Page 1

LG

Synchro

Air Conditioner

SERVICE MANUAL

LG

CAUTION

website http://www.lgservice.com

e-mail http://www.lgeservice.com/techsup.html

• BEFORE SERVICING THE UNIT, READ THE SAFETY

PRECAUTIONS IN THIS MANUAL.

• ONLY FOR AUTHORIZED SERVICE PERSONNEL.

Page 2

2 Synchro Air Conditioner

Synchro Air Conditioner Service Manual

TABLE OF CONTENTS

Model Number Nomenclature......................................................................3

Safety Precautions .......................................................................................4

Model Names...............................................................................................11

External Appearance..................................................................................12

Dimensions .................................................................................................13

Product Specifications...............................................................................21

Combination table ......................................................................................25

Installation...................................................................................................26

Operation ....................................................................................................61

Control Devices and Function...................................................................76

Schematic Diagram ....................................................................................89

Piping Diagrams .......................................................................................100

Troubleshooting Guide.............................................................................105

(3-way) Valve ............................................................................................126

Function ....................................................................................................130

Exploded View & Replacement Parts List..............................................147

Page 3

Service Manual 3

Model Number Nomenclature

Model Number Nomenclature

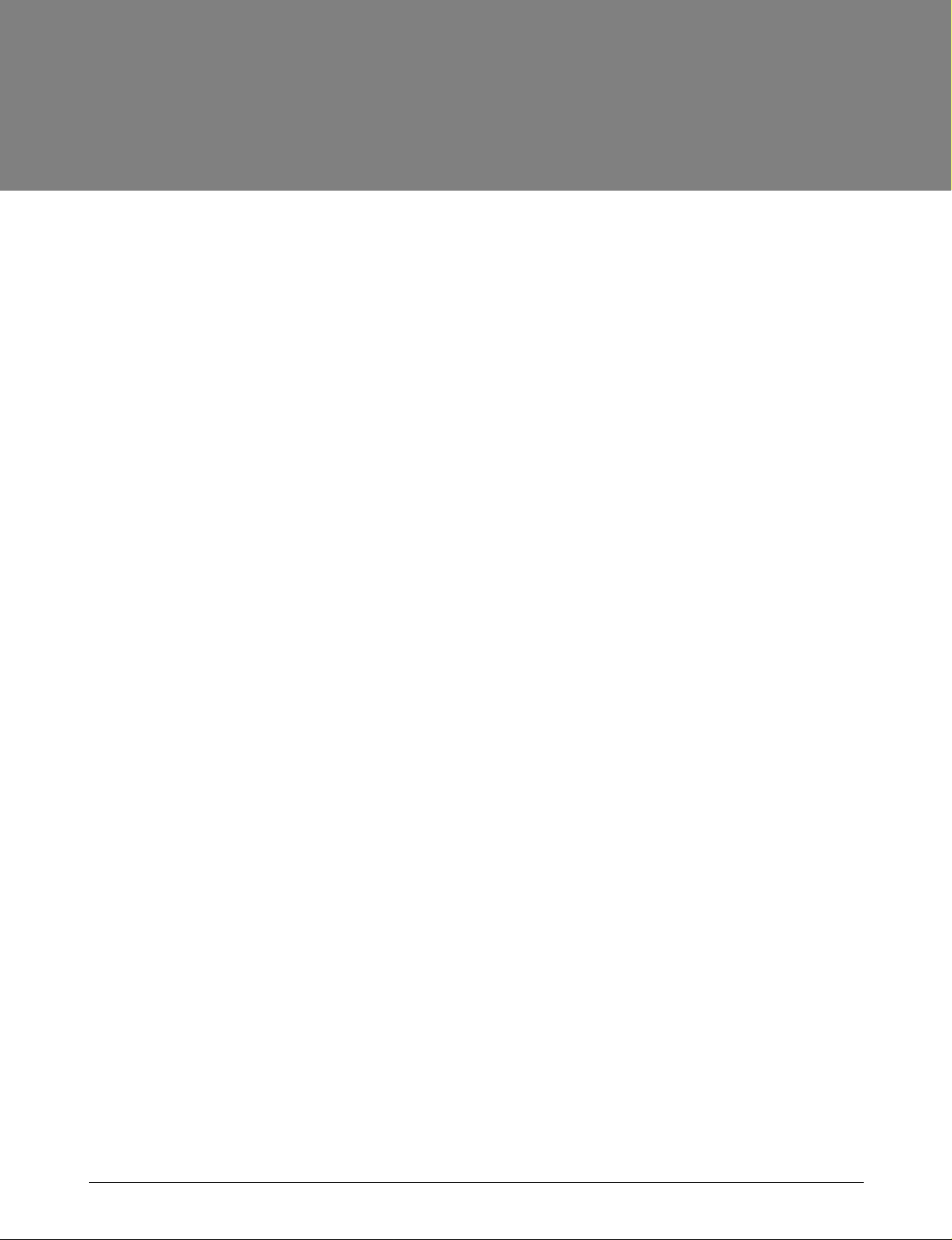

Indoor Unit

Outdoor Unit

A T N H 18 6 E L F B

Serial Number

Function

A : Basic

E : E/Grille

F : Plasma + Elevation grille

Panel type

Cassette L : Basic panel, W : Wooden panel

Duct : L

Chassis type

Cassette : E/F/D, Convertible : E/B, Duct : H/G/R

Electrical Rating

6 : 1Ø 220-240V ,50Hz

Nominal Cooling Capacity in Btu/h

Ex)18,000Btu/h '18', 24,000Btu/h '24'

Model Type

H : Heat Pump

Unit Type

N : Indoor Unit U : Outdoor Unit

Indoor Unit Type

T : Ceiling Cassette

V : Ceiling&Floor(Convertible)

B : Ceiling Concealed Duct

Refrigerent Type

A : R410A, L : R22

A U U H 100 8 0

Air Discharge Type

0 : Top discharge, A : Side discharge

Electrical Rating(Volt/Hertz/Phase)

1 : 115 / 60 / 1 2 : 220 / 60 / 1

3 : 208-230 / 60 / 1 5 : 200-220 / 50 / 1

6 : 220-240 / 50 / 1 8 : 380-415 / 50 / 3

Nominal Cooling Capacity in Btu/h

Ex)72,000Btu/h '72', 100,000Btu/h '100'

Model Type

W : DC Inverter Heat Pump(MPS Inverter)

H : Conventional Heat Pump(MPS Variable)

Unit Type

N : Indoor Unit, U : Outdoor Unit

Indoor Unit Type

2/3/4 : Multi Room, U : Universal, B : Duct, T : Cassette

Refrigerent Type

A : R410A, L : R22

Page 4

4 Synchro Air Conditioner

Safety Precautions

Safety Precautions

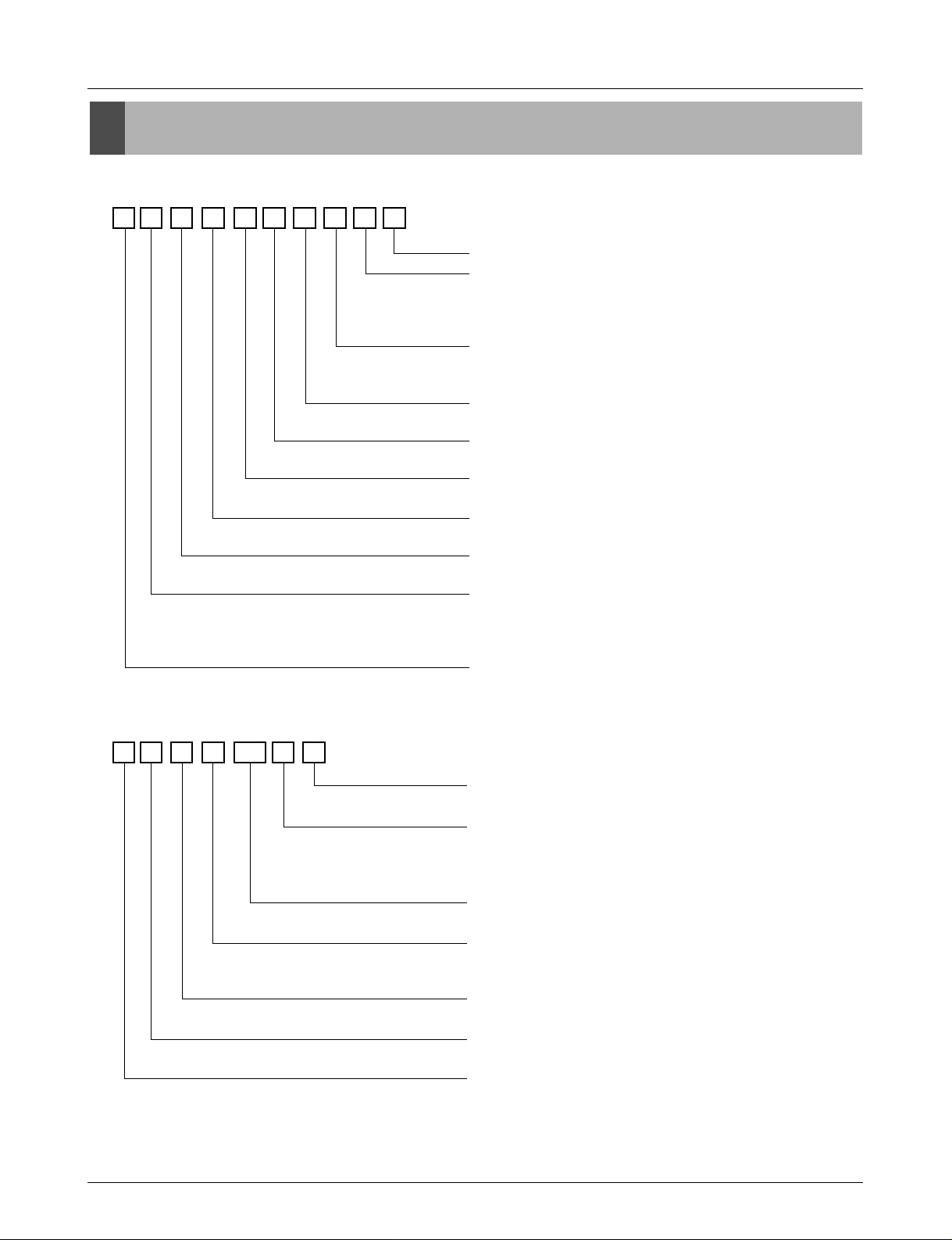

To prevent injury to the user or other people and property damage, the following instructions must

be followed.

■ Incorrect operation due to ignoring instruction will cause harm or damage. The seriousness is

classified by the following indications.

■ Meanings of symbols used in this manual are as shown below.

This symbol indicates the possibility of death or serious injury.

This symbol indicates the possibility of injury or damage to properties only.

Be sure not to do.

Be sure to follow the instruction.

WARNING

■ Installation

Have all electric work done by a licensed

electrician according to "Electric Facility

Engineering Standard" and "Interior Wire

Regulations" and the instructions given in

this manual and always use a special circuit.

• If the power source capacity is inadequate or

electric work is performed improperly, electric

shock or fire may result.

Ask the dealer or an authorized technician to

install the air conditioner.

• Improper installation by the user may result in

water leakage, electric shock, or fire.

Always ground the product.

• There is risk of fire or electric shock.

Always intstall a dedicated circuit and breaker.

• Improper wiring or installation may cause fire or

electric shock.

WARNING

CAUTION

Page 5

Service Manual 5

Safety Precautions

For re-installation of the installed product,

always contact a dealer or an Authorized

Service Center.

• There is risk of fire, electric shock, explosion, or

injury.

Do not install, remove, or re-install the unit

by yourself (customer).

• There is risk of fire, electric shock, explosion, or

injury.

Do not store or use flammable gas or

combustibles near the air conditioner.

• There is risk of fire or failure of product.

Use the correctly rated breaker or fuse.

• There is risk of fire or electric shock.

Prepare for strong wind or earthquake and

install the unit at the specified place.

• Improper installation may cause the unit to topple and result in injury.

Do not install the product on a defective

installation stand.

• It may cause injury, accident, or damage to the

product.

When installing and moving the air conditioner to another site, do not charge it with a

different refrigerant from the refrigerant

specified on the unit.

• If a different refrigerant or air is mixed with the

original refrigerant, the refrigerant cycle may

malfunction and the unit may be damaged.

Do not reconstruct to change the settings of

the protection devices.

• If the pressure switch, thermal switch, or other

protection device is shorted and operated

forcibly, or parts other than

those specified by LGE are

used, fire or explosion may

result.

Gasolin

Page 6

6 Synchro Air Conditioner

Safety Precautions

Ventilate before operating air conditioner

when gas leaked out.

• It may cause explosion, fire, and burn.

Securely install the cover of control box and

the panel.

• If the cover and panel are not installed securely,

dust or water may enter the outdoor unit and fire

or electric shock may result.

If the air conditioner is installed in a small room, measures must be taken to prevent the

refrigerant concentration from exceeding the safety limit when the refrigerant leaks.

• Consult the dealer regarding the appropriate measures to prevent the safety limit from being exceeded. Should the refrigerant leak and cause the safety limit to be exceeded, harzards due to lack of oxygen in the room could result.

■ Operation

Do not damage or use an unspecified power

cord.

• There is risk of fire, electric shock, explosion, or

injury.

Use a dedicated outlet for this appliance.

• There is risk of fire or electrical shock.

Be cautious that water could not enter the

product.

• There is risk of fire, electric shock, or product

damage.

Do not touch the power switch with wet

hands.

• There is risk of fire, electric shock, explosion, or

injury.

Page 7

Service Manual 7

Safety Precautions

When the product is soaked (flooded or

submerged), contact an Authorized Service

Center.

• There is risk of fire or electric shock.

Be cautious not to touch the sharp edges

when installing.

• It may cause injury.

Take care to ensure that nobody could step

on or fall onto the outdoor unit.

• This could result in personal injury and product

damage.

Do not open the inlet grill of the product during operation. (Do not touch the electrostatic

filter, if the unit is so equipped.)

• There is risk of physical injury, electric shock, or

product failure.

CAUTION

■ Installation

Always check for gas (refrigerant) leakage

after installation or repair of product.

• Low refrigerant levels may cause failure of

product.

Do not install the product where the noise or

hot air from the outdoor unit could damage

the neighborhoods.

• It may cause a problem for your neighbors.

Keep level even when installing the product.

• To avoid vibration or water leakage.

Do not install the unit where combustible gas

may leak.

• If the gas leaks and accumulates around the

unit, an explosion may result.

90˚

Gasolin

Page 8

8 Synchro Air Conditioner

Safety Precautions

Use power cables of sufficient current

carrying capacity and rating.

• Cables that are too small may leak, generate

heat, and cause a fire.

Do not use the product for special purposes,

such as preserving foods, works of art, etc. It

is a consumer air conditioner, not a precision

refrigeration system.

• There is risk of damage or loss of property.

Keep the unit away from children. The heat

exchanger is very sharp.

• It can cause the injury, such as cutting the finger.

Also the damaged fin may result in degradation

of capacity.

When installting the unit in a hospital, communication station, or similar place, provide

sufficient protection against noise.

•

The inverter equipment, private power generator,

high-frequency medical equipment, or radio communication equipment may cause the air conditioner to operate erroneously, or fail to operate. On the

other hand, the air conditioner may affect such

equipment by creating noise that disturbs medical

treatment or image broadcasting.

Do not install the product where it is exposed to sea wind (salt spray) directly.

• It may cause corrosion on the product. Corrosion, particularly on the condenser and evaporator fins,

could cause product malfunction or inefficient operation.

Page 9

Service Manual 9

Safety Precautions

■ Operation

Do not use the air conditioner in special

environments.

• Oil, steam, sulfuric smoke, etc. can significantly

reduce the performance of the air conditioner or

damage its parts.

Do not block the inlet or outlet.

• It may cause failure of appliance or accident.

Make the connections securely so that the

outside force of the cablemay not be applied

to the terminals.

• Inadequate connection and fastening may generate heat and cause a fire.

Be sure the installation area does not deteriorate with age.

• If the base collapses, the air conditioner could

fall with it, causing property damage, product

failure, or personal injury.

Install and insulate the drain hose to ensure that water is drained away properly based on the

installation manual.

• A bad connection may cause water leakage.

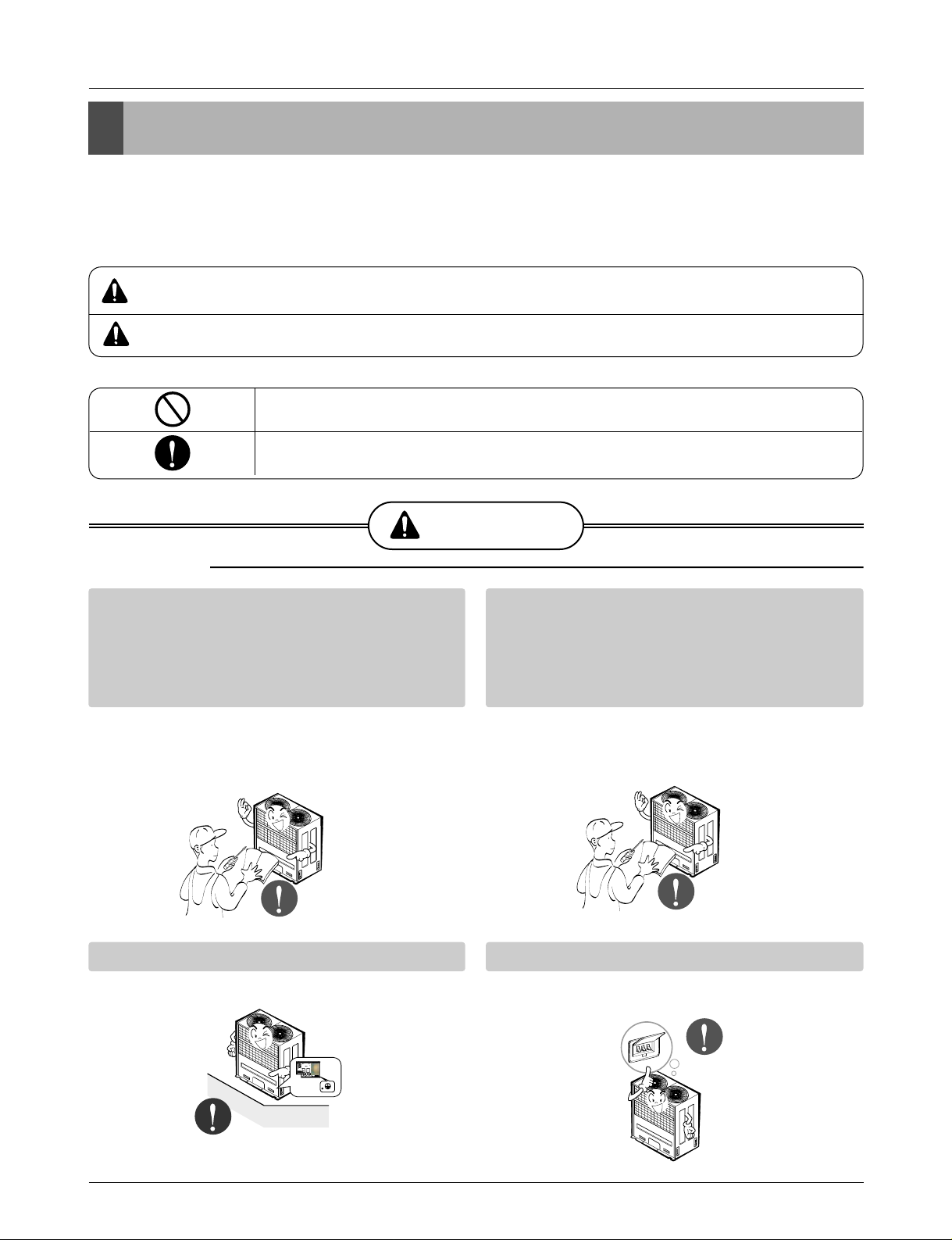

Be very careful about product transportation.

