGz~p{jo

18P

pwvkVpwovul

ju`WY

ju[W[

ju[W\

juYWX

{|uly

ju\WY

spulGv|{

h

pu

mVs mVy

juXWX

juXWY

thpuGwji

10P15P

juZtWX

|ziGwji

14P

juZ|WX

3P

15P

juZWY

19P

juZ}WX

juXWZ

29P

juZWX

juXW[

ju`WX

ju`WY

myvu{Gwji ztwzGwji

3-43 3-44

Page 69

BLOCK DIAGRAMS

pwvk

k

k

l

jrG

G

tljohupz

t

1. OVERALL BLOCK DIAGRAM

P/UP

M

A,B,C,D,E,F

PD

LD

m·V{y·

SLED

SPINs

s

LOAD

TUR_Ms

s

IC408

S3053

Motor

Drive

OPEN/CLOSE/LIMIT/UPDN/D_SENSE

IC502 SDRAM

IC503 FLASH

SPDO/SLDO/FOD/TRD

MOT_MUTE/CLOSE/OPEN

IC406

TUR ·

S8082

DRM_WEN/CAS/RAS/SEL/CLK/CKE

M00_15/A00_16

SF_DI/DO

SF_CS/SCK

MICOM_CS/DO/DI/

CLK/MAIN_RESET

IC407

BU9543KV

RF+ SERVO DSP

CD_RST

CD_DIN_DOUT

SUBSYQ;

IC501

MLC9800

MCS LOGIC

CD_R/W

BUSY; CD_16M

/LRCK/DATA

CD_MCK/BCK

USB_Ds

USB_RESET/SCL/SDA

CP_RESET/SCL/SDA

IPOD_PCTRL/RX/TX/DET/READAY

USB1

USB2

USB HUB

USB2512B

ADC_EDID_PWM_DATA/CLK

DAC_MCLK

ADC_DATA

DAC_BCK/LRCK

TUNER_SCLK/SDIO/RST/GPIO2/SEN

IC504

CP for

IPOD

IC200

CS5346

IPO L/R

POT_L/R

AUX_L/R

TUNER_L/R

iPod

p

IPO

AUDIO L/R

IC251

NJM2794

POT. IN

AUX

TU101

TUNER

VFD

DIG301

MIC

AUDIO

OUT

REMOCON/KEY/

IC100

EEPROM

VFD_STB/CLK/DO/RST

CLK/DATA

IC501

S4308

IC101

MICOM

LC87F085

LBT_RX/TX/RST

SPEANA

MIC_SIG

AUDIO OUT_L/R

LBT_DATA

LBT_CLK

IC801

FS503B

BEAT BOX

LBT_DATA

LBT_BCK

/LBT_LRCK

IC603

AK5358

DRV603

SDOUT1

AMP_OTW/SD/CLIP/READY

AMP_PDN

FL·

FR ·

IC602

RL·

PS9850

PWM

RR ·

SW1·

SW2

·

IC701

AMP IC

TAS5631

IC702

AMP IC

TAS5631

IC702

AMP IC

TAS5631

F/L

F/R

R/L

R/R

SW1

SW2

300Wx2

150Wx2

300Wx2

3-45 3-46

Page 70

2. SMPS BLOCK DIAGRAM

Rectifier Circuit

(Bridge,

CAPACITOR)

STR-A6252 for

Main Power

MAIN

TRANS

}mk

vwhtwVmhu

p w v kGV G|z iGV Gtw lnV Gk j kj

}mk

|Tj

ZY

XY}

\U]}

[U\}

ZU^}h

wTj{ys

}rr

msORVTP

Filter

Section

(Varistor,

Resistor,

Line Filter

Thermistor)

AC

Snubber

AMP Power &

UC3844 for

Main Power

FET

TRANS

MAIN

&

AMP

[_}

Digital

Power

AMP

FL

FR

SW

C

SL

SR

3-47 3-48

Page 71

3. POWER BLOCK DIAGRAM

SMPS

+12V

+3.7VA

+5.6V

IC605

MIC AMP

S4308

D102

D104

D101

TJ3965D

278P33

IPOD PWR

LM39102D

KIA7027

IC601

LDO