• Only one person should not carry the product if it weighs more

than 20 kg.

• Some products use PP bands for packaging. Do not use any PP

bands for a means of transportation. It is dangerous.

• Do not touch the heat exchanger fins. Doing so may cut your fingers.

• When transporting the Outdoor Unit, suspending it at the specified

positions on the unit base. Also support the Outdoor Unit at four

points so that it cannot slip sideways.

Page 10

10 Synchro Air Conditioner

Safety Precautions

Safely dispose of the packing materials.

•

Packing materials, such as nails and other metal or

wooden parts, may cause stabs or other injuries.

•

Tear apart and throw away plastic packaging bags

so that children may not play with them. If children

play with a plastic bag which was

not torn apart, they face the

risk of suffocation.

Turn on the power at least 12 hours before

starting operation.(In case of outdoor

temperature 5°C below)

• Starting operation immediately after turning on

the main power switch can result in severe

damage to internal parts. Keep the power switch

turned on during the operational season.

Do not touch any of the refrigerant piping

during and after operation.

• It can cause a burn or frostbite.

Do not operate the air conditioner with the

panels or guards removed.

• Rotating, hot, or high-voltage parts can cause

injuries.

Do not directly turn off the main power

switch after stopping operation.

• Wait at least 5 minutes before turning off the

main power switch.

Otherwise it may result in

water leakage or other

problems.

Auto-addressing should be done in condition of

connecting the power of all indoor and outdoour

units. Auto-addressing should also be done in

case of changing the Indoor Unit board(PCB).

Use a firm stool or ladder when cleaning or

maintaining the air conditioner.

• Be careful and avoid personal injury.

Do not insert hands or other objects through

the air inlet or outlet while the air conditioner

is plugged in.

• There are sharp and moving parts that could

cause personal injury.

Page 11

Service Manual 11

Model Names

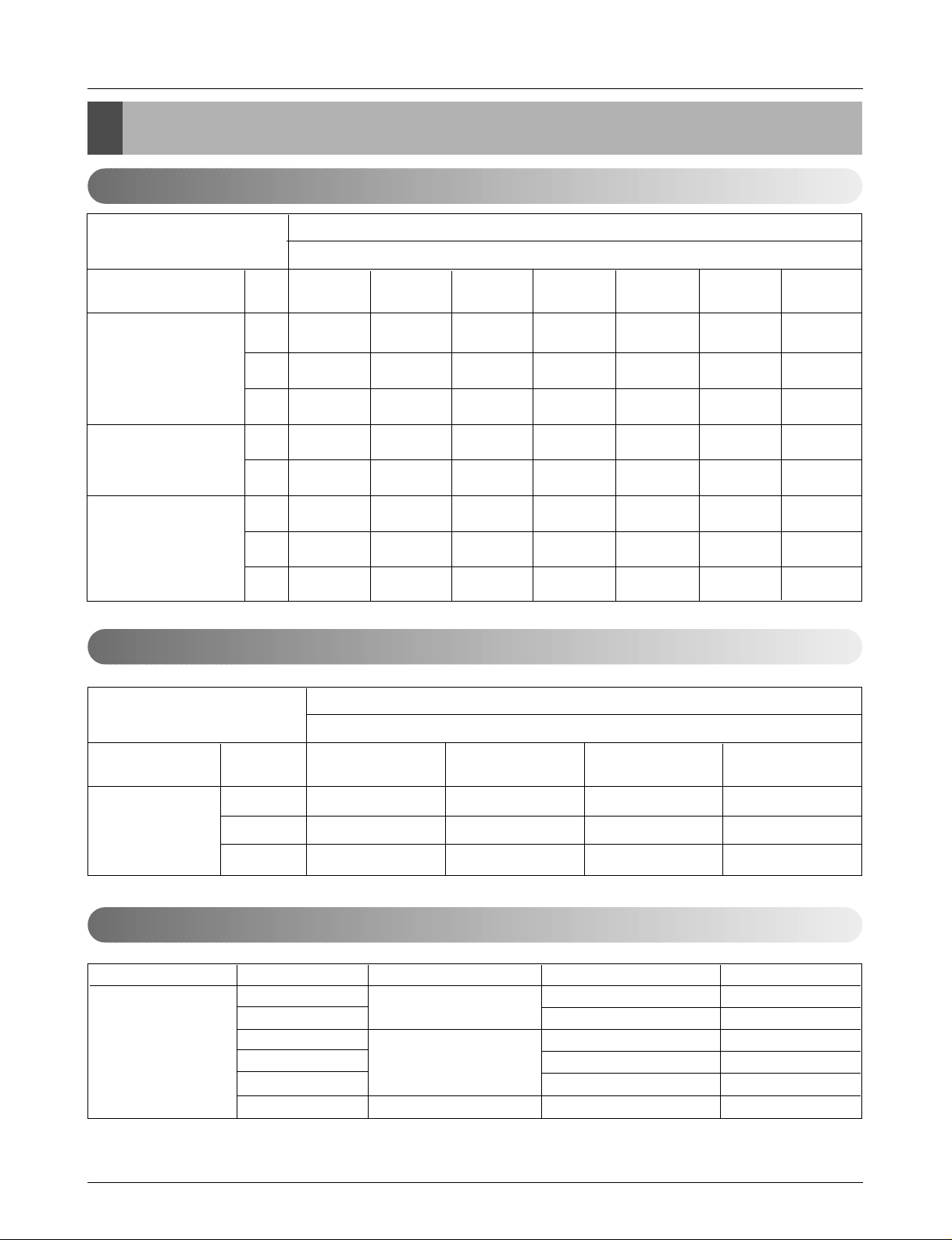

Model Names

Indoor Unit

Outdoor Unit

Branch Kit

TE

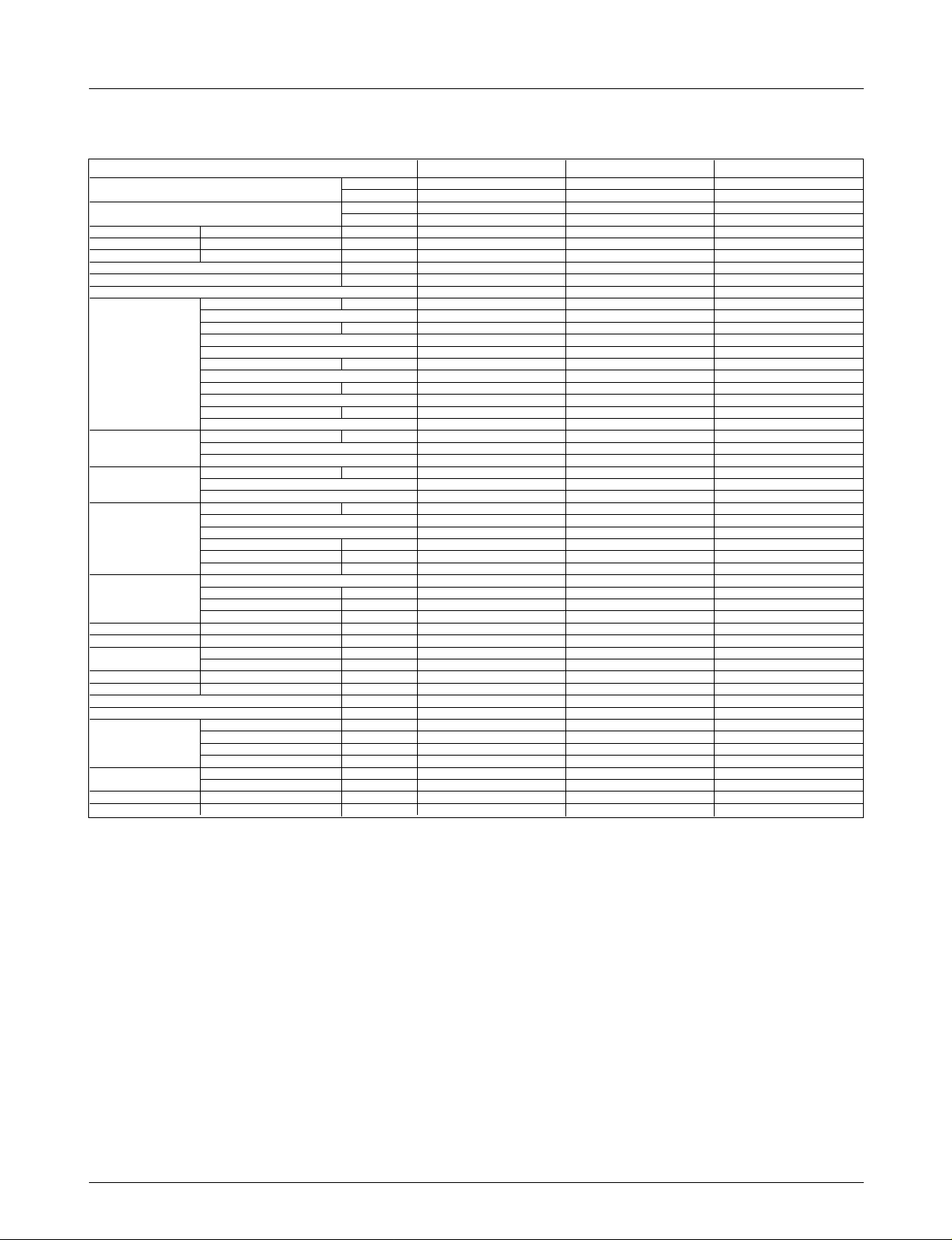

Ceiling Cassette 4-Way TF

TD

Ceiling & Floor(Convertible)

VE

VB

BH

Ceiling Concealed Duct BG

BR

Model Name

Nominal Capacity[Btu/h(Kw)]

Chassis

Name

Type

12,000

(3.5)

18,000

(5.3)

24,000

(7.0)

30,000

(8.8)

36,000

(10.6)

48,000

(14.1)

60,000

(17.6)

ATNH126ELFC ATNH186ELFC - - - -

- - ATNH246FLFC ATNH306FLFC - -

- - - - ATNH366DLFC ATNH486DLFC ATNH606DLFC

AVNH126ELAC - - - - -

- AVNH186BLAC AVNH246BLAC AVNH306BLAC - -

- ABNH186HLAC ABNH246HLAC - - -

- - - ABNH306GLAC ABNH366GLAC -

- - - - - ABNH486RLAC ABNH606RLAC

Indoor Unit

UH AUUH488C - - -

MPS Variable UY - - AUUH 728C -

UW - - - AUUH1008C

Model Name

Nominal Capacity[Btu/h(Kw)]

Type

Chassis

Name

48,000

(14.0)

60,000

(17.6)

72,000

(21.1)

100,000

(29.0)

Outdoor Unit

Name of accessory

Model No. Indoor classification Capacity Ratio(%) Remark

PMUB11A

"Synchro" Duo

50:50(1:1)

PMUB23A 40:60(2:3) Unbalance type

Branch Kit

PMUB111A 33:33:33(1:1:1)

PMUB112A "Synchro" Trio 25:25:50(1:1:2) Unbalance type

PMUB122A 20:40:40(1:2:2) Unbalance type

PMUB1111A "Synchro" Quartet 25:25:25:25(1:1:1:1)

Page 12

12 Synchro Air Conditioner

External Appearance

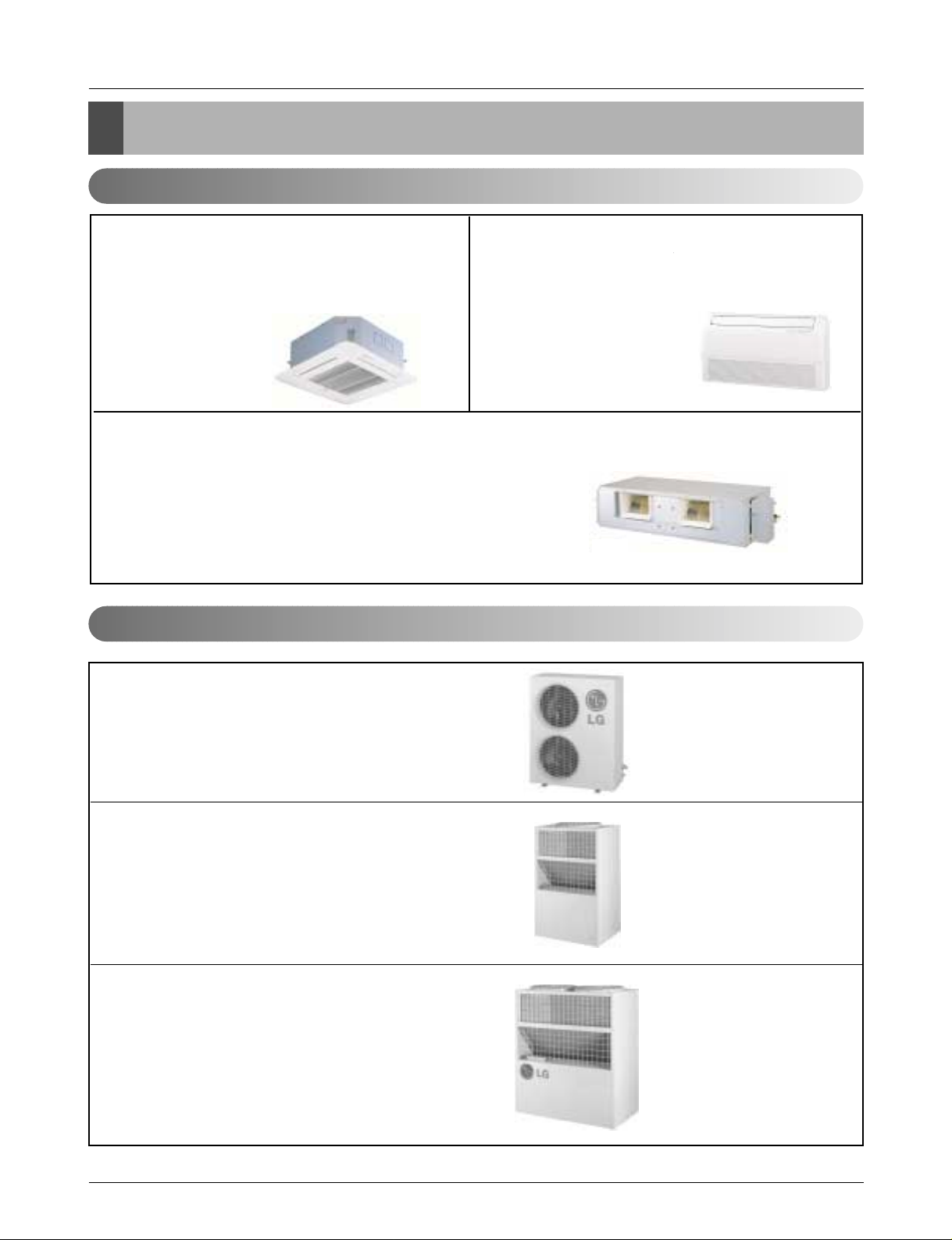

External Appearance

Indoor Unit

Outdoor Unit

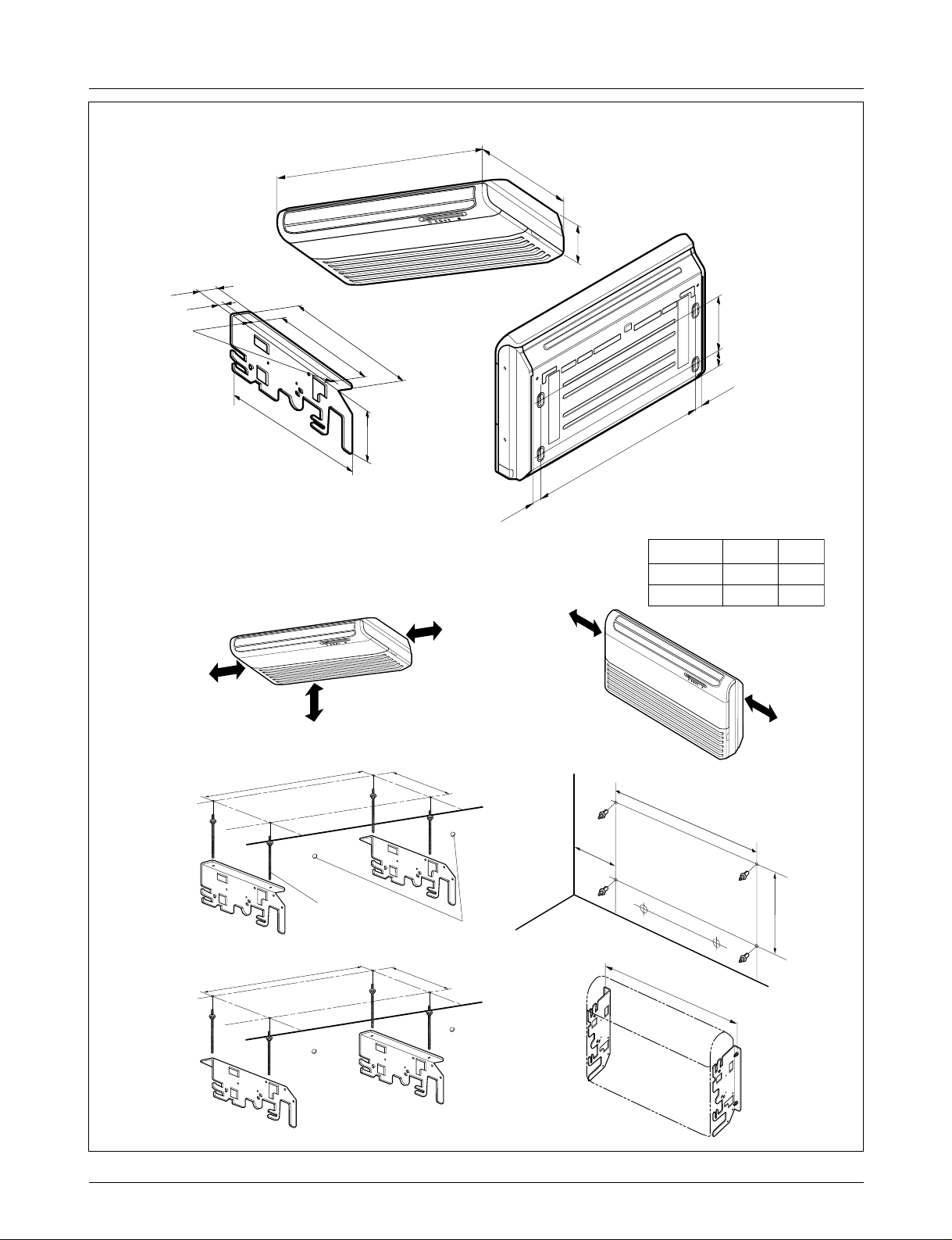

Ceiling Cassette-4Way Ceiling & Floor(Convertible)

Ceiling Concealed Duct

ATNH126ELFC / ATNH186ELFC

ATNH246FLFC / ATNH306FLFC

ATNH366DLFC / ATNH486DLFC

ATNH606DLFC

AVNH126ELAC / AVNH186BLAC

AVNH246BLAC / AVNH306BLAC

ABNH186HLAC / ABNH246BHLAC

ABNH306GLAC / ABNH366BGLAC

ABNH486RLAC / ABNH606RLAC

AUUH728C

AUUH488C

AUUH1008C

Page 13

Service Manual 13

Dimensions

Dimensions

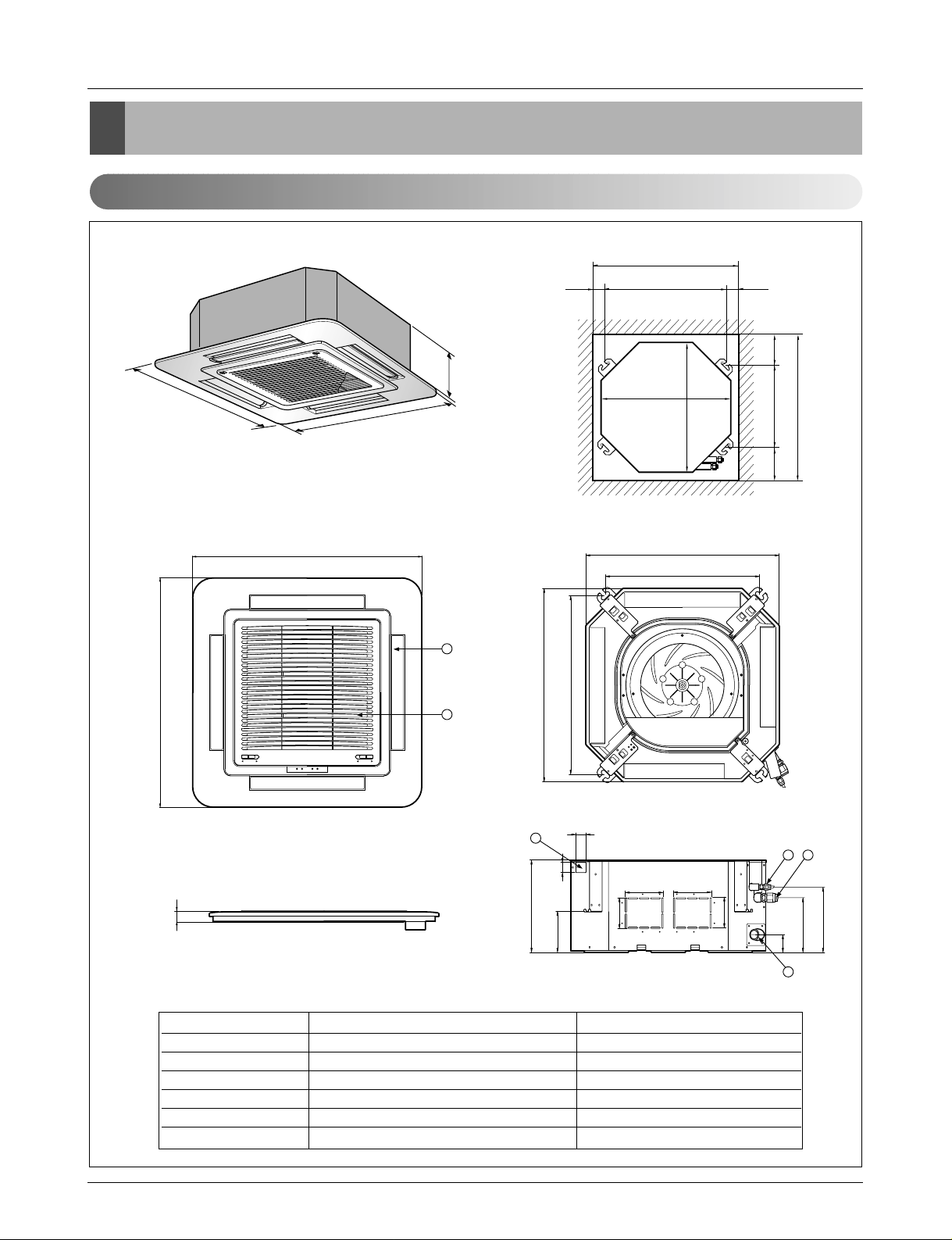

Indoor Unit

CLOSE OPEN OPEN CLOSE

269

670

30

570

269

190.5

160

52

90

90

120.4

30

521

670

570

450

40

110 110

670

670

4

132

5

6

Unit:mm

570 Unit size

570 Unit size

450 (Hanging bolt)

7575

600 (Ceiling opening)

600 (Ceiling opening)

521(Hanging bolt)

39.5

39.5

1. Cassette Type - TE(12K/18K)

(unit : mm)

Number Name Descripition

1 Liquid pipe connection ø6.35 flare

2 Gas pipe connection

12k: ø9.52, 18k: ø12.7 flare

3 Drain pipe connection

4 Power supply connection

5 Air discharge grill

6 Air suction grill

Page 14

14 Synchro Air Conditioner

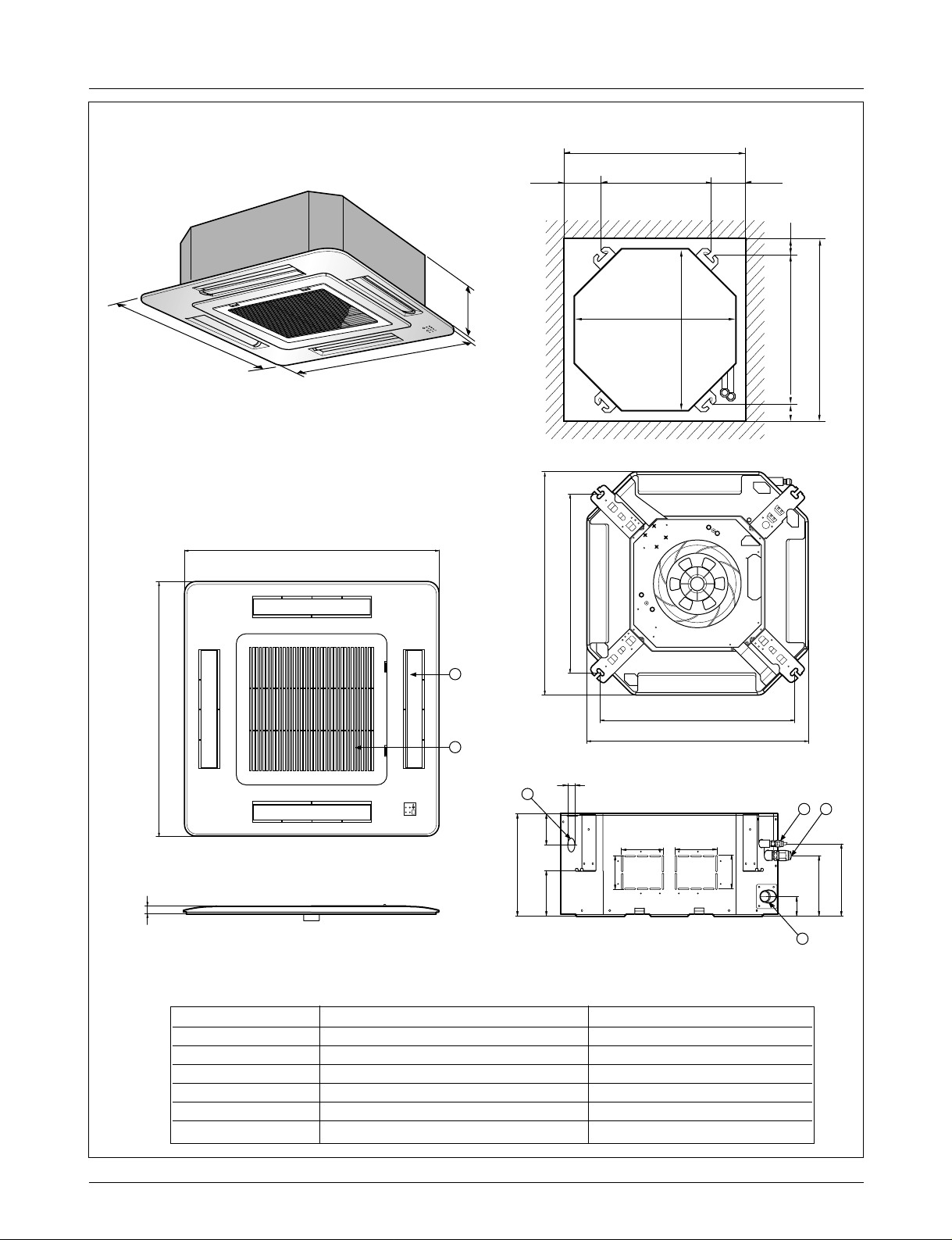

Dimensions

2. Cassette Type - TF (24K/30K)

292

850

850

850

850

744

658

572

744

292

212

150

54

90

90

192 117

70

110 110

4

132

5

6

Unit:mm

744 Unit size

744 Unit size

658 (Hanging bolt)

6666

790 (Ceiling opening)

790 (Ceiling opening)

572(Hanging bolt)

109

109

30

(unit : mm)

Number Name Descripition

1 Liquid pipe connection ø6.35 flare

2 Gas pipe connection

24K: ø12.7, 30K: ø15.88 flare

3 Drain pipe connection

4 Power supply connection

5 Air discharge grill

6 Air suction grill

Page 15

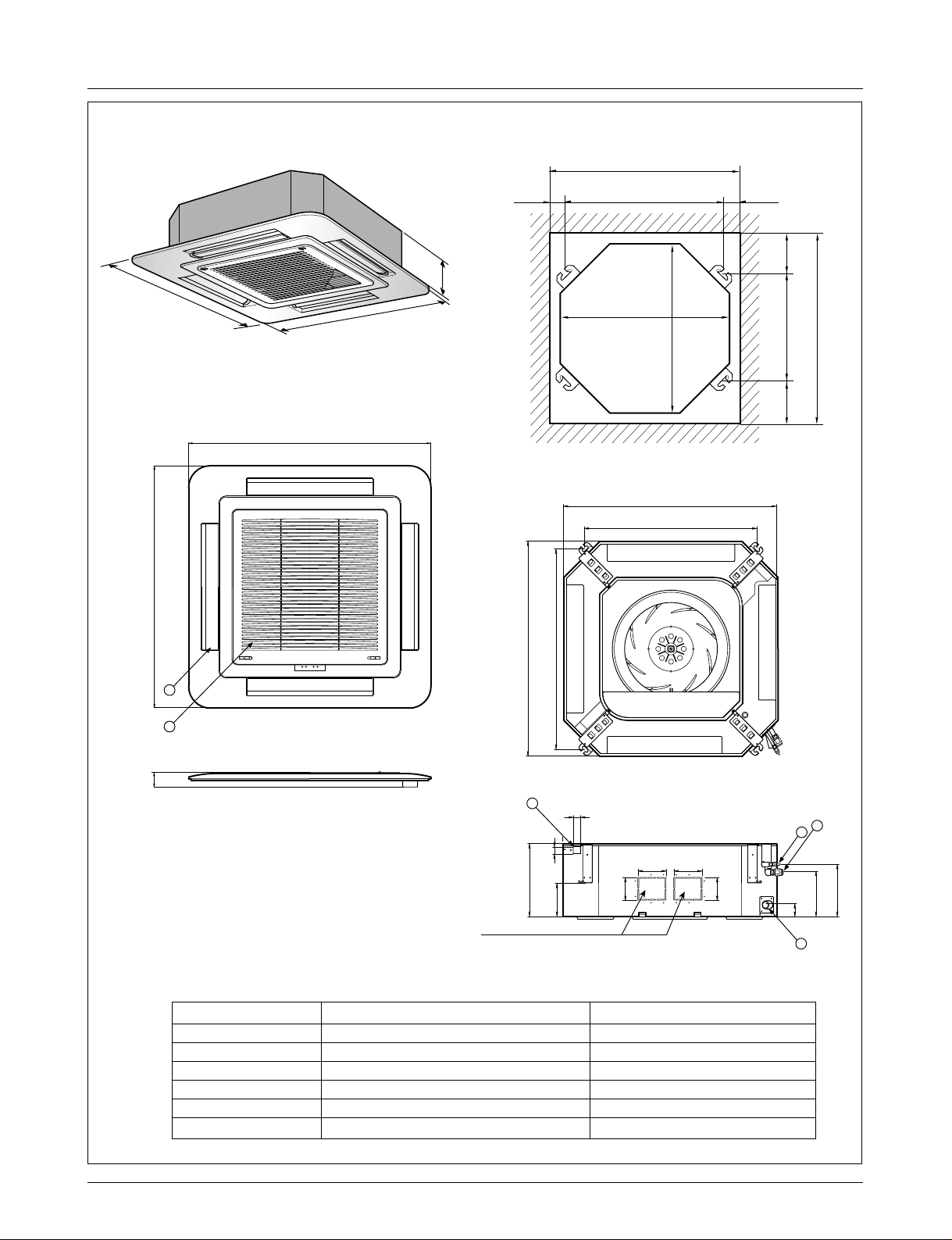

Service Manual 15

Dimensions

288

950

950

950

950

290

210.5

180

52

140

40

110

30

90

90

110

55

840

785

840

678

Fresh Air Inlet

Unit:mm

840 Unit size

840 Unit size

672 (Hanging bolt)

101.5101.5

875 (Ceiling opening)

875 (Ceiling opening)

785 (Hanging bolt)

45

45

4

5

6

1

3

2

(unit : mm)

Number Name Descripition

1 Liquid pipe connection

36K: ø6.35, 48K/60K: ø9.52 flare

2 Gas pipe connection

36K: ø15.88, 48K/60K: ø19.05 flare

3 Drain pipe connection

4 Power supply connection

5 Air discharge grill

6 Air suction grill

3. Cassette Type - TD(36K/48K/60K)

Page 16

16 Synchro Air Conditioner

Dimensions

4. Ceiling & Floor(Convertible) - VB(18K/24K), VE(12K)

63

Ø10 Stud Bolt hole

1200

R

38

392

265

468

175

(Installation Plate)

615

205

076

1

(Rear Side)

250

128

36

(Unit: mm)

More than

20cm

36

More than

20cm

Note:

1. Pipe Specification(mm)

GasLiquidModel

Ø 12.7Ø 6.3518k, 24k

Ø 15.88Ø 6.3530k

More than

20cm

More than eye-level

R

(Ceiling installation)

1076

Suspension bolt

(W3/8 or M10)

1236

265

Center-line for the

piping hole

265

(Floor/Wall installation)

more than

260

1236

1076

More than

R

20cm

265

Page 17

Service Manual 17

Dimensions

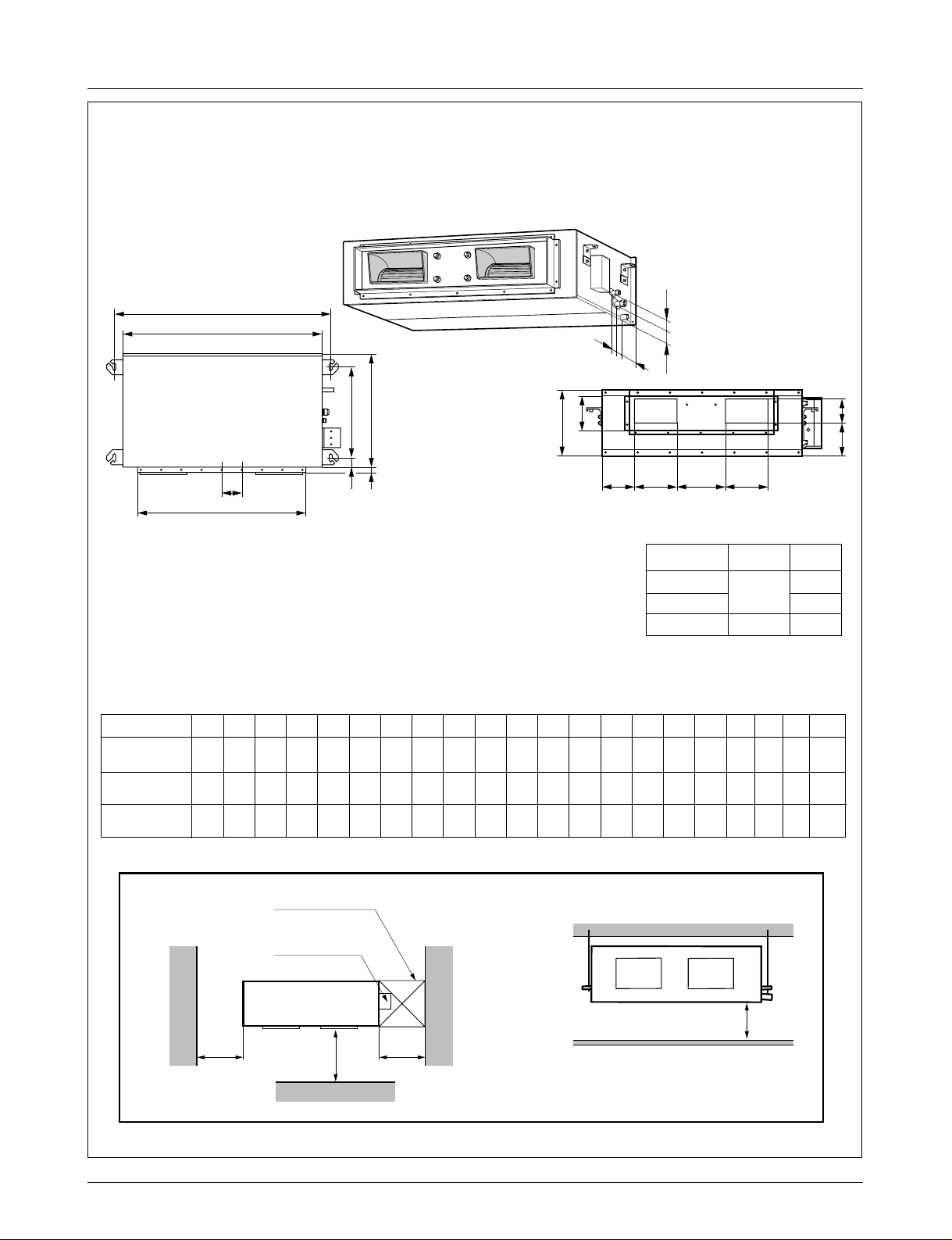

Top view

(unit: mm)

Front view

600600

Front

Inspection hole

※Suitable dimension "H" is necessary

to get a slope to drain as figure.

(600X600)

Control box

1000

H

l

i

h

j

k

A

H

CD

EF

B

(G)

ab c d

K

J

fe

Ø 12.7

Ø 15.88

Ø 6.35

Ø 9.52

18, 24k

30, 36

Ø 19.05

48, 60k

k

GasLiquidModel

1. Pipe Specification(mm)

Note:

C D E F (G) H J K a b c d e f h i j k l

355 45.5 450 30 87 750 163 260 61.5 243 212.3 243 110 130 52 66 81 30 158.5

355 45.5 450 30 87 830 186 298 229.5 243 232 243 116 160 53 59 81 19 158.5

477 56 590 30 120 1006 294 380 215 279 241 279 185 168 51 98 83 17 172

Capacity A B

932 882

1232 1182

1282 1230

ABNH186HLAC

ABNH246HLAC

ABNH306GLAC

ABNH366GLAC

ABNH486RLAC

ABNH606RLAC

(Unit: mm)

5. Ceiling Concealed Duct - BH(18K/24K), BG(30K/36K), BR(48K/60K)

Page 18

18 Synchro Air Conditioner

Dimensions

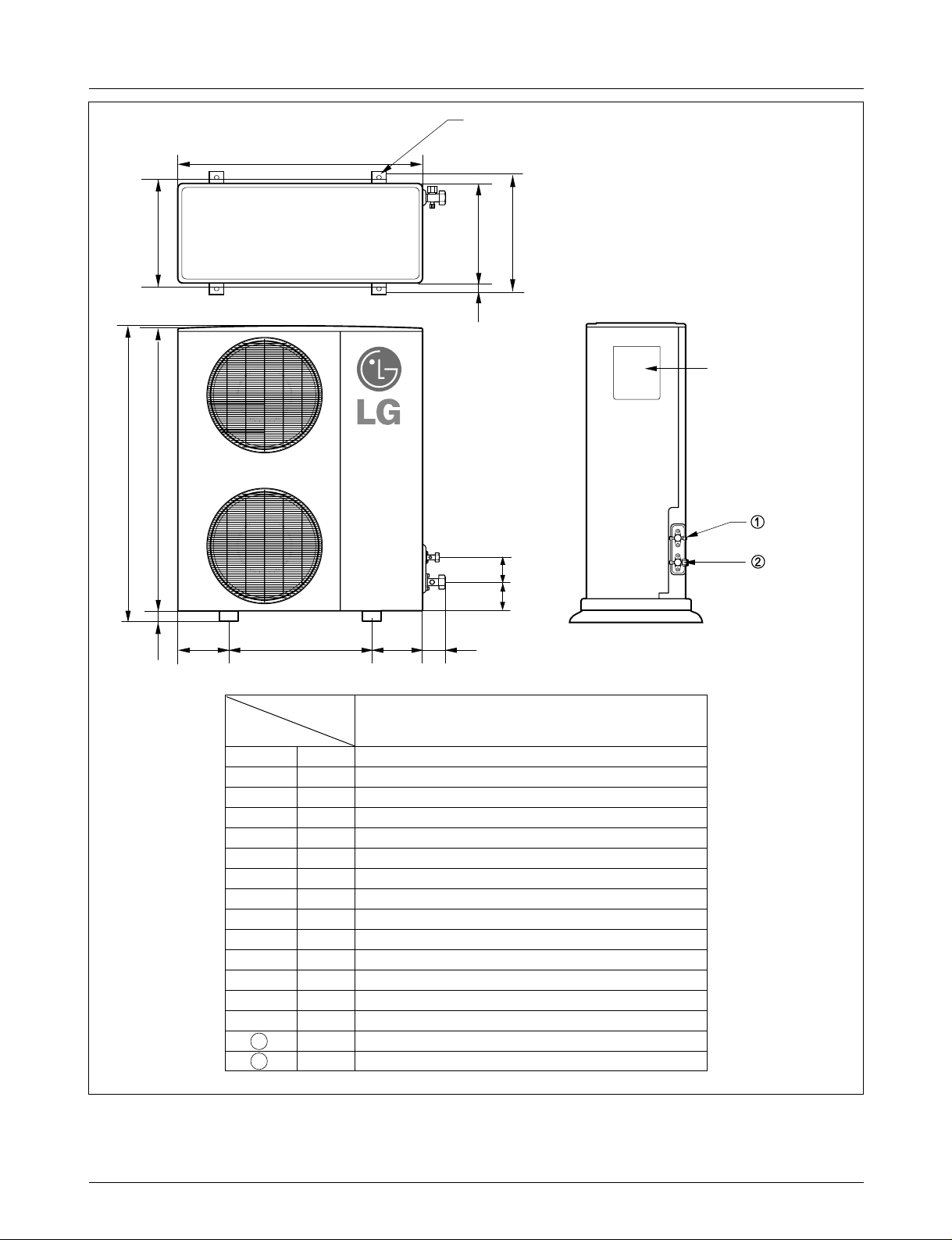

AUUH488C

L3

H

L4

W

4-hole for anchor bolts

D

L1

L2

L11

Control cover

Liquid side

3-way valve

Gas side

3-way valve

L5

L6L7 L8 L9

Model

Dimensions

AUUH488C

Wmm 900

Hmm 1

Dmm

L1 mm

L2 mm

L3 mm

L4 mm

L5 mm

L6 mm

L7 mm

L8 mm

L9 mm

L10 mm

L11

1

2

mm

mm Ø9.52

mm Ø19.05

L10

,165

370

460

45

410

1,135

30

550

175

175

112

120

83

Page 19

Service Manual 19

Dimensions

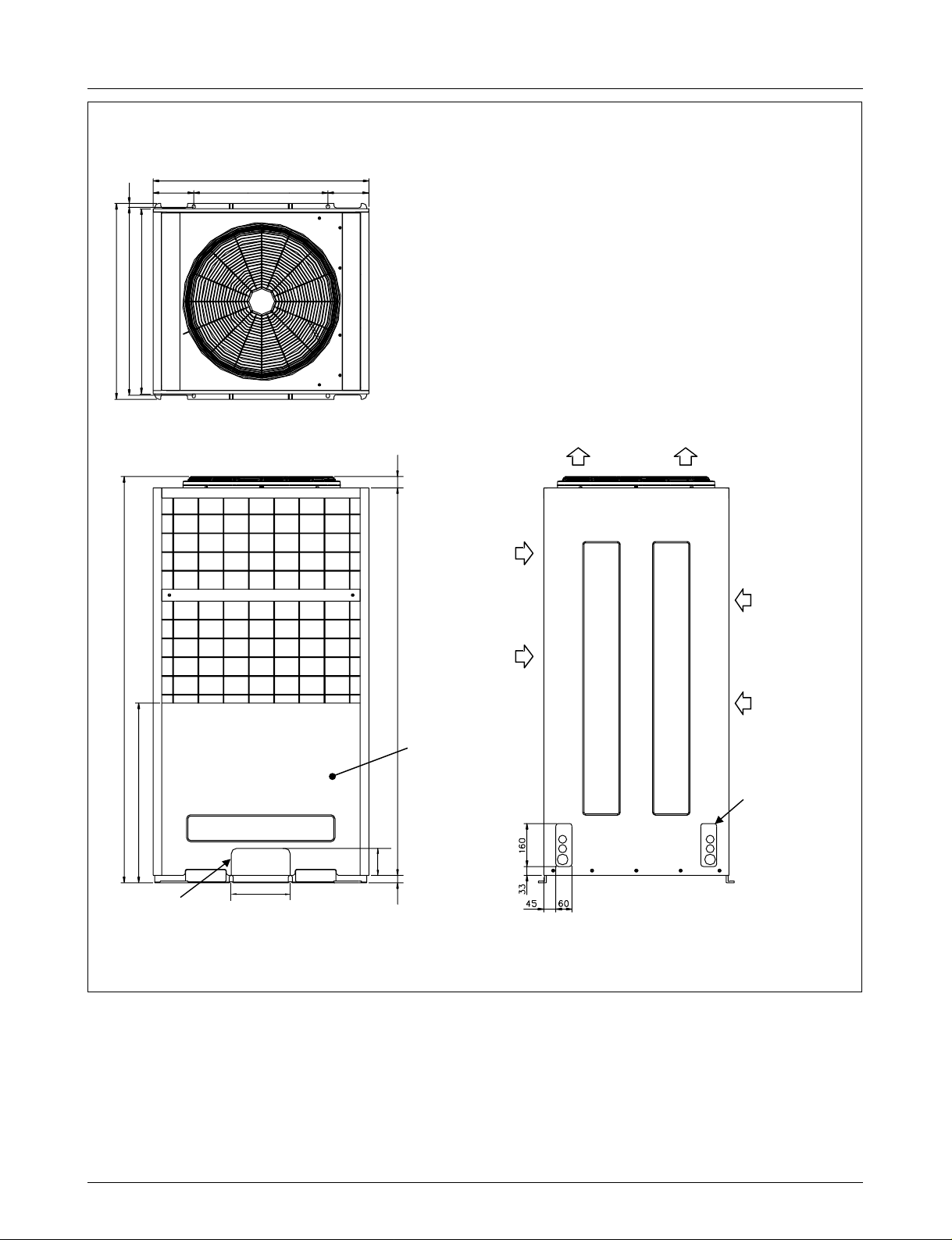

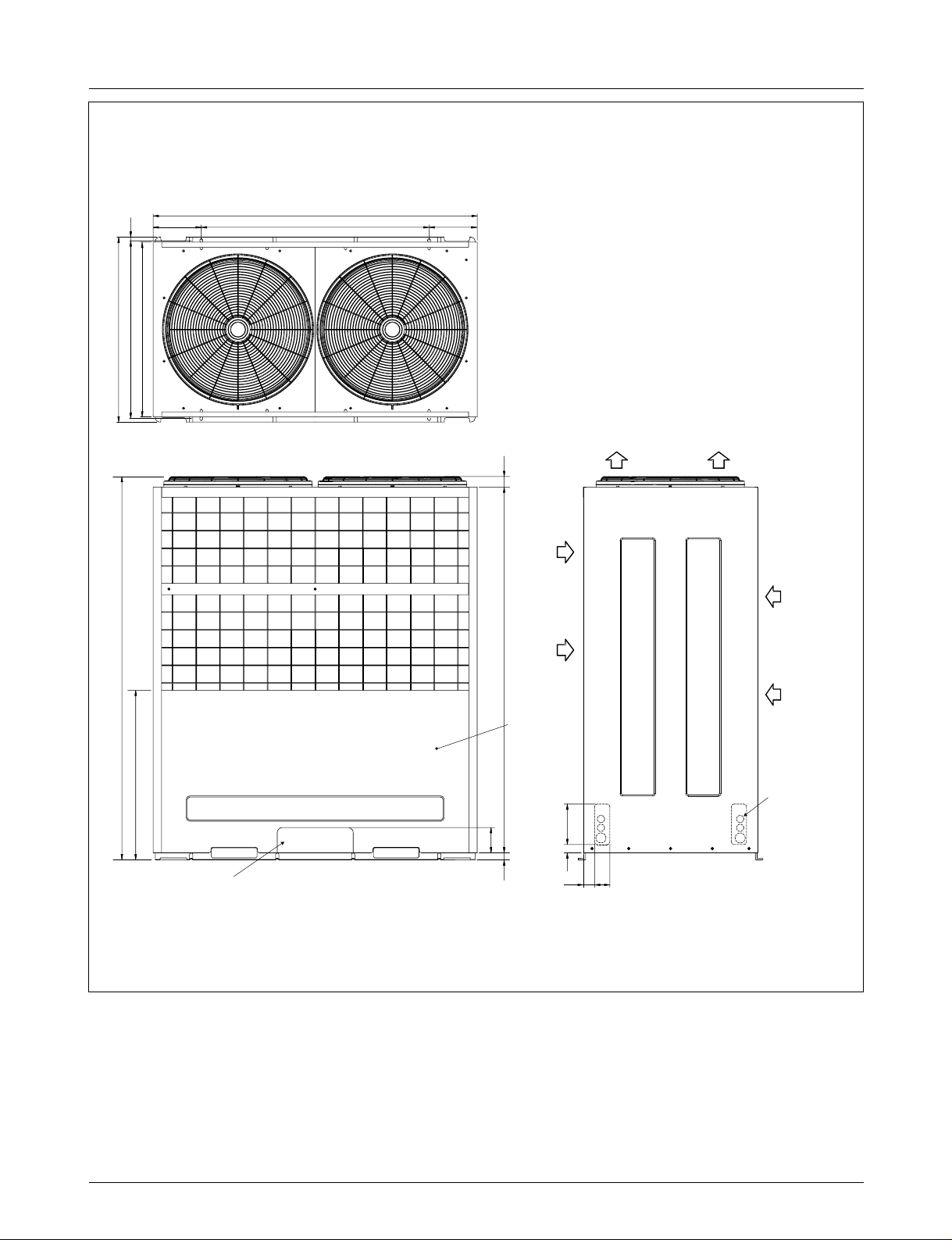

AUUH728C

Air

inlet

Air

inlet

Air outlet

Service Panel

(Unit : mm)

Knockout hole

(For the control wiring,

the power supply,

refrigerant connecting

pipe)

Knockout hole

(For the control wiring, the power supply,

refrigerant connecting pipe)

153

15

690

40

144428

100

220

1512

670

730

153

806

500(bolt hole)

700(bolt hole)

Page 20

20 Synchro Air Conditioner

Dimensions

AUUH1008C

15

730

700(bolt hole)

1555

190 900(bolt hole)

690

1280

190

48

Air outlet

Air

inlet

Air

inlet

Service Panel

670

Knockout hole

(For the control wiring,

the power supply,

refrigerant connecting

pipe)

Knockout hole

100

63 1444

33 160

45

60

(For the control wiring, the power supply,

refrigerant connecting pipe)

Page 21

Service Manual 21

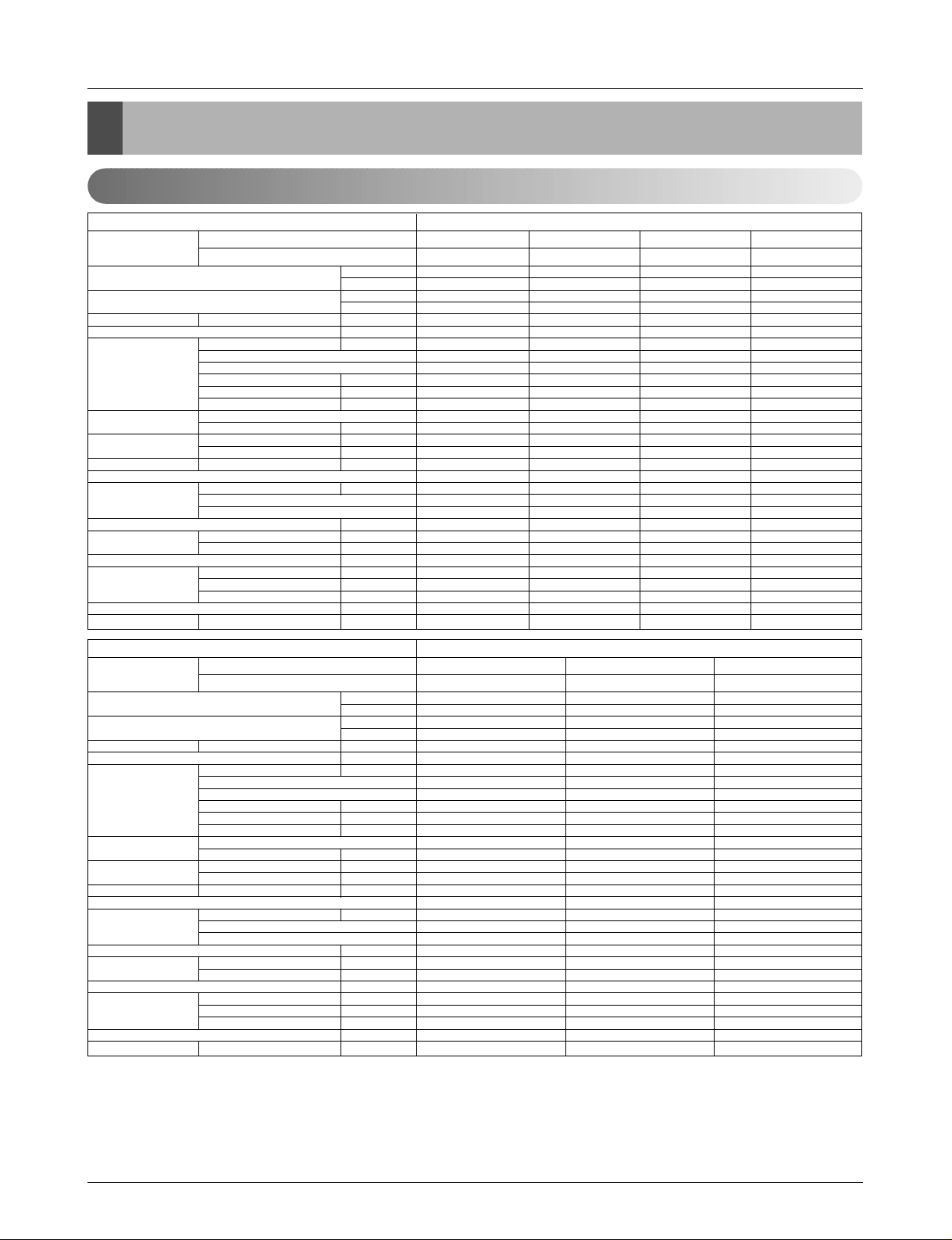

Product Specifications

3024(3517) 4536(5275) 6048(7033) 7056(8205)

12000 18000 24000 28000

3478(4044) 5116(5949) 6955(8089) 8114(9437)

13800 20300 27600 32200

9.5/8/7(336/283/247) 13/12/11(459/424/388) 15/14/13(523/494/459) 19/17/15(671/600/550)

18~30/16~30 18~30/16~30 18~30/16~30 18~30/16~30

18.3 22.4 40.3 48.6

IC-9630LGAE IC-9630LGAC OBM-3502P2 OBM-4105P2

6666

75 90 121 146

0.35 0.75 0.53 0.67

2.5/440 2.5/440 4/440 4/440

Turbo Fan Turbo Fan Turbo Fan Turbo Fan

1/13.0(330) 1/13.0(330) 1/15.0(382) 1/15.0(382)

670/620/550 720/670/620 600/540/480 650/600/550

670/620/550 720/670/620 600/540/480 650/600/550

38 / 35 / 32 41 / 39 / 37 43 / 41 / 39 45 / 42 / 39

Thermistor Thermistor Thermistor Thermistor

0.275(7.0) 0.275(7.0) 0.275(7.0) 0.275(7.0)

19 19 21 21

2R11C 2R11C 2R12C 2R12C

1.2 2.4 3 3.3

22.4*10.5*22.4 (570*269*570) 22.4*10.5*22.4 (570*269*570) 29.3*11.5*29.3 (744*292*744) 29.3*11.5*29. (744*292*744)

26.4*1.2*26.4 (670*30*670) 26.4*1.2*26.4 (670*30*670) 33.5*1.2*33.5 (850*30*850) 33.5*1.2*33.5 (850*30*850)

19(41.9) 19(41.9) 24(52.9) 24(52.9)

1/4(6.35) 1/4(6.35) 1/4(6.35) 1/4(6.35)

3/8(9.52) 1/2(12.7) 1/2(12.7) 5/8(15.88)

1.26(32) 1.26(32) 1.26(32) 1.26(32)

25.2*13.0*25.2 (640*330*640) 25.2*13.0*25.2 (640*330*640) 32.6*14.4*32.6 (828*365*828) 32.6*14.4*32.6 (828*365*828)

189/378 189/378 84/168 84/168

Rated Cooling Capacity kcal/hr(W)

Btu/hr

Ratedl Heating Capacity kcal/hr(W)

Btu/hr

Air Circulation Indoor(H/M/L)

CMM(CFM)

Setting temperature range °C

Fan motor Output W

Model

No. of Poles

Input W

Running Current A

Capacitor µF/Vac

Fan Type

No. Used / Diameter EA/inch(mm)

Fan RPM Cooling(H/M/L) rpm

Heating(H/M/L) rpm

Noise Level

(Sound Press,1m)

H/M/L dBA

Temperature controller

Coil Tube Size (OD) inch(mm)

Fins per inch

No. of Rows & Column

Dehumidification Rate l/h

Dimensions (W*H*D) Indoor inch(mm)

Panel inch(mm)

Net Weight kg(lbs)

Piping Liquid inch(mm)

Connection Gas inch(mm)

Drain hose (ID Ø)mm

Packing Dimension (W*H*D) inch(mm)

Stuffing Quantity

Without(Without) S/Parts 20/40ft

Ceiling Cassette - 4way

ATNH126ELFC

PT-HEC1

ATNH186ELFC

PT-HEC1

ATNH246FLFC

PT-HFC(F)

ATNH306FLFC

PT-HFC(F)

Indoor Unit Type

Model Indoor unit

Decoration panel

9072(10549) 12095(14067) 14112(16412)

36000 48000 56000

10433(12130) 13305(15474) 15523(18053)

41400 52800 61600

25/23/21(883/812/742) 30/28/26(1059/988/918) 34/32/30(1200/1130/1059)

18~30/16~30 18~30/16~30 18~30/16~30

52.5 58.5 107

IC-1630LGPJ IC-1640LGPH IC-14640LGPM

66 6

175 195 237

0.76 1.5 1.8

4/440 6/400 6/400

Turbo Fan Turbo Fan Turbo Fan

1/18.1(460) 1/18.1(460) 1/18.1(460)

550/510/470 600/555/520 700/650/600

550/510/470 600/555/520 700/650/600

40 / 38 / 36 43 / 41 / 39 50 / 47 / 43

Thermistor Thermistor Thermistor

0.275(7.0) 0.275(7.0) 0.275(7.0)

21 21 21

2R 12C 2R 12C 2R 12C

4 5.5 6.5

33.1*11.3*33.1 (840*288*840) 33.1*11.3*33.1 (840*288*840) 33.1*11.3*33.1 (840*288*840)

37.4*1.2*37.4 (950*30*950) 37.4*1.2*37.4 (950*30*950) 37.4*1.2*37.4 (950*30*950)

32(70.4) 32(70.4) 32(70.4)

1/4(6.35) 3/8(9.52) 3/8(9.52)

5/8(15.88) 3/4(19.05) 3/4(19.05)

1.26(32) 1.26(32) 1.26(32)

36.4*13.8*36.4 (925*350*925) 36.4*13.8*36.4 (925*350*925) 36.4*13.8*36.4 (925*350*925)

72/144 72/144 72/144

Rated Cooling Capacity kcal/hr(W)

Btu/hr

Ratedl Heating Capacity kcal/hr(W)

Btu/hr

Air Circulation Indoor(H/M/L)

CMM(CFM)

Setting temperature range °C

Fan motor Output W

Model

No. of Poles

Input W

Running Current A

Capacitor µF/Vac

Fan Type

No. Used / Diameter EA/inch(mm)

Fan RPM Cooling(H/M/L) rpm

Heating(H/M/L) rpm

Noise Level

(Sound Press,1m)

H/M/L dBA

Temperature controller

Coil Tube Size (OD) inch(mm)

Fins per inch

No. of Rows & Column

Dehumidification Rate l/h

Dimensions (W*H*D) Indoor inch(mm)

Panel inch(mm)

Net Weight kg(lbs)

Piping Liquid inch(mm)

Connection Gas inch(mm)

Drain hose (ID Ø)mm

Packing Dimension (W*H*D) inch(mm)

Stuffing Quantity

Without(Without) S/Parts 20/40ft

Ceiling Cassette - 4way

ATNH366DLFC

PT-HDC1

ATNH486DLFC

PT-HC1

ATNH606DLFC

PT-HDC1

Indoor Unit Type

Model Indoor unit

Decoration panel

Product Specifications

Indoor Unit

Notes:

1. Capacities are based on the following conditions:

Cooling : - Indoor Temperature 27˚C(80.6˚F) DB / 19˚C(66.2˚F) WB

- Outdoor Temperature 35˚C(95˚F) DB / 24˚C(75.2˚F) WB

- Interconnecting Piping Length 7.5m

- Level Difference of Zero.

Heating : - Indoor Temperature 20˚C(68˚F) DB / 15˚C(59˚F) WB

- Outdoor Temperature 7˚C(44.6˚F) DB / 6˚C(42.8˚F) WB

- Interconnecting Piping Length 7.5m

- Level Difference of Zero.

2. Capacities are Net Capacities.

3. Due to our policy of innovation some specifications may be changed without notification.

Page 22

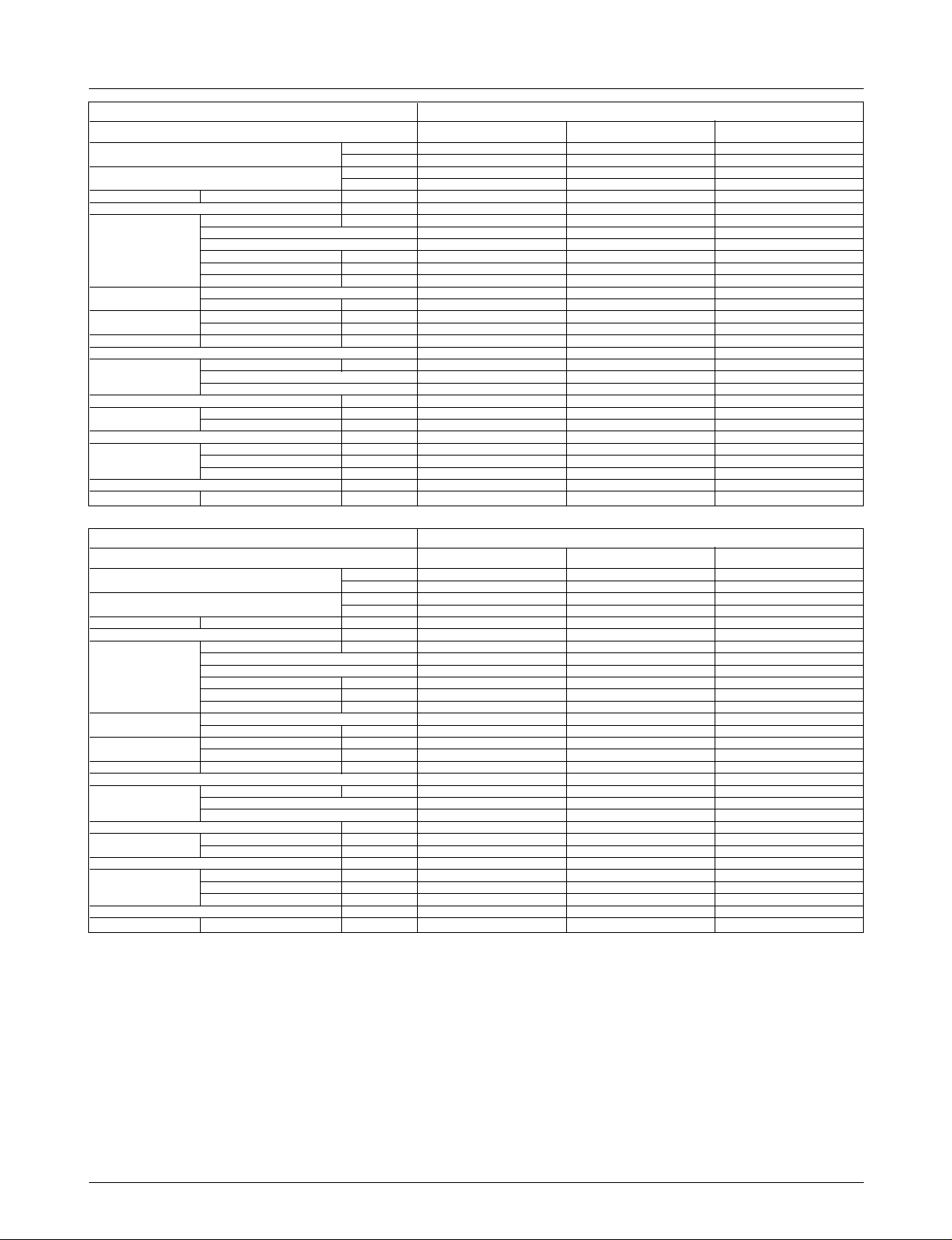

22 Synchro Air Conditioner

Product Specifications

4536(5275) 6048(7034) 7560(8791)

18000 24000 30000

5116(5949) 6955(8089) 8694(10110)

20300 27600 34500

16.5/14.5/13(583/512/459) 18/16.5/14(636/583/494) 26.5/23/20(936/812/706)

8810

18~30/16~30 18~30/16~30 18~30/16~30

118 118 211

IC-13450LG13C IC-13450LG13C IC-13450LG13J

44 4

180 180 300

0.92 0.92 1.34

6/370 6/370 6/370

Sirocco Fan Sirocco Fan Sirocco Fan

2/6.97(177) 2/6.97(177) 2/6.97(177)

1350/1310/1270 1410/1350/1250 1415/1360/1290

1350/1310/1270 1410/1350/1250 1415/1360/1290

36 / 34 /32 38 / 36 /34 40 / 38 /35

Thermistor Thermistor Thermistor

0.275(7.0) 0.275(7.0) 0.275(7.0)

21 21 21

2R 10C 3R 10C 3R 12C

2 2.5 3.3

34.6*10.2*17.7 (880*260*450) 34.6*10.2*17.7 (880*260*450) 46.5*11.7*17.7 (1180*298*450)

35(77.2) 35(77.2) 38(84)

1/4(6.35) 1/4(6.35) 1/4(6.35)

1/2(12.7) 1/2(12.7) 5/8(15.88)

25.4 25.4 25.4

44.7*13.4*22.0 (1135*340*565) 44.7*13.4*22.0 (1135*340*565) 56.5*14.8*22.9 (1435*375*582)

120/252 120/252 95/191

Rated Cooling Capacity kcal/hr(W)

Btu/hr

Ratedl Heating Capacity kcal/hr(W)

Btu/hr

Air Circulation Indoor(H/M/L)

CMM(CFM)

Setting temperature range °C

Fan motor Output W

Model

No. of Poles

Input W

Running Current A

Capacitor µF/Vac

Fan Type

No. Used / Diameter EA/inch(mm)

Fan RPM Cooling(H/M/L) rpm

Heating(H/M/L) rpm

Noise Level

(Sound Press,1m)

H/M/L dBA

Temperature controller

Coil Tube Size (OD) inch(mm)

Fins per inch

No. of Rows & Column

Dehumidification Rate l/h

Dimensions (W*H*D) Indoor inch(mm)

Panel inch(mm)

Net Weight kg(lbs)

Piping Liquid inch(mm)

Connection Gas inch(mm)

Drain hose (ID Ø)mm

Packing Dimension (W*H*D) inch(mm)

Stuffing Quantity

Without(Without) S/Parts 20/40ft

Ceiling Concealed Duct - High Static

ABNH186HLAC ABNH246HLAC ABNH306GLAC

Indoor Unit Type

Model

9072(10549) 12095(14067) 14112(16412)

36000 48000 56000

10433(12130) 13305(15474) 15523(18053)

41400 52800 61600

32/29/26(1130/1024/918) 40/35/30(1413/1236/1059) 50/45/40(1766/1413/1236)

10 15 15

18~30/16~30 18~30/16~30 18~30/16~30

272 431 431

IC-13470LG13A Y002276-1 Y002276-1

44 4

323 818 818

1.42 3.65 3.65

6/370 15/450 15/450

Sirocco Fan Sirocco Fan Sirocco Fan

2/6.97(177) 2/9.1(230) 2/9.1(230)

1415/1360/1290 1063/1035/983 1113/1063/1035

1415/1360/1290 1063/1035/983 1113/1063/1035

42 / 39 /36 44/42/40 46/44/42

Thermistor Thermistor Thermistor

0.275(7.0) 0.375(9.52) 0.375(9.52)

21 19 19

3R 12C 3R13C 4R13C

4 6 6.5

46.5*11.7*17.7 (1180*298*450) 48.4*15.0*23.2 (1230*380*590) 48.4*15.0*23.2 (1230*380*590)

38(84) 60(132) 60(132)

1/4(6.35) 3/8(9.52) 3/8(9.52)

5/8(15.88) 3/4(19.05) 3/4(19.05)

25.4 25.4 25.4

56.5*14.8*22.9 (1435*375*582) 56.9*17.9*27.6 (1445*455*700) 56.9*17.9*27.6 (1445*455*700)

95/191 57/120 57/120

Rated Cooling Capacity kcal/hr(W)

Btu/hr

Ratedl Heating Capacity kcal/hr(W)

Btu/hr

Air Circulation Indoor(H/M/L)

CMM(CFM)

Setting temperature range °C

Fan motor Output W

Model

No. of Poles

Input W

Running Current A

Capacitor µF/Vac

Fan Type

No. Used / Diameter EA/inch(mm)

Fan RPM Cooling(H/M/L) rpm

Heating(H/M/L) rpm

Noise Level

(Sound Press,1m)

H/M/L dBA

Temperature controller

Coil Tube Size (OD) inch(mm)

Fins per inch

No. of Rows & Column

Dehumidification Rate l/h

Dimensions (W*H*D) Indoor inch(mm)

Panel inch(mm)

Net Weight kg(lbs)

Piping Liquid inch(mm)

Connection Gas inch(mm)

Drain hose (ID Ø)mm

Packing Dimension (W*H*D) inch(mm)

Stuffing Quantity

Without(Without) S/Parts 20/40ft

Ceiling Concealed Duct - High Static

ABNH366GLAC ABNH486RLAC ABNH606RLAC

Indoor Unit Type

Model

Notes:

1. Capacities are based on the following conditions:

Cooling : - Indoor Temperature 27˚C(80.6˚F) DB / 19˚C(66.2˚F) WB

- Outdoor Temperature 35˚C(95˚F) DB / 24˚C(75.2˚F) WB

- Interconnecting Piping Length 7.5m

- Level Difference of Zero.

Heating : - Indoor Temperature 20˚C(68˚F) DB / 15˚C(59˚F) WB

- Outdoor Temperature 7˚C(44.6˚F) DB / 6˚C(42.8˚F) WB

- Interconnecting Piping Length 7.5m

- Level Difference of Zero.

2. Capacities are Net Capacities.

3. Due to our policy of innovation some specifications may be changed without notification.

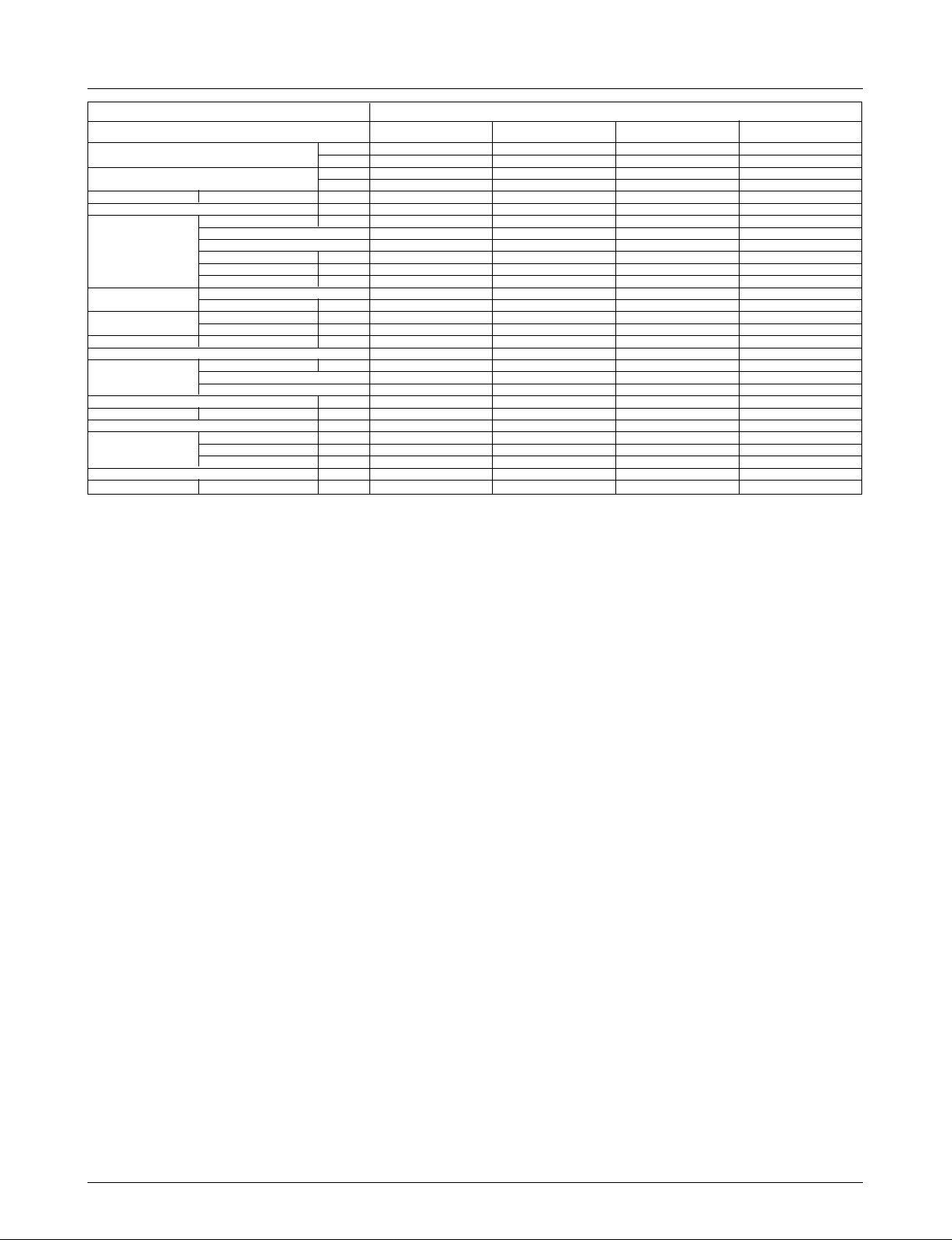

Page 23

Service Manual 23

Product Specifications

Rated Cooling Capacity kcal/hr(W)

Btu/hr

Ratedl Heating Capacity kcal/hr(W)

Btu/hr

Air Circulation Indoor(H/M/L)

CMM(CFM)

Setting temperature range °C

Fan motor Output W

Model

No. of Poles

Input W

Running Current A

Capacitor µF/Vac

Fan Type

No. Used / Diameter EA/inch(mm)

Fan RPM Cooling(H/M/L) rpm

Heating(H/M/L) rpm

Noise Level

(Sound Press,1m)

H/M/L dBA

Temperature controller

Coil Tube Size (OD) inch(mm)

Fins per inch

No. of Rows & Column

Dehumidification Rate l/h

Dimensions (W*H*D) Indoor inch(mm)

Net Weight kg(lbs)

Piping Liquid inch(mm)

Connection Gas inch(mm)

Drain hose (ID Ø)mm

Packing Dimension (W*H*D) inch(mm)

Stuffing Quantity

Without(Without) S/Parts 20/40ft

3024(3517) 4536(5274) 6048(7032) 6653(7377)

12000 18000 24000 26400

3478(4044) 5116(5949) 6955(8089) 7635(8880)

13800 20300 27600 30300

10.0/8.3/6.5(353/293/230) 13.5/12/11(477/424/388) 15/13.5/12(530/477/424) 18/16/14(636/564/494)

18~30/16~30 18~30/16~30 18~30/16~30 18~30/16~30

17.5 30 35 42.5

IC-18422LG31A IC-9430LGCG IC-9430LGCE OBM-3019P2

4444

43 53 63 81

0.23 0.23 0.27 0.38

1.5/370 1.5/370 1.5/370 1.5/370

Cross Flow Fan Cross Flow Fan Cross Flow Fan Cross Flow Fan

1/3.7(95) 1/3.1(80) 1/3.1(80) 1/3.1(80)

1240/1120/900 1090/990/890 1160/1060/960 1220/1110/1010

1240/1120/900 1090/990/890 1160/1060/960 1220/1110/1010

40 / 36 / 31 43 / 40 / 37 45 / 42 / 39 45 / 42 / 39

Thermistor Thermistor Thermistor Thermistor

0.197(5.0) 0.275(7.0) 0.275(7.0) 0.275(7.0)

20 18 20 20

2R 12C 2R 12C 2R 14C 2R 14C

1.2 2.3 3.2 3.5

35.4*7.9*19.3 (900*200*490) 47.2*8.1*24.2 (1200*205*615) 47.2*8.1*24.2 (1200*205*615) 47.2*8.1*24.2 (1200*205*615)

12(26.5) 30(66.1) 30(66.1) 30(66.1)

1/4(6.35) 1/4(6.35) 1/4(6.35) 1/4(6.35)

3/8(9.52) 1/2(12.7) 1/2(12.7) 5/8(15.88)

20 20 20 20

38.2*11.2*22.2 (970*285*565) 50.8*11.4*27.4 (1272*290*696) 50.8*11.4*27.4 (1272*290*696) 50.8*11.4*27.4 (1272*290*696)

189/383 102/219 102/219 102/219

Ceiling & Floor (Convertible)

AVNH126ELAC AVNH186BLAC AVNH246BLAC AVNH306BLAC

Indoor Unit Type

Model

Notes:

1. Capacities are based on the following conditions:

Cooling : - Indoor Temperature 27˚C(80.6˚F) DB / 19˚C(66.2˚F) WB

- Outdoor Temperature 35˚C(95˚F) DB / 24˚C(75.2˚F) WB

- Interconnecting Piping Length 7.5m

- Level Difference of Zero.

Heating : - Indoor Temperature 20˚C(68˚F) DB / 15˚C(59˚F) WB

- Outdoor Temperature 7˚C(44.6˚F) DB / 6˚C(42.8˚F) WB

- Interconnecting Piping Length 7.5m

- Level Difference of Zero.

2. Capacities are Net Capacities.

3. Due to our policy of innovation some specifications may be changed without notification.

Page 24

24 Synchro Air Conditioner

Product Specifications

Cooling Capacity kcal/hr(W)

Btu/hr

Heating Capacity kcal/hr(W)

Btu/hr

Input Cooling/Heating W

Running Current Cooling/Heating A

Starting Current Cooling/Heating A

Power Supply Ø,V,Hz

Power Factor %

Number of Connectable Indoor Units

Compressor Locked Rotor Amp. A

Type

Quantity No

Model

Maker

Capacity kcal/hr(Btu/hr)

Motor Type

Motor Input W

Oil Type

Oil Charge cc

O.L.P Type(model name)

Refrigerant Charge * g(oz)

Type

Control

Outdoor Coil Tube Size (OD) inch(mm)

Fins per inch

No. of Rows & Column/No.

Outdoor fan motor Output W

Model

No. Used / No. of Poles

Input W

Running Current A

Capacitor µF/Vac

Outdoor Fan Type

No. Used / Diameter EA/inch(mm)

Discharge Side / Top

Speed rpm

Air Circulation Outdoor CMM(CFM)

Noise Level(Sound Press,1m)

Outdoor dB(A)±1

SVC Valve Liquid inch(mm)

Gas inch(mm)

Dimensions W*H*D inch(mm)

Net Weight Outdoor kg(lbs)

Power Supply Cable No.* mm

2

Connecting Cable No.* mm

2

Max Interunit Total Piping m

Piping Length Total Main Piping m

Total Branch Piping m

For One Room m

Max. Installation Indoor Unit - Outdoor Unit m

Height Difference Indoor Unit - Indoor Unit m

Packing Dimension (W*H*D) inch(mm)

Stuffing Quantity With(Without) S/Parts 20/40ft

12096(14607) 18144(21101) 24192(28135)

48000 72000 96000

13305(15474) 19958(23211) 27820(32355)

52800 79200 110400

5300 / 5050 8000 / 7700 11100 / 11000

10.0 / 9.5 14.7 / 14.4 20 / 19.7

---

3,380~415,50 3,380~415,50 3,380~415,50

82 80 83

Single / Duo / Trio / Quartet Duo / Trio / Quartet Duo / Trio / Quartet

42 at 420V 24 / 27 63 at 420V

Rotary Rotary Scroll

232

GPT330YAA 5JS290PBA21 AR061YAA

LG Matsushita Electric LG

6854(27200) at 50Hz & 380V 6376(25301) at 50Hz & 380V 12625(50100) at 50Hz & 380V

Three Phase Induction Motor Three Phase Induction Motor Three Phase Induction Motor

2550 2680 5330

FVC68D(PVE) FV50S(PVE) FVC68D(PVE)

1200 1130 1800

Internal Type(UBUKATA) IT(Internal Thermostat) Internal Type(UP18TA057)

4200(148.1) 7100(250.4) 7800(275.1)

R-410A R-410A R-410A

L.E.V L.E.V L.E.V

0.276(7.0) 0.276(7.0) 0.276(7.0)

17 17 18

2R 52C

2R 17C + 3R 36C + 2R 17C + 2R 36C 2R 17C + 1R 36C + 2R 17C + 2R 36C

70 271 271

AMR071B9 ARE676E01 ARE676E01

2/6 1/6 2/6

168 429 429

- 1.87 1.87

6/370 10/370 10/370

Propeller Propeller Propeller

2/18.1(460) 1/20.7(526) 2/20.7(526)

Side Discharge Top Discharge Top Discharge

900 850 850

53(1872*2) 90(3179) 185(6533)

56 58 60

3/8 (9.52) 3/8 (9.52) 1/2 (12.7)

3/4 (19.05) 1 (25.4) 1 (25.4)

35.4*45.8*14.5(900*1165*370) 31.5*56.7*27.1(800*1440*690) 50.4*56.7*27.1(1280*1440*690)

105(231) 150(331) 299(659)

5*5.5 (Includes earth) 5*5.5 (Includes earth) 5*5.5 (Includes earth)

4*0.75 (Includes earth) 4*0.75 (Includes earth) 4*0.75 (Includes earth)

110 110 110

50 50 50

60 60 60

15 15 15

30 30 30

111

41.7*48.0*18.3(1060*1220*465) 34.4*61.0*29.7(875*1550*755) 53.1*62.6*29.9(1350*1590*760)

27 / 55 18 / 39 12 / 25

AUUH488C AUUH728C AUUH1008C

Model

Notes:-

1. Capacities are based on the following conditions:

Cooling: - Indoor Temperature 27˚C(80.6ÜV) DB /19˚C(66.2ÜV) WB

- Outdoor Temperature 35˚C(95ÜV) DB /24˚C(75.2ÜV) WB

Heating: - Indoor Temperature 20˚C(68ÜV) DB / 15˚C(59ÜV) WB

- Outdoor Temperature 7˚C(44.6ÜV) DB / 6˚C(42.8ÜV) WB

Piping Length - Interconnecting Pipe Length 7.5m(25ft)

- Level Difference of Zero

2. * : Full factory charge is shipped in the outdoor unit. Chargeless for 30m of piping length.

3. Due to our policy of innovation some specifications may be changed without notification.

Page 25

Service Manual 25

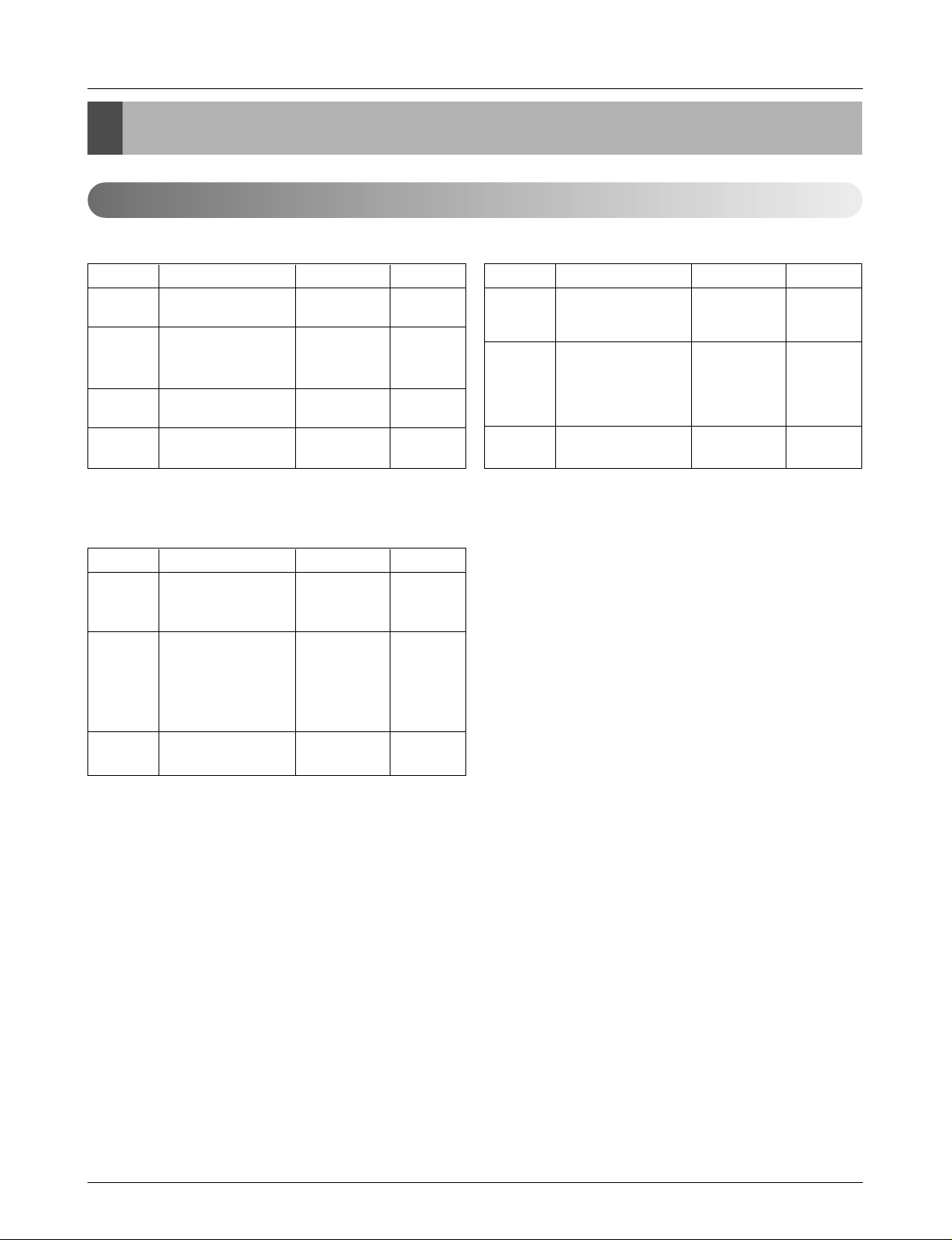

Combination table

Combination table

MPS Variable

AUUH728CAUUH488C

Synchro Combination(k Btu/h) Total(k Btu/h) Branch Kit

Duo(2 Unit)

Trio(3 Unit)

Quartet

(4 Unit)

30 + 36(2:3)

36 + 36(1:1)

18 + 24 + 24(1:2:2)

18 + 18 + 36(1:1:2)

24 + 24 + 24(1:1:1)

24 + 24 + 30(1:1:2)

18 + 18 + 18 + 18

(1:1:1:1)

68

72

66

72

72

78

72

PMUB122A

PMUB112A

PMUB111A

PMUB112A

PMUB1111A

PMUB23A

PMUB11A

Synchro Combination(k Btu/h) Total(k Btu/h) Branch Kit

Single

(1 Unit)

Trio

(3 Unit)

Duo

(2 Unit)

Quartet

(4 Unit)

48

18 + 18 + 18 (1:1:1)

12 + 12 + 12 + 12 (1:1:1:1)

18 + 24 (2:3)

24 + 24 (1:1)

24 + 30 (2:3)

48

54

42

48

54

48

PMUB23A

PMUB11A

PMUB23A

PMUB1111A

PMUB111A

-

AUUH1008C

Synchro Combination(k Btu/h) Total(k Btu/h) Branch Kit

Duo(2 Unit)

Trio(3 Unit)

Quartet

(4 Unit)

36 + 48 (2:3)

36 + 60 (2:3)

48 + 48 (1:1)

24 + 24 + 36(1:1:2)

24 + 24 + 30(1:1:2)

30 + 30 + 30(1:1:1)

30 + 30 + 36(1:1:2)

30 + 36 + 36(1:2:2)

24 + 24 +24 + 24

(1:1:1:1)

84

96

96

84

84

90

96

102

96

PMUB112A

PMUB112A

PMUB111A

PMUB112A

PMUB122A

PMUB1111A

PMUB23A

PMUB23A

PMUB11A

Page 26

26 Synchro Air Conditioner

Installation

Installation

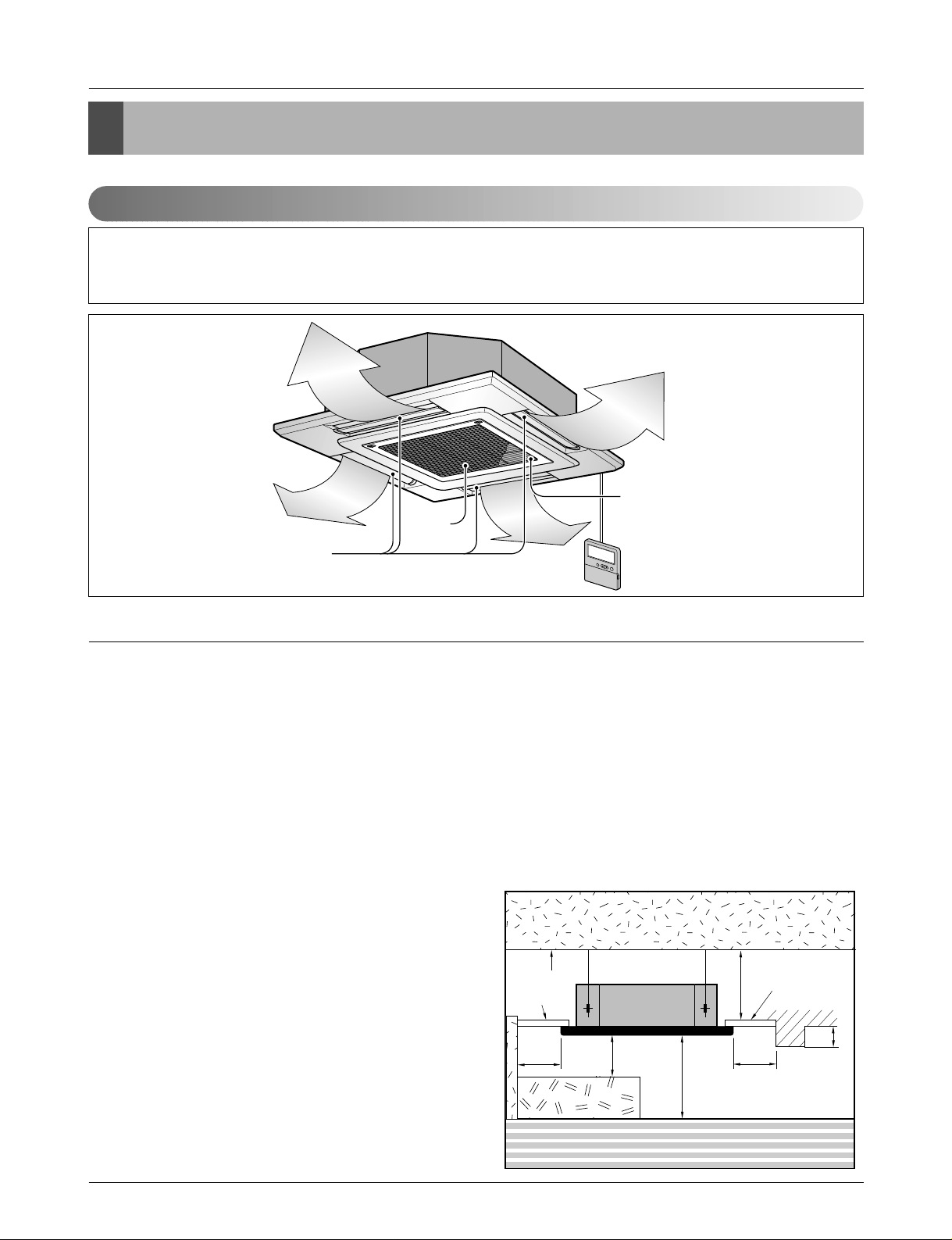

Indoor Unit_Cassette Type

• Please read this instruction sheet completely before installing the product.

• When the power cord is damaged, replacement work shall be performed by authorized personnel only.

• Installation work must be performed in accordance with the national wiring standards by authorized personnel only.

Required Parts Required Tools

• Connecting cable

• Pipes: Gas side

Liquid side

• Hanging Bolt

(W 3/8 or M10 length 650mm)

• Insulated drain hose

• Additional Drain hose

(Inner Diameter...........................32mm)

• Level

• Screw driver

• Electric drill

• Hole core drill (ø70mm)

• Flaring Tools set

• Torque Wrenches

• Hexagonal Wrench (4mm, 5mm)

• Gas-leak detector

• Owner’s Manual

• Thermometer

1. Selection of the best location

• There should not be any heat source or steam near the

unit.

• There should not be any obstacles to the air circulation.

• There should be provision of easy condensate drain.

• Taking into accounting the noise prevention criteria,

spot the installation location.

• Do not install the unit near the door way.

• Keep proper distances, of the unit, from ceiling, fence,

floor, walls and other obstacles as shown in figure.

• The indoor unit must have the maintenance space.

Unit:cm

Ceiling

Ceiling Board

Ceiling Board

30 or more

Above 250

400 or less

100

or more

50 or

more

50 or

more

30 or less

Floor

Read completely, than follow step by step.

Anti-bacteria filter

Air

Air Outlet

Intake

Page 27

Service Manual 27

Installation

2. Ceiling opening dimensions and hanging bolt location

NOTE:

• Avoid the following installation location.

1. Such places as restaurants and kitchen where considerable amount of oil steam and flour is generated.

These may cause heat exchange efficiency reduction, or water drops, drain pump mal-function.

In these cases, take the following actions;

• Make sure that ventilation fan is enough to cover all noxious gases from this place.

• Ensure enough distance from the cooking room to install the air conditioner in such a place where it may not suck oily steam.

Ceiling board

Level gauge

Ceiling

Unit:mm

570 Unit size

570 Unit size

672 (Hanging bolt)

7575

600 (Ceiling opening)

600 (Ceiling opening)

521(Hanging bolt)

39.5

39.5

TE Model TF Model TD Model

Unit:mm

744 Unit size

744 Unit size

658 (Hanging bolt)

6666

790 (Ceiling opening)

790 (Ceiling opening)

572(Hanging bolt)

109

109

Unit:mm

840 Unit size

840 Unit size

672 (Hanging bolt)

101.5101.5

875 (Ceiling opening)

875 (Ceiling opening)

785(Hanging bolt)

45

45

• The dimensions of the paper pattern for installation are the same as those of the ceiling opening dimensions.

• This air-conditioner uses a drain pump.

• Install the unit horizontally using a level gauge.

• During the installation, care should be taken not to

damage electric wires.

2. Avoid installng air conditioner in such places where cooking oil or iron powder is generated.

3. Avoid places where inflammable gas is generated.

4. Avoid place where noxious gas is generated.

5. Avoid places near high frequency generators.

Use the ventilation fan

for smoke-collecting

hood with sufficient

capacity.

Cooking table

Air conditioner

Take enough

distance

• Select and mark the position for fixing bolts and

piping hole.

• Decide the position for fixing bolts slightly tilted to

the drain direction after considering the direction

of drain hose.

• Drill the hole for anchor bolt on the wall.

CAUTION

Page 28

28 Synchro Air Conditioner

Installation

Set screw of

paper pattern (4 pieces)

Paper pattern

for installation

Ceiling board

150mm

Adjust the same height

Ceiling board

Ceiling

Flat washer for M10

(accessory)

Keep the length of the bolt

from the bracket to 40mm

Open the ceiling board

along the outer edge of the

paper pattern.

Flat washer for M10

(accessory)

Hanging bolt

(W3/8 or M10)

Nut

(W3/8 or M10)

Nut

(W3/8 or M10)

Spring washer

(M10)

Air Conditioner body

• The following parts are local purchasing.

Hanging Bolt - W 3/8 or M10

Nut - W 3/8 or M10

Spring Washer - M10

Plate Washer - M10

• Tighten the nut and bolt to prevent unit from

falling off.

3. Wiring Connection

• Open the control box cover and connect the remote control cord and Indoor power wires.

Make sure that the screws of the terminal are free from looseness.

CAUTION

Indoor

power cord

Remote

controller

cord

Control box cover

Control box cover

fitting screw(2 units)

[Air inlet side view]

Terminal Block in Indoor

1(L) 2(N) 3

WARNING

Connected to outdoor unit

Page 29

Service Manual 29

Installation

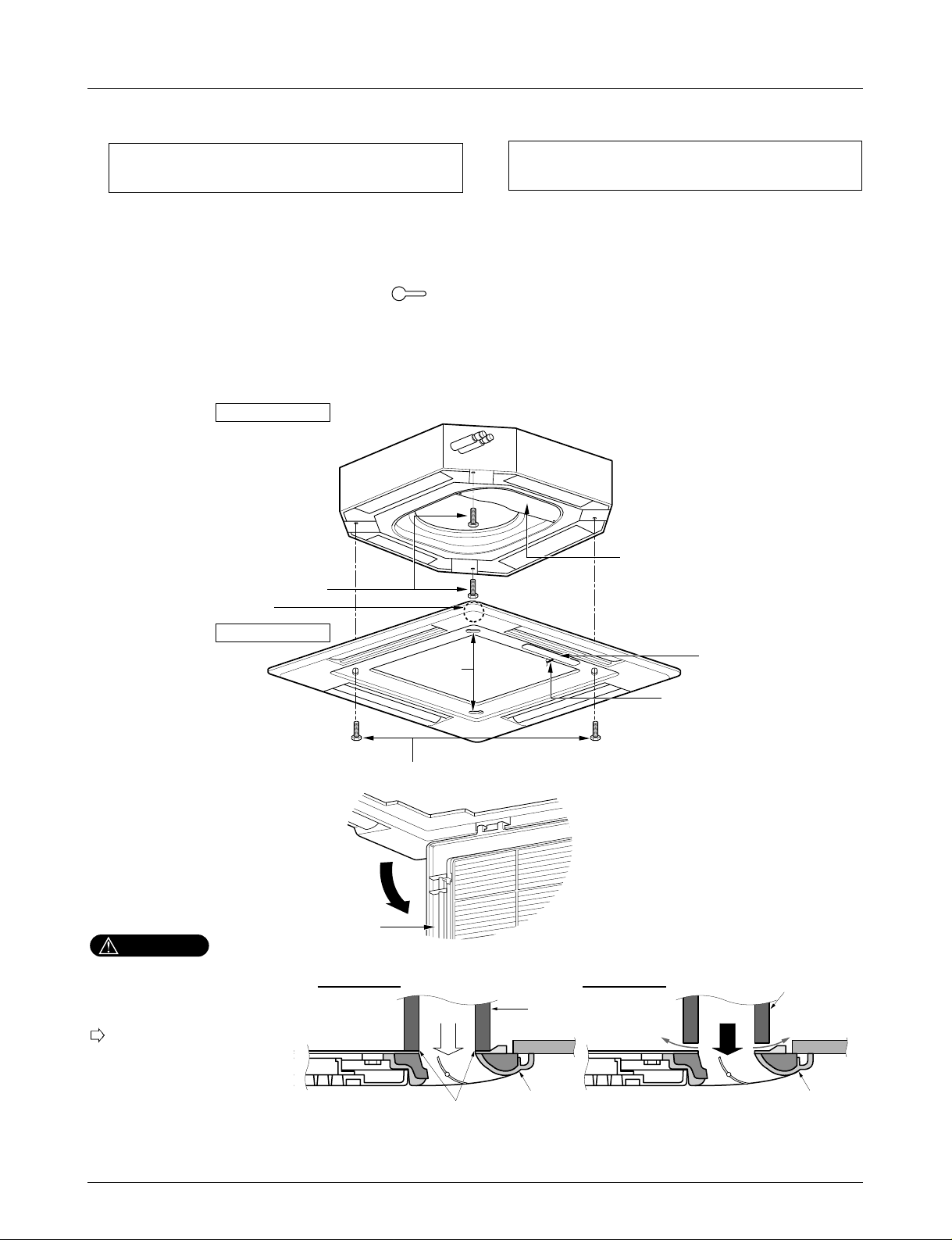

4. Installation of Decoration Panel

1. Temporarily fix two decoration panel fixing screws (hexagon M5 screw) on the unit body. (Tighten by

amount 10mm in length.)

The fixing screws (hexagon M5 screw) are included the indoor unit box.

2. Remove the air inlet grille from the decoration panel. (Remove the hook for the air inlet grille cord.)

3. Hook the decoration panel key hole ( ) on the screws fixed in step above, and slide the panel so

that the screws reach the key hole edge.

4. Retighten completely two temporarily fixed screws and other two screws. (Total 4 screws)

5. Connect the louver motor connector and display connector.

6. After tightening these screws, install the air inlet grille (including the air filter).

Decoration panel fixing screws

(hexagon M5 screws)

Temporally fitting at 2 places

(Tightening about 10mm)

Control box cover

Piping side

Inlet GrilleInlet GrilleInlet Grille

Inlet GrilleInlet Grille

Louver motor

Decoration panel fixing screws

(Hexagon M5 screw)

Air conditioner unit

Decoration panel

Key holes

Display

Lead wire for

louver motor and

display

The decoration panel has its installation

direction.

Before installing the decoration panel,

always remove the paper template.

Install certainly the decoration

panel.

Cool air leakage causes sweating.

Water drops fall.

Air conditioner

unit

Ceiling

board

Decoration panel

Decoration

panel

Fit the insulator (this part) and

be careful for cool air leakage

Good example

Air

Cool air leakage

(no good)

Bad example

Ceiling

board

Air conditioner unit

CAUTION

Page 30

30 Synchro Air Conditioner

Installation

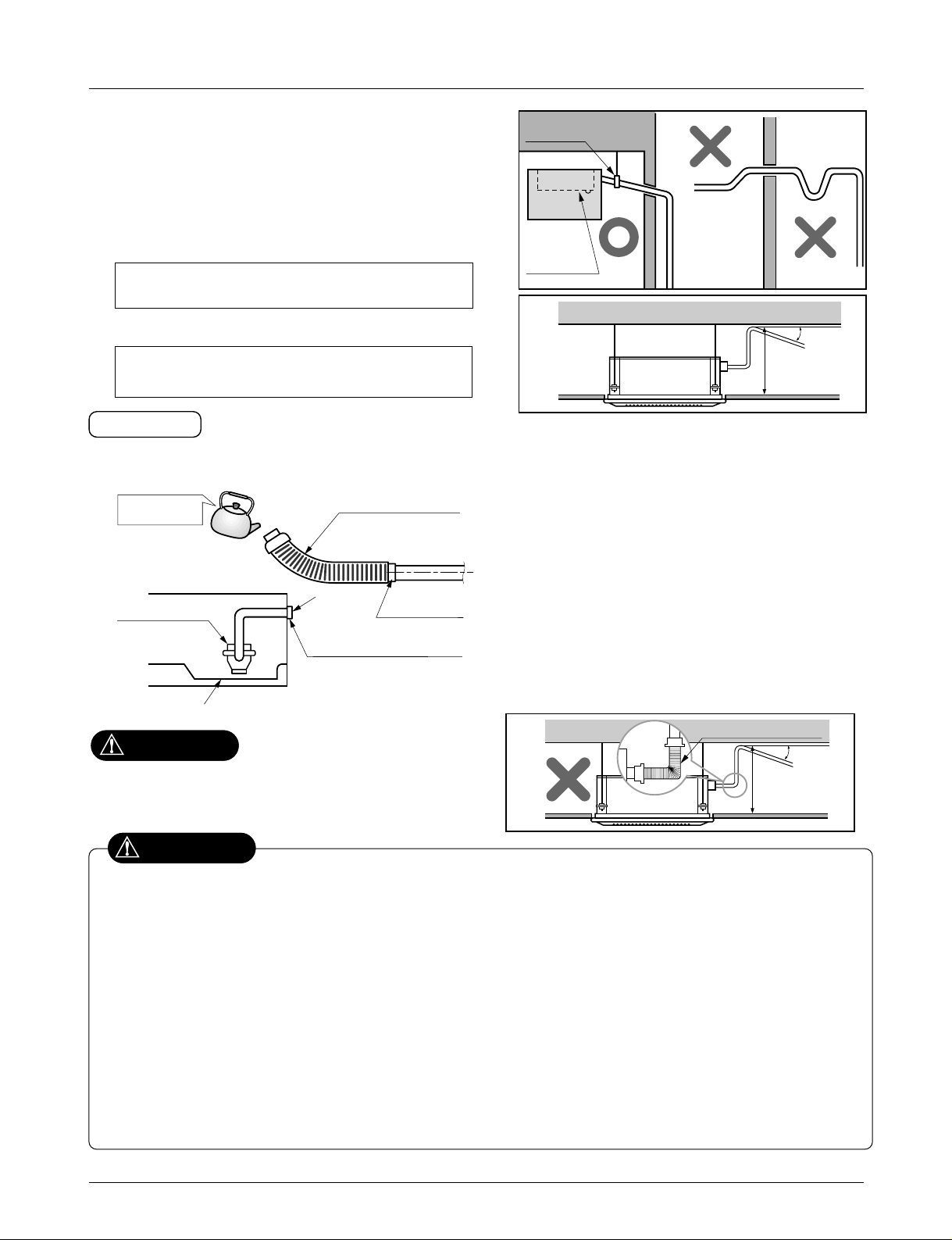

5. Indoor Unit Drain Piping

• Drain piping must have down-slope (1/50 to 1/100): be sure

not to provide up-and-down slope to prevent reversal flow.

• During drain piping connection, be careful not to exert extra

force on the drain port on the indoor unit.

• The outside diameter of the drain connection on the indoor

unit is 32mm.

•

Be sure to install heat insulation on the drain piping.

Piping material: Polyvinyl chloride pipe VP-25

and pipe fittings

The air conditioner uses a drain pump to drain water.

Use the following procedure to test the drain pump operation:

• Connect the main drain pipe to the exterior

and leave it provisionally until the test

comes to an end.

• Feed water to the flexible drain hose and

check the piping for leakage.

• Be sure to check the drain pump for normal

operating and noise when electrical wiring

is complete.

• When the test is complete, connect the

flexible drain hose to the drain port on the

indoor unit.

Heat insulation material: Polyethylene foam with

thickness more than 8 mm.

Drain test

Maintenance

drain port

Upward

routing

not allowed

Pipe clamp

Indoor unit

1/50~1/100

MAX 700mm

Feed water

Drain Pump

Drain pan

Flexible drain hose

(accessory)

Main

drain pipe

Glue the joint

Drain

port

Drain hose connection

Use the clip (accessory)

CAUTION

The supplied flexible drain hose should not be curved,

neither screwed. The curved or screwed hose may

cause a leakage of water.

1/50~1/100

MAX 700mm

Flexible drain hoseFlexible drain hose

After the confirmation of the above conditions, prepare the wiring as follows:

1) Never fail to have an individual power specialized for the air conditioner. As for the method of wiring, be guided by the

circuit diagram pasted on the inside of control box cover.

2) Provide a circuit breaker switch between power source and the unit.

3) The screw which fasten the wiring in the casing of electrical fittings are liable to come loose from vibrations to which the

unit is subjected during the course of transportation. Check them and make sure that they are all tightly fastened. (If they

are loose, it could give rise to burn-out of the wires.)

4) Specification of power source

5) Confirm that electrical capacity is sufficient.

6) Be sure that the starting voltage is maintained at more than 90 percent of the rated voltage marked on the name plate.

7) Confirm that the cable thickness is as specified in the power sources specification.

(Particularly note the relation between cable length and thickness.)

8) Never fail to equip a leakage breaker where it is wet or moist.

9) The following troubles would be caused by voltage drop-down.

• Vibration of a magnetic switch, damage on the contact point there of, fuse breaking, disturbance to the normal function of a

overload protection device.

• Proper starting power is not given to the compressor.

CAUTION

Page 31

Service Manual 31

Installation

6. Accessories

Name

Quantity

Shape

for gas pipe

for liquid pipe

Clamp metal

1 EA

Insulation for

fitting

1 SET

Drain hose

1 EA

Clamp

8 EA

Washer for

hanging backet

8 EA

(Other)

Optional Accessories(For Unit)

Standard Accessories

• Paper pattern for

installation

• Owner's manual

• Installation manual

No. Item Type Model No.

Component Parts

• Wireless remote control : 1EA

• Holder : 1EA

• Battery : 2EA

• Screw : 2EA

• Simple central controller

• Manual

• Deluxe central controller

• Manual

• Program CD

• Hard lock key, Manual

• PCB & Wire assembly

• Installation manual

(For all central control)

• PCB & Wire assembly

(For Deluxe, PC Based central

control)

• Front panel assembly

• Remote controller

• Manual

1

2

3

4

Wireless remote

control

With air purifying

function

AHWRHD

Central control

Simple

Deluxe

PC Based

PQCSA101S0

PQCSW501A0

PQCSW502A0

PQCSS501A0

PQCSS502A0

Gateway

PI485

CNU

PHNFP14A0

PQNFG00A0

Elevation Grille

Kit

Decoration

panel

PT-HEF

PT-HFF

PT-HDF

Page 32

32 Synchro Air Conditioner

Installation

Ceiling & Floor(Convertible) Type

• Please read this instruction sheet completely before installing the product.

• When the power cord is damaged, replacement work shall be performed by authorized personnel only.

• Installation work must be performed in accordance with the national wiring standards by authorized personnel only.

Required Parts Required Tools

• Installation Plate

• Four Type “A” screws

• Connecting cable

• Level

• Screw driver

• Electric drill

• Hole core drill (ø70mm)

• Pipes: Gas side ..........Ø9.52, Ø12.7, Ø15.88mm

Liquid side.............................................Ø6.35mm

• Insulated drain hose

• Insulation materials

• Flaring Tools set

• Specified Torque Wrenches

1.8kg·m...........................Liquid side piping

5.5kg·m .............................Gas side piping

Spanner .....................................Half union

• Specified Torque Wrenches

1.8kg·m...........................Liquid side piping

5.5kg·m..............................Gas side piping

• Hexagonal Wrench (4mm)

• Gas-leak Detector

• Two type “B” screws • Owner’s Manual

• Thermometer

Installation Plate (VB, 2pcs)

-1 Installation Plate (VE, 1pc)

Washer Bolt (M8 L25, 4pcs, type "A")

Floor Mount Bracket (1pcs)

Drain Hose, Insulated

Drain Hose Hanger and screw

Suspension Bolt

Bolts for Mount Bracket

Connecting Tube(mm)

• Gas side : Ø12.7, Ø15.88

• Liquid side : Ø6.35

Connecting Cable

Drain Hose Extended

Installation Parts Provided

The other Installation Parts Needed

1-1

6

5

(Floor Mounting)

(Ceiling/Wall Mounting)

7

1

2

3

4

Page 33

Service Manual 33

Installation

1. Selection of the best location

• There should not be any heat source or steam near the

unit.

• There should not be any obstacles to the air circulation.

• There should be provision of easy condensate drain.

• Taking into accounting the noise prevention criteria, spot

the installation location.

• Do not install the unit near the door way.

• Keep proper distances, of the unit, from ceiling, fence,

floor, walls and other obstacles as shown in figure.

• The indoor unit must have the maintenance space.

More than

20cm

More than eye-level

More than

20cm

R

R

More than

20cm

More than

20cm

(Ceiling installation)

(Floor/Wall installation)

2. Wiring connection

1) Connecting cables to the Indoor Unit

1. Remove the Air guide - L by loosening 2 screws after

removing the Inlet grille from the Indoor unit.

2. Connect the wires to the terminals on the control board

individually according to the outdoor unit connection.

• Ensure that the color of the wires of outdoor unit and

the terminal No. are the same as those of indoor unit

respectively

AIR GUIDE-L

INDOOR UNIT

Control

Panel

1

2

Clamp

Terminal Block in Indoor

1(L) 2(N) 3 4

Connected to outdoor unit

2) Clamping of cables

1) Arrange 2 power cables on the control panel.

2) First, fasten the steel clamp with a screw to the inner boss of control panel.

3) For the cooling model, fix the other side of the clamp with a screw strongly.

For the heat pump model, put the 0.75mm2cable(thinner cable) on the clamp and tighten it with a plastic clamp to the

other boss of the control panel.

4) In Australia, the length of power supply cord measured from the entry of the power supply cord to the middle of live pin

on the power plug should be over 1.8m.

R

Page 34

34 Synchro Air Conditioner

Installation

Drain hose

Ceiling

Ceiling

Ceiling

CAUTION

Front of view

Side of view

1. Install declination of the indoor unit is very important for the drain of the convertible type air

conditioner.

2. Minimum thickness of the insulation for the connecting pipe shall be 7mm.

3. If the Installation Plates are fixed to horizontal line, the indoor unit after installing will be declined

to the bottomside.

• The unit must be horizontal or declined to the drain hose connected when finished installation.

• The unit must be declined to the bottomside of the unit when finished installation.

Page 35

Service Manual 35

Installation

After the confirmation of the above conditions, prepare the wiring as follows:

1) Never fail to have an individual power specially for the air conditioner. As for the method of

wiring, be guided by the circuit diagram pasted on the inside of control box cover.

2) Provide a circuit breaker switch between power source and the unit.

3) The screw which fasten the wiring in the casing of electrical fittings are liable to loose due to

vibrations to which the unit is subjected during the course of transportation. Check them and

make sure that they are all tightly fastened. (If they are loose, it could give rise to burn-out of the

wires.)

4) Specification of power source

5) Confirm that electrical capacity is sufficient.

6) Be sure that the starting voltage is maintained at more than 90 percent of the rated voltage

marked on the name plate.

7) Confirm that the cable thickness is as specified in the power sources specification.

(Particularly note the relation between cable length and thickness.)

8) Never fail to equip a leakage breaker where it is wet or moist.

9) The following troubles would be caused by voltage drop-down.

• Vibration of a magnetic switch, damage on the contact point there of, fuse breaking, disturbance to

the normal function of a overload protection device.

• Proper starting power is not given to the compressor.

10) The means for disconnection from a power supply shall be incorporated in the fixed wiring and

have an air gap contact separation of at least 3mm in each active(phase) conductors.

CAUTION

Page 36

36 Synchro Air Conditioner

Installation

3. Accessories

Name

Quantity

Shape

for gas pipe

for liquid pipe

Clamp metal

1 EA

Insulation for

fitting

1 set

Drain hose

1 EA

Clamp

8 EA

Washer for

hanging backet

6 EA

(Other)

• Owner's manual

• Installation manual

Optional Accessories(For Unit)

Standard Accessories

No. Item Type Model No.

Component Parts

• Simple central controller

• Manual

• Deluxe central controller

• Manual

• Program CD

• Hard lock key, Manual

• PCB & Wire assembly

• Installation manual

(For all central control)

• PCB & Wire assembly

(For Deluxe, PC Based central

control)

1

2

Central control

Simple

Deluxe

PC Based

PQCSA101S0

PQCSW501A0

PQCSW502A0

PQCSS501A0

PQCSS502A0

Gateway

PI485

CNU

PHNFP14A0

PQNFG00A0

Page 37

Service Manual 37

Installation

Ceiling Concealed Duct Type

• Please read this instruction sheet completely before installing the product.

• When the power cord is damaged, replacement work shall be performed by authorized personnel only.

• Installation work must be performed in accordance with the national wiring standards by authorized personnel only.

Required Parts Required Tools

• Connecting cable

• Pipes: Gas side

Liquid side

• Hanging Bolt

(W 3/8 or M10 length 650mm)

• Insulated drain hose

• Additional Drain hose

(Outer Dia ................................25.4mm)

• Level

• Screw driver

• Electric drill

• Hole core drill (ø70mm)

• Flaring Tools set

• Torque Wrenches

• Hexagonal Wrench (4mm, 5mm)

• Gas-leak detector

• Owner’s Manual

• Thermometer

1. Selection of the best location

Install the air conditioner in the location that satisfies the following conditions.

• The place shall easily bear a load exceeding four times the

indoor unit’s weight.

• The place should have enough area for inspection as shown

in figure.

• The place where the unit shall be leveled.

• The place shall allow easy water drainage.(Suitable dimen-

sion “H” is necessary to get a slope to drain as figure.)

• The place shall easily connect with the outdoor unit.

• The place where the unit is not affected by an electrical

noise.

• The place where air circulation in the room will be good .

• There should not be any heat source or steam near the unit.

Top view

(unit: mm)

H

Front view

600600

Front

Inspection hole

(600X600)

Control box

1000

Air outlet vents

Air filters

Air intake vents

Wired LCD Remote Control

Page 38

38 Synchro Air Conditioner

Installation

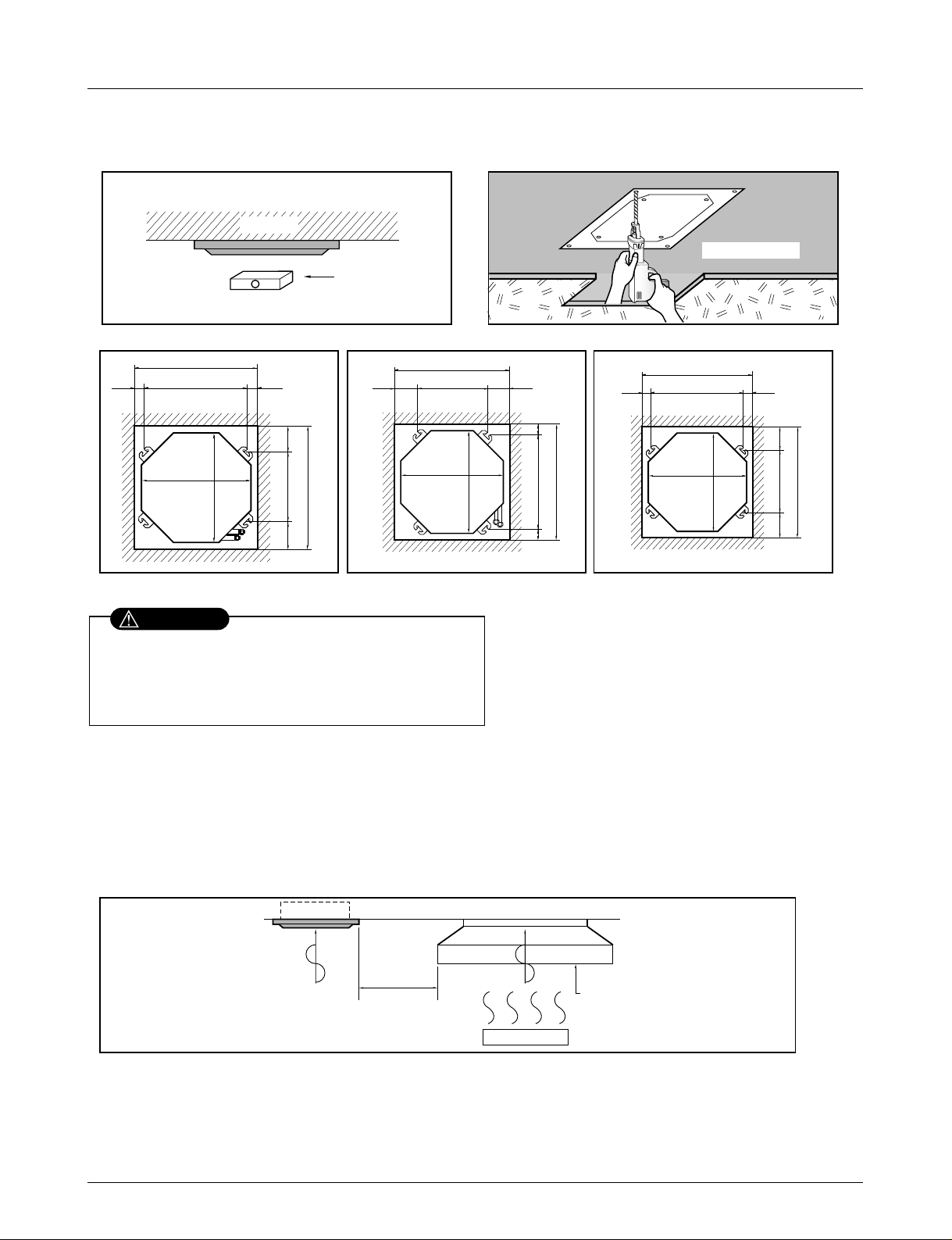

2. Ceiling dimension and hanging bolt

location

■ Installation of Unit

Install the unit above the ceiling correctly.

• Apply a joint-canvas between the unit and duct to absorb

unnecessary vibration.

• Apply a filter Accessory at air return hole.

• Refer toDimensinal Drawings.

• Install the unit leaning to a drainage hole side as a figure

for easy water drainage.

• A place where the unit will be leveled and that can support the weight of the unit.

• A place where the unit can withstand its vibration.

• A place where service can be easily performed.

CASE 1

POSITION OF SUSPENSION BOLT

CASE 2

POSITION OF CONSOLE BOLT

Drainage hole

M10 Nut

M10 SP. washer

M10 washer

X 4

X 4

(Local

supply)

X 4

M10 Nut

M10 SP. washer

M10 washer

X 4

X 4

(Local

supply)

X 4

A

B

C

1-3 mm

D

(G)

H

I

EF

NOTE:

• Throughly study the following installation locations:

1. In such places as restaurants and kitchens, considerable amount of oil steam and flour adhere to the fan, the fin of the heat

exchanger, resulting in heat exchange reduction, spraying, dispersing of water drops, etc.

In these cases, take the following actions:

• Make sure that the ventilation fan for smoke-collecting hood on a cooking table has sufficient capacity so that it draws oily

steam which should not flow into the suction of the air conditioner.

• Make enough distance from a cooking room to install the air conditioner in such a place where it may not suck in oil steam.

2. Avoid installing air conditioner in such circumstances where cutting oil mist or iron powder is in suspension in factories, etc.

3. Avoid places where inflammable gas is generated, flows in, is stored or vented.

4. Avoid places where sulfurous acid gas or corrosive gas is generated.

5. Avoid places near high frequency generators.

Page 39

Service Manual 39

Installation

• Select and mark the position for fixing bolts.

• Drill the hole for set anchor on the face of ceiling.

• Insert the set anchor and washer onto the suspen-

sion bolts for locking the suspension bolts on the

ceiling.

• Mount the suspension bolts to the set anchor firmly.

• Secure the installation plates onto the suspension

bolts (adjust level roughly) using nuts, washers and

spring washers.

Tighten the nut and bolt to prevent unit falling.

3. Connecting Cables

Connect the wires to the terminals on the control board individually according to the outdoor unit connection.

• Ensure that the color of the wires of outdoor unit and the terminal No. are the same as those of indoor unit respectively

Clamping of cables

1) Arrange 2 power cables on the control panel.

2) First, fasten the steel clamp with a screw to the inner boss of control panel.

3) For the cooling model, fix the other side of the clamp with a screw strongly. For the heat pump model, put the

0.75mm2 cable(thinner cable) on the clamp and tighten it with a plastic clamp to the other boss of the control

panel.

4) In Australia, the length of power supply cord measured from the entry of the power supply cord to the middle

of

live pin on the power plug should be over 1.8m.

Make sure that the screws of the terminal are free from looseness.

WARNING

Terminal Block in Indoor

1(L) 2(N) 3 4

Connected to outdoor unit

CAUTION

Old building New building

1 Set anchor

2 Plate washer

3 Spring washer

4 Nut

5 Suspension

bolts

Page 40

40 Synchro Air Conditioner

Installation

All thermal insulation must comply with local requirement.

INDOOR UNIT

THERMAL INSULATION

Make sure that there is no clearance here.

Overlap with thermal

insulator for piping.

Thermal insulator for refrigerant pipe

(Local supply)

Thermal insulator for

piping(Local supply)

Hose crip for thermal insulator(Local supply)

Union for liquid pipe

Refrigerant pipe and thermal

insulator(Local supply)

Union for gas pipe

Thermal insulator for refrigerant pipe

(Local supply)

Hose crip for thermal insulator

(Local supply)

5. Checking the Drainage

1. Remove the Air Filter.

2. Check the drainage.

• Spray one or two glasses of water on the evaporator.

• Ensure that water flows to drain hose from indoor

unit without any leakage.

4. Insulation

Page 41

Service Manual 41

Installation

Ceiling

CAUTION

1~3mm

Drainage hole

Drainage hole

U-Trap

B

C

A ≥ 70mm

B ≥ 2C

C ≥ 2 x SP

SP = External Pressure

(mmAq)

Ex) External Pressure

= 10mmAq

A ≥ 70mm

B ≥ 40mm

C ≥ 20mm

A

Make sure to be closed.

Unit

Drainage pipe

(Local supply)

Thermal insulator

(Local supply)

Drainage hole

CAUTION FOR GRADIENT OF

UNIT AND DRAIN PIPING

Lay the drain hose with a downware

inclination so water will drain out.

MAX 700mm

Drain Pipe

Drain Pump

1/50~1/1001/50~1/100

Front of view

• Alway lay the drain with downward inclination

(1/50 to 1/100).

Prevent any upward flow or reverse flow in any

part.

• 5mm or thicker formed thermal insulator shall

always be provided for the drain pipe.

CORRECT

• Install the P-Trap (or U-Trap) to prevent

a water leakage caused by the blocking

of intake air filter.

Applied U-Trap Dimension

1. Decline Installation of indoor unit is very important for the drain of the duct type air conditioner.

2. Minimum thickness of the insulation for the connecting pipe should be 5mm.

• The unit must be or declined to wards drain hose while installation.

CORRECT

INCORRECT

INCORRECT

Page 42

42 Synchro Air Conditioner

Installation

6. Accessories

Name

Quantity

Shape

for gas pipe

for liquid pipe

Clamp metal

1 EA

Insulation for

fitting

1 set 1 set

Drain hose

1 EA

(Other)

Clamp

6 EA

Screws for

duct flanges

• Owner's manual

• Installation manual

• Washers(8 pcs.)

Optional Accessories(For Unit)

Standard Accessories

No. Item Type Model No.

Component Parts

• Wireless remote control : 1EA

• Holder : 1EA

• Battery : 2EA

• Screw : 2EA

• Plasm air purifier kit: 1EA

• Wired remote control: 1EA

• Factory sypplied-zone control PCB

• Durchased locally-damper,

Damper moter, thermostat

• Drain Pump Assembly: 1EA

• Simple central controller

• Manual

• Deluxe central controller

• Manual

• Program CD

• Hard lock key, Manual

• PCB & Wire assembly

• Installation manual

(For all central control)

• PCB & Wire assembly

(For Deluxe, PC Based

central control)

1

2

3

4

5

6

Wireless remote

control

With air purifying

function

AHWRHS

AHWRHD(LCD)

Plasma air puirifying

filter

-

ABPAHH

ABPAGH

ABPARH

Zone Control - ABZCA

Drain Pump - ABDPG

Central Control

Simple

Deluxe

PC Based

PQCSA101S0

PQCSW501A0

PQCSW502A0

PQCSS501A0

PQCSS502A0

Gateway

PI485

CNU

PSNFP14A0

PQNFG00A0

Page 43

Service Manual 43

Installation

Connecting Pipes to the Indoor Unit

Main cause of gas leakage is defect in flaring work.

Carry out correct flaring work in the following procedure.

1. Cut the pipes and the cable.

• Use the accessory piping kit or the pipes purchased locally.

• Measure the distance between the indoor and the

outdoor unit.

• Cut the pipes a little longer than measured distance.

•

Cut the cable 1.5m longer than the pipe length.

2. Burrs removal

• Completely remove all burrs from the cut cross

section of pipe/tube.

•

Put the end of the copper tube/pipe to downward

direction as you remov e b urrs in order to a void to let

burrs drop in the tubing.

3. Putting nut on

• Remove flare nuts attached to indoor and outdoor

units, than put them on pipe/tube having completed burr removal.

(Not possible to put them on after flaring work)

4. Flaring work

•

Carry out flaring work using dedicated flaring tool

for R-410A as shown below.

Firmly hold copper tube in a bar(or die) as indicated

dimension in the table above.

5. Check

• Compare the flared work with figure below.

• If flare is noted to be defective, cut off the flared

section and do flaring work again.

Copper

tube

90°

Slanted Uneven Rough

Pipe

Reamer

Point down

Flare nut

Copper tube

Bar

Copper pipe

Clamp handle

Red arrow mark

Cone

Yoke

Handle

Bar

"A"

Inclined

Inside is shining without scratches

Smooth all round

Even length

all round

Surface

damaged

Cracked Uneven

thickness

= Improper flaring =

Outside diameter A

mm inch mm

Ø6.35 1/4 0~0.5

Ø9.52 3/8 0~0.5

Ø12.7 1/2 0~0.5

Ø15.88 5/8 0~1.0

Ø19.05 3/4 0~1.0

■ Preparation of Piping

Page 44

44 Synchro Air Conditioner

Installation

Remote Controller

Remote Controller Preparation (Convertible type)

Remote control

box body

Cord clamp

(accessory)

Lever carefully

the box open

using a screw

driver, etc.

Front case

The lower part

Face of wall

Under plate

Screw (accessory)

HOW TO MOUNT ONTO A WALL

HOW TO INSERT BATTERIES

1. Remove the battery cover from the remote controller.

• Slide the cover according to the arrow direction.

2. Insert the two batteries.

• Be sure that the (+) and (-) directions are correct.

• Be sure that both batteries are new.

3. Re-attach the cover.

• Slide it back into position.

• Fix the under plate on the wall

• Separate the under plate from Remote control box.

• Fix the cord clamps on the wall by

ø 3 tapping screws (accessory).

• Fix the remote control cord.

DISASSEMBLING

ELECTRICAL WIRING

Wire and make sure that terminal

numbers are matched on unit side and

remote controller side.

The maximum length of the cord is 100m.

If the length of the cord exceeds 50m,

use a wire size greater than 0.5mm

2

.

(Main board)

CN REMO

• Do not use rechargeable batteries, such batteries differ

from standard dry cells in

shape, dimensions, and performance.

• Romove the batteries from the

remote controller if the air conditioner is not going to be used

for some long time.

Page 45

Service Manual 45

Installation

Outdoor Unit_AUUH728C

1. Selection of the best location

• If an awning is built over the unit to prevent direct sunlight or rain exposure, make sure that heat radiation from the condenser is not restricted.

• Do not place animals and plants in the path of the warm air.

• Take the air conditioner weight into account and select a place where noise and vibration are minimum.

• Select a place so that the warm air and noise from the air conditioner do not disturb neighbors.

• Rooftop Installations : If the outdoor unit is installed on a roof structure, be sure to level the unit. Ensure

the roof structure and anchoring method are adequate for the unit location. Consult local codes regarding rooftop mounting.

2. Individual installation

Basic Space required

• A space of at least 250 mm is nessary at the back for inlet air. Tacking servicing, a space of about 750 mm

should be provided at the front.

A : 750 mm or more

B : 250 mm or more

C : Top discharge(open in principle)

D : Front inlet(open in principle)

E : Rear inlet(open in principle)

<Side View>

<Top View>

D

C

B

A

E

service space

Front

Rear

Page 46

46 Synchro Air Conditioner

Installation

A : 750 mm or more

B : 250 mm or more

When inlet air enters from right and left sides of unit

Rear

Front

A : 750 mm or more

B : 250 mm or more

C : 150 mm or more

<Top View> <Side View>

When unit is surrounded by walls

When there is an obstructure above the unit

A : 45˚ or more

B : 200 mm or more

C : 250 mm or more

D : 1000 mm or more

E : Air outlet guide (procured at the site)

F : 250 mm or more

C

A

B

C

A

B

A

B

B

B

A

B

C

E

D

F

Page 47

Service Manual 47

Installation

• Space required for collective installation and continuous installation : When installing several

units, leave the space between each block as show below considering passage for air and people.

A : Open state

B : 750 mm or more

C : 250 mm or more

D : 250 mm or more

Front

Rear

Rear

Front

3. Collective installation and continuous installation

Page 48

48 Synchro Air Conditioner

Installation

Outdoor Unit_AUUH1008C

1. Individual installation

Basic Space required

• A space of at least 250 mm is nessary at the back for inlet air. Tacking servicing, a space of about 750 mm